TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT

SUPPORT, AND GENERAL SUPPORT

I’

MAINTENANCE MANUAL

SIGNAL GENERATOR SG-1207/U

(HEWLETT-PACKARD MODEL 8642M)

‘“/, */ ’ -, ,,d>

(NSN 6625-01-233-8615) r”:‘:‘s :I,,:

COPYRIGHT AND DISCLAIMER NOTICE

Copyright - Agilent Technologies, Inc. Reproduced with the permission of Agilent

Technologies Inc. Agilent Technologies, Inc. makes no warranty of any kind with regard

to this material including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose. Agilent Technologies, Inc. is not liable for errors

contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material or data.

O-9. PACKAGING.

Original Puckuging. Containers and materials identical m rhose used in facmry packaging arc

available through Hewlett-Packard offices. If the insuument is being rammed m Hewlett-Packard

for servicing, attach a tag indicating the rype of service required, return address, mcdel number, and.

full serial number. Also mark the container FRAGILE m assure careful handling. In any

correspondence refer to the insmment by model number and full serial number.

Other PacKaging.

The following general insmxtions should be used for repackaging with

commercially available mat&&:

I. Wrap the insuument in heavy paper or plastic. (If shipping m a Hewlett-Packard office or

sen4ce center, attach a tag indictig the service rqulr-ed m xlckss, mcdd

number,

and full

serial number.)

2. Use a strong shipping container. A double wall carton made of 2.4 MPa (350 psi) test material

is aaequate.

3. Use enough shock-absorbing material (75 m 100 mm layer, 3 m 4 in.) around all sides of the

insuument m provide Frm cushion and prevent movement in dx container. Protect the front

panel withcardboard.

4. Seal the shipping container securely.

5. Mark the shipping container FRAGILE m ensure careful handling.

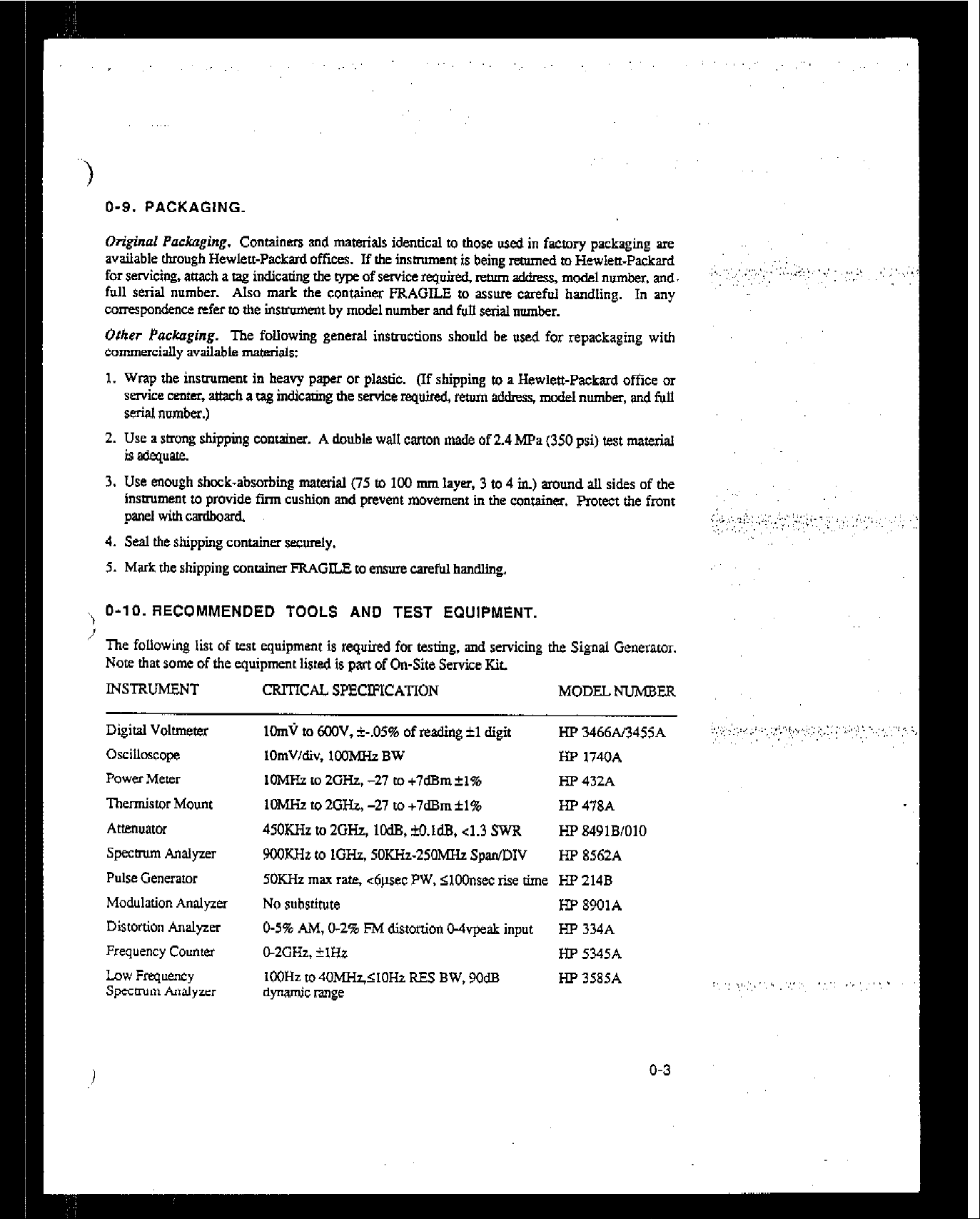

‘, O-10. RECOMMENDED TOOLS AND TEST EQUIPMENT.

The following list of test equipment is required for testing,

Note that some of the equipment listed is part

INSTRuMENT

Digital Voltmeter

Oscilloscope

Power Meter

Thermistor Mount

Attenuator

Specuum Analyzer

Pulse Generator

Modulation Analyze1

Distortion Analyzer

Frequency Counter

Low Frequency

Spccmm Analyzer

CRITICAL SP!3X=ICATION MODUNLTMBEU

1CmV m 6OOV, i-.05% of reading fl digit

lOmV/div, loOMHa BW

1OMHz m 2GHz. -21 m +7dBmfl%

1OMHz to 2GH.z. -21 m +7dBm fl%

45OKHz m 2GHz,

9OOKHir to lGHz, 5OKHz-25OMHz

5OKHz max rare, <6psec PW,

No substitute

O-5% AM, O-246 FM distonion WvpeaL input

02CHz, +lHz

IC’OHz m40MH~<10H2 RES

dynamic range

of

On-Site Service K~L

lCdB, M.1d.B. cl.3 SWR

and

servicing tie Signal Generamr.

Span/DIV

<lOOnsec rise time

BW,

9OdB

Hp 3466.413455~

m 1740A

HP 432A

HP 478A

Hf’8491B/OlO

m 8562~

HP 214B

HP 8901A

HP 334A

HP 5345A

HP 3585A

‘~

:;. :, ,, ,, ,,,

I. ,, ,,,.’ .;. :,. ,,,,. ,,,

O-1 0. RECOMMENDED TOOLS AND TEST EQUIPMENT-Continued.

,, _, ,,,“..

INSTRUMENT

CRITICAL SPEtIFICATlON MODEL NUMBER

BNCtotypeN

BNC to dual banaua

SOn BNC-BNC (2 each)

BD ASSY PS TEST CONN

Flat

Long

Short

MSMCto&)SMC(4)

(F) BNC to (R SMC (2)

MSMCTEE

OSMAfo(f)SMC(2)

50 Pin Test Connector

16 Pin Test Connector

26 Pi Test Connector

HPO8642-80053

HP 0864240959

Hl'O8662-6UO7S

HPO8662-60080

Hp12SO-0827

HP12SO-0832

HpnSO-0837

HP12SO-1697

HP12Sl-5653

HP 1251-8105

HP 1251.8248

o-4

34PinTesrConnector

20PinTeestConnector

14 Fin.Test Connector

10 Pin Test Comwtor

Binding Post

HP 1250-8601.

HP12.51-8812

HP1251-8823

w 1252-0153

HP 5021-0844

HP 34118A

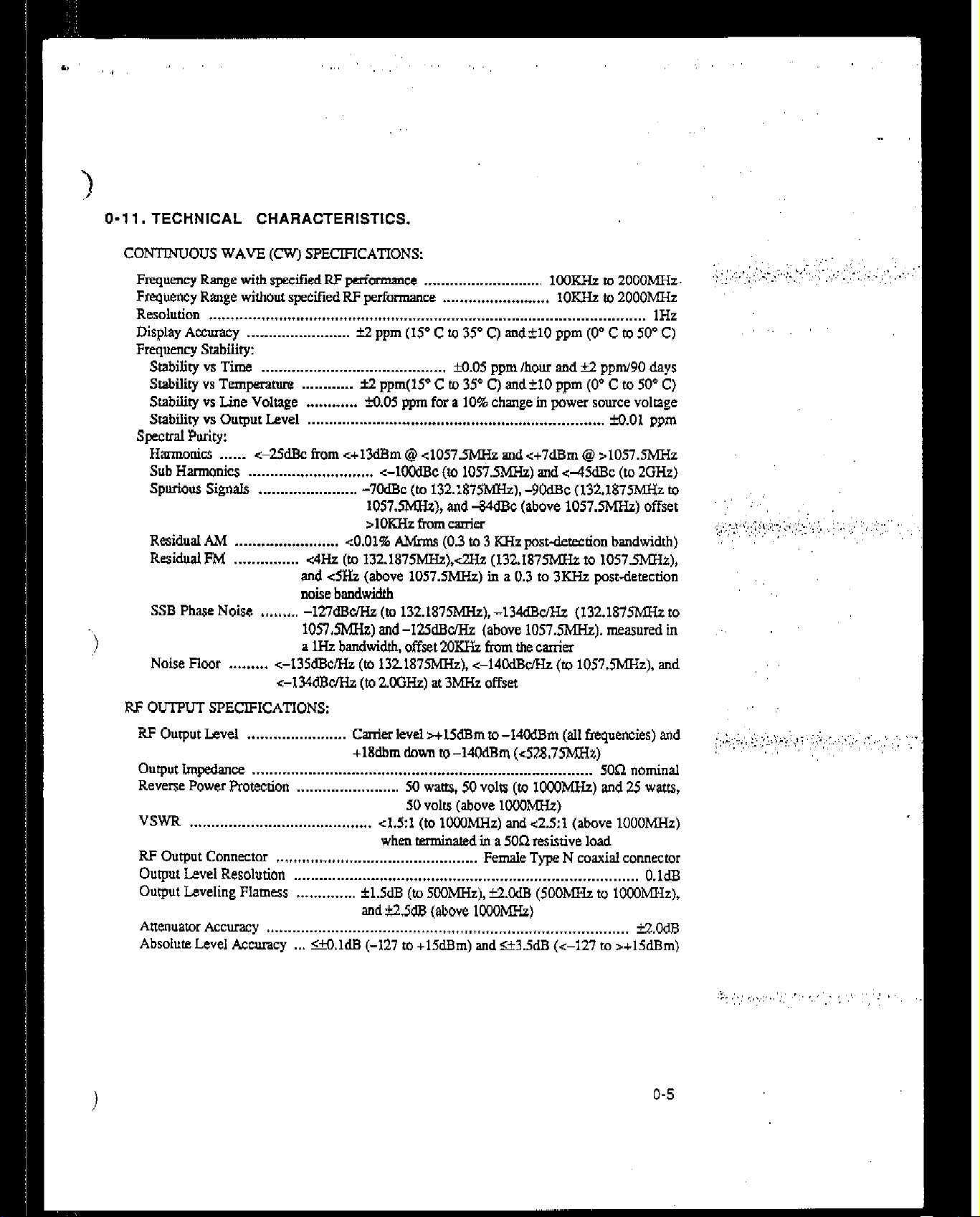

O-l 1. TECHNICAL CHARACTERISTICS.

II

CONTRiUOUS WAVE (CW) SPECIFICATIONS:

Frequency Range with specified RF performance . . . . . . . . . . . . . . . . . . . . . . . . . . 100KHz to 2OOOMHz.

Frequency

Resolution

Display Accuracy .____................... ic2 ppm (IS’ C to 35’ CJ

Frequency Smbility:

Stability

Stabiliry vs Temperaruff

Stability vs Line Voltage . . . . . . . . . . . .

Stabiliv

spectral Purity:

Hmonics

Sub Harmonics

Spurious Signals .._...._....._......... -7OdBc (10 132.:875MHz), -9OdBc (132.187mz to

Residual

Residual FM .._...._.._.... -z4Hz (to 132.1875MHz),~Wz (132.1875MXz to 1057.5MIz),

SSB Phase Noise

Noise Floor . . . . . . . . . <-135dBclMz (to 1321875MHz). <-14CklBcMz (to 1057.5MHt),

Range without specified RF performance . . . . . . . . . . . . . . . . . . . . . . . . .

.._ ._...._.................................. _ _...._..._.__........................................... 1Hz

xndk10 ppm (0” C to 50” C)

vs Time . . .._.._....._............................. M.05 ppm /how and +2 ppm/PO days

. . . . . .._.__. f2 ppm(lS’ C to 35’ C) and?10 ppm (0” C to SO” C)

X1.05

ppm for a 10% change in power source voltage

vs Output Level . . . . . .._......._..._.. _ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M.O1 ppm

. . . . . . <-25dBc from <+13&m @ <1057.5MHz and<+7dBm @ >1057.5MHz

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +lCOdBc (to 1057.5MHz) and <45dBc (to 2GHz)

1057.!MIz), and -WcIBc (above 1057.5MHz) offset

rlOKHzkImcauier

AM . . . . . . _._ . . . . . . . . . . . . . . . ~0.01% &Inns (0.3 to 3 KHz post&t&ion bandwidth)

and &Hz (above 1057.5MHz) in a 0.3 to 3KHz

noise bandwidth

. . . . . . . . .

-127dBBe/Hz (m 132.1875MHz). -134dBu’Hz (132.1875MIIr to

1057.5hfHz) and -125clBc/Hz (above 1057SMHz). measured in

a 1I-k bandwidth, offset 2OKIL from the carrier

<-134wdBc/Hz (to ZOGHZ) at 3hfHz offset

IOK& to 2000MYHt

postdetection

and

‘,‘, ,,,. ,,,,,,.t,. ,,,., :‘<,,:,‘,,:.G .;‘:: ,” .,

RF OUTPUT SPECIFICATIONS:

RF Output Level

Output Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reverse Power Protection

VSWR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ~1.5~1 (to 1MxIMHz) and <2.5:1 (above 1OOOMHz)

RF Output Connector . . . . . . . . . .._......._........................... Female

Output Level

Output Leveling Flamess +.............

Attenuamr Accuracy tt.t....................................... _ .t...t....._l_....l..................... iz.OdB

Absolute Level Accuracy .

. . . . . . . . . . . . . . . . . . . . . . . Carrier level s++15dBm

+lEdbm down to -14OdBm (-z52&75’MHz)

. . . . . . . . . . . . . . . . . . . . SO waas, 50 volts (to IOOOMHt) and 25 watts,

SO volrs (above 1CCOMH.z)

when terminated in a 5O!Z resixive load

Resolution . . . . . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . O.ldB

fl.SdB (to SOOhlHz), Yz.&lB (5cOMxz to loooM!IZ),

and ?2,5dE (above 1KJOMHz)

ti.ldB (-127 to +lSdBm) and e3.5dB (r-127 to >+15dBm)

to-M-m (all frequencies) and

5061 nominal

Type N coaxial connector

o-5

:. \‘; .,:,! ,,*:. .,,. 1 ,.,,::; ,,, ; ,,,, ;.,., :,,jI ,_., :,,: ,,,.:, :: i.’

:.,:I; “.‘,... :,, ..,,

.,

.,,

:‘:I. ‘.“.

o-l I. TECHNICAL CHARACTERISTICS-Continueds

,‘., ,’

,,:,y: .,: .‘,,,: :‘,,

,, L. ‘,,, ;:..,‘-,‘~::.~,.-,I.~~~. ,‘,,:

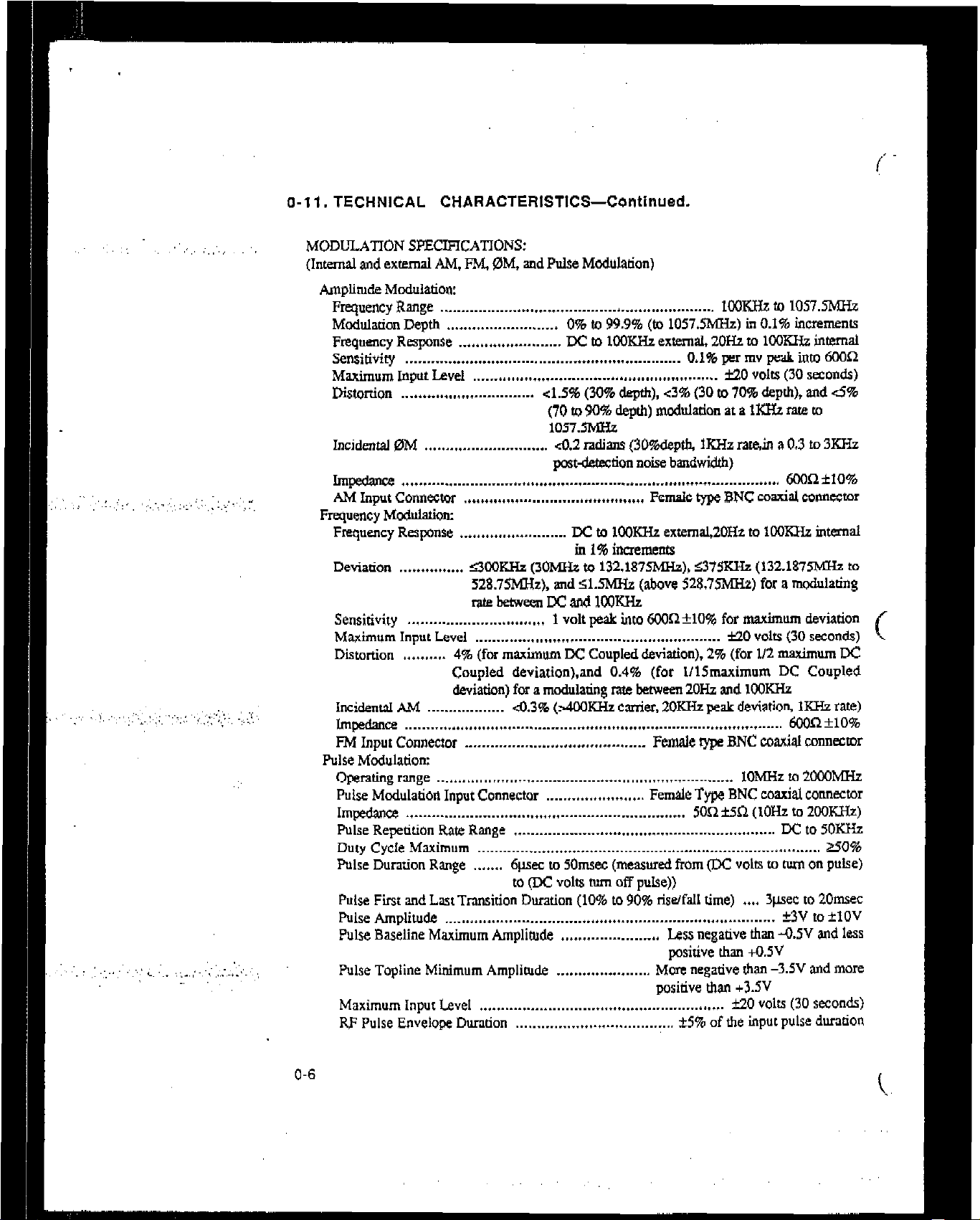

MODULAl’ION SPECIFICATIONS:

(Inted and external AM, FM. @M, and Pulse Mcdulation)

Amplintde Modulation:

Frequency Range ................................................................ IOXHz to 1057.5MH.z

Mcddation Depth ..........................

Frequency Respnse ........................

Sensitivity

................................................................

Maximum Input Level ......................................................... ti0 volU (30

0% to 99.9% (to 1057.5was) ill 0.1% increments

EC to 1cOKHz external, ZOHZ to 1OoKHz imernal

0.1% per mv peak into 6OOR

seconds)

Distottion ............................... ~1.5% (30% depth), <3% (30 to 70% depth), and 6%

(70 to 90% depth) nlodltIation at a lKH2 rate to

1057.5hxHz

Incklental OM .............................

dY.2 radians (3o%depdl, IKHZ rat&n a 0.3 to 3KHz

postbtion noise bandwidth)

Impedance

........................................................................................

6ooILflO%

AM Input Connector .......................................... Female type BNC coaxial co~mwor

Fruquency

Moddation:

Frequency Response ......................... Jx to 1oom extemal,2OHz to 1cOKHz internal

in 1% inaements

Deviation ............... S3oOKHz (3oMHz to 132.1875MHz), ~375KHz (132.1875MXh to

528.75MHt), and zX?MHz (above 528.75MHz) for a modulating

l-akb@tweenDcand1M3KI”Iz

Sensitivity ................................

1 volt peak into 6OOn+lO% for maximum deviation

Maximum Input Level ......................................................... ti0 volts (30 seconds)

Distortion ..........

4% (for maximum DC Coupled deviation), 2% (for l/2 maximum DC

Coupled cleviation).and 0.4% (for IllSmaximum DC Coupled

deviation) for a mod&&g rate between 2OHz and IOOKHz

IncidentsJ AM .................. 4.3% (z4OOKHz wrier, 2OKHz peak deviation, KHz rate)

Impedance ........................................................................................ MX)RflO%

FM Input Connector .......................................... Female type BNC coaxial connector

Pulse Modulation:

Operating rmge ..................................................................... 1oMRz to 2OcGMHz

Pulse

Modulation

Input Connector ....................... Female Type BNC coaxial connector

Imp&we ................................................................. 5OR k.5l2 (IOH to ZOOKHZ)

Pulse Repetition Rate Range ............................................................. IX to 5OKHz

Duty Cycle Maximum ................................................................................ Z50%

Pulse Duration Rage .......

6p.w to 5Omsec (measured from (DC volts to turn on pulse)

to (DC volts two off pulse))

Pulse Fit and Last Transition Duration (10% to 90% ris~fall time) .... ~&XC to 2Omsec

Pulse Amplitude ............................................................................. *3V to flOV

Pulse Baseline Maximum Amplitude ....................... Less negative than -0.5V and less

positive than +0.5V

Pulse Topline Minimum Amphde ......................

More negative than -3.5V and more

positive than +3.5V

Maximum Input Level ......................................................... k20

RF Pulse Envelop Duration .....................................

zk5% of the input pulse duration

volts

(30

SKOW

O-6

)

O-l I. TECHNICAL CHARACTERISTICS-Continued.

MODULATION SPECIFICATTCNS-Continuecb

Pulse Mcdula!k~ontinue~

RF Fuke Envelope FirsVLast Transition Duration (lo%-SO% t&fall time) .... <0.5pec

RF Pulse Envelope OvershootUndershoot ..... 40% of the RF pulse envelope amplimde

RF Puke Envelope fit and Last Settling Duration

RF Pulse Envelope On/Off Rado .............................. . ...

Phase Mcxhtlation:

Maximum Deviation

Bandwidth ............ DC to 1SRH.z external (DC coupled) and 2OHx to 15RHz intemaI and

Resolution ...... 0.7% of setting or O.OOW% of maximum deviation, whichever is greater

Accuracy ............................................... *(5% of setting +O.W radians) at KHz rate

Distortion .............................................................................. ~0.4% at 1RHz rate

External Sensitivity

Maximum Input Level ......................................................... f15 volts (30 s~onda)

................................................................. s0RrSR(10Hzto2o3KHz)

0M Input Connector .......................................... Female type BNC coaxial connector

Internal Modularion OsciIlatw

Frequency Range: ........................................................................ 2OHz M loOK&

Frequency Rcaolutlon: ...................................................................... 1% of setting

Frequency Accuracy: ............ . . .............. . .................................. . ..... . ... 2% of setting

Output Level Range: .................................................... 0 to 3 volu peak inro 6OOR

Output Level Resolution: ............... . ............................................................. 4mv

Outptt Level Accuracy (within 1 set)! .... . ........................................... *(4%+15mV)

Distortion (zO.SV peah): .... co.0296 (20Hzm 15.8KHz ). -3.15% (15.8KHz to 1OORHa)

output Impedance: ........... . ......................................................................... 6ooR

Output Connector .............................................. Female type BNC coaxial connector

......

100 radians (from 1OORHa to 1321875MHz). 25 radians (from

132.187SMHz to 264.375MHz). 50 radians (from

2E4+375MUzto528.75MH.z), IWradims(fiom 528.75hC-h

to 1057.5MHz), 200 radians (from 1057.5MHz to 2.OCI-Ia)

external (AC coupled)

................................

1 volt pk for selected peak phase deviation

........

clpssec to within fl% of Illal

value (measured from two

90% pim)

W (1OMHz to 2OOOMHa)

REAR PANEL CONNECTOR SPECIFICATIONS:

Interface Connecmr:

Type ............ ANSI I IEEE Standard 488-1978 interface with SHI, AHl, Tl, 2 5, or 6,

Ll, 2, 3, or 4, SRl, RLl, PPO, DCI, ETO, and CO functions

implemented

Control .................. AI1 front panel functions, except power switch and increment Inob,

may be controlled through the interface

X-Axis Connector ......................................................................

Z-Axis Connectar ................ TTL posidve nue for CRT display blanking during reuace

External Reference Input ................... 1.2.5 or lOMHa, G5ppm, >0.5Vp-p 5OX2 input

1OMHz Output ........................... lOMHt, >lAVp-p into 50R, 750 impedance output

.i

I

GlOVdc, 50%

o-7

: :..,

O-l 1. TECHNICAL CHARACTERISTICS-Continued.

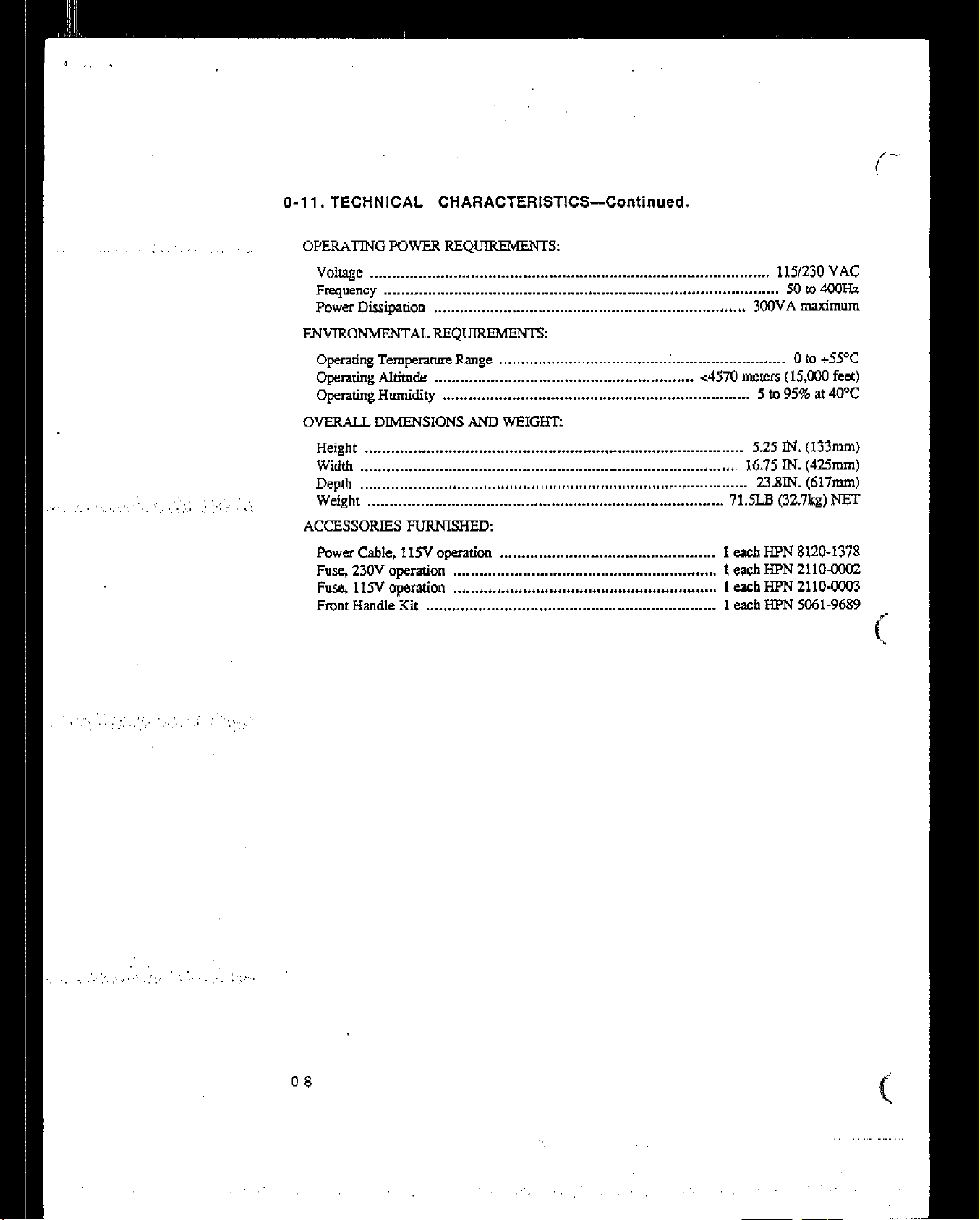

OPERATING POWER REQUIREMENTS:

Voltage ................... ......................................................................... 1151230 VAC

Frequency

Power Dissipation

...........................................................................................

........................................................................ 3WVA maximum

50 to 400Hz

ENVIRONMENTALREQUREMENT~

Operating Tempxuure Range ....................................... . .......................... 0 to +55’C

operathlg Attitude ............................................................

Operating Humidity .......................................................................

<4570 meters (15,wu feet)

5 to 95% at 4pC

OVERALL DIMENSIONS AND WEIGFIT:

Height ....................................................................................... 5.25 IN. (133m)

Width ....................................................................................... 16.75 IN. (425mm)

Depth .........................................................................................

Weight ..................................................................................

23.8IN. (617m)

71.5LB (32.7kg) NET

ACCESSORIES FURNISHED:

Power Cable, IISV option .................................................. 1 each HFN 8120-1378

Fusp 230V operation .............................................................

1 each H?N 211OaoOZ

Fuse, t15V operation ............................................................. 1 each HFN 2110-0003

Front Handle Kit ...................................................................

1 each HFN X61-9689

O-8

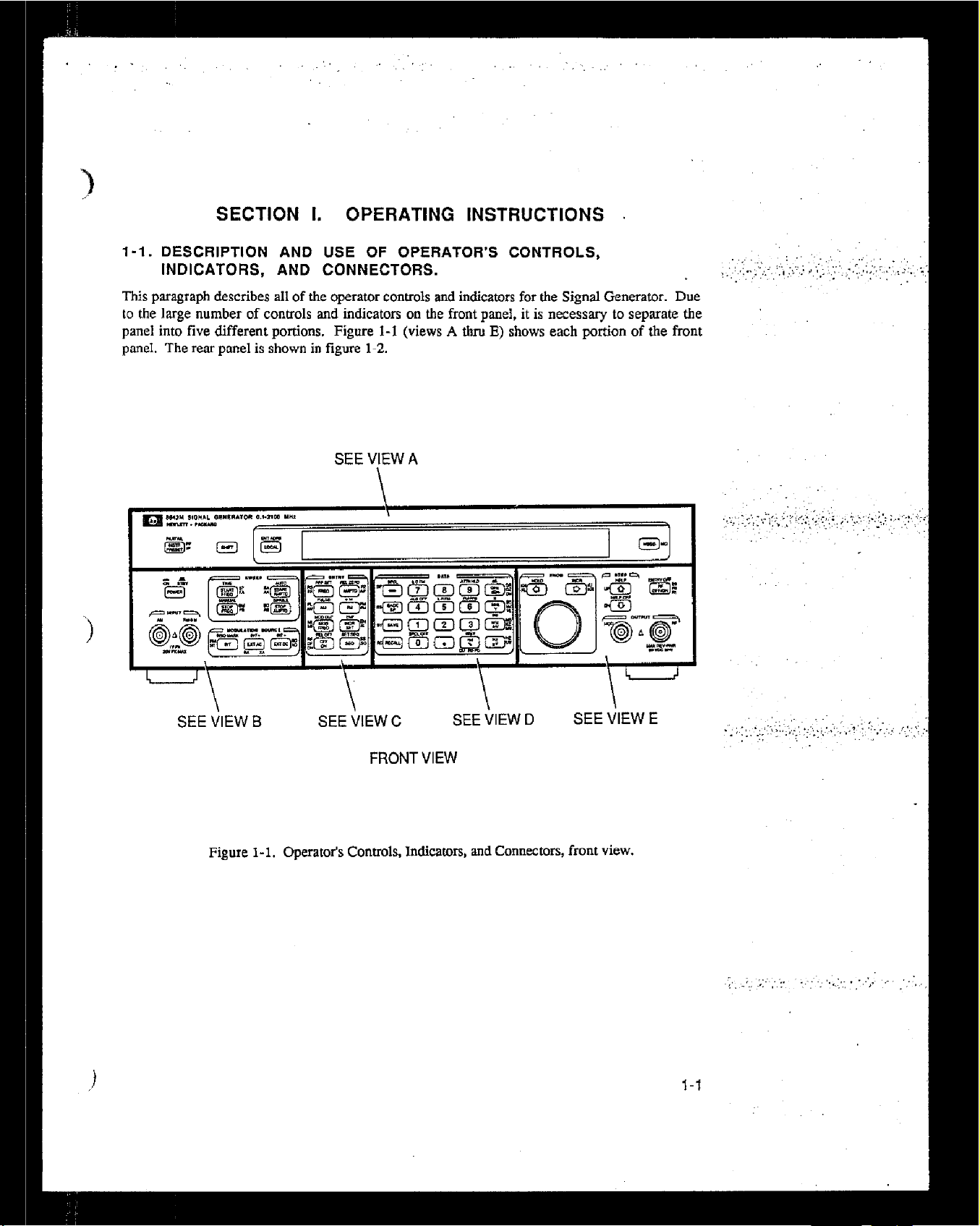

SECTION 1. OPERATING INSTRUCTIONS .

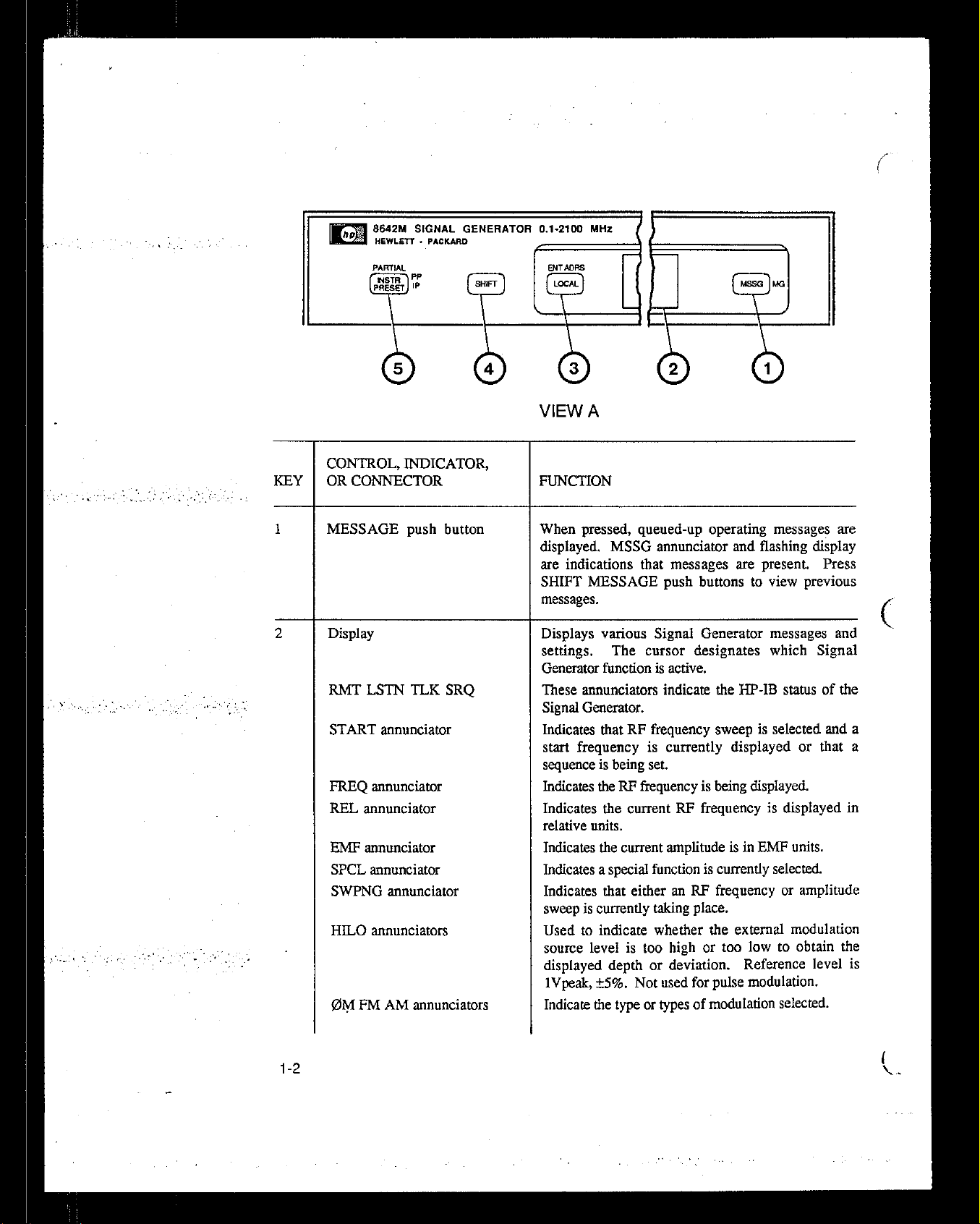

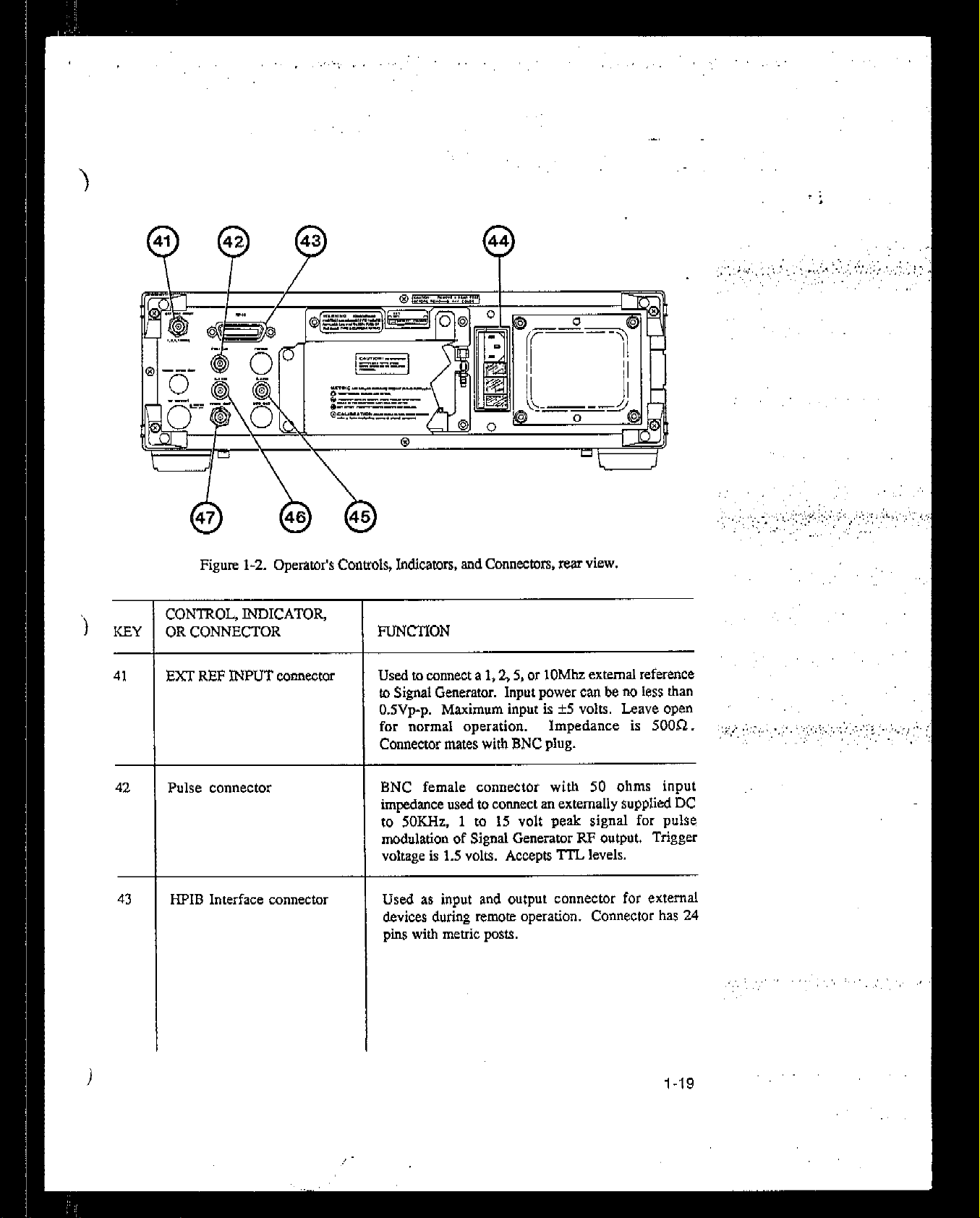

l-l. DESCRIPTION AND USE OF OPERATOR’S CONTROLS,

INDICATORS, AND CONNECTORS.

This paragraph describes all of the operator controls and indicators for the Signal Generator. Due

to the large number of controls and indicators on the front panef, it is necessary to sepruate the

panel into five different tmrtions. Figure l-l (views A thm E) shows each Dortion of the front

baneI. The rear panel is shown in figure 1-2.

SEE VIEW A

-\

SEE VIEW 0

\

SEE VIEW C

FRONT VIEW

Figure l-l. Operator’s Controls, Indicators, and Connectors, front view.

\

SEE VIEW D

\’

SEE VIEW E

+

l-f

Loading...

Loading...