KERUI ZJ14087-50DB Service Manual

Shandong Kerui Petroleum Equipment Co.,Ltd.

ZJ14087-50DB/6 VFD

Service Manual

KRE119J-000SM

Version: 2015-A

Dongying, China

ZJ14087-50DB/6 VFD Service Manual

The personnel using this manual must have basic knowledge of drilling equipments and

t description taken from other manufacturers are updated,

Without our authorization, providing this documentation to the third party in any way is

Shandong Kerui Petroleum Equipment Co.,Ltd

Preface

Thank you for using the drilling rig made by Shandong Kerui Machinery Manufacture Co.,

Ltd.

According to the division of function modules, engineering and technical personnel in our

company edit this service manual of rig ZJ14087-50DB/6 VFD house based on designing and

manufacturing of products and field service experience, which provides the corresponding

guidelines for rig installation, usage and maintenance etc.

The product described in this manual has some differences caused by the

temporary changes in technical specification and relevant technical improvement, please in kind

prevail.

In order to ensure your products operate safely and stably, please read this manual

carefully and pay more attention to the terms about safety warnings.

As there are too much components equipped with the rig, only some main points are

included in this manual, the parts not mentioned or introduced briefly can refer to

corresponding service manuals for the structure, usage, and maintenance.

Special prompt:

drilling technology, such as professional technical personnel, operators, technicians, etc.,

who are familiar with the relevant work process.

If the manuals for equipmen

the manuals take precedence of this rig service manual except special statement.

All of the information contained in the manual is based on the latest product

information when published, we reserve the right to repeal (or modify) at any time without

notice, and also never assume any responsibility and obligation;

forbidden strictly. Otherwise we are entitled to pursue their legal responsibility for

consequences.

This manual has been revised carefully, but not exclude some improper exists. Please

correct us for future revision and improvement.

I

ZJ14087-50DB/6 VFD Service Manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Imp ortant Safety

Notice

All personnel for usage, management, operation, maintenance and repair

must know this manual very well, and comply with the relevant standard. Also

pay more attention to the Warnings and Notes etc., as well as laws and

regulations, industry rules, general common-sense safety terms and attentions to

avoid personal injury and equipments damage.

This manual cannot list all safety warnings in details, so any method must be

confirmed neither harm personal safety nor damage the equipments during

operation.

Proper maintenance is very essential for safe and reliable operation, the

personnel shall maintain according to this manual.

It is very important for safe and reliable operation to repair properly and

replace with the original components; the users must repair and replace

components according to manufacturer’s authorized scope.

When the following title or mark emerge in this manual, please read seriously and

pay enough attention!

II

ZJ14087-50DB/6 VFD Service Manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Warning! Applying to the situation that heavy casualty may occur

if imprecisely observe operation process, methods, etc.

Attention! Applying to the situation that equipment damage may

occur if imprecisely complying with operation process, methods, etc.

Note! Apply to attention or separate explanation.

III

ZJ14087-50DB/6 VFD Service Manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Catalogue

Preface .................................................................................................................................................... I

Important Safety Notice ....................................................................................................................... II

Definition and warning ......................................................................................................................... 1

Safety criterion ...................................................................................................................................... 1

Ⅰ Brief introduction of electrical control system .............................................................................. 3

1.1 The composition and instruction of the electrical control system ...................................... 3

1.1.1 The composition of VFD house electrical control system .......................................... 3

1.1.2 Overview of VFD house system ................................................................................... 7

1.1.2.1 Overview of power supply system............................................................................ 7

1.2 Introduction of sub-system..................................................................................................... 7

1.2.1 Introduction of generators control system ................................................................. 7

1.2.1.1 Engine speed control module ................................................................................... 7

1.2.1.2 Voltage control module ............................................................................................. 8

1.2.1.3 Generators bus-connected module .......................................................................... 9

1.2.2 The introduction of PLC, HMI automatic control system and HMI.......................... 12

1.2.3 The introduction of driving system ............................................................................ 12

1.2.4 Auto drilling function introduction ............................................................................ 14

1.2.5 Electronic Anti-collision System for travel block ....................................................... 15

1.2.6 MCC Circuit introduction ........................................................................................ 16

1.2.7 Air conditioner introduction ................................................................................... 17

1.3 Technical parameters and working conditions .................................................................... 17

1.3.1 Main technical parameters ........................................................................................ 17

1.3.1.1 AC motor and variable-frequency motor ............................................................... 17

1.3.1.2 Main technical parameters of all Rectifier cabinets, inverter cabinets ............... 18

1.3.1.3 Main transformer ................................................................................................. 18

1.3.1.4 Main technical parameters of generators control system ................................. 19

1.3.2 A/C working condition............................................................................................. 20

Ⅱ Installation and arrangement ...................................................................................................... 23

2.1 Outer appearance and weight of equipment ...................................................................... 23

2.2 The arrangement at the well site for the equipment ...................................................... 23

2.3 Installation, cabling and grounding ...................................................................................... 23

2.3.1 Foundation on the ground ......................................................................................... 23

2.3.2 Hoisting........................................................................................................................ 23

2.3.3Grounding .................................................................................................................... 23

IV

ZJ14087-50DB/6 VFD Service Manual

Shandong Kerui Petroleum Equipment Co.,Ltd

2.3.4 Cabling ......................................................................................................................... 24

Ⅲ Startup and operation of VFD electrical control system .......................................................... 26

3.1 Generators control system (1~4# Generator cabinets, PS cabinet) ................................. 26

3.1.1 Operation of generating control system ................................................................... 26

3.1.1 .1Preparation before startup ..................................................................................... 26

3.1.1.2 Start the generators ................................................................................................ 29

3.2 PLC1 / PLC2 cabinet ........................................................................................................... 31

3.2.1 PLC1 Cabinet Operation ............................................................................................. 31

3.2.2 PLC2 Cabinet Operation ............................................................................................. 33

3.3 Top PLC cabinet Operation ................................................................................................... 35

3.4 VFD drive cabinets ................................................................................................................. 37

3.4.1 VFD drive cabinets operation ..................................................................................... 37

3.5 Auto drilling cabinet .............................................................................................................. 38

3.5.1 The operation of auto drilling cabinet....................................................................... 39

3.6 Switch cubicle(CBC1) .................................................................................................... 40

3.6.1 Switching cubicle operation ....................................................................................... 41

VFD1/VFD2 house power supply ......................................................................................... 41

3.7 MCC maintenance operation................................................................................................ 42

3.7.1 MCC drawer cubicles operation ................................................................................. 42

3.7.2 Operation of lighting distribution cabinet ................................................................ 45

3.8 Operation of the Air-conditioner.......................................................................................... 45

Ⅳ System Maintenance and Trouble-shooting ............................................................................... 46

4.1 System maintenance ............................................................................................................. 46

4.1.1 Instruction of system maintenance ........................................................................... 46

4.1.2 Daily Maintenance ...................................................................................................... 47

4.1.3 Weekly Maintenance .................................................................................................. 47

4.1.4 Quarterly Maintenance .............................................................................................. 48

4.1.5 Annual Maintenance .................................................................................................. 48

4.1.6 Maintenance of Dry-type transformer ...................................................................... 48

4.1.6.1 Transformer inspection before release to running................................................ 49

4.1.6.2 Test Running of the Transformer ............................................................................ 49

4.1.6.3 Daily maintenance of the transformer ................................................................... 49

4.1.7 Maintenance of Air Condition System....................................................................... 51

4.1.7.1 Check outdoor unit of air conditioner.................................................................... 51

4.1.7.2 Check indoor unit of air conditioner ...................................................................... 51

4.2 Common fault and analysis .................................................................................................. 51

V

ZJ14087-50DB/6 VFD Service Manual

Shandong Kerui Petroleum Equipment Co.,Ltd

4.2.1 Diesel generators set control system......................................................................... 51

4.2.1.1 Maintenance and fault analysis of DECS-100 ........................................................ 51

4.2.1.2 Maintenance and trouble shooting of 2301E ........................................................ 54

4.2.1.3 Maintenance and trouble shooting of AGC4 ......................................................... 56

4.2.2 AC drive control system .............................................................................................. 57

4.2.3 MCC control system .................................................................................................... 59

VI

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Definition and warning

To use the manual properly, please read the following definitions for the special terms and

safety marks first:

Qualified personnel: to understand this manual and alarm marks on the products, the

qualified personnel refer to the people who are familiar with the assembly, installation, startup,

operation and maintenance and master considerable skills in the practices, such as:

1. The personnel have been trained on the power on, power off, ground connection and

marks for the wiring and electrical equipments and have qualified certificates as the

safety procedure regulated.

2. The personnel have been trained on the proper maintenance and operation for the

safety equipments as the safety procedure regulated.

3. The personnel have been trained on the emergency care.

Here the safety marks used in this manual are defined as follows:

Notes

Used for additional description for the matters

related to personnel safety and equipments safety.

Caution

Used as a prompt for harms to personnel or

equipments caused possibly.

Danger

Used as a prompt for harms to personnel or

equipments caused easily.

Safety criterion

1. The electrical maintenance personnel and other related staff must have the corresponding

qualification certificates and have been trained on the operation, maintenance and

emergency care etc.

2. Do not wear metal belts or ornaments during work to prevent from electrical shock by

contacting with live wires.

3. The tool handles used should be insulated, and some special tools should be ground

1

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

connected during operation. The cabinets should be checked carefully after work finish

to ensure no tool left inside to avoid accidents.

4. The ground connection operation for system should satisfy the corresponding electrical

standard.

5. All the operations and maintenance should comply with the corresponding requirement

of electrical operating procedure and operating manual, or else serious personal injury

and damage to equipment will occur.

6. All the connectors should be plug or pull out during power off, be cautious of connectors

misplaced.

7. Before starting the driller’s station, blow it as per the explosion-proof purging

requirement, supplying power for the driller’s station by checking the pressure of the

explosion-proof purging system, when the pressure is normal, the power switch will be

on automatically.

8. Make sure the cables connection between driller’s station and the outside plug board

correct and prevent misplacing, or else the system will fail or even be damaged.

9. During the electrical control normal operation, the two doors should be closed for

keeping the indoor temperature constant and preventing from entry of dust; also the

doors should not be locked for easy escape during emergency.

10. The control cabinets have the function of insulating dangerous source and interference.

The frequency drive cabinet inside has high voltage after power on, be sure not to open

the cabinet door or operate inside.

11. During operation, be sure not to open the internal and external doors of plug board and

the louver of braking resistor compartment to avoid accidents.

12. In case of fire, cut off power and extinguish fire using CO2 fire extinguisher”.

Dry power is corrosive and will damage equipment that isn’t involved in the fire. Water

will also cause avoidable damage.

13. When the temperature is higher than 40℃, the humidity is higher than 95%, or

condensation forms, the air condition and dryer should be started for cooling and drying,

start the frequency converter and other control power after condensation dissipates.

14. If the main power source for the system is off for more than 30mins check if

condensation has formed inside electrical control cabinet before power on.

2

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Ⅰ Brief introduction of electrical control system

1.1 The composition and instruction of the electrical control system

ZJ50DB(1500hp)Land Rig AC VFD Electrical Power Control System (VFD Container) is used

for ZJ50DB(1500hp) Land Rig, which is a AC variable frequency control system for rig drilling

5000m (1500hp drawworks) with generating frequency of 50Hz, voltage of 600V.

1.1.1 The composition of VFD house electrical control system

The VFD electrical control system is comprised of generator control system (generator

control cabinet GEN, DC24V Power Supply cabinet PS), AC inverter system (drive cabinet), PLC

automatic control and network communication system (PLC cabinet PLC master station,

communication panel of drive cabinets, driller’s station PLC sub-station, HMI, IPC etc.),

frequency converter auto-drilling system(AD), energy consuming braking system, air condition

system, main transformer, motor control center (MCC Cabinet)and other major components.

etc..

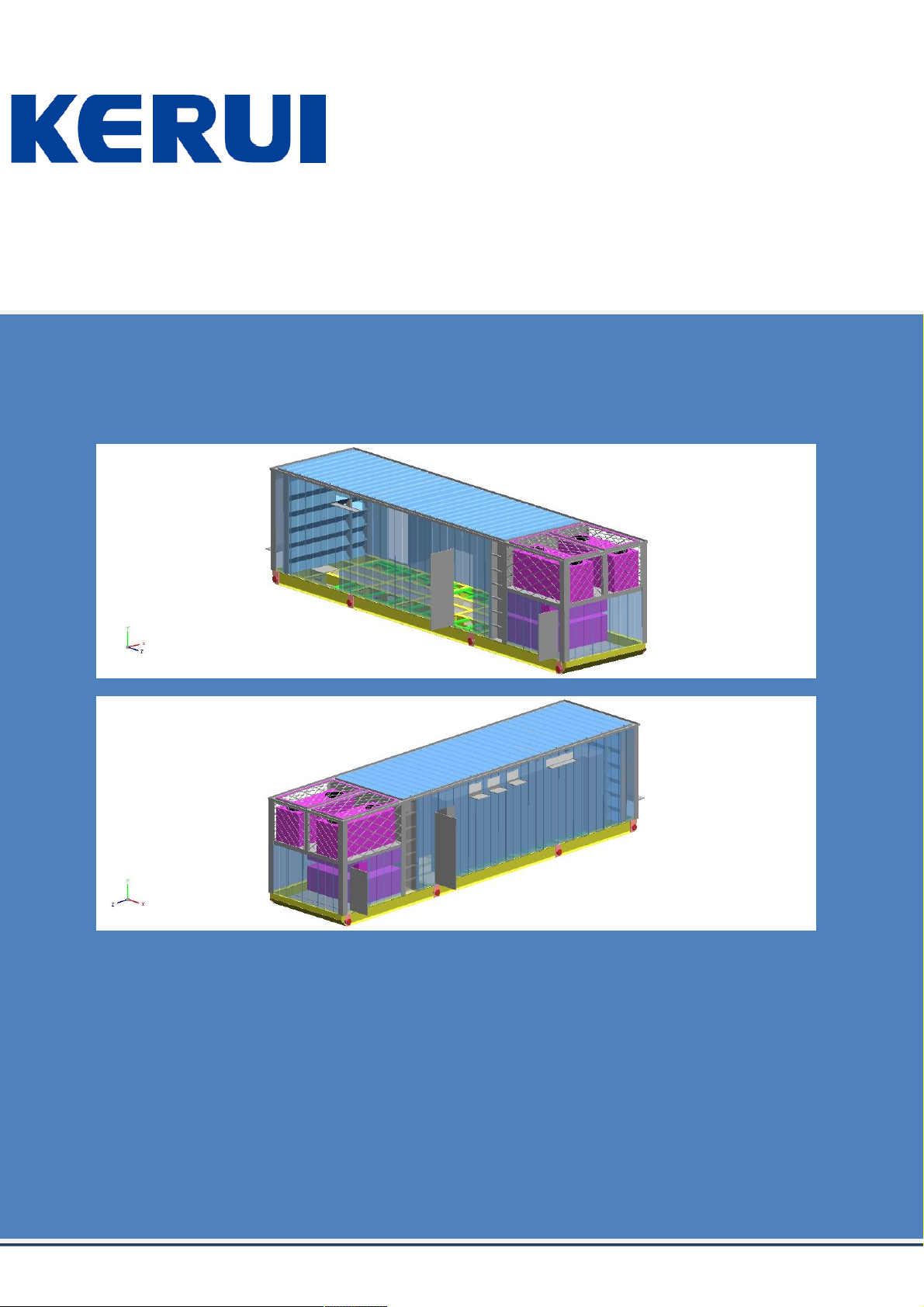

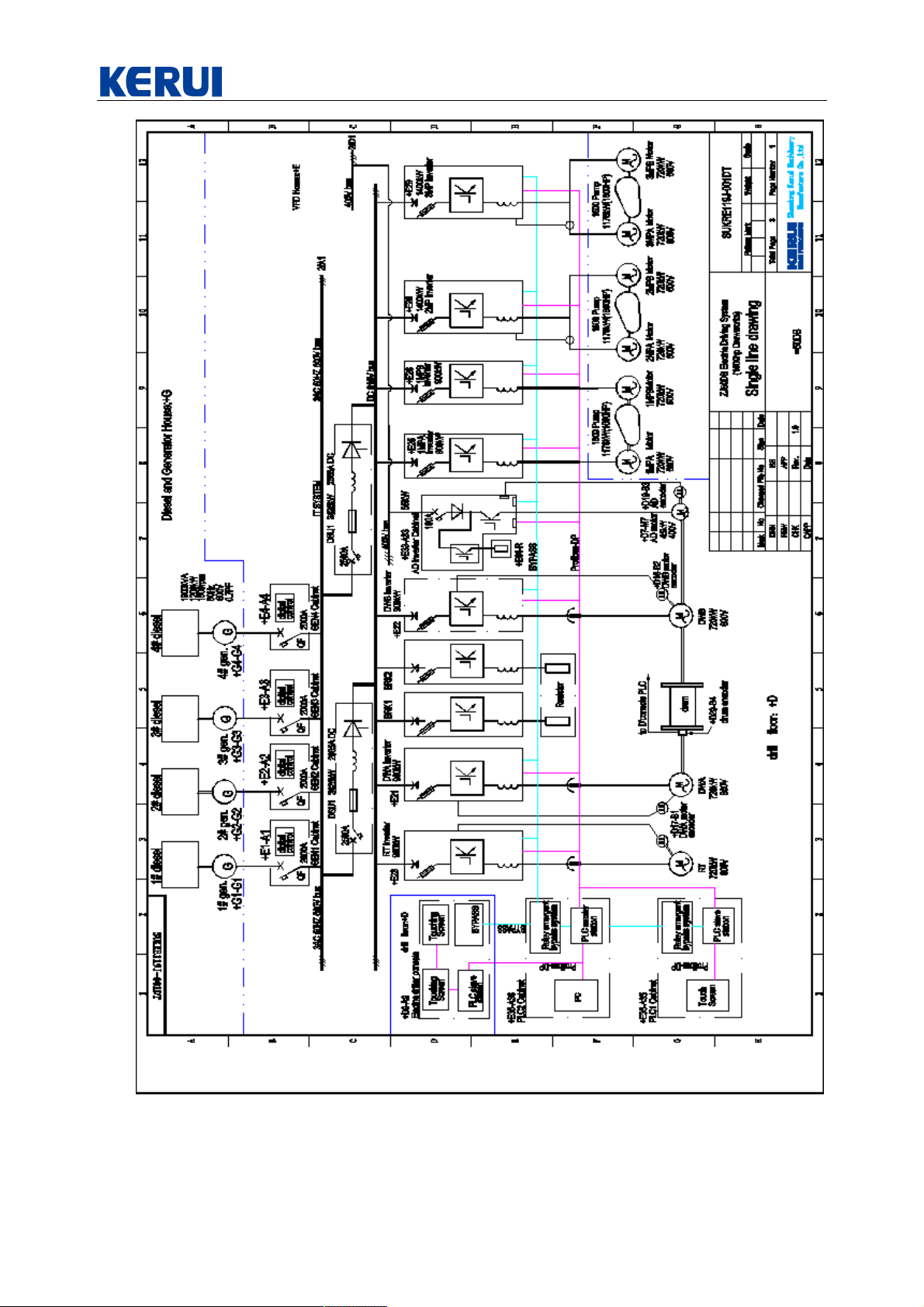

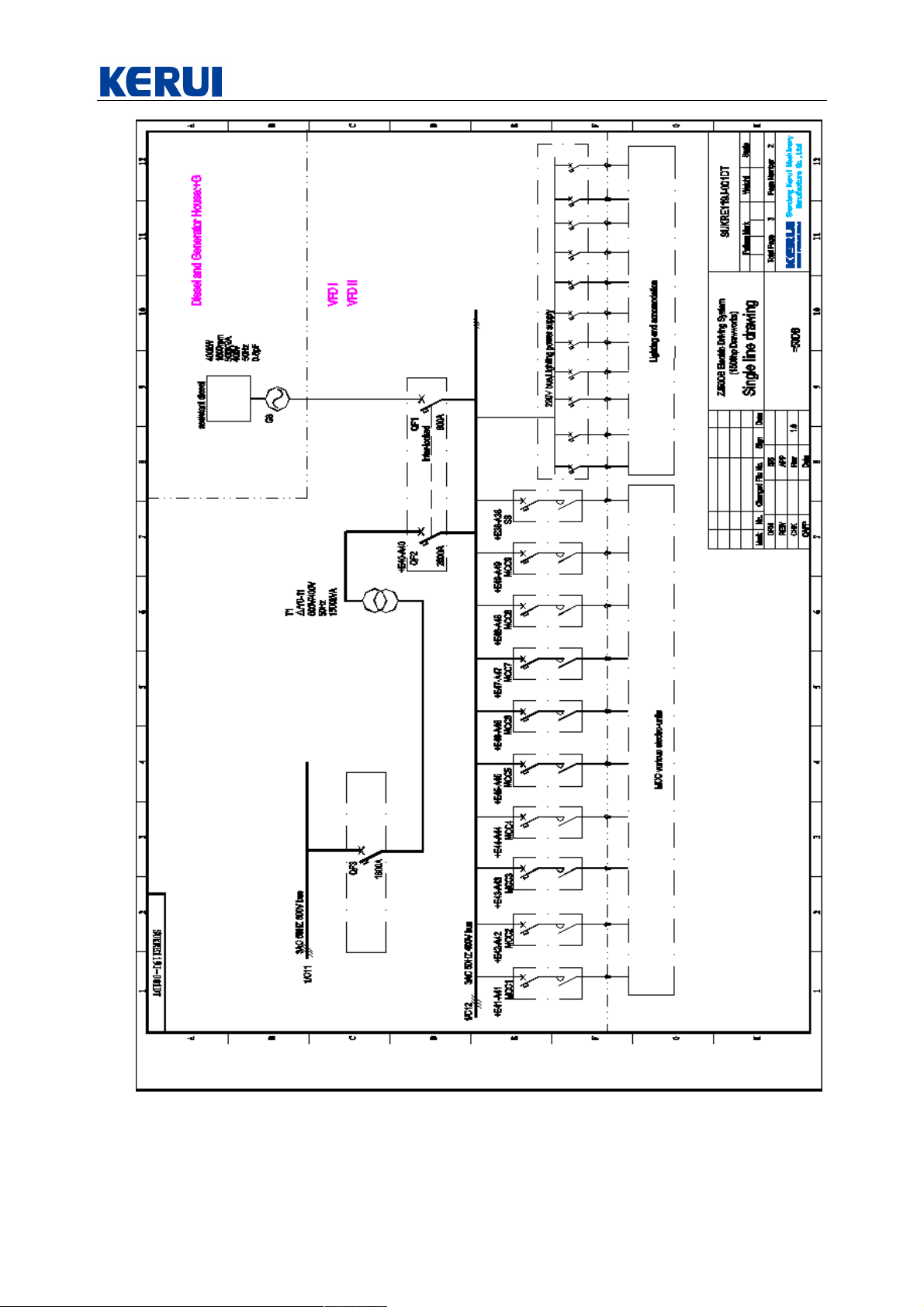

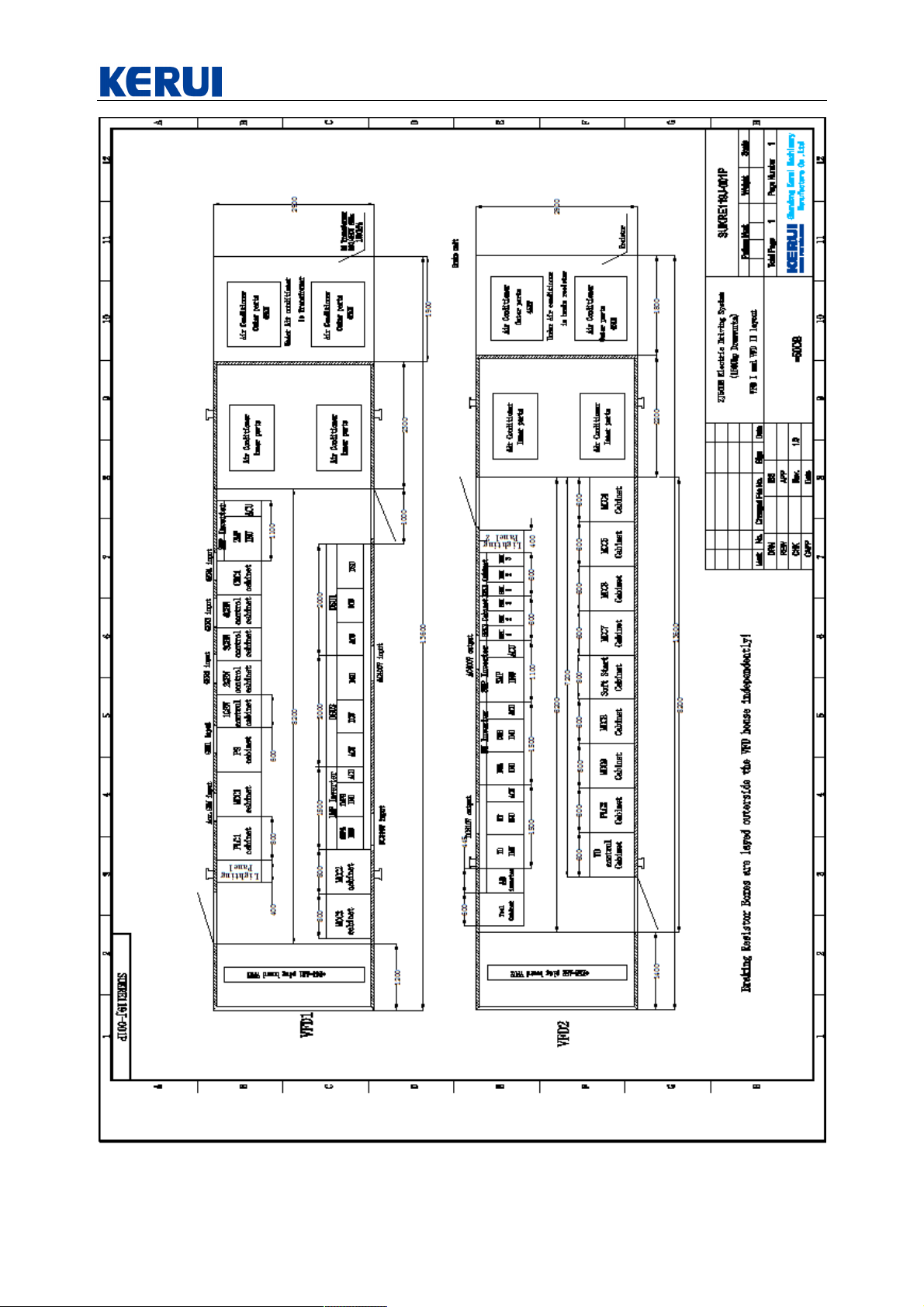

See figures 1-1a, b for electrical power system single line drawings, see figures 1-2 for

house layout. AC incoming line of main power source is 600V, 3ph, 50Hz (host supply), the

auxiliary power source is 400V, 3ph, 60Hz (auxiliary generator supply). The system is comprised

of VFD1 house, VFD2 house, driller’s control station, external power and control cables.

3

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Figure 1-1a ZJ50DB electrical power system single line drawing

4

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Figure 1-1b ZJ50DB electrical power system single line drawing

5

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Figure 1-2 ZJ50DB electrical power system VFD1/VFD2 house layout

6

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

1.1.2 Overview of VFD house system

1.1.2.1 Overview of power supply system

There are 4 generator control cabinets for bus-combined electricity generating, which

connects to the 600V common bus by ABB intelligent circuit breaker. The AC inverter is powered

by 600V bus to control the inverter duty ac motors. The auto drilling (frequency converter) is

powered by 400V bus to control auto-drilling motor. Also the 600V/400V transformer supplies

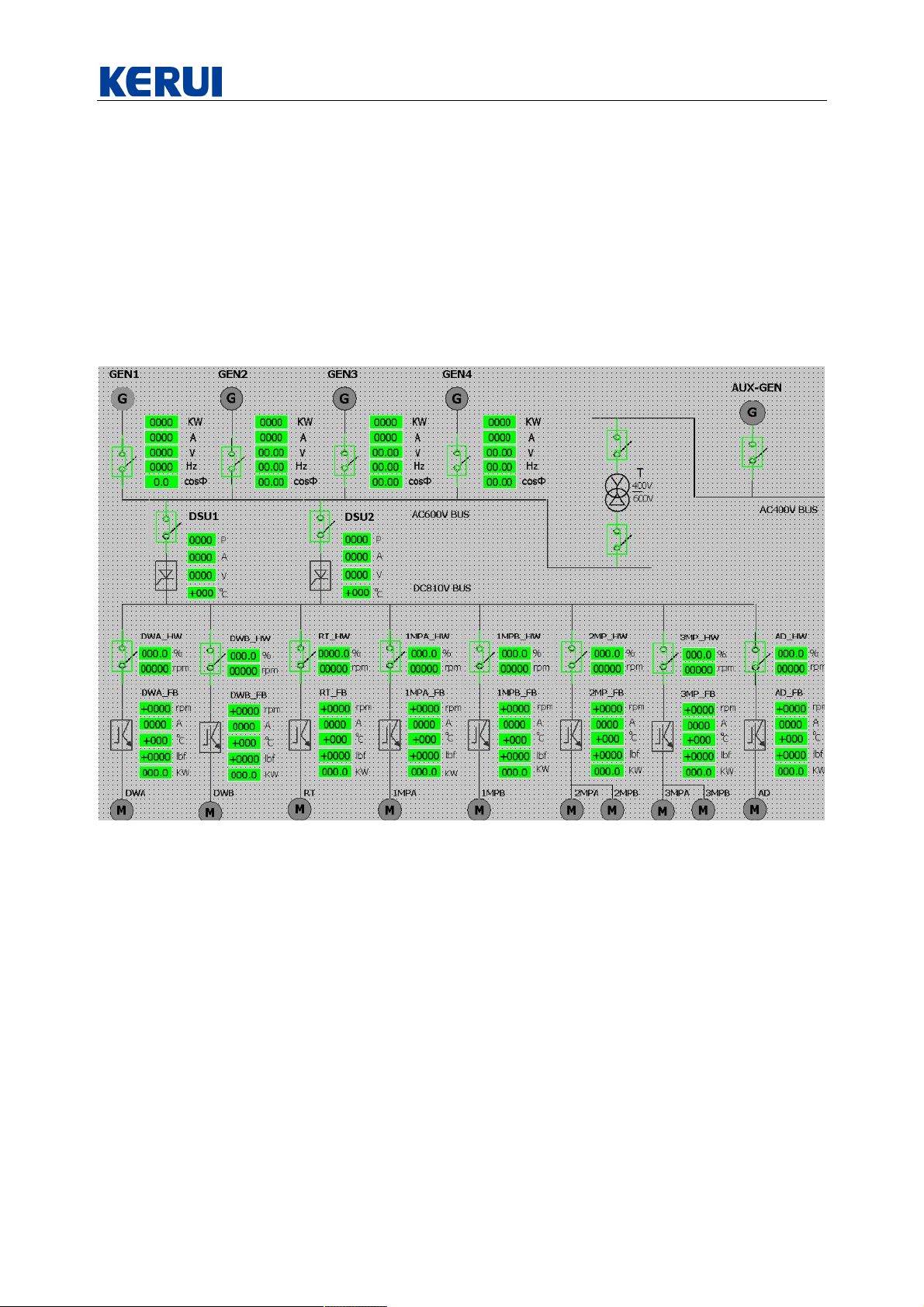

power for MCC loop. See below figure 1-3 for details:

Figure 1-3 ZJ50DB system single line drawing

1.2 Introduction of sub-system

1.2.1 Introduction of generators control system

The generator control system is comprised of 4 generator control cabinets. Each cabinet

includes 3 parts, engine speed control module, voltage control module and generators

bus-connected control module.

1.2.1.1 Engine speed control module

The engine speed control module adopts the 2301E of WOODWARD to control the rotation

speed of diesel engine and then control the frequency of generators. See below figure 1-4:

7

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Figure 1-4 2301E outside view

2301E is a digital speed regulator used for controlling the engine generator based on

microcomputer with function of load distribution automatically. This controller is designed for

controlling the diesel engine or gas engine at intermediate speed and high speed. 2301E (used

for engine at intermediate speed and high speed): 600~3600rpm. 2301E has the function of

speed controlling, load controlling, synchronization/droop transfer and fuel limited etc. See

operational manual of 2301E for specific details.

1.2.1.2 Voltage control module

The voltage control module adopts DECS-100 of Basler electric to control the exciting

voltage of AC synchronous generators, and then control the output voltage of AC generators.

See below figure 1-5:

Figure 1-5 DECS-100 outside view

8

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

The features and functions of DECS-100 are as follows:

◆

4pcs control mode: automac voltage regulation (AVR), manual or field current

regulation (FCR), power factor regulation (PF) and reactive power regulation (VAR)

◆

Steady seng for programmable

◆

Under mode AVR, DECS-100 has the function of soft start with slope adjustable and

voltage establishment control.

◆

Detect bus voltage of single phase (root-mean-square value)

◆

Detect the generator current of single phase for measuring and adjusng.

◆

Detect field current and field voltage.

◆

Input one way analog for remote rao control of given value.

◆

Input five ways contacts for system interface.

◆

One way output relay in common for alarm indicang and trip.

◆

3pcs funcons of protecon (overvoltage of magnec field, overcurrent of magnec

field, overvoltage of generator and detection)

◆

The RS-232 communication port on the back shroud is used for communicating with PC,

the DECS-100 could be set and controlled conveniently and quickly by BESTCOMS. Please refer

to the operational manual of DECS-100 for specific performance parameters and usage etc.

1.2.1.3 Generators bus-connected module

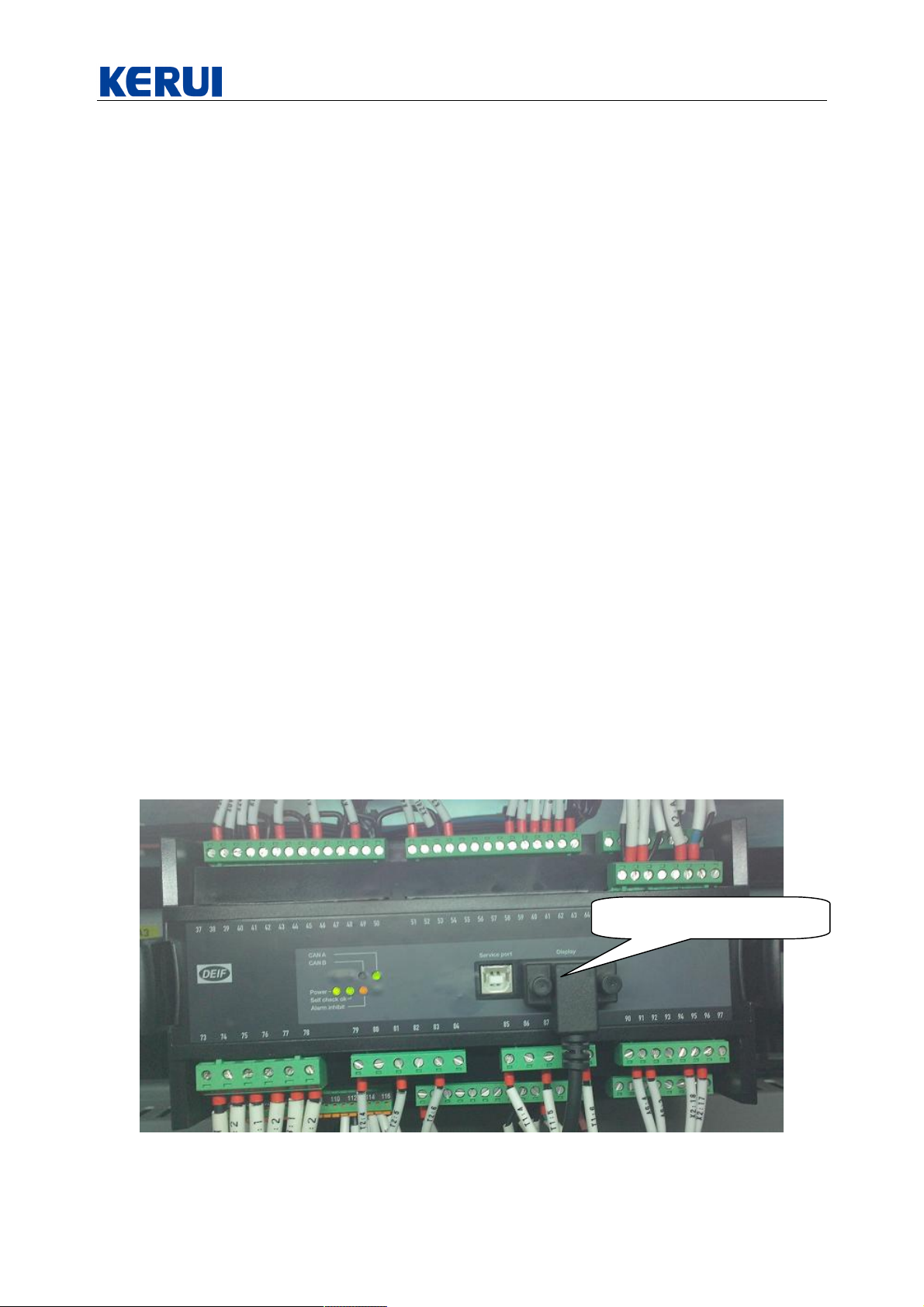

The generators bus-connected module is the bus-connected protection unit AGC4 of DEIF, which is

used for detecting bus voltage, frequency and phase, the generators are allowed to bus connected only

when the generator voltage, frequency and phase are same as the bus. see below figure 1-6:

Connect to AOP-1(serial port)

Figure 1-6 AGC4 outside view

9

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

The protection functions of AGC4 are as follows:

◆

Alarm when the voltage of three phases are not in balance.

◆

Alarm when the current of three phases are not in balance.

◆

Alarm when overvoltage.

◆

Alarm when over-current.

◆

Alarm when reverse-power.

◆

Frequency alarm and protecon funcon.

◆

Speed alarm and protecon funcon.

◆

Water temperature alarm and protecon funcon etc.. Please refer to the operational

manual of AGC4 for specific parameters, operation, model selection etc.

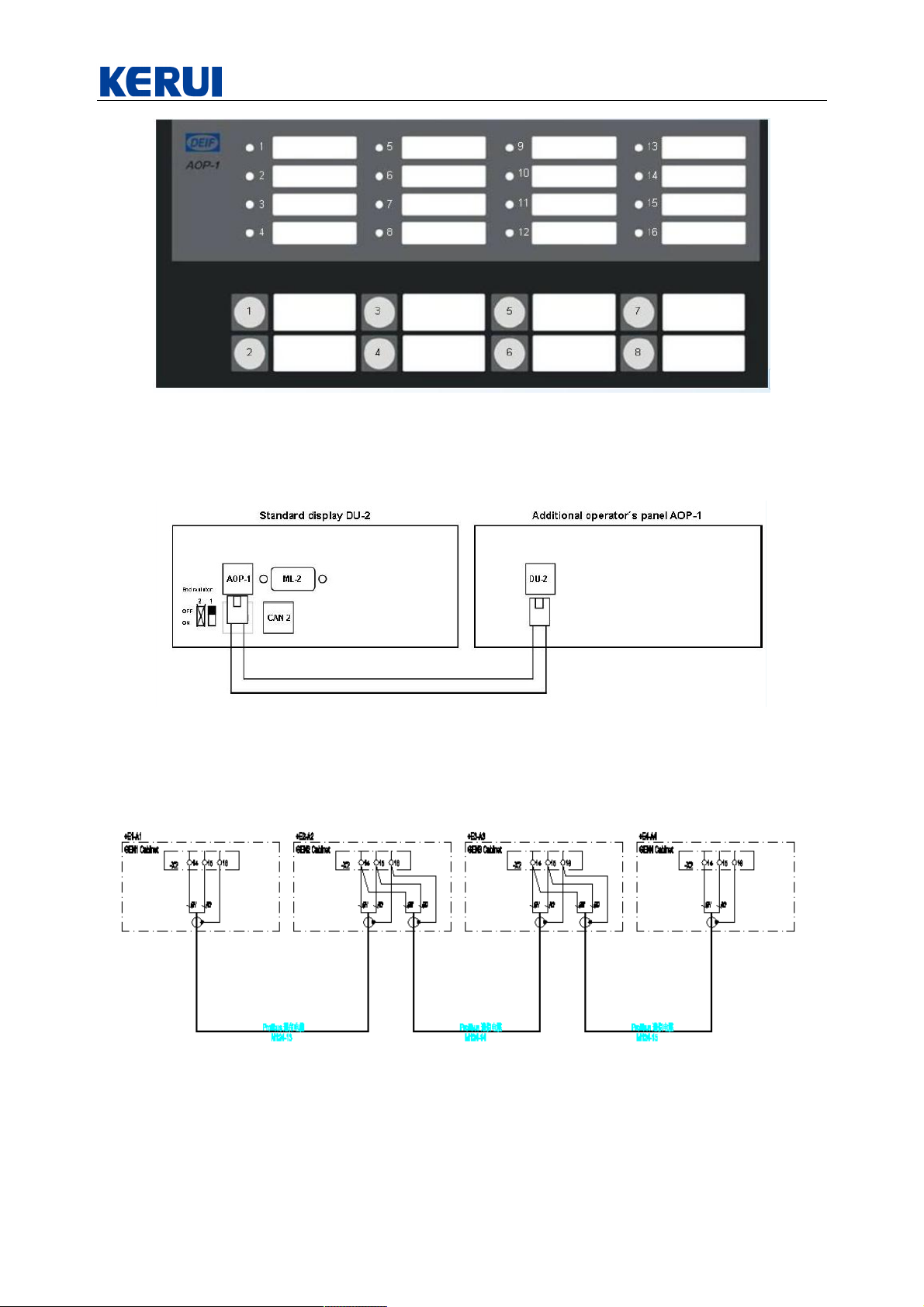

The following picture is the operational panel of AGC4, which is mainly used for operation

and parameters setting, and all the values and alarms will be displayed on the LCD monitor,

referring to the operational manual of AOP-1 for specific descriptions. see below figure 1-7a and

figure 1-7b:

Figure 1-7a LCD monitor outside view

The following picture is the additional extension panel, there are 8pcs press buttons and

16pcs lights. The specific function of each press button and light could be defined through

Utility Software 3 by user.

10

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Figure 1-7b AOP-1 outside view

The additional panel and the AOP-1 operational panel are communicated by serial ports,

see the following figure 1-7c for specific connection.

Figure 1-7c connection between AOP-1 and additional panel

The data exchanges among the 4pcs generators control cabinets are done by CAN OPEN

bus, see below figure 1-8 for details.

Figure 1-8 GEN Cabinets CAN Open communication

11

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

1.2.2 The introduction of PLC, HMI automatic control system and HMI

To adapt the petroleum drilling rig environment on site, and ensure the long, continuously,

and reliable operation for the system, the main unit uses the Siemens S7-300 programmable

controller which could resist electronic noise, electromagnetic interference, radio frequency

interference, and vibration.

The master station of system is CPU 6ES7-317-2DP (PLC2 cabinet), the sub-station includes

PLC1 cabinet of VFD1 house, electrical control cabinet of DCC, all the AC drive cabinets,

auto-drilling cabinet, HMI and IPC. The data will be exchanged through profibus DP network

communication to control the PLC of stations. See below figure1-9 for PRIFIBUS-DP network:

Figure 1-9 the PLC system communication

Profibus-DP network data will come to PLC system through network, so as to save the

connection cable, strengthen the stability. The whole system will be a complete digital, network

system.

PLC network status can also be monitored by HMI. HMI can also indicate various warning

signals and save the warning record as well.

1.2.3 The introduction of driving system

The AC driving cabinet adopted ABB ACS800 series vary frequency device, realizing the

start-stop operation of each device by choosing switches on the driller console.

12

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

The main parameters of the driving Cabinet are as follows:

ACS800-107-1160-7 2XR8i 600 wide cabinet

ABB ACS800 Frequency converter, 900kW (ABB).

Fuse on DC side.

Fiber interface:+L509.

Encoder interface module: L502.

Communication interface: K454.

Terminal strip, 1 ways-10-+10V analogue quantity input, 2 ways 4-20Ma analogue quantity input

7 ways switches quantity input, 3 ways switches quantity output.

Motor: 720kW, 600V with encoder.

Main Protection Functions of the System

Alarm indication for frequency converter faults.

Safety speed for anti-collision.

Under-voltage protection for AC inputting.

Over current and short-circuit protection.

Cooling lose of AC motors

Lockout protection for electromotor

When the transmission cabinet drive the RT, it has the torque-limit function.

AC transmission cabinet, PLC and its main cables made up of the site whole electrical

cables system, human-computer interface shows friendly, full information display, with the

function of self-diagnostic, most part of normal system failure can be indicated by the touch

screen, providing the driller and electrical engineers better operation and maintenance

guidance.

13

ZJ14087-50DB/6 VFD Service manual

Shandong Kerui Petroleum Equipment Co.,Ltd

Figure 1-10 AC driving cabinets outside view

1.2.4 Auto drilling function introduction

The auto drilling system contains VF unit (cabinets), break unit with break resistor, hook

weight load transducer, PLC, touch screen and its hardware and software.

The auto drilling system can control the drill speed and bit pressure, monitor the

parameters of bit pressure, mechanical drill speed and position of traveling block. The travel

block will have some functions such as auto slowdown, soft stop, safety braking when it is

emergent. Then we can efficiently prevent bit slip, bit freezing accidents and promote drill

speed and drilling quality.

There are two fundamental functions of the AD system. The first, during the constant

drilling pressure, the full digital variable system is used to design constant torque, auto speeding

adjusting and protecting, to achieve stable auto drilling with speed adjustable between 0.1~

36m/h ( eventually data should be after the mechanical design) and drill weight error ±5kN. The

second function is the bit feed motor as auxiliary motor for emergency, it can lift the max.

drilling string weight and lay down or rig up mast when the main motors system is in fault state.

In AD system we adopted DTC control with speed sensor and it can vary speed in a large

range. Two operation model, constant speed and constant bit weight models are designed in

the system.

The constant speed mode is normal speed control system. Motor speed is given by the

14

Loading...

Loading...