Page 1

Keysight V8486A

Power Sensor

User’s Guide

Page 2

Notices

Copyright Notice

© Keysight Technologies 1999-2018

No part of this manual may be reproduced in

any form or by any means (including electronic

storage and retrieval or translation into a foreign language) without prior agreement and

written consent from Keysight Technologies as

governed by United States and international

copyright laws.

Manual Part Number

08486-90131

Edition

Edition 6, March 1, 2018

Printed in:

Printed in Malaysia

Published by:

Keysight Technologies

Bayan Lepas Free Industrial Zone,

11900 Penang, Malaysia

Technology Licenses

The hard ware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance

with the terms of such license.

Declaration of Conformity

Declarations of Conformity for this product

and for other Keysight products may be downloaded from the Web. Go to http://www.key-

sight.com/go/conformity. You can then search

by product number to find the latest Declaration of Conformity.

U.S. Government Rights

The Software is “commercial computer software,” as defined by Federal Acquisition Regulation (“FAR”) 2.101. Pursuant to FAR 12.212

and 27.405-3 and Department of Defense FAR

Supplement (“DFARS”) 227.7202, the U.S.

government acquires commercial computer

software under the same terms by which the

software is customarily provided to the public.

Accordingly, Keysight provides the Software to

U.S. government customers under its standard

commercial license, which is embodied in its

End User License Agreement (EULA), a copy of

which can be found at http://www.key-

sight.com/find/sweula. The license set forth in

the EULA represents the exclusive authority by

which the U.S. government may use, modify,

distribute, or disclose the Software. The EULA

and the license set forth therein, does not

require or permit, among other things, that

Keysight: (1) Furnish technical information

related to commercial computer software or

commercial computer software documentation that is not customarily provided to the

public; or (2) Relinquish to, or otherwise provide, the government rights in excess of these

rights customarily provided to the public to

use, modify, reproduce, release, perform, display, or disclose commercial computer software or commercial computer software

documentation. No additional government

requirements beyond those set forth in the

EULA shall apply, except to the extent that

those terms, rights, or licenses are explicitly

required from all providers of commercial

computer software pursuant to the FAR and

the DFARS and are set forth specifically in

writing elsewhere in the EULA. Keysight shall

be under no obligation to update, revise or

otherwise modify the Software. With respect

to any technical data as defined by FAR 2.101,

pursuant to FAR 12.211 and 27.404.2 and

DFARS 227.7102, the U.S. government

acquires no greater than Limited Rights as

defined in FAR 27.401 or DFAR 227.7103-5 (c),

as applicable in any technical data.

Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED “AS IS,” AND IS SUBJECT

TO BEING CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE

LAW, KEYSIGHT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, WITH

REGARD TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS OR FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES

IN CONNECTION WITH THE FURNISHING,

USE, OR PERFORMANCE OF THIS DOCUMENT OR OF ANY INFORMATION CONTAINED

HEREIN. SHOULD KEYSIGHT AND THE USER

HAVE A SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS COVERING THE

MATERIAL IN THIS DOCUMENT THAT CONFLICT WITH THESE TERMS, THE WARRANTY

TERMS IN THE SEPARATE AGREEMENT

SHALL CONTROL.

Safety Information

CAUTION

A CAUTION notice denotes a hazard. It calls

attention to an operating procedure, practice,

or the like that, if not correctly performed or

adhered to, could result in damage to the

product or loss of important data. Do not proceed beyond a CAUTION notice until the indicated conditions are fully understood and met.

WARNING

A WARNING notice denotes a hazard. It calls

attention to an operating procedure, practice,

or the like that, if not correctly performed or

adhered to, could result in personal injury or

death. Do not proceed beyond a WARNING

notice until the indicated conditions are fully

understood and met.

2 Keysight V8486A User’s Guide

Page 3

Certification

Warranty

Keysight Technologies certifies that this product met its published specifications at the time of

shipment. Keysight further certifies that its calibration measurements are traceable to the United

States National Institute of Standard and Technology (formerly National Bureau of Standards), to

the extent allowed by that organization’s calibration facility, and to the calibration facilities of other

International Standards Organization members.

This Keysight Technologies instrument product is warranted against defects in material and

workmanship for a period of 3 years from date of shipment. During the warranty period, Keysight

Technologies will at its option, either repair or replace products which prove to be defective. For

warranty service or repair, this product must be returned to a service facility designated by

Keysight Technologies. Buyer shall prepay shipping charges to Keysight Technologies and Keysight

Technologies shall pay shipping charges, duties, and taxes for products returned to Keysight

Technologies from another country. Keysight Technologies warrants that its software and firmware

designated by Keysight Technologies for use with an instrument will execute its programming

instructions when properly installed on that instrument. Keysight Technologies does not warrant

that the operation of the instrument, or firmware will be uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside of the environmental specifications for the product, or improper site

preparation or maintenance. NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. KEYSIGHT

TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

Keysight V8486A User’s Guide

3

Page 4

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES. KEYSIGHT

TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL

THEORY.

Safety Considerations

Read the information below before using this instrument.

The following general safety precautions must be observed during all phases of operation, service,

and repair of this instrument. Failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards for design, manufacture, and intended use of

the instrument. Keysight Technologies assumes no liability for the customer’s failure to comply

with these requirements.

4 Keysight V8486A User’s Guide

Page 5

Environmental Conditions

The V8486A is designed for indoor use and in an area with low condensation. The table below

shows the general environmental requirements for this instrument.

Environmental condition Requirement

Temperature

Humidity

Altitude

Operating condition

– 0 °C to 55 °C

Storage condition

– –40 °C to 70 °C

Operating condition

– Up to 95%

Storage condition

– Up to 95% RH at 40°C (non-condensing)

Operating condition

– Up to 4550 meters

Storage condition

– Up to 7,600 meters

Keysight V8486A User’s Guide 5

Page 6

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This instrument complies with the WEEE Directive (2002/96/EC) marking requirement. This affixed

product label indicates that you must not discard this electrical or electronic product in domestic

household waste.

Product category:

With reference to the equipment types in the WEEE directive Annex 1, this instrument is classified

as a “Monitoring and Control Instrument” product.

The affixed product label is as shown below.

Do not dispose in domestic household waste.

To return this unwanted instrument, contact your nearest Keysight Service Center, or visit http://

about.keysight.com/en/companyinfo/environment/takeback.shtml for more information.

Sales and Technical Support

To contact Keysight for sales and technical support, refer to the support links on the following

Keysight websites:

– www.keysight.com/find/waveguidepowersensors

(product-specific information and support, software and

documentation updates)

– www.keysight.com/find/assist

(worldwide contact information for repair and service)

6 Keysight V8486A User’s Guide

Page 7

Table of Contents

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Limitation of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Exclusive Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC . . . . . . . . . . 6

Product category: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sales and Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1Introduction

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Recommended calibration interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Initial inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Interconnections and calibration . .

age and Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stor

Original packaging . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 General Operation

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operating precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power meter calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Power measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Modulation effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Linearity correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Specifications and Characteristics

Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Calibration Factor (C

4Service

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Zero set performance verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power linearity per

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Repair and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

formance verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Keysight V8486A User’s Guide 7

Page 8

List of Figures

List of Tables

Figure 1-1

Figure 2-1

Figure 2-2

Figure 4-1

Figure 4-2

Table 2-1 Cal factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 3-1

Table 4-1

Keysight V8486A power sensor with accessories and hardware

Precision V-band interface on the front of the power sensor . .

Typical influence of temperature on sensitivity . . . . . . . . . . . . . . . . .19

Zero set performance verification equipment setup . . . . . . . . . . . . . . 26

Power linearity performance verification equipment setup . . . . . . . . 28

Calibration factor uncertainty at 1 mW (0 dBm) . . . . . . . . . . . . . . . . . 23

Replaceable parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . 10

. . . . . 17

8 Keysight V8486A User’s Guide

Page 9

Keysight V8486A Power Sensor

User’s Guide

1 Introduction

General Information 10

Installation 12

Storage and Shipment 13

This chapter provides an overview of the V8486A power sensor and its general information.

9

Page 10

1Introduction

General Information

This User’s guide contains information about initial inspection and operation of the Keysight

V8486A power sensor.

Keysight V8486A

power sensor

Flange screws

(1390-0671)

Figure 1-1 Keysight V8486A power sensor with accessories and hardware

Warranty

The power sensor is warranted and certified as indicated on page 3 of this manual. Do not open

the power sensor. Any attempt to disassemble the power sensor will void warranty.

Description

The Keysight V8486A is a diode-based power sensor. It measures power levels in a range from –30

dBm to +20 dBm. (Specifications for the power sensor are in Table 3-1 .) The Keysight V8486A

measures at frequencies from 50 GHz to 75 GHz.

The power is determined from the ac voltage developed across the waveguide termination from the

microwave source. The diodes convert this ac voltage to dc. The dc voltage produced is

proportional to the square of the ac voltage. The dc voltage thus generated is a very low-level

voltage and requires amplification before it can be transferred via the sensor cable to the power

meter.

Hex ball driver

(8710-1539)

10

The amplification is provided by an input amplifier assembly which consists of a chopper (sampling

gate) and an input amplifier. The dc voltage is routed to the chopper circuit which converts the

Keysight V8486A User’s Guide

Page 11

Introduction 1

NOTE

CAUTION

ow-level dc voltage to an ac voltage. The chopper is driven by a square wave generated by the

l

power meter. The result is an ac output signal proportional to the dc input. The ac signal is then

amplified by the input amplifier. The relatively high-level ac signal output can now be routed by

standard cables.

The Keysight V8486A power sensor is compatible with the following power meters:

Keysight 435B Keysight E1416A

Keysight 436A Keysight E4418A/B

Keysight 437B Keysight E4419A/B

Keysight 438A Keysight 70100A

To obtain optimum accuracy for power measurements above +10 dBm, when used with the

Keysight E4418A and Keysight E4419A power meters, a firmware upgrade will be required. Refer

to your Keysight E4418A and Keysight E4419A power meter’s user’s guide for instructions on

how to obtain the revision of the firmware currently installed in the unit. The firmware revision

required is A1.03.00 (or above) for the Keysight E4418A and A2.03.00 (or above) for the Keysight

E4419A. Contact your local Keysight Technologies Sales and Service Office for more information.

In application, the power sensor is connected between a microwave source and a compatible

power meter. The power sensor provides a matched load for the microwave source for very low

SWR. The power meter indicates the power dissipated in the load in μW, mW or in dBm.

Do not disassemble the power sensor. The power sensor is extremely static-sensitive and can be

easily damaged.

Accessories

Included is a hex ball driver plus the waveguide mounting screws. Refer to Figure 1-1 for a visual

check of what should be included with your power sensor.

Recommended calibration interval

Keysight Technologies recommends a one-year calibration cycle for the V8486A power sensor.

Keysight V8486A User’s Guide

11

Page 12

1Introduction

Installation

Initial inspection

Inspect the shipping container for damage. If the shipping container or packaging material is

damaged, it should be kept until the contents of the shipment have been checked mechanically

and electrically. If there is mechanical damage or if the instrument does not pass the performance

tests, notify the nearest Keysight Technologies office. Keep the damaged shipping materials (if any)

for inspection by the carrier and a Keysight Technologies representative.

Interconnections and calibration

The Keysight V8486A power sensor has two inputs: a Type-N connector and a waveguide flange.

During calibration, the Type-N connector is connected to the calibration port of the power meter.

During measurement, the waveguide flange is connected to the device under test.

CAUTION

Connect the power sensor by turning only the nut on the Type-N connector. Damage can occur if

torque is applied to the power sensor body.

The waveguide flanges can be damaged if the flange screws are over-tightened. Do not fully

tighten one flange screw without tightening the one opposite. First insert screws and tighten

until finger tight. If you are using the hex ball driver, hold the driver between thumb and

forefinger while incrementally tightening screws opposite each other until reaching a maximum

torque of 0.42 N x m.

Use the protective packaging provided with the power sensor to protect it from dirt and

mechanical damage whenever it is not in use. Any burrs, dents or dirt on the flange or waveguide

surface will increase the SWR and change the Cal Factor.

Refer to the power meter operating and service manual for interconnecting instructions.

12

Keysight V8486A User’s Guide

Page 13

Storage and Shipment

Original packaging

Containers and materials identical to those used in factory packaging are available through

Keysight Technologies offices. If the instrument is being returned to Keysight Technologies for

servicing, attach a tag indicating the type of service required, return address, model number, and

serial number. Also, mark the container FRAGILE to assure careful handling. In any

correspondence, refer to the instrument by model number and serial number.

Introduction 1

Keysight V8486A User’s Guide

13

Page 14

1Introduction

THIS P

AGE HAS BEEN INTENTIONALLY LEFT BLANK.

14

Keysight V8486A User’s Guide

Page 15

Keysight V8486A Power Sensor

User’s Guide

2 General Operation

Operation 16

This chapter provides the V8486A general operation information on how to check and prepare your

instrument for operation.

15

Page 16

2 General Operation

Operation

Operating precautions

WARNING

BEFORE CONNECTING THE POWER SENSOR TO OTHER INSTRUMENTS, ensure that all

instruments are connected to the protective (earth) ground. Any interruption of the

protective earth grounding will cause a potential shock hazard that could result in personal

injury and cause damage to the power sensor.

CAUTION

If the following energy and power levels are exceeded, the power meter system may be

damaged.

– Maximum Average Power: 200 mW

– Maximum Peak Power: 40W

[a] 10 micro-second pulse, 0.5% duty cycle or equivalent such that 200 mW maximum average power and 40W peak power are not exceeded.

The power sensor has a precision machined V-band waveguide interface. The size and position of

the aperture, the alignment holes and pins, and the flatness of the mating faces are all very tightly

controlled. Refer to Figure 2-1.

In order to get the best possible measurement results the mating part must be of similar quality.

Connection to a V-band waveguide component in which the interface dimensions are not

accurately controlled can lead to increased SWR, inaccurate Cal Factor correction, and/or

repeatability problems. In addition, connections to a well-manufactured but dirty part can lead to

any of the above measurement problems. Conversely, always insuring connections to parts with

clean, high-quality waveguide interfaces will lead to accurate power measurements over the life of

the product.

[a]

CAUTION

16

Connection to a V-band waveguide component with a dirty, or damaged flange (for example

loose particulates, raised metal burrs or bent alignment pins) can damage the precision

interface of the power sensor. Always inspect and clean the mating part prior to connection.

Use the protective packaging provided with the sensor to protect the waveguide connector from

dirt and mechanical damage whenever it is not in use. Any burn, dents or dirt on the flange or

waveguide surface will increase the SWR and change the Cal Factor.

The Type-N connector plastic bead deteriorates when contacted by any chlorinated or aromatic

hydrocarbons such as acetone, trichlorethylene, carbon tetrachloride, benzene, etc. Clean the

connector face with a cotton swab saturated in isopropyl alcohol.

Keysight V8486A User’s Guide

Page 17

Figure 2-1 Precision V-band interface on the front of the power sensor

1.905

3.810

2× ø 1.588

ø 14.288

Bolt circle

2× ø 1.660

Units in mm

4× 4-40 UNC-2B

NOTE

Power meter calibrations

The procedure for calibration may be different for each compatible power meter. Follow the

calibration directions given in your power meter manual.

General Operation 2

Power measurements

To correct for varying responses at different frequencies a cal factor chart is included on the power

sensors. To use the cal factor at the frequency of interest, adjust the power meter's CAL FACTOR

control according to the instructions in the power meter's operating and service manual. This will

automatically correct the power readings.

If you are using a Keysight 435B or Keysight 436A, the minimum cal factor setting is 85% and the

maximum is 100%. If the cal factor setting for your frequency of interest is below the meter's

minimum or above the meter's maximum, set the cal factor control to 100%, and divide the reading

in watts units by the decimal equivalent of the cal factor. For example, if the cal factor is 75%,

divide the reading by 0.75. (This will result in a larger value of power than that displayed by the

meter.)

If the cal factor is 104%, divide the reading by 1.04. (This will result in a smaller value of power

than that displayed by the meter.)

If reading in dBm, use the chart in Table 2-1 to convert the cal factor to dB and add this value to

the reading. Interpolate for values between those shown. As above, the cal factor control should be

set to 100%. If the cal factor is 75%, add 1.25 dB to the displayed value. On the other hand, if the

cal factor is 104% subtract 0.17 dB from the displayed reading.

The above procedure has eliminated some mathematical steps; the following formula may be of

some use:

Correct dBm = Reading dBm – 10 × Log

{Cal Factor (decimal)}.

10

Keysight V8486A User’s Guide

17

Page 18

2 General Operation

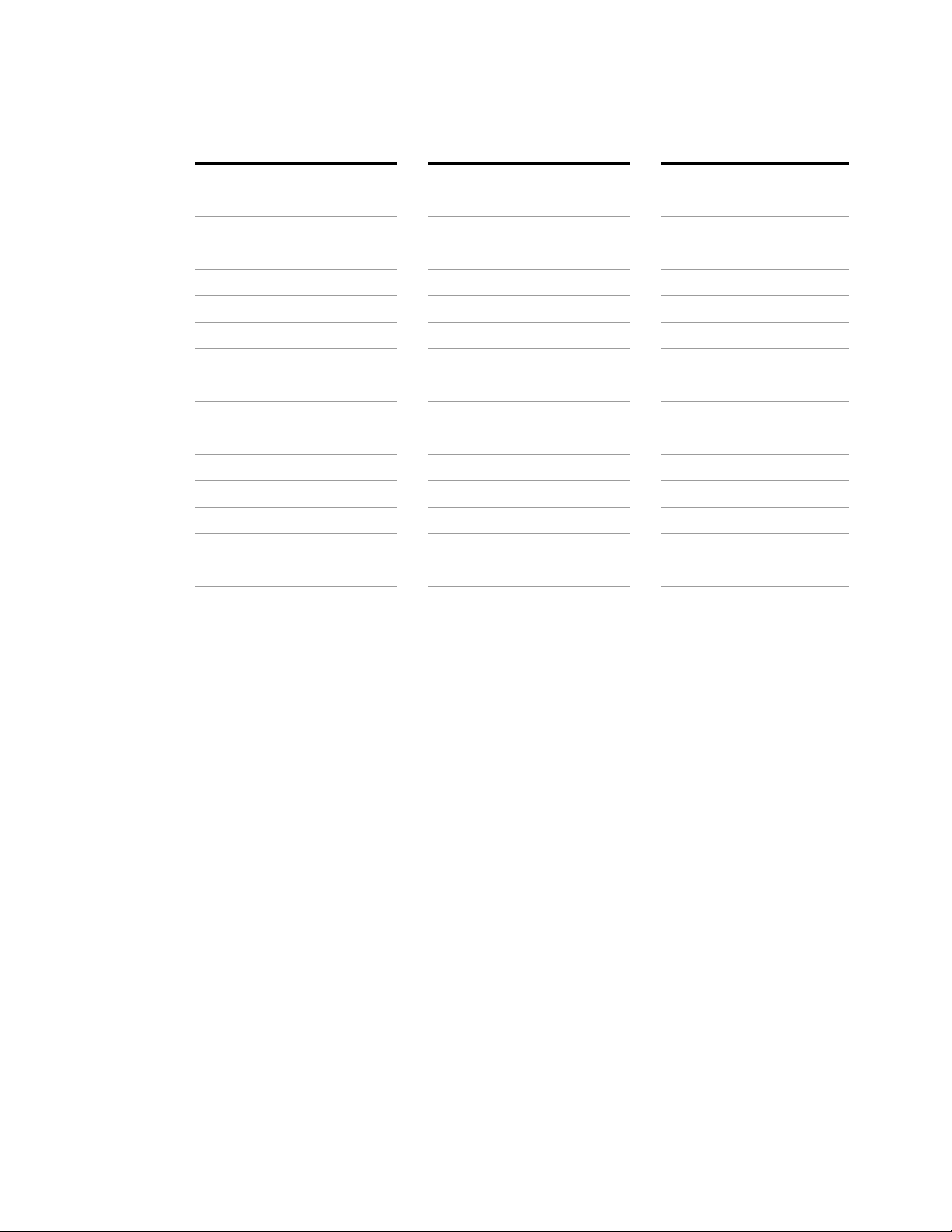

Tab le 2-1 Cal factor

Cal factor dB Cal factor dB Cal factor dB

70% 1.549 85% 0.706 115% –0.607

71% 1.487 101% −0.043 116% −0.645

72% 1.427 102% −0.086 117% −0.682

73% 1.367 103% −0.128 118% −0.719

74% 1.308 104% −0.170 119% −0.755

75% 1.249 105% −0.212 120% –0.792

76% 1.192 106% −0.253 121% −0.828

77% 1.134 107% −0.294 122% −0.864

78% 1.079 108% −0.334 123% −0.899

79% 1.024 109% −0.374 124% −0.934

80% 0.969 110% −0.414 125% −0.969

81% 0.915 111% −0.453 126% −1.004

82% 0.862 112% −0.492 127% –1.038

83% 0.809 113% −0.531 128% –1.072

84% 0.757 114% −0.569 129% –1.106

130% –1.139

18

Keysight V8486A User’s Guide

Page 19

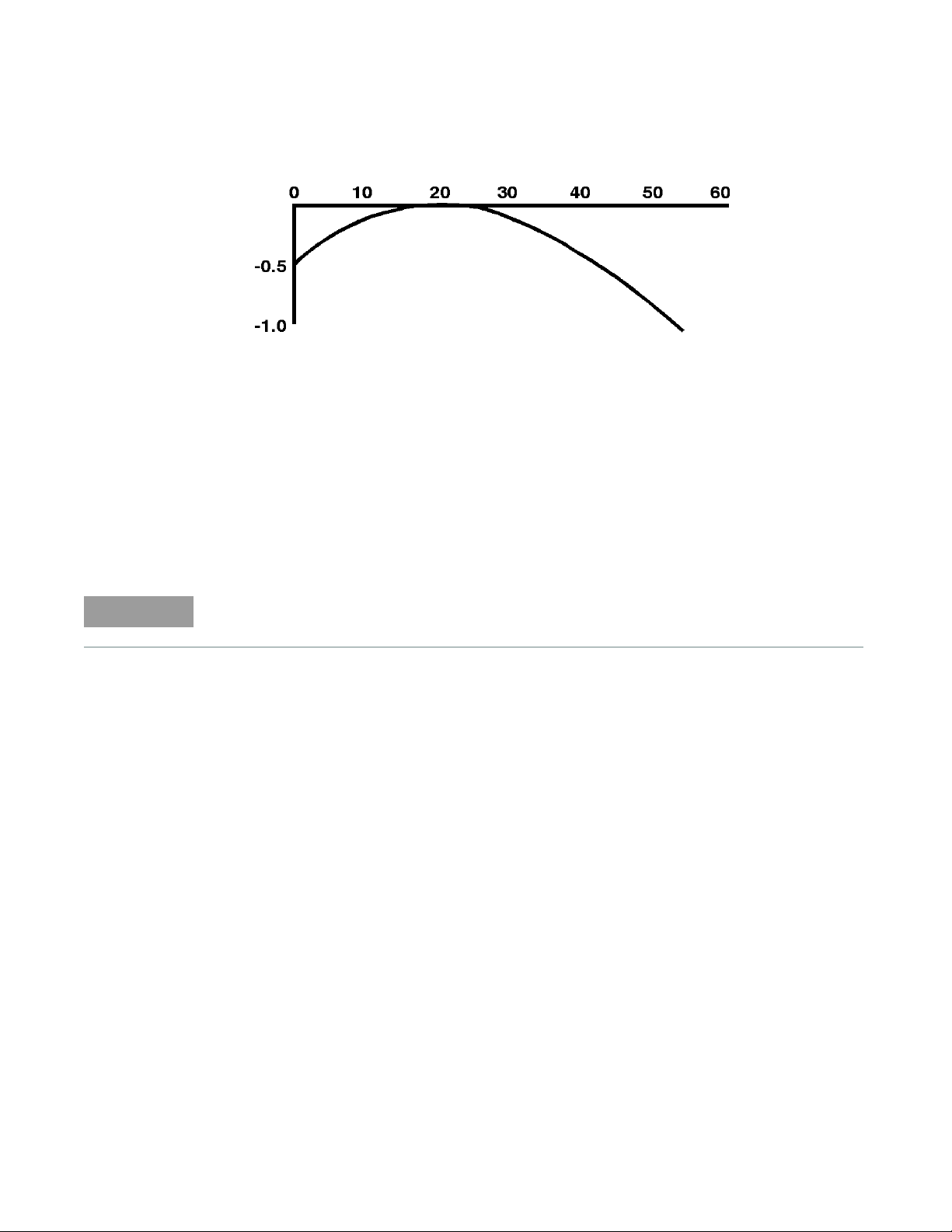

Figure 2-2 Typical influence of temperature on sensitivity

Sensitivity change, dB

Temperature, °C

NOTE

The sensitivity of the power sensor is influenced by ambient temperature. The sensor should be

calibrated at the temperature of operation to obtain the most accurate results. Typical temperature

sensitivity variations are shown in Figure 2-2.

Operating instructions

General Operation 2

To operate the power sensor, refer to the operating instructions in of the power meter operating

and service manual.

If having an open RF connection on your system is a concern, terminate the sensor Type-N

calibration port with a 50 Ω load.

Modulation effects

When measuring microwave sources that are modulated at the chopper frequency (nominally 220

Hz for the Keysight 43X family and 217 Hz for the Keysight E4418A/B and Keysight E4419A/B), or

at the first or second harmonic or submultiples of the chopper frequency, beat notes will occur.

Unless the modulation rate is exactly the chopper frequency, they can usually be eliminated by

averaging since the amplitudes are centered on the actual power. These frequencies may also be

avoided by changing the modulation frequency slightly, if possible.

If you are using a Keysight 437B, Keysight E4418A/B or Keysight E4419A/B Power Meter, a filter

setting of 128 will minimize most beat note interference. To minimize beat note interference using

a Keysight 438A Power Meter select a filter number of at least 7.

Linearity correction

For most Keysight 8480 series power sensors the correct (A type or D type) linearity correction

table is automatically selected. However, when you use the Keysight V8486A power sensor with

Keysight EPM power meters, you must override the automatic selection and select the D-type

correction. This procedure provides optimum accuracy when making power measurements

>+10dBm. Subsequent connection of another

Keysight V8486A User’s Guide

A-type sensor will result in a warning message stating the “Linearity Override May be Required”.

To select the linearity type to be applied:

19

Page 20

2 General Operation

Keysight E4418B

Press [System Inputs], Tables, Linearity ATyp DTyp.

Keysight E4419B

Press [System Inputs], Tables, A Linearity ATyp DTyp or B Linearity ATyp DTyp.

NOTE

For use with the Keysight E4418A and Keysight E4419A power meters, a firmware upgrade will

be required. Refer to your Keysight E4418A and Keysight E4419A power meter’s user’s guide for

instructions on how to obtain the revision of the firmware currently installed in the unit. The

firmware revision required is A1.03.00 (or above) for the Keysight E4418A and A2.03.00 (or

above) for the Keysight E4419A. Contact your local Keysight Technologies Sales and Service

Office for further information.

20

Keysight V8486A User’s Guide

Page 21

Keysight V8486A Power Sensor

User’s Guide

3 Specifications and

Characteristics

Specifications and Characteristics 22

Calibration Factor (CF) 23

21

Page 22

3 Specifications and Characteristics

Specifications and Characteristics

For the characteristics and specifications of the V8486A Power Sensor, refer to the datasheet at

https://literature.cdn.keysight.com/litweb/pdf/5991-3676EN.pdf.

22

Keysight V8486A User’s Guide

Page 23

Calibration Factor (CF)

The CAL FACTOR compensates for the frequency response of the sensor. CAL FACTOR data is

provided on a label attached to the sensor cover. Uncertainties of the CAL FACTOR data are listed

in Table 3-1. ISO expanded uncertainties are calculated based on an NIST-traceable transfer

standard and an analysis of factory test system uncertainties. To use CAL FACTOR data during

power measurements, see “Power measurements” on page 17.

Table 3-1 Calibration factor uncertainty at 1 mW (0 dBm)

Specifications and Characteristics 3

Frequency (GHz)

50 4.8

51 6.1

52 5.9

53 5.9

54 5.9

55 4.6

56 6.1

57 6.1

58 6.2

59 6.2

60 4.7

61 6.2

62 6.1

63 6

64 6

65 4.5

66 6.6

ISO expanded uncertainty %

[a]

(coverage factor k=2)

[a] Refer to Application Note 64-1A: Keysight literature number 5965-6630E, “Fundamentals of RF and Microwave

Power Measurements” for more information regarding ISO expanded uncertainty.

Keysight V8486A User’s Guide

67 6.7

68 6.7

69 6.6

70 4.4

71 6.7

72 6.8

73 7.0

74 7.3

75 5.1

23

Page 24

3 Specifications and Characteristics

THIS P

AGE HAS BEEN INTENTIONALLY LEFT BLANK.

24

Keysight V8486A User’s Guide

Page 25

Keysight V8486A Power Sensor

User’s Guide

4 Service

Performance Tests 26

Replaceable Parts 30

This chapter provides information on the V8486A performance tests and service.

25

Page 26

4Service

Performance Tests

This section does not establish SWR test procedures since there are several test methods and

different equipment available for testing the SWR or reflection coefficient. Therefore, the actual

accuracy of the test equipment, all source match corrections, and all harmonics must be

accounted for when measuring against instrument specifications to determine a pass or fail

condition.

To measure the SWR across the waveguide band, use a directional coupler and detector selected

for the band of interest. The directional coupler should have a directivity greater than 36 dB, such

as the Keysight V752C/D. The detector should have greater than 0.4 mV/μW sensitivity and should

be calibrated with a rotary vane attenuator with an accuracy of 2%. Incident power should be less

than +20 dBm. A convenient source is a frequency multiplier driven by a Keysight 8360 B-Series

swept signal generator.

To check the calibration factor, the power sensor should be compared with another recently

calibrated power sensor. The source should be leveled with a reference coupler that has low SWR

and high directivity to monitor or level the incident power.

For calibration factor and error analysis we suggest Keysight Application Note 64-1A: Keysight

literature number 5965-6630E, "Fundamentals of RF and Microwave Power Measurements".

Zero set performance verification

This performance verification is carried out to verify that a minimal amount of residual offset error is

present after zeroing has been performed. The offset error is caused by contamination from several

sources including the noise of the device-under-test (DUT) itself. Zero set is the difference between

the power levels indicated by the DUT, after executing zeroing and the true zero power. Ideally, this

difference should be zero.

This performance test requires a compatible Keysight power meter with the DUT and a computer

with the Keysight IO Libraries Suite installed.

System specification : ±200 nW (for V/W8486A), tested at 50 MHz

Recommended power meter : EPM (N1913A/ 14A, E4418B/ 19B), EPM-P

Procedure

1 Connect the DUT (V/W8486A) to the power meter as shown in Figure 4-1.

(E4416A/ 17A), and P-series (N1911A/ 12A)

power meters

26

DUT

Figure 4-1 Zero set performance verification equipment setup

Keysight V8486A User’s Guide

Page 27

Service 4

2 Warm up the DUT for approximately 30 minutes.

3 Launch the Interactive IO on the Keysight IO Libraries Suite to send SCPI commands to the

DUT.

4 Reset the power meter to a known state by sending "*RST" command, followed by

"SYST:PRES" command to pre-set the meter's output to default value.

5 Connect the DUT to the power meter 1 mW calibrator and perform zeroing for the DUT by

sending "CAL:ZERO:AUTO ONCE". (Use the recommended adapter for respective model)

6 Perform calibration for the DUT by sending "CAL:AUTO ONCE".

7 Set the frequency of the DUT to 50 MHz by sending "FREQ 50MHz".

8 Enable auto-averaging for the DUT by sending "AVER:COUN:AUTO ON".

9 Change the power measurement unit of the DUT to watt by sending "UNIT:POW W".

10 Disconnect the DUT from the power meter 1 mW calibrator.

11 Perform zeroing for the DUT by sending "CAL:ZERO:AUTO ONCE".

12 Set the DUT to the single trigger mode by sending "INIT:CONT OFF".

13 Read the noise level of the DUT by sending "READ" and then record the reading.

14 Repeat step 13 for 10 times and then calculate the mean value of the readings.

15 Compare the calculated mean value to the system specification. If the test fails, refer to “Repair

and adjustments” on page 30.

Power linearity performance verification

The power linearity performance verification measures the relative linearity error of the V/W8486A.

All measurements are performed at 50 MHz. The reference power level for the linearity

measurement is 0 dBm for the V8486A and W8486A.

This performance verification requires the following equipment:

– signal generator (N5182A)

– thermocouple-based average power sensor, as a reference sensor (N8481A/5A/7A)

– power meter (E4416/7A)

– power splitter (11667A)

–amplifier

– step attenuators (8494H and 8496H)

– attenuator/switch driver (11713B)

Procedure

1 Turn on the signal generator and power meter (with the reference sensor connected). Connect

the DUT (V/W8486A) to the power meter. Allow them to warm up for approximately an hour.

2 Zero and calibrate the DUT using the reference sensor with the power meter.

3 Connect the power splitter to the RF output of the signal generator. The equipment setup is as

shown in Figure 4-2.

Keysight V8486A User’s Guide

27

Page 28

4Service

Amplifier

Signal generator

10 dB step attenuator

1 dB step attenuator

Power splitter

CAUTION

DUT

Power meter

Reference

sensor

Attenuator/

switch driver

(Optional)

Figure 4-2 Power linearity performance verification equipment setup

4 Set the continuous wave signal frequency of the signal generator, DUT, and reference sensor to

50 MHz. Set DUT to AVERAGE ONLY mode.

5 Start tuning the signal generator and/or attenuator/switch driver (optional) until the DUT

measures the power level as close as 0 dBm. Record the values as P

at 0 dBm and P

DUT

ref

at 0

dBm.

Do not exceed the maximum input power (27 dBm) of the power splitter to avoid damage to

the power splitter.

6 Record the power measured by the power meter for both DUT and reference power sensor as

as P

P

DUT

7 Normalize both P

respectively.

ref

DUT

and P

to the power measured at 0 dBm, based on the following

ref

equation.

Normalization Measured power (P

DUT/ref

) Measured power at 0 dBM (P

DUT/ref at 0 dBm

)+=

28

8 Calculate the linearity error of the DUT for the power level using the following equations.

Linearity error (dB) [P

Linearity error (%) Antilog

]

DUT

norm to 0 dBm

[P

--------------------------------------------------------------------------------------------

]

DUT

norm to 0 dBm

[P

–=

]

ref

norm to 0 dBm

[P

–

ref

10

]

norm to 0 dBm

×=

1– 100

9 Compare and record the calculated linearity error against the system linearity error

specifications.

Keysight V8486A User’s Guide

Page 29

Service 4

System linearity error specification DUT error2Ref sensor error

2

+=

System linearity error specification (2%)2(0.8%)

2

+2.07%±==

10 Repeat step 6 to step 9 by sweeping through the warranted power levels for power linearity test

as in the datasheet at 50 MHz.

11 Repeat step 5 to step 11 for normal mode. If the verification fails, refer to “Repair and

adjustments” on page 30.

12 The linearity system specification is calculated using the root sum of the squares (RSS) method

by considering the error caused from reference sensor used and the DUT error in the system at

50 Mhz. The error specification caused by the reference sensor and the DUT can be found in

their respective datasheet. The RSS error specification calculation is computed by using

following equation.

Example for the DUT measured at 50 Mhz, 20 dBm:

– DUT used is V8486A

– Reference sensor used is N8481A

Keysight V8486A User’s Guide

29

Page 30

4Service

Replaceable Parts

The part numbers of the hex ball driver and the hardware are listed in Figure 1-1. In addition, the

following protective parts are replaceable:

Tab le 4-1 Replaceable parts

Part number Description Usage

1401-0214 protective cap Type-N connector

08486-40103 protective cover V-band waveguide flange

There are no other replaceable parts for this product.

Repair and adjustments

Do not attempt to repair or adjust the power sensor. Due to the extreme static sensitivity of the

power sensor, customer repair is not recommended. If your power sensor should fail or need

calibration, return it to Keysight Technologies.

CAUTION

Do not disassemble the power sensor. The power sensor is extremely static sensitive and

can be easily damaged. If the power sensor shows evidence of attempted customer repair,

the warranty may be voided.

30

Keysight V8486A User’s Guide

Page 31

Page 32

This information is subject to change

without notice. Always refer to the

English version at the Keysight

website for the latest revision.

© Keysight Technologies 1999-2018

Edition 6, March 1, 2018

Printed in Malaysia

*08486-90131*

08486-90131

www.keysight.com

Loading...

Loading...