VibWire-201-Pro User Manual 1

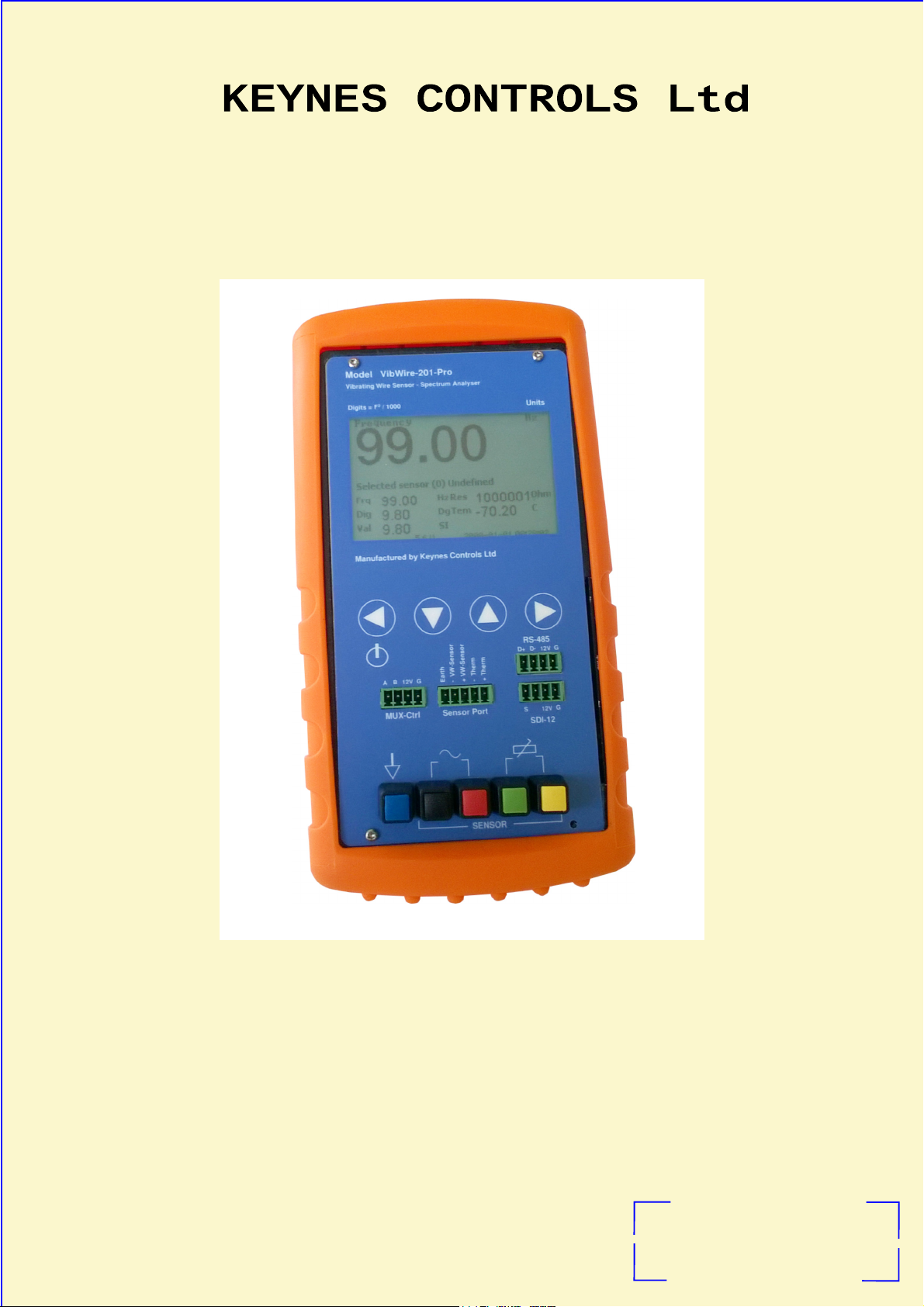

Model VibWire-101-Pro

Vibrating Wire Sensor Analyser

&

Data Recording Unit

Part No: VibWire-201-Pro

Advanced FFT Sensor Analyser

Advanced FFT Sensor Analyser

Advanced FFT Sensor AnalyserAdvanced FFT Sensor Analyser

Precision Temperature Readings

Precision Temperature Readings

Precision Temperature ReadingsPrecision Temperature Readings

User Pre-set VW Sensor Configurations

User Pre-set VW Sensor Configurations

User Pre-set VW Sensor ConfigurationsUser Pre-set VW Sensor Configurations

Sdi-12 & RS-485 Communication Ports

Sdi-12 & RS-485 Communication Ports

Sdi-12 & RS-485 Communication PortsSdi-12 & RS-485 Communication Ports

Daylight readable LCD display

Daylight readable LCD display Expansion Options

Daylight readable LCD display Daylight readable LCD display

Manufactured by Keynes Controls Ltd

Data logging to micro SD memory card

Data logging to micro SD memory card

Data logging to micro SD memory cardData logging to micro SD memory card

Up to 32 gb Storage

Up to 32 gb Storage

Up to 32 gb Storage Up to 32 gb Storage

Spreadsheet Format Data Files

Spreadsheet Format Data Files

Spreadsheet Format Data Files Spreadsheet Format Data Files

Real-time Clock

Real-time Clock

Real-time ClockReal-time Clock

Expansion Options

Expansion Options Expansion Options

- 16 x 4 Wire Inputs

- 16 x 4 Wire Inputs

- 16 x 4 Wire Inputs - 16 x 4 Wire Inputs

- 32 x 2 Wire Inputs

- 32 x 2 Wire Inputs

- 32 x 2 Wire Inputs - 32 x 2 Wire Inputs

Manufactured by KEYNES CONTROLS LTD

Tel: (0044) 118 327 6067

E-mail: sales@keynes-controls.com

VibWire-201-Pro User Manual 2

Features

Lightweight, Portable & Rugged

Compatible with most manufactures vibrating wire sensors

Real-time displays Freq (Hz), Digits (Hz2/1000), SI-Units, Spectra

FFT Spectral based algorithms for interference free measurements

Auto-resonance excitation 400 - 15 K Hz range - minimises sensor stress

Fully configured sensor operations

Large data storage - 100 million readings - SD Flash Cards to 32 Gb

Fast data recording - 1 sec to 1 hour logging intervals

No Vibrating Wire Sensor Prior operating conditions required

Expandable to 32 channels

SDI-12 and RS-485 ports for remote network connection

Optional radio interfaces for cable free operations

Firmware up gradable device - load software revisions with factory return

Benefits

Out the box solution for vibrating wire sensor measurements

Daylight readable LCD Display

Provides superior measurements by automatically reducing incorrect readings caused by noise sources

Customised FFT-based algorithm ensures readings are accurate and free from interferences

Real-time Sensor Spectra Display

No special cables or connectors required

No programming experience required to interface to 3rd party loggers and data acquisition systems..

Interfaces up to 32 channels using the MUX-16/32 Expansion unit.

High resolution—less than 0.001 Hz (industry standard is 0.1 Hz)

Low power consumption - Uses readily available AA battery life - 24 Hours continuous use

Suitable for laboratory testing and field measurement applications

Precision temperature and frequency measurements from vibrating wire sensors

Works with all RTD-temperature sensors regardless T0 resistance - 3 K, 10K etc

Free Data Storage and Display Applications Software -

Additional items commonly used with the VibWire-201-Pro Unit

MUX-16/32 Expansion Unit

This device is used to expand the number of sensor inputs

that can be used by the VibWire-201-Pro from a single

channel to 32 inputs.

This device can be powered directly from the

VibWire-201-Pro for stand-alone measurements.

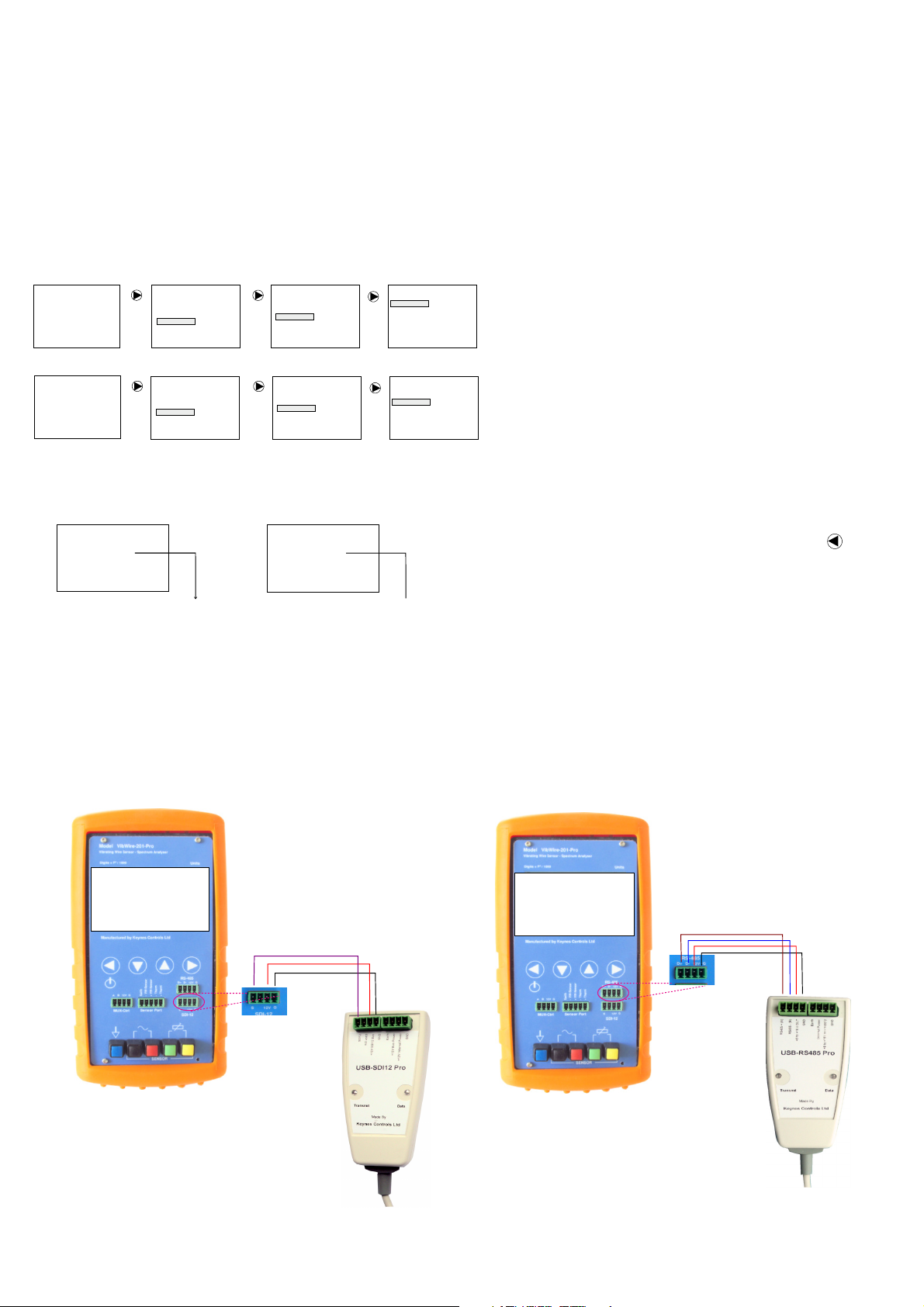

USB-SDI12-Pro Media Converter

This device is used to connect the VibWire-201-Pro to a

Windows PC remotely across the SDI-12 digital network.

The USB-SDI12-Pro can be used to power the VibWire201-Pro for fixed monitoring applications

The device supports all of the Keynes Controls SDI-12

sensor and interfaces, including many 3rd party devices.

The USB-SDI12-Pro isolates the network devices from the

Windows PC USB port and protects it against possible

damage caused by sensor failures.

USB-485-Pro Media Converter

This device is used to connect RS-485 based intelligent

devices including the VibWire-201-Pro a Windows PC.

The device not only can power sensors on the network,

but also isolates the PC USB port from any possible device

failure in order to prevent damage to the host PC.

The device supports all of the Keynes Controls RS-485

sensor and interfaces, including many 3rd party devices.

©

Copyright 2016-2017 Keynes C ontrols Ltd

No part of this manual can be re produced in part, or in whole

without the permission of Keyne s Controls Ltd.

VibWire-201-Pro User Manual 3

Page Number Description

5 Hardware Features / Controls and Ports

6 Quick User Guide - Default Thermistor part numbers - Real-time Results - Adjusting the display

7 Fitting Batteries - Battery Life - MUX-16/32 Expansion Port - Initial Start-up Screen -Low Battery Effects - Setting the Real-time Clock

8 Real-time Results -

9

10 Technical Specifications

11 Pre-set Sensor Configurations

12 Channel Expansion Options

13 Number of Channels

14 Program Commands for scanning MUX-16/32 in 32 x 2 Wire mode (3rd party loggers )

15 Frequently Asked Questions

16 Sensor Configuration Example - Piezometer

17 Sensor Configuration Example - Piezometer

18 Q-Log - Quick User Guide

Auto-timeout / Real-time Clock.

Factor Default Settings Reset

VW Sensor Installation.

Saving New Parameters - Adjusting the Time

Initial Start-up Display - Frequency Results Display - Digits Results Screen - Natural Units (SI) - Spectra Display

Spectral Features.

Digital Network Selection

Device Port Selection - SDI-12 Network Connection - RS485 Network Connection (Using USB-SDI12-Pro or USB-485-Pro media converters)

Temperature Measurements - Associated Part No - Device Configuration Software - Common VW Sensor Thermistor Part Numbers

- Sources of Error - Calibration Factor Error - User Defined Stein-hart Hart Calibration Factors

- Sensor Information

- Downloading and installing device setup software - Automatically setting the real-time clock.

Pre-defined Thermistor Calibration Parameters (Steinhart-Hart Calibration factors)

Automatically setting the real-time clock.

- 16 x 4 Wire Expansion - 32 x 2 wire expansion

- Mux-16/32 Expansion Unit Configuration Options - MUX Channel Selection Menu Options

Data Recording - Data Recording Options - Data Recording Menu System

Program Commands for scanning MUX-16/32 in 16 x 4 Wire Mode

- Switching between 2 and 4 Wire Mode Operations under SDI-12 Commands

- VW201-Pro want communicate with 3rd party logger - Network ID Number - How fast can the VibWire-201-Pro make a measurement

- Where to download the Q-LOG Software - How to make a measurements using a PC without any programming experience

- MUX-16/32 Connection Options to the VibWire-201-Pro

Temperature Compensated Calibration Factors - Results in Natural (SI) Units

Process Option setting - Pre-set Sensor Configuration Settings - Simplified Calibration Factors

Temperature Compensated Calibration Factors - Results in Natural (SI) Units

Process Option setting - Thermistor Type

Pre-set Sensor Configuration Settings

Simplified Calibration Factors

Factory Default Settings -Sample Rate Options

- Logging Configuration Window - Scanning for Devices

External Power Supply -Device identifier strings

PC Data Acquisition - Start data recording

(VW201cal software)

(VW201cal software)

19 Technical Specifications

20 Examples Of Using RS-485/SDI-12 Commands

21 Data Record to Flash Memory Card

22 Worked Example - Spot Welded VW Strain gauge

23 Temperature Calibration Factors

24 PC based Water Level Recording with Barometric Correction.

25 Temperature Measurements

26 Sensor Problems and Diagnostics

27 Free Standing Strain Gauge

Changing the ID Number (address) - Start a measurement for Instrument on a network

Isolated Power Source

Diagnostics

Removing The Memory Card

Storing the menu option

Default Sample Rates

External Power Supply

Isolated USB Media Converters

Data into engineering units - simplified formula

Adding a new thermistor type - Calibration parameters and what they mean - Sample Calibration Factors

(VW201cal software)

Device USB Configuration Port - Connection to a Data Logger

Factory Set Steinhart Hart Calibration Factors

Testing the temperature measurements

- 22 Deg C fixed point - 3.3 K Ohm temperature test resistor

- 52 Deg C fixed point - 1 K Ohm temperature test resistor

Sensor Operating Characteristics

- VW strain gauge - Pre-tension gauge mounted onto a structure

- VW strain gauge - Failed or loose weld

29 APPENDIX-A Menu System Summary

32 APPENDIX-B Sample Calibration Data Sheets

VibWire-201-Pro User Manual 4

Important Figures

Figures Description

Fig 1 Hardware Features

Fig 3 Initial Start-up Screen - no sensor connected

Fig 7 & 8 Sensor Installation

Fig 9 Adjust results display screens

Fig 10 Fitting batteries

Fig 12 Setting the real-time clock

Fig 14 - 17 Results displays

Fig 18 - 19 VW sensor spectra

Fig 20 - 21 Device Port Selection

Fig 22 SDI-12 network connection - USB-SDI12-Pro Media Converter

Fig 23 RS-485 network connection - USB-485-Pro Media Converter

Fig 24 - 25 VW201cal Software - Calibration Factors Entry Window

Fig 26 32 x 2 Wire Expansion with the MUX-16/32 Unit

Fig 27 16 x 4 Wire Expansion with the MUX-16/32 Unit

Fig 28 MUX-16/32 Control Menu System.

Fig 29 Data Recording Menu System

Fig 31 MUX-16/32 Output Port Connections for 32 x 2 Wire Mode.

Fig 32 MUX-16/32 Output Port Connections for 16 x 4 Wire Mode.

Fig 33-35 32 x Frequency / 32 x Temperature / 16 x 4 Expansion Unit Wiring Options.

Fig 39 Select individual MUX-16/32 Channel Menu System

Fig 41 VW201cal Software - Example Calibration (Frequency) factor configuration Window.

Fig 43 Preset Sensor selection Menu System

Fig 45 SDI-12 port pin-outs - USB-SDI12-Pro and VibWire-201-Pro

Fig 46 Q-LOG Configuration Window - Data Logging - PC Port Network Type Selection.

Fig 48 Scanning for Devices - Q-Log Window.

Fig 49 Q-LOG Devices List Window

Fig 50 Q-LOG Start Data Acquisition Window

Fig 53 External Power Supply

Fig 54 Recording Interval Menu Options

Set number of channels to scan.

Product Changes

VibWire-201-Pro demonstrating the ability

to calculate and display a real-time

vibrating wire sensor spectra.

Keynes Controls Ltd has an on-going policy of design review and reserves the right to amend

the design of their product and this instruction manual without notice

VibWire-201-Pro User Manual 5

Hand Held VW Logger Unit with FFT Analyser

Hand Held VW Logger Unit with FFT Analyser

Hand Held VW Logger Unit with FFT Analyser Hand Held VW Logger Unit with FFT Analyser

Hardware Features

Fig-1

Carbon fibre reinforced

ABS plastic enclosure

Power On

To power on the VibWire-201-Pro unit, hold and press the On/Off

button for 2 seconds. The device will initiate and start a measurement

operation.

The device will initialise using the last defined senso

Power Off

Hold and press the On/Off button and the device will power off

Powering on the Unit

Press and hold for 2 seconds the ‘Menu Out’ button. The device will

power on and the ‘Start-up Screen will be displayed. Repeat the

operation to power off the device.

Menu-Out

On/Off Button

r.

.

Menu-In &

Power On/Off

Button

MUX-16/32 Control Port

Sensor Port

Compatible with the

VW101 & VW108 units

Rubber protective

boot cover

Earth

Frequency

Signal connection Posts

Port

Temperature

Port

Calculations

Keynes Controls use the following calculation

Digits = Frequency 2

1000

Day Light Readable LCD Display

The LCD display is clear to read in most lighting conditions. A

back light is available for low level light environments. Three

levels or display brightness can be ‘User’ assigned.

Back light - LCD Screen

Options for High , Low, Off.

User Defined Sensors - 20 options

Use the Windows Configuration software to assign

sensor details.

Menu Control Buttons

Use the Menu-In and Menu-Out buttons to select the different

menu systems.

User the ‘Up’ and ‘Down’ menu keys to select the menu items.

RS-485 network port

SDI-12 network port

The 4 wire sensor port mounted at the bottom of the instrument is

used a general sensor test port. Bare sensor wires can be simply

connected directly into the spring terminal posts.

4 Wire Sensor Inputs + Earth

Spring Terminal Post Connectors

Real-time Clock

Temperature compensated real-time clock accurate to 50 ppm

/ Deg C.

(Hz2)

1000

Menu-InMenu-Out Down Up

Automatic Time-out

The VibWire-201-Pro will power down automatically after 30 minutes of unattended operation, unless configured to make measurements.

Protective Case

The case for the VibWire-201-Pro is manufactured from carbon fibre reinforced

ABS plastic. This makes the case highly safe from accidental damage.

The rubber boot prevents provides additional protection from the wear and tare

of site work. A rear stand enables the device to free stand while in operation.

SDHC flash memory

card slot.

Factory Default Setting Reset

Select the ‘Reset Defaults’ option shown below to reset the device to its factory

settings. The image below shows the menu operations required to undertake

this task.

Ethernet Port

Micro-USB Port

(Type B)

Fig-2

Frequency

2534.86

Selected Sensor

Frq

Hz

Res

Dg

SI

Tem

2016-01- 20 08 :40::17

6

3003.56

24.89

2534.86

Dig

6424.95

992.28

Val

Ohm

C

Menu-In

Hz

Sensor No

Logger

Multiplexe r

Remote

System

Main Menu

Menu-In

System

Set Time and Date

Speaker O N/OFF

Backlight

Info

Reset De faults

Ethernet Port

The Ethernet port is currently not used in the VibWire-201-Pro and has been added for future expansion.

Micro-USB Port (Type B)

The micro-USB port is used to configure the VibWire-201-Pro and to download data. Use the VW201pro configuration software tool assign sensor configuration

information into the instrument.

SDHC Flash Memory

The VibWire-201-Pro supports a single SDHC memory card slot. The memory card has to be pre-formatted before use.

The maximum size memory card currently supported is 32 Gb.

VibWire-201-Pro User Manual 6

Quick User Guide

VW Sensor Installation

The instructions shown in the Quick User Guide presumes that the batteries have

already been installed into the device and a vibrating wire sensor is ready for

testing.

The VibWire-201-Pro will operate with any sensor manufactures device.

The VibWire-201 comes pre-configured with default temperature sensor calibration

factors defined. The pre-set temperature sensor calibration factors are based on

a 3 K Ohm @ 25 Deg C device. The following sensor part numbers all use the

same calibration settings.

1000001

-70.20

2016-01-20 08:40::17

Hz

Ohm

C

Default Thermistor Part Numbers

YSI 44005

Vishay 1C 3001 B3

RS Part no: 151-215

1. Power On The VibWire-201-Pro.

Press and hold the ‘Power On’ for 2 seconds.

and with no sensor connected the default

Frequency display is shown opposite.

Frequency

99.00

Selected Sensor

Frq

Dig

Val

99.00

9.80

9.80

Hz

Res

Tem

Dg

SI

6

Fig-3 Initial Start-up Screen

Default screen with no sensor attached.

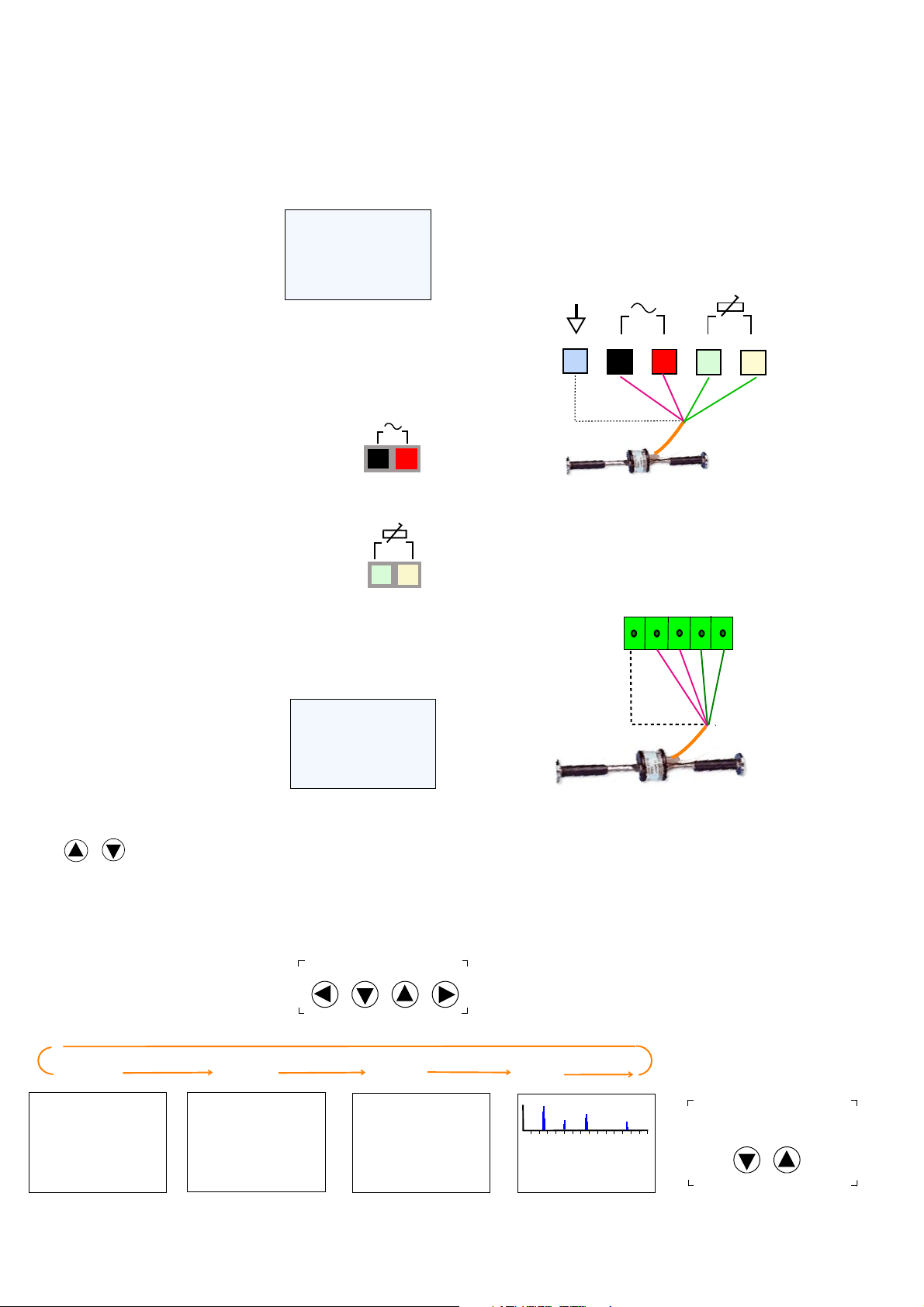

2. Connect a vibrating wire sensor to the device

Connect a single sensor to either the 5 pin terminal block input port or directly onto the

sensor port mounted at the bottom of device using the spring loaded terminal posts..

Connect the frequency output signal from the sensor to the red and

black terminal posts.

Frequency

Fig-4

Input Signal

Connection

The VibWire-201-Pro supports full 4 wire sensor operations. The device

measures frequency and temperature from any suitable vibrating wire sensor.

Connect a Vibrating Wire sensor to the 5 pin ‘Sensor Input’ port or directly to

the spring return termination posts mounted at the bottom of the unit.

1. Connect the sensor coil to the ‘Frequency Input’ port.

2. Connect the sensor thermistor (temperature) sensor to the ‘Temperature

Input’ port.

3. Use the VW201cal.exe software to define thermistor calibration factors.

Figures 7 and 8 show how to connect a vibrating wire sensor to the device.

Sensors connected to the spring loaded terminal posts

Fig-7

Earth

Frequency

Input

Frequency

Signal

Coil

+-

Temperature

Input

Sensor

Terminal

Posts

Sensors connected to the Sensor Port

Connect the vibrating wire sensor thermistor (temperature sensor)

to the green and yellow terminal posts.

Thermistor

Fig-5

Input Signal

Connection

3. Real-time Results

As soon as the vibrating wire sensor is connected to the VibWire-201-Pro then the measurements

will be displayed on the display.

3003.56

24.89

2016-01-20 08:40::17

Ohm

C

Hz

A typical display screen is shown opposite.

Fig-6

Frequency

2534.86

Selected Sensor

Frq

Dig

Val

2534.86

6424.95

992.28

Hz

Res

Tem

Dg

SI

6

3. Use the ‘Up’ and ‘Down’ keys to switch between Hz, Digits and Spectra.

Down

Up

The SI unit display remains blank until configured.

Adjusting the display

Use the keyboard ‘Up’ and ‘Down’ arrow keys to adjust the results display screens.

The display screen will be change as the

Up and Down keys are pressed.

Menu-InMenu -Out Down Up

- VW Sensor

Earth

Frequency

Signal

Coil

- Thermistor

+ Thermistor

+VW Sensor

Sensor Port

Thermistor

temperature

sensor

Fig-8

Fig-9

Frequency

Frequency

2534.86

Selected Sensor (3) EDS-20

Frq

Dig

Val

2534.86

6424.95

992.28

Hz

Dg

SI

Res

Tem

2016-01-20 08 :40::17

6

3003.56

24.89

Hz

Ohm

C

Digits

Digits

6424.95

Selected Sensor (3) EDS-20

Frq

Dig

Val

2534.86

6424.95

992.28

Hz

Dg

SI

Res

3003.56

Tem

2016-01-20 08 :40::17

6

24.89

D

Ohm

C

The results shown above are obtained using an Encardio-rite EDS-20

vibrating wire pressure sensors.

SI Units

Sensor

992.28

Selected Sensor (3) EDS-20

Frq

Dig

Val

2534.86

683.929

992.28

Hz

Dg

SU

Res

3003.56

Tem

2016-01-20 08 :40:17

6V

24.89

Nat Units

Ohm

C

Spectra

FFT Sensor Spectra

6 10 11

2534.86

6424.95

992.28

7

Hz

Dg

SI

0 1 2 3 4 5

Selected Sensor (3) EDS-20

Frq

Dig

Val

KHz

Res

Tem

6

12

13

3003.56

24.89

2016-01-20 08:4 0::17

14

Ohm

C

Use the Up and Down arrow keys

15

to switch between the results screens

Down Up

VibWire-201-Pro User Manual 7

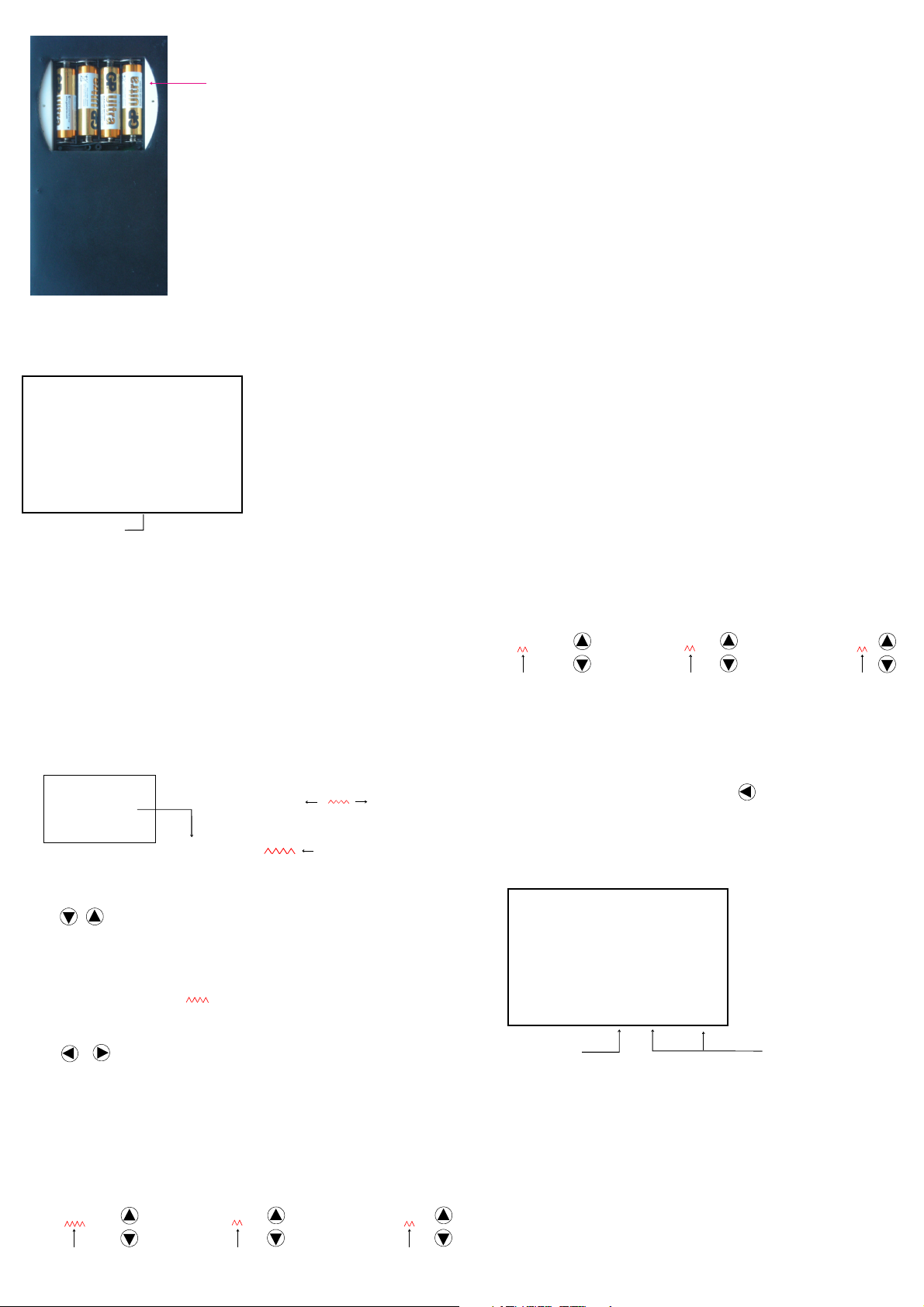

Fitting Batteries

-

-

+

+

Only fit standard AA batteries in the VibWire-201-Pro.

AA 1.5 V Cells

-

+

-

+

Initial Start-up Screen

Frequency

99.00

Selected Sensor (1)

Frq

99.00

Dig

9.80

9.80

Val

Battery level

when a new set of

batteries are installed into the unit.

Hz

Res 1000000.00

Tem -70.2

Dg

SI

2016-01-20 08:40::17

2016-01-20 08:40:17

6 V

3003.56

24.89

Fig-10

Hz

Ohm

C

Fig-11

1. Remove the battery cover from the rear of the device by simply unscrewing the securing bolts.

2. Replace the battery set in the layout shown in the image opposite.

3. Replace the battery cover and power on the unit.

The battery level indicator will show 6V when a new set of batteries has been installed See Fig 11.

Battery Life

When operating as a single channel device using a new set of batteries the VibWire-201-Pro will operate for

approximately 40 Hours continuous use.

MUX-16/32 Expansion Operations

The VibWire-201-Pro powers the MUX-16/32 expansion unit directly across the SDI-12 BUS and will reduce the

battery life of the device if used without an external power supply.

IMPORTANT NOTE

Remove the batteries from the VibWire-201-Pro should the device not be used for a long period of time.

Low Battery Level Effects

Once the battery levels falls before 4.5 V then

1. Display may not update at the correct rate and appears to flicker.

2. Measurement values can be erratic.

Once the display falls below 4.5V then the ‘Low Battery’ indicator flashes, see Figure 13 below. Should the unit

continue to operate then the display may flicker. Fit a new set of batteries.

Setting the Real-time Clock

The real time clock in the VibWire-201-Pro is configured using the ‘Set Time

and Date’ menu. See Page FF section G.

The VibWire-201-Pro can be used as a stand-alone VW sensor data logger

recording measurements automatically, and also to take single shot readings

under ‘User’ control.

Measurements are stored to the flash memory card.

See Page MM for details on selecting the ‘Time and Date’ menu.

Real-Time Clock Menu System

Set Time and Date

Date 2016-01-06

Time 08:25:30

Fig-12

Example

6th January 2016

08:25 AM 30 Seconds

Use the Up and Down keys between ‘Date’ and ‘Time’ options.

Down Up

Select Date or Time to be configured

Use the ‘Menu-Out’ and ‘Menu-In’ keys to move along the Date or Time fields.

As the keys are pressed the item indicator symbol will be displayed

under chosen item.

Menu-InMenu-Out

Once the parameter to adjust has been chosen then use the ‘Up’ and ‘

buttons to make changes.

The ‘Up’ and ‘

Down

’ buttons will increment, or decrement a parameter by 1 unit

after each action.

(Time/Date For mat)

Date Year-Month-Day

Time Hours:Minutes:S econds

(Selected Item Indicator)

Down

’

Adjusting the Time

Down

Up

Time 09 : 23: 06

Secs

Time 09 : 23: 06

Hours

Down

Up

Time 09 : 23: 06

Mins

Move through each date an and time parameter in turn making adjusts as

necessary.

Saving New Parameters

Once all parameters have been set, press the button unit the

Menu-Out

default ‘Frequency’ menu is displayed.

The new date and time values will be stored and the real-time clock settings

updated to the different menus.

Frequency

Hz

99.00

Selected Sensor (1) EDV-30

Frq

99.00

Dig

9.80

9.80

Val

Low Battery

Indicator

Note

The VW201cal.exe Windows configuration software automatically sets the

time and date used by the VibWire-201-Pro to the PC clock.

Hz

Res 1000000.12

Tem -70.2

Dg

SI

Low Battery

24.89

Ohm

C

3003.56

2016-01-21 10:40::17

2016-01-20 08:40:17

Fig-13

Date and time string will update

with the new settings.

Up

Down

Adjusting the Date

Date 2016-01-06

Year

Down

Up

Date 2016-01-06

Month

Up

Down

Date 2016-01-06

Day

Up

Down

VibWire-201-Pro User Manual 8

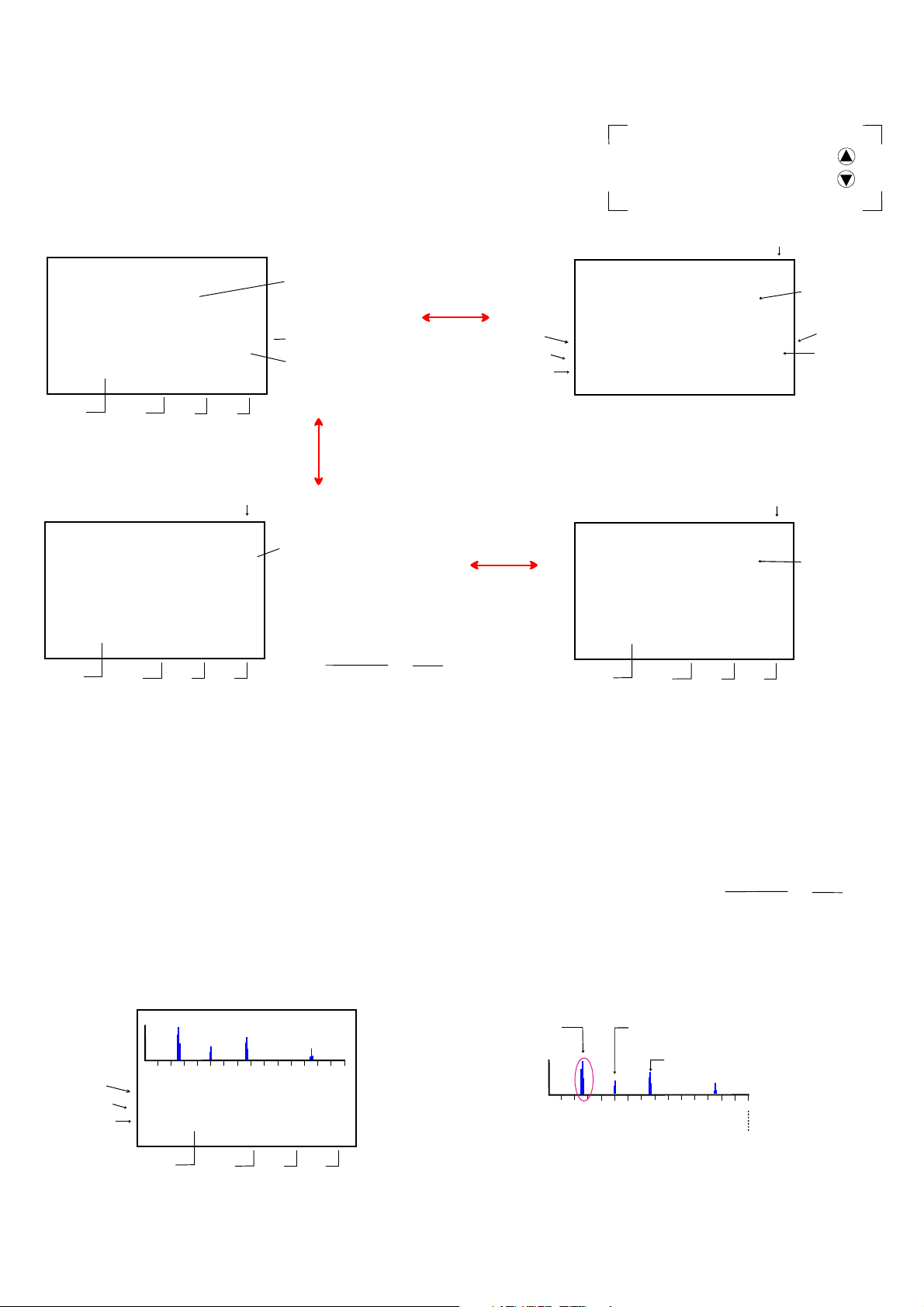

Real-time Results

Figures 14 below shows the default display that appears as soon as the device is powered on and with no sensor connected to an input port.

Upon connection of a sensor to the input port then the device automatically displays the frequency and temperature values.

With no sensor coil connected to the frequency input then the device defaults to 99.00 Hz.

Initial Start-up Screen

Frequency

99.00

Selected Sensor (4) EPP-30V

Frq

Dig

Val

SI Units

See Note 1

99.00

9.80

9.80

Battery

Voltage

Hz

Dg

SI

Res

100000.1

Tem

2016-01-20 08:40:17

6 V

Date Time

-70.20

Fig 14

Hz

Ohm

C

Fundamental Frequency

Resistance Thermistor

temperature sensor built

into a VW sensor.

Instant sensor

temperature in Deg C

Frequency Results - Hz

Frequency (Hz)

Digits - Hz2/1000

Engineering Units

Once a vibrating sensor is connected to an input port the display will change

similar to that shown above.

Frequency Results - Hz2 (Digits)

Fig-16

Digits

VW Sensor - SI Unit (Dig its)

D

Natural Units (SI)

Fundamental Frequency

2534.86

Selected Sensor (4) EPP-30V

Frq

2534.86

Dig

6424.95

992.28

Val

SI Units

Battery

Voltage

Hz

Dg

SI

Res

3003.56

Tem

2016-01-20 08:40::17

6 V

Date Time

24.89

Ohm

C

in Digits

All Keynes Controls VW sensor

instrumentations uses the digits

calculation

Digits = Frequency 2

1000

(Hz2)

1000

Use the ‘Up’ and ‘Down’ arrow keys

to switch between the different

results screens.

Fig-15

Frequency

834.69

Selected Sensor (4) EPP-30V

Frq

834.69

Dig

696.70

696.70

Val

Fig-17

Sensor

300.31

Selected Sensor (4) EPP-30V

Frq

876.86

768.36

Dig

300.31

Val

SI Units

Battery

Voltage

Important Note

Hz

Res

Tem

Dg

SI

6 V

Hz

Res

Tem

Dg

SI

5.2 V

Date Time

VW Sensor - SI Unit (Hz)

3571.73

2016-01-20 08:40:17

Ohm

C

21.07

VW Sensor - SI Unit

Nat Units

18.67

Ohm

C

3984.29

2016-01-20 08:40::17

Hz

Sensor Frequency (Hz)

Output value in

engineering

units.

Up

Down

Thermistor

Resistance Value

VW sensor

Temperature Deg C

The VibWire-201-Pro undertakes the spectral calculations on the incoming

vibrating sensor signal and gives the results immediately.

There are no ‘User’ configuration settings required to be assigned in order to

undertake a spectral calculation.

The largest peak is taken as the fundamental operating frequency of the sensor.

See Fig 19 opposite.

Spectra (Hz)

Frequency (Hz)

Digits - Hz2/1000

Engineering Units

VW Spectra Screen

FFT Sensor Spectra

992.28

6 10 11

Hz

Dg

SI

Battery

Voltage

0 1 2 3 4 5

Selected Sensor

Frq

2534.86

6424.95

Dig

Val

SI Units

7

KHz

Res

Tem

6 V

3003.56

2016-01-20 08:40::17

Date Time

12

24.89

Fig-18

131415

Ohm

C

Once the calibration factors have been set, and the process option set to ‘2’ see

Fig 24 on page 11.

All Keynes Controls VW sensor instrumentations uses the digits calculation

FFT Sensor Spectra

Fundamental

Frequency

0 1 2 3 4 5

2534.86

= Fundamental Frequency in Hz

6424.95

= Fundamental Frequency in Digits

st

1

Harmonic

Frequency

nd

2

Frequency

6 10 11

7

KHz

Digits = Frequency 2

1000

Harmonic

12

15

13

14

Maximum Operating

Frequency

(Hz2)

1000

Fig-19

Note. The example screens have been determined using a free standing

Encardo-Rite EPP-30V pressu re sensor

Copyright Keynes Controls Ltd 2015

VibWire-201-Pro User Manual 9

Selecting Remote Network Connections

The VibWire-201-Pro unit can connect to the SDI-12 and RS-485 networks for use in remote vibrating wire sensor measurements.

The SDI-12 and RS-485 ports enable the VivbWire-201-Pro to transmit sensor data into third party data logger and acquisition systems.

Device Port Selection

To select the network port type for remote data acquisition operations on the VibWire-201-Pro, use the menu system to select either of the menu items shown

below.

The device will then make measurements, and transmit data over the specified network port.

Page 30 shows the menu system built into the VibWire-201-Pro.

SDI-12 Port Operation

Frequency

2534.86

Selected Sen sor

Frq

Hz

Res

2534.86

Dig

Dg

Tem

6424.95

992.28

Val

SI

6

RS485

Port Opera

Frequency

2534.86

Selected Sen sor

Frq

Hz

Res

2534.86

Tem

Dig

Dg

6424.95

992.28

Val

SI

6

3003.56

24.89

2016-01-20 08:40::17

3003.56

24.89

2016-01-20 08:40::17

Menu-In

Hz

Ohm

C

tio

n

Hz

Ohm

C

Menu-In

Sensor No

Logger

Multiplexer

Remote

System

Sensor No

Logger

Multiplexer

Remote

System

Main Menu

Main Menu

Menu-In

Menu-In

Remote

Address

Serial Comms

Remote

Address

Serial Comms

Menu-In

Menu-In

SDI12

RS485 1200

SDI12

RS485 1200

Select Backlight

Select Backlight

Fig-20

Sets the VibWire-201-Pro to transmit data

through the SDI-12 Port

Sets the VibWire-201-Pro to transmit data

through the RS-485 Port

Fig-21

For single channel operation, once the output port is specified the sample data can be shown on the display.

SDI12 Remote Port

Remote Mode

Port = SDI-12

Address = 1

Measurement Count = 1 032

Selected Sensor

Hz

2534.86

6424.95

992.28

Dg

SI

Res

Tem

2016-01-20 08:40::17

6

Frq

Dig

Val

D

Ohm

3003.56

C

24.89

Number of measurements since

start of measurements on a

network. ID = 1.

RS485 Remote Port

Remote Mode

Port = RS485

Address = 3

Measurement Count = 1 53

Selected Sensor

Hz

Res

2534.86

Frq

Dig

6424.95

992.28

Val

3003.56

Tem

Dg

SI

2016-01-20 08:40::17

6

Number of measurements since

start of measurements on a

network. ID = 3.

24.89

Ohm

C

D

SDI-12 Network Connection

Figure 22 below shows how to connect the VibWire-201-Pro SDI-12 port to a

USB-SDI12-Pro media converter. The USB-SDI12-Pro media converter connects to a Windows PC and allows measurements from VibWire-201-Pro to

displayed directly into

Storing the menu option

Once the selected menu option is highlighted simple press the button

to store the new option.

Repeat the operation until the ‘

page 8.

RS-485 Network Connection

Figure 23 below shows how to connect the VibWire-201-Pro RS-485 port to a

USB-485-Pro media converter. The USB-485-Pro media converter connects to

a Windows PC and allows measurements from VibWire-201-Pro to displayed

directly into the Q-LOG data display and recording software.

The VibWire-201-Pro acts like any other intelligent 485 device, and will operate

with any other suitable device 3rd party device on the network.

Frequency

Menu-Out

’ display appears. See Figure 15 on

Remote Mode

Port = SDI-12

Address = 1

Measurement Count = 1032

Selected Sensor

2534.86

Frq

Dig

6424.95

992.28

Val

VibWire-201-Pro

Hz

Dg

SI

Res

Tem

2016-01-20 08:40::17

6

3003.56

24.89

Fig-22

D

Ohm

C

SDI-12 Data

SDI-12

Port

Part No: USB-SDI12-Pro

12 DC

Fig-23

Res

Tem

2016-01-20 08:40::17

6

3003.56

24.89

Ohm

C

D

+ RS-485

- RS-485

12 DC

Gnd/0V

Remote Mode

Port = RS485

Address = 3

Measurement Count = 153

Selected Sensor

Hz

2534.86

Frq

Dg

6424.95

Dig

992.28

SI

Val

Gnd/0V

Part No. USB-485-Pro

VibWire-201-Pro User Manual 10

Technical Specification

The current technical specification for the VibWire-201-Pro is:

Description

Physical Size

Weight

Battery

Auto-logging no back light

Communication Ports 1 x RS-485 Slave - 1200 Baud, 8 data, 1 stop, no parity

External Power Supply 10 - 15V DC @ 100 mA min specification

Vibrating Wire Measurements

Analogue Input 24 Bit Sigma Delta

Sensor Excitation Auto-resonance - Fully automatic

Operating Frequency 400 - 15 KHz

Measurement Resolution 0.001 Hz RMS - 20 to 70 Deg C

Measurement Accuracy ± 0.014% of reading - 20 to 70 Deg C

Spectral Analysis

Resolution

Window Function

Update Rate 0.25 Sec typical

SI Units Hz, Digits (Hz2/1000), Eng Units

Temperature Measurements

Analogue Input 24 Bit Sigma Delta

Measurement Range - 50 to 100 Deg C

Measurement Accuracy ± 0.25 % of reading - 20 to 70 Deg C

SI Units Deg C

Cal Factors Steinhart-Hart

Bridge Type Half Bridge

Expansion Options

1 x MUX-16/32 expansion unit

Scan rate 2 Sec/Chan - using expansion module

Memory Expansion 1 x SD Card = 1 .. 32 GB

(Excluding boot cover)

Height 184 mm - Width 74 mm - Depth 32 mm

125 g

4 x AA - 2000 mA/Hr

6 mA - standby - 340 Hours continuous use

20 mA/Hr with display - Low

50 mA/Hr with display mode - Full brightness

150 mA/Hr with MUX-16/32 - Peak (Note-1)

1 x SDI-12 - - 1200 Baud, 8 data, 1 stop, no parity

1 x micro USB configuration port

Differential Coil (V+) and Coil(V-) for direct connection of

sensor, excitation and resonant frequency measurement.

Digital signal processing for excellent noise rejection,

1024 line Zoom FFT - with data weighting

0.001 Hz

Hamming

(Quadratic Cal Factors)

Used for temperature compensated vibrating wire

measurements, and stand-alone temperature sensors for

Geotechnical applications. Ratio-metric measurement.

Beta Value - lower performance using Beta

1..32 - 2 Wire Freq inputs

1..32 - Temp (thermistor) inputs

1..16 - 4 Wire vibrating wire sensor inputs

250 ms update to screen

Temperature Measurements

The VibWire-201-Pro is factory set to use the most common thermistor

calibration factors that is fitted into most manufactures vibrating wire sensors.

The thermistor is used to measure temperature.

The thermistor calibration factors are taken from the sensor material

manufactures data sheet and are as accurate as possible.

The voltage input measurements are factory calibrated to traceable national

standards, and can be externally calibrated upon request. There is an extra

charge for operation.

Common VW Sensor Thermistor Part Numbers

YSI 44005

Vishay 1C 3001 B3

RS Part no: 151-215

The part numbers are for 3 K Ohm thermistor commonly used by most

different VW sensor manufacturers to measure temperature

The sensors give 3 K Ohm resistance at 25 Deg C

The most common material used in these sensors uses material type F

from GE sensing.

Under most practical applications, the in-built thermistor calibration factors will

give accurate results without the User having to be concerned with

understanding of process involved.

Simply connect the thermistor output from the sensor to the VibWire-201-Pro

and the device will instantly display the temperature.

Sources of Error

The principle source of error in field measurements will the added resistance

due to long sensor wires. The resistance added to the thermistor measurement

will give a fixed offset error. Make temperature measurements as close to the

temperature sensor as is practically possible.

Calibration Factor Error

Take care when using the calibration factors supplied on a vibrating wire sensor

manufactures data sheet. The factors are often given from sample sensors taken

from a batch and not necessarily from the individual sensor being used. Where

possible ensure that the sensor manufacturer calibrates the sensor and supplies

all test data so that the calibration factors can be verified.

Storage file format CSV - Comma Separated Variables

Logging Rates

16 x 4 Wire Mode

32 x 2 Wire

No. Pre-set Sensor Configurations

File Type Format DOS

Operating Temp Range -20 to 75 Deg C

Storage temperature >5 Deg C with batteries installed.

Note-1 - Use external supply for long term monitoring with MUX-16/32 unit

150 mA peak .

Internal to flash card

1s, 10s, 1 Min, 10 Min, 1 Hour, 6 Hours

MUX-16/32 Expansion

30 Sec/Chan

1 minutes

10 user defined sensors options

Associated Part Numbers

Part No:

VibWire-201-Pro - FFT VW Sensor Interface

USB-485-Pro - Isolated USB to 485 media converter

USB-SDI12-Pro - Isolated USB to SDI12 media converter

MUX-16/32 16 x 4 Wire/ 32 x 2 Wire Expansion unit

Device Configuration Software

The VibWire-101-Pro configuration software runs with on most modern

Windows platforms such as XP, 8.1 and 10 operating systems.

Table 1

User Defined Stein-hart-Hart Calibration Factors

The VibWire-201-Pro has the facility to enter User defined Steinhart-Hart

calibration factors.

The calibration factors are entered into the device using the VW201cal software

package. See figure 57 on Page 20.

Sensor Information

A calibration report should be provided with each vibrating wire sensor and it will

contain all the information required to convert Hertz, the frequency value output

by the sensor into appropriate SI units (e.g., displacement, pressure etc..)

1. If the values in the Calibration Report are in digits, use the following equation

to convert the VibWire-201-Pro frequency values from Hertz to digits.

Digits = Frequency 2

1000

(Hz2)

1000

2. Use the gauge factors and polynomial provided in the Calibration Report to

calculate SI units.

The VibWire-201-Pro uses:

Natural Units = A(R1)2 + B(R1) + C + K(T1-T0) - (S1-S0)

(Equ 1)

Calibration equation.

The software automatically identifies the USB port in use and allows for a true

plug and play operation. Simply enter the sensor calibration factors and select

the ‘Connect’ button to store parameters into the device.

Download the software at:

and this is expanded to:

= C(R1-R0)2 + B(R1-R0) + A + K(T1-T0) - (S1-S0)

(Equ 2)

when initial conditions in the measurements are involved.

The additional terms used in equation 2 only change the constant parameter

( A ) when used.

VibWire-201-Pro User Manual 11

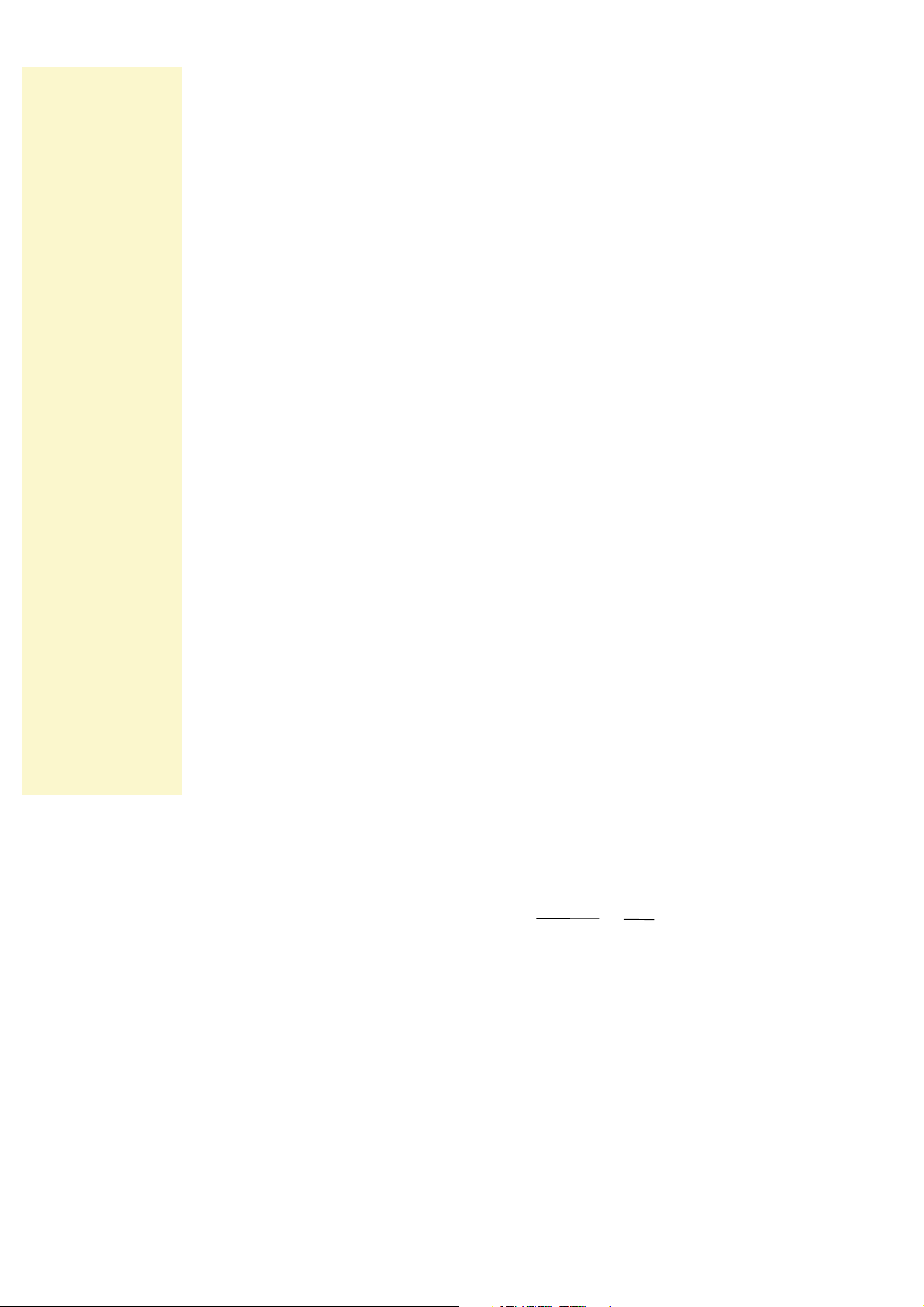

Pre-set Sensor Configurations

The VibWire-201-Pro cab be configured using the

http://www.aquabat.net/downloads/

VW201cal.zip

VW201cal.exe

software which is available as a free download at:

Features

The VW201cal software gives the User the ability to configure the VibWire-201-Pro in an easy to use Windows environment.

Automatically sets time and date to host PC.

Set the User defined frequency and temperature calibration factors.

Select preset thermistor calibration factors.

20 Pre-set sensor configuration options.

The sensor names entered into the VW201cal software appear on the VibWire-201-Pro sensor list.

The VibWire-101-Pro supports up to 20 built-in User defined vibrating wire sensor configuration options.

Sensor Configuration

Thermistor

Calibration

Factors

EPP-30V

5200 2

SI Unit = A + B(R1)+ C(R1)2 + D(T)

Process Option

0 = Frequency,1 = Digits, 2 = SI Un its

-1720.23

-2159.487

2.8388E-1

3.1728

2

-0.0870

T0

where R1 = Current Reading

T = Temp Deg C

D = Thermal Factor

Thermistor Type T0, T1, T2 ….. etc

Figure 24 opposite shows the VibWire-201-pro Setup software used for entering the calibration

factors for a Vibrating wire sensor.

This Window is used to enter the frequency component calibration factors. The calibration factors

are used to enable the VibWire-201-Pro to display measurements directly in engineering SI units.

Write configuration details

into the device.

VW sensor

calibration factors

Select Therm istor Calibrat ion Window

Default-Therm

300025

Fig 25 Default Thermistor Calibration Factors

Downloading and Installing device setup software

1.

Download the VW201cal software from:

http://www.aquabat.net/downloads/VW201cal.zip

Run the install software script.

3.35E-3

2.56E-4

2.08E-6

Fig 24

7.30E-8

Default Steinhart-Hart

calibration factors

Figure 25 opposite shows the thermistor calibration settings window for the

The factory set default thermistor parameters for T0 are displayed.

SI Units

In order for the SI unit formulae be applied the process option has to be set to

‘2’. Fig 24 above shows how this is done.

Setting the process option to 0 or 1 shows results in Hz or Digits.

VW201cal

software.

Follow the on-line instructions to install and activate the software.

Once activated the main Window shown in Fig 24 above will be displayed.

Automatically setting the Real-time Clock

The VibWire-201-Pro can be used as a stand-alone VW sensor data logger

recording measurements automatically, and also to take single shot readings

under ‘User’ control. In order to act as a logger the internal real-time clock has

to be set.

The real-time clock is used to keep track of the time and date of a measurement.

The clock is set automatically the VibWire-201-Pro is connected to the PC via

the USB cable and the ‘

Upload’

button is activated. Once the sensor data is

written into the device then the clock is automatically synced to the host PC.

Common VW Sensor Thermistor Part Numbers

The part numbers are for 3 K Ohm thermistor commonly used by most

different VW sensor manufacturers to measure temperature

The sensors give 3 K Ohm resistance at 25 Deg C

The most common material used in these sensors uses material type F

from GE sensing.

YSI 44005

Vishay 1C 3001 B3

RS Part no: 151-215

Pre-defined Thermistor Calibration Parameters

The VibWire-201-Pro uses the following predefined calibration parameters to

defining the operation of the 3 K Ohm thermistor temperature sensors built into

most Vibrating Wire sensors.

(Steinhart-Hart Factors)

A = 3.35E-3, B = 2.56E-4, C = 2.08E-6, D = 7.30E-8

VibWire-201-Pro User Manual 12

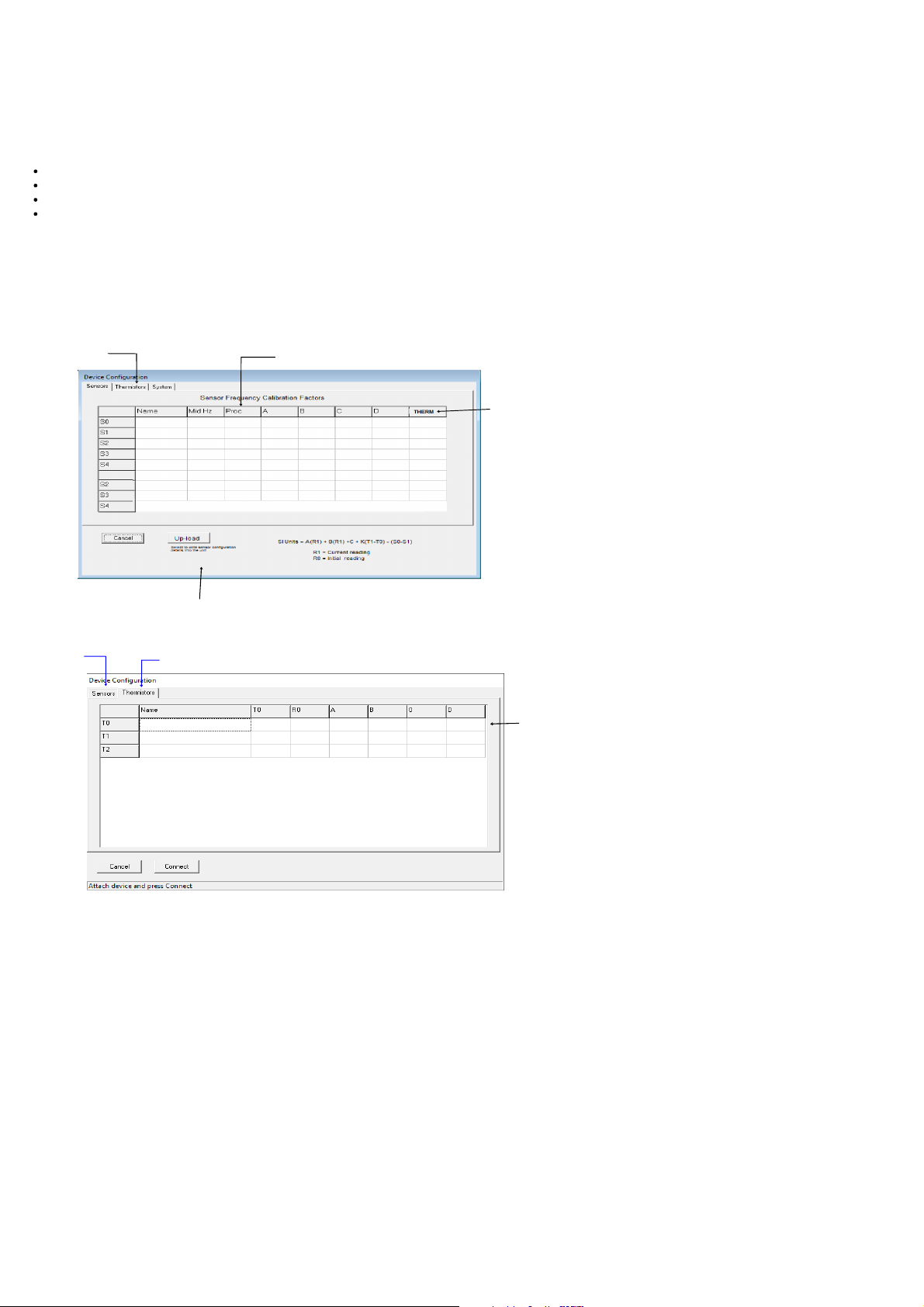

Channel Expansion Options

The VibWire-201-Pro is expanded using a single MUX-16/32 expansion unit.

The expansion unit offers 16 x 4 wire or 32 x 2 wire sensor operations.

16 x 4 wire mode offers 16 x Frequency and 16 x Temperature inputs.

The 32 x 2 Wire sensor mode offers 32 x Frequency inputs or 32 x temperature measurements.

The VibWire-201-Pro can record data internally onto a SD memory card, or remotely across a digital network to a stand-alone PC running the Keynes Controls

Q-LOG applications software.

32 x 2 Wire Expansion

Output Ports on

the MUX-16/32 Unit

-

+

Out-0 Port

(MUX-16/32)

- VW Sense

+ VW Sense

- Therm

-

+

Sensor Port

+ Therm

(VW-201-Pro)

Unit shown below is configured for 32 x 2 wire

frequency measurements.

Sequencing MUX

MUX 0

21

Selected Sensor

Frq

Hz

Res

Ohm

3003.56

C

24.89

Tem

Out-1 Port

(MUX-16/32)

2534.86

Dig

Dg

6424.95

992.28

Val

SI

Fig-26

16 x 4 Wire Expansion

4 Wire operations records frequency and temperature simultaneously.

Sequencing MUX

MUX 1

12

Selected Sensor

Frq

Hz

Res

3003.56

24.89

Tem

Dg

SI

MUX-16/32

Output Ports

Out-0 Port

(MUX-16/32)

Output Ports on

the MUX-16/32 Unit

-

+

- VW Sense

+ VW Sense

- Therm

-

+

Sensor Port

+ Therm

(VW-201-Pro)

Dig

Val

Out-1 Port

(MUX-16/32)

2534.86

6424.95

992.28

Ohm

C

Fig-27

2 Wire operations records frequency or temperature but not both at the same

time.

MUX-16/32 Expansion Unit - User manual

For 32 x 2 wire operations the output ports on the MUX-16/32 expansion unit are connected together.

Full details for configuring and the MUX-16/32 unit can be seen in the User manual.

Download the User manual at

http://www.aquabat.net/downloads/mux32manualv1.pdf

VibWire-201-Pro User Manual 13

Number of Channels

The VibWire-201-Pro data supports 4 data recording modes:

Single Channel

- Records measurements from the sensor attached directly to the instrument.

The following modes require the MUX-1632 expansion unit to be fitted:

MUX-16/32 Expansion Unit

16 x 4 Wire (VW and Temp)

32 x 2 (VW only)

32 x 2 (Freq)

- 32 x Freq

- 32 x Temp

- 16 x Freq + 16 x Temp

when using the MUX-16/32 expansion unit 32 measurement values are stored into each record.

To select the data recording mode

1. Make sure a flash memory card is installed into the VibWire-201-Pro, See Page 5 Figure 2.

2. Starting at the default ‘Frequency’ display, use the ‘

The

Mux Mode

3. Use the ‘Up’ and ‘

menu system will appear.

Down

’ keys to select the mode of operation of the instrument.

Menu In

’ key to select ‘

System Setup

’ followed by ‘

Setting Scan Mode

Frequency

2534.86

Selected Sensor

Frq

Dig

Val

2534.86

6424.95

992.28

Hz

Dg

SI

Res

3003.56

Tem

2016-01-20 08:40::17

6

24.89

Ohm

C

Menu-In

Hz

Up

Down

Main Menu

Sensor No

Logger

Multiplexer

Remote

System

Use the ‘Up’ and ‘

to select the ‘Logger’ option.

Down’ keys

Menu-In

Up

Down

System Setup

Log Now

Autolog Mode

Scanning mode

Recording Interval

Set working MUX ID

Use the ‘Up’ and ‘Down’ keys

to select the ‘Scanning mode

option.

’

Menu-In

Mux Mode

Selected Scanning mode

Single Chan

16x4 (VW and Temp)

32x2 (VW only )

32x2 (Temp only )

’ menu options.

Fig-28

Menu system define s the number of

measurements made after each scan. The

MUX-1632 expansion unit must fitted for 16x

4 wire or 32 x 2 wire operations.

Data Recording

The VibWire-201-Pro can store measurements directly on to a SD flash memory card.

Max SD Card = 32 Gb (160 million records)

DOS format file system.

The data table stores results in C.S.V. (Comma separated variable), for direct importing into spreadsheet such as Microsoft Excel.

Data Recording Options

The VibWire-201-Pro supports 3 x logging modes. Single Channel, 16 x 4 Wire and 32 x 2 Wire.

Single Channel

Both the 16 x 4 Wire and 32 x 2 wire recording modes require the use of the MUX-16/32 expansion unit.

16 x 4 Wire

16 x Frequency + 16 x temperature.

32 x 2 Wire -

- Continually records a single measurement from a sensor connected to the sensor port on the device.

1 x single measurement on demand.

Single Channel on MUX-16/32 Unit.

- 32 measurement values made up of

Important Note

The VibWire-2-1-Pro will adjust automatically to the fastest sample rate

32 x Frequency measurements.

allowed for the number of channels to be scanned.

The fastest sample rate that is allowed for a 32 channel operation

operation is 60 seconds (1 min).

Set Logging Interval

Frequency

2534.86

Selected Sensor

Frq

Dig

Val

Fig-29

2534.86

6424.95

992.28

Hz

Dg

SI

Res

3003.56

Tem

2016-01-20 08:40::17

6

24.89

Hz

Ohm

C

Menu-In

Up

Down

Main Menu

Sensor No

Logger

Multiplexer

Remote

System

Use the ‘Up’ and ‘Down’ keys to

select the ‘Logger’ option.

Menu-In

Up

Down

Logger

Log Now

Autolog Mode

Scanning mode

Recording Interval

Set working MUX ID

Use the ‘Up’ and ‘Down’ keys to

select the ‘Recording Interval’

option.

Menu-In

Down

Select Recording Interval

1 Second

10 Second

1 Minute

10 Minute

1 Hour

6 Hour

Up

1 Second - only for single chann el operations

10 Second

VibWire-201-Pro User Manual 14

17 Commands for scanning MUX-16/32 in 32 x 2 wire mode

Table 2 below shows the commands used to scan the MUX-16/32 unit in 32 x 2 wire mode.

The MUX-16/32 unit has to be set to operate in 32 x 2 Wire mode. This is done via the VibWire-101 setup menu.

See page 17, section 25.2 for instruction in setting the ‘Scan Mode’.

In 32 x 2 wire mode the channel counter displays the range 0 .. 31.

Start Measurement

Command

aM2!

aM3!

Description Channel

MUX ID=0 Chan 0..15 Chan 0 .. 15 Returns 16 values x Freq aD0! aD1! aD2! aD3!

MUX ID=0 Chan 16..31 Chan 16 .. 31 Returns 16 values x Freq aD0! aD1! aD2! aD3!

Number

No. Data Values SDI-12 Get Data Command

Channel Select Display - Fig 30

to

Table 2

Chan 0..15 Freq

Fig 31 - Output Ports used in 2 Wire mode.

32 x 2 Wire mode

Each get data command

returns 4 values.

Chan 16..31 Freq

When operating in 2 wire mode, the VibWire-101 scans the MUX-16/32 in blocks of 16 channels.

Under normal operating conditions Channels 0-15 are scanned first and the results stored into a data table. This is followed by

the scanning the final block of 16 channels and storing the measurements. Table 1 shows the sequence of the 2 blocks of

commands needed to scan the MUX-16/32 unit in 2 wire mode.

16 Switching between 2 & 4 Wire Mode Operation under SDI-12 Command

The MUX-16/32 expansion unit supports 2 and 4 wire VW sensor operations. The selection between 2 and 4 wire sensors is

undertaken using software commands only and these are issued across the MUX-16/32 using the SDI-12 control port. The same

procedure for issuing instructions for changing the ID number is followed as is used for selection the mode of operation.

The following SDI-12 command selects 2 or 4 wire sensor operation:

aXDn! (n=0 or 1) Sets 2 or 4 wire operations on the MUX-16/32.

to

Channel Select Display - Fig 31

16 x 4 Wire mode

Example SDI-12 command ‘ 0XD1!‘ sets MUX-342 with ID=0 to 4 Wire mode.

18 Commands for scanning MUX-16/32 in 16 x 4 wire mode

Table 2 below shows the commands used to scan the MUX-16/32 unit in 16 x 4 wire mode.

The MUX-16/32 unit has to be set to operate in 16 x 4 Wire mode. This is done via the VibWire-101 setup menu.

See page 17, section 25.2 of the User Manual for instructions in setting the ‘Scan Mode’.

In 16 x 4 wire mode the channel counter displays the range 0 .. 15.

Fig 32 - Sensor Output Ports

Start Measurement

Command

aM2!

Identification

MUX-0

Chan 0..15

MUX

Channel

Number

Chan 0 ..15 returns 32 values

No. Data Values SDI-12 Get Data Command

16 x Freq + 16 x Temp

aD0! aD1! aD2! aD3! aD4! aD5! aD6! aD7!

Table 3

To VW frequency

port on the VW101

To temperature

port on the VW101

After each MUX has been scanned, and all 32 sensor readings have been taken, then the following command is required

to download the data from the VibWire-101 to a data table in the AquaLOG data logger. The same command should work on

any suitable SDI-12 data logger.

Get data:

aD0! aD1! aD2! aD3! aD4! aD5! aD6! aD7!

16 x Freq Readings

16 x Temperature Readings

where each command aD0! returns 4 values

VibWire-201-Pro User Manual 15

IMPOR

The MUX

VibWire-2

Full deta

found in

http://ww

The MUX

is assign

SDI-12

TANT NOTE

-16/32 expansion

01-Pro for addition

i

ls for sensor conne

t

he User manual at

w.aquabat.net/dow

-16/32 unit operati

e

d using the Q-LOG

C

ontrol Port

16 x 4 Wire Expansion

Frequently Asked Questions

1.

u

nit is used to expa

n

d the

al channel.

c

tion and operation

can be

:

nloads/mux32m

n

g mode, 16x4 wire

software via the in-

a

nualv1.pd

or 32x2 wir

built

.

What cable is used to connect the VibWire-201-Pro to a data logger.

A single 4 core ribbon cable is all that is required for the most common SDI-12 and RS-485. No

special cabling is required for this instrument.

Figure 61 on page 21 shows the connections to a logger

f

Farnell Web Site:

e

Farnell Part No.

Manufactures Part No.

2.

What might cause an VibWire-201-Pro to not communicate with a data logger?

http::/www.farnell.co.uk

150427

05091504-01-50M

.

The maximum cable core diameter is 2 mm for

the sensor terminated with a plug for

connection to standard sensor input.

The sensor terminal posts can take larger

diameter cables.

There is no programming required for setting up and using the VibWire-201-Pro.

Sequencing MUX

MUX 1

12

Selected Sen sor

Frq

Hz

Res

3003.56

2534.86

24.89

Tem

Dig

Dg

6424.95

992.28

Val

SI

MUX-16/32

Output Ports

Output Ports on

the MUX-16/32 Unit

Out-0 Port

(MUX-16/32)

-

+

-VW Sensor

Earth

+VW Sensor

- Therm

+ Therm

-

+

Out-1 Port

Sensor Port

(VW-201-Pro)

(MUX-16/32)

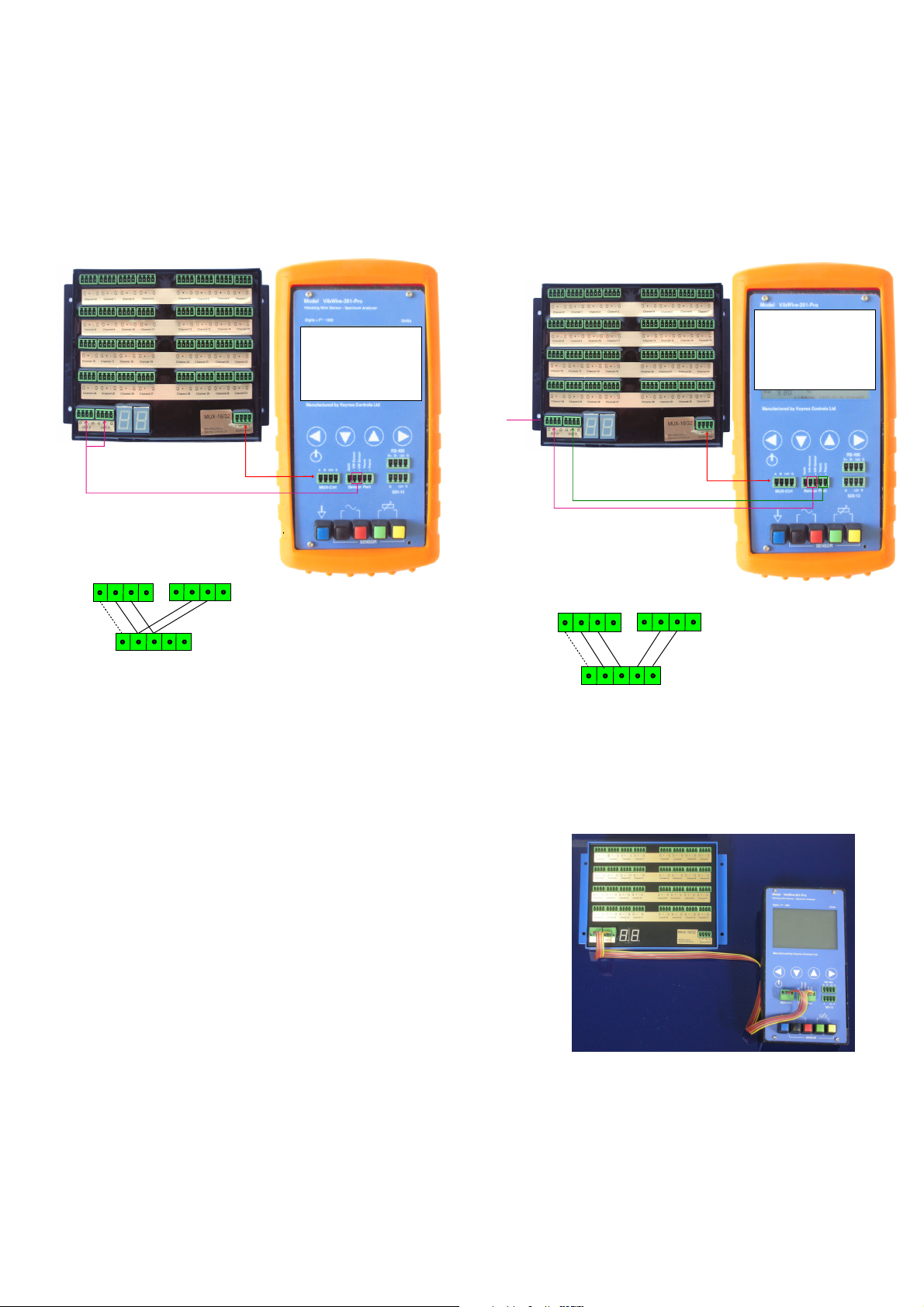

32 x 2 Wire Expansion - Frequency Measurements

Sequencing MUX

MUX 1

20

Selected Sensor

Frq

Hz

Res

3003.56

2534.86

6424.95

24.89

Dg

Tem

992.28

SI

MUX-16/32

Output Ports

Dig

Val

Ohm

C

Fig 33

Ohm

C

The most common cause for lack of communication is faulty wiring. Check that the cable cores

are correctly terminated by into the plugs. Use a DVM to test each core and pin on the plugs

for continuity.

Make sure the correct network port is selected.

For SDI-12 communications see menu system in Figure 21 on Page 9,.

For RS-485 option - see menu system on Figure 22 on page 9.

Network ID number

Make sure the ID number used to identify the VibWire-201-Pro on a network is set correctly.

See menu system on page 29 section ‘

Setting network address’

, or by the standard SDI-12

commands on page 20. A full list of User commands is shown on page 19.

The ID number for the measurement command used to acquire data from the VibWire-201-Pro

must mach the ID number set in the device.

Logger using command: 3M! 3D0! - then the ID number should be set to ‘3’.

3003.56

24.89

2016-01-20 08:40::17

D

Ohm

C

Page 30 shows the menu options to set the ID number.

IMPORTANT NOTE

Remote Mode

Port = SDI12

Address = 3

Measurement count = 4312

Selected Sensor

Frq

Dig

Val

2534.86

6424.95

992.28

Hz

Res

Tem

Dg

SI

6

When multiple devices are being used on the same network, each device must have a unique

ID number assigned. Failure to do so will prevent the VibWire-201-Pro from communicating to

a logger unit.

Out-0 Port

(MUX-16/32)

Output Ports on

the MUX-16/32 Unit

-

+

Earth

+

Sensor Port

-VW Sensor

+VW Sensor

(VW-201-Pro)

-

Out-1 Port

(MUX-16/32)

Fig 34

32 x 2 Wire Expansion - Temperature Measurements

Sequencing MUX

MUX 1

20

Selected Sensor

Frq

Hz

Res

Ohm

3003.56

MUX-16/32

Output Ports

Out-0 Port

(MUX-16/32)

Output Ports on

the MUX-16/32 Unit

-

+

Earth

- Therm

+ Therm

+

Sensor Port

(VW-201-Pro)

-

Out-1 Port

(MUX-16/32)

99.00

Dig

9.90

9.90

Val

C

24.89

Dg

Tem

SI

Fig 35

How fast can the VibWire-201-Pro make a measurement?

Currently the fastest data recording rate is 1 measurement / Second for a single channel.

The fastest sample rate is supported on the SDI-12 and 485 network measurements using the

Q-LOG free data acquisition and display software, and to the in-built data recording to the flash

memory card.

Where Can I download a copy of Q-LOG software ?.

Download a copy of the Q-LOG software at:

http://www.aquabat.net/QLOGFree/qlogv2.html

Erratic Measurements - most common cause.

When the battery level goes below 3.9 Volts the measurements can be come noisy and erratic.

Replace the batteries in the unit for a new set, or connect an external power supply. Faulty

sensor coil seating which can be seen in the sensor results spectra.

How do make measurements on my PC without any programming experience.

Use the free Keynes Controls Q-LOG software which can downloaded without restriction from

the companies web site, and one of the USB-SDI12-Pro or USB-485-Pro media converters. The

Q-LOG Windows software can be configured

The Q-LOG software gives complete control of the data acquisition operations for the VibWire201-Pro in a simple to use Windows environment. See page 18 for additional information.

The USB-SDI12-Pro and USB-485-Pro media converters can both be power the VibWire-201-Pro

direct from a PC USB port. No additional power supply is required.

Install the software - Assign USB COM Port details - Scan Network ( Identify Instruments) - Start Data Acquisition.

The Log files are stored to C:/Q-LOG/Logfiles/’Timestamp-file’.TXT in a format suitable for reading

by a spread sheet package,

‘Timestamp-file.TXT

’ is a unique log file in CSV ( Comma Separated variable).

VibWire-201-Pro User Manual 16

Selecting a MUX-16/32 Channel

The VibWire-201-Pro can be used to manually select a channel on the

MUX-16/32 expansion unit and take readings.

The feature enables the user to test sensors during an installation, or to use the

MUX-16/32 expansion unit as a switch box. The channel selection works in 16

x 4 wire and 32 x 2 wire modes.

MUX-16/32 Settings for operation with VibWire-201-Pro

Signal and Control Ports

Fig-37

The MUX-16/32 must be set to

ID = 0

The setting of the MUX-16/32 ID number is easiest set using a USB-SDI12-Pro

media converter and Q-LOG software. See Page H Appendix A for details.

Out-1 Port

(VibWire-201-Pro)

D

0V

N/A

12V

D

Control Port

(MUX-16/32)

0V

N/A

12V

Wiring diagram for the MUX-16/32

control port to the VibWire-201-Pro

Fig 36

1. Connect the MUX-Ctrl port on the VibWire-201-Pro to the Control port on the

MUX-16/32 expansion unit.

Figures 33 to 35, page 15 above show the wiring diagram for the MUX control

ports.

MUX-16/32 User Manual

Full details for the operation and configuration of the expansion unit can be

found at:

http://www.aquabat.net/downloads/mux32manualv1.pdf

MUX Control Port

Sensor Output

Ports

FFT Sensor Spect ra

0 1 2 3 4 5

Selected Sens or

2534.86

Frq

6424.95

Dig

992.28

Val

6 10 11

7

KHz

Hz

Res

Dg

Tem

SI

6 V

12

131415

3003.56

24.89

2016-01-20 08:40::17

Mux-16/32

Channel Control

Port

Ohm

C

Fig-38

Manually setting the MUX-16/32 Channel

Manually set the MUX-16/32 channel number. The channel range will depend on the scan mode assigned.

The MUX Chan number indicator will change as the ‘Up’ and ‘Down’ keys are pressed.

Fig-39

Menu-In

3003.56

24.89

2016-01-20 08:4 0::17

Hz

Ohm

C

Frequency

2534.86

Selected Sensor

Frq

Dig

Val

MUX 0 .. 15 4 Wire Mode - MUX-16/32 Channel counter changes between 0 ..15

0 .. 31 2 Wire Mode - MUX-16/32 Channel counter changes between 0 ..31

2534.86

6424.95

992.28

Hz

Res

Tem

Dg

SI

6

Main Menu

Sensor No

Logger

Multiplexer

Remote

System

Main Menu

Off - Initial Position 0 - 15 (4 Wire) and 0 - 31 (2 Wire)

Channel Select Display

Menu-In

Actions Menu

Multiplexer

Manually set MUX

Set working MUX ID

The menu system above shows the commands to follow to manually adjust

the active MUX channel.

Menu-In

MUX Chan No.

MUX Chan No.

Channel

Counter

MUX-ID No

Use the ‘Up’ and ‘

The channel counter on the MUX-16/32 will update automatically.

Sequencing MUX

MUX 0

24

Selected Sensor

Frq

Dig

Val

Hz

Res

2534.86

6424.95

992.28

Down

’ buttons to change the MUX channel.

3003.56

24.89

Tem

Dg

SI

Ohm

C

Up

Down

Off - Initial setting

MUX-ID No

The image above shows the Initial Startup display

should the MUX channel selection be activated without

a MUX-16/32 expansion unit connected.

Sequencing MUX

MUX OFF

0

Selected Sensor

Frq

2534.86

Dig

6424.95

992.28

Val

Hz

Res

Tem

Dg

SI

3003.56

24.89

Ohm

C

Fig-40

to

to

16 x 4 Wire mode

32 x 2 Wire mode

Changing the MUX Channel Number

Use the ‘Up’ and ‘

Down

’ keys to manually select the MUX-16/32 channel.

As the keys are pressed the MUX-16/32 channel will increment.

The Channel counter on the menu system will increment/decrement at the

same time as the MUX-16/32 unit.

VibWire-201-Pro User Manual 17

Sensor Configuration Example - Piezometer

The following example shows how to configure the VibWire-201-Pro to use an Encardio-rite vibrating wire piezometer water level sensor. The piezometer is

configured in a similar way as to a strain gauge but has the added complication for requiring barometric correction for true water level measurements.

The example will use the linear formula to convert frequency to pressure into SI units of k Pa. (Kilo Pascal )

A copy of a sample calibration data sheet used in this example is shown in

Appendix-A

.

The example demonstrates how to allow for initial conditions to improve the accuracy of the measurements.

Temperature Compensated Calibration Factors - Results in Natural (SI) Units

The example below demonstrates how to use the calibration factors on a sensor data sheet, and local initial conditions to determine the factors to be used by the

VibWire-201-Pro to give results in SI Units. The example sensor data sheet, see Appendix-B page 32 gives results in kPa. Use suitable scaling factors to convert

the output into other SI Units. The formula section of Q-LOG can be used to convert pressure into other SI Units.

P(kPa) = G(R1-R0) + K(T1-T0) - (S1-S0)

where G = Linear gauge factor from the calibration data sheet.

= C(R1-R0)2 + B(R1-R0) + A + K(T1-T0) - (S1-S0)

where A B and C are the calibration factors used in the VW201pro software.

— Sensor formula for conversion frequency (in Digits) to kPa

— Formula used by VW201pro software for configuration

For this example there is no C(R1-R0)2 and there is no barometer to correct for local barometric conditions.

Therefore the absolute water level measurements in kPa formula is now:

P(kPa) = B(R1-R0) + K(T1-T0) - temperature corrected absolute level readings

The initial condition measurements from the sensor are:

6064.0 Digits at 14 Deg C.

Different initial conditions will change final offset value only.

Important Information

Use the Barom-SDI12 or Barom-485 digital

barometer modules to give local barometric

levels in kPa for local atmospheric effects.

G = 2.8388E-1 - See Cal Data sheet

P(kPa) = G(R1-6064) + K(T1-14)

= 2.8388E-1*(R1-6064) - 0.087*(T1-14)

= (2.8388E-1*R1)-1721.448 - (0.087*T1)-1.218

where R0 = Initial reading in Digits

T0 = Initial sensor temperature Deg C

R1 = Current Frequency reading in Digits

T1 = Current temperature reading in Deg C

= (2.8388E-1.R1) - (0.087.T1) -1720.23

This formula gives the output from the sensor in k Pa and allows for local temperature correction.

Examining the formula now gives the parameters required for the VW201Cal software

A = -1720.23

B = 2.8388E-1

Process option - Digits

D = -0.0870

S1 = Current barometer value - SI Unit KPa

S0 = Initial Barometer reading - SI Unit KPa

Model: Barom-SDI12

Fig-42

Figure 41 shows how the VW201cal software is configured for a

Encardio-rite EPP-30V piezometer as sensor 3.

The output SI unit value will be in units kPa.

EPP-30V

VWP-2021

-1720.23

2

2

3.22346

2.8388E-1

-0.0870

T0

The output will be temperature compensated.

Process Option setting

In order for the VW201-Pro to use the calibration factors in the

software then the process option has to be set to 2.

Thermistor Type

Fig 41 - VW201Cal Software - EPP-30V Piezometer.

Menu-In

Res

Tem

6

3003.56

24.89

2016-01-20 08:40::17

Fig 43

Hz

Ohm

C

Main Menu

Sensor No

Logger

Multiplexer

Remote

System

Use the ‘

Up’

and ‘

The assigned sensor calibration factors will then be used by the VibWire-201-Pro to

determine the SI units for any sensor that is attached.

Frequency

2534.86

Selected Sensor

Frq

Hz

2534.86

Dig

Dg

6424.95

992.28

Val

SI

Menu-In

Down

’ keys to select the sensor type.

Select Sensor No

Sensor no: 3

Name: EPP-30V

Select Sensor No

Sensor no: 0

Name: Undefined

Default display with

no sensors defined.

Enter thermistor type into cell labelled ‘

Results in Deg C.

Pre-set Sensor Configuration Settings

Once the calibration factors have been determined and set into

the

VW201cal

software, then they will be automatically loaded

into the VibWire-201-Pro. This is done by simply connecting the

device to the host PC and pressing the ‘

All defines sensor types will be loaded into the device and can

be selected using the menu system. See Figure 44 opposite.

Simplified Calibration Factors

Frq

Dig

As is shown above the temperature effects on the sensor are not significant and for most applications can be ignored.

Val

If the initial conditions are:

6064.0 Digits

THERM

Connect’

’.

Button.

then the simplified formula becomes much easier to use

kPa = G (R1-6064) gain from the calibration data sheet G = 2.8388E-1 therefore kPa = 2.8388E-1(R1 - 6064) where R1=current reading

= 2.8388E-1 - 1721.44

The output on the VibWire-201-Pro will now be the height of the water above the initial condition starting point in SI units kPa.

This gives the calibration factors for the VW201cal software as A = -1721.44 and B = 2.8388E-1.

VibWire-201-Pro User Manual 18

Q-Log - Quick User Guide

The VibWire-201-Pro is integrated into the Q-LOG data acquisition software.

The VibWire-201-Pro can be used with both the SDI-12 and RS-485 ports in

the Q-LOG software.

A copy of the Q-LOG software can be downloaded at:

http://www.aquabat.net/QLOGFree/qlogv2.html

A copy of the User manual can be downloaded at:

http://www.aquabat.net/downloads/Q-log-guidev2.pdf

Factory Default Settings

The VibWire-201-Pro has the following default settings

ID = 0 Single Channel Operation for both SDI-12 and RS-485 networks

Sample Rate Options

The sample rate options for single channel operation is:

Figure 44 opposite shows how to connect a

VibWire-201-Pro to the SDI-12 network using the

USB-SDI12-Pro media converter.

Important Note

Ensure that the COMM port number for the USB

media converter and network type have been set

in the ‘Configuration’ Window of Q-LOG.

Failure to do so will prevent the software from

identifying the VibWire-201 device.

Fig-44

SDI12

12 DC

Gnd/0V

Image below shows how the

VibWire-201-pro is connected

to the USB-SDI12-Pro media

converter.

Fig-45

Remote Mode

Port = SDI-12

Address = 1

Measurement Count = 1032

Selected Sensor

2534.86

Frq

Dig

6424.95

992.28

Val

VibWire-201-P ro

Hz

Dg

SI

Res

Tem

2016-01-20 08 :40::17

6

3003.56

24.89

D

Ohm

C

1s , 10s, 30s,1 min, 10 min, 1 hour, 6 Hours.

Maximum sample rate

= 1 Hz.

Example

The example below assumes that the Q-LOG software has been installed and

that a USB-12-Pro media converter is in use. 3rd party SDI-12 media converters

will work with the Q-Log software but Keynes Controls do not support them.

USB-SDI12-Pro media converter using COMM Port 1 on the operating system.

The Q-LOG software can be used by third party media converters but they are

not supported by Keynes Controls Ltd.

Logging Configuration Window

Enter Comm Port identified for USB media converter

Example shows COMM Port-1. Use device manager to locate port no.

Data Recording Sample Rate - 60 Secs

Log Filename - 20160215_1116.txt (time stamped file)

Automatically create a new time stamped log file.

- Unique file each time selected.

Network Type Selection - SDI-12

Fig-46

Options for SDI-12 and RS485 networks

Before data can be obtained from a device on the SDI-2 network it first has to

be identified.

The procedure for identifying sensors and interfaces on a network is called

‘

Scanning for Devices

’. Figure 48 below shows how to Scan for devices.

Scanning for Devices

Select the ‘

Scan for devices

’.

The Status LED indicators on the USB-SDI12-Pro

media converter illuminate during the scanning

operations.

Fig-48

For a single device connected connected to a SDI-12 network then the device

list will appear as shown below.

Any addition sensors on the SDI-12 network require a separate and unique ID

number, and will appear in the list below.

To PC USB Port

External Power Supply

SDI-12 Data

+12V DC

0V/Gnd

Network Port on

(USB-SDI12-Pro)

SDI-12 Data

+12V DC

SDI-12 Port

(VibWire-201-Pro)

0V/Gnd

For stand-alone operations, or when multiple VibWire-201-Pro are connected

onto the network, then an external power supply should be connected to

external power supply port on the USB-SDI12-Pro.

The USB-SDI12-Pro can power 2 units directly from the USB port of a PC,

Fig-47

External +12V DC

0V/Gnd

+12V DC

0V/Gnd

Ports on the

USB-SDI12-Pro

device

SDI-12 Data

Network Port on

(USB-SDI12-Pro)

SDI-12 Data

+12V DC

SDI-12 Port

(VibWire-201-Pro)

Common Keynes Controls device identifier strings.

Product: ID string:

Network

Ports

RS-485

D+

SDI-12

12V G

D-

GS

12V

VibWire-101 VW sensor interface 13KEYNESCOVW101A011

VibWire-108 VW sensor interface 13KEYNESCOVW108A016

PIEZO-RM water level sensor 13KEYNESCOPRESR001

Barom-SDI-12 barometer 13KEYNESCOBAROMR003

I-P-I 13KEYNESCOIPINCL005

AquaDAT sensor interface 13KEYNESCOAQUDAT008

Single channel strain gage 13KEYNESCOSTRAIN027

VibWire-201-Pro 13KEYNESVWRDOA001

PC Data Acquisition - Start data recording

Select the ‘

Start Logging

’ menu option and measurements will be made and

data stored to the results file. See Fig QQ below.

If a USB-SDI12-Pro or USB-485-Pro media converter is being used then the

device status LED indicators will flash after each measurement.

Q-LOG will run with 3rd party media converters but Keynes Controls do not

support devices we don’t manufacture.

0V/Gnd

0I!013KEYNES VWRDOA001

Q-LOG Devices List Window.

Vibrating Wire R eadout Unit

D

Fig-49

Note.

When multiple devices and interfaces are on

the same network then select ‘

to set cell locations into the data table. The

Press the ‘Setup’ button - from the list

select ‘

Vibrating Wire Readout