Page 1

KT71 /

POWERED BY

Portable Appliance

Tester

Instruction Manual

Page 2

CONTENTS

1. Safe testing ………………………………………………………………… 1

2. Procedure of removing cover …………………………………………….. 3

2.1 Method of removing the cover ………………………………………... 3

2.2 Method of storing the cover …………………………………………... 3

3. Product summary and explanation ……………………………………… 4

3.1 Product summary …………………………………………………….... 4

3.2 Test function ……………………………………………………………. 5

3.3 Features ………………………………………………………………... 6

3.4 Instrument layout …………………………………………………….... 6

3.5 Explanation for indications ………………………………………….... 9

3.6 Applicable standards …………………………………………..…….. 10

4. Specification ………………………………………………………………. 11

4.1

General specification, measuring range and accuracy

4.2 Threshold and display ……………………………………………….. 12

4.3 Reference test condition …………………………………………….. 12

5. Preparation before a measurement …………………………………….. 13

5.1 Visual inspection ……………………………………………………… 13

5.2 Connection to main power supply ………………………………….. 13

5.2.1 Connection of mains cord ………………………………………. 13

5.2.2

5.2.3

5.2.4

Check the warning display of mains power voltage

Null setting (Protective conductor resistance function)

Voltage setting for insulation resistance measurement

………………… 11

………………… 14

………………... 14

………………... 16

6. Measuring method ……………………………………………………….. 17

6.1

Class I Test (Common function for both IT200mA and 20A)

6.2 Class I Test (Select the leakage current test) …………………….. 19

6.3 Class Ⅱ Test ………………………………...……………………….. 21

6.4 Class Ⅱ Test (Select the leakage current test) …………………... 23

6.5 Extension Leads Test ………………………………………………... 25

6.6 Leakage Current Test ………………………………………………... 27

7. Fuse replacement ………………………………………………………… 29

8. Case and strap assembly ………………………………………………... 30

9. Maintenance …………………………………………………..…………... 30

……………..… 17

Page 3

Electricity is dangerous and can cause injury and death. Always treat it

with the greatest of respect and care. If you are not quite sure how to

proceed, then stop, take advice from a qualified person.

This instruction manual contains warning and safety rules which must

be observed by the user to ensure safe operation of the instrument

and retain it in safe condition. Therefore, read through these operating

instructions before using the instrument.

IMPORTANT:

This instrument must only be used by a competent and trained person

and operated in strict accordance with these instructions.

KEWTECH will not accept liability for any damage or injury caused

by misuse or non-compliance with the instructions or with the safety

procedures.

It is essential to read and to understand the safety rules contained in

these instructions and with the safety procedures.

The symbol

to the related sections in the manual for safe operation of the instrument.

Be sure to carefully read instructions following each symbol

manual.

DANGER is reserved for conditions and actions that are likely

to cause serious or fatal injury.

indicated on the instrument means that the user must refer

in this

1 Safe Testing

WARNING is reserved for conditions and action s that can

cause serious or fatal injury.

CAUTION is reserved for conditions and actions that can cause

minor injury or instrument damage.

DANGER

●

This instrument can be connected only to the commercial

power of 230V+10%-10%, 50Hz.

●

For safety reasons, only use the Test Leads designed to be

used with this instrument and recommended by KEWTECH.

●Use only grounded mains outlets to supply the instrument.

Do not touch the devic e under test wh i lst testing is in

progress.

1

Page 4

2

Safe Testing

DANGER

●

Since a high voltage of 500V is being output continuously,

wh en measuri ng insulat ion r esistan ce, t he user m ay get

an electrical shock. Any capacitors in the appliance under

test may become charged during testing and may contain

hazardous voltages do not touch them.

●

When testing, always be sure to keep your fingers behind the

safety barriers on the test leads.

●

Di scon nect the instr umen t from the powe r supp ly whe n

measurement is finished.

●

Do not lea ve t he i nstrument with connected to the power

supply.

WARNING

●Never open the instrument case – because dangerous voltages

are present. Only fully trained and competent electrical engineers

should open the case.

●

If abnormal conditions of any sort are noted (such as a faulty

display, unexpected readings, broken case, cracked test leads,

etc) do not use the instrument and return it to your distributor

for inspection and repair.

●

Never attempt to use the instrument if the instrument or your

hands are wet.

CAUTION

● When using Test Leads with the crocodile clip, be sure to

check the crocodile clip is firmly connected to the metal part of

the device under test. Otherwise, inaccurate measurements or

arcing at the contacts may occur.

● The rated measuring voltage for the insulation test is 500V. DC.

If this voltage seems too high for the appliance under test

contact the appliance manufacturer for advice. The IEE Code

of Practice allows for a touch current test where an insulation

test cannot be carried out.

● When testing a faulty appliance, it may trip the circuit breaker

of main power supply during test and may cause interruption

of service. Be careful when the same main power supply is

used for PCs.

● We are not liable for loss of data on PC during testing with this

instrument. The appliance under test is powered on during

most tests, but please turn it to the OFF position after testing.

● Use a very slightly damp cloth for cleaning the instrument. Do

not use abrasives or solvents.

Page 5

3

The KT71 has a dedicated cover to protect against an impact from the

outside and to prevent the fascia, the LCD, and the connector socket from

becoming dirty. The cover can be detached and put on the back side of

the main body during measurement.

2.1 Method of removing the cover

Fig.1

2.2 Method of storing the cover

2 Procedure

of removing

cover

Fig.2

Page 6

4

3 Product

summary and

explanation

3.1 Product summary

The KT71 is a hand-held portable appliance tester, performing four

functio ns to ensure the Safet y of Class I and Class II app lia nces.

Readings are displayed on a large liquid crystal display (LCD) below

which are four bicolour LEDs, which unambiguously display a pass or fail

indication for results dictated by the IEE Code of Practice.

This ins trument is s uitab le f or performing tes ts a s required b y the

following standard.

The IEE C ode of Practice for In-servi ce Inspection and Testing of

Electrical Equipment : 2003

This instrument is designed to check the electrical safety of appliances of

Class I and Class II categories.

As a guide the IEC standard define these two categories as follows:

Class I: Appliances which have a functional insulation throughout and

an earth connected case. These are often described as earthed

appliances.

Class II: Appliances which have both functional and additional insulation

wh ere any metal part s cann ot becom e Live und er fau lt

conditions.

Page 7

5

3.2 Test Function

KT71 has the following features.

Function Tests of contents

● Pro tect ive cond ucto r res ista nce (Test

current 20A AC nominal)

Extension Lead Test

Class I Test IT200mA

● Insulation P/N-PE (Test voltage 250V DC

or 500V DC)

● Polarity (Test current 200mA DC nominal)

● Pro tect ive cond ucto r res ista nce (Test

current 200mA DC nominal)

● Insulation (Test voltage 250V DC or 500V

DC)

Product

summary and

explanation

Select Switch

+ Class I Test IT200mA

Class I Test 20A

Select Switch

+ Class I Test 20A

Class ll Test

Select Switch

+ Class II Test

Leakage Current Test

● Pro tect ive cond ucto r res ista nce (Test

current 200mA DC nominal)

●

Load current and leakage current test

● Pro tect ive cond ucto r res ista nce (Test

current 20A AC nominal)

● Insulation (Test voltage 250V DC or 500V

DC)

● Pro tect ive cond ucto r res ista nce (Test

current 20A AC nominal)

●

Load current and leakage current test

● Insulation (Test voltage 250V DC or 500V

DC)

Load current and leakage current test

●

● Load cur rent measureme nt (Maximum

appliance cu r r e n t 13A) an d le a k a g e

current test

Page 8

6

Product

summary and

explanation

3.3 Features

● Check for whether the appliance is switched ON.

●

Selection for 250V or 500V on the insulation resistance test.

● Null function for the earth bond test lead.

● Warning for the over range value by the LCD.

● Capable of judging pass/fail of tests by LEDs on the panel and by a

buzzer.

3.4 Instrument layout

Fig.3

⑴ Test socket

Insert the mains plug of the appliance to be tested to this socket for

the protective conductor resistance, insulation resistance, leakage

current test and extension lead test.

⑵ Terminal block

Connect the supplied mains cord and Test Leads to this terminal block.

⑶ Terminal for mains lead

This terminal is connected to a mains supply via M-7209.

Page 9

7

⑷ Terminal for Extension lead adaptor

For use with the KAMP S (UK) extension lead adaptor.

⑸ PE / Class II insulation probe

Connect the Test Lead with crocodile clip (M-7208) (fig 5) to this

terminal for the measurement of protective conductor resistance and

Class II insulation, and clip the metal parts of the appliance under test

with the crocodile clip.

⑹ LCD

Measured value is displayed

⑺ LED for test result

When the value of protective conductor resistance and insulation

resistance exceeds the limit dictated by applicable standards, LED

lights up in red. When it is within the limit, LED lights up in green.

⑻ Start/Stop switch

A measurement starts by pressing this switch.

Pressing the

stops the measurements.

⑼ NULL/250V-500V switch

● The rotary dial has to be set to a Class l test for this button to be

used to zero out the test lead resistance.

Start/Stop

switch again during a Leakage Current Test

Product

summary and

explanation

● The rotary dial has to be set to Class ll for this button to be used to

select either 250 V or 500V test voltage.

⑽ Function switch

Select a function with this switch.

Select switch (Applicable for Class I and Class II function)

⑾

When the function is set at the same time as the Select switch is

being pressed, the leakage test will be conducted the insulation test.

⑿ Fuse

Protected by a 600V/10A ceramic fuse (F type Φ6.3x32mm).

User can replace this fuse.

Page 10

8

Product

summary and

explanation

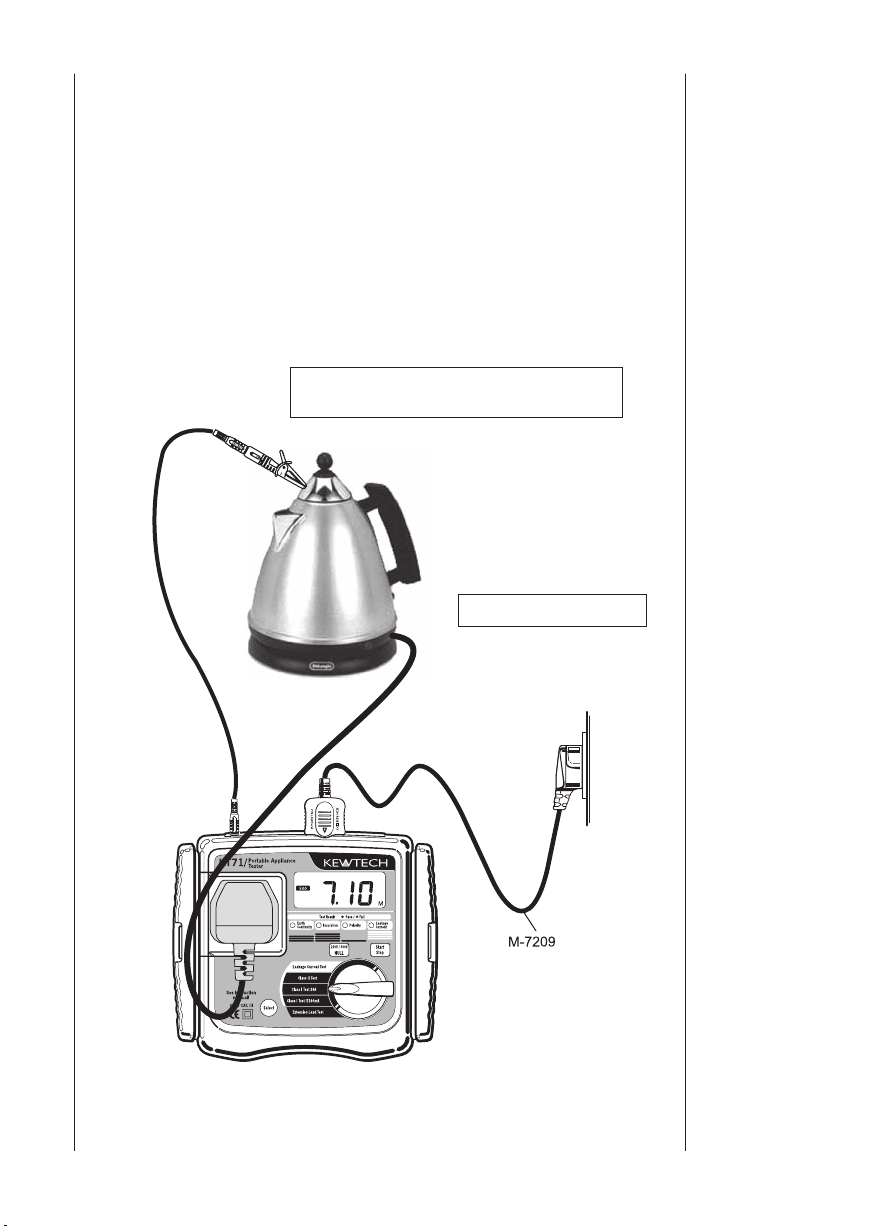

⒀ Mains cord (UK) M-7209

This mains cord can be connected to the mains supply so that the

instrument can derive power from it. To measure contact current, the

socket of the mains power supply has to have an earth terminal.

Fig.4

⒁ Test Lead with safety crocodile clip(M-7208) and Probe with Blade type

Prod(M-7163). The probe and crocodile clip are interchangeable.

Please use it according to a measurement use.

Probe with Blade Type Prod

Crocodile Clip

Fig.5

⒂ Extension leads adaptor KAMP S (UK)

This is for connecting the instrument and an extension lead (cord

reel).

IEC Connector

Fig.6

Page 11

9

3.5 Explanation for indications

LCD Display

Product

summary and

explanation

Insulation measurement voltage

Power supply voltage

(Live-Neutral) indication

Over range display: > is displayed on the LCD.

Leakage current indication

Load current indication

Null indication

Unit indication

Fig.7

Page 12

10

Product

summary and

explanation

List of display message

Disp layed whe n appliance under test is

switched off.

=> =>Value

=> =>Value

=> =>Value

=> =>Value

=> =>Value

or

(*1) Please note that the IEE Code of Practice states that the maximum

resistance should be no greater than 0.1 Ohms + the resistance of

the mains cable

Displayed when the protective conductor

resistance exceeds the threshold value. (*1)

Displayed when the insulation resistance

between LN-E is less than the threshold

value.

Di s p l ay e d wh e n th e le a k ag e cu rr e nt

exceeds the threshold value.

Displayed when the resistance between L-L

exceeds 10Ω at extension lead test.

Displayed when the resistance between

N-N exceeds 10Ω at extension lead test.

Displayed when the appliance under test is

undergoing the leakage current test.

D i sp la y ed w h en e m er ge n cy s t op is

operated at leakage current test.

Displayed when the mains voltage exceeds

the range of specifications (207V to 260V).

Testing will be diasabled.

3.6 Applicable standards

Instrument operation

The IEE Code of Practice for In-service Inspection and Testing of

Electrical Equipment : 2003

Safety

IEC/EN61010-1 CAT.III 300V-instrument

IEC/EN61010-031 CAT.III 300V(600V)-test lead

EMC

EN61326 (EN55022/EN61000-3,4)

Page 13

11

4.1

General specification, measuring range and accuracy

Measurement of protective conductor resistance - RPE

Test function IT 200mA continuity 20A continuity test

4. Specification

Measuring range 0 ~ 15.00

Resolution 10m

Open-circuit voltage 4 ~ 24V

Measuring current 200mA DC (nominal) 20A AC (nominal)

Accuracy ± (3%rdg+5dgt)

Measurement of insulation resistance - RINS

Output voltage 250V 500V

Measuring range 0.1~19.99M

Resolution 10k

Open-circuit voltage 250V (+30%/-0%) 500V (+30%/-0%)

Nominal current

Short-circuit current 2.5mA DC or less

Accuracy ± (2%rdg+3dgt)

Measurement of leakage current test (With load current test) –LEAK

1mA DC min. @250k

Ω

Ω

Ω

Ω

Ω

1mA DC min. @500k

Ω

Test function Load current test

Measuring range AC0.1~ 13.00Arms

Resolution 10mA 10μA

Accuracy ±(10%rdg ± 5dgt) ±(3%rdg ± 5dgt)

Examination time Max 5 seconds Max 10 seconds

Note: For MOV appliances use leakage current test.

Leakage current test

AC0.1~ 19.99mArms

Page 14

12

Specification

4.2 Threshold and display

Function

Protective

conductor

resistance

Insulation

resistance

Leakage

current

Polarity

Extension Lead

Class I IT200mA

Class I 20A

Class ll

Leakage Current

4.3 Reference test condition

Unless otherwise specified, this specification is dependent on the

following conditions.

(1) Ambient temperature: 23±5˚C

(2) Relative humidity: 45 ~ 75%

(3) Attitude: Horizontal

(4) AC power supply: 230V, 50Hz

(5) Altitude up to 2000m, Indoor use

Operating temperature and humidity range

0

~ +40℃ Relative humidity: 85% or less (no condensation)

℃

Storage temperature and humidity range

-20

~ +60℃ Relative humidity: 85% or less (no condensation)

℃

RPE

0.1Ω

≦

RPE

0.1Ω

≦

RPE

0.1Ω

≦

−

− −

RINS ≧ 1MΩ

RINS ≧ 1MΩ

RINS ≧ 1MΩ

RINS ≧ 2MΩ

−

LEAK

LEAK

LEAK

≦

LEAK

≦

3.5mA

≦

3.5mA

≦

0.25mA

0.75mA

Cont ≦ 10Ω

−

−

−

−

Rate voltage and frequency

Rated voltage: 230V ±10%

Rated frequency: 50Hz ±1%

Maximum rated power

Load current at test socket: 3kVA(15sec.)

Other test function: Approx.9VA

Outer dimension and weight

Outer dimension: 185(L) × 167(W) × 89(D)mm

Weight: Approx. 1.3kg (Only the instrument body)

Page 15

13

Symbols used on the instrument:

Eq uipmen t protec ted throughout by DOU BLE INSULATION o r

REINFORCED INSULATION

Caution (Refer to the accompanying instruction manual)

5.1 Visual inspection

Before starting a measurement, the user should undertake visual

checks on the mains cord, case and that the correct type and rated fuse

is fitted to the appliance under test. There should also be no evidence

of damage of a nature that may impair the electrical safety of the

appliance.

5.2 Connection to main power supply

5.2.1 Connection of mains cord

Connect the mains supply and the instrument with M-7209 mains cord.

Specification

5. Preparation

before a

measurement

M-7209

Fig.8

CAUTION

● Always be sure to check there are no abnormal conditions or

damage to the instrument and leads.

If any evidence of abnormality is found, measurement must be

stopped immediately.

● Th e outlet of t he mains power suppl y must have a n earth

terminal and be earthed.

● This instrument can be only connected to the commercial

power of 230V+10%-10%, 50Hz.

Page 16

14

Preparation

before a

measurement

5.2.2 Check the warning display of mains power voltage

The warning device can work in any position of the function switch

of the instrument. When Lo v or Hi v is displayed on the LCD at

the time of the instrument connected with the mains power source, it

means the measurement can not proceed because the mains voltage

value of the instrument is out of the specific range. Do not connect the

instrument with the mains power until the cause is identified.

WARNING

● When the voltage of mains power supply is 260V or more, Hi

v is displayed on the LCD.

● In that case, disconnect the mains cord of the instrument from

main power supply.

5.2.3 Null setting

The IEE Code of Practice pass level for protective conductor resistance

is 0.1Ω, which is a low value. So even the resistance of Test Leads will

affect the measurement result.

The KT71 ca n ca n c e l th e re s i stance of te s t le a d by pr e s s i n g

|

250V/500V

NULL

The Null function is held in memory even when the instrument is turned

off, so theres no need to Null the lead resistance every time.

However, when replacing fuses or test leads, it is recommended to do a

Null setting again.

. The procedure of Null setting is shown below.

Procedure:

(1) Set the function switch to Class I Test function. (Setting is possible

at both IT200mA and 20A.)

(2) Connect the mains supply and the instrument with the M-7209

mains cord.

Page 17

15

Fig.9

(3)

Insert Test Lead with probe (M-7208) in to the E terminal of the

instrument, and contact the tip of the Test Lead with the earth contacts

of the socket on the instrument.

|

250V/500V

Press the

between the Test Lead and the earth contacts of the socket, the

resistance of the Test Lead will be displayed on the LCD as shown in

fig.10 for 2sec.

Then, the instrument cancels the resistance value of Test Lead and

adjusts the displayed value to 0.00 as shown in fig.10.

The

Null setting cannot be done when the resistance is 3Ω or more.

A message no appears to indicate a resistance is exceeding the

NULL icon is then displayed in the LCD.

Null setting range.

NULL

s witch whil st main tai ning con tact

Preparation

before a

measurement

Display at Null setting

Fig.10

Page 18

16

Preparation

before a

measurement

|

250V/500V

(4) Null setting can be released by pressing

for 2sec. The

setting is released.

The Null setting and release can only be done in a Class I Test

function.

● Null setting can be set only with either Class I Test IT200mA or

Class I Test 20A selected.

● It is possible that there is a different setting value between

Class I Test IT200mA and Class I Test 20A.

5.2.4

Voltage setting for insulation resistance measurement

(How to change between 250V and 500V)

(1) Set the function switch to Class II Test function, and press the

|

250V/500V

NULL

the voltage selected. By pressing the

250V and 500V can be changed over.

NULL icon on the LCD will disappear when Null

CAUTION

switch. The LCD display will change to indicate

NULL

NULL

|

250V/500V

switch

switch,

Fig.11

Page 19

17

6.1 Class l Test (Common function for both IT200mA and 20A)

The purpose of the test carried out for Class I appliances is to check

the resistance of earth continuity from exposed metal parts and the

plug is below a certain level and the insulation resistance between live

and neutral connected together and earth is below 1M

protective conductor resistance and insulation resistance tests on an

appliance, connect the mains plug of the appliance to the test socket (1)

described in clause 3.4 Instrument layout and the PE probe to terminal

(5).

Use the following setups, depending upon the type of appliance.

Connect to exposed metal parts but not

rotating parts or heating elements.

Ω

. To conduct

Switch ON the power.

6. Measuring

method

Fig.12

Page 20

18

Start

RPE ≦ 0.1Ω ?

LnE ≧ 1MΩ ?

Is the appliance

switched on?

No

Ye

s

Ye

s

Ye

s

No

No

(1). Protective conductor resistance.

Lights up in red

Lights up in red

Lights up in green

Lights up in green

”no” →“Con”→”value”

will be repeated on

the LCD.

(See note 1 below)

”no” →“LnE”→”value”

will be repeated on the

LCD.

”oFF” →“ ? ” is displayed

alternately on the LCD.

Can proceed to the next

step by pressing the Start

switch again even if the

result was a fail

Re-start

Re-start

(2).Appliance switch test

(3). Insulation resistance between L/N and PE.

Value (1). and (3). will be alternately displayed on LCD

PASS

Measuring

Class I Test Flowchart

method

Note 1: The IEE Code of Practice states that the maximum resistance

should be no greater than 0.1 Ohms + the resistance of the mains cable.

Therefore if the appliance has a long mains lead then the allowable

resistance can be higher than the pre-programmed 0.1

Ω

.

Page 21

19

CAUTION

● If the Appliance switch test fails, displayed by OFF and ?

appearing alternately on the LCD, and the appliance is actually

switched on there may be a direct short between L and N.

Suspend testing immediately.

● Follow the procedure described in 5.2.3 and undertake the Null

setting before a measurement.

● The crocodile clip must make good contact with the enclosure

of the appliance.

● When the terminal is open or the resistance value exceeds

measuring range, > mark (over range display) appears on the

LCD.

● Do not touch the appliance under test whilst testing is in

progress. Since a high voltage of 500V will be present and the

user may get an electrical shock.

6.2 Class I Test (Select the leakage current test) – common to both

IT200mA and 20A function

Turning the rotary dial to either Class I Test whilst the

is being pressed down initiates a leakage current test instead of the

Insulation resistance test.

When selecting the leakage current test, exposed metal parts other than

the heating or movable parts must be clipped with Test Lead M-7208

since the appliance will switch on and activate. Pressing the

switch during the leakage current test stops the test immediately. To

restart the test, press the

has been stopped. Then (1) Protective conductor resistance will be

restarted. Fig 12 indicates how to connect the devices.

Refer to item 6.6 on details of Leakage Current Test

Start/Stop

switch again 2 sec after the test

Select switch

Start/Stop

Measuring

method

Page 22

20

Start

RPE ≦ 0.1Ω ?

LEA ≦ 3.5mA ?

No

Ye

s

Ye

s

No

(1). Protective conductor resistance.

Lights up in red

Lights up in red

Lights up in green

Lights up in green

”no” →“Con”→”value”

will be repeated on

the LCD.

(See note 1 below)

Stop the test and

”no” →“LEA”→”value”

will be repeated on the

LCD.

Standby until Start switch is pressed

again whilst indicating on the LCD.

Re-start

(2). Wait

(4). Power-on leakage current test.

(3). Appliance load current test.

Value of (1),(3) and (4) will be alternately displayed on the LCD.

5sec Measures load current of the instrument.

10sec Measures leakage current of the appliance.

LCD indicates during the measurement.

PASS

Measuring

Class I Test (Select the Leakage Current Test) Flowchart

method

Note 1: The IEE Code of Practice states that the maximum resistance

should be no greater than 0.1 Ohms + the resistance of the mains cable.

Therefore if the appliance has a long mains lead then the allowable

resistance can be higher than the pre-programmed 0.1

Ω

.

Page 23

21

CAUTION

● When the terminal is open or the resistance value, load current

and leakage current exceeds the measuring range, > (over

range display) appears on the LCD.

● If the test is stopped, a message StP appears on the LCD and

values of leakage current are not displayed.

WARNING

● W h en co nd u ct i ng a lea k ag e t e s t t h e ap p li a n ce wi l l

automatically power on and will operate in its normal manner.

It is imperative that the appliance is secured safely before the

test is carried out. Extra care needs to taken with appliances

which have heating elements and rotating parts.

● Firmly insert the plug of the appliance to the socket of the

KT71. Plugs may get hot if leakage current test is performed

with improper connection.

● Do not connect/remove the plugs during leakage current test.

It may cause a reading error. Do not use the instrument on the

device which has a power consumption of 3kVA or more.

6.3 Class ll Test

The Class ll appliances have the indication of DOUBLE INSULATION

or the

re s ista n ce of the appli ances is with i n the range define d i n the

standards.

symbol. The Class ll insulation test is to check the insulation

Measuring

method

Page 24

22

Start

Is the appliance

switched on?

LnE ≧ 2MΩ ?

No

Ye

s

Ye

s

No

(1). Appliance switch test

Lights up in red

Lights up in green

When the resistance

between L-N is about

100kΩ or more ”oFF” →

“ ? ” is displayed

alternately on the LCD.

”no” →“LnE”→ ”value”

will be repeated on the

LCD.

Re-start

(2). Insulation resistance between L/N and PE.

Va

lue of (2). will be displayed on the LCD.

PASS

Measuring

method

Connect to exposed

metal parts but not

rotating parts or

heating elements.

Class ll Test Flowchart

Switch ON the power.

Fig.13

Page 25

23

CAUTION

● If the Appliance switch test fails, displayed by OFF and ?

appearing alternately on the LCD, and the appliance is actually

switched on there may be a direct short between L and N.

Suspend testing immediately.

● When the terminal is open or the resistance value exceeds the

measuring range, > mark (over range display) appears on

the LCD.

● Do not touch the appliance under test whilst testing is in

progress. Since a high voltage of 500V will be present and the

user may get an electrical shock.

6.4 Class ll Test (Select the leakage current test)

When turning the rotary dial to the Class II Test whilst pressing the

Select switch, power-on leakage current test will be carried out instead

of Insulation resistance test. When leakage current test is chosen,

the appliance will switch on and operate in its normal manner. When

connecting the test lead do not clip a metal a rotating part or heating

element with the Test Lead M-7208.

Refer to item 6.6 on details of Leakage Current Test

Measuring

method

Page 26

24

Start

LEA ≦ 0.25mA ?

Yes

No

(1). Wait

Lights up in red

Lights up in green

Standby until the Start switch is

pressed again whilst the flashing

icon is indicated.

Stop the test and

”no” → “LEA” → ”value”

will be repeated on the

LCD.

(2). Appliance load current test.

(3). Power-on leakage current test.

Value of (2) and (3) will be displayed on the LCD.

PA

SS

5sec Measures load current of the instrument.

10sec Measures leakage current of the

appliance. LCD indicates

during the measurement.

Measuring

Class II Test (Select the Leakage Current Test) Flowchart

method

● When load current exceeds 15A or leakage current exceeds

20mA, > (over range display) appears on the LCD.

● If the test is stopped, a message StP appears on the LCD and

● W h en co nd u ct i ng a lea k ag e t e s t t h e ap p li a n ce wi l l

values of leakage current are not displayed.

automatically power on and will operate in its normal manner.

It is imperative that the appliance is secured safely before the

test is carried out. Extra care needs to taken with appliances

which have heating elements and rotating parts.

● Firmly insert the plug of the appliance to the socket of the

KT71. Plugs may get hot if leakage current test is performed

with improper connection.

● Do not connect/remove the plugs during leakage current test.

It may cause a reading error. Do not use the instrument on the

device which has a power consumption of 3kVA or more.

CAUTION

WARNING

Page 27

25

6.5 Extension Leads Test

M-7209

This test is for extension leads, and checks for;

● Protective conductor resistance between accessible conductive

parts and connection of protective earth.

●

Insulation resistance between L/N and PE.

●

Polarity check of the Live and Neutral terminal of plug and socket.

Test procedure and the connection are as follows.

Extension

leads adapter

KAMP S (UK)

Measuring

method

Fig.14

Page 28

26

Measuring

Start

RPE ≦ 0.1Ω ?

L-L & N-N ≦10Ω?

LnE ≧ 1MΩ?

No

Ye

s

Ye

s

Ye

s

No

No

(1). Protective conductor resistance test.

Lights up in red

Lights up in red

Lights up in red

Lights up in green

Lights up in green

”no” → “Con” → ”value”

will be repeated on the

LCD.

(See note 1 below)

”no” → “L-L” → ”value”

or ”no” → ”n-n” → ”value”

will be repeated on the

LCD.

”no” →“LnE”→”value”

will be repeated on the

LCD.

Re-start

Re-start

(2). Insulation resistance test between L/N and PE.

(3). Polarity test between L-L and N-N.

Value of (1) and (2) will be alternately displayed on LCD.

PA

SS

Extension Leads Test Flowchart

method

Note 1: The IEE Code of Practice states that the maximum resistance

should be no greater than 0.1 Ohms + the resistance of the mains cable.

Therefore if the appliance has a long mains lead then the allowable

resistance can be higher than the pre-programmed 0.1

Ω

.

Page 29

27

CAUTION

● Follow the procedure described in 5.2.3 and do Null setting

before a measurement, but use the short KAMP S lead instead

of the M-7208 tes t lead, by plugging the KAMP S. Into the

Extension Lead Adaptor terminal and the UK socket on the

front of the unit.

● When the terminal is open or the resistance value exceeds the

measuring range, > (over range display) appears on the

LCD.

● Do not touch the device under test whils t te s ting is in

progress. Since a high voltage of 500V will be present, the user

may get an electrical shock.

6.6 Leakage Current Test

This function is to conduct the leakage current test separately at mains

voltage, the appliance will be automatically switched on and power up in

its normal manner.

The leakage current test, measures load current of the instrument for

about 5 seconds, then measures leakage current for about 10 seconds

and both measured results are displayed. The KT71 can measure up to

20mA although the threshold value is 0.75mA in this function.

Measuring

method

●

Set the function switch to Leakage Current Test position.

●

Refer to the Fig12 or Fig13 for connection of an appliance.

● After set up is done, press the

flashing icon on the LCD at standby mode.)

● Check the switch of the appliance is ON.

● Press

● The appliance will operate for 15 seconds and indicate the final

Start/Stop

values (value after 15 sec.) of load current and the maximum value

of leakage current.

switch again.

Start/Stop

switch. (Indicated by the

Page 30

28

Start

LEA ≦ 0.75mA ?

Ye

s

No

(1). Wait

Lights up in red

Lights up in green

Standby until Start switch is pressed

again whilst the flashing icon is

indicated.

Stop the test and

”no” → “LEA” → ”value”

will be repeated on the

LCD.

(2). Appliance load current test.

(3). Power-on leakage current test.

Value of (2) and (3) will be displayed on the LCD.

PA

SS

5sec Measures load current of the instrument.

10sec Measures leakage current of the

appliance. LCD indicates

during the measurement.

Measuring

method

Leakage Current Measurement Flowchart

-

Remarks

-

Stopping the Test

1) Emergency stop and restart manually for power-on leakage current

test:

In order to stop testing the leakage current whilst measuring, press

Start/Stop

2 seconds or more from when the test has been stopped. The test will

. To start a test again, press

restart.

2) Auto stop of power-on leakage current test:

The ins trument stops measur ing immediatel y when load curre nt

exceeds 15A or leakage current exceeds 20mA (but more than 3.5mA

in Class I test function and more than 0.25mA in Class II test function).

Start/Stop

again after about

Page 31

29

WARNING

● W h en co nd u ct i ng a lea k ag e t e s t t h e ap p li a n ce wi l l

automatically power on and will operate in its normal manner.

It is imperative that the appliance is secured safely before the

test is carried out. Extra care needs to taken with appliances

which have heating elements and rotating parts.

● Firmly insert the plug of the appliance to the socket of the

KT71. Plugs may get hot if leakage current test is performed

with improper connection.

● Do not connect/remove the plugs during leakage current test.

It may cause a reading error. Do not use the instrument on the

device which has a power consumption of 3kVA or more.

Measuring

method

Wh en the f use blows d urin g use, ple ase repla ce with a n ew one

according to below procedure.

Fig.15

(1) Use a flat head screwdriver and turn about 45º to the left and remove

the fuse cap and fuse.

(2) Remove the fuse from the fuse cap and replace it with new one.

(3) Refitting is the reverse procedure.

7. Fuse

replacement

Page 32

Fuse

replacement

WARNING

● Remove mains cord from the instrument before replacing the

fuse.

● Thi s is the only use r replace able f use. N ever a ttem pt to

perform any other repairs.

CAUTION

● Please use the specified fuse (Fast acting type ceramic fuse:

600V/10A - Φ6.3x32mm).

8. Case and

strap

assembly

9. Maintenance

The strap and test lead case can be attached to the instrument as below.

Pass the strap belt down through the side panel of the main body from the

top, and up through the slots of the test lead case from the bottom. (Fig.

16).

Pass the strap through the buckle, adjust the strap for length and secure.

Fig.16

Use a very slightly damp cloth for cleaning the instrument. Do not use

abrasives or solvents.

30

Page 33

Kewtech Corporation Ltd.

Midas House, Unit 2b

Stones Courtyard

High Street, Chesham

Buckinghamshire HP

www.kewtechcorp.com

5 IDE

31

Page 34

Tel:01494 792212

92-1890A 07-01

Loading...

Loading...