Page 1

Agilent X-Series

E6607B Wireless

Communications

Test Set

Notice: This document contains references to

Agilent. Please note that Agilent’s Test and

Measurement business has become Keysight

Technologies. For more information, go to

www.keysight.com.

Getting Started Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies, Inc. 2012-2014

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

Trademark

Acknowledgements

Microsoft “ is a U.S. registered trademark

of Microsoft Corporation.

Windows “ and MS Windows “ are U.S.

registered trademarks of Microsoft

Corporation.

Adobe Reader “ is a U.S. registered

trademark of Adobe System Incorporated.

Java™ is a U.S. trademark of Sun

Microsystems, Inc.

MA TLAB “ is a U.S. registered trademark

of Math Works, Inc.

Norton Ghost™ is a U.S. trademark of

Symantec Corporation.

Copyright 2008-9 Agilent Technologies

Inc.

Licensed under the Apache License, Version 2.0 (the "License");

you may not use this file except in compliance with the License.

You may obtain a copy of the License at:

http://www.apache.org/licenses/

LICENSE-2.0

Unless required by applicable law or

agreed to in writing, software

distributed under the License is

distributed on an "AS IS" BASIS,

WITHOUT WARRANTIES OR CONDITIONS OF ANY KIND, either express or

implied.

See the License for the specific

language governing permissions and limitations under the License.

Manual Part Number

E6607-90033

Print Date

December 2014

Printed in USA

Agilent Technologies, Inc.

1400 Fountaingrove Parkway

Santa Rosa, CA 95403

Warranty

The material contained in this document is provided “as is,” and is

subject to being changed, without

notice, in future editions. Further,

to the maximum extent permitted

by applicable law, Agilent disclaims

all warranties, either express or

implied, with regard to this manual

and any information contained

herein, including but not limited to

the implied warranties of merchantability and fitness for a particular purpose. Agilent shall not

be liable for errors or for incidental

or consequential damages in connection with the furnishing, use, or

performance of this document or of

any information contained herein.

Should Agilent and the user have a

separate written agreement with

warranty terms covering the material in this document that conflict

with these terms, the warranty

terms in the separate agreement

shall control.

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance

of a U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DF AR 252.227-7014

(June 1995), or as a “commercial item” as

defined in F AR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S.

Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.22714 (June 1987) or DFAR 252.227-7015

(b)(2) (November 1995), as applicable in

any technical data.

Safety Notices

A CAUTION notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in damage to the product or loss of

important data. Do not proceed

beyond a CAUTION notice until

the indicated conditions are fully

understood and met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice,

or the like that, if not correctly

performed or adhered to, could

result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated conditions are fully

understood and met.

Page 3

Warranty

This Agilent Technologies product is warranted against defects in material and

workmanship for a period of one year from the date of shipment. during the warranty

period, Agilent Technologies will, at its option, either repair or replace products that

prove to be defective.

For warranty service or repair, this product must be returned to a service facility

designated by Agilent Technologies. Buyer shall prepay shipping charges to Agilent

Technologies shall pay shipping charges to return the product to Buyer. However,

Buyer shall pay all shipping charges, duties, and taxes for products returned to Agilent

Technologies from another country.

Where to Find the Latest Information

Documentation is updated periodically. For the latest information about this test set,

including firmware upgrades, application information, and product information, see

the following URLs:

http://www.agilent.com/find/ext

To receive the latest updates by email, subscribe to Agilent Email Updates:

http://www.agilent.com/find/emailupdates

Information on preventing test set damage can be found at:

http://www.agilent.com/find/tips

Page 4

Compliance

This product has been designed and tested in accordance with accepted industry standards, and has been

supplied in a safe condition. The documentation contains information and warnings that must be followed

by the user to ensure safe operation and to maintain the product in a safe condition.

Canadian EMC Requirements

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 Canada.

Acoustic Noise Requirements

Acoustic Noise Emission Geraeuschemission

LpA <70 dB

Operator Position

Normal Position

Per ISO 7779

Acoustic Noise -- Further

Information

Ambient Temperature <40

LpA < 70 dB

Am Arbeitsplatz

Normaler Betrieb

Nach DIN 45635 t.19

Supplemental Information

(Values given are per ISO 7779 standard in the “Operator

Sitting” position)

° C Nominally under 55 dBA Sound Pressure. 55 dBA is gen-

erally considered suitable for use in quiet office environments.

Ambient Temperature >40° C Nominally under 65 dBA Sound Pressure. 65 dBA is gen-

erally considered suitable for noisy office environments.

(The fan speed, and thus the noise level, increases with

increasing ambient temperature.)

Page 5

In This Guide…

This guide contains the following information:

1 Quick-Start

This chapter explains how to initial ize the test se t and generate and view a

signal.

2 Front and Rear Panel Features

Refer to this chapter for information on front- and rear-panel key

functionality, and display annotations.

3 Test Set Operating System

This chapter describes the Microsoft Windows OS configuration and the

settings used with the Agilent test set software.

4 Using Microsoft Windows

The information in this chapter provides some guidelines for using the

Microsoft Windows feature capabilities with the test set.

5 Troubleshooting

This chapter details some basic steps that may solve any problems you are

experiencing with either the test set or Microsoft Windows OS.

Page 6

Contents

1 Quick-Start

Initial Inspection 12

Table. Verifying the contents 12

Shipping problems? 13

Test Set Location and Rack Mounting Requirements 13

Turning on the test set the first time 14

Initializing the test set using a USB mouse 14

Initializing the test set using front-panel navigation 19

Anti-Virus Software and Firewalls 23

Shortening the Test Set Power-On Time 23

Instrument Information 24

Power requirements 24

Environmental Conditions (Operating) 25

Ventilation 26

Instrument Maintenance 26

Protecting against electrostatic discharge 28

2 Front and Rear Panel Features

Front-Panel Features (E6607A/B) 30

V irtual Front Panel 33

When the Test Set is Controlled Remotely 34

Display Annotations 35

Rear-Panel Features 37

Front and Rear Panel Symbols 39

3 Test Set Operating System

Agilent Software Installed 42

Agilent U9065A & U9060A software 42

Customer Installation of Software 43

3rd party software verified by Agilent 43

Getting Started Guide 7

Page 7

Installation of other 3rd party software 43

User Accounts 44

Administrator login 44

User login 44

AgilentOnly user account 44

Agilent service user accounts 44

Customer creation of accounts 45

Agilent X-Series Licensing Options 46

Fixed Perpetual 46

Transportable Perpetual 46

Time-Based Licenses 47

Licensing New Measurement Application Software - After Initial Purchase 48

Transporting a License Between X-Series Test Sets 50

Windows Configuration 53

Settings that can be changed 53

Settings that must not be changed 54

Configuring Printers 56

Configuring LAN 57

Hostname 57

IP Address & Gateway 57

Windows Security 58

Windows Firewall 59

Automatic updates 59

Virus protection 60

Spyware protection 61

System Maintenance 62

Backup 62

System restore 62

Disk defragmenting 62

USB Connections 63

Hard Drive Partitioning and Use 64

Backing-up the factory calibration data 65

Hard Drive Recovery Process 67

Updating the software 69

Configuring recovery prompt timing 71

8 Getting Started Guide

Page 8

4 Using Microsoft Windows Operating System

Navigating Windows Without a Mouse 74

Remote Desktop: Using the X-Series test set remotely 78

Overview of Remote Desktop operation 78

Setting up Remote Desktop operation 78

How to locate the computer name of the test set 80

Running a Remote Desktop session 82

The Virtual Front Panel 91

Embedded Web Server: Using the X-Series Test Set Remotely 92

Accessing the test set through the Internet 92

Accessing the Web Control tab 96

Selecting the Get Data tab 97

Selecting the Get Image tab 98

Selecting the SCPI Telnet tab 100

Selecting the Help Tab 102

Capturing/Printing Displays and Windows 103

Windows Shortcuts and Miscellaneous Tasks 104

Windows shortcuts (key combinations) 104

Windows taskbar auto-hide feature 105

Windows startup folder 107

5 Troubleshooting

Check the Basics 110

Problems with Microsoft Windows Operating System 112

Returning a test set for Service 113

Calling Agilent Technologies 113

Locations for Agilent Technologies 113

Read the Warranty 114

Service Options 114

Service Tag 114

Packaging the T e st Set 116

Index

Getting Started Guide 9

Page 9

10 Getting Started Guide

Page 10

Agilent X-Series Wireless Communications Test Set

Getting Started Guide

1

Quick-Start

This section explains how to initialize the test set and generate and view a signal.

The following topics can be found in this section:

“Initial Inspection" on page 12

“Test Set Location and Rack Mounting Requirements" on page 13

“Turning on the test set the first time" on page 14

“Anti-V irus Software and Firewalls" on page 23

“Shortening the Test Set Power-On Time" on page 23

“Instrument Information" on page 24

Agilent Technologies

11

Page 11

1 Quick-Start

Initial Inspection

Inspect the shipping container and the cushioning material for signs of stress. Retain the

shipping materials for future use, as you may wish to ship the test set to another location

or to Agilent Technologies for service.

Verifying the contents

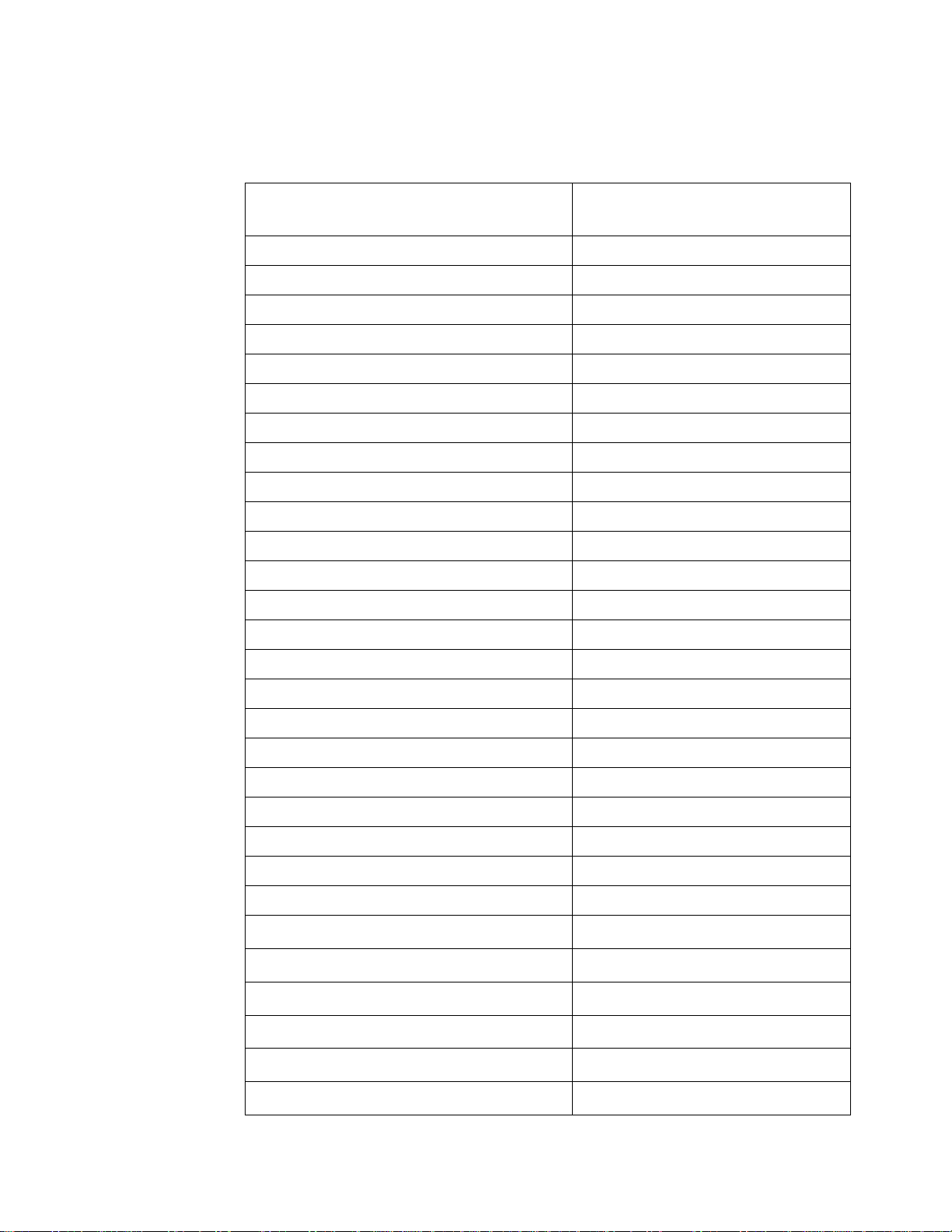

Item Deliverable Description

Getting Started Guide Provides first-time power on instructions,

Agilent IO Libraries disk Software for establishing and configuring

licensing information, operating system

information, and general hardware

information.

PC to test set interfaces.

Optical mouse An optical USB mouse to simplify screen

navigation.

E6607B Safety and

Regulations Guide

Power cable Connection for test set power.

For use with E6607B Wireless

Communications Test Set.

12 Getting Started Guide

Page 12

Shipping problems?

If the shipping materials are damaged or the contents of the container are incomplete:

• Contact the nearest Agilent Technologies office.

• Keep the shipping materials for the carrier’s inspection.

• If you must return an test set to Agilent Technologies, use the original (or

comparable) shipping materials. See “Returning a test set for Service" on page 113.

Test Set Location and Rack Mounting Requirements

Locating the test set

Make sure that the fan inlet and exhaust vent areas on the sides of the test set are not

obstructed. The minimal required clearance is 2 inches. Airflow restrictions cause

additional airflow noise and cause the fans to speed up so they can draw in enough air for

the required cooling resulting in excessive audible noise.

Cooling and rack mounting

Quick-Start 1

Do not rack mount the test set side-by-side with any other instrument with side-by-side

ventilation. Make sure the exhaust air from the first instrument is directed away from the

inlet of the second unit. If the pre-heated air from the first instrument is directed into the

second instrument, it can cause excessive operating temperatures in the second unit and

can cause instrument failures. The test set draws air in from the left side and exhausts air

from the right side.

Getting Started Guide 13

Page 13

1 Quick-Start

Turning on the test set the first time

Initial power-on of the test set can be accomplished using either of the following

methods:

• “Initializing the test set using a USB mouse" on page 14

• “Initializing the test set using front-panel navigation" on page 19

During the initial power-on process, the test set turns off and restarts

several times. This only happens during the initial installation process.

Initializing the test set using a USB mouse

Steps Actions Notes

1 Connect the mouse

2 Power on the test set a Position the test set so you

• Connect the mouse to one

of the USB ports on the test

set.

have easy access to the

power cord and plug it in.

b Press the power switch

(located in the lower left

corner of the test set front

panel) to turn the test set

on.

• See “Test Set Location and Rack Mounting

Requirements and “Power requirements" on page 24

for more details.

• The test set can require more than 5 minutes to

power-on. This is affected by Windows start-up

requirements.

• The Agilent Technologies screen appears followed

by a screen that allows you to select the operating

system.

• At this time, it is safe to turn off the test set before

starting the Setup Wizard.

14 Getting Started Guide

Page 14

Steps Actions Notes

Quick-Start 1

3 Launch Microsoft Setup

Wizard

• Highlight Microsoft

Windows and press

to start the pre-installed

operating system.

a The analyzer performs the following steps:

Enter

• Windows S tartup window

• Black screen

• Windows blue please wait message window, “Please wait wh ile windows prepares

to setup”

• Blue Agilent window

• The following Welcome window appears giving you info rmation about the End-

User License Agreement.

• At this time, it is safe to turn off the instrument before initializing the software.

After launching the setup, do not turn off the instrument or remove power before the

Setup Wizard comple tes and the system restarts. Turning off the instrument may corrupt

the system and the application may not operate.

4 Reboot and logon a Click

Getting Started Guide 15

OK • When the instrument restarts, the following message

window appears:

Page 15

1 Quick-Start

Steps Actions Notes

• This window appears and covers the LaunchXSA window.

If you do not check the “Do not show this message again” check box, this message will

be displayed each time the analyzer is turned on. No application will start while this

message is displayed. Before continuing, make sure that you carefully read the AntiVirus message and determine what action is appropriate.

5 Disable the Anti-Virus

message

6 Verify the installation a On the test set, press

7 View a signal a Press

a Select the check box and

click

Continue.

System, Show, System.

b Verify that the purchased

application(s) appear in the

list.

Input/Output,

RF Calibrator, 50 MHz.

b Press

c Press

d Press

AMPTD Y Scale, Ref

Value

, 10, dBm.

FREQ, Center Freq,

50, MHz.

SPAN X Scale,

Span, 8, MHz.

• Messages similar to the following continue to

appears:

• The system reboots.

• Several required processes continue.

• The system reboots.

• The XSA application initializes

• If you require further assistance, contact the Agilent

support team.

Online assistance: http://www.agilent.com/find/assist

• To view a signal without attaching any RF cables to

the test set, route the internal 50 MHz calibration

signal to the test set input.

• Set the reference level to 10 dBm.

• Set the analyzer center frequency to 50 MHz.

• Set the analyzer span to 8 MHz.

16 Getting Started Guide

Page 16

Steps Actions Notes

The 50 MHz reference signal appears on the display.

Quick-Start 1

8 Generate and view signal a Connect the ends of a short

RF cable to the RF Input

and RF Output connectors

on the front panel.

b Press

c Press

d Press

e Press

f Press

g Press

h Press

i Press

Input/Output,

RF Input, RF Input Port,

RF In.

Input/Output, More,

RF Output Port,

RF Output.

Source, RF Output,

On.

Source, Amplitude,

RF Power, 0, dBm.

Freq, Center Freq, 1,

GHz.

AMPTD Y Scale,

Ref Value, 10, dBm.

FREQ, Center Freq,

1, GHz.

SPAN X Scale,

Span, 8, MHz.

• The purpose is to use a loopback cable to verify that

the test set’s source can generate a signal and the test

set’s analyzer can measure it.

• Because there are four RF ports on the front panel, it

is necessary to specify which ports are used for the

input and output.

• You need to choose frequency and power-level

settings for the source; you also need to specify that

the source output is on.

• You need to specify the center frequency, span, and

reference power level for the analyzer.

Getting Started Guide 17

Page 17

1 Quick-Start

Steps Actions Notes

The 1 GHz signal appears on the display.

18 Getting Started Guide

Page 18

Initializing the test set using front-panel navigation

The following keys are used in the initialization process:

Quick-Start 1

Steps Actions Notes

1 Power on the test set a Position the test set so you

have easy access to the

power cord and plug it in.

b Press the power switch

(located in the lower left

corner of the test set front

panel) to turn the test set

on.

• See “Test Set Location and Rack Mounting

Requirements and “Power requirements" on page 24

for more details.

• The test set can require more than 5 minutes to power-

on. This is affected by Windows start-up

requirements.

• The Agilent T echnologies sc reen appears followed by

a screen that allows you to select the operating

system.

• At this time, it is safe to turn off the test set before

starting the Setup Wizard.

After launching the Setup Wizard, do not turn off the test set or remove power before the

Setup Wizard completes and the system restarts. Turning off the test set may corrupt the

system and the application may not operate.

Getting Started Guide 19

Page 19

1 Quick-Start

Steps Actions Notes

2 Launch the Microsoft

Setup Wizard

a Highlight Microsoft

Windows and press

to start the pre-installed

operating system.

a The analyzer performs the following steps:

Enter

• Windows S tartup window

• Black screen

• Windows blue please wait message window, “Please wait while windows prepares

to setup”

• Blue Agilent window

• The following Welcome window appears giving you info rmation about the End-

User License Agreement.

• At this time, it is safe to turn off the instrument before initializing the software.

After launching the setup, do not turn off the instrument or remove power before the

Setup Wizard completes and the system restarts. Turning off the instrument may corrupt

the system and the application may not operate.

3 Reboot and logon a Click

20 Getting Started Guide

OK • When the instrument restarts, the following message

window appears:

Page 20

Steps Actions Notes

• This window appears and covers the LaunchXSA window.

If you do not check the “Do not show this message again” check box, this message will

be displayed each time the analyzer is turned on. No application will start while this

message is displayed. Before continuing, make sure that you carefully read the Anti-Virus

message and determine what action is appropriate.

Quick-Start 1

4 Disable the Anti-Virus

message

5 Verify the installation a Press

6 View a signal a Press

a Press Select to select the

check box and

continue.

System.

b Verify that the purchased

application(s) appear in the

list.

RF Calibrator, 50 MHz.

b Press

Value

c Press

50, MHz.

d Press

Span, 8, MHz.

Enter to

System, Show,

Input/Output,

AMPTD Y Scale, Ref

, 10, dBm.

FREQ, Center Freq,

SPAN X Scale,

• Messages similar to the following continue to

appears:

• The system reboots.

• Several required processes continue.

• The system reboots.

• The XSA application initializes

• If you require further assistance, contact the Agilent

support team.

Online assistance: http://www.agilent.com/find/assist

• To view a signal without attaching any RF cables to

the test set, route the internal 50 MHz calibration

signal to the test set input.

• Set the reference level to 10 dBm.

• Set the analyzer center frequency to 50 MHz.

• Set the analyzer span to 8 MHz.

Getting Started Guide 21

Page 21

1 Quick-Start

Steps Actions Notes

The 50 MHz reference signal appears on the display.

7 Generate and view signal a Connect the ends of a short

RF cable to the RF Input

and RF Output connectors

on the front panel.

b Press

c Press

d Press

e Press

f Press

g Press

h Press

i Press

Input/Output,

RF Input, RF Input Port,

RF In.

Input/Output, More,

RF Output Port,

RF Output.

Source, RF Output,

On.

Source, Amplitude,

RF Power, 0, dBm.

Freq, Center Freq, 1,

GHz.

AMPTD Y Scale,

Ref Value, 10, dBm.

FREQ, Center Freq,

1, GHz.

SPAN X Scale,

Span, 8, MHz.

• The purpose is to use a loopback cable to verify that

the test set’s source can generate a signal and the test

set’s analyzer can measure it.

• Because there are four RF ports on the front panel, it

is necessary to specify which ports are used for the

input and output.

• You need to choose frequency and power-level

settings for the source; you also need to specify that

the source output is on.

• You need to specify the center frequency, span, and

reference power level for the analyzer.

22 Getting Started Guide

Page 22

Steps Actions Notes

The 1 GHz signal appears on the display.

Quick-Start 1

Anti-Virus Software and Firewalls

No anti-virus software is shipped with the test set. It is recommended that you install

anti-virus software if your test set is connected to the LAN. Check with your IT

department to see what they recommend.

The test set is shipped with the Windows firewall enabled. Do not modify the default

network settings as this may cause problems with the operating system of the test set.

Shortening the Test Set Power-On Time

The test set desktop includes a shortcut to the ConfigureApplications.exe application that

lets you control your test set power-on configuration. You can set the configuration to

pre-load only the applications that you typically run. This can significantly shorten the

time it takes for your test set to power-on. You can also access this functionality by

pressing:

If (after power-on) you want to access an application that you did not pre-load, it will

take a little longer to bring it up once you press the application softkey . This longer timeframe is only for the first access after power-on. After the initial access, mode

(application) switching will operate as quickly as if the application was pre-loaded.

System, Power On, Configure Applications.

Getting Started Guide 23

Page 23

1 Quick-Start

Instrument Information

Power requirements

The only physical installation of your Agilent test set is a connection to a power source.

Line voltage does not need to be selected.

This test set does not contain customer serviceable fuses.

This is a Safety Class 1 Product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket outlet provided with a protective earth contact.

Any interruption of the protective conductor inside or outside of the

product is likely to make the product dangerous. Intentional

interruption is prohibited. (IEC 348 clauses 17.3.3c & 17.3.4)

Failure to ground the test set properly can result in personal injury.

Before turning on the test set, you must connect its protective earth

terminals to the protective conductor of the main power cable. Insert

the main power cable plug into a socket outlet that has a protective

earth contact only . DO NOT defeat the earth-grounding pr otection by

using an extension cable, power cable, or autotransformer without a

protective ground conductor.

This product is designed for use in Installation Category II and Pollution

Degree 2 per IEC 61010 Second Edition and IEC 664 respectively.

This instrument has autoranging line voltage input. Before switching on

the instrument, be sure the supply voltage is within the specified range.

The Mains wiring and connectors shall be compatible with the connector

used in the premise electrical system. Failure, to ensure adequate earth

grounding by not using the correct components may cause product

damage, and serious injury.

24 Getting Started Guide

Page 24

Quick-Start 1

AC power cord

The test set is equipped with a three-wire power cord, in accordance with international

safety standards. This cable grounds the test set cabinet when connected to an

appropriate power line outlet. The cable appropriate to the original shipping location is

included with the test set. See:

http://www.agilent.com/find/powercords

Always use the three-prong AC power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord can

cause product damage.

This instrument has auto-ranging line voltage input; be sure the supply

voltage is within the specified range and voltage fluctuations do not to

exceed 10 percent of the nominal supply voltage:

100/120 VAC 50/60 Hz,

220/240 VAC 50/60 Hz,

270 W Max.

If this product is not used as specifi ed, the pr otect ion pr ovid ed by the

equipment could be impaired. This product mu st be used in a normal

condition (in which all means for protection are intact) only.

Install the instrument so that the detachable power cord is readily

identifiable and easily reached by the operator. The detachable power

cord is the instrument disconnecting device. It disconnects the mains

circuits from the mains supply before other parts of the instrument.

The front panel switch is only a standby switch and is not a LINE

switch. Alternatively, an externally installed switch or circuit breaker

(which is readily identifiable and is easily reached by the operator)

may be used as a disconnecting device.

Environmental Conditions (Operating)

This product is designed for use in the following conditions:

• For indoor use only

• Temperature 5°C to 50°C

• Altitude up to 3048 meters

• 0% Relative Humidity to 90% Relative Humidity up to 40°C, and li nearly decreasing

to 50% Relative Humidity up to 50°C; non-condensing..

This product is designed for use in Installation Category II and

Pollution Degree 2.

Getting Started Guide 25

Page 25

1 Quick-Start

Ventilation

Instrument Maintenance

VENTILATION REQUIREMENTS: When installing the product in a

cabinet, the convection into and out of the product must not be restricted.

The ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by 4

watts dissipated in the cabinet. If the total power dissipated in the

cabinet is greater than 800 watts, then forced convection must be used.

Cleaning the instrument

To prevent electrical shock, disconnect the test set from mains before

cleaning. Use a dry cloth or one slightly dampened with water to

clean the external case parts. Do not attempt to clean internally.

o

C for every 100

Cleaning the connectors

Cleaning connectors with alcohol shall only be done with the

instrument power cord removed, and in a well-ventilated area. Allow

all residual alcohol moisture to evaporate, and the fumers to

dissapate prior to energizing the instrument.

Battery Information

The test set uses a lithium battery located on the CPU board. This is not an operator

replaceable part. See “Returning a test set for Service" on page 113. Replaceable parts

must be approved or supplied by Agilent Technologies.

You can order the service documentation for the instrument through your Agilent Sales

and Service office.

Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended. Discard used

batteries according to the manufacturer’s instructions.

Do not throw batteries away but collect as small chemical waste.

26 Getting Started Guide

Page 26

Quick-Start 1

Getting Started Guide 27

Page 27

1 Quick-Start

Protecting against electrostatic discharge

Electrostatic discharge (ESD) can damage or destroy electronic components (the

possibility of unseen damage caused by ESD is present whenever components are

transported, stored, or used).

Test equipment and ESD

To help reduce ESD damage that can occur while using test equipment:

Do not use these first three techniques when working on circuitry with

a voltage potential greater than 500 volts.

• Before connecting any coaxial cable to a test set connector for the first time each day ,

momentarily short the center and outer conductors of the cable together.

• Personnel should be grounded with a 1 MΩ resistor-isolated wrist-strap before

touching the center pin of any connector and before removing any assembly from the

test set.

• Be sure that all instruments are properly earth-grounded to prevent build-up of st atic

charge.

• Perform work on all components or assemblies at a static-safe workstation.

• Keep static-generating materials at least one meter away from all components.

• Store or transport components in static-shielding containers.

• Always handle printed circuit board assemblies by the edges. This reduces the

possibility of ESD damage to components and prevent contamination of exposed

plating.

Additional information about ESD

• For more information about ESD and how to prevent ESD damage, contact the

Electrostatic Discharge Association (http://www.esda.org). The ESD standards

developed by this agency are sanctioned by the American National Standards

Institute (ANSI).

28 Getting Started Guide

Page 28

Agilent X-Series Wireless Communications Test Set

Getting Started Guide

2

Front and Rear Panel Features

This section describes the following features:

“Front-Panel Features (E6607A/B)" on page 30

“Display Annotations" on page 35

“Rear-Panel Features" on page 37

“Front and Rear Panel Symbols" on page 39

Agilent Technologies

29

Page 29

2 Front and Rear Panel Features

Front-Panel Features (E6607A/B)

Item

Description

#Name

1 Menu Keys Key labels appear to the left of the menu keys to identify the current function

of each key. The displayed functions are dependent on the currently selected

Mode and Measurement, and are directly related to the most recent key press.

2 Measurement Keys These keys select the Mode, and the Measurement within the mode. They also

control the initiation and rate of recurrence of measurements.

3 Setup Keys These keys set the parameters used for setting up the test set in the current

Mode.

4 Marker Keys Markers are often available for a measurement, to measure a very specific

point/segment of data within the range of the current measurement data.

5 Utility Keys These keys control system-wide functionality such as

• test set configuration information and I/O setup,

• printer setup and printing,

• file management, save and recall,

• test set presets.

6 Probe Power Supplies power for external high frequency probes and accessories.

7 Headphones Output Headphones can be used to hear any available audio output.

8 Back Space Key Press this key to delete the previous character when entering alphanumeric

information. It also works as the Back key in Help and Explorer windows.

9 USB Connectors Standard USB 2.0 ports, Type A. Connect to external peripherals such as a

mouse, keyboard, DVD drive or hard drive.

10 Delete Key Press this key to delete files, or to perform other deletion tasks.

30 Getting Started Guide

Page 30

Front and Rear Panel Features 2

Item

Description

#Name

11 Local/Cancel/(Esc) Key If you are in remote operation the Local key

• returns test set control from remote back to local (the front panel).

• turns the display on (if it was turned off for remote operation).

• can be used to clear errors. (Press the key once to return to local control,

and a second time to clear error message line.)

If you have not already pressed the units or Enter key, Cancel exits the

currently selected function without changing its value.

Esc works the same as it does on a pc keyboard. It

• exits Windows dialogs

• clears errors

• aborts printing

• cancels operations.

This key also exits the help system if it has been accessed.

12 Numeric Keypad Enters a specific numeric value for the current function. Entries appear on the

upper left of the display, in the measurement information area.

13 Enter and Arrow Keys The Enter key terminates data entry when either no unit of measure is needed,

or you want to use the default unit.

The arrow keys

• Increment and decrement the value of the current measurement selection.

• Navigate help topics.

• Navigate, or make selections, within Windows dialogs.

• Navigate within forms used for setting up measurements.

• Navigate within tables.

The arrow keys cannot be used to move a mouse

pointer around on the display.

14 Menu/ (Alt) Key Alt works the same as a pc keyboard. Use it to change control focus in

Windows pull-down menus.

15 Ctrl Key Ctrl works the same as a pc keyboard. Use it to navigate in W i ndows

applications, or to select multiple items in lists.

16 Select / Space Key Select is also the Space key and it has typical pc functionality. For example, in

Windows dialogs, it selects files, checks and unchecks check boxes, and picks

radio button choices. It opens a highlighted Help topic.

17 Tab Keys Use these keys to move between fields in Windows dialogs.

18 Knob Increments and decrements the value of the current active function.

19 Return Key Exits the current menu and returns to the previous menu. Has typical pc

functionality.

20 Full Screen Key Pressing this key turns off the softkeys to maximize the graticule display area.

Getting Started Guide 31

Page 31

2 Front and Rear Panel Features

Item

#Name

21 Help Key Initiates a context-sensitive help display for the current Mode. Once Help is

22 Speaker Control Keys Enables you to increase or decrease the speaker volume, or mute it.

23 Window Control Keys These keys select between single or multiple window displays. They zoom the

24 Power Standby/ On Turns the test set on. A green light indicates power on. A yellow light

Description

accessed, pressing a front panel key brings up the help topic for that key

function. Use the Local/Cancel/(Esc) key to exit help.

current window to fill the data display, or change the currently selected

window. They can be used to switch between the Help window navigation

pane and the topic pane.

indicates standby mode.

The front-panel switch is a standby switch, not a LINE

switch (disconnecting device). The test set continues to

draw power even when the line switch is in standby.

The main power cord can be used as the system

disconnecting device. It disconnects the mains circuits

from the mains supply

If the test set is being controlled remotely from another

computer, pressing this switch does not deactivate the

test set. See “When the Test Set is Controlled

Remotely" on page 34.

25 RF I/O 1 Connector RF Input/Output port #1

(communicates with both the source and the analyzer).

26 RF I/O 2 Connector RF Input/Output port #2

(communicates with both the source and the analyzer).

27 RF Output The test set RF output port (communicates only with the source).

28 RF Input The test set RF input port (communicates only with the analyzer).

32 Getting Started Guide

Page 32

Front and Rear Panel Features 2

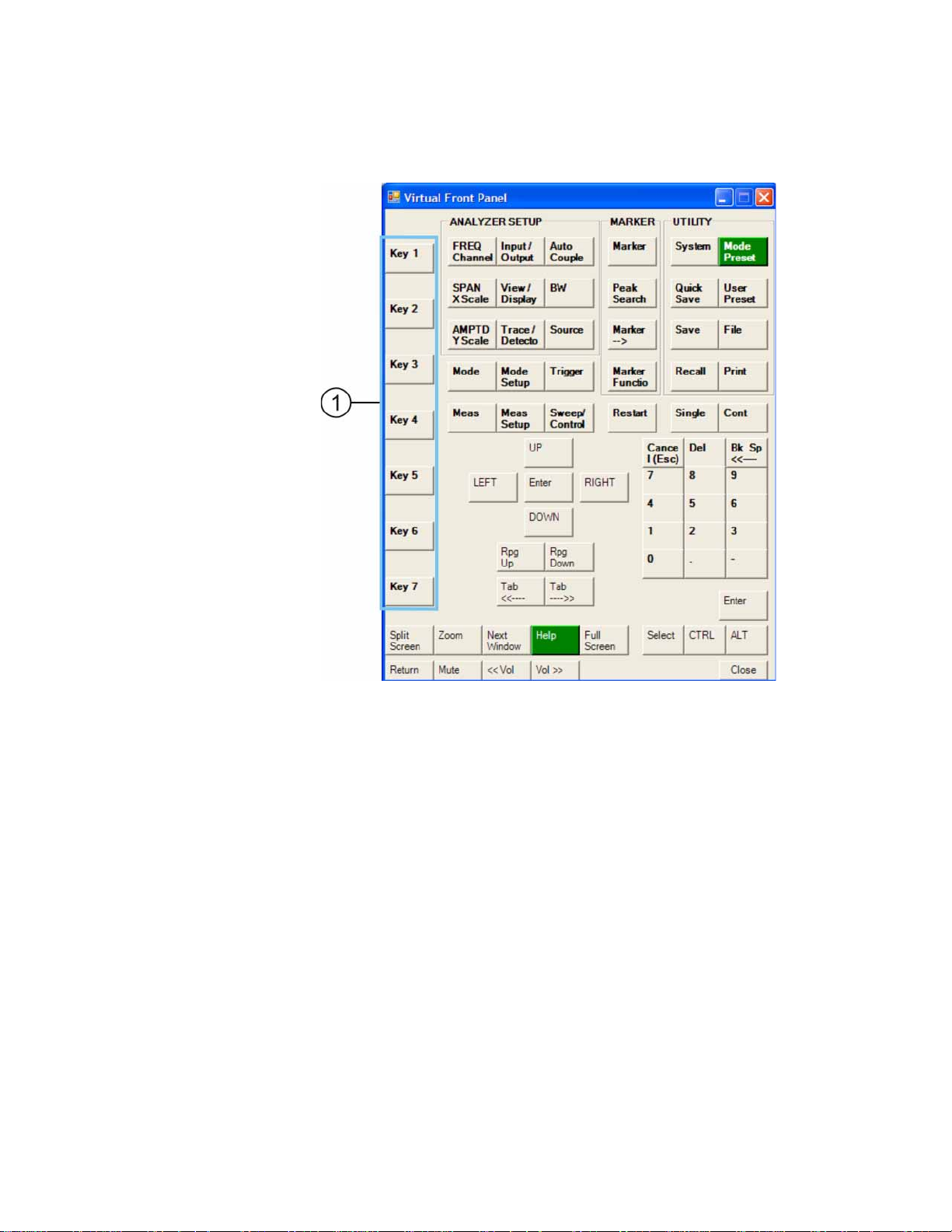

Virtual Front Panel

If you have a PC mouse, monitor, and keyboard plugged in (or through a Remote

Desktop), you can navigate the front panel functions using the virtual front panel (VFP)

shown below. Acc ess the VFP as follows:

1. Right-click the mouse.

2. Left-click Utility (1) in the menu, as shown below.

3. Left-click Virtual Front Panel (2) in the menu, as shown below.

NOTE The PC mouse and monitor are required when using the VFP. For ease in using the VFP,

the PC keyboard is recommended.

:

On the VFP the keys labeled "Key 1" through "Key 7" function as the menu keys. Using

the mouse to click on a combination of the VFP keys and the menu keys on the display

screen, you can operate the instrument as if it had conventional front-panel keys.

Getting Started Guide 33

Page 33

2 Front and Rear Panel Features

When the Test Set is Controlled Remotely

The test set can be controlled remotely, from another computer. When the test set is

being controlled remotely, a message similar to the following is displayed on the

monitor:

Computer Locked

This computer is in use and has been locked. Only A-E6607CNEN538\user or an administrator can unlock this computer. Press

Ctrl-Alt-Del to unlock this computer.

Under these circumstances, pressing the front-panel Power switch does not immediately

turn instrument power off. Instead, the following message appears:

Other people are logged on to this computer. Shutting down

windows might cause them to lose data. Do you want to continue

shutting down?

Pressing and holding down the Power button will force a power shutdown.

34 Getting Started Guide

Page 34

Display Annotations

This section describes the display annotation as it is on the Sequence Analyzer

measurement application display. Other measurement application modes have some

annotation differences.

Front and Rear Panel Features 2

Item Description Function Keys

1 Measurement bar - Shows general measurement

settings and information.

Indicates single/continuous

measurement.

Some measurements include limits that the data is

tested against. A Pass/Fail indication may be shown in

the lower left of the measurement bar.

2 Active Function (measurement bar) - when the current

active function has a settable numeric value, it is

shown here.

3 Banner - shows the name of the selected application

that is currently running.

Getting Started Guide 35

All the keys in the test set Setup part

of the front panel.

Currently selected front panel key.

Mode

Page 35

2 Front and Rear Panel Features

Item Description Function Keys

4 Measurement title - shows title information for the

current measurement, or a title that you created for the

measurement.

5 Settings panel - displays system information that is not

specific to any one application.

• Input/Output status - RLTS indicate Remote,

Meas

View/Display, Display, Title

Local and System, I/O Config

Input/Output, Amplitude, System

and others

Listen, Talk, SRQ

• Input impedance and coupling

• Selection of external frequency reference

• Setting of automatic internal alignment routine

6 Active marker frequency, amplitude or function value

Marker

7 Settings panel - time and date display. System, Control Panel

8 Trace and detector information Trace/Detector,

Clear Write (W) Trace A verage (A) Max

Hold (M) Min Hold (m)

Trace/Detector,

More,

Detector,

Average (A) Normal (N) Peak (P)

Sample (S) Negative Peak (p)

9 Key labels that change based on the most recent key

Softkeys

press.

10 Displays information, warning and error messages.

Message area - single events, Status area - conditions

11 Measurement settings for the data currently being

displayed in the graticule area. In the example above:

center frequency, resolution bandwidth, video

bandwidth, frequency span, sweep time and number of

sweep points.

Keys in the test set Setup part of the

front panel.

36 Getting Started Guide

Page 36

Rear-Panel Features

Front and Rear Panel Features 2

Item

# Name

1 EXT REF IN Inpu t for an external frequency reference signal: 1 to 50 MHz

2 GPIB A General Purpose Interface Bus (GPIB, IEEE 488.1) connection that can

be used for remote test set operation.

3 USB Connector USB 2.0 port, T ype B. USB TMC (test and measurement class) connects to

an external pc controller to control the test set and for data transfers over a

480 Mbps link.

4 USB Connectors Standard USB 2.0 por ts , Type A. Connect to external peripherals such as a

mouse, keyboard, printer, DVD drive, or hard drive.

5 MONITOR Allows connection of an external VGA monitor.

6 LAN A TCP/IP Interface that is used for remote test set operation.

7 Line power input The AC power connection. See the product specifications for more details.

8 Removable Hard

Drive

9 DIGITAL BUS Reserved for future use.

10 ANALOG OUT Reserved for future use.

Standard on E6607A.

Description

11 TRIGGER 2

OUT

Getting Started Guide 37

A trigger output used to synchronize other test equipment with the test set.

Configurable from the Input/Output keys.

Page 37

2 Front and Rear Panel Features

Item

# Name

12 TRIGGER 1

OUT

13 SYNC Reserved for future use.

14 TRIGGER 2 IN Allows external triggering of measurements.

15 TRIGGER 1 IN Allows external triggering of measurements.

16 NOISE

SOURCE

DRIVE +28 V

(PULSED)

17 SNS SERIES

NOISE

SOURCE

18 10 MHz OUT An output of the test set internal 10 MHz frequency reference signal. It is

A trigger output used to synchronize other test equipment with the test set.

Configurable from the Input/Output keys.

Not functional in the EXT Test Set.

Not functional in the EXT Test Set.

used to lock the frequency reference of other test equipment to the test set.

Description

38 Getting Started Guide

Page 38

Front and Rear Panel Symbols

This symbol is used to indicate power ON (green LED).

This symbol is used to indicate power STANDBY mode (yellow

LED).

This symbol indicates the input power required is AC.

The instruction documentation symbol. The product is marked with

this symbol when it is necessary for the user to refer to instructions in

the documentation.

The CE mark is a registered trademark of the European Community.

The RCM Mark is a Compliance Mark accord ing to the ACMA

Labelling Requirement.

This is a marking of a product in compliance with the Canadian

Interference-Causing Equipment Standard (ICES-001).

Front and Rear Panel Features 2

This is also a symbol of an Industrial Scientific and Medical Group 1

Class A product (CISPR 11, Clause 4).

The CSA mark is a registered trademark of the Canadian Standards

Association International.

This symbol indicates separate collection for electrical and electronic

equipment mandated under EU law as of August 13, 2005. All electric

and electronic equipment are required to be separated from normal

waste for disposal (Reference WEEE Directive 2002/96/EC).

Indicates the time period during which no hazardous or toxic

substance elements are expected to leak or deteriorate during normal

use. Forty years is the expected useful life of the product.

This symbol on all primary and secondary packaging indicates

compliance to China standard GB 18455-2001.

To return unwanted products, contact your local Agilent office, or see

http://www.agilent.com/environment/product/ for more information.

Getting Started Guide 39

Page 39

2 Front and Rear Panel Features

40 Getting Started Guide

Page 40

Agilent X-Series Wireless Communications Test Set

Getting Started Guide

3

Test Set Operating System

This chapter describes the Microsoft Windows configuration and the settings used with

the Agilent test set software. It includes information about changing some of the system

settings. And it describes the Windows operating system configuration and the software

installations that are present on the hard disk drive when the test set leaves the factory.

The front panel of the test set has been designed with the keys needed to navigate

windows for: accessing menus, traversing in dialogs, selecting items, and depressing

displayed buttons. It is possible to use the front panel for changing Windows

configuration items, but it is much easier to perform these tasks with a USB mouse and

external keyboard. For specifics on navigating using the front panel, see “Navigating

Windows Without a Mouse" on page 74.

“Agilent Software Installed" on page 42

“Customer Installation of Software" on page 43

“User Accounts" on page 44

“Agilent X-Series Licensing Options" on page 46

“Licensing New Measurement Application Software - After Initial Purchase" on

page 48

“Windows Configuration" on page 53

“Configuring Printers" on page 56

“Configuring LAN" on page 57

“Windows Security" on page 58

“System Maintenance" on page 62

“USB Connections" on page 63

“Hard Drive Partitioning and Use" on page 64

“Hard Drive Recovery Process" on page 67

Agilent Technologies

41

Page 41

3 Test Set Operating System

Agilent Software Installed

Agilent U9065A & U9060A software

The Agilent U9065A Sequence Analyzer Application and the Agilent U9060A IQ

Analyzer application are installed by default in the test set, with fixed perpetual licenses

(no purchase order required).

Additional measurement applications are available. Each application requires a license

to execute the software. All of these applications are installed by the factory at the time

of manufacture, even if the licenses have not been purchased. You may purchase

additional licenses at a later date.

42 Getting Started Guide

Page 42

Customer Installation of Software

3rd party software verified by Agilent

Agilent has verified that the following programs are compatible with the test set

applications:

• Symantec AntiVirus™ Corporate Edition version 10

• MathWorks MATLAB

Installation of other 3rd party software

The X-Series platform is an open Windows environment, so you can install nonapproved software on the test set. However, installation of non-approved software may

affect test set performance. Agilent does not warrant the performance of the test set with

non-approved software installed.

Test Set Operating System 3

Before installing any additional programs on the test set, you should exit

the test set application.

Also, you must not remove any applications or programs that are installed

on the test set when it is shipped from the factory.

If you install programs other than those that Agilent has tested, it could cause problems

with the test set's applications. If this happens, you should try uninstalling the program

that has caused the problem, or try changing the program's configuration. If this does not

correct the problem, you may have to use the Agilent Recovery system to reinstall the

test set's system software.

Getting Started Guide 43

Page 43

3 Test Set Operating System

User Accounts

Administrator login

The Administrator account ships from the factory with the password “agilent4u”. Using

the Administrator account you can perform the following operations:

• Install software

• Configure network and printer access

• Access all files on the test set

• Add or change user accounts and passwords

• Change Windows settings

• Run any application

User login

The default user account that ships from the factory is “Instrument” with the password

“measure4u”. This user is a member of the Power Users group. Using the Instrument

account you can perform the following operations:

• Install software

• Configure network and printer access

• Access files on the test set that are accessible to the Power Users group

• Run applications that are accessible to the Power Users group

AgilentOnly user account

The test set contains a user account called “AgilentOnly” that can be used by Agilent’s

customer support in the event that the Administrator password was changed and has

since been lost or forgotten. You must not remove or modify the AgilentOnly account.

Agilent service user accounts

User accounts are defined for Agilent’s use if it is necessary to service the test set.

44 Getting Started Guide

Page 44

Customer creation of accounts

You can create additional user accounts and decide on the level of security granted to any

new user accounts created. For example, the level of security can be assigned as

administrator, power user, user, backup operators. User names are not case sensitive but

passwords are case sensitive.

For the test set software to operate, the user account executing the software

must be assigned Administrator or Power User privileges. Otherwise, the

test set software will not operate correctly.

It is Agilent’s expectation that each user’s My Documents folder is mapped to the D:

drive. This is to avoid overwriting the user’s data in the event the Agilent Recovery must

be performed. Also, this facilitates convenient backup by copying the contents of the D:

drive to external media. All users accounts created by the factory already have My

Documents mapped to the D: drive. Please map all new users My Documents folders to

the D: drive.

Test Set Operating System 3

Getting Started Guide 45

Page 45

3 Test Set Operating System

Agilent X-Series Licensing Options

The Agilent X-Series test sets use three licensing types: Fixed Perpetual, Transportable

Perpetual, and Trial. These licensing types are available on all existing measurement

applications except the Sequence Analyzer Measurement Application (U9065A), which

requires a fixed perpetual license. Fixed Perpetual licenses are also required to enable

hardware options.

Fixed Perpetual

Fixed Perpetual licenses are the traditional license type (Fixed) with the same duration

(Perpetual) that have been available for all features since the X-Series introductions.

Fixed Perpetual licenses are identified by the “F” in the second character and “P” in the

third character of the option designator:

Example: U9080A-1FP

A license key is instrument model and serial number dependent. You can only install the

license key on the specific instrument for which it was created.

Transportable Perpetual

Transportable Perpetual licenses are an optional license type offering deployment

duration which is not fixed to a specific instrument model and serial number.

Transportable Perpetual licenses are identified in the product structure by a “T” in the

second character and “P” in the third character of the option designator:

Example: U9080A-1TP

Transportable Perpetual licenses require a connection to the Agilent server only for

managing the check-in/out of the license. The Agilent licensing server also provides for

storage of unused licenses which have been transported off instruments but are awaiting

assignment to new instruments. The server will limit the number of transports per 30 day

period per application license to 10.

Unlike Fixed Perpetual licenses which are pre-installed at the factory with new

instrument purchases, Transportable Perpetual licenses require redemption and

installation of the license before the first use. This allows the user to determine on which

instrument to initially install the application license.

Agilent recommends that instruments be at the same instrument software release to

ensure the latest code is available on each instrument so that the user experience is

identical between instruments. This is particularly important when transporting the

license for a newly-released application which may only be available in the latest latest

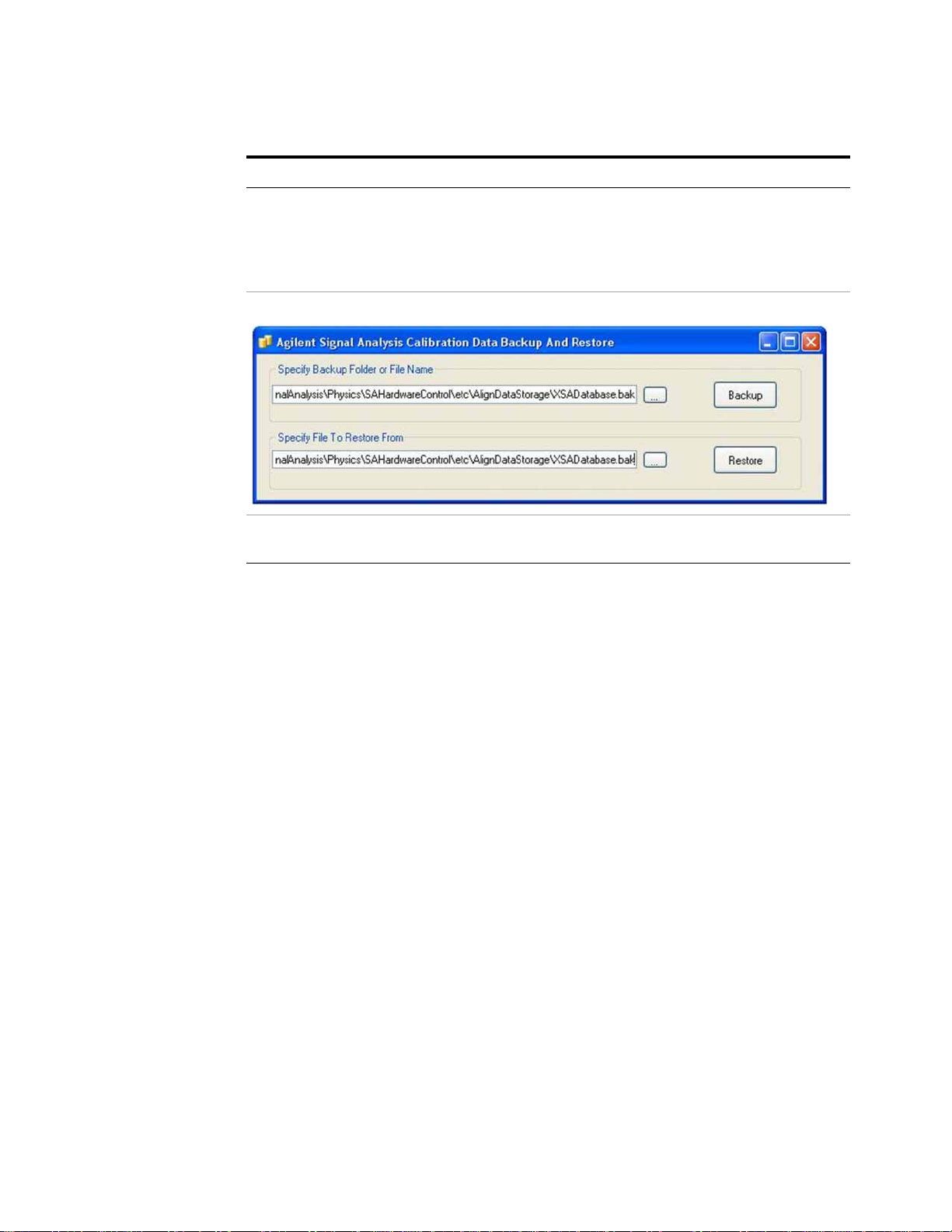

software release.

46 Getting Started Guide

Page 46

Time-Based Licenses

Time-based licenses are fixed licenses (that is, not transportable from one instrument to

another) that are limited in duration. Time-based licenses are identified by the “F” in the

second character and a numeral (indicating duration in months) in the third character of

the option designator:

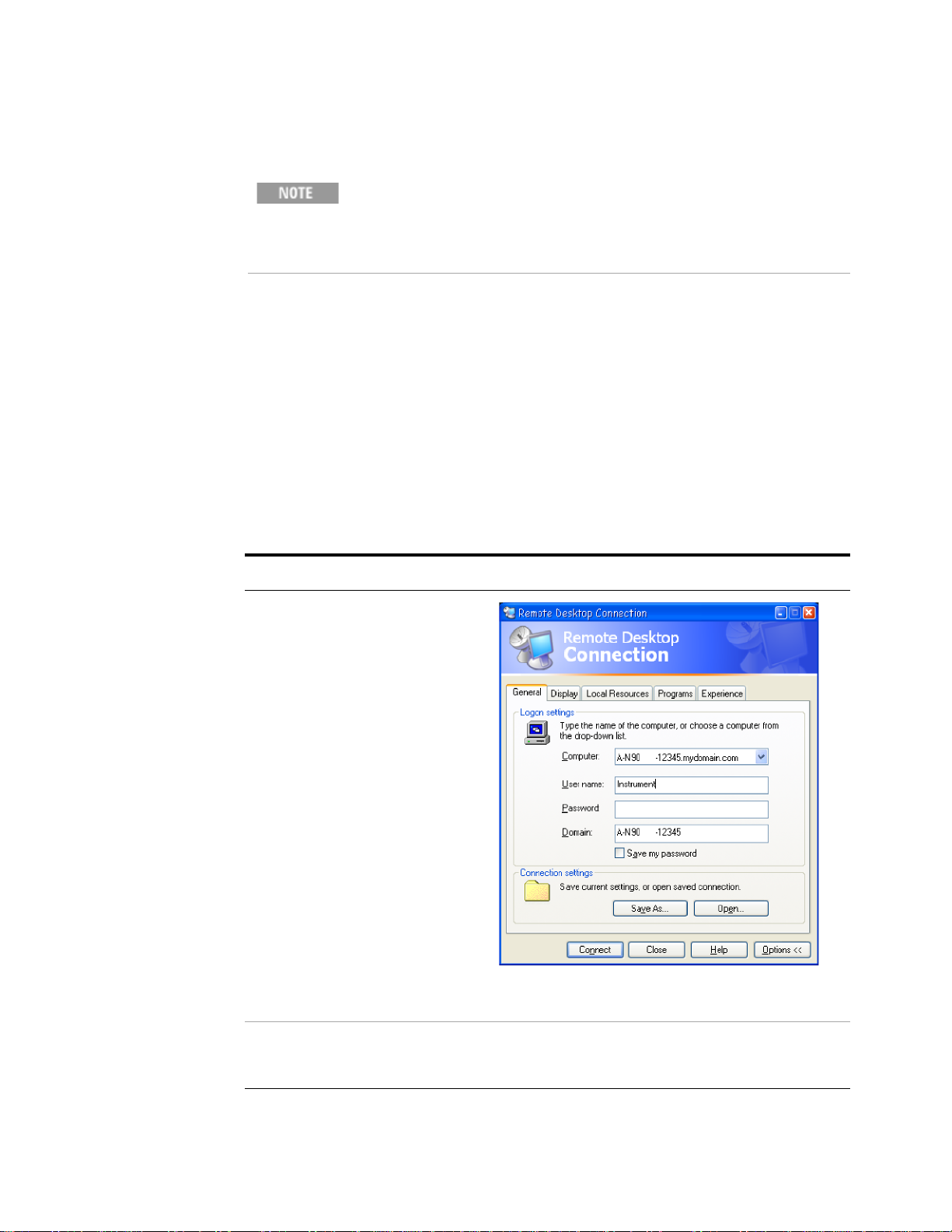

Example: U9080A-1F3

A license key is instrument model and serial number dependent. You can only install the

license key on the specific instrument for which it was created.

Trial license s

Trial licenses are available so that you may try applications before you buy the full

applications. These licenses are time limited for a 14 day period, and are restricted to one

trial for an individual application per instrument. The restriction is enforced through the

license redemption process of the Agilent Software Licensing (ASL) system.

Trial licenses are only available for measurement applications and not available for

enabling hardware capability.

Test Set Operating System 3

Trial licenses are not installed in the factory and no entitlement certificates are created

for distribution with new instrument shipments. Trial licenses are not available for order,

but are available from the Agilent Web site after completing a brief registration:

http://www.agilent.com/find/xseries_trial

Trial Licenses are identified by the license designator “-TRL”.

Example: N9071A-TRL

If a product has multiple tiers (levels of functionality), the –TRL license enables all tiers

for the duration of the license. If you have a base tier and want a trial license for a higher

tier, you can install the –TRL license. When the duration expires the entitlement is

reverted back to the base tier.

Getting Started Guide 47

Page 47

3 Test Set Operating System

Licensing New Measurement Application Software - After Initial Purchase

Additional measurement application software can be ordered after your initial purchase

of the E6607B test set. Software upgrades are provided in a kit that includes an option

based Entitlement Certificate, a license agreement, and a USB storage device. The

licenses are downloaded from the license Web site onto the storage device so they can be

loaded into the instrument.

If you do not want to wait for your upgrade kit to arrive, licenses can be installed using

any available USB storage device. If you choose to do this, we recommend that the latest

version of the instrument software be installed. This ensures that the measurement

application being licensed and activated is installed and is the most current version.

The latest revision of the software may be downloaded from:

http://www.agilent.com/find/ext

A license key is usually for one instrument model and serial number combination. The

license key will only install itself on that instrument.

No calibration is required after a test set application installation.

Installation procedure over USB

Step Action Notes

1 Redeem the Option

Upgrade Entitlement

Certificate

2 Save the license file

3 Load the license file

• Follow the instructions on the Certificate After redeeming your Option Upgrade

Entitlement Certificate you will receive

an e-mail with an attached License File.

• Save the .lic file to the root directory of a

USB storage device

• Connect the USB storage device to one of

the test set USB ports.

Alternatively the license file can be manually installed over USB or LAN by placing the

license file in the following folder on the test set.

Windows will detect the new hardware

and may display the configuration menu.

The test set automatically loads the

license file. (This may take a few

minutes) Upon completion, the Agilent

License Manager displays a “Successful

License Installation” message.

C:\Program Files\Agilent\licensing

48 Getting Started Guide

Page 48

Step Action Notes

Test Set Operating System 3

4 Verify installation a Cycle the power on the signal test set.

b Press System, Show, System.

c Verify that the new application appears in

the list.

The application will not be available for

use until after the power has been cycled

This displays the list of installed

applications.

If you require further assistance, please

contact the Agilent support team.

Online assistance: http://

www.agilent.com/find/assist

If you do not have access to the Internet,

contact your local Agilent Technologies

Sales and Service Office, or if in the

United States, call 1-800-829-4444.

Getting Started Guide 49

Page 49

3 Test Set Operating System

Transporting a License Between X-Series Test Sets

Transportable licenses can be identified by the letters "TP" in their option desi gnator . For

example, U9063A-2TP indicates the license is transportable and perpetual. To transport

this license from one X-Series test set to another, Agilent recommends that both test sets

be at the same instrument software release. This ensures that the user experience is

identical between instruments.

As a minimum, the instrument software release in the test set that will receive the

transportable license (the "target instrument") must at least be able to support the desired

application.

The X-Series signal test sets support several ways of transporting licenses. The

procedure below will focus on the most common procedure, where neither of the test

sets has access to an internet connection. For this procedure to work, a PC with an

internet connection is required

You will need the following:

• USB flash drive

• USB keyboard

•USB mouse

We will refer to the test set from which the transportable license will be removed as the

"source instrument". We will refer to the test set which will receive the transportable

license as the "target instrument".

Procedure for Transporting a License, Neither Test Set Connected to the

Internet

Step Action Notes

1 Connect the USB devices

to the source instrument

2 Verify software version

in each test set

3 Obtain the Host ID from

the Target Instrument

• Connect the USB flash drive, USB

keyboard, and USB mouse to the USB

ports on the source instrument.

• On each test set, press System, Show,

System and make note of the Instrument

S/W Revision on each.

• On the target instrument, press System,

Show, System, and make note of the

Host ID.

It will be necessary to use one or more of

the rear panel ports to connect the USB

devices.

Ideally, the revisions will be the same.

But at least, both versions should be able

to support the application whose license

is being transported.

This information will be needed to issue

the license for the target instrument. The

Host ID is the model number, followed

by a comma, followed by the serial

number.

50 Getting Started Guide

Page 50

Step Action Notes

Test Set Operating System 3

4 Start the License

Manager on the Source

Instrument

5 Transport the

Transportable License

from Source Instrument

6 Get New License from

ASL Transportation Web

page

• On the source instrument, press System,

More, Licensing… It may take a minute

for the Agilent License Manager screen to

be fully populated with all the installed

licenses.

a On the source instrument, locate the

desired license to be transported and

highlight it. Its option designator should

include the letters "TP".

b .Right-click on the mouse and select

Delete.

c Click Yes in the License Deletion

Confirmation dialog box.

d After a few seconds, a Transport License

dialog box will appear. Click OK and

save the *.url files on the USB flash drive,

with a name such as

"PhaseNoise_License.url"

a Insert USB flash drive into PC that is

connected to the internet

b On the PC, locate the *.url file on the

USB flash drive that was saved in the

previous step and click on it.

c After a few seconds, the ASL

Transportation W eb page will appear . One

field, the New Host ID will be empty.

d Enter the Host ID of the target instrument

(step 3 above) into the field marked New

Host ID.

e Click Submit.

Be sure you are selecting a transportable

license and not a fixed perpetual license.

Although you are "deleting" the

transportable license, the ultimate action

will be to transport it.

The information in this dialog box will

be used to issue a new license for the

target instrument.

The PC must have an internet connection

and an available USB port.

Most of the fields have been populated

from the information in the *.url file.

Be very careful when entering the New

Host ID. A mistake made in entering the

New Host ID will result in an invalid

license being issued. Be sure there is a

comma between the model number and

serial number. There should be no spaces

in the Host ID.

7 Save License File to

USB Flash Drive

Getting Started Guide 51

a The ASL Transportation Web page will

indicate that a license file is available and

display two links to the license file. Rightclick on the license file and select Save

Target As…

b Save the license file to the root level of

the USB flash drive, keeping the ".lic" file

extension.

c Close the Save dialog and exit the ASL

Transportation Web page.

Either link can be used to either display

or save the license file.

The license file must be saved to the root

level of the USB flash drive for it to be

recognized by the target instrument.

Page 51

3 Test Set Operating System

Step Action Notes

8 Install License File in

Target Instrument

a With the target instrument running, insert

the USB flash drive into one of the front

panel USB ports. After a few minutes,

you should see a message saying

"Successful License Installation"

b Cycle power on the target instrument.

c O nce the test set has re-booted, the

application should be ready to use on the

target instrument.

The Agilent License Services running on

the target instrument looks for *.lic files

whenever it detects a USB device has

been inserted. If the contents of the *.lic

file are appropriate for the instrument,

the license will be installed

automatically.

Newly-installed licenses are only

recognized by the instrument software

on power-up.

52 Getting Started Guide

Page 52

Windows Configuration

The Windows settings have been optimized for the best measurement performance. Any

modifications to these settings may degrade test set performance and measurement

speed. In general, most Windows System settings (typically set through the Windows

Control Panel) should not be modified. Those that can be safely modified are listed

below.

Settings that can be changed

You may change the following Windows settings or administrative tasks (available from

the Windows Control Panel) to select your personal preferences.

Test Set Operating System 3

To recover from pro blem s caused by changin g Windows systems settings,

you may have to reinstall the Windows system and test set application using

the Agilent Recovery process.

You may use

this feature

Before changing any Windows System settings, exit the test set

application.

To do this ...

Configure Microsoft Automatic Updates.

Install and configure an Anti Virus program.

Setup new test set user accounts.

Do not delete or modify the “Agilent-Only” user

account.

Add the test set to a network.

Getting Started Guide 53

Page 53

3 Test Set Operating System

You may use

this feature

To do this ...

Install and configure a printer.

Set the time and date.

Modify System Properties, Advanced Tab settings of Performance,

for Best Performance

Settings that must not be changed

Avoid changing any settings in this section. Changes to the following settings may

degrade test set performance, screen displays, and measurement speed.

Adjust

. Leave all other settings unchanged.

Do NOT use this

feature

To do this...

Do not change Power Options. (Power Scheme, Power Button,

Hibernate)

Do not modify System Properties, Hardware Tab settings (Device

Manager, Drivers).

Do not modify System Properties, Advanced Tab settings (Performance

(except

Recovery , Environment Variables, Error Reporting)

Adjust for Best Performance), User Profiles, Startup and

Do not remove installed Fonts.

Do not change the following Display Settings:

• Screen Saver settings

• The screen resolution, 1024 x 768

• DPI setting from Normal size (96 DPI)

54 Getting Started Guide

Page 54

Test Set Operating System 3

Do NOT use this

feature

To do this...

Do not delete or modify the “AgilentOnly” user account.

In addition, DO NOT:

• Add, delete, or modify hard-disk drive partitions.

• Delete or modify Agilent registry entries.

• Change the contents of any directories containing the name “Agilent”

• Stop these services:

— The MSSQL$CDF service or uninstall the “Microsoft SQL Server Desktop

Engine”

— The IIS server or tamper with any virtual directories (or their contents) that came

configured with the test set.

• Uninstall these libraries, interfaces, or programs:

— The Agilent I/O Libraries

— The .NET Framework or any Hotfixes or Service Packs for the .NET Framework

— The “Microsoft Visual J# .NET Redistributable Package 1.1"

— Programs that begin with “Agilent”

— The Adobe Acrobat Reader

•Modify

— The Agilent I/O Library “GPIB27”, “GPIB28” interfaces shown as configured

Instrument I/O in the Agilent Connection Expert or I/O Config.

Getting Started Guide 55

Page 55

3 Test Set Operating System

Configuring Printers

Printers are configured using the Microsoft Windows Control Panel. It is easily accessed

from the Windows Start menu or from under the front panel

process is most easily done using a USB mouse and an external keyboard. If you do not

have a mouse it can be done using front-panel keys. See “Navigating Windows Without

a Mouse" on page 74.

When setting up a new printer, you may need to load the printer driver (unless you are

using a network printer that your IT department has set up to include the driver). The

manufacturer of the printer supplies the driver software and process. That may require

that you attach an external USB disk drive. An alternative is to connect the test set to the

LAN and download the driver from the printer manufacturer’s internet site.

System key. This setup

56 Getting Started Guide

Page 56

Configuring LAN

Hostname

The Computer Name, or hostname, is pre-configured from the factory. It must be a

unique name so that it does not conflict with other equipment on your LAN. The preconfigured Computer Name is A-E6607B-xxxxx, where xxxxx represents the last 5

digits of the test set serial number.

To change the Computer Name consult the Microsoft Windows Help and Support

Center.

IP Address & Gateway

The test set is pre-configured to obtain an IP Address using DHCP. The IP Address and

Gateway can be changed. Consult the Microsoft Windows Help and Support Center to

configure the LAN.

Test Set Operating System 3

Getting Started Guide 57

Page 57

3 Test Set Operating System

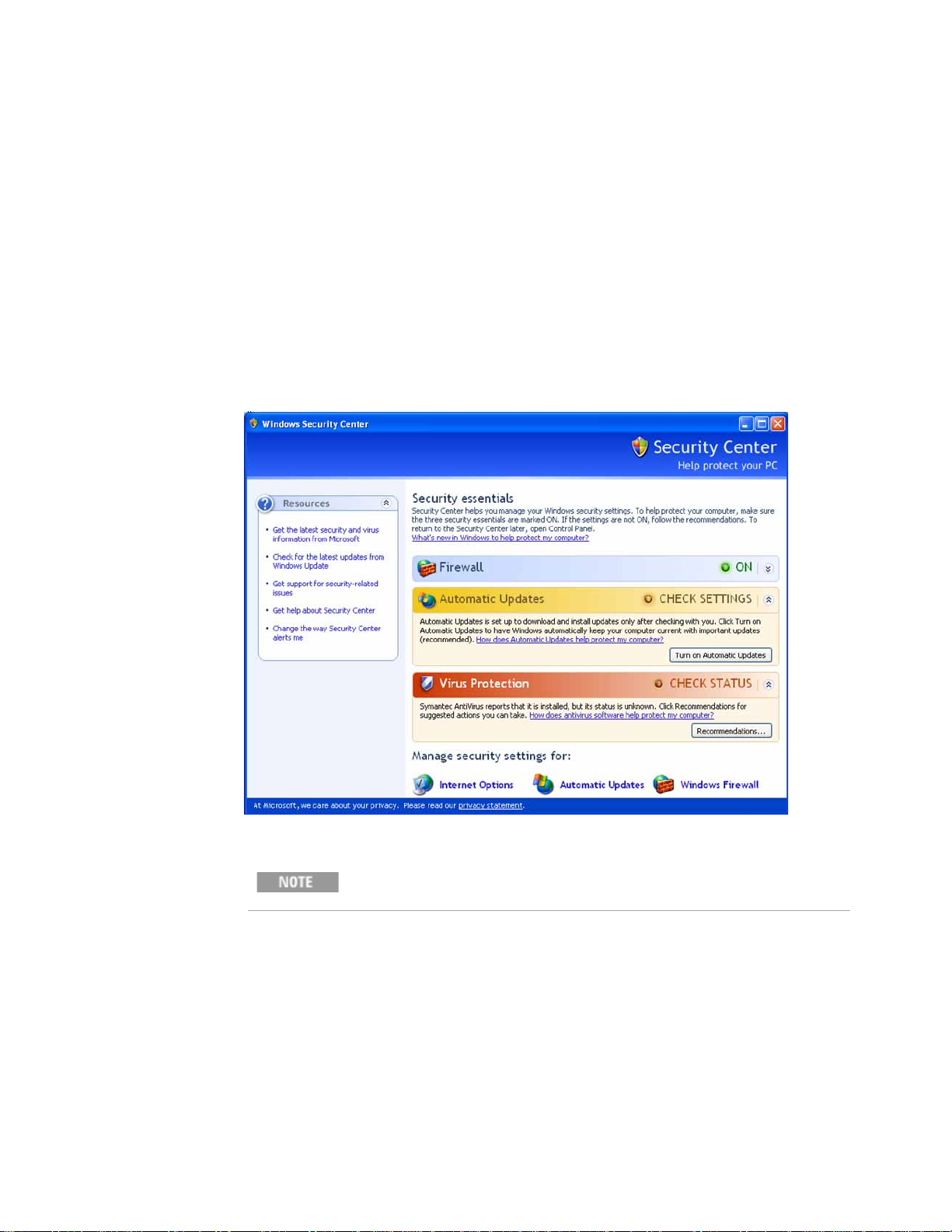

Windows Security

Microsoft recommends the following to ensure the test set Windows operating system is

protected:

• Use an internet firewall.

• Get the latest critical Windows updates.

• Use up-to-date antivirus software.

To check the status or make changes in the security settings for your test set, open the

Windows Security Center, click

Start, Control Panel, and then click Security Center.

The window may look slightly different on your test set.

58 Getting Started Guide

Page 58

Windows Firewall

The test set is shipped with the Windows Firewall enabled.

Test Set Operating System 3

Windows Firewall

operation of the test set over a network. Modifying these settings may cause the test set

to not operate properly.

Automatic updates

The default test set setting is to automatically check for critical Windows Updates and

notify you, if the test set has internet access.

You can change the configuration of the Microsoft Automatic Updates. You can choose

not to have automatic updates. Then you can manually update Windows by accessing

Internet Explorer and from the Tools menu select Windows Update.

The window may look slightly different on your test set.

Exceptions for programs and ports have been added to allow proper

Getting Started Guide 59

Page 59

3 Test Set Operating System

Virus protection

There is no antivirus software included with your test set. Antivirus application software

has been tested to be comp atible with the test set. See the section on “3rd party software

verified by Agilent" on page 43 for anti-virus software that has been tested by Agilent.

Be aware that downloading and installing Windows Updates can be

network and CPU usage intensive (impacting the test set performance), and

some Windows Updates automatically reboot the test set. It is

recommended that Windows Updates be performed when the test set is not

in normal use.

Having antivirus software installed may have a slight impact on the test set

performance.

60 Getting Started Guide

Page 60

Test Set Operating System 3

Spyware protection

There is no anti-spyware software installed on the test set. This should not be a problem

if you do not use the test set for a lot of internet browsing. Having spyware in the test set

could have an impact on the test set performance.

Getting Started Guide 61

Page 61

3 Test Set Operating System

System Maintenance

Backup

It is recommended that you have a regular backup strategy. Your IT department may

already have a backup strategy in place which is suitable for the test set and its data.

Using the Agilent Recovery system in conjunction with a regular backup strategy should

allow full recovery of the test set data.

The Windows operating system has a Backup utility that you can use to archive files and

folders in case of a hard disk drive failure. See the Microsoft Windows Help and Support

Center for more information on this utility. You can also use third party backup utilities.

However, you must ensure that this third party software is compatible with the test set's

system software. See “Customer Installation of Software" on page 43 for more

information.

When performing backups, we recommend that you backup the data to an external

storage device connected to the network or one of the test set's USB connectors. Also,

you should perform backups at times when the test set is not being used for normal

operations as it may impact the test set's overall performance.

System restore