Keysight P937 A Series, P9370A, P9372A, P9373A, P9374A Service Manual

...

Keysight P937xA Streamline Series USB

Vector Network Analyzers

P9370A, 300 kHz to 4 GHz

P9371A, 300 kHz to 6.5 GHz

P9372A, 300 kHz to 9 GHz

P9373A, 300 kHz to 14 GHz

P9374A, 300 kHz to 20 GHz

P9375A, 300 kHz to 26.5 GHz

Service Guide

Notices

© Keysight Technologies, Inc. 2019

No part of this manual may be

reproduced in any form or by any

means (including electronic storage

and retrieval or translation into a

foreign language) without prior

agreement and written consent from

Keysight Technologies, Inc. as

governed by United States and

international copyright laws.

Trademark Acknowledgments

Manual Part Number

P9370-90004

Edition

Edition 1, April 2019

Published in USA/Malaysia

Keysight Technologies Inc.

1400 Fountaingrove Parkway

Santa Rosa, CA 95403

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,”

AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO THE

MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, KEYSIGHT

DISCLAIMS ALL WARRANTIES,

EITHER EXPRESS OR IMPLIED WITH

REGARD TO THIS MANUAL AND ANY

INFORMATION CONTAINED HEREIN,

INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

KEYSIGHT SHALL NOT BE LIABLE FOR

ERRORS OR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE

FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT

OR ANY INFORMATION CONTAINED

HEREIN. SHOULD KEYSIGHT AND THE

USER HAVE A SEPARATE WRITTEN

AGREEMENT WITH WARRANTY

TERMS COVERING THE MATERIAL IN

THIS DOCUMENT THAT CONFLICT

WITH THESE TERMS, THE WARRANTY

TERMS IN THE SEPARATE

AGREEMENT WILL CONTROL.

Technology Licenses

The hardware and/or software

described in this document are

furnished under a license and may be

used or copied only in accordance

with the terms of such license.

U.S. Government Rights

The Software is “commercial

computer software,” as defined by

Federal Acquisition Regulation (“FAR”)

2.101. Pursuant to FAR 12.212 and

27.405-3 and Department of Defense

FAR Supplement (“DFARS”) 227.7202,

the U.S. government acquires

commercial computer software under

the same terms by which the software

is customarily provided to the public.

Accordingly, Keysight provides the

Software to U.S. government

customers under its standard

commercial license, which is

embodied in its End User License

Agreement (EULA), a copy of which

can be found at

http://www.keysight.com/find/sweula

The license set forth in the EULA

represents the exclusive authority by

which the U.S. government may use,

modify, distribute, or disclose the

Software. The EULA and the license

set forth therein, does not require or

permit, among other things, that

Keysight: (1) Furnish technical

information related to commercial

computer software or commercial

computer software documentation

that is not customarily provided to the

public; or (2) Relinquish to, or

otherwise provide, the government

rights in excess of these rights

customarily provided to the public to

use, modify, reproduce, release,

perform, display, or disclose

commercial computer software or

commercial computer software

documentation. No additional

government requirements beyond

those set forth in the EULA shall apply,

except to the extent that those terms,

rights, or licenses are explicitly

required from all providers of

commercial computer software

pursuant to the FAR and the DFARS

and are set forth specifically in writing

elsewhere in the EULA. Keysight shall

be under no obligation to update,

revise or otherwise modify the

Software. With respect to any

technical data as defined by FAR

2.101, pursuant to FAR 12.211 and

27.404.2 and DFARS 227.7102, the

U.S. government acquires no greater

than Limited Rights as defined in FAR

27.401 or DFAR 227.7103-5 (c), as

applicable in any technical data.

Safety Notices

A CAUTION notice denotes a hazard. It

calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not

proceed beyond a CAUTION notice

until the indicated conditions are fully

understood and met.

A WARNING notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered to,

could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

Where to Find the Latest Information

For the latest information about these products, including the P937xA Help System, instrument software upgrades,

application information, and product information, browse to one of the following URLs:

https://www.keysight.com/find/usb-vna

To receive the latest updates by email, subscribe to Keysight Email Updates at the following URL:

http://www.keysight.com/find/emailupdates

Information on preventing analyzer damage can be found at:

http://www.keysight.com/find/tips

Safety and regulatory information can be found in the Startup Guide, available online at:

http://literature.cdn.keysight.com/litweb/pdf/P9370-90001.pdf

Is your product software up-to-date?

Periodically, Keysight releases software updates to fix known defects and incorporate product enhancements. To search for

software updates for your product, go to the Keysight Technical Support website at:

https://www.keysight.com/find/usb-vna

3

4

Table of Contents

1. Safety and Regulatory Information

Information in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrostatic Discharge Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inspect for Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instruction for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Instrument Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

For the AC/DC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Equipment Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Environmental Conditions (Operating). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Contents

2. General Product Information

Information in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Analyzer Options, Accessories, and Upgrades Available. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Keysight Support, Services, and Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Service and Support Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Contacting Keysight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Shipping Your Network Analyzer for Service or Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3. Tests, Adjustments, and Troubleshooting

Information in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Get the Hardware Required for your GPIB Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Verify the Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Protect Against Electrostatic Discharge (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Allow the Analyzer to Warm Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Review the Principles of Connector Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

About System Verification and Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Keysight P937xA PXIe Service Guide 5

Contents

Instrument Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

System Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Certificate of Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

ANSI/NCSL Z540.3-2006 and ISO/IEC 17025 Verification . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Non-Standards Compliant Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

The Operator’s Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

System Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

What the System Verification Verifies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Measurement Uncertainty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Measurement Traceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Performing System Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Test Management Environment (TME) Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Guidelines for Ordering Power-Sensor Calibration Service . . . . . . . . . . . . . . . . . . . . . . . .46

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10 MHz Frequency Reference Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Source Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Receiver Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Check the Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4. Replaceable Parts Listings

Information in This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Assembly Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Replaceable Parts Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Entire Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Miscellaneous Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Accessories Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

5. Removal and Replacement Procedures

Information in This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Electrostatic Discharge (ESD) Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Connector Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Parts Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Front Panel Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

6 Keysight P937xA PXIe Service Guide

Removing and Replacing the A3 Front Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chassis Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Removing and Replacing the A1 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Module Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Removing and Replacing the A2 Module Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Post-Repair Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Ingot Chassis Utilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6. General Product Information

Information in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Error Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Using Error Terms as a Diagnostic Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Performing Measurement Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Using Flowgraphs to Identify Error Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Manual Access to Error Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Error Term Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Accessing the Keysight License Manager (KLM) and Installing Your License Files . . . . . . . . 95

Contents

Firmware Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

How to Check the Current Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Keysight P937xA PXIe Service Guide 7

Contents

8 Keysight P937xA PXIe Service Guide

Safety and Regulatory Information

Information in This Chapter

Keysight P937xA PXIe Service Guide

1 Safety and Regulatory Information

Information in This Chapter

This chapter provides safety information that will help protect you and your

network analyzer. It also contains information that is required by various

government regulatory agencies.

Section Title Summary of Content

Safety Symbols Descriptions of CAUTION and WARNING symbols used

throughout this manual.

General Safety

Considerations

Electrostatic Discharge

Protection

Regulatory Information Definitions of instrument markings.

A list of safety points to consider when servicing your

network analyzer.

A discussion of electrostatic discharge (ESD) and related

recommendations and requirements for ESD protection.

Instructions for disposing of the analyzer’s lithium battery.

Start Page

page 10

page 11

page 12

page 14

9

1-

Safety and Regulatory Information

Safety Symbols

Safety Symbols

The following safety symbols are used throughout this manual. Familiarize

yourself with each of the symbols and its meaning before operating this

instrument.

Denotes a hazard. It calls attention to a procedure that, if not correctly

performed or adhered to, would result in damage to or destruction of the

product. Do not proceed beyond a caution note until the indicated

conditions are fully understood and met.

Denotes a hazard. It calls attention to a procedure which, if not correctly

performed or adhered to, could result in injury or loss of life. Do not

proceed beyond a warning note until the indicated conditions are fully

understood and met.

10 Keysight P937xA PXIe Service Guide

Safety and Regulatory Information

General Safety Considerations

General Safety Considerations

Before Applying Power

If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

The measuring terminals on this instrument are designed to be used with

external signals described in Measurement Category I, but NOT with

external signals described in Categories II, III, and IV. The input of this

instrument cannot be connected to the mains.

The Mains wiring and connectors shall be compatible with the connector

used in the premise electrical system. Failure to ensure adequate earth

grounding by not using the correct components may cause product

damage, and serious injury.

Servicing

These servicing instructions are for use by qualified personnel only. To

avoid electrical shock, do not perform any servicing unless you are

qualified to do so.

Operating Conditions

Operator is responsible for maintaining safe operating conditions. To

ensure safe operating conditions, P937xAs should not be operated beyond

the full temperature range documented in the P937xA Data Sheet

(http://literature.cdn.keysight.com/litweb/pdf/5992-2765EN.pdf). Not

maintaining safe operating conditions can result in shorter P937xA

lifespans, improper P937xA performance, and user safety issues. If

P937xAs are allowed to exceed the specified full temperature range,

P937xA surface temperatures can cause discomfort or burns if touched. If

a P937xA exceeds the full temperature range, always allow it to cool

before touching it or removing it from the chassis.

This product is designed for use in Installation Category II and Pollution

Degree 2 environment.

Keysight P937xA PXIe Service Guide 11

1-

Safety and Regulatory Information

Electrostatic Discharge Protection

Electrostatic Discharge Protection

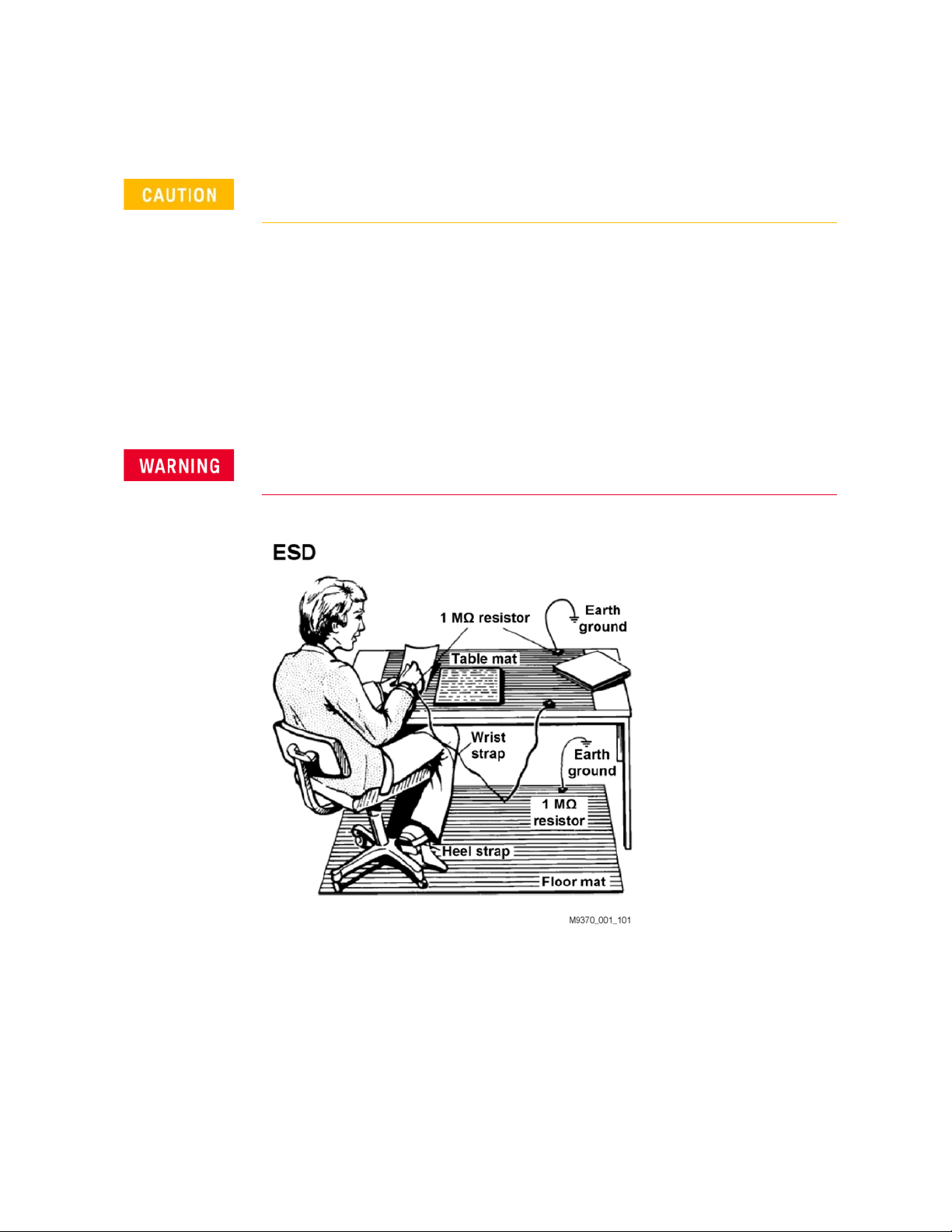

Most causes of instrument failure can be avoided if you will apply the

information in this section. PLEASE READ!

Electrostatic discharge (ESD) can damage or destroy electronic components.

Use a static-safe work station to perform all work on electronic assemblies.

Figure 1-1 on page 1-12 shows a static-safe work station using two types of

ESD protection: conductive table-mat and wrist-strap combination, and

conductive floor-mat and heel-strap combination. Both types, when used

together, provide a significant level of ESD protection. Of the two, only the

table-mat and wrist-strap combination provides adequate ESD protection

when used alone. To ensure user safety, the static-safe accessories must

provide at least 1 meg-ohm of isolation from ground.

Do NOT use these techniques for a static-safe work station when

working on circuitry with a voltage potential greater than 500 volts.

Figure 1-1 ESD protection setup

Unpack the P937xA network analyzer from the shipping containers. Keep the

black plastic port protectors and the shipping containers for possible reuse.

12 Keysight P937xA PXIe Service Guide

Safety and Regulatory Information

Electrostatic Discharge Protection

Inspect for Damage

After unpacking a network analyzer, inspect it for any shipping damage. Report

any damage to the shipping agent immediately, as such damage is not covered

by the warranty.

To avoid damage when handling the network analyzers, do not touch

exposed connector pins.

Keysight P937xA PXIe Service Guide 13

1-

Safety and Regulatory Information

Regulatory Information

Regulatory Information

This section contains information that is required by various government

regulatory agencies.

Instruction for Use

This product has been designed and tested in accordance with accepted

industry standards, and has been supplied in a safe condition. The

documentation contains information and warnings that must be followed by

the user to ensure safe operation and to maintain the product in a safe

condition.

EMC

Complies with the essential requirements of the European EMC Directive as

well as current editions of the following standards (dates and editions are cited

in the Declaration of Conformity):

- IEC/EN 61326-1

- CISPR Pub 11 Group 1, class A

- AS/NZS CISPR 11

- ICES/NMB-001

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme a la norme NMB-001 du Canada.

14 Keysight P937xA PXIe Service Guide

Safety

Safety and Regulatory Information

Regulatory Information

Acoustic statement (European Machinery Directive)

- Acoustic noise emission

- LpA <70 dB

- Operator position

- Normal operation mode per ISO 7779

Complies with the following standard (dates and editions are cited in the

Declaration of Conformity): IEC/EN 61010-1.

Keysight P937xA PXIe Service Guide 15

1-

Safety and Regulatory Information

Regulatory Information

Instrument Markings

Some instrument markings may not appear on your analyzer.

This symbol marks the ON position of the power line switch.

This symbol marks the ON position of the power line switch.

This symbol marks the standby position of the power line switch.

This symbol marks the OFF position of the power line switch.

This symbol marks the OFF position of the power line switch.

The instruction documentation symbol. The product is marked with this symbol when it

is necessary for the user to refer to the instructions in the documentation.

This symbol indicates separate collection for electrical and electronic equipment,

mandated under EU law as of August 13, 2005. All electric and electronic equipment

are required to be separated from normal waste for disposal (Reference WEEE

Directive, 2002/96/EC).

This symbol is used to identify a terminal which is internally connected to the product

frame or chassis.

The CE mark is a registered trademark of the European Community (if accompanied by

a year, it is the year when the design was proven). This product complies with all

relevant directives.

The Keysight email address is required by EU directives applicable to our product.

The CSA mark is a registered trademark of the CSA International.

16 Keysight P937xA PXIe Service Guide

Safety and Regulatory Information

Regulatory Information

This is a symbol of an Industrial Scientific and Medical Group 1 Class A product.

(CISPR 11, Clause 5)

Direct current.

The RCM mark is a registered trademark of the Australian Communications and Media

Authority.

China Restricted Substance Product Label. The EPUP (environmental protection use

period) number in the center indicates the time period during which no hazardous or

toxic substances or elements are expected to leak or deteriorate during normal use

and generally reflects the expected useful life of the product.

ISO standard recycling symbol. This symbol satisfies the requirements for the China

standard GB 18455-2001 as required by the China RoHS regulations for

paper/fiberboard packaging.

South Korean Certification (KC) mark; includes the marking's identifier code

which follows this format: MSIP-REM-Kst-ZZZZZZZZZZZZZZ.

USB connectors.

Kensington security Lock.

For the AC/DC Adapter

For safety reasons, only equipment Keysight approved accessories should

be used with the instrument.

No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock do not remove covers.

Use only the designated AC/DC adapter supplied with the instrument.

Use a Keysight supplied power cord that is the same or better electrical

rating.

Operated at an ambient temperature: 0 to 40°C.

(Linearly derate, at rate of 3 watts per degree C, from 90W at 40°C to 45 W

at 55°C, 30W at –20°C).

Maximum output rating: +15V/6.0 A.

Input rating: AC 100–240 V, 50–60Hz

Keysight P937xA PXIe Service Guide 17

1-

Safety and Regulatory Information

Regulatory Information

To prevent electrical shock, disconnect the AC to DC adapter from the

mains before cleaning. Use a dry cloth or one slightly dampened with

water to clean the external case parts. Do not attempt to cleans internally.

When the is connected to the AC/DC adapter, position the adapter so the

power cord is readily accessible. The power cord is the disconnecting

device. It removes main power to the AC/DC adapter. The front panel

switch is only for the DC power within the instrument, and not for the

AC/DC adapter. Alternately, an AC switch or circuit breaker (which is

readily identifiable and is easily reached by the operator) may be installed

and used as a disconnecting device to remove mains power from the

AC/DC adapter.

The AC/DC adapter has an auto–ranging line voltage input – be sure the

supply voltage is within the specified range.

The AC/DC adapter is for indoor use only.

Never use a modified or damaged charger. Use the original AC–DC

adapter ONLY.

The AC/DC adapter is designed for use in Installation Category II and

Pollution Degree 2 per IEC 61010-1.

18 Keysight P937xA PXIe Service Guide

Safety and Regulatory Information

Regulatory Information

Equipment Installation (AC/DC Adapter)

Use Keysight supplied power cord or one with same or better electrical

rating.

This instrument has auto-ranging line voltage input; be sure the supply

voltage is within the specified range and that voltage fluctuations do not to

exceed 10 percent of the nominal supply voltage.

Install the instrument so that the detachable power cord is readily

identifiable and is easily reached by the operator. The detachable power

cord is the instrument disconnecting device. It disconnects the mains

circuits from the mains supply before other parts of the instrument. The

front panel switch is only a standby switch and is not a LINE switch.

Alternatively, an externally installed switch or circuit breaker (which is

readily identifiable and is easily reached by the operator) may be used as a

disconnecting device.

Equipment Operation (AC/DC Adapter)

To prevent electrical shock, disconnect the Keysight Technologies P937xA

from mains before cleaning. Use a dry cloth or one slightly dampened with

water to clean the external case parts. Do not attempt to clean internally.

Position equipment to ensure easy access to disconnecting device.

Operator Equipment Maintenance and Service (AC/DC Adapter)

Use Keysight supplied power cord or one with same or better electrical

rating.

Keysight P937xA PXIe Service Guide 19

1-

Safety and Regulatory Information

Regulatory Information

Declaration of Conformity

A declaration of conformity is available upon request, or a copy is available on

the Keysight Technologies Web site at

http://www.keysight.com/go/conformity or by contacting Keysight - see

“Contacting Keysight” on page 22.

Equipment Ratings

The instruments can operate with mains supply voltage fluctuations up to

± 10% of the nominal voltage.

Instrument

DC input

External AC power adapter

Efficiency Level

Input 100 to 240 VAC,

Output 15 VDC ±5%, 6A max (90W max @40°C,

Power consumption (from the mains) 120V, 52 watts max

Environmental Conditions (Operating)

The instruments can operate with mains supply voltage fluctuations up to

± 10% of the nominal voltage.

Environmental Conditions (Operating)

For indoor use only

15 to 24 VDC

VI

50 to 60 Hz,

1.5 A to 0.75 A

linearly derate to 45W at 55°C)

240V, 62 watts max

Altitude up to: 3000m (9,842.2 ft)

Temperature: 0 to 55°C

Humidity:

Type tested at 95% RH, +40°C

20 Keysight P937xA PXIe Service Guide

General Product Information

Information in This Chapter

Keysight P937xA PXIe Service Guide

2 General Product Information

Information in This Chapter

Section Title Summary of Content

Maintenance Cleaning instructions for the external surfaces of your

network analyzer.

Information about electrical maintenance of your analyzer.

Analyzer Options,

Accessories, and Upgrades

Available

Keysight Support, Services,

and Assistance

A hyperlink to the network analyzer Configuration Guide,

which includes a list of options, accessories, and upgrades

available for the network analyzer.

The Internet address (URL) for Keysight assistance.

Service and support options available.

Calibration options available.

Important information about shipping your analyzer to

Keysight for service or repair.

Start Page

page 20

page 21

page 22

19

2-

General Product Information

Maintenance

Maintenance

To remove dirt or dust from the external case of the network analyzer P937xA,

clean the case using a dry or slightly-dampened cloth only.

To prevent electrical shock, remove analyzer module from chassis slot for

cleaning. Use a dry cloth or one slightly dampened with water to clean the

external case parts. Do not attempt to clean internally.

20 Keysight P937xA PXIe Service Guide

General Product Information

Analyzer Options, Accessories, and Upgrades Available

Analyzer Options, Accessories, and Upgrades Available

To see a list of the options, accessories, and upgrades available for the

network analyzers, including ordering information, refer to the Keysight PNA

Family Microwave Network Analyzers Configuration Guide, available online at

https://literature.cdn.keysight.com/litweb/pdf/5992-2823EN.pdf?id=29746

38

Keysight P937xA PXIe Service Guide 21

2-

General Product Information

Keysight Support, Services, and Assistance

Keysight Support, Services, and Assistance

Information on the following topics is included in this section.

— Service and Support Options

— Contacting Keysight

— Shipping Your Network Analyzer for Service or Repair

Service and Support Options

The network analyzer’s standard warranty is a 1-year return to Keysight

Technologies service warranty.

There are many other repair and calibration options available from the

Keysight Technologies support organization. These options cover a range

of service agreements with varying response times. Contact Keysight for

additional information on available service agreements for this product.

Refer to Contacting Keysight.

Contacting Keysight

Assistance with test and measurement needs and information on finding a

local Keysight office are available on the Web at:

www.keysight.com/find/assist

contact your Keysight field engineer.

. If you do not have access to the Internet, please

In any correspondence or telephone conversation, refer to the Keysight

product by its model number and full serial number. With this information,

the Keysight representative can determine whether your product is still

within its warranty period.

Shipping Your Network Analyzer for Service or Repair

Should it become necessary to return a network analyzer for repair or service,

follow the steps below:

1. Review the warranty information shipped with your product.

2. Contact Keysight to obtain a Return Material Authorization (RMA) and

return address. For assistance finding Keysight contact information, go to

www.keysight.com/find/assist (worldwide contact information for repair

and service).

3. Write the following information on a tag and attach it to the network

analyzer.

4. Name and address of owner. A P.O. box is not acceptable as a return

address.

22 Keysight P937xA PXIe Service Guide

General Product Information

Keysight Support, Services, and Assistance

5. network analyzer serial numbers. The serial number label is located on the

bottom panel of the module. The serial number can also be read from the

Soft Front Panel (SFP) interface, after the hardware is installed.

6. Description of the failure or service required.

7. On the shipping label, write ATTENTION REPAIR DEPARTMENT and the

RMA number.

8. Ship the analyzer module using the original packaging materials. Shipping

the analyzer module in anything other than the original packaging may

result in non-warranted damage.

Keysight P937xA PXIe Service Guide 23

2-

General Product Information

Keysight Support, Services, and Assistance

24 Keysight P937xA PXIe Service Guide

Tests, Adjustments, and Troubleshooting

Information in This Chapter

Keysight P937xA PXIe Service Guide

3 Tests, Adjustments, and Troubleshooting

Information in This Chapter

This chapter contains procedures to help you check, verify, adjust, and

troubleshoot your network analyzer.

— The checks verify the operation of the assemblies in your network analyzer.

— The verification compares the operation of your analyzer to a gold standard.

— The adjustments allow you to tune your network analyzer for best

performance.

— The troubleshooting assists you in finding the cause of a failure.

Section Title Summary of Content Start Page

Before You Begin Items to consider or procedures to perform before testing is

begun:

—Verify the Operating Environment.

—Protect Against Electrostatic Discharge.

—Allow the Analyzer to Warm Up.

—Review the Principles of Connector Care.

About System

Verification and

Performance Tests

ANSI/NCSL Z540.3-2006

and ISO/IEC 17025

Verification

Non-Standards

Compliant Verification

Descriptions of:

—System Specifications

—Instrument Specifications

—System Verification Procedure

—Performance Tests

—Certificate of Calibration

The ANSI/NCSL Z540.3-206 and ISO/IEC 17025 process of

verifying your network analyzer.

The Non-Standards Compliant process of verifying your

network analyzer.

page 27

page 28

page 31

page 32

25

3-

Tests, Adjustments, and Troubleshooting

Information in This Chapter

Section Title Summary of Content Start Page

Preliminary Checks Performing the Operator’s Check.

page 33

Checking your test cables.

NOTE Perform these checks before performing

system verification.

System Verification What the system verification does.

page 36

How to perform the verification test.

How to interpret the results.

Test Management

Environment (TME)

A list of equipment needed and TME webpage link

information.

page 45

Performance Tests

Troubleshooting A list of troubleshooting suggestions. page 51

26 Keysight P937xA PXIe Service Guide

Tests, Adjustments, and Troubleshooting

Before You Begin

Before You Begin

Before checking, verifying, or adjusting the analyzer, refer to the following

paragraphs to:

— get the required Service Test equipment

— make sure the operating environment is within its requirements

— make sure that proper electrostatic discharge (ESD) protection is provided

— make sure the analyzer has warmed up properly to achieve system stability

— review the principles of connector care

Get the Hardware Required for your GPIB Instruments

The hardware required to connect your GPIB instruments to the network

analyzer depends on the type of controller you use.

— Because the P937xA uses a remote controller, you need a GPIB card for the

PC.

Verify the Operating Environment

For Operating Environment information, refer to the online Data Sheet at

http://literature.cdn.keysight.com/litweb/5992-2765EN.pdf.

Protect Against Electrostatic Discharge (ESD)

For information on protecting against electrostatic discharge (ESD), refer to the

online Startup Guide at

http://literature.cdn.keysight.com/litweb/pdf/P9370-90001.pdf.

Allow the Analyzer to Warm Up

To achieve the maximum system stability, allow the network analyzer to

warm up for at least 15 minutes.

Review the Principles of Connector Care

For online information on connector care, go to

http://na.support.keysight.com/pna/connectorcare/Connector_Care.htm.

Keysight P937xA PXIe Service Guide 27

3-

Tests, Adjustments, and Troubleshooting

About System Verification and Performance Tests

About System Verification and Performance Tests

The performance of the network analyzer is specified in two ways: system

specifications and instrument specifications. It is the end user’s responsibility

to determine which set of specifications is applicable to their use of the

network analyzer.

A network analyzer measurement “system” includes the network analyzer,

calibration kit, test cables, and any necessary adapters. The system verification

software is used to verify the system’s conformance to the “system”

specifications. A “pass” result demonstrates that the network analyzer test

cables and adapters perform correctly as a system. It DOES NOT demonstrate

that any one component performs according to its individual specifications. A

change to any part of this measurement system requires a re-verification of the

system.

Instrument specifications specify the network analyzer’s uncorrected

measurement port characteristics and its output and input behavior. The

performance tests are used to verify the module’s conformance to “instrument”

specifications. Refer to “Test Management Environment (TME) Performance

Tests” on page 45.

System Specifications

System specifications specify warranted performance of the measurement

system when making error-corrected measurements using the same

calibration kit and test cables used during the system verifications routine.

System specifications are applicable only when the measurement system is

used to make error-corrected measurements.

The network analyzer’s system specifications are described in the Data Sheet,

available online at

http://literature.cdn.keysight.com/litweb/5992-2765EN.pdf.

System specifications are expressed in two ways:

— residual errors of the measurement system shown as tabular specification

values

— graphs of measurement uncertainty versus reflection and transmission

coefficients

System specifications are verified in one of the following ways:

— Complete the system verification procedure using a certified verification kit

and certified calibration kit that will be used for future measurements.

— Complete all of the performance tests using a certified calibration kit that

will be used for future measurements. This alternative verifies both the

system specifications and the instrument specifications for the network

analyzer.

28 Keysight P937xA PXIe Service Guide

Loading...

Loading...