Page 1

Keysight Infiniium

MXR/EXR-Series Real-Time

Oscilloscopes

User's Guide

Page 2

Notices

CAUTION

WARNING

© Keysight Technologies, Inc. 2014-2020

No part of this manual may be reproduced in

any form or by any means (including

electronic storage and retrieval or

translation into a foreign language) without

prior agreement and written consent from

Keysight Technologies, Inc. as governed by

United States and international copyright

laws.

Manual Part Number

54925-97013

Edition

Sixth edition, November 2020

Available in electronic format only

Published by:

Keysight Technologies, Inc.

1900 Garden of the Gods Road

Colorado Springs, CO 80907 USA

Print History

54925-97000, May 2020

54925-97005, June 2020

54925-97006, November 2020

54925-97010, September 2020

54925-97011, November 2020

54925-97013, November 2020

Warranty

The material contained in this document is

provided "as is," and is subject to being

changed, without notice, in future editions.

Further, to the maximum extent permitted

by applicable law, Keysight disclaims all

warranties, either express or implied, with

regard to this manual and any information

contained herein, including but not limited

to the implied warranties of

merchantability and fitness for a particular

purpose. Keysight shall not be liable for

errors or for incidental or consequential

damages in connection with the furnishing,

use, or performance of this document or of

any information contained herein. Should

Keysight and the user have a separate

written agreement with warranty terms

covering the material in this document that

conflict with these terms, the warranty

terms in the separate agreement shall

control.

Technology License

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in

accordance with the terms of such license.

U.S. Government Rights

The Software is "commercial computer

software," as defined by Federal Acquisition

Regulation ("FAR") 2.101. Pursuant to FAR

12.212 and 27.405-3 and Department of

Defense FAR Supplement ("DFARS")

227.7202, the U.S. government acquires

commercial computer software under the

same terms by which the software is

customarily provided to the public.

Accordingly, Keysight provides the Software

to U.S. government customers under its

standard commercial license, which is

embodied in its End User License Agreement

(EULA), a copy of which can be found at

www.keysight.com/find/sweula. The

license set forth in the EULA represents the

exclusive authority by which the U.S.

government may use, modify, distribute, or

disclose the Software. The EULA and the

license set forth therein, does not require or

permit, among other things, that Keysight:

(1) Furnish technical information related to

commercial computer software or

commercial computer software

documentation that is not customarily

provided to the public; or (2) Relinquish to,

or otherwise provide, the government rights

in excess of these rights customarily

provided to the public to use, modify,

reproduce, release, perform, display, or

disclose commercial computer software or

commercial computer software

documentation. No additional government

requirements beyond those set forth in the

EULA shall apply, except to the extent that

those terms, rights, or licenses are explicitly

required from all providers of commercial

computer software pursuant to the FAR and

the DFARS and are set forth specifically in

writing elsewhere in the EULA. Keysight

shall be under no obligation to update,

revise or otherwise modify the Software.

With respect to any technical data as

defined by FAR 2.101, pursuant to FAR

12.211 and 27.404.2 and DFARS 227.7102,

the U.S. government acquires no greater

than Limited Rights as defined in FAR 27.401

or DFAR 227.7103-5 (c), as applicable in any

technical data.

Safety Notices

This product has been designed and tested

in accordance with accepted industry

standards, and has been supplied in a safe

condition. The documentation contains

information and warnings that must be

followed by the user to ensure safe

operation and to maintain the product in a

safe condition.

A CAUTION notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly

performed or adhered to, could

result in personal injury or death.

Do not proceed beyond a WARNING

notice until the indicated

conditions are fully understood and

met.

2 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 3

Infiniium MXR/EXR-Series Real-Time Oscilloscopes—At a Glance

~

~

+ +

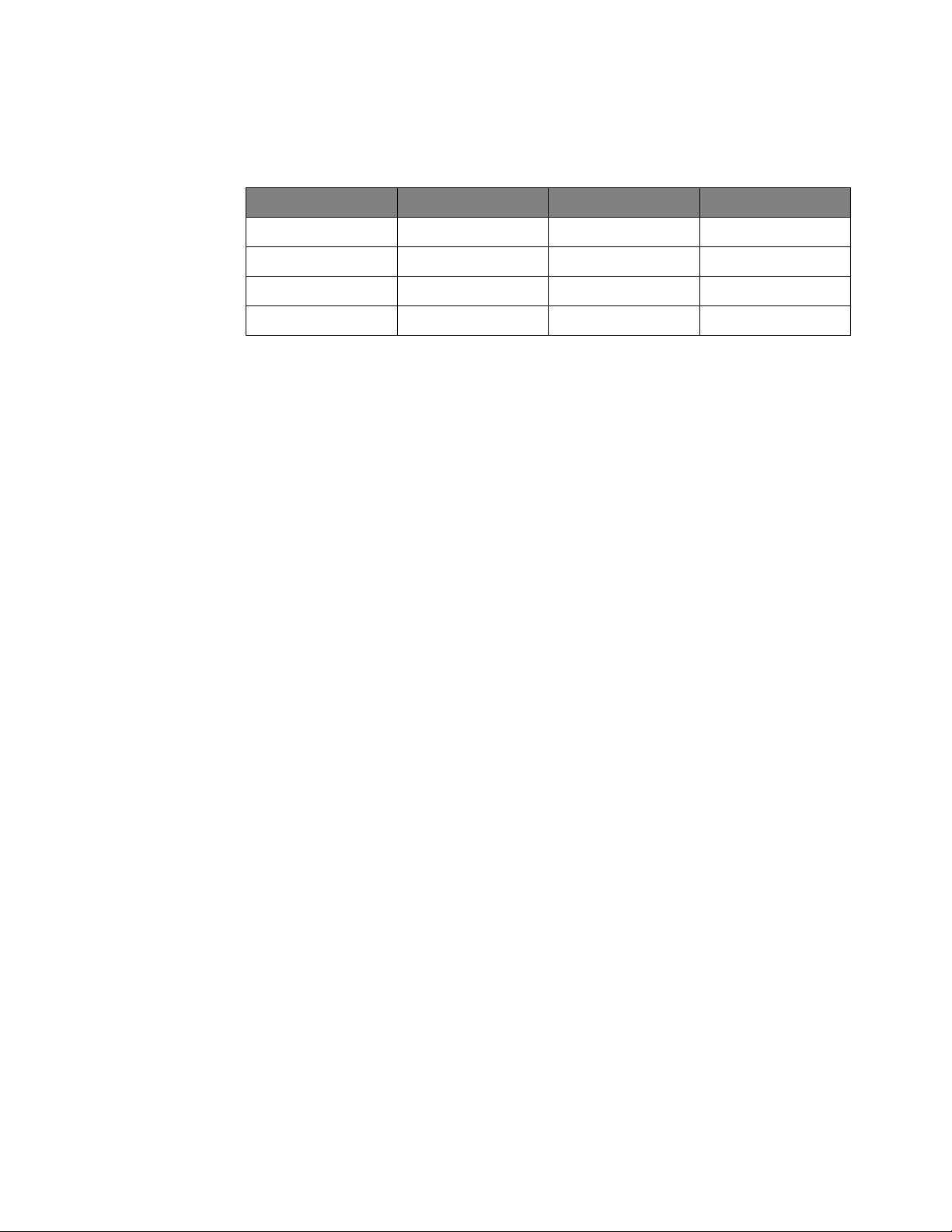

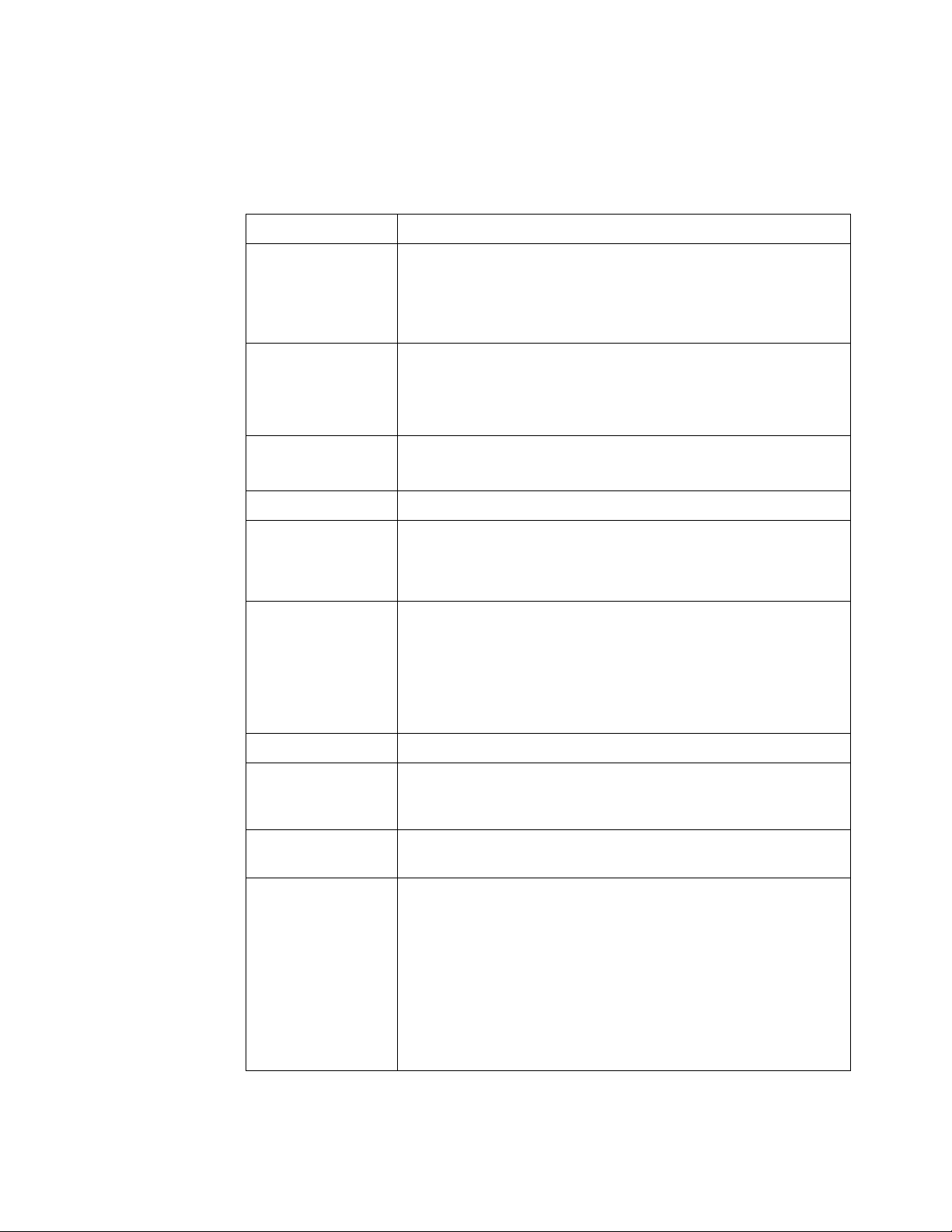

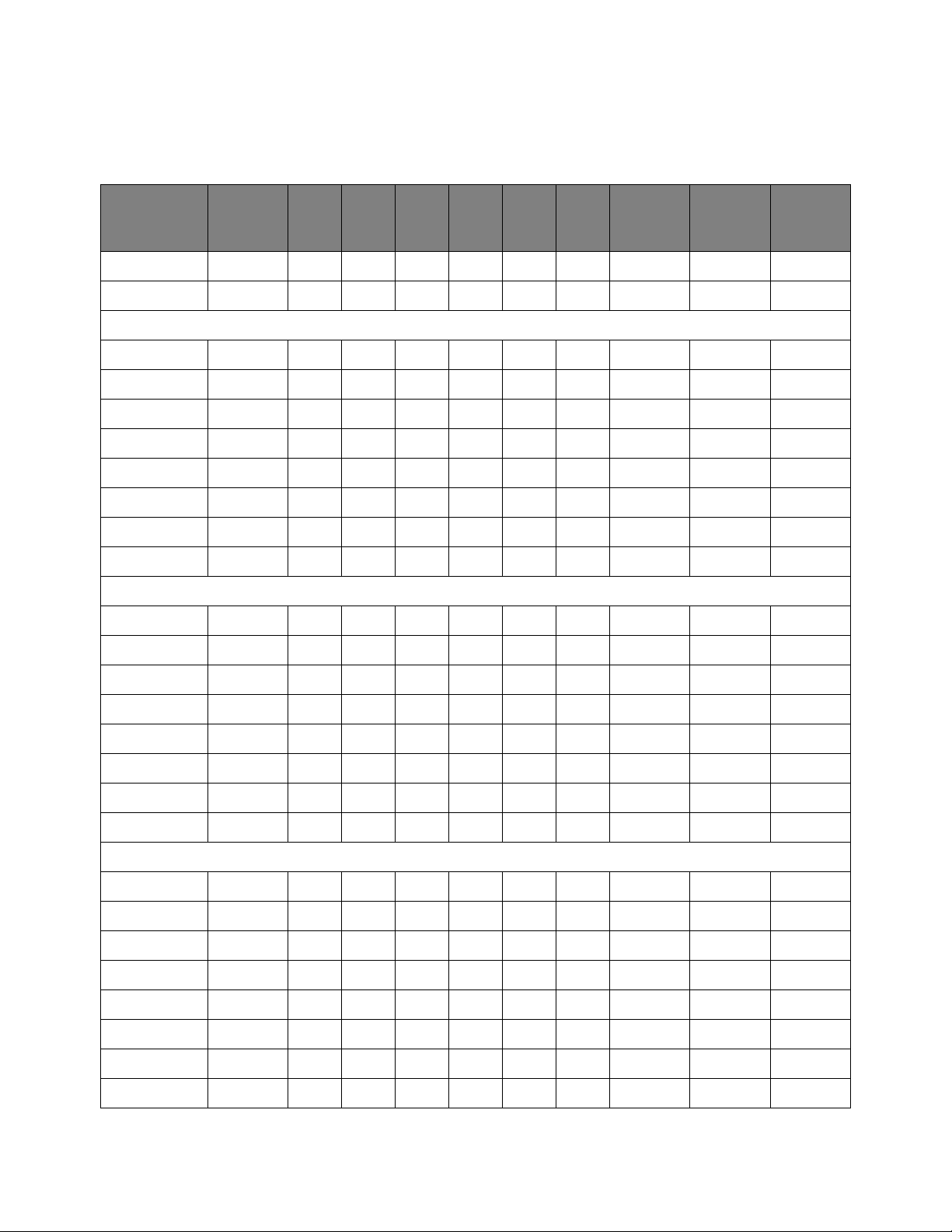

Table 1 Infiniium MXR-Series real-time oscilloscopes

8-Channel Model 4-Channel Model Bandwidth Sampling rate

MXR608A MXR604A 6 GHz 16 GSa/s

MXR408A MXR404A 4 GHz 16 GSa/s

MXR258A MXR254A 2.5 GHz 16 GSa/s

MXR208A MXR204A 2 GHz 16 GSa/s

MXR108A MXR104A 1 GHz 16 GSa/s

MXR058A MXR054A 500 MHz 16 GSa/s

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 3

Page 4

Table 2 Infiniium EXR-Series real-time oscilloscopes

8-Channel Model 4-Channel Model Bandwidth Sampling rate

EXR258A EXR254A 2.5 GHz 16 GSa/s

EXR208A EXR204A 2 GHz 16 GSa/s

EXR108A EXR104A 1 GHz 16 GSa/s

EXR058A EXR054A 500 MHz 16 GSa/s

In addition to the number of input channels, bandwidths, and sampling rates

described in the previous table, the Keysight Infiniium MXR/EXR-Series real-time

oscilloscopes deliver these features:

• 10-bit analog-to-digital converter (ADC) with low noise and high effective

number of bits (ENOB), with additional high-resolution settings that increase

the effective number of bits at lower bandwidths.

• Hardware acceleration and high waveform update rates that make it more likely

to capture waveform anomalies.

• 16 digital input channels (1-bit vertical resolution) enabled with the MSO

license.

A mixed-signal oscilloscope (MSO) lets you debug your mixed-signal designs

using analog signals and tightly correlated digital signals simultaneously. The

16 digital channels have a 8 GSa/s sample rate, with a 400 MHz toggle rate.

Thresholds levels can be set per nibble.

• Many trigger modes including: edge, glitch, pulse width, pattern/state, runt,

setup and hold, edge transition, edge then edge, timeout, window, OR'd edges,

Nth edge, and burst. Also available are sequential triggering and InfiniiScan

(Zone triggering and finders for measurements, serial bit streams, runts, and

non-monotonic edges).

• Protocol triggering and decode options for many types of protocols including:

ARINC-429, BroadR-Reach/100BaseT1, CAN, CAN-FD, eSPI, eUSB2, Ethernet

10BT, Ethernet 100BT, I2C, I2S (LJ, RJ, TDM), LIN, Manchester, MIL-STD 1553,

MIPI-I3C, Quad-SPI, RS-232/UART, SENT, Spacewire, SPI, SPMI, SVID, USB

2.0, USB-PD, and more.

• Protocol decode and search options for even more protocols.

• Built-in counter and digital voltmeter (DVM) hardware for the analog input

channels.

• Built-in, license-enabled waveform generator with: sine, square, ramp, pulse,

DC, noise, sine cardinal, exponential rise, exponential fall, cardiac, Gaussian

pulse, PRBS, and demo waveforms output to the GEN OUT side-panel BNC

connector. Generated signals can be used to provide stimulus to a device under

test (DUT) or for demos.

• Front-panel knobs and keys for: default and autoscale setups, acquisition run

control (run, stop, and single), horizontal settings (time/division, trigger

4 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 5

position, zoom window, and time navigation), vertical settings (scaling down to

1 mV/div in hardware and offset), multiple markers (to check voltage or

at any point on a waveform), trigger level, digital channels, protocol decode,

clearing acquisitions from the display, and more.

Knobs are pushable for making quick selections.

• 15.6 inch color 1920x1080 (FHD) capacitive touch screen display with

multi-touch (gestures), handles, and resizing allows oscilloscope operation

without an external pointing device.

• High-capacity removable solid state hard drive for fast boot-up, storing setups,

and saving measurement results.

• USB 3.0 and LAN ports make printing, saving, and sharing data easy.

• VGA and DisplayPort ports on the motherboard I/O panel for displaying the

screen on a different monitor.

• 64-bit Windows operating system and graphical user interface with familiar

menus, toolbars, etc. Ability to install other Windows applications like vector

signal analysis (VSA) software.

• Eight analog channel waveform memories and one digital channels waveform

memory for comparing with other channels or math waveforms.

• More than 50 automated measurements and measurement statistics.

• Up to 16 math function waveforms selectable from these operations: add,

subtract, multiply, divide, d/dt, integrate, invert, FFT magnitude, FFT phase,

magnify/duplicate, square, square root, absolute value, low pass filter, high

pass filter, averaged value, smoothing, envelope, magnify, maximum,

minimum, peak-peak, measurement trend, bus chart, and user-defined

functions with MATLAB analysis.

Δ-time

• New analysis tools including: Fault Hunter and Power Analysis.

• Legacy Infiniium analysis tools including: histograms, mask testing (now with

multiple masks for separate waveforms), jitter, real-time eye, equalization,

crosstalk, and phase noise.

• Supports many compliance testing applications for technologies like:

100BASE-T1, 1000BASE-T1, 10/100/1G Ethernet, 10GBASE-T, 10GBASE-CX4,

Broad-R Reach, CPRI, DDR2/LPDDR2, DDR3/LPDDR3, Energy Efficient

Ethernet, HDMI, MGBASE-T (2.5G/5G), MIPI C-PHY, MIPI D-PHY, MIPI M-PHY,

MOST, NBASE-T (2.5G/5G), OBSAI, ONFI, PCI Express Gen 1-4, Serial RapidIO,

TC8 (OPEN), USB 2.0, and XAUI.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 5

Page 6

In This Guide

This guide provides the information you need to begin using the Infiniium

MXR/EXR-Series real-time oscilloscopes.

Chapter 1, “Setting Up,” starting on page 11, includes unpacking steps, power

and air flow requirements, and other setup information.

Chapter 2, “Getting Started,” starting on page 21, familiarizes you with the inputs

and outputs, front-panel knobs and keys, the graphical user interface, and

describes how to perform basic operations with the oscilloscope.

Chapter 3, “Demos and Online Help,” starting on page 49, describes the Infiniium

oscilloscope application's online demos and online help contents. The online help

describes in detail how to use the Infiniium oscilloscope.

Chapter 4, “Other Oscilloscope Tasks,” starting on page 53, describes the Infiniium

oscilloscope application's online help contents and online demos. The online help

describes how to use the Infiniium oscilloscope application in detail.

Chapter 5, “Calibrating the Oscilloscope,” starting on page 59, describes how to

perform a user calibration.

Chapter 6, “Testing Performance,” starting on page 65, describes the procedures

used to verify that the oscilloscope is operating within specification.

Chapter 7, “Troubleshooting,” starting on page 107, describes what to do if you

encounter any problems with your MXR/EXR-Series oscilloscope.

For More Information

• For detailed information on how to use the oscilloscope, see the Infiniium

oscilloscope application's online help. See "Accessing the Online Help" on

page 51.

• For information on controlling the oscilloscope from a remote computer, see

the Oscilloscopes Programmer's Guide found in the Infiniium oscilloscope

application's online help.

For technical assistance, contact your local Keysight Technologies representative

at http://www.keysight.com/find/contactus.

6 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 7

Contents

1 Setting Up

Infiniium MXR/EXR-Series Real-Time Oscilloscopes—At a Glance / 3

In This Guide / 6

Inspecting Package Contents / 12

Environmental Characteristics / 13

Positioning for Proper Airflow / 14

Tilting the Oscilloscope for Easier Viewing / 15

Connecting Accessories and a LAN Cable to the Oscilloscope / 16

Connecting Power to the Oscilloscope / 17

Turning On the Oscilloscope / 18

Changing the Administrator Password / 19

2 Getting Started

Front Panel Connectors / 22

Side Panel Connectors / 23

Knobs and Keys on the Front Panel / 26

Channel inputs / 22

Probe compensation terminal / 22

Motherboard I/O / 23

Digital channels connector / 24

GEN OUT / 24

AUX OUT / 24

10 MHz REF IN (50Ω)/24

Maximum input voltage at 10 MHz REF IN input / 24

10 MHz REF OUT (50Ω)/24

AUX TRIG IN (50Ω)/25

Maximum voltage at AUX TRIG IN input / 25

TRIG OUT / 25

Graphical User Interface (GUI) / 28

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 7

Page 8

Connecting Oscilloscope Probes / 30

Maximum input voltage at analog inputs / 30

Verifying Basic Oscilloscope Operation / 31

Default Setup and Autoscale / 32

Using Default Setup / 32

Using Autoscale / 32

Starting and Stopping Waveform Acquisitions / 33

Clearing the Waveform Display / 33

Adjusting the Horizontal Settings / 35

Adjusting the Horizontal Scale / 35

Adjusting the horizontal trigger position (delay) / 36

Magnifying a part of the waveform using Zoom / 36

Using the Navigate Controls / 37

Setting the scale, position, and timebase reference point / 37

Adjusting the Vertical Settings / 39

Turning an analog channel on or off / 40

Adjusting an analog channel's vertical scale and offset / 40

Trigger Level and Other Controls / 41

Entry Knob / 41

[Multi Purpose] Key / 41

Setting Up Triggers / 42

Waveform Generator / 43

Saving and Printing / 44

Using the Touch Screen / 44

Using Markers / 45

Making Measurements / 46

Using Quick Measurements / 47

Using Digital Channels and Protocol Decode / 48

Controlling Digital Channels / 48

Decoding Serial Protocol Data / 48

3 Demos and Online Help

Using the Demo Wizard / 50

Accessing the Online Help / 51

8 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 9

4 Other Oscilloscope Tasks

Changing Windows Operating System Settings / 54

Installing Application Programs on Infiniium / 55

Forcing a Default Setup / 56

Hard Drive Recovery / 57

Cleaning the Oscilloscope / 58

5 Calibrating the Oscilloscope

When to Perform a User Calibration / 60

Equipment Required / 61

Calibration Time / 62

Calibration Procedure / 63

6 Testing Performance

Performance Verification General Information / 66

Performance Test Interval / 66

Performance Test Record / 66

Test Order / 66

Test Equipment / 66

Input Impedance Test / 67

Offset Accuracy Test / 69

DC Gain Accuracy Test / 76

Analog Bandwidth—Maximum Frequency Test / 79

Time Scale Accuracy (TSA) Test / 86

Performance Test Record / 89

7 Troubleshooting

Verifying Basic Operation / 108

Before You Contact Keysight / 113

Returning the Oscilloscope to Keysight for Service / 114

Power Up the oscilloscope / 108

Run the oscilloscope self tests / 109

Run the keyboard, LED, and touch screen self tests / 109

Run a user calibration / 112

Verify system performance / 112

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 9

Page 10

Index

10 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 11

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes

User's Guide

1 Setting Up

Inspecting Package Contents / 12

Environmental Characteristics / 13

Positioning for Proper Airflow / 14

Tilting the Oscilloscope for Easier Viewing / 15

Connecting Accessories and a LAN Cable to the Oscilloscope / 16

Connecting Power to the Oscilloscope / 17

Turning On the Oscilloscope / 18

Changing the Administrator Password / 19

This chapter shows how to set up and prepare your Infiniium oscilloscope for

first-time use.

11

Page 12

1 Setting Up

Inspecting Package Contents

✔ Inspect the shipping container for damage.

• Keep the shipping container or cushioning material until you have inspected

the contents of the shipment for completeness and have checked the

oscilloscope mechanically and electrically.

• If the shipping container is damaged, or the cushioning materials show signs

of stress, notify the carrier and your Keysight Technologies Sales Office.

Keep the shipping materials for the carrier's inspection. The Keysight

Technologies Sales Office will arrange for repair or replacement at

Keysight's option without waiting for claim settlement.

✔ Inspect the oscilloscope.

If there is mechanical damage or a defect, or if the oscilloscope does not

operate properly or does not pass performance tests, notify your Keysight

Technologies Sales Office.

✔ Verify that you received the following items in the Infiniium oscilloscope

packaging.

• Infiniium oscilloscope

• Power cord

• Keyboard

• Mouse (USB optical)

• Accessory pouch (mounts on rear of oscilloscope)

• Front panel cover

• Calibration cable

• Quick Start poster

• 500 MHz passive probes (one for each of the analog channel inputs)

• Digital channels cable, BNC probe tip adapter, and 17-channel flying lead

kit (with the MSO option)

If anything is missing, contact your nearest Keysight Technologies Sales Office.

✔ Verify that you received the options and accessories you ordered and that none

were damaged.

For a complete list of options and accessories available for the

MXR/EXR-Series real-time oscilloscopes, see:

• Infiniium MXR-Series Real-Time Oscilloscopes Data Sheet

• Infiniium EXR-Series Real-Time Oscilloscopes Data Sheet

12 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 13

Environmental Characteristics

Environment Indoor use only

Ambient Temperature Operating: +5 °C to +40 °C

Non-operating: –40 °C to +70 °C

CAUTION: If storing the oscilloscope above +40 °C, make sure the flip-out

front feet are retracted.

Humidity Operating: maximum relative humidity 80 percent for temperatures up to

31 °C, decreasing linearly to 50 percent relative humidity at 40 °C

Non-operating: up to 95 percent relative humidity, non-condensing, at

40 °C; decreasing linearly to 50 percent relative humidity at 70 °C

Altitude Operating: up to 3,000 meters (9,842 feet)

Non-operating: up to 15,300 meters (50,000 feet)

Weight 32 lbs (14.5 kg)

Setting Up 1

Dimensions Height = 328 mm (12.91 in, with flip-out front feet and handle retracted)

Width = 445 mm (17.52 in)

Depth = 224 mm (8.82 in, including knobs and rear feet)

Safety UL 61010-1:2010/CAN/CSA C22.2 No. 61010-1-12

IEC 61010-1:2017

IEC 61010-2-030:2017

UL 61010-2-030:2018

CAN/CSA-22.2 No. 61010-2-030-17

Installation Category II

Voltage Fluctuations Note that the mains supply voltage fluctuations are not to exceed ±10% of

the nominal supply voltage. Temporary overvoltages may not exceed the

allowed voltage fluctuations of +10% nominal.

Pollution Degree The Infiniium MXR/EXR-Series real-time oscilloscopes may be operated in

environments of Pollution Degree 2.

Pollution Degree

Definitions

Pollution Degree 1: No pollution or only dry, non-conductive pollution

occurs. The pollution has no influence. Example: A clean room or

climate-controlled office environment.

Pollution Degree 2. Normally only dry non-conductive pollution occurs.

Occasionally a temporary conductivity caused by condensation may occur.

Example: General indoor environment.

Pollution Degree 3: Conductive pollution occurs, or dry, non-conductive

pollution occurs which becomes conductive due to condensation which is

expected. Example: Sheltered outdoor environment.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 13

Page 14

1 Setting Up

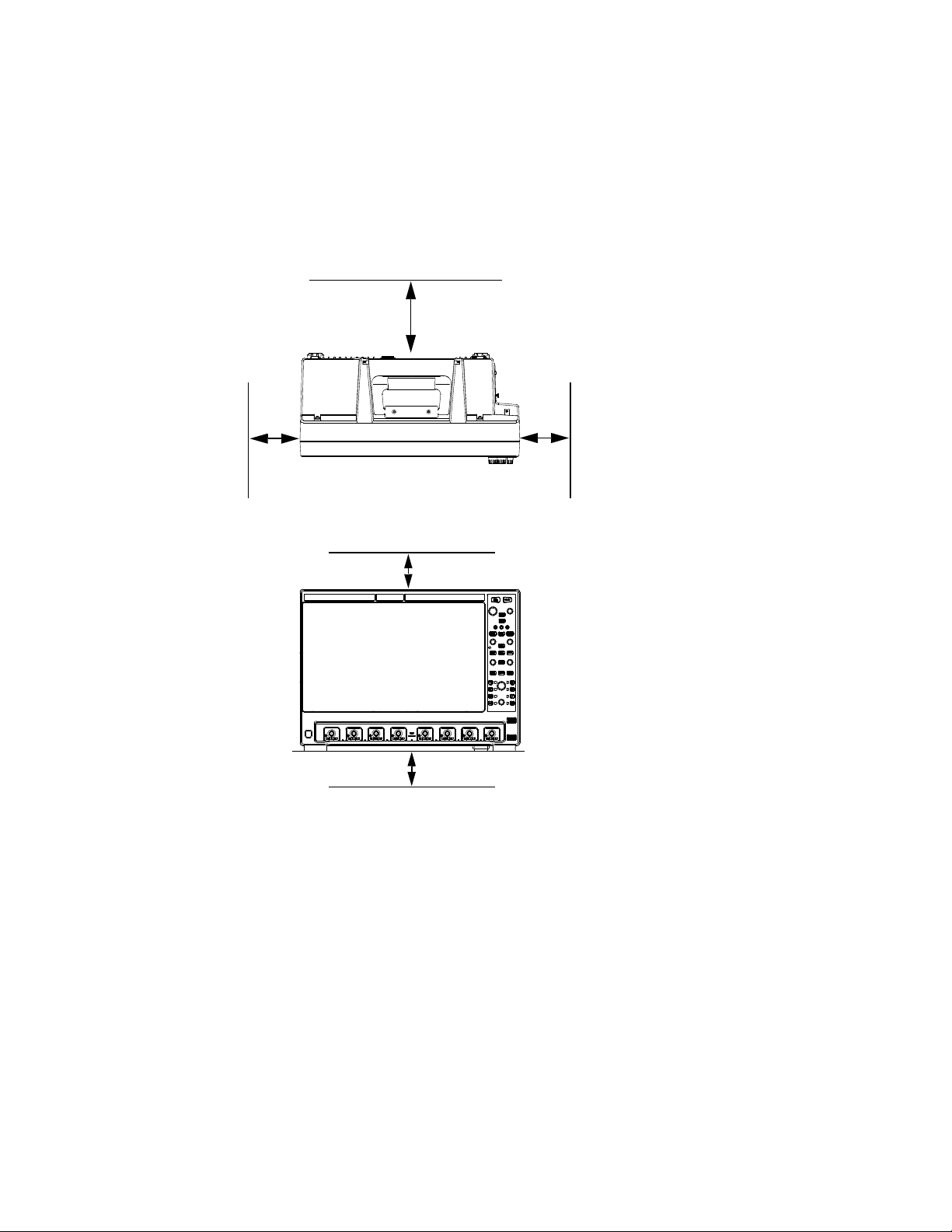

Front view

Minimum 0 mm

Minimum 25.4 mm

Minimum bottom clearance:

No intrusion into the space

under the oscilloscope as

defined by the feet. Feet must

rest on hard surface.

Top view

Minimum 0 mm

Minimum 25.4 mm

Rear panel

Minimum 75 mm

Positioning for Proper Airflow

Position the oscilloscope where it will have sufficient clearance for airflow around

the back and sides.

Figure 1 Positioning the MXR/EXR-Series oscilloscope with sufficient clearance

14 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 15

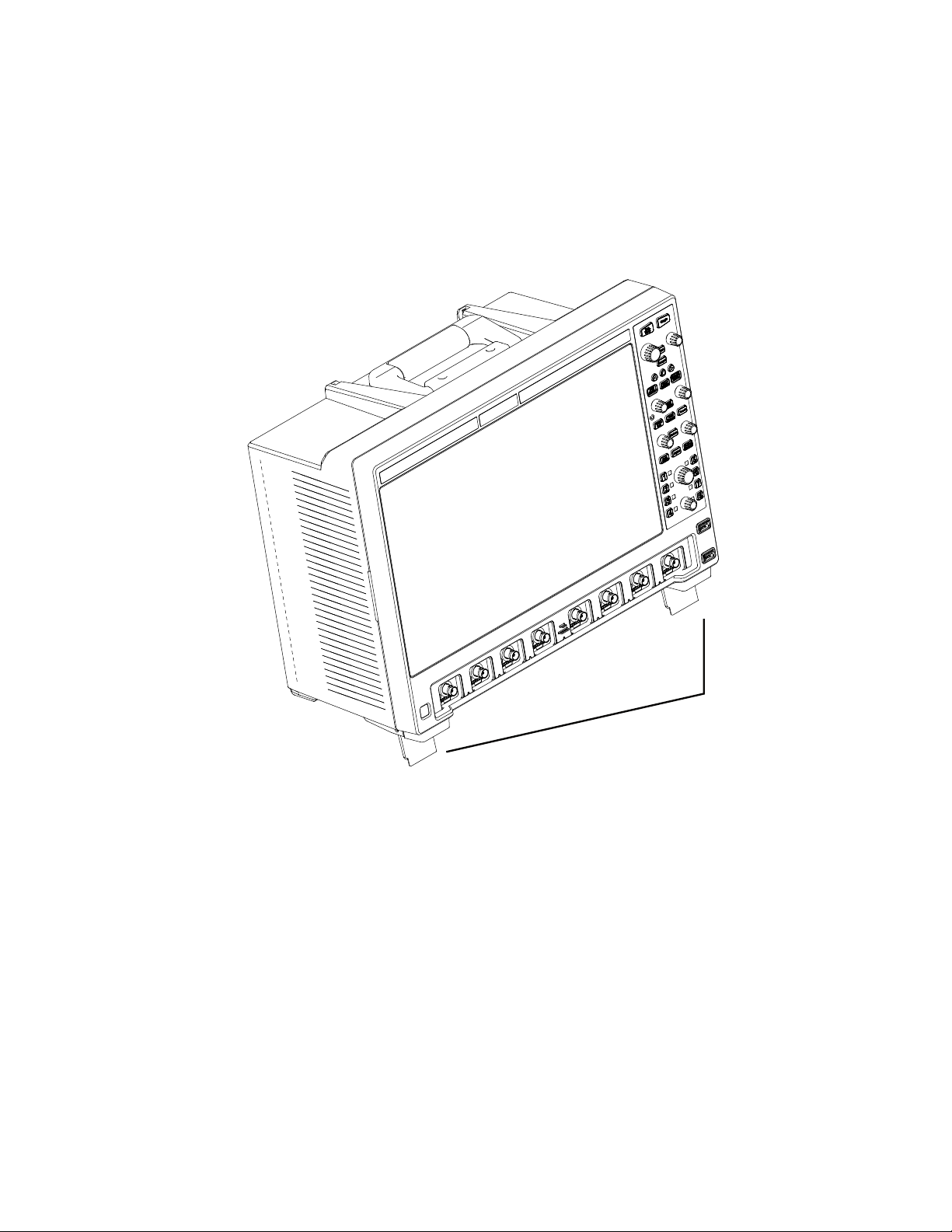

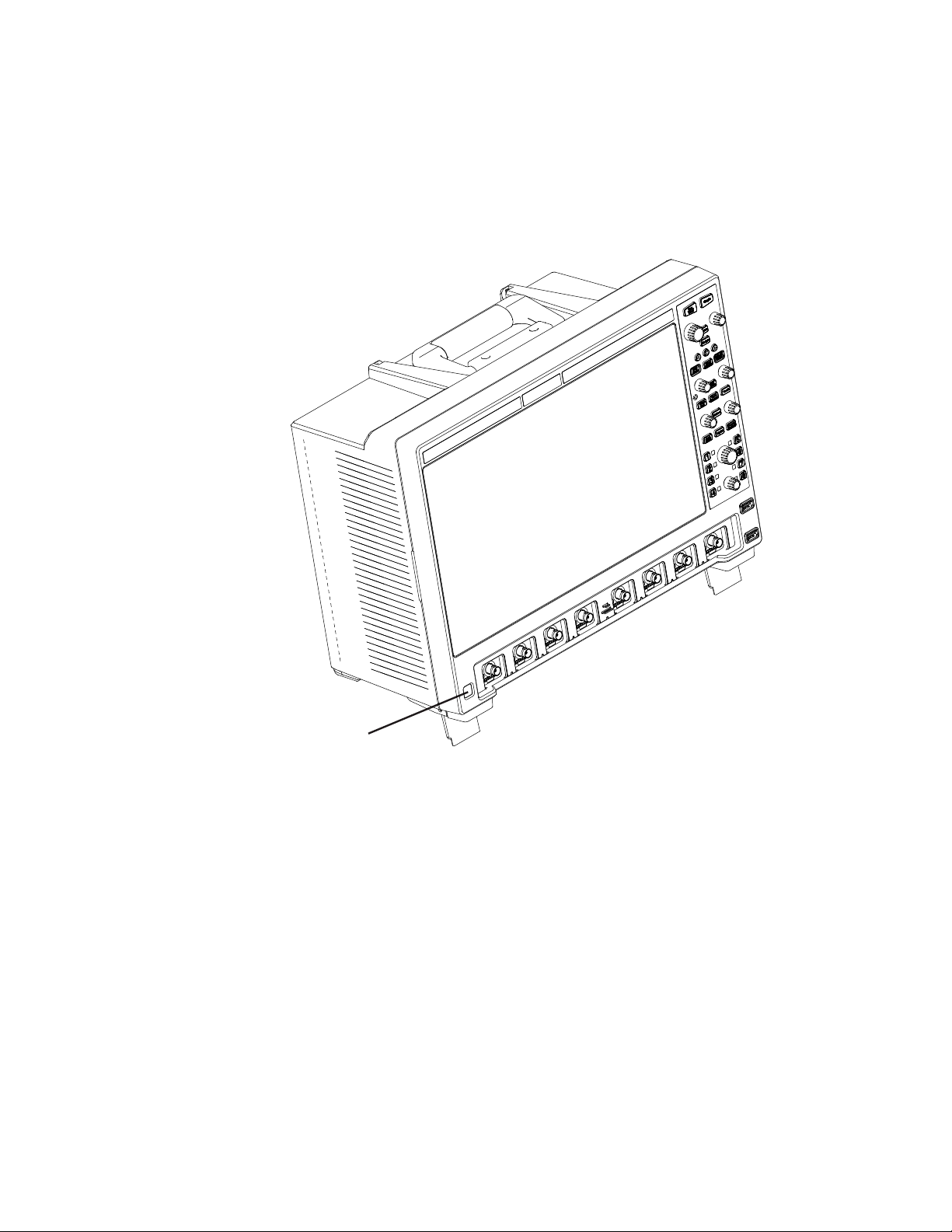

Tilting the Oscilloscope for Easier Viewing

Flip-out tabs

Tabs under the front feet of the oscilloscope can be flipped out to tilt the

oscilloscope for easier viewing.

Setting Up 1

Figure 2 Latching the front feet

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 15

Page 16

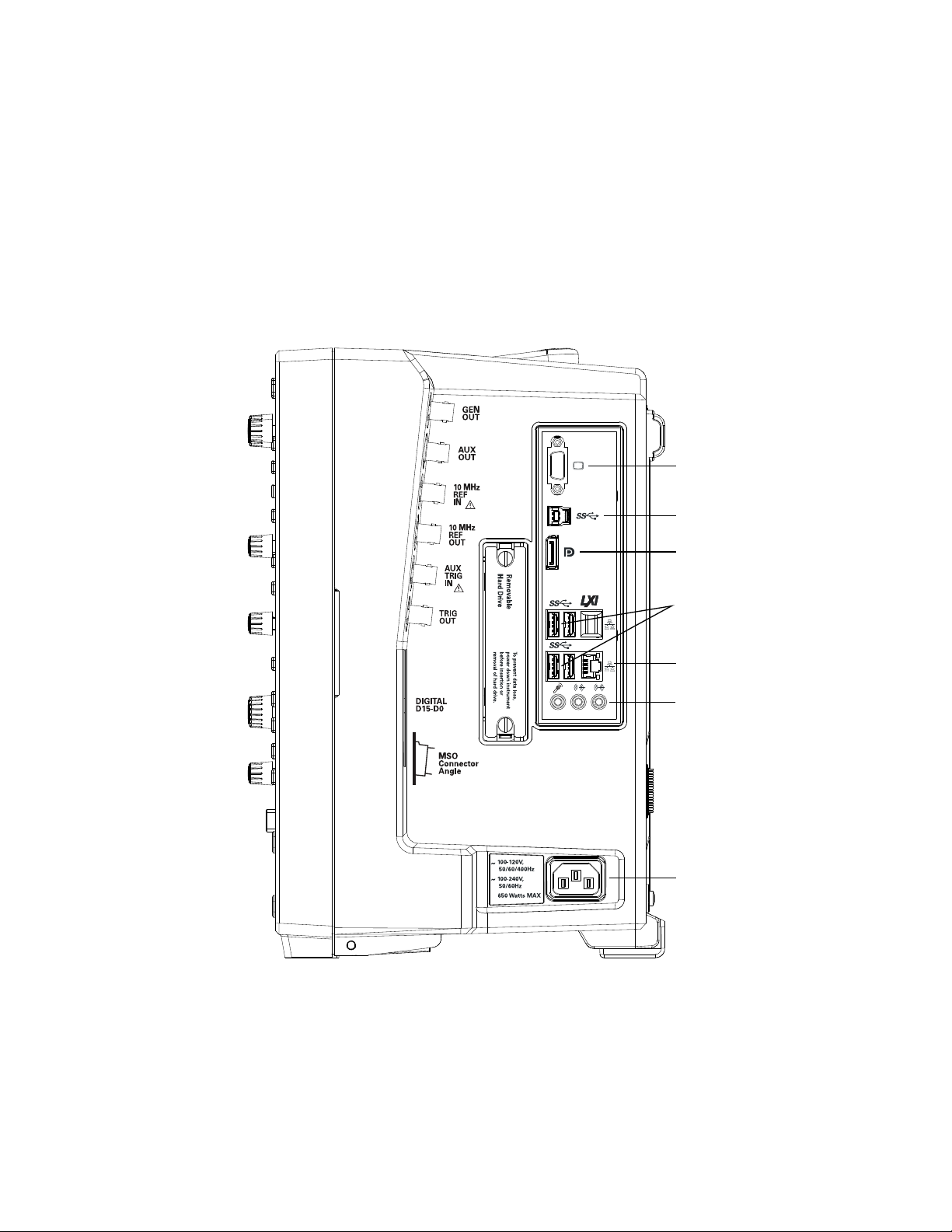

1 Setting Up

Removable

Hard Drive

To prevent data loss,

power down instrument

before insertion or

removal of hard drive.

~

~

650 Watts MAX

100-240V,

50/60Hz

100-120V,

50/60/400Hz

10 MH z

REF

OUT

AUX

OUT

IG><

DJI

AUX

TRIG

IN

GEN

OUT

10 MH z

REF

IN

DIGITAL

D15-D0

MSO

Connector

Angle

External monitor

connector

Audio connectors

AC power input

Mouse and keyboard

connectors (USB 3

host ports)

LAN connector

DisplayPort

USB 3 Device port

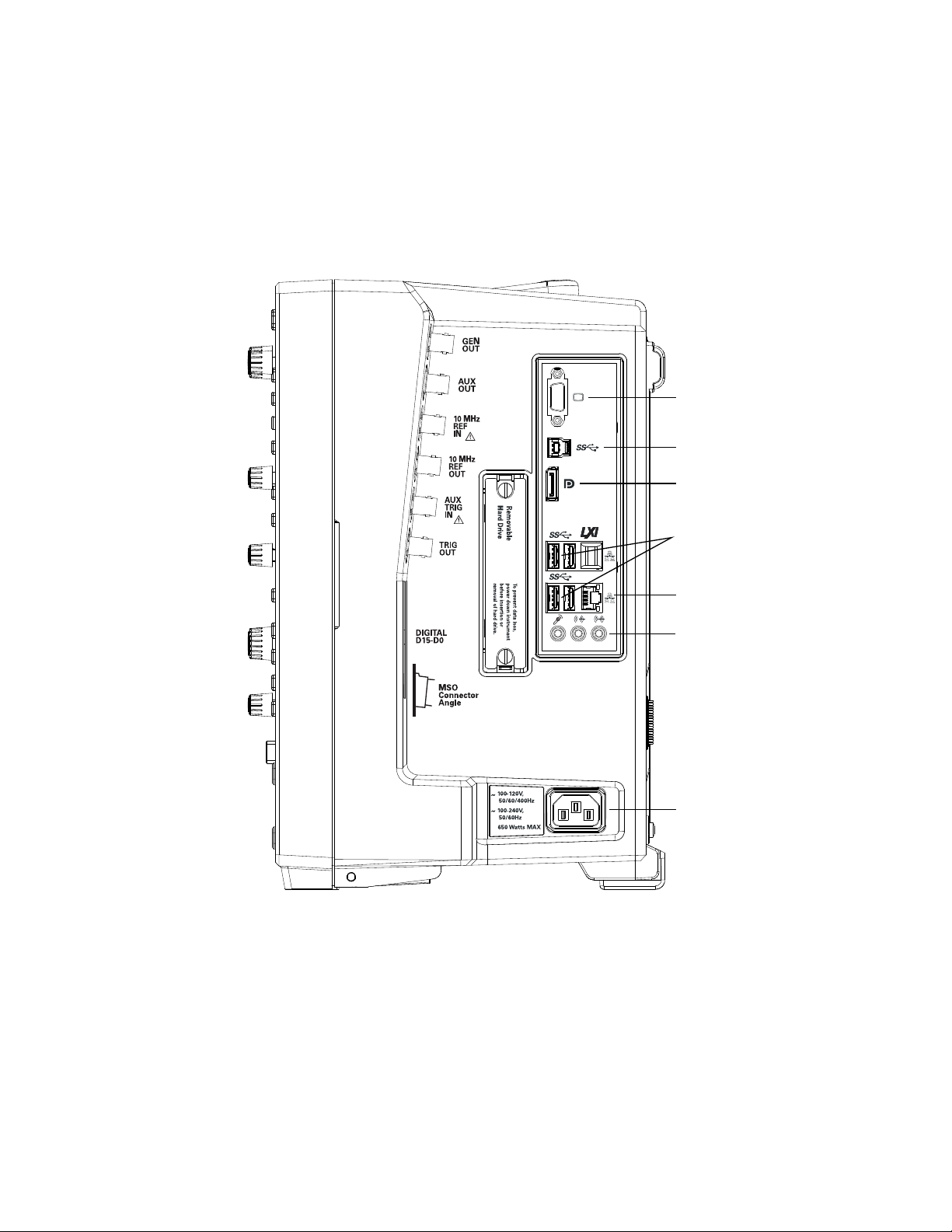

Connecting Accessories and a LAN Cable to the Oscilloscope

1 Plug the mouse and keyboard into the USB host ports. Four host ports are on

the side panel, with two more on the front panel.

2 If you want to connect to a Local Area Network, connect your LAN cable to the

RJ-45 connector on the side panel. Connect the other end to an open LAN

port.

Figure 3 Side panel

16 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 17

Connecting Power to the Oscilloscope

CAUTION

WARNING

Table 3 Power requirements

Power 100-120 V, 50/60/400 Hz

100-240 V, 50/60 Hz

650 W MAX on 8-channel models

450 W MAX on 4-channel models

Connect the power cord to the side of the oscilloscope, then to a suitable AC

voltage source. Route the power cord so the oscilloscope's feet do not pinch the

cord.

The power cord is the disconnecting device for Mains. Position the equipment so

the power cord is easily reached by the operator.

Use only the power cord that came with the oscilloscope

Setting Up 1

The power cord provided is matched to the country of origin of the order.

To avoid electric shock, be sure the oscilloscope is properly grounded.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 17

Page 18

1 Setting Up

Turning On the Oscilloscope

Press the power switch in the lower left corner of the oscilloscope front panel.

Figure 4 Turning On the oscilloscope

After a short initialization period, the oscilloscope display appears. The

oscilloscope is ready to use.

You can connect and disconnect probes and cables while the oscilloscope is

turned on.

Turning Off the

Oscilloscope

To turn the oscilloscope off, press the power switch at the lower left corner of the

oscilloscope front panel. The oscilloscope will go through a normal Windows

operating system shutdown process.

18 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 19

Changing the Administrator Password

On Keysight Infiniium MXR/EXR-Series real-time oscilloscopes with the

Windows 10 operating system, depending on when the oscilloscope was

manufactured, the default Administator user account password is either

"keysight4u" or "Keysight4u!". Change the Administrator password to something

more secure (and less well-known).

See Also • "Changing Windows Operating System Settings" on page 54

• "Installing Application Programs on Infiniium" on page 55

Setting Up 1

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 19

Page 20

1 Setting Up

20 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 21

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes

User's Guide

2 Getting Started

Front Panel Connectors / 22

Side Panel Connectors / 23

Knobs and Keys on the Front Panel / 26

Graphical User Interface (GUI) / 28

Connecting Oscilloscope Probes / 30

Verifying Basic Oscilloscope Operation / 31

Default Setup and Autoscale / 32

Starting and Stopping Waveform Acquisitions / 33

Adjusting the Horizontal Settings / 35

Adjusting the Vertical Settings / 39

Trigger Level and Other Controls / 41

Using Markers / 45

Making Measurements / 46

Using Digital Channels and Protocol Decode / 48

This chapter describes how to use the Infiniium MXR/EXR-Series oscilloscope's

inputs and outputs, front panel controls, and user interface.

• The familiar front-panel oscilloscope interface with knobs and keys is optimized

for common tasks and basic measurements.

• With the graphical user interface for the Infiniium MXR/EXR-Series

oscilloscope you can access all of the oscilloscope's configuration and

measurement features through an easy-to-use system of windows, menus,

toolbars, dialog boxes, and buttons.

• You have the option of using either the front panel controls or the user interface

for many common tasks.

21

Page 22

2 Getting Started

~

~

+ +

Front Panel Connectors

On the Infiniium MXR/EXR-Series oscilloscopes, the channel inputs, probe

compensation terminal, and ground lug appear on the lower part of the front

panel. Two USB 3.0 host ports are also located here.

Figure 5 Front panel connectors

Channel inputs

Your Infiniium oscilloscope comes with 10:1 500 MHz passive probes for each

analog input channel.

The AutoProbe interface also works with the InfiniiMax probing system.

See "Connecting Oscilloscope Probes" on page 30.

Probe compensation terminal

This terminal has a square wave signal that is used to adjust compensated passive

probes.

You can also output a DC level on this terminal using the Infiniium oscilloscope

application's Calibration Output dialog box (Utilities > Calibration Output...).

22 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 23

Side Panel Connectors

Removable

Hard Drive

To prevent data loss,

power down instrument

before insertion or

removal of hard drive.

~

~

650 Watts MAX

100-240V,

50/60Hz

100-120V,

50/60/400Hz

10 MH z

REF

OUT

AUX

OUT

IG><

DJI

AUX

TRIG

IN

GEN

OUT

10 MH z

REF

IN

DIGITAL

D15-D0

MSO

Connector

Angle

External monitor

connector

Audio connectors

AC power input

Mouse and keyboard

connectors (USB 3

host ports)

LAN connector

DisplayPort

USB 3 Device port

The Infiniium MXR/EXR-Series oscilloscope's right side panel has the motherboard

I/O connectors, reference clock synchronization connectors, and BNC connectors.

Getting Started 2

Motherboard I/O

Figure 6 Infiniium MXR/EXR-Series oscilloscope side panel I/O

The motherboard provides these inputs/outputs/ports in the oscilloscope: four

USB ports for peripherals, an external monitor connector, a USB III device port (for

remote control of the oscilloscope from a PC), a LAN port, and speaker and

microphone connectors.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 23

Page 24

2 Getting Started

CAUTION

Digital channels connector

GEN OUT

AUX OUT

10 MHz REF IN (50Ω)

The MSO option includes a 17-channel flying lead set logic probe, an MSO cable,

and a calibration fixture.

Waveform generator signals are output to this BNC connnector. See "Waveform

Generator" on page 43.

This output signal is selected by the Infiniium oscilloscope application's

Calibration Output dialog box. It can be a DC level, the probe compensation signal

(a square wave used to adjust compensated passive probes), the trigger out

signal, or a demo signal.

The 10 MHz REF IN (50Ω) BNC connector is used to synchronize the oscilloscope's

horizontal timebase system to a reference clock that you provide.

Maximum input voltage at 10 MHz REF IN input

The clock you provide must meet the following specifications:

• Input frequency lock range: 10 MHz ±20 ppm

• Amplitude, sine wave input: 356 mVpp (-5 dBm) min to 5 Vpp (+18 dBm) max

• Amplitude, square wave input: 285mVpp min to 4Vpp max

• Input impedance: 50Ω (typical)

To use an external reference clock, connect the external clock to the 10 MHz REF

IN (50Ω) BNC connector; then, in the Infiniium oscilloscope application's

Horizontal dialog box (Setup > Horizontal...), enable the External 10 MHz Reference

Clock.

10 MHz REF OUT (50Ω)

You can use the 10 MHz REF OUT (50Ω) BNC connector to send the oscilloscope's

10 MHz reference clock output signal to another instrument's reference clock

input.

The output has these characteristics:

• Amplitude into 50Ω (internal or external timebase reference selected): 1.65 ±0.05 Vpp

(8.3 ±0.3 dBm) sine wave

24 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 25

• Frequency accuracy, internal timebase reference selected: 10 MHz ±(8 ppb initial +

CAUTION

75 ppb/year aging)

• Frequency accuracy, external timebase reference selected: external reference

frequency (input to 10 MHz REF IN 50Ω)

AUX TRIG IN (50Ω)

You can set up the oscilloscope to trigger on the auxiliary trigger signal connected

to this BNC input.

Maximum voltage at AUX TRIG IN input

The input impedance is 50Ω, and the signal you provide must be 5 Vpp maximum

between -5 V and +5 V.

TRIG OUT

Getting Started 2

Pulses corresponding to oscilloscope triggers can be sent to this BNC output. TTL

levels into a high impedance load are output.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 25

Page 26

2 Getting Started

Horizontal controls

Entry knob

Vertical controls

Markers controls

Trigger controls

Setup and Display controls

Acquisition run controls

Analysis controls

Knobs and Keys on the Front Panel

Figure 7 Front panel controls

26 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 27

Getting Started 2

The Infiniium MXR/EXR-Series oscilloscope front panel controls provide direct

access to the functions needed to perform the most common measurements.

Knobs and keys let you directly set vertical and horizontal parameters. You can see

the oscilloscope's configuration at a glance.

The oscilloscope uses color consistently throughout the front panel and user

interface. For example, the color of the knob for channel 1 is the same color as the

waveform for channel 1. All configuration items and values related to channel 1 are

displayed in the same color.

The MXR-Series oscilloscopes have the [RTSA] front panel key for the RTSA

(Real-Time Spectrum Analysis) mode. At the same location in the EXR-Series

oscilloscopes is the [Fault Hunter] key for the Fault Hunter analysis feature.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 27

Page 28

2 Getting Started

Set horizontal

scale &

position

Open Channel

dialog box

Drag/drop

measurements

Acquisition

run controls

Add waveforms

Customize

Results display

Ground indicator

Open Horizontal

dialog box

Zoom on/off

Open Add Markers

dialog box

Menu bar

Set vertical

scale &

offset

Clear display Open Acquisition

dialog box

Pin/unpin

controls

Memory bar

Open Trigger

dialog box

Trigger

slope

Set

trigger

level

Undo/Redo

Grid selection

modes:

draw

rectangle

drag

waveform

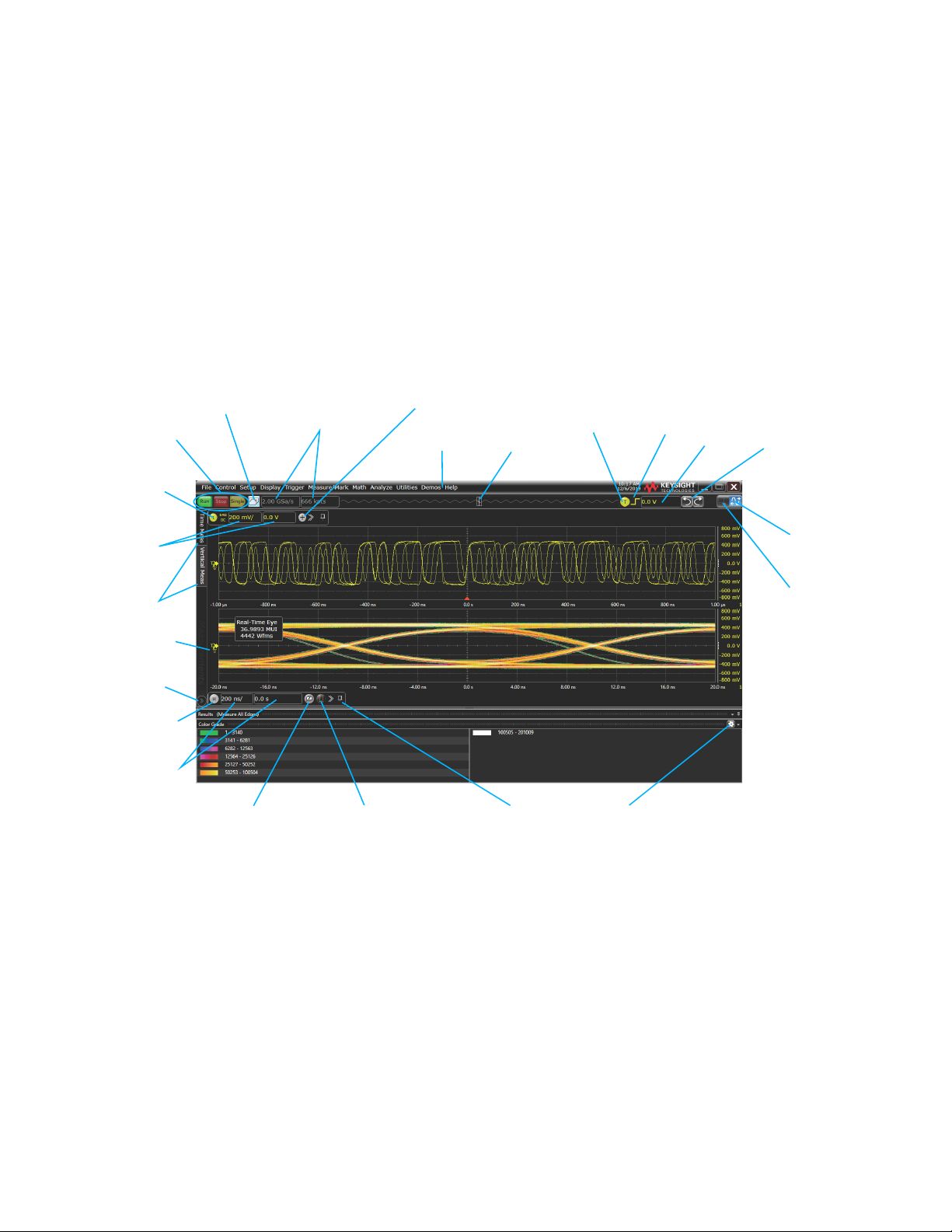

Graphical User Interface (GUI)

The user interface is arranged so the most common functions affecting the

waveform display are located around the edge of the waveform display area.

Context-sensitive menus are available by right-clicking something in the waveform

display area, such as a grid, a signal, a bookmark, or a measurement. You can

mouse over or touch other areas, such as the drag-and-drop measurements area

and horizontal and acquisition control regions, to find more information about

those areas or to enter data.

Figure 8 Infiniium oscilloscope display

28 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 29

Getting Started 2

Table 4 Infiniium oscilloscope display descriptions

Menu bar Use menu selections to perform defined operations and access every

function the oscilloscope provides.

Grid selection modes The selected grid mode determines whether you draw a selection box or

manipulate waveforms when you touch the screen.

Waveform display area The waveform display area shows up to eight waveform windows. Several

display options are available, such as grids or horizontal and vertical

scales.

Results pane A Results pane is visible at the bottom of the display when you do

something that produces results, such as taking a measurement or using

bookmarks. When it is not needed, the Results pane is not visible.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 29

Page 30

2 Getting Started

~

~

+ +

8 or 4 analog input channels where probes are connected

CAUTION

CAUTION

Connecting Oscilloscope Probes

Figure 9 MXR/EXR-Series oscilloscope probe connectors

Maximum input voltage at analog inputs

Do not exceed the maximum input voltage rating.

The maximum input voltage for the 50 Ω input impedance setting is ±5 V.

The maximum input voltage for the 1 MΩ input impedance setting is 30 Vrms or

±40 Vmax (DC+Vpeak).

Probing technology allows for testing of higher voltages; the included N2873A 10:1

probe supports 300 Vrms or ±400 Vmax (DC+Vpeak). No transient overvoltage

allowed. Mains isolated circuits only.

When measuring voltages over 30 V, use a 10:1 probe.

The Keysight Infiniium MXR/EXR-Series oscilloscopes are not rated for

Measurement Category II, III, or IV.

For complete documentation on Keysight oscilloscope probes for your Infiniium

oscilloscope, see the Probe Resource Center at: keysight.com/find/prc

To connect oscilloscope probes:

1 Attach the probe connector to the desired oscilloscope channel or trigger input

using the probe instructions.

2 Connect the probe to the circuit of interest using the browser or other probing

accessories.

30 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 31

Verifying Basic Oscilloscope Operation

~

~

+ +

Front panel connector

with square wave label

Channel 1 input

1 Connect one end of the passive probe cable to oscilloscope input channel 1.

2 Connect the other end of the passive probe cable to the front panel Probe

Comp terminal with the square wave label.

Figure 10 Verifying basic oscilloscope operation

Getting Started 2

3 Press [Default Setup] on the front panel.

The display will pause momentarily while the oscilloscope is configured to its

default settings. The oscilloscope is now in a known operating condition.

4 Press [Auto Scale] on the front panel.

The display will pause momentarily while the oscilloscope adjusts the time/div

setting and vertical scale so the oscilloscope can best display the input signals.

You should then see a square wave with about four cycles on screen and a

peak-to-peak amplitude of approximately five divisions.

If you do not see the waveform, make sure your power source is adequate, the

oscilloscope is properly powered on, and the cable is connected securely to the

front panel connector output.

5 Move the mouse around the mouse surface and verify that the on-screen

pointer follows the mouse movement.

6 Press the [Touch] key on the front panel to turn on the touch screen. Press and

hold your finger to the screen. A right-click menu appears, which verifies that

the touch screen is working properly.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 31

Page 32

2 Getting Started

NOTE

Default Setup and Autoscale

With the setup and display controls you can quickly get a stable waveform display,

clear the display, and set the oscilloscope to a known starting condition.

Figure 11 [Auto Scale] and [Default Setup] keys

Using Default Setup

To reset the oscilloscope to its default setup, press [Default Setup]. You can use the

Undo button to undo a default setup.

Save the Current Oscilloscope Configuration

Before using the default setup, you may want to save the current oscilloscope configuration

for later use. See the online help for instructions on saving setups, and for information on the

exact configuration that is set when you use the default setup. See "Accessing the Online

Help" on page 51.

Using Autoscale

To automatically configure the oscilloscope to best display the current input

signal(s), press [Auto Scale] or choose Control > Autoscale.

32 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 33

Starting and Stopping Waveform Acquisitions

Use the acquisition run controls to run and stop acquisitions or make a single

acquisition. The boxed area of the memory bar above the waveform display area

shows which portion of the channel's acquisition memory you are viewing.

Figure 12 Acquisition run control keys and buttons

•To start waveform acquisition, press [Run/Stop] or click Run.

Getting Started 2

The oscilloscope begins acquiring data. When the event that triggers the

oscilloscope is found (or, in the Auto sweep mode when a good amout of time

has elaped without the trigger event — see "Setting Up Triggers" on page 42),

the oscilloscope finishes acquiring data, updates the display, and then starts

another acquisition cycle.

•To stop waveform acquisition, press [Run/Stop] or click Stop. Data that was last

acquired remains on the screen.

• To make a single acquisition, press [Single] or click Single.

• You can also choose the Run, Stop, and Single commands from the Control

menu.

• To set up how you want the signals to be sampled, such as sampling rate and

mode, choose Setup > Acquisition....

Clearing the Waveform Display

Figure 13 [Clear Display] key

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 33

Page 34

2 Getting Started

When you press [Clear Display] or click , the oscilloscope clears acquired

waveform data from the display in preparation for another acquisition. If the

oscilloscope is in Run mode and is receiving triggers, it will update the display as it

collects new waveform data.

Clearing the waveform display also resets averaging, infinite persistence, color

grade persistence, histograms, and the mask testing database.

34 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 35

Adjusting the Horizontal Settings

Horizontal

position knob

Horizontal

scale knob

Magnify part of

the waveform in

a new window

Turn Zoom mode on/off

Set horizontal scale

(time per division)

Set horizontal position

(delay)

Use the horizontal controls to configure the horizontal scale and horizontal

position of the waveform. You can view a magnified section of the waveform using

the zoom window.

To adjust the horizontal scale and position, use gestures on the touch screen or

use the horizontal knobs, horizontal controls, or Horizontal dialog box.

Adjusting the Horizontal Scale

Getting Started 2

Figure 14 Front panel horizontal knobs and controls

Figure 15 Graphical user interface horizontal controls

• The horizontal scale knob is the larger of the two horizontal control knobs. To

stretch the waveform horizontally (displaying fewer seconds per division), turn

the knob clockwise. To shrink it horizontally, turn the knob counter-clockwise.

• Push and turn the horizontal scale knob to change the scaling in finer (Vernier)

increments.

• You can also use multi-touch gestures to stretch or shrink the waveform.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 35

Page 36

2 Getting Started

NOTE

Adjusting the horizontal trigger position (delay)

• To adjust the horizontal scale using the controls in the horizontal toolbar,

mouse over or touch the horizontal scale field and use the resulting controls to

set a particular horizontal scale. Click the scale field to enter an exact value, or

click the "narrower" or "wider" buttons.

• The horizontal position knob is the smaller of the two horizontal control knobs.

Turn the knob to move the waveform to the right or left.

• Moving the waveform to the right shows more of the pre-trigger data (data

acquired before the trigger event). Moving it to the left shows more post-trigger

data.

• When you drag a waveform, the horizontal position will change for all channels

and functions on the display. Waveform memories will also move if you select

the Tie to Timebase box in the Waveform Memories dialog box.

• To adjust the horizontal position using the controls in the horizontal toolbar,

mouse over or touch the horizontal position field and use the resulting controls

to set a particular horizontal position (time relative to the trigger at the

highlighted horizontal reference point).

Magnifying a part of the waveform using Zoom

• To turn on zoom, press the key or click the Zoom button .

The waveform display area splits into two regions. The top one is the main

timebase. The bottom is the zoomed timebase, which represents an expansion

of the acquired waveform data. A section of the waveform in the main timebase

window is highlighted to indicate the part shown in the zoomed timebase

window.

The horizontal scale and position controls now change how the waveform is

shown in the zoomed timebase window. The horizontal scale will change the

amount of magnification, while the position will change the part of the

waveform in the main window that is shown in the zoomed window.

• To turn off zoom, press or click again.

Avoid Overdriving Vertical Input Amplifiers

When zooming on a waveform with the oscilloscope running, be careful to keep the signal

within the screen vertically to avoid overdriving the vertical input amplifiers. Overdriving

causes waveform distortion and erroneous measurement results.

"ADC clipping" indicators appear when a signal exceeds the input voltage range of the ADC.

These indicators can sometimes appear when a signal appears to be within the vertical range

of the screen due to DSP filtering, but it really is not.

36 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 37

Using the Navigate Controls

Navigation can be performed for acquisition history (which is available when

running acquisitions are stopped), time, segmented memory acquisitions, protocol

search, measurement limit test, and mask test.

The [Navigate] key opens the Navigate dialog box where you can choose what to

navigate.

Press the navigation keys to step or play backward, stop (when

navigation is being played), or step or play forward. When playing, you can press

Getting Started 2

the or keys multiple times to speed up the playback. There are three speed

levels.

Additionally, the graphical user interface provides first and last buttons for

navigating to the first or last item in the collection, and somtimes there is a

play button for playing items.

The navigation controls also appear in the horizontal controls bar and can be

displayed or hidden by clicking the clock button.

Setting the scale, position, and timebase reference point

To set scale, position, and timebase reference, use the Horizontal dialog box or set

up the zoomed timebase window.

To access the Horizontal dialog box, click the in the horizontal toolbar, or

choose Setup > Horizontal... from the main menu.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 37

Page 38

2 Getting Started

The Timebase Reference range is from 0 to 100% of the screen. The center of the

screen is at 50%. The slider correlates to the hollow orange triangle at the bottom

of the display area, showing where the horizontal offset is on the screen.

38 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 39

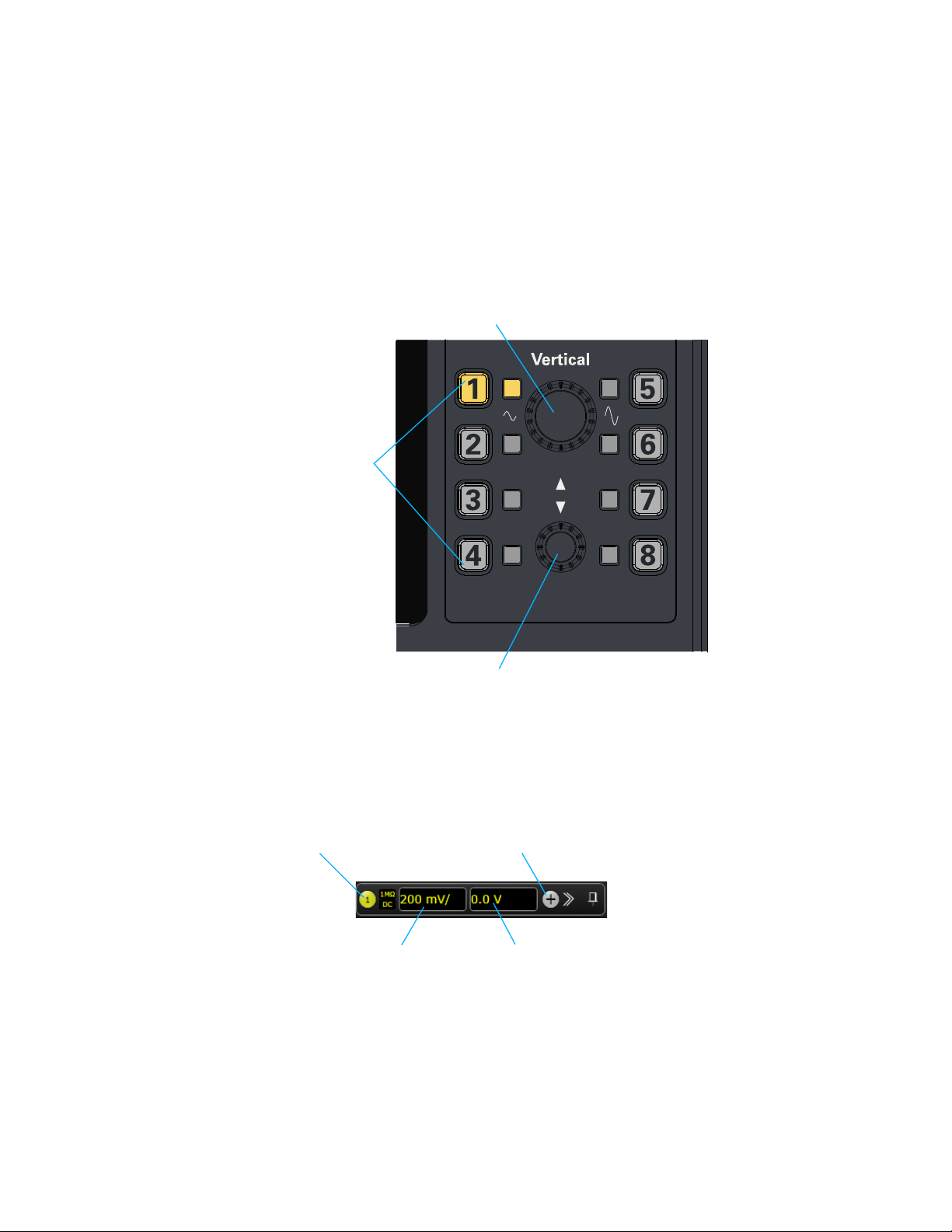

Adjusting the Vertical Settings

Vertical offset knob: adjusts

vertical offset (position) of

selected channel

Vertical scale knob: adjusts

vertical scale of selected channel

Turn waveforms on/off

Set vertical scale Set vertical offset

Use the vertical controls to set the vertical scaling and vertical offset for each

analog channel, and to turn the display on or off for a specific channel.

Getting Started 2

Figure 16 Front panel vertical controls

Figure 17 Graphical user interface vertical controls

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 39

Page 40

2 Getting Started

NOTE

Turning an analog channel on or off

Adjusting an analog channel's vertical scale and offset

To turn an analog channel on or off, press the channel number key on the front

panel or click the Add Waveforms button . When you turn off a channel, the

current vertical scale and offset fields for that channel disappear.

If you are not using a particular analog channel, you can turn it off to simplify the

waveform display and increase the display update rate. Functions continue to run

on a channel source that is turned off. Data acquisition continues for a channel if a

function requires it.

Using an Analog Channel as Trigger

Any analog channel can be used as a trigger source. If you need a trigger but do not need all

analog channels, you can use an analog channel as a trigger without displaying it by turning

the analog channel display off.

To adjust the vertical scale and offset, use the vertical scale and offset knobs,

vertical user interface controls, or Channel dialog box.

The vertical scale knob is the larger of the two knobs for a channel. Turn the knob

to make the waveform bigger (fewer volts per division) or smaller. You can also

mouse over or touch the vertical scale field and use the resulting controls to set an

exact value for the scaling.

The vertical offset knob is the smaller knob for a channel. Turn it to move the

waveform up or down.

You can drag the waveform or its ground reference indicator to the desired vertical

offset if the grid is in drag mode .

Choose Setup > Channel N... or click a channel number to open the Channel dialog

box, in which you can set the vertical scale, offset, skew, and labels. You can also

specify the characteristics of a probe, or perform a probe calibration.

For Keysight Technologies probes that are compatible with the AutoProbe

interface, the oscilloscope will automatically set these characteristics (except for

skew) after identifying the probe when it is connected to the channel input.

40 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 41

Trigger Level and Other Controls

Set trigger level

Entry knob

Press to perform

configured action

(like Quick Meas)

Enable/disable

touch screen

Enable/disable

waveform

generator

output

Capture screen,

save to hard drive

Around the Trigger Level knob, centrally located on the front panel, are controls for

performing various tasks.

Getting Started 2

Figure 18 Front panel trigger level (and other) controls

Entry Knob

The Entry knob is a multiplexed knob that can used to adjust values in selected

dialog box fields.

The curved arrow LED on the front panel illuminates whenever the Entry knob

can be used to adjust a value. The value being adjusted is displayed in a popup

message box.

Also, when the symbol appears in a field, you can use the Entry knob to adjust

values.

The Entry knob can sometimed be pushed to make a selection or default value

setting.

[Multi Purpose] Key

The [Multi Purpose] key can be configured to perform one of many quick actions,

such as loading a setup file, saving composite data or a measurement report to a

file, saving the screen image to a bitmap file, or performing automatic

measurements.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 41

Page 42

2 Getting Started

Setting Up Triggers

The action taken when [Multi Purpose] is pressed (or when Utilities > Multipurpose is

chosen) depends on the feature selected in the Customize Multipurpose dialog

box (Utilities > Customize Multipurpose...).

Use the graphical user interface trigger controls to set the conditions on which the

oscilloscope will trigger and acquire an input signal. You can set up a variety of

trigger conditions.

Figure 19 Graphical user interface trigger controls

For example, to set up an Edge trigger:

1 Click the T button in the graphical user interface to open the Trigger dialog box.

2 In the Trigger dialog box, select the Edge trigger type.

3 Select the Source .

You can choose any channel or the Aux (AUX TRIG IN) or Line (the 50% level of

the oscilloscope's AC power source signal) input as the source for an edge

trigger.

4 Enter the voltage level at which the oscilloscope will trigger either by using the

Level field or by turning the Trigger Level knob.

5 Select a rising edge, falling edge, or both edges slope to trigger on.

6 Select the desired Sweep:

42 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 43

• When Triggered is selected, the oscilloscope must find the trigger before

saving and displaying captured data.

• When Auto is selected, if a trigger does not occur within a certain amount of

time, an acquisition is automatically saved and displayed. In Auto trigger

mode, you are able to see your signals while setting up the desired trigger.

Use the Trigger dialog box to select any of the modes of triggering, the parameters

and conditions for each trigger mode, and advanced configuration items.

You can also mouse over the Trigger Level field and use the resulting controls to

set a particular trigger level when the oscilloscope is set for edge trigger on a

particular channel. You can drag the trigger reference indicator at the left side of

the display, or drag the trigger line itself, which appears when you click or touch

the grid.

Waveform Generator

The built-in license-enabled waveform generator can output sine, square, ramp,

pulse, DC, noise, sine cardinal, exponential rise, exponential fall, cardiac, Gaussian

pulse, PRBS, and demo waveforms on the GEN OUT output.

Getting Started 2

Noise can be added to all waveform types except: noise and demo.

AM, FM, or FSK modulation can be performed on all waveform types except:

square, pulse, DC, noise, Gaussian pulse, and demo.

The [Wave Gen] key enables or disables the waveform output on GEN OUT.

To select the waveform type and its parameters in the graphical user interface,

choose Setup > Waveform Generator... to open the Waveform Generator dialog box.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 43

Page 44

2 Getting Started

Saving and Printing

Using the Touch Screen

You can press the [Save Screen] key to capture and save a screen image to the

oscilloscope's hard drive in the C:\Users\Public\Documents\Infiniium\Screen

Images\ folder.

In the graphical user interface, you can:

•Choose File > Save > and use the menu selections to save composite files

(setups and waveforms), setup files, waveform data, screen images, or

measurement data. You can also save waveforms to waveform memoriies.

•Choose File > Copy Screen Image to easily copy and paste a screen image into a

document.

•Choose File > Print... to send screen images and setup data to a specified printer.

Note that you can customize the [Multi Purpose] key to perform a QuickPrint.

1 To enable the touch screen so it responds to multi-touch gestures, similar to

those used on tablets and smart phones, press [Touch] or choose Utilities > User

Preferences... and select the Enable Touch Screen check box.

2 Touch the drag waveform icon to highlight it.

Now you can use gestures to flick items horizontally, drag a waveform vertically,

drag horizontally to change the horizontal delay, pinch horizontally to adjust

time/div and delay settings, pinch vertically to adjust a waveform's V/div and

offset settings, or tap to select waveforms and other selections on the display.

44 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 45

Using Markers

Open Markers dialog box

Turn to move a marker;

push to change the marker

Getting Started 2

Use the Markers controls to display and adjust markers.

Markers make it easier to make precise measurements because the marker

measurement readouts show exact voltage and time positions for the markers. The

measurements are based on actual waveform data from the acquisition system,

not on approximations based on the display position, so you can be sure the values

are highly accurate.

Using the markers controls, you can control multiple sets of markers within the

oscilloscope grid.

Figure 20 Front panel markers controls

Both time and voltage differences between the markers are updated continuously

on the screen. By default, the markers track the source waveform. Voltage

measurements from the markers are the value of the waveform at the time set with

the marker arrow keys.

• To add a marker, press the [Markers] key or choose Measure/Mark > Add Markers...

or click the Markers button ; then, select the sources and mode.

Notice the drawing in the Mode area of the Marker dialog box.

• To select one of the markers, push one of the marker Position knobs. Turn the

knob to move the marker. Push the knob again to select the next marker.

• Marker 1 has a solid line pattern on the waveform display. It is associated with

the first available source on the display.

• You can drag a marker to quickly move to the position you want on the

waveform.

• You can use the front panel Position knob for fine adjustment, or use the Add

Marker dialog box to set the marker position precisely.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 45

Page 46

2 Getting Started

Expand and collapse

the measurement icons

Drag and drop

measurement icons

showing most commonly

used measurements

Making Measurements

To make a measurement, either drag a measurement icon to the waveform event

you want to measure, or click a measurement icon and use the resulting dialog box

to specify which source you want to measure.

Figure 21 Drag-and-drop measurements

For measurements on waveform features, such as those that involve waveform

edges, if you click the measurement icon and specify a source, the measurement

defaults to using the feature closest to the horizontal reference point. If you make

the measurement using drag and drop, the measurement uses the waveform

feature closest to the point where you drop the icon.

The most commonly used measurements are available in the drag-and-drop area.

Others are available from the Add Measurement dialog box (Measure/Mark > Add

Measurement...).

46 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 47

When you drag and drop a measurement icon on a waveform, the icon outline

changes color to match the color of each waveform it touches so you can easily

see which waveform will be measured.

For edge-sensitive measurements, a circled number appears in the waveform

marker color when you drop the measurement icon on a waveform. This number

shows exactly where the measurement is being made. It appears next to the

measurement readout in the Results pane. This feature helps you distinguish

measurement results from each other when you make multiple measurements on

the same waveform but at different waveform features.

Using Quick Measurements

The default [Multi Purpose] key action is QuickMeas (see "[Multi Purpose] Key" on

page 41). With this configuration:

• To turn on the quick measurement display, press [Multi Purpose]. The 10 preset

measurements defined in the Quick Measurement configuration are enabled

and results appear on the screen for the first waveform source.

Getting Started 2

• To measure parameters for another waveform, press [Multi Purpose] until that

waveform is the one shown in the measurements window in the Results pane.

Continuing to press [Multi Purpose] cycles through each of the waveforms

available.

• To turn off the quick measurement display, cycle through all channels until the

measurements are turned off.

See the Infiniium oscilloscope application's online help for information on how to

configure the quick measurement capability. See "Accessing the Online Help" on

page 51.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 47

Page 48

2 Getting Started

Enable or disable

protocol decode

(currently

not

available)

Turn digital channels

on or off

Using Digital Channels and Protocol Decode

On the front panel, just above the Vertical controls, are keys for digital channels

and protocol decode.

Figure 22 Front panel [Digital] and [Protocol Decode] keys

Controlling Digital Channels

If your oscilloscope's MSO option is enabled, choose Setup > Digital Channels... to

open the Digital dialog box so you can set up controls for the digital channels.

To turn the digital channels on, click the Add Waveforms button and select the

check box next to the , or press [Digital].

Decoding Serial Protocol Data

• To open the Protocol Decode dialog box so you can define parameters for

selected decodes, choose Setup > Protocol Decode... or press [Protocol Decode].

You can perform up to four decodes at the same time using p1-p4.

• After selecting the protocol decode parameters, click Auto Setup to

automatically configure the oscilloscope for the selected decode type.

• Decoded acquisition data appears in the Protocol Listing window.

48 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 49

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes

User's Guide

3 Demos and Online Help

Using the Demo Wizard / 50

Accessing the Online Help / 51

The graphical user interface has a Demo Wizard that illustrates many oscilloscope

features and capabilities. There is also online help that describes oscilloscope

features and capabilities in more detail.

49

Page 50

3 Demos and Online Help

Using the Demo Wizard

Your MXR/EXR-Series oscilloscope comes with a built-in demo wizard that

showcases many Infiniium oscilloscope features. To see the demos, choose Demos

> Tutorials & Demos... (or Help > Tutorials & Demos...). You can then select a specific

demo, such as one for a particular protocol or one for a user interface showing

bookmarks.

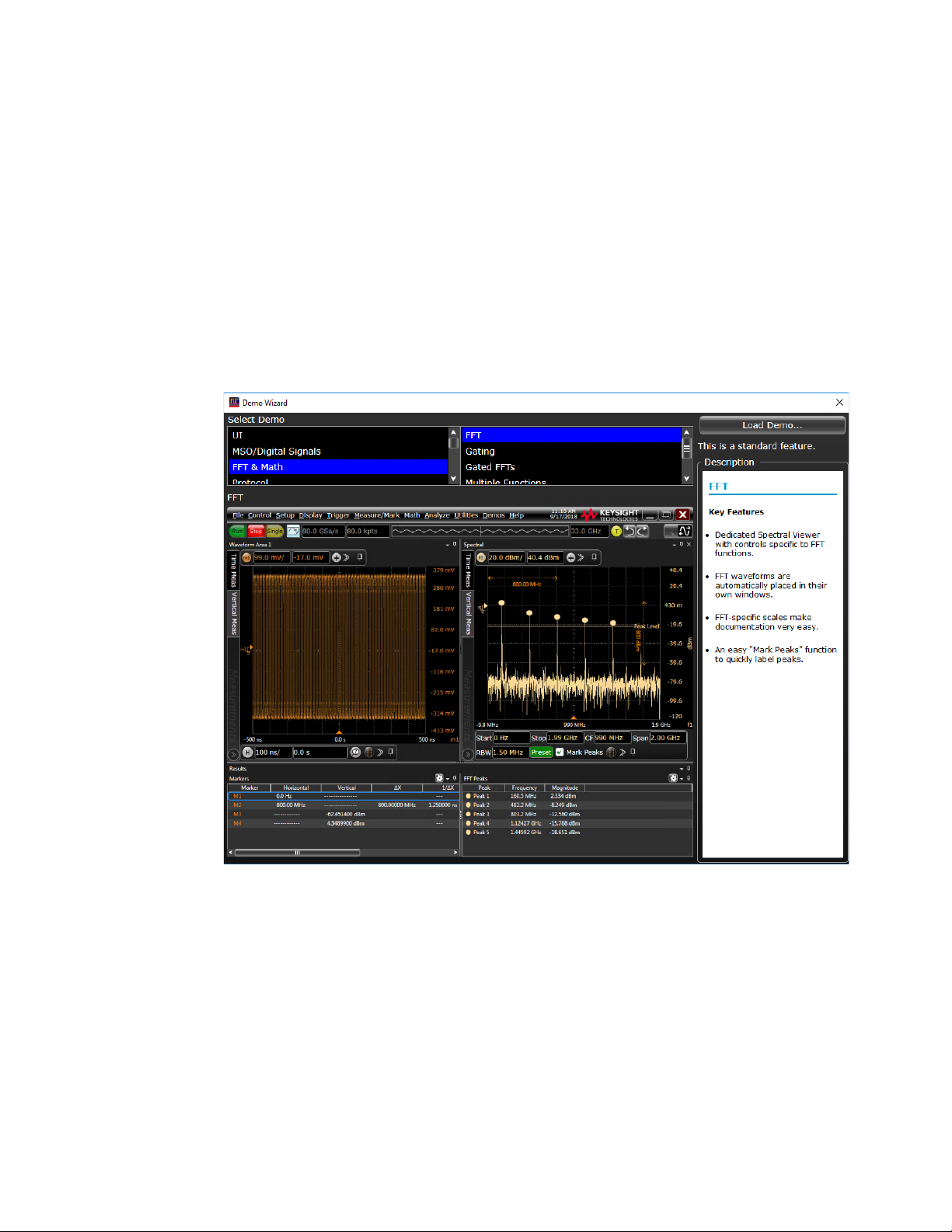

For example, the following screen display shows the initial demo page for the FFT

function. To experiment with the demo, click Load Demo....

Figure 23 FFT Demo

50 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 51

Accessing the Online Help

Displays the Help topic

for this dialog box

There are two ways to access the online help:

• Click the question mark near the top right corner of a dialog box to open the

help topic for that dialog box (Figure 24).

•Choose Help > Contents... from the main menu to open the online help home

page (Figure 25).

Demos and Online Help 3

Figure 24 Help button for dialog box Help

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 51

Page 52

3 Demos and Online Help

Figure 25 Online Help home page

There are several ways to find the information you need:

•Use the Search tab to search for a word or phrase. Use quotation marks to

search for an exact phrase, such as "add waveform".

•Use the Contents tab to browse topics by double-clicking topics in the left pane.

•Use the Index tab to type in a keyword and search the index for that keyword, or

scroll through the alphabetical list to find a topic.

•Use the Favorites tab to add preferred help topics to a list for easy reference.

For more details on using online help, click How to Use This Help under the Help and

More Information topic in the Contents tab.

52 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 53

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes

User's Guide

4 Other Oscilloscope Tasks

Changing Windows Operating System Settings / 54

Installing Application Programs on Infiniium / 55

Forcing a Default Setup / 56

Hard Drive Recovery / 57

Cleaning the Oscilloscope / 58

This chapter describes tasks you may need to perform during ongoing use of the

oscilloscope.

53

Page 54

4 Other Oscilloscope Tasks

NOTE

Changing Windows Operating System Settings

Exit the oscilloscope application before changing any Windows operating system settings

outside of the oscilloscope application.

Many Windows operating system settings can be changed to suit your own

personal preferences. However, some operating system settings should not be

changed because doing so would interfere with the proper operation of the

oscilloscope.

• Do not change the Power Options.

• Do not change the Language settings.

• Do not remove Fonts.

• Do not change the screen resolution from 1920 by 1080 pixels.

• Do not use the Administrative Tools to enable or disable Internet Information

Services (IIS) Manager. Use the Infiniium Remote Setup dialog box (Utilities >

Remote...) to enable or disable the Web Server.

• Do not delete or modify the Infiniium Administrator user account.

54 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 55

Installing Application Programs on Infiniium

NOTE

CAUTION

The Infiniium oscilloscope has an open Windows operating system, which lets you

install your own application software. Any application that runs on Microsoft

Windows 10 and uses 16 GB of RAM or less may be installed on your Infiniium

oscilloscope.

Exit the oscilloscope application before installing any software.

Installing an application that does not meet these requirements may break the

oscilloscope application and require a hard drive recovery.

Other Oscilloscope Tasks 4

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 55

Page 56

4 Other Oscilloscope Tasks

Forcing a Default Setup

If your Infiniium oscilloscope is not working properly when you start it up, follow

these steps to perform a default setup and return the Infiniium to normal

operation.

1 Choose Control > Default Setup or press [Default Setup].

2 If the oscilloscope is still not working properly, choose Control > Factory Default

to return the oscilloscope to the default settings it had when it left the factory.

3 If the oscilloscope is still not working properly, turn it off.

4 Turn the oscilloscope back on. If it does not successfully restart, try recycling

the power again.

5 As soon as the Windows load screen disappears, press [Default Setup]. If the

oscilloscope still does not successfully restart, follow the instructions for

recovering the hard drive. See "Hard Drive Recovery" on page 57.

56 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 57

Hard Drive Recovery

If you need to recover your Infiniium oscilloscope hard drive, follow these steps:

1 Back up your calibration and license files if they are still accessible:

a If the Infiniium application is available, launch the Keysight License Manager

(Utilities > Launch License Manager...) and capture a screen shot of the page. It

lists the transportable and fixed perpetual licenses that Keysight will need to

reissue.

b Copy the calibration folder (C:\ProgramData\Infiniium\cal) to an external

device, such as a flash drive.

c Copy the license file (C:\ProgramData\Infiniium\license.dat), which contains

legacy licenses, to an external device.

2 Turn off the oscilloscope.

3 Make sure a keyboard and mouse are connected to the USB host ports.

4 Turn on the oscilloscope and watch closely for the system prompts. As soon as

you see the prompt to choose Microsoft Windows or Instrument Image

Recovery System, select Instrument Image Recovery System and follow the

on-screen instructions.

Other Oscilloscope Tasks 4

5 Once the recovery process is finished and the oscilloscope is running, check in

the About Infiniium dialog box under installed options to see if all of the options

you ordered are installed. If the options are not installed, install them using the

license keys provided on the oscilloscope option license certificates you

received, or refer to the back of the oscilloscope.

6 Restore the calibration folder and license files back to their original locations.

7 Restart the oscilloscope application to ensure the license.dat file reflects any

factory bandwidth licenses.

8 Send an email message to csg.support@keysight.com. Provide the License

Manager screen shot page you captured earlier, the oscilloscope's model and

serial number from the rear panel of the scope, and the zip file you created

earlier.

9 From the oscilloscope desktop, launch the Infiniium application. When the

application is active, perform an oscilloscope self-test (Utilities > Self Test...).

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 57

Page 58

4 Other Oscilloscope Tasks

WARNING

CAUTION

WARNING

Cleaning the Oscilloscope

To prevent electrical shock, disconnect the Infiniium oscilloscope from mains before

cleaning.

Clean the Infiniium oscilloscope with a soft dry cloth or one slightly dampened

with a mild soap and water solution to clean the external case parts. Do not

attempt to clean internally.

Do not use too much liquid in cleaning the oscilloscope. Water can enter the Infiniium

oscilloscope panels, damaging sensitive electronic components.

To avoid electrostatic discharge (ESD), wear a grounded wrist strap when cleaning

connectors.

Use alcohol to clean connectors. The power cord must be removed, and the

oscilloscope must be in a well-ventilated area. Allow all residual alcohol moisture to

evaporate, and the fumes to dissipate prior to powering up the oscilloscope. Dispose

of the cleaning materials in a responsible manner.

58 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 59

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes

User's Guide

5 Calibrating the Oscilloscope

When to Perform a User Calibration / 60

Equipment Required / 61

Calibration Time / 62

Calibration Procedure / 63

A calibration is simply an oscilloscope self-adjustment. The purpose of a

calibration is performance optimization.

There are two ways to calibrate an Infiniium MXR/EXR-Series oscilloscope:

•A user calibration, also known as a self calibration, includes the minimum set of

calibrations and is intended to be run by oscilloscope users. It can include a

time scale calibration.

•A service calibration is performed only by Keysight Service Center technicians.

This chapter describes how to run a user (self) calibration.

59

Page 60

5 Calibrating the Oscilloscope

When to Perform a User Calibration

When to perform a user calibration:

• Standard calibration only—When the oscilloscope's operating temperature

(after the 30-minute warm-up period) is more than ±5 °C different from that of

the last calibration. Be sure to perform a standard user calibration (do not

perform the time scale cal)—even if one was recently performed—when

environmental temperature conditions cause the oscilloscope's operating

temperature to change, such as when the oscilloscope is moved to a test rack

or chamber.

• Standard and time scale cal—When it has been more than 1 year since the last

time scale calibration, or when you replace the acquisition board.

60 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 61

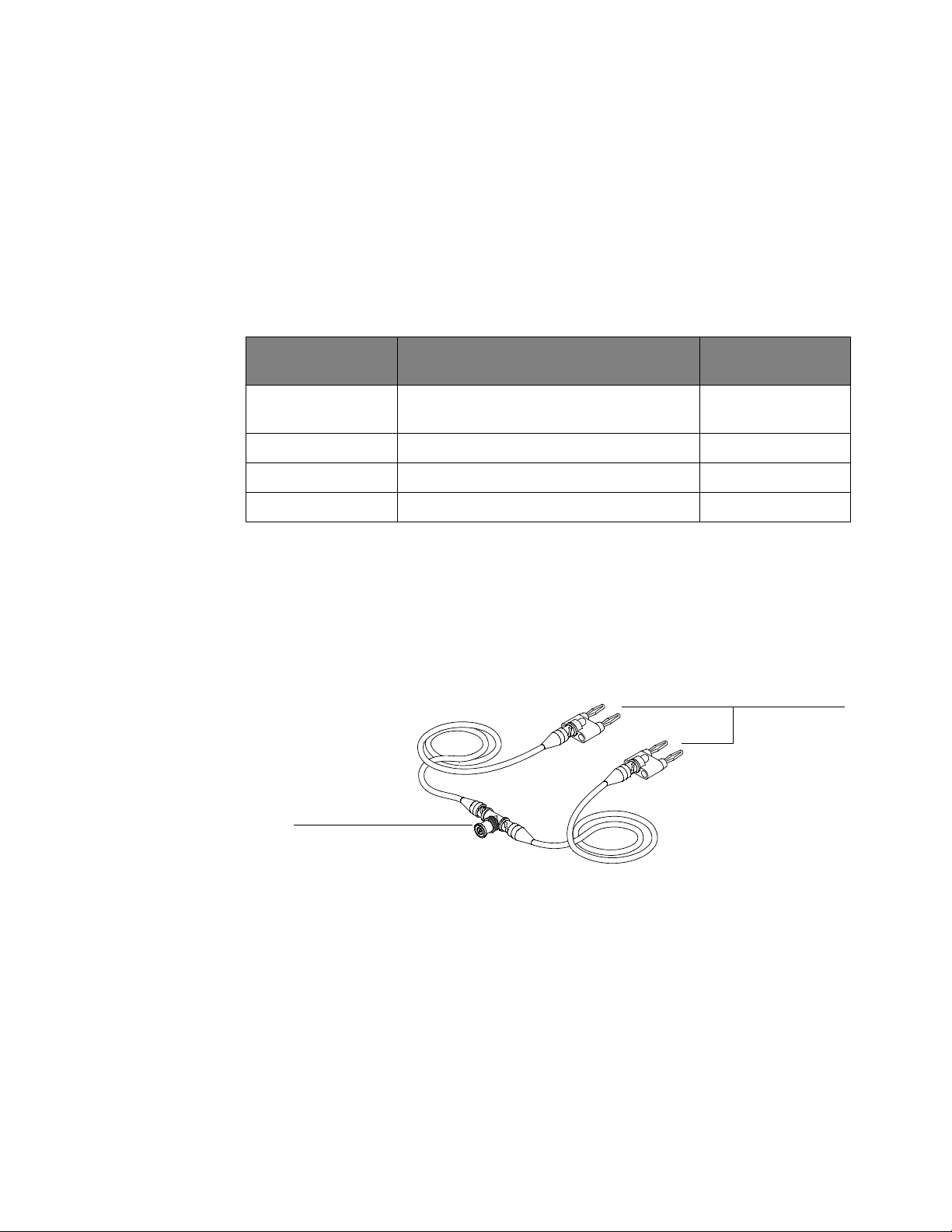

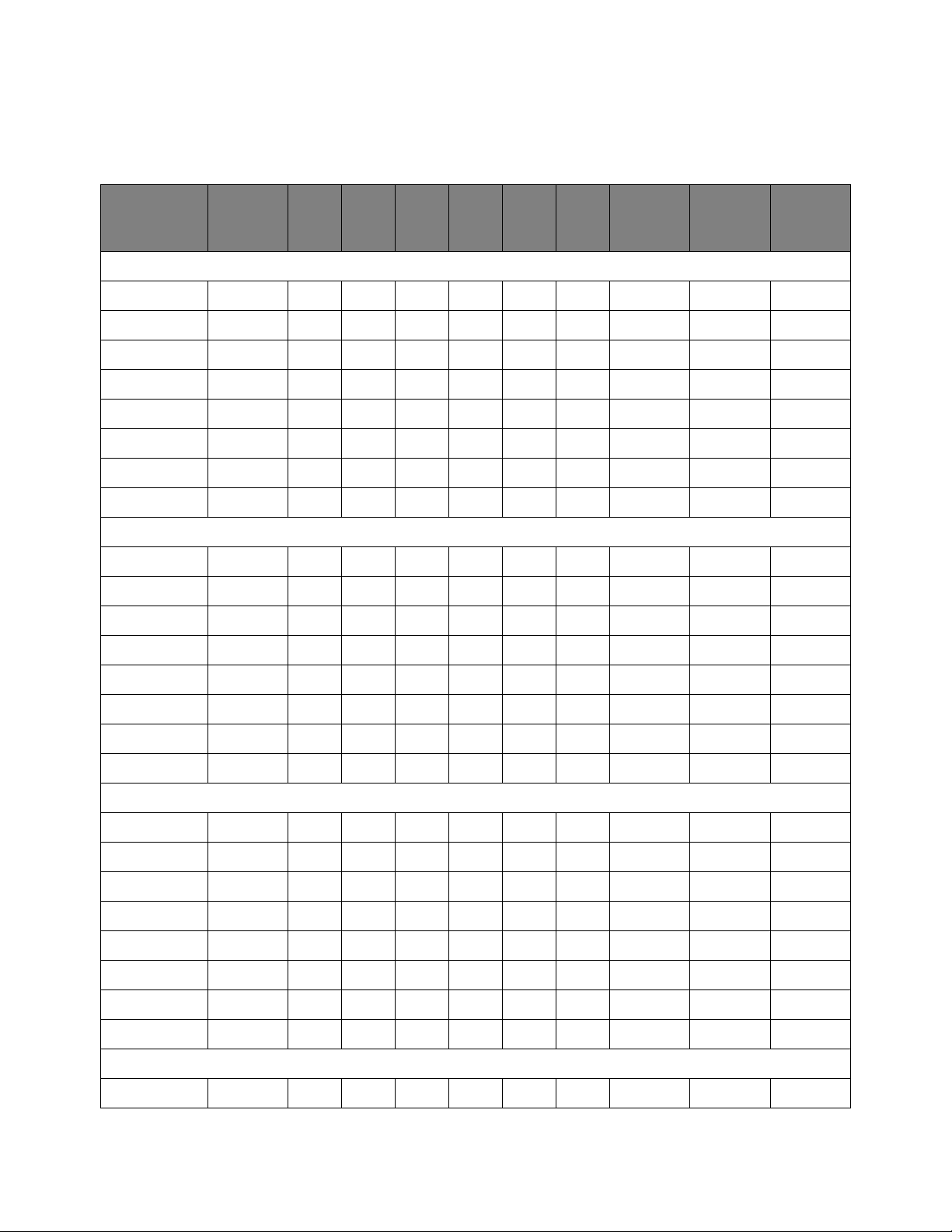

Equipment Required

Equipment Critical specifications Recommended part number

Calibrating the Oscilloscope 5

50 Ω BNC Cable 50 Ω characteristic impedance

BNC cable

10 MHz Signal Source

(required for time scale

calibration)

Frequency accuracy better

than ±41 ppb

54609-61609

53220A with Opt. 010

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 61

Page 62

5 Calibrating the Oscilloscope

Calibration Time

It takes approximately 70 minutes to run the user calibration on the oscilloscope,

including the time required to change cables from channel to channel.

62 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 63

Calibration Procedure

NOTE

CAUTION

Clear this

Performing a user calibration will invalidate the oscilloscope's Certificate of Calibration. If

NIST (National Institute of Standards and Technology) traceability is required, perform the

procedures in Chapter 6, “Testing Performance,” starting on page 65 using traceable

sources.

1 Let the oscilloscope warm up before running the calibration.

The oscilloscope must be warmed up (with the oscilloscope application running) for at

least 30 minutes at ambient temperature before starting the calibration procedure.

Failure to allow warm up may result in inaccurate calibration.

2 Click Utilities > Calibration....

3 Clear the Cal Memory Protect check box.

Calibrating the Oscilloscope 5

You cannot run a user calibration if this check box is selected. See the following

figure.

4 Click Start Frame Cal; then, follow the instructions on the screen.

The routine will prompt you to follow these steps:

a Disconnect everything from all inputs and Aux Out.

b Select the level of calibration you want to perform.

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide 63

Page 64

5 Calibrating the Oscilloscope

NOTE

When performing the time scale calibration using the 53220A-010 universal frequency

counter/timer, the precision 10 MHz reference is available from the Int Ref Out connector on

the rear panel of the 53220A counter/timer.

• Standard Calibration — Time scale calibration will not be performed. Time

scale calibration factors from the previous time scale calibration will be

used and the 10 MHz reference signal will not be required. The remaining

calibration procedure will continue.

• Standard Calibration and Time Scale Calibration—Time scale calibration

will be performed. This option requires you to connect a 10 MHz

reference signal to channel 1 that meets the following specifications.

Failure to use a reference signal that meets these specifications will result

in an inaccurate calibration.

• Frequency: 10 MHz, max ±41 ppb = 10 MHz, max ±0.41 Hz

• Amplitude: 0.2 V peak-to-peak to 5.0 V peak-to-peak

• Wave shape: Sine or Square

c Connect the 50 Ω BNC cable from Aux Out to each of the channel inputs as

requested.

d Connect the 50 Ω BNC cable to Aux Trig In as requested.

e Follow the directions for calibrating the digital channels (models with MSO

option).

f A Passed/Failed indication is displayed for each calibration section.

If any section has failed, wait until the calibration is complete and then select

the Enable Details check box for information on the failures. Also check the cable

connections.

5 When the calibration procedure is complete, click Close.

64 Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes User's Guide

Page 65

Keysight Infiniium MXR/EXR-Series Real-Time Oscilloscopes

User's Guide

6 Testing Performance

Performance Verification General Information / 66

Input Impedance Test / 67

Offset Accuracy Test / 69

DC Gain Accuracy Test / 76

Analog Bandwidth—Maximum Frequency Test / 79

Time Scale Accuracy (TSA) Test / 86

Performance Test Record / 89

Full performance verification for the MXR/EXR-Series oscilloscopes consists of

three main procedures: