Page 1

Keysight M9614A/M9615A

PXIe 5-Channel

Precision Source/Measure Unit

Startup Guide

Page 2

Notices

Copyright Notice

© Keysight Technologies 2020

No part of this manual may be reproduced in

any form or by any means (including electronic storage and retrieval or translation into

a foreign language) without prior agreement

and written consent from Keysight Technologies as governed by United States and international copyright laws.

Manual Part Number

M9615-90000

Edition

Edition 1, May 2020

Edition 2, August 2020

Edition 3, October 2020

Published by:

Keysight Technologies Japan K.K.

9-1, Takakura-cho, Hachioji-shi, Tokyo

192-8550 Japan

Regulatory Compliance

This product has been designed and tested in

accordance with accepted industry standards,

and has been supplied in a safe condition. To

review the Declaration of Conformity, go to

www.keysight.com/go/conformity.

Warranty

THE MATERIAL CONTAINED IN THIS DOCUMEN T IS PROVIDED “AS I S,” A ND IS SUBJ ECT

TO BEING CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE

LAW, KEYSIGHT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, WITH

REGARD TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

KEYSIGHT SHALL NOT BE LIABLE FOR

ERRORS OR FOR INCIDENTAL OR CONSE-

QUENTIAL DAMAGES IN CONNECTION WITH

THE FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR OF ANY INFORMATION CONTAINED HEREIN. SHOULD KEYSIGHT AND THE USER HAVE A SEPARATE

WRITTEN AGREEMENT WITH WARRANTY

TERMS COVERING THE MATERIAL IN THIS

DOCUMENT THAT CONFLICT WITH THESE

TERMS, THE WARRANTY TERMS IN THE SEPARATE AGREEMENT SHALL CONTROL.

KEYSIGHT TECHNOLOGIES DOES NOT WARRANT THIRD-PARTY SYSTEM LEVEL (COMBINATION OF CHASSIS, CONTROLLERS,

MODULES, ETC.) PERFORMANCE, SAFETY,

OR REGULATORY COMPLIANCE, UNLESS

SPECIFICALLY STATED.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance

with the terms of such license.

U.S. Government Rights

The Software is “commercial computer software,” as defined by Federal Acquisition Regulation (“FAR”) 2.101. Pursuant to FAR 12.212

and 27.405-3 and Department of Defense FAR

Supplement (“DFARS”) 227.7202, the U.S.

government acquires commercial computer

software under the same terms by which the

software is customarily provided to the public.

Accordingly, Keysight provides the Software

to U.S. government customers under its standard commercial license, which is embodied

in its End User License Agreement (EULA), a

copy of which can be found at http://

www.keysight.com/find/sweula. The license

set forth in the EULA represents the exclusive

authority by which the U.S. government may

use, modify, distribute, or disclose the Software. The EULA and the license set forth

therein, does not require or permit, among

other things, that Keysight: (1) Furnish technical information related to commercial computer software or commercial computer

software documentation that is not customar-

ily provided to the public; or (2) Relinquish to,

or otherwise provide, the government rights

in excess of these rights customarily provided

to the public to use, modify, reproduce,

release, perform, display, or disclose commercial computer software or commercial

computer software documentation. No additional government requirements beyond those

set forth in the EULA shall apply, except to the

extent that those terms, rights, or licenses are

explicitly required from all providers of commercial computer software pursuant to the

FAR and the DFARS and are set forth specifically in writing elsewhere in the EULA. Keysight shall be under no obligation to update,

revise or otherwise modify the Software. With

respect to any technical data as defined by

FAR 2.101, pursuant to FAR 12.211 and

27.404.2 and DFARS 227.7102, the U.S. government acquires no greater than Limited

Rights as defined in FAR 27.401 or DFAR

227.7103-5 (c), as applicable in any technical

data.

Safety Summary

The following general safety precautions must

be observed during all phases of operation,

service, and repair of this product. Failure to

comply with these precautions or with specific

warnings elsewhere in this manual may impair

the protections provided by the product. In

addition, it violates safety standards of design,

manufacture, and intended use of the product.

Keysight Technologies assumes no liability for

customer’s failure to comply with these

requirements.

- Do not use this product in any manner not

specified by the manufacturer. The protective

features of this product may be impaired if it is

used in a manner not specified in the operation instructions.

- This product is INDOOR USE product.

- This product complies with POLLUTION

DEGREE 2 defined in IEC 61010-1.

Page 3

- If an instrument is marked CAT I (IEC Mea-

WARNING

WARNING

>

^

surement Category I), or it is not marked with

a measurement category, its measurement

terminals must not be connected to line-voltage mains.

- System installation, safety and performance

are the responsibility of the assembler of the

system.

The persons who plan, supervise, consign, and

implement the installation, start-up, maintenance, and delivery of this product are

required to carefully read documents related

to the equipment and take and implement

safety measures to prevent accidents. Also,

safety and performance of the system in which

the equipment is installed are the responsibility of the assembler responsible for the system

construction.

Equipment built in the system may be heavy.

So there is the possibility of physical disability

in the person by moving the equipment to a

high place or moving it from a high place. To

prevent accidents, take appropriate safety

work means.

DANGEROUS PROCEDURE WARNINGS

Warnings, such as above WARNING, shall be

complied. Procedures throughout in this manual prevent you from potentially hazard. Their

instructions contained in the warnings must

be followed.

BEFORE APPLYING POWER

Verify that all safety precautions are taken.

Make all connections to the instrument before

applying power. Note the instrument's external markings described under “Safety Symbols”.

GROUND THE INSTRUMENT

This is Safety Class I instrument. To minimize

shock hazard, the instrument chassis and cabinet must be connected to an electrical

ground. The power terminal and the power

cable must meet International Electrotechnical Commission (IEC) safety standards.

DO NOT OPERATE IN AN EXPLOSIVE

ATM OSP HER E

Do not operate the instrument in the presence

of flammable gases or fumes. Operation of any

electrical instrument in such an environment

constitutes a definite safety hazard.

DO NOT REMOVE COVERS

No operator serviceable parts inside. Refer

servicing to qualified personnel. To prevent

electrical shock do not remove covers.

IN CASE OF DAMAGE

Instruments that appear damaged or defective

should be made inoperative and secured

against unintended operation until they can be

repaired by qualified service personnel.

Return the instrument to a Keysight Technologies sales or service office for services and

repair to ensure that safety features are maintained.

USE ONLY THE SPECIFIC ACCESSORIES

Specific accessories satisfy the requirements

for specific characteristics for using the

instrument. Use the specific accessories,

cables, adapters, and so on for safety reasons.

Safety Symbols

The general definitions of safety symbols used

on equipment or in manuals are listed below.

Direct current.

Alternating current.

Earth ground terminal.

Protective conductor terminal. For

protection against electrical shock

in case of a fault. Used with field

wiring terminals to indicate the terminal which must be connected to

ground before operating equipment.

Frame or chassis terminal. A connection to the frame (chassis) of the

equipment which normally includes

all exposed metal structures.

Grounded terminal which indicates

the earth potential.

On supply.

Off supply.

Standby supply. The equipment will

be marked with this symbol is not

completely disconnected from AC

mains when power switch is in the

standby position.

In position of a bi-stable push

switch.

Out position of a bi-stable push

switch.

Hazardous voltage and potential for

electrical shock. Do not touch terminals that have this symbol when

the equipment is on.

Hot surface. Avoid contact. Surfaces are hot and may cause personal injury if touched.

Low temperature or freezing conditions. Avoid contact. Surfaces are

cold and may cause personal injury

if touched.

Heavy object. Lifting can cause

back injury. Use mechanical lifting

device to move.

Page 4

Caution, refer to accompanying

CAUTION

WARNING

CAT I

یࡈ߇ΰח

넩韥韥鱉꽺ꓩ끞쀍陲꾅ꩡ끞뼕ꑞ놶냱ꈑ

놶뼞ꫦ뵾閵ꌱꗐ냵韥韥ꈑ閵뇊끞쀍陲꾅

ꩡ끞뼍鱉陲끥놹볁閹ꫢ넍끥ꇙ閵넽걪鱽鲙

놶끞뼑鲙

ꩡ끞녅껽驩ꓭ냵ಯ꽺ꓩ끞ꗞꭖ뭪겕韥녅녡ರ꾅ꎁ

(*)

documentation. The equipment

will be marked with this symbol

when it is necessary for the user

to refer to the instruction manual.

Read operator's manual. To indicate that the operator's manual or

card should be read before continuing the operation.

Affixed to product containing

static sensitive devices--use antistatic handling procedures to

prevent electrostatic discharge

damage to component.

IEC Measurement Category I

The CE mark shows that the

product complies with all applicable European Directives.

The CSA mark is a registered

trademark of the Canadian Standards Association.

The RCM mark is a registered

trademark of the Australian Communications Authority. This signifies compliance with the

Australian EMC Framework Regulations under the terms of the

Radio communications Act.

This ISM device complies with Canadian

ICES-001.

Cet appareil ISM est conforme à la norme

NMB-001 du Canada.

This is the symbol for an Industrial, Scientific

and Medical, Group 1 Class A product. (CISPR

11)

Korea’s safety and EMC mark

China RoHS - Environmentally

Green Product Label

China RoHS - Product with Toxic

Substance 40 yr EPUP

The Chinese mark for paperbased packaging materials;

Paperboard and Corrugated

Fiberboard

Plastic Material Coding Identification

A CAUTION denotes a hazard. It calls attention

to an operating procedure or practice, that, if

not correctly performed or adhered to could

result in damage to the product or loss of

important data. Do not proceed beyond a

CAUTION notice until the indicated conditions

are fully understood and met.

A WARNING denotes a hazard. It calls attention to an operating procedure or practice,

that, if not correctly performed or adhered to,

could result in personal injury or death. Do not

proceed beyond a WARNING notice until the

indicated conditions are fully understood and

met.

Waste Electrical and

Electronic Equipment

(WEEE) Directive 2002/

96/EC

This product complies with the WEEE Directive (2002/96/EC) marking requirements. The

affixed label ind icates that you must not discard this electrical/ electronic product in

domestic household waste.

Product Category: With reference to the

equipment types in the WEEE directive Annex

1, this product is classified as a “Monitoring

and Control instrumentation” product.

Do not dispose in domestic household waste.

To return unwanted products, contact your

local Keysight office or visit the following

website for more information.

http://about.keysight.com/en/companyinfo/

environment/

South Korean EMC Declaration

Information to the user:

This equipment has been conformity assessed

for use in business environments. In a residential environment this equipment may

cause radio interference.

(*) This EMC statement applies to the equipment only for use in business environment.

Cleaning Precautions

To prevent electrical shock, disconnect the

Keysight Technologies instrument from mains

before cleaning. Use a dry cloth or one slightly

dampened with water to clean the external

case parts. Do not attempt to clean internally.

To clean the connectors, use alcohol in a wellventilated area. Allow all residual alcohol

moisture to evaporate, and the fumes to dissipate prior to energizing the instrument.

Page 5

Keysight M9614A/M9615A Precision Source/Measure Unit

Startup Guide

Contents

Introduction 7

Related Documentation 7

Step 1: Unpack and Inspect the Module 8

Electrostatic Discharge (ESD) Precautions 8

Before Unpacking 9

Inspect for Damage 9

Return the Module for Service 10

Step 2: Verify Shipment Contents 11

Step 3: Install the Software 12

Requirements 12

Installation Process 12

Step 4: Install the Module 13

Step 5: Verify Operation of the Module 15

To Check Communication 15

To Update the Firmware 16

To Perform Self Test 17

Front Panel Features 18

LED Indicators 19

Measurement Terminals 19

Trigger and Interlock Terminals 23

Connecting a DUT 24

2-Wire Connection or 4-Wire Connection 25

Page 6

F

loating 27

Guarding 28

Installing Interlock Circuit 29

Maintenance 32

Cleaning 32

Self Test 33

Self Calibration 34

Calibration 34

Function Overview 35

Limit (Compliance) 35

Operation Mode 35

Output Filter 36

Pulse Output 36

Sweep Output 36

Ranging Mode 37

Seamless Current Measurement Ranging 37

Trigger System 38

Measurement Time 39

Automatic Output On/Off 39

Output Off Mode 39

Interlock 40

Over Temperature Protection 41

Page 7

Introduction

Related Documentation

Introduction

The Keysight M9614A/M9615A 5-Channel Precision Source/Measure Unit (SMU)

delivers high channel density per a single slot module, wide output range, and

easy installation and configuration via the Keysight Connection Expert and a soft

front panel (SFP).

• M9614A PXIe 5-Channel SMU, 500 kSa/s, 100 pA, 30 V, 500 mA

• M9615A PXIe 5-Channel Precision SMU, 500 kSa/s, 10 pA, 30 V, 500 mA

Keysight also supplies software drivers that allow you to support the modules in

many popular PXI chassis and programming environments. You can control the

M9614A/M9615A using IVI drivers. LabVIEW driver is also available.

This Startup Guide, and the documentation listed below, can be found on the

Keysight web site. Visit www.keysight.com/find/m9614a or

www.keysight.com/find/m9615a to get the latest documents, specifications, and

software.

• Soft Front Panel User’s Guide

• IVI.NET Driver Reference

• IVI-C Driver Reference

• LabVIEW Driver Help

• Data sheet

• Configuration guide

Keysight M9614A/M9615A Startup Guide, Edition 3 7

Page 8

Step 1: Unpack and Inspect the Module

Step 1: Unpack and Inspect the Module

Keysight’s PXIe chassis and instrument modules are shipped in materials which

prevent static electricity damage. The modules should only be removed from the

packaging in an anti-static area ensuring that correct anti-static precautions are

taken. Store all modules in anti-static envelopes when not in use.

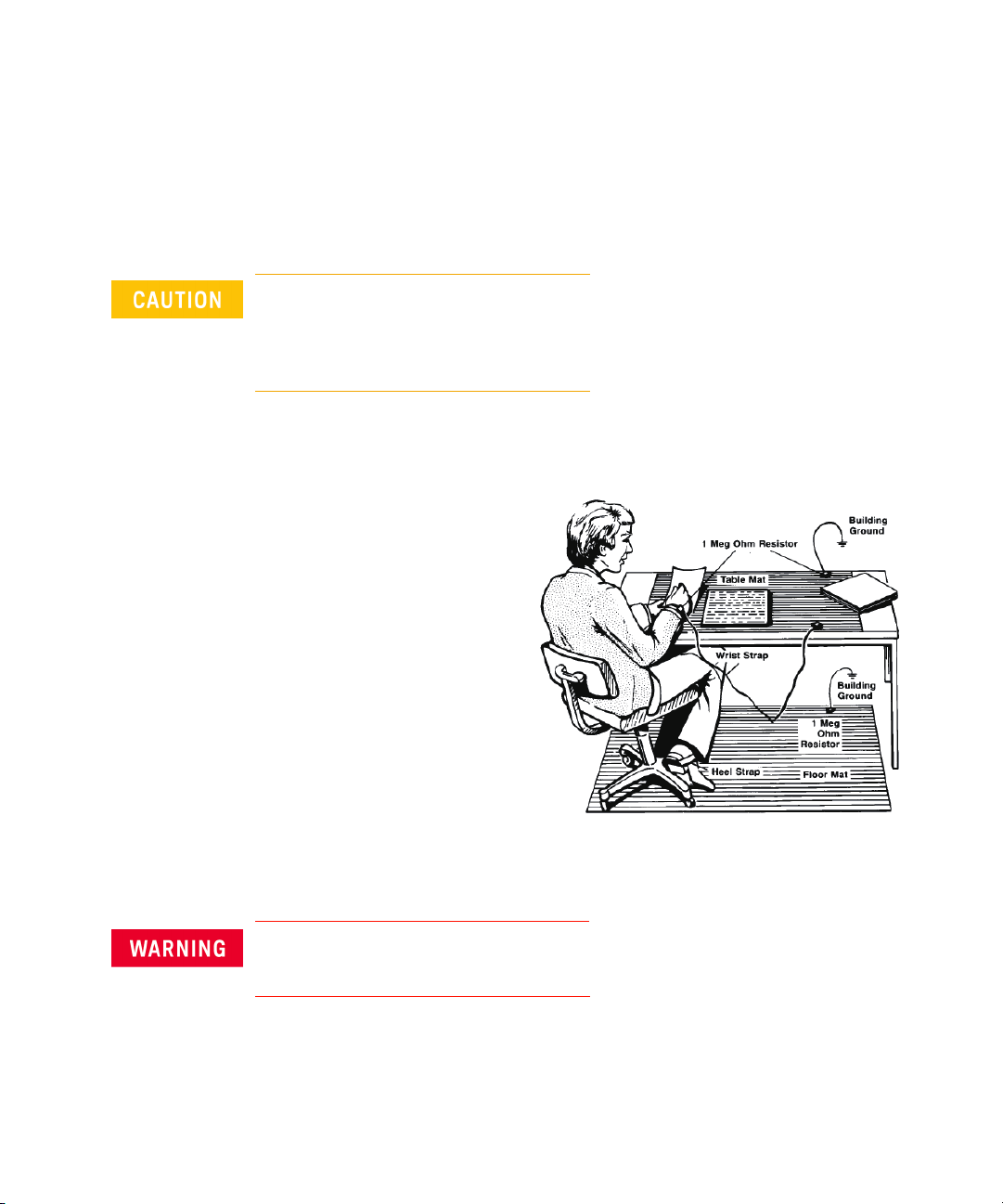

Electrostatic Discharge (ESD) Precautions

Electrostatic discharge (ESD) can

damage or destroy electronic

components. Use a static-safe

work station to perform all work

on electronic assemblies. This

figure shows a static-safe work

station using two types of ESD

protection.

• Conductive table mat and

wrist strap combination

• Conductive floor mat and heel

strap combination

Both types, when used together,

provide a significant level of ESD

protection. Of the two, only the table mat and wrist strap combination provides

adequate ESD protection when used alone. To ensure user safety, the static-safe

accessories must provide at least 1 M of isolation from ground.

DO NOT use these techniques for a static-safe work station when working on

circuitry with a voltage potential greater than 500 V.

8 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 9

Before Unpacking

Keysight M9614A/M9615A module is designed to meet IEC/EN61010-1 and must

only be installed in the PXIe chassis which is certified by a Nationally Recognized

Testing Laboratory. The PXIe chassis must already be installed on a static-safe

workbench so that you can install the module soon after unpacking.

Refer to the PXIe chassis manual for chassis installation and details.

Inspect for Damage

After unpacking a module, carefully inspect it for any shipping damage. Report

any damage to the shipping agent immediately, as such damage is not covered by

the warranty (see warranty information at the beginning of this document).

To avoid damage when handling a module, do not touch any exposed

components or connector pins.

Visit www.keysight.com/find/tips for information on preventing damage to your

Keysight equipment.

Step 1: Unpack and Inspect the Module

Keysight M9614A/M9615A Startup Guide, Edition 3 9

Page 10

Step 1: Unpack and Inspect the Module

Return the Module for Service

Should it become necessary to return a module for repair or service, follow the

steps below.

1. Review the warranty information shipped with your product.

2. Contact Keysight to obtain a Return Material Authorization (RMA) and return

address. For assistance in finding Keysight contact information, visit

www.keysight.com/find/assist.

3. Write the following information on a tag and attach it to the malfunctioning

equipment.

• Name and address of owner. A Post Office box is not acceptable as a return

address.

• Product model number (for example, M9615A)

• Product serial number (for example, MYXXXXXXXX). The serial number

label is located on the side of the module.

• Description of failure or service required

4. Carefully pack the module in its original ESD bag and packing carton. If the

original carton is not available, use bubble wrap or packing peanuts and place

the instrument in a sealed container and mark the container “FRAGILE.”

5. On the shipping label, write ATTENTION REPAIR DEPARTMENT and the RMA

number.

If any correspondence is required, refer to the product by serial number and model

number.

10 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 11

Step 2: Verify Shipment Contents

The following items are included in this shipment.

Table 1-1 Shipment Contents

Model number Description Quantity

Step 2: Verify Shipment Contents

M9614A

or M9615A

NA Quick Startup Poster 1

NA Certification of calibration (without test data) 1

NA Short bar 1

NA Connector-terminal block 2.5 mm 5-terminal 1

Consumable supplies of the M9614A/M9615A are shown in below.

Table 1-2 Consumable Supplies

Part number Description Quantity

M9601-87001 Short bar 5

M9615-87001 Connector-terminal block 2.5 mm 5-terminal 5

PXIe 5-Channel Precision Source/Measure Unit 1

Keysight M9614A/M9615A Startup Guide, Edition 3 11

Page 12

Step 3: Install the Software

Step 3: Install the Software

Install the software prior to installing the PXIe modules in the chassis so that

Keysight IO Libraries Connection Expert finds them.

Requirements

The followings are required for installing the M9614A/M9615A software.

• Controller (desktop PC, laptop PC, rackmount PC, or PXIe embedded

computer) installed with Keysight IO Libraries Suite

• Keysight PXIe chassis which has already been set up

For setting up the controller and the PXIe chassis, refer to the PXIe chassis

documentation.

Minimum 1.5 GB free space is required on the controller for installing the

M9614A/M9615A software.

Installation Process

Visit www.keysight.com/find/m9614a or www.keysight.com/find/m9615a to get

the latest version of the M9614A/M9615A software.

1. Copy the M9614A/M9615A software installer into the controller.

2. Launch the M9614A/M9615A software installer.

3. Follow the installer prompts to install the M9614A/9615A software.

4. Reboot the controller when prompted by the software installer.

If a firmware update is available, you can perform the firmware update by using

the M960x PXIe Source Measure Unit Soft Front Panel (the M960x SFP) after the

module installation. See “To Update the Firmware” on page 16.

12 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 13

Step 4: Install the Module

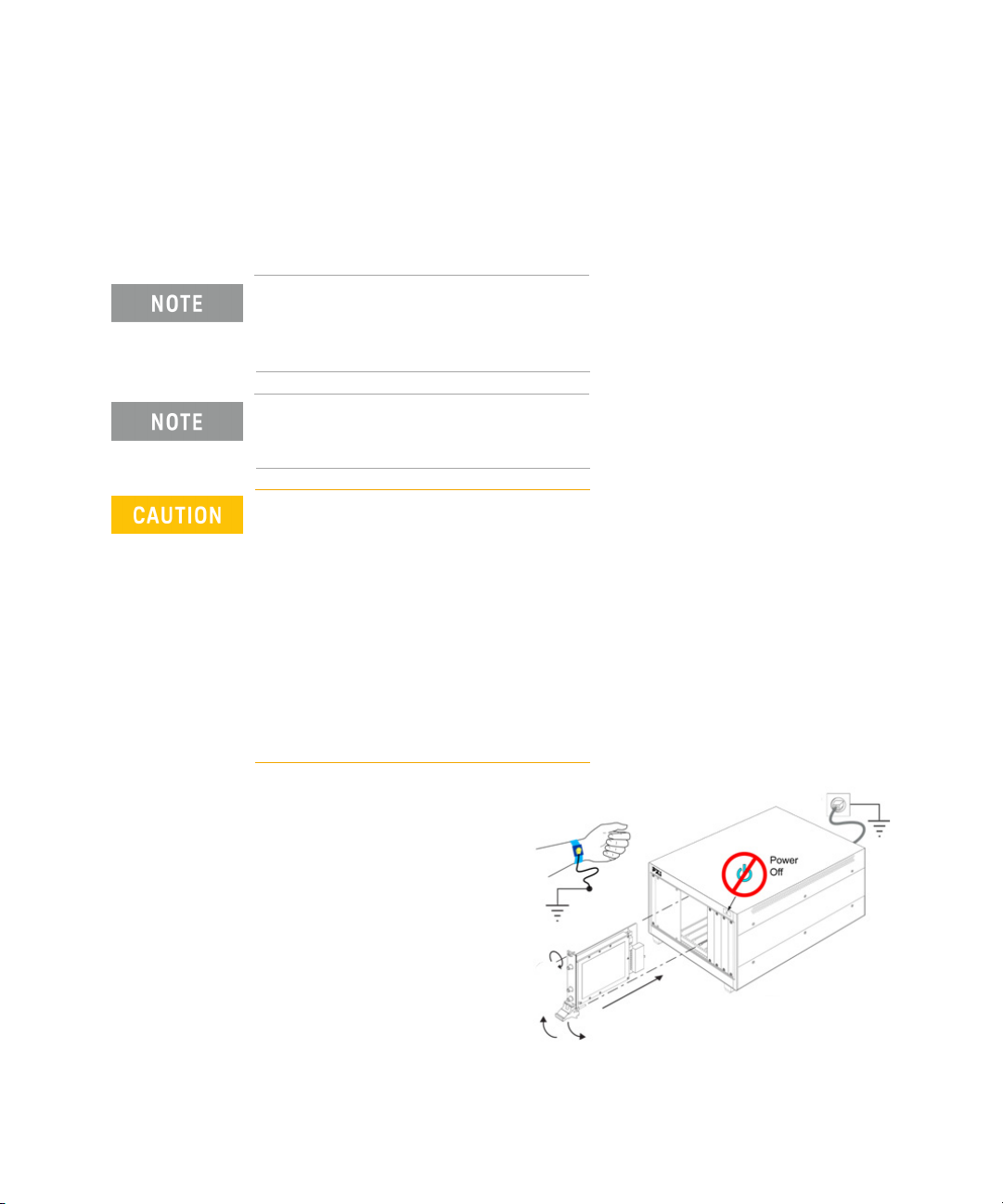

Current capacity of the PXIe chassis may restrict the module configuration. For

more information, refer to the M9614A/M9615A data sheet and the PXIe chassis

documentation.

The M9614A/M9615A module must be installed in the PXIe chassis certified by a

Nationally Recognized Testing Laboratory.

PXIe hardware does not support “hot-swap” (changing modules while power is

applied to the chassis) capabilities. Before installing or removing a module

to/from the chassis, power down the chassis to prevent damage to the module.

Place the chassis on a static-safe work station (see “Electrostatic Discharge

(ESD) Precautions” on page 8). And position it so that there is ample space

between the chassis fan intake and exhaust vents. Blockage by walls or

obstructions affects the air flow needed for cooling. Use slot blockers and filler

panels in empty slots to ensure proper operating temperatures.

Step 4: Install the Module

For more information about precautions and cooling, refer to the PXIe chassis

documentation.

Generic module installation is

shown below. It may not

reflect your module’s actual

size and chassis placement.

Install the leftmost module

first and continue installing

modules from left to right

according to the image

below.

Keysight M9614A/M9615A Startup Guide, Edition 3 13

Page 14

Step 4: Install the Module

Before the module installation, make sure that the controller is turned off.

Procedure 1. Make sure that the power cord is plugged into a grounded outlet to establish

earth ground and to prevent ESD.

2. Make sure that the chassis power switch is off.

3. If the chassis has multiple fan speed settings, ensure that the fans are set to

automatic. Do not set the fan speed to low or turn them off.

4. Remove the filler panel that covers the slot in which you want to install the

module.

5. Remove thread protectors from the top and bottom mounting screws of the

module.

6. Hold the module by the injector/ejector handle, and slide it into the slot.

• Install the module into the slot of the chassis by placing the module card

edges into the front module guides (top and bottom).

• Slide the module to the rear of the chassis and assure that the injector/

ejector handle is pushed down in the unlatched (downward) position.

• Slide the module completely into the chassis. When you begin to feel

resistance, push up on the injector/ejector handle to fully seat the module

into the chassis.

7. Latch the module by pulling up on the injector/ejector handle and secure the

front panel to the chassis using the module front-panel mounting screws.

8. Tighten the screws on the module front panel. Performance may suffer if the

screws are not securely tightened.

9. Install all chassis covers, filler panels, and air scoops after installing the

module. Also see CAUTION below.

For more information on the module installation, refer to the PXIe chassis

documentation.

Ensure that filler panels are installed in all empty slots. Missing filler panels will

impact cooling of the chassis and may cause RFI (radio frequency interference)

with other devices.

14 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 15

Step 5: Verify Operation of the Module

If you are using a remote controller (rackmount, desktop, or laptop PC), and you

have installed the interface cable, you must power up the chassis before you

power up the controller. When you power down your system, shut down the

controller before you power down the chassis.

To Check Communication

Perform the following procedure to check the communication between the

module and the controller.

1. Make sure that the chassis and the controller are turned off.

2. If you are using a remote controller, connect a PXIe cable between the chassis

and the controller.

3. Power up the chassis. Verify that the chassis fans are operating and free of

obstructions that may restrict airflow.

Step 5: Verify Operation of the Module

4. Power up the controller.

5. Check that the controller automatically recognizes the module in the device

manager; e.g. via Start menu > Windows System Tools > Control Panel >

Device Manager. The module should be visible in the device tree.

The controller might request a reboot. Reboot the controller, if requested.

6. Check if the module is also visible in the Keysight Connection Expert; e.g. via

Start menu > Keysight Connection Expert.

If something went wrong and the module is not shown in the PXIe section, it

may be necessary to reboot the controller once more.

Keysight M9614A/M9615A Startup Guide, Edition 3 15

Page 16

Step 5: Verify Operation of the Module

To Update the Firmware

If a firmware update is available, perform the following procedure to update the

firmware of the M9614A/M9615A modules.

1. Click Start menu > Keysight M960x Source Measure Unit > M960x SFP. The

Connect to Instrument dialog box will open.

2. In the list on the window, highlight the M9614A/M9615A modules to connect,

and click Connect to launch the Keysight M960x PXIe Source Measure Unit

Soft Front Panel (the M960x SFP).

3. Confirm that the Access indicator on the M9614A/M9615A front panel turns

green. Refer to Figure 1-1 and Table 1-3 for LED status.

4. Select Firmware Update... from the Utilities menu. The Firmware Update

dialog box will open.

5. Select the latest version of the firmware, if it is available.

If the select menu displays “No change”, there are no firmware updates.

6. Click Update at the bottom of the Firmware Update dialog box to start the

firmware update.

When the firmware is updated successfully, the message appears in the

Firmware Update dialog box.

7. Close the M960x SFP.

8. Restart your system; Power down the controller, then the chassis, and power

up the chassis, then the controller.

16 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 17

To Perform Self Test

You can perform the self test by using the M960x PXIe Source Measure Unit Soft

Front Panel (the M960x SFP).

Before performing the self test, turn the instrument output off and disconnect

cables from the measurement terminals.

1. Click Start menu > Keysight M960x Source Measure Unit > M960x SFP. The

Connect to Instrument dialog box will open.

2. In the list on the window, highlight the M9614A/M9615A modules to connect,

and click Connect to launch the M960x SFP.

3. Confirm that the Access indicator on the M9614A/M9615A front panel turns

green. Refer to Figure 1-1 and Table 1-3 for LED status.

4. Select Self Test... from the Utilities menu. The Self Test dialog box will open.

5. Click Run Self Test at the bottom of the Self Test dialog box to start the self

test. When the self test is completed, the results will be displayed in the Self

Test dialog box.

Step 5: Verify Operation of the Module

If the module fails the self test, it will be defective. See “Return the Module for

Service” on page 10 to return the modules to Keysight.

Use the module within the rating. If you input a signal above the rating, the

module will be damaged.

Keysight M9614A/M9615A Startup Guide, Edition 3 17

Page 18

Front Panel Features

Access indicator

Status indicator

Low force

Frame/chassis

Frame/chassis

Interlock low

External trigger 1

External trigger 2

Interlock high

Trigger and Interlock

(Frame/chassis)

High force

Low force

High sense

Low sense

Guard

Front Panel Features

This section describes the connectors and the indicators on the M9614A/M9615A

front panel.

• “LED Indicators”

• “Measurement Terminals”

• “Trigger and Interlock Terminals”

Figure 1-1 M9614A/M9615A Front Panel

18 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 19

LED Indicators

The M9614A/M9615A module has two LED indicators, Access and Status. These

indicators show the status of the module. See Tabl e 1-3 for the meanings. If the

emergency shutdown occurs, both indicators turn red.

Table 1-3 LED Statu s

LED LED state Status

Access Solid Green The module is turned on, the initialization is

Status Solid Green Output is enabled.

Front Panel Features

completed, and the operation is ready.

Flashing Green The “Identify PXIe module” feature is on.

Solid Red Emergency shutdown occurs.

Off The module is turned off.

Solid Red Emergency shutdown occurs.

Off Output is disabled.

Measurement Terminals

The M9614A/M9615A has the following measurement terminals. You can make

2-wire connection using the High force and Low force terminals or 4-wire

connection (Kelvin connection) using the High force, Low force, High sense and

Low sense terminals. The Kelvin connection is effective for high current

measurement.

Use a three-conductor AC power cord to connect the cabinet (if used) and the

instrument to an electrical ground (safety ground).

Utilisez un cordon d'alimentation CA à trois connecteurs pour connecter la

cabine (si utilisée) et l'instrument à la mise électrique à la terre (sol de sécurité).

Keysight M9614A/M9615A Startup Guide, Edition 3 19

Page 20

Front Panel Features

1: Ch1, HF

2: Ch1, LF

3: Ch2, HF

4: Ch2, LF

5: Ch3, HF

6: Ch3, LF

7: Ch4, HF

8: Ch4, LF

9: Ch5, HF

10: Ch5, LF

11: Ch1, Guard

12: Ch3, Guard

13: Ch5, Guard

14: Ch1, HS

15: Ch1, LS

16: Ch2, HS

17: Ch2, LS

18: Ch3, HS

19: Ch3, LS

20: Ch4, HS

21: Ch4, LS

22: Ch5, HS

23: Ch5, LS

24: Ch2, Guard

25: Ch4, Guard

HF, LF, HS, LS High force (HF), Low force (LF), High sense (HS), and Low sense (LS) terminals

(D-sub connector)

These terminals are used to connect a device under test (DUT). If you make the

2-wire connection, use only the HF and LF terminals, and open the HS and LS

terminals. The HS and LS terminals are used to make the 4-wire connection

(Kelvin connection).

The D-sub connector has 25 positions and consists of five-channel interfaces as

shown in the following figure and table. Each channel has five terminals: HF, LF,

HS, LS, and Guard. Although LF is shared by all channels, it is recommended to

use each HF terminal with the LF terminal of the same channel.

Table 1-4 Pin Assignment of the D-sub Connector

No. Name Description

1 Ch1, HF High force for channel 1

2 Ch1, LF Low force for channel 1

3 Ch2, HF High force for channel 2

4 Ch2, LF Low force for channel 2

5 Ch3, HF High force for channel 3

6 Ch3, LF Low force for channel 3

7 Ch4, HF High force for channel 4

20 Keysight M9614A/M9615A Startup Guide, Edition 3

8 Ch4, LF Low force for channel 4

9 Ch5, HF High force for channel 5

10 Ch5, LF Low force for channel 5

Page 21

Front Panel Features

No. Name Description

11 Ch1, Guard Guard for channel 1

12 Ch3, Guard Guard for channel 3

13 Ch5, Guard Guard for channel 5

14 Ch1, HS High sense for channel 1

15 Ch1, LS Low sense for channel 1

16 Ch2, HS High sense for channel 2

17 Ch2, LS Low sense for channel 2

18 Ch3, HS High sense for channel 3

19 Ch3, LS Low sense for channel 3

20 Ch4, HS High sense for channel 4

21 Ch4, LS Low sense for channel 4

22 Ch5, HS High sense for channel 5

23 Ch5, LS Low sense for channel 5

24 Ch2, Guard Guard for channel 2

25 Ch4, Guard Guard for channel 4

The maximum voltage which appears in HF, HS, and Guard is expressed by the

equation: 30.5 V + V

the frame/chassis ground. V

maximum voltage of V

floating

floating

. Where V

is 0 V in the grounded measurement, and the

floating

is the voltage between Low force and

floating

is 40 V in the floating measurement.

Never connect the Guard terminal to any output, including the frame/chassis

ground or any other guard terminal. Doing so will damage the M9614A/M9615A.

Keysight M9614A/M9615A Startup Guide, Edition 3 21

Page 22

Front Panel Features

LF and

frame/chassis

Low force terminal and frame/chassis terminal

These terminals are connected together by using the short bar when the

M9614A/M9615A is shipped from the factory. The short bar must be connected to

perform the grounded measurement.

If you want to perform the floating measurement, or if you want to connect

another instrument’s ground to the Low force, remove the short bar, and leave the

terminals open. Then use the Low force terminals on the D-sub connector to

connect the other instruments.

For the floating measurement, do not apply voltage over 40 V to the Low force

terminal. V

is limited to 40 V. Failure to heed this caution may result in damage to the

M9614A/M9615A.

Do not apply current or voltage to the frame/chassis terminal. Doing so will

damage the M9614A/M9615A.

, the voltage between Low force and the frame/chassis ground,

floating

22 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 23

Trigger and Interlock Terminals

The M9614A/M9615A has the following terminals for the trigger signal

input/output and the interlock circuit status detection.

The M9614A/M9615A has a 5-pin terminal block on the front panel. The pin

assignment of the terminal block is shown in Figure 1-1. You can connect these

terminals by using a connector-terminal block furnished with the

M9614A/M9615A and ferrule terminal cables such as Keysight PX0101A-001 or

PX0101A-002 BNC to ferrule terminal cable.

Trig 1 and Trig 2 External trigger 1 and 2 terminals

These terminals are used to make synchronization with other modules or

instruments. You can specify the direction (input/output), the polarity (positive/

negative), and the pulse width of the trigger signal. The output trigger is

push-pull, and the trigger level is 0 V to 3.3 V at high impedance. The input trigger

should be the TTL level.

Intlk Interlock terminals

These terminals are used to connect an interlock circuit which is installed in your

test fixture or shielding box. The interlock circuit can be created by using two

mechanical switches and wire as shown in Figure 1-5. If the interlock terminals are

opened or the interlock circuit is opened, the output voltage is limited to 42 V or

less as you specified.

Front Panel Features

The interlock circuit is not necessary for the M9614A/M9615A because the

maximum output voltage is 30 V, but can be used to limit the output voltage to

the specified value. If you set the limit to 0 V, the interlock function will be same as

inhibit control.

For more details, see “Installing Interlock Circuit” on page 29.

Do not connect the interlock terminals to anything other than the interlock

circuit. Applying current or voltage to the terminals may damage the

M9614A/M9615A.

Keysight M9614A/M9615A Startup Guide, Edition 3 23

Page 24

Connecting a DUT

Connecting a DUT

This section describes how to connect a device under test (DUT) to the

M9614A/M9615A, and includes the following descriptions.

• “2-Wire Connection or 4-Wire Connection”

• “Floating”

• “Guarding”

To avoid touching the end of the extension cable or the terminal area with the

DUT, cover over the conductors with insulator. Also it is important to protect the

terminal area by using the grounded shield cover and such.

To prevent electrical shock and DUT damage, do not connect or disconnect the

DUT while the instrument is applying voltage or current.

When you touch the DUT after the measurement, devise a countermeasure of

residual charge and heat to prevent electrical shock and burn. Use gloves and

any tool. Also have enough time for discharge and radiation.

Afin d'éviter de toucher l'extrémité du câble d'allongement ou l'aire de la borne

avec l'appareil mis sous tension (MST), couvrez les conducteurs avec l'isolant. En

outre, il est important de protéger la zone de la borne en utilisant le couvercle

d'écran à la mise à terre, ou tout autre élément.

Afin d’éviter toute décharge électrique et dommage MST, ne branchez ou

déconnectez pas la sortie MST alors que la source de sortie est appliquée.

Lorsque vous touchez le MST après la mesure, élaborez une contre-mesure de la

charge résiduelle et du chauffage afin d'éviter tout choc électrique et toute

brûlure. Utilisez des gants et des outils. Prévoyez également d u temps pour la

décharge et la radiation.

Set the instrument output off when changing the connections. If not, the DUT may

be damaged.

24 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 25

Using the interlock circuit

The M9614A/M9615A provides an interlock function. If the interlock terminals are

open, the M9614A/M9615A cannot apply a high voltage over the limit which is

programmable, within42 V.

The interlock circuit is not necessary for the M9614A/M9615A because the

maximum output voltage is 30 V, but can be used to limit the output voltage to

the specified value.

For more details, see “Installing Interlock Circuit” on page 29.

Generally, environmental conditions, such as electromagnetic environment, have

a negative impact on the performance of the instrument. Use coaxial cables and

shielding technique to minimize the impact.

2-Wire Connection or 4-Wire Connection

When connecting a device under test (DUT), you can choose the connection type

either 2-wire connection or 4-wire connection.

Connecting a DUT

If you want to simplify the connection, use 2-wire connection by connecting the

force terminals only, while the sense terminals remain open.

To make 4-wire connection, well known as Kelvin connection, use both force and

sense terminals. Connecting the force and sense lines together at the terminal of

the DUT minimizes the measurement error by the residual resistance of the test

leads or cables. This connection is effective for low resistance measurements and

high current measurements.

The M9614A/M9615A module has five-channel interfaces, and each channel has

five terminals: HF, LF, HS, LS, and Guard. Although LF is shared by all channels, it

is recommended to use each HF with the LF of the same channel.

Keysight M9614A/M9615A Startup Guide, Edition 3 25

Page 26

Connecting a DUT

A

V

High force

2-wire connection

+

+

-

-

Low force

Frame/chassis

A

V

High force

4-wire connection

+

+

-

-

Low force

Frame/chassis

High sense

Low sense

Short bar

Short bar

DUT

High force

Low force

HF

HS

LS

LF

HF

HS

LS

LF

2-wire connection

DUT

High force

High sense

Low force

4-wire connection

Low sense

Figure 1-2 Simplified SMU Circuit Diagram

Figure 1-3 2-Wire Connection and 4-Wire Connection

26 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 27

Floating

Connecting a DUT

When the M9614A/M9615A is shipped from the factory, the Low force terminal is

connected to the frame/chassis terminal by using the short bar. The short bar

must be connected to perform the grounded measurement.

If you want to perform the floating measurement or if you want to connect another

instrument’s ground to the Low force, remove the short bar, and leave the

terminals open. Then use the Low force terminals on the D-sub connector to

connect the other instrument.

For the floating measurement, do not apply voltage over 40 V to the Low force

terminal. Doing so will damage the M9614A/M9615A.

Do not apply current or voltage to the frame/chassis terminal. Doing so will

damage the M9614A/M9615A.

To prevent electrical shock, do not touch any of measurement circuit at any time

while a floating measurement is in progress. Also use accessories that comply

with IEC 61010-031. All terminals and the extended conductors must be isolated

by using insulation caps, sleeves, etc.

Afin d’éviter toute décharge électrique, ne touchez aucune mesure de circuit à

tout moment lorsque la mesure de flotte est en cours. Utiliser également des

accessoires qui sont conformes à la norme IEC 61010-031. Toutes les bornes et

les conducteurs prolongés doivent être isolés en utilisant des bouchons

d'isolation, des manchons, etc.

Keysight M9614A/M9615A Startup Guide, Edition 3 27

Page 28

Connecting a DUT

A

DUT

x1

M9614A/M9615A

Low force

High force

Guard

Guard shield

D-sub connector

Custom cable

Shield (chassis)

Insulator

Short bar

Guarding

Guarding reduces the leakage current between the instrument and a DUT. This is

important when you perform low current measurements.

The overview of the guard technique for the grounded measurement is shown in

Figure 1-4. The guard shield is necessary to prevent the leakage current in the

measurement environment: extension cable, test fixture, shielding box, and so on.

It is important to use a triaxial cable such as Keysight PX0102A-001 Low noise

triaxial cable (1.5 m). The buffer amplifier keeps the potential of the Guard at the

same potential as the High force, so that the current does not flow between the

core and the inner shield. Therefore ideally, the current measured by the

instrument is the same as the current at the DUT terminal because there is no

leakage current. For several connection examples such as the floating

measurement, refer to the configuration guide.

Figure 1-4 Guard Technique for Grounded Measurement

28 Keysight M9614A/M9615A Startup Guide, Edition 3

If the Low force terminal connects to the outer shield of the triaxial cable in the

grounded measurement, the outer shield must be electrically isolated from the

shield of your test fixture or shielding box. Do not connect the outer shield to

anything other than the low terminal of DUT.

Never connect the guard shield to any output, including the frame/chassis

ground or any other guard terminal. Doing so will damage the M9614A/M9615A.

Page 29

Installing Interlock Circuit

Shielding box

Access door

Mechanical switches

Connector-terminal

block

Interlock high

Interlock low

(Frame/chassis)

BNC

Keysight PX0101A-001 or equivalent

Insulator

Ferrule terminal

To use the interlock function, the M9614A/M9615A interlock terminals must be

connected to the interlock circuit installed in the measurement environment such

as the shielding box. The interlock circuit is a simple electric circuit as shown in

Figure 1-5. The circuit electrically opens when the access door is opened, and

closes when the door is closed.

The M9614A/M9615A module cannot apply high voltage over the limit when the

interlock terminals are open. The limit value, or Interlock threshold voltage level, is

programmable, within 42 V. The interlock circuit is not necessary for the

M9614A/M9615A because the maximum output voltage is 30 V, but can be used

to limit the output voltage to the specified value. If you set the threshold level to

0 V, the interlock function will be same as inhibit control.

You can specify the threshold level by using the M960x PXIe Source Measure Unit

Soft Front Panel. Select M960x Settings... from the Utilities menu, and type the

value into the box.

For information on setting the threshold level by programming, refer to the driver

references.

Installing Interlock Circuit

Figure 1-5 Interlock Circuit

Keysight M9614A/M9615A Startup Guide, Edition 3 29

Do not connect the interlock terminals to anything other than the interlock

circuit. Applying current or voltage to the terminals may damage the

M9614A/M9615A.

Page 30

Installing Interlock Circuit

Requirements

• Mechanical switch (Keysight N1254A-402 or equivalent), 2 ea.

• Connector-terminal block 2.5 mm 5-terminal, 1 ea.

• BNC to ferrule terminal cable (Keysight PX0101A-001 (1.5 m), PX0101A-002

(3.0 m), or equivalent), 1 ea.

• BNC connector (jack to soldering terminals), 1 ea.

• Connection wires

Procedure 1. Mount two mechanical switches onto your shielding box, so that the switches

close when the access door is closed, and open when the access door is

opened. See Figure 1-6 for the switch dimensions.

2. Mount a BNC connector onto your shielding box. Be sure that the outer shield

of the BNC connector is electrically isolated from the shielding box.

3. Use a wire, and connect the two switches in series between the soldering

terminals of the BNC connector as shown in Figure 1-5.

4. Connect the connector-terminal block to the M9614A/M9615A.

5. Connect the BNC to ferrule terminal cable to the interlock terminals of the

M9614A/M9615A.

6. Connect the BNC to ferrule terminal cable to the BNC connector on the

shielding box.

You can also connect the mechanical switches directly to the connector-terminal

block by using connection wires and ferrule terminals.

30 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 31

Installing Interlock Circuit

3.1

35.6

8.1

14

NC

NO

COM

6.4

22.2

27.8

2.8

6.3 15.9 18.8

4.7510.3 4.3

2.8

2.8

3.2

10.3

2.8

3.1

Switch off

Units: mm

15.3

Figure 1-6 Dimension of the Interlock Switch (Keysight N1254A-402)

Keysight M9614A/M9615A Startup Guide, Edition 3 31

Page 32

Maintenance

Maintenance

This section describes the maintenance tasks of the M9614A/M9615A.

• “Cleaning”

• “Self Test”

• “Self Calibration”

• “Calibration”

Cleaning

To prevent electrical shock, disconnect the chassis from the mains before

cleaning.

Use a dry soft cloth or a soft cloth slightly dampened with water or a mild soap

and water solution to clean the external surfaces of the chassis, modules, and

accessories. Do not use detergents or chemical solvents.

Do not attempt to clean internally.

To clean the connectors, use alcohol in a well-ventilated area. Allow all residual

alcohol moisture to evaporate, and the fumes to dissipate prior to energizing the

instrument.

SHOCK HAZARD

To avoid any risk of electric shock, unplug the PXIe chassis before cleaning.

RISQUE D'ÉLECTROCUTION

Pour éviter tout risque de choc électrique, débranchez le châssis PXIe avant le

nettoyage.

Do not use too much liquid in cleaning the PXIe chassis. Water can enter the

PXIe chassis panels and damage sensitive electronic components. Make sure

that the PXIe chassis is completely dry before reconnecting the power cord.

32 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 33

Self Test

Maintenance

Keysight M9614A/M9615A provides the self test function to check the operation.

It is recommended to perform the self test for the following condition or purpose.

• If emergency shutdown occurs.

In this condition, both the Access and Status indicators turn red. The shutdown

condition will be solved after passing the self test.

• If you feel that the instrument may be defective.

• For preventive maintenance.

Before performing the self test, turn the instrument output off and disconnect

cables from the measurement terminals.

To per for m

self test

See “To Perform Self Test” on page 17.

Keysight M9614A/M9615A Startup Guide, Edition 3 33

Page 34

Maintenance

Self Calibration

Keysight M9614A/M9615A provides the self calibration function to maintain the

measurement performance. If the environmental temperature changes 5 C or

more, perform the self calibration. This is effective for the accurate measurements

by minimizing the effect of thermal drift.

For measurements with the specified accuracy, the self calibration should be

performed within the last 24 hours and after 40 minutes of warm-up. Refer to the

M9614A/M9615A data sheet for more details of the specification conditions.

Before performing the self calibration, turn the instrument output off and

disconnect cables from the measurement terminals.

To per for m

self calibration

Calibration

1. Click Start menu > Keysight M960x Source Measure Unit > M960x SFP. The

Connect to Instrument dialog box will open.

2. From the list on the window, highlight the M9614A/M9615A modules to

connect and click Connect to launch the Keysight M960x Source Measure Unit

Soft Front Panel.

3. Confirm that the Access indicator on the M9614A/M9615A front panel turns

green. Refer to Figure 1-1 and Table 1-3 for LED status.

4. Select Self Calibration... from the Utilities menu on the soft front panel to open

the Self calibration dialog box.

5. Click Run Self Cal....

Calibration and adjustments must be performed periodically so that the

instrument can meet its specifications, and keep good condition. It is

recommended to perform the calibration once a year at least. For the calibration

and adjustments, contact Keysight Technologies. Trained service personnel will

perform the calibration and adjustments.

34 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 35

Function Overview

This section introduces major functions of the M9614A/M9615A. For more

information, refer to the IVI driver references and Soft Front Panel User’s Guide.

• “Limit (Compliance)”

• “Operation Mode”

• “Output Filter”

• “Pulse Output”

• “Sweep Output”

• “Ranging Mode”

• “Seamless Current Measurement Ranging”

• “Trigger System”

• “Measurement Time”

• “Automatic Output On/Off”

Function Overview

• “Output Off Mode”

• “Interlock”

• “Over Temperature Protection”

Limit (Compliance)

Limit or compliance is the output limiter for preventing damage to a device under

test (DUT) due to overcurrent or overvoltage. Voltage compliance is for current

output channels, and current compliance is for voltage output channels.

Operation Mode

The M9614A/M9615A module provides two operation modes for source output.

The following modes can be selected depending on DUT or application.

Standard Default mode

Power Supply Transient speed priority mode

This mode can be used for a voltage source with high slew rate.

Keysight M9614A/M9615A Startup Guide, Edition 3 35

Page 36

Function Overview

DC

t

V or I

Pulse

Constant Linear single sweep Linear double sweep List sweep

Output Filter

Pulse Output

Sweep Output

The output filter assures clean source output with no spikes or overshoot.

However, using a filter may increase the settling time. You can enable or disable

this function.

The M9614A/M9615A module has the function to apply a pulsed voltage or

current as shown in Figure 1-7. You can control the pulse output and

measurement timing by setting trigger parameters.

The M9614A/M9615A module has the function to apply a sweep voltage or

current in several shapes as shown in Figure 1-7 and can perform the

measurement for each sweep step. You can control the sweep output and

measurement timing by setting trigger parameters.

List Sweep

The M9614A/M9615A module also has the function to apply an arbitrary

waveform output by specifying a list of output values and measure voltage or

current at each output value. The source output and the measurement are

performed at the specified interval. The minimum interval is 4 s.

Figure 1-7 Variety of Sweep Outputs

36 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 37

Ranging Mode

The following ranging modes are available for performing source output.

FIXED Fixed range

AUTO Auto range

BEST Best range

The following table summarizes which ranging mode can be used in each case.

Table 1-5 Ranging M ode

Function Overview

Only the specified range is used. This mode is available for all

source output.

The range is automatically selected to provide the best

resolution of the source output value. It is possible to specify

the minimum range in the auto range operation. This mode is

available for source output except sweep output.

The minimum range covering the whole sweep output is

automatically selected. This mode is available for linear sweep

output.

FIXED AUTO BEST

Output except sweep

Linear sweep output

List sweep output

Seamless Current Measurement Ranging

The M9614A/M9615A module provides the seamless current measurement

ranging. This function allows you to measure current with the best resolution

without changing ranges.

In this function, current measurement is performed by using multiple ranges

simultaneously, and then the value with the best resolution is automatically

selected. The multiple ranges involved in the measurement are determined based

on an internal algorithm that uses the current limit (compliance) and the lowest

current range settings.

Keysight M9614A/M9615A Startup Guide, Edition 3 37

Page 38

Function Overview

Trigger System

Trigger system can be used to control the timing of the source output and the

measurement.The M9614A/M9615A supports the ARM-TRIGger model in 1999

SCPI Command Reference. This trigger model is applied to two device actions:

transient (Source) and measurement (Measure). They can be operated

independently or simultaneously.

PXI Trigger and External Trigger

The M9614A/M9615A has two trigger terminals on the front panel, External

trigger 1 and 2, as described in “Trigger and Interlock Terminals” on page 23. In

addition to the external trigger terminals, eight trigger lines on the PXIe chassis

backplane are available.

The external triggers and the trigger lines on the PXIe chassis backplane can be

used as trigger sources or outputs of the trigger system to synchronize the

M9614A/M9615A with other modules or instruments.

Trigger Input

The following trigger source settings are available.

• AUTO

Trigger source best suitable for the present Operation Mode. This trigger mode

is automatically selected by the internal algorithm.

• TIMER

Triggers at the specified interval

• EXT1 or EXT2

Triggers synchronizing with a signal from an external trigger

• PXI0, PXI1, PXI2, PXI3, PXI4, PXI5, PXI6, or PXI7

Triggers synchronizing with a signal from the PXIe chassis backplane

Trigger Output

The M9614A/M9615A provides the trigger output at the specified timing. Trigger

output terminal can be selected from the external trigger terminals on the front

panel (EXT1 and EXT2) and the trigger lines on the PXIe chassis backplane (PXI0,

PXI1, ..., PXI7).

38 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 39

Measurement Time

Measurement time depends on aperture time, measurement range, and other

measurement conditions. It can be expressed by the following equation.

Measurement time = Aperture time + Overhead time

Aperture time is the time required to acquire the measurement data. You can

specify this value. For accurate and reliable measurement, the aperture should be

increased.

Overhead time includes other factors such as range change or data

compensation. This value depends on the measurement conditions and cannot be

specified.

Automatic Output On/Off

The M9614A/M9615A module has output on/off settings when the trigger system

changes the status. You can enable or disable these settings independently.

Auto Output On Channel output is automatically turned on just before the

trigger system is initiated.

Auto Output Off Channel output is automatically turned off when all triggers

changes the status from busy to idle.

Function Overview

Output Off Mode

The output off mode is effective immediately after the source output is turned off.

The mode should be specified before enabling the source output. The following

settings are available for the output off mode.

High impedance Output switch: off

Voltage source setup is not changed.

Current source setup is not changed.

Normal Output switch: off

Source function: Voltage source

Output voltage: 0 V

Current compliance: 100 A at the 100 A range

Keysight M9614A/M9615A Startup Guide, Edition 3 39

Page 40

Function Overview

Interlock

Zero Source function: Voltage source

Output voltage: 0 V

Current compliance: 100 A at the 100 A range

The output off mode is ignored if an emergency condition such as interlock open

and over temperature protection is detected. Then the output voltage is

immediately set to 0 V, and the output switch is set to off.

The interlock function is designed to prevent electrical shock when you touches

the measurement terminals and also to prevent DUT damages caused by

undesirable high voltage.

The M9614A/M9615A module cannot apply high voltage over the interlock

threshold voltage level when the interlock terminals are open. The interlock

threshold voltage level is programmable within 42 V, and the default value is

42 V. Set the threshold voltage to the voltage you think still safe. If the threshold

voltage level is set to 0 V, the interlock function is same as inhibit control.

For details on installing the interlock circuit, see “Installing Interlock Circuit” on

page 29.

The interlock function works as follows.

• When the interlock terminals are open, the maximum output is limited to the

threshold voltage level.

• When the interlock terminals are shorted, the module can apply the maximum

output voltage of the channel.

• If the interlock terminals are opened in a high voltage condition over the

threshold voltage level, the output voltage is immediately set to 0 V, and the

output switch is set to off.

40 Keysight M9614A/M9615A Startup Guide, Edition 3

Page 41

Over Temperature Protection

The over temperature protection is effective in preventing damages to the module

due to high temperature. When the over temperature is detected by the internal

sensor, emergency shutdown occurs; the output voltage is immediately set to 0 V,

and the output switch is set to off.

If the emergency shutdown occurs, perform the self test. See “Self Test” on page

33.

Function Overview

Keysight M9614A/M9615A Startup Guide, Edition 3 41

Page 42

This information is subject to change without notice.

© Keysight Technologies 2020

Edition 3, October 2020

*M9615-90000*

M9615-90000

www.keysight.com

Loading...

Loading...