Page 1

Keysight 53210A/53220A/

53230A 350 MHz Universal

Frequency Counter/Timer

Assembly Level

Service Guide

Page 2

Notices

Copyright Notice

© Keysight Technologies 2011–2020

No part of this manual may be repro-

duced in any form or by any means

(including electronic storage and

retrieval or translation into a foreign

language) without prior agreement and

written consent from Keysight Technologies as governed by United States and

international copyright laws.

Trademarks

Microsoft and Windows are U.S.

registered trademarks of Microsoft

Corporation.

Manual Part Number

53220-90010

Edition

Edition 9, December 2020

Printed in:

Printed in Malaysia

Published by:

Keysight Technologies

Bayan Lepas Free Industrial Zone,

11900 Penang, Malaysia

Technology Licenses

The hardware and/or software

described in this document are furnished under a license and may be

used or copied only in accordance with

the terms of such license.

Declaration of Conformity

Declarations of Conformity for this

product and for other Keysight products may be downloaded from the

Web. Go to http://www.keysight.com/

go/conformity. You can then search by

product number to find the latest Declaration of Conformity.

U.S. Government Rights

The Software is “commercial computer

software,” as defined by Federal Acquisition Regulation (“FAR”) 2.101. Pursuant to FAR 12.212 and 27.405-3 and

Department of Defense FAR Supplement (“DFARS”) 227.7202, the U.S.

government acquires commercial computer software under the same terms

by which the software is customarily

provided to the public. Accordingly,

Keysight provides the Software to U.S.

government customers under its standard commercial license, which is

embodied in its End User License

Agreement (EULA), a copy of which can

be found at http://www.keysight.com/

find/sweula. The license set forth in the

EULA represents the exclusive authority

by which the U.S. government may use,

modify, distribute, or disclose the Software. The EULA and the license set

forth therein, does not require or permit, among other things, that Keysight:

(1) Furnish technical information

related to commercial computer software or commercial computer software

documentation that is not customarily

provided to the public; or (2) Relinquish

to, or otherwise provide, the government rights in excess of these rights

customarily provided to the public to

use, modify, reproduce, release, perform, display, or disclose commercial

computer software or commercial computer software documentation. No

additional government requirements

beyond those set forth in the EULA

shall apply, except to the extent that

those terms, rights, or licenses are

explicitly required from all providers of

commercial computer software pursuant to the FAR and the DFARS and are

set forth specifically in writing elsewhere in the EULA. Keysight shall be

under no obligation to update, revise or

otherwise modify the Software. With

respect to any technical data as

defined by FAR 2.101, pursuant to FAR

12.211 and 27.404.2 and DFARS

227.7102, the U.S. government

acquires no greater than Limited Rights

as defined in FAR 27.401 or DFAR

227.7103-5 (c), as applicable in any

technical data.

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,”

AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO THE

MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, KEYSIGHT DISCLAIMS ALL WARRANTIES, EITHER

EXPRESS OR IMPLIED, WITH REGARD

TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS

OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION

WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT

OR OF ANY INFORMATION CONTAINED HEREIN. SHOULD KEYSIGHT

AND THE USER HAVE A SEPARATE

WRITTEN AGREEMENT WITH WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Safety Information

CAUTION

A CAUTION notice denotes a hazard. It

calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not proceed beyond a CAUTION notice until

the indicated conditions are fully

understood and met.

WARNING

A WARNING notice denotes a hazard. It

calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in personal injury or death.

Do not proceed beyond a WARNING

notice until the indicated conditions are

fully understood and met.

2 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 3

Software Updates/Licenses

Periodically, Keysight releases software updates to fix known defects and

incorporate product enhancements. To search for software updates and the latest

documentation for your product, go to the product page at:

www.keysight.com/find/53210A

www.keysight.com/find/53220A

www.keysight.com/find/53230A

A portion of the software in this product is licensed under terms of the General

Public License Version 2 (“GPLv2”). The text of the license and source code can be

found at:

www.keysight.com/find/GPLV2

This product utilizes Microsoft Windows CE. Keysight highly recommends that all

Windows-based computers connected to Windows CE instruments utilize current

anti-virus software. For more information, go to the product page at:

www.keysight.com/find/53210A

www.keysight.com/find/53220A

www.keysight.com/find/53230A

Keysight 53210A/53220A/53230A Assembly Level Service Guide 3

Page 4

Assistance

This product comes with the standard product warranty. Warranty options,

extended support contacts, product maintenance agreements and customer

assistance agreements are also available. Contact your nearest Keysight

Technologies Sales and Service office for further information on Keysight

Technologies' full line of Support Programs.

Certification

Keysight Technologies certifies that this product met its published specifications

at time of shipment from the factory. Keysight Technologies further certifies that

its calibration measurements are traceable to the United States National Institute

of Standards and Technology, to the extent allowed by the Institute's calibration

facility, and to the calibration facilities of other International Standards

Organization members.

Exclusive Remedies

The remedies provided herein are the customer's sole and exclusive remedies.

Keysight Technologies shall not be liable for any direct, indirect, special,

incidental, or consequential damages, whether based on contract, tort, or any

other legal theory.

4 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 5

Lithium Battery Recycling

The 53210A/53220A/53230A counters contain a 3 V “coin cell” lithium battery.

Keysight recommends that this battery be replaced every year at the instrument’s

1-year calibration interval. Replacement procedures are provided in the 53210A/

53220A/53230A Service Guide.

Option 300 provides battery operation of the 53210A/53220A/53230A using a 12

lithium battery. Performance of this battery will degrade over time as a function of

the number of battery charge/discharge cycles.

Refer to local, state, or Federal regulations when disposing of, or recycling either

battery.

Safety Symbols

The following symbols on the instrument and in the documentation indicate

precautions which must be taken to maintain safe operation of the instrument.

Standby Power. Unit is not completely

disconnected from AC mains when

power switch is in standby position.

Frame or chassis (ground) terminal

Caution, risk of danger (refer to this

manual for specific Warning or Caution

information)

Keysight 53210A/53220A/53230A Assembly Level Service Guide 5

CAT I

IEC Measurement Category I. Do NOT

connect inputs to AC mains or to

circuits derived from AC mains.

Page 6

Safety Information

The following general safety precautions must be observed during all phases of

operation of this instrument. Failure to comply with these precautions or with

specific warnings or operating instructions in the product manuals violates safety

standards of design, manufacture, and intended use of the instrument. Keysight

Technologies assumes no liability for the customer's failure to comply with these

requirements.

General

Do not use this product in any manner not specified by the manufacturer. The

protective features of this product may be impaired if it is used in a manner not

specified in the operation instructions.

Before applying power

Verify that all safety precautions are taken. Note the instrument's external

markings described under "Safety Symbols".

Ground the instrument

The Keysight 53210A/53220A/53230A is provided with a grounding-type power

plug. The instrument chassis and cover must be connected to an electrical ground

to minimize shock hazard. The ground pin must be firmly connected to an

electrical ground (safety ground) terminal at the power outlet. Any interruption of

the protective (grounding) conductor or disconnection of the protective earth

terminal will cause a potential shock hazard that could result in personal injury.

Fuses

The Keysight 53210A/53220A/53230A is provided with an internal line fuse

appropriate for the line voltages listed on the instrument. This fuse is not user

accessible.

6 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 7

Do not operate in an explosive atmosphere

Do not operate the instrument in the presence of flammable gases or fumes.

Do not operate near flammable liquids

Do not operate the instrument in the presence of flammable liquids or near

containers of such liquids.

Do not remove the instrument cover

Only qualified, service-trained personnel who are aware of the hazards involved

should remove instrument covers. Always disconnect the power cable and any

external circuits before removing the instrument cover.

Do not modify the instrument

Do not install substitute parts or perform any unauthorized modification to the

product. Return the product to a Keysight Sales and Service Office for service and

repair to ensure that safety features are maintained.

In case of damage

Instruments that appear damaged or defective should be made inoperative and

secured against unintended operation until they can be repaired by qualified

service personnel.

Cleaning the instrument

Clean the outside of the instrument with a soft, lint-free, slightly-dampened cloth.

Do not use detergents or chemical solvents.

Keysight 53210A/53220A/53230A Assembly Level Service Guide 7

Page 8

WARNING

Do not connect the input channels of the 53210A/53220A/53230A to AC

line-voltage mains or to circuits derived from AC mains. The instrument

must be used in CAT I (isolated from mains) applications only. Do not use in

other IEC Measurement Category (CAT II, CAT III, or CAT IV) applications.

Failure to observe these precautions may result in electric shock and serious

personal injury.

WARNING

Protection limits

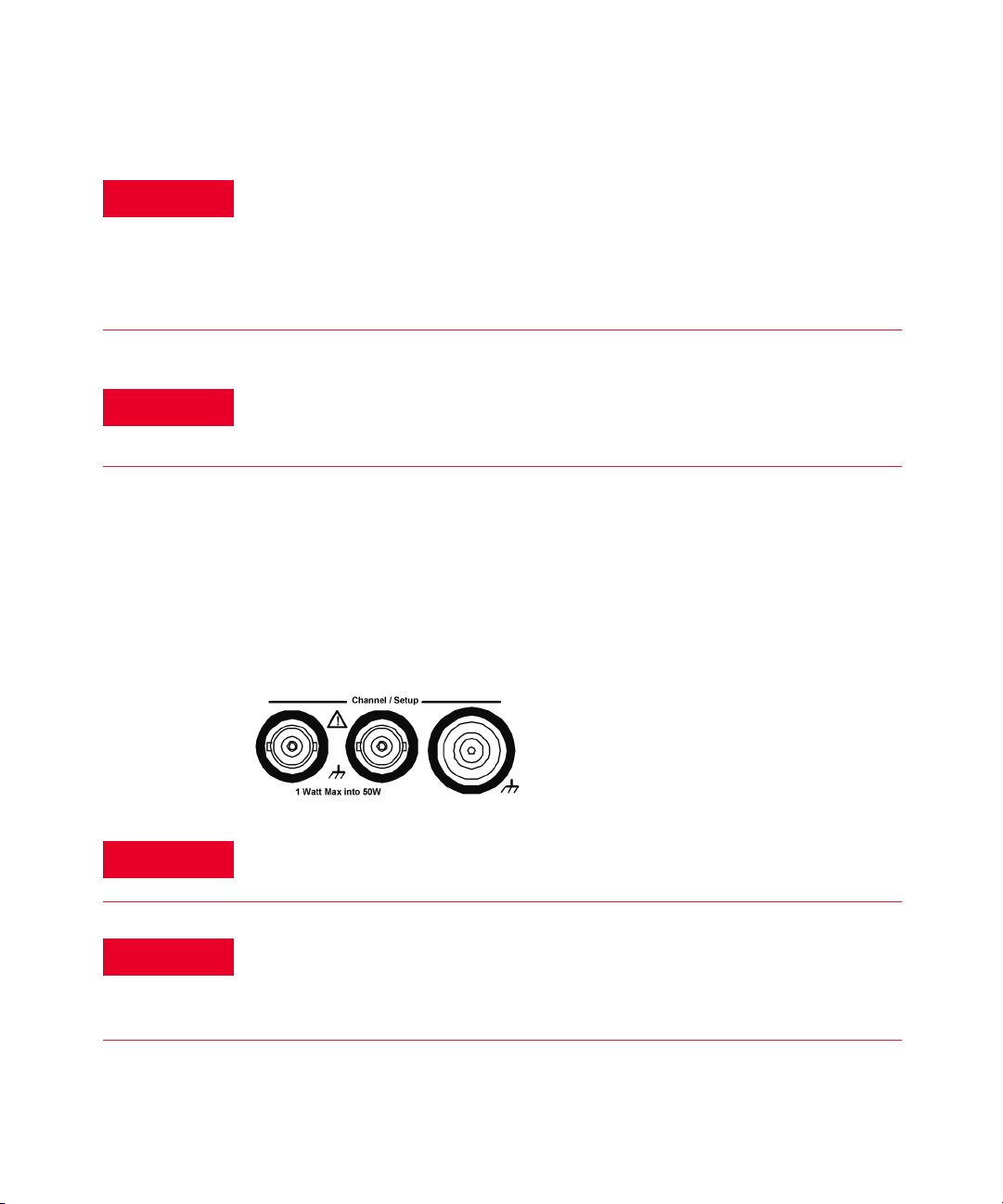

WARNING

The BNC shells of the input terminals are connected to the instrument

chassis. Verify signal polarity before making any connections to the input

terminals.

The Keysight 53210A/53220A/53230A 350 MHz Universal Frequency Counter/

Timer provides protection circuitry to prevent damage to the instrument and to

protect against the danger of electric shock, provided the Protection Limits are

not exceeded and the instrument is properly grounded. To ensure safe operation

of the instrument, do not exceed the Protection Limits defined on the front panel:

During battery operation, the maximum measured signal supplied by the

user is +42 V.

WARNING

8 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Product Options 201/202 add parallel Channel 1 and Channel 2 inputs to the

rear panel of the instrument. Signals on the center conductor of either

panel’s channel BNCs are also present on the corresponding center

conductor of the BNC on the opposite panel.

Page 9

Installing the instrument

The Keysight 53210A/53220A/53230A operates in the following line-voltage

ranges:

100 V to 240 V, 50 Hz to 60 Hz

100 V to 127 V, 440 Hz

90 VA Max

Instrument ventilation is through the sides and rear. Do not obstruct the

ventilation holes in any of these locations.

Battery operation

When operating the 53210A or 53220A under battery power (Option 300), failure

to observe the following warnings may result in damage to the instrument,

electric shock, and serious personal injury:

WARNING

WARNING

Keysight 53210A/53220A/53230A Assembly Level Service Guide 9

Connect the instrument chassis to earth ground during battery operation to

minimize shock hazard. Any interruption or disconnection of the protective

earth terminal will cause a potential shock hazard that could result in

personal injury.

Under battery power, the instrument chassis may float to the potential of the

measured signal supplied by the user.

Page 10

Waste Electrical and Electronic Equipment (WEEE) Directive

This instrument complies with the WEEE Directive marking requirement. This

affixed product label indicates that you must not discard this electrical or

electronic product in domestic household waste.

Product category:

With reference to the equipment types in the WEEE directive Annex 1, this

instrument is classified as a “Monitoring and Control Instrument” product.

The affixed product label is as shown below.

Do not dispose in domestic household waste.

To return this unwanted instrument, contact your nearest Keysight Service Center,

or visit http://about.keysight.com/en/companyinfo/environment/takeback.shtml

for more information.

Sales and Technical Support

To contact Keysight for sales and technical support, refer to the support links on

the following Keysight websites:

– www.keysight.com/find/53210A

www.keysight.com/find/53220A

www.keysight.com/find/53220A

(product-specific information and support, software and

documentation updates)

– www.keysight.com/find/assist

(worldwide contact information for repair and service)

10 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 11

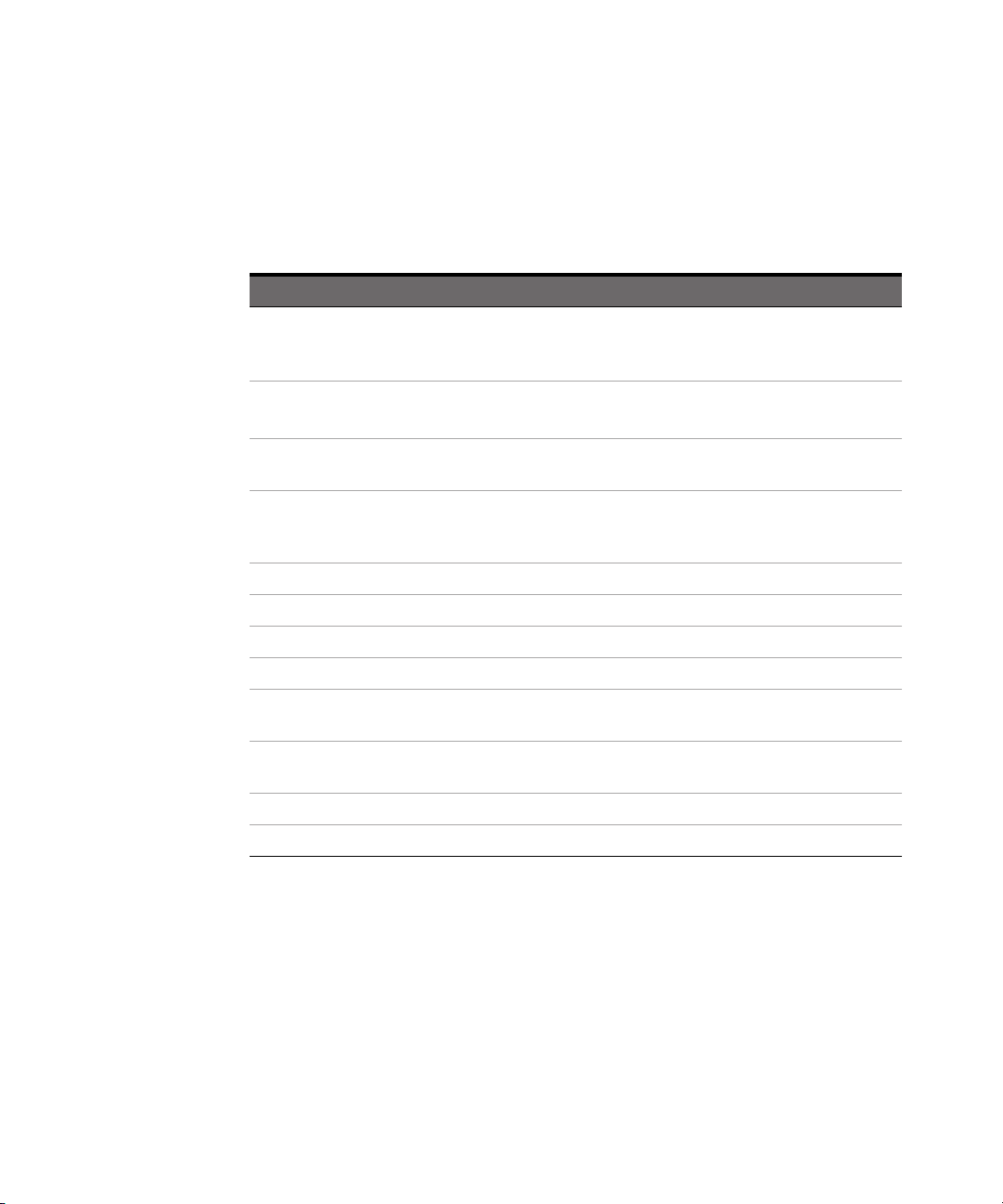

Table of Contents

Software Updates/Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Exclusive Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Lithium Battery Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Before applying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Ground the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Do not operate in an explosive atmosphere . . . . . . . . . . . . . . . . . . . .7

Do not operate near flammable liquids . . . . . . . . . . . . . . . . . . . . . . . .7

Do not remove the instrument cover . . . . . . . . . . . . . . . . . . . . . . . . .7

Do not modify the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

In case of damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cleaning the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Protection limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Installing the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Battery operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Waste Electrical and Electronic Equipment (WEEE) Directive . . . . . . .10

Product category: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Sales and Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1 Performance Tests

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Recommended calibration cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Internal auto-calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Equipment required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Power-On Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Keysight 53210A/53220A/53230A Assembly Level Service Guide 11

Page 12

Self-Test (Q) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Run internal self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Keysight 53210A/53220A/53230A Operational Verification . . . . . . . . . 33

Frequency checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Termination checks (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Keysight 53210A/53220A/53230A Complete Performance Tests . . . . 37

Test 1: (Q) Absolute time base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Test 2: (Q) Frequency accuracy - channels 1 and 2 . . . . . . . . . . . . . 44

Test 3: Single period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Test 4: (Q) Pulse width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Test 5: (Q) Time interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Test 6a: (Q) Frequency accuracy - channel 2/3, option 106

(6 GHz microwave channel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Test 6b: (Q) Frequency accuracy - channel 2/3, option 115

(15 GHz microwave channel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Test 7a: (Q) Pulse burst frequency - 53230A channel 3 option 150 with

option 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Test 7c: (Q) Pulse burst frequency - 53230A channel 3 option 150 with

option 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Keysight 53210A/53220A/53230A Operational Verification and Perfor-

mance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Keysight 53210A/53220A/53230A Performance Test Record

(Tests 1 to 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2 Service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Returning the counter to Keysight Technologies for service . . . . .102

About the Keysight 53210A/53220A/53230A calibration menu . . 102

The Keysight 53210A/53220A/53230A calibration procedures . . . 102

Pre-troubleshooting information . . . . . . . . . . . . . . . . . . . . . . . . . .102

Troubleshooting information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Returning the Instrument to Keysight Technologies for Service . . . .106

Operating checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Is the instrument inoperative? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

12 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 13

Does the instrument fail self-test? . . . . . . . . . . . . . . . . . . . . . . . . .106

Types of service available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Extended service contracts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Obtaining repair service (worldwide) . . . . . . . . . . . . . . . . . . . . . . . .107

To provide repair information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

To pack in the original packaging materials . . . . . . . . . . . . . . . . . .109

To pack in commercially available materials . . . . . . . . . . . . . . . . . .109

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

About the Keysight 53210A/53220A/53230A Calibration Menu . . . .111

Overview of the Keysight 53210A/53220A/53230A calibration menu .

111

To get help with the calibration menu functions . . . . . . . . . . . . . .113

To view the calibration menu and security status from the counter front

panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

To lock the counter against calibration . . . . . . . . . . . . . . . . . . . . . .116

To unlock the counter for calibration: . . . . . . . . . . . . . . . . . . . . . . .118

To change to a new security code . . . . . . . . . . . . . . . . . . . . . . . . . .119

The Keysight 53210A/53220A/53230A Calibration Procedures . . . . .120

Equipment required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Determine the counter firmware version . . . . . . . . . . . . . . . . . . . . .121

Calibration cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Calibration string: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Internal reference oscillator calibration . . . . . . . . . . . . . . . . . . . . .123

Summary of oscillator calibration procedure: . . . . . . . . . . . . . . . . .128

Remote oscillator calibration summary: . . . . . . . . . . . . . . . . . . . . .128

Voltage calibration (internal DACs) . . . . . . . . . . . . . . . . . . . . . . . . .129

Option 106 microwave channel frequency calibration . . . . . . . . . .135

Option 115 microwave channel frequency calibration . . . . . . . . . .142

Internal auto-calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

To view the calibration count . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Resetting the security code to a null . . . . . . . . . . . . . . . . . . . . . . . .153

Pre-Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Recommended test equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Repair considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Keysight 53210A/53220A/53230A Assembly Level Service Guide 13

Page 14

After service considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Troubleshooting the Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Unit is inoperative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Unit fails self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Power supply check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Checking the battery and battery charger . . . . . . . . . . . . . . . . . . . 166

Performing the counter self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

To determine the counter firmware version . . . . . . . . . . . . . . . . . . 172

Reseat the boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Re-run the counter self test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Command errors (-100...) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Execution errors (-200...) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Hardware errors (-240, -241, -250...) . . . . . . . . . . . . . . . . . . . . . . . 177

Device-specific errors (-300..., +800) . . . . . . . . . . . . . . . . . . . . . . . 178

Query errors (-400...) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Calibration errors (700...) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Self-test errors (901...) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

3 Replacing Assemblies

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Do this first . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

To Remove the Cover and Rear Bezel . . . . . . . . . . . . . . . . . . . . . . . . .187

To Remove the Internal DC Battery Assembly (Option 300) . . . . . . . . 189

To Remove the GPIB Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

To Remove a 6.0 GHz or 15.0 GHz Microwave Channel Assembly (Options

106/115) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Re-installing the microwave channel assembly . . . . . . . . . . . . . . . 192

To Remove the Processor Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

To Remove the Front Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . .196

To remove the display assembly from the front panel . . . . . . . . . . 199

14 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 15

To Remove the Motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

To Remove the AC Power Supply Assembly . . . . . . . . . . . . . . . . . . . .201

4 Retrofitting Options

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Do This first . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

To Retrofit Ultra-High Stability Timebase (Option 010) . . . . . . . . . . .206

To Retrofit the GPIB Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

GPIB connector parts (P/N 53200U-400) . . . . . . . . . . . . . . . . . . . .207

Preliminary steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

GPIB connector installation procedure . . . . . . . . . . . . . . . . . . . . . .208

To Retrofit the Internal Battery DC Power (Option 300) . . . . . . . . . . .209

Option 300 DC power input assembly parts . . . . . . . . . . . . . . . . . .209

Preliminary steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

Battery assembly installation procedure . . . . . . . . . . . . . . . . . . . . .210

To Retrofit the 53210A (Channel 1) or 53220A/53230A

(Channels 1/2) Rear Panel Inputs (Option 201) . . . . . . . . . . . . . . .215

Option 201 rear panel channel 1/2 parts . . . . . . . . . . . . . . . . . . . .215

Preliminary steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

Channels 1/2 rear panel retrofit procedure . . . . . . . . . . . . . . . . . .217

To Retrofit the 53210A Channel 2 Front Panel Input

(Option 106 or Option 115, plus Front Panel Option 202) . . . . . . .219

Option 106/115 channel 2 parts . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Option 202 front panel channel 2 parts . . . . . . . . . . . . . . . . . . . . .219

Preliminary steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Channel 2 front panel retrofit procedure (53210A) . . . . . . . . . . . .222

To Retrofit the 53210A Channel 2 Rear Panel Input, 6.0 GHz (Option 106)

or 15.0 GHz (Option 115) plus Rear Panel Option 203 . . . . . . . . . .229

Option 106/115 channel 2 parts . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Option 203 rear panel channel 2 parts . . . . . . . . . . . . . . . . . . . . . .229

Preliminary steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Channel 2 rear panel retrofit procedure (53210A) . . . . . . . . . . . . .232

Keysight 53210A/53220A/53230A Assembly Level Service Guide 15

Page 16

To Retrofit the 53220A/53230A Channel 3 Input, 6.0 GHz

(Option 106) or 15.0 GHz (Option 115) plus Front panel option 202 .

234

Option 202 front panel channel 3 parts . . . . . . . . . . . . . . . . . . . . . 234

Preliminary steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

Front panel installation procedure (Option 202 only) . . . . . . . . . .237

To Retrofit the 53220A/53230A Channel 3 Input, 6.0 GHz

(Option 106) or 15.0 GHz (Option 115) plus Rear Panel Option 203 . .

244

Option 203 rear panel channel 3 parts . . . . . . . . . . . . . . . . . . . . . .244

Preliminary steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

Rear panel installation procedure (Option 203 only) . . . . . . . . . . . 247

To Retrofit Option 150 (Pulse Microwave Measurements) for the 53230A

249

Retrofitting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

5 Replaceable Parts

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

Contacting Keysight Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . .253

By telephone (in the United States): . . . . . . . . . . . . . . . . . . . . . . . . 253

For mail correspondence, use the address below: . . . . . . . . . . . . . 253

How To Order A Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

6 Backdating

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

Serial numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Backdating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .264

To determine the counter firmware version . . . . . . . . . . . . . . . . . . 264

Procedure Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Information concerning Option 106 “Microwave Input”, FW Rev (27.0)

266

16 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 17

Option 106 microwave channel frequency calibration . . . . . . . . . .266

Backdating Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

Backdating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

Keysight 53210A/53220A/53230A Assembly Level Service Guide 17

Page 18

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

18 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 19

List of Figures

Figure 1-1 Operational verification setup for Keysight 53210A/220A/

Figure 1-2 Termination Check Setup . . . . . . . . . . . . . . . . . . . . . . .35

Figure 1-3 Absolute timebase test setup . . . . . . . . . . . . . . . . . . .39

Figure 1-4 Test setup for channel 1/2 frequency accuracy tests .44

Figure 1-5 Test Setup for Single Period . . . . . . . . . . . . . . . . . . . .51

Figure 1-6 Pulse width test setup . . . . . . . . . . . . . . . . . . . . . . . . .57

Figure 1-7 Time interval (channel 1 to 2) test setup . . . . . . . . . . .62

Figure 1-8 Option 106 ( 6 GHz ) microwave channel 2/3 test setup

Figure 1-9 Option 115 ( 15 GHz ) microwave channel 2/3 test setup

Figure 1-10 Option 106/150 microwave channel 3 test setup . . . .79

Figure 1-11 Option 115/150 microwave channel 3 test setup . . . .85

Figure 2-1 The front panel at a glance . . . . . . . . . . . . . . . . . . . .103

Figure 2-2 Front panel display . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Figure 2-3 Calibration procedure summary . . . . . . . . . . . . . . . .114

Figure 2-4 Information screen . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Figure 2-5 Oscillator calibration setup . . . . . . . . . . . . . . . . . . . .124

Figure 2-6 DC voltage source and DMM connections . . . . . . . .132

Figure 2-7 Microwave source connection to Channel 3 . . . . . . .135

Figure 2-8 Microwave source connection to Channel 3 . . . . . . .143

Figure 2-9 Counter top internal view . . . . . . . . . . . . . . . . . . . . . .160

Figure 2-10 Bottom internal view . . . . . . . . . . . . . . . . . . . . . . . . .161

Figure 2-11 ac Power Supply Testpoint Locations on the Motherboard

Figure 2-12 Battery folded in the service position . . . . . . . . . . . .167

Figure 2-13 Test Button and Charge Indicator . . . . . . . . . . . . . . .168

Figure 3-1 Handle removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Figure 3-2 Rear Bezel And Cover Removal . . . . . . . . . . . . . . . . .188

Figure 3-3 Battery assembly temporary position for service or

Figure 3-4 Top view of counter showing GPIB assembly . . . . . .191

230A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

67

73

assembly (top view, internal battery removed, test

points visible.) . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Keysight 53210A/53220A/53230A Assembly Level Service Guide 19

Page 20

Figure 3-5 Front flange resting on plastic tab . . . . . . . . . . . . . . 193

Figure 3-6 Processor PC board . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Figure 3-7 Front rubber bumper removal . . . . . . . . . . . . . . . . . . 196

Figure 3-8 Front panel removal . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Figure 4-1 Connector Locking Tab . . . . . . . . . . . . . . . . . . . . . . . 210

Figure 4-2 Jumper cable installed . . . . . . . . . . . . . . . . . . . . . . .211

Figure 4-3 Digital and Y-cables. . . . . . . . . . . . . . . . . . . . . . . . . . 212

Figure 4-4 Test button and charge indicator . . . . . . . . . . . . . . .212

Figure 4-5 Battery assembly connectors . . . . . . . . . . . . . . . . . . 213

Figure 4-6 Battery assembly held by three small tabs . . . . . . . . 214

Figure 4-7 Option 201 rear input channels 1 and 2 . . . . . . . . . . 217

Figure 4-8 53210A channel 2 front panel Option 106/202 . . . . 221

Figure 4-9 Processor printed circuit board . . . . . . . . . . . . . . . . .222

Figure 4-10 T20 TORX screw on motherboard . . . . . . . . . . . . . . . 223

Figure 4-11 Connector-adapter installation . . . . . . . . . . . . . . . . . 224

Figure 4-12 Semi-rigid cable position . . . . . . . . . . . . . . . . . . . . . . 225

Figure 4-13 Front flange resting on plastic tab . . . . . . . . . . . . . . 227

Figure 4-14 53210A channel 2 rear panel Option 106/203 . . . . . 231

Figure 4-15 Channel 2 assembly installed on top of the motherboard,

with the SMA edge connector pointing toward the rear

of the counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Figure 4-16 53220A/53230A Option 106/202. . . . . . . . . . . . . . . .236

Figure 4-17 Processor printed circuit board. . . . . . . . . . . . . . . . .237

Figure 4-18 T20 TORX screw on motherboard . . . . . . . . . . . . . . . 238

Figure 4-19 Connector-adapter parts . . . . . . . . . . . . . . . . . . . . . . 240

Figure 4-20 Semi-rigid cable position . . . . . . . . . . . . . . . . . . . . . . 241

Figure 4-21 53220A/53230A rear panel option 106/203. . . . . . . 246

Figure 4-22 Channel 3 assembly installed on top of the motherboard,

with the female SMA edge connector pointing toward

the rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Figure 5-1 Keysight 53210A/53220A/53230A Counters, top view

(cover off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

Figure 5-2 Keysight 53210A/53220A/53230A Counters, bottom view

(cover off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

Figure 6-1 Information screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Figure 6-2 Microwave source connection to channel 3 . . . . . . . 267

20 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 21

List of Tables

Table 1-1 Recommended test equipment for operational verification

and performance tests . . . . . . . . . . . . . . . . . . . . . .28

Table 1-2 The Keysight 53210A/53220A/53230A performance

tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Table 2-1 Recommended test equipment for calibration . . . . .120

Table 2-2 Option 106 calibration frequencies and power levels . . .

139

Table 2-3 Option 115 calibration frequencies and power levels . . .

147

Table 2-4 Recommended equipment for test and troubleshooting

155

Table 2-5 Keysight 53210A/53220A/53230A assembly

identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Table 2-6 DC power supply voltages . . . . . . . . . . . . . . . . . . . . .165

Table 5-1 Table of replaceable parts . . . . . . . . . . . . . . . . . . . . .256

Table 6-1 Instruments this guide directly applies to . . . . . . . . .262

Keysight 53210A/53220A/53230A Assembly Level Service Guide 21

Page 22

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

22 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 23

Keysight 53210A/53220A/53230A 350 MHz Universal Frequency

Counter/Timer

Assembly Level Service Guide

1 Performance Tests

Introduction 24

Power-On Test 29

Self-Test (Q) 31

Keysight 53210A/53220A/53230A Operational Verification 33

Keysight 53210A/53220A/53230A Complete Performance Tests 37

Keysight 53210A/53220A/53230A Operational Verification and Performance

Test Record 90

Keysight 53210A/53220A/53230A Performance Test Record (Tests 1 to 7)

91

Verifying specifications.

23

Page 24

1 Performance Tests

Introduction

This chapter provides procedures to test the electrical performance of

the Keysight 53210A/53220A/53230A Frequency Counters, using the

specifications provided on the CD-ROM (“Keysight 53210A/53220A/53230A

Specifications”) that came with your counter. Successful completion of all the

performance tests verifies the counter is meeting all factory specifications.

Four types of testing are provided:

– Power-on test

– Counter self-test

– operational Verification Tests

– Complete performance tests

This chapter is organized as follows:

– Introduction

– Power-On Test

– Self-Test (Q)

– Keysight 53210A/53220A/53230A Operational Verification

– Keysight 53210A/53220A/53230A Complete Performance Tests

– Keysight 53210A/53220A/53230A Operational Verification and Performance

Test Record

– Keysight 53210A/53220A/53230A Performance Test Record (Tests 1 to 7)

24 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 25

Chapter overview

Power-on test

When the counter is first turned ON, a limited turn-on test is performed to verify

the counter is sufficiently functional to perform basic operations.

Self-test

Running the counter Self-Test initiates a series of checks against internal

standards. Successful completion of the Self-Test provides a high confidence level

that the counter is completely functional. No external test equipment is required

for this operator-initiated test.

Operational verification

The operational verification is an abbreviated check that may be performed to give

a strong degree of confidence that the instrument is capable of making basic

measurements accurately without running the complete performance tests. An

operational verification is useful for incoming inspection and routine preventative

maintenance.

Complete performance verification tests

Performance Tests 1

The complete performance verification tests verify the specifications listed on the

Keysight 53210A/53220A/53230A Product Reference CD-ROM as “Keysight

53210A/53220A/53230A Specifications.” All tests can be performed without

accessing the inside of the instrument. The complete performance tests are

recommended as acceptance tests upon initial receipt of your counter. They will

also help you to become familiar with its performance and operation. Complete

performance tests should be run at least once a year to ensure the counter is

meeting all specifications.

Quick performance check A combination of selected performance tests

(marked ‘Q’) plus the counter Self-Test provides a simple method to achieve a

high confidence in the counter’s ability to both functionally operate and to meet

specifications. These tests represent the absolute minimum set of performance

checks recommended following any service activity.

Keysight 53210A/53220A/53230A Assembly Level Service Guide 25

Page 26

1 Performance Tests

Auditing the counter’s performance for the quick check points (designated by a

‘Q’) verifies performance for normal accuracy drift mechanisms.

This test does not check for abnormal component failures. To perform the quick

performance check, do the following:

– Perform the counter Self-Test as shown on page 31.

– Perform only the performance verification tests indicated with the letter Q at

the beginning of the test.

– If the counter fails the quick performance check, repair may be required. Refer

to “Troubleshooting the Counter” on page 162.

Remote testing of the counter

All of the counter tests may be run using an automated test system and remote

programming commands. Three interfaces are provided in each counter to allow

operation over an interface from a remote computer: GPIB, LAN, and USB. Refer

to the SCPI Programmer’s Reference for information on the remote commands

available for controlling the counter.

Performance test record

The results of the operational verification, and performance tests should be

recorded on a copy of the Performance Test Record, located at the end of the

complete performance tests section in this chapter.

Test considerations

For optimum performance, all performance tests should comply with the following

recommendations:

– Ensure that the ambient temperature for running the Performance Tests is

stable and between 18 degrees C and 28 degrees C. Ideally, the tests should

be performed at 23o C ±1o C.

– Ensure that ambient relative humidity is less than 80%.

– See page 37 for warm-up considerations.

– Keep the instrument cables as short as possible, consistent with the

impedance requirements. Use only RG-58 or equivalent 50 cable for

measurements.

26 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 27

– To verify the total number of accuracy places for frequency measurements, it

may be necessary to turn off Auto-Digit control. Use this set of key depressions

to turn AutoDigits OFF:

[Digits] / (AutoDigits) / <Off>

– The softkey menus shown in the test procedures represent the functionality of

the 53230A. The softkey menus for the 53210A and 53220A may be different

depending on the function selected.

Recommended calibration cycle

The counter requires periodic verification of operation. Depending on the use and

environmental conditions, aging, and measurement accuracy required, the

counter should be checked using the operational verification procedure at least

once every year. The recommended calibration cycle for specification accuracy is

also one year.

Internal auto-calibration

An Internal Auto-Calibration feature is available (see Chapter 2, "Service") that

uses internal instrument standards to refine the accuracy of the counter. It is

recommended that Auto-Cal be performed regularly (such as at the beginning of a

shift change, starting a contemporary series of measurements, after a large

ambient temperature change, etc.) for optimum counter performance.

Performance Tests 1

NOTE

Keysight 53210A/53220A/53230A Assembly Level Service Guide 27

Auto-calibration is also a subset of the counter self-test.

Page 28

1 Performance Tests

Equipment required

Table 1-1 Recommended test equipment for operational verification and

Instrument Required characteristics Recommended model

performance tests

100 MHz to 15 GHz; Freq Accy at

Microwave signal generator

Pulse generator

RF signal generator

Primary frequency standard

(10 MHz house standard)

DC power supply Adjustable to 5.000V Keysight 6234A or equivalent

Digital multimeter (DMM) Microvolt accuracy Keysight 34410A or equivalent

SMA(m)-to-BNC(f) adapters (3) Keysight 1250-1200

Type N(m)-to-BNC(f) adapter Keysight 1250-0780

BNC-to-dual banana plug BNC(f) to banana plug (m)

50 coaxial cable with

BNC connectors (5)

3.5mm cables (2) DC-18 GHz,matched pair Keysight 11500E

Coaxial BNC tee connector Keysight 1250-0781

6 GHz and 15 GHz:

PW Accy: ±10%

5 nSec pulse width

40 pSec

± 2.000E-12

10 MHz

Absolute accuracy >

1 x 10-10

BNC(m) to BNC(m), 48 inches Keysight 10503A

±10ppb;

±

Keysight E8257D-520-UNW or

equivalent

Keysight 81134A or equivalent

Stanford Research Systems

CG635

Stanford Research Systems

FS725 Rubidium Timebase or

equivalent

Keysight E9637A or Newark

10M4161

28 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 29

Power-On Test

1 Inspect the counter for any damage. Make sure no cables are connected to the

2 Connect the power cord to the counter, and connect the other end of the

Performance Tests 1

input channels (rear and front panels) of the counter.

power cord to the primary power source.

NOTE

It is normal for the fan in the counter to run at different speeds as necessary

(depending upon internal temperature) when the counter is in standby mode.

Power to the timebase is continuous to maintain long term measurement

reliability, and the fan helps maintain timebase temperature stability.

3 Verify the following condition for the Power LED with power off (lower L/H

corner of the front panel).

– No OCXO or OCXO in Off mode - LED is off when power is off.

– OCXO present, heated by AC power - LED is on solid when power

is off.

– OCXO present, heated by battery power - LED blinks when power

is off.

4 Press the POWER key (lower left-hand corner of the front panel) to turn on the

counter. Verify the following results:

– The front panel display turns white as all pixels are illuminated.

– The LED under the power switch is on solid.

– After several seconds, a screen is briefly displayed that shows the status

and ID of the IP Address and the GPIB address. The factory default GPIB

address is 3. (“Disabled” means the GPIB is turned Off under [Utility] / (I/O

Config).

– The counter is now ready to measure frequency of a signal applied to

CHANNEL 1 input as indicated by illumination of the Freq softkey and

Channel 1 annunciator.

NOTE

Keysight 53210A/53220A/53230A Assembly Level Service Guide 29

An auto-cal is performed at power-on. (See “To run auto calibration:” on

page 150 for more information.)

Page 30

1 Performance Tests

NOTE

NOTE

If a fail message is displayed at power-on, refer to “Troubleshooting the

Counter” on page 162 of this service guide.

5 Mark Pass or Fail in the Keysight 53210A/53220A/53230A Power-ON Test

Record, Test 1, at the end of this chapter.

The power-on hardware initialization activities check the following circuits for

operation:

– Front panel display driver

– Power manager

– Battery (if installed)

– GPIB

– Measurement board hardware

30 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 31

Self-Test (Q)

Performance Tests 1

A brief power-on test occurs automatically whenever you turn on the counter. This

limited test assures that the counter is functional.

NOTE

NOTE

It is recommended that the counter Self-Test be performed to ensure that the

instrument is completely functional before running the Operational Verification

or Performance Tests.

SELF-TEST and the remote command *TST perform the same internal tests.

An auto-calibration is performed as a subset of the counter Self-Test.

(See “Internal auto-calibration” on page 149 for more information.)

After turn-on, or at any time a reasonable operational status needs to be verified,

the internal Self-Test can be run.

Run internal self-test

1 Disconnect any input signal(s) from the counter.

2 Press the Utility key and then the Instr Setup softkey.

Keysight 53210A/53220A/53230A Assembly Level Service Guide 31

Page 32

1 Performance Tests

The Instrument Setup menu softkeys are displayed:

3 Press the Self Test softkey. The display shows:

– “Performing Self-Test. Please wait...” (displayed for several seconds.)

– If the self-test passes, “Self-Test Passed.” is momentarily displayed.

NOTE

If “Self-Test Failed” is displayed or any other failure is indicated, refer to the

troubleshooting section in Chapter 2, "Service" on page 101.

4 Mark Pass or Fail in the “Keysight 53210A/53220A/53230A Performance Test

Record (Tests 1 to 7)” on page 91.

32 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 33

Performance Tests 1

Keysight 53210A/53220A/53230A Operational Verification

The operational verification consists of checks that may be performed at any time

to give a high degree of confidence that the instrument is operating properly,

without running the complete performance tests.

These checks represent the minimum set of tests recommended following any

option retrofit installations (Refer to Chapter 4, "Retrofitting Options").

If you are unfamiliar with the operation of the counter, you can review the

“Keysight 53210A/53220A/53230A Quick Start Tutorial.” However, the

procedures in this chapter are written so that little operational experience is

necessary. The procedures should be followed in the order in which they appear.

Frequency checks

1 Connect the counter’s rear-panel Int Ref Out as shown in

Figure 1-1 to the front panel Channel 1 input connector.

Int Ref

Out

Ch 1

Figure 1-1 Operational verification setup for Keysight 53210A/220A/230A

NOTE

Keysight 53210A/53220A/53230A Assembly Level Service Guide 33

If the counter has Option 201 (rear panel input connectors) installed, connect

the Int Ref Out to the rear panel Channel 1 input connector and NOT the front

panel Channel 1 input connector.

Page 34

1 Performance Tests

2 Press the Preset key to preset the counter.

3 Verify the display shows a frequency reading of approximately 10,000,000 Hz.

4 Mark Pass or Fail in the “Keysight 53210A/53220A/53230A Performance Test

Record (Tests 1 to 7)” on page 91.

NOTE

NOTE

The remaining steps apply only to the Keysight 53220A and Keysight

53230A53230A since the Keysight 53210A does not have a second RF frequency

input.

5 In the same way as for Channel 1, connect the Int Ref Out to the Channel 2 input

connector (front or rear panel).

6 Press the Channel 2 button.

If necessary, press the Freq/Period key to read the Channel 2 frequency.

– Channel 1 annunciator is not lit. Channel 2 annunciator is lit.

7 Verify the display shows a frequency reading of approximately 10,000,000 Hz.

8 Mark Pass or Fail in the “Keysight 53210A/53220A/53230A Performance Test

Record (Tests 1 to 7)” on page 91.

9 Disconnect the test setup.

34 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 35

Termination checks (optional)

Performance Tests 1

NOTE

Once the termination checks have been successfully performed, it is usually not

necessary to run them again unless the counter’s motherboard has been

replaced.

1 Press the Preset key to preset the counter.

2 Connect a digital multimeter (DMM) to CHANNEL 1 as shown in Figure 1-2, and

set it to measure ohms (set DMM to appropriate Ohms range). On the DMM,

use a dual-banana plug-to-BNC connector.

DMM

HI

LO

Ch 1

Figure 1-2 Termination Check Setup

3 Press the Channel 1 key.

– The LED turns on and the Channel 1 Setup softkeys are displayed:

Keysight 53210A/53220A/53230A Assembly Level Service Guide 35

Page 36

1 Performance Tests

4 Select the following:

– Coupling: DC

– The DC annunciator indicates DC input coupling for Channel 1.

– Impedance: 50 Ω

– The 50 Ω annunciator turns on, indicating a 50 Ω input impedance for

5 Verify the DMM reads approximately 50 Ohms.

6 Mark Pass or Fail in the “Keysight 53210A/53220A/53230A Performance Test

Record (Tests 1 to 7)” on page 91.

7 Select the following:

– Impedance: 1 MΩ.

– The 1 MΩ annunciator turns on, indicating a 1 MΩ input impedance for

Channel 1.

8 Verify the DMM reads approximately 1.000 MOhm.

9 Mark Pass or Fail in the “Keysight 53210A/53220A/53230A Performance Test

Record (Tests 1 to 7)” on page 91.

10 Repeat steps 2 through 9 for RF Channel 2 for the Keysight 53220A/53230A

counters ONLY, since the Keysight 53210A counter does not have a standard

RF Channel 2.

11 Mark Pass or Fail in the Keysight 53220A/53230A Operational Verification Test

Record, Tests 6a and 6b for Chan 2, starting on page 91.

12 Disconnect the test setup.

Channel 1.

NOTE

36 Keysight 53210A/53220A/53230A Assembly Level Service Guide

This completes the operational verification testing for the Keysight 53210A/

53220A/53230A.

Page 37

Performance Tests 1

Keysight 53210A/53220A/53230A Complete Performance Tests

The following seven performance tests, when successful, verify that the counter

meets the instrument specifications as provided on the CD ROM that came with

your Keysight 53210A/53220A/53230A Counter. See also the information on

running a ‘QUICK’ performance test on page 25. Before running these tests,

review the “Test considerations” on page 26.

Record the results of the performance tests in the appropriate place on the

“Keysight 53210A/53220A/53230A Performance Test Record (Tests 1 to 7)” on

page 91.

To verify the total number of accuracy places for frequency measurements, it may

be necessary to turn off Auto-Digit control. Use this set of key depressions to turn

AutoDigits OFF:

[Digits] / (AutoDigits) / <Off>

NOTE

If the instrument is currently located in the calibration environment with the

power removed, turn on the instrument and allow a 45 minute warm-up period

before starting the Performance Test procedures. Upon receipt and delivery to

the calibration environment, turn on the instrument and allow a 2½ hour

warm-up/stabilization period before starting the procedures.

If it is known that the instrument has been in storage or decommissioned

(unused) for several months, turn on the instrument and allow it to stabilize for

72 hours. Periodically monitor the aging (drift) rate relative to the counter’s

24-hour specification. If the aging rate exceeds the 24-hour specification, allow

an additional stabilization period and continue to monitor the rate relative to the

specification. The counter has stabilized when aging remains within the 24-hour

rate. Otherwise, the 45 minute or 2½ warm-up period applies.

An instrument that has not or will not be used for several months should be

stored in the same ambient environment and orientation in which it will

eventually be used.

Keysight 53210A/53220A/53230A Assembly Level Service Guide 37

Page 38

1 Performance Tests

Table 1-2 The Keysight 53210A/53220A/53230A performance tests

[a]

Test description

Test 1: Absolute time base

Test 2: Frequency accuracy - channels 1 and 2

Test 3: Single period

Test 4: Pulse width

Test 5: Time interval

Test 6: Frequency accuracy - microwave channel options 106 and 115

Test 7: Pulse burst frequency - 53230A channel 3 option 150

[a] Other counter measurement functions are mathematically derived by the processor from the

parameters verified by these performance tests.

Test 1: (Q) Absolute time base

This test uses the Keysight 53210A/53220A/53230A Frequency Counters to

measure the absolute frequency of the internal 10 MHz clock.

Equipment

– FS725 Rubidium timebase (or equivalent)

– CG635 signal generator (E8257D-520 is a valid substitute)

– Keysight 10503 BNC cables (2)

CG635 signal generator setup

1 Set Output Channel: Q

2 Set Output Level: +7 dBm

3 Set Frequency: 10 MHz

38 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 39

Performance Tests 1

Counter setup

1 Connect the equipment as shown in Figure 1-3.

FS725

Rubidium

Timebase

CG635

Signal

Generator

Figure 1-3 Absolute timebase test setup

2 Press the Preset key on the front panel to preset the counter.

– Display shows:

– Instrument has been preset.

– Channel 1 annunciator is lit.

3 Press the Trigger key.

– The following softkeys are displayed:

Ch 1

4 Press and set:

– Trigger Source: Manual

– Wait For Trig is displayed.

– Rdgs/Trigger: 100.

Keysight 53210A/53220A/53230A Assembly Level Service Guide 39

Page 40

1 Performance Tests

5 Press the Freq Period key.

– The following softkeys are displayed:

6 Press the Freq softkey.

– The following softkeys are displayed:

7 Press and set:

– Noise Rejection: Off

8 Press the Frequency/Period key.

– The following softkeys are displayed:

*

*Opt 150

*

*Opt 150

– If Advanced is appears, press Auto to select Auto measurement mode.

NOTE

40 Keysight 53210A/53220A/53230A Assembly Level Service Guide

The 53210A does not have an Auto measurement mode.

Page 41

9 Press the Channel 1 input key.

– The following softkeys are displayed:

10 Press and set:

– Coupling: DC

– Input Impedance: 50 Ω

– Range: 5 V

– Level Setup / Auto Level: Off

– Level Setup / Input Level: 0.000 V

– BW Limit: Off

– Probe: None

11 Press the Math key.

– The Math softkeys are displayed:

Performance Tests 1

12 Press to set:

– All Math: On

Keysight 53210A/53220A/53230A Assembly Level Service Guide 41

Page 42

1 Performance Tests

13 Press the Statistics softkey:

– The Statistics softkeys are displayed:

14 Press to set:

– Statistics: On

– The display shows:

42 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 43

Absolute timebase test procedure

Performance Tests 1

NOTE

The test limits provided for this procedure assume the following:

– The previous complete calibration of the instrument (factory or Service

Center) was performed at 23 ± 5 °C,

– This test is performed within the same temperature range.

– The instrument was re-calibrated and re-adjusted following its specified

initial 30-day warm-up period. This replaces the factory calibration

uncertainty with the uncertainty of the primary frequency standard (or similar

standard) recommended in Table 1-1, with an absolute accuracy of

-10

< 1x10

or better.

– For counters in operation greater than 1-year, test limits are ½ of the limits

provided below and in the performance test record.

– Temperature error or factory calibration uncertainty should be added to the

time base test limits if the conditions stated above are not met.

1 Press the Trigger key to manually trigger the counter.

– Counter takes 100 readings and fills in Math functions.

2 Verify the ‘Mean’ displays a reading of:

– 10 MHz ± 10 Hz (for standard timebase)

– 10 MHz ± 0.5 Hz (for Option 010 high stability timebase)

[1]

[2]

3 Record the ‘Mean’ test value, Test 1, in the “Keysight 53210A/53220A/53230A

Performance Test Record (Tests 1 to 7)” on page 91.

4 Proceed to Test #2 or disconnect the test setup.

[1] For counter operation > 1 year: 10 MHz ± 5 Hz (standard timebase)

[2] For counter operation > 1 year: 10 MHz ± 0.25 Hz (Option 010 high stability timebase)

Keysight 53210A/53220A/53230A Assembly Level Service Guide 43

Page 44

1 Performance Tests

Test 2: (Q) Frequency accuracy - channels 1 and 2

This set of tests verifies the Channel 1 and 2 frequency accuracy specifications of

the Keysight 53210A/53220A/53230A Frequency Counters.

Equipment

– FS725 Rubidium timebase

– CG635 synthesized signal generator (E8257D-520 is a valid substitute)

– Keysight 10503A BNC cables (3)

CG635 signal generator setup

1 Set output channel: Q

2 Set output level: +7 dBm

3 Set frequency: 10 MHz

Counter setup

1 Connect the test equipment to the counter as shown in Figure 1-4.

FS725

Rubidium

Timebase

CG635

Signal

Generator

Ext

Ref

In

Ch 1

Figure 1-4 Test setup for channel 1/2 frequency accuracy tests

44 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 45

Performance Tests 1

2 With the external reference connected, use the following key sequence to

select (as necessary) the time base source to ‘Auto’ or ‘External’, and the

external reference frequency of 10 MHz:

3 Press the Preset key to preset the counter.

– Display shows:

– Instrument has been preset.

– Ext Ref is shown in the upper right-hand corner of the display.

– The following softkeys are displayed:

*

*Opt 150

4 Press and set:

– Measurement mode: Advanced / Auto

NOTE

Keysight 53210A/53220A/53230A Assembly Level Service Guide 45

The 53210A does not have an Auto measurement mode.

Page 46

1 Performance Tests

5 Press the Freq softkey.

– The following softkeys are displayed:

6 Press and set:

– Noise Rejection: Off

7 Press the Trigger key.

– The following softkeys are displayed:

8 Press and set:

– Trigger Source: Manual

– Wait For Trig is displayed.

– Rdgs/Trigger: 100

9 Press the Gate key.

– The Gate softkeys are displayed:

10 Press and set:

– Gate src: Timed

– Gate time: 10 mSec

– Gate out: On

– Polarity: Norm

46 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 47

11 Press the Channel 1 input key.

12 Press and set:

– Coupling: DC

– Input impedance: 50 Ω

– Range: 5 V

– BW Limit: Off

– Level Setup / Auto Level: Off

– Level Setup / Input Level: 0.000 V

13 Press the Math key.

– The following softkeys are displayed:

Performance Tests 1

14 Press and set:

– All math: On

Keysight 53210A/53220A/53230A Assembly Level Service Guide 47

Page 48

1 Performance Tests

15 Press the Statistics softkey.

– The Statistics softkeys are displayed:

16 Press to set:

– Statistics: On

– The display shows:

Frequency accuracy test procedure

1 Press the Trigger key to manually trigger the counter.

– Counter takes 100 readings and fills in Math functions.

2 Verify the ‘Mean’ is:

– 10 MHz ± 100 mHz (for 53210A)

– 10 MHz ± 10 mHz (for 53220A/53230A)

3 Verify the ‘Std Dev’ is less than:

– 140 mHz (for 53210A)

– 70 mHz (for 53220A)

– 14 mHz (for 53230A)

48 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 49

Performance Tests 1

4 Record the ‘Mean’ and ‘Std Dev’, Test 2a, for Channel 1 (10 MHz), in the

“Keysight 53210A/53220A/53230A Performance Test Record (Tests 1 to 7)” on

page 91.

5 Press the Reset Stats softkey.

6 Set CG635 output frequency to 115 MHz and repeat step 1.

7 Verify the ‘Mean’ is:

– 115 MHz ± 1.150 Hz (for 53210A)

– 115 MHz ± 0.115 Hz (for 53220A/53230A)

8 Verify the ‘Std Dev’ is less than:

– 1610 mHz (for 53210A)

– 805 mHz (for 53220A)

– 161 mHz (for 53230A)

9 Record the ‘Mean’ and ‘Std Dev’, Test 2a, for Channel 1 (115 MHz), in the

“Keysight 53210A/53220A/53230A Performance Test Record (Tests 1 to 7)” on

page 91.

10 Press the Reset Stats softkey.

11 Set CG635 output frequency to 350 MHz, and repeat step 1.

12 Verify the ‘Mean’ is:

– 350 MHz ± 3.5 Hz (for 53210A)

– 350 MHz ± 0.350 Hz (for 53220A/53230A)

13 Verify the ‘Std Dev’ is less than:

– 4 900 mHz (for 53210A)

– 2 450 mHz (for 53220A)

– 490 mHz (for 53230A)

14 Record the ‘Mean’ and ‘Std Dev’, Test 2a, for Channel 1 (350 MHz), in the

“Keysight 53210A/53220A/53230A Performance Test Record (Tests 1 to 7)” on

page 91.

15 Press the Reset Stats softkey.

16 Repeat the procedure above (steps 1 to 15) for Channel 2. Be sure to set up

Channel 2 (steps 11 and 12 under “Counter Setup”.)

Keysight 53210A/53220A/53230A Assembly Level Service Guide 49

Page 50

1 Performance Tests

NOTE

Step 16 applies only to the 53220A and 53230A. The 53210A does not have a

Channel 2 for RF frequencies. Also, selecting Channel 2 automatically resets the

statistics.

17 Record the ‘Mean’ and ‘Std Dev’ for all three Channel 2 frequencies, Test 2b,

Channel 2, in the “Keysight 53210A/53220A/53230A Performance Test Record

(Tests 1 to 7)” on page 91.

18 Press the Reset Stats softkey.

19 Proceed to Test #3 or disconnect the test setup.

Test 3: Single period

This test measures a single period of a signal. The period is measured from rising

edge to rising edge on a single channel.

NOTE

Test #3 applies to the 53220A and 53230A only.

Equipment

– FS725 Rubidium timebase

– CG635 Synthesized signal generator

– Keysight 10503 BNC cables (3)

CG635 signal generator setup

1 Set Output Channel: Q

2 Set Output Level: +7 dBm

3 Set Frequency: 1 MHz

50 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 51

Counter setup

1 Connect the equipment as shown in Figure 1-5.

FS725

Rubidium

Timebase

CG635

Signal

Generator

Ext Ref In

Performance Tests 1

Ch 1

Figure 1-5 Test Setup for Single Period

2 Press the Preset key to preset the counter.

– Display shows:

– Instrument has been preset.

– Ext Ref is shown in the upper right-hand corner of the display.

3 On the Counter, press the Time Interval key.

– The following softkeys are displayed:

Keysight 53210A/53220A/53230A Assembly Level Service Guide 51

Page 52

1 Performance Tests

4 Press the Single Period softkey.

– The following softkeys are displayed:

5 Press and set:

– Auto Level: Off

– Level: 0 V

– Noise Rej: Off

6 Press the Channel 1 key.

– The Channel 1 Setup menu softkeys are displayed.

7 Press and set:

– Coupling: DC

– Impedance: 50 Ω

– Range: 5 V

– BW Limit: Off

8 Press the Trigger key.

– The trigger softkeys are displayed:

52 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 53

9 Press and set:

– Source: Manual

– Wait For Trig is displayed.

– Trig Delay: 0 Seconds

– Rdgs/Trigger: 100

10 Press the Math key.

– The following softkeys are displayed:

11 Press and set:

– All Math: On

12 Press the Statistics softkey:

– The Statistics softkeys are displayed:

Performance Tests 1

Keysight 53210A/53220A/53230A Assembly Level Service Guide 53

Page 54

1 Performance Tests

13 Press to set:

– Statistics: On

– The display shows:

Single period test procedure

1 Press the Trigger key.

– Counter takes 100 readings and fills in Math functions.

2 Verify the ‘Mean’ is:

– 1.00 uSec ± 0.200 nSec (53220A)

– 1.00 uSec ± 0.100 nSec (53230A)

3 Verify the ‘Std Dev’ is less than:

– 0.140 nSec (53220A)

– 0.028 nSec (53230A)

4 Record the ‘Mean’ and ‘Std Dev’ for 1 MHz, Channel 1, Test 3a, in the

Keysight 53220A/53230A Performance Test Record starting on page 91.

5 Press the Reset Stats softkey.

6 Set the CG635 output frequency to 250 MHz.

7 Press the Trigger key.

– Counter takes 100 readings and fills in Math functions.

54 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 55

Performance Tests 1

8 Verify the ‘Mean’ is:

– 4.00 nSec ± 0.200 nSec (53220A)

– 4.00 nSec ± 0.100 nSec (53230A)

9 Verify the ‘Std Dev’ is less than:

– 0.140 nSec (53220A)

– 0.028 nSec (53230A)

10 Record the ‘Mean’ and ‘Std Dev’ for 250 MHz, Channel 1, Test 3b, in the

Keysight 53220A/53230A Performance Test Record starting on page 91.

11 Press the Reset Stats softkey.

12 Repeat steps 1 to 11 for Channel 2. Be sure to perform the Channel 2 setup

(see steps 6 and 7 under “Counter Setup”.)

NOTE

Selecting Channel 2 automatically resets the statistics.

13 Record the ‘Mean’ and ‘Std Dev’ for 1 MHz and 250 MHz, Channel 2, Test 3c

and 3d, in the Keysight 53220A/53230A Performance Test Record starting on

page 91.

14 Press the Reset Stats softkey.

15 Proceed to Test #4 or disconnect the setup.

Keysight 53210A/53220A/53230A Assembly Level Service Guide 55

Page 56

1 Performance Tests

Test 4: (Q) Pulse width

This test uses the Keysight 53220A/53230A Counter to measure the width of a

narrow pulse from a pulse generator.

NOTE

Test #4 applies to the 53220A and 53230A only.

Equipment

– FS725 Rubidium timebase

– Keysight 81134A pulse generator

Keysight 10503 BNC cables (3)

– Keysight 15443A (SMA) cable or Keysight 11500E (3.5 mm) cable

– Keysight 1250-1200 BNC(f)-to-SMA(m) adapter (2)

81134A setup

– Output Level: 1 Vpp

– Period: 66.6 nSec

– Pulse Width: 5 nSec

56 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 57

Counter setup

1 Connect the equipment as shown in Figure 1-6.

FS725

Rubidium

Timebase

81134A

Pulse

Generator

Ext Ref In

Performance Tests 1

Ch 1

Figure 1-6 Pulse width test setup

2 Press the Preset key to preset the counter.

– Display shows:

– Instrument has been preset.

– Ext Ref is shown in the upper right-hand corner of the display.

3 Press the Time Interval key.

– The following softkeys are displayed:

Keysight 53210A/53220A/53230A Assembly Level Service Guide 57

Page 58

1 Performance Tests

4 Press the Pulse Width softkey.

– The following softkeys are displayed:

5 Press and set:

– Set width: pos

– auto level: Off

– Input level: +0.00 V

– Set noise rejection: Off

6 Press the Trigger key.

Front panel display shows:

7 Press and set:

– Source: Manual

– Wait For Trig is displayed

– Rdgs/Trigger: 100

– Trig Delay: 0 Seconds

58 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Page 59

8 Press the Channel 1 key:

– The Channel 1 Setup softkeys are displayed:

9 Press and set:

– Coupling: DC

– Input Impedance: 50 Ω

– Range: 5 V

– BW Limit: OFF

10 Press the Math key.

– The following softkeys are displayed:

Performance Tests 1

11 Press and set:

– All math: On

12 Press the Statistics softkey:

– The Statistics softkeys are displayed:

Keysight 53210A/53220A/53230A Assembly Level Service Guide 59

Page 60

1 Performance Tests

13 Press to set:

– Statistics: On

– The display shows:

Pulse width test procedure

1 Press the Trigger key.

– Counter takes 100 readings and fills in Math functions.

2 Verify the ‘Mean’ is:

– 5 ± 0.4 nSec (53220A)

– 5 ± 0.2 nSec (53230A)

3 Verify the ‘Std Dev’ is less than:

– 0.140 nSec (53220A)

– 0.028 nSec (53230A)

4 Record the Mean and Standard Deviation for Channel 1, Test 4a, in the

“Keysight 53210A/53220A/53230A Performance Test Record (Tests 1 to 7)” on

page 91.

5 Repeat steps 1 to 3 for Channel 2 (Test 4b). Be sure to do the Channel 2 setup

first. (See steps 8, 9 in the Counter setup above.)

NOTE

60 Keysight 53210A/53220A/53230A Assembly Level Service Guide

Selecting Channel 2 automatically resets the statistics.

Page 61

6 Record the Mean and Standard Deviation for Channel 2, Test 4b, in the

“Keysight 53210A/53220A/53230A Performance Test Record (Tests 1 to 7)” on

page 91.

7 Proceed to Test #5 or disconnect the test setup.

Test 5: (Q) Time interval

This test verifies the time interval specifications between Channel 1 and

Channel 2.

Performance Tests 1

NOTE

NOTE

Test #5 applies to the 53220A and 53230A only.

Equipment

– FS725 Rubidium timebase

– Keysight 81134A pulse generator

– Keysight 10503 BNC cables (2)

– Keysight 11500E (3.5) mm cables (2)

– Keysight 1250-1200 BNC(f)-to-SMA(m) adapter

The 3.5 mm cables must be the exact same length or erroneous

measurements will occur.

81134A setup

– Output Level: 1 Vpp

– Period: 66.6 nSec

– Pulse Width Ch1: 5 nSec

– Pulse Width Ch2: 5 nSec

– Delay Ch2: 49.9 nSec