Kester 977 Data Sheet

®

977

977

VOC-Free No-Clean Liquid Flux

VOC-Free No-Clean Liquid Flux

For Lead-bearing and Lead-free alloys

For Lead-bearing and Lead-free alloys

Product Description

Kester 977 is an organic water-soluble, waterbased, no-clean chemistry for high quality soldering

of electronic circuit board assemblies. Designed

for wave soldering applications, Kester 977

provides good wetting on most surface finishes.

The flux was specifically designed to reduce

bridging, which is commonly associated with

VOC -free no-clean fluxes.

Kester 977 has excellent soldering properties for

improved productivity without sacrificing reliability

of the assembly. The flux leaves bright shiny solder

joints and will not attack properly cured solder

masks or FR-4 Epoxy-Glass laminate. The minimal

amount of residue remaining after soldering is

non-conductive, non-corrosive and need not be

removed. The residues left after soldering will not

interfere with in-circuit testing. Kester 977 is not

detrimental to the Surface Insulation Resistance

(SIR) of the soldered assembly.

Physical Properties

Specific Gravity: 1.012 ± 0.010

Antoine Paar DMA 35 @ 25°C

Percent Solids (typical): 3.25

Tested to J-STD-004, IPC-TM-650, Method 2.3.34

Acid Number: 27.0 ± 1.0 mg KOH/g of flux

Tested to J-STD-004, IPC-TM-650, Method 2.3.13

pH (10% solution): 3.0

Hanna Instruments 8314 @ 25°C

Flash Point: >100°C (212°F)

Reliability Properties

Copper Mirror Corrosion: Low

Tested to J-STD-004, IPC-TM-650, Method 2.3.32

Corrosion Test: Low

Tested to J-STD-004, IPC-TM-650, Method 2.6.15

Performance Characteristics:

• Biodegradable at pH of 2.0 or greater

• Chemically compatible with most solder masks

and board laminates

• Does not degrade Surface Insulation

Resistance

• No offensive odors

• Bright, shiny solder connections

• Classified as ORL0 per J-STD-004

• Compliant to Bellcore GR-78

Silver Chromate: Pass

Tested to J-STD-004, IPC-TM-650, Method 2.3.33

Chloride and Bromides: None Detected

Tested to J-STD-004, IPC-TM-650, Method 2.3.35

Fluorides by Spot Test: Pass

Tested to J-STD-004, IPC-TM-650, Method 2.3.35.1

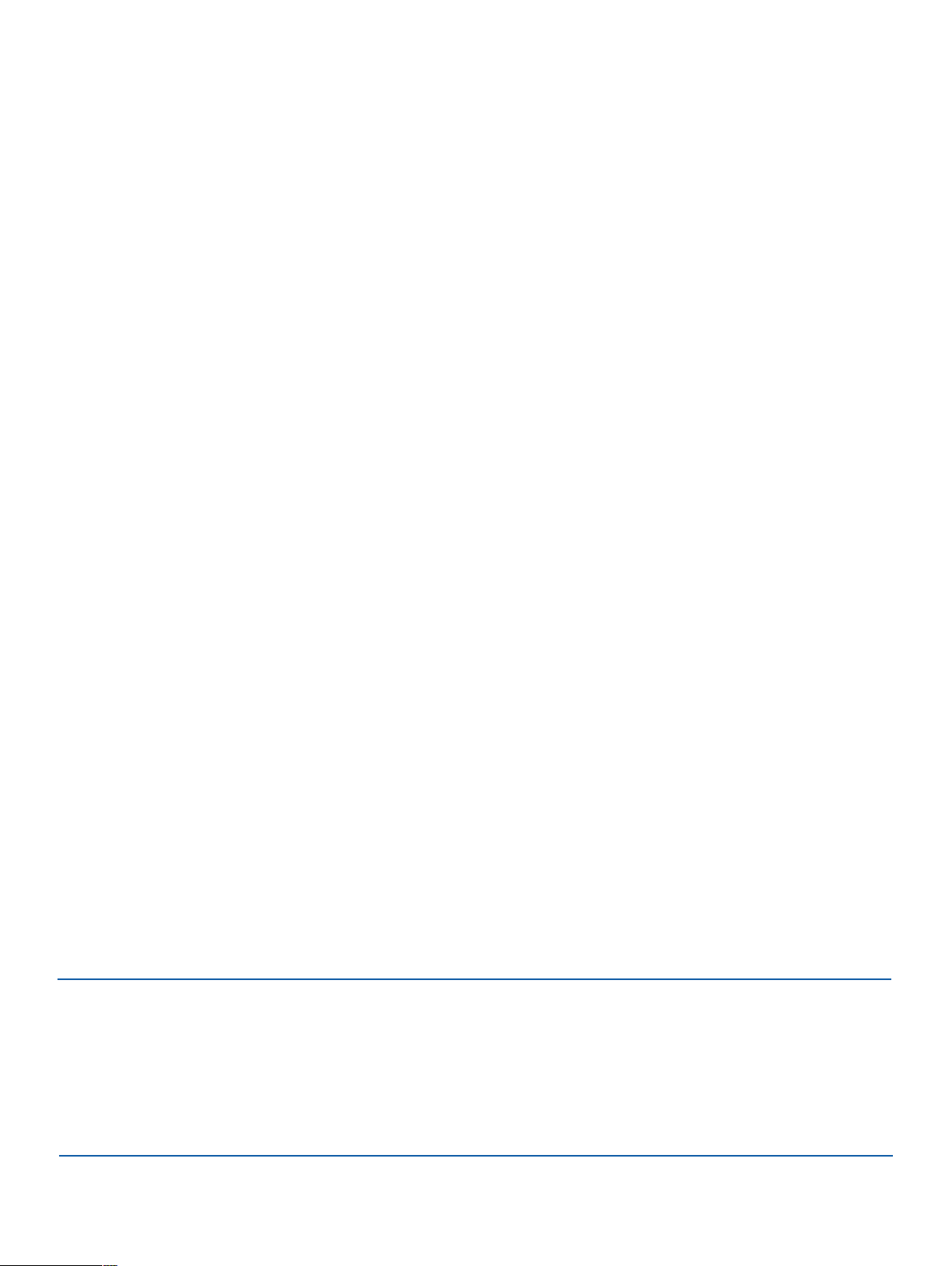

SIR, IPC (typical): Pass

Tested to J-STD-004, IPC-TM-650, Method 2.6.3.3

977 PU

8.4 ´ 108W

2.8 ´ 109W

3.5 ´ 109W

Day 1

Day 4

Day 7

Blank 977 PD

4.1 ´109W 7.1 ´ 108W

7.0 ´109W 1.3 ´ 109 W

8.0 ´109W 1.7 ´ 109W

977

Application Notes

Flux Application:

Kester 977 can be applied to circuit boards by a spray or dip process. Flux deposition should be 120-240 mg

of solids/cm

flux from the circuit board and prevent dripping on the preheater surface.

Process Considerations:

The optimum preheat temperature for most circuit assemblies is 90-115°C (194-239°F) as measured on the

top or component side of the printed circuit board. Dwell time in the wave is typically 2-4 seconds. The wave

soldering speed should be adjusted to accomplish proper preheating and evaporate excess water, which

could cause spattering. For best results, speeds of 1.4-1.8 m/min (4½-6 ft/min) are used. The surface tension

has been adjusted to help the flux form a thin film on the board surface allowing rapid water evaporation.

Elimination of Splattering:

Since VOC-free fluxes are water-based, splattering can be a problem. Splattering occurs when water comes

in contact with molten solder, so it may be necessary to use forced air to drive off the water. Manufacturers

have reported that blowing hot air at 0.28-0.85 m

circuit boards.

Flux Control:

Acid number is normally the most reliable method to control the flux concentration of low solids, no clean

fluxes. Evaporative loss is minimal because this flux is water-based. To check concentration, a simple

acid-base titration should be used. PS-20 Test Kit and procedure are available from Kester.

2

(750-1500 mg of solids/in2). An air knife after the flux tank is recommended to remove excess

3

/hr (10-30 ft3/hr) greatly assists in drying the water off the

Cleaning:

Kester 977 flux residues are non-conductive, non-corrosive and do not require removal in most applications.

If residue removal is required, plain DI water at 43-54°C (110-130°F) may be used.

Storage and Shelf Life:

Because this formulation is water based, it is subject to freezing. A minimum storage temperature of 4°C

(40°F) is recommended. If frozen, the Kester 977 is easily reconstituted by stirring at room temperature.

Shelf life is 3 years from date of manufacture when handled properly and held at 4-25°C (40-77°F).

Health & Safety:

This product, during handling or use, may be hazardous to health or the environment. Read the Material

Safety Data Sheet and warning label before using this product.

World Headquarters: 800 West Thorndale Avenue, Itasca, Illinois, 60143-1341 USA

Phone: (+1) 630-616-4000 • Email: customerservice@kester.com • Website: www.kester.com

Asia Pacific Headquarters

500 Chai Chee Lane

Singapore 469024

(+65) 6449-1133

customerservice@kester.com.sg

European Headquarters

Zum Plom 5

08541 Neuensalz

Germany

(+49) 3741 4233-0

customerservice@kester-eu.com

Japanese Headquarters

20-11 Yokokawa 2-Chome

Sumida-Ku

Tokyo 130-0003 Japan

(+81) 3-3624-5351

jpsales@kester.com.sg

The data recommendations presented are based on tests, which we consider reliable. Because Kester has no control over the conditions of use, we disclaim any responsibility connected with the

use of any of our products or the information presented. We advise that all chemical products be used only by or under the direction of technically qualified personnel who are aware of the potential hazards involved and the necessity for reasonable care in their handling. The technical information contained herein is consistent with the properties of this material but should not be used in

the preparation of specifications as it is intended for reference only. For assistance in preparing specifications, please contact your local Kester office for details.

Rev: 22Mar10

Loading...

Loading...