Keyboard Instruments Rhodes Service manual

Wednesday, May 24, 2000 Rhodes Service Manual Page: 1

RHODES Keyboard Instruments U.S.A.

Post Office Box 4137 1300 East Valencia

Fullerton, California 92634

Copyright © 1979 CBS Musical Instruments A Division of CBS Inc.

(714) 879-8080

P/N 34.0119.000 Printed in U.S.A.

Frames (800 X 600)

- No Frames (640 x 480)

Rhodes Help Desk

This manual was scanned using OCR and may be subject to typographical errors.

Report any problems or comments to badrats@badrat.com .

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/index.html

Wednesday, May 24, 2000 Rhodes Service Manual: Table of Contents Page: 1

Table of Contents

Section I Latest Design RHODES Piano

Chapter 1 The RHODES Tone Source 1-1

Chapter 2 The RHODES Modular Action 2-1

Damper Release Bar 2-1

Damper Push Rod Assembly 2-2

Damper Module 2-2

Action Rail 2-3

Harp Supports 2-3

Multiple Hammer Flange 2-4

Chapter 3 Instructions For Disassembly 3-1

Harp Cover Removal 3-1

Nameboard Assembly Removal 3-1

Harp Assembly Removal 3-1

Damper Release Bar Removal 3-1

Damper Module Removal 3-2

Hammer Removal 3-3

Removal of Keyboard Assembly from Cabinet 3-3

Stage Piano 3-3

Suitcase Piano 3-4

Action Rail and Harp Removal 3-4

Harp Support Removal 3-5

Cheekblock Removal 3-5

Key Removal 3-5

Chapter 4 Dimensional Standards and Adjustments 4-1

Key Dip 4-1

Escapement 4-1

Damper Clearance 4-3

Damper Module Adjustment 4-4

Tension 4-4

Alignment 4-4

Striking Line 4-5

Re-Establishing Striking Line 4-6

Timbre Adjustment 4-7

Volume Adjustment 4-7

Chapter 5 Tuning The RHODES Piano 5-1

Electronic Tuning 5-2

Stretch Tuning 5-3

How to Follow The Chart 5-5

Chapter 6 Repair Procedures and Techniques 6-1

Tone Generator Assembly Replacement Procedure 6-1

Key Pedestal Modification Procedure 6-4

Worn Key Bushing Repair Procedure 6-7

Key Cap Replacement Procedure 6-8

Full-Skirt Type Key Cap 6-9

One- And Two-Piece Type Key Cap 6-9

Section II Early Design RHODES Piano

Chapter 7 Early Design RHODES Piano - Tone Source (Prior to July 1975) 7-1

The Tine 7-2

Chapter 8 Early Design RHODES Pianos - Action (Prior to September 1975) 8-1

The Action 8-1

Chapter 9 Early Design RHODES Pianos - Maintenance and Rejuvenation 9-1

Chapter 10 Early Design RHODES Pianos - Dimensional Standards and Adjustments 10-1

Key Dip 10-1

Damper Control 10-2

Escapement 10-2

Signal Strength 10-4

Section III Electrical and Electronic Service Aids

Chapter 11 Diagrams, Schematics and Pictorials 11-1

List of Illustrations

Figure

Title

Number

1-1 Tuning Fork Comparison 1-1

1-2 RHODES Tuning Fork 1-1

2-1 RHODES Modular Action - Single Key View 2-1

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/toc.html

Page

Number

Wednesday, May 24, 2000 Rhodes Service Manual: Table of Contents Page: 2

2-2 RHODES Damper Modules - Bass, Mid and Treble Configurations 2-3

2-3 RHODES Modular Action - Exploded View 2-4

3-1 RHODES Harp/Action Assembly - Exploded View 3-2

3-2 RHODES Stage Piano - Bottom View 3-3

3-3 RHODES Suitcase Piano Top - Bottom View 3-4

4-1 RHODES Modular Action - Single Key Depressed 4-1

4-2 Escapement Distances 4-1

4-3 Escapement Adjustment Locations 4-2

4-4 Adjustment Location 1 4-3

4-5 RHODES Damper Arm - Tension Adjustment 4-4

4-6 RHODES Damper Arm - Alignment Adjustment 4-4

4-7 RHODES Harp/Action Assembly 4-6

4-8 Timbre Adjustment Diagram 4-7

4-9 Volume Adjustment Diagram 4-7

5-1 RHODES Tone Bar Assembly 5-1

5-2 Harp Position for Tuning the RHODES 5-2

5-3 Typical Dial - Electronic Tuning Device 5-4

5-4 Stretch Tuning Chart 5-6

6-1 Tone Generator Assembly Removal/Replacement 6-2

6-2 Tine Cutting Measurement Chart 6-3

6-3 Felt Strip - Cutting Line Dimension 6-5

6-4 Key Pedestal - Pencil Line Dimension 6-6

6-5 Key Pedestal - 5/32" Felt Piece Mounted 6-6

6-6 Key Pedestal - Felt Modification Complete 6-7

6-7 Key Bushing Tightener 6-8

6-8 Key Identification Chart 6-10

7-1

RHODES First Stage Tone Bar Assembly 7-1

7-2 RHODES Second Stage Tone Bar Assembly 7-2

7-3 RHODES Third Stage Tone Bar Assembly 7-2

7-4 RHODES Original Tine Design 7-2

7-5 RHODES Second Stage Tine Design 7-3

7-6 RHODES Swaged Tine Design 7-3

8-1 RHODES Original Action Design 8-1

8-2 RHODES Second Stage Action Design 8-1

8-3 RHODES Third Stage Action Design 8-2

8-4 RHODES Fourth Stage Action Design 8-2

9-1 Tear Drop Hammer Head - Groove Removal 9-1

9-2 Tear Drop Hammer Head - Reshaping to Striking Line 9-1

9-3 RHODES Hammer - Shim Placement 9-3

9-4 Early Design Damper 9-3

9-5 Double-Shoulder Hammer Head 9-4

9-6 RHODES Early Design Harp/Action Assembly - Cut-Away View 9-5

10-1 RHODES Early Design Single Key View 10-1

10-2 RHODES Early Design Harp/Action Assembly - Exploded View 10-3

10-3 RHODES Original Pickup Coil Series/Parallel Arrangement 10-4

10-4 RHODES Modified Pickup Coil Series/Parallel Arrangement 10-4

10-5 RHODES Bus Wire Re-Routing Diagram 10-4

11-1 Schematic - Preamplifier Assembly - 100 Watt Suitcase and Janus I 11-2

11-2 Printed Circuit Board - Preamplifier Assembly - 100 Watt Suitcase and Janus I 11-3/11-4

11-3 Schematic - Dual 50 Watt Power Amplifier - 100 Watt Suitcase and Janus I 11-5

11-4 Schematic - Power Amplifier - Janus I 11-6

11-5 Printed Circuit Board - +/-15 Volt Regulator - 100 Watt Suitcase and Janus I Power Amplifier 11-7/11-8

11-6 Printed Circuit Board - 50 Watt Power Amplifier - Suitcase Piano 11-9/11-10

11-7 Printed Circuit Board - 50 Watt Power Amplifier - Janus I 11-11/11-12

11-8 Schematic - Preamplifier - 80 Watt Suitcase and Super Satellite 11-13

11-9 Schematic - Power Module - 80 Watt Suitcase 11-14

11-10

Schematic - Power Supply Regulator Assembly (Peterson Design) -80 Watt Suitcase 11-15

11-11 Circuit Board Assembly - Power Supply Regulator (Peterson Design) -80 Watt Suitcase 11-16

11-12 Schematic - Power Amplifier, Master and Slave - Super Satellite 11-17

11-13 Schematic - Power Control Panel, Master - Super Satellite 11-18

11-14 Schematic - Power Control Panel, Slave - Super Satellite 11-19

11-15 Schematic-Converter Kit I 11-20

11-16 Schematic - Converter Kit II 11-21

11-17 Schematic - Preamplifier and Power Amplifier (Jordan Design) -Suitcase Piano (Pre 1969) 11-22

11-18 Connection Diagram - All Printed Circuit Boards - Instructor Console 11-23

11-19 Schematic - Preamplifier and Power Amplifier - Student Piano (First Version - 1968) 11-24

11-20 Schematic - Preamplifier and Power Amplifier - Instructor Piano (First Version - 1968) 11-25

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/toc.html

Wednesday, May 24, 2000 Rhodes Service Manual: Table of Contents Page: 3

11-21 Wiring Diagram - Instructor Console 11-26

11-22 Schematic - Master Circuit Board - Instructor Console 11-27

11-23 Schematic - Power Supply - Instructor Console 11-28

ACKNOWLEDGEMENT

Appreciation is due to all who have been involved in producing this manual. Specifically, to our Sales Force, the Retail and Service dealers and the artists who offered suggestions. Last, but by

no means least, to our own highly qualified Product Development, Production, Service and Marketing personnel whose many hours of labor and years of expertise have produced what we believe

to be a comprehensive aid to servicing and understanding the RHODES Piano.

RHODES Keyboard Instruments U.S.A.

FOREWORD

Since its inception in 1965, the RHODES Piano has remained relatively constant in terms of design concept. However, there have been changes in the methods of achieving those design concepts.

Those concepts which have remained constant throughout the history of the RHODES are:

1. Method of Tone Production. As will be shown in detail, the Tone is produced by a series of modified tuning forks (one for each note) referred to as "Tone Bar Assemblies." Each such

assembly lies adjacent to an adjustable Pickup. The Pickup Coils are all alike and are adjustable as to gap very much as are the points on the Distributor of an automobile. Because of the

unique construction features, each note can be adjusted for Volume, Timbre and Pitch.

2. The Action. Consisting of only three moving parts, the Action is unique in design. While the structure and materials used have changed, the concept has remained unchanged.

This Manual has a two-fold purpose; one, as a maintenance and repair guide; and two, as a detailed description of the various vintage models together with instructions for upgrading and

modernizing the various models wherever possible.

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/toc.html

Wednesday, May 24, 2000 Chapter One: The Rhodes Tone Source Page: 1

CHAPTER ONE

THE RHODES TONE SOURCE

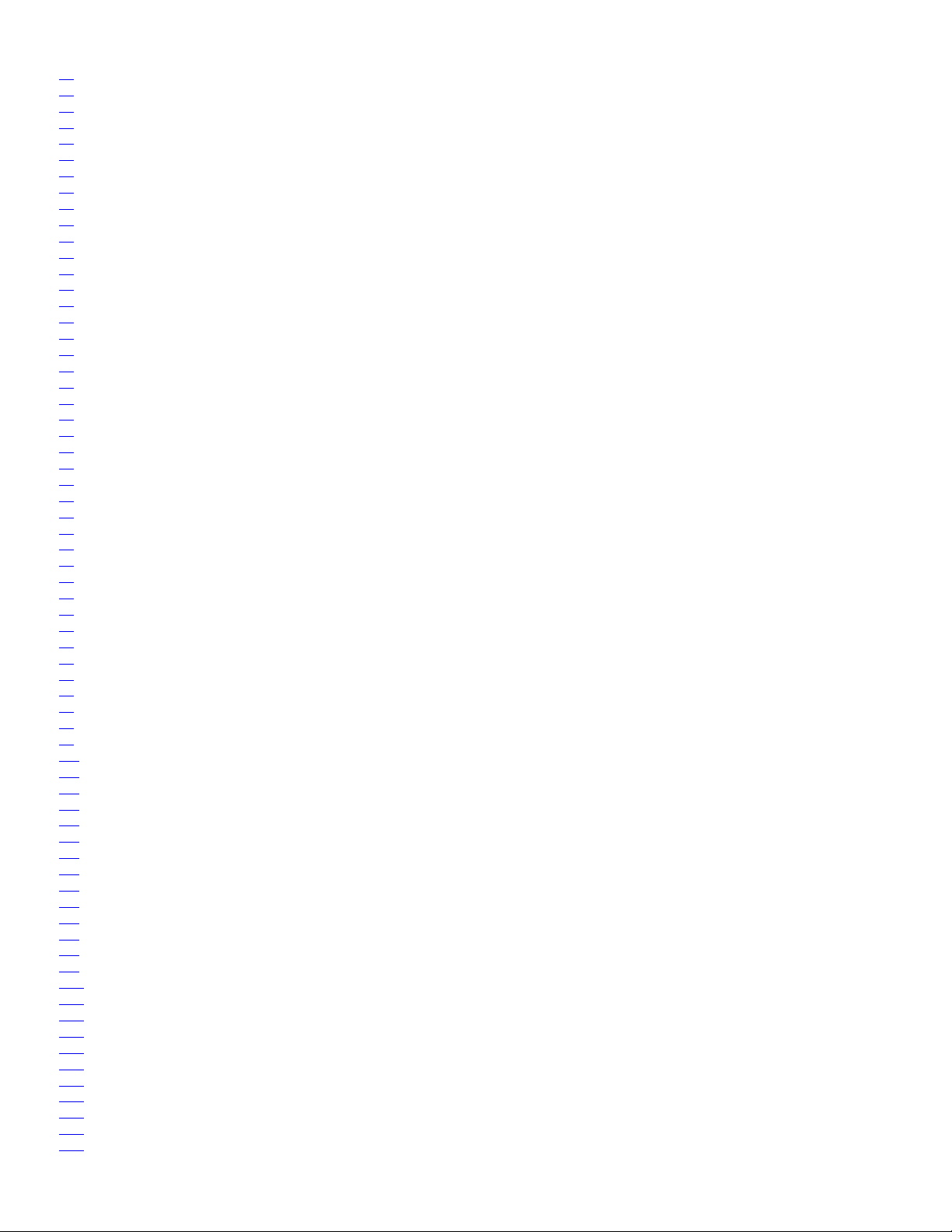

The unique tone of your RHODES Piano derives from the principle of the tuning fork. While the common tuning fork has two legs of equal length and mass, the tuning forks in your RHODES

Piano differ from these in one very important way (Figure 1-1). The two prongs of our tuning fork are not of the same mass, shape or size. They are alike only in pitch. The lower, more resilient

leg (Tine) responds visibly to the blow of a Hammer by vibrating in a wide arc at a certain frequency.

Figure 1-1. Tuning Fork Comparison

The upper leg (Tone Bar), while not so visible, does vibrate at the same frequency. The importance of this upper leg can easily be demonstrated by the following simple experiments.

1. Strike any note, preferably in the mid-range of the Piano. With the Sustain Pedal down, squeeze the upper leg with the fingers. The tone will die immediately.

2. Perform the same experiment, but this time touch the upper leg very lightly. The vibration will be distinctly felt under the fingers.

This patented concept of the tuning fork offers many advantages (Figure 1-2). One of these is that the upper leg (Tone Bar) supports some pitch variation in the lower leg (Tine). In other words,

assuming G to be the target pitch, the lower leg could be deliberately tuned to F, F#, G, G# or A without any appreciable loss of support from the upper leg. This opens up a world of

possibilities, as will be shown.

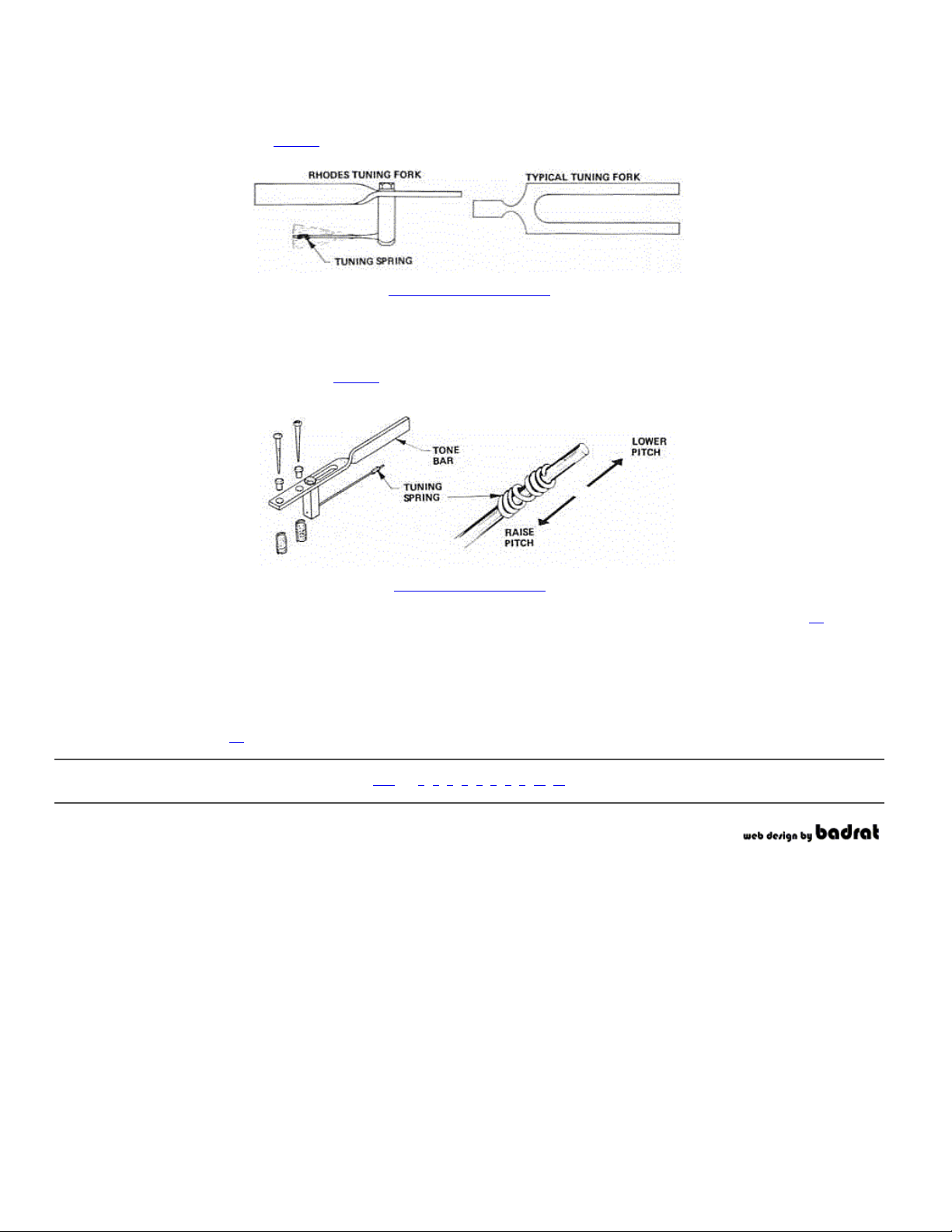

Figure 1-2. RHODES Tuning Fork

You will note a small coil Spring on the lower leg so designed as to be a tight fit. This coil Spring acts as a counter-weight and, therefore, as a pitch control. Moving this Spring will result in a

change of pitch. By this means, then, it is possible to arrive at a fine tuning merely by sliding the Spring to the desired spot on the Tine. See Tuning Your RHODES Piano, Page 5-1.

The Tines in your RHODES Piano, like the strings of a guitar, are subject to breakage under stress. We here at the factory are constantly on the alert for ways to achieve the longest possible life in

these as well as in all other component parts of your Piano. In actual tests, Tines picked at random have withstood in excess of 6,000,000 blows in a test machine. This machine is so constructed

as to simulate actual playing conditions. Despite this, steel wire of even the finest quality, invariably has flaws along its surface. If these microscopically small flaws occur in a node point, they

can become the point of eventual fracture. This is offered to explain the fact that, while one person's Piano may play for many years under constant use with no more than a couple or three broken

Tines, another musician may experience a similar breakage within a shorter period of time.

For reasons just described, the Tines cannot be covered in the general warranty of the Piano.

In anticipation of this, we have devised a simple procedure for replacement - one which the musician can perform in about the time it takes to replace a guitar string. Refer to Tone Generator

Assembly Replacement Procedure, Page 6-1.

TOC - 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/ch1.html

Wednesday, May 24, 2000 Chapter Two: The Rhodes Modular Action Page: 1

CHAPTER TWO

THE RHODES MODULAR ACTION

DAMPER RELEASE BAR

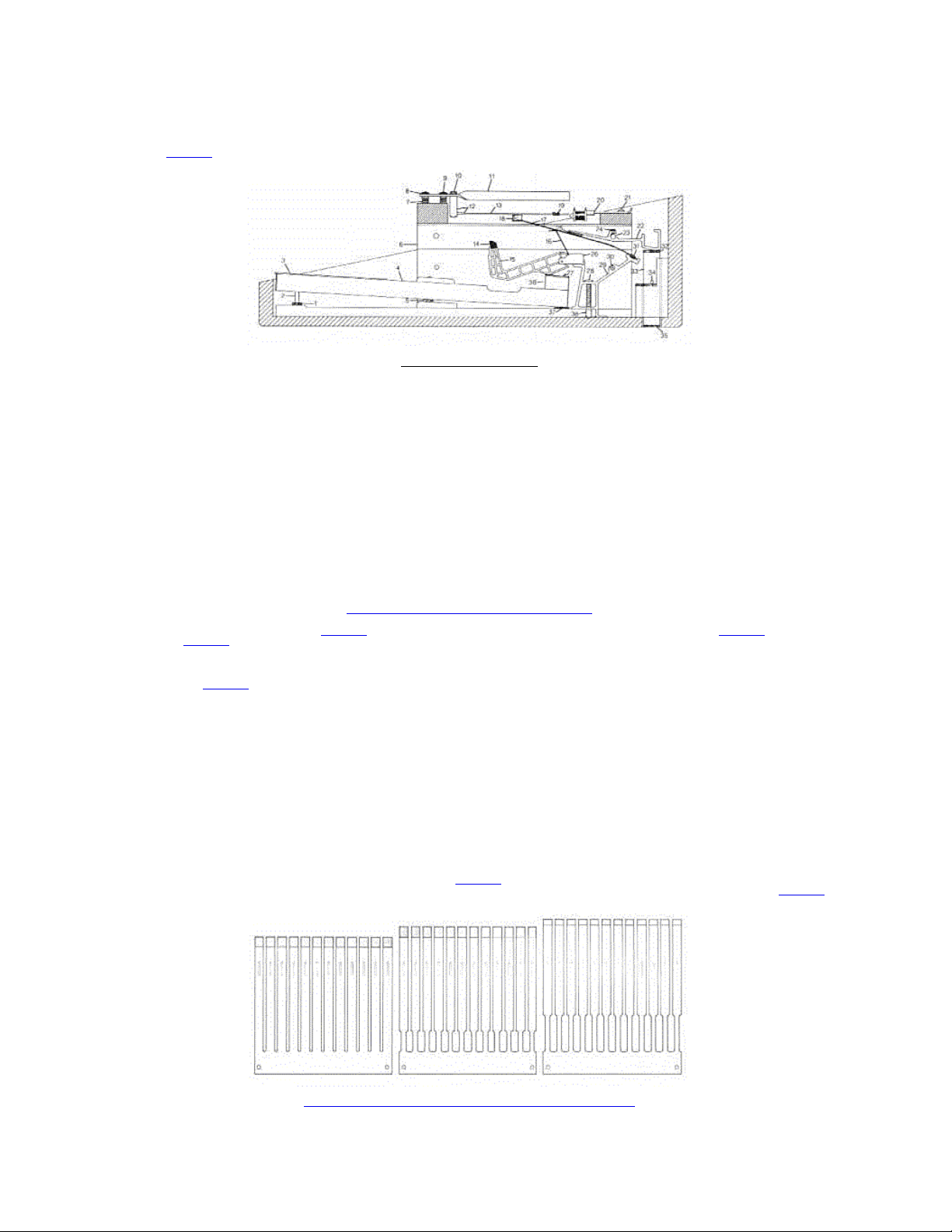

The Damper Release Bar (Figure 2-1, 22) provides a foot-activated mechanical means of disengaging all Dampers allowing all Tines to vibrate freely.

REFERENCE DESIGNATION

1. Front Guide Pin Felt

2. Front Guide Pin

3. Key Cap

4. Key

5. Balance Rail Felt

6. Harp Support

7. Tone Bar Assembly

Mounting Spring

8. Tone Bar Assembly

Mounting Grommet

9. Tone Bar Assembly

Adjustment Screw

10. Tone Generator

Mounting Screw

11. Tone Bar

12. Tone Generator

Assembly

13. Tine

14. Hammer Tip

The Damper Release Bar is locked in place by two Pivot Pins (Figure 2-1, 23) which slide into two bushed holes provided in the aluminum Harp Supports (Figure 2-1, 6). These pins are held in

place by two locking Screws (Figure 2-1, 24).

DAMPER PUSH ROD ASSEMBLY

The Damper Push Rod Assembly (Figure 2-1, 33) is a short length of wooden dowel capped on each end with felt and held in place by a sleeve built into the back structure of the Piano housing.

Forced upward by the thrust of the Sustain Rod, it, in turn, pushes upward on the back surface of the Damper Release Bar causing its leading edge to bear downward on all of the Dampers thus

disengaging them from the Tines. With the Dampers thus released, all Tines are now free to vibrate sympathetically with the struck tones as is the case with an acoustic piano. The difference

becomes apparent when a comparison is made between the resultant sound of a chord where only those Dampers involved with a particular chord are released and then the sound of the same

chord when all Dampers are released.

1. The Damper Push Rod, in its rest position, should bear solidly against the back surface of the Damper Release Bar. An ideal setting would be that where all play between the Damper

Release Bar and the Damper Arms is removed. This can be accomplished by adding felt either to the top of the Push Rod or to the mating surface of the Damper Release Bar. Extreme care

should be exercised to avoid possible disengagement of the Dampers. Conversely, it can be seen that excessive play or lag in the linkage will result in a loss of touch sensitivity by the

foot.

2. SUITCASE PIANO ONLY:

In its rest position, the bottom surface of the Push Rod should be reasonably flush with the outer surface of the bottom of the Piano. There is a slot on the top surface of the Sustain Rod

providing screwdriver adjustment on the top of the Amplifier Enclosure.

DAMPER MODULE

The Damper Arms are now provided in fixed multiples of twelve known as Damper Modules (Figure 2-1, 17). This change was made to preclude the possibility of side shift in shipping and is the

epitome of simplicity. It consists of tempered aluminum stamped into Modular configurations to accommodate the Damping requirements in Bass, Mid and Treble ranges (Figure 2-2).

15. Hammer

16. Bridle Strap

17. Damper Module

18. Damper Felt

19. Tuning Spring

20. Pickup Assembly

21. Pickup Adjustment

Screw

22. Damper Release Bar

23. Damper Release Bar

Pivot Pin

24. Damper Release Bar

Pivot Pin Locking

Screw

25. Damper Release Bar

Felt

26. Multiple Hammer

Flange

27. Key Pedestal Felt

28. Action Rail Mounting

Screw

29. Action Rail

30. Harp Support-To-Action

Rail Mounting Screw

31. Damper Module

Mounting Screw

32. Push Rod Assembly

Top Felt

33. Push Rod Assembly

34. Push Rod Assembly

Balance Pivot

35. Push Rod Assembly

Bottom Felt

36. Action Rail Mounting

T-Nut

37. Keybed Felt

38. Key Pedestal

Figure 2-1. RHODES Modular Action - Single Key View

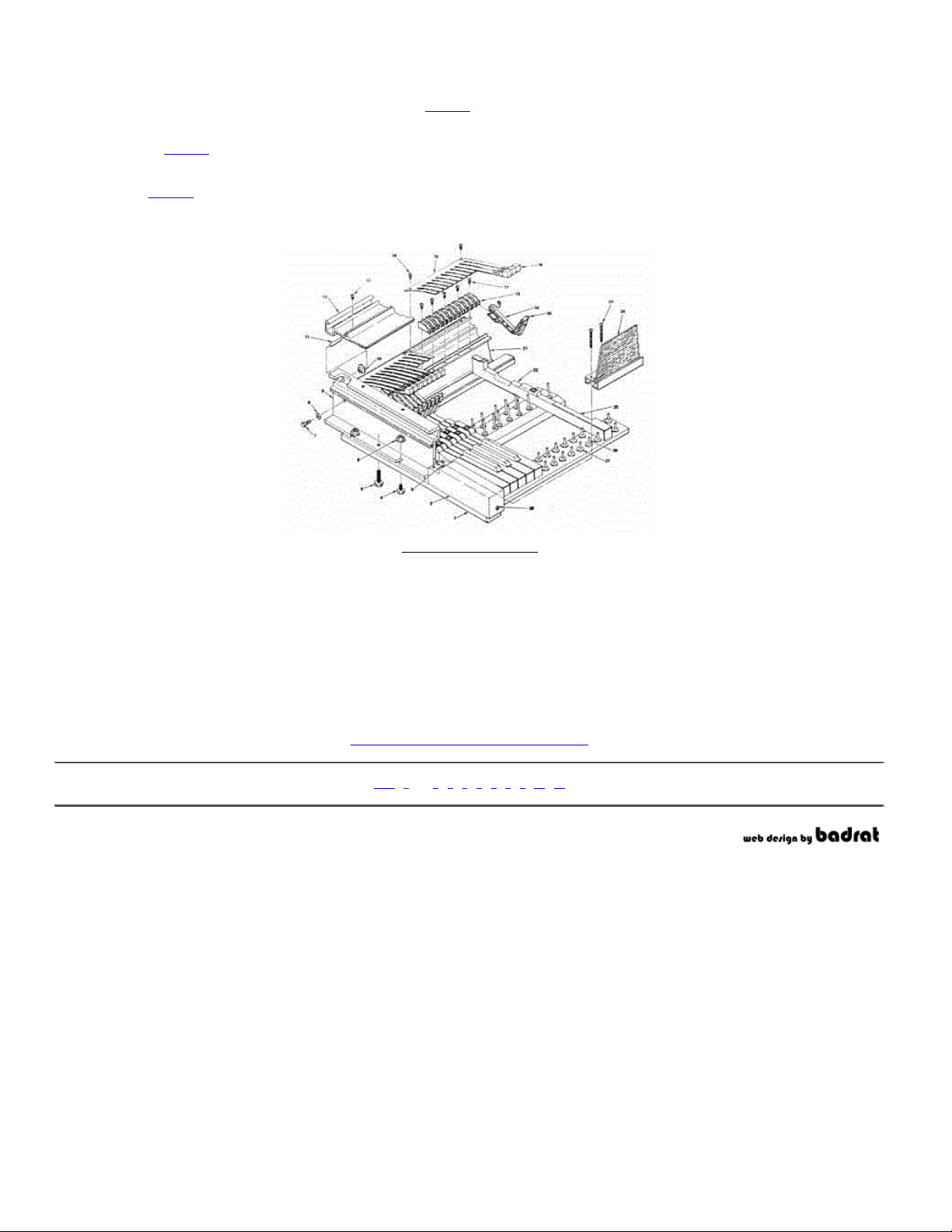

Figure 2-2. RHODES Damper Modules - Bass, Mid & Treble Configurations

The Bass Damper Module is shortest with full width Arms to provide the strength and tension needed to properly damp the long Tines in the Bass area. Progressing up the Keyboard to the Treble,

the Tines become shorter and therefore the Damper Modules are designed to provide graduated strength and tension according to the need throughout the range of the Keyboard. In keeping with

the various damping requirements, the Damper Felts as well are designed to accommodate the three areas - the Bass with long, wide Felts; the Middle with Felts of medium length and width; and

the Treble which uses short, narrow Felts.

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/ch2.html

Wednesday, May 24, 2000 Chapter Two: The Rhodes Modular Action Page: 2

ACTION RAIL

With the Damper Release Bar and the Damper Modules removed, the new Action Rail (Figure 2-1, 29) is revealed to be a sturdy, extremely accurate aluminum extrusion.

HARP SUPPORTS

The new Harp Supports (Figure 2-3, 9) are fabricated from heavy aluminum extrusions sturdy enough to hold the assembly in place undamaged by a direct six-foot drop.

MULTIPLE HAMMER FLANGE

The Hammer Flange (Figure 2-3, 18) is molded in multiples of twelve. This also was redesigned in this manner to preclude the possibility of side shift in shipping.

It should be noted that the Multiple Flanges are molded of a hard A. B. S. material with a 15% teflon content, thus providing lifetime lubrication.

1. Keybed

2. Cheekblock

3. Cheekblock Rear

Mounting Screw

4. Harp Support Mounting Screw

5. Keybed Mounting Screw

6. Captive-Washer Mounting Nut

7. Harp Support-to-Action

Rail Mounting Screw

8. Washer

9. Harp Support

10. Nylon Pivot Bushing

11. Damper Release Bar

Pivot

12. Damper Release Bar

13. Pivot Mounting Screw

14. Damper Module

Mounting Screw

15. Damper Module

16. Damper Felt

17. Hammer Flange

Mounting Screw

18. Multiple Hammer

Flange

19. Hammer

20. Hammer Tip

REFERENCE DESIGNATION

21. Action Rail

22. Key

23. Nameboard Mounting

Screw

24. Nameboard

25. Key Cap

26. Guide Pin

27. Guide Pin Felt

28. Cheekblock Front

Mounting Screw

Figure 2-3. RHODES Modular Action - Exploded View

TOC - 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/ch2.html

Wednesday, May 24, 2000 Chapter Three: Instructions for Disassembly Page: 1

CHAPTER THREE

INSTRUCTIONS FOR DISASSEMBLY

Access to the specific areas for needed adjustments or repair is easily accomplished by following the procedures outlined here.

1. Harp Cover Removal

The Cover is formed of A. B. S. material and is practically impervious to damage. To remove, lift up on the two back corners of the molded top. With this done, simply pull the front

edge free.

2. Nameboard Assembly Removal

Disconnect Harp Cable from Harp Jack. With a #2 Phillips Screwdriver, loosen and remove the four (4) screws which mount the Nameboard to the Cheekblocks (two (2) of which are

found behind the Nameboard on each end). After removing screws, lift Nameboard Assembly up and away.

3. Harp Assembly Removal

The Harp Assembly (Figure 3-1) consists of three major assemblies. The Harp Frame, the Tone Bar Rail and the Pickup Rail.

The Tone Bar Rail and the Pickup Rail are seated into the Harp Frame and secured by fourteen (14) Mounting Screws. Two metal Harp Brackets are then mounted to join the two.

The Harp Assembly is secured to the two aluminum Harp Supports by four (4) Screws (two (2) on each end) as well as the Harp Pivot Links located on each end. Complete removal of

the Harp, then, is accomplished by removing the four Mounting Screws as well as the two Screws which secure the Harp Pivot Links.

4. Damper Release Bar Removal

The Damper Release Bar (Figure 2-3, 12) is secured to the aluminum Harp Supports by two removable Pivot Pins (Figure 2-3, 11).

a. Loosen one Screw (Figure 2-3, 13) on either end of the Damper Release Bar.

b. With a small flat-blade screwdriver, slide the Pivot Pin out from the Damper Release Bar through the Nylon Bushing (Figure 2-3, 10) in the Harp Support (Figure 2-3, 9).

c. Slide the entire Damper Release Bar loose from the Bushing in the other Harp Support.

Removal of the Damper Release Bar is required in order to reach the Damper Modules for adjustment or removal.

Figure 3-1. RHODES Harp/Action Assembly - Exploded View

5. Damper Module Removal

a. Remove Damper Module Mounting Screws.

b. Carefully push down on each Damper Arm with one hand and gently pull Bridle Strap forward with the other hand so as to slide Bridle Strap away from the formed tongue in the

Damper Arm without causing damage to the tongue.

c. Pull Damper Module out of detent lip in Action Rail.

6. Hammer Removal

It is not necessary to unscrew or displace any of the supporting structures to remove a Hammer. Hold the Hammer Head with the thumb and index finger then rotate either left or right

while at the same time twisting on the vertical axis until the protruding ear (pin) pops out of the Hammer Flange. Then, simply lift out, exercising care to ease the Bridle Strap off the

Damper Arm Tongue.

7. Removal of Keyboard Assembly from Cabinet

CAUTION

This procedure should be accomplished with the Nameboard

Assembly mounted to prevent the Keys from falling out.

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/ch3.html

Wednesday, May 24, 2000 Chapter Three: Instructions for Disassembly Page: 2

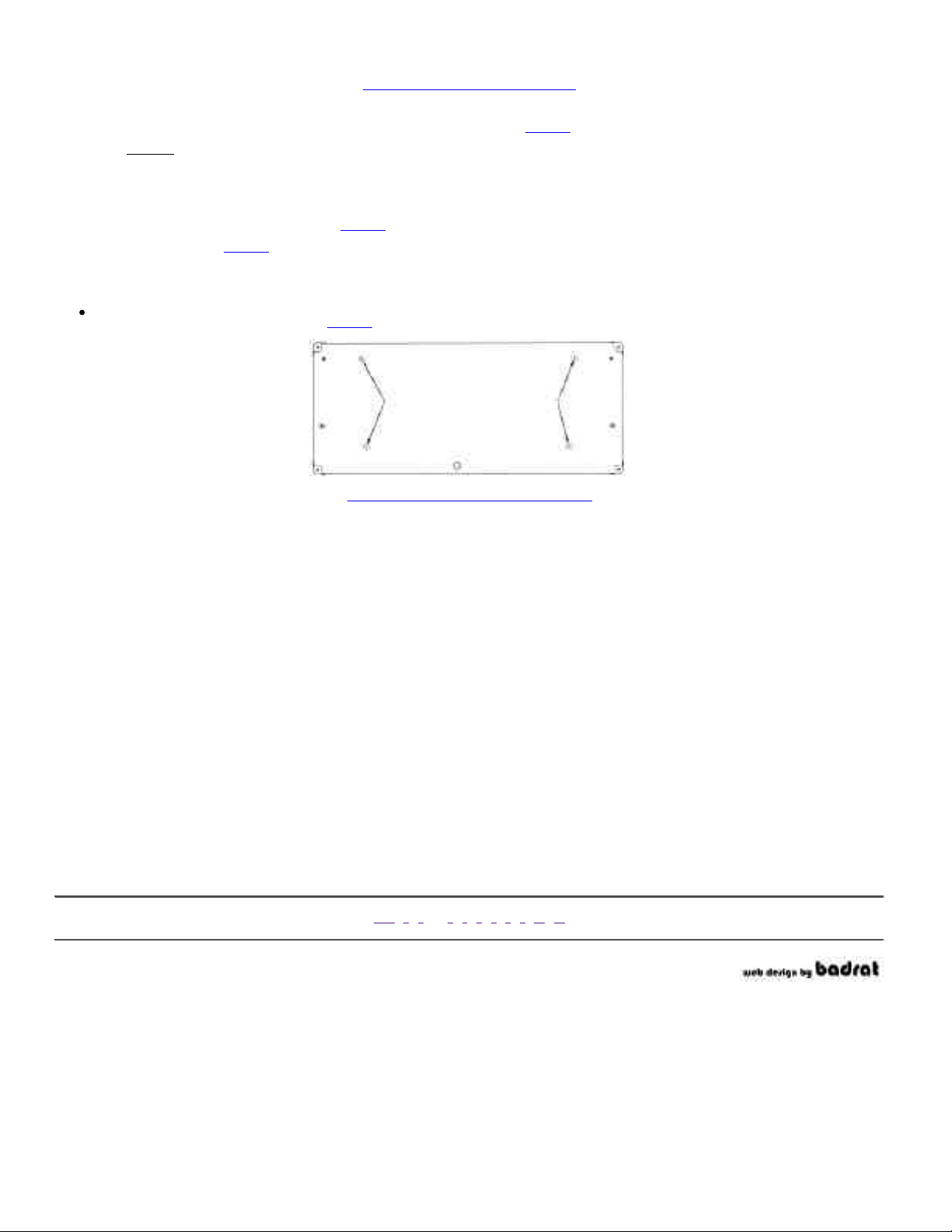

Figure 3-2. RHODES Stage Piano - Bottom View

Stage Piano

a. Position the Piano so that the Keys are pointing up with the bottom surface of the Cabinet facing you (Figure 3-2).

CAUTION

Before proceeding with Step b., support the Keybed with one

hand to prevent the Keybed from falling out when the

Mounting Screws are removed.

b. Using a #2 Phillips Screwdriver, remove the two Screws (Figure 3-2, 1) which secure the Cabinet to the Cheekblock cleat on the Keybed.

c. Remove the two large Screws (Figure 3-2, 2) which mount the Keybed to the Cabinet.

d. Place Piano on its bottom surface and remove Keyboard Assembly by lifting out of Cabinet.

Suitcase Piano

Proceed as with a Stage Piano, again observing the CAUTION on the previous page, following Steps a, b, and c. In addition, since the bottom surface on the Suitcase Piano is of a

thinner plywood than the Stage Piano, the four Glides (Figure 3-3, 1) must be removed as well. Proceed with Step d.

Figure 3-3. RHODES Suitcase Piano Top - Bottom View

8. Action Rail and Harp Support Removal

NOTE

The Action Rail is securely locked to both Harp Supports by

means of the Harp Support-To-Action Rail Mounting Screws.

While these Screws can easily be removed, it is suggested that

the two Harp Supports and the Action Rail be maintained as

a 3-piece Assembly.

a. Place the Keyboard on its bottom surface as in a playing position.

b. Remove the Captive-Washer Nuts that secure the Harp Supports to the Keybed.

c. Exercising care not to lose the T-Nuts from the under side, remove the Action Rail Mounting Screws.

d. Grasp the Action Rail with both hands and lift off the three-piece assembly.

9. Harp Support Removal

a. Disassemble Piano as outlined through 7. b.

b. Remove the Harp Support-To-Action Rail Mounting Screws.

c. Lift Harp Support up and away from Action Rail.

10. Cheekblock Removal

This operation is accomplished by removing both the front and rear Cheekblock Mounting Screws.

11. Key Removal

After removing the Nameboard Assembly, simply lift up on the front of the Key to free it from the front and center Guide Pins, then pull the Key out from under the Hammer.

TOC - 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11

file:///Macintosh%20HD/Desktop%20Folder/Fender%20Rhodes%20Manual%20%C4/ch3.html

Loading...

Loading...