Page 1

Keysight RP7900 Series

Regenerative Power System

This manual provides the documentation for the following

instruments: RP7951AT, RP7952AT, N6991A, RP7951A,

RP7952A, RP7953A, RP7961A, RP7962A, and RP7963A

Advanced

Service Guide

Page 2

Notices

CAUTION

WARNING

Copyright Notice

© Keysight Technologies 2019

No part of this manual may be repro-

duced in any form or by any means

(including electronic storage and

retrieval or translation into a foreign

language) without prior agreement and

written consent from Keysight Technologies as governed by United States and

international copyright laws.

Manual Part Number

RP7900-90000

Edition

Edition 1, July 11, 2019

Printed in:

Printed in Malaysia

Published by:

Keysight Technologies

Bayan Lepas Free Industrial Zone,

11900 Penang, Malaysia

Technology Licenses

The hardware and/or software

described in this document are furnished under a license and may be

used or copied only in accordance with

the terms of such license.

Declaration of Conformity

Declarations of Conformity for this

product and for other Keysight products may be downloaded from the

Web. Go to http://www.keysight.com/

go/conformity. You can then search by

product number to find the latest Declaration of Conformity.

U.S. Government Rights

The Software is “commercial computer

software,” as defined by Federal Acquisition Regulation (“FAR”) 2.101. Pursuant to FAR 12.212 and 27.405-3 and

Department of Defense FAR Supplement (“DFARS”) 227.7202, the U.S.

government acquires commercial computer software under the same terms

by which the software is customarily

provided to the public. Accordingly,

Keysight provides the Software to U.S.

government customers under its standard commercial license, which is

embodied in its End User License

Agreement (EULA), a copy of which can

be found at http://www.keysight.com/

find/sweula. The license set forth in the

EULA represents the exclusive authority

by which the U.S. government may use,

modify, distribute, or disclose the Software. The EULA and the license set

forth therein, does not require or permit, among other things, that Keysight:

(1) Furnish technical information

related to commercial computer software or commercial computer software

documentation that is not customarily

provided to the public; or (2) Relinquish

to, or otherwise provide, the government rights in excess of these rights

customarily provided to the public to

use, modify, reproduce, release, perform, display, or disclose commercial

computer software or commercial computer software documentation. No

additional government requirements

beyond those set forth in the EULA

shall apply, except to the extent that

those terms, rights, or licenses are

explicitly required from all providers of

commercial computer software pursuant to the FAR and the DFARS and are

set forth specifically in writing elsewhere in the EULA. Keysight shall be

under no obligation to update, revise or

otherwise modify the Software. With

respect to any technical data as

defined by FAR 2.101, pursuant to FAR

12.211 and 27.404.2 and DFARS

227.7102, the U.S. government

acquires no greater than Limited Rights

as defined in FAR 27.401 or DFAR

227.7103-5 (c), as applicable in any

technical data.

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,”

AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO THE

MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, KEYSIGHT DISCLAIMS ALL WARRANTIES, EITHER

EXPRESS OR IMPLIED, WITH REGARD

TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS

OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION

WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT

OR OF ANY INFORMATION CONTAINED HEREIN. SHOULD KEYSIGHT

AND THE USER HAVE A SEPARATE

WRITTEN AGREEMENT WITH WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Safety Information

A CAUTION notice denotes a hazard. It

calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not proceed beyond a CAUTION notice until

the indicated conditions are fully

understood and met.

A WARNING notice denotes a hazard. It

calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in personal injury or death.

Do not proceed beyond a WARNING

notice until the indicated conditions are

fully understood and met.

2 Keysight RP7900 Series Advanced Service Guide

Page 3

Safety Notices

WARNING

WARNING

The following general safety precautions must be observed during all phases of

operation of this instrument. Failure to comply with these precautions or with

specific warnings or instructions elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instrument. Keysight

Technologies assumes no liability of the customer’s failure to comply with the

requirements.

The equipment is for industrial use. Equipment operators are subject to all

applicable safety regulations. Along with the warning and safety notices in this

manual, all relevant safety, accident prevention, and environmental regulations

must also be followed. In particular, the operators of the equipment:

– Must be informed of the relevant safety requirements.

– Must have read and understood the operating manual before using the

– Must use the designated and recommended safety equipment.

General

Do not use this product in any manner not specified by the manufacturer.

The protective features of this product may be impaired if it is used in a

manner not specified in the operating instructions.

equipment.

Keysight RP7900 Series Advanced Service Guide 3

Environmental conditions

Never use the instrument outside of the specified environmental conditions

described in the Environmental Characteristics of the RP7900 Series

Operating and Service Guide.

Page 4

WARNING

Heavy weight

WARNING

WARNING

Danger to hands and feet. To avoid personal injury and damage to the

instrument, always use a sturdy cart or other suitable device to move the

instrument. Do not lift the instrument alone; always use two people to lift

the instrument.

SHOCK HAZARD - Ground the instrument

This product is provided with a protective earth terminal. To minimize shock

hazard, the instrument must be connected to the AC mains through a

grounded power cable, with the ground wire firmly connected to an

electrical ground (safety ground) at the power outlet. Any interruption of the

protective (grounding) conductor or disconnection of the protective earth

terminal will cause a potential shock hazard that could result in injury or

death.

Before applying power

Verify that all safety precautions are taken. All connections must be made

with the unit turned off, and must be performed by qualified personnel who

are aware of the hazards involved. Improper actions can cause fatal injury as

well as equipment damage. Note the instrument's external markings

described under Safety Symbols and Regulatory Markings.

4 Keysight RP7900 Series Advanced Service Guide

Page 5

WARNING

SHOCK HAZARD, LETHAL VOLTAGES

WARNING

WARNING

WARNING

WARNING

Many models generate voltages greater than 60 VDC, with some models

rated at 950 VDC! Ensure that all instrument connections, load wiring, and

load connections are either insulated or covered using the safety covers

provided, so that no accidental contact with lethal voltages can occur.

SHOCK HAZARD

Never touch cables or connections immediately after turning off the unit.

Depending on the model, lethal voltages can remain at the output terminals

for several seconds after turn-off. Verify that there is no dangerous voltage

on the output or sense terminals before touching them.

SHOCK HAZARD from external energy sources

Because the instrument can be used as a load to sink current, hazardous

voltages from an external energy source such as a battery may be present on

the output terminals even with the unit turned off. Provision must be made

to disconnect the external energy source before touching the output or

sense terminals.

Keysight RP7900 Series Advanced Service Guide 5

Do not operate in an explosive atmosphere

Do not operate the instrument in the presence of flammable gases or fumes.

Do not remove the instrument cover

Only qualified, service-trained personnel who are aware of the hazards

involved should remove instrument covers. Always d isconnect the power

cable and any external circuits before removing the instrument cover.

Page 6

WARNING

Do not modify the instrument

WARNING

WARNING

WARNING

Do not install substitute parts or perform any unauthorized modification to

the product. Return the product to a Keysight Sales and Service Office for

service and repair to ensure that safety features are maintained.

Fuses

The instrument contains an internal fuse, which is not customer accessible.

Cleaning

To prevent electric shock, always disconnect the AC mains before cleaning.

Use a dry cloth or one slightly dampened with water to clean the external

case parts. Do not use detergent or chemical solvents. Do not attempt to

clean internally.

In case of damage

Instruments that are not functioning correctly, appear damaged or defective

should be made inoperative and secured against unintended operation until

they can be repaired by qualified service personnel.

6 Keysight RP7900 Series Advanced Service Guide

Page 7

Safety Symbols and Regulatory Markings

Alternating current (AC) Protective earth (ground) terminal

Earth (ground) terminal

Frame or chassis (ground) terminal Caution, risk of electric shock

Standby supply. Unit is not completely

disconnected from AC mains when

switch is off.

The ETL mark is a registered trademark

of Intertek. The text indicates product

compliance with the Canadian

Interference- Causing Equipment

Standard (ICES-001).

Caution, risk of danger (refer to this

manual for specific Warning or Caution

information)

The CE mark is a registered trademark

of the European Community. This CE

mark shows that the product complies

with all the relevant European Legal

Directives.

ICES/NMB-001 - This ISM device

complies with the Canadian ICES-001.

Cet appareil ISM est conforme a la

norme NMB-001 du Canada.

ISM GRP 1-A - This is an Industrial

Scientific and Medical (ISM) Group 1

Class A product.

This product is marked with the ACMA

RCM mark for compliance in Australia/

New Zealand. A copy of the

Manufacturer's Australia Declaration of

Conformity for this instrument can be

obtained by contacting your local

Keysight Technologies Sales

Representative.

This symbol indicates the time period

during which no hazardous or toxic

substance elements are expected to

leak or deteriorate during normal use.

Forty years is the expected useful life

of the product.

This symbol is a South Korean Class A

EMC Declaration. This is a Class A

instrument suitable for professional

use and in electromagnetic

environment outside of the home.

Keysight RP7900 Series Advanced Service Guide 7

Page 8

South Korean Class A EMC Declaration

Information to the user:

This instrument has been conformity assessed for used in business environments.

In a residential environment this equipment may caused radio interference.

This EMC statement applies to the equipment only for use in business

environment.

사 용 자 안 내 문

이 기 기 는 업 무 용 환 경 에 서 사 용 할 목 적 으 로 적 합 성 평 가 를 받 은 기 기 로 서 가 정

용 환 경 에 서 사 용 하 는 경 우 전 파 간 섭 의 우 려 가 있 습 니 다 .

사용자 안내문은 " 업무용 방송통신기자재 " 에만 적용한다 .

8 Keysight RP7900 Series Advanced Service Guide

Page 9

Waste Electrical and Electronic Equipment (WEEE) Directive

This instrument complies with the WEEE Directive marking requirement. This

affixed product label indicates that you must not discard this electrical or

electronic product in domestic household waste.

Product category:

With reference to the equipment types in the WEEE directive Annex 1, this

instrument is classified as a “Monitoring and Control Instrument” product.

The affixed product label is as shown below.

Do not dispose in domestic household waste.

To return this unwanted instrument, contact your nearest Keysight Service Center,

or visit http://about.keysight.com/en/companyinfo/environment/takeback.shtml

for more information.

Sales and Technical Support

To contact Keysight for sales and technical support, refer to the support links on

the following Keysight websites:

– www.keysight.com/find/RP7900

(product-specific information and support, software and

documentation updates)

– www.keysight.com/find/assist

(worldwide contact information for repair and service)

Keysight RP7900 Series Advanced Service Guide 9

Page 10

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

10 Keysight RP7900 Series Advanced Service Guide

Page 11

Table of Contents

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Symbols and Regulatory Markings . . . . . . . . . . . . . . . . . . . . . . . .7

South Korean Class A EMC Declaration . . . . . . . . . . . . . . . . . . . . . . . . .8

Waste Electrical and Electronic Equipment (WEEE) Directive . . . . . . . .9

Product category: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Sales and Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1 Troubleshooting

Safety Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Before, During, and After Troubleshooting . . . . . . . . . . . . . . . . . . . . . .15

Introduction to the Titan HV (RP7900 Series) Architecture . . . . . . . . .16

Titan HV architecture: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

General Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . .26

List of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Hardware Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Required equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Hardware trouble shooting procedure . . . . . . . . . . . . . . . . . . . . . . . 32

2Disassembly

Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . . . . . .40

Disassembly Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Disassembly Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Removing/Installing flat flexible cables (FFC) or ribbon cables . . . .42

Assembly procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Removing the top chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Removing the PFC control board . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Removing the digital personality module PCA . . . . . . . . . . . . . . . . .48

Removing the isolation and isolation attic board (top and bottom) from

the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Keysight RP7900 Series Advanced Service Guide 11

Page 12

Removing the regulation magnitcs PCA from the regulation PCA . 55

Removing the isolation partition, insulator regulation, and chassis

module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Removing the output and back plane assembly . . . . . . . . . . . . . . . 59

Removing the bias bracket from the chassis . . . . . . . . . . . . . . . . . . 62

Removing the constellation and P600 assembly from the chassis . 63

Removing the GPIB board from the chassis . . . . . . . . . . . . . . . . . . . 65

Removing the IO board from the chassis . . . . . . . . . . . . . . . . . . . . . 66

Removing the front panel from the chassis . . . . . . . . . . . . . . . . . . . 67

Removing the front frame vent from the chassis . . . . . . . . . . . . . . . 70

Removing the fan bracket assembly from the chassis . . . . . . . . . . . 71

3Replaceable Parts

RP7900 Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12 Keysight RP7900 Series Advanced Service Guide

Page 13

Keysight RP7900 Series Regenerative Power System

Advanced Service Guide

1 Troubleshooting

Safety Precaution 14

Before, During, and After Troubleshooting 15

Introduction to the Titan HV (RP7900 Series) Architecture 16

General Troubleshooting Information 26

List of Error Codes 27

Hardware Troubleshooting Guide 31

This chapter lists the possible errors and their description and discusses the

procedures for troubleshooting the Keysight RP7900 Series Regenerative Power

System.

13

Page 14

1 Troubleshooting

WARNING

CAUTION

Safety Precaution

A WARNING notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that, if not correctly performed or adhered to,

could result in personal injury or death. Do not proceed beyond a WARNING

notice until the indicated conditions are fully understood and met.

A CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that, if not correctly performed or adhered to,

could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

Read the information in the “Safety Notices” on page 3 and the “Safety Symbols

and Regulatory Markings” on page 7 before proceeding with the rest of this

chapter.

Ensure that all safety precautions are observed during all phases of operation of

this instrument. Failure to comply with these precautions or with specific warnings

or instructions elsewhere in this manual or in the RP7900 Series Operating and

Service Guide violates safety standards of design, manufacture, and intended use

of the instrument. Keysight Technologies assumes no liability of the customer’s

failure to comply with the requirements.

This manual serves as a complement to the RP7900 Series Operating and Service

Guide. Only qualified, service-trained personnel who have read the Operating and

Service Guide prior to this should attempt the procedures listed in this manual.

14 Keysight RP7900 Series Advanced Service Guide

Page 15

Before, During, and After Troubleshooting

1 Before turning on the unit under test (UUT):

– Make sure all connections are done correctly.

– Connect the 3-phase power cord to the UUT before connecting the plug to

3-phase main power trunk.

2During test:

– DO NOT probe any area of the UUT as there is HIGH RAIL VOLTAGE present

while the UUT is powered ON.

– If you wish to measure any test points, always ensure that the DMM probes

stay on the measurement area before powering on the UUT.

3 After test:

– Turn off the UUT and all other testing equipment.

– Unplug the 3-phase power cord immediately.

– DO NOT touch any location of the UUT as the HIGH RAIL VOLTAGE is slowly

discharging (the RAIL LED is RED).

– Wait 5 minutes or until the RAIL LED is OFF before performing any

disassembly procedure.

Troubleshooting 1

Keysight RP7900 Series Advanced Service Guide 15

Page 16

1 Troubleshooting

Introduction to the Titan HV (RP7900 Series) Architecture

Listed below are the Titan HV models (RP7900 Series):

– RP7951AT, RP7952AT, N6991AT

– RP7951A, RP7952A, RP7953A: Using AC input 208 Vrms

– RP7961A, RP7962A, RP7963A: Using AC input 400 Vrms

Specification RP7951A/RP7961A RP7952A/RP7962A RP7953A/RP7963A

DC ratings

Voltage source:

Current source and sink:

Power:

A Titan HV unit consists of:

– 3-phase AC/DC front end

– DC/DC isolation stage

– Non-isolated DC/DC regulation stage

– Control board and digital personality module (DPM)

[1]

: Using AC input 208 Vrms

0 to 500 V

0 to ±20 A

5 kW

0 to 500 V

0 to ±40 A

10 kW

0 to 950 V

0 to ±20 A

10 kW

– Output board

–Bias board

– Customer interface board (P600 and carrier)

[1] Limited distirbution/customers only. Not available for sale to the public on www.keysight.com.

16 Keysight RP7900 Series Advanced Service Guide

Page 17

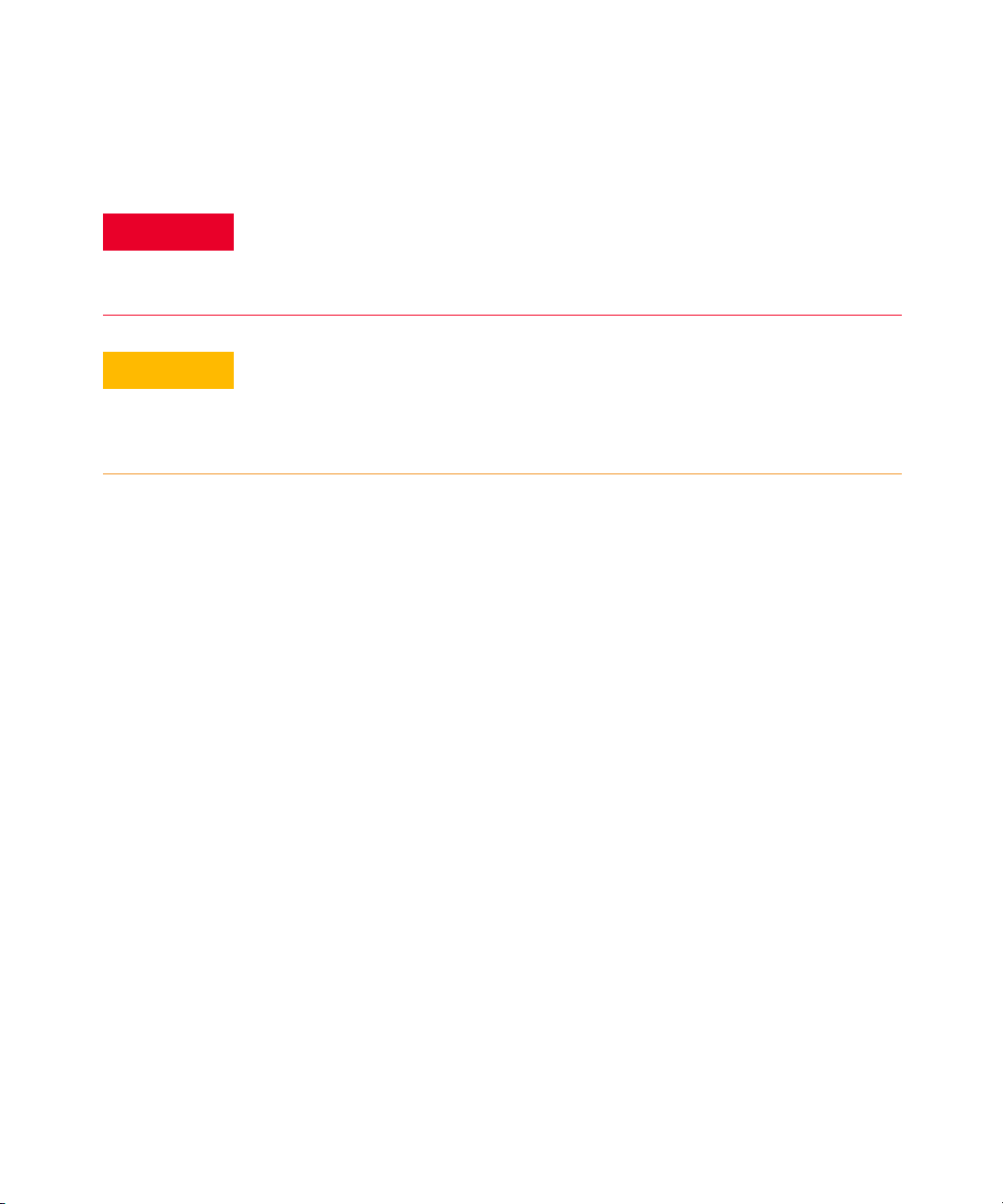

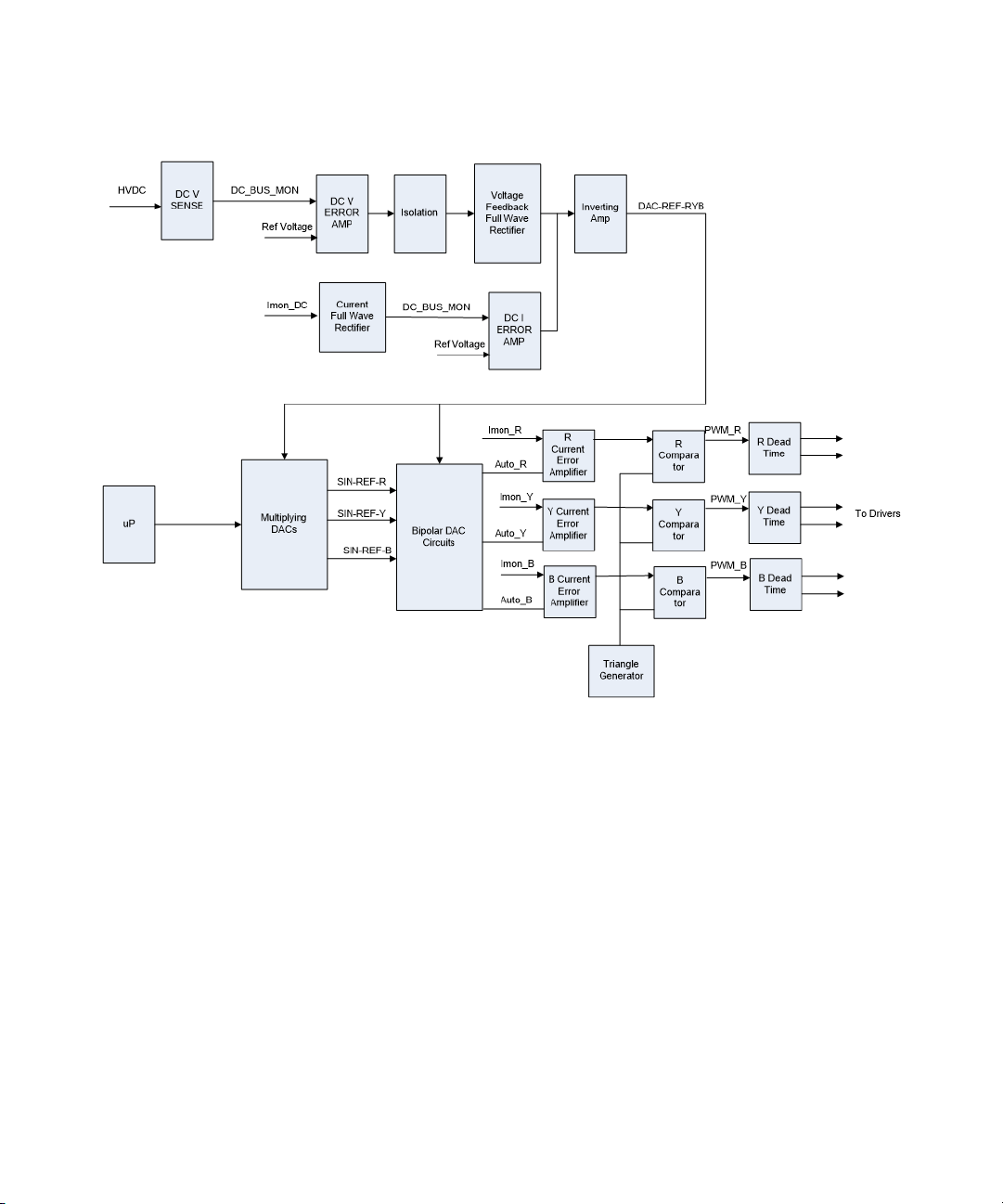

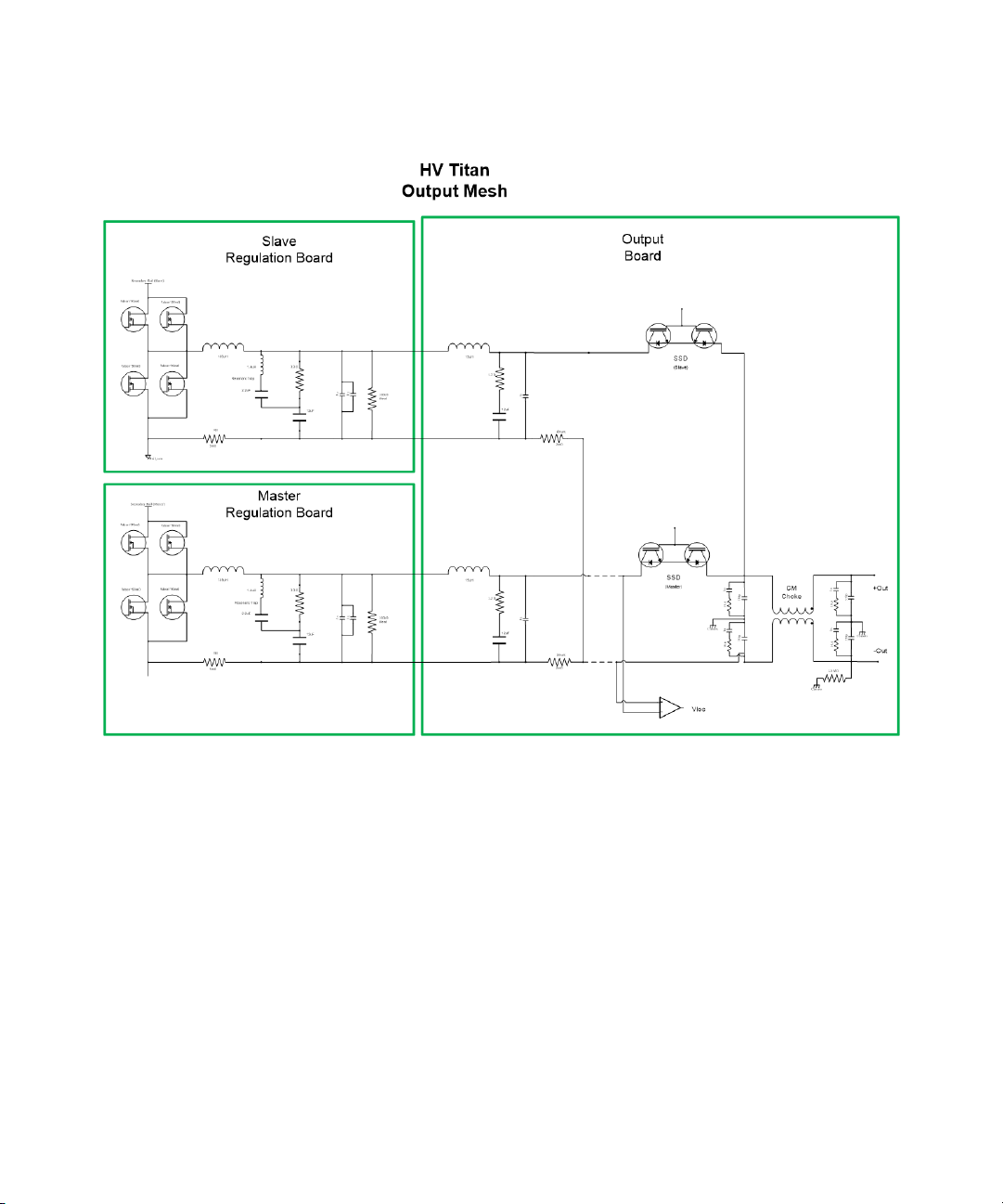

Titan HV architecture:

Shown below is the block diagram for a Titan HV unit.

– Titan HV 5 kW models (RP7951A/RP7961A): One pair of isolation board and

regulation board.

– Titan HV 10 kW models (RP7952A/RP7962A/RP7953A/RP7963A): Two pairs of

isolation board and regulation board.

Troubleshooting 1

Keysight RP7900 Series Advanced Service Guide 17

Page 18

1 Troubleshooting

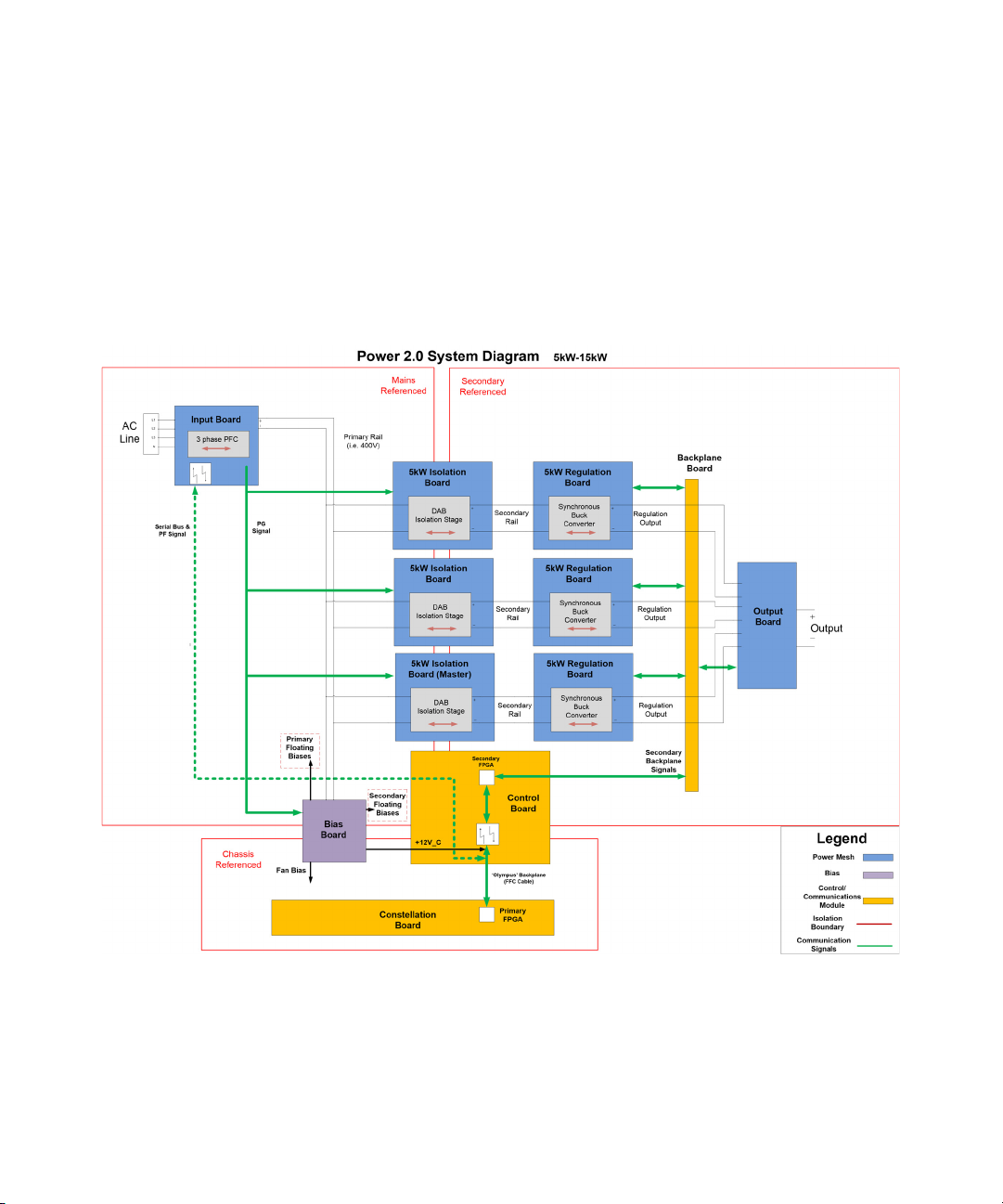

– Power Good (PG) signal: If the PG signal is not detected, the input board can

– Power Fault (PF) signal: If the PF signal is detected, the input board asserts

shut down the isolation boards and bias board and create a “Channel Fail”

error code at display.

this signal when it determines if the output power should be inhibited to

preserve rail charge in the event of a line fault.

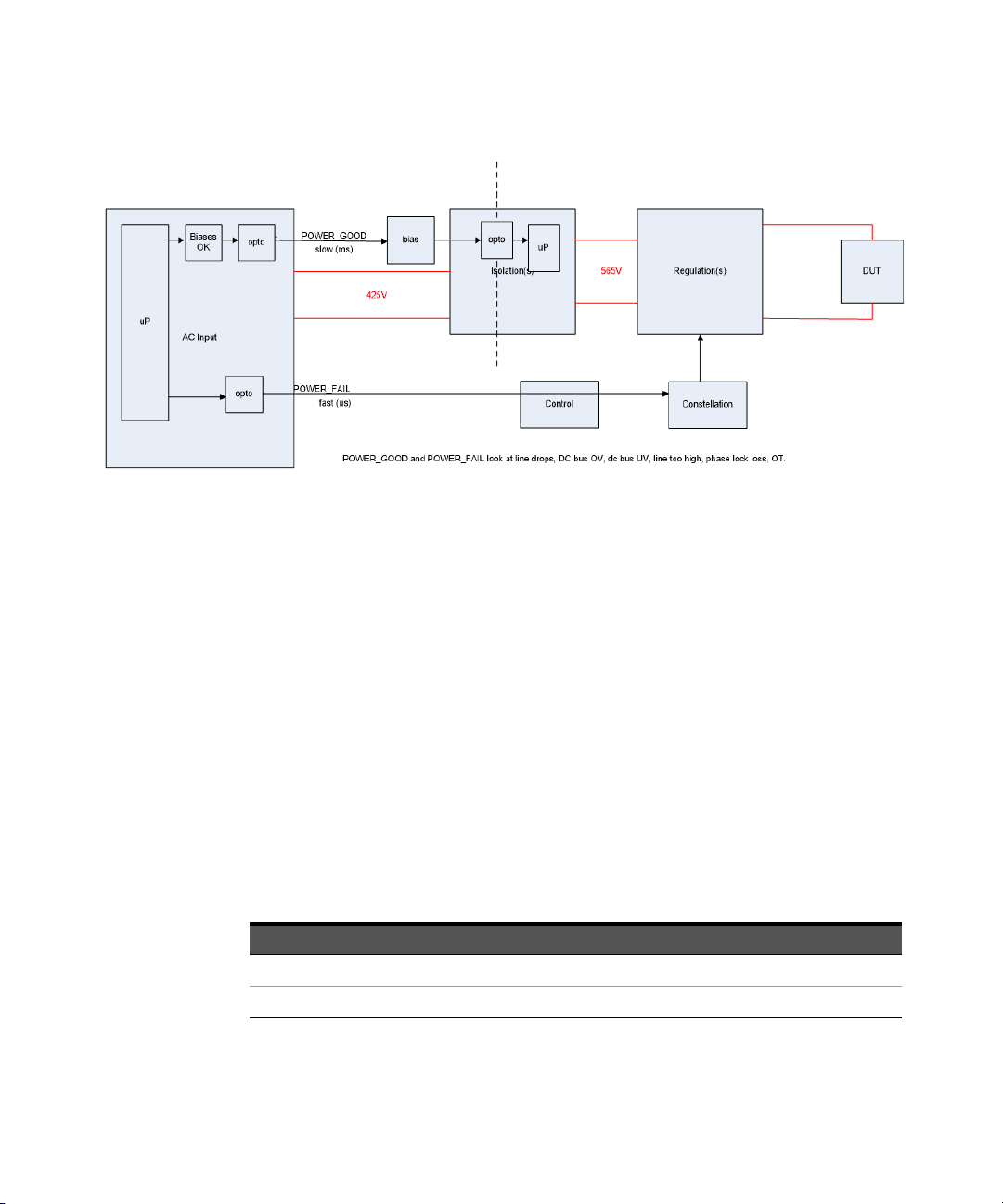

3-phase AC/DC front end:

The 3-phase AC/DC front end consists of the Power Factor Correction (PFC)

bias-control board, PFC driver board, and PFC inverter board. Its main function is

to convert the 3-phase AC input voltage to the require DC voltage as shown in

table below.

The AC front end will assert a PF signal to the secondary FPGA when the line

conditions are severe enough that the output power should be restricted or if the

rail voltage dips below a ‘power fault’ level. The purpose of this signal is to quickly

notify the regulation board to temporarily latch its output in the event of a brief

line drop out.

Model AC 3-phase input DC output

RP7951A, RP7952A, RP7953A 208 Vrms 425 Vdc

RP7961A, RP7962A, RP7963A 400 Vrms 980 Vdc

18 Keysight RP7900 Series Advanced Service Guide

Page 19

Troubleshooting 1

PFC inverter board operation

– The inverter boards consists of fuses, relay, big relay, and hall current sensors.

– The AC 3-phase input will go through the fuses. By turning on the bias, the AC

input will go through a small relay with a resistor path in order to have a soft

charge on the capacitor in the driver board. After that, the big relay will be

turned on when you hear the second clicking sound.

– The current passes through the hall sensor into the choke followed by the IGBT

and output capacitors.

PFC driver board operation

– The PFC driver boards consists of photo-detectors and big capacitors. The

gate driver output is influenced by signals from the photo-detector circuitry.

During normal operation, if the supply voltage is above the UVLO threshold,

the output of the photo-detector will drive the IGBTs of the output stage.

Keysight RP7900 Series Advanced Service Guide 19

Page 20

1 Troubleshooting

PFC bias control board operation

– The PFC bias control board consists of AC/DC current sensing, instantaneous

– The main purpose of the PFC control board is to provide the protection when

– The DC bus voltage monitors the output capacitor voltage. The center tap

– The function of the dead time circuit is to make sure that the gates will not be

– The triangle wave generator function acts as a reference signal, which

– The IPEAK_fault signal (peak current latch signal) will go into the inhibit logic

current protection, IGBT DESAT and PEAK current latch circuitry, AC/ DC

voltage sensing circuitry, current control loop, DC voltage error amplifier, and

dead circuitry.

abnormalities are detected on the peak current and to control and adjust the

DC output voltage.

monitors voltage across one capacitor whereas the DC bus monitors voltage

across the output cap. The main function of the center tap sensing is to ensure

that the voltage across is balanced.

turned on at the same time. It allows certain delays to prevent a short circuit.

compares the IMON signal, which eventually determines the PWM gate duty

cycle. This is a triangle waveform with a frequency of 33 kHz.

circuitry. In normal mode, IPEAK_latched and OC_latched must always stay

high whereas the Inhibit_R,Y,B depends on the Inverter_ON_R,Y,B to decide

whether it needs to turn the gate drive on or off. If the Inhibit_R,Y,B signal goes

low, the microprocessor will shut down the gate immediately.

20 Keysight RP7900 Series Advanced Service Guide

Page 21

Troubleshooting 1

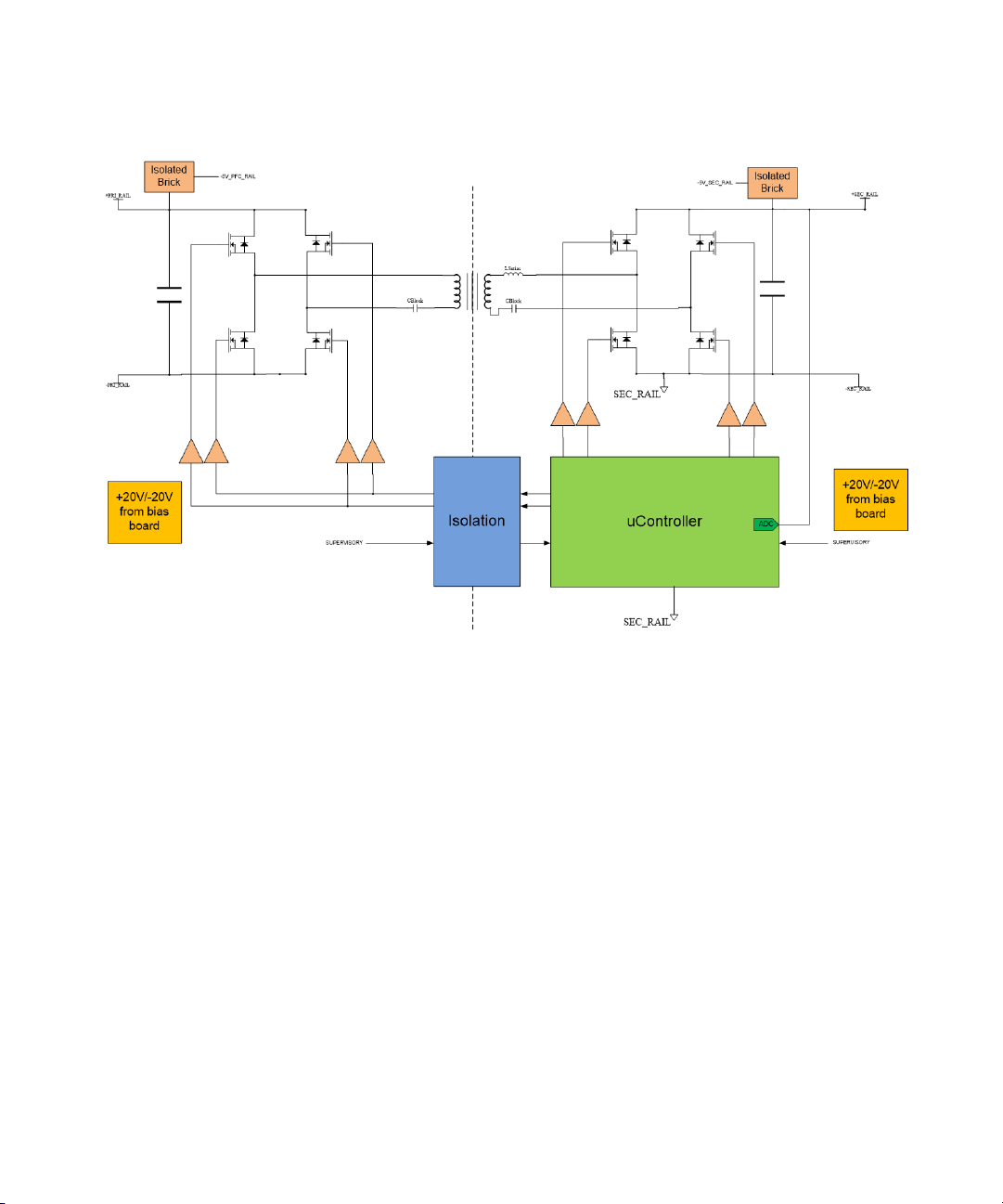

Isolation and isolation attic board operation

– The isolation board consists of a H bridge circuitry that can step up and step

down the voltage to the required voltage level. Its main function is to provide

the isolation between the primary and secondary circuits. It receives the DC

voltage from the AC front end and then adjusts the voltage level to 565 V. The

isolation attic board consist of a transformer and over-current protection

circuitry.

– The isolation board protects itself from ‘live’ conditions, such as local over

temperature (OT) and rail over voltage (OV) or low voltage (LV). The source of

a rail OV/LV will either be an issue with its input, an internal malfunction, or a

regulation board malfunction.

Keysight RP7900 Series Advanced Service Guide 21

Page 22

1 Troubleshooting

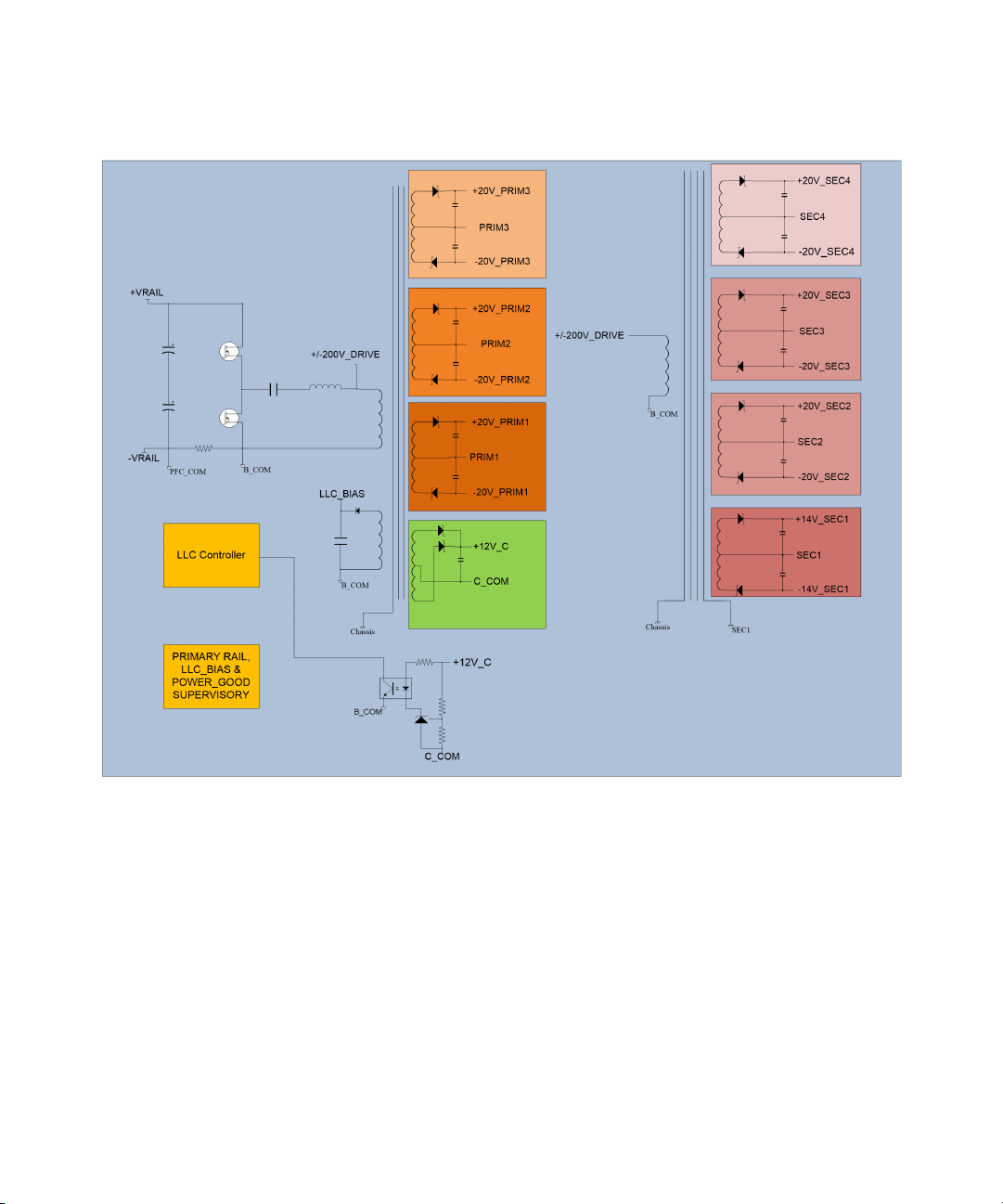

Bias board operation

– The bias board is made of a half-bridge LLC with two flying shielded

transformers.

– It receives the PG signal and outputs voltage (425 V or 980 V) from the AC

front end, steps down the voltage, and provides the bias voltages to the

respective modules.

– It communicates using the PG signal from the front-end.

Provides ±23 V to the isolation board

Provides ±23 V to the regulation board

Provides +12 V to the chassis fan

Provides ±15 V to the control board

22 Keysight RP7900 Series Advanced Service Guide

Page 23

Troubleshooting 1

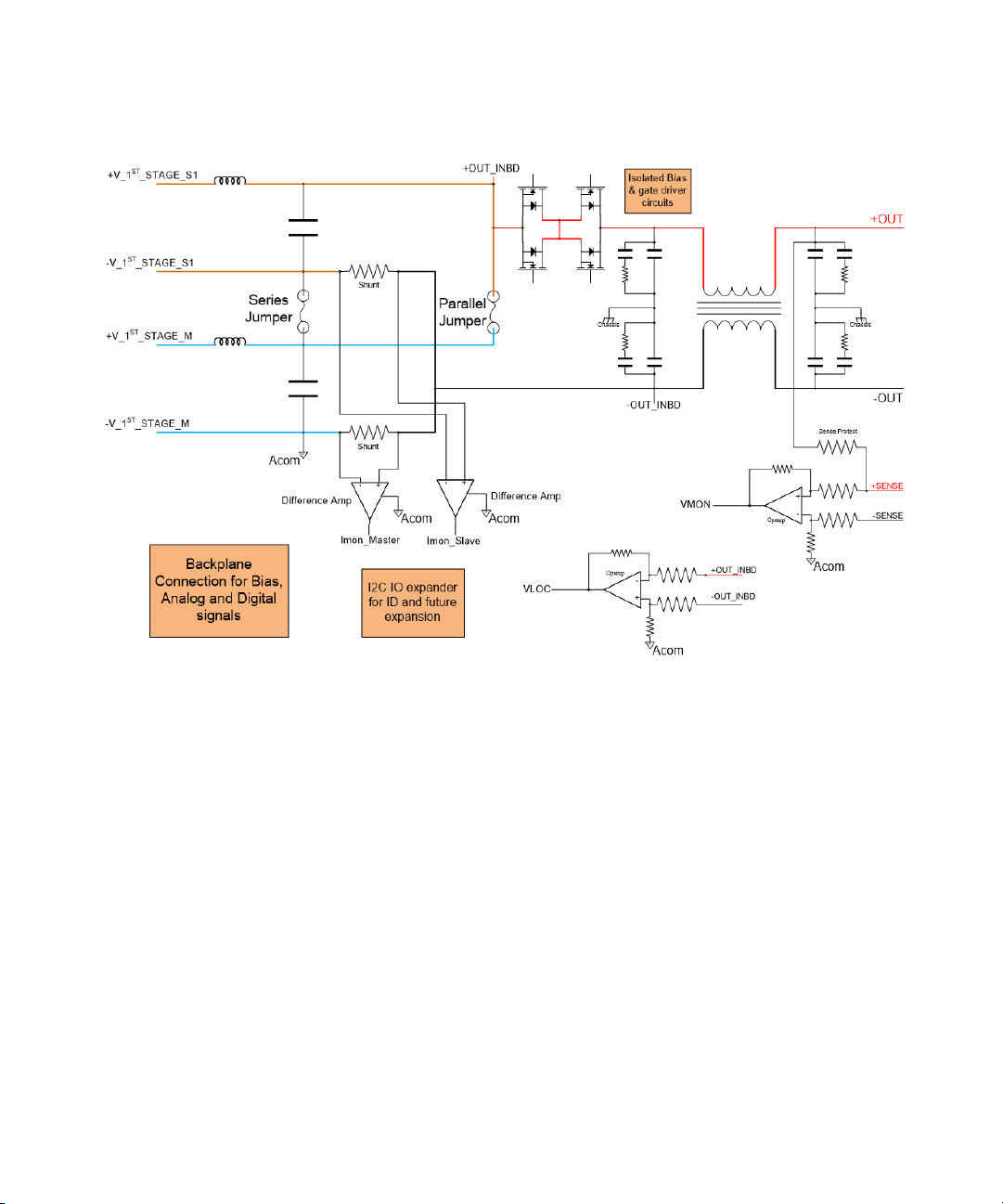

Output board operation

– The output board contains an accuracy shunt resistor, a common mode choke,

filtering circuitry, and a solid state output disconnect circuit up to 40 A.

– Feedback circuitry such as V

accuracy of the voltage or current. The output board has different

configuration, such as parallel or series — it depends on the unit model

whether it is a high voltage or high current model. The output board will

provide the second level of filtering to the output.

Keysight RP7900 Series Advanced Service Guide 23

mon

and I

will be used to fine tune the

Mon

Page 24

1 Troubleshooting

MASTER/SLAVE board operation

– The master slave circuitry allows communication between the units. This

allows the user to talk with only the master when paralleling units.

24 Keysight RP7900 Series Advanced Service Guide

Page 25

Troubleshooting 1

Digital personality module (DPM) operation

– The DPM modules consists of the FPGA, AUX DAC, and AUX ADC, which main

purpose is to process the signal received. The calibration files will be stored in

the DPM.

P600 and constellation boards operation

– The P600 is the processor board, which will store the firmware.

– The constellation board is the interface board, which is equipped with other

communication peripherals such as the USB port, LAN port, and GPIB ports.

Keysight RP7900 Series Advanced Service Guide 25

Page 26

1 Troubleshooting

NOTE

General Troubleshooting Information

Refer to the RP7900 Series Operating and Service Guide for more details on the

recommended ETE information.

Model Firmware

RP7951AT, RP7952AT, N6991AT B_01_02_730 Available

RP7951, RP7952A, RP7953A , RP7961A,

RP7962A, RP7963A

– To obtain the latest firmware for the RP795xA and RP796xA series, go to

www.keysight.com/find/RPS2firmware.

– For firmware updates that are available only for Keysight’s Internal Support, go

to the RP7900 Series SharePoint folder for more information, or contact your

respective product helpdesk representative.

You will need to use the Firmware Update Utility to install the latest firmware for

your instrument. Refer to the Firmware Update Utility Instructions for more

information on how to update your instrument’s firmware.

The availability of INTERNAL ONLY firmware updates are depend on the product

requirements, and may be applicable to selected models only.

For more information, see www.keysight.com/find/RP7900.

Refer to the “List of Error Codes” on page 27 before attempting the hardware

troubleshooting procedure.

B_01_02_749 Not available

Keysight SD1000A SDS (safety

disconnect system) port functionality

26 Keysight RP7900 Series Advanced Service Guide

Page 27

List of Error Codes

The front-panel ERR annunciator turns on when there are one or more errors in

the error queue.

The front panel report errors from all I/O sessions and the global error queue. To

read the error queue from the front panel, press the [ERROR] key or alternatively,

send the

one error from the queue.

Error

Description Potential remedy

code

No error

0

This is the response to the ERR? query when there are no errors.

Calibration state is off

101

Calibration is not enabled. The instrument will not accept calibration commands.

Calibration password is incorrect

102

The calibration password is incorrect.

Calibration is inhibited by switch setting

103

Calibration mode is locked out by the calibration switch.

Bad sequence of calibration commands

104

Calibration commands have not been entered in the proper sequence.

Unexpected output current

105

The measured output current is outside the acceptable range.

Zero measurement out of range error

106

The “zero” measurement value is outside the acceptable range.

Programming cal constants out of range

107

The programmed calibration constant is outside the acceptable range.

Measurement cal constants out of range

108

The measurement calibration constant is outside the acceptable range.

Over voltage cal constants out of range

109

The over voltage calibration constant is outside the acceptable range.

Troubleshooting 1

SYSTem:ERRoR? command from the remote interface to read and clear

N/A

Check the CAL switch position

Reset the calibration password

Check the CAL switch position

Refer to the Calibration

procedure in the Operating and

Service Guide

Refer to the Calibration

procedure in the Operating and

Service Guide and the “Hardware

Troubleshooting Guide” on

page 31.

Keysight RP7900 Series Advanced Service Guide 27

Page 28

1 Troubleshooting

Error

Description Potential remedy

code

Wrong V+I

110

The instrument was unable to set the correct voltage or current value.

Wrong status

114

An incorrect status function has been reported.

Refer to the “Hardware

Troubleshooting Guide” on

page 31.

Locked out by internal switch setting

116

This function has been locked out by an internal switch.

Calibration error

117

A calibration error has occurred. Do not save calibration constants. Try

re-calibrating the unit.

Hard ware error channel <1>

200

A hardware error has occurred on the output.

Invalid configuration

201

An invalid parallel or SDS configuration is not allowed.

Self-test fail

202

A self test failure has occurred.

Compatibility function not implemented

203

The requested compatibility function is not available.

NVRAM checksum error

204

A checksum error has occurred in the instrument’s nonvolatile random access

memory.

NVRAM full

205

The nonvolatile random access memory of the instrument is full.

File not found

206

The internal calibration file or the internal channel attribute file was not found in

NVRAM.

Refer to the Operating and

Service Guide

Refer to the Calibration

procedure in the Operating and

Service Guide

Refer to the “Hardware

Troubleshooting Guide” on

page 31.

Check hardware model number

and firmware revision

Refer to the “Hardware

Troubleshooting Guide” on

page 31.

Check firmware revision

Check the P600 and constellation

flash memory or EEPROM

Check the DPM

Cal file version error

207

The calibration file was written or read using old firmware. The firmware must be

updated.

Running backup firmware

208

The instrument is presently running the backup (previous) version of the firmware.

Update the firmware revision

Check the P600 firmware

programming

28 Keysight RP7900 Series Advanced Service Guide

Page 29

Error

Description Potential remedy

code

Frame NVRAM error

210

A non-volatile RAM error has occurred in the instrument.

State file not loaded

212

A previously saved output state file has failed to load.

Troubleshooting 1

Check the P600 and constellation

flash memory or EEPROM

Line frequency error

214

A discrepancy has occurred between the line frequency and the line frequency

setting.

Hard ware failure

215

A hardware failure has occurred on the power supply

Option not installed

302

The option that is programmed by this command is not installed.

There is not a valid acquisition to fetch from

303

There is no valid data in the measurement buffer.

Volt and curr in incompatible transient modes

304

Voltage and current cannot be in Step and List mode at the same time.

A triggered value is on a d ifferent range

305

A triggered value is on a different range than the one that is presently set.

Too many list points

306

Too many list points have been specified.

List lengths are not equivalent

307

One or more lists are not the same length.

This setting cannot be changed while transient trigger is initiated

308

Setting cannot be changed while the instrument is waiting for or executing a trigger

sequence.

Cannot initiate voltage and current in fixed mode

309

Cannot initiate transient generator. Either the voltage or current function is set to

Fixed mode.

Check the AC line frequency

setting

Refer to the “Hardware

Troubleshooting Guide” on

page 31.

Install the required option

Refer to the Operating and

Service Guide

The command is not supported by this model

310

This instrument either does not have the hardware capability or the options

required to support this command.

Keysight RP7900 Series Advanced Service Guide 29

Page 30

1 Troubleshooting

Error

Description Potential remedy

code

Settings conflict error

315

A data element could not be programmed because of the present instrument state.

Mass storage error

316

The mass storage memory has been exceeded.

Invalid format

317

An invalid data format was found in the command string.

Firmware update error

320

This may be due to the instrument hardware not being able to support the firmware

version.

Inconsistent arb settings

324

The arb settings are inconsistent; most likely a mismatch in the arb lengths.

Initiated with no sense function enabled

327

A measurement has been initiated without specifying the

measurement(sense)function.

Too many measurement points

328

Too many measurement points have been specified.

Illegal parameter value

331

The parameter value is out of range or does not exist.

Master/slave error

332

An error has occurred in the master/slave configuration

Safety Disconnect error

333

An error has occurred in the SDS unit.

Refer to the Operating and

Service Guide

Check the hardware revision or

firmware programming setup

Refer to the Operating and

Service Guide

Check the master/slave

connection or the hardware

Check the SDS connection or the

hardware

30 Keysight RP7900 Series Advanced Service Guide

Page 31

Hardware Troubleshooting Guide

Required equipment

You will need the equipment listed below to perform the hardware

troubleshooting.

– DC electronic load: EA-EL 9750-75HP or Chroma 63206A-1200-240A or

equivalent

– Digital multimeter

– Keysight high performance Infiniium oscilloscope

–Current probe

– Differential probe

– Guild-line shunt

– DC power supply

– Cables and connectors

Troubleshooting 1

Keysight RP7900 Series Advanced Service Guide 31

Page 32

1 Troubleshooting

Hardware trouble shooting procedure

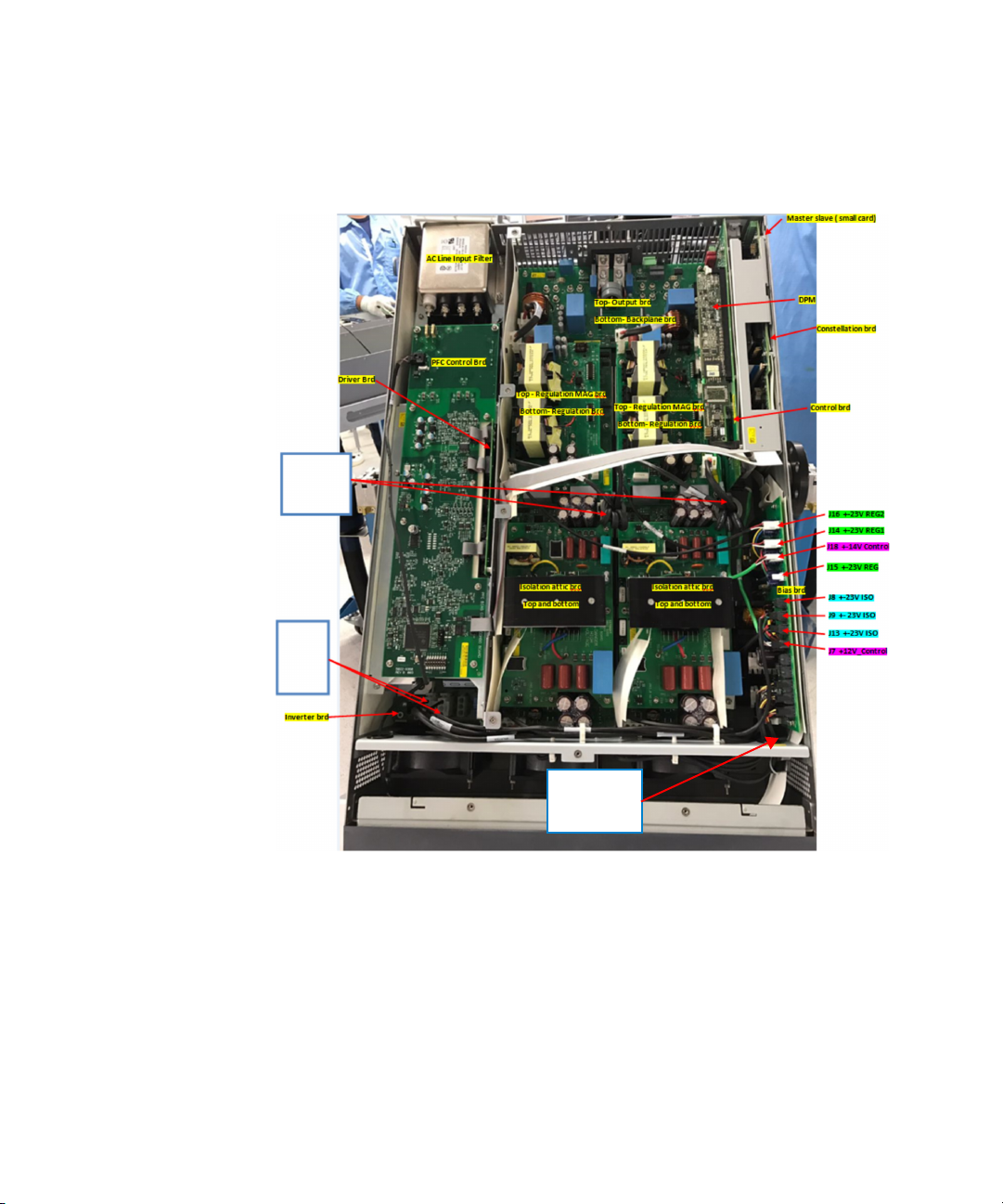

1 Visually inspect all the LED indicators as shown below:

Figure 1-1 Location of the LED indicators

32 Keysight RP7900 Series Advanced Service Guide

Page 33

Troubleshooting 1

G

C

A

Figure 1-2 Close-up location of DPM and constellation board LED

indicators

A Constellation board/P600 board LED

– Yellow LED flashing indicates that the firmware programming is done

properly and that the unit is booted up properly.

B PFC microcontroller LED

– There are two LEDs on the PFC microcontroller board, one red and one

green.

– Red LED off and green LED flashing constantly indicates that the

processor is running and everything is operating normally (i.e. the PFC

module is programmed properly).

– Solid red LED and green LED flashing constantly indicates that a

self-test error is being annunciated.

– Red LED flashing and green LED off indicates that a fault code is being

annunciated.

CDPM processor LED

– Green LED indicates that the unit has booted up properly.

DAC module rail LED

– Red LED indicates that there is rail voltage present.

Keysight RP7900 Series Advanced Service Guide 33

Page 34

1 Troubleshooting

2 Inspect all the flex cables and AWG cables connection and verify that they are

3 Measure the PFC output and ensure that the reading is 425 V for the 3-phase,

4 Make sure there is a 425 V (or 980 V, depending on the model) and a 10 V

E Isolation microcontroller LED

– Green LED flashing indicates that everything is operating normally.

– Solid green LED on indicates a soft start.

– Solid red LED indicates that a microcontroller error has occurred.

F Isolation board rail voltage LED

– Red LED indicates that 425 V (or 980 V, depending on the model) goes

into the isolation board.

G Regulation board rail voltage LED

– Red LED indicates that 565 V goes into the regulation board.

HBias board LED

– Red LED indicates that 425 V (or 980 V, depending on the model) and

the Power Good (PG) signal goes into the bias board.

correct. Make sure no connector pins are bent when the boards are installed to

the backplane.

208 V models or 980 V for the 3-phase, 480 V models.

Power Good (PG) signal going into the bias board. The bias board powers the

remaining boards.

5 Measure the isolation board output. Ensure that the reading is 565 V.

6 Verify that all biasing voltage from bias boards are correct. Refer to Figure 1-4

and Figure 1-5 for the biasing voltage test point locations and values.

7 Isolate the defective board(s) by disconnecting the cables connecting the

defective board(s) to the other boards.

– Disconnect the cable from the AC output to the isolation board to verify

that the AC board is functioning properly.

– Disconnect the cable connecting the isolation board to the regulation board

to verify that the isolation is good.

– Disconnect the cable from the regulation board to the output board to

verify that the regulation is good.

34 Keysight RP7900 Series Advanced Service Guide

Page 35

Troubleshooting 1

– For the control board, measure the V

mon

loc

, and I

signals that goes

mon

, V

into the board and verify that the values are accurate. Send the following

SCPI commands via the remote interface:

DIAG:MEAS:VOLT:LOC? – measures the local voltage from the aux ADC

DIAG:MEAS:AUX:CURR? - measures the current from the aux ADC

DIAG:MEAS:AUX:POWER? - measures the power from the aux ADC

DIAG:MEAS:MAIN:POW:LOC? - measures the local power from the main ADC

SCPI Command

DIAG:MEAS:VOLT:LOC?

Expected return value

21.45 V 499.72 V

[a]

Expected return value

DIAG:MEAS:AUX:CURR? 1.00 A 8.007 A

DIAG:MEAS:AUX:POWER? 20.11 W 4003.14 W

DIAG:MEAS:MAIN:POW:L

OC?

[a] Instrument setting - Voltage: 20 V, Current: 1 A

[b] Instrument setting - Voltage: 500 V, Current: 8 A

0.0806 W 16.013 W

8 Refer to the troubleshooting flow chart in Figure 1-3 for further details.

[b]

Keysight RP7900 Series Advanced Service Guide 35

Page 36

1 Troubleshooting

START

Set t he U UT vo ltage to 20 V

Measure d 20 V

at UUT output?

• Check the current accuracy with a load

or with the output terminal shorted.

• If it is a perfor mance is sue, pro ceed to

re-calibrate and re-verify.

Any error

message?

NO YES

PFC red LED

indicator on?

Isolation red LED

indicator on or rail

volta ge pr esent ?

Measure

the isolation circui t.

Is it 565 V?

Is t he re gulat ion rail

voltage indicator on?

NO

YES

YES

YES

• PF: Verify the incoming power fault channel. If the verification fails,

check the biasing voltage to the PCA. The MOSFET may be shorted.

Swap the PFC module.

• OT: Some components may be shorted or if there is a faulty sensor.

• OC: The regulation MOSFE T may be shorted. Swap the regulation

board.

• Self-test error: Verify if there are any incompatible firmware in any

of the modules.

• Check the PFC microcontroller LED.

• Check the PFC self-test LED sequence.

• Swap the PFC module.

YES

NO

• Check t he ca ble co nnecti ng to th e PFC.

• Check t he P FC ra il voltag e an d PG sign al.

• Swap the PFC module.

NO

• Check t hat the bias ing v olta ge (± 23 ~ ±24 V) g oes i nto the isol ation

primary and secondary circuit.

• Check that the microcontroller has been programmed with the

correct firmware.

• The MOSFET on the isolation board may be shorted. Swap the

isolation b oard.

NO

• Check t he ca ble co nnecti ng to th e iso lation.

• Check that the biasing voltage (±23 ~ ±24 V) goes into the

regulation board.

NO

Measure

the regulation output.

Is it 20 V?

YES

• Check the ILmon signal on the regulation board.

• The MOSFET on the regulation board may be shorted. Swap the

regulation board and the magnetic board.

NO

Verify that the

output board is producing

20 V at the bus bar .

YES

• Check the Vmon, Imon, and Vloc signal on the output board.

• Check i f a ny IG BTS ar e s horte d on t he o utp ut boa rd.

• Swap the output board.

NO

Verify that the

con tro l bo ar d V mon a nd

Imon signals are good.

YES

• Check that the biasing voltage (±24 V) goes into the control board.

• Check t he back plan e con nect ors.

• Check the FFC cable connecting to the control board.

• Swap the control board.

NO

Swap the DPM

YES

END

Figure 1-3 Hardware troubleshooting flow chart

36 Keysight RP7900 Series Advanced Service Guide

Page 37

Troubleshooting 1

Isolation

Brd Output

565Vdc

PFC AC

Output

425Vdc

425V and 10V

PG goes into

the Bias Brd

RP7951A, RP7952A, RP7953A, RP 7951AT, RP7952AT, N6991A

(3-phase, 208 V models)

Figure 1-4 Bias voltage test points for 3-phase, 208 V models

Keysight RP7900 Series Advanced Service Guide 37

Page 38

1 Troubleshooting

Isolation

Brd Output

565Vdc

PFC AC Output

980Vdc

980V and 10V

PG goes into

the Bias Brd

RP7961A, RP7962A, RP7963A (3-phase, 480 V models)

Figure 1-5 Bias vol tage test points for 3-phase, 480 V models

38 Keysight RP7900 Series Advanced Service Guide

Page 39

Keysight RP7900 Series Regenerative Power System

WARNING

Advanced Service Guide

2 Disassembly

Electrostatic Discharge (ESD) Precautions 40

Disassembly Tools 41

Disassembly Tips 42

Disassembly Procedures 43

This chapter discusses the disassembly procedures for troubleshooting and

repairing the Keysight RP7900 Series Regenerative Power System.

SHOCK HAZARD. Only qualified, service-trained personnel who are aware of

the hazards involved should remove instrument covers. Always disconnect

the power cable and any external circuits before removing the instrument

cover.

39

Page 40

2 Disassembly

Electrostatic Discharge (ESD) Precautions

Almost all electrical components can be damaged by electrostatic discharge

(ESD) during handling. Component damage can occur at electrostatic discharge

voltages as low as 50 volts. The following guidelines will help prevent ESD

damage when servicing the instrument or any electronic device.

– Disassemble instruments only in a static-free work area.

– Use a conductive work area to reduce static charges.

– Use a conductive wrist strap to reduce static accumulation.

– Minimize handling.

– Keep replacement parts in original static-free packaging.

– Remove all plastic, foam, vinyl, paper, and other static-generating materials

from the immediate work area.

40 Keysight RP7900 Series Advanced Service Guide

Page 41

Disassembly Tools

Table 2-1 Disassembly tools

Tool Use

T10 Torx driver All disassembles

T20 Torx driver Removing the output and back plane assembly

Flat blade driver Removing the fan bracket assembly from the chassis

7 mm Hex driver Removing the output and back plane assembly

8 mm Hex driver Removing the PFC control board

9/32 Hex driver Removing the GPIB board from the chassis

Disassembly 2

Keysight RP7900 Series Advanced Service Guide 41

Page 42

2 Disassembly

Disassembly Tips

Removing/Installing flat flexible cables (FFC) or ribbon cables

– Note the position of the conductive side of the cable for re-installation.

– To remove the FFC cable, gently lift up on the tabs located on the short ends of

the plastic connector until the cable is released. Remove the cable.

– To install the FFC cable, insert the cable into the slot in the connector. Using a

small screwdriver or your fingers, apply gentle, even pressure to the tabs until

the connector clicks and locks the cable into place. After installation, check

the cable to ensure the cable is straight and securely aligned within the

connector.

Assembly procedures

To assemble the instrument, reverse the procedures described in the

“Disassembly Procedures” on page 43.

42 Keysight RP7900 Series Advanced Service Guide

Page 43

Disassembly Procedures

Removing the top chassis

1 First, remove all cables, wires, or power cord that are connected to the

instrument before performing any disassembly.

2 Remove the 7 screws (0515-1946) on the top chassis of the instrument.

Disassembly 2

3 Next, remove the 3 screws (0515-0430) at the rear panel of the instrument.

Keysight RP7900 Series Advanced Service Guide 43

Page 44

2 Disassembly

NOTE

4 Then, remove the 10 screws (0515-1946) on both sides of the instrument as

shown below.

5 Gently remove the top chassis cover (5003-2346).

Ensure that a proper insulator is installed on the top cover. If the existing

insulator is damaged or worn out, please replace the existing insulator with a

new insulator (5188-9218).

44 Keysight RP7900 Series Advanced Service Guide

Page 45

Removing the PFC control board

1 First, remove all the cables that are connected to the PFC control board.

Disassembly 2

2 Next, remove the 2 screws (0515-0430) shown below.

Keysight RP7900 Series Advanced Service Guide 45

Page 46

2 Disassembly

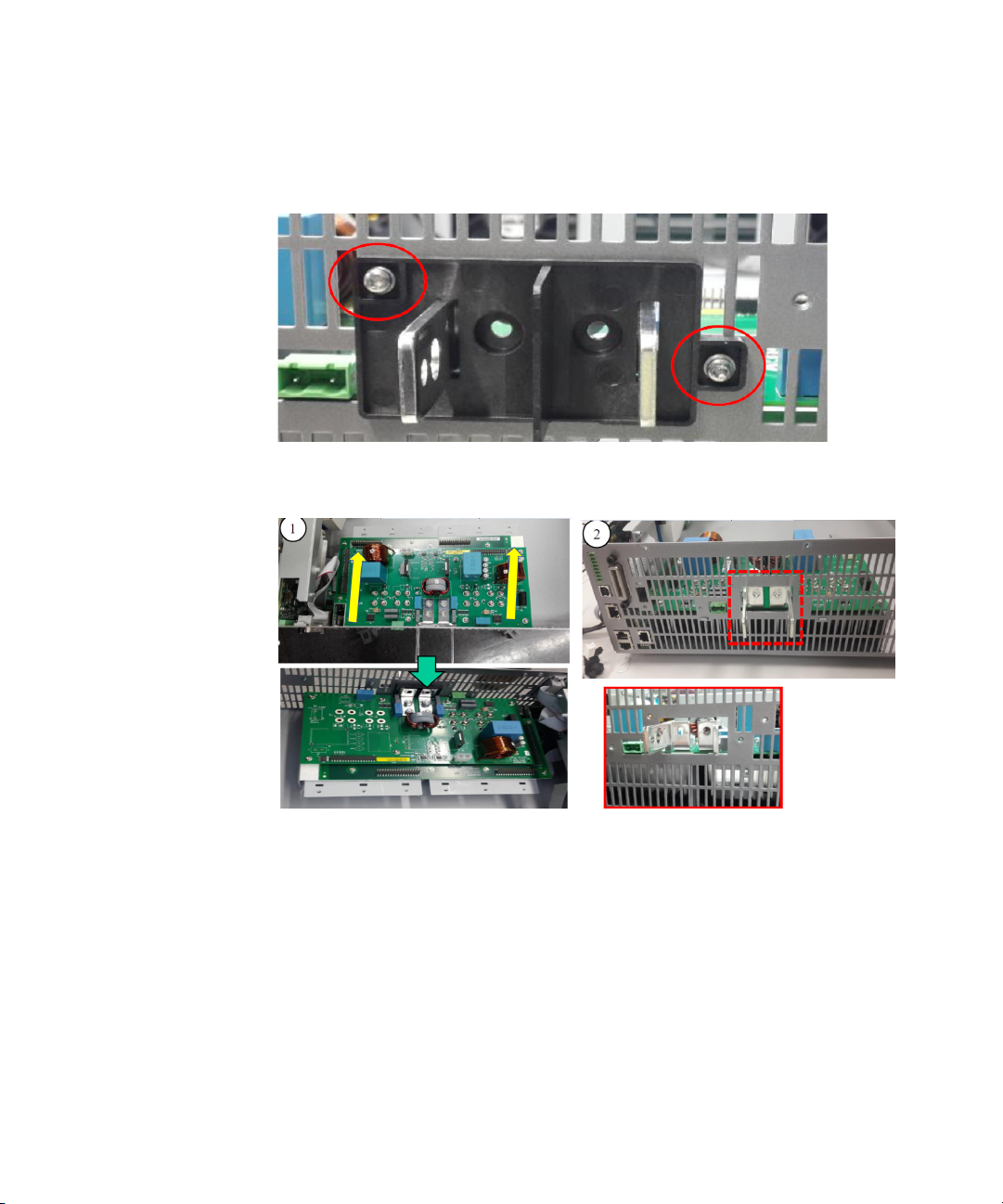

3 Then, unsecure the 2 screws (0515-0430) shown below from the chassis.

4 Use an 8 mm Hex driver to remove the nut-hex (0535-0077) and then remove

the flat washer lock (2190-0629).

46 Keysight RP7900 Series Advanced Service Guide

Page 47

Disassembly 2

5 Flip the instrument to its bottom to remove the 5 screws (0515-1946) shown

below.

6 Finally, pull out the PFC control board from the chassis.

Keysight RP7900 Series Advanced Service Guide 47

Page 48

2 Disassembly

Removing the digital personality module PCA

1 First, gently unlock the connector pin and pull out the digital personality

module PCA (5067-5271) from its casing.

2 Next, remove the screw on the digital personality module PCA bracket.

48 Keysight RP7900 Series Advanced Service Guide

Page 49

Disassembly 2

3 Then, remove the screw securing the control PCA to the constellation bracket.

4 Next, remove the bias control cable.

Keysight RP7900 Series Advanced Service Guide 49

Page 50

2 Disassembly

5 Then, remove the constellation FFC cable at the back of the digital personality

module PCA.

6 Finally, remove the control insulator from the constellation bracket.

50 Keysight RP7900 Series Advanced Service Guide

Page 51

Disassembly 2

Removing the isolation and isolation attic board (top and bottom) from the chassis

1 First, remove the air guard insulator and cables from the isolation and isolation

attic board.

2 Next, remove the 10 screws (0515-0430) shown below on the isolation PCA

and isolation attic PCA.

Keysight RP7900 Series Advanced Service Guide 51

Page 52

2 Disassembly

3 Then, remove both PCAs from the chassis module by removing the 12 screws

(0515-0667) shown below.

4 Finally, remove the 400 V isolation attic PCA (5067-6590) from the 400 V AC in

isolation PCA (5067-6589) as shown below.

52 Keysight RP7900 Series Advanced Service Guide

Page 53

Disassembly 2

Set aside the 400 V isolation attic PCA and the 400 V AC in isolation PCA.

Keysight RP7900 Series Advanced Service Guide 53

Page 54

2 Disassembly

Removing the regulation magnitcs PCA from the regulation PCA

1 First, remove the 8 screws (0515-0430) shown below securing the regulation

magnitcs PCA to the regulation PCA.

2 Next, remove both PCAs from the chassis by removing the 12 screws

(0515-0667) shown below.

54 Keysight RP7900 Series Advanced Service Guide

Page 55

Disassembly 2

3 Finally, remove the regulation magnitcs PCA from the regulation PCA as shown

below.

Removing the isolation partition, insulator regulation, and chassis module

1 First, remove the isolation partition (5066-1924) from the chassis module.

Keysight RP7900 Series Advanced Service Guide 55

Page 56

2 Disassembly

2 Next, remove the insulator regulation (5188-9219) from the chassis module.

3 Then, remove the 6 screws (0515-0430) shown below securing the chassis

module to the rear tray.

56 Keysight RP7900 Series Advanced Service Guide

Page 57

Disassembly 2

4 Flip over the chassis. Remove the 8 screws (0515-1946) shown below securing

the chassis module to the chassis.

5 Finally, remove the chassis module from the chassis.

Keysight RP7900 Series Advanced Service Guide 57

Page 58

2 Disassembly

Removing the output and back plane assembly

1 First, remove the 2 screws (0515-0430) shown below.

2 Next, tear off the “+ (red)” and “– (black)” labels on the output terminal.

58 Keysight RP7900 Series Advanced Service Guide

Page 59

Disassembly 2

3 Then, remove the 2 screws (0515-0382) shown below to securing the bezel to

the buss bar using a T-20 Torx driver and a 7 mm Hex driver.

The screws are secured using a nut-hex (0535-1097) and a flat washer lock

(3050-0893) as shown below.

Keysight RP7900 Series Advanced Service Guide 59

Page 60

2 Disassembly

4 Remove the 2 screws (0515-0372) shown below securing the bezel plate

(5066-1911).

5 Finally, pull out the output and backplane assembly from the chassis as shown

below.

60 Keysight RP7900 Series Advanced Service Guide

Page 61

Removing the bias bracket from the chassis

1 First, remove all the cables attached on this board.

2 Next, remove the bias bracket from the chassis by removing the 3 screws

(0515-1946) shown below.

Disassembly 2

Keysight RP7900 Series Advanced Service Guide 61

Page 62

2 Disassembly

Removing the constellation and P600 assembly from the chassis

1 First, remove the 3 screws (0515-1946) shown below securing the

constellation and P600 assembly to the chassis.

2 Next, remove the constellation and P600 assembly from the chassis.

62 Keysight RP7900 Series Advanced Service Guide

Page 63

Disassembly 2

NOTE

– The FFC cable is secured to the constellation and P600 assembly connector

via glue at both sides. If you need to replace the constellation and P600

assembly, carefully remove the glue first before you remove the FFC cable.

– When reconnecting the FFC cable to the constellation and P600 assembly

reapply the glue (on both sides of the cable) using a glue gun to secure the

FFC cable to the constellation and P600 assembly. Ensure that the FFC cable

is inserted properly before applying the glue.

Keysight RP7900 Series Advanced Service Guide 63

Page 64

2 Disassembly

Removing the GPIB board from the chassis

1 First, remove the 2 standoff-hex screws (0380-5630) shown below securing

the GPIB board to the chassis using a 9/32 Hex driver.

2 Next, pull the GPIB board out from the chassis.

64 Keysight RP7900 Series Advanced Service Guide

Page 65

Removing the IO board from the chassis

1 First, remove the IO board from the chassis by removing the 2 screws

(0515-0430) shown below.

2 Next, pull the IO board out from the chassis.

Disassembly 2

Keysight RP7900 Series Advanced Service Guide 65

Page 66

2 Disassembly

Removing the front panel from the chassis

1 First, remove the FFC cable connected to the front panel display.

66 Keysight RP7900 Series Advanced Service Guide

Page 67

Disassembly 2

NOTE

– The FFC cable is secured to the front panel display connector via glue at both

sides. Carefully remove the glue first before you remove the FFC cable.

– When reconnecting the FFC cable to the front panel display, reapply the glue

(on both sides of the cable) using a glue gun to secure the FFC cable to the

front panel display connector.

Keysight RP7900 Series Advanced Service Guide 67

Page 68

2 Disassembly

2 Next, remove the AC switch cable (5188-9483) on the front panel.

3 Then, remove the screws on the right and left side of the front panel.

68 Keysight RP7900 Series Advanced Service Guide

Page 69

4 Finally, pull out the front panel from the chassis as shown below.

Removing the front frame vent from the chassis

1 First, remove the 2 screws (0515-1103) on the right side and left side of the

front frame vent.

Disassembly 2

Keysight RP7900 Series Advanced Service Guide 69

Page 70

2 Disassembly

Removing the fan bracket assembly from the chassis

2 Next, pull out the front frame vent (5066-1923) as shown below.

1 First, flip the chassis over and remove the 3 screws (0515-1946) shown below

securing the fan bracket assembly to the chassis.

70 Keysight RP7900 Series Advanced Service Guide

Page 71

Disassembly 2

2 Remove the 2 screws (0515-1946) on the right side and left side of the fan

bracket assembly as shown below.

3 Remove the fan bracket assembly as shown below.

Keysight RP7900 Series Advanced Service Guide 71

Page 72

2 Disassembly

NOTE

4 Finally, remove the 4 bumper feet (0403-1294) shown below using a flat blade

driver.

You will need to use a mallet and a slot screwdriver to assemble back the 4

bumper feet to the chassis.

72 Keysight RP7900 Series Advanced Service Guide

Page 73

Disassembly 2

Keysight RP7900 Series Advanced Service Guide 73

Page 74

2 Disassembly

74 Keysight RP7900 Series Advanced Service Guide

Page 75

Keysight RP7900 Series Regenerative Power System

Advanced Service Guide

3 Replaceable Parts

RP7900 Replaceable Parts List 76

The following table documents the replaceable parts description, Keysight part

numbers, and applicable models.

75

Page 76

3 Replaceable Parts

N6991AT

RP7951AT

RP7952AT

RP7951A

RP7952A

RP7953A

RP7961A

RP7962A

RP7963A

RP7900 Replaceable Parts List

Tab le 3-1 RP7900 replaceable parts list

Keysight part

number

RP7951AT-60011 TESTED AC INPUT ASSEMBLY ✔✔✔

RP7951A-60012 TESTED AC INPUT ASSEMBLY ✔✔✔

RP7961A-60002 TESTED AC INPUT ASSEMBLY - 480VAC ✔✔✔

RP7951AT-60008

RP7951A-60002

RP7951AT-60007 TESTED FAN BRACKET ASSEMBLY - 5KW ✔✔ ✔ ✔

RP7952AT-60011 TESTED FAN BRACKET ASSEMBLY - 10KW ✔✔✔✔✔

RP7951AT-60006 TESTED FRONT PANEL ASSEMBLY ✔✔✔✔✔✔✔✔✔

5067-6764 TESTED MASTER SLAVE/DISCONNECT PCA ✔✔✔✔✔✔✔✔✔

RP7951AT-60009 TESTED OUTPUT AND BACK PLANE ASSEMBLY - 5KW ✔✔ ✔ ✔

RP7952AT-60012 TESTED OUTPUT AND BACK PLANE ASSEMBLY - 10KW ✔✔ ✔

RP7953A-60002 TESTED OUTPUT AND BACK PLANE ASSEMBLY - 10KW, 950V ✔✔

5067-6715 TESTED PCA BIAS HV TITIAN ✔✔✔✔✔✔

5067-6728 TESTED PCA HV TITAN HV RAIL BIAS BOARD - 480VAC ✔✔✔

Description

TESTED CONSTELLATION AND P600 ASSEMBLY FOR RP795XAT &

N6991AT

TESTED CONSTELLATION AND P600 ASSEMBLY FOR RP795XA &

RP796XA

✔✔✔

✔✔✔✔✔✔

5067-6720 TESTED PCA DIGITAL PERSONALITY MODULE FOR TITAN ✔✔✔✔✔✔✔✔✔

5067-6713 TESTED PCA DISCONNECT BOX INTERFACE ✔✔✔✔✔✔✔✔✔

5067-6721 TESTED PCA HV TITAN CONTROL BOARD ✔✔✔✔✔✔✔✔✔

5067-6719 TESTED PCA ISOLATION ATTIC ✔✔✔✔✔✔

5067-6726 TESTED PCA HV TITAN 480VAC ATTIC BOARD ✔✔✔

5067-6718 TESTED PCA HV TITAN ISOLATION ✔✔✔✔✔✔

5067-6727 TESTED PCA HV TITAN HV RAIL ISOLATION BOARD - 480VAC ✔✔✔

76 Keysight RP7900 Series Advanced Service Guide

Page 77

Table 3-1 RP7900 replaceable parts list (continued)

N6991AT

RP7951AT

RP7952AT

RP7951A

RP7952A

RP7953A

RP7961A

RP7962A

RP7963A

Replaceable Parts 3

Keysight part

number

5067-6716 TESTED PCA HV TITAN REGULATION BOARD ✔✔✔✔✔✔✔✔✔

5067-6714 TESTED PCA MASTER SLAVE HV TITIAN ✔✔✔✔✔✔✔✔✔

5067-6717 TESTED PCA REGULATION MAGNITCS ✔✔✔✔✔✔✔✔✔

5067-6031 BUS BAR CONNECTION KIT ✔✔✔✔✔✔✔✔✔

1420-0356 BUTTON CELL ✔✔✔✔✔✔✔✔✔

5188-9488 CABEL FFC FRONT DISPLAY ✔✔✔✔✔✔✔✔✔

5188-9483 CABLE AC SWITCH ✔✔✔✔✔✔✔✔✔

8121-2942

1400-3204

5003-2343 CHASSIS BASE ✔✔✔✔✔✔✔✔✔

1400-3414

5188-9511 CM CHOKE CABLE ✔✔✔✔✔✔✔✔✔

1254-3092

Description

CABLE-ASSEMBLY FLAT RIBBON 30AWG 20-CONDUCTOR 2.3A

PBT 19.50-IN-LG BLACK 2-ROW DOUBLE-ENDED REVERSE

FEMALE IDC

CABLE-TIE SELF-LOCKING 172-MIL-DIA 4-IN-LG 95-MIL-WIDE

36-MIL-THK NYLON 6/6 NATURAL

CLAMP-CABLE PRESSURE SENSITIVE ADHESIVE MOUNTING

1.062-IN-LG 1-IN-WIDE NORYL WHITE

CONNECTOR-HEADER VERTICAL BOARD-STACKER

THROUGH-HOLE 16-PIN 2.54MM 2-ROW

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

1254-3101

1251-4669

1254-3082

5188-8435 CONSTELLATION FLEXIBLE FLAT CABLE ✔✔✔✔✔✔✔✔✔

5003-2346 COVER TOP ✔✔✔✔✔✔✔✔✔

0403-1294 FOOT STAND ✔✔✔✔✔✔✔✔✔

CONNECTOR-HEADER VERTICAL BOARD-STACKER

THROUGH-HOLE 4-PIN 2.54MM 2-ROW

CONNECTOR-HEADER VERTICAL THROUGH-HOLE 14-PIN 2.54MM

1500VAC 3A 2-ROW

CONNECTOR-SOCKET HEADER VERTICAL THROUGH-HOLE 16-PIN

2.54MM 250VAC 3A 2-ROW

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

Keysight RP7900 Series Advanced Service Guide 77

Page 78

3 Replaceable Parts

N6991AT

RP7951AT

RP7952AT

RP7951A

RP7952A

RP7953A

RP7961A

RP7962A

RP7963A

Tab le 3-1 RP7900 replaceable parts list (continued)

Keysight part

number

9170-2466 INDUCTOR-CORE-FERRITE 55 OHM +-25PCT 40X10X6.5-MM FLAT ✔✔✔✔✔✔✔✔✔

9170-2466 INDUCTOR-CORE-FERRITE 55 OHM +-25PCT 40X10X6.5-MM FLAT ✔✔✔✔✔✔✔✔✔

5188-9485 INSULATOR BIAS PCA ✔✔✔✔✔✔✔✔✔

5188-9509 INSULATOR CONTROL BOARD ✔✔✔✔✔✔✔✔✔

5190-8766 INSULATOR CONTROL TO CONTROL RIBBON CBL HOLD ✔✔✔✔✔✔✔✔✔

5188-9218 INSULATOR COVER TOP ✔✔✔✔✔✔✔✔✔

5188-9216 INSULATOR MODULE ✔✔✔✔✔✔✔✔✔

5188-9490 INSULATOR PFC SIDE ✔✔✔✔✔✔✔✔✔

5188-9219 INSULATOR REGULATION ✔✔✔✔✔✔✔✔✔

5188-9522 LABEL SET FOR N6991AT ✔

5188-9507 LABEL SET FOR RP7951AT ✔

5188-9508 LABEL SET FOR RP7952AT ✔

5188-9518 LABEL SET FOR RP7951A ✔

5188-9519 LABEL SET FOR RP7952A ✔

5188-9524 LABEL SET FOR RP7953A ✔

Description

RP7961A-80001 LABEL SET FOR RP7961A ✔

RP7962A-80001 LABEL SET FOR RP7962A ✔

RP7963A-80001 LABEL SET FOR RP7963A ✔

1254-2876

1254-2880

0535-0031

MENTOR CONNECTOR-HEADER VERTICAL SMT 34-PIN 2.54MM

2-ROW

MENTOR CONNECTOR-HEADER VERTICAL SMT 70-PIN 2MM 3.2A

2-ROW

NUT-HEX W/LOCK-WASHER M3X0.5 2.4MM-THK 5.5MM-A/F

STEEL NI-PLATED

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

78 Keysight RP7900 Series Advanced Service Guide

Page 79

Table 3-1 RP7900 replaceable parts list (continued)

N6991AT

RP7951AT

RP7952AT

RP7951A

RP7952A

RP7953A

RP7961A

RP7962A

RP7963A

Replaceable Parts 3

Keysight part

number

0535-0082

0535-0077

0535-1097

5188-9520 PACKAGING KIT FOR TITAN HV ✔✔✔✔✔✔✔✔✔

0361-1962

0361-1962

0361-1963

0361-1963

0515-1103

0515-1946

0515-1142

Description

NUT-HEX W/LOCK-WASHER M4X0.7 3.2MM-THK 7MM-A/F STEEL

NI-PLATED

NUT-HEX W/LOCK-WASHER M5X0.8 5.1MM-THK 8MM-A/F STEEL

ZN-PLATED

NUT-HEX WITH TOOTH-WASHER M4X0.70 3.2MM-HT 7MM-A/F

SST 18-8

RIVET PUSH-IN DOME-HD 3.5MM-LG 2MM-MAX-PNL-THK

NYLON-6 BLACK

RIVET PUSH-IN DOME-HD 3.5MM-LG 2MM-MAX-PNL-THK

NYLON-6 BLACK

RIVET PUSH-IN OVAL-HD 8MM-HEAD-DIA 8.6MM-LG NYLON 6/6

BLACK-FINISH

RIVET PUSH-IN OVAL-HD 8MM-HEAD-DIA 8.6MM-LG NYLON 6/6

BLACK-FINISH

SCREW-MACHINE 90-DEG-FLAT-HD TORX-T10 M3X0.5 10MM-LG

SST-300 PASSIVATED

SCREW-MACHINE 90-DEG-FLAT-HD TORX-T10 M3X0.5 6MM-LG

SST 300 PASSIVATED

SCREW-MACHINE PAN-HD TORX-T20 M4X0.7 8MM-LG SST-300

PASSIVATED

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

0515-0375

0515-2194

0515-0430

0515-0430

SCREW-MACHINE W/CREST-CUP-CON-WASHER PAN-HD

TORX-T10 M3X0.5 16MM-LG SST-300 PASSIVATED

SCREW-MACHINE W/CREST-CUP-CON-WASHER PAN-HD

TORX-T10 M3X0.5 50.5MM-LG SST-300 PASSIVATED

SCREW-MACHINE W/CREST-CUP-CON-WASHER PAN-HD

TORX-T10 M3X0.5 6MM-LG SST-300 PASSIVATED

SCREW-MACHINE W/CREST-CUP-CON-WASHER PAN-HD

TORX-T10 M3X0.5 6MM-LG SST-300 PASSIVATED

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

Keysight RP7900 Series Advanced Service Guide 79

Page 80

3 Replaceable Parts

N6991AT

RP7951AT

RP7952AT

RP7951A

RP7952A

RP7953A

RP7961A

RP7962A

RP7963A

Tab le 3-1 RP7900 replaceable parts list (continued)

Keysight part

number

0515-0372

0515-0382

0515-0383

0515-0433

0515-0367

0515-0374

0515-0667

0515-2246

0380-5630

Description

SCREW-MACHINE W/CREST-CUP-CON-WASHER PAN-HD

TORX-T10 M3X0.5 8MM-LG SST-300 PASSIVATED

SCREW-MACHINE W/CREST-CUP-CON-WASHER PAN-HD

TORX-T20 M4X0.7 12MM-LG SST-300

SCREW-MACHINE W/CREST-CUP-CON-WASHER PAN-HD

TORX-T20 M4X0.7 16MM-LG SST-300 PASSIVATED FINISH

SCREW-MACHINE W/CREST-CUP-CON-WASHER PAN-HD

TORX-T20 M4X0.7 8MM-LG SST-300 PASSIVATED

SCREW-MACHINE W/CREST-CUP-WASHER PAN-HD TORX-T8

M2.5X0.45 8MM-LG SST-300 PASSIVATED

SCREW-MACHINE WITH CREST-CUP-CON-WASHER PAN-HD

TORX-T10 M3X0.5 10MM-LG SST-300 PASSIVATED FINISH

SCREW-MACHINE WITH CREST-CUP-CON-WASHER PAN-HD

TORX-T10 M3X0.5 25MM-LG SST-300 PASSIVATED

SCREW-MACHINE WITH SQUARE-DOME-WASHER SLOTTED

TORX-T10 M3X0.5 8MM-LG SST PASSIVATED

STANDOFF-HEX MALE-FEMALE 4-40-THD 7.1MM-A/F 8.6MM-LG

STEEL ZN-PLATED BLACK

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

0380-4812

0380-1934

3050-0891

3050-2376

3050-0893

STANDOFF-HEX MALE-FEMALE M3X0.5 5.5MM-A/F 6MM-LG

SST-303 NATURAL-FINISH

STANDOFF-HEX MALE-FEMALE M3X0.5 6MM-A/F 10MM-LG SST

PASSIVATED

WASHER-FLAT METALLIC 3.2MM-ID 7MM-OD 0.5MM-THK SST A2

PASSIVATED

WASHER-FLAT METALLIC 4.2MM-ID 8MM-OD 0.8MM-THK STEEL

NI-PLATED

WASHER-FLAT METALLIC 4.4MM-ID 8.85MM-OD 0.8MM-THK SST

PASSIVATED

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

80 Keysight RP7900 Series Advanced Service Guide

Page 81

Table 3-1 RP7900 replaceable parts list (continued)

N6991AT

RP7951AT

RP7952AT

RP7951A

RP7952A

RP7953A

RP7961A

RP7962A

RP7963A

Replaceable Parts 3

Keysight part

number

2190-0629

2190-0644

2190-0586

9010-0321

Description

WASHER-LOCK EXT-TOOTH-TYP-A 5.3MM-ID 10MM-OD

0.6MM-THK SPRING-STEEL ZN-PLATED

WASHER-LOCK EXT-TOOTH-TYP-B 3.15MM-ID 7.35MM-OD

0.5MM-THK SST PASSIVATED

WASHER-LOCK HELICAL 4.1MM-ID 7.6MM-OD 0.9MM-THK SST

PASSIVATED

WINDOWS EMBEDDED COMPACT OTHER MOBILE 7 EMB ESD OEI

(C7P) RUNTIME/LICENSE

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

✔✔✔✔✔✔✔✔✔

Keysight RP7900 Series Advanced Service Guide 81

Page 82

3 Replaceable Parts

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

82 Keysight RP7900 Series Advanced Service Guide

Page 83

This information is subject to change

without notice. Always refer to the

Keysight website for the latest revision.

© Keysight Technologies 2019

Edition 1, July 11, 2019

Printed in Malaysia

*RP7900-90000*

RP7900-90000

www.keysight.com

Loading...

Loading...