KEY RK-2001W4 Operation Manual

OPERATION MANUAL

RK-2001W4

SOLID FUEL FIRED

BOILER TEMPERATURE CONTROLLER

Wersja E128

Table of Contents.

Introduction ................................................................................................... 3

Operation ...................................................................................................... 3

Method of determining the set temperature of the boiler .............................. 4

Working in combination with exhaust gas sensor ......................................... 5

Working in combination with a room thermostat .......................................... 6

Alarms .......................................................................................................... 6

Setting up the user parameters. ..................................................................... 7

The desired boiler temperature [C 45] ............................................................. 7

Central heating pump work [co C] – WINTER/SUMMER ............................... 7

Total bacteria control in the hot water tank [cu u] ........................................... 8

The temperature measured by the additional sensor [u50 °] .......................... 8

The temperature measured emissions [150 °] ................................................ 8

Parameter setting – the service mode ............................................................ 8

Table 2. Service parameters list ...................................................................... 9

Pressure fan work parameters ........................................................................ 10

Central heating pump parameters .................................................................. 11

Settings of the sensor operation mode and additional pump .......................... 11

Setting the operating temperature range of the boiler .................................... 12

Boiler overheating protection .......................................................................... 13

No fuel ............................................................................................................. 13

Multifpurpose output ....................................................................................... 13

Setting the exhaust gas temperature control parameters ............................... 14

Testing of device's outputs .............................................................................. 14

Factory defaults .............................................................................................. 14

Exiting service mode ....................................................................................... 15

Device removal ............................................................................................... 15

Specifications .................................................................................................. 15

Connection diagram of the RK-2001W4 ......................................................... 16

Schemes of connecting additional devices ..................................................... 16

3

1. Application.

Controller RK-2001W4 is a device designed for temperature control in solid fuel fired

boilers equipped with:

- blower,

- central heating pump,

- domestic hot water pump, mixing pump or a pump charging the accumulative tank

(optional),

- household thermostat or exhaust gases temperature sensor (optional),

- signalling device or an additional boiler (optional).

2. Connection.

Before connecting the controller to the power supply, check if: power cords of the

controller, the blower and the central heating circulation pump are properly plugged

in the appropriate slots at the back of the device. The boiler water temperature and

the exhaust gases temperature sensors should be installed in a measurement

openings of the boiler. The schematics of connecting the regulator is shown in

picture 2.

CAUTION! Before plugging in the controller first check if the wiring system is

properly grounded and if the screw terminals of the output connector are tightened.

CAUTION! The total power of the devices connected to the controller must not

exceed 700W.

The unused outputs may remain disconnected.

3. Operation.

Turning on the controller is signalized by a brief switching on all the light indicators

on the display to enable to check their status. After the regulator has been

connected to the power supply, it returns to its most recent mode (before turning it

off or power failure).

The front panel of the controller (picture 1) includes:

1 – power switch,

2 – boiler temperature and parameters indicator,

3 – boiler thermostat knob,

4 – Ok button used for programming activation and parameters confirmation,

5 – STOP button also used for parameters selection and alarm cancellation,

6 – START button also used for parameters selection.

4

Picture 1. Front panel of the RK-2001W4 controller.

The basic operation of the regulator depends on setting the desired temperature with

the thermostat knob. The remaining functions are carried out according to the

programmed parameters of the service mode. The change of thermostat parameters

is shown on the display for a few seconds, e.g. [C 65] and defines the value of the

boiler water temperature the regulator is going to reach.

ressing the START (6) button activates both the blower and the possibility of its

control. The STOP (5) button allows the user to stop the work of the blower, e.g. in

order to refuel the boiler. If the regulator is out of the user’s mode, the temperature

of the boiler water is shown on the display and the last symbol indicates the working

mode status:

[50°-] - stands for the STOP mode

[50°C] is the WORK mode

[50°c] indicates maintaining the heating while in the WORK mode

[50°U] means heating the domestic hot water in SUMMER mode

[50°u] is maintaining the heating while in SUMMER mode

.[70°d] indicates the bacteria eradication mode – heating the domestic

hot water up to 75°C

3.1. The method of determining the desired temperature of boiler water.

The temperature maintained in the boiler (the programmed one) depends on the

working mode of the household thermostat input (the exhaust gases sensor) as well

as on the additional pump working mode. Table 1 contains the list of all parameters

values possible to set.

5

If the circulation system is equipped with the accumulative tank, the desired boiler

water temperature equals the value set with the thermostat knob (3).

If the heating system is equipped with the domestic hot water tank, the higher of two

component temperatures is accepted as the desired boiler water temperature –

either the temperature needed by the central heating circulation or the boiler water

temperature necessary to heat up the domestic hot water tank.

In all other cases (no additional pump and when the mixing pump is installed) the

desired boiler water temperature is the same as the temperature needed by the

central heating circulation.

The temperature necessary to heat up the tank is taken into account when the

domestic water temperature is too low only and it equals the total of the programmed

hot water temperature [u 50] and the value of its increase [uP 5].

The temperature needed by the central heating circulation is determined on the

basis of the value set with the thermostat knob (3) and the household thermostat

input status. If the exhaust gases sensor is connected, then the central heating

temperature equals the value set with the knob. If the household thermostat is

connected and its contacts are opened, the central heating temperature is the same

as the minimum boiler temperature [L 45], and if its contacts are opened, the central

heating temperature equals the value set with the knob.

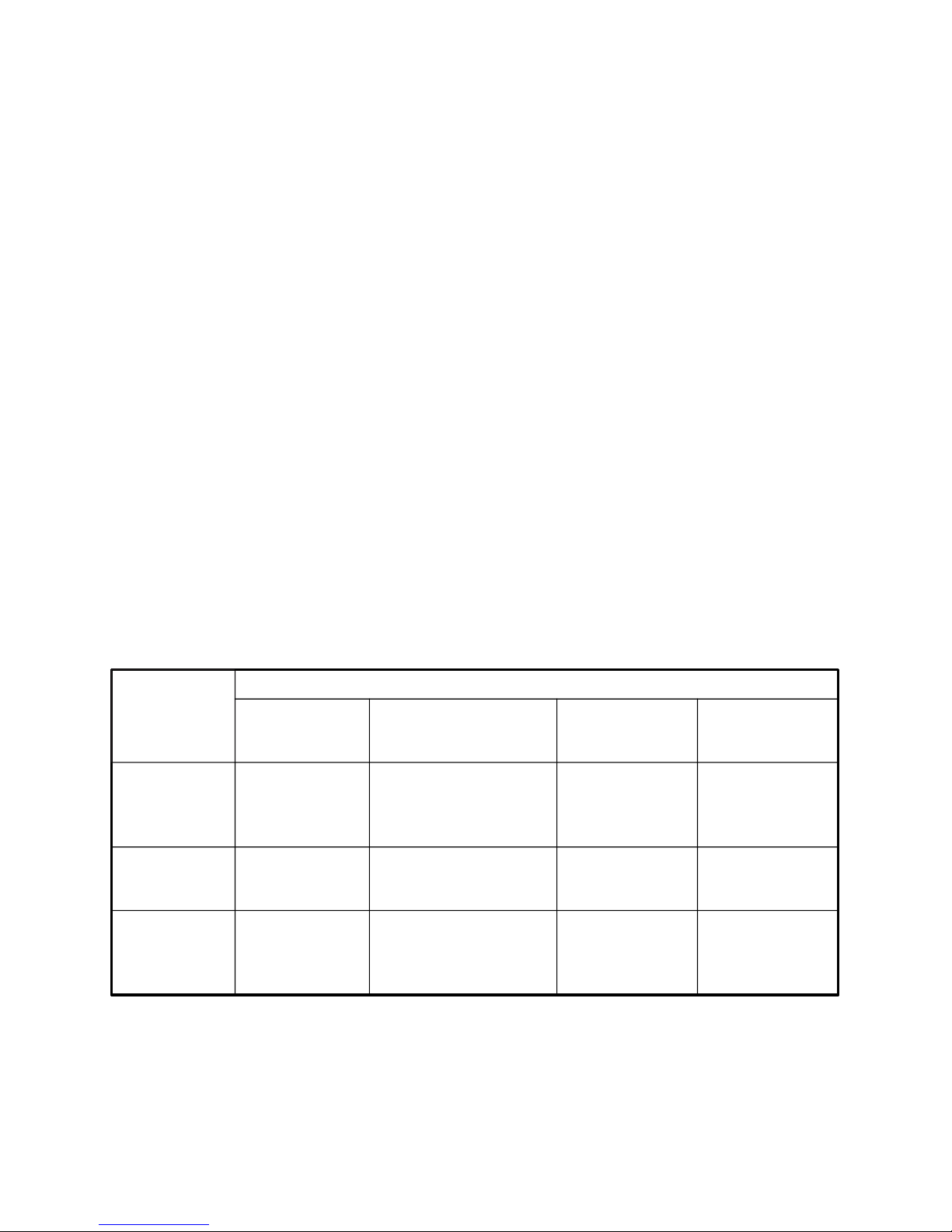

Table 1. Methods of establishing the desired temperature of boiler water.

Thermostat

input

Additional pump working mode

None

[ur 0]

Domestic hot water

[ur 1] lub [ur 2] Mixing pump

[ur 3]

Accumulator

[ur 4]

Exhaust gases

sensor

Set with knob

Of which higher:

– Set with knob

– Domestic water

heating temperature

Set with knob Set with knob

Thermostat

contacts

opened

Minimum

Domestic water

heating temperature Minimum Set with knob

Thermostat

contacts closed

Set with knob

Of which higher:

– Set with knob

Domestic water

heating temperature

Setpoint knob Set with knob

3.2. System with the exhaust gases sensor operation.

If the heating system has been equipped with the exhaust gases temperature sensor

and the temperature of the boiler water approaches the desired value, the regulator

will switch into the mode of stabilizing the boiler water temperature.

6

3.3. System with the household thermostat operation.

If the heating system is equipped with the household thermostat, the desired

temperature of the boiler water depends on the status of its contacts (3.1.). As an

addition the central heating pump work may, depending on the service settings, be

influenced by the household thermostat.

4. Alarms.

The correctness of the inside circuits and the temperature sensors work is tested

continuously. When a failure is detected, the information of the errors that has

appeared is displayed and the adequate action is undertaken.

The [FUEL] caption when displayed indicates fuel demand alarm. After the boiler has

been refuelled, the alarm can be cancelled with the STOP button.

The [Hot] caption is displayed alternately with the exhaust gases temperature e.g.

[°410] means the temperature of 400°C has been exceeded by the exhaust gases. In

such case the blower is turned off by the regulator (it is turned on during draught cycle

only). The regular work is resumed after the temperature of the exhaust gases has

decreased below 250°C.

The [E 1] error indicates that a failure in the boiler sensor circuit has occurred. The

error will induce the blower to turn off and the central heating pump to turn on. After

the reason for the alarm has been removed, it can be cancelled with the STOP button.

The [E 2] error indicates that the boiler overheating has occurred. The error will

induce the blower to turn off and the central heating pump to turn on. The alarm can

be cancelled with the STOP button after the boiler water temperature has decreased.

The [E 8] indicates that a failure of the additional sensor circuit has occurred. If the

additional output operates in the domestic hot water pump working mode, then the

topping up the hot water tank is ceased. When the output works as a mixing pump, the

protection of the return temperature is turned off. If the additional pump is intended to

charge the accumulative tank, then it is turned on permanently. It is not necessary to

cancel the alarm manually (it is cancelled automatically after the reason for failure has

been removed).

The [E128] indicates that a failure of the exhaust gases temperature sensor has

occurred. In case of the alarm, the regulator operation is continued in the stabilizing

the boiler temperature mode. The alarm does not need cancelling manually (it is

cancelled automatically after the reason for failure has been removed).

When several errors occur at the same time, the total of their codes is shown on the

display, e.g. the [E 3] caption indicates both failure of the boiler temperature sensor

and boiler overheating have occurred.

Loading...

Loading...