Page 1

Keysight N9911X

Economical Waveguide

Calibration Components

User’s Guide

Page 2

Page 3

User’s Guide N9911-90002

Page 4

Notices

CAUTION

WARNING

© Keysight Technologies 2013, 2014

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Keysight Technologies as governed by United

States and international copyright laws.

Manual Part Number

N9911-90002

Edition

August 2014

Keysight Technologies

1400 Fountaingrove Parkway

Santa Rosa, CA 95403

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Keysight disclaims all warranties, either express or implied, with

regard to this manual and any information contained herein, including

but not limited to the implied warranties of merchantability and fitness for

a particular purpose. Keysight shall

not be liable for errors or for incidental or consequential damages in connection with the furnishing, use, or

performance of this document or of

any information contained herein.

Should Keysight and the user have a

separate written agreement with

warranty terms covering the material

in this document that conflict with

these terms, the warranty terms in

the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Keysight Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Notices

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and met.

If software is for use in the performance of

a U.S. Government prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

Page 5

Printing Copies of Documentation from the

Web

To print copies of documentation from the Web, download the PDF file

from the Keysight web site:

•Go to http://www.keysight.com.

• Enter the product model number (Ex: N9911X) in the Search bar.

• Click Search.

• Click the Manuals hyperlink.

• Click the hyperlink title for the document you want to print - this

downloads the PDF

• Print the document after the PDF has fully downloaded.

User’s Guide N9911-90002

Page 6

User’s Guide N9911-90002

Page 7

Contents

1. General Information

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Recording the Components Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

When to Calibrate the Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

How to Calibrate the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2. Specifications

Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Temperature—What to Watch Out For . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Typical VSWR Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Instrument Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Dimension Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

3. Use, Maintenance, and Care of the Components

Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Cleaning the Mating Plane Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Aligning Two Precision Flanges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Tightening a Flange Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Inspecting a Flange Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connecting a Termination to a Waveguide-to-Coax Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Connecting an Offset Shim Between a Flush Short and Waveguide-to-Coax Adapter . . . . . . . . . . . . . . . . . . . 3-8

Connecting a Flush Short to a Waveguide-to-Coax Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Handling and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

4. Troubleshooting

Troubleshooting Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Where to Look for More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Returning a Component to Keysight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Contacting Keysight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Component Dimensions

Flange Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Waveguide-to-Coax Adapter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Termination Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Offset Shim Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Flush Short Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

User’s Guide N9911-90002

Page 8

Contents

User’s Guide N9911-90002

Page 9

1 General Information

User’s Guide N9911-90002 1- 1

Page 10

General Information

Overview

Overview

N9911X Economical Waveguide Calibration Components are used to calibrate FieldFox analyzers. With the

calibration data properly loaded in the analyzer and a measurement calibration completed, systematic errors

are minimized. For information on components available to purchase, refer to the online document Keysight

N9911X Economical Waveguide Calibration Components Configuration Guide (part number N9911-90003).

1- 2 User’s Guide N9911-90002

Page 11

General Information

Recording the Components Serial Numbers

Recording the Components Serial Numbers

The N9911X Economical Waveguide Components are individually serialized (serial numbers are labeled onto

the body of each component). Record these serial numbers in the appropriate table. Recording the serial

numbers will prevent confusion with similar components.

The N9911X calibration components are manufactured by Flann Microwave. Each component is imprinted

with a Flann logo, part ID number, and serial number. To determine the Keysight option number for a

component, use the cross-references in the following tables.

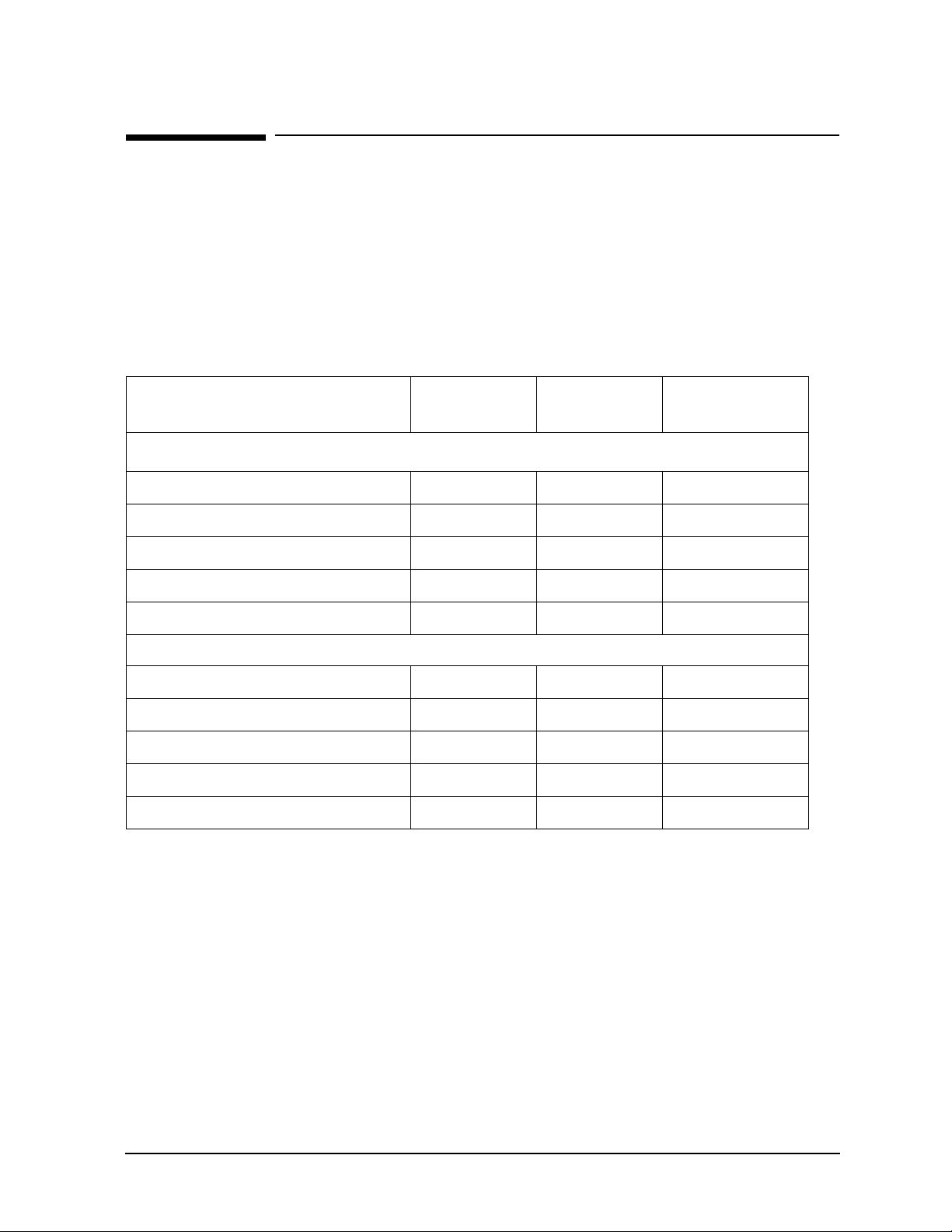

Table 1-1 Serial Number Record, Waveguide Designators C-Band/WR137/WG14, 5.38 – 8.18 GHz

Description Component

Serial Number

Calibration Components – Metric

Adapter 1, waveguide to type-N (male) coax

Adapter 2, waveguide to type-N (male) coax

Termination

Flush short

¼ wavelength offset shim

Calibration Components – English (Imperial)

Adapter 1, waveguide to type-N (male) coax

Adapter 2, waveguide to type-N (male) coax

Termination

Flush short

¼ wavelength offset shim

Keysight

Option Number

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

–110

–110

–111

–112

–113

–115

–115

–116

–117

–118

Flann

Part ID Number

14091–NM70–6332

14091–NM70–6332

14045–6333

14191–6334

14491–02–6335

14091–NM70–6136

14091–NM70–6136

14045–3703

14191–704

14491–02–3483

User’s Guide N9911-90002 1-3

Page 12

General Information

Recording the Components Serial Numbers

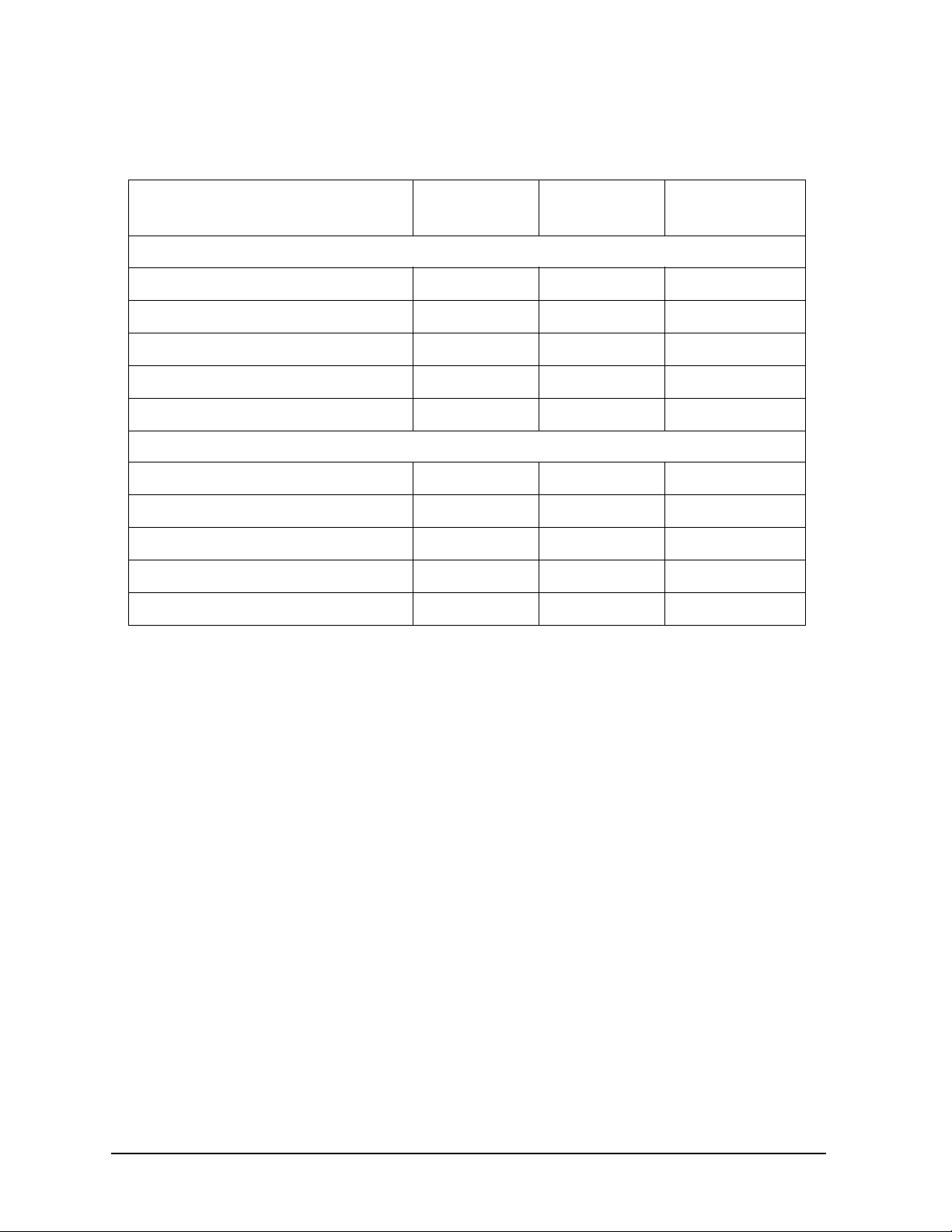

Table 1-2 Serial Number Record, Waveguide Designator X-Band/WR90/WG16, 8.2 – 12.5 GHz

Description Component

Serial Number

Calibration Components – Metric

Adapter 1, waveguide to type-N (male) coax

Adapter 2, waveguide to type-N (male) coax

Termination

Flush short

¼ wavelength offset shim

Calibration Components – English (Imperial)

Adapter 1, waveguide to type-N (male) coax

Adapter 2, waveguide to type-N (male) coax

Termination

Flush short

¼ wavelength offset shim

Keysight

Option Number

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

–210

–210

–211

–212

–213

–215

–215

–216

–217

–218

Flann

Part ID Number

16091–NM70–6336

16091–NM70–6336

16045–6337

16191–6338

16491–02–6339

16091–NM70–6141

16091–NM70–6141

16045–5509

16191–2547

16491–02–2401

1- 4 User’s Guide N9911-90002

Page 13

General Information

Recording the Components Serial Numbers

Table 1-3 Serial Number Record, Waveguide Designator Ku-Band/WR62/WG18, 11.9 – 18 GHz

Description Component

Serial Number

Calibration Components – Metric

Adapter 1, waveguide to type-N (male) coax

Adapter 2, waveguide to type-N (male) coax

Termination

Flush short

¼ wavelength offset shim

Calibration Components – English (Imperial)

Adapter 1, waveguide to type-N (male) coax

Adapter 2, waveguide to type-N (male) coax

Termination

Flush short

¼ wavelength offset shim

Keysight

Option Number

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

–310

–310

–311

–312

–313

–315

–315

–316

–317

–318

Flann

Part ID Number

18091–NM–6340

18091–NM–6340

18045–6341

18191–6342

18491–02–6343

18091–NM–6024

18091–NM–6024

18045–2546

18191–4127

18491–02–4095

User’s Guide N9911-90002 1-5

Page 14

General Information

Recording the Components Serial Numbers

Table 1-4 Serial Number Record, Waveguide Designator K-Band/WR42/WG20, 17.6 – 26.7 GHz

Description Component

Serial Number

Calibration Components – Metric

Adapter 1, waveguide to 3.5 mm (male) coax

Adapter 2, waveguide to 3.5 mm (male) coax

Termination

Flush short

¼ wavelength offset shim

Calibration Components – English (Imperial)

Adapter 1, waveguide to 3.5 mm (male) coax

Adapter 2, waveguide to 3.5 mm (male) coax

Termination

Flush short

¼ wavelength offset shim

Keysight

Option Number

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

N9911X

–310

–310

–311

–312

–313

–315

–315

–316

–317

–318

Flann

Part ID Number

20091–JM–2371

20091–JM–2371

20045–2376

20191–6349

20491–02–6351

20091–JM–2372

20091–JM–2372

20045–5174

20191–6348

20491–02–6350

1- 6 User’s Guide N9911-90002

Page 15

General Information

Preventive Maintenance

Preventive Maintenance

The best techniques for maintaining the integrity of the components include:

• routine visual inspection

• routine cleaning

• proper connection techniques

All of these are described in Chapter 3. Failure to detect and remove dirt or metallic particles on a mating

plane surface can degrade repeatability and accuracy and can damage any component mated to it. Improper

connections resulting from poor connection techniques, can also damage these components.

When to Calibrate the Analyzer

An analyzer calibration remains valid as long as the changes in the systematic error are insignificant. This

means that changes to the uncorrected leakages (directivity and isolation), mismatches (source match and

load match), and frequency response of the system are small (<10%) relative to accuracy specifications.

Change in the environment (especially temperature) between calibration and measurement is the major

cause in calibration accuracy degradation. The major effect is a change in the physical length of external and

internal cables. Other important causes are dirty and damaged test port connectors and calibration

standards. If the connectors become dirty or damaged, measurement repeatability and accuracy is affected.

Fortunately, it is relatively easy to evaluate the general validity of the calibration. To test repeatability,

remeasure one of the calibration standards. If you can not obtain repeatable measurements from your

calibration standards, maintenance needs to be performed on the test port connectors, cables and

calibration standards. Also, maintain at least one sample of the device under test or some known device as

your reference device.

How to Calibrate the Analyzer

Your analyzer’s calibration user interface prompts you through each step in a 1-port or a 2-port calibration

procedure. For detailed information on using your analyzer, refer to the appropriate user guide. See “Where

to Look for More Information” on page 4-3.

User’s Guide N9911-90002 1-7

Page 16

General Information

Preventive Maintenance

1- 8 User’s Guide N9911-90002

Page 17

2 Specifications

User’s Guide N9911-90002 2- 1

Page 18

Specifications

Environmental Requirements

Environmental Requirements

Table 2-1 Environmental Requirements

Parameter Limits

Temperature

Operating

Storage -20 °C to +70 °C

1. The temperature range over which the calibration components maintain performance to their specifications.

1

+4 °C to +40 °C

Temperature—What to Watch Out For

Changes in temperature can affect electrical characteristics. Therefore, the operating temperature is a

critical factor in performance. During a measurement calibration, the temperature of the calibration

components must be stable and within the range shown in

Tab le 2- 1.

IMPORTANT Avoid unnecessary handling of the components during calibration because your fingers act

as a heat source and may increase the temperature of the component.

2- 2 User’s Guide N9911-90002

Page 19

Specifications

Typical VSWR Values

Typical VSWR Values

Tab le 2- 2 and Tab le 2 - 3 list the typical VSWR values for the N9911X terminations and waveguide-to-coax

adapters.

Tab le 2- 2 Ty p i c a l VS WR Va l u e s f or Ter mi n a t i o ns

Keysight

Option Number

for Termination

N9911X–111

N9911X–116 English

N9911X–211

N9911X–216 English

N9911X–311

N9911X–316 English

N9911X–411

N9911X–416 English

Waveguide Band Designator Thread

Ty p e

Metric

C-Band, WR137, WG14

(Imperial)

Metric

X-Band, WR90, WG16

(Imperial)

Metric

Ku-Band, WR62, WG18

(Imperial)

Metric

K-Band, WR42, WG20

(Imperial)

Frequency VSWR,

Maximum

1.10

5.38 to 8.18 GHz

8.2 to 12.5 GHz 1.02

11.9 to 18 GHz 1.02

17.6 to 26.7GHz 1.03

1.02

Table 2-3 Typical VSWR Values for Waveguide-to-Coax Adapters

Keysight

Option Number

for Adapter

Waveguide Band Designator Thread

Ty p e

Frequency VSWR,

Maximum

N9911X–110

N9911X–115 English

N9911X–210

N9911X–215 English

N9911X–310

N9911X–315 English

N9911X–410

N9911X–415 English

User’s Guide N9911-90002 2-3

C-Band, WR137, WG14

X-Band, WR90, WG16

Ku-Band, WR62, WG18

K-Band, WR42, WG20

Metric

5.38 to 8.18 GHz 1.10

(Imperial)

Metric

8.2 to 12.5 GHz 1.10

(Imperial)

Metric

11.9 to 18 GHz 1.10

(Imperial)

Metric

17.6 to 26.7GHz 1.20

(Imperial)

Page 20

Specifications

Instrument Interface Specifications

Instrument Interface Specifications

Table 2-4 N9911X Instrument Interface Specifications

Waveguide

Band

Designator

C-Band/

WR137/

WG14

X-Band/

WR90/

WG16

Ku-Band/

WR62/

WG18

K-Band/

WR42/

WG20

Thread Type Compatible Flange Type

Metric Flange (UAR 70, PAR 70, CAR 70, UDR 70, RDR 70, PDR 70)

English

(Imperial)

Metric Flange (UBR 100, PBR 100, CBR 100, UDR 100, PDR 100, RDR 100)

English

(Imperial)

Metric Flange (UBR 140, PBR 140, CBR 140, UDR 140, PDR 140, RDR 140)

English

(Imperial)

Metric Flange (UBR 220, PBR 220, CBR 220, UDR 220, PDR 220, RDR 220)

English

(Imperial)

Flange (UG-441/U, UG-344/U, UG-343B/U, UG-440B/U, UG-1733/U, UG-1732/U,

UG-1356/U, UG-1357/U, CPR 137F, CPR 137G)

Flange (UG-39/U, UG-135/U, M3922/53-009, M3922/53-010, M3922/53-015,

M3922/53-016, UG-40B/U, UG-136B/U, M3922/59-013, M3922/59-014,

UG-1736/U, UG-1737/U, UG-1360/U, UG-1361/U, CPR 90F, CPR 90G)

Flange (UG-419A/U, UG-1665/U, M3922/53-011, M3922/53-012, M3922/53-017,

M3922/53-018, UG-541A/U, UG-1666/U)

Flange (UG-595/U, UG-597/U, UG596A/U, UG-598A/U, M3922/70-027,

M3922/70-028)

2- 4 User’s Guide N9911-90002

Page 21

Specifications

Dimension Specifications

Dimension Specifications

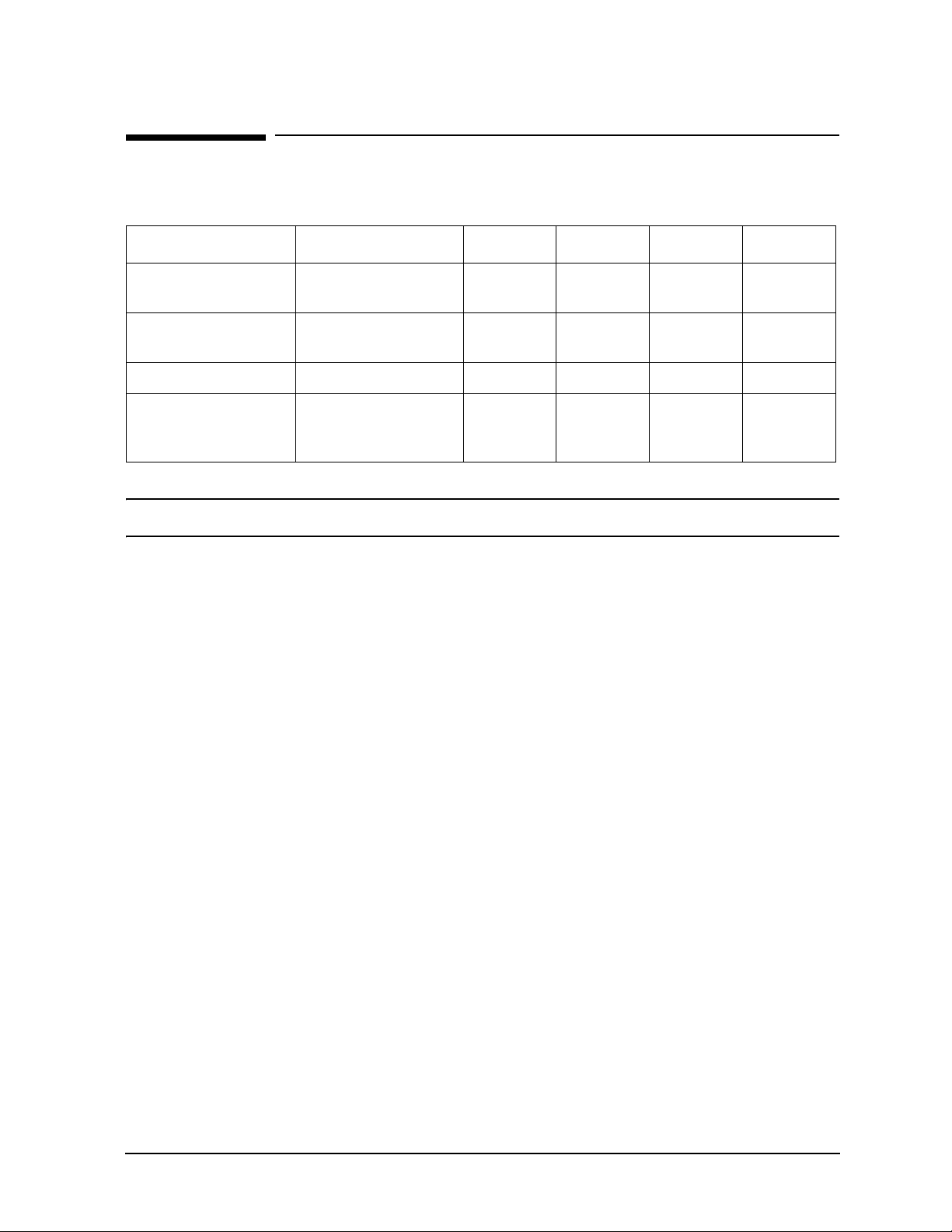

Table 2-5 N9911X Dimension Specifications

Component Parameter WR137 WR90 WR62 WR42

Adapter,

waveguide-to-coax

Termination Waveguide aperture

Flush short Shorting face flatness 25 um 25 um 25 um 25 um

1/4 wavelength offset

shim

Waveguide aperture

tolerance

tolerance

Waveguide aperture

tolerance

46 um MAX 25 um MAX 23 um MAX 20 um MAX

46 um MAX 25 um MAX 23 um MAX 20 um MAX

46 um MAX,

14.711 mm

+/– 45 um

25 um MAX,

9.63 mm

+/– 35 um

23 um MAX,

6.668 mm

+/– 30 um

20 um MAX,

4.501 mm

+/– 25 um

NOTE Refer to the Appendix for graphics showing the component dimensions.

User’s Guide N9911-90002 2-5

Page 22

Specifications

Dimension Specifications

2- 6 User’s Guide N9911-90002

Page 23

3 Use, Maintenance, and Care of the Components

User’s Guide N9911-90002 3- 1

Page 24

Use, Maintenance, and Care of the Components

Electrostatic Discharge

Electrostatic Discharge

Protection against electrostatic discharge (ESD) is essential while connecting, inspecting, or cleaning

connectors attached to a static-sensitive circuit (such as those found in test sets).

Static electricity can build up on your body and can easily damage sensitive internal circuit elements when

discharged. Static discharges too small to be felt can cause permanent damage. Devices such as calibration

components and devices under test (DUT), can also carry an electrostatic charge. To prevent damage to the

test set, components, and devices:

• always wear a grounded wrist strap having a 1 MW resistor in series with it when handling components

and devices or when making connections to the test set.

• always use a grounded antistatic mat in front of your test equipment.

• always wear a heel strap when working in an area with a conductive floor. If you are uncertain about the

conductivity of your floor, wear a heel strap.

• always ground yourself before you clean, inspect, or make a connection to a static-sensitive device or

test port. You can, for example, grasp the grounded outer shell of the test port or cable connector briefly.

• always ground the center conductor of a test cable before making a connection to the analyzer test port

or other static-sensitive device. This can be done as follows:

1. Connect a short to one end of the cable to short the center conductor to the outer conductor.

2. While wearing a grounded wrist strap, grasp the outer shell of the cable connector.

3. Connect the other end of the cable to the test port.

• Remove the short from the cable.

Figure 3-1 shows a typical ESD protection setup using a grounded mat and wrist strap.

Figure 3-1 ESD Protection Setup

3- 2 User’s Guide N9911-90002

Page 25

Use, Maintenance, and Care of the Components

Visual Inspection

Visual Inspection

Visual inspection and, if necessary, cleaning should be done every time a connection is made. Inspect

mating surfaces for dirt, dust, foreign particles, or scratches, which can degrade component performance. A

damaged mating surface can damage any good surface connected to it. If necessary, clean all mating

surfaces.

Magnification is helpful when inspecting mating surfaces, but it is not required and may actually be

misleading. Defects and damage that cannot be seen without magnification generally have no effect on

electrical or mechanical performance. Magnification is of great use in analyzing the nature and cause of

damage and in cleaning mating surfaces, but it is not required for inspection.

User’s Guide N9911-90002 3-3

Page 26

Use, Maintenance, and Care of the Components

Cleaning the Mating Plane Surfaces

Cleaning the Mating Plane Surfaces

1. Use Compressed Air or Nitrogen

WARNING Always use protective eyewear when using compressed air or nitrogen.

Use compressed air (or nitrogen) to loosen particles on the mating plane surfaces. Clean air cannot

damage a component or leave particles or residues behind.

You can use any source of clean, dry, low-pressure compressed air or nitrogen that has an effective

oil-vapor filter and liquid condensation trap placed just before the outlet hose.

Ground the hose nozzle to prevent electrostatic discharge, and set the air pressure to less than 414 kPa

(60 psi) to control the velocity of the air stream. High-velocity streams of compressed air can cause

electrostatic effects when directed into a component. These electrostatic effects can damage the

component. Refer to “Electrostatic Discharge” earlier in this chapter for additional information.

WARNING Keep isopropyl alcohol away from heat, sparks, and flame. Store in a tightly closed

container. It is extremely flammable. In case of fire, use alcohol foam, dry chemical, or

carbon dioxide; water may be ineffective.

Use isopropyl alcohol with adequate ventilation and avoid contact with eyes, skin, and

clothing. It causes skin irritation, may cause eye damage, and is harmful if swallowed or

inhaled. It may be harmful if absorbed through the skin. Wash thoroughly after handling.

In case of spill, soak up with sand or earth. Flush spill area with water.

Dispose of isopropyl alcohol in accordance with all applicable federal, state, and local

environmental regulations.

2. Clean the Mating Plane Surfaces

a. Apply a small amount of isopropyl alcohol to a lint-free cleaning swab.

b. Clean the mating plane surfaces.

c. Let the alcohol evaporate, then blow the mating plane surface dry with a gentle stream of clean,

low-pressure compressed air or nitrogen. Always completely dry a component before you reassemble

or use it.

3. Inspect

a. Inspect the mating plane surface to make sure that no particles or residue remain. “Visual

Inspection” on page 3-3.

3- 4 User’s Guide N9911-90002

Page 27

Use, Maintenance, and Care of the Components

Connections

Connections

Good connections require a skilled operator. Slight errors in operator technique can have a significant effect

on measurements and measurement uncertainties. The most common cause of measurement error is poor

connections.

The following procedures illustrate how to make good connections.

IMPORTANT Unlike threaded components, the WR-90, WR-62, WR-42 waveguide mating planes are

flanges that you must carefully screw together. Always connect waveguide in the same

flange orientation. For example, use the label as a reference and always connect

components with the labels facing the same direction.

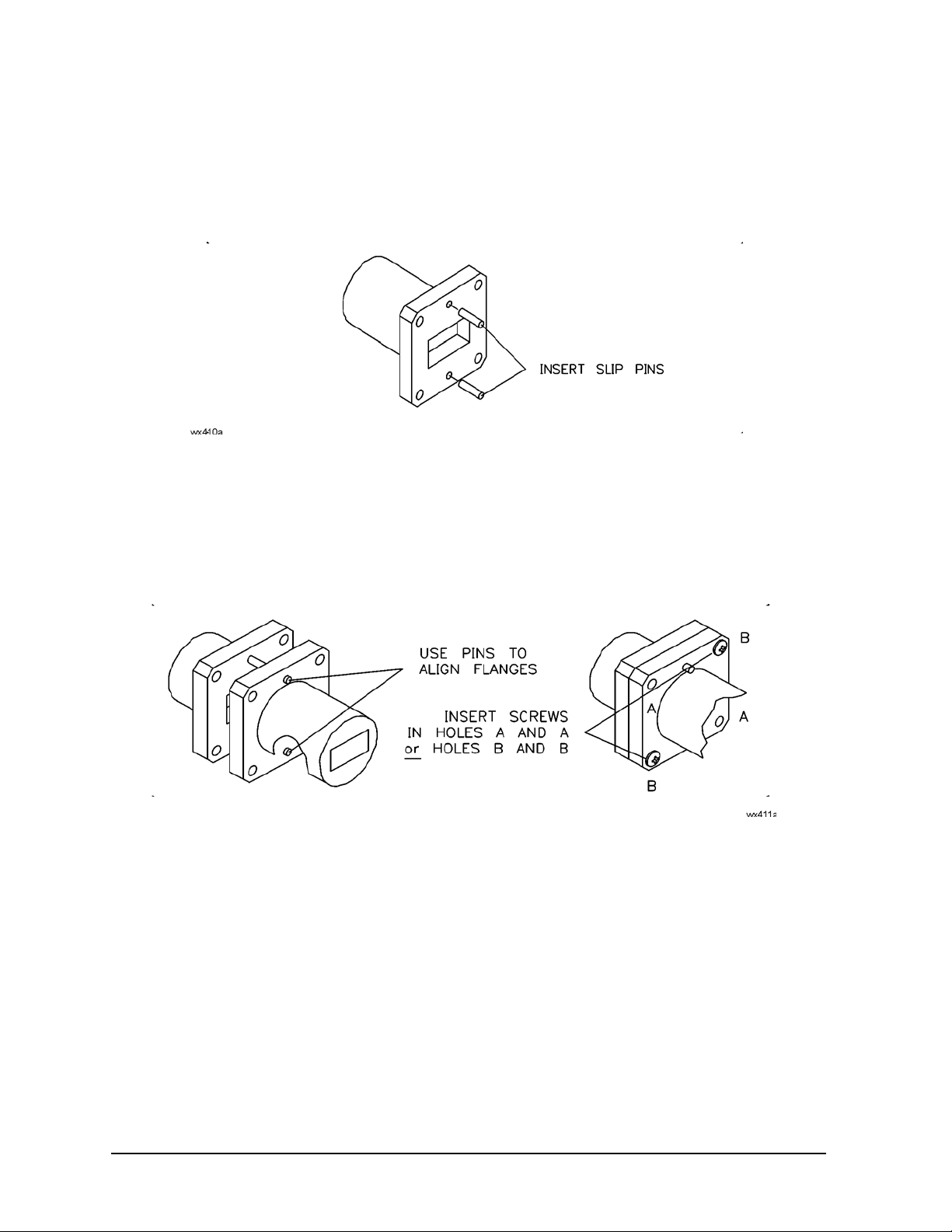

Aligning Two Precision Flanges

A precision flange has two precision alignment holes, as shown in Figure 3-2. A non-precision flange has

only screw holes.

Figure 3-2 Precision Alignment Holes

User’s Guide N9911-90002 3-5

Page 28

Use, Maintenance, and Care of the Components

Connections

1. Place the slip pins in the top and bottom holes of one flange, as shown in Figure 3-3.

Figure 3-3 Inserting Slip Pins

2. Using the pins as guides for the adapter, offset shim, and waveguide-to-coax adapter, carefully align the

flanges and insert two screws in the diagonal corner holes, as shown in Figure 3-4.

Figure 3-4 Aligning Flanges

3. Place a lock washer and nut on each screw, and finger tighten.

4. Insert the remaining two screws.

5. Place a lock washer and nut on each screw, and finger tighten.

6. Remove the slip pins.

7. Go to “Tightening a Flange Connection” on page 3-7.

3- 6 User’s Guide N9911-90002

Page 29

Use, Maintenance, and Care of the Components

Connections

Tightening a Flange Connection

NOTE The best connection has symmetrical pressure applied as you gradually tighten the screws.

1. In an “X” pattern (for equal compression), tighten all four screws using a hex ball driver. Do not

over-tighten. See Figure 3-5.

2. Visually inspect the connection. Refer to the following section “Inspecting a Flange Connection.”

Figure 3-5 “X” Screw Pattern

Inspecting a Flange Connection

Inspect the flange connection as follows:

1. Place an electric light or white paper behind the connection.

2. Check the flange matings for any gap. A good connection has no gaps between the connected

waveguide flanges, and the waveguide walls are flush. There is no step or offset.

3. Ensure that all four screws are equally tight.

User’s Guide N9911-90002 3-7

Page 30

Use, Maintenance, and Care of the Components

Connections

Connecting a Termination to a Waveguide-to-Coax Adapter

Figure 3-6 Termination and Adapter

Connecting an Offset Shim Between a Flush Short and Waveguide-to-Coax Adapter

Create an offset short by connecting the offset shim between the short and the appropriate adapter, as

shown in Figure 3-7.

Figure 3-7 Shim, Flush Short, and Adapter (Creates an Offset Short)

3- 8 User’s Guide N9911-90002

Page 31

Use, Maintenance, and Care of the Components

Connecting a Flush Short to a Waveguide-to-Coax Adapter

Figure 3-8 Flush Short and Adapter

Connections

User’s Guide N9911-90002 3-9

Page 32

Use, Maintenance, and Care of the Components

Handling and Storage

Handling and Storage

• Install the protective end caps and store the calibration components when not in use.

• Never store components loose in a box, or in a desk or bench drawer. This is the most common cause of

component damage during storage.

• Keep components clean.

• Do not touch mating plane surfaces. Natural skin oils and microscopic particles of dirt are easily

transferred to a component and are very difficult to remove.

• Do not set components contact-end down on a hard surface. The plating and the mating plane surfaces

can be damaged if the interface comes in contact with any hard surface.

3- 10 User’s Guide N9911-90002

Page 33

4 Troubleshooting

User’s Guide N9911-90002 4- 1

Page 34

Troubleshooting

Troubleshooting Process

Troubleshooting Process

If you suspect a bad calibration, or if your analyzer does not pass performance verification, follow the steps

in Figure 4-1

Figure 4-1 Troubleshooting Flowchart

4- 2 User’s Guide N9911-90002

Page 35

Tr ou b le s h oo t in g

Where to Look for More Information

Where to Look for More Information

This manual contains limited information about analyzer system operation. For detailed information on using

a FieldFox analyzer, refer to the appropriate user guide.

To view an online FieldFox user guide, use the following steps:

1. Go to www.keysight.com.

2. Enter your FieldFox model number (Ex: N9928A) in the Search box and click Search.

3. Click Manuals.

4. Click the title/hyperlink for the document PDF you want to view.

If you need additional information, see “Contacting Keysight” on page 4-4.

Returning a Component to Keysight

If an N9911X component requires service, contact Keysight Technologies for information on where to send it

- see “Contacting Keysight” on page 4-4. Please provide the following information:

• your company name and address

• a technical contact person within your company, and the person's complete telephone number

• the Keysight option number, Flann part ID number, and serial number of the component (refer to

“Recording the Components Serial Numbers” on page 1-3)

• the type of service required

•a detailed description of the problem and how the component was being used when the problem

occurred

NOTE When returning a component to Keysight, install the protective end caps on the component.

User’s Guide N9911-90002 4-3

Page 36

Troubleshooting

Contacting Keysight

Contacting Keysight

Assistance with test and measurement needs and information on finding a local Keysight office are

available on the Web at:

www.keysight.com/find/assist

If you do not have access to the Internet, please contact your Keysight field engineer.

NOTE In any correspondence or telephone conversation, refer to the Keysight product by its model

number and full serial number. With this information, the Keysight representative can

determine whether your product is still within its warranty period.

4- 4 User’s Guide N9911-90002

Page 37

5 Component Dimensions

User’s Guide N9911-90002 5- 1

Page 38

Component Dimensions

Table 5-1 List of Figures

Figure Title and Location

“Flange, Waveguide Designators C-Band/WR137/WG14, Metric” on page 5-5

“Flange, Waveguide Designators C-Band/WR137/WG14, English (Imperial)” on

page 5-6

“Flange, Waveguide Designators X-Band/WR90/WG16, Metric” on page 5-6

“Flange, Waveguide Designators X-Band/WR90/WG16, English (Imperial)” on

page 5-7

“Flange, Waveguide Designators Ku-Band/WR62/WG18, Metric” on page 5-7

“Flange, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial)” on

page 5-8

“Flange, Waveguide Designators K-Band/WR42/WG20, Metric” on page 5-8

“Flange, Waveguide Designators K-Band/WR42/WG20, English (Imperial)” on

page 5-9

“Adapter, Waveguide Designators C-Band/WR137/WG14, Metric, Keysight Part

Number N9911X-110” on page 5-10

“Adapter, Waveguide Designators C-Band/WR137/WG14, English (Imperial),

Keysight Part Number N9911X-115” on page 5-11

“Adapter, Waveguide Designators X-Band/WR90/WG16, Metric, Keysight Part

Number N9911X-210” on page 5-12

“Adapter, Waveguide Designators X-Band/WR90/WG16, English (Imperial),

Keysight Part Number N9911X-215” on page 5-13

“Adapter, Waveguide Designators Ku-Band/WR62/WG18, Metric, Keysight Part

Number N9911X-310” on page 5-14

“Adapter, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial),

Keysight Part Number N9911X-315” on page 5-15

“Adapter, Waveguide Designators K-Band/WR42/WG20, Metric, Keysight Part

Number N9911X-410” on page 5-16

“Adapter, Waveguide Designators K-Band/WR42/WG20, English (Imperial),

Keysight Part Number N9911X-415” on page 5-17

“Termination, Waveguide Designators C-Band/WR137/WG14, Metric, Keysight

Part Number N9911X-111” on page 5-18

5- 2 User’s Guide N9911-90002

Page 39

Component Dimensions

Table 5-1 List of Figures

Figure Title and Location

“Termination, Waveguide Designators C-Band/WR137/WG14, English (Imperial),

Keysight Part Number N9911X-116” on page 5-19

“Termination, Waveguide Designators X-Band/WR90/WG16, Metric, Keysight Part

Number N9911X-211” on page 5-20

“Termination, Waveguide Designators X-Band/WR90/WG16, English (Imperial),

Keysight Part Number N9911X-216” on page 5-21

“Termination, Waveguide Designators Ku-Band/WR62/WG18, Metric, Keysight

Part Number N9911X-311” on page 5-22

“Termination, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial),

Keysight Part Number N9911X-316” on page 5-23

“Termination, Waveguide Designators K-Band/WR42/WG20, Metric, Keysight Part

Number N9911X-411” on page 5-24

“Termination, Waveguide Designators K-Band/WR42/WG20, English (Imperial),

Keysight Part Number N9911X-416” on page 5-25

“Offset Shim, Waveguide Designators C-Band/WR137/WG14, Metric, Keysight

Part Number N9911X-113” on page 5-26

“Offset Shim, Waveguide Designators C-Band/WR137/WG14, English (Imperial),

Keysight Part Number N9911X-118” on page 5-27

“Offset Shim, Waveguide Designators X-Band/WR90/WG16, Metric, Keysight Part

Number N9911X-213” on page 5-28

“Offset Shim, Waveguide Designators X-Band/WR90/WG16, English (Imperial),

Keysight Part Number N9911X-218” on page 5-29

“Offset Shim, Waveguide Designators Ku-Band/WR62/WG18, Metric, Keysight

Part Number N9911X-313” on page 5-30

“Offset Shim, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial),

Keysight Part Number N9911X-318” on page 5-31

“Offset Shim, Waveguide Designators K-Band/WR42/WG20, Metric, Keysight Part

Number N9911X-413” on page 5-32

“Offset Shim, Waveguide Designators K-Band/WR42/WG20, English (Imperial),

Keysight Part Number N9911X-418” on page 5-33

“Flush Short, Waveguide Designators C-Band/WR137/WG14, Metric, Keysight

Part Number N9911X-112” on page 5-34

User’s Guide N9911-90002 5-3

Page 40

Component Dimensions

Table 5-1 List of Figures

Figure Title and Location

“Flush Short, Waveguide Designators C-Band/WR137/WG14, English (Imperial),

Keysight Part Number N9911X-117” on page 5-35

“Flush Short, Waveguide Designators X-Band/WR90/WG16, Metric, Keysight Part

Number N9911X-212” on page 5-36

“Flush Short, Waveguide Designators X-Band/WR90/WG16, English (Imperial),

Keysight Part Number N9911X-217” on page 5-37

“Flush Short, Waveguide Designators Ku-Band/WR62/WG18, Metric, Keysight

Part Number N9911X-312” on page 5-38

“Flush Short, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial),

Keysight Part Number N9911X-317” on page 5-39

“Flush Short, Waveguide Designators K-Band/WR42/WG20, Metric, Keysight Part

Number N9911X-412” on page 5-40

“Flush Short, Waveguide Designators K-Band/WR42/WG20, English (Imperial),

Keysight Part Number N9911X-417” on page 5-41

5- 4 User’s Guide N9911-90002

Page 41

Flange Dimensions

NOTE The dimensions shown in the following graphics are in millimeters.

Figure 5-1 Flange, Waveguide Designators C-Band/WR137/WG14, Metric

Component Dimensions

Flange Dimensions

User’s Guide N9911-90002 5-5

Page 42

Component Dimensions

Flange Dimensions

Figure 5-2 Flange, Waveguide Designators C-Band/WR137/WG14, English (Imperial)

Figure 5-3 Flange, Waveguide Designators X-Band/WR90/WG16, Metric

5- 6 User’s Guide N9911-90002

Page 43

Component Dimensions

Figure 5-4 Flange, Waveguide Designators X-Band/WR90/WG16, English (Imperial)

Flange Dimensions

Figure 5-5 Flange, Waveguide Designators Ku-Band/WR62/WG18, Metric

User’s Guide N9911-90002 5-7

Page 44

Component Dimensions

Flange Dimensions

Figure 5-6 Flange, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial)

Figure 5-7 Flange, Waveguide Designators K-Band/WR42/WG20, Metric

5- 8 User’s Guide N9911-90002

Page 45

Component Dimensions

Figure 5-8 Flange, Waveguide Designators K-Band/WR42/WG20, English (Imperial)

Flange Dimensions

User’s Guide N9911-90002 5-9

Page 46

Component Dimensions

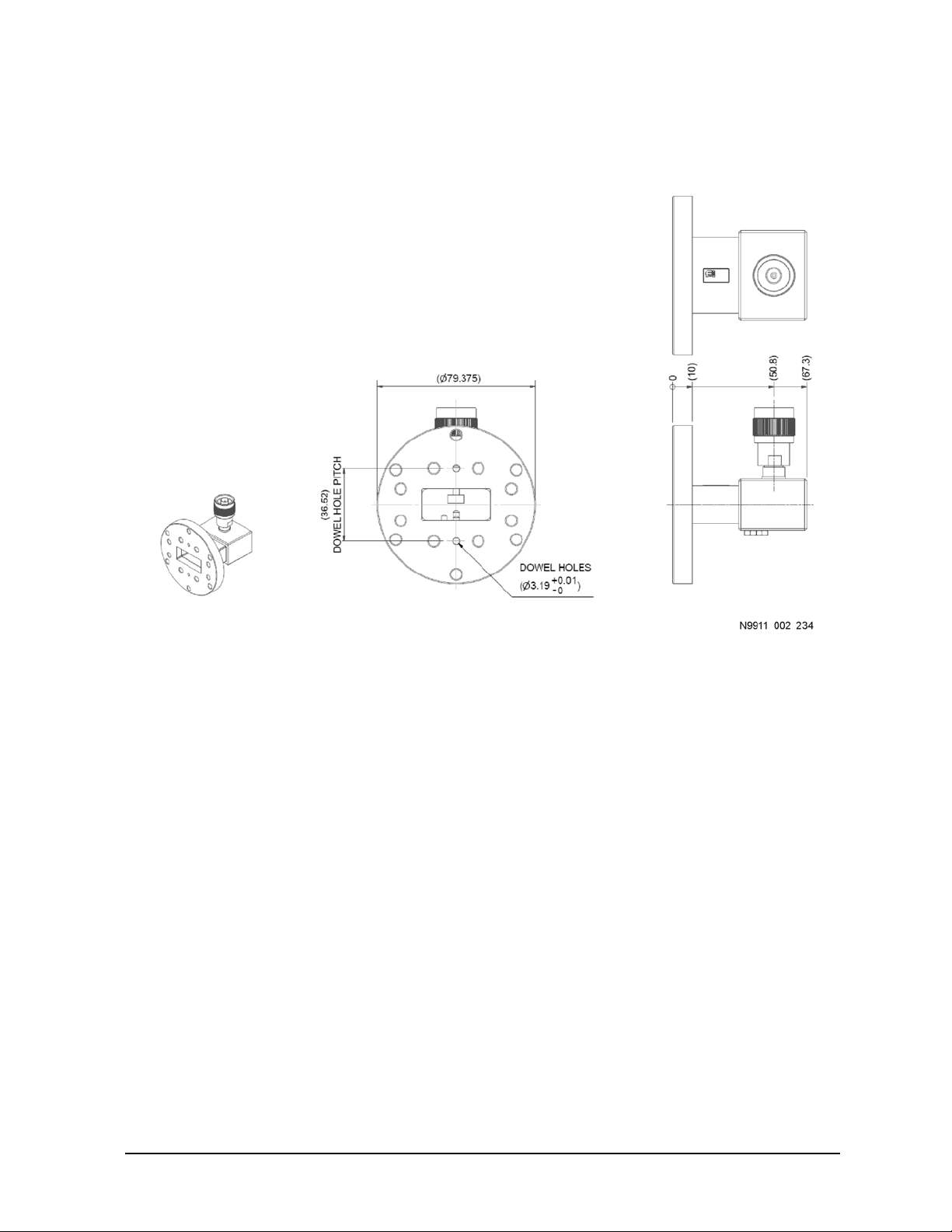

Waveguide-to-Coax Adapter Dimensions

Waveguide-to-Coax Adapter Dimensions

NOTE The dimensions shown in the following graphics are in millimeters.

Figure 5-9 Adapter, Waveguide Designators C-Band/WR137/WG14, Metric, Keysight Part Number

N9911X-110

5- 10 User’s Guide N9911-90002

Page 47

Component Dimensions

Waveguide-to-Coax Adapter Dimensions

Figure 5-10 Adapter, Waveguide Designators C-Band/WR137/WG14, English (Imperial), Keysight

Part Number N9911X-115

User’s Guide N9911-90002 5-11

Page 48

Component Dimensions

Waveguide-to-Coax Adapter Dimensions

Figure 5-11 Adapter, Waveguide Designators X-Band/WR90/WG16, Metric, Keysight Part Number

N9911X-210

5- 12 User’s Guide N9911-90002

Page 49

Component Dimensions

Waveguide-to-Coax Adapter Dimensions

Figure 5-12 Adapter, Waveguide Designators X-Band/WR90/WG16, English (Imperial), Keysight Part

Number N9911X-215

User’s Guide N9911-90002 5-13

Page 50

Component Dimensions

Waveguide-to-Coax Adapter Dimensions

Figure 5-13 Adapter, Waveguide Designators Ku-Band/WR62/WG18, Metric, Keysight Part Number

N9911X-310

5- 14 User’s Guide N9911-90002

Page 51

Component Dimensions

Waveguide-to-Coax Adapter Dimensions

Figure 5-14 Adapter, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial), Keysight

Part Number N9911X-315

User’s Guide N9911-90002 5-15

Page 52

Component Dimensions

Waveguide-to-Coax Adapter Dimensions

Figure 5-15 Adapter, Waveguide Designators K-Band/WR42/WG20, Metric, Keysight Part Number

N9911X-410

5- 16 User’s Guide N9911-90002

Page 53

Component Dimensions

Waveguide-to-Coax Adapter Dimensions

Figure 5-16 Adapter, Waveguide Designators K-Band/WR42/WG20, English (Imperial), Keysight Part

Number N9911X-415

User’s Guide N9911-90002 5-17

Page 54

Component Dimensions

Termination Dimensions

Termination Dimensions

NOTE The dimensions shown in the following graphics are in millimeters.

Figure 5-17 Termination, Waveguide Designators C-Band/WR137/WG14, Metric, Keysight Part

Number N9911X-111

5- 18 User’s Guide N9911-90002

Page 55

Component Dimensions

Termination Dimensions

Figure 5-18 Termination, Waveguide Designators C-Band/WR137/WG14, English (Imperial),

Keysight Part Number N9911X-116

User’s Guide N9911-90002 5-19

Page 56

Component Dimensions

Termination Dimensions

Figure 5-19 Termination, Waveguide Designators X-Band/WR90/WG16, Metric, Keysight Part

Number N9911X-211

5- 20 User’s Guide N9911-90002

Page 57

Component Dimensions

Termination Dimensions

Figure 5-20 Termination, Waveguide Designators X-Band/WR90/WG16, English (Imperial), Keysight

Part Number N9911X-216

User’s Guide N9911-90002 5-21

Page 58

Component Dimensions

Termination Dimensions

Figure 5-21 Termination, Waveguide Designators Ku-Band/WR62/WG18, Metric, Keysight Part

Number N9911X-311

5- 22 User’s Guide N9911-90002

Page 59

Component Dimensions

Termination Dimensions

Figure 5-22 Termination, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial),

Keysight Part Number N9911X-316

User’s Guide N9911-90002 5-23

Page 60

Component Dimensions

Termination Dimensions

Figure 5-23 Termination, Waveguide Designators K-Band/WR42/WG20, Metric, Keysight Part

Number N9911X-411

5- 24 User’s Guide N9911-90002

Page 61

Component Dimensions

Termination Dimensions

Figure 5-24 Termination, Waveguide Designators K-Band/WR42/WG20, English (Imperial), Keysight

Part Number N9911X-416

User’s Guide N9911-90002 5-25

Page 62

Component Dimensions

Offset Shim Dimensions

Offset Shim Dimensions

NOTE The dimensions shown in the following graphics are in millimeters.

Figure 5-25 Offset Shim, Waveguide Designators C-Band/WR137/WG14, Metric, Keysight Part

Number N9911X-113

5- 26 User’s Guide N9911-90002

Page 63

Component Dimensions

Offset Shim Dimensions

Figure 5-26 Offset Shim, Waveguide Designators C-Band/WR137/WG14, English (Imperial), Keysight

Part Number N9911X-118

User’s Guide N9911-90002 5-27

Page 64

Component Dimensions

Offset Shim Dimensions

Figure 5-27 Offset Shim, Waveguide Designators X-Band/WR90/WG16, Metric, Keysight Part

Number N9911X-213

5- 28 User’s Guide N9911-90002

Page 65

Component Dimensions

Offset Shim Dimensions

Figure 5-28 Offset Shim, Waveguide Designators X-Band/WR90/WG16, English (Imperial), Keysight

Part Number N9911X-218

User’s Guide N9911-90002 5-29

Page 66

Component Dimensions

Offset Shim Dimensions

Figure 5-29 Offset Shim, Waveguide Designators Ku-Band/WR62/WG18, Metric, Keysight Part

Number N9911X-313

5- 30 User’s Guide N9911-90002

Page 67

Component Dimensions

Offset Shim Dimensions

Figure 5-30 Offset Shim, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial),

Keysight Part Number N9911X-318

User’s Guide N9911-90002 5-31

Page 68

Component Dimensions

Offset Shim Dimensions

Figure 5-31 Offset Shim, Waveguide Designators K-Band/WR42/WG20, Metric, Keysight Part

Number N9911X-413

5- 32 User’s Guide N9911-90002

Page 69

Component Dimensions

Offset Shim Dimensions

Figure 5-32 Offset Shim, Waveguide Designators K-Band/WR42/WG20, English (Imperial), Keysight

Part Number N9911X-418

User’s Guide N9911-90002 5-33

Page 70

Component Dimensions

Flush Short Dimensions

Flush Short Dimensions

NOTE The dimensions shown in the following graphics are in millimeters.

Figure 5-33 Flush Short, Waveguide Designators C-Band/WR137/WG14, Metric, Keysight Part

Number N9911X-112

5- 34 User’s Guide N9911-90002

Page 71

Component Dimensions

Flush Short Dimensions

Figure 5-34 Flush Short, Waveguide Designators C-Band/WR137/WG14, English (Imperial), Keysight

Part Number N9911X-117

User’s Guide N9911-90002 5-35

Page 72

Component Dimensions

Flush Short Dimensions

Figure 5-35 Flush Short, Waveguide Designators X-Band/WR90/WG16, Metric, Keysight Part

Number N9911X-212

5- 36 User’s Guide N9911-90002

Page 73

Component Dimensions

Flush Short Dimensions

Figure 5-36 Flush Short, Waveguide Designators X-Band/WR90/WG16, English (Imperial), Keysight

Part Number N9911X-217

User’s Guide N9911-90002 5-37

Page 74

Component Dimensions

Flush Short Dimensions

Figure 5-37 Flush Short, Waveguide Designators Ku-Band/WR62/WG18, Metric, Keysight Part

Number N9911X-312

5- 38 User’s Guide N9911-90002

Page 75

Component Dimensions

Flush Short Dimensions

Figure 5-38 Flush Short, Waveguide Designators Ku-Band/WR62/WG18, English (Imperial), Keysight

Part Number N9911X-317

User’s Guide N9911-90002 5-39

Page 76

Component Dimensions

Flush Short Dimensions

Figure 5-39 Flush Short, Waveguide Designators K-Band/WR42/WG20, Metric, Keysight Part

Number N9911X-412

5- 40 User’s Guide N9911-90002

Page 77

Component Dimensions

Flush Short Dimensions

Figure 5-40 Flush Short, Waveguide Designators K-Band/WR42/WG20, English (Imperial), Keysight

Part Number N9911X-417

User’s Guide N9911-90002 5-41

Page 78

Component Dimensions

Flush Short Dimensions

5- 42 User’s Guide N9911-90002

Page 79

Index

A

adapter

dimensions

alcohol, isopropyl

precautions for use of

aligning

precision flanges

assistance

contacting keysight

C

calibration

bad

components, overview

frequency

how to perform

when to perform

cleaning

connectors

mating plane surfaces

component

adapter

adapter, waveguide-to-coax

cleaning

connecting

dimensions

flush short

handling

maintenance

offset shim

overview

performance

failure

serial number, record

specifications

electrical

storage

temperature

termination

typical VSWR values

visual inspection

compressed air

for cleaning

connecting

flanges

flush short to adapter

for ESD protection

offset shim between short and

termination to adapter

connector

cleaning

mating plane surfaces

contacting Keysight Technologies

4-4

, 4-2

, 3-8

, 3-10

, 3-5, 3-7

adapter

, 5-10

, 3-4

, 3-5

, 4-4

, 1-2

, 1-7

, 1-7

, 1-7

, 3-4

, 3-4

, 3-8, 3-9

, 3-4

, 3-5

, 5-1

, 3-8, 3-9

, 3-10

, 1-7

, 3-8

, 1-2

, 4-2

, 1-3

, 2-5

, 2-2

, 3-8

, 2-3

, 3-3

, 3-4

, 3-9

, 3-2

, 3-8

, 3-8

, 3-4

, 3-4

, 4-3,

D

damage

caused by electrostatic discharge

deviation from nominal phase

dimensions

E

electrical

electrostatic discharge, See ESD

environmental

ESD

F

flange

flowchart, troubleshooting

flush short

frequency

G

general information

H

handling

how often to calibrate

how to calibrate

I

inspection

instrument interface specifications

isopropyl alcohol

, 5-10

adapter

flange

, 5-5

flush short

offset shim

shim

short

specifications

termination

characteristics, effects of

specifications

typical VSWR values

regulations

requirements

protection

connect

dimensions

dimensions

of calibration

specification

, 5-34

, 5-26

, 5-26

, 5-34

, 2-5

, 5-18

temperature, 2-2

, 2-5

, 3-4

, 2-2

, 3-2

, 3-7

, 5-5

, 5-34

, 1-7

, 2-5

, 1-1

, 3-10

, 1-7

flange connection

, 3-3

visual

precautions for use of

, 3-7

, 2-5

, 2-3

, 4-2

, 1-7

, 3-4

, 3-2

, 2-4

K

Keysight Technologies

contacting

L

load, See termination

M

maintenance, preventive

mat, for ESD protection

mating plane surfaces

cleaning

connector

N

nitrogen, for cleaning

numbers, serial

O

offset shim

dimensions

offset short, creating

oxygen

P

performance, verification

precision flanges

preventive maintenance

procedures

aligning flanges

cleaning

tightening flanges

R

recording component serial numbers

regulations, environmental

requirements

environmental

temperature

return component to Keysight

return loss specification

S

serial numbers

service

shim dimensions

short

dimensions

part numbers

specifications

characteristics

component

deviation from nominal phase

, 4-3, 4-4

, 1-7

, 3-2

, 3-4

, 3-4

, 3-4

, 1-3

, 5-26

, 3-8

, 3-4

, 4-2

, 3-5

, 1-7

, 3-5

, 3-4

, 3-7

1-3

, 3-4

, 2-2

, 2-2

, 4-3

, 2-5

, 1-3

, 4-3

, 5-26

, 5-34

, 1-3, 1-4, 1-5, 1-6

, 2-1

, 2-5

, 2-5

, 2-5

,

User’s Guide N9911-90002 Index-1

Page 80

Index

dimension, 2-5

electrical

frequency

instrument interface

return loss

static electricity

storage

T

table mat, for ESD protection

temperature

cautions about

requirements

termination

dimensions

troubleshooting, flowchart

typical VSWR values

component

, 2-5

, 2-5

, 2-4

, 2-5

, 3-2

, 3-10

, 2-2

, 2-2

, 5-18

, 4-2

, 2-3

, 3-2

V

visual inspection

VSWR typical values

W

when to calibrate the analyzer

wrist strap, for ESD protection

, 3-3

, 2-3

, 1-7

, 3-2

Index-2 User’s Guide N9911-90002A

Loading...

Loading...