S

Agilent 81110A 165/330MHz

Agilent 81104A 80 MHz Pulse/Data Generator

RRRReeeeffffeeeerrrrenc

S1

ence

e GGGGuuuuiiiide

encenc

e e

de

dede

Reference Guide

Agilent 81110A 165/330 MHz,

Agilent 81104A 80 MHz

Pulse/Pattern Generators

Part No. 81110-91021

Printed in Germany April 2000

Edition 1.1, E0400

NNNNoooottttiiiicccceeee

Notice

Copyright

Agilent Technologies 1998, 2000

Herrenberger Str. 110140

71034 Boeblingen

Germany

All rights reserved. Reproduction, adaptation or translation without prior

written permission is prohibited, except as allowed under the copyright

laws.

Warranty

This Agilent product has a warranty against defects in material and

workmanship for a period of three years from date of shipment. During

the warranty period, Agilent Technologies will, at its option, either repair

or replace products that prove to be defective. For warranty service or

repair, this product must be returned to a service facility designated by

Agilent Technologies. The Buyer shall pay Agilents round-trip travel

expenses. For products returned to Agilent Technologies for warranty

service, the Buyer shall prepay shipping charges to Agilent and Agilent

shall pay shipping charges to return the product to the Buyer. However,

the Buyer shall pay all shipping charges, duties and taxes for products

returned to Agilent Technologies from another country. Agilent

Technologies warrants that its software and firmware designated by

Agilent for use with an instrument will execute its programming

instructions when properly installed on that instrument. Agilent does not

warrant that the operation of the instrument software, or firmware, will

be uninterrupted or error free.

4

NNNNoooottttiiiicccceeee

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by the Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse, operation

outside of the environmental specifications for the product, or improper

site preparation or maintenance.

No other warranty is expressed or implied. Agilent Technologies

specifically disclaims the implied warranties of merchantability and

fitness for a particular purpose.

Exclusive Remedies

The remedies supplied are the Buyers sole and exclusive remedies.

Agilent Technologies shall not be liable for any direct, indirect, special,

incidental, or consequential damages, whether based on contract, tort or

any other legal theory.

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Agilent products. For any assistance,

contact your nearest Agilent Sales Office.

Certification

Agilent Technologies Company certifies that this product met its

published specifications at the time of shipment. Agilent further certifies

that its calibration measurements are traceable to the United States

Institute of Standards and Technology, to the extent allowed by the

Institute's calibrating facility, and to the calibration facilities of other

International Standards Organization members.

5

AAAAbbbbou

out t

ouou

t thhhhiiiis

t tt t

s bbbbooooooookkkk

s s

About this book

This guide provides reference information primarily for programming the

Agilent 81104A and Agilent 81110A via remote control.

Chapter 1 General Programming Aspects on page 13 gives general

hints for programming instruments like the Agilent 81110A using SCPI

commands.

Chapter 2 Programming Reference on page 25 provides detailed

information on the SCPI commands supported by the instrument.

Chapter 3 Specifications on page 101 lists the instruments technical

specifications and provides exact definitions for the instruments

parameters.

For an introduction and information on the Agilent 81110As user

interface, please refer to the Quick Start Guide, p/n 81110-91020.

The information is valid for Agilent 81104A and Agilent 81110A. Where

required the differences are explicitly mentioned. Possible

configurations are:

6

OOOOuuuuttttppppuuuut

t MMMMoooodddduuuulllleeeessss

t t

Output Modules

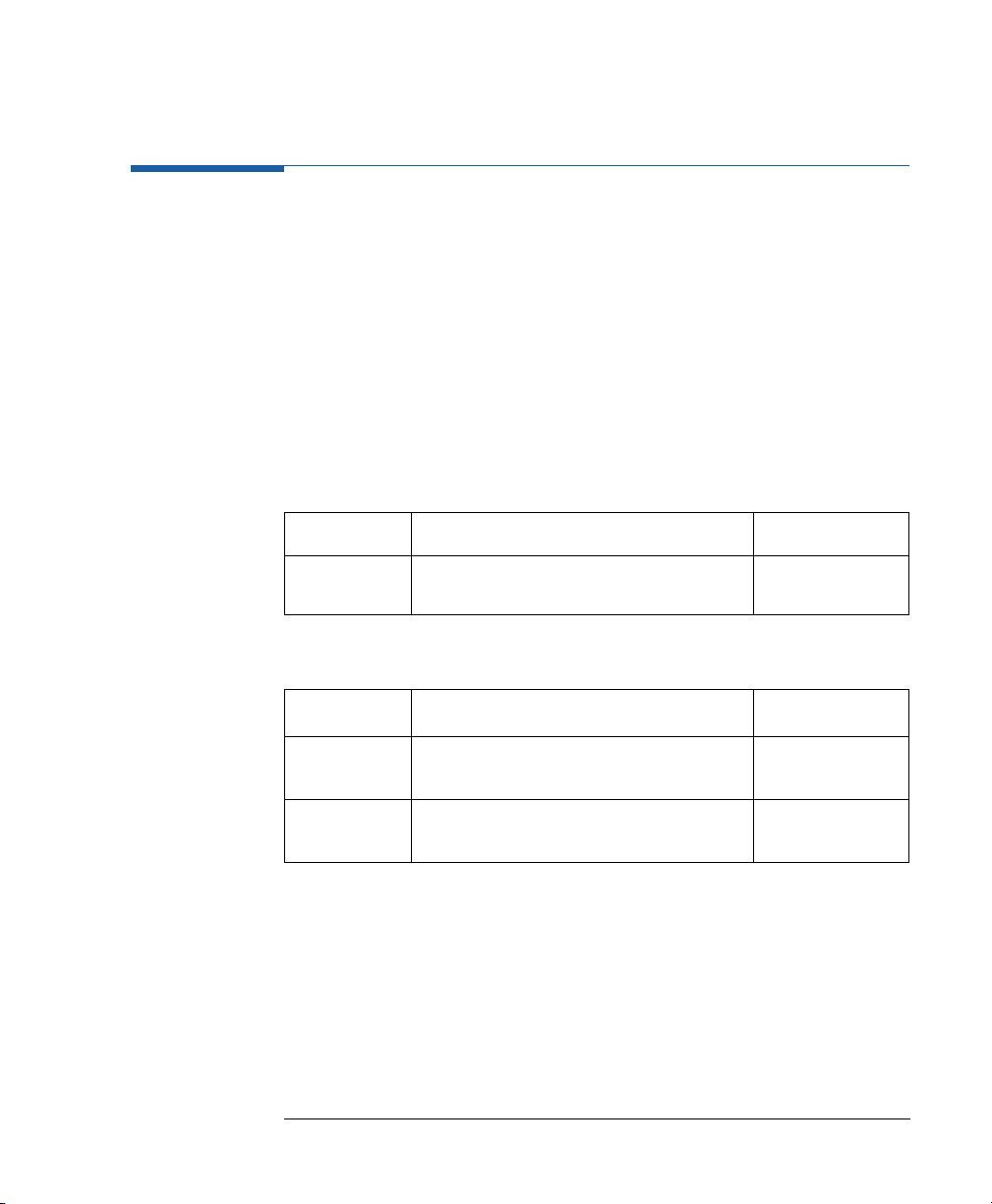

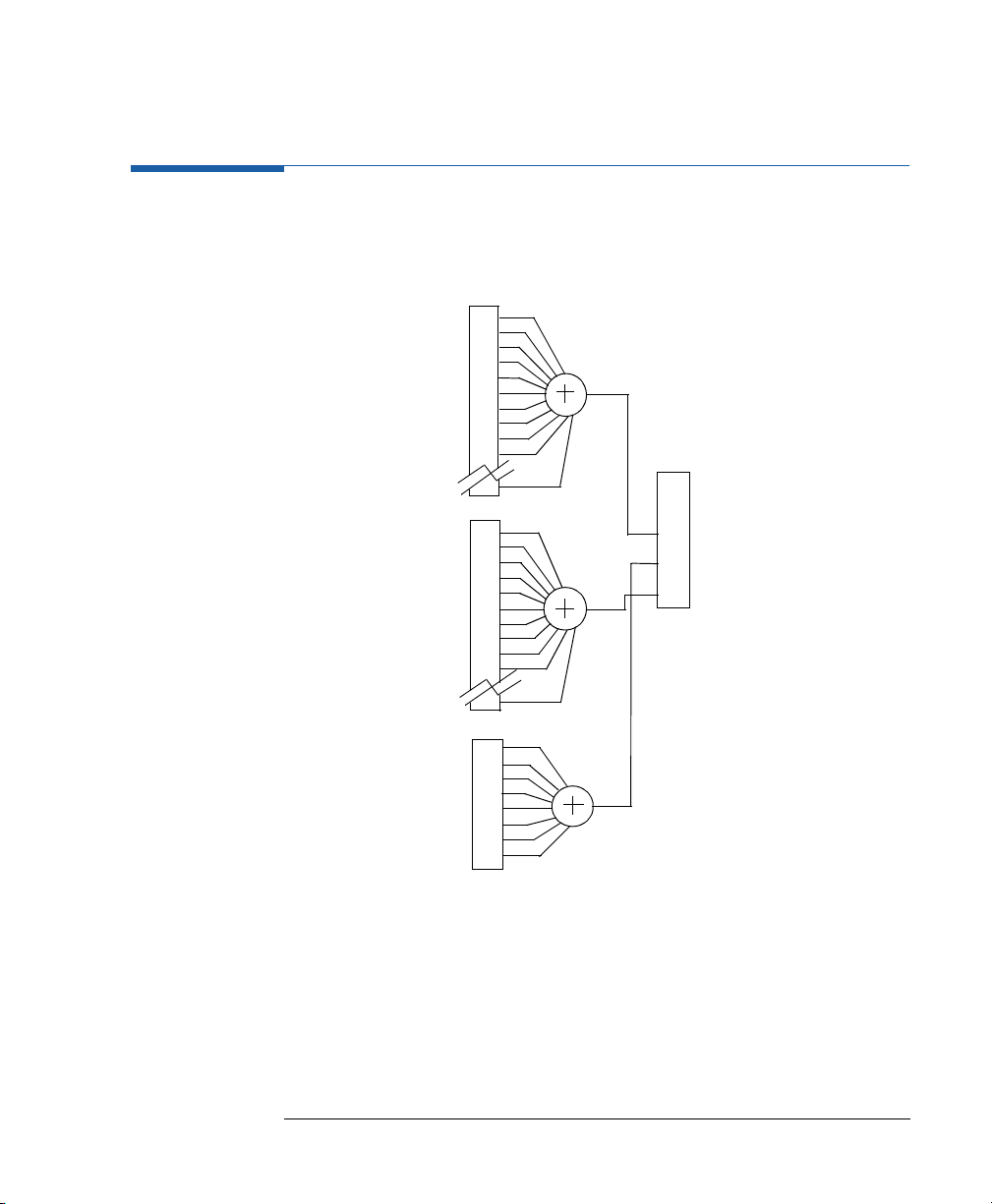

Both the Agilent 81110A and Agilent 81104A mainframes can be

configured with either one or two output modules. These output modules

must be of the same type.

The standard mainframe configuration is with one output module only.

This manual describes the configuration with two output modules. Some

of the features described here are not available for the standard

configuration.

Output Modules for Agilent 81104A Mainframes

Module Description Max. Quantity

Agilent

81105A

10V/ max.80 MHz Output Channel 2

Output Modules for Agilent 81110A Mainframes

Module Description Max. Quantity

Agilent

81111A

Agilent

81112A

10V/ max. 165 MHz Output Channel 2

3.8V/ max. 330 MHz Output Channel 2

7

SSSSaaaaffffeeeetttty

y IIIInnnnffffoooorrrrmmmmaaaattttiiiioooonnnn

y y

Safety Information

Safety

This is a Safety Class 1 instrument (provided with terminal for protective

earthing). Before applying power, verify that the correct safety

precautions are taken (see the following warnings). In addition, note the

external markings on the instrument that are described under Safety

Symbols. Do not operate the instrument with its covers removed.

Replace fuse only with specified type.

Warning

Before turning on the instrument, you must connect the protective earth

terminal of the instrument to the protective earth conductor of the

(mains) power cord. The mains plug must only be inserted in a socket

outlet with a protective earth contact. Do not negate the protective

action by using an extension power cord without a protective grounding

conductor. Grounding one conductor of a two-conductor outlet is not

sufficient protection.

Service instructions are for trained service personnel. To avoid

dangerous electric shock, do not perform any service unless qualified to

do so. Do not attempt internal service or adjustment unless another

person, capable of rendering first aid and resuscitation, is present.

If you energize this instrument using an auto-transformer (for voltage

reduction), make sure that the common terminal is connected to the

earth terminal of the power source.

Whenever it is likely that the ground protection is impaired, you must

make the instrument inoperative and secure it against any unintended

operation.

Do not operate the instrument in the presence of flammable gases or

fumes. Operation of any electrical instrument in such an environment

constitutes a definite safety hazard.

Do not install substitute parts or perform any unauthorized modification

to the instrument.

8

SSSSaaaaffffeeeetttty

y IIIInnnnffffoooorrrrmmmmaaaattttiiiioooonnnn

y y

Capacitors inside the instrument may retain a charge even if the

instrument is disconnected from its source of supply.

Safety Symbols

Instruction Manual symbol: The instrument is marked with this symbol

when it is necessary for you to refer to the instruction manual in order to

protect against damage to the instrument.

Protected conductor symbol.

In the manuals:

WWWWAAAARRRRNNNNIIIINNNNGGGG

CCCCAAAAUUUUTTTTIIIIOOOONNNN Cautions call attention to a procedure, practice, or the like, which, if not

Warnings call attention to a procedure, practice, or the like,

which, if not correctly performed or adhered to, could result in

personal injury or loss of life. Do not proceed beyond a Warning

until the indicated conditions are fully understood and met.

correctly performed or adhered to, could result in damage to or

destruction of part or all of the equipment. Do not proceed beyond a

Caution until the indicated conditions are fully understood and met.

9

SSSSaaaaffffeeeetttty

y IIIInnnnffffoooorrrrmmmmaaaattttiiiioooonnnn

y y

10

CCCCoooonnnntttteeeennnnttttssss

Notice ......................................................................................... 4

About this book ......................................................................... 6

Output Modules ......................................................................... 7

Safety Information .................................................................... 8

Chapter 1

Chapter 2

General Programming Aspects

The GP-IB Interface Bus ......................................................... 14

Agilent 81110A Remote Control ............................................ 15

Programming Recommendations ............................................ 16

Common Command Summary ................................................. 18

Status Model ............................................................................ 19

Programming Reference

Agilent 81110A/81104A SCPI Command Summary ............... 26

Default Values, Standard Settings ......................................... 33

Programming the Instrument Trigger Modes ........................ 39

SCPI Instrument Command List ........................................... 43

xi

CCCCoooonnnntttteeeennnnttttssss

Chapter 3

Specifications

Declaration of Conformity ................................................... 102

Agilent 81110A/81104A Specifications ............................... 103

General ................................................................................................. 103

Timing Specifications ......................................................................... 105

Level Specifications ............................................................................ 109

Clock Sources ...................................................................................... 111

External Input ...................................................................................... 113

Output Modes ...................................................................................... 114

Trigger Modes ...................................................................................... 115

Trigger and Strobe Specifications ..................................................... 116

Human Interface .................................................................................. 118

Memory ................................................................................................. 118

Remote Control ................................................................................... 119

Pulse Parameter Definitions ................................................ 120

xii

1General Programming

1

Aspects

This chapter provides general information on writing GP-IB/SCPI

programs for instruments like the Agilent 81104A and the Agilent 81110A.

Detailed information on programming the Agilent 81104A and

Agilent 81110A can be found in Chapter 2 Programming Reference on

page 25.

13

General Programming Aspects

TTTThe

he GGGGPPPP----IIIIB

he he

B IIIInnnntttteeeerrrrffffaaaacccce

B B

e BBBBuuuussss

e e

The GP-IB Interface Bus

The GP Interface Bus is the interface used for communication between a

controller and an external device, such as the Agilent 81110A. The GP-IB

conforms to IEEE standard 488-1987, ANSI standard MC 1.1, and IEC

recommendation 625-1.

If you are not familiar with the GP-IB, please refer to the following

books:

The Institute of Electrical and Electronic Engineers: IEEE Standard

488.1-1987, IEEE Standard Digital Interface for Programmable

Instrumentation.

The Institute of Electrical and Electronic Engineers: IEEE Standard

488.2-1987, IEEE Standard Codes, Formats, and Common

Commands for Use with IEEE Standard 488.1-1987.

14

GGGGPPPP----IIIIB A

B Addddddddrrrreeeess

B AB A

MMMMooooddddeeees

s oooof

s s

OOOOppppeeeerrrraaaattttiiiioooonnnn

General Programming Aspects

AAAAggggiiiilllleeeennnntttt 81110

81110A

A RRRReeeemmmmooootttte

8111081110

A A

Agilent 81110A Remote Control

ss You can only set the GP-IB address from the front panel of the instrument

ssss

(refer to the Quick Start Guide).

The default GP-IB address is 10.

f

f f

The Agilent 81110A has two modes of operation:

Local

The instrument is operated using the front panel keys.

Remote

After receiving the first command or query via the GP-IB, the

instrument is put into remote state. The front panel is locked.

To return to local operating mode, press SHIFT (LOCAL).

e CCCCoooonnnnttttrrrroooollll

e e

15

General Programming Aspects

PPPPrrrrooooggggrrrraaaammmmmmmmiiiing

ng RRRRec

ecoooommmmmmmmeeeennnnddddaaaattttiiiioooonnnnssss

ng ng

ecec

Programming Recommendations

Here are some recommendations for programming the instrument:

Start programming from the default setting. The common command

for setting the default setting is:

*RST

Switch off the automatic update of the display to increase the

programming speed. The device command for switching off the

display is:

:DISPlay OFF

The SCPI standard defines a long and a short form of the commands.

For fast programming speed it is recommended to use the short

forms. The short forms of the commands are represented by upper

case letters. For example the short form of the command to set 100 ns

double pulse delay is:

:PULS:DOUB:DEL 100NS

To improve programming speed it is also allowed to skip optional

subsystem command parts. Optional subsystem command parts are

depicted in square brackets, e.g.: enable double pulse mode by

[SOURce]:PULSe:DOUBle[1|2][:STATe] ON|OFF. Sufficient to

use:

:PULS:DOUB ON # enables double pulse mode for

# output 1

The commands to set the timing and level parameters, except of

period/frequency, have to be specified for output 1 and output 2. If

there is no output specified the command will set the default output

1.

So, for setting a high level of 3 Volts for output 1 and output 2 the

commands are:

:VOLT:HIGH 3V # sets high level of 3 V at out 1

:VOLT1:HIGH 3V # sets high level of 3 V at out 1

:VOLT2:HIGH 3V # sets high level of 3 V at out 2

16

General Programming Aspects

PPPPrrrrooooggggrrrraaaammmmmmmmiiiinnnng

It is recommended to test the new setting which will be programmed

on the instrument by setting it up manually. Enable the outputs so

that the instruments error check system is on and possible parameter

conflicts are immediately displayed. When you have found the correct

setting, then use this to create the program. In the program it is

recommended to send the command for enabling outputs (for

example, :OUTPut1 ON) as the last command. With this procedure

it is possible to switch off the error check system

(:SYSTem:CHE Ck OFF) to increase programming speed. The error

check is enabled again by sending *RST.

*RST # set default settings

:DISP OFF # switch off display update

:SYST:CHEC OFF # switch off error check

... # other commands to set modes

... # and parameters

:OUTP1 ON # enable the output 1

Selftest of the instrument can be invoked by the common command

*TST

The Agilent 81110A offers auto calibration for the period (VFO), delay

and width circuitry by the device command :CALibration. It is

recommended to query whether the calibration is passed by sending

:CALibration?.

g RRRReeeeccccoooomm

mmen

g g

mmmm

enddddaaaattttiiiioooonnnnssss

enen

If it is important to know whether the last command is completed

then send the common command

*OPC?

17

General Programming Aspects

CCCCoooomm

mmoooon

n CCCCoooomm

mmaaaannnnd

mmmm

n n

mmmm

d SSSSuuuummmmmmmmaaaarrrryyyy

d d

Common Command Summary

This table summarizes the IEEE 488.2 common commands supported by

the Agilent 81110A/81104A:

Command Parameter Description

*CLS Clear the status structure

*ESE <0255> Set the Standard Event Status register mask

*ESE? Read the state of the Standard Event Status enable register

*ESR? Read the state of the Standard Event Status event register

*IDN? Read the Instrument's Identification string

*LRN? Read the complete Instrument Setting

*OPC Set the Operation Complete bit when all pending actions

are complete

*OPC? Read the status of the Operation Complete bit

*OPT? Read the installed options

*RCL <09> Recall a complete Instrument Setting from memory

*RST

*SAV <19> Save the complete Instrument Setting to memory

*SRE <0255> Set the Service Request Enable Mask

*SRE? Read the Service Request Enable Mask

*STB? Read the Status Byte

*TRG Trigger

*TST? Execute instrument's self-test

*WAI Wait until all pending actions are complete

Reset the instrument to standard settings

18

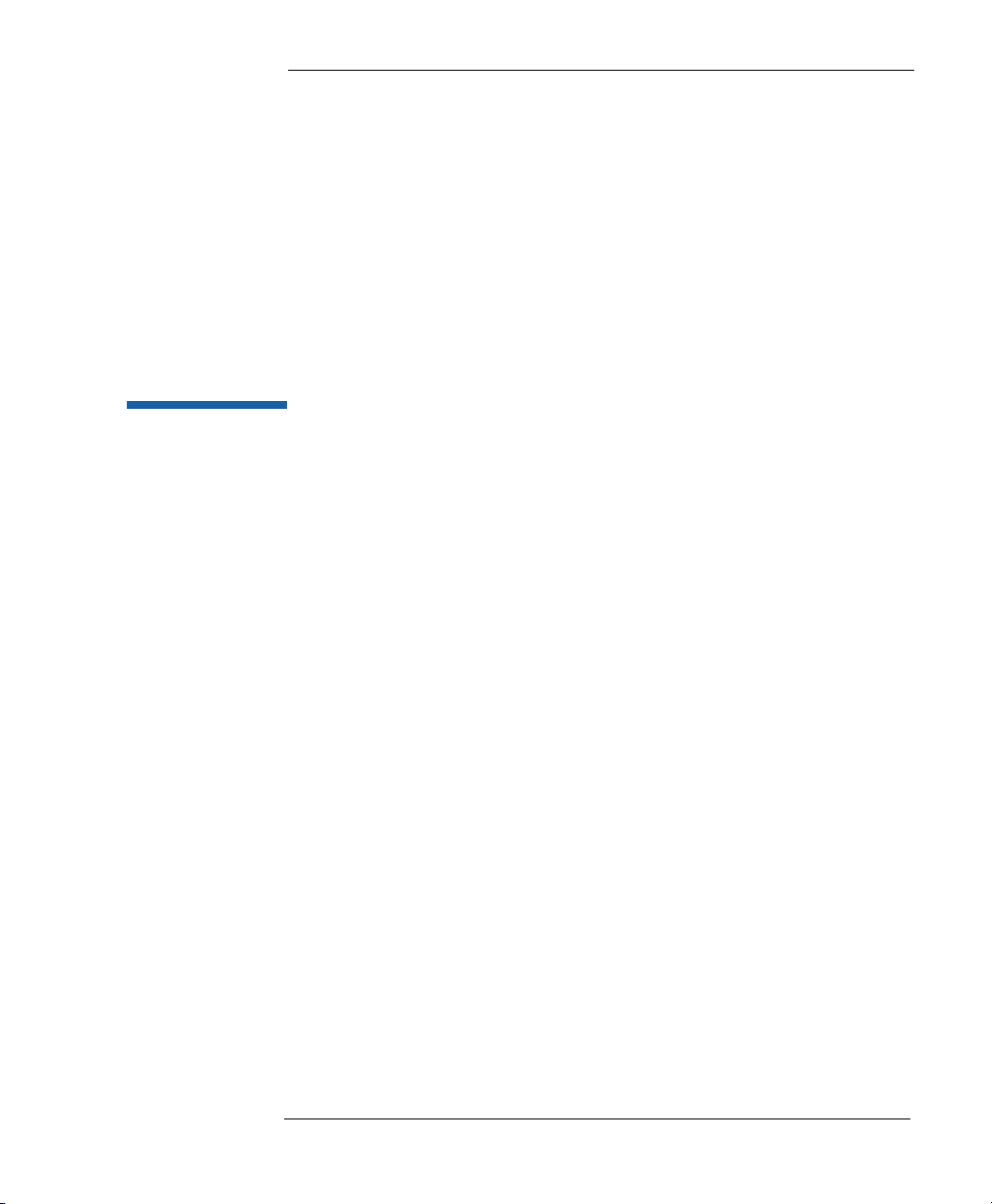

Status Model

QUES

TIONABLE STATUS

Voltage warning

Current Warning

Timing Warning

Frequency Warning

Operation Complete

Query Error

Device Depend en t Er ro r

Execution Error

Command Error

Power On

0

1

2

3

4

5

6

7

8

9

15

OPERation Status

0

1

2

3

4

5

6

7

8

9

15

Standard Event Status

0

1

2

3

4

5

6

7

(NOT USED)

General Programming Aspects

SSSSttttaaaattttuuuus

Status

Byte

0

1

2

3

MAV

4

5

SRQ

6

7

s MMMMod

odeeeellll

s s

odod

The instrument has a status reporting system conforming to IEEE 488.2

and SCPI. The figure above shows the status groups available in the

instrument.

19

General Programming Aspects

SSSSttttaaaattttuuuus

s MMMMooooddddeeeellll

s s

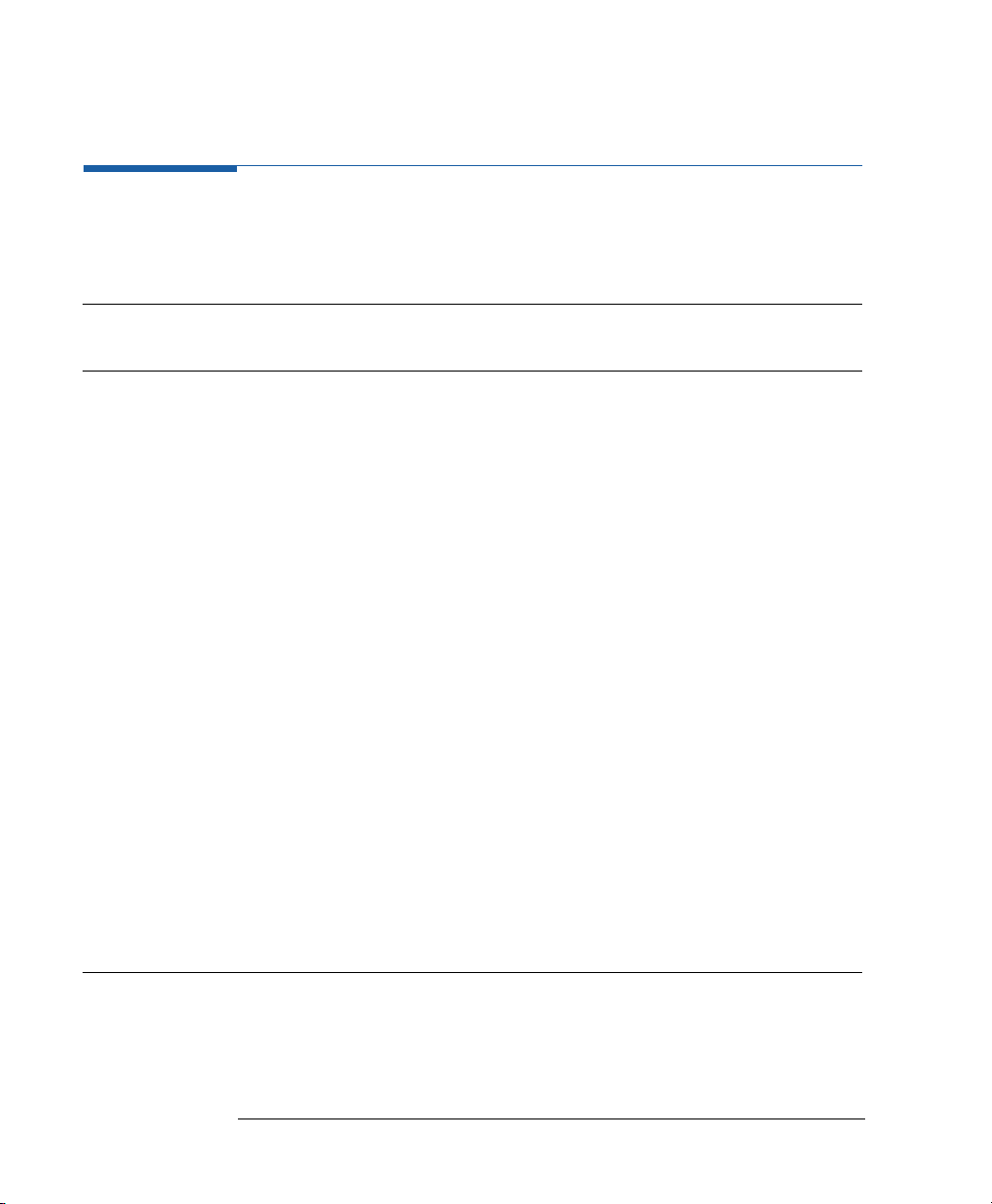

Each status group is made up of component registers, as shown in the

figure below.

Condition Register

Hardware

and Firmware

condition

Transition Filters

1

0

PTR NTR

1

0

Event Register

Latched

Enable

Register

OR

Summary Bit

Condition Register

A condition register contains the current status of the hardware and

firmware. It is continuously updated and is not latched or buffered. You

can only read condition registers. If there is no command to read the

condition register of a particular status group, then it is simply invisible

to you.

Transition Filters

Transition filters are used to detect changes of state in the condition

register and set the corresponding bit in the event register. You can set

transition filter bits to detect positive transitions (PTR), negative

transitions (NTR) or both. Transition filters are therefore read-write

registers. They are unaffected by *CLS.

Event Register

An event register latches transition events from the condition register as

specified by the transition filters or records status events. Querying

(reading) the event register clears it, as does the *CLS command. There is

no buffering, so while a bit is set, subsequent transition events are not

recorded. Event registers are read-only.

20

General Programming Aspects

SSSSttttaaaattttuuuus

s MMMMod

odeeeellll

s s

odod

Enable Register

The enable register defines which bits in an event register are included in

the logical OR into the summary bit. The enable register is logically

ANDed with the event register and the resulting bits ORed into the

summary bit. Enable registers are read-write, and are not affected by

or querying.

*CLS

Although all status groups have all of these registers, not all status

groups actually use all of the registers. The following table summarizes

the registers used in the instrument status groups.

Registers in Group

Status Group

QUEStionable

OPERation1

Standard Event Status

Status Byte

1 Present, but not used. COND and EVEN always 0.

*ESR?

2 Use

3 Use

4 Use

5 Use

*ESE

*STB?

*SRE

to query.

to set,

to query

to set,

CONDitio

nNTRPTREVENtENABLe

√√√√√

xxxxx

xxx

xxx

*ESE?

to query

*SRE?

to query

2

√

4

√

3

√

5

√

21

General Programming Aspects

SSSSttttaaaattttuuuus

s MMMMooooddddeeeellll

s s

Status Byte

The status byte summarizes the information from all other status groups.

The summary bit for the status byte actually appears in bit 6 (RQS) of the

status byte. When RQS is set it generates an SRQ interrupt to the

controller indicating that at least one instrument on the bus requires

attention. You can read the status byte using a serial poll or *STB?

Bit Description

0 Unused, always 0

1 Unused, always 0

2 Unused, always 0

3 QUESTionable Status Summary Bit

4 MAVMessage AVailable in output buffer

5 Standard Event Status summary bit

6 RQS; ReQuest Service

7 OPERation Status summary Bit, unused

Standard Event Status Group

Bit Description

0 Operation Complete, set by *OPC

1Unused, always 0

2 Query Error

3 Device Dependent Error

4 Execution Error

5 Command Error

6Unused, always 0

7Power On

22

General Programming Aspects

OPERation Status Group

This Status Group is not used in the instrument.

Bit Description

0 Unused, always 0

1 Unused, always 0

2 Unused, always 0

3 Unused, always 0

4 Unused, always 0

5 Unused, always 0

6 Unused, always 0

7 Unused, always 0

8 Unused, always 0

9 Unused, always 0

SSSSttttaaaattttuuuus

s MMMMod

odeeeellll

s s

odod

10 Unused, always 0

11 Unused, always 0

12 Unused, always 0

13 Unused, always 0

14 Unused, always 0

15 Always 0

23

General Programming Aspects

SSSSttttaaaattttuuuus

s MMMMooooddddeeeellll

s s

QUEStionable Status Group

Bit QUEStionable

0 Voltage warning

1 Current warning

2 Time warning

3 Unused, always 0

4 Unused, always 0

5 Frequency warning

6 Unused, always 0

7 Unused, always 0

8 Unused, always 0

9 Unused, always 0

10 Unused, always 0

11 Unused, always 0

12 Unused, always

13 Unused, always 0

14 Unused, always 0

15 Always 0

The QUEStionable Status group is used to report warning conditions

amongst the voltage, current, pulse timing and frequency parameters.

Warnings occur when a parameter, although not outside its maximum

limits, could be causing an invalid signal at the output because of the

actual settings and uncertainties of related parameters.

24

2

2Programming Reference

This chapter provides reference information on the following topics:

Agilent 81110A/81104A SCPI Command Summary on page 26

Default Values, Standard Settings on page 33

Programming the Instrument Trigger Modes on page 39

SCPI Instrument Command List on page 43

For general programming information, please refer to Chapter 1

General Programming Aspects on page 13.

25

Programming Reference

AAAAggggiiiillllen

ent

t 81110

81110AAAA////81104

enen

t t

8111081110

81104A

A SSSSCP

8110481104

A A

CPI

CPCP

I CCCCoooomm

mman

I I

mmmm

and

d SSSSuuuumm

anan

d d

mmaaaarrrryyyy

mmmm

Agilent 81110A/81104A SCPI Command Summary

Command Parameter Description

see

page

:ARM

[:SEQuence[1]|:STARt]

[:LAYer[1]]

:EWIDth

[:STATe] ON|OFF|1|0

:FREQuency <value>

:IMPedance <value>

:LEVel <value>

:PERiod <value>

:SENSe EDGE|LE Vel

:SLOPe POS|NEG |EITH

:SOURce IMM|INT[1]|INT2|

EXT[1]|MAN

:CHANnel

:MATH OFF|PLUS

:CALibration[:ALL]

(Trigger mode and source)

Set/read External Width mode

Set/read trigger frequency, when PLL

(INT2) used as source

Set/read impedance at EXT INPUT

Set/read threshold level at EXT INPUT

Set/read trigger period,when PLL (INT2)

used as source

Set/read trigger on edge or gate on level

Set/read trigger slope at EXT INPUT

Set/read trigger source

(VCO | PLL | EXT INPUT | MAN key)

Set/read addition of channels 1 and 2 at

output 1

Set/read calibration of period (VFO), delay and width circuitries

44

44

45

45

46

47

47

48

48

49

26

AAAAggggiiiilllleeeennnnt

t 81110

81110AAAA////81104

t t

8111081110

Command Parameter Description

81104A

A SSSSCCCCPPPPI

8110481104

A A

Programming Reference

I CCCCoooomm

mmaaaannnnd

mmmm

d SSSSuuuummmmmmmmaaaarrrryyyy

d d

I I

see

page

:DIGital

[:STIMulus]

:PATTern

:DATA[1|2|3] [<start>,]<data>

:PRBS[1|2|3] [<n>,]<length>

:PRESet[1|2|3] [<n>,]<length>

[:STATe] OFF|ON|0|1

:UPDate OFF|ON|ONCE

:SIGNal[1|2]

:FORMat RZ|NRZ

:DISPlay

[:WINDow]

[:STATe] ON|OFF|1|0

:MMEMory

:CATalog? [A:]

:CDIRectory [<name>]

:COPY <source>[,A:],

<dest>[,A:]

:DELete <name>[,A:]

:INITialize [A:[DOS]]

:LOAD

:STATe <n>,<name>

:STORe

:STATe <n>,<name>

Set/read pattern data [from Bit<start>]

Set PRBS 2n1 data (n = 7 to 12)

Set preset pattern with frequency

÷

CLOCK

Switch Pattern mode on or off

Update the hardware with pattern data

Set/read data format of output channel

Set/read frontpanel display state

Read directory of memory card

Change directory on memory card

Copy a file on memory card

Delete a file from memory card

Initialize memory card to DOS format

Load file from memory card to memory n

Store memory n to memory card

n (n = 2 to 16384)

50

52

53

54

54

55

55

55

56

57

57

57

58

58

27

Programming Reference

AAAAggggiiiillllen

ent

t 81110

81110AAAA////81104

enen

t t

8111081110

81104A

A SSSSCP

8110481104

A A

CPI

CPCP

I CCCCoooomm

mman

I I

mmmm

and

d SSSSuuuumm

anan

d d

mmaaaarrrryyyy

mmmm

Command Parameter Description

:OUTPut[1|2]

[:NORMal]

[:STATe] OFF|ON|1|0

:COMPlement

[:STATe] OFF|ON|1|0

:IMPedance

[:INTernal] <value>

:EXTernal <value>

:POLarity NORM|INV

[:SOURce]

:CURRent[1|2]

[:LEVel]

[:IMMediate]

[:AMPLitude] <value>

:OFFSet <value>

:HIGH <value>

:LOW <value>

:LIMit

[:HIGH] <value>

:LOW <value>

:STATe ON|OFF| 1|0

:FREQency

[:CW|:FIXed] <value>

:AUTO ONCE

Set/read normal output state

Set/read complement output state

Set/read internal source impedance of

output

Set/read expected external load impedance at output

Set/read output polarity

Set/read channel amplitude current

Set/read channel offset current

Set/read channel high-level current

Set/read channel low-level current

Set/read maximum current limits

Set/read minimum current limits

Enable/Disable the current limits

Set/read frequency of pulses

Measure frequency at CLK IN

see

page

59

59

59

60

60

61

62

63

64

65

65

66

66

67

28

AAAAggggiiiilllleeeennnnt

t 81110

81110AAAA////81104

t t

8111081110

Command Parameter Description

81104A

A SSSSCCCCPPPPI

8110481104

A A

Programming Reference

I CCCCoooomm

mmaaaannnnd

mmmm

d SSSSuuuummmmmmmmaaaarrrryyyy

d d

I I

see

page

[:SOURce]

:HOLD[1|2] VOLT|CURR

:PHASe[1|2]

[:ADJust] <value>

:PULSe

:DCYCle[1|2] <value>

:DELay[1|2] <value>

:HOLD TIME|PRATio

:UNIT S|SEC|PCT|DEG|RAD

:DOUBle[1|2]

[:STATe] OFF|ON

:DELay <value>

:HOLD TIME|PRATio

:UNIT S|SEC|PCT

:HOLD[1|2] WIDTh|DCYCle|TDELay

:PERiod <value>

:AUTO ONCE

:TDELay[1|2] <value>

:TRANsition[1|2]

:HOLD TIME|WRATio

:UNIT S|SEC|PCT

[:LEADing] <value>

:TRAiling <value>

:AUTO OFF|ON|ONCE

(continued)

Switch between VOLtage and CURRent

command subtrees

Set/read channel phase

Set/read channel dutycycle

Set/read channel delay (to leading edge)

Hold absolute delay or delay as period

fixed with varying frequency

Set/read delay units

Enable/disable double pulses per period

Set/read delay between double pulses

Hold absolute delay or delay as period

fixed with varying frequency

Set/read delay units

Hold Width|Dutycycle|Trailing edge delay fixed with varying frequency

Set/read pulse period

Measure pulse period at CLK IN

Set/read trailing edge delay

Hold absolute transitions|transitions as

width ratio fixed with varying width

Set/read transition-time units

Set/read leading-edge transition

Set/read trailing-edge transition

Couple trailing edge to leading edge

68

68

69

70

71

71

72

72

73

74

74

75

76

76

77

77

78

79

80

29

Programming Reference

AAAAggggiiiillllen

ent

t 81110

81110AAAA////81104

enen

t t

8111081110

81104A

A SSSSCP

8110481104

A A

CPI

CPCP

I CCCCoooomm

mman

I I

mmmm

and

d SSSSuuuumm

anan

d d

mmaaaarrrryyyy

mmmm

Command Parameter Description

see

page

[:SOURce]

:TRIGger[1|2]

:VOLTage TTL|ECL

:WIDTh[1|2] <value>

:ROSCillator

:SOURce INTernal|EXTernal

:EXTernal

:FREQuency <value>

:VOLTage[1|2]

[:LEVel]

[:IMMediate]

[:AMPlitude] <value>

:OFFset <value>

:HIGH <value>

:LOW <value>

:LIMit

[:HIGH] <value>

:LOW <value>

:STATe ON|OFF| 1|0

(continued)

Set/read TRIGGER|STROBE OUTput levels

Set/read channel pulse width

Set/read PLL reference source

Set/read frequency of external PLL reference

Set/read channel amplitude voltage

Set/read channel offset voltage

Set/read channel high-level voltage

Set/read channel low-level voltage

Set/read maximum voltage limit

Set/read minimum voltage limit

Enable|Disable the voltage limits

80

81

82

82

83

84

85

86

87

87

88

30

Loading...

Loading...