VibWire-108

Vibrating Wire Sensor Interface Unit

User Manual Version 1.05 - Otcober 2008

Introduction

The following document details the model types, configuration

and operational features for the Keynes Controls VibWire-108

range of vibrating wire sensor interface.

The VibWire-108 units contains 8 x 4 wire sensor inputs and The

sensor interface consists of two inputs, one for the vibrating wire

sensor and the other for temperature/analogue input.

This document shows all the different hardware configurations and

User options available for the operation of the instrument.

All instruments are supplied with on-board frequency display and

a speaker also with or without analogue output ports.

Hardware Options

VibWire-108-RS485 RS 485 serial comms unit

VibWire-108-SDI12 SDI-12 serial comms unit

VibWire-108 Analogue Output

.

Instrument Scanning Operations

The VibWire-108 is a multiplexed instrument and as such scans

each channel before working out the sensor frequency and moving

on to the next channel. Only after all of the sensor inputs are

scanned are the results made available for data transmission across

the various communications networks or analogue output interface.

Configuration

The only time the sensor inputs require any configuration is when

the analogue output channels are to be used. For SDI-12 and

RS485 the sensor inputs operate automatically.

Real-time Operations

The VibWire-108 can be set to operate in real-time mode with the

real-time display operating on a single channel only. This is ideal

for testing and setting up sensors as any adjustment to the sensor is

instantly shown on the display.

Power Consumption

All of the VibWire systems use advanced power management

operations to minimise the power consumption and so make the

instrument ideal for stand-alone remote applications. Power

requirements are:

Power Supply 11-18V DC @ 0.25A

Scanning mode: 70mA aprox 30 seconds / scan

Display mode: 90mA continuous

SDI-12/RS485 network: Waiting for command 20mA continuous

Analog output mode: 25mA continuous

Solar Panels 4.8W cell gives 1 Reading /Hr indefinitely

Photo VibWire-108

Field Operations

There are various VW-108 models available offerings cable free,

GPRS modem, SDI-12/RS-485 serial port communications and

analogue outputs. All instruments no mater the model contain an

on board frequency display, ceramic speaker and User keyboard.

In order to ensure that the VibWire-108 systems operate as reliably

as possible they all contain lightening protection on sensor inputs

and isolated serial ports for digital data transmission.

The VibWire-108 series of instruments support everything needed

to make and report accurate vibrating wire sensor readings and also

to act as local display and diagnostic tool and report data across all

of the most common communication interfaces and data

transmission networks.

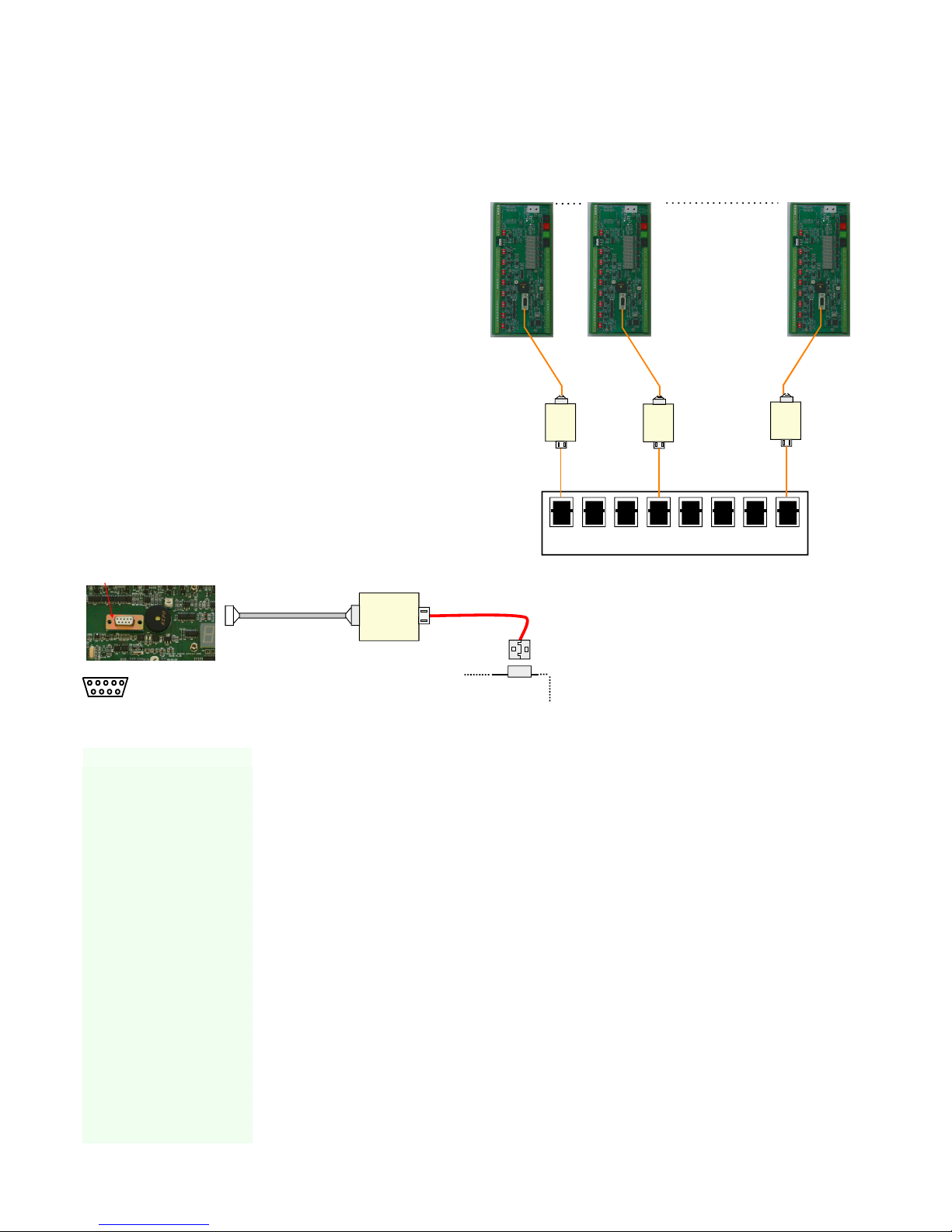

Fully Integrated Data Logger

The VibWire-108 has been fully integrated to the Keynes Gateway

data logger and communications interface. The Gateway can act as

a communications interface for connecting the VibWire-108 to

range of cable free networks such as GPRS and ZigBee. The

Gateway also supports USB data stick recording making it ideal for

fixed site recording.

The Gateway also controls the power management for the

VibWire-108 and switches off any third party equipment when not

in use to minimise systems power requirements.

Keynes Controls Reserves the right to make changes without notification. Refer to

the network drawing for details of the electrical connections.

Index

Page No. Description

1 Introduction

Instrument Scanning Operations

Power Consumption

2 Index

3 USB Data Recording

Gateway Settings for USB Data Recording

4 SDI-12 Serial Network Connection

Starting SDI-12 on the VibWire-108

5 RS-485 Serial Network Connections

Starting Data Acqusition Operations on a 485 Network

6 VibWire-108 Serial Port Communications

Command Structure and Operations across an RS-485 Network

Timing Constraints RS-485 / SDI-12 Network

Data Access Time

RS-485/ SDI-12 Commands

7 Start Measurement Commands

Initial Configuration

Table Of Commands SDI12 & RS-485

Communication ports Settings for SDI-12 & RS-485 network

8 Examples Of Using RS-485 / SDI-12 Instructions

Changing the ID Number (address)

ID Number Query

Start Measurements upon distributed instruments upon a network

9 Start Concurrent measurements on a number of distributed instruments

Read values from VibWire-108

Temperature / Current loop Data Format

10 Connection to an analogue data acquisition system

Technical specification - analogue output ports

Theory of operation

Starting Analogue Output Ports

11 Optimising the Analogue Output Settings

Integration to NDACS 6000 Logger

12 Real-time Frequency Display

Loud speaker

Sensor Problems

13 Vibrating Wire Sensor Installation

Lightening Protection

Multiple instrument installation

PCB Jumper Settings

14 Local Cable Free Systems

Local operation under 500 m to Gateway

Configuring the VibWire-108 for Data Transmission

Setting Data Transmission Rates

Setting Sensor Polling Rate

15 Antenna Installation

Typical Antenna solutions for 2.4 GHz Applications, Basic System Installation,

Directional Antenna Systems - External Mounting, Omni-directional antenna - External Mounting

16 Mesh networks, Network Operations

17 User Command Summary

18 GPRS Operations

Terminal Port & Hyperterminal Connection, GPRS Modem Configurations, Data Management

User Display & Speaker Unit

19 Database Operations

Data integrity Operations, Data Summary plots, Global Solutions, Local Systems

GPRS modem specifications

20 Example GPRS network configuration settings

Terminal Port & Hyper-terminal Connection

21 Serial Port to USB Communications

Active Comms Port

22 Serial Port to Ethernet Communication

Technical Specifications

23 Vibrating Wire Sensors

24 Vibrating Wire Sensor Applications

25 Case Study - Bore Hole Pump Control, Stand-alone Weir Control System with Data Logger

3

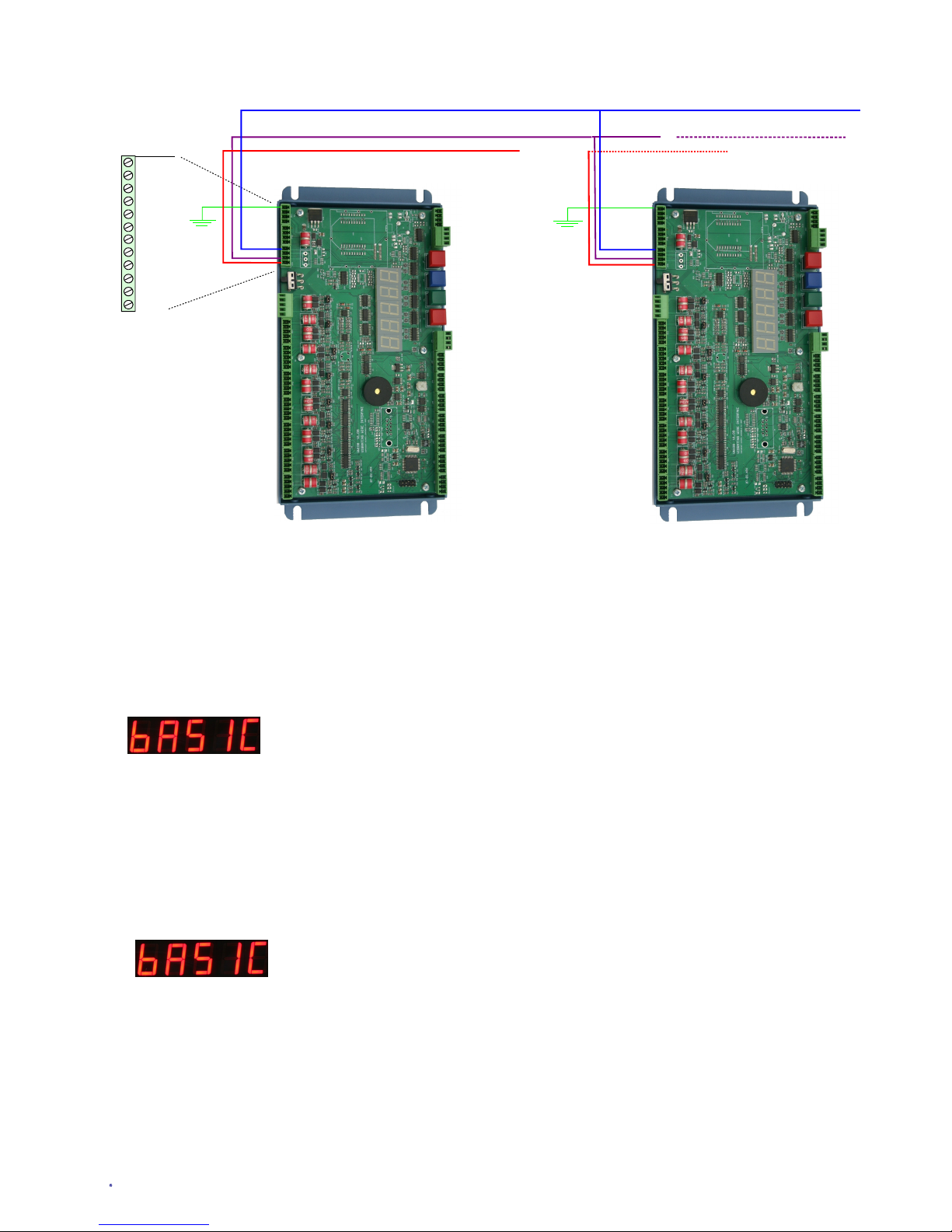

Add example of USB logging with example

Record data to a usb stick at 1 minute interval using 2 x VibWire108 instruments on an SDI-12 network to the Gateway data

recorder. Make sure the uSB adapter is connected to the Gateway.

Step 1 - Configuring the VibWire-108

There are 2 parameters needed to be set within the VibWire-108

when configuring operation with the Gateway or in fact any other

SDI-12 based device.

Number of Channels to scan (default =8) See page 17

Instrument ID number (0-9) (See Page 17)

Set ID number on the first instrument to 0

Set ID number on the second instrument to 4

Gateway Logger Parameters

Go the USB Data Recording menu options from the Gateway

menu system

1. Baud rate = 9600 (default) no need to adjust

2. MyFile.csv comma separated variable

User defined filename

3. Highest Column = K

For this example setting he Highest column to K represents

11 data values ie the 11th letter in the alphabet.

Column 1 = record number

Column 2 = Date

Column 3 = Time

Columns 4 - 11 representing data values returned from the

VibWire-108 instruments.

See Gateway Manual for full details.

USB Data Recording Applications

The VibWire-108 data can be stored to the USB memory stick

when used in collaboration with an SDI-12 network data recoreder.

The Keynes Gateway supports SDI-12 network and USB data

recording making it ideal for stand-alone permanent data recording

applications.

The Gateway and USB interface are both immersion proof and so

Suitable for operation in the harshest of environments. Should a

site flood then the instrumentation will still operate.

USB Data Recording

Data from a VibWire-108 can be stored directly to USB memory

stick using the Keynes Gateway data recorder with the USB

interface attachment.

Configuring VibWire-108 for USB Data Recording:

1. Set the number of channels to be scanned.

2. Activate the SDI-12 Port (See page 4)

The VibWire-108 only reports data for channels set to be scanned.

The lower the number of scanned channels the faster the instrument

responds and the lower the amount of power need for operations.

3. To store data to the USB data stick via the Gateway Logger

Using the 9 pin serial port on the Gateway and a teriminal program

on a laptop or other suitable programming device, configure the

Gateway to undertake the following operations:

A) Set the sample rate - typically 1 Scan / Min

B) Define the data table for storage for the Frequency &

temperature parameters

C) Assign storage as USB from the Gateway menu.

See

http://keynes-controls.com/2008/Downloads/GatewayManualV102.pdf

For full Gateway manual details.

Gateway Programming Options for USB Data Recording

1 Baud rate 9600 (Default)

2 Filename Prefix MYLOG (Name of file)

3 Highest Column AF (Last column in table)

4 Logging interval (mins) 1 (Data storage rate)

SDI-12 Configuration Parameters

Set the output to be SErAL -- serial port output. This will activate

the data to be sent out across SDI-12 network.

Channel Scanning

The lower the number of channels scanned on the VibWire-108

then the faster the instrument returns results and the lower the

amount of power required for operations.

VibWire-108

USB Flash Drives

1 - 8 Gb storage

Part No.

NP-GAT-USB-01

USB interface for Gateway

SDI-12 Network

Minimum VibWire-108 system

Suitable for USB data recording

Item 3, the highest column is the position in the Gateway internal

data table into which data is stored.

Once the USB adapter is fitted onto the Gateway and the unit is set

to record then information starts to be stored to the USB stick. The

VibWire-108 will be activated from the Gateway and powered off

between scans to save power. To replace the USB stick simply pull

and and swap with another device.

SDI-12 serial data transmitted

Earth

12V DC

12V DC

SDI-12 Serial Network Connection

Figure 7

Starting SDI-12 on the VibWire-108 Instrument Identifier

To activate the analogue output channels on the VibWire-108. Each instrument deployed on the SDI-12 multi-drop network

must have a unique instrument identifier set in order to identify

1. Starting at specific instrument on the network. For the SDI-12 network this

identifier is 0-9.

See Page 8 for details on setting the ID number.

2. Select “Menu In” button

3. Use the Up & Down Keys to select the option “Seral”

“Analg C0d C1d C2d C3d C4d C5d C6d C7d” are the other options available

Once the “Seral” output is selected the “Menu Out” key has to be pressed to confirm this option.

4. The VW-108 will return to the display

and now the SDI-12/RS-485 port for the instrument is now activated.

4

Earth

Earth

Earth

Earth

NPN-4

NPN-3

NPN-4

NPN-3

485 + / SDI-12

485 -

+ 12V

Gnd

The SDI-12 multi-drop network requires only 1 wire to be

connected between instruments for the communication of data.

This ensures that the installation and use of the SDI-12 network

very simple operation. The SDI-12 network has a limited range but

is ideally suited when connecting instruments together within an

enclosure or when systems are deployed locally.

Each instrument can have its own independent power supply but

must have the two dedicated network wires connected as shown

above in Fig 7. A unique instrument identifier has to configured in

order to access data from a dedicated instrument. Any data logger

supporting the SDI-12 network can obtain information from the

VibWire-108-SDI12.

Ensure that a good Earth

connection is made and fitted to

each instrument in order that

the lightening protection

discharge tubes will operate.

SDI-12 data on pin 4

0V or Ground

Pin 4 on each instrument are daisy chained together for SDI-12

operations

Starting Data Acquisition Operation on a 485 Network

To activate the SDI-12/ 485 output channels on the VibWire-108

1. Starting at

2. Select “Menu In” button

3. Use the Up & Down Keys to select the option “SErAL”

“Analg C0d C1d C2d C3d C4d C5d C6d C7d” are the other options available

Once the “SErAL” output is selected the “Menu Out” key has to be pressed to confirm this option.

4. The VW-108 will return to the display

and now the SDI-12/RS-485 port of the instrument are now activated.

Instrument Identifier

Each instrument deployed on the RS-485 multi-drop network must have a unique instrument identifier set in order to identify specific

instrument on the network. For the RS-485 network this identifier is 0-9 and a-z

See Page 8 for details on setting the ID number.

Earth, -RS485, +RS485 lines are connected in common to all units

RS-485 Serial Network Connections

Figure 7

Copyright Keynes Controls 2005- 2006 Release Version 1.06

12V DC

12V DC

RS485 - Common to all instruments

RS485 + Common to all instruments

Earth

Earth

Earth

Earth

NPN-4

NPN-3

NPN-4

NPN-3

485 + / SDI-12

485 -

+ 12V

Gnd

1

4

1 Gnd

2 Power

3 - RS485

4 + RS485 / SDI12

Control Signal Lines

5

VibWire-108 Serial Port Communications

The instructions below detail the operations to follow to operate the VibWire-108 across both the SDI-12 and RS-485 serial networks.

No sensor configuration details need be applied to the VibWire-108 when operating with the cable free transmitter, RS-485 or SDI-12

network. Simply connect the sensors to the interface as shown in Fig 2 and initiate the commands listed below.

Recommended Test

Use a single instrument only when undertaking initial measurements with a VibWire-108 on the RS-485 or SDI-12 network. This

simplifies the software and will speed up the understanding of the command used to obtain data. It is very easy to test the results

measured across the RS-485 and SDI-12 network with the ones shown on-board frequency display of the unit.

The results obtained across the RS-485 and SDI-12 network will be same as those shown on the display for a specified channel.

The default instrument address for a unit straight out of the box is 0

Issue command 0M! to start measurement operations. The VibWire-108 will scan all channels

0D0! returns items of data address data 4d1, data 4d1, data 4d1, data 4d1

Ensure that each instrument used on a network has a unique ID number assigned within its configuration in order to correctly identify

the data that is being recorded.

Command Structure and Operations Across An RS-485 Network

The VibWire-108 uses a command structure across the RS-485 network very similar to that used by the SDI-12 network in order to

simplify the overall system operations. Understanding the control of the instrument on one network be that RS-485 or SDI-12 will make

using the the unit on the other a very simple operation.

The RS-485 and SDI-12 network both operate at the same speed of 1200 baud.

Even though this is a relatively slow rate, as networks go, it is more than adequate for the small amounts of data transmitted by the

instrument.

No break characters are transmitted in an RS-485 command and any sent will be ignored by the instrument.

A short delay of approximately 10 ms is added between a command received by VibWire-108 and its transmission of data since this

delay is used to allow time for the host PC to turn off its transmitter when using soft-negotiation for data flow control operations.

Under normal RS-485 data transmission operations the RTS line on the serial port is used for flow control operations.

Keynes Controls recommends an RS-485 interface with Hardware negotiation is used to control the VibWire-108 across a network.

Timing Constraints RS-485 / SDI-12 Network

There are no timing constraints for the transmission of instructions and receipt of data across an RS-485 network compared to the

operations on and SDI-12 network.

Data Access Time

Typically the VibWire-108 takes 5 seconds to complete the scan of the first sensor and a further 3 seconds for any other sensor

connected to the instrument. The actual response time for the instrument is dependent upon number of sensor fitted and can interrogated

using the

RS-485/ SDI-12 Commands

The commands used by instruments on the SDI-12 and RS485 network are the same

In the following commands 'a' and 'b' are the address of the instrument and can only be integers 0 to 9 or the characters a - z.

where

'ttt' represents a time in seconds (0 to 999 seconds)

'n' or 'nn' represends a number of channels (00 to 99 channels)

\r and \n are the Carrigde Return and Line Feed characters - ASCII 13 and 10.

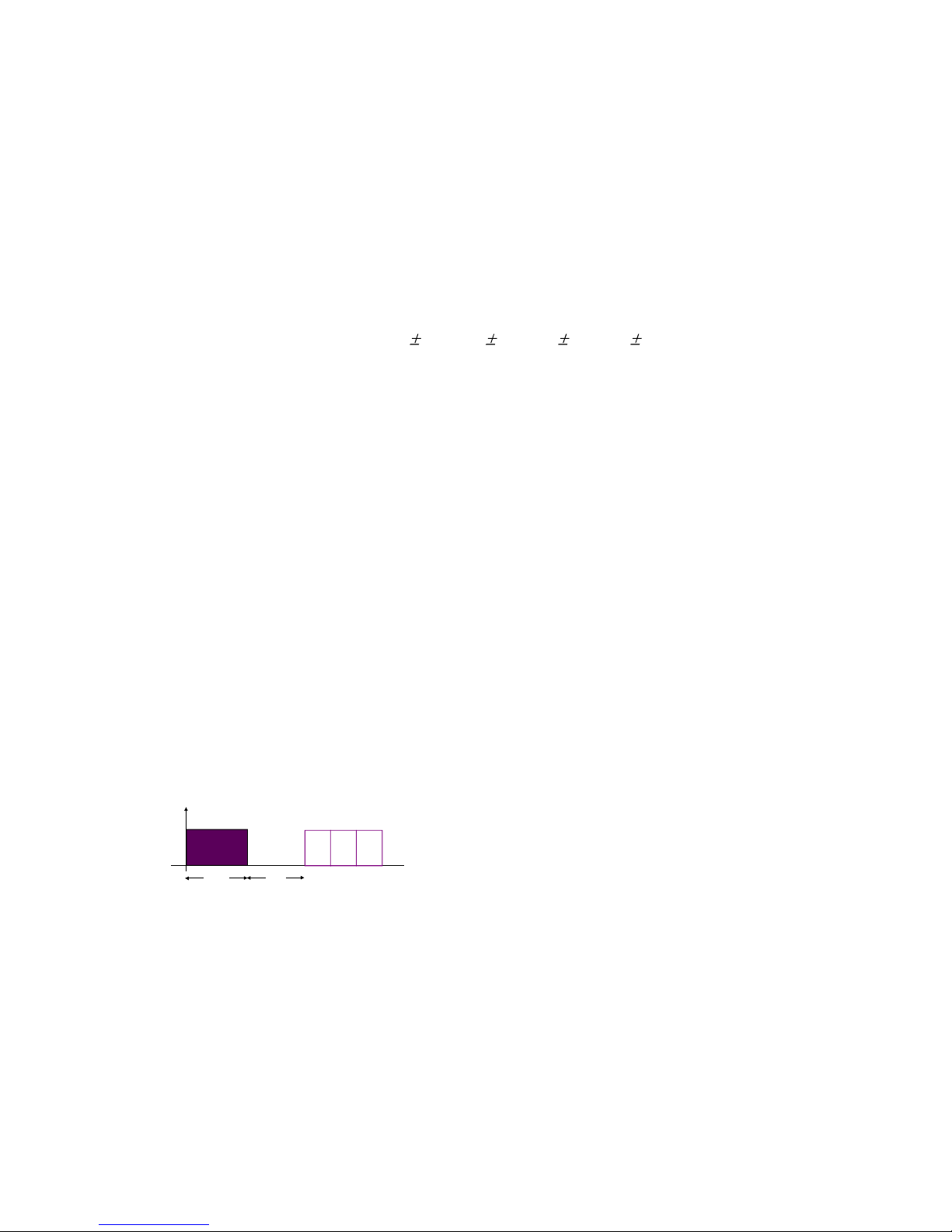

12 mS

8 mS

SDI-12 Data

Figure 8 shows timing delay used on SDI-12 serial bus

prior to sending data

Page 6

Start Measurement Commands

There are 2 separate commands supported by the VibWire-108 for initiating measurements across an RS-485 network and are named

‘aM!’ and ‘aC!’. Table 1 includes a complete description of the commands used by the VibWire-108

The ‘aM!’ starts a measurement and responds as soon as the data is ready to be transmitted from the instrument. This command returns

all instrument sensor inputs as a string

The ‘aC!’ command starts concurrent operations that are used to initiate measurements upon multiple instruments deployed across the

network. The ‘aC!’ command frees the RS-485 bus so that other devices can operate freely.

Initial Configuration

To setup a multi-instrument RS-485 network the ID number used to select an instrument on the network has to be adjusted from the

default factory settings. It is recommended that each instrument is individually configured before being deployed in order that there is

no confusion within the configuration settings.

Care is to be taken that each instrument to be deployed has a unique ID number to ensure that data is correctly identified.

The initial factory set ID number for each instrument is 0.

Table Of Commands

The following commands are all those supported by the VibWire-108 for use on the SDI-12 nad 485 multi-drop serial networks.

Additional Information

1 Strain gauge data is given as frequency in units (Hz) The RS-485 commands are almost identical in their

2 Temperature data is given in millivolts (0000.0 to 2500.0) format and use to those used on an SDI-12 network.

3 Communication ports Settings for SDI-12 & RS485 network. 1200 baud 8 bit no parity

Description Master VibWire-108 Response

Acknowledge active a! a\r\n

Send ID:

provided to complement SDI-12 protocol

aI! a13KEYNESCOVibWire-1080001\r\n

Part Description assigned by Keynes

Address query

identifies instrument address

and commonly used on single instrument

operations only.

?!

Used to make command set SDI-12

compatible

a\r\n

Where a = number 0 - 9 for SDI-12

0 -9 letters a - z for RS485

A - Z

change Address:

used to change instrument address from

default to new one for network operations

aAb!

a = initial address b = new address

b\r\n

a : b = number 0 - 9 or a - z

Start Measurement

instruct an instrument to make

measurement

aM!

a = address of instrument

example 0M! starts scan for ID 0

a0608\r\n

instrument with address a returns 8 x

vibwire & 8 x temp after 60 seconds

Concurrent measurement:

Used for polling multiple instruments on

a network to start to make readings. This

command frees RS-485 bus for other devices

aC!

start measurement instrument address a

a06016\r\n

initial response only after receipt of instruct and no response when data ready

to be sent.

Send data

data returned

aND! = Vib + Vib + Therm + Therm

and has same format for each command

aD0! aD1! aD2! or aD3!

aD0! = channel 0 and 3 VibWire Sens

aD1! = channel 4 and 7 VibWire Sens

aD2! = channel 0 and 3 Therm/analog

aD3! = channel 4 and 7 Therm/analog

+xxxx.x+xxxx.x+xxxx.x+xxxx.x\r\n

Copyright Keynes Controls 2005- 2006 Release Version 1.06

Page 7

Copyright Keynes Controls 2005- 2006 Release Version 1.06

8

Examples Of Using RS-485/SDI-12 Instructions

The following examples show how to undertake the various tasks needed to setup and make readings across the RS-485 and SDI-12

networks.

The

SDI-12 networks only supports up to 10 instruments with address range: 0 to 9

Changing the ID Number (address)

The following example demonstrates how to change the instrument ID number from the default factory setting 0 to 5.

Use the command ‘aAb’ where a = Start ID b = Final ID

master sends: ‘0A5’ Instrument responds 5\r\n Return New Line (5 representing new ID number)

ID Number Query

This command has been included to remain compatible with the SDI-12 and should be used for used with single instrument operations

only. Useful command when identifying ID numbers for instruments to be deployed on a multi-instrument network.

The example below is to show the ID number of a single instrument

Use the command ‘?!’ .

master sends:: ‘?!’ Instrument responds 3\r\n Return New Line (3 is the ID number)

Start Measurements On Distributed Instruments Upon A Network

The following example shows how to start measurements on instruments with ID numbers 2, 7, and 9 respectively.

For this example the instruments are instructed to start readings one at a time and the network is not freed up until each instrument

responds that the readings are being undertaken.

The instruments will start their measurement operations but will not send data across the network until instructed to do so.

Use the command ‘aM!’ where a = Instrument ID Number

Examples of use.

The following example is based upon a simple application of 3 x VibWire-108 units connected together on a local network. Unit 1 with

address 2 has 4 vibrating wire sensors, Unit 2 with address 7 has 6 sensors connected and finally Unit 3 has only 2 sensors connected.

master sends: ‘2M!’ Instrument responds ‘20144\r\n’ indicated readings available after 60 secs

followed by ‘2\r\n’ when the measurement is completed

7M! ‘70206\r\n’

‘7\r\n’

9M! ‘90082\r\n’

‘9\r\n’

Note. For this command the RS-485 network will not become available until each instrument completes its measurement cycle.

Start Concurrent Measurements on a Number of Distributed Instruments

The following example shows how to start measurements on multiple instruments deployed on RS-485 and SDI-12 networks.

Concurrent measurements ‘aC!’ differ from the ‘aM!’ command as they free the network after the initial command response to allow

other devices to operate. Concurrent measurements enable multiple instruments to respond faster to measurement commands.

The ‘aC!’ command initiates the measurement cycle within the instrument to start reading from the sensors however the data still has

to be requested from the VibWire-108 before being sent across the network.

Example of concurrent measurements for instruments with ID numbers 1, 6, and 7 respectively.

For this example the instruments are instructed to start readings one at a time and the network is not freed up until each instrument

responds that the readings are being undertaken.

The instruments will start their measurement operations as soon as the command is received but will not send data across the network

until instructed to do so.

Use the command ‘aM!’ where a = Instrument ID Number

master sends: ‘1C!’ - 4 sensors Instrument responds ‘10144\r\n’ indicated readings available after 14 secs

The network is free for other devices as soon as this response is returned.

‘6C!’ -3 sensors ‘60113\r\n’

‘7C!’ - 5 sensors ‘70175\r\n’

Read Values From The VibWire-108

No matter which instruction ‘aM!’ or ‘aC!’ is used to initiate measurement operations for the VibWire-108 has to be instructed to send

data when it becomes available. It takes the instrument 60 seconds to make sensor values available after being instructed to make a

measurement. The vibrating wire readings are in Units Hz. The Temp/Current loop input are in Units mV..

Use the command: ‘aD0!’ -- Vibrating Wire inputs 0 - 3

‘aD1!’ -- Vibrating Wire inputs 4 - 7

‘aD2!’ -- Temp/current loop inputs 0 - 3 (values in mV)

‘aD3!’ -- Temp/current loop inputs 4 - 7 (values in mV

Instrument responds: ‘a+xxxx.x+xxxx.x+xxxx.x+xxxx.x\r\n’ xxxx.x is the format of the number returned - 1 decimal place

for example to read all the sensor data back from an instrument with ID = 4

master sends: ‘4D0!’ Instrument responds: ‘4+1011.3+1204.4+1101.3+1190.7’ Vibrating wire data

‘4D1!’ Instrument responds: ‘4+1021.5+0000.0+1141.2+0000.0’ 0000.0 is returned when no sensor installed

Temperature/Current loop Data Format

‘4D2!’ Instrument responds: ‘4+0050.6+0056.1+0101.2+0000.0’ shows results with only 3 temp/loop values

‘4D3!’ Instrument responds: ‘4+0051.4+0058.3+0110.2+0015.3’

No Data is available Instrument responds ‘a\r\n’ or this example ‘4\r\n’

Note. The temperature values are in mV only. Thermistor linearisation is needed is convert the results into engineering values.

Copyright Keynes Controls 2005- 2006 Release Version 1.06

Page 9

Connection to an analogue data acquisition system

The following details show how to configure and optimise the VibWire-108 analogue outputs to operate with a analogue input data

acquisition system or logger unit.

Technical Specifications - Analogue Output Ports

8 x 0 - 2.5V DC single analogue output ports - 16 bit DAC

8 x thermistor outputs - 3.3 KOhm completion resistors

Theory of Operation

The VW-108 can be connected to an external data acquisition system or data logger

using the analogue output ports fitted onto the instrument. In order that the correct values

can be interpreted by the logger/acquisition system they are first scaled into a suitable

analogue signal by the VW-108 before being passed on for measurement. Each output

channel can be uniquely configured to support any manufactures sensor.

When defining the operation of the analogue output each channel has to have the sensor

operating characteristics defined. For the VW-108 this means that the minimum operating

frequency and span are set into the instrument.

Once the operating frequencies for the sensor are assigned the instrument scales the measured sensor frequency

over the range 0V = minimum frequency and 2.5V = maximum frequency.

Connection to an Analogue Input or Data Acquisition System

The analogue output ports are singles ended and as such,; care should be taken

When connecting to a differential input channel.

- Sense = 0V (single ended ) or -Vin (Differential Input)

+ Sense = +Vin

VibWire-108 Analogue Port Configuration

Low Frequency := 500 - 3000Hz defined in 100 Hz intervals

Range := 100 Hz steps.

Starting Analogue Output Ports

To activate the analogue output channels on the VibWire-108

1. Starting at

2. Select “Menu In” button

3. Use the Up & Down Keys to select the option “Analg”

“Serial C0d C1d C2d C3d C4d C5d C6d C7d” are the other options available

Once the “Analg” output is selected the “Menu Out” key has to be pressed to confirm this option.

4. The VW-108 will return to the display

and now the analogue output channels for the instrument is now activated.

Each of the vibrating wire sensor inputs can be individually configured. Setting the analogue output channel is only needed

when using the instrument with an external data logger or analogue acquisition system and is not required when measurements

are to be made across and SDI-12/RS485/RS232 digital serial network.

Menu-out

Down

Up

Menu-in

0V

- Vin

+Vin

+2.5V

0V

- Vin

+Vin

+2.5V

0V

- Vin

+Vin

+2.5V

NDACS Logger

+

Sense

-

+

Therm

-

+

Sense

-

+

Therm

-

User Control Keys

Page 10

Figure 9

The example shown in Fig 9 shows the analogue

output from the VibWire-108 connected to the

NDACS logger unit. The NDACS logger

supports a full differential input and so the

connection to any other logger or acquisition

system will be the same.

Optimising the Analogue Output Settings

Example 1

The VibWire-108 contains 8 independently configurable analogue output ports and they are used to represent the output signal

from the sensor.

Each analogue output is of the range 0 - 2.5V DC and any analogue output must scale a result to within this range

Care should be taken to ensure that the output signal is scaled as close as possible to sensor range

For example, Channel 0 is used to output a signal from a sensor with operating range of 1452 - 3176 Hz

It is not possible to set the output range of the DAC directly to represent the absolute range of the sensor and so it must be set

to cover the sensor range with the minimum overlap in order to obtain the highest resolution.

a range of

0V = 1400 Hz & 2.5V = 3200 Hz so CH0 LF = 1400 and CH0 RA = 3200 - 1400 = 1800 Hz

will give the highest resolution for this example

DAC Resolution output port = 16 Bit so Frequency Resolution = 1800 / 65536 = 0.03 Hz

in practice accuracy of around 0.5 Hz can be achieved when connecting the VW-108 to an analogue data acquisition system

after allowing for the losses due to the Digital-analogue and Analogue-digital conversion process. The 0.5 Hz measurement

accuracy is achieved using the NDACS loggers.

Only when operating the VibWire-108 with an active analogue output port need the operating characteristics for the vibrating

wire sensor be defined.

For general purpose operations the analogue output should be set to represent the full operating range of the sensor.

Integration to NDACS 6000 Logger

Example 2

A vibrating wire pressure sensor with operating frequency 400 Hz to 1000 Hz connected to channel 5 on the VW-108

and the analogue output is to be connected to an NDACS 6000 logger unit.

CH5 LF = 400 CH5 RA = 600 ( where range = 1000 - 400) and CH(0-7).RA is the range parameter.

the NDACS input channel range is to be set to 2.5 V

therefore 0V = 400 Hz and 2.5V = 1000 Hz

The NDACS will use the ‘Scaled Current’ process option A = 1 B = 0 C = 2.5 D = 400 E = 1000

The data logger will scale the results over the full range Resolution = 600/65536 = 0.01 Hz

I

n practice an measurement accuracy of 0.05 Hz will be achieved after allowing for losses in the analogue conversion process.

Page 11

Real-time Frequency Display

All of the VibWire-108 models contain a 5 digit 7 segment display and this can be used to display the instantaneous frequency from any

of the vibrating wire sensor inputs.

Sensors can be deployed a considerable distance from the sensor interface and may well be have been embedded into a structure. To

ensure that the sensors are operating correctly simply observe the sensor operating frequency and then confirm the result is within the

operating range as specified by the manufacturer.

When operating in a real-time mode the instrument frequency display responds instantly to effects upon the sensor.

To use the VibWire-108 as a real-time frequency display follow the instructions below:

Assigning Real-time Frequency Display

To activate the real-time frequency display

1. Starting at

The “Basic” menu item is the first menu item available after the instrument is powered on.

2. Select “Menu In” button

3. Use the Up & Down Keys to select the option

The Display above shows the option required to place Channel 0 for real-time frequency output

the other options available are:

“Analg Seral C0d C1d C2d C3d C4d C5d C6d C7d” C0d = Channel 0 ........ C7d = Channel 7

Once the “C0d” option is selected then the “Menu Out” key has to be pressed to confirm this option.

4. The VW-108 will now display the real-time sensor frequency for channel 0.

The above example shows a typical real-time frequency result .

Sensor problems

Should a clean ping not be heard when the vibrating wire strain

gauge is being sampled by the instrument the following guide

should help.

1) If there is only random noise on the speaker for the defined

channel then check the wiring and circuit resistance. The most

common error is an open circuit. Locate and fix the broken

cable.

2) If a ping can be heard but it is faint then the sensor cable may be

too long, or a to high cable resistance is being used causing

degradation of the signal amplitude. Finally the gauge

sensitivity may be to low.

3) If the ping is not a pure tone then the gauge is possibly faulty.

The gauge may have become damaged during installation.

4) If a low frequency hum is heard then noise pick can be a

problem. If the gauge cabling is routed near a transformer,

electric motor, high current power cables, etc, then relocate or

reorient the gauge for minimum pickup. Ensure that only

shielded cable is used and that the shielding is terminated at a

single point to prevent capacitive pickup.

Loud Speaker

Page 12

All of the VW-108 range of instruments are supplied with an

internal ceramic speaker. The speaker can be activated and the

sensor ping and resultant echo can be heard.

The speaker used in collaboration of the frequency display should

enable nearly all sensors to be tested no matter their location using

only the VW-108 interface unit.

Figure 10

Loud Speaker

On/Off Switch

Frequency

Display

Speaker

Vibrating Wire Sensor Installation

The vibrating wire sensors are connected directly into the Sensor Input channels on the VibWire-108 and supports full 4 wire gauge

sensors. The instrument contains a completion resistor for the thermistor sensor enabling the temperature reading to be made along with

the vibrating wire sensor readings.

Connection to the instrument is as follows:

Earth

Earth

Earth

Earth

Amoured Cable

Sheath

+

Sense

-

+

Therm

-

+

Sense

-

+

Therm

-

Analogue Outputs

Sensor Inputs

Common Earth/Gnd Points

In order to ensure that there are sufficient points to terminate sensor

sheathing when amoured cable is used to connect a sensor to the

VibWire-108 the following terminal points are internally wired in

common:

Earth

Earth

Earth

Earth

Gnd

On the power supply connection terminals

Therm Sense -

on both the sensor input and analogue output terminals.

Fig 14 shows how the channels are wired together to form common

earth connection. Effectively all of the Earth, Gnd, S

ense

- and T

herm

- terminals are wired together.

Any earth Sheathing from armoured cable etc.. can be connected to

any of terminals mentioned above for ease of installation.

Lightening Protection

The lightening protection within the VibWire-108 cannot protect

the instrument from a direct lightening strike. It is used to protect

the instrument from local ground strikes close to the sensors and

cabling.

All of the sensor inputs are protected by transorb and gas discharge

tubes. The transorb are high capacitance devices and are not used

on all systems as they can distort low level signals to a point where

the instrument can not be accurately measured. The transorb does

protect the instrument at lower levels than the gas discharge tube,

and starts to become active around 12V.

The gas discharge tube protection activates at around 92V DC and

resets instantaneously after

Fig 14 shows the VibWire-108 connected to a system earth using

the Earth terminators mounted adjacent to the power connectors.

+

Sense

-

+

Therm

-

VW-108

Thermistor

Multiple Instrument Installation

Figure 16 shows how to Earth multiple instruments within a single

enclosure. Ensure that good quality cable of around 2.5 mm

diameter core is used to connect the instruments earths together and

that a good connection to a main system earth is obtained. The

Earth connection is essential for the lightening protection to work.

Figure 11

Figure 12

Figure 13

Figure 16

PCB Jumper Settings

All of the VibWire-108 models support

thermistor, analogue input for the range

0 - 2.5 V DC and current loop inputs.

For current loop operations such as

those 0- 20 mA, 4- 20 mA then external

excitation is required.

Jumper Open = 0-2.5V DC

4-20 mA loop

Jumper Closed = Thermistor

PCB Jumpers

Figure 15

Figure 14

Menu-out

Down

Up

Menu-in

Earth

Earth

Earth

Earth

Earth

Earth

Local Cable Free Systems

The VibWire-108 uses the Gateway communications interface and a ZigBee modem to create a mesh network solution. Single

instruments as as multiple devices can be combined to create a fully integrated solution. Data from the VibWire-108 or in fact any other

instruments on the SDI-12 network is stored within the Gateway prior to transmission across the network. When using the Gateway

nearly any 3rd part radio modem can be used.

Fig 17 - VibWire-108 with Zigby interface

Local Operation - Under 500 m to Gateway

The VibWire-108 mounted in a plastic or GRPS IP65 enclosure as

shown in Figure 17A with the antenna mounted in effective line of

site to the data logger or Keynes Gateway systems will operate to

a range of approximately 500m. Depending upon conditions at the

deployment site it is possible to get greater distances than 500 m so

long as there is little interference or no obstructions to the signal

path.

Mesh Network Operations

The mesh network operation is a feature of the ZigBee modem and

is not part of the Keynes Software. Simply installing a ZigBee

modem to the Gateway will give a system the full benefits of this

type of network operation.

Cable Free & Mesh Network Solutions

The VibWire-10 can be group together with other instruments or

used singularly onto a mesh network or any other type of local

cable free network using the Keynes Gateway Data Logger.

The Gateway is configured to record data from the VibWire-108

and then can be set to broadcast the results continually at a set time

to save power.

Mesh - ZigBee Network Configuration

For mesh network operations the only configuration parameters

that needs to be set for VibWire-108 are:

1. Number of channels to Scan / Instrument (see Page 17)

2. Instrument Identifier number (See Page 17)

The VibWire-108 needs about 500 mS to boot before a Scan

command will be activated.

Once all the instruments are connected on the SDI-12 network to

the Gateway and the unique ID numbers are set then scanning

operations can take place.

Allow

Power Up = 500 ms (Gateway Config Parameter)

For the VibWire-108 to settle after being initialised before starting

a scan. The Gateway stores all the acquired data and is configured

to broadcast the results across the mesh network.

The ZigBee network operations are a feature of the modem only

and not part of any Gateway itself. The Gateway only passes data

to the ZigBee modem. The ZigBee modem controls the mesh

network operations transparently.

Example. Two VibWire-108 instruments are connected to a

single Gateway interface to create a 16 channel sensor system to

transmit data on to a ZigBee mesh network. The scan rate to 1

reading each minute.

VibWire-108 Configuration

1. Set the Number of channels to Scan to 8 for both instruments.

2. Set ID = 0 for instrument 1

ID = 1 for instrument 2

SDI-12 Setup - Data Acquisition Rate

The acquisition rate is controlled by the interval used to send the

start measurement commands to the instruments on a network.

Using SDI-12 Setup menu option within the Gateway

Sample Interval (seconds) : = 60 (1min) or 3600 (1Hr)

The Gateway issues the !m command and waits for the ViBWire108 to respond. Once the data is ready it is stored into the data table

of the Gateway prior to transmission across the network.

Full details are within the Gateway Manual

14

Figure 17 above shows the VibWire-108 as a single instrument

solution in collaboration with Gateway Interface.

Fig 17A Complete 8 channel vibrating wire sensor system

VibWire-108

Gateway

GPRS Modem

SDI-12 connection

1 m

1.5 m

For the best results the directional antenna

should be located away from any nearby

objects and greater than 1.5 m above the ground

1 m

800 m - 1 km line of sight ra nge

3 - 8 dB gain

omni-directio nal

antenna

1.5 m

1 - 2.5 km r ange

depending antenna gain and keepin g

antenna in lin e of sight o f each other .

7 - 27 db G ain

directional

antenna

Antenna Type

Dish

Frequency

2400 - 2500 MHz

Gain

9 dBi

20 dBi

25 dBi

Polarisation

Vertical

Beamwidth

(Azimuth / Elevation) 60° / 60°

Antenna type

YAGI

Frequency

2400 - 2500 MHz

Gain

13 dBi

Polarisation

Linear

Beamwidth

(Azimuth / Elevation) 44° / 48°

Product code

OMNI-A0050

Frequency

2400 - 2500 MHz

Gain

8 dBi

Polarisation

Vertical

Beamwidth

(Azimuth / Elevation) 360° / 16°

Antenna Type

Panel Antenna

Frequency

2400 - 2500 MHz

Gain

14 dBi

Polarisation

Linear (Vertical or Horizontal)

Beam width

(Azimuth / Elevation) 43° / 43°

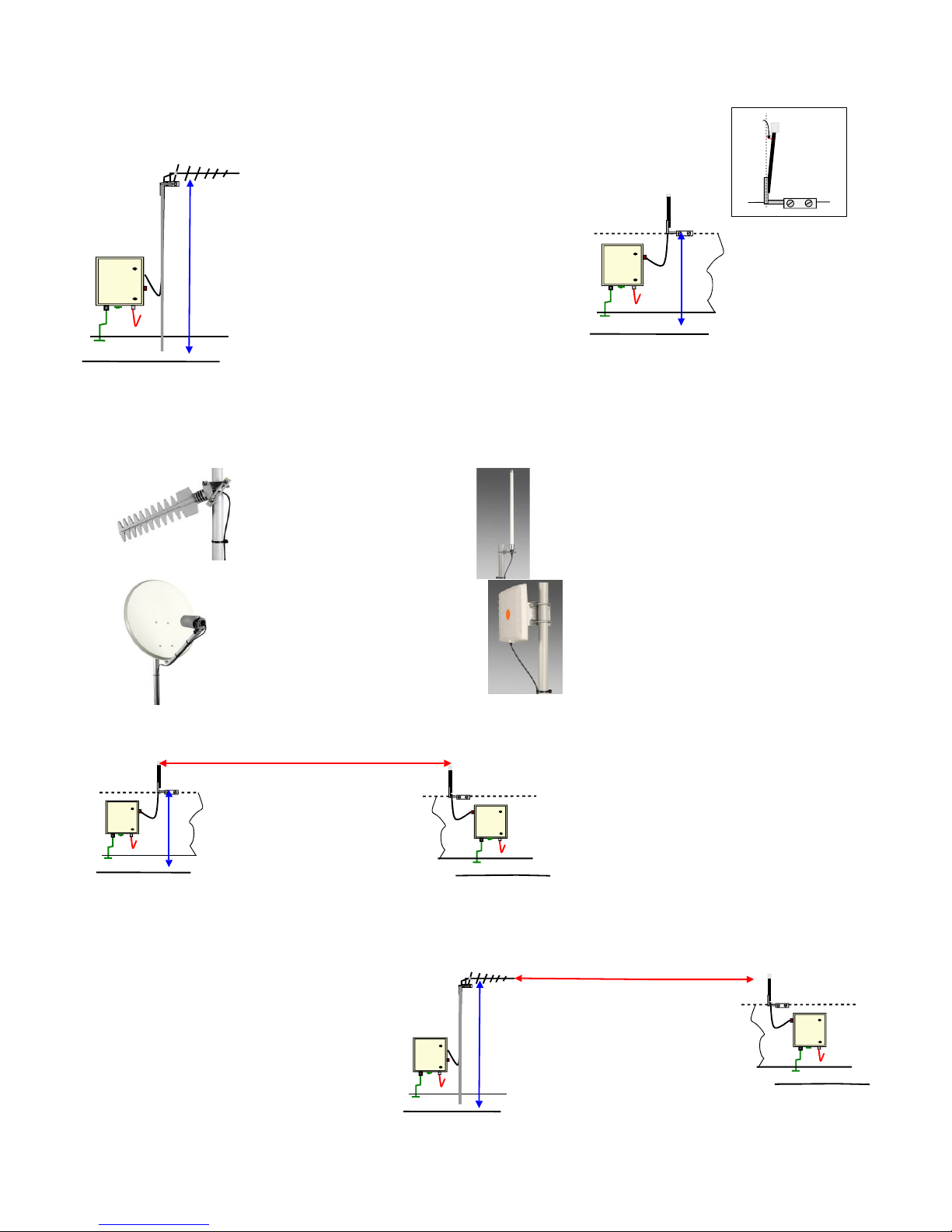

Typical Antenna Solutions for 2.4 GHz Applications

3 Deg

Antenna Installation

In order to achieve the optimum range or the highest signal strength

for the chosen antenna systems then care has to be taken with the

choice and deployment

Basic System Installation

Omni-directional antenna - external mounting

For instruments that are deployed fairly close

together and in clear line of sight of each other

then omni-directional antenna systems will be

ideal for data transmission. Omni-directional

antenna systems are the simplest install and

maintain.

For optimum range mount the antenna clear of

any object and about 1 m above the ground. Any

change in this deployment will degrade the

range and this degradation will depend upon the

environmental conditions prevailing at the site.

Directional antenna Systems - external mounting

Directional antenna offer increased range for the

same transmitted power by restricting the

transmitted signal to a specified direction. In order

to get the best results it is important to keep the

antenna clear of any local metallic objects above

the ground. Deploy the antenna about 1.5 m above

the ground and make sure any mast system being

used is firmly installed.

Ensure that the directional antenna is pointing

absolutely at the data logging system antenna and

that the polarisation between remote systems is the

same ie. Vertical-to-Vertical or Horizontal-toHorizontal polarisation.

Figure 18

Figure 19

Figure 20

Figure 21

Circular polarised antenna systems are the only type that should be

use when systems with mixed polarisation antenna are to be used

together.

For optimum range tilt the standard omnidirectional antenna 3 deg from the

vertical in the directional of the receive

unit

Keep the antenna 1m above the ground

and free from any close objects.

Antenna systems available from

Round Solutions GmbH & Co KG Im Steingrund 3, D-63303 Dreieich, Germany

Tel: +49 (0) 6103 960510 Fax: +49 (0) 6103 960509

www.roundsolutions.com

Node

1

Node

2

Node

3

Node

4

Node

6

Node

5

Data Recording

Outstatio

n

550 m

6

5

0

m

6

5

0

m

7

0

0

m

550 m

Node 1

Node 2

Node 3

Node 4

Node 6

Node 5

Data Record ing

Outstation

550 m

6

5

0

m

550 m

16

Internally Mounted antenna within IP65 enclosure

0 m - 300 m line of sight range

3 - 5 dB gain

omni-directional antenna

GRP or Plastic

IP65 enclosure only

Earth Termination

The VibWire-108 supports direct

connection of a number of the smaller

omni-directional antennas

These antennas can be fitted within

the IP65 enclosure but it is essential

that this enclosure must be GRP or

plastic in order to minimise any

signal attenuation.

The range is reduced compared to

externally mounted antenna but

installation is considerably reduced.

Earth

Termination

0 - 15 m line of sight range

GRP or Plastic

IP65 enclosure only

Internal Embedded Chip Antenna

For systems deployed within a 15m line of sight or when local

expansion of a instrument box is required then a VibWire-108

system with local cable free interface should be used.

A number of cable free instruments can be mounted within a

single enclosure and configured to operate as a mesh network.

An additional instrument is easy to add as all that is required is

to power the unit and connect in the sensors.

Chip antenna systems only operate over very small distances

but have the advantage that the antenna fits on the instrument

PCB see Fig 23A.

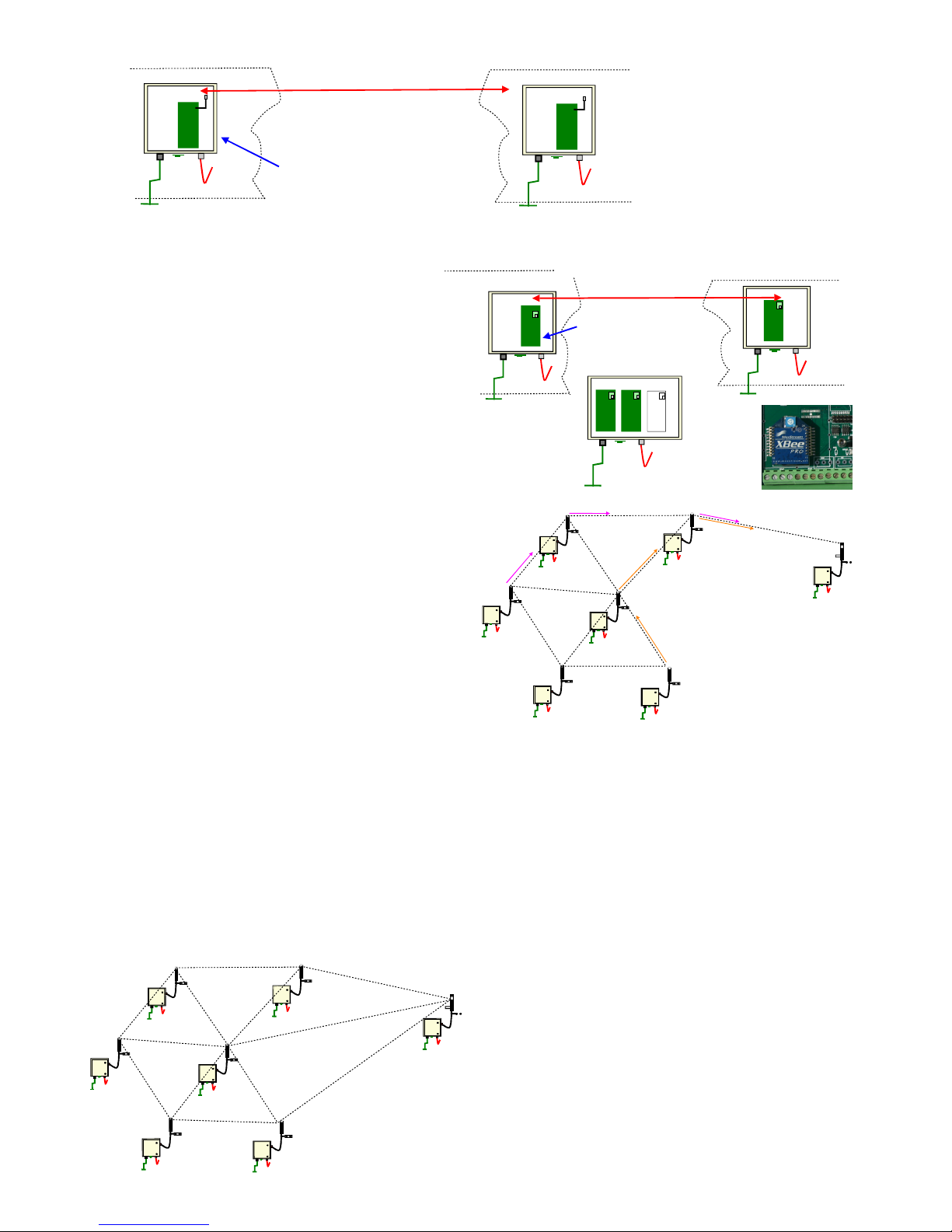

Mesh Networks

(available last quarter 2006)

Networking

Spread Spectrum Type: DSSS (Direct Sequence Spread Spectrum)

Networking Topology: Peer-to-peer, point-to-point & point-to-

multipoint

Error Handling: Retries & acknowledgements

Filtration Options: PAN ID, channel and addresses

Channel Capacity: XBee: 16 Channels

Addressing: 65,000 network addresses available for each

channel

Encryption: 128-bit AES (coming soon)

General

Frequency Band: 2.4000 - 2.4835 GHz

Data 250,000 bps

Industrial (-40 – 85° C) temperature rating

U.FL RF Connector, Chip or Integrated

Whip antenna options

Fig 23A

Network Operations

The transceiver unit embedded within the VibWire-108 can used

for direct point-to-point communications as well as forming a node

within a mesh network.

For Point-to-Point communications each instrument talks directly

to the data recording outstation. A mesh network routes the data

from one instrument to the next until it reaches the data recorder.

The Keynes Controls Gateway products are fully integrated to the

VibWire-108 and can be used as a cable free data recorder, an

interface between the mesh network, GPRS mobile phone and local

area networks.

The mesh networks operate by routing data between one node and

the next until it reaches the desired location. The mesh network can

also correct for data path loss so long as another route can be found.

Fig 24 shows a simple mesh network with multiple nodes. Upon

occasion when the direct link between Node-1, Node-6 and the

Data Recording Outstation fail then data can be routed

automatically via Node-5. This operation ensures that data

communication remains very reliable even different sections of the

network are blocked. Fig 25 shows the mesh network operational

with new data route.

Fig 24

Fig 25

Figure 22

Figure 23

Basic

Disp

PEROD

ID

Tra

Tra.int

CH0.LF

CH0.RA

CH1.LF

Menu-up & Down

Analg

Activate analogue outputs

SDi12l

Activate SDI-12 or 485 ports for data

C0d

Channel 0 Real-time results display

C1d

Channel 1 Real-time results display

C2d

Channel 2 Real-time results display

C3d

Channel 3 Real-time results display

C4d

Channel 4 Real-time results display

C5d

Channel 5 Real-time results display

C6d

Channel 6 Real-time results display

C7d

Channel 7 Real-time results display

Per

Freq

Pst

1S

5S

15S

1MIN

1HR

6HR

24HR

ID Range

0..255

1S 0T

2S 0T

4S 0T

8S 0T

1S 1T

2S 2T

4S 4T

8S 8T

5 S

60 S

360 S

500

600

700

800

900

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

100

200

300

400

500

600

700

800

900

1000

5000

Menu-in & Out

Per = Period Freq = Frequency in Hz Pst = Percentage of range

Sensor activation period

Instrument identifier = 0 - 255

Select number and type of sensor output for data

transmission when operating in cable free mode

Updated rate for transmitted data

Analogue output scaling only

Low frequency

Vibrating wire sensor

Frequency range

DISP := This option is used to select the type of engineering

results that are shown on the 7 segment display.

Per = 1/ Freq = period of oscillation in milli Sec

Freq = XXXX.X in Hz

Pst = Percentage of range

the percentage of range is used to optimise the settings

for the analogue output port in order to achieve the best

result

Example. A vibrating wire sensor showing a PSt = 0.1 on the

display and settings of LF (Low frequency) of 500 Hz and range

of 2000 Hz. This indicates that the results from the sensor is only

operating over the lower 10% of the defined range i.e 500 - 700 Hz

For the assigned range above the analogue output port has a scaling

of 0 - 2.5V DC using a 16 bit DAC (65536 levels) and will therefore

have 0V = 500 Hz & 2.5V = 2500 Hz, so

resolution = (2500-500)/65536 = 0.03 Hz.

However with the instrument adjusted to operate over the range of

500 to 700 Hz as observed above then

0V = 500 Hz & 2.5V = 700 Hz so resolution = 200/65536

= 0.003 Hz

PEROD := Sensor Excitation Period

This option defines the update period for the sensor excitation and

measurement operation. There is always a trade off between the

sensor update rate and the power supply requirements of the

instruments.

For fast dynamic changes a fast sensor update rate is required but

for slow static measurements only a low update rate is required.

User Command Summary

PEROD := Sensor Activation Period

Defines the sensor scan period for the instrument.

When fitted the analogue output channels are updated after

each scan.

1S, 5S, 15S, 1min, 1Hr, 6Hr, 24Hr.

ID := System identifier number

Each instrument requires a unique identification number

that is required to locate a specific instrument upon a

network. Currently the identifier is an integer of range 0 ..

255 offering a maximum

TRa := Transmission Data Options. (Not used RS485/SDI-12)

To optimise the network bandwidth in order to ensure the

maxium number of sensors can be deployed the User is

allowed to select the number and type of sensor inputs used

on the VibWire-108 for data transmission across a network.

1S 0T represents 1 vibrating wire sensors - no temperature

2S 0T represents 2 vibrating wire sensors - no temperature

1S 1T represents 1 vibrating wire sensor - 1 temp sensor

2S 2T represents 2 vibrating wire senors - 2 temp sensors

Tra.int := Defines the rate of data transmission across a cable free

network.

The transceiver fitted inside the VibWire-108 is

powered on during the data transmission operation and

powered off into a sleep mode between updates.

The faster the data transmission rate the greater the

power required to drive the instrument. A compromise

is needed to adjust power requirements to the amount

of data to be transmitted to guarantee that not readings

are lost.

(Not used on RS485/SDI-12 networks)

5S, 60S, 360S

(Operations of Version 1.06 instruments only)

17

Network Transmission Costs

There are no unexpected costs associated with operating the VibWire-108on a network as the Gateway supports both Pay-As-You-Go and contract

SIMMS within the modem for most major network suppliers.

Data transmission per scan is as low a 5K so it is easy to obtain the best

price plan on Pay-As-You-Go operations and the correct contract SIMM

agreement to minimise contract costs. What ever option is taken the User

determines how much data is transmitted.

Data Management

Each of the instruments is identified by an assigned name and its

information stored into a database. Once the data is being recorded it can

accessed and processed to produce reports, plots and trends and even

shown on a web page within a 3GL mobile phone.

User Display & Speaker Unit

During installation a User can observe the sensor frequency directly within

the on-board display. For sensors deployed a long way from the

instrument, embedded into a structure or down holes then a useful feature

to determine if the vibrating wire sensors are operating correctly is simply

to listen to the returned sensor signal. Should the signal be a tone then the

sensor is functioning. However should this signal be very distorted then it

shows clear signs that the sensor has malfunctioned. Both a frequency

display and embedded speaker are standard parts of this instrument.

Process Measurement Solutions

18

Group of instruments on local network connected to a mesh network

VibWire-108

NP-ANG-108

VibWire-108

SLAVE - 2 SLAVE - 10SLAVE - 1

SDI-12 network

GPRS modem

Telit GT-863-PY Modems

Telit GM862/3/4 modules

Part No.

NP-GT-863-PY

Power Supply Management

The Gateway not only controls the communications across the

SDI-12 network but also controls power management for the

modem or radio interface. The Gateway powers off third party

systems such as the GPRS modem when not in use to save power.

Single & Multiple Instrument Operations

The VibWire-108 uses the Keynes Gateway to communicate across

the GPRS network. The VibWire-108 communicates data to the

Gateway across a local SDI-12 bus.

Single instrument operations the VibWire-108 ID = 0

For multiple instrument operations each VibWire-108 must have a

unique ID number defined. Failure to define a unique ID number

will result in corrupt or unreliable data.

GPRS Operations

The VibWire-108 connects to the GPRS network vai the use of the

Keynes Gateway interface or any other data logger that supports

modem operations.

The Gateway acts as a control interface for the VibWire-108. It

controls the acquisition of data and stores the results for

transmission. When a number of instruments are in use the data is

gathered into a single record in a table for transmission across the

network. Information can be sent straight away or buffered for later

upload.

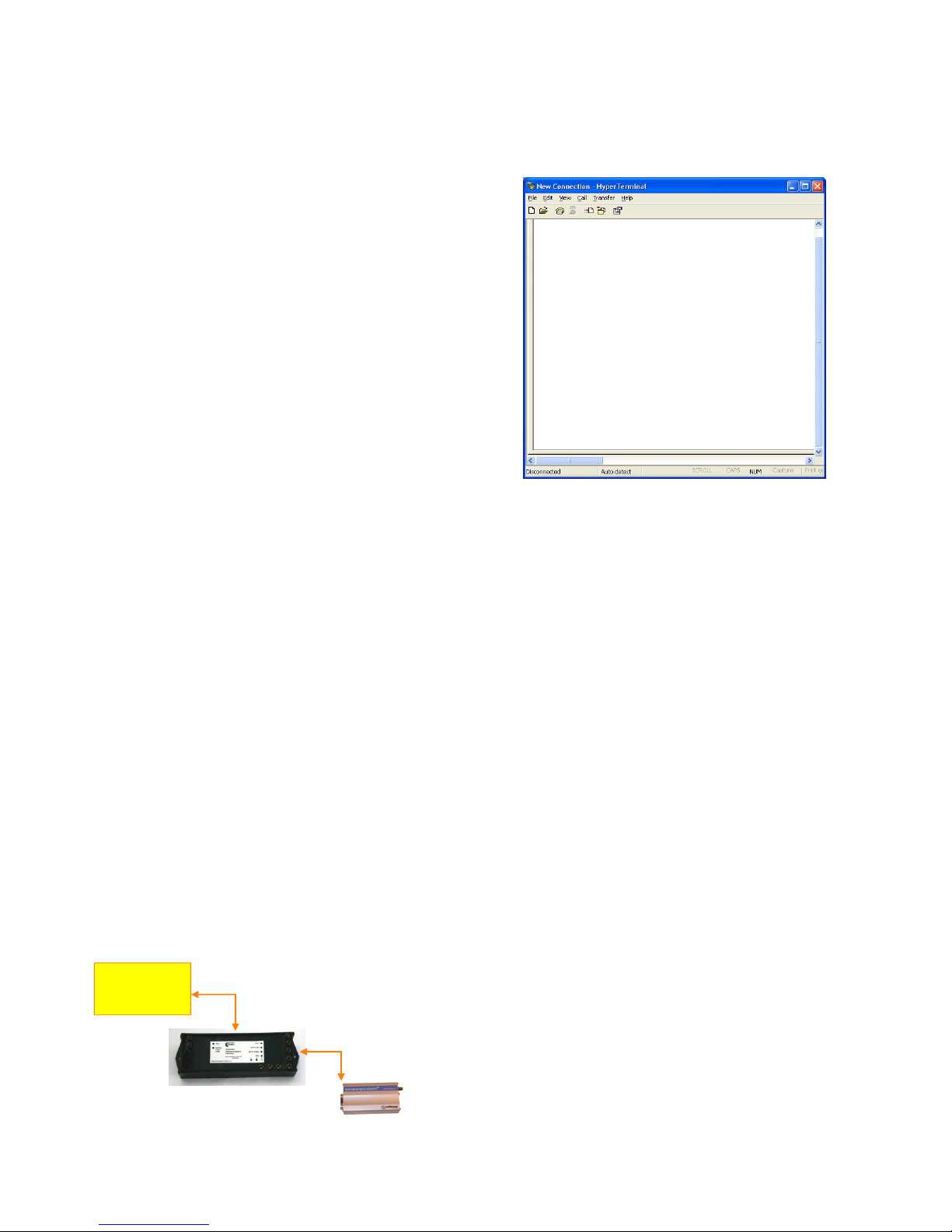

Terminal Port & Hyper-terminal Connection

The Gateway is configured using a terminal emulator program and

a serial port connection to a laptop or PC. The serial port on the

Gateway is configured by default to be:

9600 Baud

8 Data Bit

No Parity

1 stop bit

A 9 Pin RS232 cross over cable is required to connect the Gateway

to a laptop/PC serial port.

For full details see the Gateway manual.

See http://www.keynes-controls.com/2008/Downloads/GatewayManV101.pdf

The RS-232 port on the front of the instrument uses a standard 9

pin D connector modem cable to connect to a PC.

Modem Configuration For GPRS Network

The following parameters are all that need be assigned in order to send data

from the Gateway across the network and all set using the terminal port.

The VibWire-108 connects to a GPRS network as shown in Fig X above

APN (access point number)

Username

Network Password

IP Address (instrument gateway)

Instrument Tag name

Data Storage Operations

Data is stored within the Gateway prior to transmission across the

GPRS network and can be set to transfer data at a pre-set time or

immediately upon being acquired.

In the unfortunately condition that the GPRS network fails then

data is stored with in the Gateway until it can de accessed by the

User, or when the GPRS network becomes available when a new

download can take place.

Data Transmission Rate on GPRS Network

The interval for sending data cross the GPORS network is defined

within the Gateway by:

GPRS Menu

Default connection interval (hrs) = 1 ( 1 hr)

Global Solutions

For widely distributed systems with instruments deployed anywhere

within a GPRS network then only a Internet connection will be required to

gather information from the instruments no matter where they are located

and how they are deployed. Instruments can be deployed globally and all

the information easily brought back to a single location for storage and

processing.

Local Systems

The database software can be integrated to locally deployed instruments

and can be used as the data logger in many applications. It is best deployed

when there is a secure fixed site with adequate power is available on a

stand-alone dedicated computer system

The most practical method of integrating the database to the locally

deployed instrument systems is by reading transmitted data from across the

local networks and these can be any combination of SDI-12/RS485 serial

port networks, Ethernet and Cable free 2.4 GHz cable free mesh network.

GPRS/GSM Modem Specifications

•

Dual Band 900/1800 MHz GM862-GPRS

• Quad Band 850/900/1800/1900 MHz on

GM862-QUAD

• Output Power: Class 4 (2W) at GSM 900 MHz

• Class 1 (1W) at GSM 1800/1900 MHz

• Integrated SIM card reader

• ROSH compliant

• Operating temperature range -20 to +70 Deg C

• Automatic network identification

• Automatic connection

• Remote network data services

• 50 Ohm antenna termination

• Antenna connector - SMA/M

• Pay-as-you-go SIMM card data services

Figure 30 shows everything needed to get 8 channels of vibrating wire sensors onto

a GPRS or 2.4 GHz cable free network. The solar panel shown is a 6W cell and this

with the battery backup will give 1 reading per hour indefinitely. For short periods

the scan rate can be increased for faster sampling.

Flexible Data Scan Operations

The Gateway scans the VibWire-108 instruments

and transmits the data across the GPRS network at

a specified rate and goes into stand-by mode

between scans to save power.

Standby - Power Saving

The Gateway goers into standby mode in between

scans. The VibWire-108 and the modem are

powered off until needed.

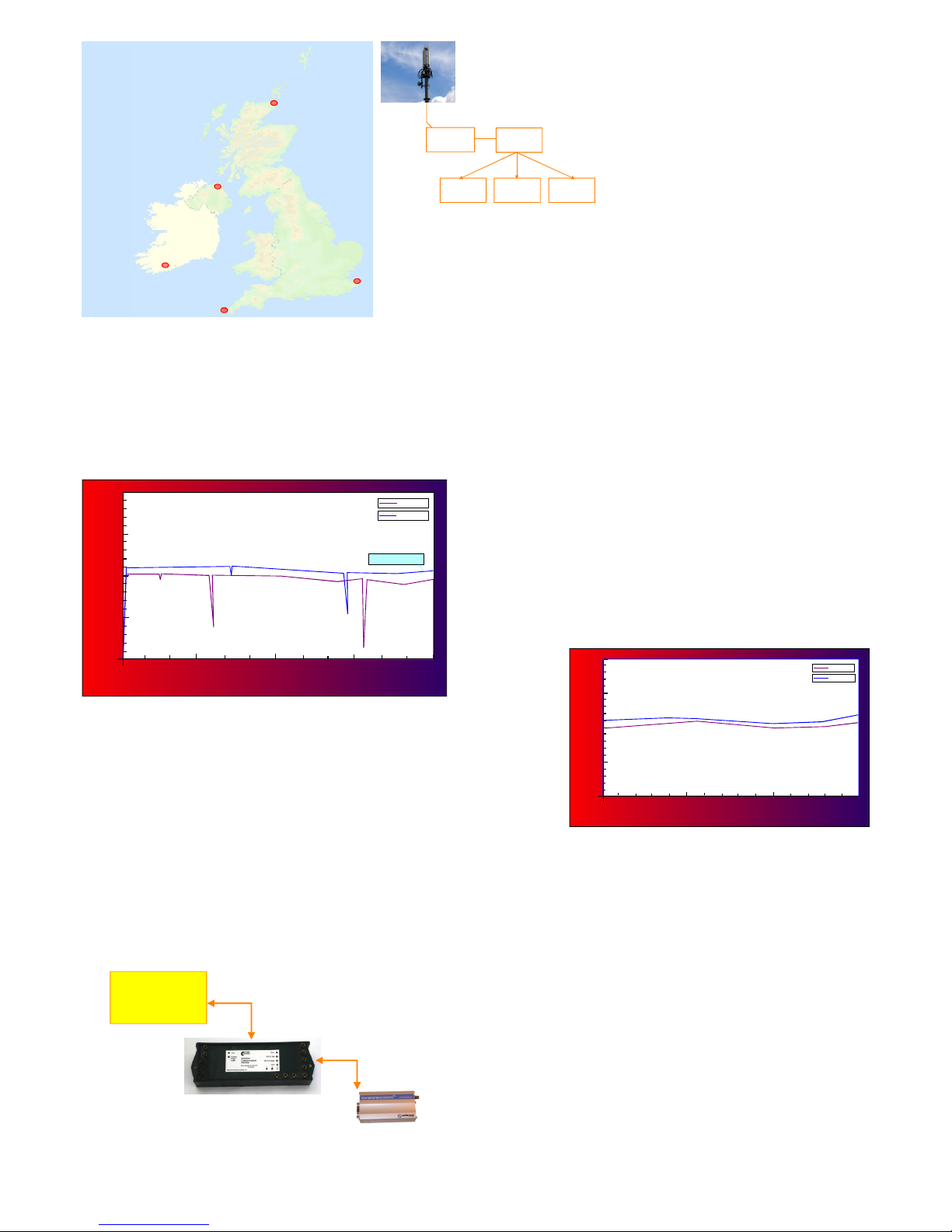

Machine

Gateway

SQL

Database

Generate

Reports

Archive

Results

Web Based

Reports

Mobile Phone

GPRS/GSM network

connection

06:00

12:00

18:00

23:59

GPRS Operations

The VibWire-108-GPRS enables true cable free

operations to be undertaken any where that a mobile

phone network exists and when used in collaboration

with the Keynes network database systems.

Information can be gathered and stored into a single

database for many instruments deployed upon the

GPRS network so long as suitable Internet connection

can be made. No longer does a databse have to be

located near to or directly connected to the instruments

making the measurements.

Database Operations

The Keynes Controls database application utilises the free issue MySQL

software and a series of Java applets to gather and format the instrument

data into a format suitable for archiving. A wide range of third party add

on software is available to support graphical interpretation of data within

the database. Keynes Controls can also supply a web server interface

enabling data to be displayed across the world wide web.

06:00

12:00

18:00

23:59

Sensor Frequency Hz

Updated at 10min Interval

Time (Hours)

0

500

1000

1500

2000

Sensor 1

Sensor 2

Sept 11th 2006

Data Integrity Operations

When acquiring data across local networks the Keynes Controls software

checks and automatically maintains the data integrity of any

measurements. Before data is archived it is verified to be correct and any

mistake in a value is recovered from the specified instrument before data

storage.

Data Summary Plots

Most types of data analysis can be undertaken when the information is

archived within the database. This analysis can be as simple as detecting

and reporting missed data, statistical analysis upon a range of

measurements and all results can be presented upon a range of summary

plots both in local Windows and on web pages.

Monthly Sum mary - Sensor Freque ncy Hz

Average Valu e - Sept 2006

Time (Days)

1

500

1000

1500

2000

Sensor 1

10 th

20 th

30 th

Sensor 2

Fig 28 - Daily Data Summary Plot

Fig 29 - Monthly Data Summary Plot

19

Figure 30

VibWire-108

Gateway

GPRS Modem

SDI-12 connection

Example GPRS Configuration Settings

The following examples show the AT commands needed to

connect to the 4 most popular GPRS networks in the UK. Other

networks will be configured very similar to the ones below.

Virgin: SMS 800 Texts

PAYG: GPRS CONFIGURATION

:

at+cgdcont=1,"IP","goto.virginmobile.uk","0.0.0.0",0,0

at#userid="user"

at#passw=""

at#sktset=0,4000,"82.152.20.37"

at#sktop

Vodafone: subscription only service

Data10 tarrif: 10MB + £2/MB there after

PAY-as-you-go tarrif

at+cgdcont=1,"IP","pp.vodafone.co.uk","0.0.0.0",0,0

at#userid="web"

at#passw="web"

at#sktset=0,4000,"82.152.20.37"

at#sktop

T-Mobile: depending on t-zone add-on

Zone dependent service

at+cgdcont=1,"IP","general.t-mobile.uk","0.0.0.0",0,0

at#userid="user"

at#passw="wap"

at#sktset=0,4000,"82.152.20.37"

at#sktop

Orange:

Mobile office Pay-As-You-Go Service

Normal PAYG You may need to add access to data :

at+cgdcont=1,"IP","orangeinternet","0.0.0.0",0,0

at#userid=""

at#passw=""

at#sktset=0,4000,"82.152.20.37"

at#sktop

Terminal Port & Hyper-terminal Connection

The VibWire-108 is connected to a Keynes Gateway unit that acts

as a data buffer for the sensor data as well as the control interface

for the modem.

20

VibWire-108 with GSM /GPRS Modem

VibWire-108

Gateway

GPRS Modem

SDI-12 connection

at+cgdcont=1,"IP","orangeinternet","0.0.0.

0",0,0

at#userid=""

at#passw=""

at#sktset=0,4000,"82.152.20.37"

at#sktop

Example above shows instructions required to operate instrument

on the Orange GPRS network and has been included to the

operation of the terminal program.

Figure 32

1

9

RS232 to USB

Converter

U

S

B

C

a

b

l

e

9 Pin Male

Connector

9 Pin Female

Connector

Terminal Port

Pin-out of terminal port

USB port

on PC

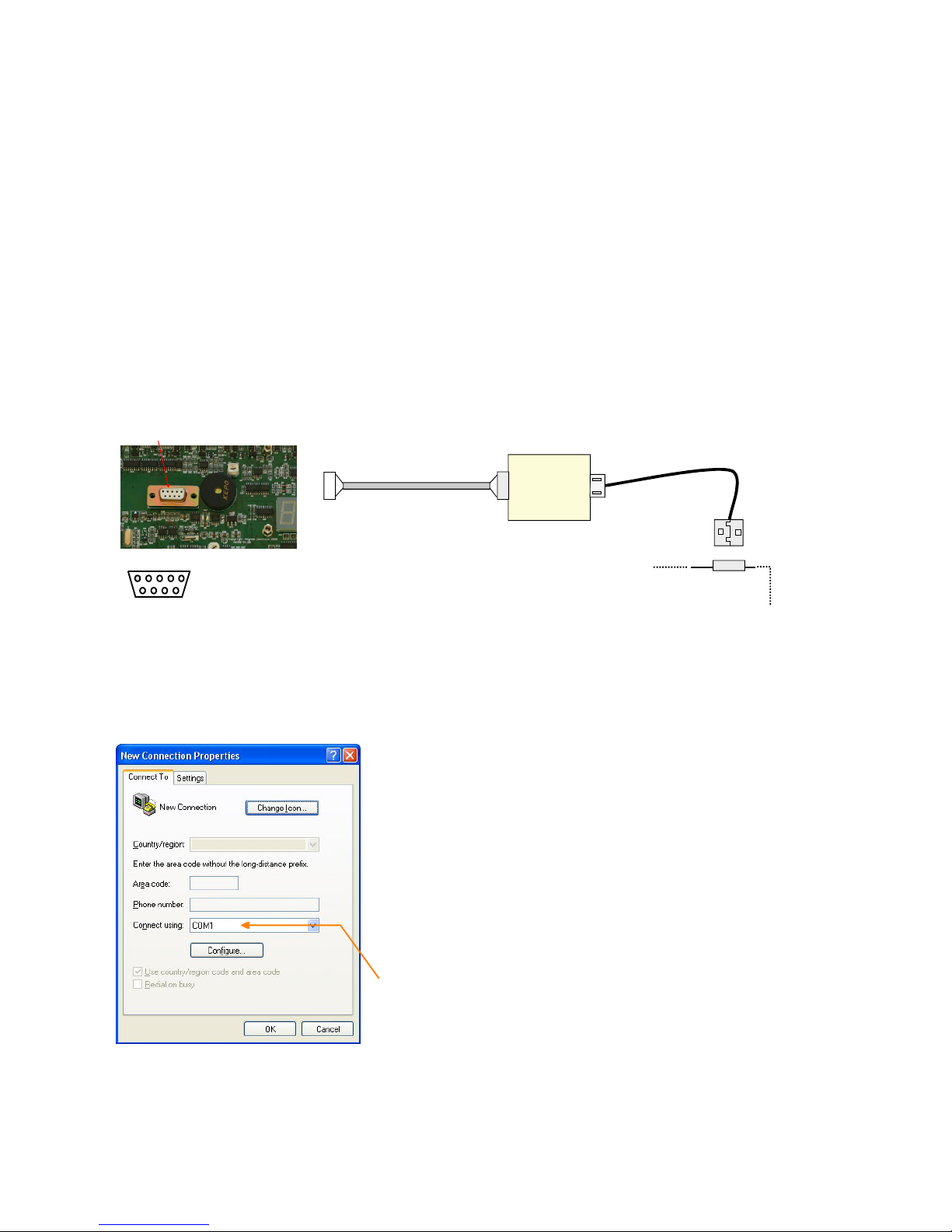

Serial Port to USB Communication

Using a serial port to USB converter it is possible to communicate

to the VibWire-108 using a standard USB port on on laptop or PDA

in order to configure the terminal or download information.

Any terminal program can be used but a common application

program is the Microsoft Hyper-terminal and this is used in the

example below.

Serial Port Interface Cable

A standard 9 pin serial port cable terminated with male and female

D-connectors is all that is required to communicate to the

instrument.

Port Control Options

Set any serial port configuration to RS232 mode - only Rx / Tx

lines are used.

Active Port

Active Comms Port.

Once the USB interface is installed into the PC the driver software

within a Windows based operating system identifies the active port

name.

Take care to select the serial port identifier when using the terminal

program to talk to the instrument.

Failure to assign the correct serial port within the terminal program

will prevent communication to the instrument.

The terminal configuration window below shows Hyper-terminal

set to operate under serial port Com-1.

21

Figure 31

Figure 42

1

9

RS232 to

Ethernet

Converter

9 Pin Male

Connector

9 Pin Female

Connector

Terminal Port

Pin-out of terminal port

Ethernet port

on PC

Ethernet Cross Over Cable

Serial Port to Ethernet Communication

Using a serial port to Ethernet converter it is possible to communicate to

the VibWire-108 using a standard Ethernet port on a laptop or PDA in

order to configure the terminal or download information.

Any terminal program can be used but a common application program is

the Microsoft Hyper-terminal and this is used in the example below.

Serial Port Interface Cable

A standard 9 pin serial port cable terminated with male and female Dconnectors is all that is required to communicate to the instrument.

There are many different manufactures of Serial port to Ethernet

converters that can be used with the VibWire-108. Keynes Controls do not

restrict the operations of the instruments to any particular model.

Some interesting sites for converter modules are:

http://www.perle.co.uk/products/Serial-to-Ethernet.shtml

http://www.hw-group.com/products/converter/index_en.html

Port Control Options

Set any serial port configuration to RS232 mode - only Rx / Tx

lines are used.

Communications

In order to communicate with a laptop or other computer system take care

to ensure the network settings for the converter module are compatible to

the host PC or network onto which it will be attached.

Typical Network Layout

2

0

m

100 m

Ethernet Hub/Switch

RS-232 to

Serial

Converter

22

Figure 33

Figure 44

Description

Frequency Display

6 Segment LED display - resolution 0.1 Hz

Vibrating Wire Inputs

8 multiplexed inputs

Analogue Output

16 bit 0 - 2V DC - scaled to frequency

Scan Time

2 - 30 Secs scan option s2,4,8 chan-

Line Resistance

Upto 2 K ohms

Analogue Inputs

8 inputs 0- 2.5V DC

or 300 - 5 K Ohm RTD

Lightning Protection

Gas Discharge Tube - option Transorb

Vibrating Wire Frequency

400 - 6 K Hz auto resonance

Operating Voltage

9 - 24V DC

Sensor Input

Full Differential

Power Supply

Scanning mode

70 mA Duration 30 secs

Display mode

90 mA Continuous

SDI-12 mode

20 mA Continuous while waiting for commands

RS4-85 mode

20 mA Continuous while waiting for commands

Analogue output mode

25 mA Continuous

Technical specifications are may change without notification and the power options mentioned above are approximate.

Technical Specifications

GEOSENSE Vibrating Wire piezometers and transducers use the well-proven method of

converting fluid pressures on a sensitive diaphragm into a frequency signal.

Frequency signals i.e. those generated using vibrating wire sensors are particularly suitable

for demanding environments such as that often occur within Civil Engineering applications

Vibrating wire sensors ideally suit the harsh civil engineering environment since the signals

are capable of long transmission distances without degradation, tolerant of wet wiring

conditions and resistant to external electrical noise.

Specifications

Excitation:

Pluck or swept frequency

Voltage Protection:

Semitron BiPolar 230 V

Thermistor:

3k Ohms at 25 oC

Over-range:

minimum twice pressure

Resolution:

0.025% FSO (minimum)

Accuracy:

< 0.25 % FSO (see Notes)

Thermal Effect:

< 0.02% FSO /oC

Operating range:

-20 oC +100 oC

Cable:

2 pair PVC outer sheath.

Typical range:

3500-2200 Hz

Nominal zero value:

3130 Hz

For additional details contact

Geotechnical Centre . Rougham Industrial Estate . Rougham . Bury St Edmunds . Suffolk . IP30 9ND . England

Tel: +44 (0) 1359 271167 . Fax: +44 (0) 1359 271168 . email: info@mgsgeosense.co.uk. www.mgsgeosense.co.uk

Vibrating Wire Sensors

The VibWire-108 supports most manufacturers sensors and a small summary of these is shown below.

Crack meter

Crack meters are available with ranges up to 100 mm

Resolution

0.025% of range

Accuracy

± 0.2% of range

Temperature effect

–0.02mm/°C (typical)

Operating temperature

–30 to +70°C

Cable: 2 and 4 Core screened

Joint meters are available with ranges up to 100 mm

Resolution:

0.025% of range

Accuracy:

± 0.2% of range

Temperature effect:

–0.02mm/°C (typical)

Operating temperature:

–30 to +70°C

Cable:

2 Core screened

Gauge Type:

TSR/5.5/T surface mounting strain gauge.

Gauge factor:

3.025 x 10-3 micro-strain per Hz squared.

Measurement range:

> 3000 micro-strain.

Resolution:

Generally better than 1 micro-strain.

Coil Resistance:

Approximately 100 ohms.

Operating temp range:

-200C to 800C.

Thermal coefficient:

11 ppm per 0C.

Effective Gauge length:

50 mm ( nominal )

De-bonded length:

175 mm

Overall length:

1.39 m

Standard diameter :

15 mm

Resolution :

0.5 micro-strain

Strain range:

2500 micro-strain

Thermal expansion:

12 ppm /deg C

Range:

3,000 micro-strain, set mid-range.

Resolution:

1 micro-strain

Accuracy:

± 0.1% FS.

Thermal Coefficient:

11 ppm / °C.

Operating Temp:

-20 °C to 80 °C.

The details on this page have been obtained from the sensor manufacturers web

sites and are liable for change at any time.

Surface strain gauge

Joint meters

Rebar Strain meter

Embedment Strain Gauge

For additional details see

BELL LANE, UCKFIELD, EAST SUSSEX, TN22 1QL, ENGLAND

Website www.soil.co.uk Tel: 01825 761740

Gage Technique International

PO Box 30

Trowbridge, Wiltshire

BA14 8YD, England

Tel: +44(0)1761 431777

Fax: +44(0)1761 431888

enquiries@gage-technique.com

www.gage-technique.com

23

Figure 35

Figure 36

Figure 37

24

Surface strain gauge

Vibrating Wire

strain gauge

Crack meter

Gauge

Crack meter gauge expands

in length as the crack grows

in size.

Displacement sensor on the

beam and attached to the

vertical support will increase

with the sliding motion of beam

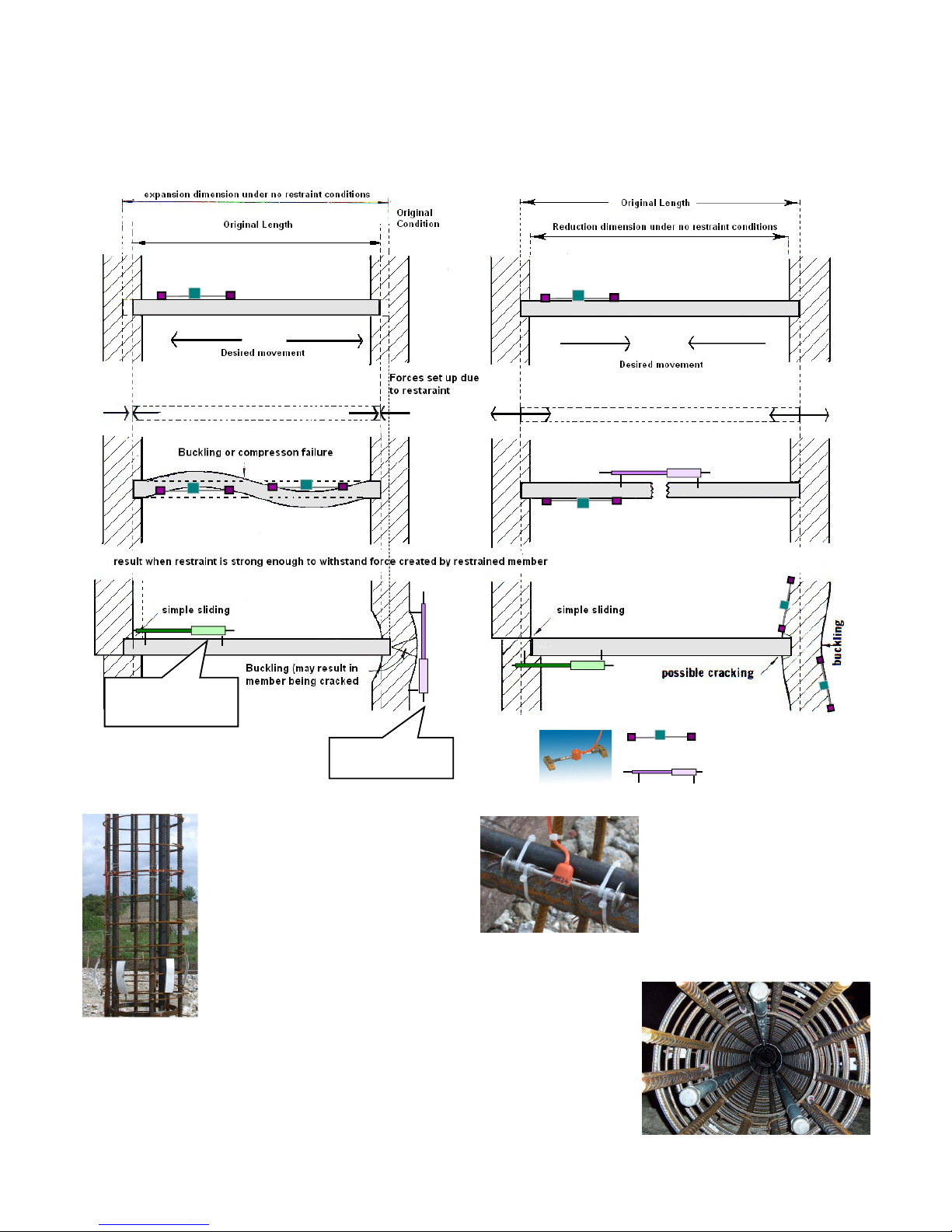

Vibrating Wire Sensor Applications

The details below show just a few of the applications for which

vibrating wire sensors are used. The best results from the

instrumentation are only achieved when a good understanding for

the overall structural behaviour is available. The examples

demonstrate the common uses of structural monitoring within civil

engineering applications.

The embedment or dumbbell gauge

(See Fig 40) is designed to measure

strain in concrete. This vibrating wire

strain gauge is typically tied to a

reinforcing cage. It is usual to install

them in arrays of three or four gauges

at several depths horizons within the

structure.

Fig 39

Figures 38 and 39 show sister bar gauges and

examples of their installation and use. The

sister bar strain gauge comprises of two

lengths of ribbed rebar welded to a central

gauge section. The central gauge section has

a miniature stainless steel, vibrating wire

strain gauge element, fitted along the

longitudinal axis of the gauge. Incorporated

within the gauge section are two coils for

excitation and output of the vibrating wire

strain gauge element. This type of gauge is

particularly rugged and reliable. They are

particularly applicable for strain

measurements in mass concrete pours where

placing of concrete is remote and

uncontrolled such as typically occurs in

diaphragm walls or deep piles.

The sister bars can be connected to a single

VibWire-108 instrument and data

Fig 38

Fig 40

A lot of vibrating wire sensor applications are undertaken with the

sensors buried into the structure such as within concrete or within

a bore hole. The vibrating wire sensors maintain very accurate

results without need for re-calibration over many years and generally more reliable than other forms of sensor, less prone to failure

in damp conditions and relatively easy to install.

Page 25

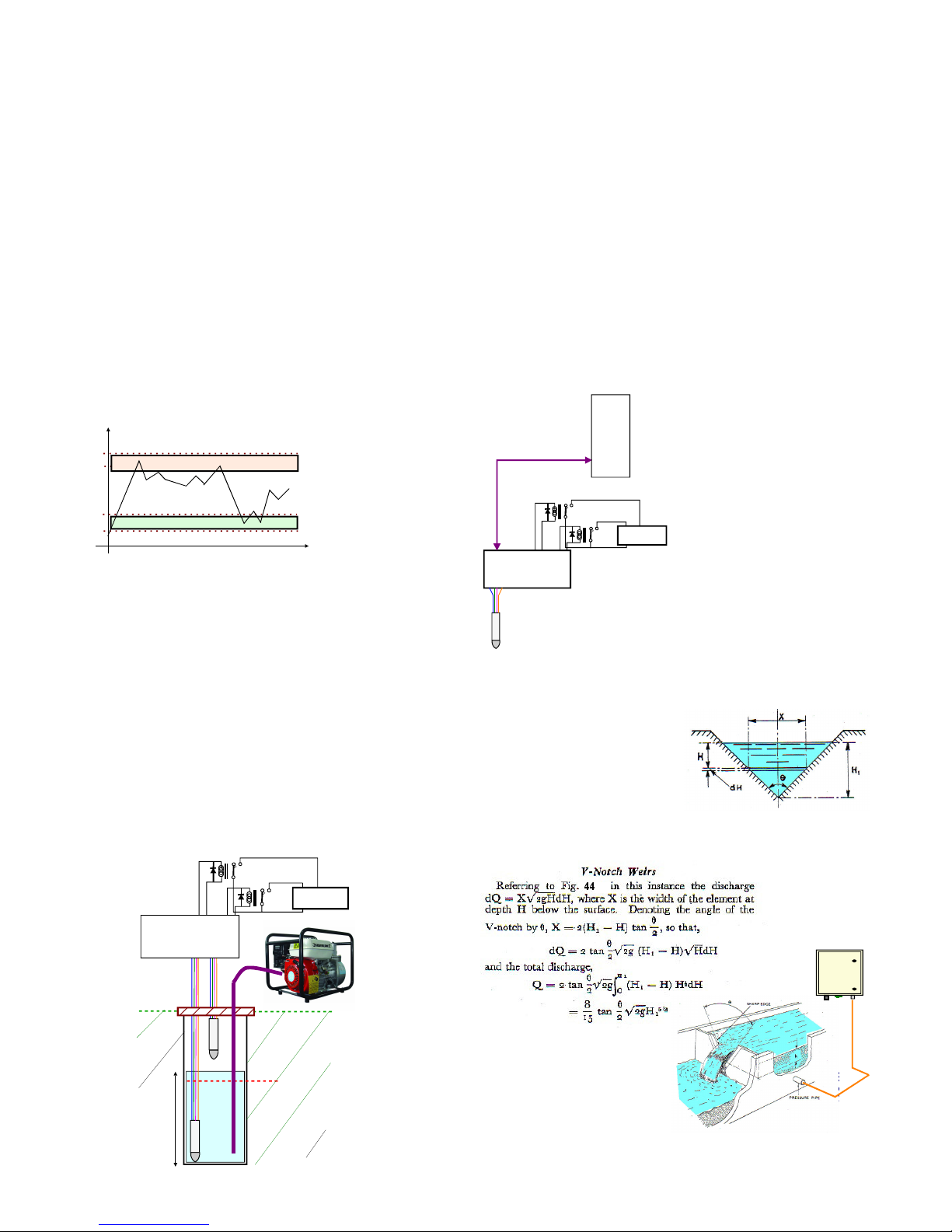

Case Study - Bore Hole Pump Control

The following examples detail the use the VibWire-108 range of

instruments within water flow and control systems. Two examples

are shown. The first example demonstrates the VibWire-108 as a

stand-alone control system used to monitor bore hole water and the

second example, shows how the VibWire-108 is used with a data

logger to report on and control the water flow in a v-notch weir.

Bore Hole Water Level Control

The VibWire-108 can be configured to operate as a stand-alone

control system when used with Vibrating wire peizometers and the

transistor output ports.

Fig 43 shows a sealed bore hole with 2 peizometers deployed. The

lower level sensor reports the water level height. The top sensor

acts as a reference and reports the internal bore hole pressure only.

The water level height measurement can be in error if there is a

build up of gas pressure in the hole and it is to correct for gas

pressure changes that the reference is fitted.

+12v DC

Trans Out

+12v DC

Trans Out