Operating and Service Manual

Agilent Technologies

85133E/F/H

NMD-2.4 mm -f- to 2.4 mm

Flexible

Test Port Return Cables

Agilent Part Number: 85133-90017

Printed in USA

Print Date: February 2008

Edition 5

Supersedes: October 2007

© Copyright 1990, 2006 - 2008 Agilent Technologies, Inc. All rights reserved.

Documentation Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED "AS IS," AND IS

SUBJECT TO BEING CHANGED, WITHOUT NOTICE, IN FUTURE EDITIONS.

FURTHER, TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW,

AGILENT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED WITH

REGARD TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. AGILENT

SHALL NOT BE LIABLE FOR ERRORS OR FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR ANY INFORMATION CONTAINED HEREIN. SHOULD

AGILENT AND THE USER HAVE A SEPARA TE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE WARRANTY TERMS IN THE SEPARATE

AGREEMENT WILL CONTROL.

DFARS/Restricted Rights Notice

If software is for use in the performance of a U.S. Government prime contract or

subcontract, Software is delivered and licensed as “Commercial computer software” as

defined in DFAR 252.227-7014 (June 1995), or as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer software” as defined in FAR 52.227-19 (June 1987) or

any equivalent agency regulation or contract clause. Use, duplication or disclosure of

Software is subject to Agilent Technologies’ standard commercial license terms, and

non-DOD Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR 52.227-19(c)(1-2) (June 1987). U.S. Government users

will receive no greater than Limited Rights as defined in FAR 52.227-14 (June 1987) or

DFAR 252.227-7015 (b)(2) (November 1995), as applicable in any technical data.

ii 85133E/F/H

CAUTION

The cable center conductor is fragile and will be seriously damaged if the

cable is stretched, bent too tightly, or bent too oft en. Cables break when the

bend radius is too small—less than 2.5” (6 cm) for 1.85 mm cables, and less

than 4” (10 cm) for 2.4 mm cables.

Use the following guidelines with cables:

• Never coil the cable too tightly.

• Never allow the cable to hang down from an instrument test port, or a

storage fixture, or while holding it.

• Never bend the cable an excessive number of times.

85133E/F/H iii

Printing Copies of Documentation from the Web

To print copies of documentation from the Web, download the PDF file from the Agilent

web site:

•Go to http://www.agilent.com.

• Enter the document’s part number (located on the title page) in the Search box.

• Click Search.

• Click on the hyperlink for the document.

• Click the printer icon located in the tool bar.

iv 85133E/F/H

1. General Information

The Cable Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

85133E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

85133F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

85133H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Connector Designators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Clarifying the Terminology of a Connector Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Incoming Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2. Specifications

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Supplemental Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Center Conductor Pin Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3. Use, Maintenance, and Care of the Cables

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Look for Obvious Defects and Damage First. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Inspect the Mating Plane Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Precision Slotless Connectors (2.4 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Cleaning Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Gaging Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connector Gage Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

When to Gage Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Gaging Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Making Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

How to Make a Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

How to Separate a Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Handling and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Avoiding Cable Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Contents

4. Replaceable Par ts

Ordering Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Ordering One Cable in a Cable Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Returning a Cable or Cable Set to Agilent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Contacting Agilent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Information About Network Analyzers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

A. Connector Care Quick Reference

Principles of Microwave Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

85133E/F/H

1

Contents

2

85133E/F/H

1 General Information

85133E/F/H 1-1

General Information

The Cable Sets

The Cable Sets

The Agilent 85133E/F/H flexible cable sets are designed for use with Agilent network

analyzers that have male NMD-2.4 mm test ports.

85133E

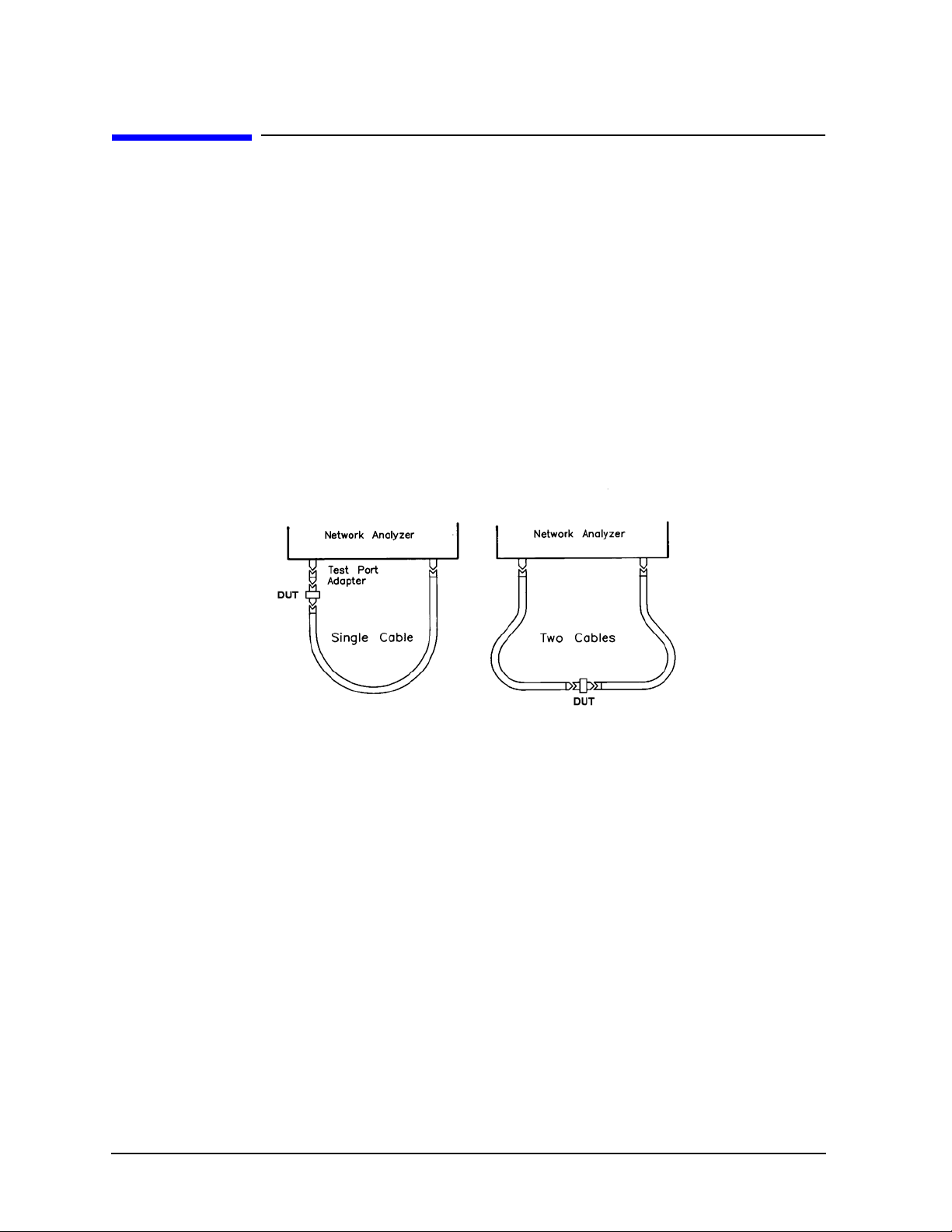

The 85133E set contains a single cable. Use it when a DUT is connected, with the

appropriate adapter, directly to the test set test port. See Figure 1-1.

85133F

The 85133F set contains two cables. Each is shorter than the 85133E cabl e. Use the

85133F cables when a DUT is connected between cable ends. See Figure 1-1.

Figure 1-1 Cable Configurations

85133H

The 85133H set contains a single cable – the -f- to -m- cable from the 85133F cable set. It is

shorter than the 85133E single cable. See Figure 1-1.

Connector Designators

NMD Connectors

NMD denotes a connector that has larger than standard coupling threads for greater

stability. NMD connectors are used on test cables, test ports, test port adapters, and test

port cables.

Female slotted NMD test port connectors are used on the test set end of adapters and

cables, and cannot be connected to standard male connectors.

Male NMD connectors are used on tes t sets (as test p orts), and on the DUT end of adapters

and cables. Male connectors have both the larger threads (for use with test port adapters)

and standard threads (for direct coupling to a DUT).

1-2 85133E/F/H

General Information

Incoming Inspection

PSC Connectors

PSC denotes a precision slotless connector. Precision slotless connectors are metrology

grade connectors that have better electrical performance, better repeatability, and are

more durable than slotted connectors.

Clarifying the Terminology of a Connector Interface

In this document and in the prompts of the PNA calibration wizard, the gender of cable

connectors and adapters is referred to in terms of the center conductor. For example, a

connector or device designated as 1.85 mm –f– has a 1.85 mm female center conductor.

8510-series , 872 x , a nd 87 5x ON LY: In contrast, during a measurement calibration, the

network analyzer softkey menus label a 1.85 mm calibration device with reference to the

sex of the analyzer’s test port connector—not the calibration device connector. For

example, the label SHORT(F) refers to the short that is to be connected to the fem a le test

port. This will be a male short from the calibration kit.

Table 1-1 Clarifying the Sex of Connectors: Examples

Terminology Meaning

Short

–f–

Short (f) Male short (male center conductor) to be connected to female port

A connector gage is referred to in terms of the connector that it measures. For instance, a

male connector gage has a female connector on the gage so that it can measure male

devices.

Female short (female center conductor)

Incoming Inspection

Verify that the shipment is complete by referring to Table 4-1 on page 4-4.

If the case or any device appears damaged, or i f the shipment is incompl ete, not ify Agilent.

See “Contacting Agilent” on page 4-3. Agilent will arrange for repair or replacement of

incomplete or damaged shipments without waiting for a settlement from the

transportation company.

When you send the cable set to Agilent, include the following information:

• your company name and address

• the name of a technical contact person within your company, and the person’s complete

phone number

• the model number and serial number of the cable set

85133E/F/H 1-3

General Information

Preventive Maintenance

• the part number and serial number of the device

• the type of ser v i ce re q u i red

•a detailed description of the problem

Preventive Maintenance

The best techniques for maintaining the integrity of the cables include:

• routine visual inspection

• cleaning

• proper gaging

• proper connection techniques

• proper storage

All of the above are described in Chapter 3. Failure to detect and remove dirt or metallic

particles on a mating plane surface can degrade repeatability and accuracy and can

damage any connector mated to it. Improper connections, resulting from center conductor

values being out of limits (see Table 2 on page 2-4), or from bad connections, can also

damage cable connectors.

Replaceable Parts

See Table 4-1 on page 4-4 for a complete list of cable set contents and their associated part

numbers (you can order a single cable rather than the entire cable set), and for

recommended items not included with the cable set. Refer to “Contacting Agilent” on

page 4-3 for information about communicating with Agilent.

1-4 85133E/F/H

2 Specifications

85133E/F/H 2-1

Specifications

Environmental Requirements

Environmental Requirements

Table 2-1 Environmental Requirements

Parameter Limits

Operating temperature +20 °C to +26 °C (+68 °F to +79 °F)

Storage temperature −40 °C to +75 °C (−40 °F to +167 °F)

Altitude

Operation < 4,500 meters (≈15,000 feet)

Storage < 4,500 mete rs (≈15,000 feet)

Relative humidity Always non-condensing

Operation Up to 80% at 30°C

Storage Up to 95% at 40°C

Electrical Specifications

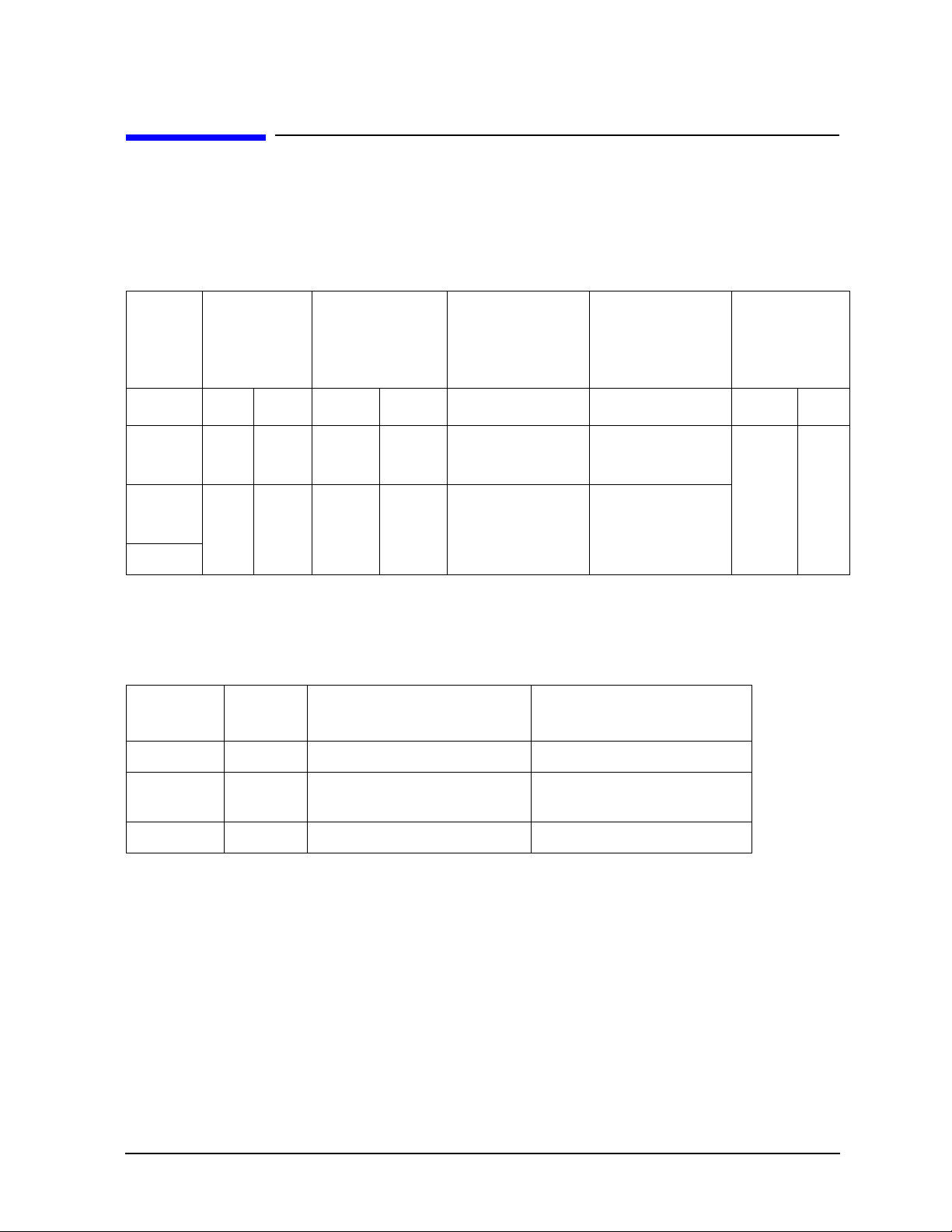

Table 2-2 Electrical Specifications

Cable SWR Return Loss

(dB)

85133E ≤1.44 ≥15 ≤0.1 + 0.57√f

85133F ≤0.1 + 0.38√f

85133H

a. f = frequency in GHz.

Insertion

Loss (dB)

+ 0.02f

+ 0.017f

Frequency Range

a

(GHz)

DC to 50

2-2 85133E/F/H

Specifications

Supplemental Characteristics

Supplemental Characteristics

T able 2-3 lists supp lementa l perfor mance char acte ristic s. These are not specifi cati ons, but

are intended to provide additional information useful to your application. Supplemental

characteristics are typical (but not warranted) performance parameters.

Table 2-3 Supplemental Characteristics (1 of 3)

Cable Cable Length Approximate

Electrical Length

cm in m ft cm in

85133E 97.2 38.25 1.125 3.690 <0.15 dB Change

85133F 62.9 24.75 0.7376 2.418 <0.08 dB Change

85133H

a. (f) = frequency in GHz.

b. With a 90°, 2.5-inch bend radius.

c. After three 90°, 2.5-inch bend radius/straighten cycles.

Magnitude and

Phase Stability

With a 90°

a,b

Bend

<0.17° (f) + 0.5°

<0.08° (f) + 0.5°

Random Use

Magnitude and

Phase Stability

<0.07 dB Change

<0.09° (f) + 0.5°

<0.04 dB Change

<0.04° (f) + 0.5°

Table 2-3 Supplemental Characteristics (2 of 3)

Cable Set N umber

of Cables

85133E 1 NMD-2.4 mm -f- Slotted PSC-2.4 mm -f- Slotless

Test Set End Connector Typ e DUT End Connector Type

Minimum

Recommended

a,c

Bend Radius

6.352 2.5

85133F 2 NMD-2.4 mm -f- Slotted NMD-2.4 mm -m- and

PSC-2.4 mm -f- Slotless

85133H 1 NMD-2.4 mm -f- Slotted NMD-2.4 mm -m-

Center Conductor Pin Depth

Center conductor pin depth is the distance the center conductor mating plane differs from

being flush with the outer conductor mating plane. See Figure 2-1 The pin depth of a

center conductor can be in one of two states: either protruding or recessed.

Protrusion is the condition in which the center conductor extends beyond the outer

conductor mating plane. This c ondition will indi cate a pos itive value on the c onnector gage.

Recession is the condition in which the center conductor is set back from the outer

conductor mating plane. This condition will indi cate a negative value on the connector

gage.

85133E/F/H 2-3

Loading...

Loading...