Page 1

Keysight W6600A-Series

LPDDR4 BGA Interposers

Installation Guide

Page 2

Notices

CAUTION

WARNING

© Keysight Technologies 2016, 2017

No part of this manual may be reproduced in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Keysight

Technologies as governed by United States

and international copyright laws.

Manual Part Number

W6601-97000

Edition

Second Edition, August 2017

Available in electronic format only

Keysight Technologies

1900 Garden of the Gods Road

Colorado Springs, CO 80907 USA

Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED "AS IS," AND IS SUBJECT TO BEING CHANGED, WITHOUT

NOTICE, IN FUTURE EDITIONS. FURTHER,

TO THE MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, KEYSIGHT DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR

IMPLIED WITH REGARD TO THIS MANUAL

AND ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. KEYSIGHT SHALL NOT BE LIABLE

FOR ERRORS OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION

WITH THE FURNISHING, USE, OR PERFORMANCE OF THIS DOCUMENT OR ANY

INFORMATION CONTAINED HEREIN.

SHOULD KEYSIGHT AND THE USER HAVE A

SEPARATE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT CONFLICT

WITH THESE TERMS, THE WARRANTY

TERMS IN THE SEPARATE AGREEMENT WILL

CONTROL.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

U.S. Government Rights

The Software is "commercial computer software," as defined by Federal Acquisition

Regulation ("FAR") 2.101. Pursuant to FAR

12.212 and 27.405-3 and Department of

Defense FAR Supplement ("DFARS")

227.7202, the U.S. government acquires

commercial computer software under the

same terms by which the software is customarily provided to the public. Accordingly,

Keysight provides the Software to U.S. government customers under its standard commercial license, which is embodied in its

End User License Agreement (EULA), a copy

of which can be found at

sight.com/find/sweula

forth in the EULA represents the exclusive

authority by which the U.S. government may

use, modify, distribute, or disclose the Software. The EULA and the license set forth

therein, does not require or permit, among

other things, that Keysight: (1) Furnish technical information related to commercial

computer software or commercial computer

software documentation that is not customarily provided to the public; or (2) Relinquish

to, or otherwise provide, the government

rights in excess of these rights customarily

provided to the public to use, modify, reproduce, release, perform, display, or disclose

commercial computer software or commercial computer software documentation. No

additional government requirements beyond

those set forth in the EULA shall apply,

except to the extent that those terms, rights,

or licenses are explicitly required from all

providers of commercial computer software

pursuant to the FAR and the DFARS and are

set forth specifically in writing elsewhere in

the EULA. Keysight shall be under no obligation to update, revise or otherwise modify

the Software. With respect to any technical

data as defined by FAR 2.101, pursuant to

FAR 12.211 and 27.404.2 and DFARS

227.7102, the U.S. government acquires no

greater than Limited Rights as defined in

FAR 27.401 or DFAR 227.7103-5 (c), as

applicable in any technical data.

http://www.key-

. The license set

Safety Notices

A CAUTION notice denotes a hazard. It

calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not proceed beyond a CAUTION notice until

the indicated conditions are fully

understood and met.

A WARNING notice denotes a hazard.

It calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

2 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 3

In This Guide

This document provides installation information for the following Keysight products:

W6601A LPDDR4 BGA Interposer, 200-ball, 2-wings

U4208A 61-pin ZIF from left wing probe/cable (160 pin direct connect to LA).

This probe/cable is for use with the W6601A interposer.

U4209A 61-pin ZIF from right wing probe/cable (160 pin direct connect to LA)

This probe/cable is for use with the W6601A interposer.

W6602A LPDDR4 RC BGA Interposer, 200-ball, rigid

U4207A Zero ohm, 34 channels, Soft Touch Pro, single-ended probe/cable (160 pin direct connect to LA)

This probe/cable is for use with the W6602A interposer.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 3

Page 4

4 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 5

Contents

1 Introduction to W6600-Series Interposers

2 Introduction to W6601A LPDDR4 BGA Interposer

In This Guide 3

Compatibility with Logic Analyzer Modules 9

W6601A LPDDR4 BGA Interposer, 200-ball, 2-wings 12

Software Configurations 12

W6601A Technical Features Summary 13

W6601A Riser 13

U4208A 61-pin ZIF Probe / Cable (for Left Wing) 14

U4209A 61-pin ZIF Probe / Cable (for Right Wing) 15

Hardware and Software Requirements 16

Mechanical Considerations 18

W6601A Interposer Dimensions 18

W6601A Riser Dimensions 19

W6601A Keep-Out Volume 19

3 Introduction to W6602A LPDDR4 BGA Interposer

W6602A LPDDR4 RC BGA Interposer, 200-ball, Rigid 22

Software Configurations 23

W6602A Technical Features Summary 24

W6602A Riser 24

U4207A Zero ohm, 34 channels, Soft Touch Pro, Single-ended Probe/Cable 25

Hardware and Software Requirements 26

Mechanical Considerations 28

W6602A Interposer Dimensions 28

W6602A Riser Dimensions 29

4 W6600A-Series Interposers and Riser Soldering Guidelines

Recommended Soldering Guidelines 33

Soldering Steps 34

Interposer Fabrication Notes 36

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 5

Page 6

Contents

5 Setting up the W6601A Interposer

W6601A Interposer Setup - Overview 38

Step 1 - Soldering the W6601A Interposer 39

Step 2 - Connecting the W6601A Interposer to U4208A and U4209A Probe Cables 40

W6601A Interposer Wings Pinout 41

Step 3 - Connecting the U4208A and U4209A Probe Cables to a U4164A Logic

Analyzer 43

Logic Analyzer Channels to Signals Mapping 43

Signals not probed by the Logic Analyzer 45

6 Setting up the W6602A Interposer

W6602A Interposer Setup - Overview 48

Step 1 - Soldering the W6602A Interposer 49

Step 2 - Making Clock Qualifier Connections 50

W6602A Clock Connectors 50

U4207A Flying Leads Orientation 51

Step 3 - Connecting the W6602A Interposer to U4207A Probes 53

Step 4 - Connecting the U4207A Probe Pods to the Logic Analyzer Module Pods 54

For Two 16-bit Channels DRAM Configuration 54

For a Single 32-bit Channel DRAM Configuration 56

W6602A Interposer Footprints Pinout 58

W6602A Clock Connectors Pinout 59

W6602A Clock Qualifier and RESET Connections 60

Logic Analyzer Channels to Signals Mapping 61

Signals not probed by the Logic Analyzer 62

7 Setting Up the Logic Analyzer for W6600A-series Interposers

Before You Start 64

Loading a Configuration File 65

To save a configuration file 65

Troubleshooting Problems with Thresholds and Sample Positions Setup 66

8 Making Power Integrity Measurements using W6600A Series Interposers

Overview 68

Power Integrity Measurement Setup 68

6 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 7

W6600A-Series Interposers Power Filter Capacitors 69

W6601A Power Filter Capacitors 69

W6602A Power Filter Capacitors 70

Correlating Power Integrity Measurements with Memory Analysis Measurements 71

9 Characteristics, Regulatory, Safety and Storage Information

Operating Characteristics 74

Storage, Inspection, Baking, and Cleaning Guidelines 75

Guidelines for Shelf Life and Solder-ability of W6600A-series Interposers 75

Cleaning of W6601A Interposer Gold Fingers 75

Regulatory Notices 76

WEEE Compliance 76

China RoHS 76

Index

Contents

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 7

Page 8

Contents

8 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 9

Keysight W6600A-series LPDDR4 BGA Interposers

NOTE

Installation Guide

1 Introduction to W6600-Series

Interposers

The W6600A-series LPDDR4 BGA Interposers enable probing of 200-pin JEDEC standard footprint

directly at the ball grid array using the Keysight U4164A logic analyzer. These interposers provide

you:

• single touch probing of DQ signals

• capture of CA, Control, and DQ signals at data rates tested up to 3200MT/s.

• access to LPDDR4 DQ signals above 2.5Gb/s without double probe load by utilizing the Quad

Sampling features of a U4164A logic analyzer module.

A W6600A-series interposer interposes between the DRAM being probed and the PC board where

the DRAM would normally be soldered. The interposer is designed to be soldered to the PCB

footprint for the DRAM on top of either the LPDDR riser included with the W6600-series BGA

interposer or an optional Grypper socket (not included with the interposer) or both. The DRAM being

probed is then soldered to the top side of the interposer.

Each DRAM signal in the common footprint passes directly from the bottom side of the interposer to

the top side of the interposer.

Currently, in this series, Keysight provides the following interposers:

W6600A-series Interposer Description

W6601A LPDDR4 BGA Interposer,

200-ball, 2-wings

W6602A LPDDR4 RC BGA

Interposer, 200-ball, rigid

All probing including BGA interposers, become a part of the system under test when installed.

Maximum data rates and performance results will vary by systems under test, BGA rework, and

probing irregularities.

Compatibility with Logic Analyzer Modules

The W6600-series interposers are compatible with the Keysight U4164A AXIe-based logic analyzer

module.

All W6600A-series interposers are tested for via connections through the interposer and

signal trace connectivity to the wing connections.

A flexible interposer with two wings

Provides access to partial DQ signals and only one channel of CA signals on an LPDDR4 200

ball DRAM.

Refer to the chapter “Introduction to W6601A LPDDR4 BGA Interposer" on

page 11.

A rigid interposer

Provides access to all DQ and CA signals for both channels of an LPDDR4 200 ball DRAM.

Refer to the chapter “Introduction to W6602A LPDDR4 BGA Interposer" on

page 21.

Page 10

1 Introduction

10 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 11

Keysight W6600A-series LPDDR4 BGA Interposers

Installation Guide

2 Introduction to W6601A

LPDDR4 BGA Interposer

W6601A LPDDR4 BGA Interposer, 200-ball, 2-wings / 12

U4208A 61-pin ZIF Probe / Cable (for Left Wing) / 14

U4209A 61-pin ZIF Probe / Cable (for Right Wing) / 15

Hardware and Software Requirements / 16

Mechanical Considerations / 18

This chapter introduces the hardware components that are needed for the W6601A LPDDR4 BGA

interposer setup. It also lists the software requirements as well as describes the mechanical

considerations such as various dimensions and KOV that you should know before you start setting up

and using the W6601A interposer.

Page 12

2 Introduction to W6601A LPDDR4 BGA Interposer

2 Flex wings with

ZIF connectors

Pin 1 Marking

NOTE

W6601A LPDDR4 BGA Interposer, 200-ball, 2-wings

The W6601A interposer has two flexible wings, each with a set of fingers for Zero Insertion Force

(ZIF) connections that connect it to a U4208A or a U4209A 61-pin ZIF probe/cable. For the left wing

of the interposer, you use the U4208A probe/cable and for the right wing of the interposer, you use

the U4209A probe/cable. These cables are then connected to the U4164A Logic Analyzer module’s

pods.

The following figure shows a W6601A interposer’s top view.

Figure 1 W6601A Interposer

The W6601A interposer supports dual bank 16-bit data LPDDR4 200 ball DRAM that is being used as

a single 32-bit channel device. The interposer probes a subset of the DQ data lines of both banks of

such an LPDDR4 BGA 200 DRAM.

If the DRAM is used as two single x16 channel devices, then the W6601A interposer can

probe only CA signals from channel A.

This interposer is optimized to work with the U4164A logic Analyzer module to achieve higher data

rates with smaller KOV.

Software Configurations

The W6601A interposer can be used in the following three logic analyzer software configurations:

• 10 GHz Timing mode

• State mode under 2500 Mb/s (double edge clocking)

• State mode over 2500 Mb/s (single edge clocking)

This interposer effectively utilizes the single touch probing and quad sampling features of the

U4164A logic analyzer module thereby allowing you to probe LPDDR4 DQ signals above 2.5Gb/s

without double probe load. (In quad sampling, four samples are captured per clock edge at two

different thresholds. Two samples are taken at each threshold.)

12 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 13

For probing signals under 2.5Gb/s, you can use the W6601A interposer with the U4164A module’s

Pin 1 Marking

NOTE

dual clock edge clocking and dual sample mode instead of the quad sample mode. The U4164A

module’s dual sampling with dual thresholds allows you to capture separate Read and Write samples

per clock edge.

W6601A Technical Features Summary

• Probes a JEDEC LPDDR4 BGA 200 footprint. Maximum of 10 mm wide X 15 mm long LPDDR4

DRAM package can fit on top of the W6601A interposer without an additional riser or a socket to

provide clearance for the RC components.

• For the two flex wings of the interposer, the recommended bend radius is 2.5 mm (0.09") if flex is

bent at a rigid portion of the interposer.

• Logic analyzer connections are made using U4208A and U4209A ZIF probe cables. The

U4208A/U4209A ZIF connectors doors open on the top of the W6601A wings and away from

these wings.

• An isolation Tip Resistor (100 Ohms) and RC components network is present on the W6601A

interposer. No RC network present on the U4208A/U4209A probe cables. Also, there are no RCs

on the bottom of the interposer.

• Has a power plane and separate ground planes - 1.1 V (VDD2/VDDQ) and 1.8 V (VDD1).

• Also provides VDD and VDDQ power filter capacitors to allow you to make power integrity

measurements using the Keysight Power Rail probe and Infiniium S-series oscilloscope.

Introduction to W6601A LPDDR4 BGA Interposer 2

W6601A Riser

An LPDDR4 BGA 200 ball riser is provided with each W6601A interposer to allow the interposer to

clear surrounding devices. Optionally, you can use a Grypper socket. It is not provided with the

interposer.

The following figure displays a riser that is provided with the W6601A interposer.

Figure 2 Riser that accompanies the W6601A interposer

The LPDDR 200 ball riser includes ground planes for optimal signal integrity. Due to these

ground planes, the riser’s alignment with the DRAM should be such that the TOP side of the

riser must point towards the DRAM and the Pin 1 indicator on the riser must orient towards the

“A1” pin of the DRAM.

To know how to solder the riser to the W6601A interposer and PC board, refer to the chapter

“W6600A-Series Interposers and Riser Soldering Guidelines" on page 31.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 13

Page 14

2 Introduction to W6601A LPDDR4 BGA Interposer

Connector to connect

to the left flex wing of

the W6601A interposer

Two pods to connect

to the Logic Analyzer

pods

U4208A 61-pin ZIF Probe / Cable (for Left Wing)

One U4208A probe cable is required to connect a W6601A interposer’s left wing to a U4164A Logic

Analyzer module.

Figure 3 U4208A 61-pin ZIF probe cable

To know how to connect a W6601A interposer to a U4208A probe/cable, refer to the following topics

in this guide:

• “Step 2 - Connecting the W6601A Interposer to U4208A and U4209A Probe Cables" on page 40

To get information such as its characteristics, specifications, pinout, safety information, accessories,

and dimensions of the U4208A probe/cable, refer to the Keysight U4200A-Series Probes and Cables

User Guide (part number U4200-97000) available on www.keysight.com.

14 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 15

U4209A 61-pin ZIF Probe / Cable (for Right Wing)

Connector to connect to the right flex

wing of the W6601A interposer

Two pods to connect to the Logic

Analyzer pods

One U4209A probe cable is required to connect a W6601A interposer’s right wing to a U4164A Logic

Analyzer module.

Introduction to W6601A LPDDR4 BGA Interposer 2

Figure 4 U4209A 61-pin ZIF probe cable

To know how to connect a W6601A interposer with a U4209A probe/cable, refer to the topic:

• “Step 2 - Connecting the W6601A Interposer to U4208A and U4209A Probe Cables" on page 40

To get information such as its characteristics, specifications, pinout, safety information, accessories,

and dimensions of the U4209A probe/cable, refer to the Keysight U4200A-Series Probes and Cables

User Guide (part number U4200-97000) available on www.keysight.com.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 15

Page 16

2 Introduction to W6601A LPDDR4 BGA Interposer

Hardware and Software Requirements

Before you start installing the W6600A-series interposers, ensure that you have the following list of

hardware and software components needed for these interposers.

Hardware Requirements for W6601A

U4164A AXIe-based Logic Analyzer Module

M9502A 2-slot or M9505A 5-slot AXIe chassis to install the U4164A module

M9536A embedded controller or host PC with PCI express adapter card for the chassis

W6601A LPDDR4 Interposer(s)

U4208A 61-pin ZIF probe cables to connect the W6601A interposer to Logic Analyzer module

One cable needed for each interposer

U4209A 61-pin ZIF probe cables to connect the W6601A interposer to Logic Analyzer module

One cable needed for each interposer

Software Requirements Licensing Description

Logic and Protocol Analyzer software version 6.30 or

higher.

(Required)

B4661A Memory Analysis Software Tools Package

version 6.30 or higher. (Required)

The below-mentioned licensed/unlicensed software features from the B4661A software package are required for W6601A.

Default LPDDR configuration files

(Required)

DDR Setup Assistant and DDR Eyefinder software

version 6.30 or higher.

(Required)

DDR Custom Configuration Creator Tool version 6.30

or higher

(Required)

B4661A-2FP LPDDR Bus Decoder software version

6.30 or higher.

(Recommended)

B4661A-3FP DDR 2/3/4 Protocol Compliance and

Analysis toolset version 6.30 or higher.

(Recommended)

Unlicensed base software with

additional licensing options

Includes unlicensed as well as

licensed features

Available as an unlicensed standard

feature with the B4661A package.

Available as an unlicensed standard

feature with the B4661A package.

Available as an unlicensed standard

feature with the B4661A package.

Available as a licensed feature with

the B4661A package

Available as a licensed feature with

the B4661A package

Base software platform for configuring and using Keysight’s logic

analyzer modules.

Base software package that includes configuration files and tools

to help you perform DDR/LPDDR post-process as well as

real-time protocol compliance violation testing, decode and view

memory transactions, and set up your logic analyzer for

DDR/LPDDR data capture and analysis.

Includes default XML configuration files for use with the W6601A

interposer.

A wizard- like application to help you set up your U4164A logic

analyzer properly for use with the W6600A-series interposers.

Allows you to define the footprint layout as per your custom

probing solution used in the DDR/LPDDR setup and then create

an XML configuration file based on this footprint information.

Allows you to decode and view transactions, commands, and

data from a LPDDR1, LPDDR2, LPDDR3 or LPDDR4 SDRAM

memory bus in your device under test.

A set of tools to:

• evaluate and analyze the captured LPDDR data.

• perform real-time or post process compliance.

• set up a trigger on the specified address.

• graphically profile the distribution of memory accesses.

B4661A-4FP DDR 2/3/4 Memory Analysis Viewer

version 6.30 or higher.

(Recommended)

16 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Available as a licensed feature with

the B4661A package

A viewer installed and displayed within the Logic and Protocol

Analyzer GUI to analyze:

• memory traffic statistics.

• refresh rate and self-refresh periods.

• distribution of memory accesses.

• memory performance measurements.

Page 17

Introduction to W6601A LPDDR4 BGA Interposer 2

NOTE

You can install the above-mentioned software components by downloading the required

executables from the Keysight web site at: www.keysight.com/find/lpa-sw-download.

The following table displays the number of W6600-series interposers and cables required to provide

connections to channels of your logic analyzer module.

DRAM Data Width Access to Number of Interposers Number of ZIF Probes Number of Logic Analyzer

LPDDR4 200 ball

DRAM used as a

single 32-bit

channel device

Dual bank 16 bit • Ck_A

• All Channel A CA and control

signals for Bank 0 and Bank 1

• All DBI signals

• Subset of DQS and DQ

signals from all byte lanes.

One W6601A One U4208A for the

left wing

One U4209A for the

right wing

Modules

One U4164A module

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 17

Page 18

2 Introduction to W6601A LPDDR4 BGA Interposer

Mechanical Considerations

W6601A Interposer Dimensions

The following figure shows the dimensions of a W6601A LPDDR4 BGA interposer.

Figure 5 Dimensions of a W6601A interposer (Top View)

18 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 19

W6601A Riser Dimensions

NOTE

All dimensions are in inches.

Introduction to W6601A LPDDR4 BGA Interposer 2

W6601A Keep-Out Volume

You must install the W6601A interposer on a riser (shipped with the interposer) or a grypper

socket to provide clearance to surrounding DRAM.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 19

Page 20

2 Introduction to W6601A LPDDR4 BGA Interposer

Figure 6 KOV of a W6601A interposer

20 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 21

Keysight W6600A-series LPDDR4 BGA Interposers

Installation Guide

3 Introduction to W6602A

LPDDR4 BGA Interposer

W6602A LPDDR4 RC BGA Interposer, 200-ball, Rigid / 22

U4207A Zero ohm, 34 channels, Soft Touch Pro, Single-ended Probe/Cable / 25

Hardware and Software Requirements / 26

Mechanical Considerations / 28

This chapter introduces the hardware components that are needed for the W6602A LPDDR4 BGA

interposer setup. It also lists the software requirements as well as describes the mechanical

considerations such as various dimensions that you should know before you start setting up and

using the W6602A interposer.

Page 22

3 Introduction to W6602A LPDDR4 BGA Interposer

NOTE

NOTE

W6602A LPDDR4 RC BGA Interposer, 200-ball, Rigid

The W6602A interposer is a rigid interposer that connects to U4207A zero ohm, Soft Touch Pro,

single-ended probes/cables. These cables are then directly connected to the U4164A Logic Analyzer

module’s pods.

The W6602A LPDDR4 BGA Interposer enables passive probing of 200-pin JEDEC standard footprint

directly at the ball grid array using the Keysight U4164A logic analyzers.

The W6602A interposer with the U4207A cable passively monitors the LPDDR4 200-ball DRAM

package. After tuning the Keysight logic analyzer, Command/Address bits can be reliably

captured up to 3200 MT/s using this interposer and cable. However, at some data rates, the logic

analyzer may not be able to provide an error-free capture of all DQ data bits.

The W6602A interposer can work in the following configurations of a 200 ball LPDDR4 DRAM:

• An LPDDR4 DRAM used as two 16-bit channels

• An LPDDR4 DRAM used as a single 32-bit channel

This interposer supports:

• probing of all CA and DQ/DQS signals for both channels of a 200 ball LPDDR4 DRAM.

• high speed data capture (data rates up to 3.2 Gb/s)

• lower system loading

If the DRAM is used as a single 32-bit channel device, then the W6602A interposer probes and

uses only one set of CA signals as the single channel 32-bit configuration implies that the two

CA channels on the DRAM are identical.

22 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 23

Introduction to W6602A LPDDR4 BGA Interposer 3

J1 and J2 footprints to attach the interposer to U4207A

probes using retention modules

Pin 1

Marking

The following figure shows a W6602A interposer’s top view.

Figure 7 W6602A Interposer

The W6602A interposer has two connectorless footprints, J1 and J2 on its top side. A retention

module (shipped with the U4207A Soft Touch Pro probe) is soldered to each footprint. Each retention

module attaches to a U4207A probe. These probes are then connected to the Logic Analyzer

module’s pods.

Software Configurations

The W6602A interposer can be used in the following seven logic analyzer software configurations:

• 10 GHz Timing mode

• CHA State mode 16 DQ under 2500MT/s (double edge clocking)

• CHA State mode 16 DQ over 2500MT/s (single edge clocking)

• CHA State mode 32 DQ under 2500MT/s (double edge clocking)

• CHA State mode 32 DQ over 2500MT/s (single edge clocking)

• CHB State mode 16 DQ under 2500MT/s (double edge clocking)

• CHB State mode 16 DQ over 2500MT/s (single edge clocking)

This interposer effectively utilizes the single touch probing and quad sampling features of the

U4164A logic analyzer module thereby allowing you to probe LPDDR4 DQ signals above 2.5Gb/s

without double probe load. (In quad sampling, four samples are captured per clock edge at two

different thresholds. Two samples are taken at each threshold.) The Quad Sample State mode is only

available with the U4164A-02G licensed speed grade option.

For probing signals under 2.5Gb/s, you can use the W6602A interposer with the U4164A module’s

dual clock edge clocking and dual sample mode instead of the quad sample mode. Dual Sample

state mode supports data rates on LPDDR4 up to 2500MT/s and is available with the U4164A-01G

licensed speed grade option. The U4164A-02G licensed option supports all modes of operation and

the highest data rates.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 23

Page 24

3 Introduction to W6602A LPDDR4 BGA Interposer

Pin 1 Marking

NOTE

W6602A Technical Features Summary

• Probes a JEDEC LPDDR4 BGA 200 footprint. Maximum of 10 mm wide X 15 mm long LPDDR4

DRAM package can fit on top of the W6601A interposer without an additional riser or a socket to

provide clearance for the RC components.

• Logic analyzer connections are made using U4207A Soft Touch Pro probe cables.

• RC components network is present on the top of the W6602A interposer. No RC network present

on the U4207A probe cables. Also, there are no RCs on the bottom of the interposer.

• The maximum non destructive input voltage for W6602A is 40 Vdc.

• Has a power plane and separate ground planes - 1.2 V (VDDQ) and 1.8 V (VDD1).

• Also provides VDD and VDDQ power filter capacitors to allow you to make power integrity

measurements using the Keysight Power Rail probe and Infiniium S-series oscilloscope.

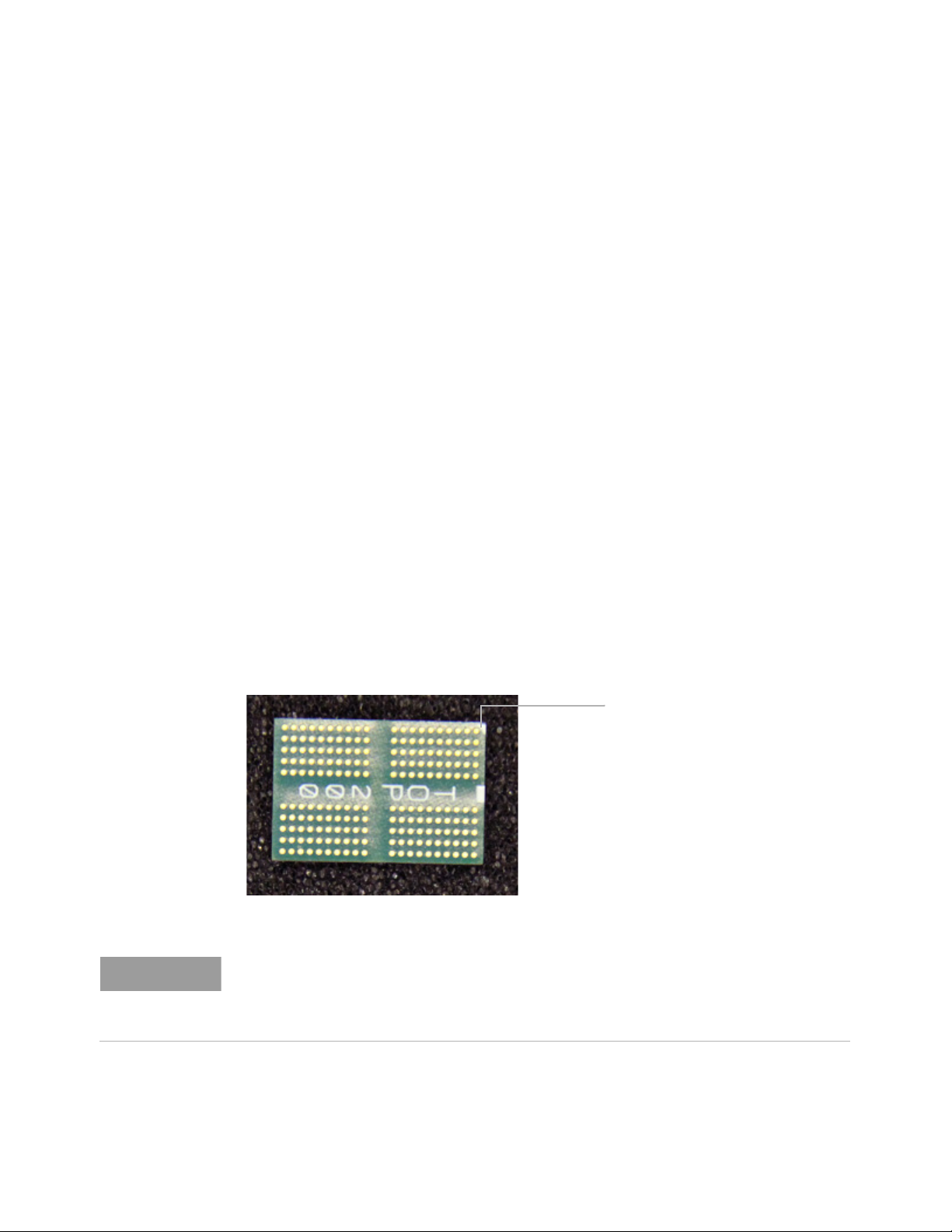

W6602A Riser

An LPDDR4 BGA 200 ball riser is provided with each W6602A interposer to allow the interposer to

clear surrounding devices. Optionally, you can use a Grypper socket. It is not provided with the

interposer.

The following figure displays a riser that is provided with the W6602A interposer.

Figure 8 Riser that accompanies the W6602A interposer

The LPDDR 200 ball riser includes ground planes for optimal signal integrity. Due to these

ground planes, the riser’s alignment with the DRAM should be such that the TOP side of the

riser must point towards the DRAM and the Pin 1 indicator on the riser must orient towards the

“A1” pin of the DRAM.

To know how to solder the riser to the W6602A interposer and PC board, refer to the chapter

“W6600A-Series Interposers and Riser Soldering Guidelines" on page 31.

24 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 25

Introduction to W6602A LPDDR4 BGA Interposer 3

Soft Touch Pro

Connector to

connect to the

W6602A

interposer’s J1/J2

footprint via an

E5403A retention

module

Four pods to

connect to the

Logic Analyzer

pods

Clock

Connection

Flying Leads

U4207A Zero ohm, 34 channels, Soft Touch Pro, Single-ended Probe/Cable

Two U4207A probe cables are required for a W6602A interposer connections to U4164A logic

analyzers.

Figure 9 U4207A probe cable

To know how to connect a W6602A interposer to a U4207A probe/cable, refer to the following topics

in this guide:

• “Step 3 - Connecting the W6602A Interposer to U4207A Probes" on page 53

To get information such as its characteristics, specifications, pinout, safety information, accessories,

and dimensions of the U4207A probe/cable, refer to the Keysight U4200A-Series Probes and Cables

User Guide (part number U4200-97000) available on www.keysight.com.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 25

Page 26

3 Introduction to W6602A LPDDR4 BGA Interposer

Hardware and Software Requirements

Before you start installing the W6602A interposer, ensure that you have the following list of hardware

and software components needed for these interposer.

Hardware Requirements for W6602A

One U4164A Logic Analyzer module (with option -02G) for each LPDDR4 16-bit channel configuration

or

Two U4164A modules (with option -02G) combined via cables to form a module set for a single 32-bit channel configuration

M9502A 2-slot or M9505A 5-slot AXIe chassis to install the U4164A modules

M9537A embedded controller or host PC with PCI express adapter card for the chassis

W6602A LPDDR4 Interposer with 200-ball riser

Two U4207A probe cables to connect the W6602A interposer to Logic Analyzer modules

(Two cables needed for each interposer regardless of the software configuration in which the interposer is used.)

Software Requirements Licensing Description

Logic and Protocol Analyzer software version 6.40 or

higher.

(Required)

B4661A Memory Analysis Software Tools Package

version 6.40 or higher. (Required)

The below-mentioned licensed/unlicensed software features from the B4661A software package are required for W6602A.

Default LPDDR configuration files

(Required)

DDR Setup Assistant and DDR Eyefinder software

version 6.40 or higher.

(Required)

DDR Custom Configuration Creator Tool version 6.40

or higher

(Required)

B4661A-2FP LPDDR Bus Decoder software version

6.40 or higher.

(Recommended)

B4661A-3FP DDR 2/3/4 Protocol Compliance and

Analysis toolset version 6.40 or higher.

(Recommended)

Unlicensed base software with

additional licensing options

Includes unlicensed as well as

licensed features

Available as an unlicensed standard

feature with the B4661A package.

Available as an unlicensed standard

feature with the B4661A package.

Available as an unlicensed standard

feature with the B4661A package.

Available as a licensed feature with

the B4661A package

Available as a licensed feature with

the B4661A package

Base software platform for configuring and using Keysight’s logic

analyzer modules.

Base software package that includes configuration files and tools

to help you perform DDR/LPDDR post-process as well as

real-time protocol compliance violation testing, decode and view

memory transactions, and set up your logic analyzer for

DDR/LPDDR data capture and analysis.

Includes default XML configuration files for use with the W6601A

interposer.

A wizard- like application to help you set up your U4164A logic

analyzer properly for use with the W6600A-series interposers.

Allows you to define the footprint layout as per your custom

probing solution used in the DDR/LPDDR setup and then create

an XML configuration file based on this footprint information.

Allows you to decode and view transactions, commands, and

data from a LPDDR1, LPDDR2, LPDDR3 or LPDDR4 SDRAM

memory bus in your device under test.

A set of tools to:

• evaluate and analyze the captured LPDDR data.

• perform real-time or post process compliance.

• set up a trigger on the specified address.

• graphically profile the distribution of memory accesses.

B4661A-4FP DDR 2/3/4 and ONFi Memory Analysis

Viewer version 6.40 or higher.

(Recommended)

26 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Available as a licensed feature with

the B4661A package

A viewer installed and displayed within the Logic and Protocol

Analyzer GUI to analyze:

• memory traffic statistics.

• refresh rate and self-refresh periods.

• distribution of memory accesses.

• memory performance measurements.

Page 27

Introduction to W6602A LPDDR4 BGA Interposer 3

NOTE

You can install the above-mentioned software components by downloading the required

executables from the Keysight web site at: www.keysight.com/find/lpa-sw-download.

The following table displays the number of W6602A interposers and cables required to provide

connections to channels of your logic analyzer module.

DRAM Data Width Access to Number of

LPDDR4 200

ball DRAM

Two 1 6-bit

channels

or

Single 32-bit

channel

• All CA and

DQ signals

for both

channels

(A and B)

Interposers

One W6602A Two U4207A

Number of

U4207A Probes

probes for each

W6602A

interposer

Number of Logic Analyzer Modules

For a single 32-bit channel DRAM configuration

• Two U4164A modules combined via cables to

form a module set representing one logical

module. Refer to the installation guide of your

logic analyzer module to know how to create a

module set.

For two 16-bit channels DRAM configuration

• Two U4164A independent modules, one for

each 16-bit channel.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 27

Page 28

3 Introduction to W6602A LPDDR4 BGA Interposer

0.067” thickness

Mechanical Considerations

W6602A Interposer Dimensions

The following figure shows the dimensions of a W6602A LPDDR4 BGA interposer.

Figure 10 Dimensions of a W6602A interposer (Top View)

28 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 29

W6602A Riser Dimensions

Introduction to W6602A LPDDR4 BGA Interposer 3

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 29

Page 30

3 Introduction to W6602A LPDDR4 BGA Interposer

30 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 31

Keysight W6600A-series LPDDR4 BGA Interposers

Installation Guide

4 W6600A-Series Interposers

and Riser Soldering Guidelines

Recommended Soldering Guidelines / 33

Soldering Steps / 34

Interposer Fabrication Notes / 36

In this chapter, Keysight provides the soldering guidelines and information for W6600A-series

interposer installation. However, Keysight cannot guarantee the successful interposer installation

due to variations in processes and equipment used at individual BGA rework facilities.

Keysight recommends that interposers be installed by companies with specific expertise in this

advanced type of processing.

Keysight does not endorse any specific BGA rework facility but recommends using a reputable and

experienced BGA rework facility for the installation of BGA interposers. The following links are

provided as a convenience to users investigating BGA rework facilities.

Information on BGA Rework Facilities

Circuit Technology Center

Haverhill, MA

USA

BGA Rework and Repair Services

http://www.circuitrework.com/services/bga.shtml

Keysight Technologies Adapter Rework

http://www.circuitrework.com/features/671.shtml

eTech

Round Rock, TX

www.eTech-WEB.com

Singularity Electronic Systems

Portsmouth, NH

www.singularitysys.com

Page 32

4 Interposers and Riser Soldering Guidelines

Recommended Reading

BGA Component Rework Procedures

http://www.circuitrework.com/guides/9-0.shtml

BGA Component Rework Process Flow

http://www.circuitrework.com/guides/9-1-1.shtml

BGA Component Rework Inspection

http://www.circuitrework.com/guides/9-1-2.shtml

BGA Component Rework Profile Development, Standard Method

http://www.circuitrework.com/guides/9-2-1.shtml

BGA Component Rework Profile Development, Smart Track Method

http://www.circuitrework.com/guides/9-2-2.shtml

BGA Component Rework, Eutectic Solder Ball

http://www.circuitrework.com/guides/9-3-1.shtml

BGA Component Reballing, Fixture Method

http://www.circuitrework.com/guides/9-4-1.shtml

32 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 33

Recommended Soldering Guidelines

These guidelines are intended for anyone who has decided to install the winged / rigid BGA

interposers themselves, or would like to provide guidelines to their regular contract manufacturer.

• The W6600A-series interposers are assembled using lead free or leaded soldering processes.

• Observe standard lead-free rework guidelines and processes when applying LPDDR memory

devices and attaching a riser to an interposer and DIMM.

• Typical time-above-liquidus (220°C in the case of SAC305 solder) is 30 to 90 seconds with 60

seconds as the good nominal target.

• The peak temperature at the SAC305 solder joints should be a minimum of 235°C.

• It is best to limit the peak temperature on the package of the IC at a maximum of 245°C.

• To minimize heating effects on components mounted on the interposer assembly, a leaded solder

process can be used to attach a riser, when it is compatible with your prototype debug and

validation methodologies.

• The maximum processing temperature that the W6600A-series interposers can withstand is 260

°C for not more than 90 seconds.

• The W6600A-series interposers are supplied without solder balls. Depending on the exact

attachment order, either leaded or lead-free solder may be preferred to attach the interposer to

the DUT. The design of the interposer supports either choice.

Interposers and Riser Soldering Guidelines 4

Applicable only to the winged interposers in the series such as the W6601A interposer

• The flex wings on Keysight BGA interposers are made with Pyralux AP, the flex material, and

Pyralux FR, the coverlay material with adhesive. Both of these materials have high moisture

absorption characteristics, and always require baking prior to processing. Review the DuPont

baking recommendation before processing.

• The flexible “wings” on the interposer may need to be bent upwards before soldering to avoid

mechanical contact with components adjacent to the interposer on the DUT. If interposer wings

are bent during the soldering process, precautions must be taken to ensure that the wings do not

move during the process. Applying heat to a bent wing has the tendency to cause the wing to

relax and this can result in movement during the soldering process that can damage the integrity

of the solder joints.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 33

Page 34

4 Interposers and Riser Soldering Guidelines

Soldering Steps

These steps and guidelines apply only to the proper method of attaching BGA interposers to their

target host boards. These do not attempt to provide instructions on how to attach BGA balls to the

interposer, nor do these attempt to suggest a flux or a solder paste process.

1 Profile Development

a Profile must conform to the solder paste specification. Use the lowest possible temperatures

that will insure reflow.

b Profile must also provide a slow ramp up to temperature.

c It is recommended that the profile be developed using a non-functional sample interposer in a

location on a sample target that is similar to the actual target.

d The highest processing temperature must be in the range of 240 °C to 260 °C. The maximum

processing time at the highest temperature must not exceed 90 seconds.

2Material Baking

a Prior to soldering, bake interposer (to eliminate moisture) for 2-10 hours at 250° F (121° C).

b Shield flex areas.

c Polyimide films absorb moisture quickly; therefore, soldering and reflow should be done within

30 minutes after baking.

d A 7 or 9 zone conventional oven is beneficial. A conventional oven is preferred over infra-red.

e Vacuum ovens are also used to remove water. Lower temperatures, such as 150-175 F (65-80

C) can be used. This method also reduces the oxidation of the exposed copper pads.

f After baking, if the units are not reflowed within a few hours, these should be re-baked or

placed in a desiccant chamber.

3 Heat Shielding (applicable only to winged interposers in this series such as the W6601A

interposer).

a Kapton tape is applied to the bottom-side covering the gold contact area and wrapping

around the outside edge to the top-side.

b Three layers of Kapton tape are applied to the top-side covering the entire wing extending over

to the rigid board.

c Additional insulating of the wing area is done by applying a thick coating of the high

temperature peelable masking to the Kapton tape covering the entire area to reduce the

exposure to the hot gas heat cycle.

4 Host assembly components must be shielded using Kapton tape, aluminum heat shield blanket,

or plates.

5 Site Preparation

a If the interposer is being installed onto a new board with gold pads, these pads should be

pre-tin to ensure the pads wet properly, and to lower the chance of oxidation.

b Add solder paste to the target board using a mini-stencil. This is recommended over using flux

only.

6 Interposer Reflow

a Use the lowest possible temp for reflow - Use a slow ramp up to temperature.

b Aim the shielded wings of the interposer upwards (applicable only to winged interposers in this

series such as the W6601A interposer). The minimum bend radius must be 1.27mm (0.05 In) to

insure that the copper foil does not fracture.

c Place the interposer using vision equipped BGA placement/reflow system such as an SRT.

d Reflow per the prepared heating profile.

7 Memory placement

a Add staking epoxy to the four corners of the placed interposer, and cure at 150°C for 2

minutes. This time is defined from the moment the adhesive reaches the cure temperature. As

34 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 35

Interposers and Riser Soldering Guidelines 4

a convenience, the following link has been supplied on a staking adhesive.

https://tds.us.henkel.com/NA/UT/HNAUTTDS.nsf/web/7DA17BAB270FA76E882571870000D

6EE/$File/3609-EN.pdf

b Apply solder paste to the top-side of interposer.

c Position memory using an SRT (or equivalent) with vision system for manual placement.

d Reflow per the prepared heating profile.

8 Post Processing

a Remove flux residue.

b Remove any Kapton tape heat shielding and peelable mask material.

c Remove heat shielding from the target board.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 35

Page 36

4 Interposers and Riser Soldering Guidelines

Interposer Fabrication Notes

Operating Environment

The W6600A-series interposers are constructed of polyimide material that supports solder

attachment of the interposer using the higher temperatures required by a lead-free solder process.

The coefficient of thermal expansion for the interposer is 55 ppm/degree C. When operating in a

soldered-down environment over a wide range of temperatures, the expansion coefficient of the

interposer, DRAM, and system being probed must be matched to avoid stress related failure of the

solder connections between the Interposer and attached components. The interposer material allows

operation over an industrial temperature range of -40 to +85 degrees Celsius (non-condensing),

subject to the above constraint.

Mechanical Dimensions

When a W6600A-series interposer is soldered to a riser, flatness must be maintained on the order of

3.5 mils or less across the BGA footprint to maximize successful soldering to the interposer.

36 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 37

Keysight W6600A-series LPDDR4 BGA Interposers

Installation Guide

5 Setting up the W6601A Inter-

poser

W6601A Interposer Setup - Overview / 38

Step 1 - Soldering the W6601A Interposer / 39

Step 2 - Connecting the W6601A Interposer to U4208A and U4209A Probe Cables / 40

Step 3 - Connecting the U4208A and U4209A Probe Cables to a U4164A Logic Analyzer / 43

Page 38

5 Setting up the W4641A Interposer

CAUTION

NOTE

W6601A Interposer Setup - Overview

1 Solder the interposer, riser, and memory components. (See page 39)

2 Connect the interposer flex wings to U4208A and U4209A probe cables. (See page 40)

3 Connect the U4208A and U4209A probe cables to a U4164A Logic Analyzer module’s pods. (See

page 43)

Use ESD precautions. Electrostatic discharge can damage components on your board or in the

interposer. Use a grounded wrist strap and other ESD control measures as appropriate.

Do not open the vacuum sealed packs of the W6601A interposer until you are ready to install

the interposer. Discard these packs once the package is opened.

38 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 39

Step 1 - Soldering the W6601A Interposer

NOTE

The W6601A interposer needs to be attached to the JEDEC LPDDR4 BGA 200 footprint on the

design to be probed. The desired DRAM is soldered to the top side of the interposer. This attachment

may occur in any order (i.e. first solder the interposer to the DUT, and then solder the DRAM to the

interposer, or first solder the DRAM to the interposer, and then solder the DRAM+interposer

assembly to the DUT). The interposer is designed to tolerate lead-free soldering temperature

profiles. However, it is always recommended to apply the minimum temperature required and the

minimum number of heating/cooling cycles to reduce risk of any damage to the interposer.

The stack up of these soldered components is illustrated in the following figure.

Setting up the W4641A Interposer 5

Figure 11 PC board, riser, interposer, and DRAM stack up

A maximum of 10 mm wide X 15 mm long LPDDR4 DRAM package can fit on top of the

W6601A interposer without an additional riser or a socket between the DRAM and interposer

to provide clearance for the RC components.

Refer to the chapter “W6600A-Series Interposers and Riser Soldering Guidelines" on page 31.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 39

Page 40

5 Setting up the W4641A Interposer

CAUTION

Pod with two cables

Pod with one cable

Step 2 - Connecting the W6601A Interposer to U4208A and U4209A Probe Cables

After soldering components, you can start connecting the W6601A interposer to the U4208A and

U4209A probe cables.

Please handle the interposer with care and ensure that the wings on the W6601A interposer

are properly latched to the ZIF connectors on the U4208A and U4209A probe cables.

U4208A and U4209A cables ship with pod labels unattached. Use the sheet of labels included with

the cable shipment to label pods as follows.

As illustrated in the diagram below, you need to connect:

• the U4208A probe cable to the left wing of the interposer.

• the U4209A probe cable to the right wing of the interposer.

Figure 12 W6601A Interposer and U4208A / U4209A Probe Cable Connections

The door on the ZIF connector of the U4208A/U4209A cable closes against the top of the ZIF wing of

the interposer.

40 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 41

To attach a U4208A or a U4209A ZIF connector to a flex wing of the W6601A interposer, perform the

following three steps.

1 Angle the flex wing of the interposer into the probe cable’s ZIF connector.

2 Align the probe cable’s ZIF connector tabs with interposer’s wing notches.

3 Shut the ZIF door.

W6601A Interposer Wings Pinout

The table on the next page lists the pinout of the two wings of a W6601A interposer. The table

includes the signals being probed when using the interposer in a dual sampling mode or a quad

sampling mode (supported by the U4164A logic analyzer module).

In this table,

• Clock/Qualifier inputs are highlighted with yellow

• Signals that can be quad-sampled are highlighted with green

• Single-sampled signals are highlighted with blue

• Table cells marked with indicate pins that are not accessible.

Setting up the W4641A Interposer 5

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 41

Page 42

5 Setting up the W4641A Interposer

Table 1 W6601A Interposer Wings Pinout

Pin

2 DQ8_A DQ0_B

4

6 DMI1_A DQ7_B

8

10

12 CKt_A

14

16

18 CA4_A DQ1_B

20 CA5_A

22 DQ2_B

24

26 DQ4_B

28 DQ12_B

30 GND CKE1_A

DQ9_A

DQ15_A

CKc_A

CA2_A DMI0_B

CA3_A

W6601A Interposer Wings

Right Wing Left Wing

32 RESET_N GND

34 DQ3_B

36 DQ11_B

38 CS1_A

40

42

44

46

48

50 CKE0_A

52

54 DQ7_A

56

58

60 DQ8_B DQ0_A

Pin U4209A U4208A

DQ10_B

CS0_A

DQ9_B CA1_A

CA0_A

DMI1_B ODT_CA_A

GND

DQ15_B DMI0_A

DQS0t_A

42 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 43

Setting up the W4641A Interposer 5

NOTE

Step 3 - Connecting the U4208A and U4209A Probe Cables to a U4164A Logic Analyzer

In a W6601A interposer setup, you connect the U4208A and U4209A probe cable pods to U4164A

logic analyzer pods as per the mapping shown in the table below.

Probe Cable Pods U4164A Logic Analyzer

U4209A Cable Pods

Pod A Pod 7

Pod B Pod 1

U4208A Cable Pods

Pod A Pod 3

Pod B Pod 5

Pods

In a dual-sampled setup, the U4164A logic analyzer samples data twice per clock edge. Two

thresholds are used with one sample taken per threshold. For LPDDR systems running less

than 2.5GHz, the dual sampling allows separate thresholds and separate sample positions to

be specified for DDR Reads and Writes.

In a quad-sampled setup, four samples are taken per clock edge. Two thresholds are used

with two samples taken per threshold.

The mapping of the U4208A and U4209A probe cable pods and logic analyzer pods is also illustrated

with the help of the following diagram.

Figure 13 Connections between U4208A and U4209A probe cables and Logic Analyzer pods

Logic Analyzer Channels to Signals Mapping

When you connect the U4208A and U4209A probe cables to a U4164A Logic Analyzer as per the

connection diagram in Figure 13, the logic analyzer channels are mapped to DDR4 signals as per the

table displayed below.

These signals are automatically configured when you load one of the configuration files supplied with

the Keysight B4661A LPDDR decoder software.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 43

Page 44

5 Setting up the W4641A Interposer

Notes:

• Clock inputs for each logic analyzer pod are highlighted with yellow in this table.

• Table cells marked with indicate logic analyzer channels that are not accessible.

Table 2 Signals and Logic Analyzer Channels Mapping when using the W6601A Interposer

Logic Analyzer Pod

and its Channels

Pod 3

Signals on

U4208A probe

cable Pod A

0DQ0_B

11

2 DQ7_B 2 CA1_A

33

4 DMI0_B 4 CA0_A

55

6 DQ1_B 6 ODT_CA_A

77

8DQ2_B 8DQ7_A

99

10 DQ4_B 10 DMI0_A

11 11

12 DQ3_B 12 DQS0t_A

13 13

14 CS1_A 14 DQ0_A

Logic Analyzer Pod

and its Channels

Pod 5

Signals on

U4208A probe

cable Pod B

0CS0_A

15 15

CLK CKE1_A CLK CKE0_A

CLK# GND CLK# GND

44 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 45

Setting up the W4641A Interposer 5

Logic Analyzer Pod

and its Channels

Pod 7

Signals on

U4209A probe

cable Pod A

0DQ8_B

11

2 DQ15_B 2 CA4_A

33

4 DMI1_B 4 CA3_A

55

6 DQ9_B 6 CA2_A

77

8 DQ10_B 8 DQ15_A

99

10 DQ11_B 10 DMI1_A

11 11

12 DQ12_B 12 DQ9_A

13 13

14 14 DQ8_A

Logic Analyzer Pod

and its Channels

Pod 1

Signals on

U4209A probe

cable Pod B

0 CA5_A

15 15

CLK RESET_N CLK CKt_A

CLK# GND CLK# CKc_A

Signals not probed by the Logic Analyzer

The following signals are omitted from the Logic Analyzer connections for the W6601A interposer.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 45

Page 46

5 Setting up the W4641A Interposer

Interposer Signal Name

W6601A DNU

VDDQ

VDD1

VDD2

ODT_CA_B

CA0_B

CA1_B

DQ3_A

DQ2_A

DQ1_A

DQS0c_A

CS1_B

DQS0c_B

DQS0t_B

DQ6_B

DQ5_B

CS0_B

CKE0_B

DQ4_A

DQ5_A

DQ6_A

ZQ0

CS2_B

CKE1_B

ZQ1

CKE2_A

CKE2_B

CKt_B

DQ14_B

DQ13_b

CA2_B

CKc_B

DQ12_A

DQ13_A

DQ14_A

DQS1t_A

DQS1c_A

CA3_B

DQS1c_B

DQS1t_B

CA4_B

CA5_B

ZQ2

DQ11_A

DQ10_A

46 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 47

Keysight W6600A-series LPDDR4 BGA Interposers

Installation Guide

6 Setting up the W6602A Inter-

poser

W6602A Interposer Setup - Overview / 48

Step 1 - Soldering the W6602A Interposer / 49

Step 2 - Making Clock Qualifier Connections / 50

Step 3 - Connecting the W6602A Interposer to U4207A Probes / 53

Step 4 - Connecting the U4207A Probe Pods to the Logic Analyzer Module Pods / 54

W6602A Interposer Footprints Pinout / 58

W6602A Clock Connectors Pinout / 59

Logic Analyzer Channels to Signals Mapping / 61

Page 48

6 Setting up the W6602A Interposer

CAUTION

NOTE

WARNING

W6602A Interposer Setup - Overview

• Step 1 - Solder the riser, interposer, and memory components. (See page 49)

• Step 2 - Make clock qualifier connections. To do this, first solder the single-pin headers (shipped

with the W6602A interposer) into the clock connector(s) on top of the interposer. Then, attach the

clock qualifier connection flying leads of U4207A to these soldered single-pin headers. (See

page 50)

• Step 3 - Solder the retention modules to the connectorless footprints on top of the W6602A.

Attach the U4207A probes to these retention modules. (See page 53)

• Step 4 - Connect the U4207A probe cables to the Logic Analyzer module pods. (See page 54)

Use ESD precautions. Electrostatic discharge can damage components on your board or in the

interposer. Use a grounded wrist strap and other ESD control measures as appropriate.

Do not open the vacuum sealed packs of the W6602A interposer until you are ready to install

the interposer. Discard these packs once the package is opened.

You should exercise caution when using the sharp alignment and connector pins for the

interposer and cable to avoid personal injury.

48 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 49

Step 1 - Soldering the W6602A Interposer

NOTE

The W6602A interposer needs to be attached to the JEDEC LPDDR4 BGA 200 footprint on the

design to be probed. The desired DRAM is soldered to the top side of the interposer.

The recommended soldering sequence is:

•Riser

•Interposer

•DRAM

The interposer is designed to tolerate lead-free soldering temperature profiles. However, it is always

recommended to apply the minimum temperature required and the minimum number of

heating/cooling cycles to reduce risk of any damage to the interposer.

The stack up of these soldered components is illustrated in the following figure.

Setting up the W6602A Interposer 6

Figure 14 PC board, riser, interposer, and DRAM stack up

A maximum of 10 mm wide X 15 mm long LPDDR4 DRAM package can fit on top of the

W6602A interposer without an additional riser or a socket between the DRAM and interposer

to provide clearance for the RC components.

Refer to the chapter “W6600A-Series Interposers and Riser Soldering Guidelines" on page 31.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 49

Page 50

6 Setting up the W6602A Interposer

Step 2 - Making Clock Qualifier Connections

W6602A Clock Connectors

There are five clock connectors on top of a W6602A interposer namely, J3, J4, J5, J6, and J7. The

following diagram highlights these 2-pin clock connectors and also indicates what each of these pins

represents.

Figure 15 W6602A clock connectors and pins for these connectors

To make clock qualifier connections, you use the Single Pin Headers (part number - W6602-60001)

included in the W6602A shipment.

Figure 16 Single Pin Header

1 Solder the single pin headers into the clock connectors of the interposer from the top of the

interposer. Following are some of the recommendations for this soldering step.

• Use a soldering iron with a small tip.

• Use small diameter solder wire.

• The solder tip should touch the pad to ensure that solder wicks between the pin and pad.

50 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 51

Setting up the W6602A Interposer 6

2 Attach the clock qualifier connection flying leads of U4207A to the soldered single-pin headers.

U4207A Flying Leads Orientation

A clock qualifier connection flying lead of U4207A has two wires:

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 51

Page 52

6 Setting up the W6602A Interposer

CAUTION

While plugging in a flying lead into a clock connector on the interposer, ensure that the

black wire of this lead aligns with the GND pin (square pin) of the clock connector and the

gray wire with the signal pin (round pin) of the clock connector.

When you solder the single pin headers into the clock connectors, the shapes of the GND

pins and signal pins get hidden beneath the soldered single pin headers. In such a situation,

you can ensure the correct orientation of the flying leads by identifying the signal pin as the

pin which is the closest to that signal’s name printed on the interposer.

52 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 53

Step 3 - Connecting the W6602A Interposer to U4207A Probes

The U4207A probes attach to the interposer by soldering the E5403A retention modules to the J1

and J2 connectorless footprints on top-side of the W6602A interposer.

A kit of 5 retention modules is included in the U4207A shipment. You can order additional retention

modules kit (part number - E5403A).

Setting up the W6602A Interposer 6

Figure 17 W6602A Interposer connected to a U4207A Probe

1 Attach the retention module to the interposer from the top.

a Insert the retention module into the interposer noting the keying pin.

b Solder alignment pins from the top ensuring that solder is added until a fillet is visible on the

pin.

2 Insert the U4207A probe into the retention module.

a Ensure proper keying by aligning the Keysight logo on the probe with the one on the retention

module and place the probe end into the retention module.

b Alternate turning each screw on the probe a little until both screws are finger tight like you

would attach a cable to your PC.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 53

Page 54

6 Setting up the W6602A Interposer

NOTE

Step 4 - Connecting the U4207A Probe Pods to the Logic Analyzer Module Pods

Based on the type of DRAM configuration in which you are planning to use the W6602A interposer,

the connection of U4207A probe pods to logic analyzer pods changes.

The W6602A interposer can work in the following configurations of a 200 ball LPDDR4 DRAM:

• An LPDDR4 DRAM used as two 16-bit channels

• An LPDDR4 DRAM used as a single 32-bit channel

For Two 16-bit Channels DRAM Configuration

Two U4207A probe cables and two U4164A logic analyzer modules are needed for a W6602A

interposer used in this type of DRAM configuration setup.

For this type of DRAM configuration setup, you need to use the two U4164A

modules as independent modules, one for each 16-bit channel. This allows

you to have separate master clocks for probing the DRAM’s channel A and B

by using master clocks of each of these two modules.

Connect the pods of the U4207A cables to the logic analyzer module pods are per the mapping given

in the following table. (Even pods of the logic analyzer modules are NOT used.)

For Channel A of DRAM For Channel B of DRAM

U4207A Cable Pods U4164A Logic Analyzer

Pod C of the cable connected

to J2 on interposer

Pod B of the cable connected

to J1 on interposer

Pod A of the cable connected

to J1 on interposer

Pod D of the cable connected

to J2 on interposer

Module 1 Pods

Pod 1 Pod A of the cable connected

Pod 3 Pod D of the cable connected

Pod 5 Pod C of the cable connected

Pod 7 Pod B of the cable connected

U4207A Cable Pods U4164A Logic Analyzer

Module 2 Pods

Pod 1

to J2 on interposer

Pod 3

to J1 on interposer

Pod 5

to J1 on interposer

Pod 7

to J2 on interposer

This mapping of the cable pods and logic analyzer pods is also illustrated with the help of the

following diagram.

54 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 55

Setting up the W6602A Interposer 6

Figure 18 Connections between U4207A cables and Logic Analyzer pods for two 16-bit channels DRAM configuration

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 55

Page 56

6 Setting up the W6602A Interposer

NOTE

For a Single 32-bit Channel DRAM Configuration

Two U4207A probe cables and two U4164A logic analyzer modules are needed for a W6602A

interposer used in this type of DRAM configuration setup.

Connect the pods of the U4207A cables to the logic analyzer module pods are per the mapping given

in the following table. (Even pods of the logic analyzer modules are NOT used.)

For this type of DRAM configuration setup, you need to use the two U4164A modules

combined via cables to form a modules set representing one logical module. Refer to the

installation guide of your logic analyzer module to know how to create a modules set. This

guide is available on the module’s page on

www.keysight.com.

In this modules set, the bottom module acts as the clocking module providing the master

clock for the 32-bit single channel setup.

For a Single 32-bit Channels Configuration

U4207A Cable Pods U4164A Logic Analyzer

Pod C of the cable

connected to J2 on

interposer

Pod B of the cable

connected to J1 on

interposer

Pod A of the cable

connected to J1 on

interposer

Pod D of the cable

connected to J2 on

interposer

Bottom Module Pods

(This is the master module in

the two-modules set))

Pod 1 Pod A of the cable

Pod 3 Pod D of the cable

Pod 5 Pod C of the cable

Pod 7 Pod B of the cable

U4207A Cable Pods U4164A Logic Analyzer Top

Module Pods

(This is the top module in

the two-modules set)

Pod 1

connected to J2 on

interposer

Pod 3

connected to J1 on

interposer

Pod 5

connected to J1 on

interposer

Pod 7

connected to J2 on

interposer

The mapping of the cable pods and logic analyzer pods is also illustrated with the help of the

following diagram.

56 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 57

Setting up the W6602A Interposer 6

NOTE

Figure 19 Connections between U4207A cables and Logic Analyzer pods for a single 32-bit channel DRAM

configuration

In the 32-bit single channel setup, the W6602A interposer probes and uses only one set of CA

signals as this configuration implies that the two CA channels on the DRAM are identical.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 57

Page 58

6 Setting up the W6602A Interposer

W6602A Interposer Footprints Pinout

The diagram below illustrates the pinout of the two connectorless footprints - J1 and J2 on top of a

W6602A interposer.

Figure 20 W6602A Interposer Connectorless Footprints Pinout

58 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 59

W6602A Clock Connectors Pinout

NOTE

The diagram below illustrates the pinout of the five clock connectors - J3, J4, J5, J6, and J7 on top

of a W6602A interposer. As described in a previous section, you connect the U4207A clock

connection flying leads to these connectors.

Setting up the W6602A Interposer 6

Figure 21 W6602A Interposer Clock Connectors Pinout

Since the RESET_N signal is shared between Channel A and B of DRAM, there is only one clock

connector (J6) on the W6602A interposer for the RESET_N signal. Therefore, only one channel

has access to the RESET_N at a time. To allow a channel to access the RESET_N, you need to

connect the appropriate flying lead of U4207A to J6.

To use this clock connector for Channel A of DRAM, connect the violet flying lead of the U4207A

cable (connected to J2) to the J6 connector on interposer.

To use this clock connector for Channel B of DRAM, connect the orange flying lead of the

U4207A cable (connected to J2) to the J6 connector on interposer.

If you are using two separate modules to capture Channel A and Channel B simultaneously, and

need to include RESET in your trigger, then connect RESET to one of the channels and use the

ability to arm one module from another from the trigger menus of the two individual modules.

If the design under test requires visibility of all CKE signals from both channels simultaneously, then

an additional module for each module set will be required to connect to CKE2_CHA and CKE2_CHB

and bring these into the trace capture using flying leads. CKE captured by an additional module can

be seen in the trace and used as scan or trigger qualifiers.

Only signals routed into clock qualifier inputs on the master U4164A module in any module set can

be used as clock qualifiers.

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 59

Page 60

6 Setting up the W6602A Interposer

NOTE

W6602A Clock Qualifier and RESET Connections

The table below describes the connections to be established between the U4207A clock connection

flying leads and the CKE and RESET pin headers of the W6602A clock connectors.

The hardware configurations change depending on the logic analyzer software configuration in

which the interposer is being used. The connectivity is therefore segregated based on a

16-bits channels configurations and a 32-bits channels configuration.

Signals For Channel A in a 16-bits DRAM

CKE1_A or CKE2_A

and

CKE1_B or CKE2_B

RESET Use the purple flying lead of the

configuration

Use the orange flying lead of the

U4207A cable that you connected to

J1 on the W6602A interposer.

Connect this orange flying lead to

either CKE1_A or CKE2_A pin header

(J3 or J5 connector) of W6602A.

(In the Channel A 16-bits software

configuration, this signal is named

CKE1.)

U4207A cable that you connected to

J2 on the W6602A interposer.

Connect this purple flying lead to the

RESET pin header (J6 connector) of

W6602A.

For Channel B in a 16-bits DRAM

configuration

Use the purple flying lead of the

U4207A cable that you connected to

J1 on the W6602A interposer.

Connect this purple flying lead to

either CKE1_B or CKE2_B pin header

(J4 or J7 connector) of W6602A.

(In the Channel B 16-bits software

configuration, this signal is named

CKE1.)

Use the orange flying lead of the

U4207A cable that you connected to

J2 on the W6602A interposer.

Connect this orange flying lead to

the RESET pin header (J6

connector) of W6602A.

For a single 32-bits channels DRAM

configuration

Use the orange flying lead of the U4207A cable

that you connected to J1 on the W6602A

interposer.

Connect this orange flying lead to either CKE1_A

or CKE2_A pin header (J3 or J5 connector) of

W6602A.

(In the 32-bits single channel software

configuration, this signal is named CKE1.)

Use the purple flying lead of the U4207A cable

that you connected to J2 on the W6602A

interposer.

Connect this purple flying lead to the RESET pin

header (J6 connector) of W6602A.

60 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 61

Logic Analyzer Channels to Signals Mapping

NOTE

When you connect the U4207A cables to a Logic Analyzer as per the connection diagram in either

Figure 18 or Figure 19, the logic analyzer channels are mapped to LPDDR4 signals as per the table

displayed below. These signals are automatically configured when you load one of the configuration

files supplied with the Keysight B4661A LPDDR decoder software.

Clock inputs for each logic analyzer pod are highlighted with yellow in these tables.

Clock inputs for logic analyzer pods 3 and 7 are from the U4207A clock connection flying leads.

Table 3 Signals and Logic Analyzer Pods Mapping for a 16-bit channel DRAM configuration

For Channel A

Setting up the W6602A Interposer 6

Logic Analyzer 1

Pod

Pod 1

CLK- CK_c_A CKE1_A

CLK+ CK_t_A CLK- GND

Logic Analyzer 2

Pod

Signals on

Pod

CA5_A

CA2_A DQ3_A DQ6_A DMI1_A

CA4_A ODT_CA_A DQ4_A DQS1_t_A

DQ12_A CS1_A DQ5_A DQ13_A

CA3_A CS0_A DQS0_t_A DQ14_A

DQ11_A CA0_A DMI0_A DQ15_A

DQ10_A CS2_A DQ0_A

DQ9_A CA1_A DQ1_A

Signals on

Pod

DQ15_B

DQ14_B DQ1_B CA1_B DQ10_B

Logic Analyzer 1

Pod

Pod 3

Logic Analyzer 2

Pod

Signals on

Pod

DQ2_A

or

CKE2_A

Signals on

Pod

DQ2_B

For Channel B

Logic Analyzer 1

Pod

Pod 5

CLK+ CKE0_A RESERT_N

Logic Analyzer 2

Pod

Signals on

DQ7_A

Signals on

CS2_B

Pod

Pod

Logic Analyzer 1

Pod

Pod 7

Logic Analyzer 2

Pod

Signals on

Pod

DQ8_A

Signals on

Pod

DQ8_B

DQS1_t_B DQ0_B CS0_B DQ11_B

DQ13_B DMI0_B CA0_B DQ12_B

Pod 1

CLK+ CK_t_B CKE1_B

CLK- CK_c_B CLK+ CKE0_B

Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide 61

DMI1_B DQS0_t_B CS1_B CA3_B

DQ9_B DQ4_B ODT_CA_B CA2_B

Pod 3

Pod 5

DQ6_B DQ5_B CA4_B

DQ7_B DQ3_B CA5_B

CLK- GND RESERT_N

or

CKE2_B

Pod 7

Page 62

6 Setting up the W6602A Interposer

Signals not probed by the Logic Analyzer

The following signals are omitted from the Logic Analyzer connections for the W6602A interposer.

Interposer Signal Name

W6602A DQS0_c_A

DQS1_c_A

DQS0_c_B

DQS1_c_B

62 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 63

Keysight W6600A-series LPDDR4 BGA Interposers

Installation Guide

7 Setting Up the Logic Analyzer

for W6600A-series Interposers

Before You Start / 64

Loading a Configuration File / 65

Troubleshooting Problems with Thresholds and Sample Positions Setup / 66

Page 64

7 Setting Up the Logic Analyzer for W6600A-Series Interposers

Before You Start

Ensure that all the software components listed in the topic “Hardware and Software

Requirements" on page 16 and “Hardware and Software Requirements" on page 26 are installed on

the host computer and the required software licenses are also obtained and installed.

64 Keysight W6600A-series LPDDR4 BGA Interposers Installation Guide

Page 65

Loading a Configuration File

NOTE

NOTE

When you install the Keysight B4661A Memory Analysis software package, a set of XML LPDDR

configuration files is installed as a part of the standard unlicensed features of this package. Based on

the software configuration (see page 12 and page 23) in which you want to use your W6600A-series

interposer with the logic analyzer, you can load an appropriate configuration file from this set in the