15. Back Light .................................................................................. 47

16. Memory Function ........................................................................ 48

16.1 How to save the data ......................................................... 48

16.2 Recall the saved data ......................................................... 50

16.3 Delete the saved data .

16.4 Transfer the stored data to PC ............................................ 53

17. General ...................................................................................... 54

18. Battery replacement .................................................................... 55

19. Fuse replacement ........................................................................

20. Servicing and Calibration ............................................................. 56

21. Pat test with the Pat adapter 1 ..................................................... 57

22. Zs tables .................................................................................... 58

23. Case and strap assembly .............................................................

The KT65DL incorporates Anti Trip Technology (ATT) which electronically

bypasses RCDs when performing loop impedance tests. This saves time and

money by not having to take the RCD out of the circuit during testing and is a

safer procedure to follow.

With the ATT function enabled, a test of 15mA or less is applied between

line & earth. It enables l

rated at 30mA and above.

Please read this instruction manual carefully before using this equipment.

oop impedance measurements without tripping RCDs

....................................................... 51

55

60

Contents

1

1 Safe Testing

Electricity is dangerous and can cause injury and death. Always treat

it with the greatest of respect and care. If you are not quite sure how

to proceed, stop and take advice from a qualified person.

1 This instrument must only be used by a competent and trained person

and operated in strict accordance with the instructions. Kewtech will

not accept liability for any damage or injury caused by misu

c

ompliance with the instructions or with the safety procedures.

2 It is essential to read and to understand the safety rules contained

in these instructions. They must always be observed when using the

instrument.

3 This instrument is designed to work in distribution systems where the line

to earth has a maximum voltage of 300V 50/60Hz and for some ranges

where line to line has a maximum

B

e sure to use it within this rated voltage.

For use in the continuity testing and insulation testing modes this

instrument must be used ONLY on circuits which are de-energized.

4 When conducting tests do not touch any exposed metalwork associated

with the installation. Such metalwork may become live for the duration of

the test.

5 Never open the instrument case (except

replacement and in this case disconnect all leads first) because

dangerous voltages are present. Only fully trained and competent

electrical engineers should open the case. If a fault develops, return the

instrument to Kewtech for inspection and repair.

6 If the overheat symbol appears in the display disconnect the instrument

from the mains supply and allow to cool down.

abnormal conditions of any sort are noted (such as a faulty display,

7 If

unexpected readings, broken case, cracked test leads, etc) do not use

the tester and return it to Kewtech for repair.

8 For safety reasons only use accessories (test leads, probes, fuses,

cases, etc) designed to be used with this instrument and recommended

by Kewtech. The use of other accessories is prohibited as they are

y to have the corre

unlikel

9 When testing, always be sure to keep your fingers behind the finger

guards on the test leads.

10 During testing it is possible that there may be a momentary degradation

of the reading due to the presence of excessive transients or discharges

on the electrical system under test. Should this be observed, the test

must be repeated to obtain a correct reading.

Kewtech.

ct safety features.

voltage of 500V 50/60Hz.

for fuse and battery

If in doubt, contact

se or non-

2

11 Do not operate the function selector whilst the instrument is connected to

a circuit. If, for example, the instrument has just completed a continuity

test and an insulation test is to follow, disconnect the test leads from the

circuit before moving the selector switch.

12 Do not rotate rotary switch when test button is depressed. If the function

switch is inadvertently moved to a new function

depressed or in lock-down position the test in progress will be halted.

13 Always check the test lead resistance before carrying out tests. This

ensures the leads are ok before taking measurements. The resistance

of leads and/or crocodile clips may be significant when measuring

low resistances. If crocodile clips can be avoided for low resistance

measurements, this will red

14 When carrying out Insulation Resistance tests, always release the test

button and wait for charged capacitances to totally discharge before

removing the test leads from the test circuit.

uce the erro

r due to lead accessories

when the test button is

Safe Testing

3

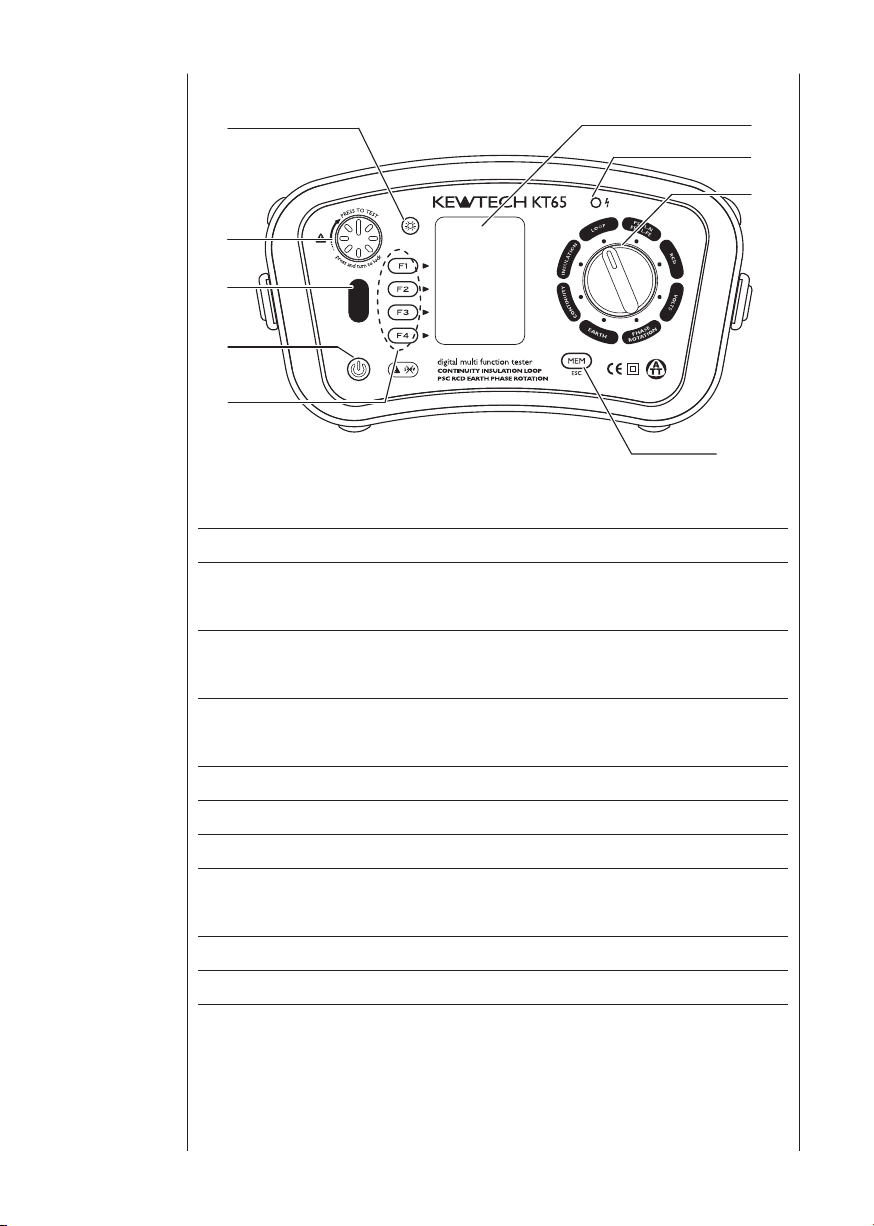

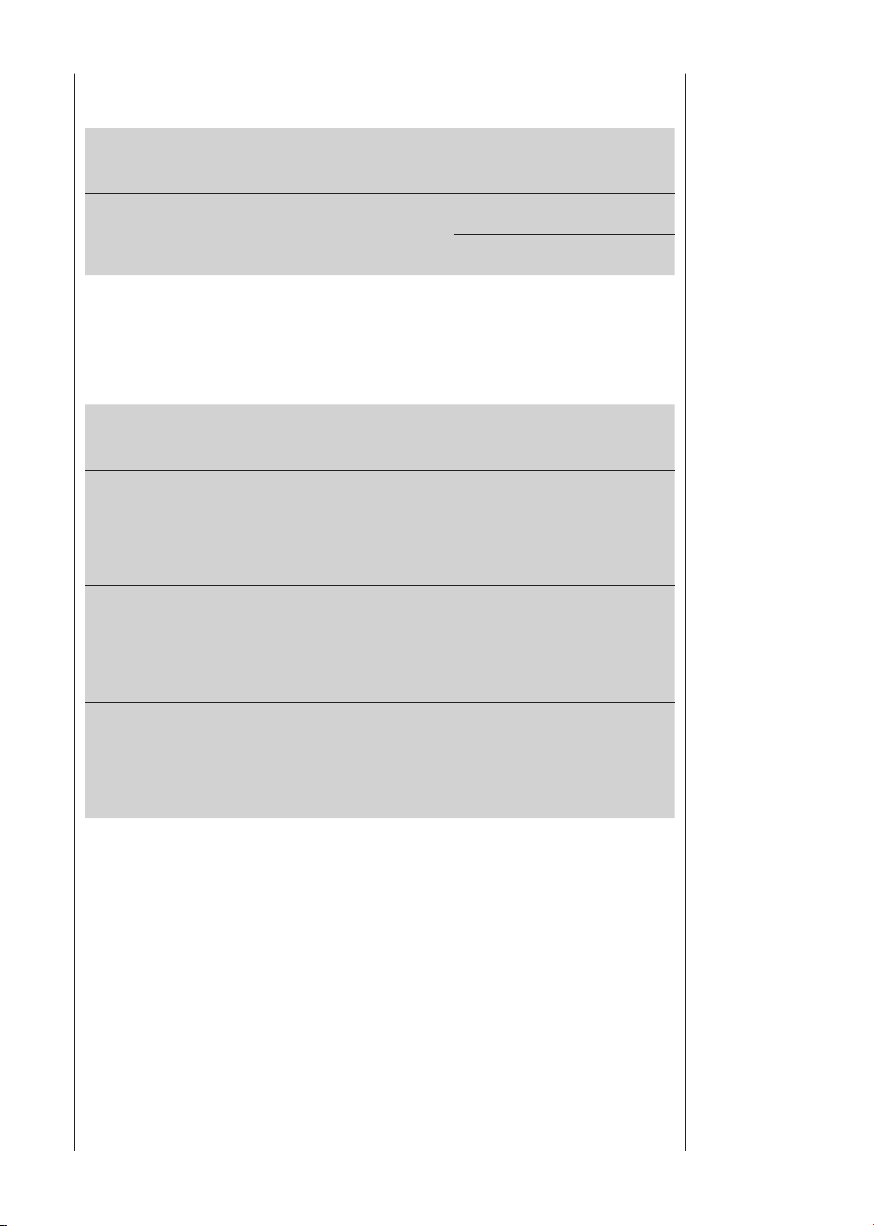

2 Instrument

(6)

(1)

(3)

(4)

(5)

(7)

(8)

(2)

(9)

layout

Fig. 1

Name Operation

(1) Back Light Button

(2) Test Button

(3) Touch Pad

(4) Power Switch Power Switch

(5) Function Switch Function setting (F1 ~ F4)

(6) Display (LCD) Dot Matrix LCD 160(W)X240(H)

(7) Insulation resistance LED

(8) Rotary Switch Selects measurement functions.

(9) MEM (ESC) Button Activates Memory Function, or ESC Key

Switches on/of f the Backlight of the

Display(LCD)

Starts measurements. (press and rotate

for lock down feature)

Checks the electrical potential at the PE

terminal

Aler ts that the test voltage is

output

being

4

Input Terminal

(1)

(2)

(3)

(4)

Instrument

layout

Fig. 2

Function Terminal

Terminal Names for :

INSULATION,

CONTINUITY

(1)

LOOP,

PFC/PSC,

RCD,

VOLTS

Terminal Name for

(2)

PHASE ROTATION

Te r mi n al Na m e fo r

(3)

EARTH

(4) Optical Adapter Co

L : Line

PE : Protective Earth

N : Neutral (for LOOP,PSC/PFC, RCD)

L1 : Line1

L2 : Line2

L3 : Line3

H(C) : Terminal for auxiliary earth spike

E : Terminal for the earth electrode

S(P) : Terminal for auxiliary earth spike

(current)

(potential)

mmunication port

for Model8212USB

5

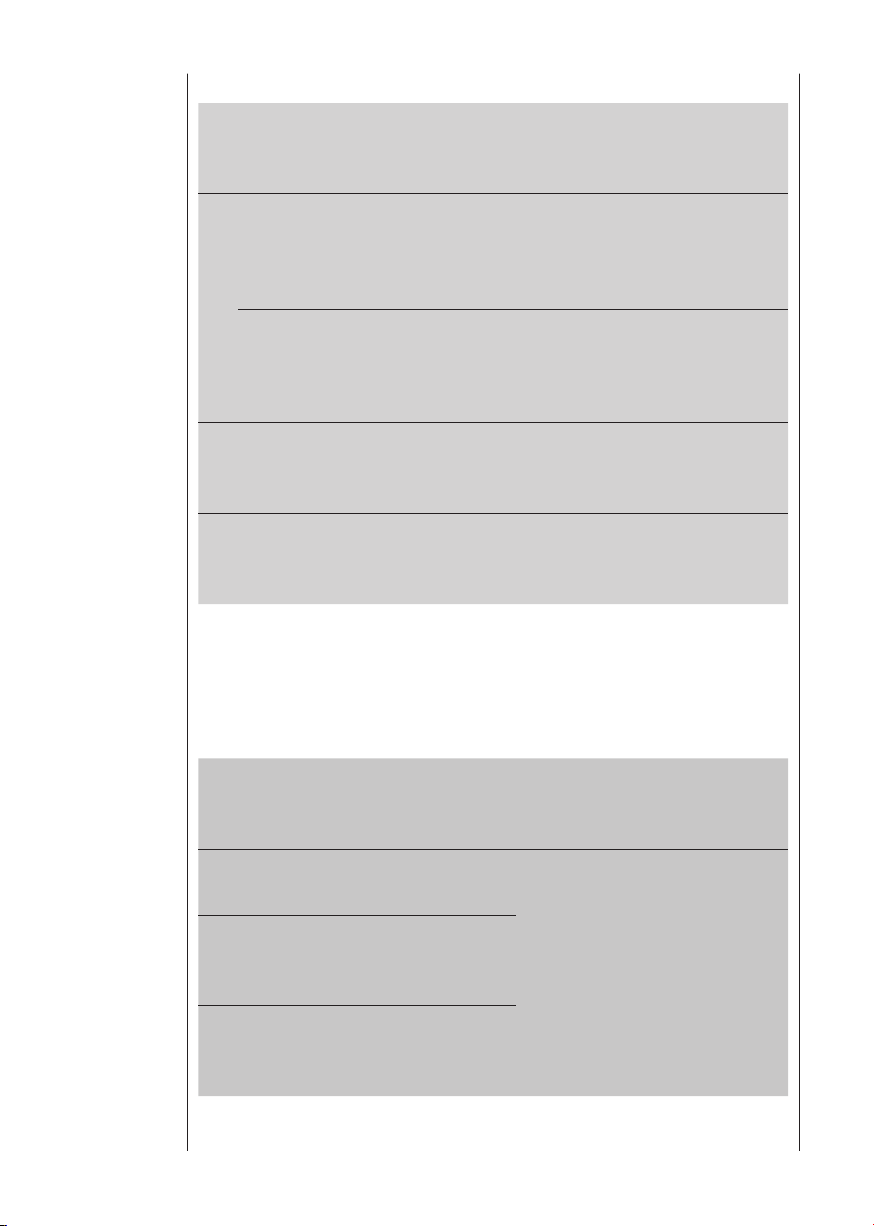

Accessories

Blue(Neutral)

Brown(Line)

Green(Protective Earth)

Blue(Neutral or L3)

Green(Protective Earth

or L2)

Brown(Line or L1)

Yellow S(P)10m

Green E 5m

Red H(C) 20m

Auxiliary Earth Spikes x2

3

1. Main Test Lead (KAMP12)

Fig. 3

2. Remote Test Lead (ACC064SP)

Fig. 4

3. Distribution Board Test Lead (ACC065)

g. 5

Fi

4. Test Lead Carry pouch・・・x1

5. Carrying Bag・・・x1

6. Instruction Manual・・・x1

7. Shoulder Strap・・・x1

8. Buckle・・・x2

9. Battery・・・x8

10. Optional Accessory

PAT ADAPTER - See Page57

・

Earth Tests Lead(Model7228) and Auxiliary Earth Spikes

・

Fig. 7

Fig. 6

Model8212USB with PC Software KEW Report.

・

Fig. 8

6

The KT65DL Multi-Function tester performs eight functions in one instrument.

1 Continuity

2 Insulation resistance

3 Loop impedance

4 Prospective short circuit current

5 RCD

6 Voltage

7 Phase rotation

8 Earth resistance

Continuity function has the following features:

Live circuit warning Live Circuit warning on the display.

Fuse Protection Continuity Function has a fuse protection function

to prevent a

Wi th this func tion, a fuse ra rely bl ow while

measuring continuity on live conductors.

Continuity Null Allows automat i c sub t r a ction of test lead

resistance from continuity measurements.

Continuity 2Ω Buzzer Buzzer sounds at 2Ω or le ss at Conti nuity

function. (Switchable on or off)

Insulation function has the following features:

Live circuit warning Live Circuit wa

Auto discharge Electric charges stored in capacitive circuits

are discharged automatically after testing by

releasing the test button.

Insulation Resistance LED LED lights up while making measurements at

Insulation function and alerts that test voltage is

being output.

fuse blow at live working.

rning on the display.

4 Features

Loop impedance, PSC/PFC and RCD testing functions have the following

features:

ymbols indicate if the wiring of the

Wiring check Three Wirin

circuit under test is correct.

Over temperature protection

Phase angle selector The test can be selected from either the positive

Detects overheating of the internal resistor (used

for LOOP and PSC/PFC tests) and of the current

control MOS FET (used for RCD tests) displaying

a wa rning symbol and automatic ally halting

further measurements.

(0 ° ) or from th

voltage. This selector is used in the RCD mode to

g s

e n

egative (180 ° ) half cycle of

7

Features

obtain the maximum trip time of an RCD for the

test selected.

UL value selector Select UL (limit of contact voltage) 25V or 50V.

Where Uc (contact voltage) exceeds UL value at

RCD testing, Uc > UL will be displayed without

starting the measurement.

ALL testing functions have the following

Touch Pad Gives an alert, when touching the Touch Pad,

while the PE terminal is connected to Line by

take.

mis

Memory Function Save the measured data in the internal memory.

The da t a can be ed i t e d on a PC by us i n g

Communication Adapter Model8212USB and PC

Software KEW Report.

Auto power off Automatically switches the instrument off after

a period of approxim ately 10 mi nutes. Th e

Auto power off mode can only be cancelled by

switching the instrument on again.

8

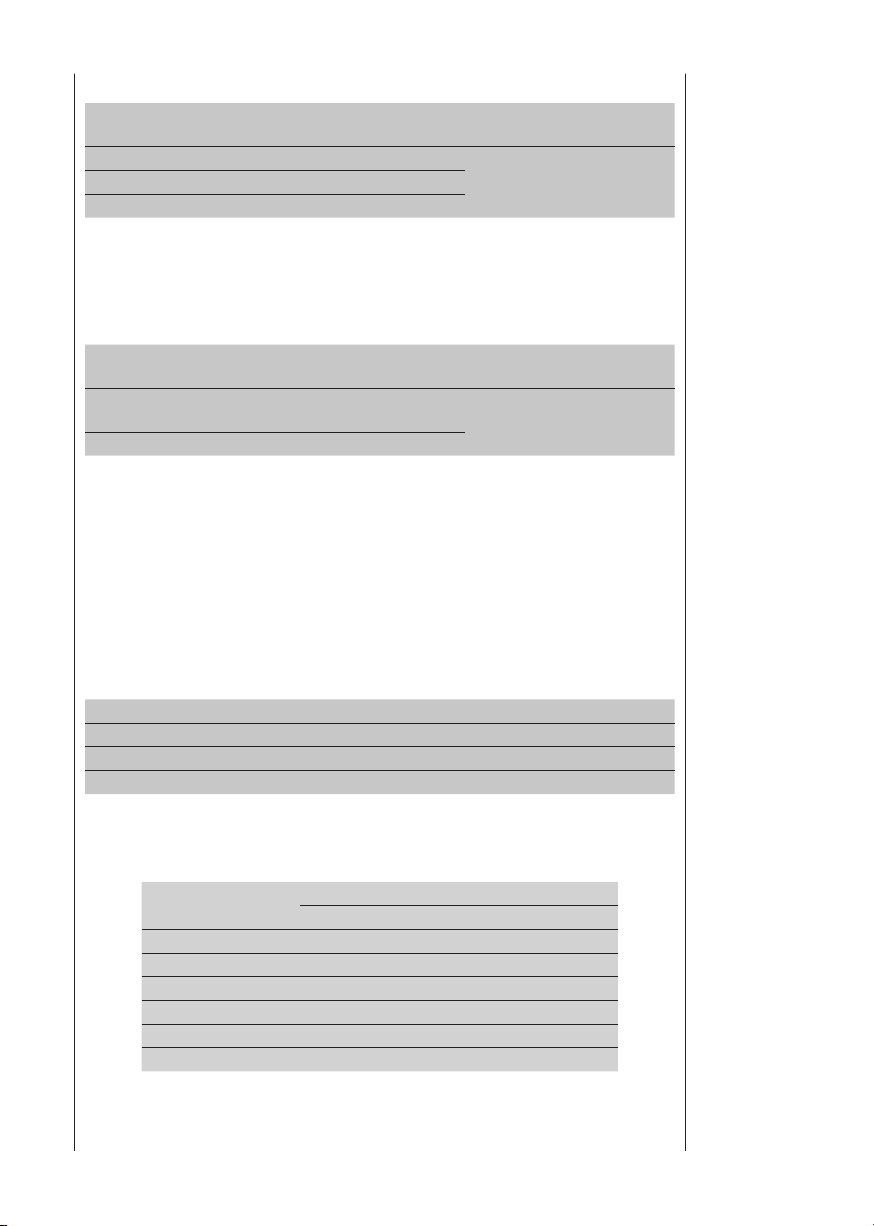

5.1 Measurement Specification

Continuity

5 Specification

Open Circuit

Voltage (DC)

5V±20%(*1)

2Ω Buzzer : Buzzer sounds when measured resistance is 2Ω or less.

2Ω Buzzer Accuracy : 2Ω±0.4Ω

(*1) Voltages are output when measurement resistance is under 2100 ohm.

Insulation Resistance

Open Circuit

Voltage (DC)

250V+25% -0%

500V+25% -0%

1000V+20% -0%

Short Circuit

Current

Greater than

200mA

Rated Current Range Accuracy

1mA or greater

@ 250kΩ

1mA or greater

@ 500kΩ

1mA or greater

@ 1MΩ

Range Accuracy

20/200/2000Ω

Auto-Ranging

20/200MΩ

Auto-Ranging

20/200/1000MΩ

Auto-Ranging

20/200/2000MΩ

Auto-Ranging

0~0.19Ω ±0.1Ω

0.2~2000Ω

0~19.99MΩ:

±(2%rdg+6dgt)

20~200MΩ:

±(5%rdg+6dgt)

0~199.9MΩ:

±(2%rdg+6dgt)

200~1000MΩ:

±(5%rdg+6dgt)

0~199.9MΩ:

±(2%rdg+6dgt)

200~2000MΩ:

±(5%rdg+6dgt)

±(2%rdg+8dgt)

9

Specification

Loop Impedance

Function

0.01

ΩRes

L-PE

0.001

ΩRes

L-PE

(ATT)

L-N / L-L

*2 : at 230V

*3 : 230V+10%-15%

*4: 50V~100V

*5: voltages except for *3 and *4

Rated

Voltage

50~260V

50/60Hz

230V

+10%-15%

50/60Hz

100~260V

50/60Hz

50/60Hz

L-N:50~300V

L-L:300~500V

Nominal Test Current

at 0Ω External Loop:

Magnitude/Duration(*2)

20Ω: 6A/20ms

200Ω: 2A/20ms

2000Ω:

15mA/500ms

2Ω: 6A/90ms

L-N: 6A/60ms

N-PE: 10mA/

approx. 5s

20Ω: 6A/20ms

Range Accuracy

20/200/2000Ω

Auto-Ranging

2Ω

20/200/2000Ω

Auto-Ranging

(L-N < 20Ω)

20Ω

±(3%rdg+4dgt) *3

±(5%rdg+15dgt) *4

±(3%rdg+8dgt) *5

±(3%rdg+35mΩ)

±(3%rdg+6dgt) *3

±(3%rdg+8dgt) *4

±(3%rdg+4dgt) *3

±(5%rdg+15dgt) *4

±(3%rdg+8dgt) *5

PSC (L-N/L-L) / PFC (L-PE)

Nominal Test Current

at 0Ω External Loop:

Magnitude/Duration(*6)

Function

PSC

PFC

PFC (ATT)

*6: at 230V

Rated

Voltage

50~500V

50/60Hz

50~260V

50/60Hz

100~260V

50/60Hz

6A/20ms

6A/20ms

2A/20ms

15mA/500ms

L-N: 6A/60ms

N-PE: 10mA/

approx. 5s

Range Accuracy

2000A/20kA

Auto-Ranging

PSC/PFC

accuracy is

derived from

measured loop

impedance

specification and

measured voltage

specification

10

RCD

Accuracy

Function Rated Voltage

X1/2

X1 +2%~+8% 0%~+10%

X5 +2%~+8% 0%~+10%

Ramp(◢) ±4% ± 10%

Auto

RCD Trip Current Duration

Function Type

Trip

Current

Duration

(ms)

230V+10%-15%

50/60Hz

Depending on the accuracy at each function.

Measurement sequence:

X1/2 0°→X1/2 180°→X1 0°→X1 180°→X5 0°→X5 180°

Measurements with x5 are not carried out for RCDs with nominal

current of 100mA or more.

AC 2000 2000 2000 2000 2000 2000

G

X1/2

X1

X5

Ramp

(◢)

A 2000 2000 2000 2000 2000 n.a

AC 2000 2000 2000 2000 2000 n.a

S

A 2000 2000 2000 2000 2000 n.a

AC 550 550 550 550 550 550

G

A 550 550 550 550 550 n.a

AC 1000 1000 1000 1000 1000 n.a

S

A 1000 1000 1000 1000 1000 n.a

AC 410 410 410 n.a n.a n.a

G

A 410 410 410 n.a n.a n.a

AC 410 410 410 n.a n.a n.a

S

A 410 410 410 n.a n.a n.a

AC

G

A n.a

AC

S

A n.a

Trip Current

AC Type A Type

-8%~-2% -10%~0%

RCD Trip Current Duration

10 30 100 300 500 1000

Goes up by 10% from 20% to 110%

00ms×10 times

3

Goes up by 10% from 20% to 110%

500ms×10 times

Trip Time

±(1%rdg+3dgt)

.a

n

n.a

Specification

Earth

Measuring

Frequency

825Hz

Range Accuracy

20/200/2000Ω

Auto-Ranging

20Ω range : ±(3%rdg+0.1Ω)

200/2000Ω range : ±(3%rdg+3dgt)

(Auxiliary earth resistance 100±5%)

11

Specification

PHASE ROTATION

Rated Voltage

Remarks

50-500V

50/60Hz

Volts

Function Rated voltage Measuring Range Accuracy

Frequency

Possible number of tests with fresh batteries.

Continuity : Approx. 2000 times min. at load 1Ω

Insulation Resistance : Approx. 1000 times min. at load 1MΩ (1000V)

LOOP/PFC/PSC : Approx. 1000 times min. (ATT)

RCD : Approx. 2000 times min. (G-AC X1 30mA)

EARTH : Approx. 10

OLT/PHASE ROTATION : Approx. 50H

V

Reference Conditions

Correct phase sequence: are displayed 1.2.3 and

Reversed phase sequence: are displayed 3.2.1 and

Volts

Ambient temperature 23±5℃

Relative humidity 45% to 75%

25~500V

45~65Hz

25~500V

45~65Hz

25~500V ±(2%rdg+4dgt)

45~65Hz ±(0.5%rdg+2dgt)

00 times min. at load 10Ω

mark

mark

Nominal system voltage and

frequency

Altitude Less than 2000m

5.2 Operating error

Continuity (EN61557-4)

Operating range compliant with

EN61557-4 operating error

0.20~1999MΩ ±30%

The influencing variations used for calculating the operating error are denoted

as follows;

Temperature : 0℃ and 35℃

Supply voltage : 8V to 13.8V

230V, 50Hz

Maximum percentage

operating error

12

Insulation Resistance(EN61557-2)

Volt

250V 0.25~199.9MΩ

1000V 1.00~1999MΩ

The influencing variations used for calculating the operating error are denoted

as follows;

Temperature : 0℃ and 35 ℃

Supply voltage : 8V to 13.8V

Loop Impedance(EN61557-3)

Volt

L-PE

L-N 0.40~19.99Ω

The influencing variations used for calculating the operating error are denoted

as follows;

Temperature : 0 ℃ and 35 ℃

Phase angle : At a phase angle 0° to 18°

System frequency : 49.5Hz to 50.5Hz

System voltage : 230V+10%-15%

Supply voltage : 8V to 13.

H

armonics :

D.C quantity : 0.5% of the nominal voltage

Operating range compliant with

EN61557-2 operating error

Operating range compliant with

EN61557-3 operating error

0.40~1999Ω

(0.001ΩRes:0.400~1.999Ω)

8V

5% of 3rd harmonic at 0° phase angle, 5% of 5th harmonic

at 180° phase angle, 5% of 7th harmonic at 0° phase angle

Maximum percentage

operating error

±30%500V 0.50~999MΩ

Maximum percentage

operating error

±30%

Specification

RCD(EN61557-6)

Function Operating error of trip current

X1/2 -10%~0%

X1, X5 0%~+10%

Ramp -10%~+10%

The influencing variations used for calculating the operating error are denoted

as follows;

Temperature : 0 ℃ and 35 ℃

Earth electrode Resistance (shall not exceed below) :

IΔn (mA)

10 2000 2000

30 600 600

100 200 200

300 130 65

500 80 40

1000 40 20

System voltage : 230V+10%-15%

Supply voltage : 8V to 13.8V

Earth electrode resistance (Ω max.)

UL50V UL25V

Table.1

13

Specification

Earth Resistance (EN61557-5)

Operating range compliant with EN61557-5

operating error

5.00~1999Ω ±30%

The influencing variations used for calculating the operating error are denoted

as follows;

Temperature : 0 ℃ and 35℃

Series interference voltage : 3V

Resistance of the probes and auxiliary

earth electrode resistance : 100 x RA, 50kΩ or less

Supply voltage : 8V to 13.8V

5.3 General specification

ment dimensions 2

Instru

Instrument weight:- 1350g (including batteries.)

Reference conditions Specifications are based on the following

1. Ambient temperature: 23±5° C:

2. Relative humidity 45% to 75%

3. Position: horizontal

4. AC power source 230V, 50Hz

5. DC power source: 12.0 V, ripple content 1%

6. Altitude up to 2000m, Indoor use

tery type E

Bat

Operating temperature and humidity.

0 to +40 ℃ , relative humidity 80% or less, no

Storage temperature and humidity

-20 to +60℃ , relative humidity 75% or less, no

Display Dot Matrix LCD 160(W) X 240(H) pixels.

Overload protection The continuity test circuit is protected by a

The insulation resistance test circuit is protected

35 X 136 X 114mm

conditions, except where otherwise stated:-

or less

ight LR6,AA or R6 batteries.

condensation

condensation.

0.5A/600 V fast acting (HRC) ceramic fuse

mounted in the batt

spare fuse is also stored.

by a resistor against 1000 V AC for 10 seconds.

Maximum percentage

operating error

ery compartment, where a

14

5.4 Applied standards

Instrument operating IEC/EN61557-1,2,3,4,5,6,7,10

Standard

Safety standard IEC/EN 61010-1(2001),

CATIII (300V) -Instrument

IEC/EN 61010-031(2008)

CATII (250V)-Test Lead KAMP12

CATIII (600V)-Test Lead ACC065

CATIII (1000V)-Test Lead ACC064SP

CATIII (300V)-Test Lead Model7228

Protection degree IEC 60529 (1989 + A1) IP40

EMC EN 61326

EN55022/24

Specification

This manual and product may use the foll

a

dopted from International Safety Standards;

CAT.III Measurement category CAT III applies to;

Primary electrical circuits of the equipment connected directly

to the distribution panel, and feeders from the distribution

panel to outlets.

Equipment protected throughout by DOUBLE INSULATION or

REINFORCED INSULATION;

Caution (refer to accompanying documents)

Caution, risk of electric shock

Protection against wrong connection is up to 500V

Earth Ground

owing symbols

15

Specification

5.5 List of Display Message

Low battery warning

Tem p erat u re moni t o r f o r in t e r nal resistan c e ,

available at Loop, PSC/PFC & RCD function. Further

measurements are suspended until the

disappears.

Measuring Measurements in progress

Live Circuit Live circuit warning (Continuity / Insulation Function)

PE Hi V

L-N >20Ω

Noise

N - PE Hi V

Uc > UL

no

Caution : Presence of 100V or more at PE terminal,

appears when touching the Touch Pad

Alert : Presence of 20Ω or more between Line Neutral at ATT measurement

Caution : Presence of noise in the circuit under test

during ATT measurement. ATT function should be

isabled to continue measurements.

d

Caution: Presence of high voltage between NEUTRAL

- EARTH during ATT measurement. ATT function

should be disabled to continue measurements.

Caution : Uc at RCD measurement is exceeding the

preset UL value (25 or 50V).

Error message : When on the RCD function, RCD

tripped before measuring RCD trip time. Selected

IΔn value may not be correct.

on the LOOP, PSC/PFC function, supply may

When

have been interrupted.

symbol

OK

NO

×

Hi, RS Hi

R

H

No 3-phase system

Wiring check for LOOP, PSC/PFC function

Appears when all results passed during the RCD Auto

Test function.

Appears when any results failed during the RCD Auto

Test function.

Appears when a Probe resistance of H terminal

(RH) or of S terminal (RS) at Earth measurement is

exceeded the measurable range.

Appears to indicate wrong connection at Phase

Rotation check.

16

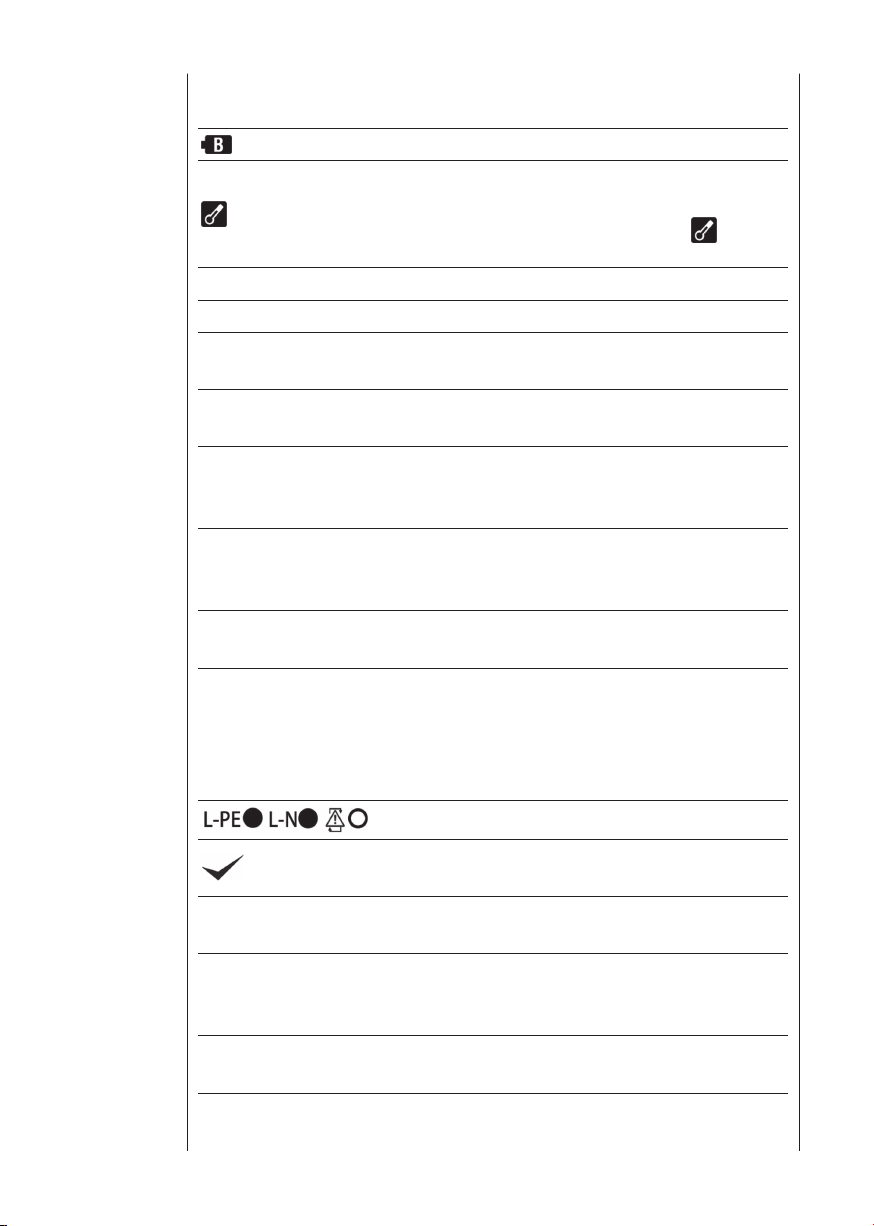

Setting for following three parameters

1. Press the Config Button

(F4) when powering on

KT65. (Fig.9)

2. Then, Configuration

Screen (Fig.10) is

displayed.

KT65

TESTER

MULTI FUNCTION

Config

Push

Touch Pad :

UL :

OFF

Configuration

Back Light :

ON

50V

ESC

▲ UL value・・・・・・・・Selects a UL value for RCD function

▲ Touch Pad・・・・・・Enables / disables Touch Pad function

▲ Back Light・・・・・・Selects Backlight ON / OFF. When ON is selected, the

Backlight automatically turns on at powering on the instrument.

Setting method

Fig. 9 Fig. 10

6 Configuration

3. Press the F1 – F3 Button to change following setting.

Parameter Selection Initial value

F1 UL value 25V, 50V 50V

F2 Touch Pad ON, OFF ON

F3 Back Light ON, OFF OFF

4. Press the ESC Button (F4) when setting change is completed, and return to

the normal screen.

17

7 Continuity

NULL OFF

PAT OFF

ON

Ω

Brown

(Red)

Green

Warning: Ensure that circuits to be tested are not live.

Disconnect the instrument from the circuit under test before operating

the function switch.

To select the low resistance range select CONTINUITY.

7.1 Test Procedure

The object of continuity testing is to measure only the resistance of the parts

of the wiring system under test. This measurement should not include the

s u

resistance of any test lead

sed. The resistance of the test leads needs to

be subtracted from any continuity measurement. The KT65DL is provided with

a continuity null feature which allows automatic compensation for any test

lead resistance.

You should only use the test leads supplied with the instrument.

Operation of Function Switch

F1 Switches on / off NULL function

F2 Switches on / off 2Ω buzzer

PAT mode setting.

F3

(PAT OFF, CL1 0.1Ω, CL1 0.3Ω)

Fig. 11

F4 N/A

Proceed as follows:1 Select the continuity test by rotating the Rotary switch.

2 Press F3 switch to select PAT mode setting.

3 Insert the Test Leads to the L and PE terminal on KT65DL respectively as

shown in Fig.12.

L terminal

Brown cord of ACC065, or

ACC064SP Remote Test Lead

PE terminal

Green cord of ACC065

Fig. 12

4 Connect the ends of the test leads firmly together (see Fig.13) and press

and lock down the test button. The value of the lead resistance will be

displayed.

18

NULL

ON

Ω

Measuring

NULL

ON

Ω

Measuring

PAT OFF

Fig. 13

5 Press the Continuity Null (F1) button, this will null out the lead resistance and

the indicated reading should go to zero.

6 Release the test button. Press the test button and ensure the display reads

zero before proceeding. While using the Continuity null function, NULL

is displayed on the LCD as indicated in Fig.13. The null value will be stored

even if the instrument is powered off. This memorised null value can be

cancelled by disconnecting the test leads and pushing the Continuity Null

button (F1) with the test button pressed or locked. When this is cancelled

you will know because NULL OFF is displayed on the LCD.

CAUTION - before taking any measurements

always check the leads have

been zeroed.

7 Connect the test leads to the circuit whose resistance is required (see

Fig.14 for a typical connection arrangement), having first made sure that

the circuit is not live. Note that Live Circuit warning will be displayed on

the LCD if the circuit is live - but check first anyway!

8 Press the test button and read the circuit resistance from the display. Th

re

ading will have the test lead resistance already subtracted if the Continuity

null function has been used.

9 Note that if the circuit resistance is greater than 20Ω the instrument will

autorange to the 200Ω, if it is greater than 200Ω it will autorange to the

2000Ω range.

Note: If the reading is greater than 2000Ω the overange symbol >

will remain displayed.

The results of measurements can be

adversely affected by impedances of

additional operating circuits connected in parallel or by transient currents.

Continuity

e

19

Continuity

Test at socket

between L and E

T

emporary lin

k

NULL

ON

Ω

NULL

ON

Ω

Measuring

PAT CL1 0.3

Ω

Pass or fail mark

Fig. 14

▲ If PAT mode Is selected, pass( ) or fail(X) mark is displayed during

measurement. Pass or fail mark is displayed on LCD according to the

following table.

MODE Measured Value Result

Less than 0.1 Ω Pass (

)

CL1 0.1 Ω

Over 0.1 Ω Fail (X)

Less than 0.3 Ω Pass (

)

CL1 0.3 Ω

Fig. 15

Over 0.3 Ω Fail (X)

) function

7.2 2Ω Buzzer (

Use F2 Button to enable / disable the 2Ω Buzzer. The Buzzer sounds when

measured resistance is 2Ω or less while this function is enabled. Buzzer does

not sound if it is disabled.

20

Warning: Ensure that circuits to be tested are not live.

Disconnect the instrument from the circuit under test before operating

the function switch.

To select the insulation resistance range select INSULATION.

8.1.1 The nature of insulation resistance

Live conductors are separated from each other and from earth by insulation,

which has a resistance which is high enough to ensure that the current

ween conductors and to earth is kept at an acceptably low level. Ideally

bet

insulation resistance is infinite and no current should be able to flow through

it. In practice, there will normally be a current between live conductors and

to earth, this is known as leakage current. This current is made up of three

components, which are:-

1. capacitive current

2. conduction current, and

3. surface leakage curre

8

.1.2 Capacitive Current

The insulation between conductors which have a potential difference between

them behaves as the dielectric of a capacitor, the conductors acting as

the capacitor plates. When a direct voltage is applied to the conductors, a

charging current will flow to the system which will die away to zero (usually

in less than a second) when the effective capacitor becomes charged. Thi

charge must be removed from the system at the end of the test, a function

which is automatically performed by the KT65DL. If an alternating voltage

is applied between the conductors, the system continuously charges and

discharges as the applied voltage alternates, so that there is a continuous

alternating leakage current flowing to the system.

nt.

8 Insulation

s

Fig. 16

21

Insulation

8.1.3 Conduction Current

Since the insulation resistance is not infinite, a small leakage current flows

through the insulation between conductors. Since Ohm's Law applies, the

leakage current can be calculated from

applied voltage (V)

Leakage current (μA) =

insulation resistance (MΩ)

Fig. 17

8.1.4 Surface Leakage Current

Where insulation is removed, for the connection of conductors and so on,

current will flow across the surfaces of the insulation between the bare

conductors.

the surfaces of the insulation between the conductors. If the surfaces are

clean and dry, the value of the leakage current will be very small. Where the

surfaces are wet and/or dirty, the surface leakage current may be significant.

If it becomes large enough, it may constitute a flashover between the

conductors.

Whether this happens depends o

on the applied voltage; this is why insulation tests are carried out at higher

voltages than those normally applying to the circuit concerned.

The amount of leakage current depends on the condition of

n t

he condition of the insulation surfaces and

Fig. 18

8.1.5 Total Leakage Current

The total leakage current is the sum of the capacitive, conduction and surface

leakage current described above. Each of the currents, and hence the

total leakage current, is affected b

conductor temperature, humidity and the applied voltage.

If the circuit has alternating voltage applied, the capacitive current (8.1.2) will

y factors such as ambient temperature,

22

always be present and can never be eliminated. This is why a direct voltage is

used for insulation resistance measurement, the leakage current in this case

quickly falling to zero so that it has no effect on the measurement. A high

voltage is used because this will often break down poor insulation and cause

flashover due to surface leakage (see 8.1.4), thus showing up potential faults

which would n

The insulation tester measures the applied voltage level and the leakage

current through the insulation. These values are internally calculated to give

the insulation resistance using the expression:-

Test voltage (V)

Insulation resistance (MΩ) =

Leakage current (μA)

As the capacitance of the system charges up, so the charging current falls to

zero and a steady insulation resistance reading indicates that the capacitance

of the syste

and will be dangerous if left with this charge. The KT65DL provides an

automatic path for discharging current as soon as the test button is released

to ensure that the circuit under test is safely discharged.

If the wiring system is wet and/or dirty, the surface leakage component of the

leakage current will be high, resulting in lo

the case of a very large electrical installation, all the individual circuit insulation

resistances are effectively in parallel and the overall resistance reading will be

low. The greater the number of circuits connected in parallel the lower will be

the overall insulation resistance.

ot be pre

s fully charged. The system is charged to the full test voltage,

m i

sent at lower levels.

w i

nsulation resistance reading. In

Insulation

8.2 Damage to Voltage-Sensitive Equipment

An increasing number of electronic-bas

connected to electrical installations. The solid state circuits in such equipment

are likely to be damaged by the application of the levels of voltage used

to test insulation resistance. To prevent such damage, it is important that

voltage-sensitive equipment is disconnected from the installation before the

test is carried out and reconnected again immediately after

which may need to be disconnected before the test include:-

▲ Electronic fluorescent starter switches

▲ Passive infra-red detectors (PIRs)

▲ Dimmer switches

▲ Touch switches

▲ Delay timers

▲ Power controllers

▲ Emergency lighting units

▲ Electronic RCDs

ed items of equipment are being

wards. The devices

23

Insulation

250V

PAT OFF

MΩ

Brown Green

(Red)

▲ Computers and printers

▲ Electronic point-of-sale terminals (cash registers)

▲ Any other device which includes electronic components.

8.3 Preparation for measurement

Before testing, always check the following:1 The low battery Indication is not displayed

2 There is no visually obvious damage to the tester or to the test leads

3 Test the continuity of the test leads by switching to continuity test

and

shorting out the lead ends. A high reading will indicate that there is a faulty

lead or that the fuse is blown.

4 Make sure the circuit to be tested is not live. Live Circuit warning is

displayed if the instrument is connected to a live circuit but test the circuit

as well!

Operation of Function Switch

F1 N/A

F2 N/A

PAT mode setting.

F3

(PAT OFF, CL1, CL2)

F4 Voltage setting

Fig. 19

8.4 Insulation resistance measurement

The KT65DL has three selectable test voltages of 250V, 500V and 1000V

DC.

1 Select INSULATION function with the Rotary switch.

2 Press the VOLT Switch (F4) and select desirable voltage range.

3 Press F3 switch to select PAT mode setting.

(In case of 1000V range, PAT mode is not selectable.)

t t

4 Inser

he Test Leads to the L and PE terminal on the KT65DL respectively

as shown in Fig.20.

L terminal

Brown cord of ACC065, or

ACC064SP Remote Test Lead

PE terminal

Green cord of ACC065

Fig. 20

24

5 Attach the test leads to the circuit or the appliance under test (see Figs 21

Note: insulation testing must only be undertaken on

1000V

MΩ

1

de-energised circuits

1000V

MΩ

& 22)

Fig. 21

6 If the Live Circuit warning is displayed on the LCD and/or the buzzer

sounds, do not press the test button but disconnect the instrument from

the circuit. Make the circuit dead before proceeding.

Insulation

Fig. 22

7 Press the test button, the display will show the insulation resistance of the

circuit or the appliance to which

8

Note that if the circuit resistance is greater than 20MΩ, the instrument will

the instrument is connected.

autorange to the 200MΩ range. If it is greater than 200MΩ at the 500V

or 1000V range, it will autorange to the 2000MΩ range.If it is greater than

200MΩ at the 500V range, it will autorange to the 1000MΩ range. If it is

greater than 200MΩ at the 1000V range, it will autorange to the 2000MΩ

range.

9

When testing is complete release the test button before disconnecting

the test leads from the circuit or from the appliance. This will ensure that

the charge built up by the circuit or the appliance during insulation test is

25

Insulation

250V

Measuring

PAT CL1

MΩ

CL1

>1M

Ω

Pass or fail mark

dissipated in the discharge circuit. In the discharging process, Live Circuit

warning will be displayed on the LCD and the live circuit warning buzzer will

sound.

▲ If PAT mode Is selected, pass(

) or fail(X) mark is displayed during

measurement. Pass or fail mark is displayed on LCD according to the

following table.

MODE Measured Value Result

Over 1M Ω Pass (

)

CL1

Less than 1MΩ Fail (X)

Over 2M Ω Pass (

)

CL2

Fig. 23

Less than 2MΩ Fail (X)

WARNING

Never touch the circuit, test lead tips or the appliance under test during

insulation testing because high voltages exist.

CAUTION

Never turn the Rotary switch whilst the test button is depressed as this may

damage the instrument.

Always release the test button first after

testing before removing the test

leads from the circuit. This is to ensure that charges stored in the circuit

capacitance have been totally discharged.

Note: If the reading measured greater than 2000MΩ (200MΩ at 250V

1000MΩ at 500V) the over range reading > will be displayed.

26

9.1 Principles of measurement of fault loop impedance and PFC

If an electrical installation is protected by over-current protective devices

including circuit breakers or fuses, the earth loop impedance should be

measured.

In the event of a fault the earth fault loop impedance should be low enough (and

the prospective fault current high enough) to allow automatic disconnection

of the electrical suppl

time interval. Every circuit must be tested to ensure that the earth fault loop

impedance value does not exceed that specified or appropriate for the overcurrent protective device installed in the circuit. The KT65DL takes a current

from the supply and measures the difference between the unloaded and

loaded supply voltages. From this differenc

loop resistance.

TT System

For a TT system the earth fault loop impedance is the sum of the following

impedances;

▲Impedance of the power transformer secondary winding.

▲ Impedance of the phase conductor resistance from the power transformer

to the location of the fault.

▲ The impedance of the protective conductor from the fault location to the

earth system.

▲Resistanc

▲Resistance of the power transformer earth system (Ro).

e of the local eart

y by the circuit protection device within a prescribed

e it is possible to calculate the

h system (R).

9 LOOP/PSC/PFC

The figure below shows (dotted line) the Fault loop impedance for TT systems.

Fig. 24

27

LOOP/PSC/PFC

According to the International Standard IEC 60364, for TT systems the

characteristics of the protective device and the circuit resistance shall fulfill

the following requirements:

Ra x Ia ≤ 50V Where:

Ra is the sum of the resistances in Ω of the local earth system and the

protective conductor for the exposed conductive parts.

50 is the maximum safety touch voltage limit (it can be 25V in particular

c

ases like construction sites, agricultural premises, etc.).

Ia is the current causing the automatic disconnection of the protective device

within the maximum disconnecting times required by IEC 60364-41:

- 200 ms for final circuits not exceeding 32A (at 230 / 400V AC)

- 1000 ms for distribution circuits and circuits over 32A (at 230 / 400V AC)

The compliance with the above rules shall be verified by:

1) Measurement of the resistance Ra of the local earth system by Loop tester

or Earth tester.

2) Verification of the characteristics and/or the effectiveness of the RCD

associated protective device.

Generally in TT systems, RCDs are used as a protective device and in this

case, Ia is the rated residual operating current IΔn. For instance in a TT

system protected by a RCD the max Ra values are:

Rated residual operating current IΔn

RA (with touch voltage of 50V) 1667 500 167 100 50 (Ω)

RA (with touch voltage of 25V) 833 250 83 50 25 (Ω)

Shown below is a practical example of verification of the protection by RCD in

a TT system according to the international Standard IEC 60364.

30 100 300 500 1000 (mA)

28

Ω

L - PE

L-PE

L-N

230

V

50.0Hz

ATT

:ON

!

Fig. 25

For this example the max permissible value is 1667 Ω (RCD =30mA and

contact voltage limit of 50 V). The instrument reads 12.74 Ω, thus the

condition RA ≤ 50/Ia is respected. However, considering that the RCD

is essential for protection, it must be tested (Please refer to RCD TESTS

section).

TN System

For TN systems the earth fault loop impedance is the sum of the following

impedances.

▲ Impedance of

the power transformer secondary winding.

▲ Impedance of the phase conductor from the power transformer to the

location of the fault.

▲ Impedance of the protective conductor from the fault location to the power

transformer.

LOOP/PSC/PFC

The figure below shows (dotted line) the Fault loop impedance for TN systems.

Fig. 26

29

LOOP/PSC/PFC

According to the International Standard IEC 60364, for TN system the

characteristics of the protective device and the circuit impedance shall fulfill

the following requirement:

Zs x Ia ≤ Uo Where:

Zs is the Fault loop impedance in ohm.

Uo is the nominal voltage between phase to earth (typically 230V AC for both

single phase and three phase circuits).

Ia is the current causing the automatic disconnec

within the maximum disconnecting times required by IEC 60364-41 that are:

- 400 ms for final circuits not exceeding 32A (at 230 / 400V AC)

- 5 s for distribution circuits and circuits over 32A (at 230 / 400V AC)

The compliance with the above rules shall be verified by:

1) Measurement of the fault loop impedance Zs by Loop tester.

2) Verification of the characterist

protective device. This verification shall be made:

- for circuit-breakers and fuses, by visual inspection (i.e. short time or

instantaneous tripping setting for circuit-breakers, current rating and type for

fuses);

- for RCDs, by visual inspection and test using RCD testers recommending

that the disconnecting times mentioned above are met (Please se

TEST section).

ics and/or the effectiveness of the associated

tion of the protective device

e RCD

For instance in a TN system with nominal mains voltage Uo = 230 V protected

by MCBs (Miniature Current Breakers) required by BSEN 60898, the max Zs

values could be:

30

Protected by BSEN 60898 MCB with Uo =230V

MCB

(Disconn.Time

0.4 and 5s)

MCB

(Disconn.

Time 0.4s)

MCB

(Disconn.

Time 5s)

B C D D

Current rating Zs (Ω) Zs (Ω) Zs (Ω) Zs (Ω)

6 7.28 3.64 1.82 3.64

10 4.37 2.19 1.09 2.19

16 2.73 1.37 0.68 1.37

20 2.19 1.09 0.55 1.09

25 1.75 0.87 0.44 0.87

32 1.37 0.68 0.34 0.68

40 1.09 0.55 0.27 0.55

50 0.87 0.44 0.22 0.44

63 0.69 0.35 0.17 0.35

Source: BS7671:2008 AMD 3:2015

The most comprehensive loop testers or Multifunction testers also have

the Prospective Fault current measurement. In this case, Prospective Fault

current measured values must be higher than the Ia of the protective device

concerned.

Below is a practical example of verifi cation of the protection by MCB in a TN

system according to the International Standard IEC 60364.

LOOP/PSC/PFC

Fig. 27

31

LOOP/PSC/PFC

PSC

A

230

V

L-N

50.0Hz

L-PE

L-N

!

Maximum value of Zs (in the table above) for this example is 2.73 Ω (MCB

16A, characteristic B).

The inst rument rea ds 1.14 Ω(or 202 A on Fault current range) and

consequently the condition Zs x Ia ≤ Uo is met.

In fact the Zs of 1.14 Ω is less than 2.73 Ω.

In other words, in case of a fault between phase and earth, the wall socket

tested in this example is protected because the MCB will trip within th

d

isconnection time required.

9.2 Principles of the measurement of line impedance and PSC

The method for measuring Line – neutral impedance and line-line impedance

is exactly the same as for earth fault loop impedance measurement with the

exception that the measurement is carried out between line and neutral or

line and line.

e

Prospective short circuit or fault current at any point within an electrica

installation is the current that would flow in the circuit if no circuit protection

operated and a complete (very low impedance) short circuit occurred.

The value of this fault current is determined by the supply voltage and the

impedance of the path taken by the fault current. Measurement of prospective

short circuit current can be used to check that the protective devices within

the system will

operate within safety limits and in accordance with the safe

design of the installation. The breaking current capacity of any installed

protective device should be always higher than the prospective short circuit

current.

l

Fig. 28

32

9.3. Operating instructions for LOOP and PSC/PFC

L-PE

Ω

ATT : ON

230V

50.0Hz

L-PE

L-N

!

PFC

A

230V

50.0Hz

L-PE

ATT

:ON

L-PE

L-N

!

9.3.1 Initial Checks: to be carried out before any testing

1. Preparation

Always inspect your test instrument and lead accessories for abnormality or

damage:

If abnormal conditions exist DO NOT PROCEED WITH TESTING. Have the

instrument checked by Kewtech.

Operation of Function Switch

LOOP

F1 Switches measurement mode:

L-PE or L-N/L-L

F2 ATT setting (on or off)

Select resolution 0.01Ω or 0.001Ω

F3

(In case of L-PE)

Fig. 29

F4 Loop limit value setting.

PSC/PFC

F1

Switches measurement mode:

PFC or PSC

F2

ATT setting (on or off)

F3

N/A

F4

Fig. 30

N/A

LOOP/PSC/PFC

(1) Press the Power button and turn on the instrument. Turn the Function

switch and set it to either the LOOP or PSC/PFC position.

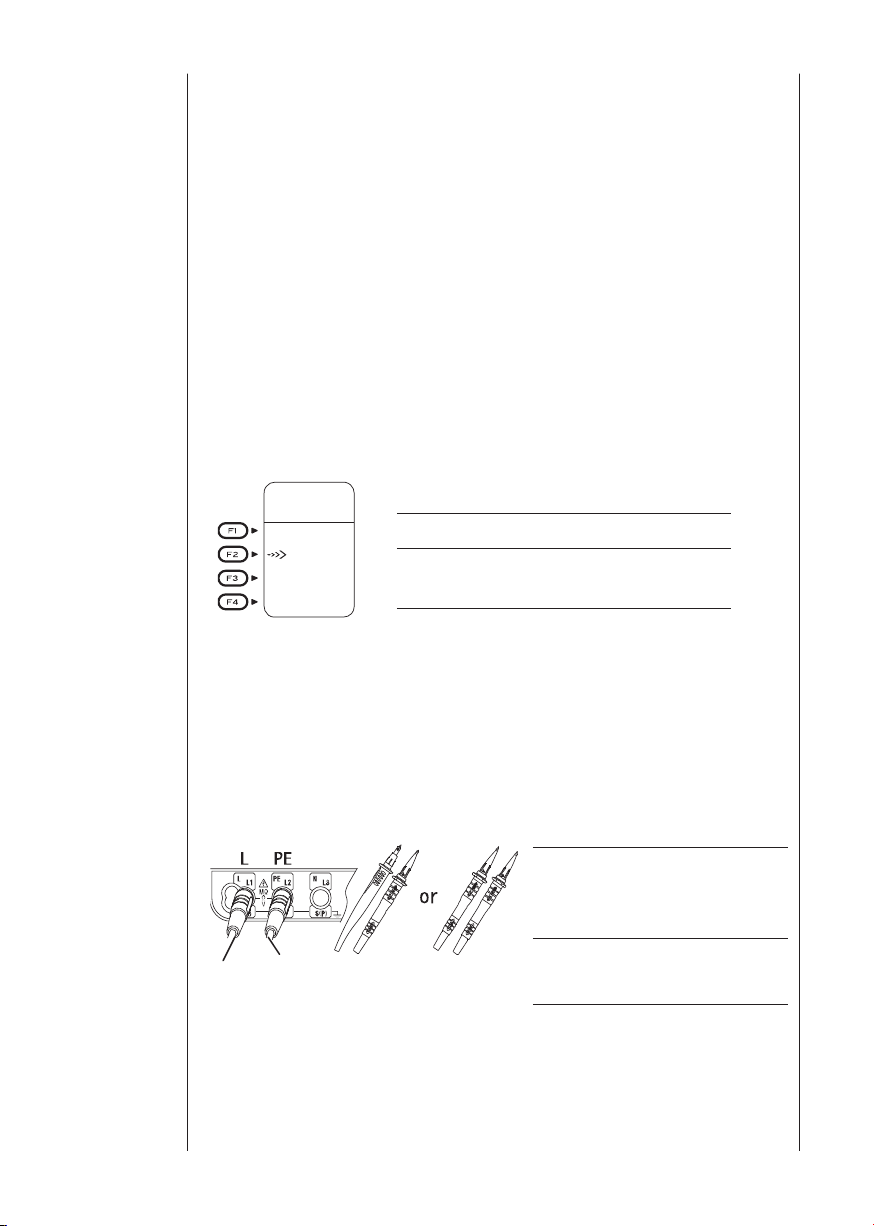

(2) Insert the Test Lead into the instrument. (Fig.31)

Fig. 31

33

LOOP/PSC/PFC

50 - 300V

>300V<

50V

L-N/L-L

Ω

<50V

LOOP

A

L-N

L-L

<50V

PSC

L-N

Ω

230V

50.0Hz

LOOP

A

230V

50.0Hz

L-N

PSC

L-L

Ω

400V

50.0Hz

LOOP

A

400V

50.0Hz

L-L

PSC

<50V

50 - 300V

>300V

L-PE

L-N

!

L-PE

L-N

!

L-PE

L-N

!

L-PE

L-N

!

L-PE

L-N

L-PE

L-N

!

!

L-N/L-L

L-N L-L

L-N L-L

L-N/L-L

(3) Press the MODE switch(F1) and select L-N to measure Loop(L-N/L-L) or

PSC or select L-PE to measure earth loop impedance or PFC.

Display changes automatically as follows depending on the applied

voltages while LOOP(L-N/L-L) or PSC is selected.

Fig. 32

(4) Pressing the ATT switch (F2) disables ATT mode. Then ATT OFF is

displayed on the LCD.

ithout tripping

▲ ATT(Anti Trip Technology) is to measure LOOP resistanc

es w

the RCDs rated at 30mA or more. ATT ON is displayed while it is

activated.

(5)Press the Resolution switch (F3) to select 0.01Ω resolution or 0.001Ω

resolution (only available with ATT OFF).

2. Wiring Check

After the connection, ensure that the symbols for Wiring check on the LCD

are in the status indicated in Fig.31 before pressing the test button.

If the status of the symbols for Wiring check differ from Fig.31 or symbol

is indicated on the LCD, DO NOT PROCEED AS THERE IS INCORRECT WIRING.

The cause of the fault must be investigated and rectified.

3. Voltage Measurement

When the instrument is first connected to the system, it will display the lineearth voltage (MODE L-PE) or line-neutral voltage (MODE L-N/L-L) which is

updated every 1s. If this voltage is not normal or as expected, DO NOT

PROCEED.

34

9.3.2 Measurement of LOOP and PSC/PFC

a. Measurement at Mains Socket Outlet

Connect the mains test lead to the instrument. Insert the moulded plug of

mains test lead into the socket to be tested. (see Fig.33)

Press MODE Switch (F1) and select L-N or PSC to measure between

Line – Neutral, or L-PE or PFC to measure between Line-PE.

Carry out the initial checks

the t

Press the test button. A beep will sound as

value of loop impedance will be displayed.

b. Measurement at the distribution board

Connect the distribution board lead ACC065 to the instrument.

Measurement of Line – Earth Loop Impedance and PFC

Press the Mode Switch (F1) and select L-PE or PFC.

Connect the green PE lead of the ACC065 to the earth,

the blue N lead to the neutral of the distribution board and the brown

t

o one line of the distribution board. (See Fig.34)

Measurement of Line – Neutral Loop Impedance and PSC

Press the Mode Switch (F1) and select L-N/L-L or PSC.

Connect the blue N lead of the ACC065 to the neutral of the distribution

board, the brown L lead to one line of the distribution board. (See Fig.35)

Carry out the initial checks

Press the test button. A beep will sound as the test is con

value of loop impedance will be displayed. When disconnecting from the

distribution board, it is good practice to disconnect the line first.

est is conducted and the

ducted a

LOOP/PSC/PFC

L lead

nd the

c. Measurement between LINE-LINE

Connect the distribution board lead ACC065 to the instrument.

Press the Mode Switch(F1) and select L-N/L-L or PSC.

Connect the blue N lead of the ACC065 to the line of the distribution

board, the brown L lead to an

(See Fig.36)

Carry out the initial checks

Press the test button. A beep will sound as the test is conducted and the

value of loop impedance will be displayed.

▲ If the display shows '>' then this usually means the value measured

exceeds the range.

▲ ATT mode enables a measurement without tripping the RCDs with the rated

residual current of 30mA or more.

▲ Measur

ement in ATT mode requires longer time than that is required for the

other measurements (approx. 7 sec). When measuring a circuit with a large

other line of the distribution board

.

35

LOOP/PSC/PFC

Ω

L-PE

230

V

50.0Hz

L-PE

L-N

!

ATT

:ON

electrical noise present, the 'Noise' Message is displayed on the LCD and

the measurement time will be extended to 20 sec. If the 'NOISE' symbol

is displayed on the LCD, it is recommended to disable the ATT mode and

take a measurement (RCDs may trip).

If an impedance of 20Ω or more is measured bet ween L-N during

▲

measurements with ATT enabled, L-N>20Ωis displayed on the LCD

and no measurement can be made. In this case, disable the ATT function

and make a measurement. When a large contact voltage exists in the circuit

under test,N-PE HiVis displayed on the LCD and no measurement can

be made. In this case, disable the ATT function and make measurement. Be

aware that if the ATT mode is disabled, RCDs may trip.

▲ Measured result may be influenced depending on the phase angle of the

distribution system when making measurement near a transformer and

the result may lower than the actual impedance value. Errors in measured

result are as follows.

System Phase

Difference

Error

(approx.)

10° -1.5%

20° -6%

30° -13%

▲ In case of PFC Function,ATT mode is automatically enabled after one

measurement when making a measurement with ATT mode disabled.

Fig. 33 Connection for using Outlet

36

PE

Ω

L-PE

230

V

50.0Hz

L-PE

L-N

!

ATT

:ON

PSC

A

230

V

L-N

50.0Hz

L-PE

L-N

!

PSC

A

230

V

L-N

50.0Hz

L-PE

L-N

!

Fig.34 Connection for distribution

LOOP/PSC/PFC

Fig.35 Connection for Line – Neutral measurement

Fig.36 Connection for Line – Line measurement

37

LOOP/PSC/PFC

L-PE

Ω

ATT : ON

230V

50.0Hz

L-PE

L-N

!

Limit : OFF

Prot. :FUSE gG

In : 16A

BACK

t : 0.4s

LOOP LIMIT SETTING

L-PE

Ω

ATT : ON

230V

50.0Hz

L-PE

L-N

!

Limit : 2.70

Ω

9.3.3 How to set loop limit value

KT65DL displays limit value of loop measurement (Zs) according to the

protection device in measuring circuit. The setting method is the following

procedure. When L-PE measurement is selected, loop limit value is displayed.

(1)Press F4 switch in stand-by mode.(fig37-1)

LOOP LIMIT SETTING screen is displayed.(fig37-2)

he

(2) Press F1( Prot.) Switch to selec t t

protection device. You can select in the

following protection devices. If OFF is

selected, Limit value is not displayed.

Protection device:

MCB B, MCB C, MCB D, MCB TYPE1,

MCB TYPE2, MCB TYPE3, MCB TYPE4,

FUSE 88-2, FUSE 88-3, RCD (TT), OFF

(3) Press F2 Switch to select the rated

current of the protection device. If RCD

is selected, select rated residual current

(idn) of RCD.

ou can select in the following current

Y

value. (Depending on setting of switch

selected.)

F1 or F3, some current value cannot be

Fuse:5,6,10,16,20,25,32,40,45,50,63,

80,100A

MCB:5,6,10,15,16,20,25,30,32,40,50,

63A

RCD:30,100,300,500,1000mA

Fig. 37-1

Fig. 37-2

(4) P re s s F 3 s wi t ch t o s e le c t t h e

disconnection time.

Disconnection time: 0.4s, 5s, 0.4s@80%Z, 5s@80%Z

If RCD is selected, Press F3 switch to sele

value.

Limit Value:Uc25V, Uc50V, 100Ω, 200Ω

(5)Press BACK (F4) switch to return stand-by screen.

Loop limit value is displayed. (Fig37-3)

Fig. 37-3

ct Uc limit value or loop limit

38

10.1 Principles of RCD Measurement

The RCD tester is connected between phase and protective conductor on the

load side of the RCD after disconnecting the load.

A precisely measured current for a carefully timed period is drawn from the

phase and returns via the earth, thus tripping the device. The instrument

measures and displays the exact time taken for the circuit to be opened.

An RCD is a switchin

current attains a specific value. It works on the basis of the current difference

between phase currents flowing to different loads and returning current

flowing through the neutral conductor (for a single-phase installation). In the

case where the current difference is higher than the RCD tripping current, the

device will trip and disconnect

There are two parameters for RCDs; the first due to the shape of the residual

current wave form (types AC and A) and the second due to the tripping time

(types G and S).

RCD type AC will trip when presented with residual sinusoidal alternating

▲

currents whether applied suddenly or slowly rising. This type is the most

frequently used on electrical installations.

RCD type A will trip when presented with residual sinusoidal alternating

▲

currents (similar to type AC) and residual pulsating direct currents

(DC) whether suddenly applied or slowly rising. This type of RCD is not

commonly used at present, however, it is increasing in popularity and is

required by the local regulations in some countries.

Making measurement with

▲ RCD type G. In this case G stands for general type (without tripping time

delay) and is for general use and applications.

RCD type S where S stands for selective type (with tripping time delay).

▲

This type of RCD is specifically designed for installations where the time

delay characteristic is required.

g device designed for breaking currents when the residual

the supply fro

setting uses pulsating direct currents for test.

m the load.

10 RCD

Given that when the protective device is an RCD, Ia is typically 5 times

the rated residual operating current IΔn, then the RCD must be tested

recommending the tripping time, measured by RCD testers or Multifunction

ters, s

tes

60364-41 (see also LOOP/PSC/PFC section) that are:

TT system

(at 230V / 400V AC)

TN system

(at 230V / 400V AC)

hall be lower than the maximum disconnecting times required in IEC

200 ms for final circuits not exceeding 32A

1000 ms for distribution circuits and circuits over 32A

400 ms for final circuits not exceeding 32A

5 s for distribution circuits and circuits over 32A

39

RCD

×1

ms

30 mA

230V

L-PE

UL50

V

PHASE : 0

°

50.0Hz

L-PE

L-N

!

×1

ms

30 mA

230V

L-PE

UL50

V

PHASE : 0

°

50.0Hz

L-PE

L-N

!

However it is also good practice to consider even more stringent trip time

limits, by following the standard values of trip times at IΔn defined by IEC

61009 (EN 61009) and IEC 61008 (EN 61008). These trip time limits are

listed in the table below for IΔn and 5IΔn:

Type of RCD IΔn 5IΔn

General(G)

300ms

max allowed value

500ms

max allowed value

40ms

max allowed value

150ms

max allowed value

Selective(S)

130ms

min allowed value

50ms

min allowed value

Examples of instrument connection

Practical example of 3-phase + neutral RCD test in a TT system.

Fig.38

Practical example of single phase RCD test in a TN system.

Fig.39

40

Practical example of RCD test with distribution leads.

PE

×1

ms

30 mA

230V

L-PE

UL50

V

PHASE : 0

°

50.0Hz

L-PE

L-N

!

×1 / 2

ms

30 mA

L-PE

UL50

V

PHASE : 0

°

230V

50.0Hz

L-PE

L-N

!

Fig. 40

10.2 Operating Instructions for RCD

10.2.1 Initial Checks: to be carried out before any testing;

1. Preparation

Always inspect your test instrument and lead accessories for abnormality or

damage:

If abnormal conditions exist DO NOT PROCEED WITH TESTING. Have the

instrument checked by Kewtech.

Operation of Function Switch

Measurement mode setting

F1

(X1/2, X1, X5, Ramp, Auto)

F2 IΔn setting

F3 RCD Type setting (

, , , )

F4 PHASE setting (0° ,180° )

RCD

Fig. 41

1. Press the Power button and turn on the instrument.

Turn the rotary switch and select the RCD function.

2. Press the MODE switch(F1) and select any desirable measurement mode.

X1/2 For testing RCDs to verify that they are not too sensitive.

X1 For measuring the trip time.

X5 For testing at IΔn X5

RAMP (◢) For measuring the tripping level in mA.

AUTO

For automatic measurement in following sequence:

X1/2(0° ), X1/2(180° ), X1(0° ),X1 (180° ), X5(0° ), X5(180° )

41

3. Press the IΔn switch (F2) to set Rated Tripping Current (IΔn) to the rated

RCD

trip current of the RCD.

4. Press (F3) to select the RCD type.

Refer to "10.1 Principles of RCD measurement" for the details of RCD type.

5. Press (F4) to select phase at which the test current should start.

*UL value change

As a UL value, 25V or 50V is selectable. Refer to 6. Configuration in this

manual and select

2

. Wiring Check

1. Insert the Test Lead into the instrument. (Fig.42)

2. Connect the test leads to the circuit to be tested. (Fig.38, 39, 40)

3. After the connection, ensure that the symbols for Wiring check on the LCD

are in the status indicated in Fig.42 before pressing the test button.

either of them.

Fig. 42

If the status of the symbols for Wiring check differ from Fig.42 or symbol

is indicated on the LCD, DO NOT PROCEED AS THERE IS INCORRECT WIRING.

The cause of the fault must be investigated and rectified.

3. Voltage Measurement

When the instrument is first connected to the system, it will display the lineearth voltage which is updated every 1s. If this voltage is not normal or as

expected, DO NOT PROCEED.

NOTE: This is a single pha s e ( 2 30V AC) ins t r ume n t a n d unde r no

circumstances should it be connected to 2- phases or a voltage

exceeding 230VAC+10%.

If the input voltage is greater than 260V the display will indicate '>260V' and

RCD measurements can not be made even if the Test button is pressed.

42

10.2.2 RCD Measurement

a) Single Tests

1. Press the Test button

Operating time of RCD is displayed on LCD. At Ramp test, operating current

value of RCD will be displayed.

▲ ×1/2...................The Breaker should not trip.

▲ ×1......................The Breaker should trip.

▲ ×5......................The Breaker should trip.

▲ Auto Ramp(◢)..... The Breaker should trip. The tripping current should be

played.

dis

2

. Press the 0° /180° switch to change the phase and repeat step (1).

3. Change the phase again and repeat step (1).

b) Auto Test

Measurements are automatically performed under the Auto Test function in

the following

sequence: X1/2(0° ), X1/2(180° ), X1(0° ), X1(180° ), X5(0° ), X5(180° ).

1. Press F1 to select Auto

2. Press F2 & F3 to select IΔn & RCD type

3. Press the Test button. The KT65DL will aut

a

s above. When the RCD trips each time reset it.

4. Return to the tester and the results will be displayed

omatically conduct the sequence

RCD

▲ Be sure to return the tested RCD to the original condition after the test.

▲ When the Uc voltage rises to UL value or greater, the measurement is

automatically suspended and "Uc > UL" is displayed on the LCD.

urrent of the RCD, the

▲ If " IΔn" setting is greater than the rated residu

RCD will trip and "no" may be displayed on LCD.

▲ If a voltage exists between the protective conductor and earth, it may

influence the measurements.

▲ If a voltage exists between neutral and earth, it may influence the

measurements, therefore, the connection between neutral point of the

distribution system and earth should be checked before testing.

▲ If leakage currents

measurements.

▲ The potential fields of other earthing installations may influence the

measurement.

flow in the circuit following the RCD, it may influence the

al c

43

▲ Special conditions of RCDs of a particular design, for example S- type,

RCD

should be taken into consideration.

▲ The earth electrode resistance of a measuring circuit with a probe shall not

exceed table1.

▲ Equipment following the RCD, e.g. capacitors or rotating machinery, may

cause a significant lengthening of the measured trip time.

44

11.1 Principles of Earth Measurement

Constant Current Generator

H(C)Current

S(P)Potential

E(Earth)

Voltmeter

Red Green

Yellow

This Earth function is to test power distribution lines, in-house wiring system,

electrical appliances etc.

This instrument makes earth resistance measurement with fall-of-potential

method, which is a method to

obtain earth resistance value

Rx by applying AC constant

c ur r e nt I b et w ee n t he

measurement object E (earth

electrode) and H(C) (current

electrode), and f

inding out

th e po t ential diffe rence V

between E and S(P) (potential

electrode).

Rx = V / I

Fig. 43

11.2 Earth resistance Measurement

WARNING

The instrument will produce a maximum voltage of about 50V between

terminals E-H(C) in earth resistance function. Take enough caution to avoid

electric shock hazard.

CAUTION

When measuring earth resistance, do not apply voltage between measuring

terminals.

11. Earth

1. Select Earth

2

. Insert the Test Leads (Model7228: Optional Accessory) into the instrument.

(Fig.44)

3. Test Lead connection

Stick the auxiliary earth spikes S(P) and H(C) into the ground deeply. They

should be aligned at an interval of 5-10m from the earthed equipment under

test. Connect the green wire to the earthed equipment under test, the yellow

wire to the auxiliary earth sp

spike H(C) from terminals E, S(P) and H(C) of the instrument in order.

function with the Rotary Switch

ike S(P) and the red wire to the auxiliary earth

Fig. 44

45

H(C)

S(P)

E

Ω

Earth

Note :

▲ Make sure to stick the auxiliary earth spikes in the moist part of the soil.

Give enough water where the spikes have to be stuck into the dry, stony or

sandy part of the earth so that it may become moist.

▲ In case of concrete, lay the auxiliary earth spike down and water it, or put

a wet dustcloth etc. on the spike when making measurement.

Fig. 45

4. Press the test button, the display will show the earth resistance of the

circuit.

▲ If measurement is made with the probes twisted or in touch with each

other, the reading of the instrument may be affected by induction.

When connecting the probes, make sure that they are separated.

▲ If earth resistance of auxiliary earth spikes is too large, it may result

in inaccurate measurement. Make sure to stick the auxiliary earth

spike and H(C) i

nto the moist part of the earth carefully, and ensure

sufficient connections between the respective connections. High

auxiliary earth resistance may exist if R

Hi or RH Hi is displayed

S

during measurements.

▲ Large errors may occur in the measured earth resistance when earth

voltage of 10V or more exist. In this case, power off the devices which

is using earth resistance under test to reduce the eart

h voltages.

46

1. Press the Power button and turn on the instrument. Turn the rotary switch

L1

L3

L2

Correct phase sequence

Reversed phase sequence

and select the PHASE ROTATION function.

2. Insert the Test Leads into the instrument. (Fig.46)

Fig. 46

3. Connect each test leads to a circuit. (Fig.47)

12 Phase

Rotation

4. Results are displayed as follows.

▲ When a message No 3-phase system or - - - is displayed, the circuit

may not be a 3-phase system or a wrong connection may have been made.

Check the circ

▲ Presence of Harmonics in measurement voltages, such as an inverter

power supply, may influence the measured results.

Fig. 47

Fig. 48 Fig. 49

uit and the connection.

47

13 Volts

1. Press the Power button and turn on the instrument. Turn the rotary switch

and select the VOLTS function.

2. Insert the Test Leads into the instrument. (Fig.50)

Fig. 50

3. Voltage value and frequency will be displayed on the LCD when applying AC

voltage.

Note : A message DC V may be displayed when measuring AC voltages with

frequencies out of the range 45Hz - 65Hz.

14 Touch

Pad

15 Back

Light

1. The touch pad measures the potent

testers PE terminal. A message PE HiV is displayed on the LCD with the

audible buzzer if a potential difference of 100V or more is present between

the operator and the PE terminal at touching the Touch pad.

2. Touch Pad function can be enabled and disabled (ON / OFF); refer to 6.

Configuration in this manual and select ON or OFF. In case that OFF is

a w

selected,

sound.

* Initial value: ON

Note : A message PE HI V may be displayed when testing inverters or

measuring voltages containing high frequencies even if a user isn't

touching with the Touch Pad.

Pressing the Back Light Button selects Backlight ON / OFF. Backlight

automatically turns off in 60 sec after it turns on. Backlight at powering o

t

he instrument can be set either ON or OFF. Refer to 6. Configuration in this

manual how to select ON / OFF.

arning for PE HiV does not appear and the buzzer does not

ial between the operator and the

n

48

Measured result at each function can be saved in the memory of the

250V

MΩ

18.52

ALL DELETE

MEMORY MODE

ESC:MEM BUTTON

DELETE

RECALL

PAT OFF

SAVE

instrument. (MAX : 1000)

16.1 How to save the data

Save the result according to following sequence.

(1) Measured result.

Fig. 51-1

16 Memory

Function

(2) Press

to enter into SAVE MODE.

Fig. 51-2

(3) Press

▲ In case of PAT mode

(Insulation or Continuity function)

1.ID No

2.SITE No

3.DATA No

to enter into SAVE MODE.

▲ Other

1. TYPE (Selection items are shown

in the table below)

2. CIRCUIT No

3. BOARD No

4. SITE No

5. DATA No

Press the SELECT Button to choose the parameter to change.

▲In case of PAT mode : ID No → SITE No →MENU→DATA No

When saving an insulation test the ID No, automatically advances by 1.

▲Other : TYPE → CIRCUIT No → BOARD No → SITE No →MENU→ DATA No

If you select MENU and press F4(OK) switch, Recall / delete screen will

be displayed.(Fig 52-2). You can recall or delete the saved d

delete screen. Use the UP or DOWN Button and change settings.

TYPE Selection

Continuity

Insulation L/L, L/N, L/E,N/E

Loop(L-PE) Zs, Z

RCD

r1, r2, rn, R1+R2, R2

1st RCCB, 2nd RCCB,

3rd RCCB, RCBO

E

Ke ep th e UP / DO W N Ke y

presse d do wn to alter the

number quickly.

ata at Recall /

49

Normal mode

Saving

250V

PAT OFF

MΩ

18.52

SAVE

INSULATION

18.52M

Ω

250V

SITE : 01

BOARD : 01

CIRCUIT : 01

TYPE : L/L

SAVE MODE

DATA No.001

BACK

Memory

Function

(4) Press OK ( ). (Confirmed)

(5) SAVING is displayed for about 2

sec on the LCD, and then returns to

the start screen. Saving completes.

Returns to Normal mode once data

save comple t e s . (Measu re m e n t

mode)

Fig. 51-3

Fig. 51-4

50

16.2 Recall the saved data

ALL DELETE

MEMORY MODE

ESC:MEM BUTTON

DELETE

RECALL

SAVE

DOWN

UP

TYPE : L/L

BACK

INSULATION

18.52M

Ω

250V

SITE : 01

BOARD : 01

CIRCUIT : 01

RECALL MODE

DATA No.

000

250V

PAT OFF

MΩ

Save data can be displayed on LCD according to following sequence.

(1) Press to enter into Recall/

delete screen.

Memory

Function

Fig. 52-1

(2) Press

MODE.

(3) Press Up (

to enter into RECALL

) or DOWN ( )

and select Data No.

Keep the UP/DOWN Key

pressed down until a buzzer

sounds to skip the number

co n ta ini n g no da ta an d

display the next data.

Fig. 52-2

Fig. 52-3

51

DELETE ALL

DELETE

ALL DELETE

MEMORY MODE

ESC:MEM BUTTON

DELETE

RECALL

SAVE

ALL DELETE

Delete All?

ESC:MEM BUTTON

BACK

DELETE

DELETE MODE

DOWN

UP

DATA No.

000

INSULATION

18.52M

Ω

250V

BACK

TYPE : L/L

SITE : 01

BOARD : 01

CIRCUIT : 01

250V

PAT OFF

MΩ

Memory

Function

16.3 Delete the saved data

Save data can be deleted according to following sequence.

Fig. 53-1

(1) Press to enter

into Recall / d e let e

screen.

(2) Press

enter into

DELETE MODE

to

(3) Press Up

(

) or

DOWN (

and select Data

No.

)

Fig. 53-2

(2) Press to

enter into ALL

DELETE MODE

(4) Press

DELETE (

(Confirmed)

Fig. 53-3 Fig. 53-4

).

(3) Press ALL

DELETE

(

).

(Confirmed)

52

ALL DELETEDELETE

Deleting

All Deleting

DELETE

DELETE MODE

DATA No.001?

INSULATION

18.52M

Ω

250V

BACK

TYPE : L/L

SITE : 01

BOARD : 01

CIRCUIT : 01

250V

PAT OFF

MΩ

250V

PAT OFF

MΩ

Memory

Function

Fig. 53-5

(5) Press

DELETE

).

(

(Confirmed)

Fig. 53-7

(6) Returns to Normal mode when

selected data deleted.

(Measurement mode)

Fig. 53-9

Fig. 53-6

Fig. 53-8

(4) Returns to Normal mode when

selected data is deleted.

(Measurement mode)

53

Memory

Function

16.4 Transfer the stored data to PC

The stored data can be transferred to PC via Optical Adapter Model8212USB

(Optional Accessory).

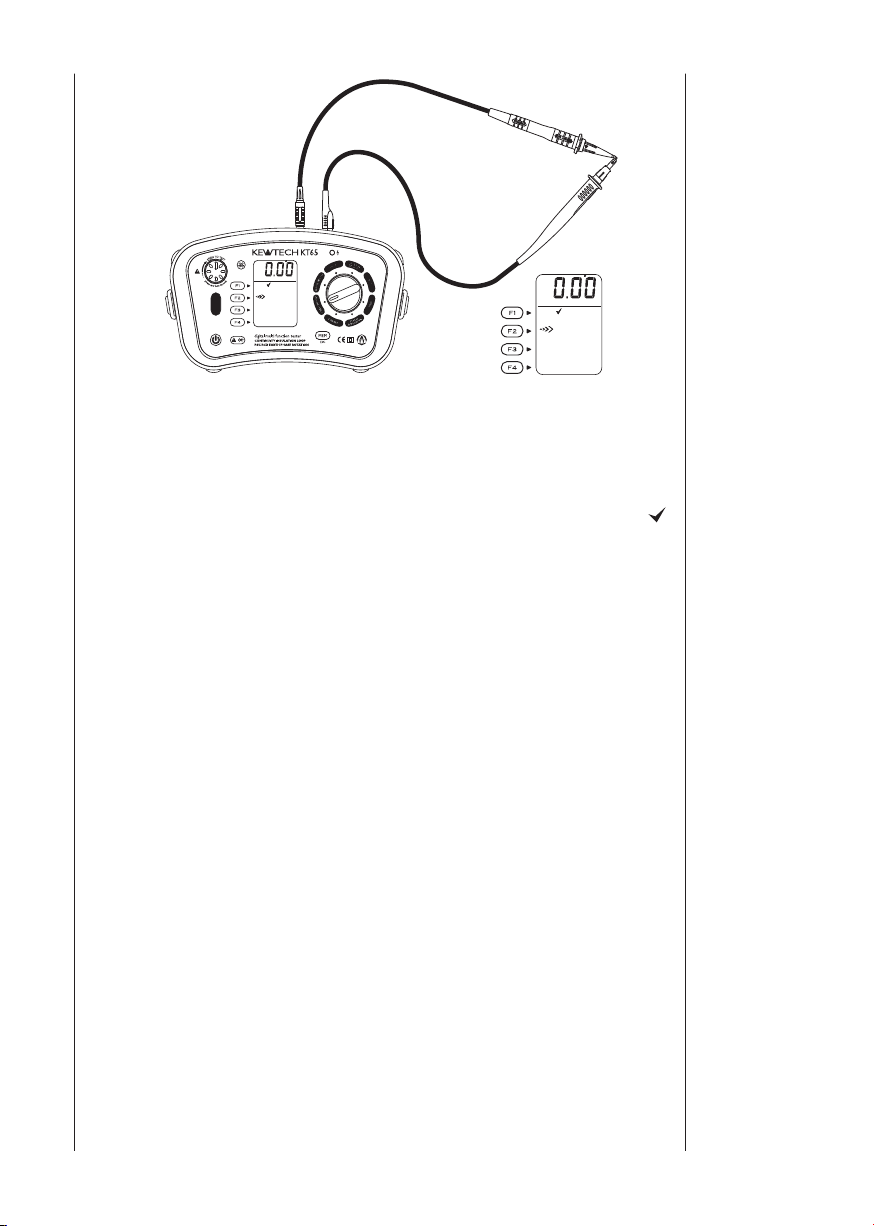

Fig. 54

●How to transfer the data:

(1) C o n n ec t Mo de l8 2 1 2 U S B to t h e

USB Port of a PC.(Special driver for

Model8212USB should be i nstalled.

S e e t h e i n st ru ct io n ma nu a l f o r

Model8212USB for further details.)

(2) Insert Model8212USB into the KT65DL

as shown in Fig 55.

hould be removed from the

Test Leads

KT65DL at this time.

(3) Power on the KT65DL . (Any function is OK.)

(4) Start special software "KEW Report" on your PC and set the communication

port.

Then click "Down load" command, and the data in the KT65DL will be

transferred to your PC.

Please refer to the instruction manual of Model 8212USB and HELP of

KEW Report for further details.

s

Fig. 55

Note: Use "KEW Report

" with version 2.20 or more

.

54

17.1 If the symbol ( )appears, this means that the test resistor is too hot

and the automatic cut out circuits have operated. Allow the instrument

to cool down before proceeding. The overheat circuits protect the test

resistor against heat damage.

17.2 The test button may be turned clockwise to lock it down. In this auto

mode, when using distribution board lead ACC065, tests are conducted

by simply disconnecting and r

ACC065 avoiding the need to physically press the test button i.e. 'hands

free'.

econnecting the red phase prod of the

17 General

17.3 When the display shows the low battery indication, (

the test leads from the instrument. Remove the battery cover and the

batteries.

17.4 If at any time during testing there is a momentary degradation of