Page 1

Keysight

E2613/4/5/6A & E2643/4A

Wedge Probe Adapters

User’s Guide

Page 2

Notices

CAUTION

WARNING

© Keysight Technologies, Inc. 1997 - 2014

No part of this manual may be reprod uced in any form

or by any means (including electronic storage and

retrieval or translation into a foreign language) without prior agreement and written consent from Keysight Technologies, Inc. as governed by United States

and international copyright laws.

Manual Part Number

E2613-92010

Second Edition, October 2014

Printed in Malaysia

Published by:

Keysight Technologies, Inc.

1400 Fountaingrove Parkway

Santa Rosa, CA, 95403

Warranty

The material contained in this document is provided

“as is,” and is subject to being changed, without

notice, in future editions. Further, to the maximum

extent permitted by applicable law, Keysight disclaims all warranties, either express or implied, with

regard to this manual and any information contained

herein, includ ing but not limited to the impl ied warranties of merchantability and fitness for a particular

purpose. Keysight shall not be liable for errors or for

incidental or consequential damages in connection

with the furnishing, use, or performance of this document or of any information contained herein.

Should Keysight and the user have a separate written agreement with warranty terms covering the

material in this document that conflict with these

terms, the warranty terms in the separate agreement

shall control.

defined in FAR 52.227-19 (June 1987) or any equivalent agency regulation or contract clause. Use, duplication or disclosure of Software is subject to Keysight

Technologies’ standard commercial license terms,

and non-DOD Departments and Agencies of the U.S.

Government will receive no greater than Restricted

Rights as defined in FAR 52.227-19(c)(1-2) (June

1987). U.S. Government users will receive no greater

than Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2) (November

1995), as applicable in any technical data.

Safety Notices

A CAUTION notice denotes a hazard. It calls

attention to an operating procedure, practice,

or the like that, if not correctly performed or

adhered to, could result in damage to the product or loss of important data. Do not proceed

beyond a CAUTION notice until the indicated

conditions are fully understood and met.

A WARNING notice denotes a hazard. It calls

attention to an operating procedure, practice,

or the like that, if not correctly performed or

adhered to, could result in personal injury or

death. Do not proceed beyond a WARNING

notice until the indicated conditions are fully

understood and met.

Technology Licenses

The hardware and/or software described in this document are furnished under a license and may be used

or copied only in accordance with the terms of such

license.

Restricted Rights Legend

If software is for use in the performance of a U.S. Government prime contract or subcontract, Software is

delivered and licensed as “Commercial computer

software” as defined in DFAR 252.227-7014 (June

1995), or as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer software” as

2

Page 3

Contents

Introduction / 5

Electrical Characteristics / 7

Critical Connection Information / 8

Differences in Supported Surface-Mounted Devices / 10

Connecting the Adapter to an IC / 13

Common Ground Plane on 16-Pin Adapters / 14

Connecting the Adapter to an Instrument / 16

Keysight Oscilloscopes and Logic Analyzers / 16

Other Instruments / 17

Cleaning an Adapter / 18

Repairing an Adapter / 19

Typical Bent Wedge Segments / 19

Severely Bent Wedge Segments / 20

Pinched Air Gap / 21

3

Page 4

4

Page 5

Keysight E2613/4/5/6A & E2643/4A

User’s Guide

Introduction

The wedge probe adapters can be installed on thin quad flat pack

(TQFP) or plastic quad flat pack (PQFP) surface-mounted

integrated circuits. This probing solution provides accurate,

mechanically non-invasive contact to the TQFP/PQFP package

pins. Accessories such as flexible leads enable you to connect to

various oscilloscope probes and logic analyzers. When the

guidelines documented in “Critical Connection Information" on

page 8 are followed, the wedge probe adapter will provide you

with many cycles of problem-free probing.

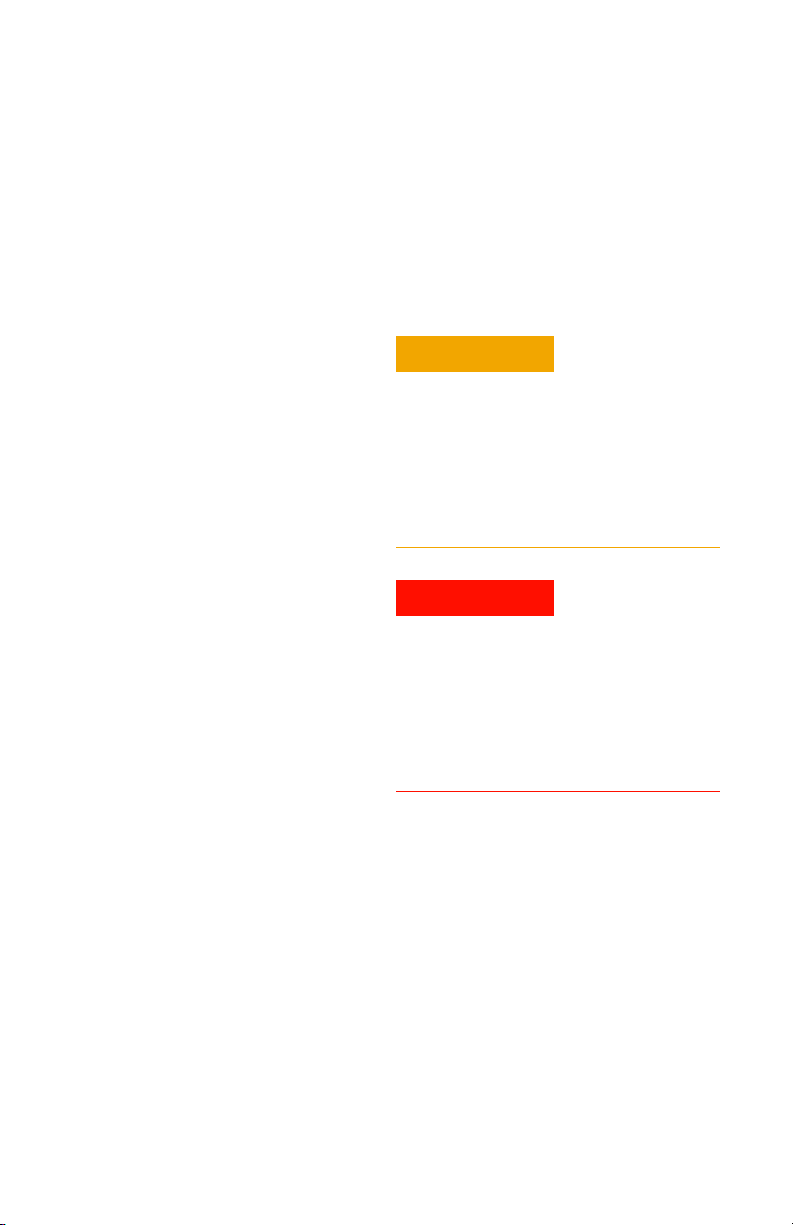

Figure 1 Adapters Connected to TQFP/PQFP Integrated Circuits

5

Page 6

Tabl e 1 shows the available adapter configurations of pin spacing

and signal probing. Each model includes a user’s guide and a

magnifying lens. The E2643/4A 16 signal adapters include 3

removable jumpers (P/N 1258-0141 for quantity of 1 jumper). The

adapters can be connected:

- Directly to 1145A and 1155A active probes.

- 1160/1/2/3/4/5A passive probes via provided dual-lead

adapter.

- N2870A series passive probes via N2877A/N2879A accessory

kits.

Tab le 1 Available Wedge Probe Adapters

Introduction

IC Pin

Adapter

E2613A 0.5 mm 3 1

E2614A 0.5 mm 8 1

E2615A 0.65 mm 3 1

E2616A 0.65 mm 8 1

E2643A 0.50 mm 16 1

E2644A 0.65 mm 16 1

Spacing

Signal

Count

Qty Image

6

Page 7

Electrical Characteristics

Electrical Characteristics

Tab le 2 Electrical Characteristics

Item Characteristic

Operating Voltage < 40V (dc + peak ac)

Operating Current 0.5A maximum

Capacitance Between Contacts 2 pF typical (all except E2643/4A)

4.33 pF typical at 1 MHz (E2643/4A)

Self-inductance 15 nH typical (all except E2643/4A)

37 nH typical at 1 MHz (E2643/4A)

Cross Coupling –31 dB typical at 100 MHz (E2643/4A)

Contact Resistance < 0.1 Ohm

7

Page 8

Critical Connection Information

Pins

IC Pin

Wedge Segment

Conductors

Figure 2 shows the adapter’s wedge segments properly inserted

between the IC pins. Two conductors in each wedge segment

make contact with the adjacent IC pins. The conductors are

connected to the adapter’s output pins. The adapters are

designed for an IC pin spacing of either 0.5 mm or 0.65 mm.

Adapters with 0.5 mm spacing are marked with orange and

adapters with 0.65 mm spacing are marked with green.

Figure 2 Adapter Conductors Inserted Between IC Pins

Critical Connection Information

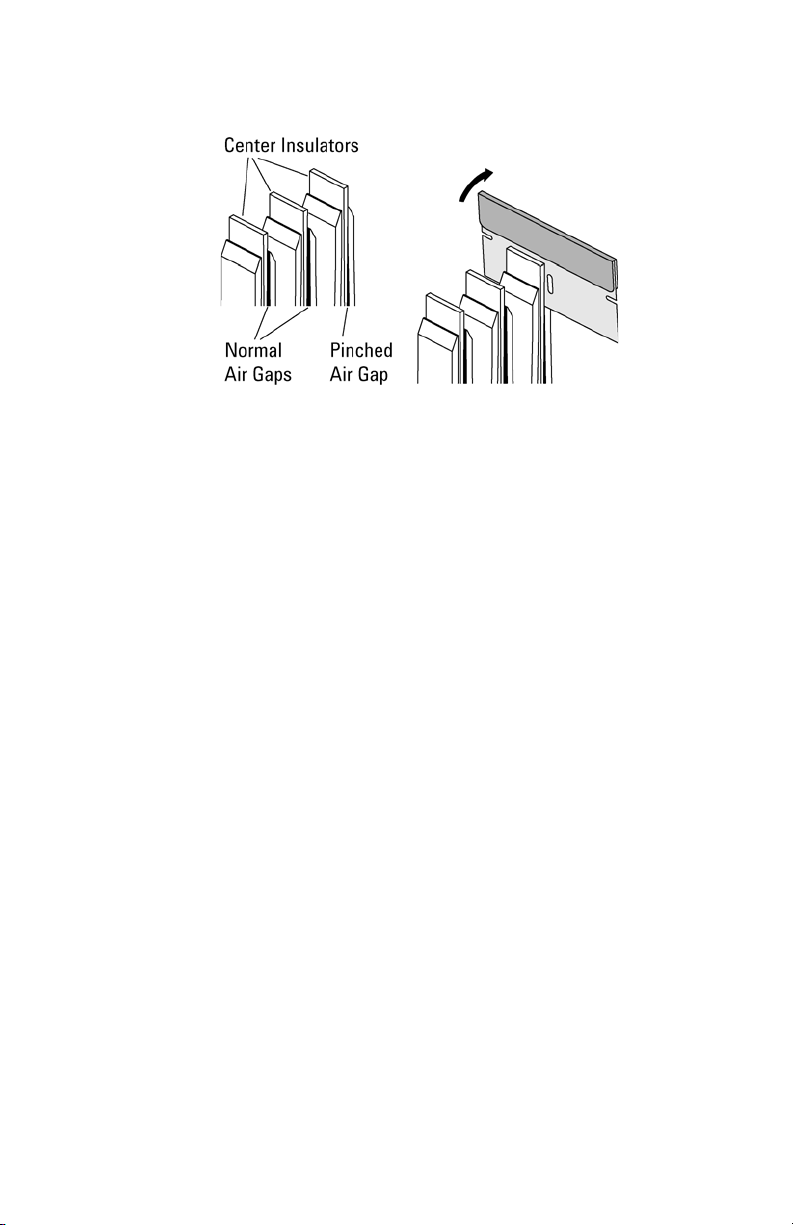

Figure 3 shows that wedge segments consists of two separate

conductors insulated from each other by a center insulator. A

shortened insulating adhesive between the center insulator and

the outer conductors creates an air gap at the tip of the wedge

segment. The air gap allows the conductors to conform as the

adapter is inserted between the IC pins.

Figure 3 Cross-Section View of Wedge Segment

The 3-signal adapter has 4 wedge segments that form 3 gaps. The

8-signal adapter has 9 wedge segments and 8 gaps. The

16-signal adapter has 17 wedge segments and 16 gaps.

8

Page 9

Critical Connection Information

CAUTION

CAUTION

CAUTION

CAUTION

NOTE

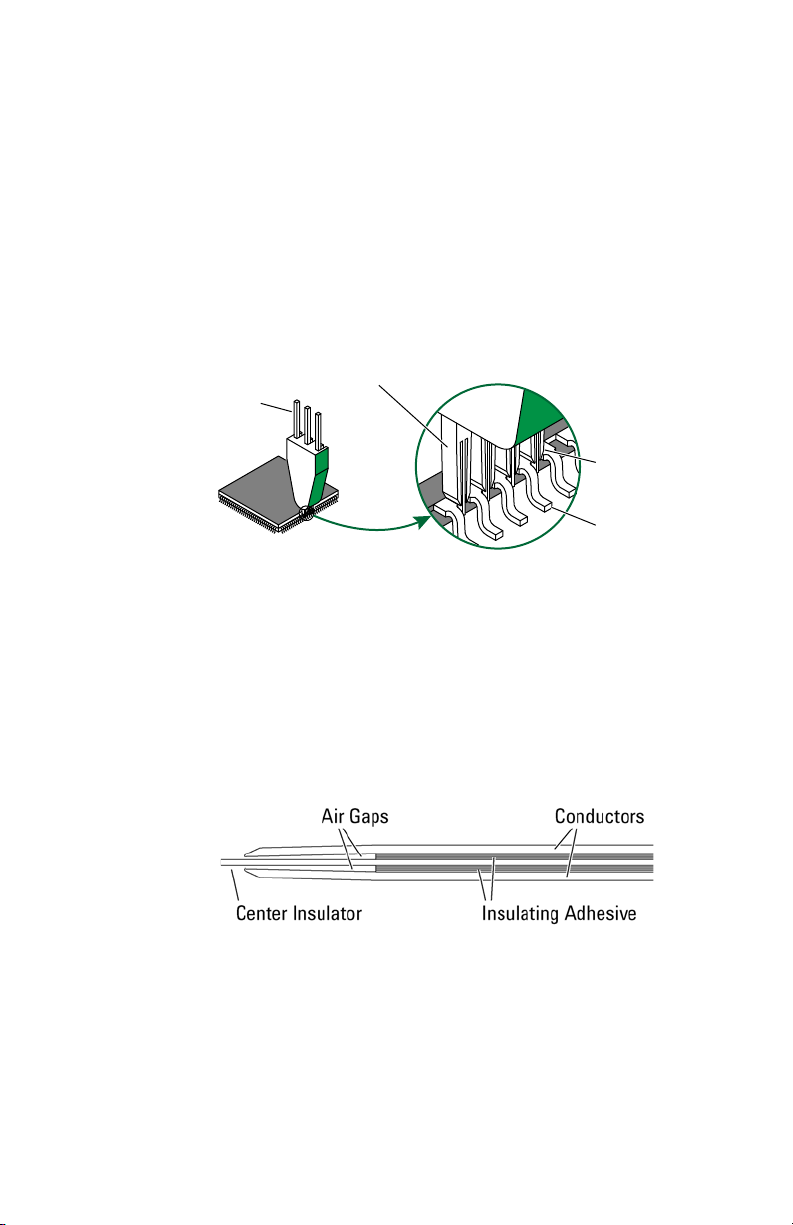

The wedge segment’s conductors provide two contact points on

each IC pin under test as shown on Figure 4. The redundant

physical connection between the wedge segments and the pins

on the IC package increases reliability of the electrical connection.

Figure 4 Two Conductors on Each IC Pin

The wedge probe adapter is a precision tool designed for probing at a

specific IC pin gap spacing. Although to the naked eye it’s difficult to see

the difference between an IC having 0.5 mm or 0.65 mm pin spacing gaps.

While it has been tested for 30,000 insertions, damage to the wedge probe

adapter can easily occur if not used with care.

Always use the magnifying glass provided to ensure the conductors of the

wedge probe adapter are accurately aligned with the dam bar gaps before

applying pressure to insert.

Ensure that you use the correct size wedge probe adapter for the part you

are probing.

If damage occurs to the wedge probe adapter, refer to “Repairing an

Adapter" on page 19.

There can be a significant variation in the pin spacing of 0.65 mm ICs. While

the 0.65 mm wedge probe adapter will work with the vast majority of

0.65 mm ICs, we can not guarantee it’s performance for all ICs.

9

Page 10

Critical Connection Information

Differences in Supported Surface-Mounted Devices

The manufacturing process for making TQFP/PQFPs uses a dam

bar, which prevents the plastic from spewing out between the pins

of the part during the molding process.

After the plastic injection process is completed, the residual metal

dam bar is removed to allow electrical isolation of each pin,

accomplished by a precision blanking die. The resulting gap

between the pins of the part is commonly referred to as the dam

bar gap. The dam bar gap is critical for this type of probing

because the wedge segments actually make electrical contact

with the pins of the TQFP/PQFP package in this area.

When probing, always check the width of the dam bar gap to

make sure it is free of excess solder. See Figure 5 on page 11.

Wicking of solder up the pin and into the dam bar region reduces

the dam bar gap width, which can prevent insertion of the wedge

probe adapter.

Confirm that the pin spacing gap, identified in Figure 5, is 0.5 mm

or 0.65 mm to ensure that the adapter will fit properly. Figure 6 on

page 12 show the supported surface-mounted integrated circuits

and dimensions for specific ICs.

10

Page 11

Critical Connection Information

Figure 5 Dam Bar Gaps and Pin Spacing

11

Page 12

Critical Connection Information

Figure 6 Supported Surface-Mounted Integrated Circuits

12

Page 13

Connecting the Adapter to an IC

CAUTION

CAUTION

To avoid damaging the adapter, study “Critical Connection Information" on

page 8 before attempting to install the adapter on an IC.

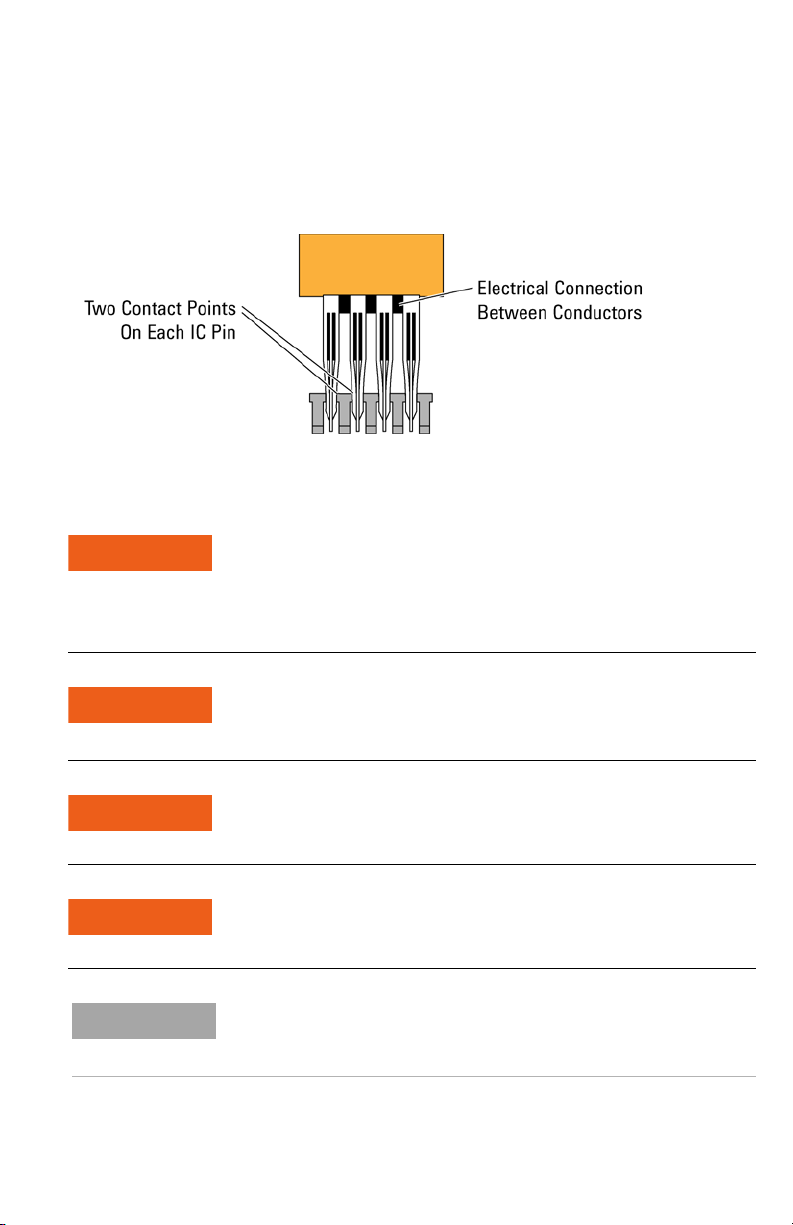

Figure 7 shows various techniques for inserting the adapter,

depending on the thickness of the IC and the location of the dam

bar gap. For most PQFP packages, the dam bar gap portion of the

IC pin is horizontal to and adjacent to the plastic body of the

package, requiring insertion of the wedge probe adapter at a 90°

angle, as shown in the top portion of the figure.

For thinner packages, such as the TQFP type, the dam bar gap

portion of the IC pin is often located on the bend of the pin,

requiring insertion of the wedge probe adapter at a lesser angle

than 90°, as shown in the bottom portion of the figure.

Connecting the Adapter to an IC

Figure 7 Adapter Insertion Techniques

Once the adapter is properly located between the IC pins and in

the dam bar gap, apply pressure so the adapter becomes fully

seated.

Ensure that the adapter is inserted at the proper angle to make contact in

the dam bar gap area.

13

Page 14

Connecting the Adapter to an IC

After the adapter is attached, it should have a very solid

connection to the IC. You should be able to attach a lead to the

adapter while maintaining a good connection to the IC. If the

adapter becomes loose after you attach it, check for one of the

following problems:

- the adapter has not been inserted far enough onto the pins of

the IC as shown in the Figure 7. Try inserting the at a different

angle, perhaps an angle of less than 30° to the board.

- the adapter has not been inserted in the dam bar gap portion

of the IC pins. The dam bar gap is located at the thicker part of

the IC pin and is generally closer to the body of the IC. Try

inserting the adapter on the portion of the IC pins closer to the

body of the IC.

- the IC may be a ceramic package which has no dam bar gap.

The adapters are not designed for this type of IC package.

Common Ground Plane on 16-Pin Adapters

Figure 8 on page 15 shows the pin number assignments for each

probe.

The top side of the 16-pin wedge probe adapters have pins

numbered 1 through 16 and provides access to IC signals. The 16

pins (marked GROUND) on the bottom side of the adapter are

connected together to provide a common ground plane. If any of

the signals acquired in the 16-signal segment from the IC are

connected to ground, a removable jumper (3 provided) can be

used to tie this IC ground signal to the ground plane connected to

the bottom 16 pins on the wedge connector. After this connection

is made, all 16 bottom pins are connected to ground.

14

Page 15

Connecting the Adapter to an IC

Figure 8 Adapters Pins

15

Page 16

Connecting the Adapter to an Instrument

Connecting the Adapter to an Instrument

Keysight Oscilloscopes and Logic Analyzers

The adapter can be easily attached to Keysight oscilloscopes or

logic analyzers. For Keysight oscilloscope probes, use a dual lead

adapter as shown below.

Figure 9 Adapters Connected Using a Dual-Lead Adapter

Tab le 3 Dual-Lead Adapters for Keysight Oscilloscope Probe Families

Keysight

Probe Family Dual lead Adapter Part Number Image

N2870A series 0960-2898 (sold separately or

with N2877A/N2879A accessory

kits)

10070 series 8710-2063

10400A series 5081-7742

16

Page 17

Other Instruments

To maintain a solid connection to the wedge probe adapter, you

will need to use a flexible lead between the probe and the wedge

probe adapter pins. Without the flexible lead, the weight of the

probe on the wedge probe adapter will most likely cause the

wedge probe adapter to disconnect from the IC.

The adapter pins are 0.635 mm square. You can build your own

flexible lead as shown in Figure 10. This requires a socket

designed to fit a 0.380 to 0.635 mm square pin at the end of the

wire that will be connected to the wedge probe adapter. You will

need to define the size of the socket at the probe end of the wire.

The probe for your instrument may include flexible leads. Also, one

of the Keysight dual-lead adapters may fit your instrument’s

probe.

Connecting the Adapter to an Instrument

Figure 10 Build Your Own Flexible Lead

17

Page 18

Cleaning an Adapter

Clean the adapter contacts before each installation. Debris on the

contacts will interfere with its function.

1 Use a common toothbrush to remove any dust between the

wedge segments. The individual wedge segments are very robust

and will not be damaged by vigorous brushing.

Figure 11 Brush in The Direction Shown

2 Use precision dusting cleaner (also known as inert dusting gas or

compressed air in a can) to remove debris loosened by the

brushing.

Cleaning an Adapter

18

Page 19

Repairing an Adapter

WARNING

Typical Bent Wedge Segments

To avoid possible injury, exercise care when using any sharp tool.

1 Use a single-edged razor blade between the wedge probe adapter

conductors to straighten them as much as possible.

2 Repeat this on each bent wedge segment conductor.

Repairing an Adapter

Figure 12 Straightening Wedge Segments

3 Hold the Wedge Probes Adapter conductors tightly together with

tweezers and flex to straighten each individual wedge segment as

shown in Figure 13 on page 20.

19

Page 20

Figure 13 Holding the Wedge Probes Adapter Conductors

NOTE

Severely Bent Wedge Segments

1 Use a x20 or x40 microscope so you can see the bent wedge

segment conductor.

2 Use a needle probe to bend the wedge segment conductor

enough that you can get tweezers on it.

3 Gently straighten out wedge segment conductors using tweezers

as shown in Figure 14 on page 21.

Repairing an Adapter

Even though the bent section often breaks due to metal fatigue, an

electrical connection is often made because there are two electrical contact

points on each pin of the TQFP/PQFP package. For more information on how

electrical connection is made, refer to “Critical Connection Information" on

page 8.

20

Page 21

Figure 14 Straightening Wedge Segment Conductors

WARNING

Pinched Air Gap

The air gap is described in “Critical Connection Information" on

page 8. Wedge segments may fail to make contact if this air gap is

closed. The following instructions tell you how to correct this

problem.

1 Turn the probe so that the wedge segments are facing up.

2 Use a x20 or x40 microscope so you can see the pinched wedge

segment.

Repairing an Adapter

To avoid possible injury, exercise care when using any sharp tool.

3 Insert the edge of a single-edged razor blade between the center

insulator and the conductor.

4 Gently pry the conductor away from the center insulator to open

the gap.

21

Page 22

Figure 15 Repairing a Pinched Air Gap

Repairing an Adapter

22

Page 23

Repairing an Adapter

23

Page 24

*E2613-92010*

Keysight Technologies, Inc.

Manual Part Number: E2613-92010

Loading...

Loading...