Page 1

Keysight TS-5020 Automotive Electronics Functional Test System

Wiring Guide And

Hardware Reference

Page 2

Page 3

Page 4

Notices

© Keysight Technologies 2006 - 2015

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Keysight Technologies as governed by United

States and international copyright laws.

Manual Part Number

E2240-90001

Edition

Edition 4, March 2015

Printed in Malaysia

Keysight Technologies Microwave Products

(Malaysia) Sdn. Bhd.

Bayan Lepas Free Industrial Zone

11900 Penang, Malaysia

Technical Assistance

You can find information about technical

and professional services, product support,

and equipment repair and service on the

Web:

http://www.keysight.com/contacts/English/noscript.html

Double-click the link to Tes t & Me a s u r e -

ment. Select your country from the

drop-down menus. The Web page that

appears next has contact information specific for your country.

If you do not have access to the Internet,

call one of the numbers in Ta b l e 1.

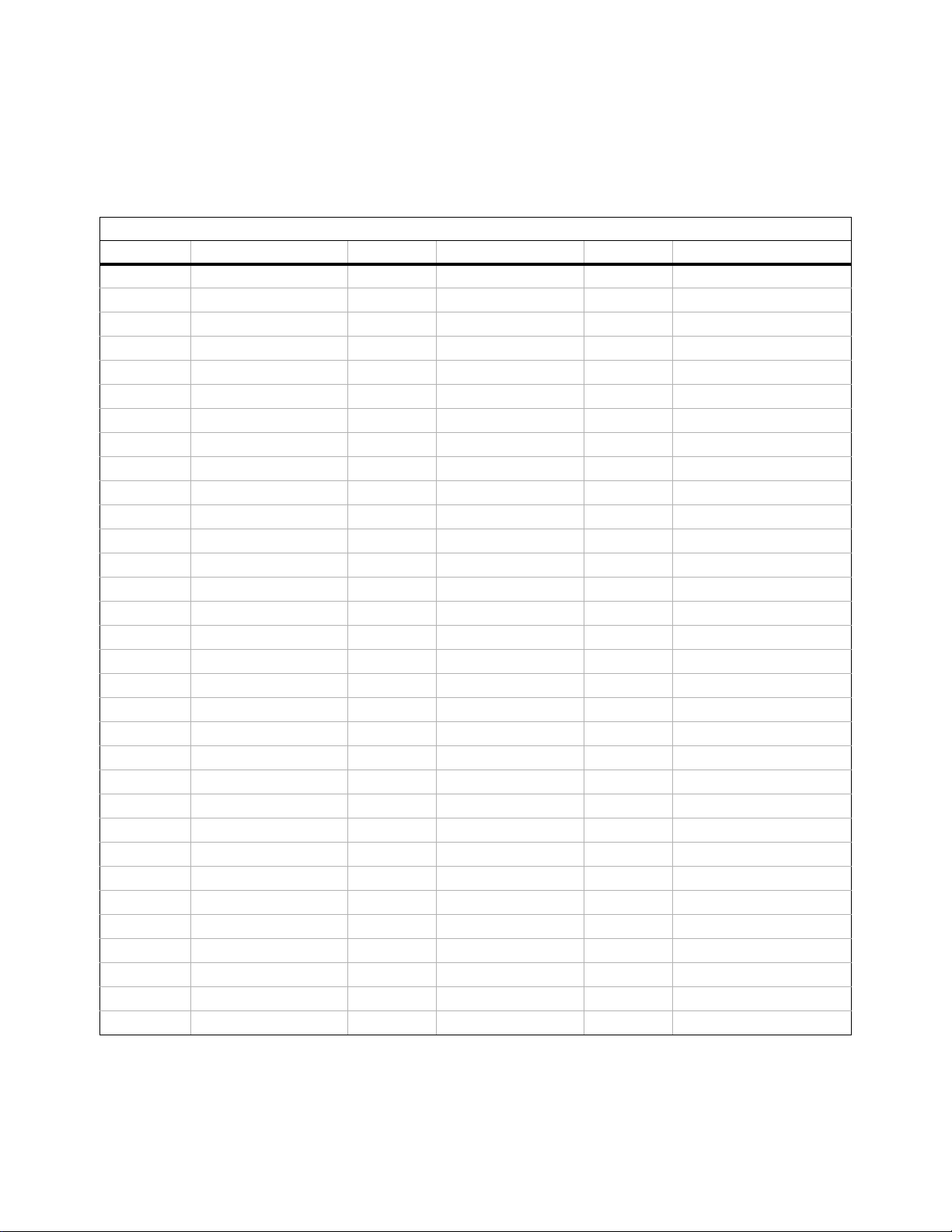

Tab l e 1 Keysight Call Centers

United States

and Canada:

Europe: (41 22) 780 8111

Japan: Measurement

Latin America: 305 269 7548

Asia-Pacific: (85 22) 599 7777

United States

and Canada:

Te s t a n d

Measurement Call

Center

(800) 452 4844

(toll-free in US)

Assistance Center

(81) 0426 56 7832

Te s t a n d

Measurement Call

Center

(800) 452 4844

(toll-free in US)

Page 5

Contents

1 Legal Information

Legal Information 1-2

Warranty 1-2

Technology Licenses 1-2

Restricted Rights Legend 1-2

Service And Support 1-3

Keysight On The Web 1-3

Keysight By Phone 1-3

2 Safety and Regulatory Information

Safety Information 2-2

Safety Summary 2-2

Safety Notice 2-2

General 2-2

Environmental Conditions 2-3

Before Applying Power 2-3

Ground The System 2-4

Fuses 2-4

Operator Safety Information 2-4

Safety Symbols and Regulatory Markings 2-5

Electrostatic Discharge (ESD) Precautions 2-7

End of Life: Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC 2-8

3 System Overview

System Intended Use 3-2

Instructions For Use 3-2

Test System Specifications and Capabilities 3-3

Test Capabilities – Measurement Sample Methods 3-4

System Capability DC Accuracy Sample 3-4

Test System Interface Description 3-6

Test System Interface Connectors 3-6

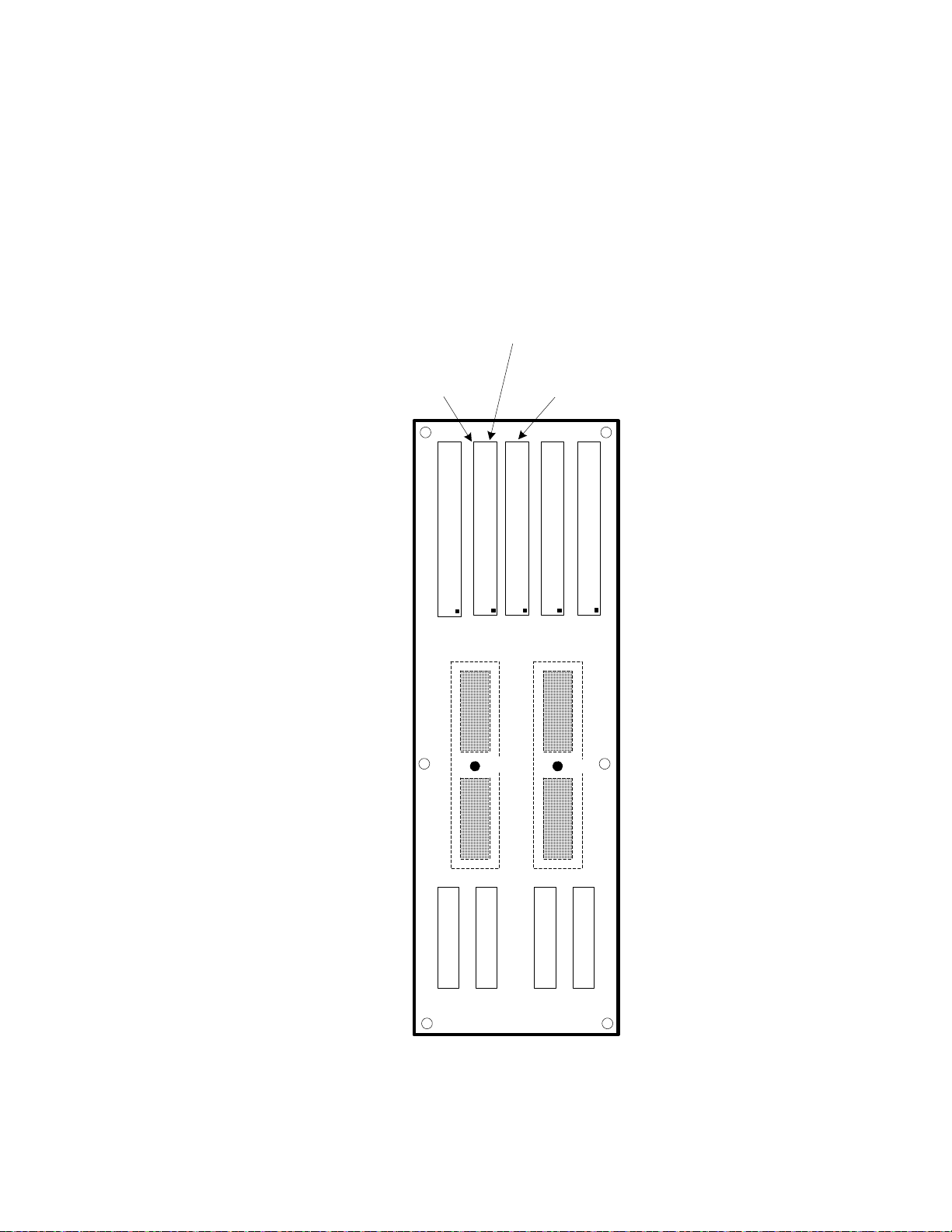

Rack Layout with Express Connect Test System Interface 3-28

Rack Layout with L2000 (TITAN) Test System Interface 3-29

System Block Diagrams with Express Connect Test System Interface 3-30

System Block Diagrams with L2000 (TITAN) Test System Interface 3-31

The Keysight 34980A Multifunction Switch/Measure Unit 3-32

Slot Allocation of the 34980A 3-32

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference iii

Page 6

PC Cards 3-36

Keysight 53131 Universal Counter 3-36

Keysight 53220 Universal Counter 3-36

Keysight 33220 Function/Arbitrary Waveform Generator 3-37

Power Supplies 3-37

Keysight N6700 MPS 3-37

Channel Names 3-38

4 System Interconnects

System Interconnects for Express Connect Interface 4-2

Connector Keying 4-2

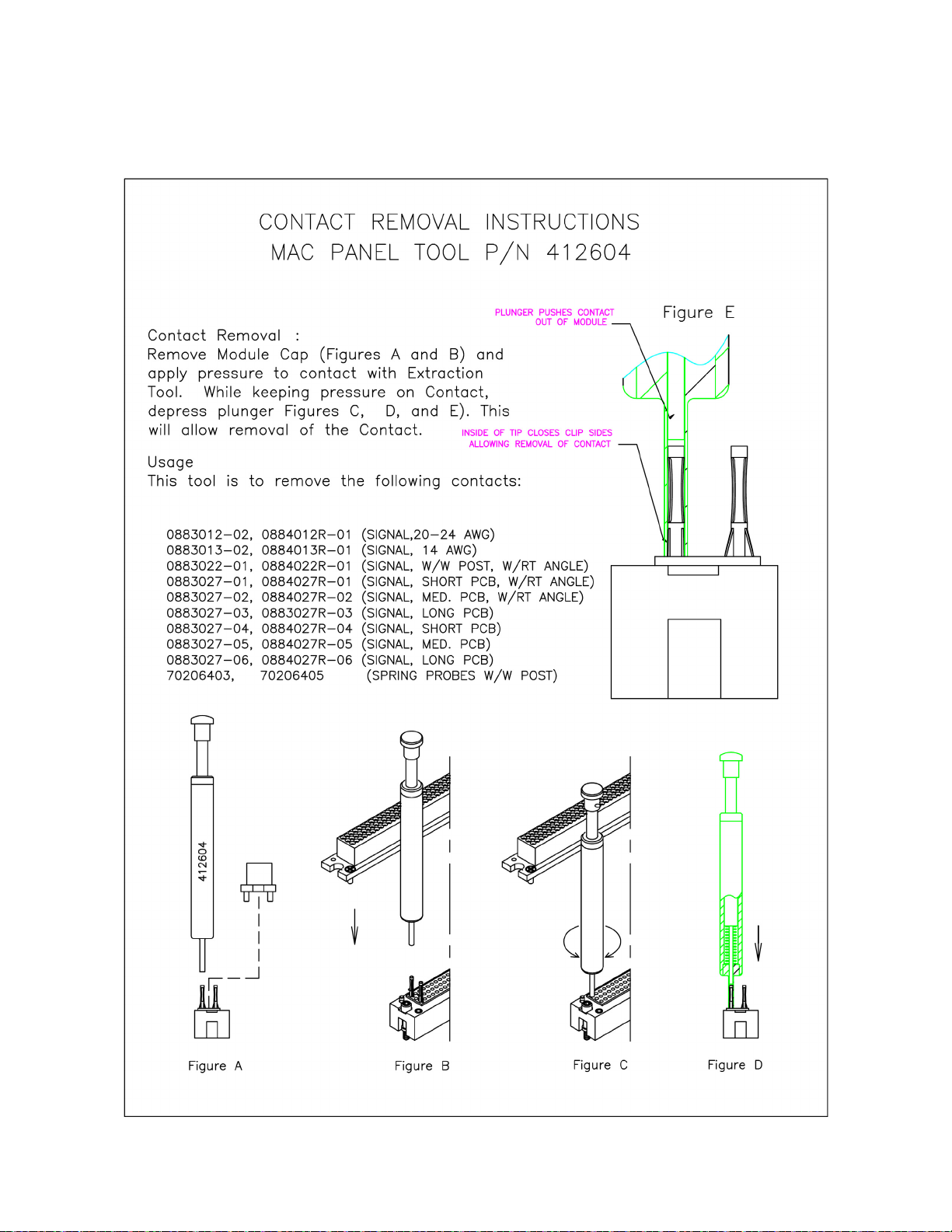

Connectors and Tools 4-3

Connecting Wiring to Test Connectors TC1- TC8 4-3

Crimping Wires to Contacts 4-4

Inserting Contacts and Assembling the Connectors 4-5

Connecting To The Test System Interface 4-6

ESD Protection Measures 4-7

Test Connector Signal Definitions 4-9

General TC Pins Assignment 4-13

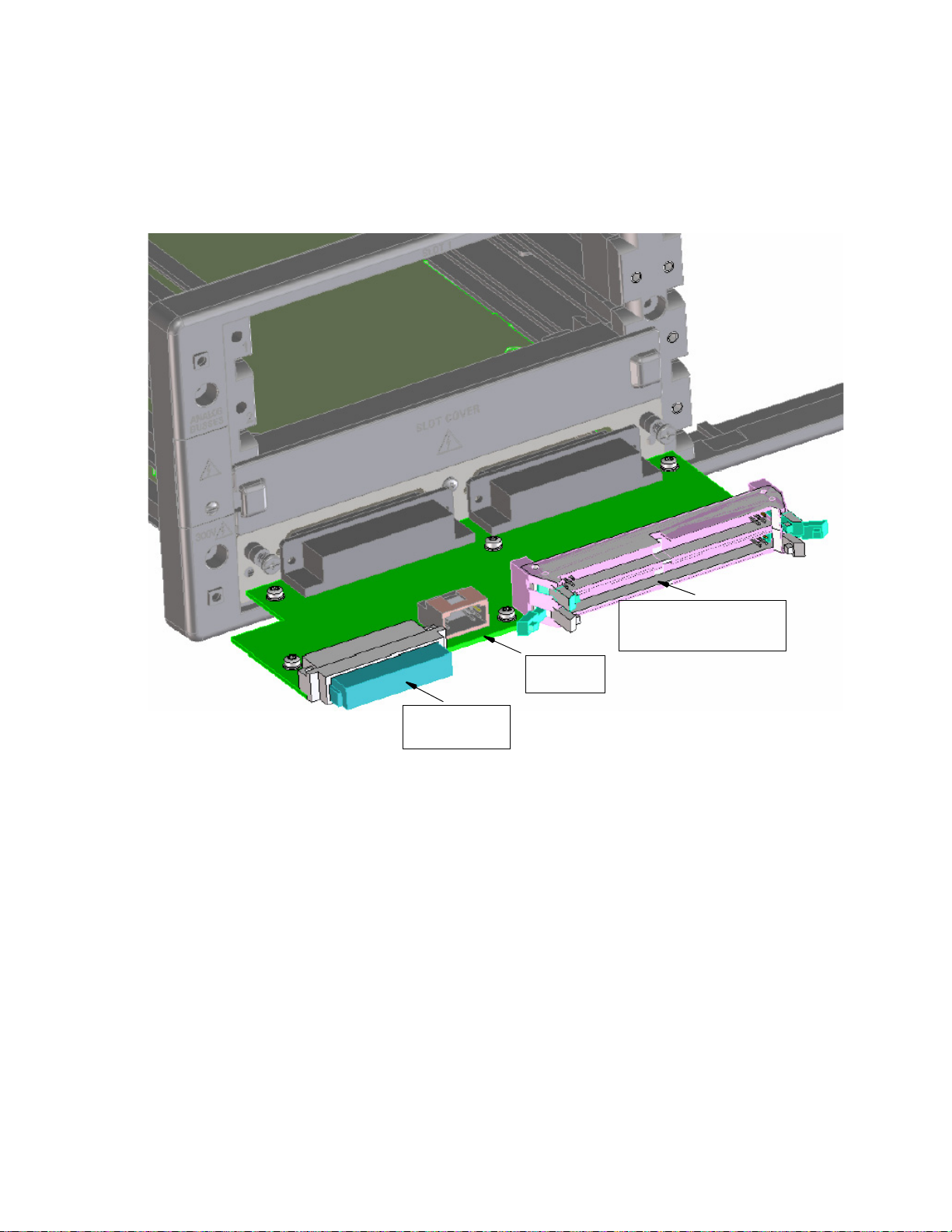

Express Connect PCA Connector Definition and Pin Access 4-15

High-Power Connector 4-21

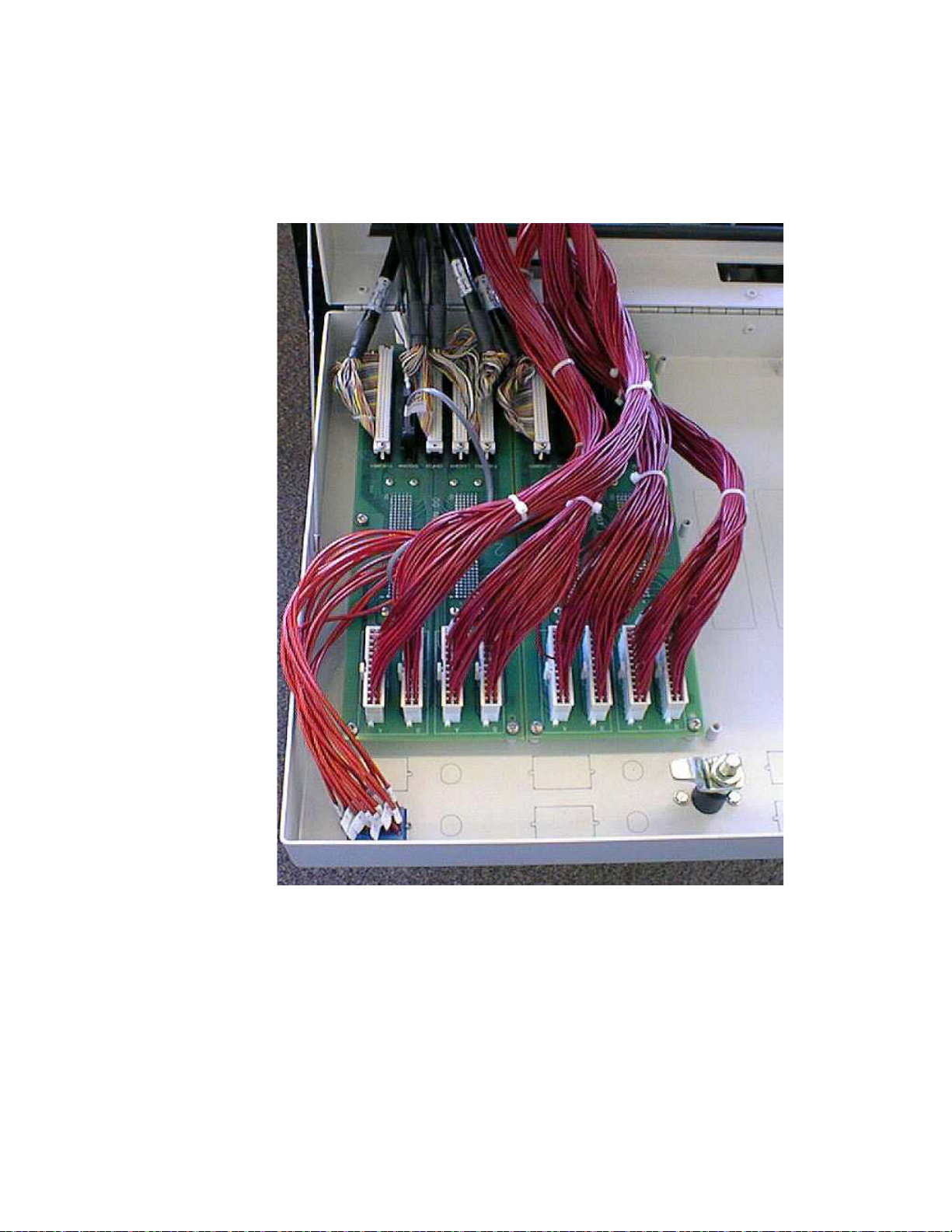

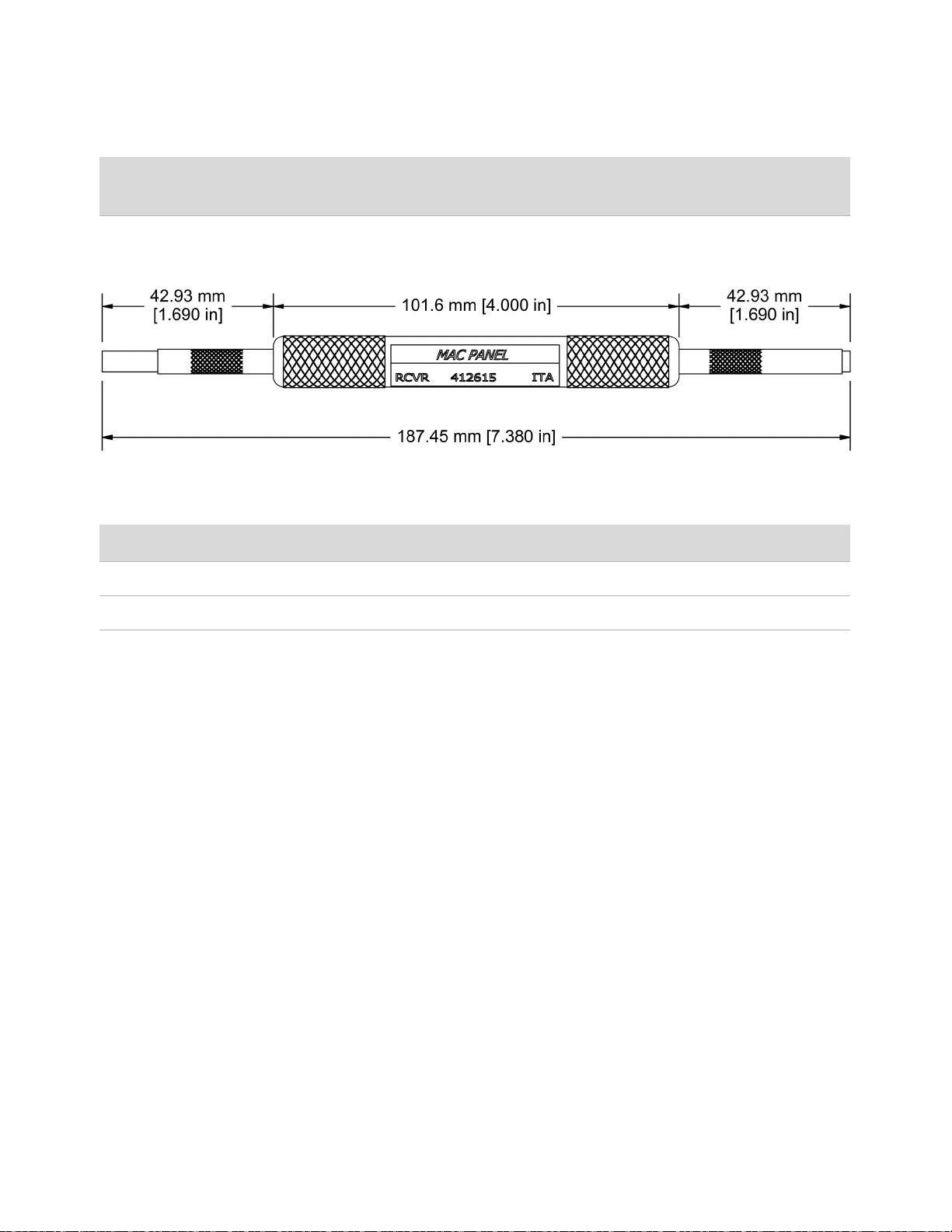

System Interconnect for Mac Panel Interface 4-23

L2000 (TITAN) Connectors and Tools 4-23

5 Test System Interface Cables

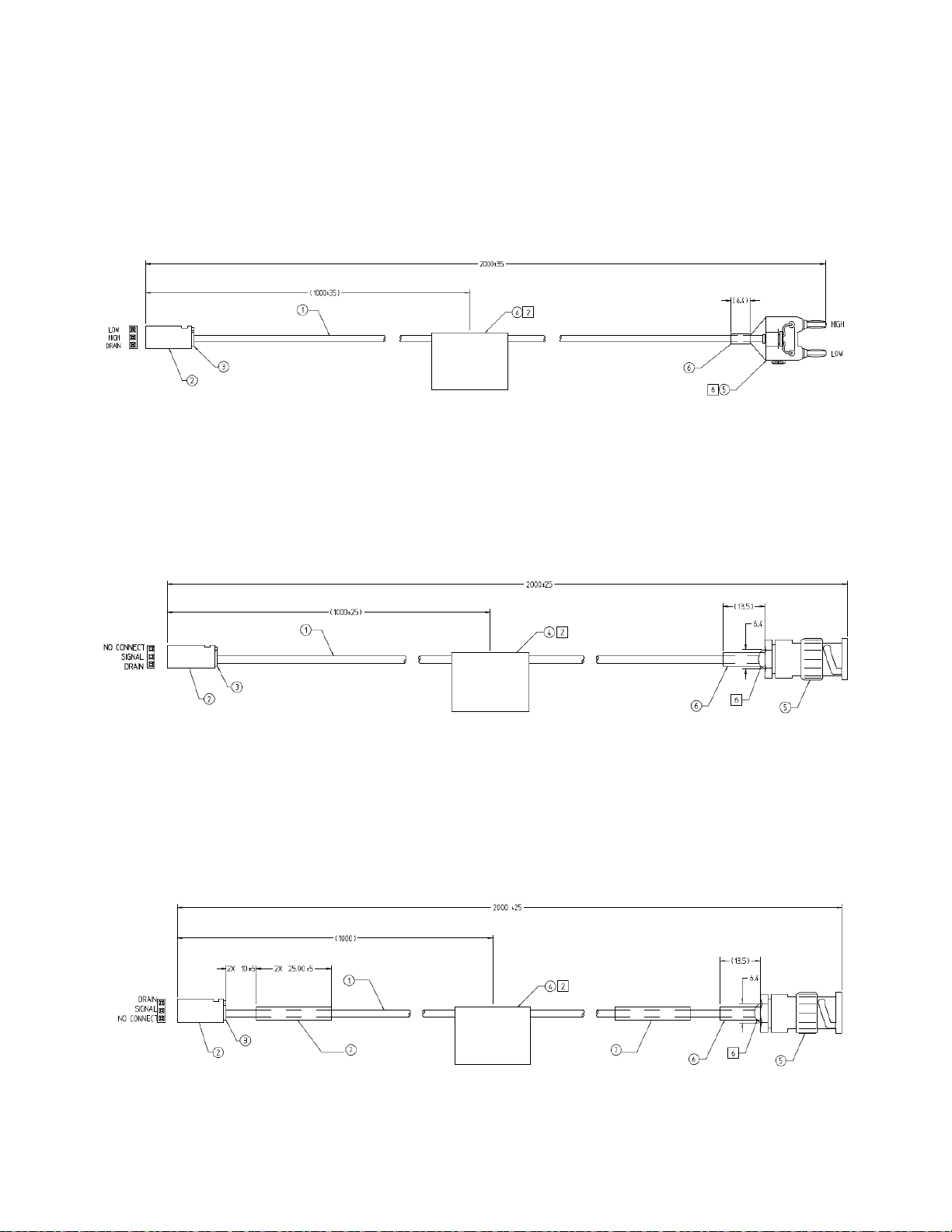

U8970-61702 Dual Banana Metric Cable for GPIB/LXI DMM 5-3

U8970-61701 Cable BNC Coax to 3x1 (Non-Isolated) 5-3

U8970-61700 Cable Isolated Instrument BNC 5-3

Cables For Express Connect Interface 5-4

E6170-61623 Twinax DMM To Inst Matrix Cable 5-4

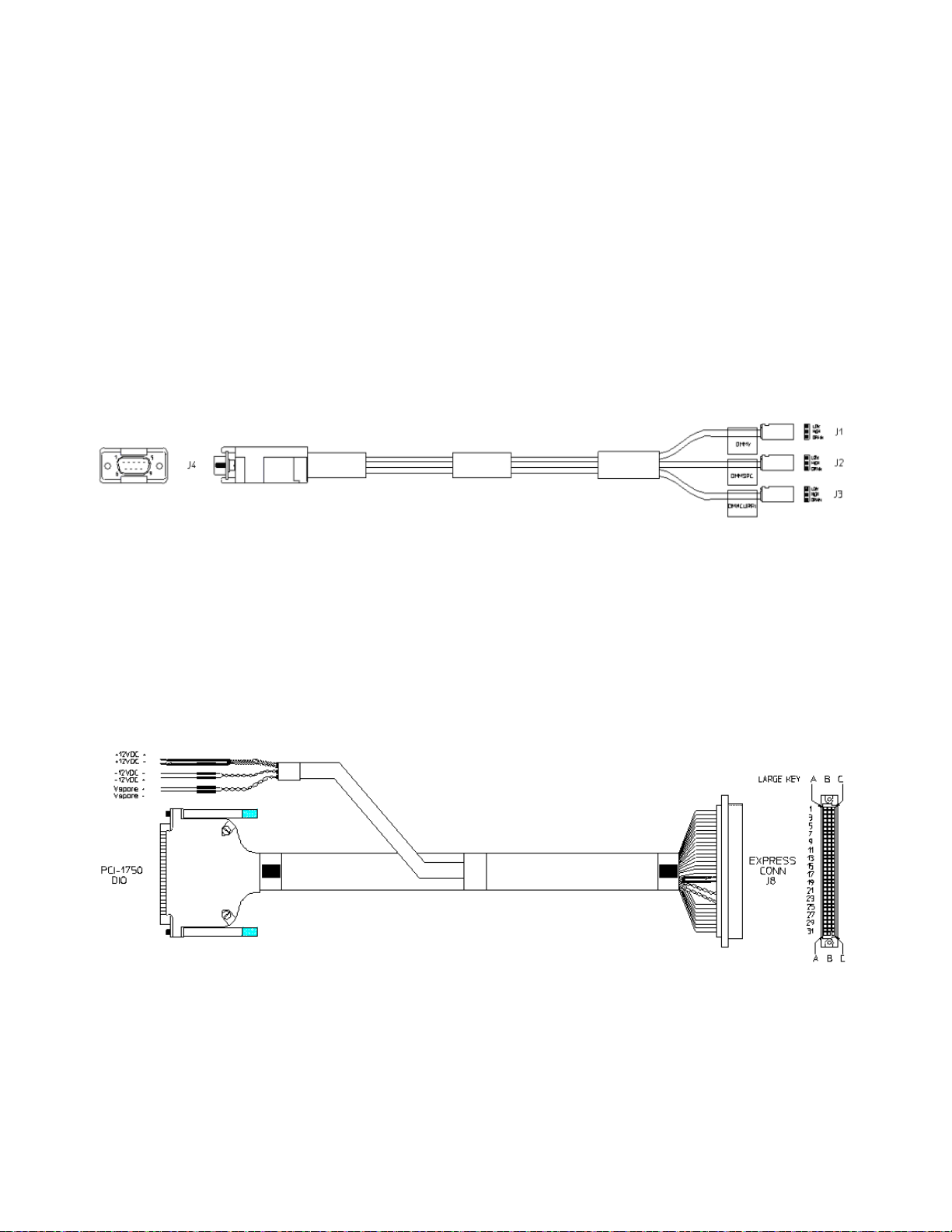

E6170-61626 DIO And Utility Power Supply To ICA Cable 5-4

E6170-61627 DMM Trig 34980 To ICA 5-6

E6170-61628 DAC 34951 To ICA Cable 5-6

E6170-61629 GP Relay 34938A And Power Supply To ICA Cable 5-8

E6170-61620 General Purpose 96-96 DINC Cable 5-10

E6170-61621 48 Channel Load Card Express Connect Cable 5-10

E6170-61630 CAN PCI To ICA Cable 5-11

E6170-61605 Cable for 8-CH/16-CH/24-CH Load Card to Express Connect 5-12

E6230-61603 Cable for 8-CH Heavy Duty Load Card to Express Connect 5-13

Cables For L2000 (TITAN) Interface 5-14

iv TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 7

E6218-61601 Cable, One Matrix (34933A) to L2000 (TITAN) 5-14

E6218-61614 CABLE, E6175A TO L2000 (TITAN) 5-15

E6218-61615 CABLE, E6176A TO L2000 (TITAN) 5-15

E6218-61620 CABLE, N9379A TO L2000 (TITAN) 5-16

E6218-61621 CABLE, 34951-DAC TO L2000 (TITAN) 5-17

E6218-61622 CABLE, 34980-DMM (TRIG) TO L2000 (TITAN) 5-17

E6218-61624 CABLE, E6178B TO L2000 (TITAN) 5-18

E6218-61625 CABLE, ONE U7177A TO L2000 (TITAN) 5-19

E6218-61627 CABLE, DIO TO L2000 (TITAN) 5-20

E6218-61628 CABLE, PS TO L2000 (TITAN) (MED CURRENT) 5-20

E6218-61629 CABLE, 34938 TO L2000 (TITAN) 5-21

E6218-61630 CABLE, CAN TO L2000 (TITAN) 5-21

E2240-61621 Cable, 34934A to ICA (TITAN) 5-22

E2240-61622 Cable, 34939A to ICA (TITAN) 5-23

E2240-61623 Cable, Electronic Load to ICA (TITAN) 5-24

E2240-61626 Cable, System Resources E6198B and PCI DIO 1750 5-25

E6218-61619 Cable, System Resources To L2000 (TITAN) 5-26

E6218-61626 CABLE, Dual 24-CH Load Card To L2000 (TITAN) 5-27

6 Replaceable And Spare Parts

Keysight E2230A Replaceable Parts 6-2

Keysight E2240A Recommended Spare Parts for Express Connect 6-4

Keysight E2240A Recommended Spare Parts for L2000 (TITAN) 6-5

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference v

Page 8

THIS PAGE IS INTENTIONALLY LEFT BLANK

vi TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 9

List of Figures

1 Legal Information

2 Safety and Regulatory Information

3 System Overview

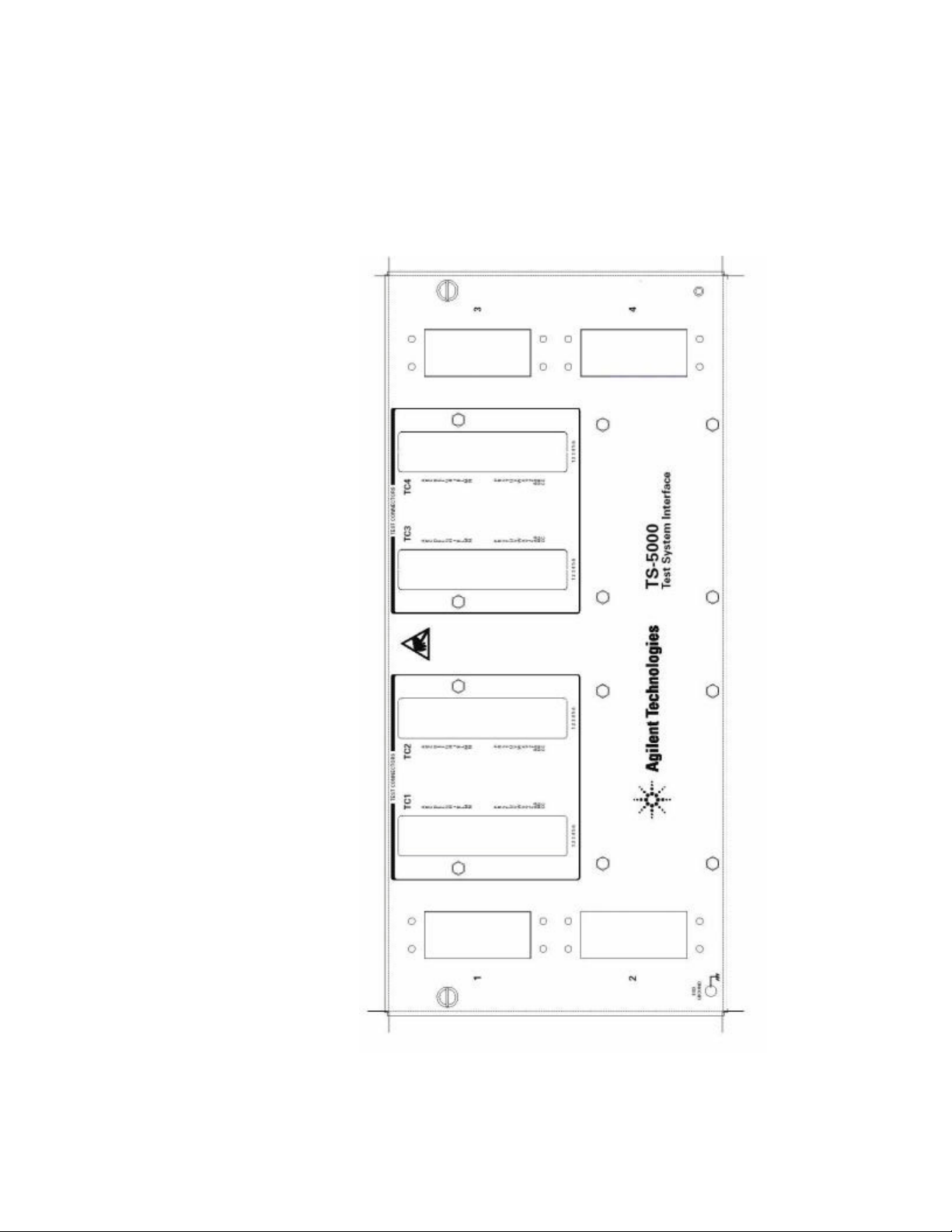

Figure 3-1. Express Connect Test System Interface TC1 Through TC4 3-7

Figure 3-2. Express Connect Test system Interface TC1 Through TC8 3-8

Figure 3-3. Macpanel L2000 (TITAN) Test System Interface 3-10

Figure 3-4. Typical TS-5020 System Rack with Express Connect Layout 3-28

Figure 3-5. Typical TS-5020 System with L2000 (TITAN) test interface 3-29

Figure 3-6. TS-5020 Simplified System with Express Connect Block Diagram 3-30

Figure 3-7. TS-5020 Simplified System with L2000 (TITAN) Block Diagram 3-31

Figure 3-8. Rear View Of 34980A Multifunction Switch / Measure Unit 3-32

Figure 3-9. Cut-out View of Slot 4 with Terminal Card To Create Instument/Pin

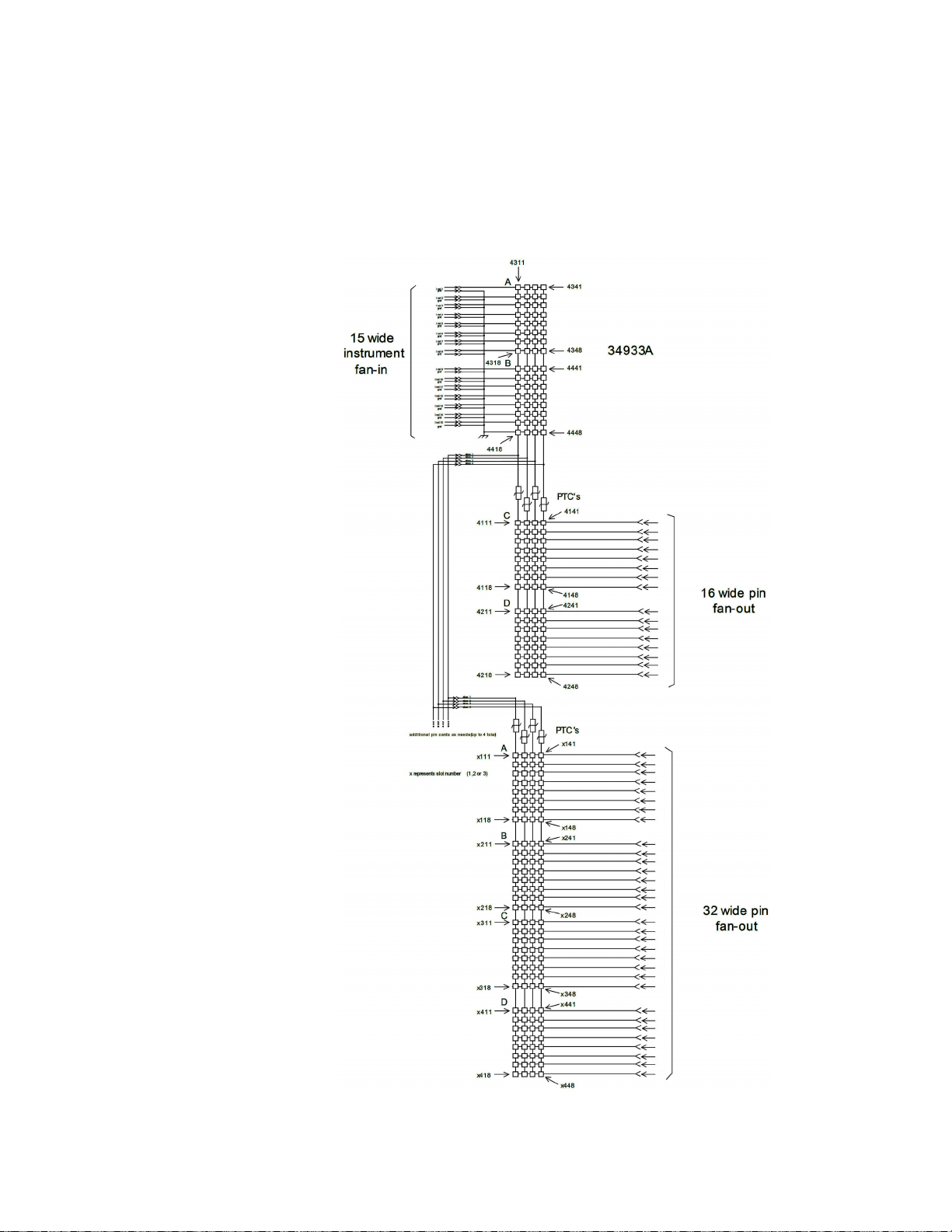

Figure 3-10. Multiple 34933A configured as Instrumentation and Pin Matrix 3-34

Figure 3-11. Multiple 34934A configured as Instrumentation and Pin Matrix 3-35

Matrix 3-33

4 System Interconnects

Figure 4-1. TC1-TC4 Connector Keying 4-2

Figure 4-2. TC1-TC8 Connector Key Configuration 4-2

Figure 4-3. Crimping Wires to Contacts 4-4

Figure 4-4. Assembling TC1 to TC4 4-5

Figure 4-5. Connecting To The Test System Interface 4-6

Figure 4-6. Adding A Grounding Strap To Reduce ESD 4-7

Figure 4-7. Wrist Strap ESD Connector 4-8

Figure 4-8. Removing A Test Connector Contact 4-8

Figure 4-9. TC1 Pinouts 4-11

Figure 4-10. TC2 Pinouts 4-12

Figure 4-11. TCn Pin Assignments 4-13

Figure 4-12. TCn+1 Pin Assignments 4-14

Figure 4-13. PCA Layout For Full Profile Express Connect (For TC1-TC8 Use) 4-15

Figure 4-14. View of Full Profile Express Connect PC Assembly (2 of 4 possible PC

Assembly shown) 4-16

Figure 4-15. PCA Layout For Low Profile Express Connect (For TC1-TC4 Use) 4-17

Figure 4-16. TS-5020 System Connector (J6 or J60) TC1 and TC2 Assignments 4-18

Figure 4-17. TS-5020 System Connector (J6 or J60) TCn Assignments 4-19

Figure 4-18. TS-5020 Configuration Connector (J7 or J40) 4-20

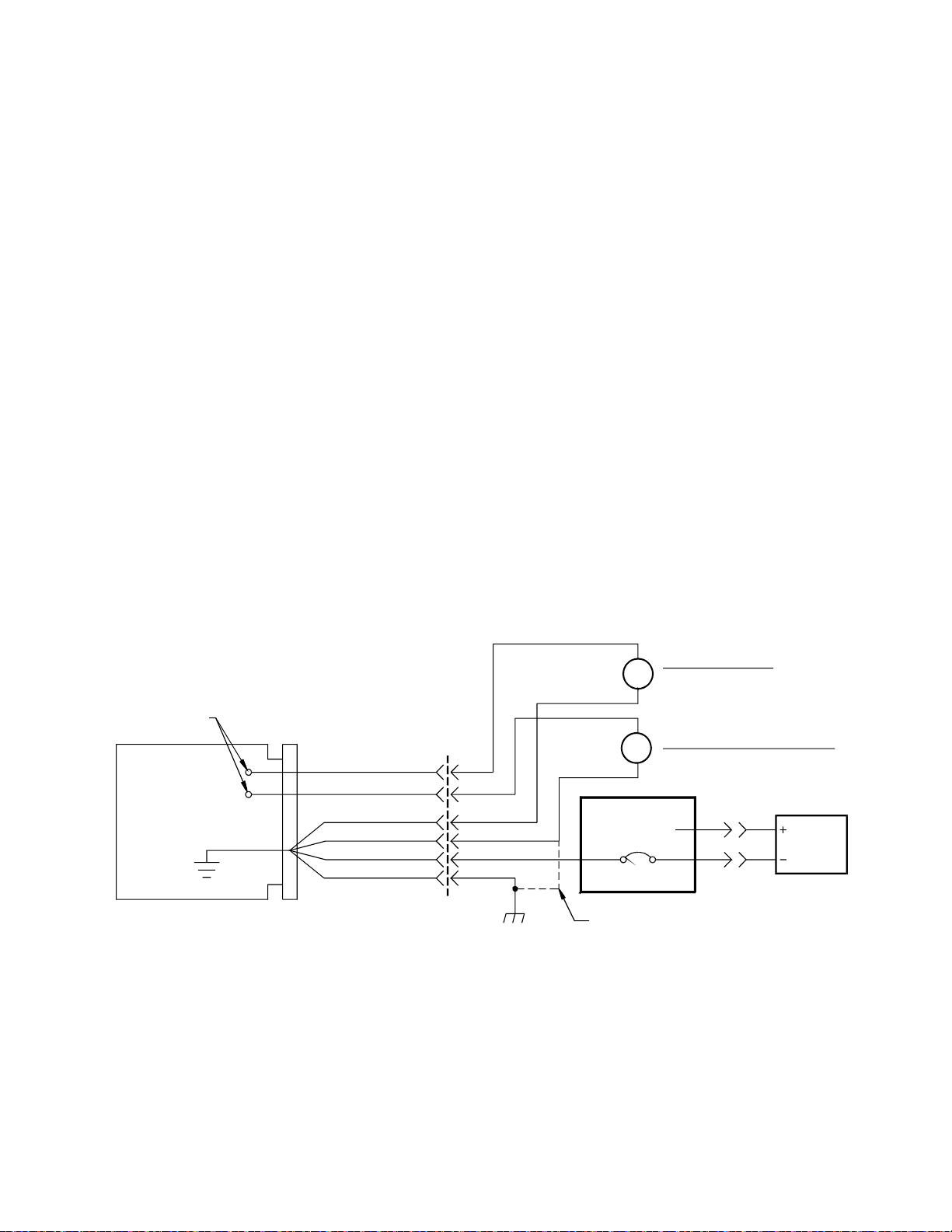

Figure 4-20. Recommended System Grounding 4-22

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference vii

Page 10

5 Test System Interface Cables

Figure 5-1. U8970-61702 (Dual Banana Metric Cable) 5-3

Figure 5-2. U8970-61701 (Cable BNC Coax to 3x1) 5-3

Figure 5-3. U8970-61700 (Cable Isolated Instrument BNC) 5-3

Figure 5-4. E6170-61623 Twinax DMM To Inst Matrix Cable 5-4

Figure 5-5. E6170-61626 DIO And Utility Power Supply To ICA Cable 5-4

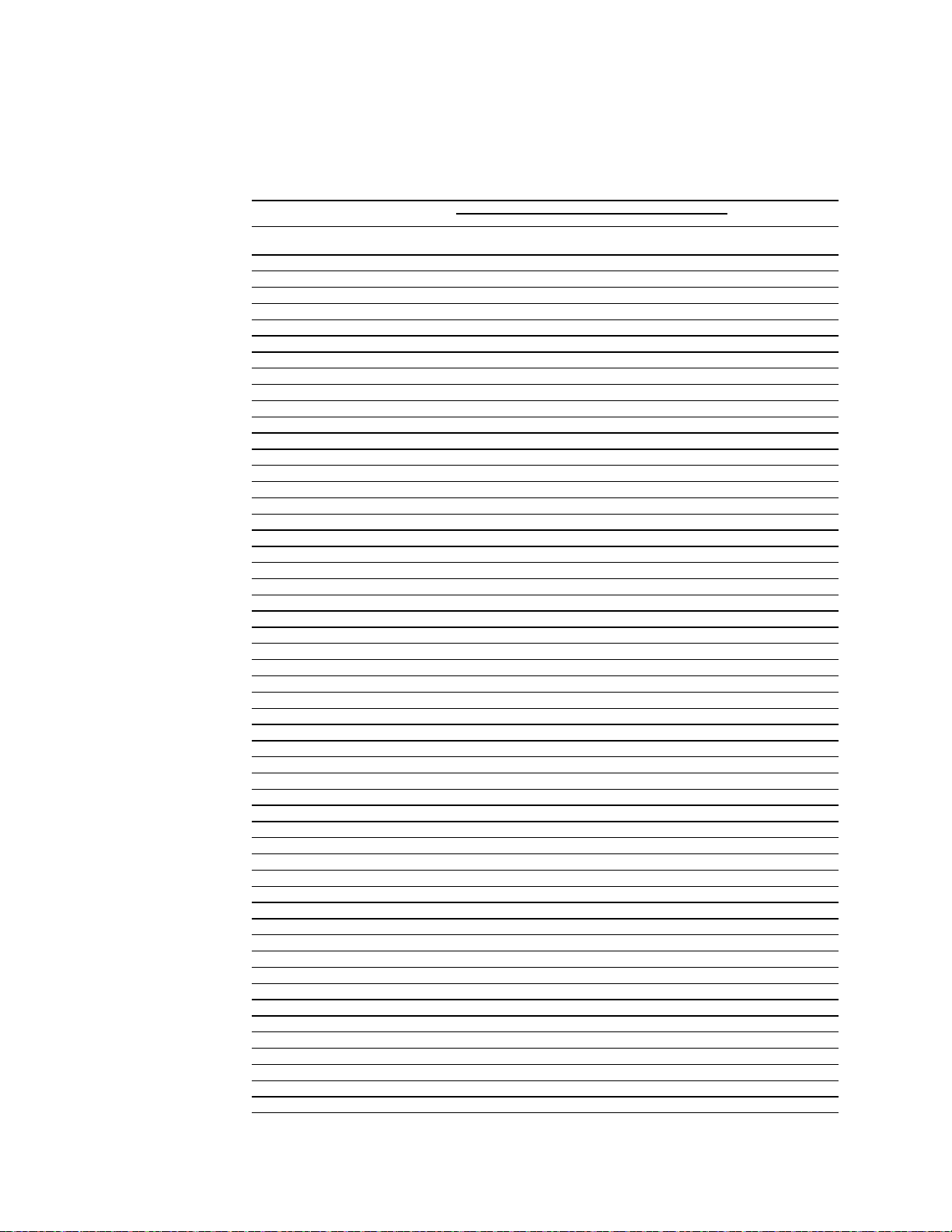

Figure 5-6. E6170-61627 DMM Trig 34980 To ICA 5-6

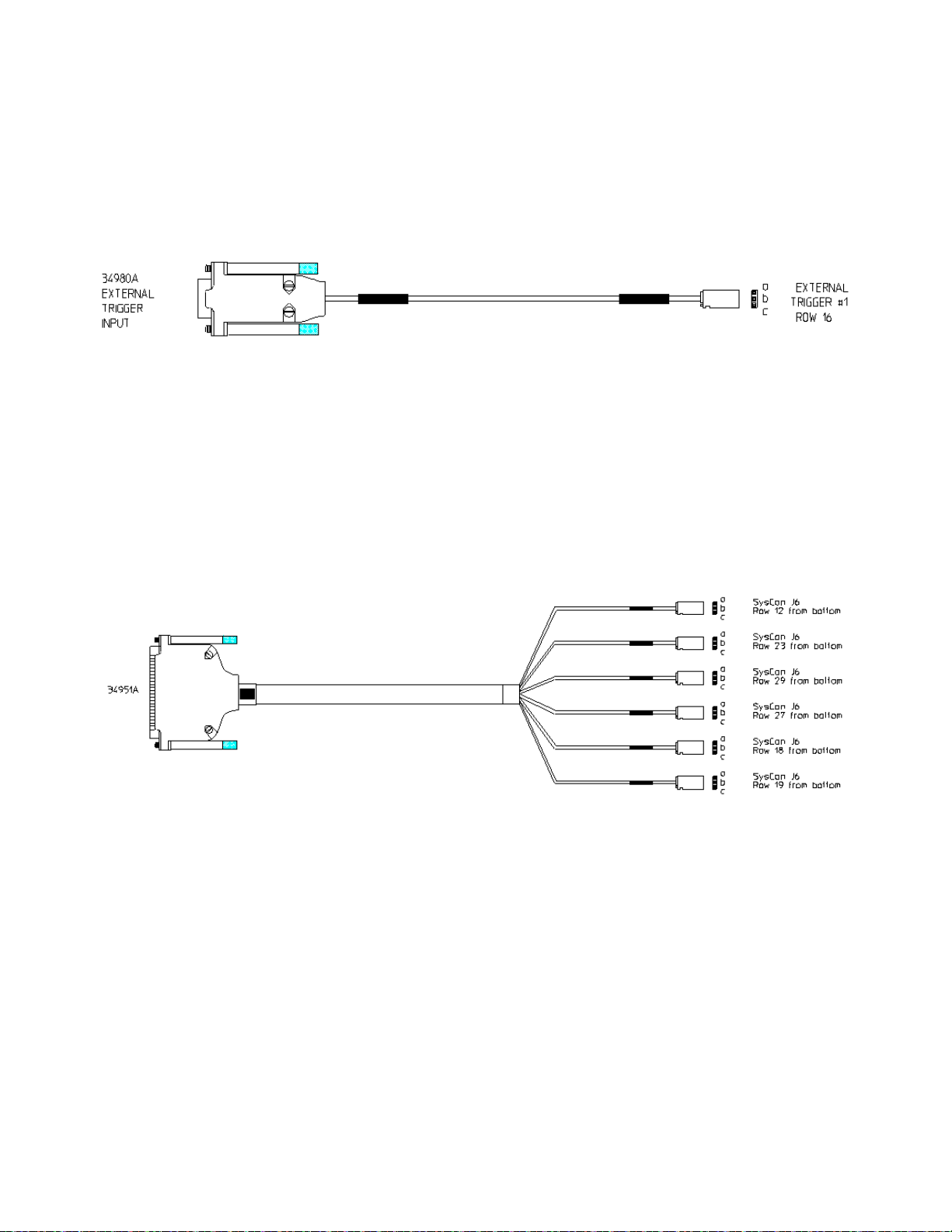

Figure 5-7. E6170-61628 DAC 34951 To ICA Cable 5-6

Figure 5-8. E6170-61629 Cable 5-8

Figure 5-9. E6170-61620 General Purpose 96-96 DINC Cable 5-10

Figure 5-10. E6170-61621 48 Channel Load Card Express Connect Cable 5-10

Figure 5-11. E6170-61630 CAN PCI To ICA Cable 5-11

Figure 5-12. E6170-61605 Cable for Load card to Express Connect. This cable can be used

for E6175A, N9377A, E6176A, E6177A, U7177A and N9378A. 5-12

Figure 5-13. Cable for E6178B 8-CH Heavy duty Load card to Express Connect 5-13

Figure 5-14. E6218-61601 Cable, One Matrix (34933A) to L2000 (TITAN) 5-14

Figure 5-15. E6218-61614 CABLE, E6175A TO L2000 (TITAN) 5-15

Figure 5-16. E6218-61615 Cable, E6176A to L2000. This cable is used for E6176A and

N9377A 5-15

Figure 5-17. E6218-61620 CABLE, N9379A TO L2000 (TITAN) 5-16

Figure 5-18. E6218-61621 CABLE, 34951-DAC TO L2000 (TITAN) 5-17

Figure 5-19. E6218-61622 CABLE, 34980-DMM (TRIG) TO L2000 (TITAN) 5-17

Figure 5-20. E6218-61624 CABLE, E6178B TO L2000 (TITAN) 5-18

Figure 5-21. E6218-61625 Cable, One U7177A to L2000. This cable is used for E6177A,

U7177A and N9378A. 5-19

Figure 5-22. E6218-61627 CABLE, DIO TO L2000 (TITAN) 5-20

Figure 5-23. E6218-61628 CABLE, PS TO L2000 (TITAN) (MED CURRENT) 5-20

Figure 5-24. E6218-61629 CABLE, 34938 TO L2000 (TITAN) 5-21

Figure 5-25. E6218-61630 CABLE, CAN TO L2000 (TITAN) 5-21

Figure 5-26. E2240-61621 Cable, 34934A to ICA (TITAN). One cable requires two TITAN

receiver block. 5-22

Figure 5-27. E2240-61622 Cable, 34934A to ICA (TITAN) 5-23

Figure 5-28. E2240-61623 Cable, Electronic Load to ICA (TITAN). This cable has an in-line

50A fuse. 5-24

Figure 5-29. E2240-61626 Cable, System Resources E6198B and PCI DIO 1750. This cable

combines the system resources cable for E6198B with the cable for PCI DIO

1750. 5-25

Figure 5-30. E6218-61619 Cable, System Resources to L2000 (TITAN). This cable

combines the system resources cable for E6218A with the cable for PCI DIO

1750. 5-26

Figure 5-31. E6218-61626 Cable, Dual 24-CH Load Card to L2000 (TITAN). This cable

combines 2 24-CH load card cable to a single receiver block. 5-27

6 Replaceable And Spare Parts

viii TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 11

List of Tables

1 Legal Information

2 Safety and Regulatory Information

3 System Overview

Table 1-1. Keysight Call Centers and Regional Headquarters 1-3

Table 2-1. Environment Requirements 2-3

Table 2-2. Safety Symbols and Regulatory Markings 2-5

Table 2-3. Suggested Anti-Static Solutions for Site Planning 2-7

Table 3-1. Typical TS-5020 Instrumentation 3-3

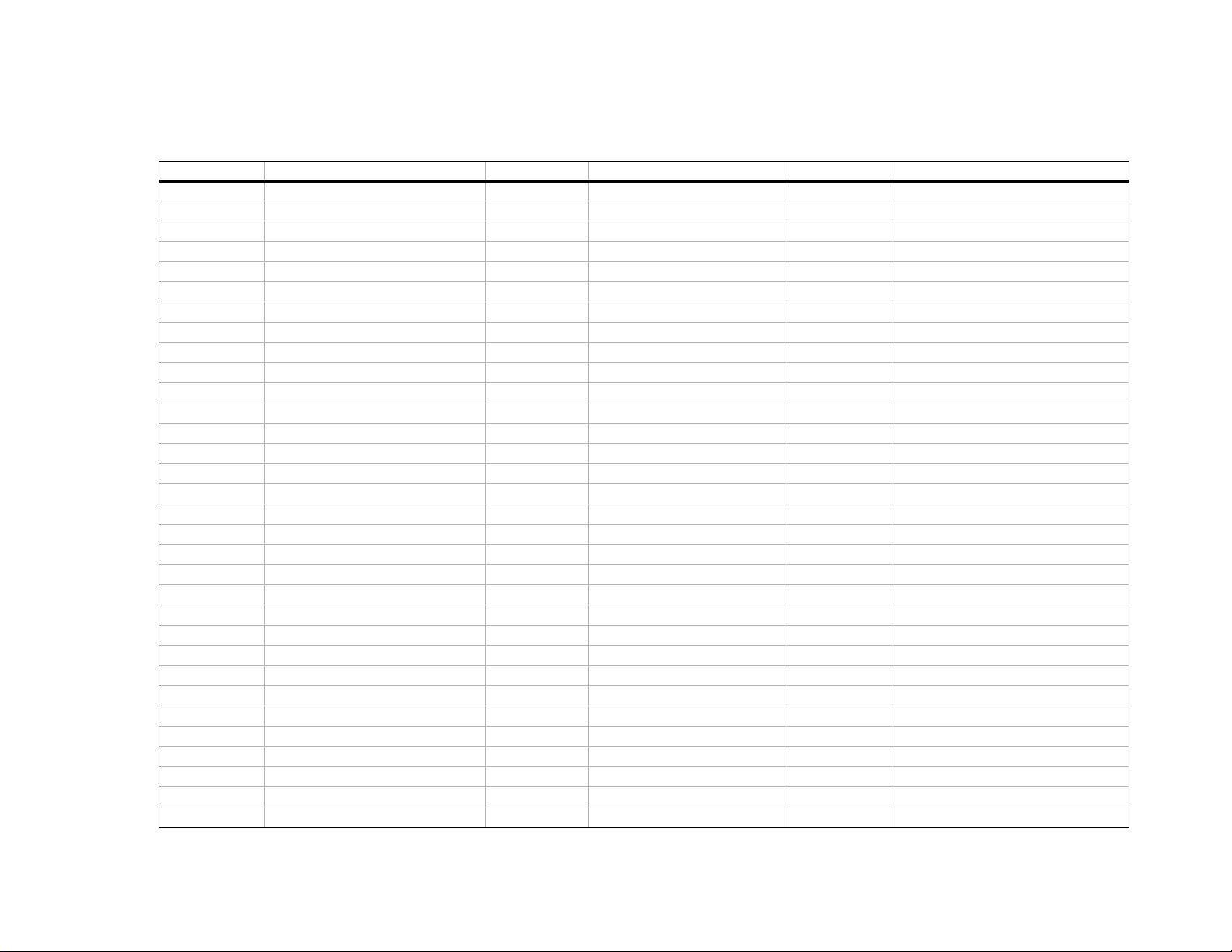

Table 3-2. L2000 (TITAN) Slot 1 (System) 3-11

Table 3-3. L2000 (TITAN) Slot 2 (Instruments) 3-12

Table 3-4. L2000 (TITAN) Slot 3 (DAC) 3-13

Table 3-5. L2000 (TITAN) Slot 4 (RS232) 3-14

Table 3-6. L2000 (TITAN) Slot 6 (Pin Matrix 1st Card 34933A) 3-15

Table 3-7. L2000 (TITAN) Slot 7 to 9 (Matrix Card 34933A) 3-16

Table 3-8. L2000 (TITAN) Slot 6 (Pin Matrix 1st Card (34934A)) 3-17

Table 3-9. L2000 (TITAN) Slot 7 (Pin Matrix 1st Card (34934A)) 3-18

Table 3-10. L2000 (TITAN) Slot 8/21/23 (Pin Matrix Card (34934A)) 3-19

Table 3-11. L2000 (TITAN) Slot 9/22/24 (Pin Matrix Card (34934A)) 3-20

Table 3-12. L2000 (TITAN) Slot 12 to 15 (GP relay Card (34938A)) 3-21

Table 3-13. L2000 (TITAN) Slot 12 to 15 (GP relay Card (34939A)) 3-22

Table 3-14. L2000 (TITAN) Slot 11 to 20 (24-CH Load Card) 3-23

Table 3-15. L2000 (TITAN) Slot 13 to 20 (16-CH Load Card) 3-24

Table 3-16. L2000 (TITAN) Slot 13 to 20 (48-CH Load Card) 3-25

Table 3-17. L2000 (TITAN) Slot 13 to 20 (8-CH Load Card) 3-26

Table 3-18. L2000 (TITAN) Slot 16 & 18(Heavy Duty Load Card & Electronic Load) 3-27

Table 3-19. L2000 (TITAN) Slot 25 (RF) 3-27

4 System Interconnects

Table 4-1. TCx Signal Definitions 4-9

5 Test System Interface Cables

Table 5-1. E6170-61626 Cable Pinout Table 5-5

Table 5-2. E6170-61628 Cable Pinout Table 5-7

Table 5-3. E6170-61629 Cable Pinout Table 5-9

6 Replaceable And Spare Parts

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference ix

Page 12

THIS PAGE IS INTENTIONALLY LEFT BLANK

x TS-5020 Automotive Electronics Functional Test System

Page 13

1 Legal Information

Warranty .... 1-2

Technology Licenses .... 1-2

Restricted Rights Legend .... 1-2

Service And Support .... 1-3

Keysight On The Web .... 1-3

Keysight By Phone .... 1-3

Page 14

1 Legal Information

Legal Information

Warranty

The material contained in this document is provided “as is,” and

is subject to being changed, without notice, in future editions.

Further, to the maximum extent permitted by applicable law,

Keysight disclaims all warranties, either express or implied,

with regard to this manual and any information contained

herein, including but not limited to the implied warranties of

merchantability and fitness for a particular purpose. Keysight

shall not be liable for errors or for incidental or consequential

damages in connection with the furnishing, use, or performance

of this document or of any information contained herein.

Should Keysight and the user have a separate written

agreement with warranty terms covering the material in this

document that conflict with these terms, the warranty terms in

the separate agreement shall control.

Technology Licenses

The hardware and/or software described in this document are

furnished under a license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of a U.S. Government

prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in

DFAR 252.227-7014 (June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted computer software” as

defined in FAR 52.227-19 (June 1987) or any equivalent agency

regulation or contract clause. Use, duplication or disclosure of

Software is subject to Keysight Technologies’ standard

commercial license terms, and non-DOD Departments and

Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR 52.227-19(c)(1-2)(June

1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14 (June 1987) or

DFAR 252.227-7015 (b)(2)(November 1995), as applicable in any

technical data.

1-2 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 15

Service And Support

Keysight On The Web

Keysight By Phone

Legal Information 1

Any adjustment, maintenance, or repair of this product must be

performed by qualified personnel. Contact your customer

engineer through your local Keysight Technologies Service

Center.

You can find information about technical and professional

services, product support, and equipment repair and service on

the Web:

Double-click the link to Test & Measurement. Select your country

from the drop-down menus. The Web page that appears next has

contact information specific for your country

http://www.keysight.com/

If you do not have access to the Internet, call one of the

numbers in

Table 1-1 Keysight Call Centers and Regional Headquarters

United States and Canada: Test and Measurement Call Center

Europe: (41 22) 780 8111

Japan: Measurement Assistance Center

Latin America: 305 269 7548

Asia-Pacific: (85 22) 599 7777

Table 1-1.

(800) 452 4844 (toll-free in US)

(81) 0426 56 7832

Manufacturing Address

Keysight Technologies Microwave Products (Malaysia) Sdn. Bhd.

Bayan Lepas Free Industrial Zone,

11900 Penang,

Malaysia.

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 1-3

Page 16

1 Legal Information

THIS PAGE IS INTENTIONALLY LEFT BLANK

1-4 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 17

2 Safety and Regulatory Information

Safety Information .... 2-2

Safety Summary .... 2-2

Safety Notice .... 2-2

General .... 2-2

Environmental Conditions .... 2-3

Before Applying Power .... 2-3

Ground The System .... 2-4

Fuses .... 2-4

Operator Safety Information .... 2-4

Safety Symbols and Regulatory Markings .... 2-5

Electrostatic Discharge (ESD) Precautions .... 2-7

End of Life: Waste Electrical and Electronic Equipment (WEEE)

Directive 2002/96/EC .... 2-8

Page 18

2 Safety and Regulatory Information

CAUTION

WARNING

WARNING

Safety Information

Safety Summary

Safety Notice

The following general safety precautions must be observed

during all phases of operation of this instrument. Failure to

comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Keysight

Technologies assumes no liability for the customer's failure to

comply with these requirements.

A CAUTION notice denotes a hazard. It calls attention to an

operating procedure, practice, or the like, that, if not correctly

performed or adhered to, could result in damage to the product or

loss of important data. Do not proceed beyond a CAUTION notice

until the indicated conditions are fully understood and met.

A WARNING notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that, if not correctly performed or

adhered to, could result in personal injury or death. Do not proceed

beyond a WARNING notice until the indicated conditions are fully

understood and met.

General

This product is provided with a protective earth terminal. The

protective features of this product may be impaired if it is used

in a manner not specified in the operation instructions.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE. Do not operate the

product in the presence of flammable gases or flames.

2-2 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 19

WARNING

DO NOT REMOVE RACK PANELS OR INSTRUMENT COVERS. Operating

WARNING

°

°

CAUTION

personnel must not remove any rack panels or instrument covers.

Component replacement and internal adjustments must be made only

by qualified service personnel. Products that appear damaged or

defective should be made inoperative and secured against unintended

operation until they can be repaired by a qualified service personnel.

The protection provided by the TS-5020 system may be impaired if

the system is used in a manner not specified by Keysight.

Environmental Conditions

Safety and Regulatory Information 2

The TS-5020 Automotive Electronics Functional Test System is

designed for indoor use only.

mental requirements.

Table 2-1 Environment Requirements

Environment Conditions Requirements

Maximum Altitude 2000 meters

Temperature (Operation) 5 C to 40 C

Maximum Relative Humidity The test system is designed to operate

This product is designed for use in Installation Category II and

Pollution Degree 2, per IEC 61010-1 and 664 respectively.

Before Applying Power

Table 2-1 shows general environ-

in the range from 5% to 80% relative

humidity (non-condensing).

Verify that the product is set to match the available line voltage

and all safety precautions are taken. Note the external markings

of the instruments described in

Regulatory Markings”.

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 2-3

“Safety Symbols and

Page 20

2 Safety and Regulatory Information

WARNING

WARNING

WARNING

Ground The System

Fuses

To minimize shock hazard, the instrument chassis and cover

must be connected to an electrical protective earth ground. The

instrument must be connected to the ac power mains through a

grounded power cable, with the ground wire firmly connected

to an electrical ground (safety ground) at the power outlet. Any

interruption of the protective (grounding) conductor or

disconnection of the protective earth terminal will cause a

potential shock hazard that could result in personal injury.

Use only fuses with the required rated current, voltage, and

specified type (normal blow, time delay). Do not use repaired

fuses or short-circuited fuse holders. To do so could cause a

shock or fire hazard.

In order to avoid electrical hazards, all system internal fuses must

be replaced by trained and qualified personnel.

Operator Safety Information

Module connectors and Test Signal cables connected to them

cannot be operator accessible.

M

Cables and connectors are considered inaccessible if a tool (e.g.

screwdriver, wrench, socket, etc.) or a key (equipment in a

locked cabinet) is required to gain access to a conductive

surface connected to any cable conductor (High, Low or Guard).

Assure the equipment under test has adequate insulation

between the cable connections and any operator-accessible parts

(doors, covers, panels shields, cases, cabinets, etc.)

Verify there are multiple and sufficient protective means (rated

for the voltages you are applying) to assure the operator will

NOT come into contact with any energized conductor even if

one of the protective means fails to work as intended. For

2-4 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 21

Safety symbols

Safety and Regulatory Information 2

example, the inner side of a case, cabinet, door cover or panel

can be covered with an insulating material as well as routing the

test cables to the front panel connectors of the module through

non-conductive, flexible conduit such as that used in electrical

power distribution.

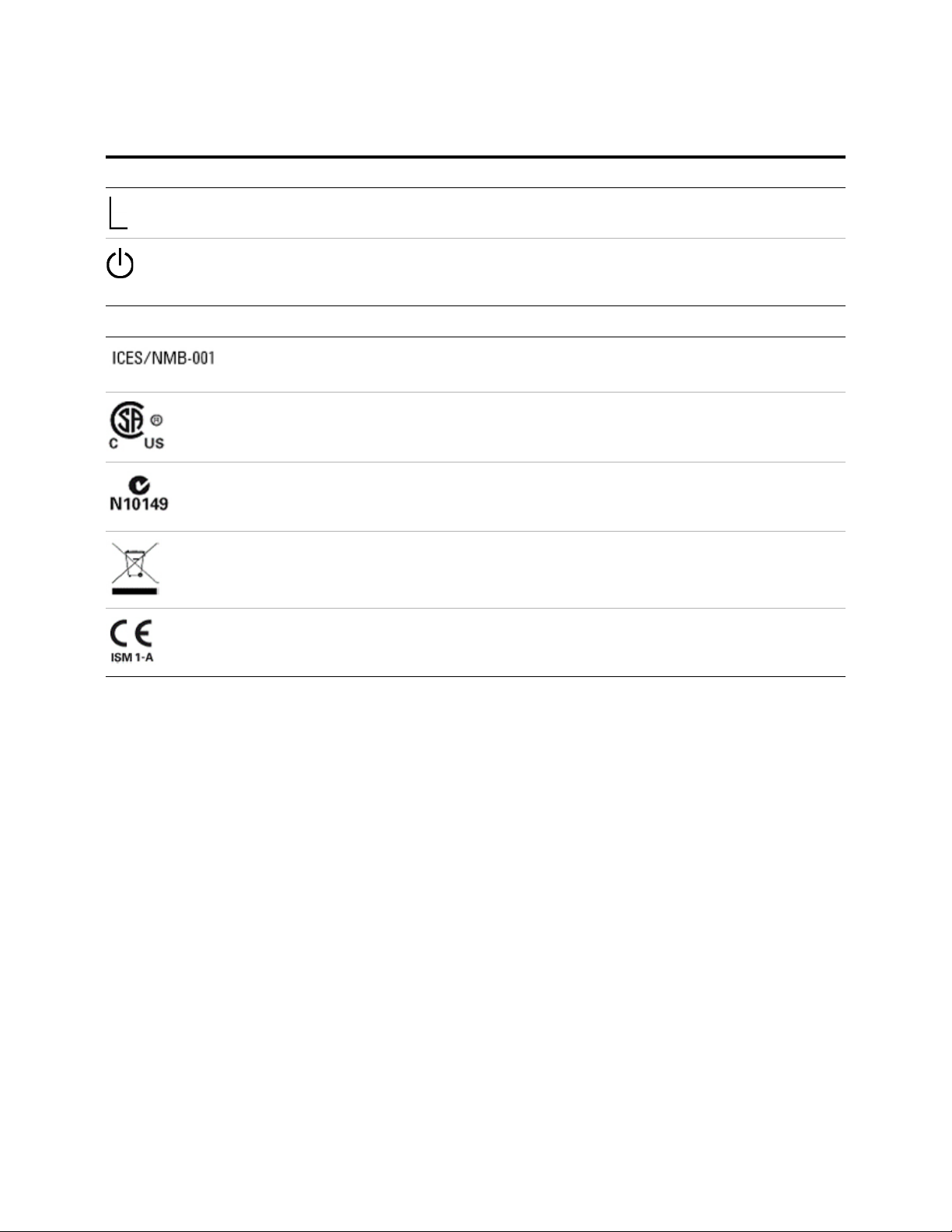

Safety Symbols and Regulatory Markings

Symbols and markings on the system, in manuals and on

instruments alert you to potential risks, provide information

about conditions, and comply with international regulations.

Table 2-2 defines the symbols and markings you may find in a

manual or on an instrument.

Table 2-2 Safety Symbols and Regulatory Markings

Warning: risk of electric shock.

Warning: hot surface

Caution: refer to accompanying documents.

Laser radiation symbol: marked on products that have a laser output.

Alternating current.

Both direct and alternating current.

Three-phase alternating current.

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

Terminal is at earth potential. Used for measurement and control circuits designed to be operated

with one terminal at earth potential.

Terminal for neutral conductor on permanently installed equipment.

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 2-5

Page 22

2 Safety and Regulatory Information

Safety symbols

Terminal for line conductor on permanently installed equipment.

Standby (supply); units with this symbol are not completely disconnected from ac mains when this

switch is off. To completely disconnect the unit from ac mains, either disconnect the power cord, or

have a qualified electrician install an external switch.

Regulatory markings

This text indicates that the ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

The CSA mark is a registered trademark of the Canadian Standards Association. A CSA mark with

the indicators “C” and “US” means that the product is certified for both the U.S. and Canadian

markets, to the applicable American and Canadian standards.

The C-tick mark is a registered trademark of the Spectrum Management Agency of Australia. This

signifies compliance with the Australia EMC Framework regulations under the terms of the Radio

Communication Act of 1992.

This instrument complies with the WEEE Directive (2002/96/EC) marking requirement. This affixed

product label indicates that you must not discard this electrical/electronic product in domestic

householdwaste.

The CE mark is a registered trademark of the European Community. This CE mark shows that the

product complies with all the relevant European Legal Directives.

2-6 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 23

Electrostatic Discharge (ESD) Precautions

CAUTION

Static electricity is destructive to your production process and

the TS-5020. Careless handling and poor site planning can cause

system reliability problems and reduce your product yield. The

system may not be as easily damaged as the modules you will be

testing, but good anti-static planning will help ensure high

reliability.

The ESD symbol below indicates areas where ESD caution must

be exercised. This is to prevent damage to instruments and/or

test disruption.

ESD Symbol

Caution: Static Sensitive.

Electrostatic discharge in this area may cause equipment damage or

test disruption.

Safety and Regulatory Information 2

While not an exhaustive list of anti-static precautions, Table 2-3

shows suggestions to consider as you plan your system area:

Table 2-3 Suggested Anti-Static Solutions for Site Planning

Precaution Suggested Solution

Anti-static flooring Plan to use an anti-static floor

covering or mats.

Grounding straps Plan for foot straps in conjunction

with anti-static flooring and wrist

straps for system operators.

The system test rack is secured to the pallet of the shipping crate

and wrapped with a plastic wrap. Do not move the crate or the test

rack and pallet to a static sensitive area until you have removed the

plastic wrap from the test rack.

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 2-7

Page 24

2 Safety and Regulatory Information

End of Life: Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This product complies with the WEEE Directive (2002/96/EC)

marking requirement. The affixed product label (see below)

indicates that you must not discard this electrical/electronic

product in domestic household waste.

Product Category:

With reference to the equipment types in the WEEE directive

Annex 1, this product is classified as a “Monitoring and Control

Instrumentation” product.

Do not dispose in domestic household waste

To return unwanted products, contact your local Keysight

office, or see:

http://www.keysight.com/environment/product

for more information.

2-8 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 25

3 System Overview

System Intended Use .... 3-2

Instructions For Use .... 3-2

Test System Specifications and Capabilities .... 3-3

Test Capabilities – Measurement Sample Methods .... 3-4

System Capability DC Accuracy Sample .... 3-4

Test System Interface Description .... 3-6

Test System Interface Connectors .... 3-6

Rack Layout with Express Connect Test System Interface .... 3-28

Rack Layout with L2000 (TITAN) Test System Interface .... 3-29

System Block Diagrams with Express Connect Test System Interface ....

3-30

System Block Diagrams with L2000 (TITAN) Test System Interface .... 3-31

The Keysight 34980A Multifunction Switch/Measure Unit .... 3-32

Slot Allocation of the 34980A .... 3-32

PC Cards .... 3-36

Keysight 53131 Universal Counter .... 3-36

Keysight 53220 Universal Counter .... 3-36

Keysight 33220 Function/Arbitrary Waveform Generator .... 3-37

Power Supplies .... 3-37

Page 26

3 System Overview

WARNING

System Intended Use

Instructions For Use

The Keysight TS-5020 systems are designed to be used in high

volume Electronic Control Modules (ECM) manufacturing sites.

The systems can test ECU’s with 5-80 pins with voltages

0-60Vdc and currents in the 0-30Amp ranges. Typical

applications for TS-5020 system include testing of smart

sensors and ECMs for Antilock-brake, airbag, remote keyless

entry, climate control, sunroof and windows.

The Keysight TS-5020 systems contain all of the

instrumentation needed to test most electronics modules. You

may also add additional instruments and cabling to increase the

test capabilities of the system. The locations of the instruments

and test system interface or mass interconnect are standardized

as much as possible. Because the Keysight TS-5020 Series uses

open system standards, and is configurable by the system

integrator, systems at your site may be different from the

factory configurations.

In the event that additional instrumentation is added that will

shift the center of gravity, a rack stability test must be completed

to verify the stability of the modified rack.

Typical system operation is dependant on the target application. The

system is to be modified by trained personal for the target test module

application. Typically, the test system development process consists of:

• Identify the number of load resources required and assign load

resources

• Identify the number of measurement resources required and assign

measurement resources

• Identify ECM serial interface communications needs and assign

serial resource

• Identify fixture control resources required and assign I/O & power

resources

• Construct test fixture and test system interconnect cabling

required for the specific application

• Develop TXSL based test-plan for specific application

• Develop Software operator user interface for specific application

• Validate and deploy test system to manufacturing site.

3-2 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 27

Test System Specifications and Capabilities

p

g

Ag ilent Technologies Quad 4x8 reed relay switch modu le.

34938A Agilent Technologies 20 Chann el, 5am p form A switch.

34951A Agilent Technologies 4 Channel isolated +/-16V DAC.

Ag ilent Technologies Un iversal Counter

33220A Agilent Technologies 20M hz Function/Arbitrary W aveform Generator

y

N6762A Agilent Technologies Power supply

y

N665xA Agilent Technologies Power supply

Agilent Technologies 21 slot switch/load unit

E6176A Agilent Technologies 16 Ch loadcard

E6178B Agilent Technologies 8 Ch Heavy Duty loadcard

N9377A Agilent Technologies 16 Ch dual load

Ag ilent Technologies 8 Ch low resistance loadca rd

The TS-5020 test system specifications are derived directly from

the specifications of the instrumentation that make up the

system. The overall test system measurement capability is a

combination of the measurement uncertainty as specified by

the individual instrumentation combined with the system

switch paths of the switching sub-systems.

For test system instrumentation specifications &

characteristics, refer directly to the manufacturer

documentation.

may be configured into the system. Refer to the manufacturer

supplied datasheets for detailed specifications.

Table 3-1 Typical TS-5020 Instrumentation

Table 3-1 lists various instrumentations that

System Overview 3

P/N Mfg Descri

34980A A

34933A

34934A Agilent Technologies Quad 4x32 Reed Matrix

34939A Agilent Technologies 64 Channel From A GP Sw itch

53131A

53220A Agilent Technologies 350 MH z Universal Frequency Co un ter /Tim e r

N6752A Agilent Technologie s P o w e r suppl

N664xA Agilent Technologie s P o w e r suppl

E6198B

E6175A Agilent Technologie s 8 C h loa dc ard

E6177A Agilent Technologies 24 Ch loadcard

U7177A Agilent Technologies 24 Ch loadcard with current sense

N9378A

N9379A Agilent Technologie s 4 8 C h high density loadcard

ilent Technologies 8 slot switch /m easu rem ent u nit w / d mm .

tion

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-3

Page 28

3 System Overview

Test Capabilities – Measurement Sample Methods

The following test capabilities calculations help you determine

if the Keysight TS-5020 Test System can meet your Electronic

Control Module (ECM) test requirements. The test capabilities

of the Keysight TS-5020 system include the specifications of the

individual instruments used in the test(s) combined with the

offsets in the system environment due to the measurement

paths. The largest contributors to measurement variations are

the instruments and the relays in the paths. The process for

determining system capabilities is:

• Determine the accuracy required to test the ECM. For example, a

particular output driver test measurement requires a measurement

of 12.5 volts ±10 mV.

• Determine the path, including the number of relays, to the DUT

from the based DMM.

• Determine the specification of the instrument from the module

manual specifications section for the particular range which will be

used for the test.

• Calculate the sum of the accuracy uncertainty due to instrument

modules' specifications and system switch paths, and compare it

to accuracy required by the DUT.

System Capability DC Accuracy Sample

relay in the measurement path needs to be included in the algorithm for

calculating the system-level capability. The source voltage of 12.5 volts

is supplied by Power Supply. The 1-year Accuracy vs. Aperture (±(% of

reading + volts)) specification of the Keysight 34980A internal DMM

for dc voltage on the 100-volt range for 16.7/20 milliseconds is

0.0045% + 0.6 millivolt.

The relays for the measurement system route through the 34933 matrix

card, and are all the specified at 50 microvolts offset.

The calculated system capability (accuracy) on the 100-volt range, using

16.7/20 millisecond aperture range, when using the Keysight 34980A

internal DMM within its defined accuracy conditions is:

3-4 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 29

System Overview 3

DMM DC Accuracy + offset

+ relay V offset (DvmHi to abus1)

+ relay V offset (abus1 to Row matrix relay)

+ relay V offset (row matrix relay to abus2)

+ relay V offset (abus2 to DvmLo)

(This equals 4 relay offsets of 50uV each)

Calculated system capability = ±[(0.0045%*12.5 + 0.6 mV) + 4*50uV]

= ±1.36 mV

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-5

Page 30

3 System Overview

Test System Interface Description

The Keysight TS-5020 Test System Interface provides a common

connection interface between the test stand and your test

fixture/Unit Under Test (UUT). The Test System Interface

provides flexibility for specific test requirements and is

pre-wired and integrated to test stand equipment,

Test System Interface Connectors

There two types of Test system Interface Connectors;

• Express Connect

• Macpanel L2000 (TITAN)

Express Connect Test System Interface

The Express Connect Test System Interface can contain either

of the following sets of test connectors:

• TC1 through TC4

• TC1 through TC8

Test connectors TC1 to TC4 or TC1 to TC8 provide the majority

of the connections to the UUT.

These connectors are 156-pin, ITT Cannon Zero-Insertion-Force

connectors.

Figure 3-1 and Figure 3-2 show the outline of the connector

sets.

3-6 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 31

System Overview 3

Figure 3-1 Express Connect Test System Interface TC1 Through TC4

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-7

Page 32

3 System Overview

Figure 3-2 Express Connect Test system Interface TC1 Through TC8

3-8 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 33

System Overview 3

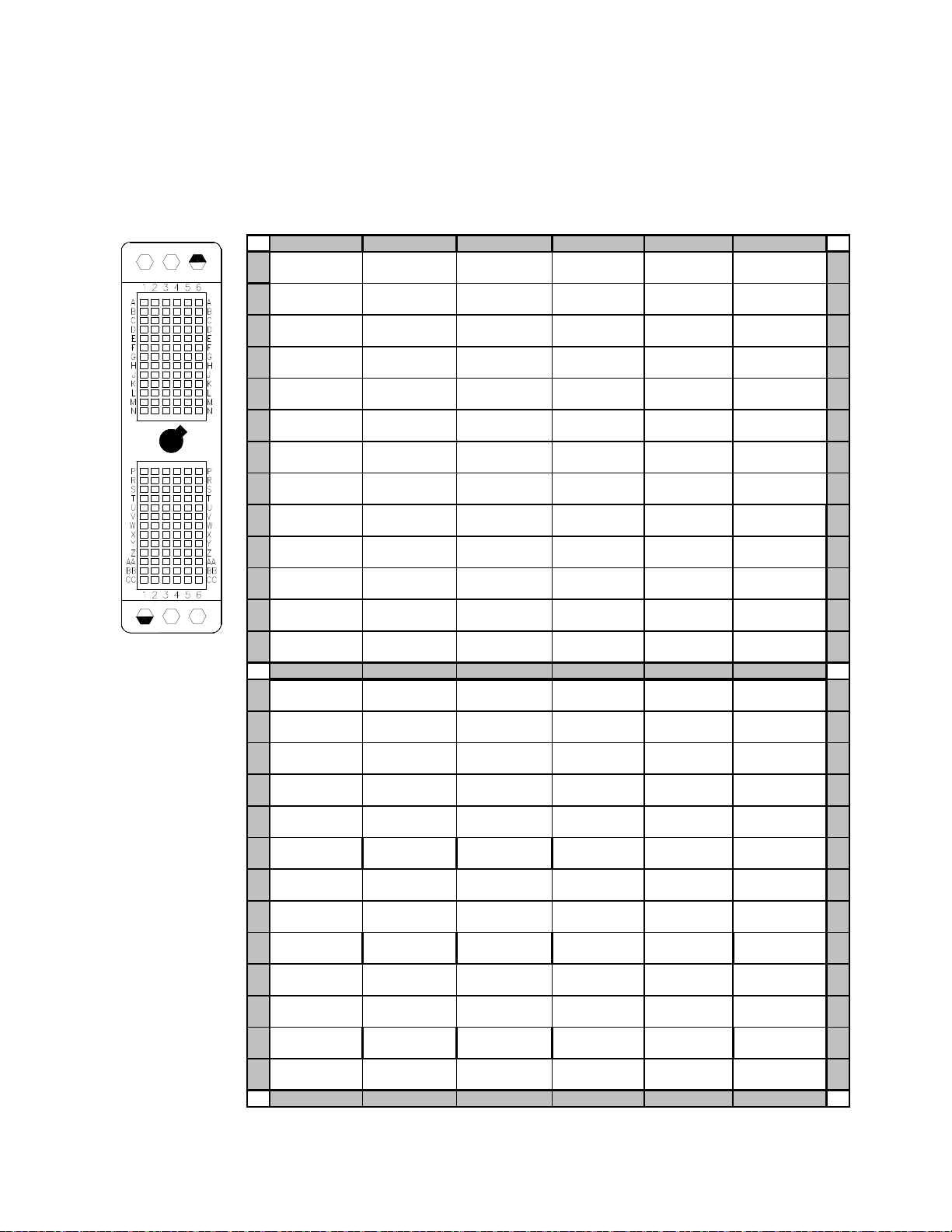

Macpanel L2000 (TITAN) Test System Interface

The Macpanel L2000 (TITAN) Test system Interface contain

either of the of the following sets of test connectors:

• S1 - System

• S2 - Instruments

• S3 - DAC

• S4 - RS232

• S5 - User define

• S6 - Matrix card

• S7 - Matrix card

• S8 - Matrix card

• S9 - Matrix card

• S10 - GP Relay Card

• S11 - 24-CH Load Card

• S12 - GP Relay Card

• S13 - 24-CH Load Card/GP Relay Card

• S14 - 16-CH Load Card/GP Relay Card

• S15 - 48-CH Load Card/GP Relay Card

• S16 - Heavy Duty Load Card/Electronic Load

• S17 - 24-CH Load Card

• S18 - Heavy Duty Load Card

• S19 - 16-CH Load Card

• S20 - 48-CH Load Card

• S21 - Matrix card

• S22 - Matrix card

• S23 - Matrix card

• S24 - Matrix card

• S25 - RF Interconnection

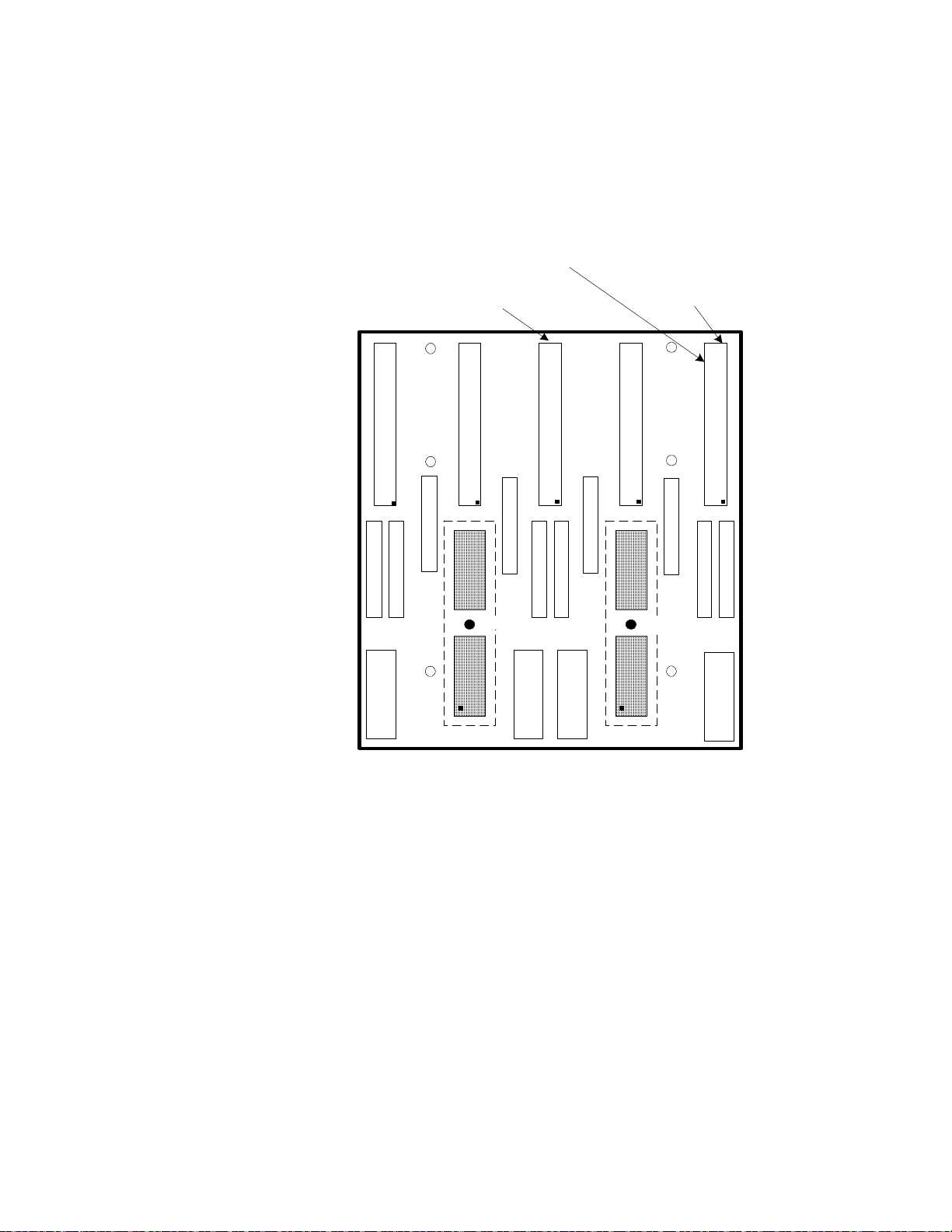

Figure 3-3 shows the outline of the connector sets.

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-9

Page 34

3 System Overview

Figure 3-3 Macpanel L2000 (TITAN) Test System Interface

3-10 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 35

System Overview 3

Tab l e 3 -2 L2000 (TITAN) Slot 1 (System)

Contact # Signal Contact # Signal Contact # Signal

1System Gnd33

2 Digital In (0) 34

3 Digital In (2) 35

4 Digital In (4) 36

5 Digital In (6) 37

6 Open Drain Out (0) 38

7 Open Drain Out (2) 39

8 Open Drain Out (4) 40

9 Open Drain Out (6) 41

10

11 Isense- (1) 43

12 Isense- (2) 44

13 Isense- (3) 45

14 Isense- (4) 46

15 PB Sense (1) 47

16 PB Sense (3) 48

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31 +12Vdc supply 63

32 System Gnd 64

No connection 42 PCI1750 DI 74 No connection

No connection 49 PCI1750 DO 81 No connection

No connection 50 PCI1750 DO 82 No connection

No connection 51 PCI1750 DO 83 No connection

No connection 52 PCI1750 DO 84 No connection

No connection 53 PCI1750 DO 85 No connection

No connection 54 PCI1750 DO 86 No connection

No connection 55 PCI1750 DO 87 No connection

No connection 56 PCI1750 DO 88 No connection

No connection 57 PCI1750 DO 89 No connection

No connection 58 PCI1750 DO 90 TX+

No connection 59 PCI1750 DO 91 TX-

PCI1750Com 60 PCI1750 DO 92 RX+

PCI1750IGND 61 PCI1750 DO 93 RX-

No connection 62 PCI1750 DO 94 No connection

PCI1750 DI 65 System Gnd

PCI1750 DI 66 Digital In (1)

PCI1750 DI 67 Digital In (3)

PCI1750 DI 68 Digital In (5)

PCI1750 DI 69 Digital In (7)

PCI1750 DI 70 Open Drain Out (1)

PCI1750 DI 71 Open Drain Out (3)

PCI1750 DI 72 Open Drain Out (5)

PCI1750 DI 73 Open Drain Out (6)

PCI1750 DI 75 Isense+ (1)

PCI1750 DI 76 Isense+ (2)

PCI1750 DI 77 Isense+ (3)

PCI1750 DI 78 Isense+ (4)

PCI1750 DI 79 PB Sense (2)

PCI1750 DI 80 PB Sense (4)

PCI1750 DO 95 +24Vdc supply

PCI1750 DO 96 System Gnd

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-11

Page 36

3-12 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Tab l e 3 -3 L2000 (TITAN) Slot 2 (Instruments)

Contact # Signal Contact # Signal Contact # Signal

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1

2

3

4

5

6

7

8

9

com1 Gnd

com1 CD

com1 RTS

com2 Gnd

com2 CD

com2 RTS

CAN1.1(+) (softing1)

CAN1.2(+) (softing1)

Spare instrument(+)

Spare instrument(+)

Digitizer/DSO CH3_H

Digitizer/DSO CH4_H

Spare instrument(+)

Spare instrument(+)

Spare instrument(+)

Spare instrument(+)

Spare instrument(+)

Spare instrument(+)

Spare instrument(+)

Spare instrument(+)

Spare instrument(+)

DMM Ext Trig (+)

DMM Gnd

ChassisGND

DUT PS1(+)

DUT PS1(-)

DUT PS2(+)

DUT PS2(-)

DUT PS3(+)

DUT PS3(-)

DUT PS4(+)

DUT PS4(-)

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

com1 Rx

com1 DTR

com1 CTS

com2 Rx

com2 DTR

com2 CTS

CAN1.1(-) (softing1)

CAN1.2(-) (softing1)

Spare instrument(-)

Spare instrument(-)

Digitizer/DSO CH3_L

Digitizer/DSO CH4_L

Spare instrument(-)

Spare instrument(-)

Spare instrument(-)

Spare instrument(-)

Spare instrument(-)

Spare instrument(-)

Spare instrument(-)

Spare instrument(-)

Spare instrument(-)

No connection

No connection

ChassisGND

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

com1 DSR

com2 DSR

CAN1.1(shield) (softing1)

CAN1.2(shield) (softing1)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

Spare instrument(shield)

No connection

No connection

ChassisGND

DUT PS1(S+)

DUT PS1(S-)

DUT PS2(S+)

DUT PS2(S-)

DUT PS3(S+)

DUT PS3(S-)

DUT PS4(S+)

DUT PS4(S-)

3 System Overview

com1 Tx

com1 RI

com2 Tx

com2 RI

Page 37

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-13

Tab l e 3 -4 L2000 (TITAN) Slot 3 (DAC)

Contact # Signal Contact # Signal Contact # Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

DAC1 Ch1 Hi

DAC1 Ch1 Hi Sense

DAC1 Ch2 Hi

DAC1 Ch2 Hi Sense

DAC1 Ch3 Hi

DAC1 Ch3 Hi Sense

DAC1 Ch4 Hi

DAC1 Ch4 Hi Sense

DAC2 Ch1 Hi

DAC2 Ch1 Hi Sense

DAC2 Ch2 Hi

DAC2 Ch2 Hi Sense

DAC2 Ch3 Hi

DAC2 Ch3 Hi Sense

DAC2 Ch4 Hi

DAC2 Ch4 Hi Sense

DAC3 Ch1 Hi

DAC3 Ch1 Hi Sense

DAC3 Ch2 Hi

DAC3 Ch2 Hi Sense

DAC3 Ch3 Hi

DAC3 Ch3 Hi Sense

DAC3 Ch4 Hi

DAC3 Ch4 Hi Sense

DAC4 Ch1 Hi

DAC4 Ch1 Hi Sense

DAC4 Ch2 Hi

DAC4 Ch2 Hi Sense

DAC4 Ch3 Hi

DAC4 Ch3 Hi Sense

DAC4 Ch4 Hi

DAC4 Ch4 Hi Sense

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

DAC1 Ch1 Lo

DAC1 Ch1 Lo Sense

DAC1 Ch2 Lo

DAC1 Ch2 Lo Sense

DAC1 Ch3 Lo

DAC1 Ch3 Lo Sense

DAC1 Ch4 Lo

DAC1 Ch4 Lo Sense

DAC2 Ch1 Lo

DAC2 Ch1 Lo Sense

DAC2 Ch2 Lo

DAC2 Ch2 Lo Sense

DAC2 Ch3 Lo

DAC2 Ch3 Lo Sense

DAC2 Ch4 Lo

DAC2 Ch4 Lo Sense

DAC3 Ch1 Lo

DAC3 Ch1 Lo Sense

DAC3 Ch2 Lo

DAC3 Ch2 Lo Sense

DAC3 Ch3 Lo

DAC3 Ch3 Lo Sense

DAC3 Ch4 Lo

DAC3 Ch4 Lo Sense

DAC4 Ch1 Lo

DAC4 Ch1 Lo Sense

DAC4 Ch2 Lo

DAC4 Ch2 Lo Sense

DAC4 Ch3 Lo

DAC4 Ch3 Lo Sense

DAC4 Ch4 Lo

DAC4 Ch4 Lo Sense

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

DAC1 Trigger

DAC1 Ext Clk

DAC1 Gnd

DAC1 Gnd

No Connection

No Connection

No Connection

No Connection

DAC2 Trigger

DAC2 Ext Clk

DAC2 Gnd

DAC2 Gnd

No Connection

No Connection

No Connection

No Connection

DAC3 Trigger

DAC3 Ext Clk

DAC3 Gnd

DAC3 Gnd

No Connection

No Connection

No Connection

No Connection

DAC4 Trigger

DAC4 Ext Clk

DAC4 Gnd

DAC4 Gnd

No Connection

No Connection

No Connection

No Connection

System Overview 3

Page 38

3-14 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Tab l e 3 -5 L2000 (TITAN) Slot 4 (RS232)

Contact # signal Contact # signal Contact # signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

com3 Gnd

com3 CD

com3 RTS

com4 Gnd

com4 CD

com4 RTS

com5 Gnd

com5 CD

com5 RTS

com6 Gnd

com6 CD

com6 RTS

com7 Gnd

com7 CD

com7 RTS

com8 Gnd

com8 CD

com8 RTS

com9 Gnd

com9 CD

com9 RTS

com10 Gnd

com10 CD

com10 RTS

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

com3 Rx

com3 DTR

com3 CTS

com4 Rx

com4 DTR

com4 CTS

com5 Rx

com5 DTR

com5 CTS

com6 Rx

com6 DTR

com6 CTS

com7 Rx

com7 DTR

com7 CTS

co8 Rx

com8 DTR

com8 CTS

com9 Rx

com9 DTR

com9 Rx

com10 Rx

com10 DTR

com10 CTS

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

com10 DSR

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

3 System Overview

com3 Tx

com3 DSR

com3 RI

com4 Tx

com4 DSR

com4 RI

com5 Tx

com5 DSR

com5 RI

com6 Tx

com6 DSR

com6 RI

com7 Tx

com7 DSR

com7 RI

com8 Tx

com8 DSR

com8 RI

com9 Tx

com9 DSR

com9 RI

com10 Tx

com10 RI

Page 39

System Overview 3

Tab l e 3 -6 L2000 (TITAN) Slot 6 (Pin Matrix 1st Card 34933A)

Contact # Signal Contact # Signal Contact # Signal

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1

2

3

4

5

6

7

8

9

matrix001.row1

matrix001.row2

matrix001.row3

matrix001.row4

matrix001.row5

matrix001.row6

matrix001.row7

matrix001.row8

matrix001.row9

matrix001.row10

matrix001.row11

matrix001.row12

matrix001.row13

matrix001.row14

matrix001.row15

matrix001.row16

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-15

Page 40

3 System Overview

Tab l e 3 - 7 L2000 (TITAN) Slot 7 to 9 (Matrix Card 34933A)

Contact # Signal Contact # Signal Contact # Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

matrix00x.row1

matrix00x.row2

matrix00x.row3

matrix00x.row4

matrix00x.row5

matrix00x.row6

matrix00x.row7

matrix00x.row8

matrix00x.row9

matrix00x.row10

matrix00x.row11

matrix00x.row12

matrix00x.row13

matrix00x.row14

matrix00x.row15

matrix00x.row16

matrix00x.row17

matrix00x.row18

matrix00x.row19

matrix00x.row20

matrix00x.row21

matrix00x.row22

matrix00x.row23

matrix00x.row24

matrix00x.row25

matrix00x.row26

matrix00x.row27

matrix00x.row28

matrix00x.row29

matrix00x.row30

matrix00x.row31

matrix00x.row32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

3-16 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 41

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-17

Tab l e 3 -8 L2000 (TITAN) Slot 6 (Pin Matrix 1st Card (34934A))

Contact # signal Contact # signal Contact # signal

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1

2

3

4

5

6

7

8

9

matrix001.row1

matrix001.row2

matrix001.row3

matrix001.row4

matrix001.row5

matrix001.row6

matrix001.row7

matrix001.row8

matrix001.row9

matrix001.row10

matrix001.row11

matrix001.row12

matrix001.row13

matrix001.row14

matrix001.row15

matrix001.row16

matrix001.row17

matrix001.row18

matrix001.row19

matrix001.row20

matrix001.row21

matrix001.row22

matrix001.row23

matrix001.row24

matrix001.row25

matrix001.row26

matrix001.row27

matrix001.row28

matrix001.row29

matrix001.row30

matrix001.row31

matrix001.row32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

matrix001.Inst17

matrix001.Inst18

matrix001.Inst19

matrix001.Inst20

matrix001.Inst21

matrix001.Inst22

matrix001.Inst23

matrix001.Inst24

matrix001.Inst25

matrix001.Inst26

matrix001.Inst27

matrix001.Inst28

matrix001.Inst29

matrix001.Inst30

matrix001.Inst31

matrix001.Inst32

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

No connection

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

System Overview 3

Page 42

3-18 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Tab l e 3 -9 L2000 (TITAN) Slot 7 (Pin Matrix 1st Card (34934A))

Contact # Signal Contact # Signal Contact # Signal

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1

2

3

4

5

6

7

8

9

matrix001.row33

matrix001.row34

matrix001.row35

matrix001.row36

matrix001.row37

matrix001.row38

matrix001.row39

matrix001.row40

matrix001.row41

matrix001.row42

matrix001.row43

matrix001.row44

matrix001.row45

matrix001.row46

matrix001.row47

matrix001.row48

matrix001.row49

matrix001.row50

matrix001.row51

matrix001.row52

matrix001.row53

matrix001.row54

matrix001.row55

matrix001.row56

matrix001.row57

matrix001.row58

matrix001.row59

matrix001.row60

matrix001.row61

matrix001.row62

matrix001.row63

matrix001.row64

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

matrix001.row65

matrix001.row66

matrix001.row67

matrix001.row68

matrix001.row69

matrix001.row70

matrix001.row71

matrix001.row72

matrix001.row73

matrix001.row74

matrix001.row75

matrix001.row76

matrix001.row77

matrix001.row78

matrix001.row79

matrix001.row80

matrix001.row81

matrix001.row82

matrix001.row83

matrix001.row84

matrix001.row85

matrix001.row86

matrix001.row87

matrix001.row88

matrix001.row89

matrix001.row90

matrix001.row91

matrix001.row92

matrix001.row93

matrix001.row94

matrix001.row95

matrix001.row96

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

3 System Overview

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

Page 43

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-19

Table 3-10 L2000 (TITAN) Slot 8/21/23 (Pin Matrix Card (34934A))

Contact # Signal Contact # Signal Contact # Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

matrix00x.row1

matrix00x.row2

matrix00x.row3

matrix00x.row4

matrix00x.row5

matrix00x.row6

matrix00x.row7

matrix00x.row8

matrix00x.row9

matrix00x.row10

matrix00x.row11

matrix00x.row12

matrix00x.row13

matrix00x.row14

matrix00x.row15

matrix00x.row16

matrix00x.row17

matrix00x.row18

matrix00x.row19

matrix00x.row20

matrix00x.row21

matrix00x.row22

matrix00x.row23

matrix00x.row24

matrix00x.row25

matrix00x.row26

matrix00x.row27

matrix00x.row28

matrix00x.row29

matrix00x.row30

matrix00x.row31

matrix00x.row32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

matrix00x.row33

matrix00x.row34

matrix00x.row35

matrix00x.row36

matrix00x.row37

matrix00x.row38

matrix00x.row39

matrix00x.row40

matrix00x.row41

matrix00x.row42

matrix00x.row43

matrix00x.row44

matrix00x.row45

matrix00x.row46

matrix00x.row47

matrix00x.row48

matrix00x.row49

matrix00x.row50

matrix00x.row51

matrix00x.row52

matrix00x.row53

matrix00x.row54

matrix00x.row55

matrix00x.row56

matrix00x.row57

matrix00x.row58

matrix00x.row59

matrix00x.row60

matrix00x.row61

matrix00x.row62

matrix00x.row63

matrix00x.row64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

System Overview 3

Page 44

3-20 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Table 3-11 L2000 (TITAN) Slot 9/22/24 (Pin Matrix Card (34934A))

Contact # Signal Contact # Signal Contact # Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

matrix00x.row65

matrix00x.row66

matrix00x.row67

matrix00x.row68

matrix00x.row69

matrix00x.row70

matrix00x.row71

matrix00x.row72

matrix00x.row73

matrix00x.row74

matrix00x.row75

matrix00x.row76

matrix00x.row77

matrix00x.row78

matrix00x.row79

matrix00x.row80

matrix00x.row81

matrix00x.row82

matrix00x.row83

matrix00x.row84

matrix00x.row85

matrix00x.row86

matrix00x.row87

matrix00x.row88

matrix00x.row89

matrix00x.row90

matrix00x.row91

matrix00x.row92

matrix00x.row93

matrix00x.row94

matrix00x.row95

matrix00x.row96

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

matrix00x.row97

matrix00x.row98

matrix00x.row99

matrix00x.row100

matrix00x.row101

matrix00x.row102

matrix00x.row103

matrix00x.row104

matrix00x.row105

matrix00x.row106

matrix00x.row107

matrix00x.row108

matrix00x.row109

matrix00x.row110

matrix00x.row111

matrix00x.row112

matrix00x.row113

matrix00x.row114

matrix00x.row115

matrix00x.row116

matrix00x.row117

matrix00x.row118

matrix00x.row119

matrix00x.row120

matrix00x.row121

matrix00x.row122

matrix00x.row123

matrix00x.row124

matrix00x.row125

matrix00x.row126

matrix00x.row127

matrix00x.row128

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

UUTCOM

3 System Overview

Page 45

System Overview 3

Table 3-12 L2000 (TITAN) Slot 12 to 15 (GP relay Card (34938A))

Contact # Signal Contact # Signal Contact # Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

loadcard00x.Ch1

loadcard00x.Ch2

loadcard00x.Ch3

loadcard00x.Ch4

loadcard00x.Ch5

loadcard00x.Ch6

loadcard00x.Ch7

loadcard00x.Ch8

loadcard00x.Ch9

loadcard00x.Ch10

loadcard00x.Ch11

loadcard00x.Ch12

loadcard00x.Ch13

loadcard00x.Ch14

loadcard00x.Ch15

loadcard00x.Ch16

loadcard00x.Ch17

loadcard00x.Ch18

loadcard00x.Ch19

loadcard00x.Ch20

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

loadcard00x.Pwr1

loadcard00x.Pwr2

loadcard00x.Pwr3

loadcard00x.Pwr4

loadcard00x.Pwr5

loadcard00x.Pwr6

loadcard00x.Pwr7

loadcard00x.Pwr8

loadcard00x.Pwr9

loadcard00x.Pwr10

loadcard00x.Pwr11

loadcard00x.Pwr12

loadcard00x.Pwr13

loadcard00x.Pwr14

loadcard00x.Pwr15

loadcard00x.Pwr16

loadcard00x.Pwr17

loadcard00x.Pwr18

loadcard00x.Pwr19

loadcard00x.Pwr20

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

No Connection

TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference 3-21

Page 46

3 System Overview

Table 3-13 L2000 (TITAN) Slot 12 to 15 (GP relay Card (34939A))

Contact # Signal Contact # Signal Contact # Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

loadcard00x.Ch1

loadcard00x.Ch3

loadcard00x.Ch5

loadcard00x.Ch7

loadcard00x.Ch9

loadcard00x.Ch11

loadcard00x.Ch13

loadcard00x.Ch15

loadcard00x.Ch17

loadcard00x.Ch19

loadcard00x.Ch21

loadcard00x.Ch23

loadcard00x.Ch25

loadcard00x.Ch27

loadcard00x.Ch29

loadcard00x.Ch31

loadcard00x.Ch33

loadcard00x.Ch35

loadcard00x.Ch37

loadcard00x.Ch39

loadcard00x.Ch41

loadcard00x.Ch43

loadcard00x.Ch45

loadcard00x.Ch47

loadcard00x.Ch49

loadcard00x.Ch51

loadcard00x.Ch53

loadcard00x.Ch55

loadcard00x.Ch57

loadcard00x.Ch59

loadcard00x.Ch61

loadcard00x.Ch63

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

loadcard00x.Ch2

loadcard00x.Ch4

loadcard00x.Ch6

loadcard00x.Ch8

loadcard00x.Ch10

loadcard00x.Ch12

loadcard00x.Ch14

loadcard00x.Ch16

loadcard00x.Ch18

loadcard00x.Ch20

loadcard00x.Ch22

loadcard00x.Ch24

loadcard00x.Ch26

loadcard00x.Ch28

loadcard00x.Ch30

loadcard00x.Ch32

loadcard00x.Ch34

loadcard00x.Ch36

loadcard00x.Ch38

loadcard00x.Ch40

loadcard00x.Ch42

loadcard00x.Ch44

loadcard00x.Ch46

loadcard00x.Ch48

loadcard00x.Ch50

loadcard00x.Ch52

loadcard00x.Ch54

loadcard00x.Ch56

loadcard00x.Ch58

loadcard00x.Ch60

loadcard00x.Ch62

loadcard00x.Ch64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

loadcard00x.Pwr1-2

loadcard00x.Pwr3-4

loadcard00x.Pwr5-6

loadcard00x.Pwr7-8

loadcard00x.Pwr9-10

loadcard00x.Pwr11-12

loadcard00x.Pwr13-14

loadcard00x.Pwr15-16

loadcard00x.Pwr17-18

loadcard00x.Pwr19-20

loadcard00x.Pwr21-22

loadcard00x.Pwr23-24

loadcard00x.Pwr25-26

loadcard00x.Pwr27-28

loadcard00x.Pwr29-30

loadcard00x.Pwr31-32

loadcard00x.Pwr33-34

loadcard00x.Pwr35-36

loadcard00x.Pwr37-38

loadcard00x.Pwr39-40

loadcard00x.Pwr41-42

loadcard00x.Pwr43-44

loadcard00x.Pwr45-46

loadcard00x.Pwr47-48

loadcard00x.Pwr49-50

loadcard00x.Pwr51-52

loadcard00x.Pwr53-54

loadcard00x.Pwr55-56

loadcard00x.Pwr57-58

loadcard00x.Pwr59-60

loadcard00x.Pwr61-62

loadcard00x.Pwr63-64

3-22 TS-5020 Automotive Electronics Functional Test System Wiring Guide and Hardware Reference

Page 47

System Overview 3

Table 3-14 L2000 (TITAN) Slot 11 to 20 (24-CH Load Card)

Wiring Table for E6177A/U7177A/N9378A

Contact # Signal Contact # Signal Contact # Signal

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1

2

3

4

5

6

7

8

9

loadcard10x.Ch1

loadcard10x.Ch2

loadcard10x.Ch3

loadcard10x.Ch4

loadcard10x.Ch5

loadcard10x.Ch6

loadcard10x.Ch7

loadcard10x.Ch8

loadcard10x.Ch9

loadcard10x.Ch10

loadcard10x.Ch11

loadcard10x.Ch12

loadcard10x.Ch13

loadcard10x.Ch14

loadcard10x.Ch15

loadcard10x.Ch16

loadcard10x.Ch17

loadcard10x.Ch18

loadcard10x.Ch19

loadcard10x.Ch20

loadcard10x.Ch21

loadcard10x.Ch22

loadcard10x.Ch23

loadcard10x.Ch24

loadcard10y.Ch1

loadcard10y.Ch23

loadcard10y.Ch3

loadcard10y.Ch4

loadcard10y.Ch5

loadcard10y.Ch6

loadcard10y.Ch7

loadcard10y.Ch8

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

loadcard10y.Ch9

loadcard10y.Ch10

loadcard10y.Ch11

loadcard10y.Ch12

loadcard10y.Ch13

loadcard10y.Ch14

loadcard10y.Ch15