User’s and Service Guide

Agilent Technologies 85057B

2.4 mm Verification Kit

This manual applies to 85057B verification kits with serial number prefix

3105A.

Agilent Part Number: 85057-90015

Printed in USA

Print Date: November 2005

Supersedes: Ja nuary 2002

© Copyright 1995, 2002, 2005 Agilent Technologies, Inc. All rights reserved.

Documentation Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED "AS IS," AND IS

SUBJECT TO BEING CHANGED, WITHOUT NOTICE, IN FUTURE EDITIONS.

FURTHER, TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW,

AGILENT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED WITH

REGARD TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. AGILENT

SHALL NOT BE LIABLE FOR ERRORS OR FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR ANY INFORMATION CONTAINED HEREIN. SHOULD

AGILENT AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE WARRANTY TERMS IN THE SEPARATE

AGREEMENT WILL CONTROL.

DFARS/Restricted Rights Notice

If software is for use in the per formance of a U.S. Go vernment prime contract or

subcontract, Software is delivered and licensed as “Commercial computer software” as

defined in DFAR 252.227-7014 (June 1995), or as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer sof tware” as defined in FAR 52.227-19 (June 1987) or

any equivalent agency regulation or contract clause. Use, duplication or disclosure of

Software is subject to Agilent Technologies’ standar d commercial license terms, and

non-DOD Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR 52.227-19(c)(1-2) (J une 1987). U.S. Government users

will receive no greater than Limited Rights as defined in FAR 52.227-14 (June 1987) or

DFAR 252.227-7015 (b)(2) (November 1995), as applicable in any technical data.

Assistance

Product maintenance agreements and other customer assistanc e agreements are availa ble

for Agilent products.

For any assistance, contact Agilent Technologies. Refer to page 5-5 for a list of Agilent contacts.

ii 85057B

Printing Copies of This Document

To print copies of this document, download the PDF file from the Agilent Web site:

• Go to http://www.agilent.com.

• Enter the document’s part number (located on the title page) in the Quick Search box.

• Click GO.

85057B iii

iv 85057B

Contents

1. General Information

Verification Kit Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Compatible Network Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Equipment Required but Not Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Incoming Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Recording the Device Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Clarifying the Terminology of a Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2. Specifications

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Temperature—What To Watch Out For. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Mechanical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Pin Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Supplemental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Airline Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

3. Use, Maintenance, and Care of the Devices

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Look for Obvious Defects and Damage First. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

What Causes Connector Wear?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Inspect the Mating Plane Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Inspect Female Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Cleaning Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Gaging Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Connector Gage Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

When to Gage Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Gaging Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Gaging 2.4 mm Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Gaging the Airline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

How to Make a Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Preliminary Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Final Connection Using a Torque Wrench. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Connecting the Airline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

How to Separate a Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Handling and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

4. Performance Verification

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

How Agilent Verifies the Devices in Your Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Recertification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

How Often to Recertify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Where to Send a Kit for Recertification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

85057B iii

Contents

5. Troubleshooting

Troubleshooting Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Returning a Kit or Device to Agilent Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Contacting Agilent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

6. Replaceable Parts

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

iv 85057B

1 General Information

85057B 1-1

General Information

Verification Kit Overview

Verification Kit Overview

The Agilent 85057B 2.4 mm verification kit provides a set of standards with known

characteristics, traceable to a reference (golden) standard in Agilent Technologies

calibration lab. This set of standards is used to verify your measurement calibration and

also to verify that your network analyzer sy stem is ope rati ng within it s specif ications. The

frequency range covered by the 85057B is from 45 MHz to 50 GHz.

Kit Contents

The 85057B verification kit includes the following items:

• 20 dB attenuator

• 40 dB attenuator

•25Ω mismatch airline

•50Ω airline

• data disks that contain factory-measured verification data.

Refer to Chapter 6, “Replaceable Parts,” fo r a complete l ist of c ontents an d their asso ciated

part numbers.

NOTE A file containing the verification data for your kit is maintained for one year

from the time of measurement. If you lose this data, see “Contacting Agilent”

on page 5-5 for a list of telephone numbers.

Compatible Network Analyzers

The 85057B verification kit is intended to be used with the 85056A 2.4 mm calibr ation kits

and any of the following Agilent network analyzers:

• 8510

• 872x Series

•PNA Series

The verification data disk provided for use with each of the network analyzers listed above

contains the factory-measured S-p arameter data f or the de vices in thi s kit. It also contains

the uncertainty limits used in the system verification procedure. This data is unique to

each kit.

NOTE A backup copy of each verification data disk and printout should be made

immediately upon receipt of this kit. Refer to your analyzers user’s guide for

instructions on duplicating a disk.

1-2 85057B

General Information

Incoming Inspection

Equipment Required but Not Supplied

Certain items are required or recommended for successful operation of the verification kit but are not included in the kit . R ef e r to T able on page 6-2 for ordering information.

Incoming Inspection

Verify that the shipment is complete by referring to Table 6-1 on page 6-2. Check for damage. The fo am-lined storage c ase pr ovides prote ction dur ing shippi ng . Verify

that this case and its contents are not damaged.

If the case or an y de v i ce appears dam ag ed, or if the ship m e n t is incomple te, re fe r to

“Contacting Agilent” on page 5-5. Agilent will arrange for repair or replacement of

incomplete or damaged shipments without waiting for a settlement from the

transportation company. Refer to “Returning a Kit or Device to Agilent Technologies” on

page 5-4 for instructions.

Recording the Device Serial Numbers

In addition to the kit serial number, the devices in this kit are individually serialized

(serial numbers are labeled into the body of each device). Record these serial numbers in

Table 1-1. Recording the serial numbers wi ll prevent confusing the devices in this kit with

similar devices from other kits.

Table 1-1 Serial Number Record for the 85057B

Device Serial Number

Verification kit 20 dB attenuator 40 dB attenuator 50Ω airline 25Ω mismatch airline

___________________________

___________________________

___________________________

___________________________

___________________________

85057B 1-3

General Information

Clarifying the Terminology of a Connector Interface

Clarifying the Terminology of a Connector Interface

In this document and in the prompts of the PNA calibration wizard, the sex of connectors

and adapters is referred to in terms of the center conductor. For example, a connector or

device designated as 1.85 mm –f– has a 1.85 mm female center conductor.

8510-series , 872 x , a nd 87 5x ON LY: In contrast, during a measurement calibrat ion, the network analyzer softkey menus label a 1.85 mm calibration device with reference to the sex of the analyzer’s test po rt connector—not the calibr ation device connector. For example , the label SHORT(F) refers to the sh ort that is to be co n n ected to the fe m a l e te st port. This will be a male short from the calibration kit.

Table 1-2 Clarifying the Sex of Connectors: Examples

Terminology Meaning

Short

–f–

Short (f) Male short (male center conductor) to be connected to female port

A connector gage is referred to in terms of the connector that it measures. For instance, a

male connector gage has a female connector on the gage so that it can measure male

devices.

Female short (female center conductor)

Preventive Maintenance

The best techniques for maintaining the in teg rity of the devices in this kit include:

• routine visual inspection

• cleaning

• proper gaging

• proper connection technique s

All of these are described in Chapter 3. Failure to detect and remove dirt or metallic

particles on a mating plane surface can degrade repeatability and accuracy and can

damage any connector mated to it. Improper connections, resulting from pin depth values

being out of specification (see Table 2-2 on page 2-4), or from bad connect ion techniques,

can also damage these devices.

1-4 85057B

2 Specifications

2-1

Specifications

Environmental Requirements

Environmental Requirements

Table 2-1 Environmental Requirements

Parameter Required Values/Ranges

Temperature

Operating

Storage

Error-corrected range

Altitude

Operating < 4,500 meters (≈15,000 feet) Storage < 15,000 meters (≈50,000 feet)

Relative humidity Always non–condensing

Operating 0 to 80% (26 °C maximum dry bulb) Storage 0 to 90%

a. The temperature range over which the calibration standards maintain conformance to their

b. The allowable network analyzer ambient temperature dr ift during measurement calibra tion and

a

b

specifications.

during measurements when the network analyzer error correction is turned on. Also, the range

over which the network analyzer maintains its specified performance while correction is turned on.

+20 °C to +26 °C (+68 °F to +79 °F)

−40 °C to +75 °C (−40 °F to +167 °F)

±1 °C (1.8 °F) of measurement calibration temperature

Temperature—What To Watch Out For

Due to the small dimensions of the devices, electrical characteristics will change with

temperature. Theref ore, the operat ing temperature is a critical facto r in their performance ,

and must be stable before use.

IMPORTANT Avoid unnecess ary handling of the devices during use because your fingers

are a heat source.

2-2 85057B

Specifications

Mechanical Characteristics

Mechanical Characteristics

Mechanical characteristics such as center conductor protrusion and pin depth are not

warranted performance specifications. They are, however, important supplemental

characteristics related to elect rical performance. Agilent Technologies verifies the

mechanical characteristics of the devices in this kit with special gaging processes and

electrical testing. This ensures that the device connectors do not exhibit any improp er pin

depth when the kit leaves the factory.

“Gaging Connectors” on page 3-7 explains how to use gages to determine if the kit devices

have maintained their mechanical integrity. Refer to Table 2-2, “Connector Pin Depths,”

for allowable recession.

Pin Depth

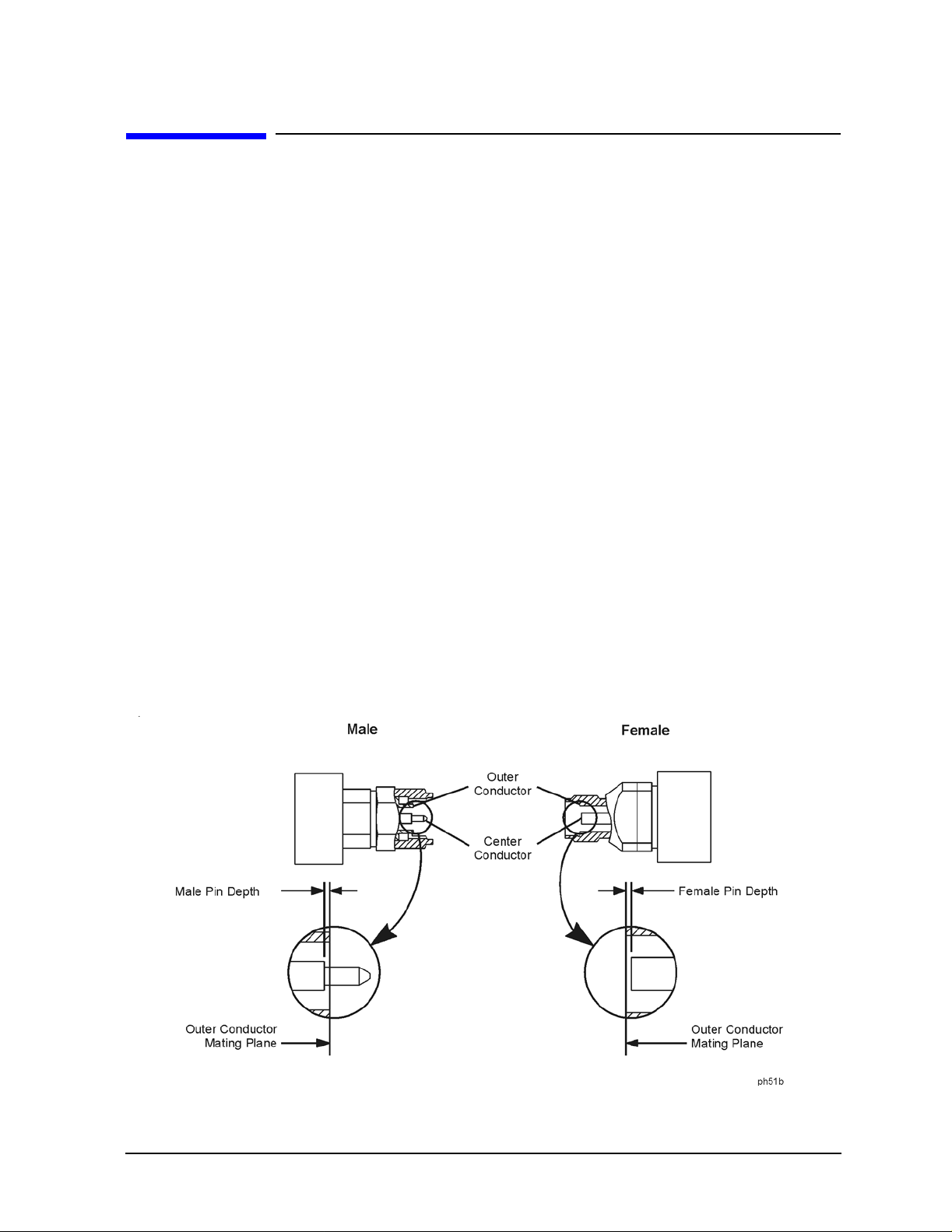

Pin depth is the distance the center conductor mat ing plane differs from being flush with

the outer co n d uctor mati ng plane. See Figure 2-1. The pin depth of a connector can be in

one of two conditions:

• Protrusion is the condition in which the center conductor extends beyond the outer

conductor mating plane. This condition will indicate a positive value on the connector

gage.

• Recession is the condition in which the center conductor is set back from the outer

conductor mating plane. This condit ion will indicate a negative value on the connector

gage.

Figure 2-1 Connector Pin Depth

85057B 2-3

Specifications

Mechanical Characteristics

Supplemental Characteristics

The following tables list the dimensions of the 50Ω airline and the 25Ω mismatch airline.

These are supplemental mechanical char acteristics , and from these characteri stics you can

calculate expected electrical performance.

Table 2-2 Connector Pin Depths

Connectors

millimeters inches

Attenuators 0.000 to −0.025 0.0000 to −0.001 Airlines

a

a. The relationship between the length of the inner conductor and the

length of the outer conductor determines the airline center conductor

recession. Refer to “Gaging the Airline” on page 3-1 0.

0.0000 to −0.013 0.0000 to −0.0005

Allowable Recession

Using these mechanical dimensions , you can calculat e the expect ed elec trical pe rformance

with the equations in the following publications:

• Nelson, Robert E., and Marlene R. Coryell, "Electrical P arameters of Precisi on, Coaxial,

Air-Dielectric Transmission Lines", U.S. National Bureau of Standards Monograph No.

96.

• Somlo, P.I., "The Computation of Coaxial Line Step Capacitances", IEEE Transactions

on Microwave Theory and Techniques, Volume MTT-15, No. 1, J anuary, 1967.

The measurement method in these publications provides a general idea of the expected

device characteristic impedance. Variations in connector interface s can have a large effect

on your actual electrical measurements.

2-4 85057B

Specifications

Mechanical Characteristics

Airline Characteristics

The dimensions of the airline outer conductor are s hown in Figure 2-2. There are two similar outer conductors in each kit. They are specifically matched to each center conductor.

The dimensions of the 50Ω airline and the 25Ω mismatch airline are shown in Figure 2 -3

and Figure 2-4.

CAUTION The center and outer conductors of the airlines i n this kit have been

mechanically measured and matched. Do not use the center or oute r

conductors provided in th i s kit with a cent er or outer con ductor from an y

other airline. Damage to the airline or attaching connector may result.

Figure 2-2 Airline Outer Conductor

Dimension millimeters inches

D −Diameter 2.400 ±0.0025 0.0945 ±0.0001 L −Length

85057B 2-5

49.991 ±0.025

1.968 ±0.001

Specifications

Mechanical Characteristics

Figure 2-3 50Ω Airline Center Conductor

Dimension millimeters inches

d 1.0423 ±0.003 0.04104 ±0.00012

∆L +0.0025/−0.013 +0.0001/ −0.0005

Figure 2-4 25Ω Mismatch Airline Center Conductor

Dimension millimeters inches

d 1.0423 ±0.008 0.04104 ±0.0003

d

1

l

1

l

2

∆L +0.0025/−0.013 +0.0001/−0.0005

1.58 ±0.005 0.0622 ±0.0002

37.46 ±0.019 1.4748 ±0.0007

6.22 ±0.050 0.2449 ±0.002

2-6 85057B

Loading...

Loading...