Page 1

Agilent 8703B

Lightwave Component Analyzer

Programmer’s Guide

Page 2

Notices

© Agilent Technologies, Inc.

July 2004

proceed beyond a caution sign

until the indicated conditions

are fully understood and met.

No part of this manual may be

reproduced in any form or by

any means (including electronic storage and retrieval or

translation into a foreign language) without prior agreement and written consent from

Agilent Technologies, Inc. as

governed by United States and

international copyright lays.

Manual Part Number

08703-90058

Edition

July 2004

Printed in Malaysia

Agilent Technologies, Inc.

Digital Signal Analysis

1400 Fountaingrove Parkway

Santa Rosa, CA 95403, USA

Warranty

The material contained in this

document is provided “as is,”

and is subject to being

changed, without notice, in

future editions. Further, to the

maximum extent permitted by

applicable law, Agilent disclaims all warranties, either

express or implied, with regard

to this manual and any information contained herein,

including but not limited to the

implied warranties of merchantability and fitness for a

particular purpose. Agilent

shall not be liable for errors or

for incidental or consequential

damages in connection with

the furnishing, use, or performance of this document or of

any information contained

herein. Should Agilent and the

user have a separate written

agreement with warranty

terms covering the material in

this document that conflict

with these ter ms, th e warra nty

terms in the separate agreement shall control.

WARNING

Warning denotes a hazard. It

calls attention to a procedure

which, if not correctly performed or adhered to, could

result in injury or loss of life.

Do not proceed beyond a

warning sign until the indicated conditions are fully

understood and met.

Restricted Rights Legend.

Use, duplication, or disclosure

by the U.S. Government is subject to restrictions as set forth

in subparagraph (c) (1) (ii) of

the Rights in Technical Data

and Computer Software clause

at DFARS 252.227-7013 for

DOD agencies, and subparagraphs (c) (1) and (c) (2) of

the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Safety Notices

CAUTION

Caution denotes a hazard. It calls

attention to a procedure

which, if not correctly performed or adhered to, could

result in damage to or destruction of the product. Do not

2

Page 3

Contents

1. Introduction to Instrument Control

Introduction to Instrument Control 1-2

Instrument Control using the VXIplug&play Driver 1-3

Instrument Control using BASIC 1-9

2. Alphabetical Command Reference

Alphabetical Command Reference 2-2

Keys to Programming Commands 2-3

Programming Commands 2-14

8703A Commands Not Supported in the 8703B 2-76

3. Command Listings

Alphabetical List of Commands 3-2

OPC-Compatible List of Commands 3-4

4. GPIB Programming

GPIB Programming 4-2

Analyzer Command Syntax 4-3

Analyzer Operation 4-7

GPIB Operation 4-8

Calibration 4-19

Display Graphics 4-22

Disk File Names 4-25

5. Reading Analyzer Data

Reading Analyzer Data 5-2

Output Queue 5-3

Command Query 5-3

Identification 5-3

Output Syntax 5-4

Marker Data 5-5

Array-Data Formats 5-7

Trace-Data Transfers 5-8

Stimulus-Related Values 5-9

6. Data Processing Chain

Data Processing Chain 6-2

Data Arrays 6-2

Common Output Commands 6-3

Fast Data Transfer Commands 6-4

Data Levels 6-4

Learnstring and Calibration-Kit String 6-5

7. Error Reporting

Error Reporting 7-2

Status Reporting 7-3

The Status Byte 7-6

Contents-1

Page 4

Contents

The Event-Status Register and Event-Status Registers B and L 7-7

Error Output 7-8

Error Messages in Numerical Order 7-9

8. Programming Examples

Example Programs 8-2

Measurement Process 8-3

Programming Examples 8-5

Measurement Setup Examples 8-9

Measurement Calibration Examples 8-26

Measurement Data Transfer Examples 8-63

Measurement Process Synchronization Examples 8-74

Analyzer System Setup Examples 8-84

List-Frequency and Limit-Test Table Examples 8-92

Report Generation Examples 8-106

Limit Line and Data Point Special Functions 8-125

Contents-2

Page 5

1

Introduction to Instrument Control 1-2

Instrument Control using the VXIplug&play Driver 1-3

Instrument Control using BASIC 1-9

Introduction to Instrument Control

Page 6

Introduction to Instrument Control

Introduction to Instrument Control

Introduction to Instrument Control

In this chapter, you can find an introduction to the remote operation of your analyzer using an

external controller. You should be familiar with the operatio n of the analyz er before at tempting to

remotely control the analyzer over the Gener al Purpose Int erface B us (GPIB). Ref er to the user ’s

guide for operating information. For information on the instrument’s preset state and memory

allocation, refer to the 8703B Lightwave Component Analyzer Reference manual.

This manual is not intended to teach programming or to discuss GPIB theo ry except at an

introductory level. Programming examples that demonstrate the remote operation of the

analyzer are documented in Chapter 8, “Programming Examples” and are also provided o n the

CD-ROM that was shipped with this manual. All example programs are provided in BASIC, and

most are also provided in Visual C++ and Visual BASIC for use with the VXIplug&play driver.

1-2

Page 7

Introduction to Instrument Control

Instrument Control using the VXIplug&play Driver

Instrument Control using the VXIplug&play Driver

VXIplug&play is a term indicating conformance to a set of system-level standards produced by

the VXIplug&play Systems Alliance. The charter of the alliance was “to improve the

effectiveness of VXI-based solutio ns by increasing ease-of-use and improving the interoperability

of multi-vendor VXI systems.”

Installing the VXIplug&play driver on your computer will allow you to control the analyzer via

common programming environments without having to learn the instrument-specific mne monics.

Requirements

The VXIplug&play driver for your analyzer is designed for a PC operating Windows 95 or

Windows NT version 3.51 or higher. The driver requires a virtual instrument software

architecture (VISA)-compatible GPIB interface, and the VISA I/ O Library version 1.1 or higher.

The driver is compatible with the following programming environments:

• Microsoft Visual Basic, version 4.0 o r higher

• Microsoft Visual C++, version 4.0 or higher

• Borland C++, version 4.5 or higher

• Agilent VEE, version 3.2 or higher

• National Instruments LabWindows/CVI, version 4.0.1 or higher

• National Ins truments LabVIE W, version 4.0.1 or high e r

Installing the VXIplug&play Driver

NOTE This procedure assumes that you have installed a VISA-compatible GPIB interface

and the VISA I/O library, version 1.1 or higher. It also assumes that you have

installed—and are familiar with—one of the programming environments listed

above.

1. The install program for t he VXIplug&play driver for your analyzer is located in the root

directory of the CD-ROM that accompanied this manual. The file is titled “875x.exe”

a. If you need to order a new CD-ROM, contact Agilent Technologies and order part number

08703-10202.

b. You can also download the file from the Web. Go to http://www.tm.agilent.com and follow

the “Software and Driver” and “Instrument Driver” links.

2. Run “875x.exe” to install the VXIplug&play driver on your computer. The default directory

that is used by the install-shield is vxipnp\winxx\875x, where winxx designates the operating

system in use by your computer, such as winnt, win95, etc.

3. If you have difficulty installing the VXIplug&play driver, contact Agilent Te chnologies by

calling the nearest sales or service office.

1-3

Page 8

Introduction to Instrument Control

Instrument Control using the VXIplug&play Driver

System Setup

1. Use an GPIB interconnect cable (such as 10833A/B/C/D) to connect the analyzer to the GPIB

interface card on your computer.

2. Switch on the computer.

3. Switch on the analyzer.

a. To verify the analyzer's address, press:

Local, SET ADDRESSES, ADDRESS: 8703

The analyzer has only one GPIB interface, though it occupies two addresses: one for the

instrument and one for the display. The display address is equal to the instrument address

with the least-significant bit incremented. The display address is automatically set each

time the instrument address is set.

The default analyzer addresses are:

—16 for the instrument

—17 for the display

CAUTION Other devices connected to the bus cannot occupy the same address as the

analyzer or the display.

The analyzer should now be displaying t he instrument's address in the upper right section

of the display. If the address is not 16, return the address to its default setting (16) by

pressing:

16, x1, Preset

b. Set the system control mode to either “pass-control” or “talker/listener” mode. These are

the only control modes in which the analyzer will accept commands over GPIB. To set the

system-control mode, press:

Local, TALKER/LISTENER

or

Local, USE PASS CONTROL

1-4

Page 9

Introduction to Instrument Control

Instrument Control using the VXIplug&play Driver

Verifying the Bus Connection

Check the interface bus connection and operation by following the appropriate procedure (for

the type of interface card you are using) below.

Interface Bus Verification Procedure (GPIB Interface Card)

1. Check the bus connection by running the VISA Assistant in the I/O Libraries. The VISA

Assistant will automatically report what it finds on the bus. Notice that the VISA Assistant is

reporting instruments at addresses 16 and 17. As mentioned earlier, these addresses

designate the instrument and its display, respectively.

Figure 1-1. VISA Assistant Window

2. To further verify GPIB operation, send a preset command to the analyzer by doing the

following in the VISA Assistant window:

a. Single-click on “GPIB0::16::INSTR” to highlight it.

b. Make sure that the “Formatted I/O” tab is selected.

c. Enter PRES; in the text box.

d. Click on “viPrintf.”

e. This command should preset the analyzer. If an instrument preset does not occur, there is

a problem. Check all GPIB address settings and physical connections. Most GPIB probl ems

are caused by an incorrect address or faulty/loose GPIB cables.

1-5

Page 10

Introduction to Instrument Control

Instrument Control using the VXIplug&play Driver

Interface Bus Verification Procedure (National Instruments Card)

1. Check the bus connection by running Win32 VISA Interactive Control. When this program is

run, it automatically reports what it finds on the bus. Notice that the program is reporting

instruments at addresses 16 and 17. As mentioned earlier, these addresses designate the

instrument and its display, respectively.

Figure 1-2. Win32 VISA Interactive Control Window: Bus Report

2. To further verify GPIB operation, double click on “GPIB0::16::INSTR” and then perform the

following steps.

a. Make sure that the “Basic I/O” tab is selected.

b. Click on the “Write” tab.

c. Enter PRES; in the “Buffer” text box.

d. Click on “Execute.”

e. This command should preset the analyzer. If an instrument preset does not occur, there is

a problem. Check all GPIB address settings and physical connections. Most GPIB probl ems

are caused by an incorrect address or faulty/loose GPIB cables.

1-6

Page 11

Instrument Control using the VXIplug&play Driver

Figure 1-3. Win32 VISA Interactive Control: Sending a Command

Introduction to Instrument Control

Controlling the Analyzer with the VXIplug&play Driver

The “Programming Examples” CD-ROM that was shipped with this manual includes many

example programs that can be used to control your analyzer . The fol lowing sections provide some

information on using the VXIplug&play driver with the Visual C++ and Visual BASIC

programming environment s.

Using Visual BASIC to Control the Analyzer

When using Visual BASIC, you will need to include the two fil es listed below in your proje ct. They

were installed on your computer in the following directories when you installed the driver:

• \vxipnp\winxx\875x\875x.bas

• \vxipnp\winxx\include\visa32.bas

NOTE The directories shown above are the default locations for these files. (“winxx”

indicates the operating system you are using, such as winnt, win95, etc.) If you

designated a different path during installation, you will need to amend the path

above to include the specific path that you indicated during installation.

1-7

Page 12

Introduction to Instrument Control

Instrument Control using the VXIplug&play Driver

Using Visual C++ to Control the Analyzer

When using Visual C++, you will need to include the file listed below in your pro ject . The file was

installed on your computer in the following directory when you installed the driver:

\vxipnp\winxx\lib\msc\875x_32.lib

NOTE The directory shown above is the default location for this file. (“winxx” indicates

the operating system you are using, such as winnt, win95, etc.) If you designated a

different path during installation, you will need to ame nd the path above to include

the specific path that you indicated during installation.

1-8

Page 13

Introduction to Instrument Control

Instrument Control using BASIC

Instrument Control using BASIC

This section describes how to control the analyzer using BASIC 6.2 (or higher), or BASIC for

Windows 6.3 (or higher) on one of the following computers:

• HP 9000 Series 200/300

• HP 9000 Series 700 with BASIC-UX

• PC with a GPIB interface card installed

.

Table 1-1. Additional BASIC 6.2 Programming Information

Description Agilent

Part Number

BASIC 6.2 Programming Guide 98616-90010

BASIC 6.2 Language Reference (2 Volumes) 98616-90004

Using BASIC for Instrument Control, Volume I 82303-90001

Using BASIC for Instrument Control, Volume II 82303-90002

BASIC for Windows Manual Set E2060-90100

Table 1-2. Additional GPIB Information

Description Agilent

Part Number

BASIC 6.2 Interface Reference 98616-90013

Tutorial Description of the General Purpose Interface Bus 5021-1927

Required Equipment

• Computer running BASIC 6.2 (or higher) or BASIC for Windows 6.3 (or higher)

• Supported GPIB interface card

• GPIB interconnect cables (such as 10833A/B/C/D)

System Setup and GPIB Verification

1. Connect the analyzer to the computer with an GPIB cable.

1-9

Page 14

Introduction to Instrument Control

Instrument Control using BASIC

Figure 1-4. The Analyzer System with Controller

2. Switch on the computer, and launch BASIC or BASIC for Windows.

3. Switch on the analyzer.

a. To verify the analyzer's address, press:

Local, SET ADDRESSES, ADDRESS: 8703

The analyzer has only one GPIB interface, though it occupies two addresses: one for the

instrument and one for the display. The display address is equal to the instrument address

with the least-significant bit incremented. The display address is automatically set each

time the instrument address is set.

The default analyzer addresses are:

—16 for the instrument

—17 for the display

CAUTION Other devices connected to the bus cannot occupy the same address as the

analyzer.

The analyzer displays the instrument's address in the upper right section of the display. If

the address is not 16, return the address to its default setting (16) by pressing:

16, x1, Preset

1-10

Page 15

Introduction to Instrument Control

Instrument Control using BASIC

b. Set the system control mode to either “pass-control” or “talker/listener” mode. These are

the only control modes in which the analyzer will accept commands over GPIB. To set the

system-control mode, press:

Local, TALKER/LISTENER

or

Local, USE PASS CONTROL

4. Check the interface bus by performing a simple command from the computer controller. Type

the following command on the controller:

OUTPUT 716;”PRES;”

Execute, or Return

NOTE HP 9000 Series 300 computers use the Return key as both execute and enter. Some

other computers may have an

function. For reasons of simplicity, the notation

Enter, Execute, or Exec key that performs the same

Return is used throughout this

document.

This command should preset the analyzer. If an instrument preset does not occur, there is a

problem. Check all GPIB addresses and connections. Most GPIB problems are caused by an

incorrect address or faulty/loose GPIB cables.

1-11

Page 16

Introduction to Instrument Control

Instrument Control using BASIC

Sending Commands

A remote controller can manipulate the functions of the analyzer by sending commands to the

analyzer via the General Purpose Interface Bus (GPIB). The commands used are specific to the

analyzer. Remote commands executed over the bus take precedence over manual commands

executed from the instrument's fr ont pane l. R em ote co mmands are executed as soon as they are

received by the analyzer. A command only applies to the active channel (except in cases where

functions are coupled between channel s). Most commands are equivalent to front-pane l hardkeys

and softkeys.

Command Structure in BASIC

Consider the following BASIC command for setting the analyzer's start frequency to 50 MHz:

OUTPUT 716;”STAR 50 MHZ;”

The command structure in BASIC has several different elements:

the BASIC command statement OUTPUT - The BASIC data-output statement.

the appendage 716 - The data is directed to interface 7 (GPIB), and

on to the device at address 16 (the analyzer). This

appendage is terminated with a semicolon. The next

appendage is STAR, the instrument mnemonic for

setting the analyzer's start frequency.

data 50 - a single operand used by the root mnemonic STAR

to set the value.

unit MHZ - the units that the operand is expressed in.

terminator ; - indicates the end of a command, enters the data,

and deactivates the active-entry area.

The “STAR 50 MHZ;” command performs the same function as pressing the following keys on

the analyzer's front panel:

Start, 50, M/u

STAR is the root mnemonic for the start key, 50 is the data, and MHZ are the units. Where possible,

the analyzer's root mnemonics are derived from the equivalent key label. Otherw ise they are

derived from the common name for the function. Chapter 2, “Alphabetical Command Reference”

lists all the root mnemonics and all the different units accepted.

The semico lon (;) following MHZ terminates the command within the analyzer. It removes start

frequency from the active-entry ar ea, and prep ares the analyzer f or the next co mmand. If the re is

a syntax error in a command, the analyzer will ignore the comm and and look for the next

terminator. When it finds the next terminator, it starts processing incoming commands normally.

Characters between the syntax error and the next terminator are lost. A line feed also acts as a

terminator. T he BASIC OUTPUT statement transmits a carriage return/line feed following the data.

This can be suppressed by putting a semicolon at the end of the statement.

1-12

Page 17

Introduction to Instrument Control

Instrument Control using BASIC

The OUTPUT 716; statement will transmit all items listed (as long as they are separated by

commas or semicolons) including:

• literal information enclosed in quotes

• numeric variables

•string variables

•arrays

A carriage return/line feed is transmitted after each item. Again, this can be suppressed by

terminating the commands with a semicolon. The analyzer automatically goes into remote mode

when it receives an OUTPUT command from the controller. When this happens, the front-panel

remote (R) and listen (L) GPIB status indicators illuminate. In remote m ode, the analyzer ignores

any data that is input with the front-panel keys, w ith the exception of

Local. Pressing Local,

returns the analyzer to manual operation, unless t he universal GPIB command LOCAL LOCKOUT

7 has been issued. There are two ways to exit from a local lockout. Either issue the LOCAL 7

command from the controller or cycle the line power o n the analyzer.

Setting a parameter such as start frequency is just one form of command the analyzer will accept.

It will also accept simple commands that require no operand at all. For example, execute:

OUTPUT 716;"AUTO;"

In response, the analyzer autoscales the active channel. Autoscale only applies to the active

channel, unlike start frequency, which applies to both channels as long as the channels are

stimulus-coupled.

The analyzer will also accept commands that switch various f unctions on and off. For example, to

switch on dual-channel display, execute:

OUTPUT 716;"DUACON;"

DUACON is the analyzer root mnemonic for “dual-channel display on.” This causes the analyzer to

display both channels. To go back to single-channel display mode, for example, switching off

dual-channel display, execute:

OUTPUT 716;"DUACOFF;"

The construction of the command starts with the root mnemonic DUAC (dual-channel display)

and ON or OFF is appended to the root to form the entire command.

The analyzer does not distinguish between upper- and lower-case letters. For example, execute:

OUTPUT 716;"auto;"

NOTE The analyzer also has a debug mode to aid in troubleshooting systems. W h en the

debug mode is ON, the analyzer scrolls incoming GPIB commands across the

display. To manually activate the debug mode, press

Local, GPIB DIAG ON. To

deactivate the debug mode from the controller, execute:

OUTPUT 716;"DEBUOFF;"

Command Query

Suppose the operator has changed the power level from the front panel. The computer can find

1-13

Page 18

Introduction to Instrument Control

Instrument Control using BASIC

the new power level using the analyz er's command-query function. If a question mark is

appended to the root of a command, the analyzer will output the value of that function.

For instance, POWE 7 DB; sets the analyzer's output power to 7 dB, and POWE?; outputs the

current RF output power at the test port to the system controller. For example:

Type SCRATCH and press

Type EDIT and press

10 OUTPUT 716;"POWE?;"

20 ENTER 716;Reply

30 DISP Reply

40 END

Return, to clear old programs.

Return, to access the edit mode. Then type in:

NOTE Most commands can also be queried by sending the command (without a value)

and then sending the OUTPACTI command, as in the following example that queries

the power value:

10 OUTPUT 716;”POWE;OUTPACTI;”

Running the Program The computer will display the preset source-power level in dBm. Change

the power level by pressing

Local, Power, XX, x1. Now run the program again.

When the analyzer receives POWE?, it prepares to transmit the current RF source-power level.

The BASIC statement ENTER 716 allows the analyzer to transmit information to the computer by

addressing the analyzer to talk. This illuminates the analyzer front-panel talk (T) light. The

computer places the data transmitted by the analyzer into the variables listed in the ENTER

statement. In this case, the analyzer transmits t he output power , whi ch gets placed in the variable

Reply .

The ENTER statement takes the stream of binary-data output from the analyzer and reformats it

back into numbers and ASCII strings. With the formatting set to its default state, the ENTER

statement will format the data into real variables, integers, or ASCII strings, depending on the

variable being filled. The variable list must match the data the analyzer has to transmit. If there

are not enough variables, data is lost. If there are too many variables for the data available, a

BASIC error is generated.

The formatting done by the ENTER statement can be changed. The formatting can be

deactivated to allow binary transfers of data. Also, the ENTER USING statement can be used to

selectively control the formatting.

ON/OFF commands can be also be queried. The reply is a one (1) if the function is active, a zero

(0) if it is not active. Similarly , if a command controls a function that is underline d on the analyzer

softkey menu when active, querying that command yields a one (1) if the command is underlined,

a zero (0) if it is not. For example, press

Meas. Though there are seven options on the

measurement menu, only one is underlined at a time. The un derlined o ption will r eturn a one (1 )

when queried.

1-14

Page 19

Introduction to Instrument Control

Instrument Control using BASIC

For instance, rewrite line 10 as:

10 OUTPUT 716;"DUAC?;"

Run the program once and note the result. Then press Local, Display, DUAL CHAN, to toggle the

display mode, and run the program again.

Another example is to rewrite line 10 as:

10 OUTPUT 716;"PHAS?;"

In this case, the program will display a one (1) if phase is currently being displayed. Since the

command only applies to the active channel, the response to the PHAS? inquiry depends on

which channel is active.

Operation Complete

Occasionally, there is a need to query the analyzer as to when certain analyzer operations have

completed. For instance, a program should not have the operator connect the next calibration

standard while the analyzer is still measuring the current one. To provide such information, the

analyzer has an “operation complete” reporting mechanism, or OPC command, that will indicate

when certain key commands have completed operation. The mechanism is activated by sending

either OPC or OPC? immediately before an OPC-compatible command. When the command

completes execution, bit 0 of th e event-status register will be set. If OPC was queried with OPC ?,

the analyzer will also output a one (1) when the command completes execution.

As an example, type SCRATCH and press

Return.

Type EDIT and press Return.

Type in the following program:

10 OUTPUT 716;"SWET 3 S;OPC?;SING;"

Set the sweep time to 3 seconds, and OPC a single sweep.

20 DISP "SWEEPING"

30 ENTER 716;Reply The program will halt at this point until the analyzer

completes the sweep and issues a one (1).

40 DISP "DONE"

50 END

1-15

Page 20

Introduction to Instrument Control

Instrument Control using BASIC

Running the Program Running this program causes the computer to display the sweeping

message as the instrument executes the sweep. The computer will display DONE just as the

instrument goes into hold. When DONE appears, the program could then continue on, being

assured that there is a valid data trace in the instrument.

Preparing for Remote (GPIB) Control

At the beginning of a program, the analyzer is taken from an unknown state and brought under

remote control. This is done with an abort/clear sequence. ABORT 7 is used to halt bus activity

and return control to the computer. CLEAR 716 will then prepare the analyzer to receive

commands by:

• clearing syntax errors

• clearing the input-command buffer

• clearing any messages waiting to be output

The abort/clear sequence readies the analyze r to receive GPIB commands. T he next step i nvolves

programming a known state into the anal yzer. The most convenient way to do this is to preset the

analyzer by sending the PRES (preset) command. If preset cannot be used, the status-reporting

mechanism may be employed. When using the status-report ing register , CLES (Clear Status) can

be transmitted to the analyzer to clear all of the status-reporting registers and their enables.

Type SCRATCH and press

Return.

Type EDIT and press Return. Type in the following program:

10 ABORT 7 This halts all bus action and gives acti ve co nt ro l to

the computer.

20 CLEAR 716 This clears all GPIB errors, resets the GPIB interface, and

clears the syntax errors. It does not affect the

status-reporting system.

30 OUTPUT 716;"PRES;" Presets the instrument. This clears the status-reporting

system, as well as resets all of the front-panel settings,

except for the GPIB mode and the GPIB addresses.

40 END Running this program brings the analyzer to a known

state, ready to respond to GPIB contro l.

The analyzer will not respond to GPIB commands unless the remote line is asserted. When the

remote line is asserted, the analyzer is addressed to listen for commands from the controller. In

remote mode, all the front-panel keys are disabled (with the exception of

Local, and the

line-power switch). ABORT 7 asserts the remote line, which remains asserted until a LOCAL 7

statement is executed.

Another way to assert the remote line is to execute:

REMOTE 716

This statement asserts the analyzer's remote-o peration mode and addresses the analyzer t o listen

for commands from the controller. Press any front-panel key except

front-panel keys will respond until

1-16

Local, has been pressed.

Local. Note that none of the

Page 21

Introduction to Instrument Control

Instrument Control using BASIC

Local, can also be disabled with the sequence:

REMOTE 716

LOCAL LOCKOUT 7

After executing the code above, none of the front-panel keys will respond. The analyzer can be

returned to local mode temporarily with:

LOCAL 716

As soon as the analyzer is addressed to listen, it goes back into local-lockout mode. The only way

to clear the local-lockout mode, aside from cycling line power, is to execute:

LOCAL 7

This command un-asserts the remote line on the interface. This puts the instrument into local

mode and clears the local-lockout comm and. Return the instrument to remote mode by pressing:

Local, TALKER/LISTENER

or

Local, USE PASS CONTROL

I/O Paths

One of the features of BASIC is the use of input/output paths. The instrument may be addressed

directly by the instrument's device number as shown in the previous examples. However, a more

sophisticated approach is to declare I/O paths such as: ASSIGN @Nwa TO 716. Assigning an I/O

path builds a look-up table in the computer's memory that contains the device-address codes and

several other parameters. It is easy to quickly change addresses th roughout the entir e program at

one location. I/O operation is more efficient because it uses a table, in place of calculating or

searching for values related to I/O. In the more elaborate examples where file I/O is discussed, the

look-up table contains all the information about the file. Execution time is decreased, because the

computer no longer has to calculate a device's address each time that device is addressed.

For example:

Type SCRATCH and press

Return.

Type EDIT and press Return.

Type in the following program:

10 ASSIGN @Nwa TO 716 Assigns the analyzer to ADDRESS 716.

20 OUTPUT @Nwa;"STAR 50 MHZ;" Sets the analyzer' s start frequency to 50 MHz.

NOTE The use of I/O paths in binary-format transfers allows the user to quickly

distinguish the type of transfer taking place. I/O paths are used throughout the

examples and are highly recommended for use in device input/output.

1-17

Page 22

Introduction to Instrument Control

Instrument Control using BASIC

1-18

Page 23

2

Alphabetical Command Reference 2-2

Keys to Programming Commands 2-3

Programming Commands 2-14

8703A Commands Not Supported in the 8703B 2-76

Alphabetical Command Reference

Page 24

Alphabetical Command Reference

Alphabetical Command Reference

Alphabetical Command Reference

In this chapter, you can find an alphabetical list and brief descriptions of the supported

commands for controlling the Agilent 87 03B remotely.

NOTE Some commands have a range of values associated with them. If you send a

value that is beyond the analyzer’s capability, the analyzer will default to the

closest allowed value. Refer to the individual commands for the specific range

of values allowed.

Symbol Conventions

<num> Required numerical data.

<choice1|choice2|…|choicen> An appendage that is part of the command. For example,

FORMAT<DOS|LIF> indicates that the actual commands are

FORMATDOS and FORMATLIF .

<$> Indicates a character string operand which must be enclosed

by double quotes.

| An either/or choice in an appendage or optional data.

[ ] Optional data.

A terminator indicates the end of a command string, and this manual uses a semicolon as the

terminator in all syntax examples. The analyzer also interprets line feeds and GPIB end or

identify (EOI) messages as terminators. Terminators are not necessary for the analyzer to

interpret commands correctly, however in the case of a syntax error, the analyzer will attempt to

recover at the next terminator. Therefore, it is recommended that you conclude each command

with a terminator.

Because this chapter is an “Alphabetical Command Reference,” the commands have been listed

alphabetically, rather than by function, in both the “Syntax” sections and the “Description ”

sections. Therefore, commands grouped together in the “Syntax” sections, are grouped

alphabetically and/or due to common syntax form, not necessarily due to common functionality.

The softkeys listed in the “Front Panel Equivalents” tables may no t be in the first menu viewed

when the associated hardkey is pressed. In many cases, more than one key press will be required

to locate the softkey. Refer to your analyzer’s reference guide for the exact location of any

softkey.

Some commands that do not have an associated query syntax can be queried by sending the

command (without a value) and then sending t he OUTPACTI command, as in the following

example that queries the segment power value:

10 OUTPUT 716;”SEGPOWER;OUTPACTI;”

Many of the commands that do have a listed query syntax can also be queried in this manner.

2-2

Page 25

Keys to Programming Commands

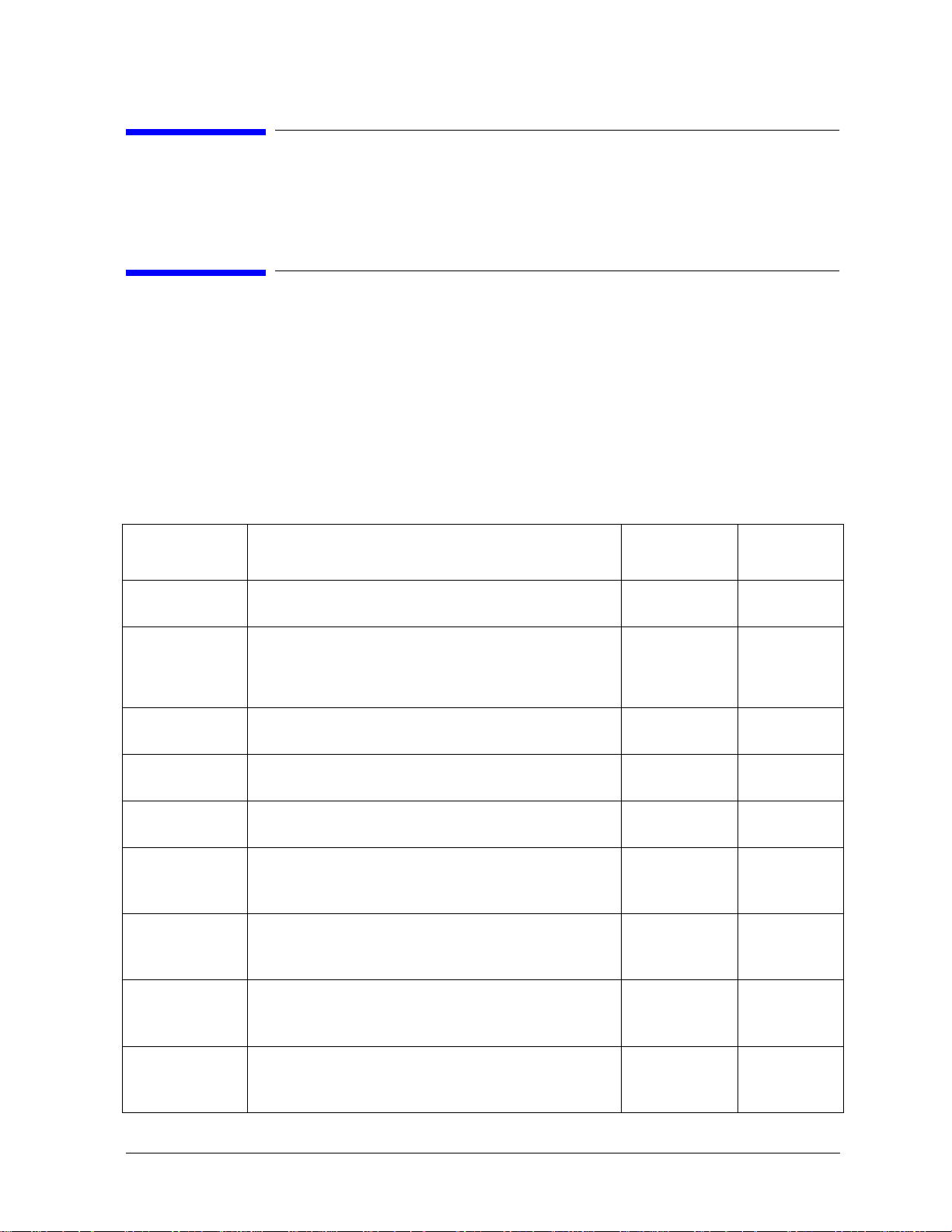

Table 2-1.Front Panel Equivalen ts (1 of 11)

Hardkey Softkey Command

Avg AVERAGING FACTOR AVERFACT

AVERAGING <ON |OFF> AVERO <ON|OFF>

AVERAGING RESTART AVERREST

IF BW [ ] IFBW

SMOOTHING APERTURE SMOOAPER

SMOOTHING ON OFF SMOOO <ON|OFF>

Cal ISOLATION ISOL

Cal ALTERNATE A and B ALTAB

Alphabetical Command Reference

Keys to Programming Commands

Cal ALTERNATE RFL/TRAN ALTAB

Cal CORRECTION ON OFF CORR

Cal DEFINE STANDARD DEFS

Cal DONE 1-PORT CAL SAV1

Cal DONE 2-PORT CAL SAV2

Cal DONE RESP ISOL’N CAL RAID

Cal DONE: DONE

Cal DONE: RESPDONE

Cal EXTENSION PORT 1 PORT1

Cal EXTENSION PORT 2 PORT2

Cal EXTENSIONS ON OFF PORE

Cal FULL 2-PORT CALIFUL2

Cal FWD ISOL’N FWDI

Cal FWD MATCH FWDM

Cal FWD TRA N S FWDT

Cal INTERPOL ON OFF CORI

Cal ISO L’N STD RAIISOL

Cal ISOLATION DONE ISOD

Cal MAXIMUM FREQUENCY MAXF

Cal OMIT ISOLATION OMII

2-3

Page 26

Alphabetical Command Reference

Keys to Programming Commands

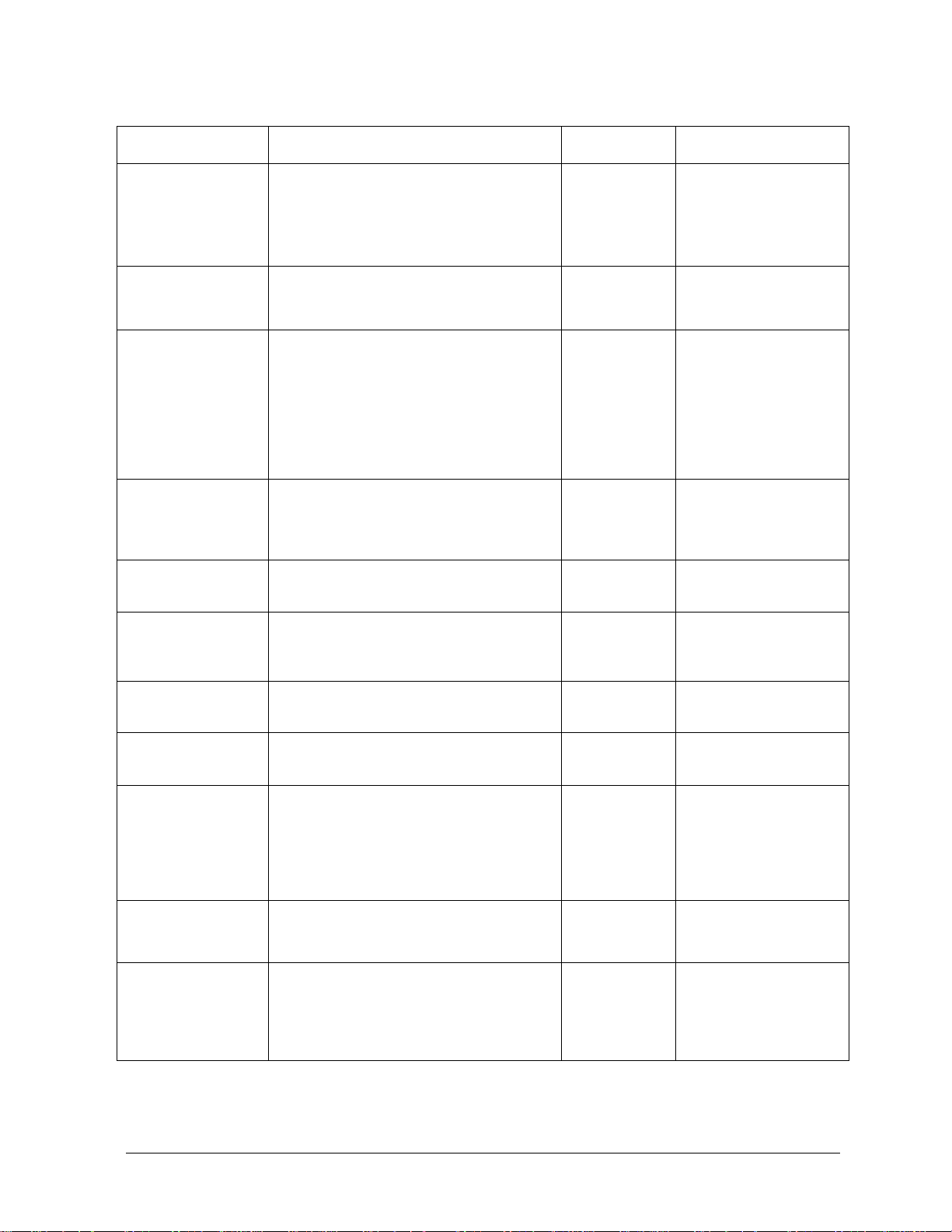

Table 2-1. Front Panel Equivalen ts (2 of 11)

Hardkey Softkey Command

Cal REFLECTION REFL

Cal RESPONSE CALIRESP

Cal RESPONSE RAIRESP

Cal RESPON SE & ISOL’N CALIRAI

Cal Respons e & Match (E/O) CA LIEORM

Cal Respons e & Matc h (O/E) CALIOERM

Cal Response & Match: Done RAMD

Cal RESUME CA L SEQUENCE RESC

Cal REV ISOL’N REVI

Cal REV MATCH REVM

Cal REV TRAN S REVT

Cal S11 1-PORT CALIS111

Cal S11A CLASS11A

Cal S11B CLASS11B

Cal S11C CLASS11C

Cal S22 1-PORT CALIS221

Cal S22A CLASS22A

Cal S22A CLASS22B

Cal S22A CLASS22C

Cal SET Z0 SETZ

Cal SLIDING LOAD DONE SLID

Cal SPECIFY CLASS DONE CLAD

Cal standar d listed under softkey 1 STANA

Cal standar d listed under softkey 2 STANB

Cal standar d listed under softkey 3 STANC

Cal standar d listed under softkey 4 STAND

Cal standar d listed under softkey 5 STANE

Cal standar d listed under softkey 6 STANF

Cal standar d listed under softkey 7 STANG

Cal STANDARDS DONE REFD

Cal STANDARDS DONE TRAD

2-4

Page 27

Table 2-1. Front Panel Equivalen ts (3 of 11)

Hardkey Softkey Command

Cal TESTSET SW n Sweeps TSS WIn

Cal TRANSMISSN TRAN

Cal VELOCITY FACTOR VELOFACT

Center CENT

Chan 1 N/A CHAN1

Chan 2 N/A CHAN2

Chan 3 N/A CHAN3

Chan 4 N/A CHAN4

Copy LINE TYPE DATA LINTD ATA

LINE TYPE MEMORY LINTMEMO

LIST VALUES LISV

Alphabetical Command Reference

Keys to Programming Commands

NEXT PAGE NEXP

OP PARAMS OPEP

PLOT PLOT

RESTORE DISPLAY RESD

2-5

Page 28

Alphabetical Command Reference

Keys to Programming Commands

Table 2-1. Front Panel Equivalen ts (4 of 11)

Hardkey Softkey Command

Display 2x:[1&2][3&4] D2XUPCH2

2x:[1&3][2&4] D2XUPCH3

4x:[1][2][3][4] D4XUPCH2

4x:[1][3][2][4] D4XUPCH3

AUX CHAN ON OFF AUXC <ON|OFF>

BACKGROUND INTENSITY BACI

BEEP DONE ON OFF BEEPDONE <ON|OFF>

BEEP FAIL ON OFF BEEPFAIL <ON|OFF>

BEEP WARN ON OFF BEEPWARN <ON|OFF>

BRIGHTNESS CBRI

DATA ->MEMORY DATI

DATA and MEMORY DISPDATM

DATA/MEM DISPDDM

DATA-MEM DISPDMM

DATA+MEM DISPDPM

DATA*MEM DISPDTM

MEM1/MEM2 DISPM1DM

MEM1-MEM2 DISPM1MM

MEM1+MEM2 DISPM1PM

MEM1*MEM2 DISPM1TM

MEM2/MEM1 DISPM2DM

MEM2-MEM1 DISPM2MM

MEM/DATA DISPMDD

MEM-DATA DISPMMD

MATH->MEM MATI

MEM1->MEM2 MEM1I

MEM2->MEM1 MEM2I

2-6

DEFAULT COLORS DEFC

DISPLAY: DATA DISPDATA

DUAL CHAN ON OFF DUAC <ON|OFF>

FREQUENCY BLANK FREO

INTENSITY INTE

Page 29

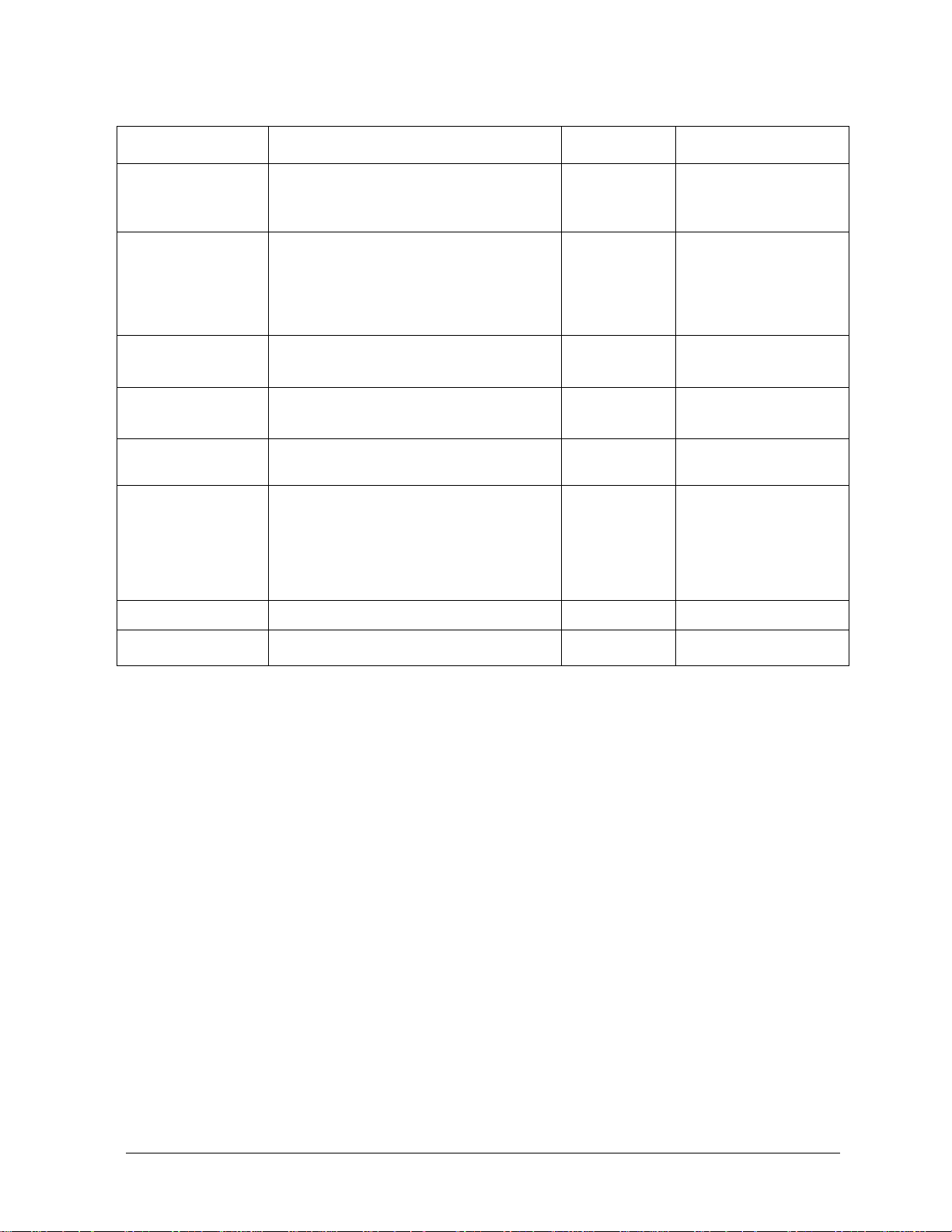

Table 2-1. Front Panel Equivalen ts (5 of 11)

Hardkey Softkey Command

down N/A DOWN

Entry Off N/A ENTO

Format DELAY DELA

IMAGINARY IMAG

LIN MAG LINM

LOG MAG LOGM

PHASE PHAS

POLAR POLA

REAL REAL

SMITH CHART SMIC

SWR SWR

Alphabetical Command Reference

Keys to Programming Commands

Local ADDRESS: CONTROLLER AD DRCONT

ADDRESS: DISK ADDRDISC

ADDRESS: P MTR/GPIB ADDRPOWM

DISK UNIT NUMBER DISCUNIT

GPIB DIAG ON OFF DEBU <ON|OFF>

PLTR PORT GPIB ADDRPLOT

PRNTR PORT GPIB ADDRPRIN

USE PASS CONTROL USEPASC

Marker all OFF MARKOFF

D MODE OFF DELO

D REF = D FIXED MKR DELRFIXM

D REF = n DELR

FIXED MKR AUX VALUE MARKFAUV

FIXED MKR STIMULUS MARKFSTI

FIXED MKR VALUE MARKFVAL

MARKER n MARKn

MKR ZERO MARKZERO

2-7

Page 30

Alphabetical Command Reference

Keys to Programming Commands

Table 2-1. Front Panel Equivalen ts (6 of 11)

Hardkey Softkey Command

Marker Fctn DISP MKRS ON OFF DISM

G + jB MKR SMIMGB

POLAR LIN MKR POLMLIN

SMITH LIN MKR SMIMLIN

POLAR LOG MKR POLMLOG

SMITH LOG MKR SMIMLOG

MARKER -> CENTER MA RKCENT

MARKER -> DELAY MARKDELA

MARKER -> SPAN MARKSPAN

MARKER -> START MARKSTAR

MARKER -> STOP MARKSTOP

MARKERS: CONTIN UOUS MARKCONT

MARKERS: COUPLED MARKCOUP

MARKERS: DISCRETE MARKDISC

MARKERS: UNCOUP LED MARKUNCO

MEASURE: STATS MEASTAT

SMITH R + jX MKR SM IMRX

POLAR Re/Im MKR POLMRI

SMITH Re/Im MKR SMIMRI

Marker Search BANDWIDTH MARK3DB

SEARCH LEFT SEAL

SEARCH RIGHT SEAR

SEARCH: MAX MARKMAXI

SEARCH: MAX SEAMAX

SEARCH: MIN MARKMINI

SEARCH: MIN SEAMIN

SEARCH: OFF SEAOFF

2-8

SEARCH: TARGET SEATARG

TRACKING ON OFF TRACK

WIDTH VALUE WIDV

WIDTHS ON OFF WIDT

Page 31

Table 2-1. Front Panel Equivalen ts (7 of 11)

Hardkey Softkey Command

Meas B MEASB

AMEASA

A/B AB

A/R AR

B/R BR

CONVERSION 1/S CONV1DS

CONVERSION OFF CONVOFF

CONVERSION Y:Ref l CONVYREF

CONVERSION Y:Tran s CONVYTRA

CONVERSION Z:Refl CO NVZREF

CONVERSION Z:Trans CONVZT RA

Alphabetical Command Reference

Keys to Programming Commands

E/O Trans MEASEO1

O/E Trans (Port 1) MEASOE1

O/E Trans (Port 2) MEASOE2

O Refl MEASO1

O Trans MEAS001

RMEASR

Refl:FWD S11 (A/R) S11

Refl:REV S22 (B/R) S22

Trans:FWD S21 (B/R) S21

Trans:REV S12 (A/R) S12

Power N/A POWE

PORT POWER PORTP

PWR RANGE AUTO MAN PWRR <PMAN| P AUTO>

RANGE n PRAN

SOURCE PWR ON OFF SOUP <ON|OFF>

Preset N/A PRES

N/A RST

2-9

Page 32

Alphabetical Command Reference

Keys to Programming Commands

Table 2-1. Front Panel Equivalen ts (8 of 11)

Hardkey Softkey Command

Save/Recall CLEAR CLEAREG <01-31>

CLEAR ALL CLEARALL

DATA ARRAY ON OFF EXTMDATA

DATA ONLY EXTMDATO

FILE NAME TITF

FORMAT ARY ON OFF EXTMFORM

FORMAT INT DISK INID

GRAHPICS ON OFF EXTMGRAP

INTERNAL DISK INTD

LOAD LOAD

RAW ARRAY ON OFF EXTMRAW

READ FILE TITLES REFT

SAVE SAVEREG

SAVE FILE when GRAPH FMT [ ] is set to CSV and

FILETYPE: GRAPHIC is selected.

SAVE FILE when GRAPH FMT [ ] is set to JPG and

FILETYPE: GRAPHIC is selected.

SAVE USING ASCII SAVUASCI

SAVE USING BINARY SAVUBINA

TITLE TITREG

Scale Ref AUTOS CALE AUTO

ELECTRICAL DELAY ELED

MARKER -> REFERENCE MARKREF

PHASE OFFSET PHAO

REFERENCE POSITI ON REFP

REFERENCE VALUE REFV

SCALE / DIV SCAL

Span N/A SPAN

SAVECSV

SAVEJPG

Start N/A STAR

Stop N/A STOP

2-10

Page 33

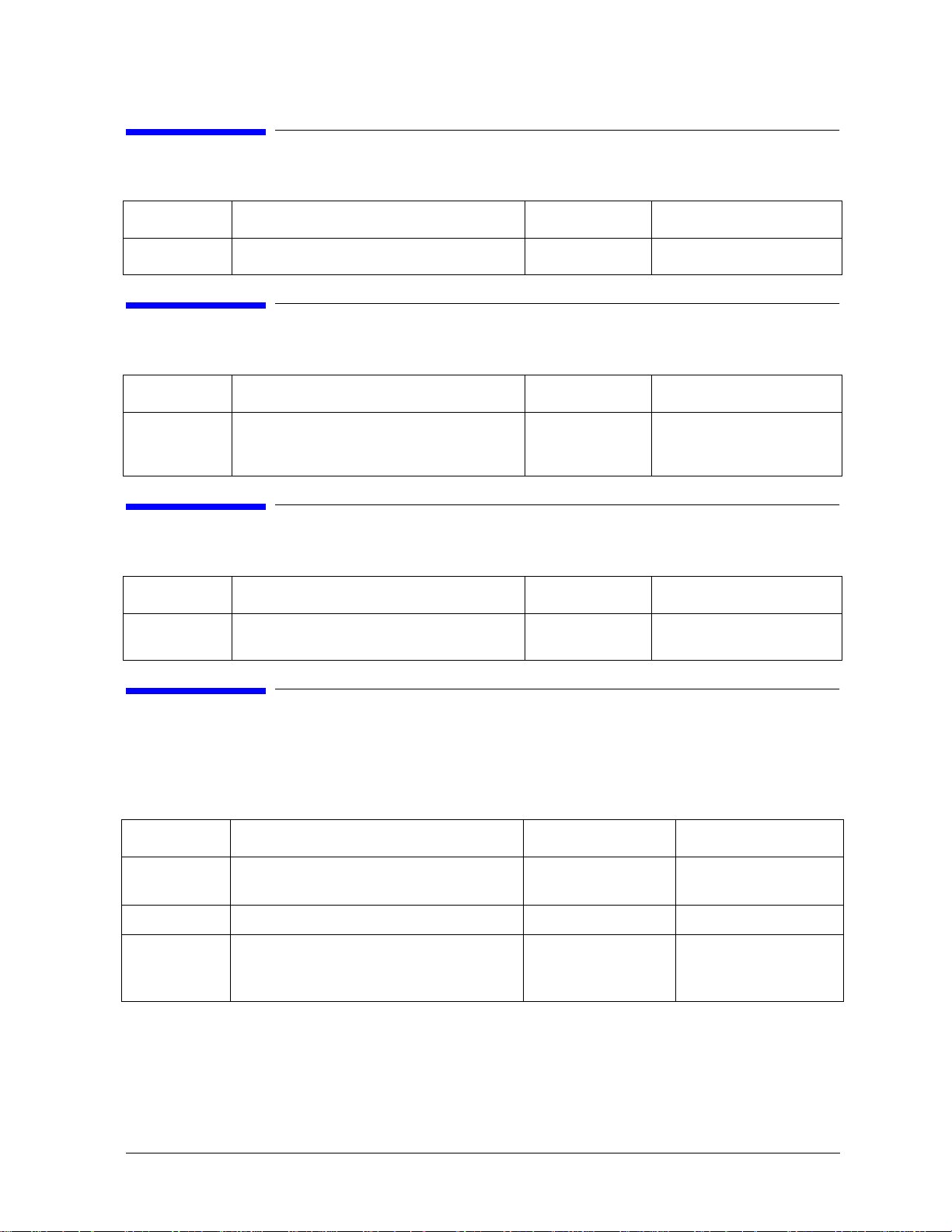

Table 2-1. Front Panel Equivalen ts (9 of 11)

Hardkey Softkey Command

Sweep Setup ALL SEGS SWEEP ASEG

CONTINUOUS CONT

CONTINUOUS FRER

COUPLED CH ON OFF COUC

CW FREQ CWFREQ

CW TIME CWTIME

EXT TRIG ON SWEEP EXTTON

HOLD HOLD

LIN FREQ LINFREQ

LIST FREQ LISFREQ

LIST IF BW ON OFF LISIFBWM

Alphabetical Command Reference

Keys to Programming Commands

LIST POWER ON OFF LISPWRM

LIST TYPE: STEPPED LISTTYPELSTP

LIST TYPE: SWEPT LISTTYPELSWP

LOG FREQ LOGFREQ

MANUAL TRG ON POINT MANTRIG

MEASURE RESTAR T REST

NUMBER of GROUPS NUMG

NUMBER of POINTS POIN <NUM>

POWER SWEEP POWS

SEGMENT IF BW SEGIFBW

SEGMENT POWER SEGPOWER

SINGLE SING

SINGLE SEG SWEEP SSEG

STEP SIZE STPSIZE

SWEEP TIME AUTO SWEA

SWEEP TIME MANUAL SWET <NUM>

TRIGGER: TRIG OFF EXTTOFF

EDIT LIST EDITLIST

Sweep Setup or Cal CLEAR LIST YES CLEL

Sweep Setup or System STEP SWP ON OFF STEPSWP ON|OFF>

2-11

Page 34

Alphabetical Command Reference

Keys to Programming Commands

Table 2-1. Front Panel Equivalents (10 of 11)

Hardkey Softkey Command

System AMPLITUDE OFFSET LIMIAMPO

BEEP FAIL ON OFF BEEPFAIL ON|OFF>

BW DISPLAY on OFF BWLIMDISP ON|OFF>

BW TEST on OFF BWLIMTEST ON|OFF>

CLEAR LIST CLER

CLEAR LIST YES CLEAL

DELTA LIMITS LIMD

DEMOD: AMPLITUDE DEMOAMPL

DEMOD: OFF DEMOOFF

DEMOD: PHASE DEMOPHAS

EDIT LIMIT LINE EDITLIML

EDIT RIPL LIMIT EDITRLIM

FIRMWARE REVISION SOFR

FLAT LINE LIMTFL

FREQUENCY BAND SELBND

HARMONIC OFF HARMOFF

HARMONIC SECOND HARMSEC

HARMONIC THIRD HARMTHIR

LIMIT LINE ON OFF LIMILINE

LIMIT TEST ON OFF LIMITEST

LOWER LIMIT LIML

MARKER -> AMP. OFS. LIMIMAOF

MARKER -> CW MARKCW

MARKER -> MIDDLE MARKMIDD

MARKER -> STIMULUS MARKSTIM

MAXIMUM BANDWIDTH BWLIMMAX

MAXIMUM FREQUENCY RLIMSTP

2-12

MAXIMUM RIPPLE RLIMM

MIDDLE VALUE LIMM

MINIMUM BANDWIDTH BWLIMMIN

MINIMUM FREQUENCY RLIMSTR

N DB POINTS BWLI MDB

Page 35

Table 2-1. Front Panel Equivalents (11 of 11)

Hardkey Softkey Command

Alphabetical Command Reference

Keys to Programming Commands

System or Sweep Setup or

Cal

up N/A UP

SEGMENT DELETE SDEL

DONE EDITDONE

DONE SDON

EDIT SEGMENT SEDI

SEGMENT ADD SADD

2-13

Page 36

Alphabetical Command Reference

Programming Commands

Programming Commands

AB

AB; or AB?;

Command Description Range Query Response

AB Measures and displays A/B on the active

channel.

N/A

<0|1><

L

>

F

ADDR

ADDR<CONT|DISC|PLOT|POWM|PRIN><num>; or ADDR<CONT|DISC|PLOT|POWM|PRIN>?;

Sets the GPIB address for the following peripherals.

Command Description Range Query Response

ADDRCONT Controller GPIB address. The address

where control is returned after a pass

control.

ADDRDISC External disk drive GPIB address. integers 0–30

ADDRPLOT Plotter GPIB address. integers 0–30

ADDRPOWM Power meter GPIB address. integers 0–30

ADDRPRIN Printer GPIB address. integers 0–30

integers 0–30

<num><

<num><

<num><

<num><

<num><

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

ADJB

ADJB

Executes autobiasing of optical modulator. No query response

ALTAB

ALTAB; or ALTAB?;

Command Description Range Query Response

ALTAB Places the analyzer in the alternate inputs

measurement mode, where A and B

measurements are made on alternate

sweeps. See also “CHOPAB.”

2-14

N/A

<0|1><

L

>

F

Page 37

Alphabetical Command Reference

AR

AR; or AR?;

Command Description Range Query Response

AR

AR Measures and displays A/R on the active

channel.

N/A

<0|1><

L

>

F

ASEG

ASEG; or ASEG?;

Command Description Range Query Response

ASEG Uses all segments for list frequency sweep.

See also “SSEG”

N/A

<0|1><

L

>

F

AUTB;

AUTB<ON|OFF>;

Enable or disable autobiasing of optical modulator.

AUTO

AUTO;

Command Description Range Query Response

AUTO Auto scale the active channel. N/A N/A

AUXC

AUXC<ON|OFF>; or AUXC?;

Command Description Range Query Response

AUXC Enables and disables auxiliary channels 3

and 4. OPC-compatible.

Example

10 OUTPUT 716;”CHAN1;AU XCON;” Turns on channel 3

20 OUTPUT 716;”CHAN2;AU XCON;” Turns on channel 4

N/A

<0|1><

L

>

F

2-15

Page 38

Alphabetical Command Reference

AVER

AVER

AVERFACT<num>; or AVERFACT?;

AVERO<ON|OFF>; or AVERO?;

AVERREST;

Command Description Range Query Response

AVERFACT Sets the averaging factor on the active channel. integers 0–999

AVERO Turns averaging on and off on the active

channel.

AVERREST Restarts the averaging on the active channel. N/A N/A

N/A

<num><

<0|1><

BACI

BACI<num>; or BACI?;

Command Description Range Query Response

BACI Sets the background intensity of the

display.

integers 0–100

<num><

L

>

F

BEEP

BEEP<DONE|WARN|FAIL><ON|OFF>; or BEEP<DONE|WARN|FAIL>?;

Command Description Range Query Response

BEEPDONE Causes the analyzer's warning beeper to

sound at the completion of functions such

as save, done with calibration standard,

and data trace saved.

N/A

<0|1><

L

>

F

L

>

F

L

>

F

BEEPFAIL Causes the analyzer's warning beeper to

sound in the event of a limit test failure.

BEEPWARN Causes the analyzer's warning beeper to

sound when a warning message is

generated.

N/A

N/A

<0|1><

<0|1><

L

>

F

L

>

F

BR

BR; or BR?;

Command Description Range Query Response

BR Measures and displays B/R on the active

channel.

2-16

N/A

<0|1><

L

>

F

Page 39

Alphabetical Command Reference

BSAMP

BSAMP<ON|OFF>;

Switch B , sampler to : ON = LW, OFF = R F.

BWLIMDB

BWLIMDB<num>; or BWLIMDB?;

Command Description Range Query Response

BSAMP

BWLIMDB Enters the N dB Point, the amplitude below

the peak that is used to measure the filter’s

bandwidth.

-500 to 500 dB

<num><

L

>

F

BWLIMDISP

BWLIMDISP<ON|OFF>; or BWLIMDISP?;

Command Description Range Query Response

BWLIMDISP Turns the measured bandwidth value in the

upper left corner of the displa y on and off.

The measured bandwidth valu e is displayed

near the bandwidth Pass/Wide/Narrow

message.

N/A

<0|1><

L

>

F

BWLIMMKR

BWLIMMKR<ON|OFF>; or BWLIMMKR?;

Command Description Range Query Response

BWLIMMKR

Turns the limit bandwidth marker on and

off.

N/A

<0|1><

L

>

F

BWLIMMAX

BWLIMMAX<num>[HZ|KHZ|MHZ|GHZ]; or BWLIMMAX?;

Command Description Range Query Response

BWLIMMAX Enters the maximum bandwidth value. If the

measured bandwidth is greater than this

value, the filter fails the bandwidth test.

a. Refer to “Preset State and Memory Allocation” in your analyzer’s reference guide.

stimulus range

a

<num><

L

>

F

2-17

Page 40

Alphabetical Command Reference

BWLIMMIN

BWLIMMIN

BWLIMMIN<num>[HZ|KHZ|MHZ|GHZ]; or BWLIMMIN?;

Command Description Range Query Response

BWLIMMIN Enters the minimum bandwidth value. If the

measured bandwidth is less than this value,

the filter fails the bandwidth test.

a. Refer to “Preset State and Memory Allocation” in your analyzer’s reference guide.

stimulus range

a

<num><

L

>

F

BWLIMSTAT

BWLIMSTAT;

Command Description Range Response

BWLIMSTAT Returns the results of the bandwidth test. A

returned value of 0 indicates that the filter

passed the bandwidth test. A returned

value of −1 indicates that the filter failed

the bandwidth test because it is narrower

than the bandwidth limit. A returned value

of 1 indicates that the filter failed the

bandwidth test because it is wider than the

bandwidth limit.

N/A

<−1|0|1><

L

>

F

BWLIMTEST

BWLIMTEST<ON|OFF>; or BWLIMTEST?;

Command Description Range Query Response

BWLIMTEST Turns the bandwidth test on and off. N/A

<0|1><

L

>

F

BWLIMVAL

BWLIMVAL;

Command Description Range Response

BWLIMVAL Returns the measured bandwidth value. N/A

<num><

L

>

F

CALI

CALI<EORM|OERM|FUL2|RAI|RESP|S111|S221>;

2-18

Page 41

Alphabetical Command Reference

CALI<EORM|OERM|FUL2|RAI|RESP|S111|S221>?;

Command Description Range Query Response

CALK35MM

CALIEORM

Select E/O response and match

<011>

calibration.

CALIOERM

Select O/E response and match

<011>

calibration.

CALIFUL2

a

Begins the sequence for a short, load, open,

N/A

thru (SLOT) 2-port calibration.

CALIRAI Begins the sequence for a response and

N/A

isolation calibration.

CALIRESP Begins the sequence for a response

N/A

calibration.

CALIS111 Begins the sequence for an S11 1-port

N/A

calibration (ES models), or a reflection

1-port calibration (ET models).

CALIS221

a

Begins the sequence for an S22 1-port

calibration.

N/A

a. The result of the query command only tells if the particular type of calibration is currently active. It does not

provide information on the status of the cal sequence

.

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

L

L

L

L

L

CALK35MM

>

F

>

F

>

F

>

F

>

F

CALK35MM;

Command Description Range Query Response

CALK35MM Selects the 3.5mm calibration kit

coefficients.

N/A N/A

CBRI

CBRI<num>; or CBRI?;

Command Description Range Query Response

CBRI Adjusts the color brightness of the selected

display feature.

integers 0–100

<num><

L

>

F

2-19

Page 42

Alphabetical Command Reference

CENT

CENT

CENT<num>[HZ|DB]; or CENT?;

Command Description Range Query Response

CENT Sets the center stimulus value. If a list

frequency segment is being edited, sets the

stimulus range

a

<num><

L

>

F

center of the list segment.

a. For frequency or power sweeps, refer to “Preset State and Memory Allocation,” in your analyzer’s reference guide.

For CW time: 0 to 24 hours. For frequency sweep, transform on:

on:

±1/time step.

± 1/frequency step. For CW time sweep, transform

2-20

Page 43

Alphabetical Command Reference

CHAN

CHAN<1|2|3|4>;

Makes channel 1, 2, 3, or 4 the active channel. OPC-compatible. No query response.

NOTE These commands should use OPC? to prevent timing errors with subsequent

commands. Example code written in BASIC:

10 OUTPUT 716;"OPC?;CHAN2;"

20 ENTER 716;OPC

CLAD

CLAD;

Command Description Range Query Response

CLAD Class done (modify cal kit, specify class). N/A N/A

CHAN

CLASS

CLASS<11A|11B|11C|22A|22B|22C>;

These commands call reflection standard classes during a calibration sequence. If only one

standard is in the class, it is measured. If there is more than one, the standard being used must be

selected with STAN<A|B|C|D|E|F|G>. If there is only one standard in the class, these commands

are OPC-compatible.

Command Description Range Query Response

CLASS11A S11A: S11 (forward reflection) 1-port, open N/A N/A

CLASS11B S11B: S11 (forward reflection) 1-port, short N/A N/A

CLASS11C S11C: S11 (forward reflection) 1-port, load N/A N/A

CLASS22A S22A: S22 (reverse reflection) 1-port, open N/A N/A

CLASS22B

CLASS22C

EXAMPLE To measure the female open of a type-N cal kit:

S22B: S22 (reverse reflection) 1-port, short N/A N/A

S22C: S22 (reverse reflection) 1-port, load N/A N/A

OUTPUT 716;"CLASS11A;OPC?;STANB;"

ENTER 716 OPC;

2-21

Page 44

Alphabetical Command Reference

CLEAREG

CLEAREG

CLEAREG<num>;

CLEARALL;

Command Description Range Query Response

CLEAREG Clears save/recall registers 01 through 31.

CLEAREG01 through CLEAREG05 are the

same as CLEA1 through CLEA5.

OPC-compatible.

CLEARALL Clears all the save/recall registers.

OPC-compatible.

two-digit

integers 01–31

N/A N/A

N/A

CLEAL

CLEAL;

Command Description Range Query Response

CLEAL Clears the limit line list. Should be

preceded by EDITLIML.

N/A N/A

CLEL

CLEL;

Clears the currently selected list. This could be a frequency list, power loss list, or limit test list.

Must be preceded by an “EDIT” command. No query response.

CLES

CL[E]S;

Command Description Range Query Response

CLES Clears the status byte register, the

event-status registers, and the enable

registers.

CLS

Same as

CLES.

N/A N/A

N/A N/A

CLER

CLER;

Clears (or deletes) the all of existing ripple test limits. No query response.

2-22

Page 45

COEFA

COEFA<1-4> [value]

Set numerator coefficients of response model.

COEFB

COEFB<1-4> [value]

Set denominator coefficients of response model.

COEFDELA

COEFDELA [value];

Set delay coefficient of response model.

COEFK;

Alphabetical Command Reference

COEFA

COEFK;

Sets constant coefficient of response model.

CONS

CONS;

Continues the sequence that was paused.

CONT

CONT; or CONT?;

Command Description Range Query Response

CONT Places the analyzer in continuous sweep

trigger mode.

N/A

<0|1><

L

>

F

2-23

Page 46

Alphabetical Command Reference

CONV

CONV

CONV<1DS|OFF|YREF|YTRA|ZREF|ZTRA>; or CONV<1DS|OFF|YREF|YTRA|ZREF|ZTRA>?;

These 6 commands convert the S-parameter data to:

Command Description Range Query Response

CONV1DS Inverted S-parameters. N/A

CONVOFF Turns S-parameter conversion off. N/A

CONVYREF Y:reflection (admittance). N/A

CONVYTRA Y:transmission (transmission). N/A

CONVZREF Z:reflection (impedance). N/A

CONVZTRA Z:transmission (transmission). N/A

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

CORI

CORI<ON|OFF>; or CORI?;

Command Description Range Query Response

CORI Turns interpolative error correction on and

off.

N/A

<0|1><

L

>

F

CORR

CORR<ON|OFF>; or CORR?;

Command Description Range Query Response

CORR Turns error correction on and off. N/A

<0|1><

L

>

F

COU

COU<C><ON|OFF>; or COU<C>?;

Command Description Range Query Response

COUC Couples and uncouples the stimulus

between the channels.

N/A

<0|1><

L

>

F

COUS

COUS<ON|OFF>;

2-24

Page 47

Alphabetical Command Reference

Switch coupling to measurement parameter ON or OFF.

CWFREQ

CWFREQ<num>[HZ|DB]; or CWFREQ?;

Command Description Range Query Response

CWFREQ

CWFREQ Sets the CW frequency for power sweep and

CW frequency modes. While the list

stimulus range

a

<num><

L

>

F

frequency table segment is being edited, it

sets the center frequency of the current

segment. See also “MARKCENT.”

a. For frequency or power sweeps, refer to “Preset State and Memory Allocation,” in the analyzer’s reference guide.

For CW time: 0 to 24 hours. For frequency sweep, transform on:

on:

±1/time step.

±1/frequency step. For CW time sweep, transform

CWTIME

CWTIME; or CWTIME?;

Command Description Range Query Response

CWTIME Selects CW time as the sweep type. N/A

<0|1><

L

>

F

D2XUPCH

D2XUPCH<2|3>; or D2XUPCH<2|3>?;

Command Description Range Query Response

D2XUPCH2 Sets up a two-graticule display with

channel 2 on top.

D2XUPCH3 Sets up a two-graticule display with

channel 3 on top.

N/A

N/A

<0|1><

<0|1><

L

>

F

L

>

F

D4XUPCH

D4XUPCH<2|3>; or D4XUPCH<2|3>?;

Command Description Range Query Response

D4XUPCH2 Sets up a four-graticule display with

channel 2 in the upper right quadrant of

the display.

D4XUPCH3 Sets up a four-graticule display with

channel 3 in the upper right quadrant of

the display.

N/A

N/A

<0|1><

<0|1><

L

>

F

L

>

F

2-25

Page 48

Alphabetical Command Reference

DATI

DATI

DATI;

Stores the data trace in channel memory. OPC-compatible. No query response.

DEBU

DEBU<ON|OFF>; or DEBU?;

Command Description Range Query Response

DEBU Turns the GPIB debug mode on and off.

When on, the analyzer scrolls incoming

GPIB commands across the display.

N/A

<0|1><

L

>

F

DEFC

DEFC;

Sets the d efault co lors for al l display f eatures. N o q uery res ponse.

DEFS

DEFS<num>;

Command Description Range Query Response

DEFS Begins standard definition during cal kit

modification. “<num>” is the standard

number.

integers 1–8 N/A

DEL

DEL<O|RFIXM>; or DEL<O|RFIXM>?;

DELR<num>; or DELR<num>?;

Command Description Range Query Response

DELO Turns delta marker mode off. N/A

DELR Makes the indicated marker the delta

reference.

DELRFIXM Makes the fixed marker the delta reference. N/A

integers 1–5

2-26

<0|1><

<0|1><

<0|1><

L

>

F

L

>

F

L

>

F

Page 49

Alphabetical Command Reference

DELA

DELA; or DELA?;

Command Description Range Query Response

DELA

DELA Displays the data formatted as group delay. N/A

<0|1><

L

>

F

DEMO

DEMO<AMPL|OFF|PHAS>; or DEMO<AMPL|OFF|PHAS>?;

Command Description Range Query Response

DEMOAMPL Turns on transform demodulation and sets

the transform demodulation to amplitude

demodulation. Only has a meaningful effect

with a CW time transform.

DEMOOFF Turns the transform demodulation

function off.

DEMOPHAS Sets the transform demodulation to phase

demodulation. Only has a meaningful effect

with a CW time transform.

N/A

N/A

N/A

<0|1><

<0|1><

<0|1><

L

>

F

L

>

F

L

>

F

DISC

DISC<UNIT><num>; or DISC<UNIT>?;

Command Description Range Query Response

DISCUNIT Specifies which disk in an external

multiple-disk drive to be used for

save/recall.

integers 0–30

<num><

L

>

F

DISM

DISM<ON|OFF>; or DISM?;

Command Description Range Query Response

DISM When on, displays the response and

stimulus values for all markers that are

turned on; when off, only the active

marker's value is displayed.

N/A

<0|1><

L

>

F

DISP

DISP<DATA|DATM|DDM|DMM|MEMO|DPM|DTM|M1DM|M1MM|M1PM|M1TM|M2DM|M2MM|MATH|MMD

2-27

Page 50

Alphabetical Command Reference

DONE

|MDD>;

DISP<DATA|DATM|DDM|DMM|MEMO|DPM|DTM|M1DM|M1MM|M1PM|M1TM|M2DM|M2MM|MATH|MMD

|MDD>?;

These commands display the indicated combinations of data and trace me mo ry on the active

channel.

Command Description Range Query Response

DISPDATA Data only. N/A

DISPDATM Data and memory. N/A

DISPDDM Data divided by memory (linear division,

N/A

log subtraction). See also “DIVI.”

DISPDMM Data minus memory (linear subtraction).

N/A

See also “MINU.”

DISPMEMO Memory only. N/A

DISPDPM

DISPDTM

DISPM1DM

DISPM1MM

DISPM1PM

DISPM1TM

DISP

M2DM

Display data plus memory. N/A

Display data times memory. N/A

Display memory 1 divided by memory 2. N/A

Display memory 1 minus by memory 2 N/A

Display memory 1 plus memory 2. N/A

Display memory 1 times memory 2. N/A

Display memory 2 divided by memory 1. N/A

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

<0|1><

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

L

>

F

DISP

M2MM

DISPMATH

DISPMMD

DISP

MDD

Display memory 2 minus memory 1. N/A

Display math results N/A

Display memory minus data N/A

Display memory divided by data N/A

<0|1><

<0|1><

<0|1><

<0|1><

L

>

F

L

>

F

L

>

F

L

>

F

DONE

DONE;

Done with a class of standards, during a calibration. Only needed when multiple standards are

measured to complete the class. OPC-compatible. No query response.

DONM

DONM;

2-28

Page 51

Alphabetical Command Reference

DOSEQ

Done modifying a test sequence. No query response.

DOSEQ

DOSEQ<1-6>;

Start sequence 1-6. No query response.

DOWN

DOWN;

Decrements the value displayed in the active entry area (em ulates pressing the down-arrow key ).

No query response.

2-29

Page 52

Alphabetical Command Reference

DRIVPORT

DRIVPORT

DRIVPORT<ON|OFF>;

Drive port; ON = LW, OFF = RF.

DUAC

DUAC<ON|OFF>; or DUAC?;

Command Description Range Query Response

DUAC Turns dual channel display on and off. N/A

<0|1><

L

>

F

EDIT

EDIT<DONE|LIML|LIST>;

Command Description Range Query Response

EDITDONE Done editing list frequency, limit table, cal

sensor table, or power loss list.

OPC-compatible.

EDITLIML Begins editing limit table. N/A N/A

EDITLIST Begins editing list frequency table. N/A N/A

N/A N/A

EDITRLIM

EDITRLIM;

Begins the editing of the ripple limit list. No query response.

ELED

ELED<num>[S]; or ELED?;

Command Description Range Query Response

ELED

2-30

Sets the electrical delay offset. ±10 seconds

<num><

L

>

F

Page 53

Alphabetical Command Reference

ENTO

ENTO;

Command Description Range Query Response

ENTO

ENTO Removes displayed information from the

active entry area on the screen.

N/A N/A

EOCAL

EOCAL;

Internal E/O service calibration parameter.

ESE

ESE<num>; or ESE?;

Command Description Range Query Response

ESE Enables the selected event-status register

bits to be summarized by bit 5 in the status

byte. An event-status register bit is enabled

when the corresponding bit in the operand

<num> is set.

integers 0–255

<num><

L

>

F

ESNL

ESNL<num>; or ESNL?;

Command Description Range Query Response

ESNL Enables the selected event-status register L

bits to be summarized by bit 2 in the status

byte. An event-status register bit is enabled

when the corresponding bit in the operand

<num> is set.

integers 0–4095

<num><

L

>

F

ESL?

ESL?;

Command Description Range Query Response

ESL? Query only. Outputs event-status register. N/A

<num><

L

>

F

2-31

Page 54

Alphabetical Command Reference

EXTM

EXTM

EXTM<DATA|FORM|GRAP|RAW><ON|OFF>; or EXTM<DATA|FORM|GRAP|RAW>?;

These commands include the indicated information when an instrument state is stored to the

internal floppy disk drive or an external disk.

Command Description Range Query Response

EXTMDATA Adds error corrected data (real and

imaginary pairs) along with the other files.

EXTMFORM Formatted trace data. Uses currently

selected format for data.

EXTMGRAP User graphics. N/A

EXTMRAW Raw data arrays (real and imaginary pairs). N/A

a. See Figure 6-1 on page 6-3. This error corrected data is the same as that output by the OUTPDATA command.

N/A

a

N/A

<0|1><

<0|1><

<0|1><

<0|1><

L

>

F

L

>

F

L

>

F

L

>

F

EXTT

EXTT<ON|OFF>; or EXTT?;

Command Description Range Query Response

EXTT Activates or deactivates the external

trigger mode. OPC-compatible.

N/A

<0|1><

L

>

F

FORM

FORM<1|2|3|4|5>;

These 5 commands set the data format for array transfers in and out of the instrument:

Command Description Range Query

Response

FORM1 The analyzer's internal binary format, 6 bytes-per-data point.

The array is preceded by a four-byte header. The first two

bytes represent the string “#A”, the standard block header.

The second two bytes are an integer representing the number

of bytes in the block to follow. FORM1 is best applied when

rapid data transfers, not to be modified by the computer nor

interpreted by the user, are required.

FORM2 IEEE 32-bit floating-point format, 4 bytes-per-number,

8 bytes-per-data point. The data is preceded by the same

header as in FORM1. Each number consists of a 1-bit sign, an

8-bit biased exponent, and a 23-bit mantissa. FORM2 is the

format of choice if your computer is not a PC, but supports

single-precision floating-point numbers.

2-32

N/A N/A

N/A N/A

Page 55

Alphabetical Command Reference

Command Description Range Query

Response

FREO

FORM3 IEEE 64-bit floating-point format, 8 bytes-per-number,

16 bytes-per-data point. The data is preceded by the same

header as in FORM1. Each number consists of a 1-bit sign, an

11-bit biased exponent, and a 52-bit mantissa. This format

may be used with double-precision floating-point numbers.

No additional precision is available in the analyzer data, but

FORM3 may be a convenient form for transferring data to

your computer.

FORM4 ASCII f loating-point format. The data is transmitted as ASCII

numbers, as described in “Output Syntax” on page 5-4. There

is no header. The analyzer always uses FORM4 to transfer

data that is not related to array transfers (i.e. marker

responses and instrument settings). Data is comma delimited.

FORM5 PC-DOS 32-bit floating-point format with 4 bytes-per-number,

8 bytes-per-data point. The data is preceded by the same

header as in FORM1. The byte order is reversed with respect

to FORM2 to comply with PC-DOS formats. If you are using a

PC-based controller, FORM5 is the most effective format to

use.

FREO

FREO;

N/A N/A

N/A N/A

N/A

Frequency blank. Turns frequency notation off. Once the frequency notation has been turned off

(blanked), it cannot be turned back on until a preset or recall is initiated. No query response.

FRER

FRER; or FRER?;

Command Description Range Query Response

FRER Places the analyzer in GPIB free run mode.

(Same as continuous sweep trigger mode.)

See “CONT.”

N/A

<0|1><

L

>

F

FWD

FWD<I|M|T>;

These commands are OPC-compatible if there is only one standard in the class. If there is just one

standard, that standard is measured automatically. If there is more than one standard in the class,

2-33

Page 56

Alphabetical Command Reference

HOLD

the standard being used must be selected with the STAN command.

Command Description Range Query Response

FWDI Selects the forward isolation calibration

class during a 2-port calibration sequence.

FWDM Selects the forward match calibration class

during a 2-port calibration sequence.

FWDT Selects the forward transmission

calibration class during a 2-port calibration

sequence.

N/A N/A

N/A N/A

N/A N/A

HOLD

HOLD; or HOLD?;

Command Description Range Query Response

HOLD Puts the sweep trigger into hold mode. N/A

<0|1><

L

>

F

IDN?

IDN?;

Command Description Range Query Response

IDN? Query only. Outputs the identification string:

where 87NNEX is the model number of the

instrument, xxxxxxxxxx is the serial number of

the instrument, and X.XX is the firmware

revision of the instrument.

N/A See command description

IFBW

IFBW<num>[HZ]; or IFBW?;

Command Description Range Query Response

IFBW Sets the IF bandwidth. Choose from 10, 30,

100, 300, 1000, 3000

<num><

L

>

F

IMAG

IMAG; or IMAG?;

Command Description Range Query Response

IMAG Selects the imaginary display format. N/A

<0|1><

L

>

F

2-34

Page 57

Alphabetical Command Reference

INI

INI

INI<D>;

Initializes the internal disk. All previous information on the disk will be destroyed. No query

response.

INPU

INPUCALC<num><array>;

INPU<CALK|DATA|FORM><array>;

INPULEAS<learnstring>; or INPULEAS?;

INPURAW<1|2|3|4><array>;

All of these commands (with a few noted exceptions) input an array and require that you set the

format for data transfers with the FORM command. All of these commands have an associated

OUTPut command that is used to transfer data from the analyzer. See “OUTP,” later in this

chapter.

Command Description Range Query

Response

INPUCALC

INPUCALK

INPUDATA Inputs an error corrected data array, using the current

INPUFORM Inputs a formatted data array, using the current setting

INPULEAS

INPURAW1 Inputs raw data array 1 (S

INPURAW2 Inputs raw data array 2 (S

b

b

Error coefficient array

Inputs a cal kit array in FORM1 only. Can be read out

with the OUTCALK command. After the transfer, the data

should be saved into the user cal kit area with the

SAVEUSEK command.

setting of the FORM command.

of the FORM command.

Inputs a learn string in FORM1 only. Can be read out

with the OUTPLEAS command, or with INPULEAS?.

received, the analyzer stops sweeping, error-corrects the

data, then formats and displays the data.

received, the analyzer stops sweeping, error-corrects the

data, then formats and displays the data.

a

<num>.

data). After the data is

11

data). After the data is

21

two-digit

integers 01–12

N/A N/A

N/A N/A

N/A N/A

N/A

N/A N/A

N/A N/A

N/A

<data><

L

>

F

INPURAW3 Inputs raw data array 3 (S

received, the analyzer stops sweeping, error-corrects the

data, then formats and displays the data.

INPURAW4 Inputs raw data array 4 (S

received, the analyzer stops sweeping, error-corrects the

data, then formats and displays the data.

data). After the data is

12

data). After the data is

22

N/A N/A

N/A N/A

2-35

Page 58

Alphabetical Command Reference

INPU

a. These commands input an individual error coefficient array. Before sending an array, issue a CALIXXXX; command,

where XXXX specifies the calibration type. (See “CALI” earlier in this book.) Then input the array or arrays. Lastly

store the data with the SAVC command. The instrument goes into hold, displaying uncorrected data. Complete the