Page 1

Operating and

Service Guide

Keysight Truevolt Series

Digital Multimeters

Page 2

Notice: This document contains referencesto Agilent Tech-

nologies. Agilent's former Test and Measurement business

has become Keysight Technologies. For more information,

go to www.keysight.com.

Page 3

Safety and Regulatory Information 11

Notices 11

Manual Information 11

Software Revision 11

Warranty 11

Technology Licenses 11

Restricted Rights Legend 12

Safety Notices 13

Safety Symbols 13

Safety Information 14

General 14

Measurement Limits 16

Input Terminal Measurement Limits 18

Sense Terminal Measurement Limits 18

IEC Measurement Category II 19

Keysight 34138A Test Lead Set 19

Test Lead Ratings 19

Operation 19

Maintenance 19

Declaration of Conformity 20

Welcome 21

Introductory Information 21

User Information 21

SCPI Programming Reference 22

Service and Repair 22

Performance Verification 22

Calibration Procedures 22

Introduction to the Instrument 23

Instrument at a Glance 23

Display – Easily display, save and document your measurement results 23

Measurements – Keysight’s Truevolt measurement performance with modern I/O accessibility 23

Programming Language 23

Front Panel at a Glance 24

Front Panel Keys 24

Rear Panel at a Glance 25

Models and Options 26

Options Installed at Factory 26

Options Installed by Distributor or End Customer 26

Remote Interface Configuration 27

Connectivity Software 27

GPIB Configuration 27

LAN Configuration 28

Web Interface 31

LAN Configuration Procedure 32

More about IP Addresses and Dot Notation 33

Firmware Update 34

Contacting Keysight Technologies 35

Quick Start 36

Prepare Instrument for Use 36

Setting the AC Mains Line Voltage Selector and Fuse Installation 37

Connect Power and I/O Cables 39

4

Keysight TruevoltSeries Operating and Service Guide

Page 4

Adjust the Carrying Handle 40

Use Built-in Help System 41

View the help information for a front panel key 41

View the list of help topics and use interactive demos 42

View the list of recent instrument errors. 43

View the help information for displayed messages. 43

Rack Mount the Instrument 44

Removing the Handle and Bumpers 44

Rack Mounting a Single Instrument 44

Rack Mounting Instruments Side-by-Side 44

Sliding Support Shelf 45

Features and Functions 46

Continuous, Data Log, and Digitize Modes 47

Continuous Mode 47

Data Log Mode 47

Digitize Mode 47

Data Log and Digitize Mode Default Settings 48

Additional Data Log Default Settings 48

Additional Digitize Default Settings 49

Front Panel Menu Reference 50

[Acquire] key 54

[Math] key 54

[Display] key 54

[Utility] key 55

Measurements 56

DC Voltage 57

AC Voltage 60

DC Current 62

AC Current 64

Resistance 66

Temperature (34460A and 34461A) 69

Temperature (34465A and 34470A) 71

Capacitance 76

Continuity 77

Diode 78

Frequency and Period 79

Data Logging 81

Digitizing 86

Level Triggering 91

Secondary Measurements 93

Triggering and Readings 95

Instrument trigger model 95

Trigger delay and multiple samples 97

Storing and clearing readings 98

Probe Hold 100

Math - Introduction 101

Math - Null 102

Math - dB/dBm Scaling 103

Math - Scaling 105

Math - Smoothing 108

Math - Statistics 109

Math - Limits 110

Keysight TruevoltSeries Operating and Service Guide

5

Page 5

Display - Introduction 114

Selecting the Display 114

Number 116

Bar Meter 121

Trend Chart (Continuous Measurement Mode) 124

Trend Chart (Digitize and Data Log Modes) 127

Histogram 133

Utility Menu - Introduction 138

Utility - Autocalibration (34465A/70A only) 139

Utility - Store and RecallState and Preference Files 140

Utility Menu - Manage Files 142

Utility Menu - I/O Configuration 144

Utility Menu - Test/Admin 147

Utility Menu - System Setup 149

Web Interface 152

Welcome Page 152

Instrument Monitor and Control Page 153

Configuration Page 157

Help 158

Measurement Tutorial 159

Measurement Considerations 160

Metrology 161

DC Measurement Considerations 162

Thermal EMF Errors 162

Loading Errors (DC Voltage) 162

Noise Rejection 163

Rejecting Power–Line Noise Voltages 163

Common Mode Rejection (CMR) 163

Noise Caused by Magnetic Loops 163

Noise Caused by Ground Loops 164

Resistance Measurement Considerations 165

Removing Test Lead Resistance Errors 165

Minimizing Power Dissipation Effects 166

Errors in High Resistance Measurements 166

True RMS AC Measurements 167

True RMS Accuracy and High–Frequency Signal Content 168

Estimating High–Frequency (Out–of–Band) Error 169

Other Primary Measurement Functions 171

Frequency and Period Measurement Errors 171

DC Current 171

Temperature Measurements 172

NULL Reading 173

Autozero On/Off 173

Making High–Speed AC Measurements 173

Making High–Speed DC and Resistance Measurements 174

Capacitance 175

Capacitance Measurement Considerations 176

Digitizing Measurements 177

The Sampling Rate 177

Level Triggering 178

About Digitize Mode 178

Data Log and Digitizing Local Remote Interaction 180

6

Keysight TruevoltSeries Operating and Service Guide

Page 6

Data Log Mode 181

Data Log Mode Features 181

Data Logging and the Trend Chart Display 185

Data Log and Digitizing Local Remote Interaction 186

Level Triggering 187

About Level Trigger 187

Other Sources of Measurement Error 189

Settling Time Effects 189

Loading Errors (AC volts) 189

Measurements Below Full Scale 190

High-Voltage Self-Heating Errors 190

AC Current Measurement Errors (Burden Voltage) 190

Low–Level Measurement Errors 191

Common Mode Errors 191

Leakage Current Errors 192

Unnecessary Signal Errors 192

How Sample Rate/Interval is Determined 193

SCPI Programming Reference 194

Related Information 194

IO Libraries and Instrument Drivers 194

Keysight Truevolt Series Documentation 194

Web Interface 194

Introduction to the SCPI Language 195

Syntax Conventions 195

Command Separators 196

Using the MIN,MAX and DEF Parameters 196

Querying Parameter Settings 196

SCPI Command Terminators 197

IEEE-488.2 Common Commands 197

SCPI Parameter Types 197

Using Device Clear 199

Commands by Subsystem 199

ABORt 201

FETCh? 202

INITiate[:IMMediate] 203

OUTPut:TRIGger:SLOPe {POSitive|NEGative}OUTPut:TRIGger:SLOPe? 204

R? [<max_readings>] 205

READ? 206

ROUTe:TERMinals? 207

TEST:ALL? 208

UNIT:TEMPerature {C|F|K}UNIT:TEMPerature? 209

CALCulate Subsystem Introduction 210

CALibration Subsystem 237

CONFigure Subsystem 243

DATA Subsystem 256

DISPlay Subsystem 259

FORMat Subsystem 261

HCOPy Subsystem 263

IEEE 488.2 Common Commands 264

LXI Subsystem 277

MEASure Subsystem 280

MMEMory Subsystem - General Purpose File Management 291

Keysight TruevoltSeries Operating and Service Guide

7

Page 7

MMEMory Subsystem - STATe and PREFerence Files 296

MMEMory Subsystem - Data Transfer Commands 301

SAMPle Subsystem 306

SENSe Subsystem Introduction 313

STATus Subsystem 386

SYSTem Subsystem - General Purpose Commands 392

SYSTem Subsystem - I/O Configuration 405

SYSTem Subsystem LOCK Commands 419

SYSTem Subsystem LICense Commands 422

TRIGger Subsystem 427

Command Quick Reference 434

Configuration Commands 434

Measurement Commands 434

Measurement Configuration Commands 434

Sample Commands 441

Triggering Commands 441

Calculation (Math) Commands 442

Reading Memory Commands 444

Calibration Commands 445

State Storage and Preferences Commands 445

General Purpose File Management Commands 446

Data Transfer Commands 447

IEEE-488 Commands 447

Format Subsystem 448

System-Related Commands 448

Interface Locking Commands 449

License Management Commands 450

Interface Configuration Commands 450

Status System Commands 451

Range, Resolution and Integration Time (shown in Aperture and NPLCs) 452

Resolution and Integration Time for DC Measurements 455

Automatic Trigger Delays 456

DC Voltage Default Delays 456

DC Current Default Delays 456

Resistance (2-wire) Default Delays 457

Resistance (4-wire) Default Delays 457

AC Voltage Default Delays 457

AC Current Default Delays 458

Frequency and Period 458

VM Comp Output (BNC) 459

SCPI Error Messages 460

Command Errors (-100…) 462

Execution Errors (-200…) 464

Device-Specific Errors (-300…) 467

Query Errors (-400…) 467

Network Errors (+100...) 467

Instrument Errors (+200…) 468

Miscellaneous Errors (+300... and +500..) 468

Licensing and Self-test Errors (+600...) 469

Calibration Errors (+700...) 471

Miscellaneous Errors (+800...) 473

Power-On and Reset State 474

Factory Default Settings 474

8

Keysight TruevoltSeries Operating and Service Guide

Page 8

Service and Repair 477

Types of Service Available 477

Obtaining Repair Service (Worldwide) 477

Repackaging for Shipment 478

Cleaning 478

Electrostatic Discharge (ESD) Precautions 478

Power Supplies 479

Troubleshooting 482

Troubleshooting Procedure 483

Self-Test Procedures 486

Power-On Self-Test 486

FullSelf-Test 486

User Replaceable Parts 487

Disassembly 488

Tools Required 488

General Disassembly Procedure 489

Battery Replacement 492

Tools Required 492

Procedure 493

3 A and 10 A Current Path Fuse Replacement 494

Tools Required 494

Testing the Fuses 495

Internal Fuse Replacement Procedure 496

Installing the Optional GPIB Interface 497

Tools Required 497

Installation Procedure 497

Retain GPIB Cover Plate 497

Security Code Override 499

Which Procedure Should I Use? 499

Procedure A: For Firmware Revision Ending in 02, or Greater 500

Procedure B: For Firmware Revision Ending in 01 502

Performance Verification 503

Quick Performance Check 504

Performance VerificationTests 505

Recommended Test Equipment 505

Zero Offset Verification 506

DC Volts and DC Current Gain Verification 510

Frequency Accuracy Verification 515

AC Voltage and AC Current Verification 516

High Current Verification 521

Capacitance Verification (Optional Verification Test) 522

Calibration Adjustment Procedures 523

Calibration Procedures 524

Input Connections 525

Test Considerations 525

Recommended Test Equipment 526

Calibration Adjustment Process 527

Gain Calibration Adjustment Overview 528

Gain and Flatness Calibration Adjustment Overview 529

Entering Calibration Values and Storing Calibration Constants 530

Calibration Security 531

Keysight TruevoltSeries Operating and Service Guide

9

Page 9

Calibration Message 532

Calibration Count 533

Aborting a Calibration in Progress 534

Security Code Override 535

34460A and 34461A Calibration Procedures 540

ADC and Zero Calibration 541

AC Voltage Low Frequency Gain and Flatness Calibration 543

AC Voltage Gain and Flatness Calibration 544

AC Current Gain and Flatness Calibration 545

AC Zero Calibration 546

Frequency Accuracy Calibration 547

DC Voltage Gain Calibration 548

Ohms Gain Calibration 549

DC Current Gain Calibration 550

AC Current 10 A Gain Calibration 551

DC Current 10 A Gain Calibration 552

Capacitance Offset Calibration (Optional) 553

Finishing Calibration 554

34465A and 34470A Calibration Procedures 555

ADC and Zero Calibration 556

AC Voltage Low Frequency Gain and Flatness Calibration 558

AC Voltage Gain and Flatness Calibration 559

AC Current Gain and Flatness Calibration 560

AC Zero Calibration 561

Frequency Accuracy Calibration 562

DC Voltage Gain Calibration 563

Ohms Gain Calibration 564

DC Current Gain Calibration 565

DC High Voltage Gain Calibration 566

AC Current 10 A Gain Calibration 567

DC Current 10 A Gain Calibration 568

Capacitance Offset Calibration (Optional) 569

Finishing Calibration 570

Index 571

10

Keysight TruevoltSeries Operating and Service Guide

Page 10

Safety and Regulatory Information

Safety and Regulatory Information

Notices

© Keysight Technologies, Inc. 2013 - 2018

No part of this manual may be reproduced in any form or by any means (including electronic storage and

retrieval or translation into a foreign language) without prior agreement and written consent from Keysight Technologies, Inc. asgoverned by United States and international copyright laws.

Manual Information

Part Number: 34460-90901, Edition 6, ( November 27, 2018)

Keysight Technologies, Inc.

900 S. Taft Ave.

Loveland, CO 80537 USA

Software Revision

For the latest firmware, go to the product page at www.keysight.com/find/truevolt.

The latest product documentation is available at www.keysight.com/find/truevolt-doc. For doc-

umentation for mobile devices, see www.keysight.com/find/truevolt-mobilehelp.

A portion of the software in this product is licensed under terms of the General Public License Version 2

("GPLv2"). The text of the license and source code can be found at www.keysight.com/find/GPLV2.

This product uses Microsoft Windows CE. Keysight highly recommends that all Windows-based computers connected to Windows CE instruments use current anti-virus software. For more information, see

www.keysight.com/find/truevolt.

Warranty

The material contained in this document is provided "as is," and is subject to being changed, without

notice, in future editions. Further, to the maximum extent permitted by applicable law, Keysight disclaims

all warranties, either express or implied, with regard to this manual and any information contained herein,

including but not limited to the implied warranties of merchantability and fitnessfor a particular purpose.

Keysight shall not be liable for errors or for incidental or consequential damages in connection with the furnishing, use, or performance of this document or of any information contained herein. Should Keysight

and the user have a separate written agreement with warranty terms covering the material in this document that conflict with these terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in this document are furnished under a license and may be used

or copied only in accordance with the terms of such license.

Keysight TruevoltSeries Operating and Service Guide

11

Page 11

Safety and Regulatory Information

Restricted Rights Legend

U.S. Government Restricted Rights. Software and technical data rights granted to the federal government

include only those rights customarily provided to end user customers. Keysight provides this customary

commercial license in Software and technical data pursuant to FAR 12.211 (Technical Data) and 12.212

(Computer Software) and, for the Department of Defense, DFARS 252.227-7015 (Technical Data – Commercial Items) and DFARS 227.7202-3 (Rights in Commercial Computer Software or Computer Software

Documentation).

12

Keysight TruevoltSeries Operating and Service Guide

Page 12

Safety and Regulatory Information

Safety Notices

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like that,

if not correctly performed or adhered to, could result in damage to the product or loss of important data.

Do not proceed beyond a CAUTION notice until the indicated conditions are fully understood and met.

A WARNING notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or adhered to, could result in personal injury or death. Do not proceed beyond a WARNING notice until the indicated conditions are fully understood and met.

Safety Symbols

Alternating current

Frame or chassis terminal

Standby supply. Unit is not completely disconnected from AC mains power when switch is off.

Risk of electric shock

Refer to accompanying documents

The CE mark is a registered trademark of the European Community.

The CSA mark with the 'c' and 'us' subscript indicates the instrument is certified to the applicable Canadian and United States of America standards respectively.

CAT II

(300V)

ISM 1-A This text indicates that the instrument is an Industrial Scientific and Medical Group 1 Class A product

ICES/NMB001

IEC Measurement Category II. Inputs may be connected to AC mains power (up to 300 VAC)

under Category II overvoltage conditions.

This product ismarked with the ACMA RCM mark for compliance in Australia / New Zealand. A

copy of the Manufacturer’s Australia Declaration of Conformity for this instrument can be

obtained by contacting your local Keysight Technologies Sales Representative.

(CISPR 11, Clause 4).

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

Keysight TruevoltSeries Operating and Service Guide

13

Page 13

Safety and Regulatory Information

This product complies with the WEEE Directive (2002/96/EC) marking equipment. The affixed

product label indicates that you must not discard thiselectrical/electronic product in

domestic household waste.

To return unwanted products, contact your local Keysight office, or see www.key-

sight.com/environment/product/ for more information.

This equipment isClass A suitable for professional use and is for use in electromagnetic environments outside of the home.

Contains one or more of the 6 hazardous substances above the maximum concentration value (MCV), 40

Year EPUP.

Safety Information

General

Do not use this product in any manner not specified by the manufacturer. The protective features of this

product may be impaired if it is used in a manner not specified in the operation instructions. Do not install

substitute parts or perform any unauthorized modification to the product. Return the product to a Keysight Technologies Sales and Service Office for service and repair to ensure that safety features are maintained.

Product Grounding

The instrument is a Class 1 product and is provided with a grounding-type power cord set. The instrument chassis and cover are connected to the instrument electrical ground to minimize shock hazard.

The ground pin of the cord set plug must be firmly connected to the electrical ground (safety ground)

terminal at the power outlet. Any interruption of the protective earth (grounding) conductor or disconnection of the protective earth terminal will cause a potential shock hazard that could result in personal injury or death.

Cleaning

To prevent electrical shock, disconnect the instrument from AC mains power and disconnect all test

leads before cleaning. Clean the outside of the instrument using a soft, lint-free, cloth slightly

dampened with water.Do not use detergent or solvents.Do not attempt to clean internally.If needed,

contact a KeysightTechnologies Sales and Service office to arrange for proper cleaning to ensure

that safety features and performance are maintained.

AC Power Cord

Removal of the AC power cord is the disconnect method to remove power from the instrument. Be

sure to allow for adequate access to the power cord to permit disconnection from AC power. Use

only the Keysightspecified power cord for the country of use or one with equivalent ratings.

14

Keysight TruevoltSeries Operating and Service Guide

Page 14

Safety and Regulatory Information

Do Not Remove Instrument Cover

Only qualified, service-trained personnel should remove the cover from the instrument. Service:

Unplug instrument from wall outlet, remove power cord, and remove all probes from all terminals

before servicing.

AC Mains Power Line Fuse

For continued protection against fire, replace the line fuse only with fuses of the specified type and rating. The instrument must be disconnected from AC mains power, and all measurement terminals

must be disconnected before changing the fuse.

Current Measurement Protection Fuse

For continued protection against fire, replace current-protection fuses only with fuses of the specified

type and rating. The instrument must be disconnected from AC mains power, and all measurement terminals must be disconnected before changing the fuse.

Front/Rear Switch

Do not change the position of the Front/Rear switch on the front panel while signals are present on

either the front or rear set of terminals. The switch is not intended as an active multiplexer. Switching

while current or high voltage is present may cause instrument damage and lead to the risk of electric

shock.

Do Not Operate in an Explosive Atmosphere

This instrument is not designed to be operated in an explosive environment. The instrument enclosure

complies with the IP 20 rating.

In Case of Damage

An instrument that appears damaged or defective should be made inoperative and secured against

unintended operation until qualified service personnel can repair it.

Self-Test

Before measuring any hazardous voltage or current, remove all test leads to the instrument, run the

TEST:ALL? query from the remote interface, and read the result to verify that the instrument is performing properly.

The TEST:ALL? query is a self-testthat returns +0 if the instrument passes and +1if the instrument

fails. You can also perform this query from the front panel by pressing [Shift] > [Utility] > Test/Admin >

Self Test > Full Test. If this self-test fails, make sure thatthe instrument is repaired and passes the

complete self-test before continuing.

Measuring AC Power Mains

The HI, LO, and current input terminals may be connected to AC mains power in IEC Category II installations for line voltages up to 300VAC. To avoid the danger of electric shock, do not connect the inputs

to AC mains power for line voltages above 300 VAC. See IEC Measurement Category II for further

information.

Keysight TruevoltSeries Operating and Service Guide

15

Page 15

Safety and Regulatory Information

Measuring Current with A Current Transformer

If a current transformer is used for measuring current, you must use a current transformer with

internal secondary protection. Using a current transformer without protection may result in a hazardous voltage resulting in a severe shock or death. In addition, this may cause damage to the instrument.

Crest Factor

Exceeding the crest factor limit may result in an inaccurate or lower reading display. Do not exceed

the crest factor limit to avoid instrument damage and risk of electric shock. The crest factor limit is listed in the product data sheet at www.keysight.com/find/truevolt-doc.

Measurement Limits

To avoid instrument damage and the risk of electric shock, do not exceed any of the Measurement Limits defined in the following section.

This product complies with EN/IEC 61326-2-1, for sensitive test and measurement equipment:

When subjected to transient radiated and/or conducted electromagnetic phenomena, the

product may have temporary loss of function or performance which is self-recovering. Recovery may take longer than 10 seconds.

When subjected to continuously present electromagnetic phenomena, some degradation of

performance may occur.

Unless otherwise noted in the specifications, this instrument or system is intended for indoor

use in an installation category II, pollution degree 2 environment per IEC 61010-1 and 664

respectively. It is designed to operate at a maximum relative humidity of 5% to 80% at 40 °C or

less (non-condensing). This instrument or system is designed to operate at altitudes up to

3000 meters, and at temperatures between 0 and 55 °C.

Measurement Limits

The Truevolt Series DMMs provide protection circuitry to prevent damage to the instrument and to protect

against the danger of electric shock, provided the Measurement Limits are not exceeded. To ensure safe

operation of the instrument, do not exceed the Measurement Limits shown on the front and rear panel,

and defined as follows:

16

Keysight TruevoltSeries Operating and Service Guide

Page 16

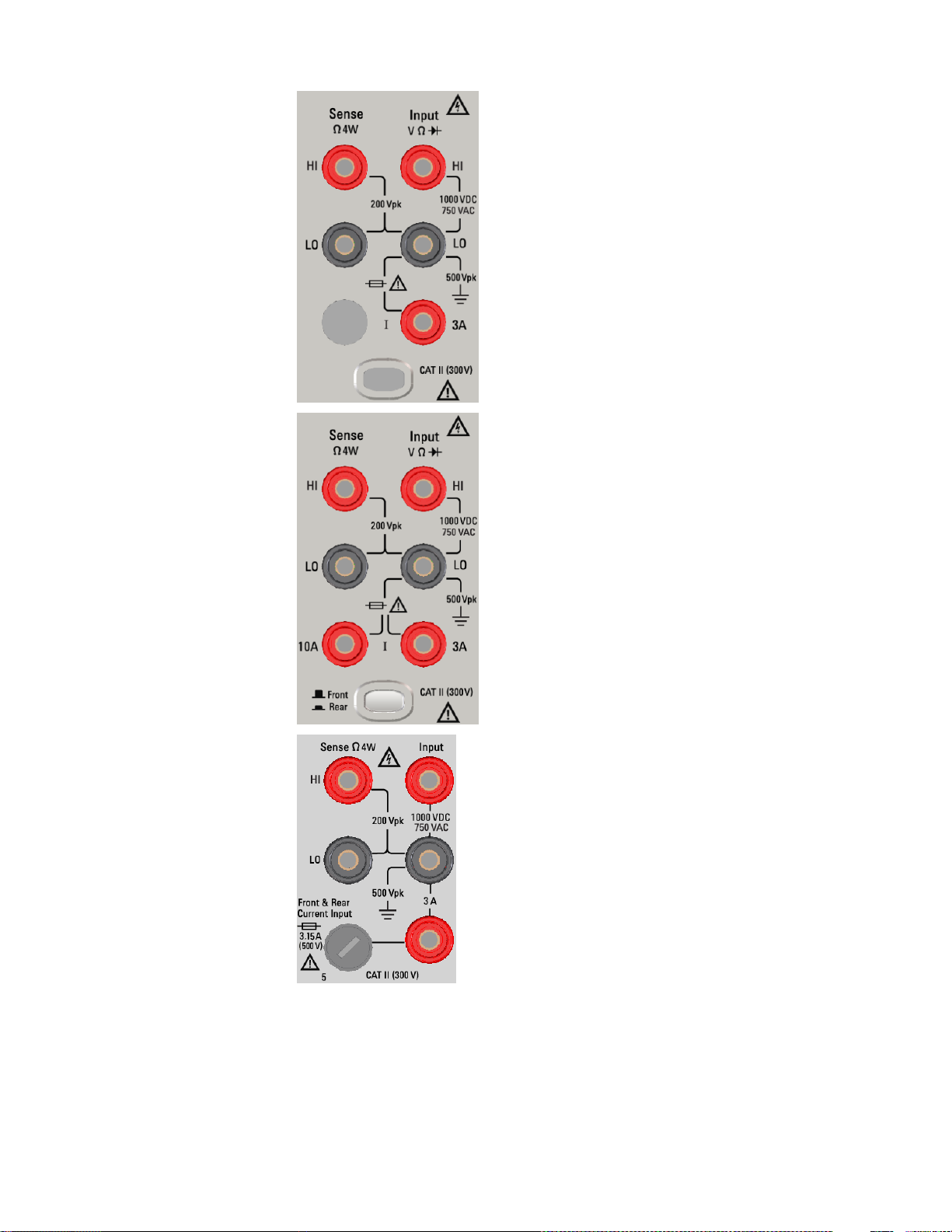

34460A Front Panel

Terminal Area

Safety and Regulatory Information

34461A, 34465A, 34470A

Front Panel

Terminal Area

34461A, 34465A, 34470A

Rear Panel

Terminal Area

Keysight TruevoltSeries Operating and Service Guide

17

Page 17

Safety and Regulatory Information

For the 34461A, 34465A, and 34470A, the Front/Rear switch selects the terminal set to be

used. DO NOT operate this switch while signals are present on the front or rear terminals.

The user-replaceable 3 A current-protection fuse is on the rear panel. There are 3 A and 10 A

(34461A, 34465A and 34470A) current-protection fuses located inside the unit. Contact your

Keysight Sales and Service Center or refer to product service documentation for replacement

instructions.

To maintain protection, replace fuses only with fuses of the specified type and rating.

Input Terminal Measurement Limits

Measurement Limits are defined for the input terminals:

Main Input (HI and LO) Terminals. The HI and LO input terminals are used for voltage, resistance, fre-

quency (period), capacitance, and diode test measurements. Two Measurement Limits are defined for

these terminals:

l

HI to LO Measurement Limit. The Measurement Limit from HI to LO (Input terminals) is 1000 VDC or

750 VAC, which is also the maximum voltage measurement. This limit can also be expressed as 1000

Vpk maximum.

l

LO to Ground Measurement Limit. The LO input terminal can safely "float" a maximum of 500 Vpk

relative to ground, where ground is defined as the Protective Earth Conductor in the AC mains power

cord connected to the instrument.

As implied by the above limits, the Measurement Limit for the HI input terminal is a maximum of 1500 Vpk

relative to ground when LO is at its maximum of 500 Vpk relative to ground.

Current Input Terminal. The current input ("I") terminal has a Measurement Limit of 3 A or 10 A (DC or

AC) between the "I" terminal (3 A or 10 A) and the LO input terminal. Note that the current input terminals

will always be at approximately the same voltage as the LO terminal, unless a current protection fuse is

open. The 10 A terminal isnot available on the 34460A.

Sense Terminal Measurement Limits

The HI and LO sense terminals are used for DCV ratio measurements and four-wire resistance and temperature measurements. The Measurement Limit is 200 Vpk for all of the terminal pairings: LO sense to LO

input, HI sense to LO input, and HI sense to LO sense.

The 200 Vpk limit on the sense terminals is the Measurement Limit. Operational voltages in resistance measurements are much lower – up to ± 12 V in normal operation.

18

Keysight TruevoltSeries Operating and Service Guide

Page 18

Safety and Regulatory Information

IEC Measurement Category II

To protect against the danger of electric shock, the Keysight Truevolt Series DMM protects the user from

AC mains power overvoltage events. When measuring AC mains, the HI and LO input terminals may be

connected to AC mains power up to 300 VAC under Measurement Category II conditions as defined

below.

IEC Measurement Category II includes electrical devices connected to AC mains power at an outlet on a

branch circuit. Such devices include most small appliances, test equipment, and other devices that plug

into a branch outlet or socket. The instrument may be used to make measurements with the HI and LO

inputs connected to AC mains power in such devices, or to the branch outlet itself (up to 300 VAC).

However, the instrument may not be used with its HI and LO inputs connected to AC mains power in permanently installed electrical devices such asthe main circuit-breaker panel, sub-panel disconnect boxes,

or permanently wired motors. Such devicesand circuits are subject to overvoltages that may exceed the

instrument’s protection capabilities.

Voltages above 300 VAC may be measured only in circuits that are isolated from AC mains power. However,

transient overvoltages are also present on circuits that are isolated from ACmains power. The instrument is

designed to safely withstand occasional transient overvoltages up to 1500 Vpk when measuring voltages

greater than 300 VAC. Do not use this equipment to measure circuits where transient overvoltages could

exceed this level.

Keysight 34138A Test Lead Set

The Keysight 34138A Test Lead Set, described below, is compatible with the Truevolt Series DMMs.

Test Lead Ratings

l Test Leads - 1000V, 15A

l Fine Tip Probe Attachments - 300V

l 3A Mini Grabber Attachment - 300V, 3A

l SMT Grabber Attachments - 300V, 3A

Operation

The Fine Tip, Mini Grabber, and SMT Grabber attachments plug onto the probe end of the Test Leads.

Maintenance

If any portion of the Test Lead Set is worn or damaged, do not use. Replace with a new Keysight 34138A

Test Lead Set.

If the Test Lead Set is used in a manner not specified by KeysightTechnologies, the protection

provided by the Test Lead Set may be impaired. Also, do not use a damaged or worn Test Lead Set. Personal injury or death may result.

Keysight TruevoltSeries Operating and Service Guide

19

Page 19

Safety and Regulatory Information

Declaration of Conformity

Declarations of Conformity for this product and for other Keysight products may be downloaded from the

Keysight Regulatory Web site:

http://regulations.products.keysight.com/DoC/search.htm

20

Keysight TruevoltSeries Operating and Service Guide

Page 20

Welcome

Welcome

This Operating and Service Guide contains information for using, programming, and servicing the Keysight

Truevolt Series Digital Multimeters (DMMs). If you have feedback on this document, please go to www.key-

sight.com/find/truevolt-docfeedback.

Introductory Information

Safety and Regulatory Information

Models and Options

Quick Start

Contacting Keysight Technologies

Introduction to the Instrument

User Information

Front Panel Menu Reference

Features and Functions

Remote Interface Configuration

LAN Configuration Procedure

Web Interface

Measurements

Triggering and Readings

Probe Hold

Math

Display

Utility Menu

Measurement Tutorial

Keysight TruevoltSeries Operating and Service Guide

21

Page 21

Welcome

SCPI Programming Reference

Welcome to SCPI

Introduction to the SCPI Language

Commands by Subsystem

Command Quick Reference

Range, Resolution, and NPLC

Resolution Table

VM Comp Output

SCPI Error Messages

Power-On and Reset State

Service and Repair

Service and Repair

Disassembly

Troubleshooting

Power Supplies

Self-Test Procedures

Battery Replacement

Installing the Optional GPIB Interface

User Replaceable Parts

Performance Verification

Performance Verification

Calibration Procedures

Calibration Procedures

34460A and 34461A Calibration Procedures

34465A and 34470A Calibration Procedures

Firmware Update

22

Keysight TruevoltSeries Operating and Service Guide

Page 22

Introduction to the Instrument

Introduction to the Instrument

The Keysight Technologies 34460A/61A/65A instruments are 6½-digit digital multimeters (DMMs); the

34470A is a 7½-digit DMM.

Instrument at a Glance

Front Panel at a Glance

Rear Panel at a Glance

Models and Options

Contacting Keysight Technologies

Instrument at a Glance

The instrument’s combination of bench-top and system features make it a versatile solution now and in

the future. The instrument can make a wide range of accurate and flexible measurements.

Display – Easily display, save and document your measurement results

l High usability with an intuitive, menu driven user interface

l Histogram, trend chart (not available on the 34460A), meter, and numeric views on a high-resolution

color display

l USB, LAN (optional on 34460A), and optional GPIB interface

l Drag and drop, driverless USB connectivity

Measurements – Keysight’s Truevolt measurement performance with modern I/O accessibility

l Patented, metrology-level performance that serves as the foundation for all measurements

Programming Language

l SCPI (Standard Commands for Programmable Instruments) programming language

Keysight TruevoltSeries Operating and Service Guide

23

Page 23

Introduction to the Instrument

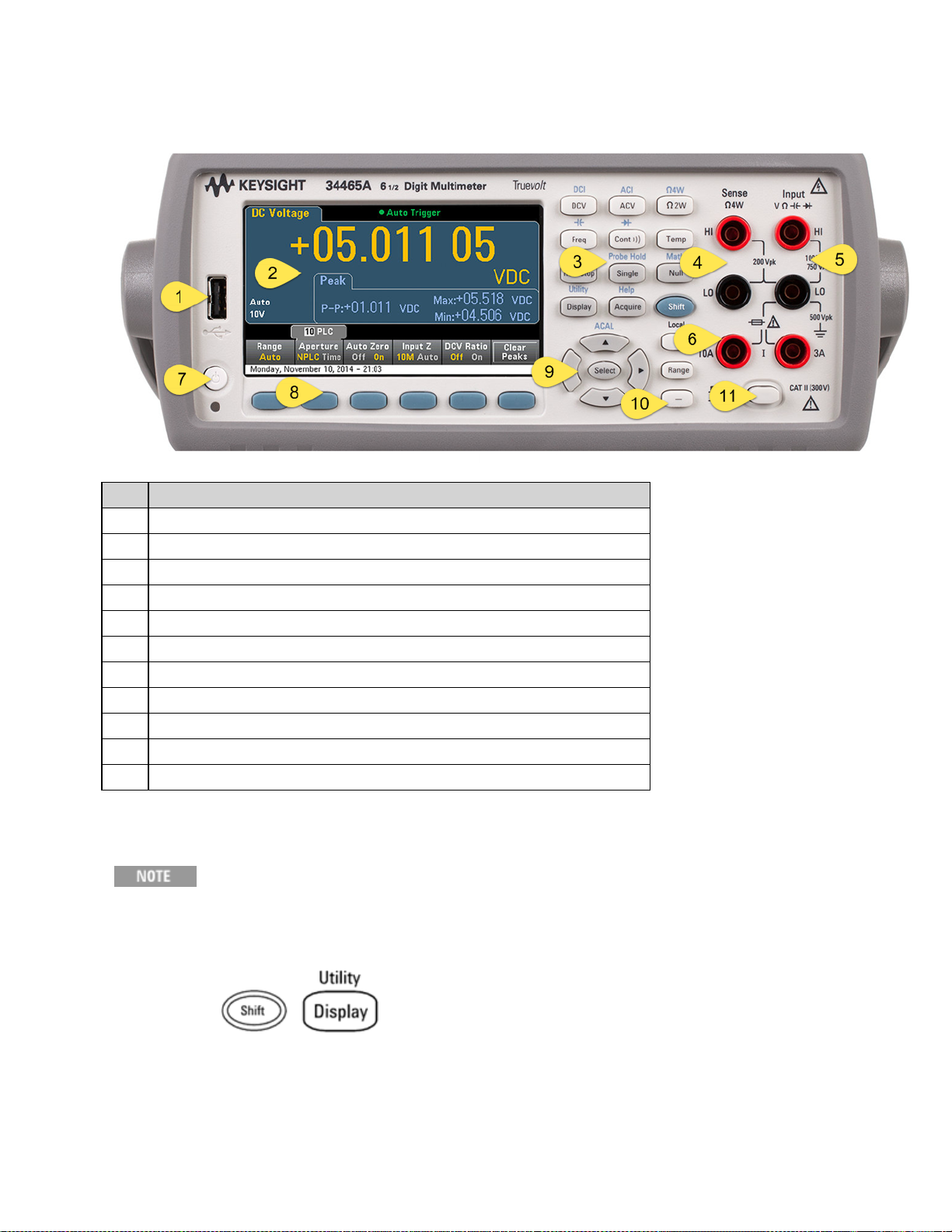

Front Panel at a Glance

Item Description

1 USB Port

2 Display

3 Measurement Configuration and Instrument Operation Keys

4 HI and LO Sense Terminals

5 HI and LO Input Terminals

6 AC/DC Current Input Terminals (10 A terminal not available on 34460A)

7 On/Standby Switch

8 Softkeys

9 Cursor Navigation Keypad

10 Range Selection Keys

11 Front/Rear Switch (34461A/65A/70A only)

Front Panel Keys

Some of the front panel keys have text above them. This indicates that the key has a

function that you can access by pressing and releasing [Shift] before pressing the key.

For example, if you press and release [Shift] before pressing [Display], you will access

the [Utility] function:

24

Keysight TruevoltSeries Operating and Service Guide

Page 24

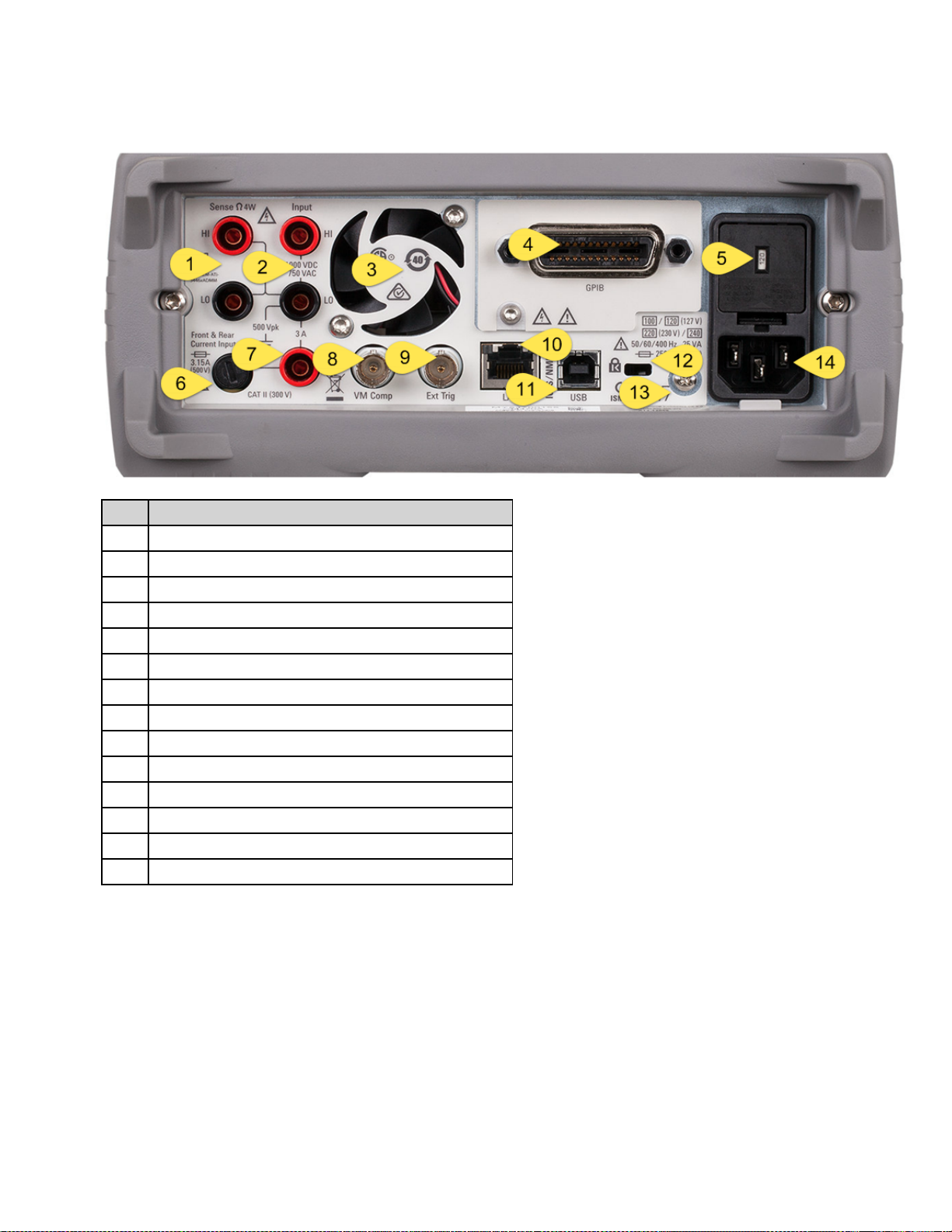

Rear Panel at a Glance

Introduction to the Instrument

Item Description

1 HI and LO Sense Terminals (34461A/65A/70A only)

2 HI and LO Input Terminals (34461A/65A/70A only)

3 Fan Vents (34461A/65A/70A only)

4 GPIB Connector (optional)

5 AC Mains Line Voltage Selector and Fuse Access

6 3 A Current Terminal Fuse

7 3 A Current Terminal (34461A/65A/70A only)

8 Voltmeter Measurement Complete Output

9 External Trigger Input

10 Local Area Network (LAN) Connector

11 USB Interface Connector

12 Instrument Cable Lock

13 Chassis Ground Screw

14 AC Mains Input

Keysight TruevoltSeries Operating and Service Guide

25

Page 25

Introduction to the Instrument

Models and Options

The available Truevolt Digital Multimeter (DMM) models are:

l 34460A - 6½-digit Basic DMM

l 34461A - 6½-digit 34401A Replacement DMM

l 34465A - 6½-digit DMM

l 34470A - 7½-digit DMM

The factory-installed options and the options that can be installed by you or a distributor are listed in the

tables below. You can determine the installed options from the instrument's front panel by pressing

[Shift] > [Help] > About.

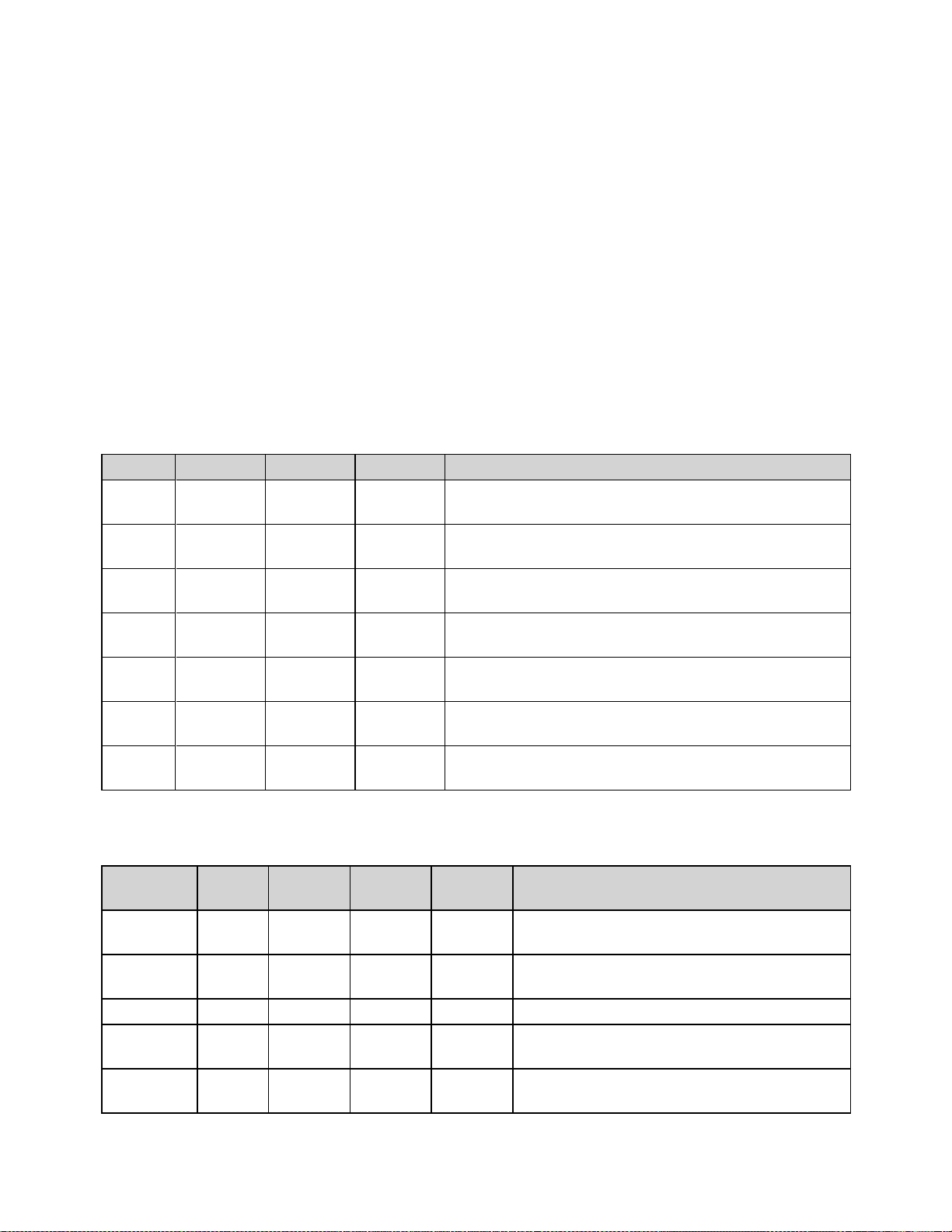

Options Installed at Factory

34460A 34461A 34465A 34470A Description

34460ALAN

34460ASEC

34460AGPB

34460AACC

34460AZ54

*N/A *N/A 34465A-

*N/A *N/A 34465A-

*N/A Standard

34461ASEC

34461AGPB

*N/A Standard

34461AZ54

*N/A Standard

34465ASEC

34465AGPB

*N/A Standard

34465AZ54

DIG

MEM

*N/A Standard

34470ASEC

34470AGPB

*N/A Standard

34470AZ54

34470ADIG

34470AMEM

Rear panel LAN/LXI web interface, external triggering for

34460A.

NISPOM and file security for Truevolt series DMMs license.

User-installable GPIB interface module

Accessory kit for 34460A - Test Leads, USB Cable

Certificate of calibration – ANSI/NCSL Z540.3-2006, printed

Digitizing and advanced triggering. Now included with

latest firmware update.

2 MB memory license

Options Installed by Distributor or End Customer

Product

Number

3446LANU Option *N/A -

3446SECU Option Option Option Option NISPOM and file security for Truevolt series

3446GPBU Option Option Option Option User-installable GPIB interface module

3446ACCU Option *N/A -

3446MEMU *N/A *N/A Option Option 2 MB memory for 34465A and 34470A Truevolt

*N/A = Not Applicable.

26

34460A 34461A 34465A 34470A Description

Standard

Standard

*N/A Standard

*N/A Standard

*N/A Standard

*N/A Standard

Enable rear panel LAN/LXI web interface,

external triggering for 34460A

DMMs license.

Accessory kit for 34460A - Test Leads, USB

Cable

DMMs license

Keysight TruevoltSeries Operating and Service Guide

Page 26

Introduction to the Instrument

Remote Interface Configuration

If you have the security option installed on your instrument, the instrument must be unsecured with the

security code to perform many of these actions.

The instrument supports remote interface communication over three interfaces: GPIB (optional), USB, and

LAN (optional on 34460A). All three are "live" at power up when the instrument ships from the factory.

l

GPIB Interface: Set the instrument's GPIB address and connect to your PC using a GPIB cable.

l

USB Interface: Use the rear-panel USB connector to communicate with your PC. For details, see USB

Settings.

l

LAN Interface: By default, DHCP is on, which may enable communication over LAN. The acronym

DHCP stands for Dynamic Host Configuration Protocol, a protocol for assigning dynamic IP addresses

to networked devices. With dynamic addressing, a device can have a different IP address every time it

connects to the network.

Connectivity Software

l

The instrument ships with the Keysight Automation-Ready CD. This CDcontains Keysight IO Librar-

ies Suite software, which must be installed to enable remote-interface operations. The CDauto-starts

and provides information on installing the software. Also includes Keysight Technologies

USB/LAN/GPIB Connectivity Guide, which contains additional information.

GPIB Configuration

Each device on the GPIB (IEEE-488) interface must have a unique whole number address between 0 and

30. The instrument ships with a default address of 10, and the GPIB address is displayed at power-on.

l This setting is non-volatile; it will not be changed by power cycling or *RST or SYSTem:PRESet.

l Your computer’s GPIB interface card addressmust not conflict with any instrument on the interface

bus.

l

Front Panel: Press [Utility] > I/O Config > GPIB Settings. From this menu, you can set the GPIB

address and turn GPIB on or off. After making changes, you must cycle power on the instrument for

the change to take effect.

l

SCPI:

SYSTem:COMMunicate:GPIB:ADDRess <address>

SYSTem:COMMunicate:ENABle {ON|1|OFF|0},GPIB

Keysight TruevoltSeries Operating and Service Guide

27

Page 27

Introduction to the Instrument

LAN Configuration

The following sections describe the primary front panel LAN configuration functions, including SCPI commands where applicable. Some LAN configuration functions can be performed only via SCPI. See SYSTem

Subsystem - I/O Configuration for all LAN configuration commands, and see LAN Configuration Procedure to configure the LAN via the front panel.

Some LAN settings require you to cycle instrument power to activate them. The instrument briefly displays a message when this is the case, so watch the screen closely as

you change LAN settings.

Resetting the LAN

You can clear the Web Interface password, turn DHCP on, and restart the LAN at any time:

l

Front Panel:[Utility] > I/O Config > LAN Reset

The message "Performing LAN Reset" is displayed while the LAN is reset.

l

SCPI: LXI:RESet

DHCP On/Off

DHCP (Dynamic Host Configuration Protocol) can automatically assign a dynamic IP addressto a LAN

device. This is typically the easiest way to configure the instrument for LAN.

l This setting is non-volatile; it will not be changed by power cycling or *RST or SYSTem:PRESet.

l

Front Panel:[Utility] > I/O Config > LAN Settings > Modify Settings

Then set the first softkey to DHCP to use DHCP to automatically assign an IP address.

l

SCPI: SYSTem:COMMunicate:LAN:DHCP {ON|1|OFF|0}

l

If you change this parameter, you must either press the Apply Changes softkey (front panel) or send

SYSTem:COMMunicate:LAN:UPDate (remote interface) for the change to take effect.

To manually set an IP address, Subnet Mask, or Default Gateway, turn DHCP off, then change the IP setup

as described below.

28

Keysight TruevoltSeries Operating and Service Guide

Page 28

Introduction to the Instrument

IP Address

You can enter a static IP address for the instrument as a four-byte integer expressed in dot notation. Each

byte isa decimal value, with no leading zeros (for example, 169.254.2.20).

l If DHCP is on, it attempts to assign an IP address to the instrument. If it fails, Auto-IP attempts to

assign an IP address to the instrument.

l Contact your LAN administrator to obtain an IP address.

l This setting is non-volatile; it will not be changed by power cycling or *RST or SYSTem:PRESet.

l

Front Panel:[Utility] > I/O Config > LAN Settings > Modify Settings

Then set the first softkey to Manual and press IP Address to enter a new IP address.

l

SCPI: SYSTem:COMMunicate:LAN:IPADdress"<address>"

l

If you change this parameter, you must either press the Apply Changes softkey (front panel) or send

SYSTem:COMMunicate:LAN:UPDate (remote interface) for the change to take effect.

Subnet Mask

Subnetting allows the LAN administrator to subdivide a network to simplify administration and minimize

network traffic. The subnet mask indicates the portion of the host address used to indicate the subnet.

l Contact your LAN administrator for details.

l This setting is non-volatile; it will not be changed by power cycling or *RST or SYSTem:PRESet.

l

Front Panel:[Utility] > I/O Config > LAN Settings > Modify Settings

Then set the first softkey to Manual and press Subnet Mask to enter a new subnet mask with the

arrow keys (for example: 255.255.0.0).

l

SCPI: SYSTem:COMMunicate:LAN:SMASk "<mask>"

l

If you change this parameter, you must either press the Apply Changes softkey (front panel) or send

SYSTem:COMMunicate:LAN:UPDate (remote interface) for the change to take effect.

Keysight TruevoltSeries Operating and Service Guide

29

Page 29

Introduction to the Instrument

Default Gateway

A gateway is a network device that connects networks. The default gateway setting is the IP address of

such a device.

l You need not set a gateway address if using DHCP.

l Contact your LAN administrator for details.

l This setting is non-volatile; it will not be changed by power cycling or *RST or SYSTem:PRESet.

l

Front Panel:[Utility] > I/O Config > LAN Settings > Modify Settings

Then set the first softkey to Manual and press More and Gateway. Then set the appropriate gateway

address using the arrow keys.

l

SCPI: SYSTem:COMMunicate:LAN:GATeway "<address>"

l

If you change this parameter, you must either press the Apply Changes softkey (front panel) or send

SYSTem:COMMunicate:LAN:UPDate (remote interface) for the change to take effect.

Hostname

A hostname is the host portion of the domain name, which is translated into an IP address.

l The instrument receives a unique hostname at the factory, but you may change it. The hostname must

be unique on the LAN.

l The name must start with letter; other characters can be an upper or lower case letters, numeric digits,

or dashes("-").

l This setting is non-volatile; it will not be changed by power cycling or *RST or SYSTem:PRESet.

l

Front Panel:[Utility] > I/O Config > LAN Settings > Modify Settings

Then press Host Name and enter the hostname with the front panel arrow keys.

l

SCPI: SYSTem:COMMunicate:LAN:HOSTname "<name>"

l

If you change this parameter, you must either press the Apply Changes softkey (front panel) or send

SYSTem:COMMunicate:LAN:UPDate (remote interface) for the change to take effect.

Domain Name

A domain name is a registered Internet name that gets translated into an IP address. You cannot set it from

the front panel or SCPI.

30

Keysight TruevoltSeries Operating and Service Guide

Page 30

Introduction to the Instrument

DNS Server

DNS (Domain Name Service) is an Internet service that translates domain names into IP addresses. The

DNS server address is the IP address of a server that performs this service.

l Normally, DHCP discovers DNS address information; you only need to change this if DHCP is unused

or not functional. Contact your LAN administrator for details.

l This setting is non-volatile; it will not be changed by power cycling or *RST or SYSTem:PRESet.

l

Front Panel:[Utility] > I/O Config > LAN Settings > Modify Settings

Then set the first softkey to Manual and press More and Primary DNS or Second DNS to enter a DNS

address using the front panel arrow keys.

l

SCPI: SYSTem:COMMunicate:LAN:DNS[{1|2}] "<address>"

l

If you change this parameter, you must either press the Apply Changes softkey (front panel) or send

SYSTem:COMMunicate:LAN:UPDate (remote interface) for the change to take effect.

Current Configuration (LAN)

l

Press[Utility] > I/O Config > LAN Settings to view the MAC address and current LAN configuration.

There is no equivalent SCPI command.

l If the instrument goes into remote, all LAN changes will be canceled and the display will go to a dif-

ferent screen. Re-selecting the LAN Settings page will display the new settings if a LAN restart took

place.

Web Interface

The instrument includes a built-in Web Interface for remote instrument access and control over LAN via a

Web browser. For details, see Web Interface.

Keysight TruevoltSeries Operating and Service Guide

31

Page 31

Introduction to the Instrument

LAN Configuration Procedure

There are several parameters that you might need to set to establish network communication using the

LAN interface. Primarily, you will need to establish an IP address. You might need to contact your network

administrator for help in establishing communication with the LAN interface.

If your instrument has the secure (SEC) option, the instrument must be unsecured to change most LAN settings.

1. Press [Utility] > I/O Config > LAN Settings.

2. You can select Modify Settings to change the LAN settings, or you can turn LAN Services on and off

or restore the LAN settings to default values.

3. To change settings, press Modify Settings. To access most items on this screen, use the first softkey

to switch from DHCP to Manual. With DHCP on, an IP address will automatically be set by DHCP

(Dynamic Host Configuration Protocol) when you connect the instrument to the network, provided

the DHCP server isfound and is able to do so. DHCP also automatically deals with the subnet mask,

gateway address, DNS, WINS, and domain name, if required. This is typically the easiest way to establish LAN communication for your instrument; all you need to do is leave DHCP on. Contact your LAN

administrator for details.

4. Establish an "IP Setup."

If you are not using DHCP (the first softkey is set to Manual), you must establish an IP setup, including

an IP address, and possibly a subnet mask and gateway address. The IP Address and Subnet Mask

buttons are on the main screen, and you press More to configure the Gateway.

Contact your network administrator for the IP address, subnet mask, and gateway to use. All IP

addresses take the dot-notation form "nnn.nnn.nnn.nnn" where "nnn" in each case is a byte value in

the range 0 through 255. You can enter a newIP address using the front panel arrow keys. Do not

enter leading zeros.

32

Keysight TruevoltSeries Operating and Service Guide

Page 32

Introduction to the Instrument

5. Configure the "DNS Setup" (optional)

DNS (Domain Name Service) is an Internet service that translates domain names into IP addresses. Ask

your network administrator whether DNS is in use, and if it is, for the host name, domain name, and

DNS server address to use.

a. Set the "hostname." Press Host Name and enter the hostname. A hostname isthe host portion of

the domain name, which is translated into an IP address. The hostname is entered as a string using

the front panel arrow keys to select and change characters. The hostname may include letters,

numbers, and dashes ("-").

b. Set the "DNS Server" addresses. From the LAN configuration screen, press More to go to the

second of three sets of softkeys.

Enter the Primary DNS and Second DNS. See your network administrator for details.

More about IP Addresses and Dot Notation

Dot-notation addresses ("nnn.nnn.nnn.nnn" where "nnn" is a byte value from 0 to 255) must be expressed

with care, as most PC web software interprets byte values with leading zeros as octal (base 8) numbers. For

example, "192.168.020.011" is actually equivalent to decimal "192.168.16.9" because ".020" is interpreted as "16" expressed in octal, and ".011" as "9". To avoid confusion, use only decimal values from 0 to

255, with no leading zeros.

Keysight TruevoltSeries Operating and Service Guide

33

Page 33

Introduction to the Instrument

Firmware Update

Use the following procedure to update instrument firmware:

Do not turn off the instrument during the update.

1. Press [Help] > About to determine what instrument firmware version iscurrently installed.

2.

Go to www.keysight.com/find/truevolt and use the links there to find the latest firmware version. If

this matches the version installed on your instrument, there is no need to continue with this procedure. Otherwise, download the firmware update utility and a ZIP file of the firmware. Detailed firmware instructions are in the Firmware Update Utility Instructions located on the download page.

3.

Unzip the ZIP file and use the firmware update utility to prepare a USB drive with the updated firmware:

4. Attach the USB drive to the instrument front panel and press [Utility] > Test / Admin > Firmware

Update to update the firmware. If the security option is installed, unlock the instrument with the secur-

ity code before installing firmware.

Important: In order to update the instrument firmware from remote, the model number in the *IDN?

response must match the actual instrument model number. If you have changed the instrument's *IDN?

response to another instrument, when attempting to update the firmware from remote, you will see this

error: The instrument is not supported by this firmware file. To update the firmware, either update using

the front panel procedure or, from remote, use SYSTem:IDENtify to set the *IDN? to match the actual

model number, update the firmware, and then use SYSTem:IDENtify again to set the *IDN? response to the

other model number.

34

Keysight TruevoltSeries Operating and Service Guide

Page 34

Introduction to the Instrument

Contacting Keysight Technologies

You can contact Keysight Technologies for warranty, service, or technical support.

In the United States: (800) 829-4444

In Europe: 31 20 547 2111

In Japan: 0120-421-345

Use www.keysight.com/find/assist to contact Keysight worldwide, or contact your Keysight Technologies rep-

resentative.

Keysight TruevoltSeries Operating and Service Guide

35

Page 35

Quick Start

Quick Start

This section describes basic procedures to help you get started quickly with the instrument.

l Prepare Instrument for Use

l Adjust the Carrying Handle

l Use Built-in Help System

l Rack Mount the Instrument

Prepare Instrument for Use

Verify that you received the following items. If anything is missing, please contact your nearest Keysight

sales office or Keysight authorized reseller.

l Power cord (for country of destination)

l Certificate of Calibration (optional)

l

Keysight Automation-Ready CD (Keysight IO Libraries Suite) (optional on 34460A)

l Supplemental documentation packet

l USB 2.0 cable (optional on 34460A)

The latest product documentation is available at www.keysight.com/find/truevolt-doc. For doc-

umentation for mobile devices, see www.keysight.com/find/truevolt-mobilehelp.

To download the Digital Multimeter Connectivity Utility, go to www.key-

sight.com/find/DMMutilitysoftware.

36

Keysight TruevoltSeries Operating and Service Guide

Page 36

Setting the AC Mains Line Voltage Selector and Fuse Installation

Before plugging the instrument into AC mains power, verify that the line voltage

setting visible on the back of the AC mains input module is correct for the AC

mains power source being connected. The line voltage selections are shown in a

box on the rear panel immediately to the left of the AC mains input module.

Other nominal line voltages are shown in parentheses.

Verify that the correct fuse is installed. To replace a blown fuse or verify the correct

fuse,

pull it gently from the fuse drawer and insert thecorrect working fuse. Use only a

5x20 mm,

time-lag, 0.25 A, 250 V certified fuse. The Keysight part number is 2110-0817.

Quick Start

AC MAINS Nominal Line Voltage

Range

100 - 115 100

120 - 127 120

202 - 230 220

240 240

AC Mains Line Voltage

Selector

Keysight TruevoltSeries Operating and Service Guide

37

Page 37

Quick Start

Use the following procedure to configure the line voltage selector:

Step1 Lift tab (1) and pull the fuse drawer (2) from the rear panel.

Step2 Remove the line-voltage selector and rotate it so the correct voltage will

appear in the fuse holder window.

Step3

Step4 Replace the fuse holder assembly by sliding it into the rear panel.

Verify that the correct fuse is installed. To replace a blown fuse or

verify the correct fuse,

pull it gently from the fuse drawer and insert the correct working

fuse. Use only a 5x20 mm,

time-lag, 0.25 A, 250 V certified fuse. The Keysight part number is

2110-0817.

38

Keysight TruevoltSeries Operating and Service Guide

Page 38

Quick Start

Product Grounding

The instrument is a Class 1 product and is provided with a grounding-type power cord set. The instrument chassis and cover are connected to the instrument electrical ground to minimize shock hazard.

The ground pin of the cord set plug must be firmly connected to the electrical ground (safety ground)

terminal at the power outlet. Any interruption of the protective earth (grounding) conductor or disconnection of the protective earth terminal will cause a potential shock hazard that could result in personal injury or death.

Connect Power and I/O Cables

Connect the power cord and LAN, GPIB, or USB cable as desired. After you turn on the instrument (as

described below), the instrument will run a power-on self test and then display a message about how to

obtain help, along with the current IP address. It also displays the GPIB address (if applicable).

The instrument's default measurement function isDC Voltage (DCV), with autoranging enabled.

Power Switch

Pressthe power switch in the lower left corner of the front panel. If the instrument does not turn on, verify

that the power cord is firmly connected and that the fuse is good and the line voltage selector is set correctly, as described above. Also make sure that the instrument is connected to an energized power source.

If the LED below the power switch is off, there is no AC mains power connected. If the LED is amber, the

instrument isin standby mode with AC mains power connected, and if it is green, the instrument is on.

In certain circumstances, the amber LED can come on even if the wrong line voltage is selected. In this

case, the instrument may not power on.

If the power-on self test fails, the display shows Error in the upper right corner. It also displays a message

describing the error. See SCPI Error Messagesfor information on error codes. See Service and Repair -

Introduction for instructions on returning the instrument for service.

To turn off the instrument, press and hold the power switch for about 500 ms. This prevents you from accidentally turning off the instrument by brushing against the power switch.

If you turn off the instrument by disconnecting power (this is not recommended), the instrument turns on

as soon as you re-apply power. You will not need to press the power switch.

Keysight TruevoltSeries Operating and Service Guide

39

Page 39

Quick Start

Adjust the Carrying Handle

The handle hasthree positions, shown below.

To adjust the handle position, grasp the sides of the handle, pull outward, and rotate the handle.

40

Keysight TruevoltSeries Operating and Service Guide

Page 40

Quick Start

Use Built-in Help System

The built-in help system provides context-sensitive help on any front panel key or menu softkey. A list of

help topics is also available to help you learn about the instrument.

View the help information for a front panel key

Pressand hold any softkey or button, such as [Display].

If the message contains more information than will fit on the display, pressthe down arrow softkey to

scroll down.

PressDone to exit Help.

Keysight TruevoltSeries Operating and Service Guide

41

Page 41

Quick Start

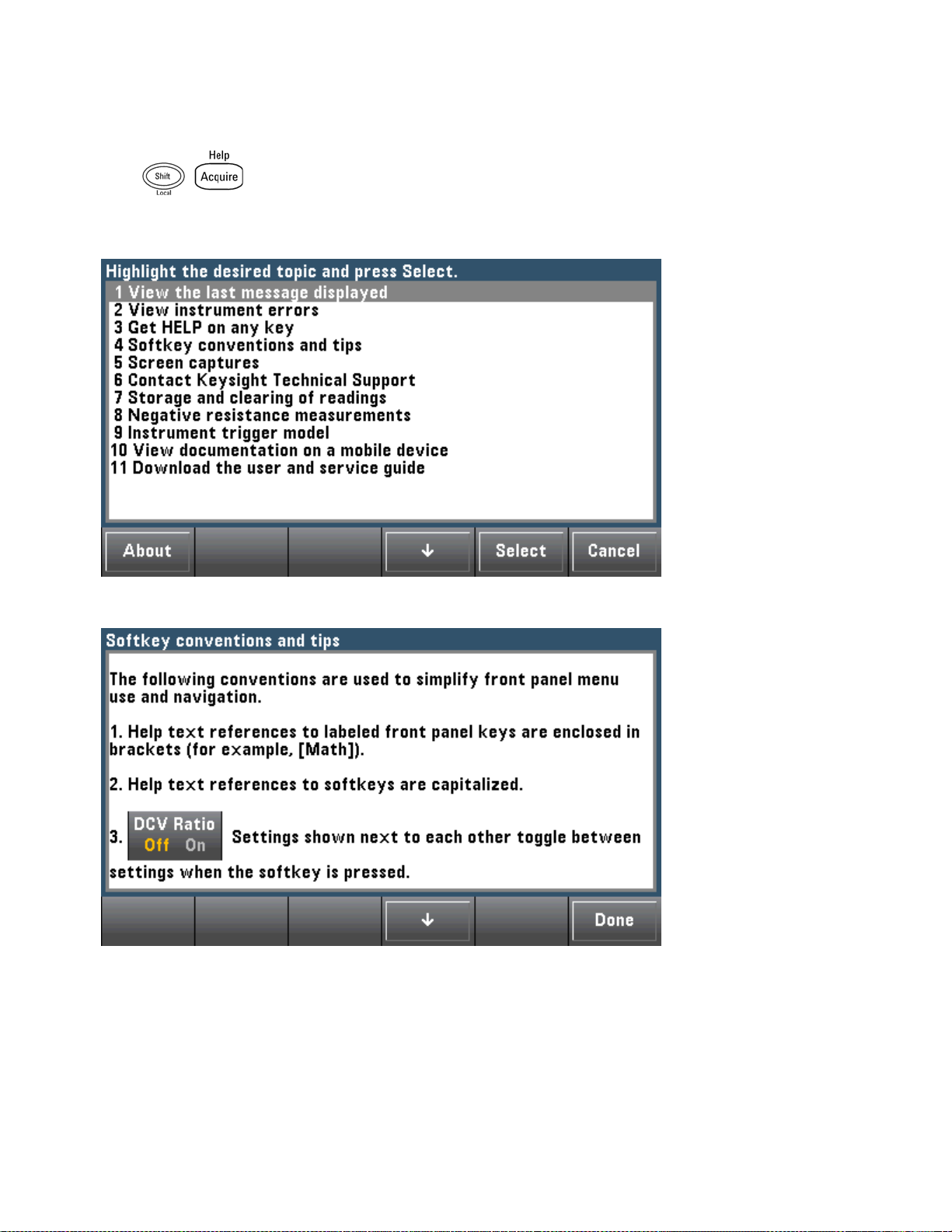

View the list of help topics and use interactive demos

Press to view the list of help topics. Press the arrow softkeys or use the front panel arrow

keys to highlight the desired topic. Then press Select. You can also press Demos to run interactive demos

on how to use the instrument.

In this case, the following help topic appears:

42

Keysight TruevoltSeries Operating and Service Guide

Page 42

Quick Start

View the list of recent instrument errors.

Press and choose View instrument errors from the list of help topics. This displays the

instrument's error queue, which includes up to 20 errors.

View the help information for displayed messages.

Whenever a limit is exceeded or any other invalid configuration isfound, the instrument displays a message. The built-in help system provides additional information on the most recent message. Press [Shift] >

[Help], select View the last message displayed, and press Select.

PressDone to exit Help.

Local Language Help

All messages, context-sensitive help, and help topics are available in English, Chinese,

French, German, Japanese, Korean, and Russian. To select the local language, press

[Utility] > System Setup > User Settings > Help Lang. Then select the desired lan-

guage.

The menu softkey labels and status line messages are not translated.

Keysight TruevoltSeries Operating and Service Guide

43

Page 43

Quick Start

Rack Mount the Instrument

You can mount the instrument in a standard 19-inch rack cabinet using one of two optional kits, each of

which includes instructions and mounting hardware. You may also mount Another Keysight System II

instrument of the same height and width beside the instrument.

To prevent overheating, do not block airflow to or from the instrument. Allow enough

clearance at the rear, sides, and bottom of the instrument to permit adequate internal

air flow.

Remove the carrying handle and the front and rear bumpers before rack-mounting the instrument.

Removing the Handle and Bumpers

To remove the handle, rotate it to vertical and pull the ends outward.

To remove the rubber bumper, stretch a corner and then slide it off.

Front Rear (bottom view)

Rack Mounting a Single Instrument

To rack mount a single instrument, order adapter kit 5063-9240.

Rack Mounting Instruments Side-by-Side

To rack mount two instruments side-by-side, order lock-link kit 5061- 8769 and flange kit 5063-9212. Be

sure to use the support rails in the rack cabinet.

44

Keysight TruevoltSeries Operating and Service Guide

Page 44

Quick Start

Sliding Support Shelf

To install one or two instruments in a sliding support shelf, order shelf 5063-9255 and slide kit 1494-

0015. For a single instrument, also order filler panel 5002-3999.

Keysight TruevoltSeries Operating and Service Guide

45

Page 45

Features and Functions

Features and Functions

This section contains details on instrument features, including front panel and remote interface operation.

Read the Front Panel Menu Reference first. See Introduction to SCPI Language for details on SCPI com-

mands and queries.

This section covers:

Front Panel Menu Reference

Measurements

Triggering and Readings

Probe Hold

Math Menu

Display Menu

Utility Menu

Web Interface

Throughout this document, "default" states and values are identified. These are the power-on default

states when the instrument is shipped from the factory.

46

Keysight TruevoltSeries Operating and Service Guide

Page 46

Features and Functions

Continuous, Data Log, and Digitize Modes

The 34465A/70A can operate in the continuous, data log, or digitize mode as described below.

The 34460A/61A DMMs always operate in the continuous mode -data log and digitize modes

are not available on these models.

Continuous Mode

Continuous mode is the default mode for all Truevolt DMMs. With the factory default settings, the DMM

continuously makes DCV measurements with autorange and autozero on, NPLC set to 10 PLCs, etc. (see

factory defaults for details).

Data Log Mode

The Data Log mode is standard on the 34465A and 34470A only, as is available only from the DMM's front

panel. Data Log mode provides a front–panel user interface that allows you to set up data logging into the

instrument’s non–volatile memory, or to internal/external file(s), without programming, and without a connection to a computer. Once you have finished collecting data, you can view it from the front panel, or you

can transfer the data to your computer. Data Log mode allows you to log a specified number of readings,

or readings acquired for a specified period of time, to instrument memory or to internal or external data

files.

To select Data Log mode, press [Acquire] Acquire > Data Log. You can then select the Sample Interval

(time between measurements - for example, 500 ms), Duration as either an amount of Time or a number of

Readings, whether to Start after a Delay or at a specific Time of Day, and whether to Log to Memory or Log

to File(s). After configuring the data logging parameters, press [Run/Stop]. Data logging will begin fol-

lowing the specified Delay or at the specified Time of Day.

Digitize Mode

The digitize mode applies only to the 34465A/70A with the DIG option, and asis available only from the

DMM's front panel. The digitized mode provides a front–panel user interface that allows you to quickly set

up digitized measurements.

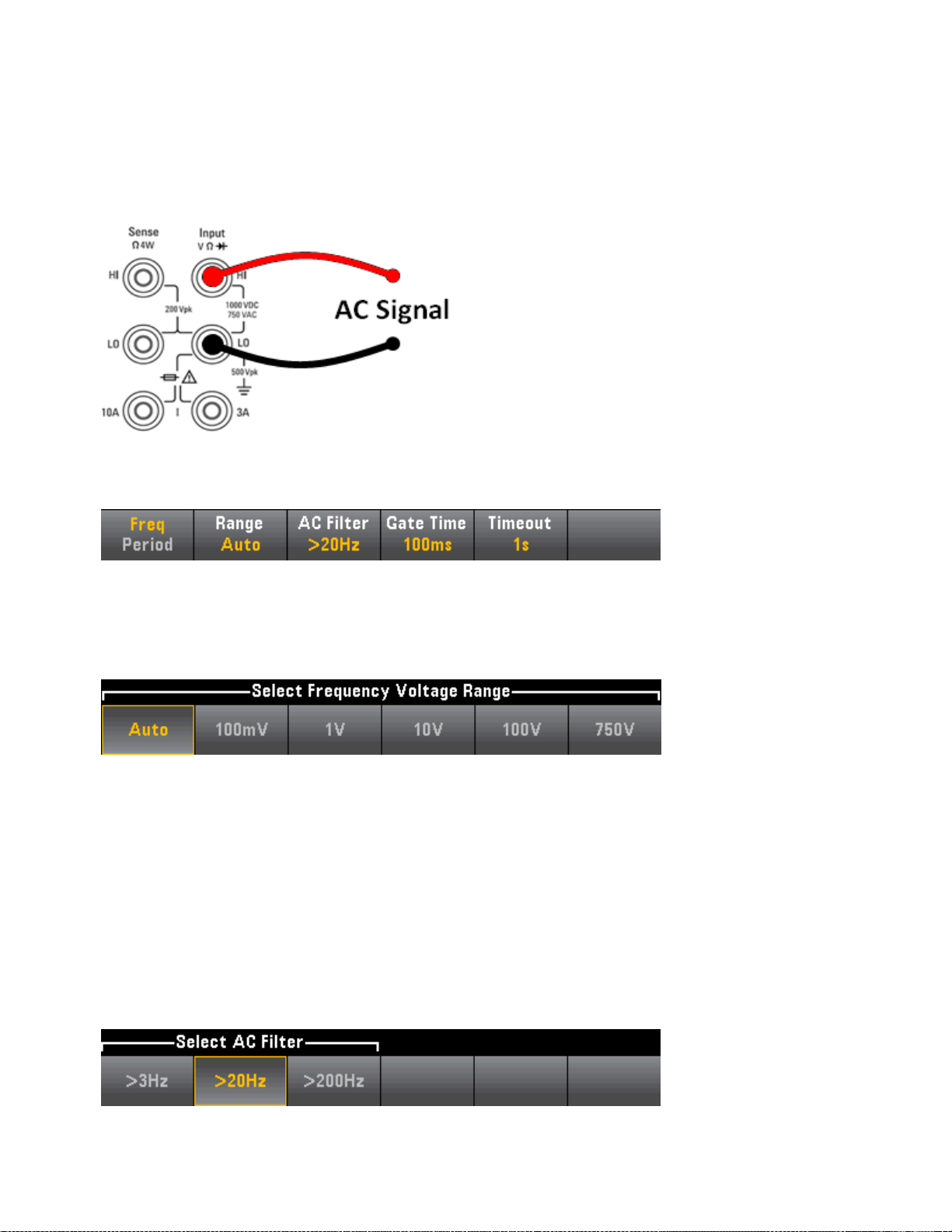

Digitizing is the processof converting a continuous analog signal, such as a sine wave, into a series of discrete samples (readings). The figure below shows the result of digitizing a sine wave. This chapter discusses

the various ways to digitize signals. The importance of the sampling rate, and how to use level triggering.

Keysight TruevoltSeries Operating and Service Guide

47

Page 47

Features and Functions

Data Log and Digitize Mode Default Settings

On entering data log or digitize mode, the DMM configures these settings:

l Trigger count set to 1 (trigger count is normally infinite when in Local and is not settable from the

front panel).

l Secondary measurements are turned off.

l Math smoothing is turned off.

l Statistics are cleared.

l Histogram is cleared.

l Trend chart is changed from the continuous, bucketized mode, to simple data graph.

Additional Data Log Default Settings

On entering data log mode, the DMM configures these settings:

l Trigger source isset to auto.

l Trigger delay is set to auto.

l Pretrigger count is set to zero.

l Samples per trigger is set according to the data log duration (time or samples).

l Sample timer is put in timer (not immediate) mode and sample time is set according to the data log

sample interval.

48

Keysight TruevoltSeries Operating and Service Guide

Page 48

Features and Functions

Additional Digitize Default Settings

On entering digitize mode, the DMM configures these settings:

l If trigger source is set to manual it is changed to auto. (external and level remain asis.)

l Limits mode is turned off.

l Scaling is turned off.

l Statistic and histogram are put in post-processing mode (computed after digitize is complete).

l On the selected function (DCV or DCI) and for the new function if changed:

l Autorange is turned off.

l Autozero is turned off.

l NPLC and aperture are set to their minimum values.

l If trigger source is external or level, the pretrigger count is set to the digitize pretrigger count setting

(default of 0).

l Samples per trigger is set according to the digitize duration (time or samples).

l Sample timer is put in timer (not immediate) mode and Sample timer is set according to the digitize

sample rate or sample interval.

l Trend Chart mode is changed to bucketized when data logging to a file.

l On return to Continuous mode, settings are left as done in data log or digitize mode except:

l Sample source is set to immediate.

l Pretrigger count is set to 0.

l Samples per trigger is set to 1.

l Trigger count is set to infinite.

Keysight TruevoltSeries Operating and Service Guide

49

Page 49

Features and Functions

Front Panel Menu Reference

The following table summarizes the front panel keys and the menu structure.

Key Purpose

Configure DC voltage measurements, including DCV ratio measurements:

Range: Autorange (default), 100 mV, 1 V, 10 V, 100 V, or 750 V

Aperture NPLC: 0.02, 0.2, 1, 10, 100. Default: 10 (34460A/61A)

0.02, 0.06, 0.2, 1, 10, 100. Default: 10 (34465A/70A without DIG option)

0.001, 0.002, 0.006, 0.02, 0.06, .2, 1, 10, 100. Default: 10 (34465A/70A with

DIG option)

See Range, Resolution and NPLC for more information.

Aperture Time (applies only to the 34465A and 34470A): (Without the

DIGoption) 200µs to 1 s (2 µs resolution), default: 100 ms. (With the DIG option)

20 µs to 1 s (2 µs resolution), default: 100 ms.

Auto Zero: Off or On (default)

Input Z: 10 MΩ (default) or HighZ (> 10 GΩ)

DCV Ratio: Off (default) or On

Configure DC current measurements:

Terminals: 3 A or 10 A

Range: Auto, 100 µA, 1 mA, 10 mA, 100 mA, 1 A, 3 A, or 10 A (when terminals set

to 10 A). The 34465A and 34470A have additional 1 µA and 10 µA DC current

ranges.

Aperture NPLC: 0.02, 0.2, 1, 10, 100. Default: 10 (34460A/61A)

0.02, 0.06, 0.2, 1, 10, 100. Default: 10 (34465A/70A without DIG option)

0.001, 0.002, 0.006, 0.02, 0.06, .2, 1, 10, 100. Default: 10 (34465A/70A with

DIG option)

See Range, Resolution and NPLC for more information.

Aperture Time (applies only to the 34465A and 34470A): (Without the

DIGoption) 200µs to 1 s (2 µs resolution), default: 100 ms. (With the DIG option)

20 µs to 1 s (2 µs resolution), default: 100 ms.

Auto Zero: Off or On (default)

Configure AC voltage measurements:

Range: Autorange (default), 100 mV, 1 V, 10 V, 100 V, or 750 V

Filter: >3 Hz, >20 Hz, >200 Hz

Configure AC current measurements:

50

Terminals: 3 A or 10 A

Range: Auto, 100 µA, 1 mA, 10 mA, 100 mA, 1 A, 3 A, or 10 A (when terminals set

to 10 A)

Filter: >3 Hz, >20 Hz, >200 Hz

Keysight TruevoltSeries Operating and Service Guide

Page 50

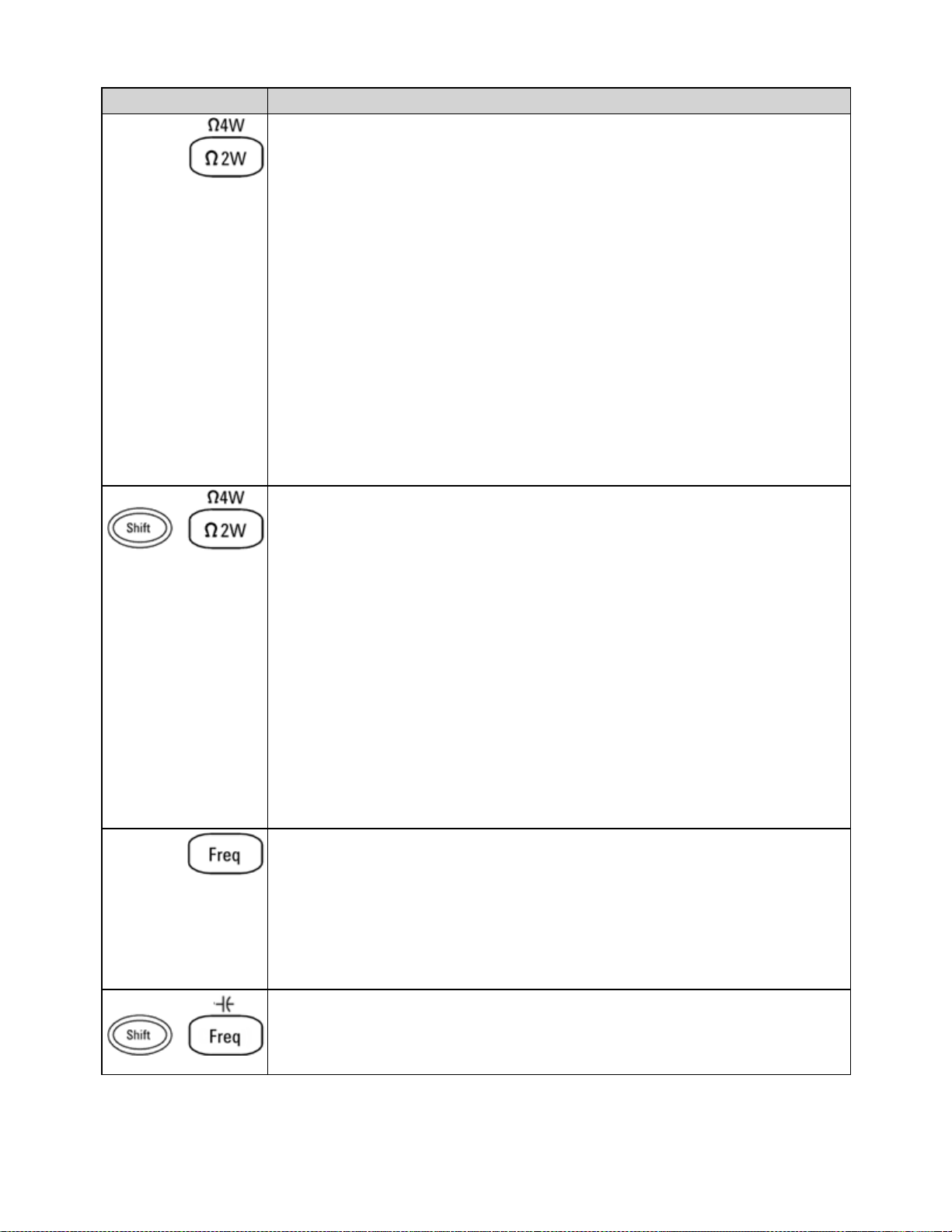

Key Purpose

Configure 2-wire resistance measurements:

Range: 100 Ω, 1 kΩ, 10 kΩ, 100 kΩ, 1 MΩ, 10 MΩ, 100 MΩ, 1 GΩ (34465A and

34470A only) or Auto (default). Note: The approximate current sourced for each

range (for example, ~1mA) is shown on each range softkey.

Aperture NPLC: 0.02, 0.2, 1, 10, 100. Default: 10 (34460A/61A)

0.02, 0.06, 0.2, 1, 10, 100. Default: 10 (34465A/70A without DIG option)

0.001, 0.002, 0.006, 0.02, 0.06, .2, 1, 10, 100. Default: 10 (34465A/70A with

DIG option)

See Range, Resolution and NPLC for more information.

Aperture Time (applies only to the 34465A and 34470A): (Without the

DIGoption) 200µs to 1 s (2 µs resolution), default: 100 ms. (With the DIG option)

20 µs to 1 s (2 µs resolution), default: 100 ms.

Auto Zero: Off or On (default)

OffstComp: Off (default) or ON. Applies only to the 34465A and 34470A.

Low Power: Disables (Off) or enables (On) low power measurements. Applies only

to the 34465A and 34470A.

Configure 4-wire resistance measurements.

Features and Functions

Range: 100 Ω, 1 kΩ, 10 kΩ, 100 kΩ, 1 MΩ, 10 MΩ, 100 MΩ, 1 GΩ (34465A and

34470A only) or Auto (default). Note: The approximate current sourced for each

range (for example, ~1mA) is shown on each range softkey.

Aperture NPLC: 0.02, 0.2, 1, 10, 100. Default: 10 (34460A/61A)

0.02, 0.06, 0.2, 1, 10, 100. Default: 10 (34465A/70A without DIG option)

0.001, 0.002, 0.006, 0.02, 0.06, .2, 1, 10, 100. Default: 10 (34465A/70A with

DIG option)

See Range, Resolution and NPLC for more information.

Aperture Time (applies only to the 34465A and 34470A): (Without the

DIGoption) 200µs to 1 s (2 µs resolution), default: 100 ms. (With the DIG option)

20 µs to 1 s (2 µs resolution), default: 100 ms.

OffstComp: Off (default) or ON. Applies only to the 34465A and 34470A.

Low Power: Disables (Off) or enables (On) low power measurements. Applies only

to the 34465A and 34470A.

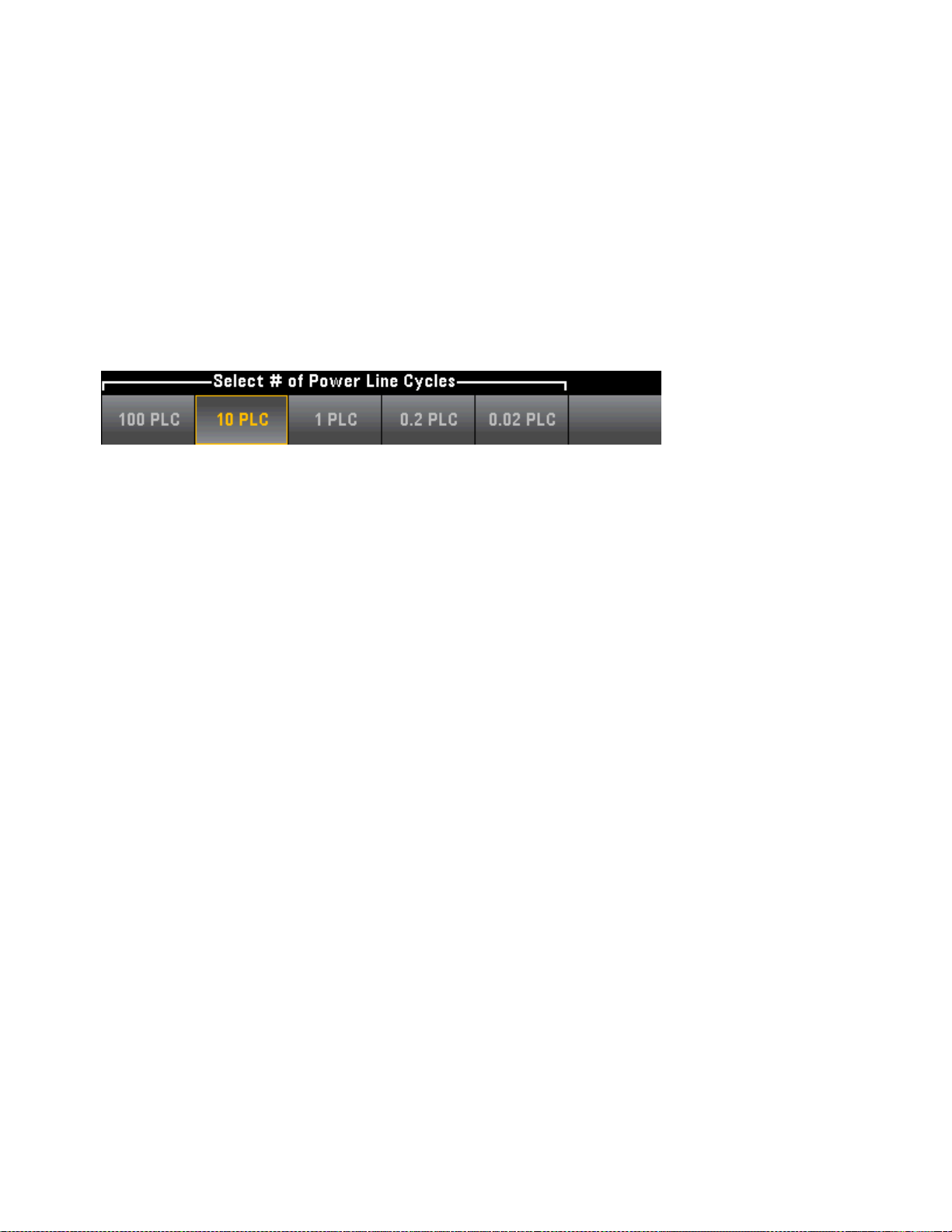

Configure frequency and period measurements. Parameters include range, AC filter,

and gate time.

Range: 100 mV, 1 V, 10 V, 100 V, 750 V, Auto (default)

Filter: >3 Hz, >20 Hz, >200 Hz

Gate Time: 10 ms, 100 ms (default), or 1 s

Timeout: 1 s (default) or Auto

Configure capacitance measurements:

Range: 1 nF, 10 nF, 100 nF, 1 µF, 10 µF, 100 µF, or Auto (default)

Keysight TruevoltSeries Operating and Service Guide

51

Page 51

Features and Functions

Key Purpose

Configure continuity measurements:

Beeper: Off or On (default)

Configure diode measurements:

Beeper: Off or On (default)

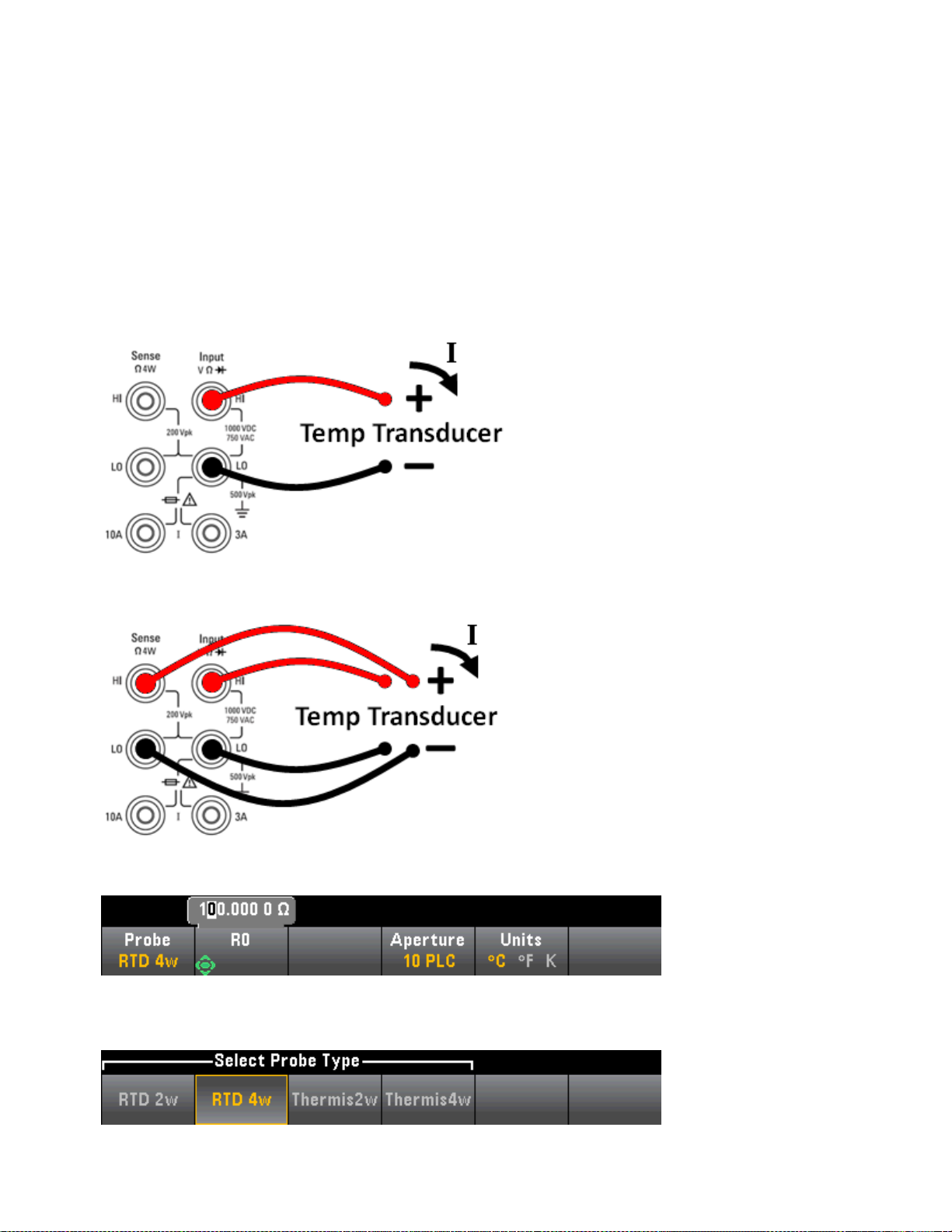

Configure 2-wire and 4-wire temperature measurements.

Probe Settings: RTD 2w, RTD 4w (default), Thermis2w, Thermis4w, TCouple

(34465A/70A only)

Additional settings for probe type RTD 2w or RTD 4w:

l

R0: R

l

Low Power: Disables (Off) or enables (On) low power measurements. Applies only

is the nominal resistance of an RTD at 0 °C. Default 100 Ω

0

to the 34465A and 34470A.

Additional settings for probe type Thermis2w and Thermis4w:

l

Low Power: Disables (Off) or enables (On) low power measurements. Applies only

to the 34465A and 34470A.

Additional settings for probe type TCouple:

l

Type: J(default), K, E, T, N, or R

l

Reference: Internal or Fixed

l

Offset Adjust:(Available for an internal reference only). -20°C to +20°C. Default:

0°C.

l

Fixed Offset: (Available for a fixed reference only)-20°C to +80°C. Default: 0°C.

Aperture NPLC: 0.02, 0.2, 1, 10, 100. Default: 10 (34460A/61A)

0.02, 0.06, 0.2, 1, 10, 100. Default: 10 (34465A/70A without DIG option)

0.001, 0.002, 0.006, 0.02, 0.06, .2, 1, 10, 100. Default: 10 (34465A/70A with

DIG option)

See Range, Resolution and NPLC for more information.

Aperture Time (applies only to the 34465A and 34470A): (Without the

DIGoption) 200µs to 1 s (2 µs resolution), default: 100 ms. (With the DIG option)

20 µs to 1 s (2 µs resolution), default: 100 ms.

Auto Zero: Off or On (default) (2-wire measurements only; not available for 4-wire

measurements)

OffstComp: Off (default) or ON. (RTD 2-wire and RTD 4-wire measurements only)

52

Open Check: TCouple measurements only.*

Units: °C, °F, or K

Start and stop measurements.

Keysight TruevoltSeries Operating and Service Guide

Page 52

Key Purpose

Reset the instrument for front panel use; equivalent to

Take a single measurement.

Take one or more hands-free measurements.

Take a null measurement.

Configure the null function, smoothing filter (applies only to the 34465A and

34470A), scaling, statistics, and limits.

Features and Functions

SYST:PRESet

.

Configure the text and graphics that appear on the display and secondary measurements.

Store and recall instrument states and preferences.

Configure I/O interfaces: LAN (optional on 34460A), USB, GPIB (optional).

Perform system administration tasks, including calibration.

Configure user preferences.

Perform file management activities, including the creation of "screen shot" files (display images).

Learn about the instrument, learn how to download or view documentation, view

the last error message, or clear error messages.

Perform autocalibration (34465A/70A only).

Select manual or auto ranging. Press to manually uprange, to

manually downrange.

Return to local control of the instrument (when in Remote mode), or indicate that

the next front panel key will be "shifted", for example [Probe Hold] instead of

[Single].

Keysight TruevoltSeries Operating and Service Guide

53

Page 53

Features and Functions

The keys that access a wide range of functions are listed below.

[Acquire] key

Softkey Description

Acquire Select Continuous mode (default measurement mode), Digitize mode, or Data Log

mode.*

Trigger Settings

VMC Out Set slope of VM Comp output.

Save Readings Save readings to a file.

* Digitize and Data Log modes are available only on the 34465A/70A. The Digitize mode requires the DIG

option.

Configure triggering.

[Math] key

The availability of the Math softkeys varies by measurement function.

Softkey Description

Null Enable/disable use of null values and specify null value to use.

Smoothing

Filter

dB / dBm (34460A/61A only) Configure dB, dBm

Scaling (34465A/70A only) Configure scaling: dB, dBm, %, Mx-B

Statistics Enable, disable, and clear statistics.

Limits Enable or disable high and low limits.

(34465A/70A only) Smoothing uses a moving average (boxcar) filter to reduce random noise