User's Guide

HP 8169A Polarization Controller

SERIAL NUMBERS

This guide applies to all instruments.

ABCDE

HP Part No. 08169-91011

Printed in the Federal Republic of Germany

First Edition

E0396

Notices

This document contains proprietary

information that is protected by

copyright. All rights are reserved.

No part of this document may be

photocopied, reproduced, or

translated to another language

without the prior written consent of

Hewlett-Packard GmbH.

c

Copyright 1993 by:

Hewlett-Packard GmbH

Herrenberger Str. 130

71034 Boeblingen

Federal Republic of Germany

Subject Matter

The information in this document is

subject to change without notice.

Hewlett-Packard makes no warranty

of any kind with regard to this

printed material, including, but not

limited to, the implied warranties of

merchantability and tness for a

particular purpose.

Hewlett-Packard shall not be liable

for errors contained herein or for

incidental or consequential damages

in connection with the furnishing,

performance, or use of this material.

Printing History

New editions are complete revisions

of the guide reecting alterations in

the functionality of the instrument.

Updates are occasionally made to

the guide between editions. The

date on the title page changes when

an updated guide is published. To

nd out the current revision of the

guide, or to purchase an updated

guide, contact your Hewlett-Packard

representative.

Control Serial Number: First Edition

applies directly to all instruments.

Warranty

This Hewlett-Packard instrument

product is warranted against defects

in material and workmanship for a

period of one year from date of

shipment. During the warranty

period, HP will, at its option, either

repair or replace products that prove

to be defective.

For warranty service or repair, this

product must be returned to a service

facility designated by HP. Buyer shall

prepay shipping charges to HP and

HP shall pay shipping charges to

return the product to Buyer.

However, Buyer shall pay all shipping

charges, duties, and taxes for

products returned to HP from

another country.

HP warrants that its software and

rmware designated by HP for use

with an instrument will execute its

programming instructions when

properly installed on that instrument.

HP does not warrant that the

operation of the instrument,

software, or rmware will be

uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not

apply to defects resulting from

improper or inadequate maintenance

by Buyer, Buyer-supplied software or

interfacing, unauthorized

modication or misuse, operation

outside of the environmental

specications for the product, or

improper site preparation or

maintenance.

No other warranty is expressed or

implied. Hewlett-Packard specically

disclaims the implied warranties of

Merchantability and Fitness for a

Particular Purpose.

First Edition : 1st September 1994 : 08169-91011 : E0994

: 1st March 1996 : 08169-91011 : E0396

Exclusive Remedies

The remedies provided herein are

Buyer's sole and exclusive remedies.

Hewlett-Packard shall not be liable

for any direct, indirect, special,

incidental, or consequential

damages whether based on contract,

tort, or any other legal theory.

Assistance

Product maintenance agreements

and other customer assistance

agreements are available for

Hewlett-Packard products.For any

assistance contact your nearest

Hewlett-Packard Sales and Service

Oce.

Certication

Hewlett-Packard Company certies

that this product met its published

specications at the time of

shipment from the factory.

Hewlett-Packard further certies

that its calibration measurements

are traceable to the United States

National Institute of Standards and

Technology, NIST (formerly the

United States National Bureau of

Standards, NBS) to the extent

allowed by the Institutes's

calibration facility, and to the

calibration facilities of other

International Standards Organization

members.

ISO 9001 Certication

Produced to ISO 9001 international

quality system standard as part of

our objective of continually

increasing customer satisfaction

through improved process control.

Safety Summary

The following general safety precautions must be observed during all phases

of operation, service, and repair of this instrument. Failure to comply with

these precautions or with specic warnings elsewhere in this manual violates

safety standards of design, manufacture

, and intended use of the instrument.

Hewlett-Packard Company assumes no liability for the customer's failure to

comply with these requirements.

General

This is a Safety Class 1 instrument (provided with terminal for

protective earthing) and has been manufactured and tested according to

international safety standards.

Operation - Before applying power

Comply with the installation section.

Additionally, the following shall be observed:

Do not remove instrument covers when operating.

Before the instrument is switched on, all protective earth terminals

, extension

cords, auto-transformers and devices connected to it should be connected to a

protective earth via a ground socket. Any interruption of the protective earth

grounding will cause a potential shock hazard that could result in serious

personal injury.

Whenever it is likely that the protection has been impaired, the instrument

must be made inoperative and be secured against any unintended operation.

Make sure that only fuses with the required rated current and of the specied

type (normal blow, time delay, etc.) are used for replacement. The use of

repaired fuses and the short-circuiting of fuseholders must be avoided.

Adjustments described in the manual are performed with power supplied to

the instrument while protective covers are removed. Be aware that energy at

many points may, if contacted, result in personal injury.

Any adjustments, maintenance, and repair of the opened instrument under

voltage should be avoided as much as possible, and when unavoidable, should

be carried out only by a skilled person who is aware of the hazard involved.

Do not attempt internal service or adjustment unless another person, capable

of rendering rst aid and resuscitation is present. Do not replace components

with power cable connected.

Do not operate the instrument in the presence of ammable gases or fumes.

Operation of any electrical instrument in such an enviroment constitutes a

denite safety hazard.

Do not install substitute parts or perform any unauthorized modication to

the instrument.

Be aware that capacitors inside the instrument may still be charged even if

the instrument has been disconnected from its source of supply.

iv

Safety Symbols

The apparatus will be marked with this symbol when it is

necessary for the user to refer to the instruction manual in

order to protect the apparatus against damage.

Caution, risk of electric shock.

Frame or chassis terminal.

Protective conductor terminal.

Hazardous laser radiation.

Warning

Caution

The WARNING sign denotes a hazard. It calls attention to

a procedure, practice or the like, which, if not correctly

performed or adhered to, could result in injury or loss of

life. Do not proceed beyond a WARNING sign until the

indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to

an operating procedure, practice or the like, which, if not

correctly performed or adhered to, could result in damage to

or destruction of part or all of the equipment. Do not proceed

beyond a CAUTION sign until the indicated conditions are fully

understood and met.

v

Contents

1. Getting Started

The Basic Operating Principle ................. 1-1

Using the Polarization Controller for Polarization Analysis ... 1-2

Editing ............................ 1-3

Editing Using the Entry Keys . . . . . . . . . . . . . . . . . 1-3

Editing Using the Modify Keys and Knob ........... 1-3

Resetting Parameters . . . . . . . . . . . . . . . . . . . . . 1-4

2. Setting a State of Polarization

Setting up the Hardware . . . . . . . . . . . . . . . . . . . .

Setting the Position of the Polarizing Filter .......... 2-1

Setting the State of Polarization ................ 2-3

Positioning the/4 and/2 Retarder Plates .......... 2-4

Using the Circle Mode .................... 2-4

Example: Setting the Optimum Transmission SoP .. .... 2-4

Set the Polarizing Filter ................. 2-5

Setting the Worst Case Transmission SoP ........ . 2-6

Setting the Optimum Transmission SoP .. ........ 2-7

3. Scanning the Poincare Sphere

Setting up the Hardware . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up and Executing a Scan ................ 3-1

Example: Measuring the Response to a \Depolarized" Signal .. 3-2

Set the Polarizing Filter ........ ........ .. 3-3

Setting Up the Instruments . . . . . . . . . . . . . . . . . 3-4

Running the Scan .... ........ ..... .... 3-4

Example: Measuring a Polarization Dependent Loss ...... 3-5

Set the Polarizing Filter ........ ........ .. 3-6

Setting Up the Instruments . . . . . . . . . . . . . . . . . 3-7

Running the Scan .... ........ ..... .... 3-7

Analyzing the Results .... ........ ...... . 3-7

2-1

Contents-1

4. Other Front Panel Functions

Setting the HP-IB Address ...... ........ ..... 4-1

Storing or Recalling Instrument Settings . . . . . . . . . . . . . 4-1

Storing a Setting . . . . . . . . . . . . . . . . . . . . . . . 4-1

Recalling a Setting . . . . . . . . . . . . . . . . . . . . . . 4-2

Resetting the Instrument . . . . . . . . . . . . . . . . . . . 4-2

5. Programming the Polarization Controller

HP-IB Interface ........................ 5-1

Setting the HP-IB Address ...... ........ ..... 5-3

Returning the Instrument to Local Control ........... 5-3

How the Polarization Controller Receives and Transmits Messages 5-3

How the Input Queue Works ................. 5-3

Clearing the Input Queue . . . . . . . . . . . . . . . . . . 5-4

The Output Queue . . . . . . . . . . . . . . . . . . . . . . 5-4

The Error Queue . . . . . . . . . . . . . . . . . . . . . . . 5-4

Some Notes about Programming and Syntax Diagram Conventions 5-4

Short Form and Long Form.................. 5-5

Command and Query Syntax ................. 5-5

6. Remote Commands

Command Summary ......................

The Common Commands . . . . . . . . . . . . . . . . . . . .

Common Status Information .. ........ ...... . 6-5

SRQ, The Service Request .... ........ ..... 6-6

*CLS .... ........ ...... ........ .. 6-7

*ESE ............................ 6-7

*ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

*ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

*OPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

*OPC? ........ ........ ..... ..... 6-10

*RCL ............................ 6-10

*RST .... ........ ...... ........ .. 6-11

*SAV ............................ 6-11

*SRE .... ........ ...... ........ .. 6-12

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

*STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

*WAI ...... ........ ...... ........ 6-14

Switching On and O the Instrument Display ...... .... 6-15

6-2

6-5

Contents-2

:DISPlay:ENABle ...................... 6-15

:DISPlay:ENABle? . . . . . . . . . . . . . . . . . . . . . 6-15

Positioning the Polarizing Filter . . . . . . . . . . . . . . . . . 6-16

[:INPut]:POSition:POLarizer ...... ........ ... 6-16

[:INPut]:POSition:POLarizer? . . . . . . . . . . . . . . . . 6-16

Setting the State of Polarization ................ 6-17

[:INPut]:CIRCle:EPSilonb . . . . . . . . . . . . . . . . . . . 6-17

[:INPut]:CIRCle:EPSilonb? ................. 6-17

[:INPut]:CIRCle:THETap ................... 6-18

[:INPut]:CIRCle:THETap?.................. 6-18

[:INPut]:POSition:HALF ................... 6-19

[:INPut]:POSition:HALF? . . . . . . . . . . . . . . . . . . 6-19

[:INPut]:POSition:QUARter . . . . . . . . . . . . . . . . . . 6-19

[:INPut]:POSition:QUARter? ................ 6-20

Scanning the Sphere . . . . . . . . . . . . . . . . . . . . . . 6-21

[:INPut]:PSPHere:RATE ........ ........ ... 6-21

[:INPut]:PSPHere:RATE?.................. 6-21

:INITiate[:IMMediate] .................... 6-21

:ABORt . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

STATus Commands . . . . . . . . . . . . . . . . . . . . . . . 6-23

Setting Up the STATus Registers .. ........ ..... 6-24

:STATus:PRESet ...................... 6-24

:STATus:OPERation:NTRansition .... ...... ....

:STATus:OPERation:NTRansition? . . . . . . . . . . . . .

6-25

6-25

:STATus:OPERation:PTRansition .............. 6-25

:STATus:OPERation:PTRansition? . . . . . . . . . . . . . 6-25

:STATus:OPERation:ENABle .. ...... ........ 6-25

:STATus:OPERation:ENABle? . . . . . . . . . . . . . . . 6-26

:STATus:QUEStionable:NTRansition . . . . . . . . . . . . . 6-27

:STATus:QUEStionable:NTRansition? ........... 6-27

:STATus:QUEStionable:PTRansition ........ ..... 6-27

:STATus:QUEStionable:PTRansition? .... ...... . 6-27

:STATus:QUEStionable:ENABle . . . . . . . . . . . . . . . 6-27

:STATus:QUEStionable:ENABle? .... ...... ... 6-28

Checking the Status .. ........ ...... ..... 6-29

:STATus:OPERation:CONDition? .............. 6-29

:STATus:OPERation[:EVENt]? . . . . . . . . . . . . . . . . 6-29

:STATus:QUEStionable:CONDition? ............. 6-30

:STATus:QUEStionable[:EVENt]? .............. 6-30

SYSTem Commands ...... ........ ...... .. 6-31

:SYSTem:ERRor? . . . . . . . . . . . . . . . . . . . . . . . 6-31

Contents-3

:SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . 6-31

7. Programming Examples

Example 1 - Checking Communication ............. 7-2

Example 2 - Status Registers and Queues ............ 7-3

Example 3 - Finding the Optimum Transmission SoP . . . . . . . 7-7

Example 4 - Finding the Polarization Dependence ........ 7-11

A. Installation

Safety Considerations ..................... A-1

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . A-1

AC Line Power Supply Requirements .............. A-2

Line Power Cable ...................... A-2

Replacing the Fuse . . . . . . . . . . . . . . . . . . . . . . A-4

Replacing the Battery .................... A-5

Operating and Storage Environment .............. A-5

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Humidity .......................... A-6

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Installation Category and Pollution Degree .......... A-6

Instrument Positioning and Cooling . . . . . . . . . . . . . . A-6

Switching on the Polarization Controller . . . . . . . . . . . . . A-7

Optical Output . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Input and Output . . . . . . . . . . . . . . . . . . . .

HP-IB Interface ........................ A-8

Connector . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

HP-IB Logic Levels . . . . . . . . . . . . . . . . . . . . . . A-9

Claims and Repackaging .................... A-10

Return Shipments to HP ................... A-10

A-7

A-8

B. Accessories

Instrument and Options .. ........ ...... .... B-1

HP-IB Cables and Adapters . . . . . . . . . . . . . . . . . . . B-1

Connector Interfaces and Other Accessories . . . . . . . . . . . B-2

Option 021, Straight Contact Connector . . . . . . . . . . . . B-2

Option 022, Angled Contact Connector ............ B-3

Contents-4

C. Specications

Specications ......................... C-1

Other Specications ...................... C-3

Declaration of Conformity ................... C-4

D. Performance Test

Insertion Loss Variation with Rotation of/4 and/2 Plates .. . D-2

Insertion Loss versus Wavelength . . . . . . . . . . . . . . . . D-5

Extinction Ratio of Polarizer .................. D-10

E. Cleaning Procedures

Cleaning Materials . . . . . . . . . . . . . . . . . . . . . . . E-1

Cleaning Fiber/Front-Panel Connectors .... ....... .. E-2

Cleaning Connector Interfaces .. ........ ..... .. E-2

Cleaning Connector Bushings . . . . . . . . . . . . . . . . . . E-3

Cleaning Detector Windows .................. E-3

Cleaning Lens Adapters ...... ........ ...... E-3

Cleaning Detector Lens Interfaces ........ ....... E-4

F. Error Messages

Display Messages ...... ........ ...... ... F-1

HP-IB Messages ........................

Command Errors . . . . . . . . . . . . . . . . . . . . . . .

Execution Errors ......................

Device-Specic Errors ...... ........ ...... F-6

Query Errors ........................ F-7

F-2

F-2

F-5

Index

Contents-5

Figures

6-1. Common Status Registers . . . . . . . . . . . . . . . . . . . 6-6

6-2. The Status Registers . . . . . . . . . . . . . . . . . . . . . 6-24

A-1. Line Power Cables - Plug Identication ............ A-2

A-2. Rear Panel Markings . . . . . . . . . . . . . . . . . . . . . A-4

A-3. Releasing the Fuse Holder .... ...... ........ A-4

A-4. The Fuse Holder . . . . . . . . . . . . . . . . . . . . . . .

A-5. Correct Positioning of the Polarization Controller ....... A-7

A-6. HP-IB Connector . . . . . . . . . . . . . . . . . . . . . . .

B-1. Straight Contact Connector Conguration . . . . . . . . . . .

B-2. Angled Contact Connector Conguration ...........

D-1. Test Setup for Measuring the Insertion Loss .......... D-2

D-2. Test Setup for Measuring the Reference Power . . . . . . . . . D-7

D-3. Test Setup for Measuring the Extinction Ratio . . . . . . . . . D-10

Tables

5-1. HP-IB Capabilities .. ........ ...... ...... 5-2

6-1. Common Command Summary . . . . . . . . . . . . . . . . . 6-2

6-2. Command List . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-3. Reset State (Default Setting) ................. 6-11

A-1. Temperature . . . . . . . . . . . . . . . . . . . . . . . . . A-6

D-1. Equipment used: ...... ...... ....... ... D-1

A-5

A-9

B-2

B-3

Contents-6

1

Getting Started

This chapter describes the basic operating principle, and the basic operating of

the polarization controller.

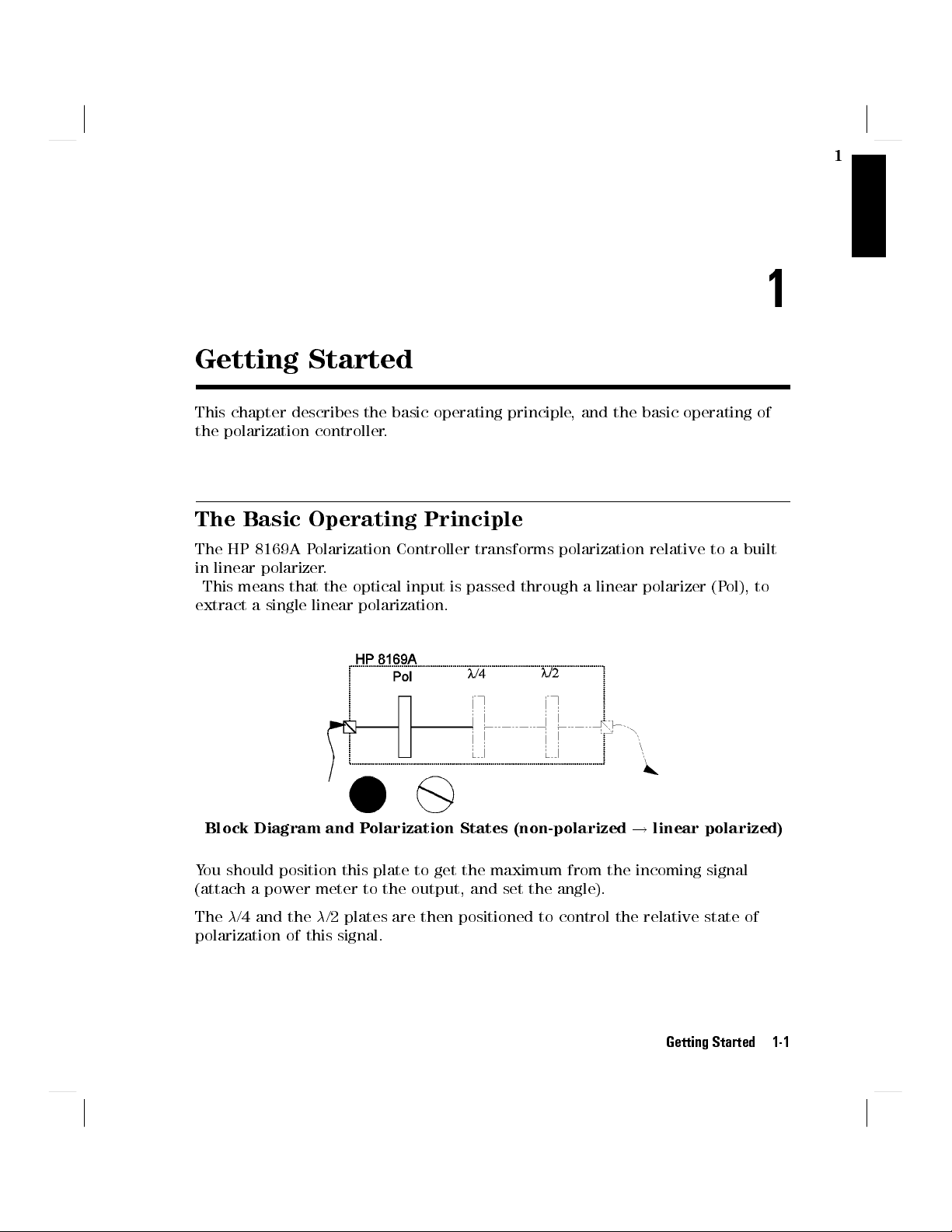

The Basic Operating Principle

The HP 8169A Polarization Controller transforms polarization relative to a built

in linear polarizer.

This means that the optical input is passed through a linear polarizer (P

extract a single linear polarization.

ol), to

1

Block Diagram and Polarization States (non-polarized!linear polarized)

You should position this plate to get the maximum from the incoming signal

(attach a power meter to the output, and set the angle).

The/4 and the/2 plates are then positioned to control the relative state of

polarization of this signal.

Getting Started 1-1

1

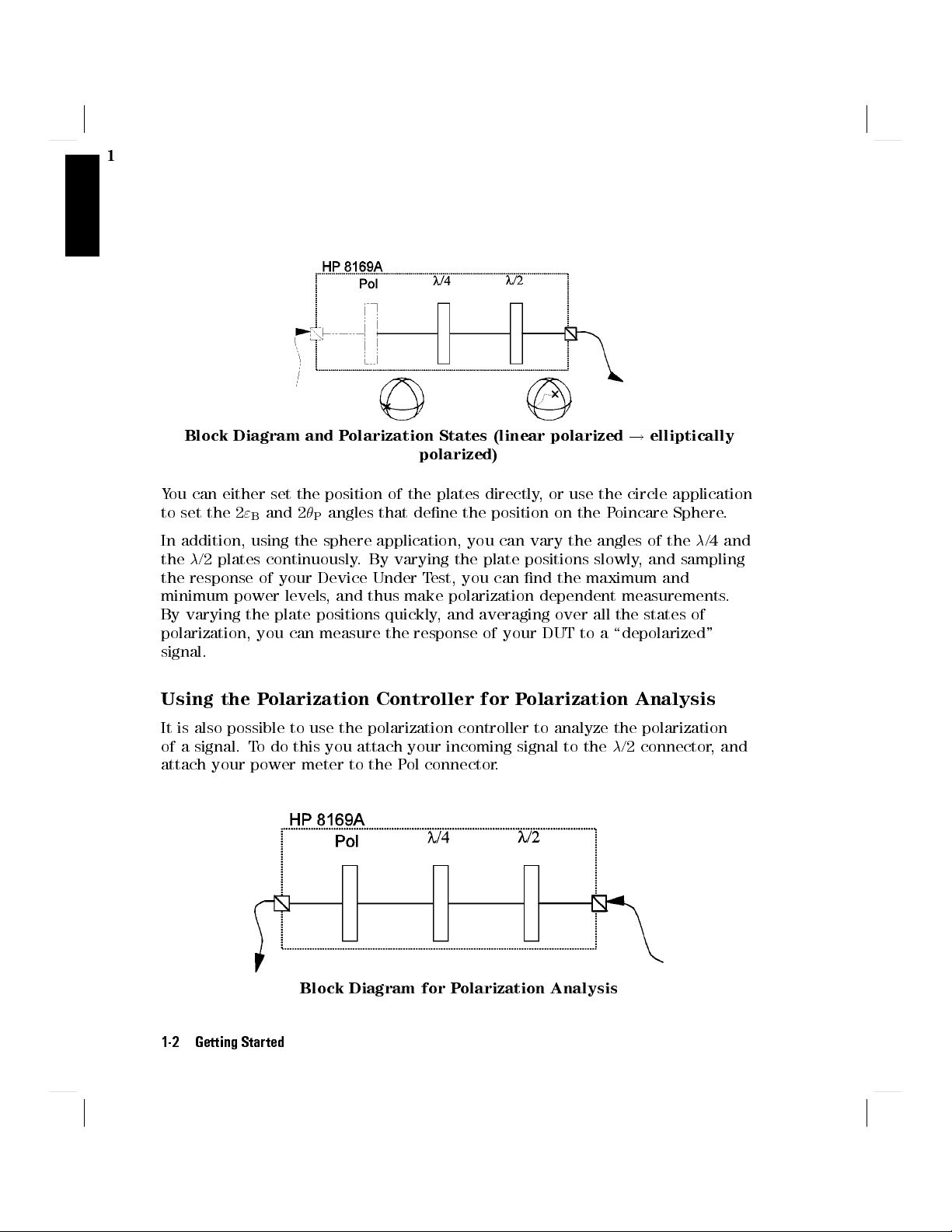

Block Diagram and Polarization States (linear polarized!elliptically

polarized)

You can either set the position of the plates directly, or use the circle application

to set the 2

In addition, using the sphere application, you can vary the angles of the/4 and

the/2 plates continuously. By varying the plate positions slowly, and sampling

the response of your Device Under Test, you can nd the maximum and

minimum power levels, and thus make polarization dependent measurements.

By varying the plate positions quickly, and averaging over all the states of

polarization, you can measure the response of your DUT to a \depolarized"

signal.

"Band 2

Pangles that dene the position on the Poincare Sphere.

Using the Polarization Controller for Polarization Analysis

It is also possible to use the polarization controller to analyze the polarization

of a signal. To do this you attach your incoming signal to the/2 connector, and

attach your power meter to the Pol connector.

Block Diagram for Polarization Analysis

1-2 Getting Started

You analyze the signal by varying the/4 and/2 plates and the polorizer lter,

and examining how this aects the power. It is beyond the scope of this manual

to explain this topic in detail.

Editing

You can edit a parameter by using

the Entry keys,

the Cursor/Vernier keys,or

the Modify knob.

Editing Using the Entry Keys

1. Make sure the correct parameter is selected (the label of the selected

parameter is displayed inverse).

1

2. Type in the new value.

5

3. Press

4

Enter

.

If you mistype the number, you can move the cursor left and right using the

5

5

Cursor keys (

and

4

(

If you want to abort editing, without changing the parameter, press

If the parameter changes back to its old value when you press

).

4

)

NNNNNNNNNNNNNNNNNNN

N

Cancel

4

5

, then the

Enter

new value would be out of the range allowed for that parameter.

Editing Using the Modify Keys and Knob

1. Make sure the correct parameter is selected (the label of the selected

parameter is displayed inverse).

2. Press any of the Cursor/Vernier keys, to activate editing.

5

5

3. Use the Cursor keys (

and

4

(

4. Change the value using the Vernier keys (

) to move to the rst digit you want to edit.

4

)

5

5

and

4

*

).

4

+

OR

Change the value using the Modify knob.

Getting Started 1-3

.

1

5. Repeat steps list item 3 to list item 4 as often as necessary.

6. Press

4

Enter

5

.

NNNNNNNNNNNNNNNNNNNN

If you want to abort editing, without changing the parameter, press

Cancel

.

If you cannot change a digit with the Vernier keys or the Modify knob, this

means that the new value would be out of the range allowed for the parameter.

Resetting Parameters

To reset any parameter

1. Make sure the correct parameter is selected (the label of the selected

parameter is displayed inverse).

NNNNNNNNNNNNNNNNNNNNNN

2.

To reset

N

Press

Default

Pol,/4,/2,2

.

5

, AND2

"

B

simultaneously, press

P

4

Home

.

1-4 Getting Started

Setting a State of Polarization

This chapter describes the two ways of setting a State of Polarization,

By positioning the polarizing lter, the/2, and the/4 plates.

By positioning the polarizing lter, and then specifying the desired position on

the Poincare sphere.

Setting up the Hardware

2

2

Note

Typically, you will connect the polarization controller directly after your source,

and before your device under test (DUT). Before connecting to the rest of your

measurement setup, you should set the position of the polarizing lter.

Setting the Position of the Polarizing Filter

The polarizing lter should be set to maximize the signal. This means aligning

the polarizing lter with the greatest linear polarization of the source. (Light

from laser sources is elliptically polarized).

When you are setting up your hardware, it is absolutely vital

that the bers are xed, and remain unmoved for the whole

of the measurement. Moving the bers changes the state of

polarization.

Setting a State of Polarization 2-1

2

Power as a function of the angle of linear polarization for laser light

1. Connect the output of the polarization controller to a power meter.

Setup for maximizing the test signal

2. With all the instruments turned on, press

4

Home

5

on the polarization

controller. This resets the positions of all the plates.

3.

Select the polarization lter.You may need to press

4

Pos

5

and/or

NNNNNNNNNNN

Pol

if the

lter is not already selected.

4. Move the lter to nd the maximum signal through the polarization

controller. One way of doing this is

a. Press the right Cursor key twice to select the units digit.

b. Watching the power meter, and using the Modify knob, adjust the angle of

the polarization lter, until you are in the area of one of the maxima.

c. Select the tenths digit.

d. Watching the power meter, and using the Modify knob, adjust the angle of

the polarization lter, until you nd the maximum.

e. Select the hundredths digit, and adjust the angle of the polarization lter

if necessary to get the absolute maximum.

2-2 Setting a State of Polarization

5. Disconnect the power meter, and connect to your DUT, and the rest of your

measurement setup, making sure to move the bers as little as possible.

Setting the State of Polarization

The state of polarization of a signal can be described by a position on the

Poincare sphere. This position is can be expressed in spherical coordinates by

two angles, called

"Band

P.

2

Pis the optical angle about the 'equator' of the sphere (that is,2

angle of 'longitude').

"Bis half the angle of elevation from the equatorial plane (that is,2

angle of 'latitude').

The coordinates for describing the state of polarization

The state of polarization is always relative to the output from the polarizing

lter.

P

"

is the

is the

B

There are two ways of setting the state of polarization,

by specifying the position of the/4 and/2 retarder plates,or

by specifying

"Band

P, the coordinates on the Poincare sphere.

Setting a State of Polarization 2-3

2

Positioning the/4 and/2 Retarder Plates

You can set the state of polarization by positioning the/4, and/2 plates.

5

1. Select a retarder plate

with the plates.

Press

NNNNNNNNNNN

/4or

NNNNNNNNNNN

/2if the plate you want is not already selected.

.You may need to press

rst to get the display

4

Pos

2. Move the plate to the position you want. (See \Editing" in Chapter 1 if you

need information on changing the angles).

Using the Circle Mode

You can set the state of polarization by specifying the coordinates on the

Poincare sphere. See \Setting the State of Polarization" for an explanation.

5

1. Select an angle.You may need to press

angles.

Press

NNNNNNNNNN

2

"Bor

NNNNNNNNNN

2

Pif the angle you want is not already selected.

rst to get the display with the

4

Circle

2. Change the angle to the value you want. (See \Editing" in Chapter 1 if you

need information on changing the angles).

Example: Setting the Optimum Transmission SoP

To nd the state of polarization which gives optimum transmission for a linear

device under test (DUT), the steps are

i. Set the polarizing lter.

ii. Find the state of polarization for worst case transmission (this is easier to

nd, because the resolution allows greater accuracy at lower power).

iii. Set the state of polarization for optimum transmission.

For this example, you will need, apart from the polarization controller, a laser

source, and a power meter (in the description below, an HP 8153A Multimeter

with a laser module and a sensor module are used). We will use the length of

ber connecting the instruments as our linear DUT.

1. With both instruments switched o, connect the laser source to the

polarization controller.

2. Connect the polarization controller to the power meter.

2-4 Setting a State of Polarization

Setup for setting the position of the polarizing lter.

3. Switch on both instruments, and enable the laser source.

4. Set the channel with the sensor module to the wavelength of the source,

and select the default averaging speed (200ms).

2

Note

Under normal circumstances you should leave the instruments

to warmup. (The multimeter needs around 20 minutes to

warmup.) Warming up is necessary for accuracy of the sensor,

and the output power of the source.

Set the Polarizing Filter.

5

5. Press

6. Press

on the polarization controller.

4

Home

5

.

4

Pos

7. Set the angle of the polarizing lter for maximum throughput.

a. Type in10and press

b. Press

4)5

twice to select the tens digit.

4

Enter

5

.

c. Using the Modify knob, increase the angle slowly until the power read on

the multimeter increases and then starts to decrease.

5

d. Press

once to select the units digit.

4

)

e. Using the Modify knob, decrease the angle slowly until the power read

on the multimeter starts to decrease.

f. Press

4)5

twice to select the hundredths digit.

Setting a State of Polarization 2-5

2

g. Using the Modify knob

the multimeter starts to decrease

maximum power.

, increase the angle slowly until the power on

. Return to the angle that gave the

Setting the Worst Case Transmission SoP.

for the worst case transmission, because we can nd this more accurately (the

resolution of the power meter stays the same, but the full scale value is lower,

therefore we can be more accurate).

We also use the fact that the relationship between power of the signal

transmitted through the DUT and polarization on the surface of the sphere

can be expressed as concentric circles about the worst case (or optimum), and

that for a linear DUT the worst case and optimum are on opposite sides of the

sphere.

Power contours about the worst case on the poincare sphere

This means that we nd the worst case position by moving around the sphere

along the equator rst (that is nding the angle of longitude of the worst case)

and then the overall worst case by moving around this line of longitude.

We set the state of polarization

2-6 Setting a State of Polarization

Power contours with a search path to the worst case transmission state of

polarization

2

8.

Press

4

Circle

5

, and

NNNNNNN

P, to select

.

P

9. Search for the line of longitude with the minimum power (use a similar

method as for the position of the polarizing lter; rst changing the tens

,

then the units, then the hundredths).

Press

NNNNNNN

"B, to select

"B.

10.

11. Search for the angle of latitude with the minimum power.

Setting the Optimum Transmission SoP.

12. Read the value for

"Bfrom the display.

13. Add 180to this value.

14. Type in the new value, and press

4

Enter

5

.

The state of polarization is now set to the value for the current setup that gives

the greatest power through the ber. This is possible here because the ber

behaves linearly.For non-linear components the polarizations for worst case and

optimum transmission will not be on opposite sides of the sphere, and the angle

between them is a characteristic of the component.

Setting a State of Polarization 2-7

3

Scanning the Poincare Sphere

This chapter describes how you can use your polarization controller to measure

polarization dependence, and how you can generate quasi-depolarized signals.

Setting up the Hardware

Note

Typically, you will connect the polarization controller directly after your source,

and before your device under test (DUT). Before connecting to the rest of your

measurement setup, you should set the position of the polarizing lter (this is

described in \Setting the Position of the Polarizing Filter" in Chapter 2).

Setting Up and Executing a Scan

When you are setting up your hardware, it is absolutely vital

that the bers are xed, and remain unmoved for the whole

of the measurement. Moving the bers changes the state of

polarization.

3

The sphere application changes the state of polarization over time,by

rotating the/2 and/4 plates. The rotations can be done slowly, to give a

quasi-randomly polarized signal, which you can use, with suitable data logging

to measure polarization dependence. The rotations can be done quickly,to

give a quasi-depolarized signal, which you can use, with suitable measurement

averaging time to measure depolarized response.

1. Press

4

Sphere

5

to select the application.

Scanning the Poincare Sphere 3-1

The

Pol

Note

when you press

lter angle shown here is the same as the one shown

4

5

. If you have already set this value, there is

Pos

no need to change it.

2. Set the speed at which theplates rotate:

3

Set

SpeedtoFast

and the averaging time of your power meter to longer

than 1s to get measure the response to depolarized signal.

If it is not already selected:

a. Move the Modify knob.

b.

Select

c.

Press

Set

SpeedtoSlow

Fast

using the Modify knob,

NNNNNNNNNNNNNNNNNNNN

4

5

,or

Enter

Select

and the averaging time of your power meter as short as

4

+

.

5

,or

NNNNN

#

possible, and use logging to measure polarization dependence.

If it is not already selected:

a. Move the Modify knob.

N

b.

Select

c.

Press

3.

When everything is setup, press

Slow

using the Modify knob,

NNNNNNNNNNNNNNNNNNNN

4

5

,or

Enter

Select

.

NNNNNNNNNNNNNN

Exec

4

*

to start the scan.

5

,or

NNNN

"

During the scan, values for the angle of/4 and/2 are shown on the display.

These values are samples. Theplates rotate continuously.

Example: Measuring the Response to a \Depolarized" Signal

To measure the response to a \depolarized" signal for a device under test (DUT),

the steps are

i. Set the polarizing lter.

ii. Set the scanning speed to

Fast

.

iii. Set the averaging time of the power meter.

iv. Start the scan, and measure the value.

For this example, you will need, apart from the polarization controller, a laser

source, and a power meter (in the description below, an HP 8153A Multimeter

3-2 Scanning the Poincare Sphere

with a laser module and a sensor module are used). A roll of ber will act as a

suitable DUT.

1. With both instruments switched o, connect the laser source to the

polarization controller.

2. Connect the polarization controller to the power meter.

Setup for setting the position of the polarizing lter.

3. Switch on both instruments, and enable the laser source.

3

Note

Under normal circumstances you should leave the instruments

to warmup. (The multimeter needs around 20 minutes to

warmup.) Warming up is necessary for accuracy of the sensor,

and the output power of the source.

4. Set the channel with the sensor module to the wavelength of the source,

and select the default averaging speed (200ms) [Press

hold

4

5

Param

to resetT].

4

Param

5

to selectT,

Set the Polarizing Filter

5

5. Press

6. Press

4

4

on the polarization controller.

Home

5

.

Pos

7. Set the angle of the polarizing lter for maximum throughput.

5

a. Type in10and press

b. Press

4)5

twice to select the tens digit.

4

Enter

.

c. Using the Modify knob, increase the angle slowly until the power read on

the multimeter increases and then starts to decrease.

Scanning the Poincare Sphere 3-3

5

d. Press

once to select the units digit.

4

)

e. Using the Modify knob, decrease the angle slowly until the power read

on the multimeter starts to decrease.

f. Press

3

g. Using the Modify knob, increase the angle slowly until the power on

4)5

twice to select the hundredths digit.

the multimeter starts to decrease. Return to the angle that gave the

maximum power.

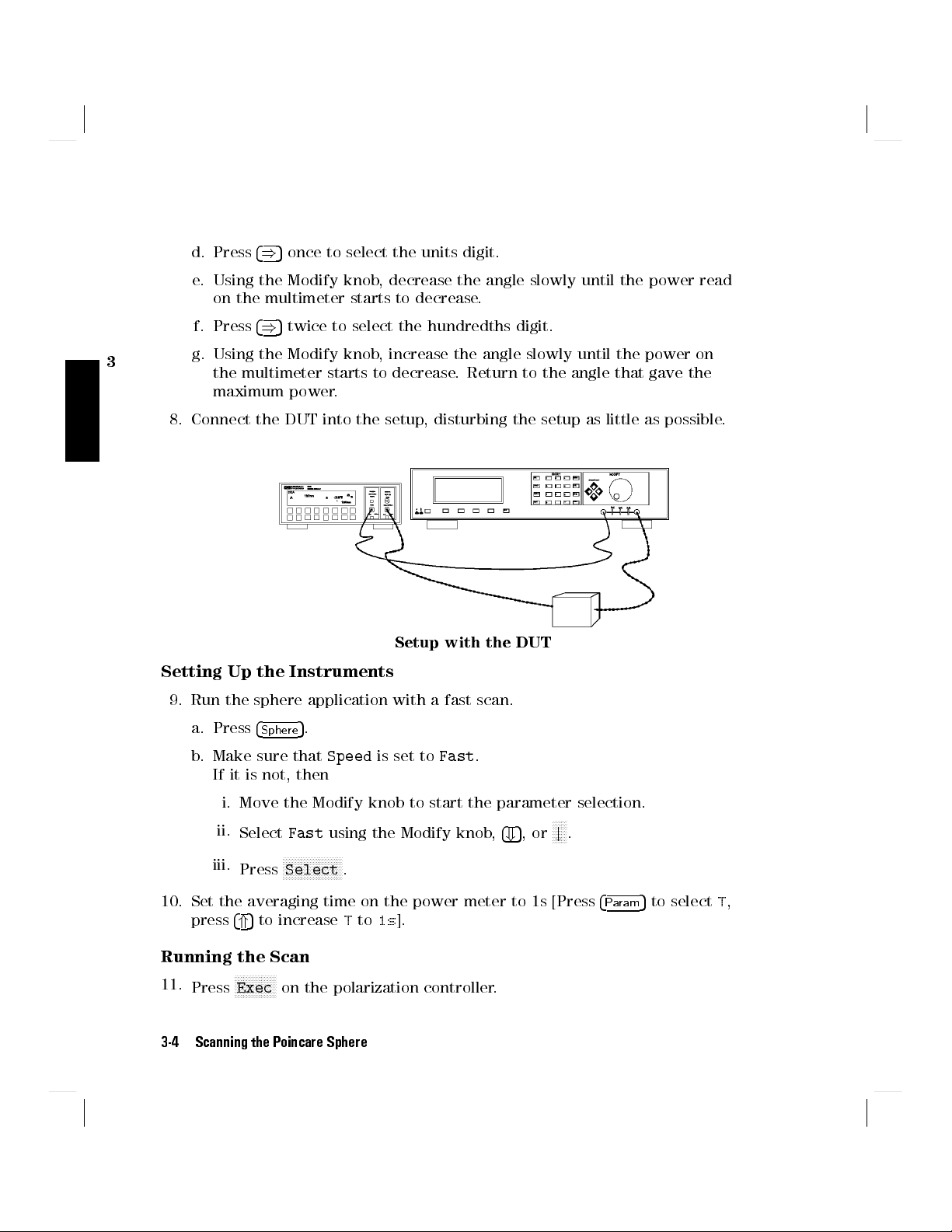

8. Connect the DUT into the setup, disturbing the setup as little as possible.

Setup with the DUT

Setting Up the Instruments

9. Run the sphere application with a fast scan.

a. Press

b. Make sure that

4

Sphere

5

.

Speed

is set to

Fast

.

If it is not, then

i. Move the Modify knob to start the parameter selection.

N

ii.

iii.

Select

Press

Fast

using the Modify knob,

NNNNNNNNNNNNNNNNNNNN

Select

.

4+5

,or

NNNN

#

.

10. Set the averaging time on the power meter to 1s [Press

press

4*5

to increaseTto1s].

Running the Scan

Press

N

Exec

on the polarization controller.

11.

NNNNNNNNNNNNN

3-4 Scanning the Poincare Sphere

4

Param

5

to selectT,

There is a slight delay while the application is initialized, and then the values of

/4 and/2 on the display begin to change.

12. When the application is running, read the value for the response of the DUT

to a depolarised signal from the display for the power sensor.

Example: Measuring a Polarization Dependent Loss

To measure the sensitivity to polarization, apply a quasi-random polarization to

the (DUT), the steps are

i. Set the polarizing lter.

ii. Set the scanning speed to

iii. Set the power meter to record.

iv. Start the scan, and record the readings for dierent polarization states.

v. Analyze the results.

For this example, you will need, apart from the polarization controller, a laser

source, and a power meter (in the description below, an HP 8153A Multimeter

with a laser module and a sensor module are used). A roll of ber will act as a

suitable DUT.

1. With both instruments switched o, connect the laser source to the

polarization controller.

2. Connect the polarization controller to the power meter.

Slow

.

3

Setup for setting the position of the polarizing lter.

3. Switch on both instruments, and enable the laser source.

Scanning the Poincare Sphere 3-5

Note

Under normal circumstances you should leave the instruments

to warmup. (The multimeter needs around 20 minutes to

warmup.) Warming up is necessary for accuracy of the sensor,

and the output power of the source.

3

4. Set the channel with the sensor module to the wavelength of the source,

and select the default averaging speed (200ms) [Press

hold

4

5

to resetT].

Param

4

Param

5

to selectT,

Set the Polarizing Filter

5. Press

6. Press

4

5

on the polarization controller.

Home

4

5

.

Pos

7. Set the angle of the polarizing lter for maximum throughput.

5

a. Type in10and press

5

b. Press

twice to select the tens digit.

4

)

4

Enter

.

c. Using the Modify knob, increase the angle slowly until the power read on

the multimeter increases and then starts to decrease.

d. Press

4)5

once to select the units digit.

e. Using the Modify knob, decrease the angle slowly until the power read

on the multimeter starts to decrease.

f. Press

4)5

twice to select the hundredths digit.

g. Using the Modify knob, increase the angle slowly until the power on

the multimeter starts to decrease. Return to the angle that gave the

maximum power.

8. Connect the DUT into the setup, disturbing the setup as little as possible.

3-6 Scanning the Poincare Sphere

Loading...

Loading...