Performance Tests and

Adjustments Manual

HP 8566B Spectrum

Analyzer

HEWLETT

F!a

HP

Printed in USA September 1993

PACKARD

Part No. 08566-90168

Notice.

The information contained in this document is subject to change

without notice.

Hewlett-Packard makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing,

performance, or use of this material.

@

Copyright Hewlett-Packard Company 1993

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

1400 Fountaingrove Parkway, Santa Rosa CA, 95403-1799, USA

Certification

Hewlett-Packard Company certifies that this product met its

published specifications at the time of shipment from the factory.

Hewlett-Packard further certifies that its calibration measurements

are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

Warranty

This Hewlett-Packard instrument product is warranted against defects

in material and workmanship for a period of one year from date of

shipment. During the warranty period, Hewlett-Packard Company

will, at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a

service facility designated by Hewlett-Packard. Buyer shall prepay

shipping charges to Hewlett-Packard and Hewlett-Packard shall pay

shipping charges to return the product to Buyer. However, Buyer shall

pay all shipping charges, duties, and taxes for products returned to

Hewlett-Packard from another country.

Hewlett-Packard warrants that its software and firmware designated

by Hewlett-Packard for use with an instrument will execute

its programming instructions when properly installed on that

instrument. Hewlett-Packard does not warrant that the operation

of the instrument, or software, or firmware will be uninterrupted or

error-free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse,

operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

HEWLETT-PACKARD SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. HEWLETT-PACKARD SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

. . .

III

Assistance

Product maintenance agreements and other customer omistance

agreemxmts

Fbr

any assistance, contact your nearest

Service

are available for

Ome.

Hewlett-Rzckard

Hewlett-Fbckard

products.

Sales and

Safety Notes

Caution

Warning

Instruction

Manual

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and its meaning before

operating this instrument.

Caution denotes a hazard. It calls attention to a procedure that, if

not correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution sign

until the indicated conditions are fully understood and met.

Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

injury or loss of life. Do not proceed beyond a warning note until

the indicated conditions are fully understood and met.

The instruction manual symbol. The product is marked with this

symbol when it is necessary for the user to refer to the instructions in

the manual.

iv

General Safety Considerations

Warning

Warning

Caution

Before this instrument is switched on, make sure it has been

properly grounded through the protective conductor of the ac

power cable to a socket outlet provided with protective earth

contact.

Any interruption of the protective (grounding) conductor, inside

or outside the instrument, or disconnection of the protective

earth terminal can result in personal injury.

There are many points in the instrument which can, if contacted,

cause personal injury. Be extremely careful.

Any adjustments or service procedures that require operation

of the instrument with protective covers removed should be

performed only by trained service personnel.

Before this instrument is switched on, make sure its primary power

circuitry has been adapted to the voltage of the ac power source.

Failure to set the ac power input to the correct voltage could cause

damage to the instrument when the ac power cable is plugged in.

V

How to Use This Manual

This manual uses the

following

conventions:

HP 8566B Documentation Description

HP 8566B

HP 8566B Operating

and Programming

Installation

and Verification

Manual

Manual

Front-Panel Ke

Screen Text

Included with the HP Model 8566B spectrum analyzer are manuals:

The Installation and Verification Manual, the Operating and

Programming Manual, and the Performance Tests and Adjustments

Manual.

HP part number 08566-90169

Contents: General information, installation, specifications,

characteristics, and operation verification.

HP part number 08566-90040

Contents: Manual and remote operation, including complete syntax

and command description.

pocket-sized Quick Reference Guide, HP part number

r) This represents a key physically located on the

instrument.

This indicates text displayed on the instrument’s

screen.

Accopanying

this manual is the seperate,

5955-8970.

HP 8566B

Performance

Tests and

Adjustments Manual

HP 8566B RF

Section

Troubleshooting

Repair

Manual

HP 8566B IF-Display

Section

Troubleshooting

Repair

Manual

and

and

HP part number 08566-90168

Contents: Electrical performance tests and adjustment procedures.

HP part number 08566-90210

Contents: RF section service information.

HP part number 08566-90085

Contents: IF-Display section service information.

vi

Contents

1. General Information

Introduction

Instruments Covered by this Manual

Operation Verification

Option 462 Instruments

Option 857 Instruments

2. Performance Tests

Introduction

Verification of Specifications

Calibration Cycle

Equipment Required

Performance Test Record

1. Center Frequency Readout Accuracy Test

2. Frequency Span Accuracy Test

3. Resolution Bandwidth Accuracy Test

4. Resolution Bandwidth Selectivity Test

5. Resolution Bandwidth Switching Uncertainty Test

6. Log

7. IF Gain Uncertainty Test

8. Amplitude Fidelity Test

9. Calibrator Amplitude Accuracy Test

10. Frequency Response Test

11. Sweep Time Accuracy Test

12. Noise Sidebands Test

13. Line-Related Sidebands Test

14. Average Noise Level Test

15. Residual Responses Test

16. Harmonic and Intermodulation Distortion Test

17. Image, Multiple, and Out of Band Responses Test

18. Gain Compression Test

19. 1st LO Output Amplitude Test

20. Sweep + Tune Out Accuracy Test

21. Fast Sweep Time Accuracy Test (~20 ms)

22. Frequency Reference Error Test

‘Iable

2-24. Performance Test Record

Test 1. Center Frequency Readout Accuracy

Test 2. Frequency Span Accuracy Test

Test 3. Resolution Bandwidth Accuracy Test

Test 4. Resolution Bandwidth Selectivity

Test 5. Resolution Bandwidth Switching Uncertainty .

Test 6. Log

Test 7. IF Gain Uncertainty

Test 8. Amplitude Fidelity

Test 9. Calibrator Amplitude Accuracy

Test 10. Frequency Response Test

.....................

.........

................

...............

...............

.....................

.............

..................

................

..............

.........

Scale

Switching Uncertainty Test

............

............

...........

..........

.............

..........

...........

............

............

.........

........

..........

........

Scale

Switching Uncertainty Test

.............

.............

........

..........

....

......

......

......

.......

.......

....

.....

.....

.......

.....

.

l-l

l-2

l-2

l-2

l-2

2-l

2-l

2-2

2-3

2-3

2-4

2-8

2-12

2-14

2-17

2-19

2-21

2-27

2-31

2-32

2-46

2-49

2-53

2-58

2-61

2-65

2-73

2-77

2-81

2-82

2-84

2-87

2-89

2-90

2-91

2-92

2-93

2-94

2-95

2-96

2-99

2-100

2-101

Contents-l

Test 11. Sweep Time Accuracy

Test 12. Noise Sidebands Test

Test 13. Line-Related Sidebands

Test 14. Average Noise Level

Test 15. Residual Responses

...........

............

...........

............

.............

Test 16. Harmonic And Intermodulation Distortion . . 2-108

Test 17. Image, Multiple, and Out-of-Band Responses . 2-109

Test 18. Gain Compression

Test 19. 1st LO Output Amplitude

Test 20. Sweep + Tune Out Accuracy

.............

..........

........

Test 21. Fast Sweep Time Accuracy (< 20 ms)

Test 22. Frequency Reference Error Test

3. Adjustments

Introduction

Safety Considerations

Equipment Required

Adjustment Tools

Factory-Selected Components

Related Adjustments

.....................

.................

.................

...................

.............

.................

Location of Test Points and Adjustments

1. Low-Voltage Power Supply Adjustments

.......

........

......

2. High-Voltage Adjustment (SN 3001A and Below) . .

2. High-Voltage Adjustment (SN 3004A and Above) . .

3. Preliminary Display Adjustments (SN 3001A and

Below)

.....................

3. Preliminary Display Adjustments (SN 3004A and

4.

Above)

Final

.....................

Display Adjustments (SN 3001A and Below)

4. Final Display Adjustments (SN 3004A and Above)

5. Log Amplifier Adjustments

6. Video Processor Adjustments

7. 3 MHz Bandwidth Filter Adjustments

8. 21.4 MHz Bandwidth Filter Adjustments

9. 3 dB Bandwidth Adjustments

............

...........

.......

.....

..........

10. Step Gain and 18.4 MHz Local Oscillator

Adjustments

11. Down/Up Converter Adjustments

..................

........

12. 10 MHz Standard Adjustment (SN 2637A and

Below)

.....................

12. 10 MHz Standard Adjustment (SN 2728A and

Above)

.....................

13. Sweep, DAC, and Main Coil Driver Adjustments . .

14. 100 MHz VCXO Adjustments

15. MN Loop Adjustments

16.

YT.0

Loop Adjustments

17.

20/30

Loop Phase Lock Adjustments

18. RF Module Phase Lock Adjustments

19. CAL Output Adjustment

20. Last Converter Adjustments

2 1. Frequency Response Adjustments

22. Analog-To-Digital Converter Adjustments

23. Track and Hold Adjustments

24. Digital Storage Display Adjustments

Low-Noise DC Supply

................

...........

.............

.............

.......

.......

.............

...........

........

.....

............

.......

....

.

.

2-103

2-104

2-105

2-106

2-107

2-l 11

2-112

2-113

2-l 14

2-115

3-l

3-2

3-2

3-2

3-3

3-3

3-3

3-25

3-31

3-41

3-48

3-56

3-63

3-65

3-69

3-73

3-76

3-82

3-89

3-94

3-100

3-104

3-108

3-113

3-126

3-132

3-135

3-146

3-160

3-166

3-169

3-174

3-206

3-209

3-212

3-218

Contents-2

Crystal Filter Bypass Network Configuration . . . . .

4.

Option 462

Introduction . . . . . . . . . . . . . . . . . . . . .

3. 6 dB Resolution Bandwidth Accuracy Test . . . . .

3. Impulse and Resolution Bandwidth Accuracy Test

4. 6 dB Resolution Bandwidth Selectivity Test . . . .

4. Impulse and Resolution Bandwidth Selectivity Test .

5. Impulse and Resolution Bandwidth Switching

Uncertainty Test . . . . . . . . . . . . . . . .

Test 3. 6 dB Resolution Bandwidth Accuracy Test (p/o

lhble

2-24, Performance Test Record) . . . . . . .

Test 3. Impulse and Resolution Bandwidth Accuracy

Test (p/o

‘Ihble

2-24, Performance Test Record)

Test 4. 6 dB Resolution Bandwidth Selectivity (p/o

Table 2-24, Performance Test Record) . . . . . . .

Test 4. Impulse and Resolution Bandwidth Selectivity

(p/o

Table

2-24, Performance Test Record) . . . . .

Test 5. Impulse and Resolution Bandwidth Switching

Uncertainty (p/o

‘Ihble

2-24, Performace Test

Record) . . . . . . . . . . . . . . . . . . . . .

9. 6 dB Resolution Bandwidth Adjustments . . . . .

9. Impulse Bandwidth Adjustments . . . . . . . . .

Option 857

5.

Introduction . . . . . . . . . . . . . . . . . . . . .

8. Option 857 Amplitude Fidelity Performance Test . .

Performance Test Record . . . . . . . . . . . . . . .

Test 8. Option 857 Amplitude Fidelity . . . . . . . .

. .

.

3-219

4-l

4-2

4-4

4-10

4-13

4-16

4-18

4-19

4-21

4-22

4-23

4-24

4-27

5-l

5-2

5-6

5-7

Major Assembly and Component Locations

6.

IF-Display Section Figure Index . . . . . . . . . . . .

RF Section Figure Index . . . . . . . . . . . . . . .

6-l

6-2

Contents3

Figures

l-l. Service Accessories, HP Part Number 08566-60001

2-l. Center Frequency Test Setup

2-2. Center Frequency Accuracy Measurement

2-3. Narrow Span Test Setup

2-4. Wide Span Test Setup

2-5. Resolution Bandwidth Measurement

2-6. 60 dB Bandwidth Measurement

2-7. Bandwidth Switching Uncertainty Measurement

2-8. Log

2-9. IF Gain Uncertainty Test Setup

2-10. IF Gain Uncertainty Measurement

2-l 1. Amplitude Fidelity Test Setup

2-12. Amplitude Fidelity Measurement

2-13. Calibrator Amplitude Accuracy Test Setup

2-14. Frequency Response Test Setup (100 Hz to 100

2-15. Frequency Response Measurement (1

2-16. Frequency Response Test Setup (100

2-17. Frequency Response Measurement (100

2-18. Frequency Response Measurement (4 MHz to 60 MHz)

2-19. Frequency Response Test Setup (60 MHz to 2.5

2-20. Frequency Response Measurement (60 MHz to 2.5

2-21. Sweep Time Accuracy Test Setup

2-22. Noise Sidebands Test Setup

2-23. Noise Sidebands Measurement

2-24. Line Related Sidebands Test Setup

2-25. Line-Related Sidebands Measurement

2-26. Average Noise Level Measurement

2-27. Residual Responses Measurement

2-28. Harmonic Distortion Test Setup

2-29. Intermodulation Distortion

2-30. Third Order Intermodulation Products

2-31. Image, Multiple, and Out-of-Band Responses Test Setup

2-32. Gain Compression Test Setup

2-33. 1st LO Output Amplitude Test Setup

2-34. Sweep + Tune Out Accuracy Test Setup

2-35. Fast Sweep Time Accuracy (~20 ms) Test Setup

2-36. Fast Sweep Time Measurement (~20 ms)

2-37. Frequency Reference Test Setup

3-l. Low-Voltage Power Supply Adjustments Setup

3-2. IF-Display Section Adjustments (SN 3001A and Below)

3-3. IF-Display Section Adjustments (SN 3004A and Above)

3-4. Location of RF Section Low-Voltage Adjustments

3-5. High Voltage Adjustment Setup

3-6. Location of High Voltage Adjustments

3-7. Location of Label and Test Point

Scale

Switching Uncertainty Measurement

to22GHz)

...................

...............

................

............

......

.........

...........

...........

..........

............

..........

......

kHz

to 100

kHz

to 60 MHz)

kHz

to 4 MHz)

..........

.............

............

..........

........

..........

..........

...........

Test

Setup

............

........

........

.........

.......

.......

...........

...........

........

...........

. .

...

....

kHz)

kHz)

GHz,

2

GHz)

....

....

...

.

.

l-9

2-4

2-6

2-8

2-10

2-13

2-15

2-18

2-20

2-21

2-23

2-27

2-29

2-31

2-33

2-35

2-36

2-37

2-38

2-39

2-41

2-46

2-50

2-51

2-53

2-55

2-59

2-62

2-66

2-69

2-71

2-73

2-77

2-81

2-82

2-84

2-85

2-88

3-25

3-26

3-27

3-29

3-32

3-33

3-34

Contents-4

3-8. Location of

AlA

Components ...........

3-9. CRT Cut-Off Voltage

3-10. Waveform at

3-l 1. Discharging the CRT Post-Accelerator Cable

3-12. High Voltage Adjustment Setup

3-13. Location of High Voltage Adjustments

3-14. Location of

3-15. Discharging the CRT Post-Accelerator Cable

3-16. Preliminary Display Adjustments Setup

3-17. Location of AlA2, AlA4, AlA5, and

3-18. AlA2, AlA4, and

AlA3TP5’ : : : : : : : : : : : : 1 : :

...........

........

AlA

Label and Test Point

........

.......

A3A2

AlA

Adjustment Locations ....

.....

.....

.....

3-19. X+ and X- Waveforms ...............

3-20. Composite X Deflection Waveform

..........

3-21. Rise and Fall Times and Overshoot Adjustment

Waveform

...................

3-22. 5OV,, Signal ....................

3-23. Preliminary Display Adjustments Setup

3-24. Location of

3-25.

AlA

Adjustment Locations

AlA

and

A3A2

............

.............

.......

3-26. X+ and X- Waveforms ...............

3-27. Composite X Deflection Waveform

3-28. Rise and

Fall

Waveform

Times and Overshoot Adjustment

...................

..........

3-29. 5OV,, Signal ....................

3-30. Location of Final Display Adjustments on AlA2,

and

AlA5.

3-31. Final Display Adjustments Setup

3-32. Location of

3-33. Log Amplifier Adjustments Setup

3-34. Location of Log Amplifier Adjustments

3-35. Video Processor Adjustments Setup

3-36. Location of Video Processor Adjustments

...................

...........

Final

Display Adjustments on

AlA

..........

........

.........

.......

3-37. 3 MHz Bandwidth Filter Adjustments Setup

AlA4,

...

.....

3-38. Location of Center, Symmetry, and 10 Hz Amplitude

Adjustments

3-39. Location of 3 MHz Peak Adjustments

..................

.........

3-40. 21.4 MHz Bandwidth Filter Adjustments Setup ....

3-41. Location of

3-42. Location of

3-43. Location of

Adjustments

3-44. Location of

A4A4

21.4 MHz LC Filter Adjustments . .

A4A4

21.4 MHz Crystal Filter Adjustments

A4A8

21.4 MHz LC Filter and Attenuation

..................

A4A8

21.4 MHz Crystal Filter Adjustments

3-45. Location of 3 dB Bandwidth Adjustments ......

3-46. Step Gain and 18.4 MHz

Setup

......................

3-47. Location of IF Gain Adjustment

3-48. Location of 10 dB Gain Step Adjustments

3-49. Location of .l dB Gain Step, 18.4 MHz LO, and +

Adjustments

..................

3-50. Down/Up Converter Adjustments Setup

3-51. Location of Down/Up Converter Adjustments

3-52. 10 MHz Frequency Standard Adjustments Setup

3-53. Location of 10 MHz Standard Adjustments

3-54. 10 MHz Frequency Standard Adjustments Setup

3-55. Location of 10 MHz Standard Adjustments

Local

Oscillator Adjustments

...........

.......

......

1OV

.....

...

......

...

......

3-36

3-37

3-38

3-40

3-42

3-43

3-44

3-47

3-49

3-50

3-50

3-51

3-52

3-53

3-54

3-57

3-58

3-58

3-59

3-60

3-60

3-62

3-64

3-65

3-66

3-69

3-70

3-73

3-74

3-76

3-78

3-80

3-82

3-83

3-84

3-85

3-86

3-90

3-94

3-96

3-97

3-98

3-100

3-101

3-105

3-107

3-109

3-112

Contents-5

3-56. Sweep and DAC Adjustments Setup

3-57. OV to +

1OV

Sweep Ramp at

A16TP3

.........

.........

3-58. Location of Sweep and DAC Adjustments

.......

3-114

3-115

3-116

3-59. Properly Adjusted DC Levels Between Sweep Ramps . 3-117

3-60. Improperly Adjusted DC Levels Between Sweep Ramps

3-61. YTO Main Coil Driver Adjustments Setup

3-62. Location of YTO Main Coil Driver Adjustments

.......

....

3-117

3-120

3-121

3-63. YTO Main Coil Driver Adjustments Setup (Alternate

3-

Procedure)

3-64. 100 MHz VCXO Adjustment Setup

3-65. Location of 100 MHz VCXO Adjustments

3-66. Typical Tuning Range of

3-67. M/N Loop Adjustment Setup

3-68. Location of PLL Adjustments

3-69. YTO Loop Adjustment Setup

3-70. Location of Assemblies, Cables, and Test Points

3-71. All YTO Loop Service Position

3-72. Typical YTO Loop Swept Frequency Response at

3-73.

AllA

Adjustment Locations

3-74. Sampler Waveform at

...................

..........

.......

A7A2

100 MHz VCXO

....

.............

............

............

....

...........

AllAl

............

AllA5TPl

..........

3-75. 30 MHz YTO Loop Sampler Response at AllJ5 IF OUT

3-76. Tuning the IF OUT Fundamental

3-77.

20/30

PLL Adjustment Setup

3-78. Location of

3-79. Location of

PLLl

Adjustments

PLL2

Adjustments

3-80. Location of PLL3 Adjustments

3-81. RF Module Phase Lock Adjustments Setup

3-82. Location of RF Module Phase Lock Adjustments

3-83. A Sampler Balance Adjustment Waveform

3-84.

Cal

Output Adjustment Setup

3-85. Location of CAL OUTPUT Adjustment

3-86. CAL OUTPUT Harmonics

..............

3-87. Last Converter Adjustments Setup

3-88. Location of Last Converter Adjustments

..........

............

............

............

............

......

...

......

............

........

..........

.......

122

3-126

3-127

3-128

3-132

3-133

3-136

3-136

3-137

3-139

3-140

3-142

3-143

3-144

3-147

3-149

3-154

3-156

3-161

3-161

3-164

3-166

3-167

3-168

3-170

3-171

3-89. Frequency Response Preliminary Adjustments Setup . 3-176

3-90. Location of Frequency Response Adjustments

....

3-177

3-91. Frequency Response Adjustments Setup (10 MHz to 2.5

GHz)

......................

3-92. Typical Coarse Frequency Response (10 MHz - 2.5

3-93. Typical Frequency Response (10 MHz - 2.5

3-94. Frequency Response Adjustments Setup (2.0

22.0

GHz)

....................

3-95. Typical Coarse Frequency Response (2

3-96. Typical Frequency Response (2.0

GHz -

3-97. Typical Coarse Frequency Response (5.8

GHz)

3-98. Typical Frequency Response (5.8

......................

GHz -

GHz -

5.8

GHz -

12.5

GHz)

GHz

5.8

GHz)

12.5

GHz)

to

...

GHz)

...

3-179

GHz)

3-181

3-182

3-185

3-187

3-188

3-191

. . 3-193

3-99. Frequency Response Adjustments Setup (18.6 to 325

GHz)

......................

3-100. Analog-To-Digital Converter Adjustments Setup

....

3-204

3-206

3-101. Location of Analog-To-Digital Converter Adjustments . 3-208

3-102. Track and Hold Adjustments Setup

3-103. Location of Track and Hold Adjustments

3-104. Digital Storage Display Adjustments Setup

........

:

.......

......

3-105. Location of Digital Storage Display Adjustments

...

3-209

3-210

3-212

3-213

Contents-6

3-106. Sample and Hold Balance Adjustment Waveforms

3-107. Waveform Before Adjustment

3-108. Low-Noise DC Supply

................

............

3-109. Crystal Filter Bypass Network Configurations

...

.....

4-l. Resolution Bandwidth Measurement .........

4-2. Impulse Bandwidth Test Setup

4-3. 6 dB Resolution Bandwidth Measurement

............

......

4-4. 60 dB Bandwidth Measurement ...........

4-5. 60 dB Bandwidth Measurement ...........

4-6. Bandwidth Switching Uncertainty Measurement

4-7. Location of Bandwidth Adjustments

4-8. Location of Bandwidth Adjustments

.........

.........

5-l. Option 857 Amplitude Fidelity Test Setup

6-l. RF Section, Top View

6-2. RF Section, Front View

6-3. RF Section, Bottom View

................

...............

..............

6-4. IF Section, Top View (SN 3001A and Below)

6-5. IF Section,

‘Ibp

View (SN 3004A and Above)

...

......

.....

.....

6-6. IF Section, Front View ...............

6-7. IF Section, Bottom View

..............

3-215

3-215

3-218

3-219

4-3

4-4

4-8

4-11

4-14

4-17

4-25

4-28

5-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

Contents-7

!Ihbles

2-l. Performance Test Cross-Reference ..........

2-2. Center Frequency Readout Accuracy .........

2-3. Narrow Span Accuracy

2-4. Wide Span Accuracy

2-5. Bandwidth Accuracy

2-6. Resolution Bandwidth Selectivity

2-7. Bandwidth Switching Uncertainty ..........

2-8. Log Scale Switching Uncertainty

2-9. IF Gain Uncertainty, 10 dB Steps ..........

2-10. IF Gain Uncertainty, 2 dB Steps

2-l 1. IF Gain Uncertainty, 0.1 dB Steps ..........

2-12. Log Scale Fidelity

2-13. Linear Amplitude Fidelity

2-14. 100 Hz to 2.5

2-15. Frequency Response (Flatness)

2-16. Sweep Time Accuracy, Sweep Times

2-17. Sweep Time Accuracy

2-18. Average Noise Level

2-19. TO1 Measurement Settings

2-20. Image and Out-of-Band Response

2-2 1. Multiple Responses

2-22. Sweep + Tune Out Accuracy ............

2-23. Fast Sweep Time Accuracy

2-24. Frequency Response (Flatness)

3-l. Adjustment Cross Reference .............

3-2. Adjustable Components

3-3. Factory-Selected Components

3-4. Standard

3-5. Standard Value Replacement 0.125 Resistors

3-6. Standard

3-5. Initial Adjustment Positions

3-6. Initial Adjustment Positions

3-7. Standard Values for

3-8. Limits for 100 MHz Harmonics

3-9. Selection Chart for Attenuator Resistors

3-10. Resistor

3-11. Power Level of Fundamental Signal

3-12. Standard

3-13. Standard Values for

3-14. Frequency Bands

3-15. Preselector Delay Compensation DAC Values

3-16.

A6A12

3-17. Parts for Low-Noise DC Supply

3-18. Crystal Filter Bypass Network Configuration for

YTX Driver Assembly Factory-Select Capacitor

Values

and

A4A8

GHz

Frequency Band

Value

Replacement Capacitors

Value

Replacement 0.5 Resistors

Values

Values

...................

for

..................

.....................

(21.4 MHz)

...............

................

................

..........

...........

...........

.................

..............

.........

...........

220

...............

................

.............

..........

.................

(~20

ms)

.........

...........

...............

............

.............

.............

A7A2L4

AlOA4C49

AlOA4R29

............

............

.........

and’AliA4R33 : : :

...........

..............

.....

ms

.......

.....

......

.......

.....

A4A4

:

2-2

2-7

2-9

2-11

2-13

2-16

2-18

2-20

2-23

2-24

2-25

2-29

2-30

2-37

2-45

2-48

2-48

2-60

2-72

2-75

2-76

2-83

2-86

2-102

3-4

3-5

3-13

3-20

3-21

3-23

3-63

3-66

3-128

3-130

3-130

3-131

3-144

3-157

3-158

3-174

3-202

3-203

3-218

3-219

Contents-8

3-19. Crystal Filter Bypass Network Configuration for

(3MHz)

. . . . . . . . . . . . . . . . . . . . .

A4A7

4-l. 6 dB Resolution Bandwidth Accuracy . . . . . . . .

4-2. Impulse Bandwidth Accuracy . . . . . . . . . . . .

4-3. 6 dB Resolution Bandwidth Accuracy . . . . . . . .

4-4. 6 dB Resolution Bandwidth Selectivity . . . . . . . .

4-5. Impulse and Resolution Bandwidth Selectivity . . . .

4-6. Bandwidth Switching Uncertainty . . . . . . . . . .

5-l. Log Amplitude Fidelity (10 Hz RBW; Option 857) . . .

5-2. Log Amplitude Fidelity (10

kHz

RBW; Option 857)

5-3. Linear Amplitude Fidelity . . . . . . . . . . . . . .

. .

3-219

4-3

4-9

4-9

4-12

4-15

4-17

5-4

5-5

5-5

Contents-9

General Information

1

Introduction

Warning

This HP 8566B Tests and Adjustments Manual contains two main

sections: Performance Tests and Adjustments Procedures. This

chapter lists the required test equipment for both sections. The

performance tests provided should be performed for the following

reasons:

w

If the test equipment for the Operation Verification Program is not

available.

w

If the instrument does not pass all of the Operation Verification

tests.

n

For complete verification of specifications not covered by the

Operation Verification program.

The adjustment procedures should be performed for the following

reasons:

w

If the results of a performance test are not within the specifications.

w

After the replacement of a part or component that affects electrical

performance.

The adjustment procedures require access to the interior of the

instrument and therefore should only be performed by qualified

service personnel. There are voltages at many points in the

instrument which can, if contacted, cause personal injury. Be

extremely careful. Adjustments should be performed only by

trained service personnel.

Power is still applied to this instrument with the LINE switch in

STANDBY. There is no OFF position on the LINE switch. Before

removing or installing any assembly or printed circuit board,

remove the power cord from the rear of both instruments and

wait for the MAINS indicators (red

Capacitors inside the instrument may still be charged even if the

instrument has been disconnected from its source of power. Use a

non-metallic tuning tool whenever possible.

LEDs)

to go completely out.

General Information

1-l

Instruments

by

this Manual

Covered

This manual contains procedures for testing and adjusting HP

8566B spectrum analyzers, including those with Option 400 (400 Hz

operation), Option 462 (impulse bandwidths and 6 dB bandwidths),

and Option 857 installed. The procedures in this manual can also

be used to adjust HP 8566A spectrum analyzers that have been

converted into HP 8566B spectrum analyzers through the installation

of an HP 8566AB Retrofit Kit (formerly HP 8566A+OlK Retrofit Kit).

Operation Verification

Option 462

Instruments

A high confidence level in the instrument’s operation can be achieved

by running only the Operation Verification Program, since it tests

most of the instrument’s specifications. It is recommended that the

Operation Verification Program be used for incoming inspection and

after repairs, since it requires much less time and test equipment.

A description of the program can be found in the Installation and

Verification manual.

Option 462 instruments require that the performance tests and

adjustment procedures listed below be performed instead of their

standard versions included in chapters two and three. Information on

Option 462 versions is located in Chapter 4, Option 462.

6 dB Bandwidths:

Test 3, 6 dB Resolution Bandwidth Accuracy Test

Test 4, 6 dB Resolution Selectivity Test

Adjustment 9, 6 dB Bandwidth Adjustment Procedure

Impulse Bandwidths:

Test 3, Impulse Resolution Bandwidth Accuracy Test

Test 4, Impulse and Resolution Selectivity Test

Test 5, Impulse and Resolution Bandwidth

Switching Uncertainty Test

Adjustment 9, Impulse Bandwidth Adjustment Procedure

Option 867

Instruments

1-2 General Information

Option 857 instruments are used in EMC receiver applications.

Information on Option 857 is located in Chapter 5, Option 857.

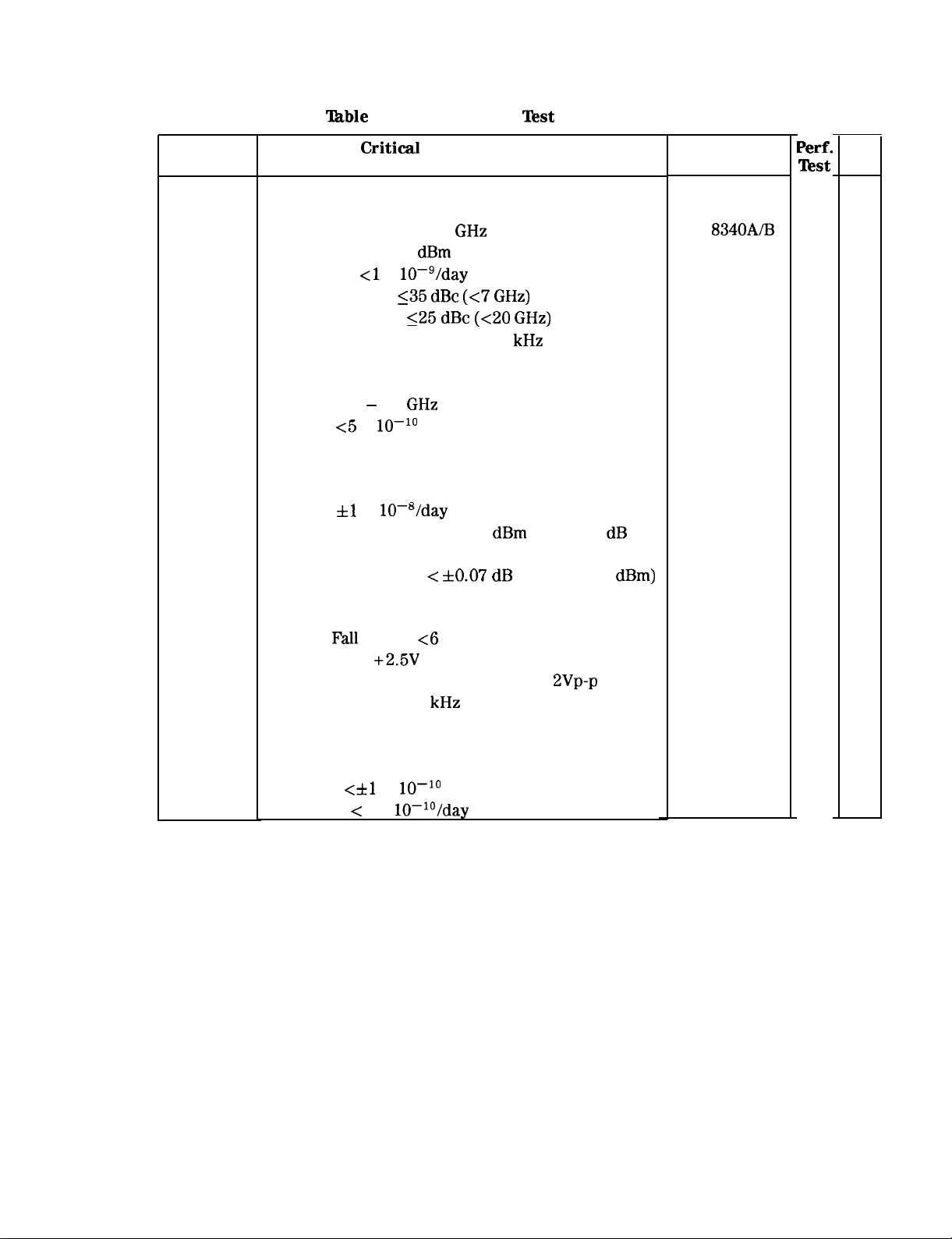

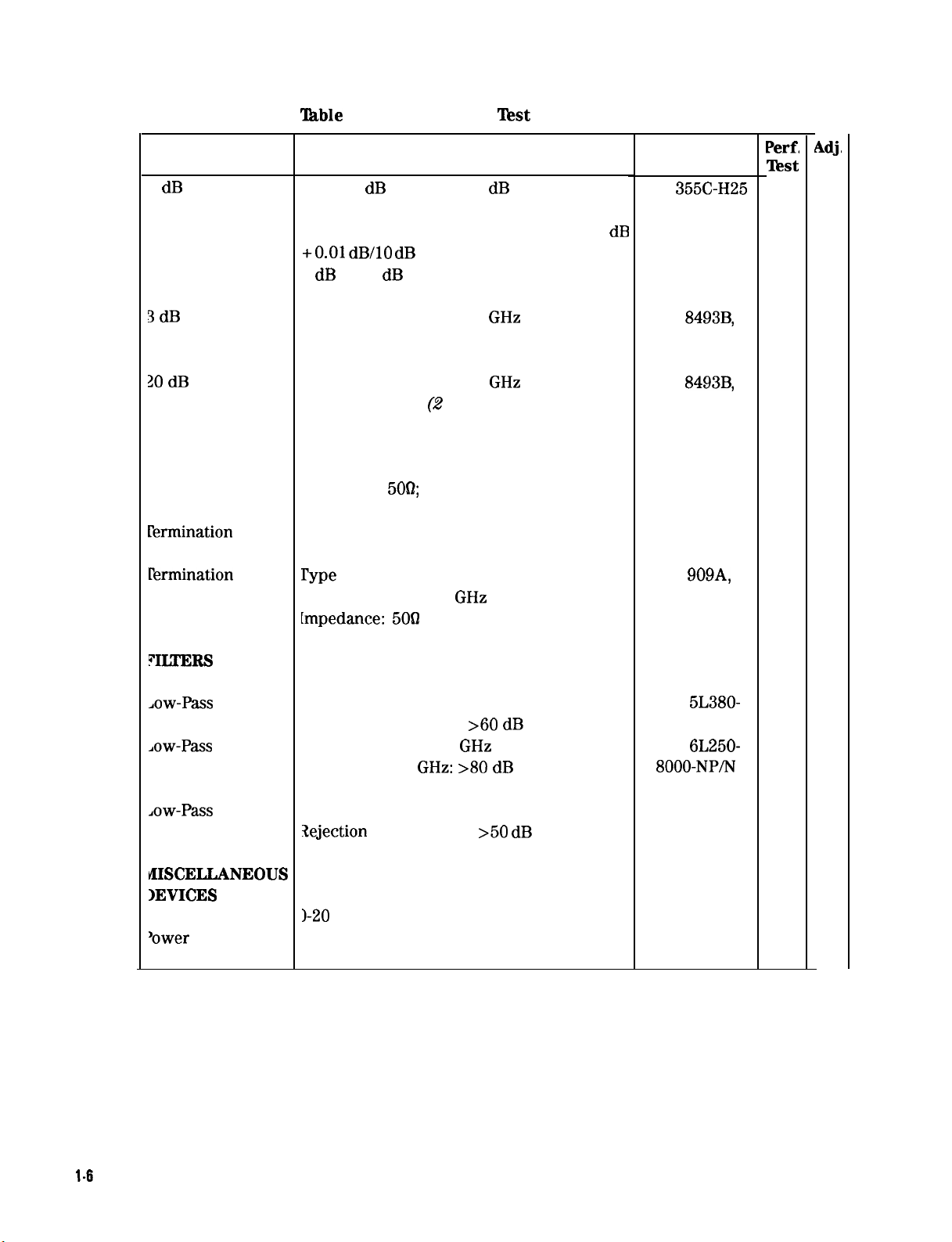

‘lhble

l-l. Recommended Test Equipment (1 of 6)

Instrumenl

SIGNAL

SOURCES

Synthesized

Sweeper

Synthesized

Signal

Generator

Frequency

Synthesizer

Critical Specifications for

Equipment Substitution

Frequency: 10 MHz to 22

Output Power: + 10

Aging Rate: ~1 x

10mg/day

Spurious Signals: 135

125

Amplitude Modulation: dc to 100

GHz

dBm

maximum (leveled)

dBc

(~7

GHz)

dBc (<20 GHz)

kHz

Leveling: Internal, External Power Meter

Frequency: 2 - 18

Stability: ~5 x

GHz

lo-lo

Frequency: 200 Hz to 80 MHz

Stability: fl x IO-“/day

Amplitude Range: + 13 to -86

dBm

with 0.01

resolution

Attenuator Accuracy: <

f0.07 dB

(+ 13 to -47

dB

dBm)

Recommended

Model

HP

8340A/B

HP 8672A

HP 3335A

Perf.

Test

X

X

X

Adj.

X

X

X

Pulse

Generator

Function

Generator

Frequency

Standard

Pulse Width: 10 nsec to 250 nsec

Rise and

Output Level:

Output: Sine Wave and Triangle Wave,

Range: 100 Hz to 500

(2 required)

Fall

Times: ~6 ns

+2.5V

BVp-p

kHz

(Sweep Function Available)

Output: 1, 2, 5, or 10 MHz

Accuracy:

Aging Rate: < 1 x

<hl

x

lo-lo

lo-lo/day

HP 8116A

HP 3312A

HP 5061B

X

X

X

X

X

General Information 1-3

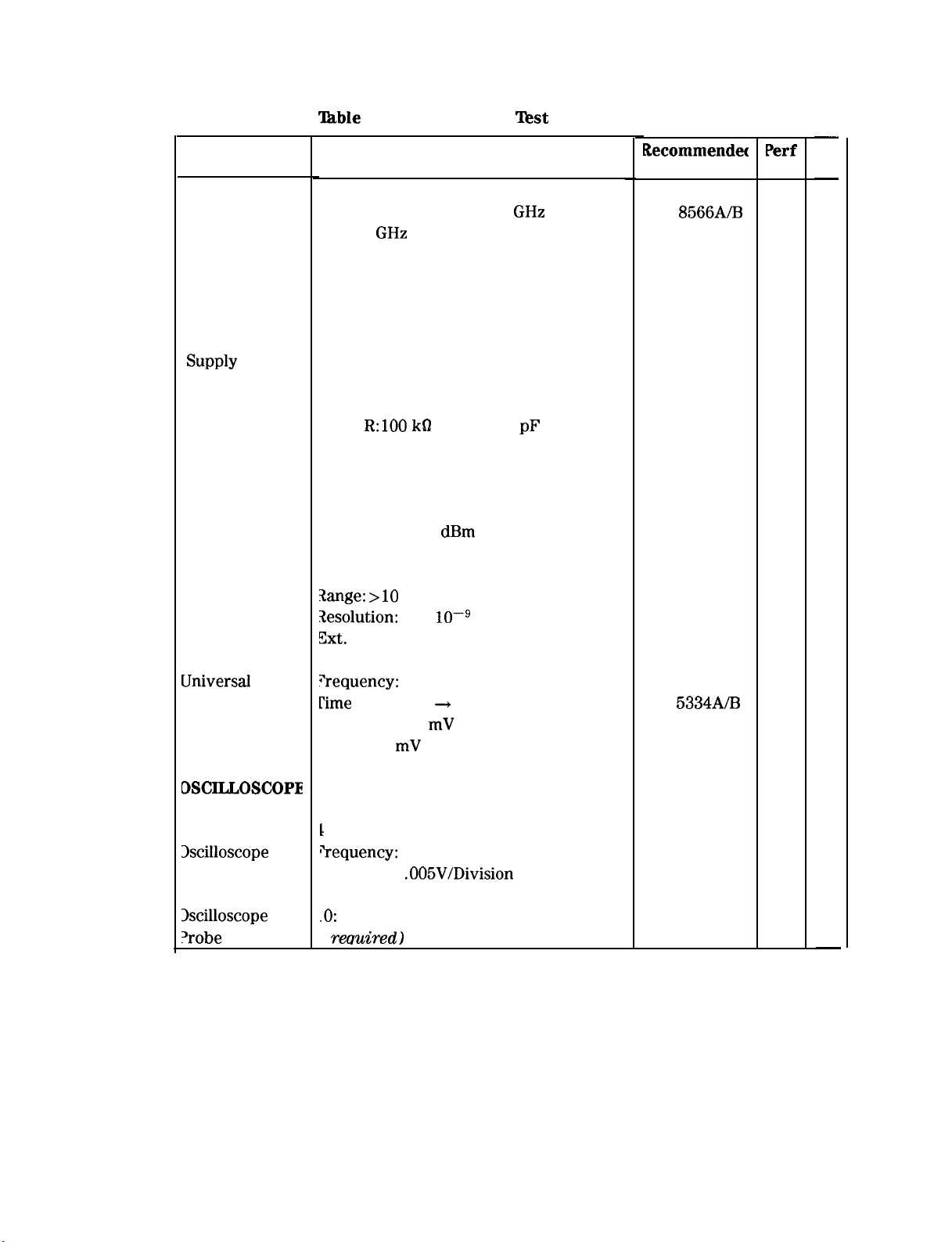

Instrument

ANALYZERS

Spectrum

Analyzer

‘able

l-l. Recommended Test Equipment (2 of 6)

Critical Specifications for

Equipment Substitution

Frequency: 100 Hz to 2.5

2 to 22

GHz

Preselected

GHz

Recommenda

Model

HP

8566A/B

Perf

Test

X

-

Adj

-

X

Active Probe

Probe Power

SUPPIY

High Frequency

Active Probe

COUNTERS

Frequency

Counter

Electronic

Counter

UniversaI

Counter

Resistive Divider for measuring fast

transition signals

For use with HP 10020A

Bandwidth: 5 Hz to 500 MHz

Input

R:lOO k62

Input C: 3

pF

Frequency: 20 MHz to 400 MHz

Sensitivity: -30

dBm

HP-IB Compatible

bnge: >lO

Xesolution:

Zxt.

Time Base: 1, 2, 5, or 10 MHz

+equency:

Time

Interval A + B: 100 ns to 200s

MHz

2 x

10Wg

gate time

dc to 100 MHz

sensitivity: 50 mV rms

Eange: 30 mV to 5V p-p

HP 10020A

HP 1122A

HP 41800A

HP 5343A

HP 5345A

HP 5316B

HP

5334AB

X

X

X

X

X

X

DSCILLOSCOPE

Digitizing

3scilloscope

1scilloscope

‘robe

1-4 General Information

1

Channel

“requency: 100 MHz

sensitivity:

.O:

1 Divider, compatible with oscilloscope

2

reauired 1

.005V/Division

HP 54501A

HP 10432A

X

X

-

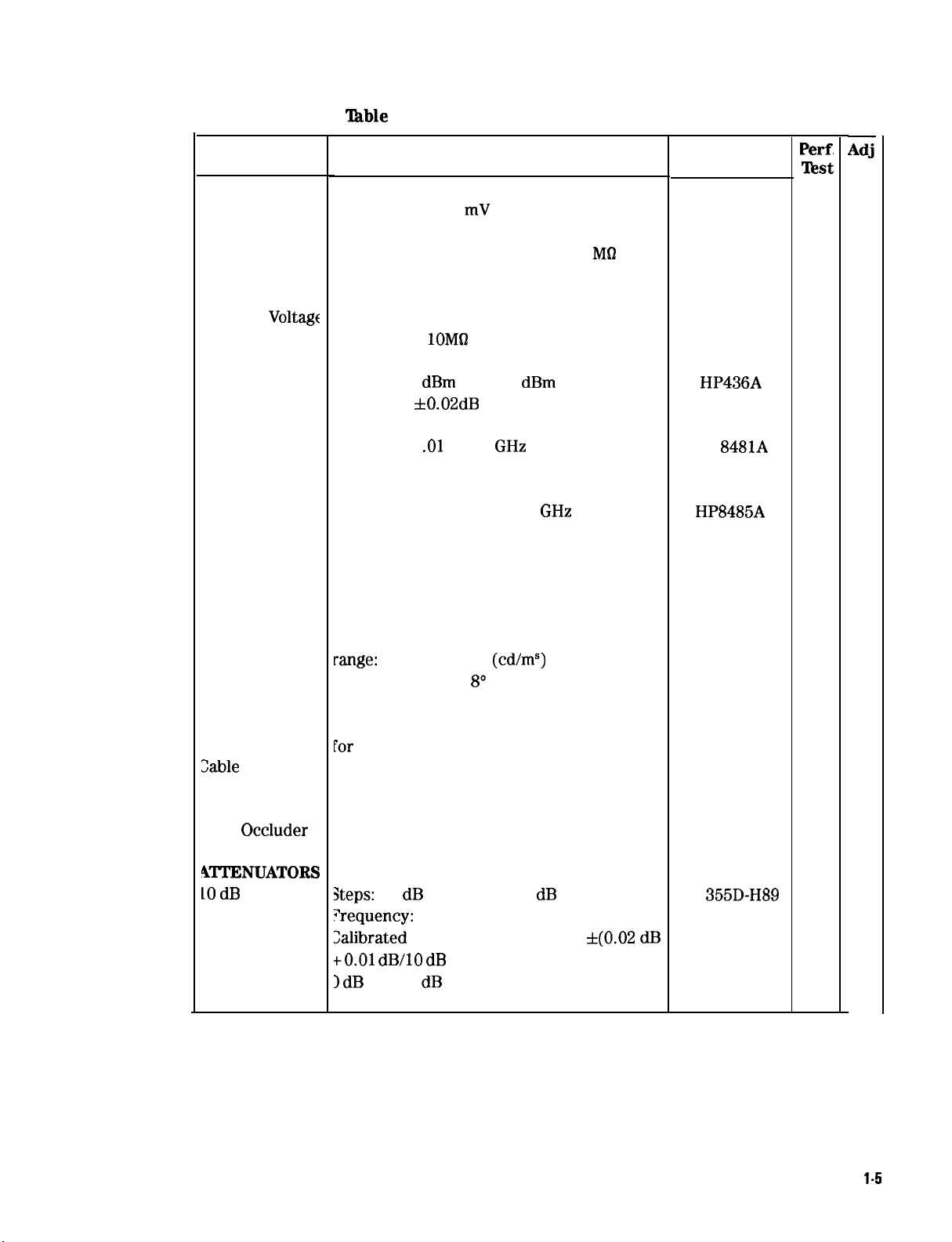

‘Ihble

l-l. Recommended Test Equipment (3 of 6)

Instrument

METERS

Digital

Voltmeter

DC High

Voltage

Probe

Power Meter

Power Sensor

Power Sensor

Digital

Photometer

Critical Specifications for

Equipment Substitution

Resolution: fO.l

mV

Range: 0 Vdc to 100 Vdc

Input Impedance 100 V Range: 10

M62

HP-IB Compatible

1000: 1 Divider

Impedance:

Range: -20

lOM62

dBm

to + 10

dBm

Accuracy: f0.02dB

Frequency:

.Ol

to 18

GHz

Compatible with HP 436A Power Meter

Frequency: 50 MHz to 26.5

GHz

Compatible with HP 436A Power Meter

Recommended

Model

HP 3456A

or

HP 3455A

HP 34111A

HP436A

HP

8481A

HP8485A

Tektronix J-16

Option 02

Perf,

Test

X

X

X

Adj

X

X

X

X

X

Photometer

Probe

Interconnect

Zable

Photometer

Light Occluder

YITENUATORS

10 dB

Step

4ttenuator

for Tektronix J-16

range:

1 to 100 NITS

acceptance angle:

(cd/m”)

8”

spectral response: CIE Photopic curve

for

Tektronix J-16

Por Tektronix J-16

3teps:

10 dB from 0 to 120

dB

?requency: 20 MHz to 1500 MHz

2alibrated

to.01 dB/lO dB

1 dB

to uncertainty error of

step) at 20 MHz from

to 120

dB

~t(O.02 dB

Tektronix

56503

Tektronix

012-0414-02

Tektronix

016-0305-00

HP

355D-H89

X

X

X

X

General information

l-5

‘Ihble

l-l. Recommended Test Equipment (4 of 6)

Instrument

1 dB Step

Attenuator

3 dB

Attenuator

30 dB

Attenuator

I’ERMINATIONS

krmination

rermination

Fermination

Critical Specifications for

Equipment Substitution

Steps: 1 dB from 0 to 12

dB

Frequency: 20 MHz to 1500 MHz

Calibrated to uncertainty error of f(0.02

+O.Ol dB/lO dB

0 dB to 12

Frequency: 200 Hz to 18

step) at 20 MHz from

dB

GHz

SMA Connectors

Frequency: 200 Hz to 18

SMA Connectors (2

Impedance:

5OQ;

BNC

GHz

required)

Impedance: 500; SMA (m)

I’ype

N Male Connector

Frequency: dc to 18

GHz

[mpedance: 5061

Recommended

Model

HP

355C-H25

dB

HP

Option 003

HP

Option 020

HP 11593A

HP 1810-0118

HP

Option 012

8493B,

8493B,

909A,

Perf,

Test

X

X

X

Adj,

X

X

X

FIIXERS

Jaw-Pass

Jaw-Pass

Jaw-Pass

vlISCELLANEOUS

IEVICES

Filter

Filter

Filter

‘recision

‘ower

Supply

kt-off Frequency: 250 MHz

Rejection at 460 MHz: >60

kt-off Frequency: 8

iejection at 14

GHz

GHz: >80 dB

ht-off Frequency: 1200 MHz

Xejection

I-20

at 1500 MHz:

volts, O-2 amperes

>50 dB

dB

K&L

5L380-

250-B/B

K&L

6L250-

8000-NP/N

HP 360B

HP 6114A

X

X

X

X

l-6

General information

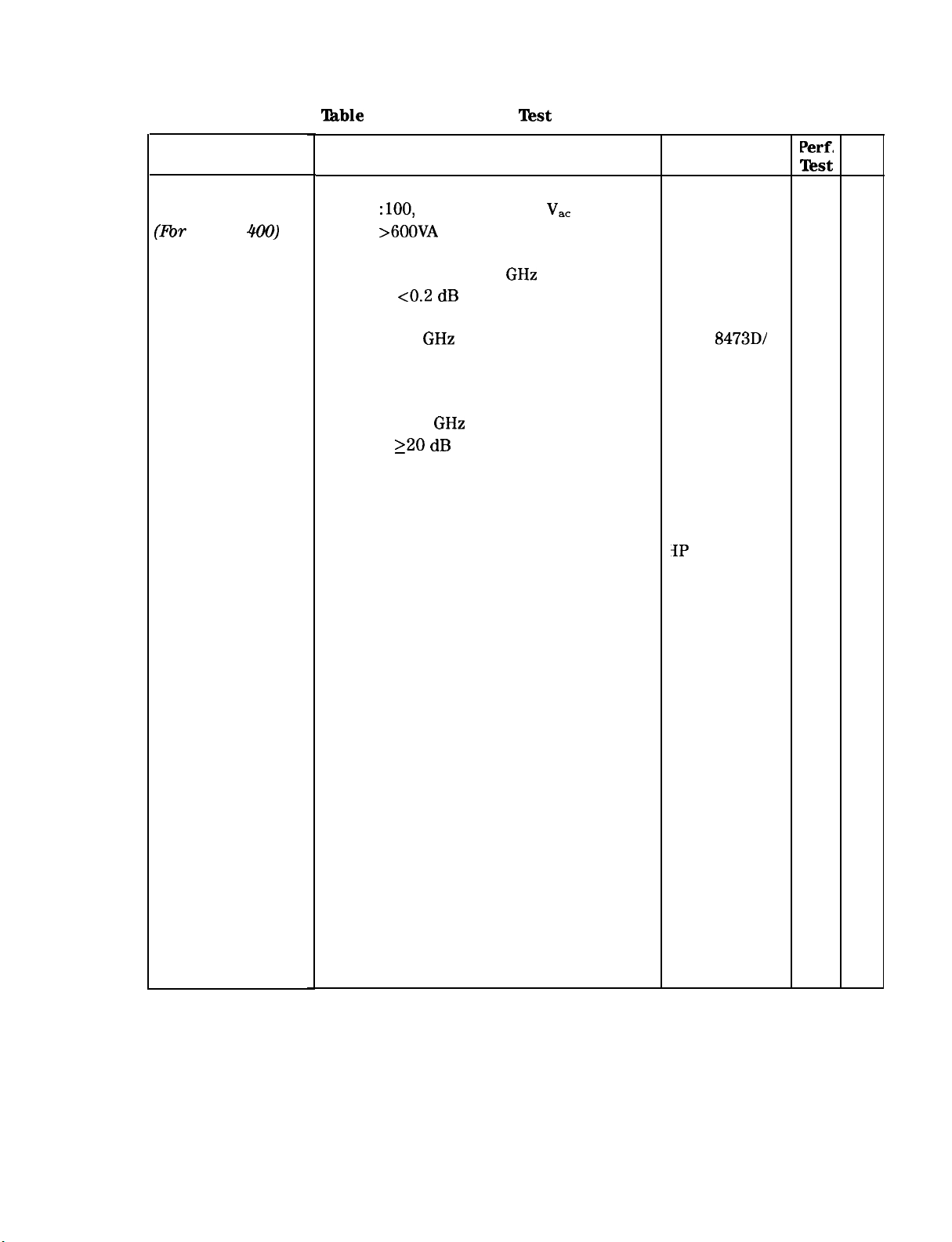

‘able

l-l. Recommended Test Equipment (5 of 6)

Instrument

AC Line-Power

Source

(Rx- Option

400)

Power

Splitter

Planar-doped

Barrier Diode

Detector

Reactive Power

Divider

SPECIAL

DEVICES

Display

Adjustment

PC Board*

Critical Specifications for

Equipment Substitution

Frequency: 400 Hz

Voltage

Power:

Frequency: 1 MHz to 22

Tracking:

10 MHz to 33

Range: 2 to 22

Isolation: 220

:lOO,

120, 220, or 240

>6OOVA

~0.2 dB

GHz

GHz

dB

V,,

GHz

Required for preliminary display adjustment!

Recommended

Model

California Instr-

uments Model

153T Opt. 400

HP 11667B

HP

8473D/

HP 8474C

Omni-Spectra

2090-6202-00

IP

85662-60088

Perf,

Test

X

X

Adj.

X

X

X

Low-Noise

DC Supply

Crystal Filter

Bypass Network

CABLES

Low-Loss Microwave

Cable

Cable

Cable

Test Cable*

(Optional)

Refer to Figure 3-109. (4

Refer to Figure 3-108.

required)

APC 3.5 (m)

BNC, 122 cm (48 in.) (3

required)

SMA (m) to SMA (m)

BNC (m) to SMB Snap-On (f)

HP 8120-4921

10503A

5061-1086

IP 85680-60093

X

X

X

X

X

X

General Information 1-7

‘Ihble

l-l. Recommended Test Equipment (6 of 6)

Instrument Critical Specifications for

Equipment Substitution

ADAPTERS

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Adapter

Type N (f) to BNC (m)

SMB snap on (m) (m)

SMB (m) to SMA (f)

SMB (m) bulkhead

Type N (f) to N (f)

Type N (m) to N (m)

Type N (m) to BNC (f) (2

BNC Tee (m)(f)(f) (2

required,

required)

SMA (f) to SMA (f)

SMA (m) to SMA (m)

BNC (f) to SMA (m)

BNC (f) to SMB (f)

Type N (m) to SMA (f)

BNC to aligator clip

Type N (f) to BNC (m)

APC-3.5 (m) to Type N (m)

Type N (m) to APC-3.5 (f)

APC-3.5 (f) TO N (f) (2

required)

APC-3.5 (f) to APC-3.5 (f)

APC-3.5 (m) to Type N (f)

BNC (f) to dual bannana plug

Type N (f) to SMA (f)

Recommended

Model

1250-0077

1250-0672

1250-0674

1250-0691

1250-1477

1250-0778

1250-0780

1250-0781

1250-l 158

1250-1159

1250-1200

1250-1236

1250-1250

1250-1292

1250-1477

1250-1743

1250-1744

1250-1745

1250-1749

1250-1750

1251-2277

HP 86290-60005

Perf.

Test

X

X

X

X

X

X

X

X

X

Adj,

X

X

X

X

X

X

X

X

X

X

X

X

X

X

BOARD

EXTENDERS

See Figure l-l.

?C Board PC Board extracting tool

Xxtractor

t

Part of Service Accessories

HP 03950-4001

X

l-8

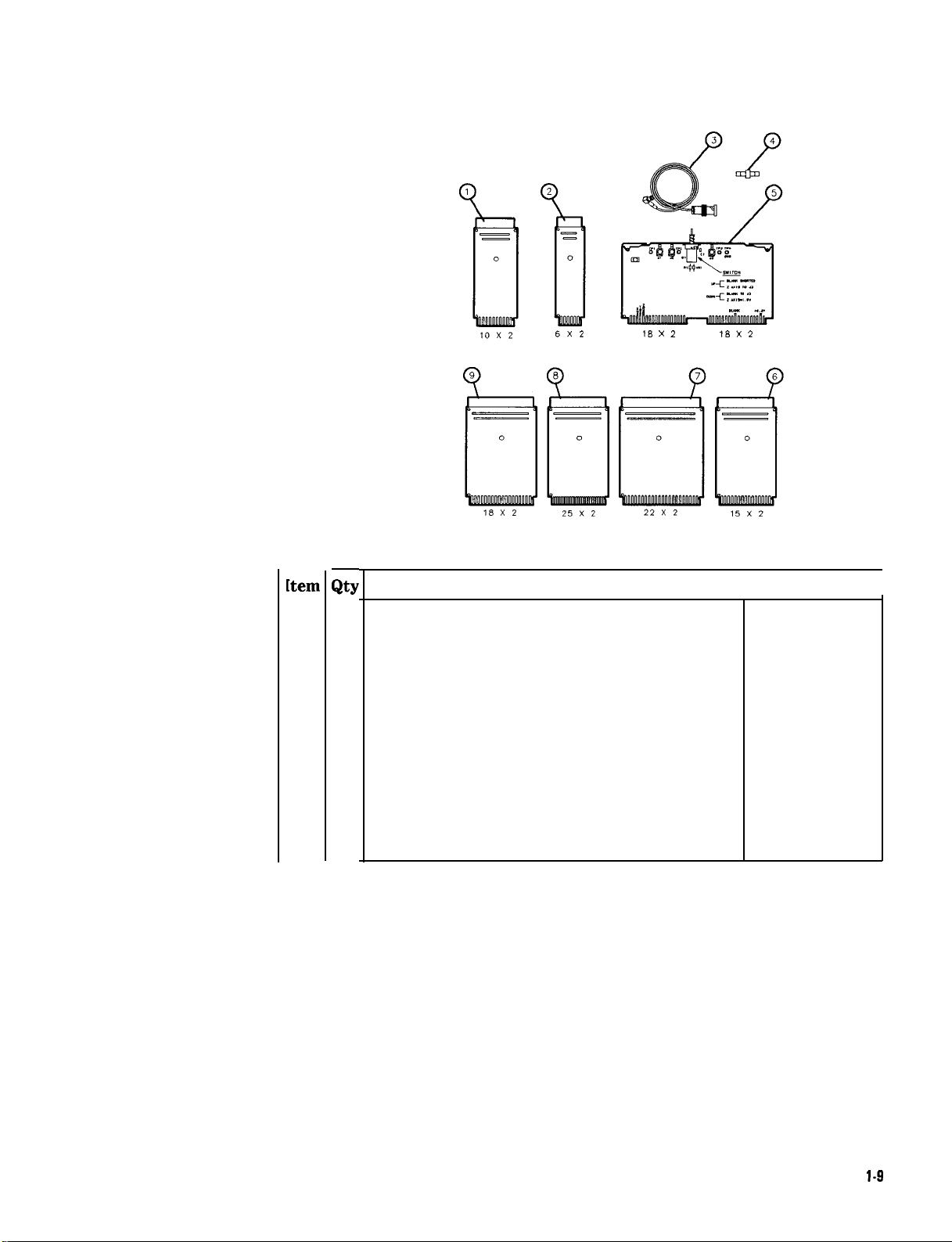

General Information

6X2

18 x 2

18 x 2

kern

1

2

3

4

5

6 3

7

8

9

G

1

Extender

2

Extender

2

Cable: 4-foot long; BNC to SMB snap-on

1

Adapter: SMB snap-on male to SMB snap-on male

1

PC Board: Display Adjustment Test

Extender

1

Extender

1

Extender

2

Extender

Figure l-l. Service Accessories, HP Part Number 08566-60001

Board:

Board:12contacts,

Board:30contacts;

Board:44contacts;

Board:50contacts;

Board:36contacts;

Description

20

contacts,

2

rows of

2

rows of

2

rows of

2

rows of

2

rows of

2

rows of

10

6

15

22

25

18

HP Fart Number

I

85680-60028

08505-60109

85680-60093

85662-60088

08505-60041

08505-60107

85680-60034

08505-60042

I

1250-0669

General Information

l-9

Performance Tksts

2

Introduction

Verifkation

Specifications

of

The procedures in this section test the instrument’s electrical

performance using the Specifications in the Installation and

Verification Manual as the performance standards. None of the

tests require access to the interior of the instrument. The manual

Performance Tests provided in this section should be performed only

if semi-automatic test equipment (for Operation Verification) is not

available or the Performance Test is not in the Operation Verification

Program. (Refer to the Installation and Verification Manual for

information on Operation Verification.)

When a complete verification of specifications is required, proceed as

follows:

1. Run the Operation Verification Program.

2. The Operation Verification Program verifies compliance with

specifications of all tests it performs. The tests not performed by

the Operation Verification Program must be done manually and are

as follows:

n

Sweep Time Accuracy (including Fast Sweep Time Accuracy)

n

Noise Sidebands

n

Harmonic and Intermodulation Distortion

n

Image, Multiple, and Out-of-Band Responses

n Frequency Reference Error

n

Center Frequency Readout Accuracy

If the results of a performance test are marginally within

specification, go to the Adjustments section of this manual and

perform the related adjustments procedures. When an adjustment is

directly related to a performance test, the adjustment procedure is

referenced under RELATED ADJUSTMENT in the performance test.

Performance Tests

2-l

‘Ihble

2-1. Performance Test Cross-Reference

Function or Characteristic Tested Test Performance Test

No.

Center Frequency Readout

Frequency Spans

3-dB

Bandwidths*

Bandwidth Shape*

Bandwidth Amplitudes*

Log Scales

IF Gains

Log and Linear Amplifier Fidelityt

CAL OUTPUT Level

Frequency Response

Sweep Times

Noise Sidebands

Line-Related Sidebands

Noise Floor

Residual Responses

Harmonic and Intermodulation Distortion

1

Center Frequency Readout Accuracy Test

2

Frequency Span Accuracy Test

3

Resolution Bandwidth Accuracy Test

4

Resolution Bandwidth Selectivity Test

5

Resolution Bandwidth Switching Uncertainty Test

6

Log Scale Switching Uncertainty Test

7

IF Gain Uncertainty Test

8

Scale Fidelity Test

9

Calibrator Amplitude Accuracy Test

10 Frequency Response Test

11

Sweep Time Accuracy Test

12 Noise Sidebands Test

13 Line-Related Sidebands Test

14

Average Noise Level Test

15 Residual Responses Test

16

Harmonic and Intermodulation Distortion Test

Image, Multiple, and Out-of-Band Responses

Gain Compression

1ST

LO OUTPUT Amplitude

SWEEP+ TUNE OUT

Fast Sweep Times

Frequency Reference

‘For Option 462 instruments, refer to Chapter 4.

tFor

Option 857 instruments, refer to Chapter 5.

Calibration

Cycle

This instrument requires periodic verification of performance. The

instrument should have a complete verification of specifications at

least every six months.

17

Image, Multiple, and Out-of-Band Responses Test

18 Gain Compression Test

19 1ST

20

21

22

LO OUTPUT Amplitude Test

SWEEP + TUNE OUT Amplitude Test

Fast Sweep Time Accuracy Test (~20 ms)

Frequency Reference Error Test

2-2 Performance Tests

Equipment

Required

Equipment required for the manual performance tests and

adjustments is listed in

equipment that satisfies the critical specifications given in the list may

be substituted for the recommended model.

‘Ikble

l-l, Recommended Test Equipment. Any

Performance

Record

Note

Test

The Operation Verification Program provides a detailed test record

when a printer is used with the controller. If manual performance

tests are done, the results of the performance tests may be tabulated

on the HP 8566B Performance Test Record at the end of this chapter.

The HP 8566B Performance Test Record lists all of the tested

specifications and the acceptable ranges for the measurement values

obtained during the tests.

Allow l/2 hour warm up time for the HP 8566B before beginning the

Performance Tests.

Performance Tests 2-3

1. Center

Frequency Readout

Accuracy

‘l&t

Related

Specifications

Adjustments

10 MHz Standard Adjustment

Sweep, DAC, and Main Coil Driver Adjustments

For spans <n X 5 MHz, f (2% of frequency span + frequency

reference error X center frequency + 10 Hz).

For spans >n X 5 MHz, f (2% of frequency span + n X 100

frequency reference error X center frequency).

n* Center Frequency

1

100 Hz to 5.8

2 5.8

GHz

to 12.5

3 12.5

4

>18.6

GHz

GHz

GHz

to 18.6

GHz

GHz

* n is the harmonic mixing number, depending on center

frequency.

kHz +

SPECTRUM ANALYZER

Figure 2-l. Center Frequency Test Setup

FAEOUENCY

STANDARD

24 Performance Tests

1. Center Frequency Readout Accuracy Test

Description

Equipment

Procedure

A synthesized signal source that is phase-locked to a known frequency

standard is used to input a signal to the analyzer. The frequency

readout of the analyzer is compared to the actual input frequency

for several different frequency settings over the analyzer’s range.

The signal source is phase-locked to a standard known to be as

accurate as the analyzer’s internal frequency reference to minimize

the “frequency reference error X center frequency” term of the

specifications.

Synthesized Sweeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . HP 8340A

Frequency Standard . . . . .

a 10 MHz standard with accuracy within

f

1 part in

lOlo

such as HP 5061A

Adapter, Type N (m) to SMA (f) , . . . . . . . . . . . . . . . . . . . . . 1250-1250

Adapter, SMA (f) to SMA (f) . . . . . . . . . . . . . . . . . . . . . .

.1250-1158

Cable Assembly, SMA Male Connectors . . . . . . . . . . . . . . . . . .5061-1086

1.

Connect CAL OUTPUT to RF INPUT.

2.

Press

c$???KJ IRECALL) @.

3.

Adjust FREQ ZERO for a maximum amplitude trace.

4.

Press

(2-j.

5.

Set the synthesized sweeper for a 2.000000

approximately 0

dBm.

GHz

signal at a level of

6.

Connect equipment as shown in Figure 2-l.

7.

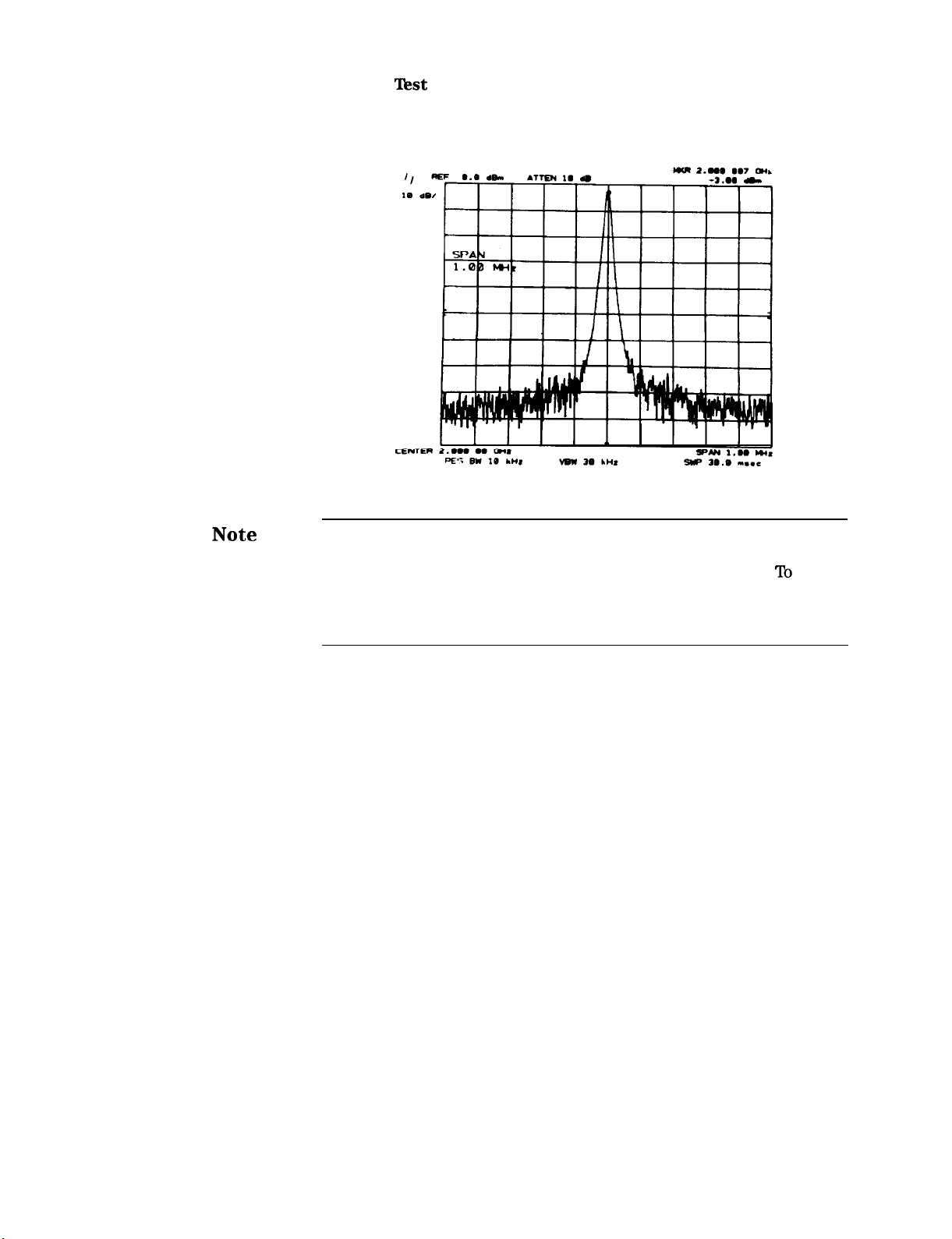

Set analyzer

CCENTER

FREQUENCY) and (FREQUENCY

SPAN)

and

synthesized sweeper frequency according to Table 2-2. At each

setting, press

Adjust

CREFERENCE

CPEAK

SEARCH],

LEVEL) as necessary to place signal peak at a

c-1

to center the signal.

convenient level.

8.

Record the CENTER FREQUENCY readout in the table for each

setting. The limits for this frequency are given in the table. Refer

to Figure 2-2.

Performance Tests 2-5

1. Center Frequency Readout Accuracy Test

Figure 2-2. Center Frequency Accuracy Measurement

Note

The spectrum analyzer CENTER FREQUENCY readout may fall

outside of the specified limits if the internal frequency reference

of the analyzer has not been calibrated within the past year.

To

eliminate the “frequency reference error X center frequency” error,

the analyzer’s 10 MHz Frequency Reference Output (on the rear

panel) may be substituted for the frequency standard.

2-6 Performance Tests

Loading...

Loading...