D3

Instlltion Guide

Models

D3-FXRD

D3-ADRD

D3-WWRD

D3-FXSQ

D3-ADSQ

D3-WWSQ

!

WARNING

Shock Hzrd. May result in serious injury or deth.

Turn power OFF at circuit breker or remove fuse. Dmge to this

product cused by wiring with power on voids the wrrnty.

Due to the risk of electric shock, a licensed electricin should instll

this power supply unit in strict complince with the Ntional Electricl

Code nd ny stte or locl code which my pply.

2|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

Contents

Product Overview 4

Included Components/Supported Models 5

Included Components 5

Supported Models 5

Specifictions 6

Instlltion 7

Part 1: Mount the D3 7

Prt 2: Wire the Fixture 12

Prt 3: Instlling Drywall 13

Part 4: Apply Spckle Flnge Trim Retiner (Mud-In Only) 13

Prt 5: Apply Joint Compound 14

Prt 6: Apply Trim 14

Additionl Opertions 16

Troubleshooting 18

Wrrnty Tech Support 19

3|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

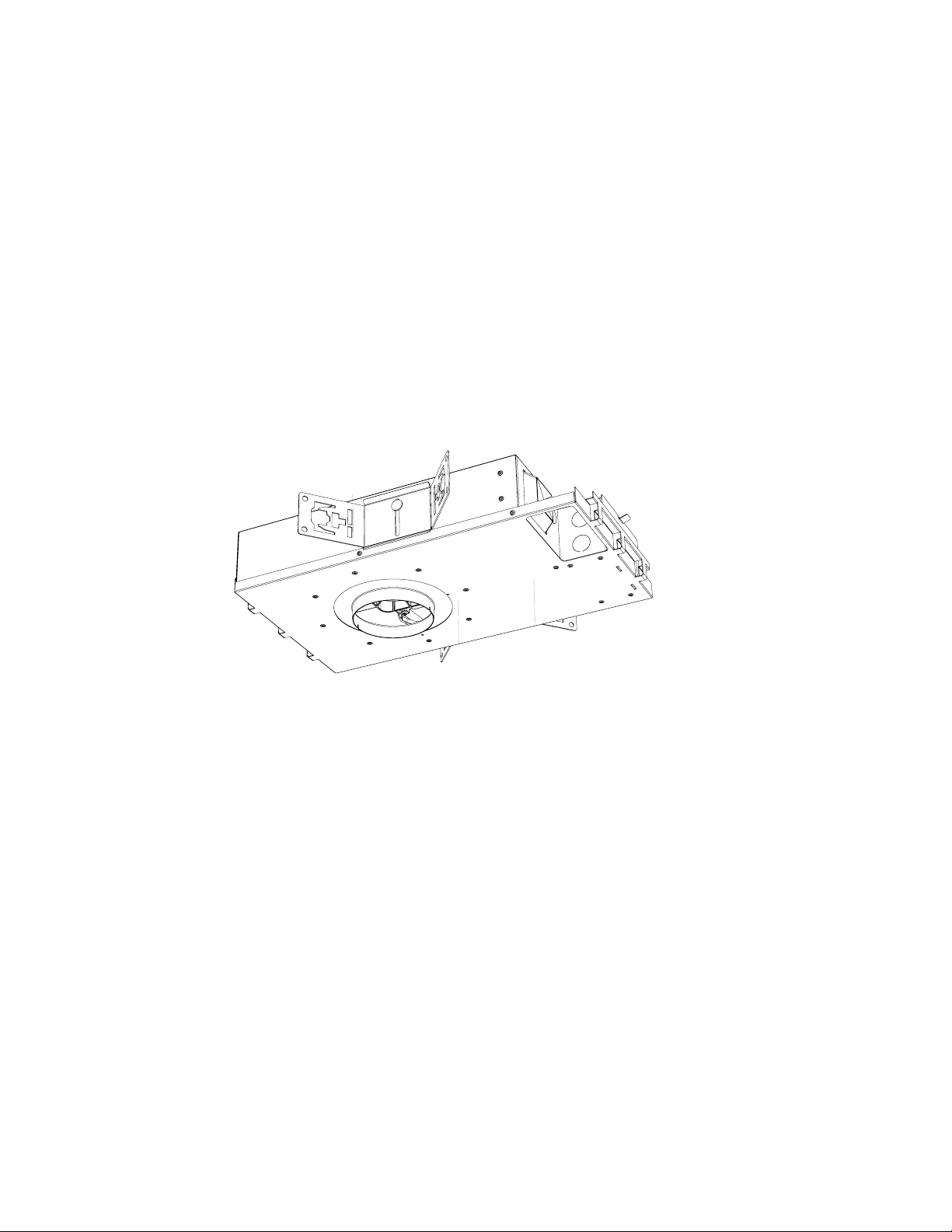

Product Overview

Ketr’s D3 family includes fixed, djustable, nd wll-wsh downlights. Every model

fetures a low-profile housing, wireless communiction, and field-replceble optics

nd electronics. With a welth of trim and optic accessories, the D3 is ideal for a large

variety of applications. It uses a fully-tunable spectrum capable of delivering high-

quality white, saturated, and pastel light.

butterfly bracket

hanger bar slot

IC rated/ airtight enclosure

aperture rotation

power supply

AC input wiring

junction box

height adjust

tilt lock

primary optic

(field replaceable)

finish trim

(field replaceable)

butterfly bracket

IC rated/ airtight enclosure

rotation indication

(square housing only)

rotation lock

4|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

Included Components/Supported Models

Included Components

( 2 ) Butterfly Brackets

Housing with Emitter Optic

(Models as specified)

( 2 ) Nailer Bars

Trim (Model as specified)

Supported Models

D3-FXRD

D3-ADRD

D3-WWRD

D3-FXSQ

D3-ADSQ

D3-WWSQ

For instructions on setting default states in Design Studio, see the Design Studio Manual available on our website. The manual has

sections dedicated to emergency mode and setting default states for Ketra lights

5|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

INSTALLATION

Specifictions

Optical Performance

Delivered Lumen Output

Beam Angle

(1 in/ 25.4 mm recess)

15° beam low glare 650 lm 882 lm 1092 lm

25° beam, low glare 623 lm 845 lm 1046 lm

40° beam, low glare 569 lm 772 lm 955 lm

60° beam, low glare 561 lm 760 lm 941 lm

15° beam high output 682 lm 928lm 1148 lm

25° beam, high output 678 lm 923 lm 1142 lm

40° beam, high output 646 lm 878 lm 1087 lm

60° beam, high output 630 lm 857 lm 1061 lm

CRI (Ra)3 >90 (R9>90) 2400K5000K TYP

Lumen Maintenance 50,000 hours to L70 @ 25 ˚C T

Color Spatial Uniformity <2 MacAdam ellipses across

Color Point Range 1400 ˚K10,000 ˚K, Fully

Equivalent Traditional Lamp 75 W halogen

Dimming Range 0.1100% lm

Power Consumption D3.13 13 W

Voltage*

Power Factor >0.9

Current 150 mA Max

Delivered Ecacy

Beam Angle

(1 in/ 25.4 mm recess)

15° beam low glare 72 lm/W 68 lm/W 61 lm/W

25° beam, low glare 69 lm/W 65 lm/W 58 lm/W

40° beam, low glare 63 lm/W 59 lm/W 53 lm/W

60° beam, low glare 62 lm/W 58 lm/W 52 lm/W

15° beam high output 76 lm/W 71 lm/W 63 lm/W

25° beam, high output 75 lm/W 71 lm/W 62 lm/W

40° beam, high output 72 lm/W 68 lm/W 59 lm/W

60° beam, high output 70 lm/W 66 lm/W 58 lm/W

9W 13W 18W

field angle

Saturated, Pastel

D3.18 18 W

120 V 60 Hz

220277 V 60 Hz

220277 V 50 Hz

9W 13W 18W

Environmental

Operating Temperature 040 °C

Storage Temperature -2080 °C

Humidity 095%, Non-condensing

Certification UL, cUL, RoHS, FCC Class B

Location UL Damp Location, UL Wet

Location Available with Lens Trim

Electrical

Mounting Options Hanger Bars / Butterfly Brackets

Field Replaceable Optics Yes

Field Replaceable

A

Light Engine

Field Replaceable

Power Supply

Additional Optic Lens Holder 2.5 in/63.5 mm Lens, ⁄ in/3.175 mm Thick

Additional Trim Lens Holder 2.75 in/69.85 mm Lens, ⁄ in/3.175 mm Thick

Housing Material Powder Coated Steel, Polymer

Lens Material Glass

Yes

Yes

Dimensions

Ceiling Hole Diameter 4 in/ 101.6 mm Flanged,

5.5 in/ 139.7 mm Mud-in

Trim Outside Diameter 4.62 in/ 117.348 mm

Trim Inside Diameter 3.75 in/ 95.25 mm

Trim Thickness ⁄ in/ 1.5875 mm

Optics Outside Diameter 2.5 in/ 63.5 mm

Trim Depth 1 in/ 25.4 mm

Ceiling Thickness 0.625 in–1.5 in/ 15.87538.1 mm

Emitter Vertical Adjustment

(tool-free)

Housing Vertical Adjustment

via Butterfly Bracket

Housing Height 3.50 in/ 88.9 mm

Housing Length 18.38 in/ 466.852 mm

Housing Width 10.07 in/ 255.778 mm

0.75 in/ 19.05 mm

1.75 in/ 44.45mm

Surge Protection 2.5 KV

Control Protocol KetraNet Mesh

* Ketra lighting products should not be connected to, or directly controlled by, AC mains line voltage dimmers. These types of dimmers may

also be referred to as phase cut, triac, forward-phase, reverse-phase, ELV, or MLV dimmers. Ketra's lighting products should only be controlled

via our digital control architecture. Ketra does not recommend switching power on/o to Ketra lighting products via relays, contactors, or

manual toggle switches. When the lighting products are disconnected from power they cannot respond to digital commands from control

devices. This could confuse end users as the lighting may be in a state that is inconsistent with the control devices. Please refer to our controls

products installation guides for more information.

6|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

INSTALLATION

Instlltion

All touch-points inside the D3 housing are colored red.

All customer-accessible screws are Phillips.

Part 1: Mount the D3

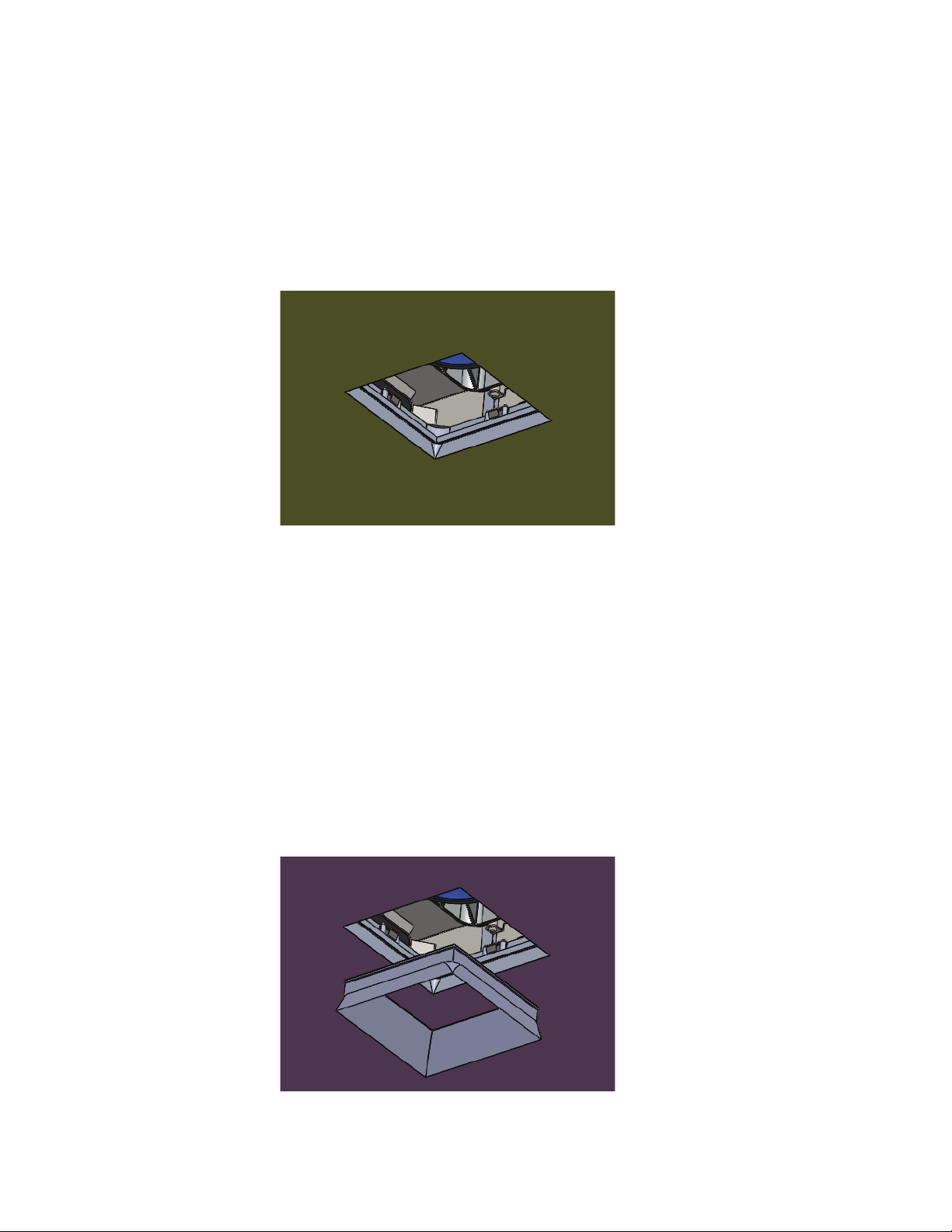

Mounting can be done with either nailer bars or butterfly brackets.

Option 1

Nailer Bars

• Allow horizontal movement

post-mounting

• Ideal with wooden studs or

t-grid ceilings

Option 2

Butterfly Brackets

• Allows horizontal or vertical movement

post-mounting

• Ideal for commercial settings

continued on next page

7|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

INSTALLATION

Option 1

MOUNTING WITH NAILER BARS

1. Attach nailer bars

a. If ceiling thickness is 0.75 in (19.05 mm) or greater: Use pliers to break o the tabs at the end

ofboth nailer bars. (see fig. 1)

b. Insert the inner nailer bar into the three housing clasps on the end of the D3 housing. Make sure

the screw is on top. (see fig. 2)

c. IInsert the outer nailer bar into the same housing clasps, locking the inner and outer halves

together. Make sure the screw is on top. (see fig. 3)

d. Repeat steps a-b for the clasps on the other end of the housing

fig. 1 (optional) fig. 2

fig. 3

2. Mount downlight in the ceiling

Note: For optimal radio communication, ensure that the radio dome is not above or adjacent to

anything metallic.

a. Use a level to ensure the nailer bars are parallel to the ground.

Note: The D3’s collar needs to be flush to the ceiling plane or 0.0625 in (1.5875 mm) above it.

b. Screw the ends of both bars into the wooden joists, fixing the housing in place. (see fig. 3)

c. T- Grid ceiling only: Bend the tabs on the nailer bars to lock them to the t-grid. (see fig. 4)

fig. 4

8|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

INSTALLATION

3. Optional: If installing a square fixture, loosen the collar's two outer screws, freeing the collar for

rotation, which then can be aligned to the fixtures per design.

a. Realign the collar using its v-shaped notches and an alignment string or laser.

b. Re-tighten the screws to lock the collar’s new position.

Option 2

MOUNTING WITH BUTTERFLY BRACKETS

1. Reposition emitter chassis

a. Remove the cardboard plug from the D3’s aperture.

b. Carefully remove the optic by turning counter-clockwise and pulling.

Note: Demonstrate caution when removing wall wash optic due to possible damaging kick.

Note: If you remove the optic, be careful not to touch the exposed silicone dome on the

emitter.

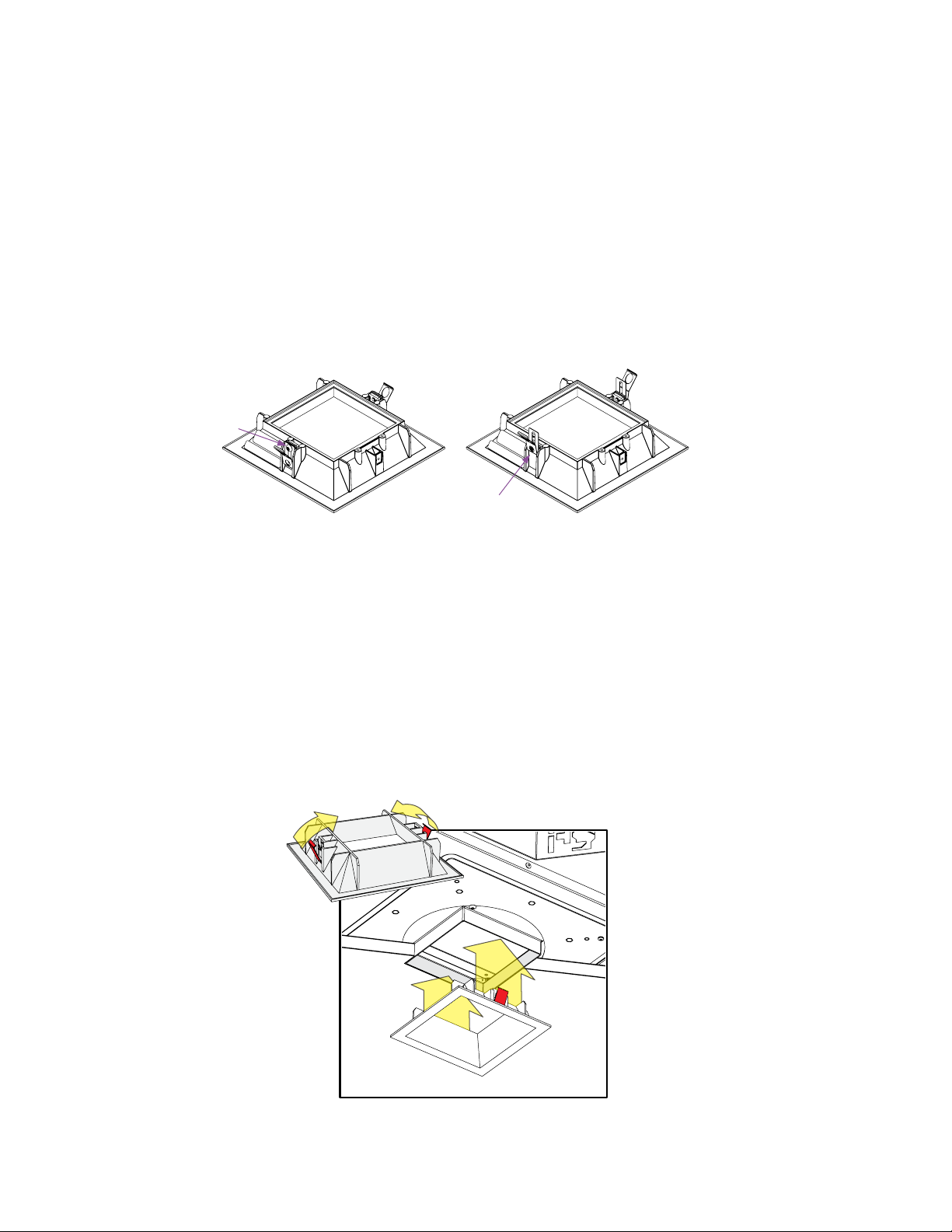

c. Unlock the tilt lock by pulling it toward the fixture aperture. The tilt lock is the red, horizontal lever

to the right or left side of the emitter chassis body. (see fig. 5)

d. Unlock the rotation lock by pulling it toward the fixture aperture. The rotation lock is the red,

vertical lever across from the emitter chassis body. (see fig. 6)

e. Tilt and rotate the emitter chassis to open an unobstructed path to the butterfly bracket openings

on either side of the housing.

fig. 5 fig. 6

continued on next page

9|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

INSTALLATION

2. Attch butterfly brckets

a. Outside the housing, undo the red wing nut and washer attached to the first butterfly

bracket’s bolt.

b. Run the bracket’s bolt through the hole in the side of the housing. (see fig. 7)

c. Reaching into the housing, thread the washer and red wing-nut back onto the bolt, fixing the

bracket in place.

d. Repeat steps a-c for the second butterfly bracket.

fig. 7

3. Restore the original emitter module conditions

a. Return the emitter chassis to its original position, locking the tilt and rotation locks.

b. Wall-wash downlight only: Reattach the optic. Press it flush to the base of the emitter chassis and

turn it clockwise until it engages the shoulder screws on either side of the emitter.

Note: The opening in the c-shaped kick reflector should face the wall.

c. Reinsert the cardboard plug to protect the optic from dust during the rest of the installation.

continued on next page

10|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

INSTALLATION

REVISIONS

ZONE

REV.

ECO DESCRIPTION

DATE

APPROVED

C

E

4. Mount downlight in ceiling

Note: For optimal radio communication, ensure that the radio dome is not above or adjacent to

anything metallic.

a. Use bar stock or C-channel (not provided) to mount the D3 in the ceiling. The supports should go

through the holes in the butterfly brackets and can be used to suspend the D3 without screws

(see fig. 8).

Note: After mounting, the D3’s collar will need to be flush to the ceiling plan or 0.0625 in (1.5875 mm)

above it.

b. Wire-tie at least one bracket to the deck using at least one tie.

fig. 8

5. Optional: If using a square aperture with a flange, realign the collar parallel to the wall.

a. Loosen the collar’s two outer screws, freeing the collar for rotation.

b. Realign the collar using its v-shaped notches and an alignment string or laser.

c. Re-tighten the screws to lock the collar’s new position.

© 2019 Ketra, Inc. All rights reserved

11|D3 INSTALLATION GUIDE

P/N 040444 Rev E

INSTALLATION

Prt 2: Wire the Fixture

1. Run power to junction box

a. A. Remove the junction box’s outer cover by pressing down on the outer latch and pulling the

cover toward you.

Note: A licensed electrician should perform all the wiring tasks. All electrical connections must

be made within the junction box.

b. Run the conduit in (and out, if this is one downlight in a sequence).

Note: Maximum of ( 8 ) no. 12 AWG through branch circuit conductors suitable for 75 ˚C

permitted in the box.

c. Run the building’s power line wires* into the junction box.

2. Splice the wires

a. Using the provided connectors, splice the D3’s flying leads into the building’s power. Make sure

the housing is grounded in accordance with local codes.

b. Replace the junction box’s outer cover.

3. Test the wiring

a. Apply power to the D3. The emitter should immediately come on to 3000 K (warm white).

Note: If the emitter comes on red, see Diagnostic Colors, page 18.

b. Wait several minutes while the D3 tests its installation conditions. Then use the color to

c. determine whether installation was successful:

• If the light stays at 3000 K, installation was successful. Continue to step d.

• If the light changes color, a problem has been detected.

Note: Magenta can indicate success or failure. It indicates success if there are no other

powered-on Ketra devices within 50 ft (15.24 m); otherwise, it indicates a problem.

To troubleshoot problems, see Diagnostic Colors, page 18.

d. After verifying a successful installation, remove power and continue to Part Three.

* Ketra lighting products should not be connected to, or directly controlled by, AC mains line voltage dimmers. These types of dimmers may also

be referred to as phase cut, triac, forward-phase, reverse-phase, ELV, or MLV dimmers. Ketra's lighting products should only be controlled via our

digital control architecture. Ketra does not recommend switching power on/o to Ketra lighting products via relays, contactors, or manual toggle

switches. When the lighting products are disconnected from power they cannot respond to digital commands from control devices. This could

confuse end users as the lighting may be in a state that is inconsistent with the control devices. Please refer to our controls products installation

guides for more information.

12|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

INSTALLATION

Prt 3: Instlling Drywall

1. Ensure that the aperture is plugged with the cardboard insert to protect the optic.

2. Cut properly-sized hole in drywall before installing drywall. Reference table for sizes.

Type Hole shape and size

Mud-In Circle with 5.5 in (139.7 mm) diameter

Flanged with square aperture Square with 4 in (101.6 mm) length/width

Flanged with round aperture Circle with 4 in (101.6 mm) diameter

3. Align the hole with the D3's aperture and install the drywall.

Part 4: Apply Mud-In Flnge Trim Retiner

Note: Skip this section if you have a flanged downlight.

1. Align the retainer assembly such that the holes in the retainer line up with the screw posts in the collar.

(see fig. 9)

2. Secure the retainer assembly using the #632 fasteners. For ceiling thickness in range 0.625 in (16.129

mm) to 1.125 in (28.575 mm), use the blue coded short set; for ceiling thickness in range 0.875 in

(225.425 mm) to 1.5 in (38.1 mm), use the red coded long set.

Note: The retainer assembly should be flush with the drywall.

fig. 9

13|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

INSTALLATION

Prt 5: Apply Joint Compound

1. Apply skim coat up to the aperture rim using a joint compound. (For mud-in versions, cover the flange

but not the retainer.) For best results, use a full ceiling float (see fig. 10).

fig. 10

2. Sand and finish the final surface before removing the aperture plug. Clean the internal surfaces of the

trim retainer with a clean rag and isopropyl alcohol.

Prt 6: Apply Trim

Mud-in and flanged downlights have dierent processes for applying their trims. Please read only the

appropriate section below.

1. Applying trim to mud-in downlight

a. Press the flangeless trim into the trim retainer (see fig. 11).

continued on next page

14|D3 INSTALLATION GUIDE

fig. 11

P/N 040444 Rev E

© 2019 Ketra, Inc. All rights reserved

INSTALLATION

REVISIONS

REV.

ECO DESCRIPTION

DATE

APPROVED

01

INITIAL RELEASE

D

C

B

8

7

6

5

4

3

2

1

2. Applying trim to flanged downlight

If your ceiling’s substrate is thicker than 0.6251 in (16.12925.4 mm), adjust the springs on either side

of your trim:

a. Using a #1 screwdriver, loosen the screw holding the spring in place.

b. Raise the spring as high (as far from the bottom of the trim) as it will go.

c. Re-tighten the screw (see fig. 12).

fig. 12

3. Compress the springs and push into the downlight aperture until the trim is flush to the ceiling.

Ensure that the springs are properly compressed and are going into the collar, not around the collar.

(see fig. 13)

4. Snap the trim into the collar.

15|D3 INSTALLATION GUIDE

fig. 13

P/N 040444 Rev E

© 2019 Ketra, Inc. All rights reserved

Additionl Opertions

Tilt Rotation (Square Trim Only)

To Raise: Push To Lower: Pull

1. Re-aiming the optic

a. Remove the trim by pulling the trim directly down from the housing.

b. Unlock the emitter chassis: reach into the D3’s housing and unlock tilt lock and rotation lock levers

(both colored red). (see fig. 14)

c. Use the degree indicators to determine degree of rotation (square trim only) and tilt.

(see fig. 15)

fig. 13

fig. 14

fig. 15

2. Adjusting optic depth

a. Remove the trim by pulling the trim directly down from the housing.

b. To set optic at the deep regress position push optic directly up. Light engine will magnetically

lock into place (see fig. 16).

c. To set optic at the low regress position pull optic directly down. Light engine will magnetically

lock into place (see fig. 17).

16|D3 INSTALLATION GUIDE

fig. 16 fig. 17

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

ADDITIONAL OPERATIONS

Align to Shoulder Pins and Insert Twist to Lock

Twist to Unlock (Rotation lock should be set) Pull to Remove (Optic is not tethered!)

3. Replacing the optic

a. Remove the trim by pulling the trim directly down from the housing.

b. Ensure that the emitter chassis is locked.

c. Grab optic and twist counterclockwise to unlock. Pull toward you to remove.

d. Install replacement optic, twisting clockwise to lock (see fig. 18).

fig. 18

4. Replacing the power supply

a. Remove the trim by pulling the trim directly down from the housing.

b. Tilt the Light Engine to 40°'s tilt and rotate to allow access to the power supply.

c. Unhook the emitter cable from the RJ45 jack on the power supply.

d. Pull power supply straight out from the docking station while depressing docking station latch.

e. Disconnect power supply quick connect (see fig. 19).

Tilt locked at 40˚. Emitter

Module in Full Regress

Unlocked and rotated so

that Emitter Module tilts

away from Power Supply

Disconnect power at the

Luminaire Disconnect

Disconnect

Emitter Module

17|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

Troubleshooting

The D3 uses built-in tests to check wiring and wireless connectivity. These tests run each time the D3 turns

on, and may take several minutes.

Note: The D3 will NOT run these tests while provisioned to a Design Studio installation.

If the D3 find a problem, it will let you know by emitting a corresponding color or, if no emitter is

connected, by flashing the indicator lights on its power supply.

DIAGNOSTIC COLORS (REQUIRES EMITTER)

The D3 will emit a color to tell you the type of problem.

Color Condition Correction

Red Invalid input voltage on the

power line

Magenta Poor wireless connectivity Ensure that the D3 is not in a metal enclosure and

Yellow Fair wireless connectivity Ensure that the D3 is not in a metal enclosure

Note: Magenta can indicate success or failure. It indicates success if there are no other powered-

on Ketra devices within 50 ft (15.24 mm); otherwise, it indicates a problem.

Ensure that input voltage matches the expected

voltage for the D3's model.

that there are no significant obstructions between

the D3 and other Ketra devices.

Note: In some circumstances, magenta is expected.

See the note below the table.

and that there are no significant obstructions

betweenthe D3 and other Ketra devices.

18|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

Wrrnty Tech Support

Limited warranty terms can be found at:

www.ketra.com/warranty

For questions and technical support please contact:

(844) 5886445

ketrasupport@lutron.com

Ketra and KetraNET are trademarks or registered trademarks of Lutron Ketra LLC, in the US and/ or

other countries.

19|D3 INSTALLATION GUIDE

© 2019 Ketra, Inc. All rights reserved

P/N 040444 Rev E

6231 E. Stssney Ln.

ketra.com

P/N 040444

Bldg. 13, Suite 400

Austin, TX 78744

P/N 040444 Rev D

ketr.com

512.872.4349

Loading...

Loading...