TITLE:

WRITTEN BY:

RICHARD ADAMS

APPROVED BY:

DENNIS J. ZOLKOS

Q.A. APPROVED:

JULIAN BERARDUCCI

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

KEROTEST MANUFACTURING CORP.

5500 SECOND AVENUE

PITTSBURGH, PA 15207

TELEPHONE: 412-521-7766

FAX: 412-521-7853

REV.: 10

DATE: 7/12/07

PAGE: 1 OF 35

KEROTEST MODEL-1 GATE VALVE

OPERATIONS MANUAL

DATE OF ORIGINAL ISSUE: DECEMBER 15, 1988

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

REVISION

DATE

DESCRIPTION OF REVISION

1

11/28/90

2 09/04/91

3 07/16/93

4 03/28/96

5 05/30/97

Added Bonnet Leak Repair, Attachment 2

6

11/21/97

Added Table 1 and r e fer enc e to it an d rev i s ed

Attachment 2

7

03/15/99

Retyped. Made various editorial changes such as

Revised 1" and 1-1/4" sizes overtorque to failur e.

8

11/17/99

Revised Bonnet Leak Repai r Proce dur e, Attachment 2

9

05/22/01

Revised Bonnet Leak Repai r Proce dur e, Attachment 2

10

07/12/07

Retyped in its entirety

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 2 OF 35

REVISION SHEET

deleting page number references. Revised packing

temperature limitations under body/wedge seating.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 3 OF 35

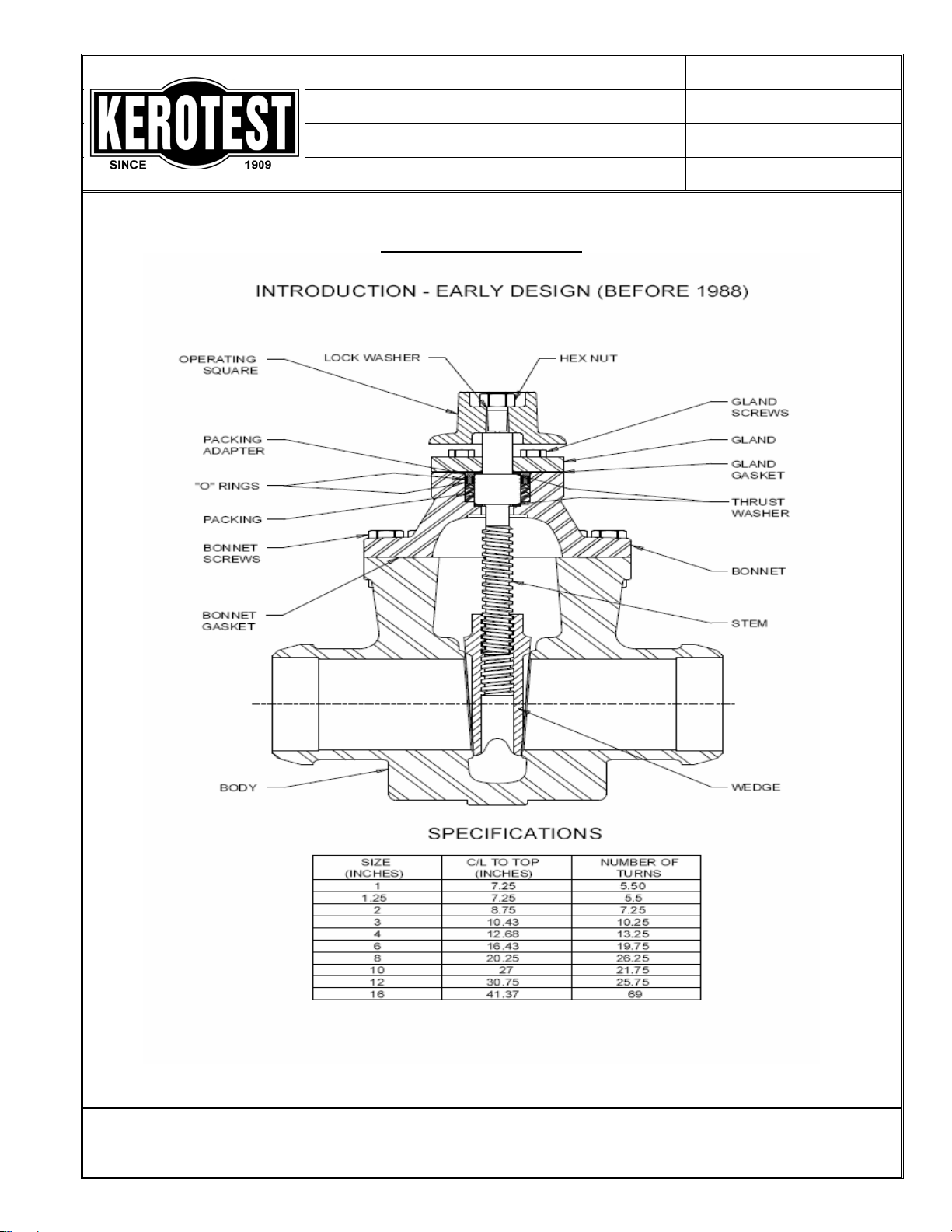

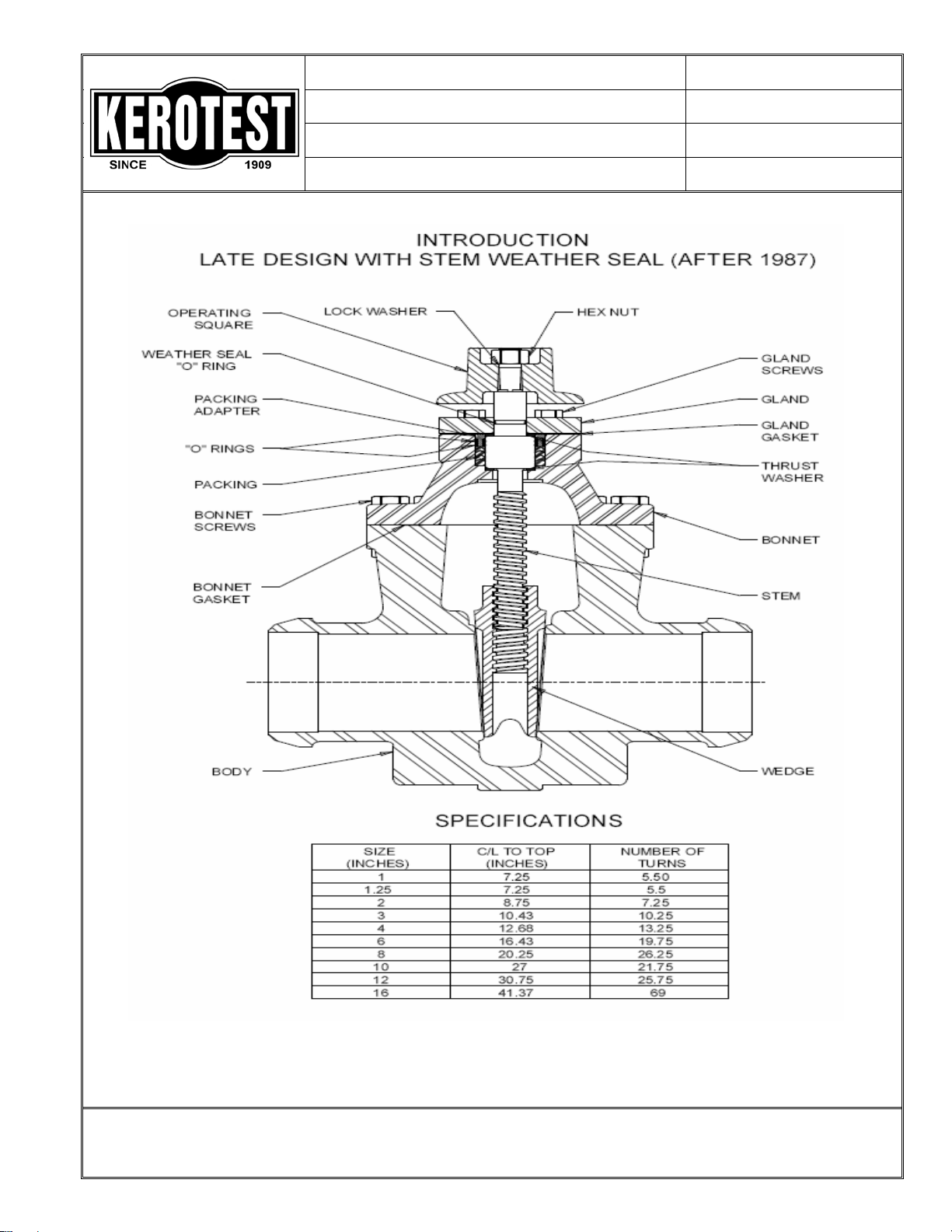

INTRODUCTION

The Kerotest Model-1 design employs the following features. These include:

• Maintenance Free

• No Gland Tightening

• No Lubrication (during cycling)

• Low Operating Torque

• Directional Solidification Weld Ends

• Patented Packing – No Environmental Leakage

• Field Repairable

The intent of this manual is to acquaint our customers with installation procedures and repair

techniques for Model-1 Gate valves.

Kerotest stands ready to service our valves no matter where the location. Technical personnel

or our field representatives are ready to service you on very short notice.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 4 OF 35

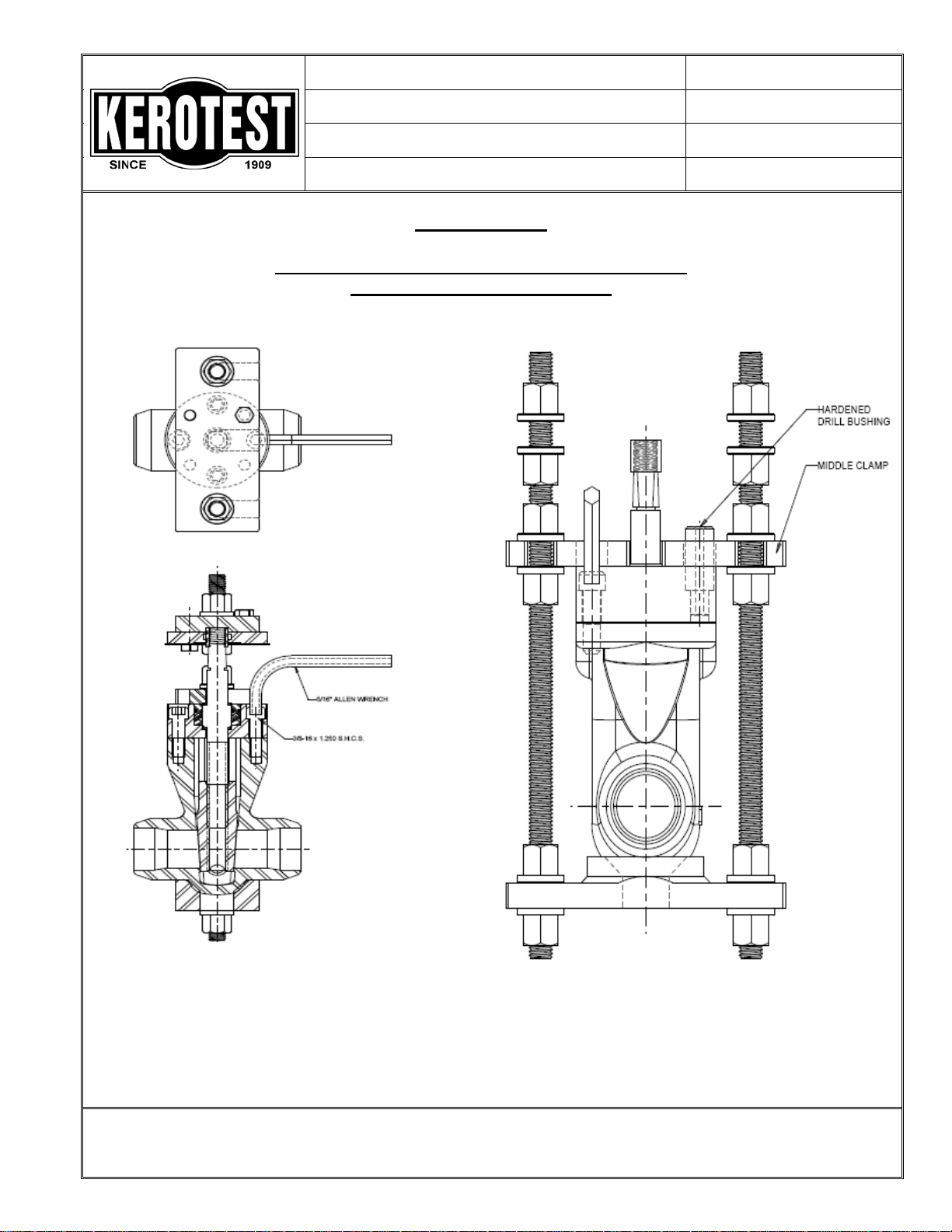

VALVE COMPONENTS

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 5 OF 35

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

HYDROSTATIC SHELL TEST

285 MOP

500 WOG

740 MOP

TIME

MINUTES

PRESSURE

(PSIG)

TIME

MINUTES

PRESSURE

(PSIG)

TIME

MINUTES

PRESSURE

(PSIG)

1" THRU 4"

2

450

2

875 2 1125

6" THRU 8"

5

450

5

875 5 1125

10" 5 450

NA

NA 5 1125

12" AND 16"

15

450

NA

NA

15

1125

HYDROSTATIC SEAT TEST

285 MOP

500 WOG

740 MOP

TIME

MINUTES

PRESSURE

(PSIG)

TIME

MINUTES

PRESSURE

(PSIG)

TIME

MINUTES

PRESSURE

(PSIG)

2" THRU 4"

2

315

2

550

2

815

6" THRU 10"

5

315

**5

550

5

815

12" AND 16"

10

315

NA

NA

10

815

*TIME LISTED PER EACH SIDE

**10" NOT APPLICABLE

AIR SHELL TEST

285 MOP

500 WOG

740 MOP

TIME

MINUTES

PRESSURE

(PSIG)

TIME

MINUTES

PRESSURE

(PSIG)

TIME

MINUTES

PRESSURE

(PSIG)

1" THRU 4"

2

150

2

150

2

150

6" THRU 10"

5

150

5

150

5

150

12" AND 16"

10

150

10

150

10

150

AIR SEAT TEST

285 MOP

500 WOG

740 MOP

TIME

SECONDS

PRESSURE

(PSIG)

TIME

SECONDS

PRESSURE

(PSIG)

TIME

SECONDS

PRESSURE

(PSIG)

1" TO 8"

30

80 TO 100

30

80 TO 100

30

80 TO 100

10",12",16"

60

80 TO 100

60

80 TO 100

60

80 TO 100

*TIME LISTED PER EACH SIDE

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 6 OF 35

TESTING

TO BE CERTAIN THAT ALL VALVES SHIPPED FROM THE FACTORY ARE BUBBLE

TIGHT, THEY ARE SUBJECTED TO THE FOLLOWING TESTS.

SIZE

SIZE

SIZE

SIZE

THE ABOVE TESTS EQUAL OR EXCEED THOSE VALVE TESTS REQUIRED BY

MSS SP-70 AND API 6D

NOTE: VALVES BUILT BEFORE CHANGE T O FEDERAL CODE IN JULY 2006 WERE

RATED AS FOLLOWS:

CLASS 150 – 275 MOP

CLASS 300 – 720 MOP

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 7 OF 35

VAL VE INSTALLATION

General Instructions

• Valves are of the wedge gate design and can be installed with either end as the inlet

side

• Valves should be installed with the wedge in the closed position

Screwed End Valves

• Valve ends have pipe threads machined per ANSI B2.1

• Apply a suitable threading compound to the threads on the pipe. The threading

compound should be applied sparingly.

• The wrench used for installing these valves should be applied to the end of the valve

next to the pipe to which it is being connected

Socket Weld End Valves

• Valve ends are machined per ANSI B16.11

• "Note" in order that the valve seats are not affected during the welding operation, the

wedge should be in the closed position

• Valves should be installed using either the electric arc or oxy-acetylene welding

methods by welders and welding procedures qualified under Section IX of the ASME

Boiler and Pressure Vessel Code or an equivalent requirement

o Valve bodies are carbon steel (ASTM A216 Gr. WCB). Type 7018 Welding Rod

is suggested for welding these (WCB) valves in the pipeline.

Flanged End Valves

• End flanged dimensions conform to ANSI B16.5

• Standard end flange faci ng is 1/16 " raised face with phonographic fi nis h

• Bolting and gasketing practice conforming to ANSI B16.5 is suggested

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 8 OF 35

• End flange bolts should not be fastened in consecutive order. Each one tightened

should be 180° opposite the previous one (see sketch below). Two passes should be

made. Once pass for half tightness and fi nal pass for full tig htness.

Butt Weld End Valves

• Valve ends are machined per ANSI B1 6.25

• "Note" in order that the valve seats are not affected during the welding operation, the

wedge should be in the closed position

• Valves should be installed using either the electric arc or oxy-acetylene welding

methods by welders and welding procedures qualified under Section IX of the ASME

Boiler and Pressure Vessel Code or an equivalent requirement

• Valve bodies are carbon steel (ASTM A216, Gr. WCB). Type 7018 Welding Rod is

suggested for welding these valves in the pipeline.

Butt Weld End X Flange End Valves

• Refer to butt weld end valves and flanged end valve for installation

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 9 OF 35

TROUBLE SHOOTING

VALVE SHUT-OFF

Throttling Valve

If valves are in the open position in a pipeline for a period of time, there is a chance that

sediment or dirt may collect inside the valve. When these valves are to be closed, it should be

done slowly. The valve should not be closed completely by "throttled" slowly. The valve

should not be closed completely but "throttled" for a short time in order that the turbulence

created will flush away any sediment or dirt that might have settled in the valve.

In the event of an emergency, the above method need not be followed, as the valve should be

closed as quickly as possible.

Body and Wedge Seating

When complete shut-off is not obtained, the valve can be reseated in the following manner.

Drive wedge into seats with moderate effort, turn back one (1) or two (2) complete turns

and again drive into seats with moderate effort. Continue this procedure until shut-off is

obtained.

Repacking Valve

Possible causes for a malfunction of the packing seal could be worn packing or utilizing valve

outside of packing temperature limitations.

Temperature limits of valve packing are -30°F to 200°F

Repack valve as described in the "Primary Repacking Proc edur e ", " S econ dar y

Repacking Procedure", or "Zero Pressure Repacking Procedure" (as applicable) which

follow both Early Design Valves and Late Design Valves with stem weather seal.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 10 OF 35

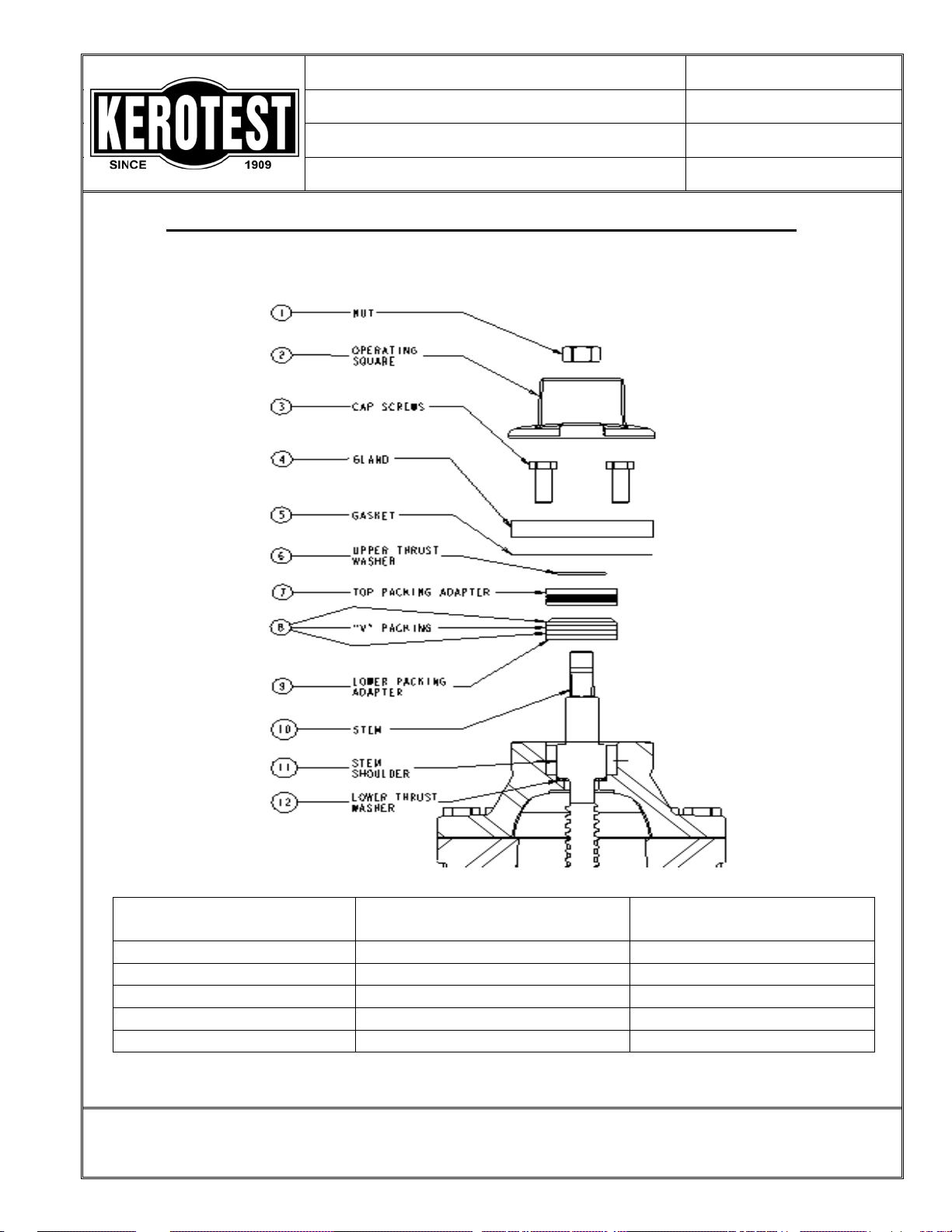

PRIMARY REPACKING PROCEDURE – EARLY DESIGN BEFORE (1988)

CONDITION 1 – VALVE UNDER PRESSURE

(REFER TO DRAWING ON PAGE 12)

1. Open valve fully. Backseat to form a seal between lower thrust washer (12) and stem

shoulder (11).

2. Remove nut (1), and operating square (2).

3. Remove two of the cap screws (3). Replace with two all thread studs (size and length

recommended in table above). Thread all thread studs into cover until they bottom.

Install a nut on each stud and tighten. Remove all remaining cap screws (3).

4. Slowly and evenly loosen the two nuts on the all thread studs, watching that the studs

do not unthread from cover as the nuts are turned. (If gland rises as the nuts are

loosened, backseat seal has not been obtained. Retighten nuts, replace and retighten

missing bolts, and then reattempt backseat seal.) Continue to loosen nuts until the top

of the nuts are flush with the top of the safety studs.

5. Rotate stem slowly with open end wrench on stem square (10) until pressure pops

packing. Backseat immediately.

Caution: Grip end of wrench and keep fingers clear. Pressure may slam gland against

wrench when packing pops.

6. If packing does not pop out, replace gland, retighten nuts on all thread studs, and

replace and tighten remaining cap screws (3). Close valve tightly and turn to Secondary

Procedure for early des i gn and continue with fourth step.

7. Remove nuts and gland (4). Upper thrust washer (6) may remain in gland (4) or on

stem (10).

8. Remove top packing adapter (7), v-rings (8), and lower packing adapter (9).

9. Lubricate new parts with light oil and insert in packing chamber as follows: Lower

packing adapter (9), v-rings (8), and top packing adapter (7).

Note: A slight leak in the backseat seal can cause difficulty in replacing the v-rings; a

straightened paper clip or smooth wire can be used on the side of the v-rings to allow

pressure to vent until the adapter can be quickly inserted and the gland bolted down.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 11 OF 35

PRIMARY REPACKING PROCEDURE – EARLY DESIGN BEFORE (1988)

CONDITION 1 – VALVE UNDER PRESSURE

10. Place upper thrust washer (6) on stem (10) if removed. Position gasket (5) and gland

(4) on cover. Insert cap screws (3) fully and tighten to torque shown in Table I. Place

operating square (2) on stem and then secure with nut (1).

Valve is ready for service.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

VALVE

ALL THREAD

STUD AND NUT SIZE

ALL THREAD

STUD LENGTH

1-1/4"

5/16 – 18 UNC

2

2" AND 3"

3/8 – 16 UNC

2-1/2

4", 6" AND 8"

3/8 – 16 UNC

3

10" AND 12"

1/2 – 13 UNC

4-1/4

16"

3/4 – 10 UNC

6-1/4

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 12 OF 35

PRIMARY REPACKING PROCEDURE – EARLY DESIG N BEFORE (1988)

CONDITION 1 – VALVE UNDER PRESSURE

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 13 OF 35

SECONDARY REPACKING PROCEDURE – EARLY DESIGN (BEFORE 1988)

CONDITION 2

VALVE UNDER PRESSURE AND PRIMARY PROCEDURE WAS UNSUCCESSFUL

(REFER TO DRAWING ON PAGE 16)

1. Close valve tightly with wrench.

2. Remove nut (1) and operating square (2).

3. Before proceeding, remember: If the valve was closed under pressure, the pressure is

trapped in the body cavity. When the stem or packing is removed, this pressure will

bleed from the body. Therefore, this procedure is not recommended for pressures in

excess of 90 PSIG. To prevent unsafe conditions, the following steps must be followed.

4. Remove two of the cap screws (3). Replace with two all thread studs (size and length

recommended in table above). Thread all thread studs into cover until they bottom.

Install a nut on each stud and tighten. Remove all remaining cap screws (3).

4.1 Slowly and evenly loosen the two nuts on the all thread studs, watching that the

studs do not unthread from cover as the nuts are turned. If gland and packing

rise as nuts are loosened, continue to slowly loosen nuts until the trapped

pressure begins to bleed. (If the bleeding pressure does not diminish, successful

seat shut-off has not been obtained.)

Using the nuts on the studs, replace the packing and the gland. Reinstall the

remaining cap screws (3) and reattempt seat shut-off.

4.1.1 When trapped pressure has been reduced to zero, remove the two

nuts, and the gland (4). Upper thrust washer (6) may remain in gland

(4) or on stem (10), top packing adapter (7), v-rings (8), and lower

packing adapter (9).

4.1.2 Lubricate new parts with light oil and insert in packing chamber as

follows: Lower packing adapter (9), v-rings (8), and top packing

adapter (7).

4.1.3 Place upper thrust washer (6) on stem (10) if removed. Position

gasket (5) and gland (4) on cover. Insert cap screws (3) fully and

tighten. Place operating square (2) on stem, secure with nut (1).

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 14 OF 35

SECONDARY REPACKING PROCEDURE – EARLY DESIGN (BEFORE 1988)

CONDITION 2

VALVE UNDER PRESSURE AND PRIMARY PROCEDURE WAS UNSUCCESSFUL

4.2 If gland and packing do not rise as nuts are loosened, continue to loosen nuts

until the top of the nuts are flush with the top of the all thread studs. Slowly

rotate the stem (10) in the same direction as closing the valve until the trapped

pressure begins to bleed. (If the bleeding pressure does not diminish, successful

seat shut-off has not been obtained.) Rotate stem in the direction for opening

valve until it contacts lower thrust washer.

Caution: Be careful not to break gate seal or packing will be subject of full

pressure and gas flow.

Retighten nuts on all thread studs and reinstall cap screws (3) in gland.

Reattempt seat shut off. When trapped pressure has been reduced to zero,

remove the two nuts and then gland (4). Rotate stem ( 10) in the same di r ecti on

as closing the valve until it is free from the wedge. Withdraw stem from valve.

(Lower thrust washer (12) may remain in the cover or on the stem (10)).

4.2.1 Remove top packing adapter (7), v-rings (8), and lower packing

adapter (9).

4.2.2 Replace lower thrust washer (12) in cover (if removed).

4.2.3 Lubricate new parts with light oil and insert in packing chamber as

follows: Lower packing adapter (9), v-rings (8), and top packing

adapter (7).

4.2.4 Insert stem (10) in cover and rotate slowly by hand in the direct ion for

opening the valve. Continue rotation until stem shoulder (11) contacts

lower thrust washer (12).

Caution: Additional stem rotation will unseat the wedge resulting in

full gas pressure and flow.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 15 OF 35

SECONDARY REPACKING PROCEDURE – EARLY DESIGN (BEFORE 1988)

CONDITION 2

VALVE UNDER PRESSURE AND PRIMARY PROCEDURE WAS UNSUCCESSFUL

4.2.5 Check if upper thrust washer (6) is in place. Position gasket (5) and

gland (4) on cover. Insert cap screws (3) fully and tighten to torque

shown in Table I. Place operating square (2) and then secure with nut

(1).

Valve is ready for service.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

VALVE

ALL THREAD

STUD AND NUT SIZE

ALL THREAD

STUD LENGTH

1-1/4"

5/16 – 18 UNC

2

2" AND 3"

3/8 – 16 UNC

2-1/2

4", 6" AND 8"

3/8 – 16 UNC

3

10" AND 12"

1/2 – 13 UNC

4-1/4

16"

3/4 – 10 UNC

6-1/4

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 16 OF 35

SECONDARY REPACKING PROCEDURE – EARLY DESIGN (BEFORE 1988)

CONDITION 2

VALVE UNDER PRESSURE AND PRIMARY PROCEDURE WAS UNSUCCESSFUL

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 17 OF 35

ZERO PRESSURE REPACKING PROCEDURE – EARLY DESIGN (BEFORE 1988)

CONDITION 3 – VALVE UNDER ZERO PRESSURE

(REFER TO DRAWING ON PAGE 18)

1. Close valve tightly with wrench.

2. Remove nut (1) and operating square (2).

3. Remove all cap screws (3) and gland (4). (Upper thrust washer (6) may remain in gland

(4) or on stem (10).)

4. Rotate stem (10) in same direction as closing the valve until it is free from the wedge.

Withdraw stem from valve. (Lower thrust washer (12) may remain in the cover or on the

stem (10).)

5. Remove top packing adapter (7), v-rings (8), and lower packing adapter (9).

6. Replace lower thrust washer (12) in cover if removed.

7. Lubricate new parts with light oil and insert in packing chamber as follows: Lower

packing adapter (9), v-rings (8), and top packing adapter (7).

8. Insert stem (10) in cover and rotate slowly by hand in the direction for opening valve.

Continue rotation until stem shoulder (11) contact lower thrust washer (12).

9. Check if upper thrust washer (6) is in place. Position gasket (5) and gland (4) on cover.

Insert cap screws (3) fully and tighten. Place operating square (2) on stem and then

secure with nut (1).

Valve is ready for service.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 18 OF 35

ZERO PRESSURE REPACKING PROCEDURE – EARLY DESIGN (BEFORE 1988)

CONDITION 3 – VALVE UNDER ZERO PRESSURE

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 19 OF 35

PRIMARY REPACKING PROCEDURE – LATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 1 – VALVE UNDER PRESSURE

(REFER TO DRAWING ON PAGE 21)

1. Open valve fully. Backseat to form a seal between lower thrust washer (13) and stem

shoulder (12).

2. Remove nut (1), and operating square (2).

3. Remove two of the cap screws (3). Replace with two all thread studs (size and length

recommended in table above). Thread all thread studs into cover until they bottom.

Install a nut on each stud and tighten. Remove all remaining cap screws (3).

4. Slowly and evenly loosen the two nuts on the all thread studs, watching that the studs

do not unthread from cover as the nuts are turned. (If gland rises as the nuts are

loosened, backseat seal has not been obtained. Retighten nuts, replace and retighten

missing bolts, and then reattempt backseat seal.) Continue to loosen nuts until the top

of the nuts are flush with the top of the safety studs.

5. Rotate stem slowly with open end wrench on stem square (11) until pressure pops

packing. Backseat immediately.

Caution: Grip end of wrench and keep fingers clear. Pressure may slam gland against

wrench when packing pops.

6. If packing does not pop out, replace gland, retighten nuts on all thread studs, and

replace and tighten remaining cap screws (3). Close valve tightly and turn to Secondary

Procedure for latest design and continue with fourth step.

7. Remove nuts and gland (4). Upper thrust washer (7) may remain on gland (4) or on

stem (11). Remove weather seal o-ring (5).

8. Remove top packing adapter (8), v-rings (9), and lower packing adapter (10).

9. Lubricate new parts with light oil and insert in packing chamber as follows: Lower

packing adapter (10), v-rings (9), and top packing adapter (8).

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 20 OF 35

PRIMARY REPACKING PROCEDURE – LATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 1 – VALVE UNDER PRESSURE

Note: A slight leak in the backseat seal can cause difficulty in replacing the v-rings; a

straightened paper clip or smooth wire can be used on the side of the v-rings to allow

pressure to vent until the adapter can be quickly inserted and the gland bolted down.

10. Place upper thrust washer (7) on stem (11) if removed. Install weather seal o-ring (5) in

stem groove. Position gasket (6) and gland, with weather seal lead-in chamfer side

down, on cover, being careful not to cut o-ring. Insert cap screws (3) fully and tighten to

torque shown in Table I. Place operating square (2) on stem and then secure with nut

(1).

Valve is ready for service.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

VALVE

ALL THREAD

STUD AND NUT SIZE

ALL THREAD

STUD LENGTH

1-1/4"

5/16 – 18 UNC

2

2" AND 3"

3/8 – 16 UNC

2-1/2

4", 6" AND 8"

3/8 – 16 UNC

3

10" AND 12"

1/2 – 13 UNC

4-1/4

16"

3/4 – 10 UNC

6-1/4

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 21 OF 35

PRIMARY REPACKING PROCEDURE – LATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 1 – VALVE UNDER PRESSURE

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 22 OF 35

SECONDARY REPACKING PROCEDURE – L ATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 2

VALVE UNDER PRESSURE AND PRIMARY PROCEDURE WAS UNSUCCESSFUL

(REFER TO DRAWING ON PAGE 25)

1. Close valve tightly with wrench.

2. Remove nut (1) and operating square (2).

3. Before proceeding, remember: If the valve was closed under pressure, the pressure is

trapped in the body cavity. When the stem or packing is removed, this pressure will

bleed from the body. Therefore, this procedure is not recommended for pressures in

excess of 90 PSIG. To prevent unsafe conditions, the following steps must be followed.

4. Remove two of the cap screws (3). Replace with two all thread studs (size and length

recommended in table abov e) . Thread al l thread studs into cover until they bottom.

Install a nut on each stud and tighten. Remove all remaining cap screws (3).

4.1 Slowly and evenly loosen the two nuts on the all thread studs, watching that the

studs do not unthread from cover as the nuts are turned. If gland and packing

rise as nuts are loosened, continue to slowly loosen nuts until the trapped

pressure begins to bleed. (If the bleeding pressure does not diminish, successful

seat shut-off has not been obtained. Using the nuts on the studs, replace the

packing and the gland. Reinstall the remaining cap screws (3) and reattempt

seat shut-off.)

4.1.1 When trapped pressure has been reduced to zero, remove the two

nuts, and the gland (4). Remove weather seal o-ring (5). Upper thrust

washer (7) may remain in gland (4) or on stem (11), top packing

adapter (8), v-rings (9), and lower packing adapter (10).

4.1.2 Lubricate new parts with light oil and insert in packing chamber as

follows: Lower packing adapter (10), v-rings (9), and top packing

adapter (8).

4.1.3 Place upper thrust washer (7) on stem (11) if removed. Install weather

seal o-ring (5) in stem groove. Position gasket (7) and gland (4), with

weather seal lead-in chamfer side down, on cover, being careful not to

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 23 OF 35

SECONDARY REPACKING PROCEDURE – L ATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 2

VALVE UNDER PRESSURE AND PRIMARY PROCEDURE WAS UNSUCCESSFUL

cut o-ring. Insert cap screws (3) fully and tighten. Place operating

square (2) on stem, secure with nut (1).

4.2 If gland and packing do not rise as nuts are loosened, continue to loosen nuts

until the top of the nuts are flush with the top of all thread studs. Slowly rotate

the stem (11) in the same direction as closing the valve until the trapped

pressure begins to bleed. (If the bleeding pressure does not diminish, successful

seat shut-off has not been obtained.) Rotate stem in the direction for opening

valve until it contact lower thrust washer.

Caution: Be careful not to break gate seal or packing will be subject to full

pressure and gas flow.

Retighten nuts on all thread studs and reinstall cap screws (3) in gland.

Reattempt seat shut-off. When trapped pressure has been reduced to zero,

remove the two nuts and then gland (4). Remove weather seal o-ring (5).

Rotate stem (11) in the same direction as closing the valve until it is free from the

wedge. Withdraw stem from valve. (Lower thrust washer (13) may remain in the

cover or on the stem (11)).

4.2.1 Remove top packing adapter (8), v-rings (9), and lower packing

adapter (10).

4.2.2 Replace lower thrust washer (13) in cover (if removed).

4.2.3 Lubricate new parts with light oil and insert in packing chamber as

follows: Lower packing adapter (10), v-rings (9), and top packing

adapter (8).

4.2.4 Insert stem (11) in cover and rotate slowly by hand in the direction for

opening the valve. Continue rotation until stem shoulder (12) contacts

lower thrust washer (13).

Caution: Additional stem rotation will unseat the wedge resulting in

full gas pressure and flow.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 24 OF 35

SECONDARY REPACKING PROCEDURE – L ATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 2

VALVE UNDER PRESSURE AND PRIMARY PROCEDURE WAS UNSUCCESSFUL

4.2.5 Check if upper thrust washer (7) is in place. Install weather seal o-ring

(5) in stem groove. Position gasket (5) and gland (4), with weather

seal lead-in chamfer side down, on cover, being careful not to cut oring. Insert cap screws (3) fully and tighten to torque shown in Table I.

Place operating square (2) and then secure with nut (1).

Valve is ready for service.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

VALVE

ALL THREAD

STUD AND NUT SIZE

ALL THREAD

STUD LENGTH

1-1/4"

5/16 – 18 UNC

2

2" AND 3"

3/8 – 16 UNC

2-1/2

4", 6" AND 8"

3/8 – 16 UNC

3

10" AND 12"

1/2 – 13 UNC

4-1/4

16"

3/4 – 10 UNC

6-1/4

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 25 OF 35

SECONDARY REPACKING PROCEDURE – LATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 2

VALVE UNDER PRESSURE AND PRIMARY PROCEDURE WAS UNSUCCESSFUL

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 26 OF 35

ZERO PRESSURE REPACKING PROCEDURE – LATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 3 – VALVE UNDER ZERO PRESSURE

(REFER TO DRAWING ON PAGE 27)

1. Close valve tightly with wrench.

2. Remove nut (1) and operating square (2).

3. Remove all cap screws (3) and gland (4). Remove weather seal o-ring (5). (Upper

thrust washer (7) may remain in gland (4) or on stem (11).)

4. Rotate stem (11) in same direction as closing the valve until it is free from the wedge.

Withdraw stem from valve. (Lower thrust washer (13) may remain in the cover or on the

stem (11).)

5. Remove top packing adapter (8), v-rings (9), and lower packing adapter (10).

6. Replace lower thrust washer (13) in cover if removed.

7. Lubricate new parts with light oil and insert in packing chamber as follows: Lower

packing adapter (10), v-rings (9), and top packing adapter (8).

8. Insert stem (11) in cover and rotate slowly by hand in the direction for opening valve.

Continue rotation until stem shoulder (12) contacts lower thrust washer (13).

9. Check if upper thrust washer (7) is in place. Install weather seal o-ring (5). Position

gasket (6) and gland (4), with weather seal lead-in chamfer side down, on cover, being

careful not to cut o-ring. Insert cap screws (3) fully and tighten to torque shown in Table

I. Place operating square (2) on stem and then secure with nut (1).

Valve is ready for service.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 27 OF 35

ZERO PRESSURE REPACKING PROCEDURE – LATEST DESIGN

WITH STEM WEATHER SEAL (AFTER 1987)

CONDITION 3 – VALVE UNDER ZERO PRESSURE

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 28 OF 35

Bonnet Gasket Leak

See Attachment 2, Model-1 Bonnet Leak Repair Procedure.

Broken Stems

This can be due to one of two possibilities: External damage (i.e. backhoe, etc.) or if the valve

when in the full open or full closed position is over torqued. See "Critical Torque Table" (Page

32).

The valve stem is designed to shear at minimum cross-sectional area at the top of stem. This

should enable you to utilize a pipe wrench on the remainder of stem protruding above the

gland. The "Secondary Repacking Procedure" may now be used to replace the broken stem.

In all cases, your area representative or factory personnel should be notified to make this

repair. Kerotest is prepared at all times to give this service at relatively short notice.

Ordering Procedure

Reorder or replacement parts procurement.

Proper identification of replacement parts or valves will improve deliveries and eliminate order-

processing errors.

When ordering replacement parts, first identify the part from the illustration in the introduction.

Locate the valve size, figure number of WOG rating from the valve body, and serial number or

date code off the identification tag (see sample below) attached to the body cover flange.

A typical replacement part order should read as follows:

3 Pieces – Stem for 8" 1F2WL (or 285 MOP) valve

Serial Number 5 07

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

GLAND CAP SCREW TORQUE VALUES

Valve Size

Torque (Ft-Lbs.)

1"

15 – 20

1-1/4"

15 – 20

2"

20 – 30

3"

20 – 30

4"

20 – 30

6"

20 – 30

8"

20 – 30

10"

45 – 60

12"

45 – 60

16"

125 – 175

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 29 OF 35

TABLE I

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

FULL PORT VALVES

Size

Equivalent Length in Feet of Pipe

1"

1.1

1-1/4"

1.5

2"

2.3

3"

3.4

4"

4.5

6"

6.8

8"

8.9

10"

10.2

12"

13.0

16"

16.5

VENTURI PORT VALVES

Size

Equivalent Length in Feet of Pipe

2" X 1-1/4"

14.2

3" X 2"

16.5

4" X 3"

13.6

6" X 4"

32.8

8" X 6"

27.2

10" X 8"

24.0

12" X 8"

65.7

16" X 12"

33.0

20" X 16"

41.0

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 30 OF 35

PRESSURE DROP

Valve pressure drop (equivalent length in feet of pipe) is indicated in the chart shown below:

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

OPERATING TORQUE (FT.-LBS.)

Valve Size

Operating Torque (Ft.-Lbs.)

1"

50

1-1/4"

50

2"

60

3"

70

4"

75

6"

125

8"

150

10"

210

12"

280

16"

450

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

VALVE OPERATION

Torque

Operating Torque

Valves are designed to operate at the prescribed torque values below.

REV.: 10

DATE: 7/12/07

PAGE: 31 OF 35

For Venturi Valve: 2" X 1-1/4" Read 1-1/4"

3" X 2" Read 2" and Etc.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

CRITICAL TORQUE (FT.-LBS.)

Valve Size

Maximum

Operating Torque

Overtorque

Till Failure

Safety Factor

1"

50

130

2.6

1-1/4"

50

130

2.6

2"

60

309

5.2

3"

70

309

4.4

4"

75

350

4.7

6"

125

735

5.8

8"

150

735

4.9

10"

210

1170

5.6

12"

280

1170

4.2

16"

450

3700

8.2

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 32 OF 35

CRITICAL TORQUE

Excessive or unlimited torque will ultimately cause a structural failure of the valve. The chart

below indicates the minimum torque value where valve failure will occur.

For Venturi Valve: 2" X 1-1/4" Read 1-1/4"

3" X 2" Read 2" and Etc.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 33 OF 35

ACCESSORIES

Handwheel

Remove operating square and replace with handwheel.

Locking Device

1. Remove nut which holds operating square in place and replace with swivel assembly

(1). (Retain lockwasher (2).)

2. Place cap (3) on swivel assembly (1).

3. Attach a padlock (not furnished) to swivel assembly to complete locking device.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

PACKING REMOVAL TOOL KIT P ART NUMBERS

Valve Size

Part Number

2" – 3"

88377692

4"

88377718

6" – 8"

88377742

10" – 12"

88377700

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 34 OF 35

ATTACHMENT I

GATE VALVE PACKING ADAPTER REMO VAL TOOL

(REFER TO DRAWING ON PAGE 35)

The subject tool is used as follows:

1. Depressurize the valve and close it completely. Remove the operating square, gland,

thrust washers and stem in the conventional way. Remove the o-rings from the I.D. of

the packing adapter.

2. Install part (1) thrust pad and dowel pin (6) until it seats on the ledge below the packing.

3. Install part (2) threaded bushing on top of part (1).

4. Install split rings (3) on top of threaded bushing and push outward until the lower lip of

the split ring engages the adapter o-ring groove.

5. Install ring (4) around O.D. of split ring.

6. Thread in cap screw (5) until it bottoms on the thrust pad (1). Continued tightening of

the screw will cause the bushing (2) to rise up against the split ring and lift the split ring

and adapter up out of the valve. Discard packing adapter.

7. Remove entire tool. Remove packing. Clean counterbores. Install new adapter with

new o-rings on both the I.D. and O.D. of adapter.

8. Reassemble valve in conventional manner and place back in service per standard

procedures.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

ATTACHMENT 1

Gate Valve Packing Adapter Removal Tool

Installation Position

Pulling Position

NO.:

KEROTEST MODEL-1

GATE VALVE

OPERATIONS MANUAL

REV.: 10

DATE: 7/12/07

PAGE: 35 OF 35

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

KEROTEST MANUFACTURING CORP.

5500 SECOND AVENUE

PITTSBURGH, PA 15207

TELEPHONE: 412-521-7766

FAX: 412-521-7853

REV.: E

DATE: 7/12/07

PAGE: 1 OF 13

ATTACHMENT 2

TO

MODEL-1 GATE VALVE OPERATIONS MANUAL

KEROTEST MODEL-1 GATE VALVE

BONNET LEAK REPAIR PROCE DURE

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

REV./

DATE

WRITTEN

BY

APPROVED

BY

Q.A.

APPROVAL

DESCRIPTION OF REVISION

A

05/30/97

R.T.A.

D.J.Z.

J.F.B.

Added Enclosure 1 and re-identified

Attachments 1-3 as Enclosures 2-4.

B

11/21/97

R.T.A.

D.J.Z.

J.F.B.

Revised Item 3 and added Bolt

Removal Guide, Enclosure 1.

C

11/17/99

R.T.A.

D.J.Z.

J.F.B.

Revised Item 1 to add caution note on

valve operation.

D

05/22/01

R.T.A.

D.J.Z.

J.F.B.

Revised Enclosure 3.

E

07/12/07

R.H.

D.J.Z.

J.F.B.

Retyped in its entirety .

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 2 OF 13

REVISION SHEET

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

Valve Size

Bolt Part

Numbers

Description

Gasket

Part Numbers

1-1/4" and

Smaller

88370085

A574 Socket HD

3/8" – 16 x 1-1/4 Long

88231220

2"

88232541

A574 Socket HD

7/16 – 14 x 1-1/4 Long

88231865

3"

88231303

A574 Socket HD

1/2 – 13 x 1-1/2 long

88232087 (275 & 500)

88232186 (720)

4"

(275 & 500)

88231303

A574 Socket HD

1/2 – 13 x 1-1/2 Long

88232350 (275 & 500)

4"

(720)

88231329

A574 Socket HD

1/2 – 13 x 1-3/4 Long

88232384 (720)

6"

88231329

A574 Socket HD

1/2 – 13 x 1-3/4 Long

88232509 (275 & 500)

88232525 (720)

8"

88232434

A574 Socket HD

5/8 – 11 x 2-1/4 long

88232558

10"

88232236

A574 Socket HD

3/4 – 10 x 3-1/4 Long

88231709

12"

88232236

A574 Socket HD

3/4 – 10 x 3-1/4 Long

88231766

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 3 OF 13

1. When a bonnet leak is detected, do not attempt to re-tighten the existi ng bonnet bol ts and ,

do not attempt to operate valv e, since loa ds appli ed could cause damaged bolts to break.

2. If the valve can be depressurized, remove bonnet and replace gasket and existing bonnet

bolts after depressurization with only factory authorized parts. Refer to Enclosure 1 for

removal of broken bolts. Kerotest part numbers for bonnet bolts and gaskets are listed

below. These parts are available from Kerotest at no charge to the customer.

Coat new bonnet gaskets with Slic-Tite TFE paste.

During bolt replacement, tighten bolts in proper sequence and to the torque values listed in

Enclosure 2.

3. If valve cannot be depressurized, remove and replace bolts one at a time (see Item 2 for

bolt part number). When replacing bonnet bolts on 1-1/4 size valves, a special Kerotest

bolt replacement fixture and procedure must be used. This is shown in Enclosure 3.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 4 OF 13

For valve sizes 2" – 6" it is strongly recommended that support clamps be used during bolt

replacement. These clamps are available from Kerotest (Part Number 72544794 for 2"

and 3" valve sizes and Part Number 72544802 for 4" and 6" valve sizes). Support clamps

are not required on 8" and larger valve sizes. Aside from this, follow the instructions in this

procedure for valve sizes 8" and larger. If using these clamps, initially place one (1) in

between the two bolts that are closest to the leak location. Another clamp should be

placed on a diametrically opposite location on the cover. See sketch below.

Replace bolts on either side of both clamps. Then move both clamps in between the next

two bolts to be replaced. Remember to always keep both clamps diametrically opposite of

each other.

During bolt replacement tighten bolts to torque listed in Enclosure 2.

4. If after replacing existing bonnet bolts leakage continues at an unacceptable level, the

following procedure may be used for valve sizes 2" and larger. This procedure must only

be performed by Kerotest Factory Trained Personnel.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

Valve Size

Number of Turns

2"

1.5

3"

1.5

4"

2.5

6"

2.5

8"

3.0

10"

4.0

12"

4.0

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 5 OF 13

A. Mainseat wedge up to double the amount of operating toque shown in Enclosure 4.

CAUTION: Only proceed if a tight enough seat seal is achieved to allow

subsequent work to be safely performed.

B. Remove bolts one at a time on each corner and install a section of all thread and nut

as shown below. At least 4 all threads are required per valve.

C. Tighten all thread nuts and remove remaining bonnet bolts

D. Start loosening the nuts evenly at each corner while applying a clockwise rotation

force to the valve actuator square. See chart below for exact number of turns for each

valve s ize.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 6 OF 13

E. After cover is raised the gasket and mating sealing surfaces can be cleaned and

polished. Re-coat the gasket and sealing surfaces with Slic-Tite TFE Paste. Reverse

the procedure above and install new bonnet bolts and tighten them in the proper

sequence and to the specified torque listed in Enclosure 2.

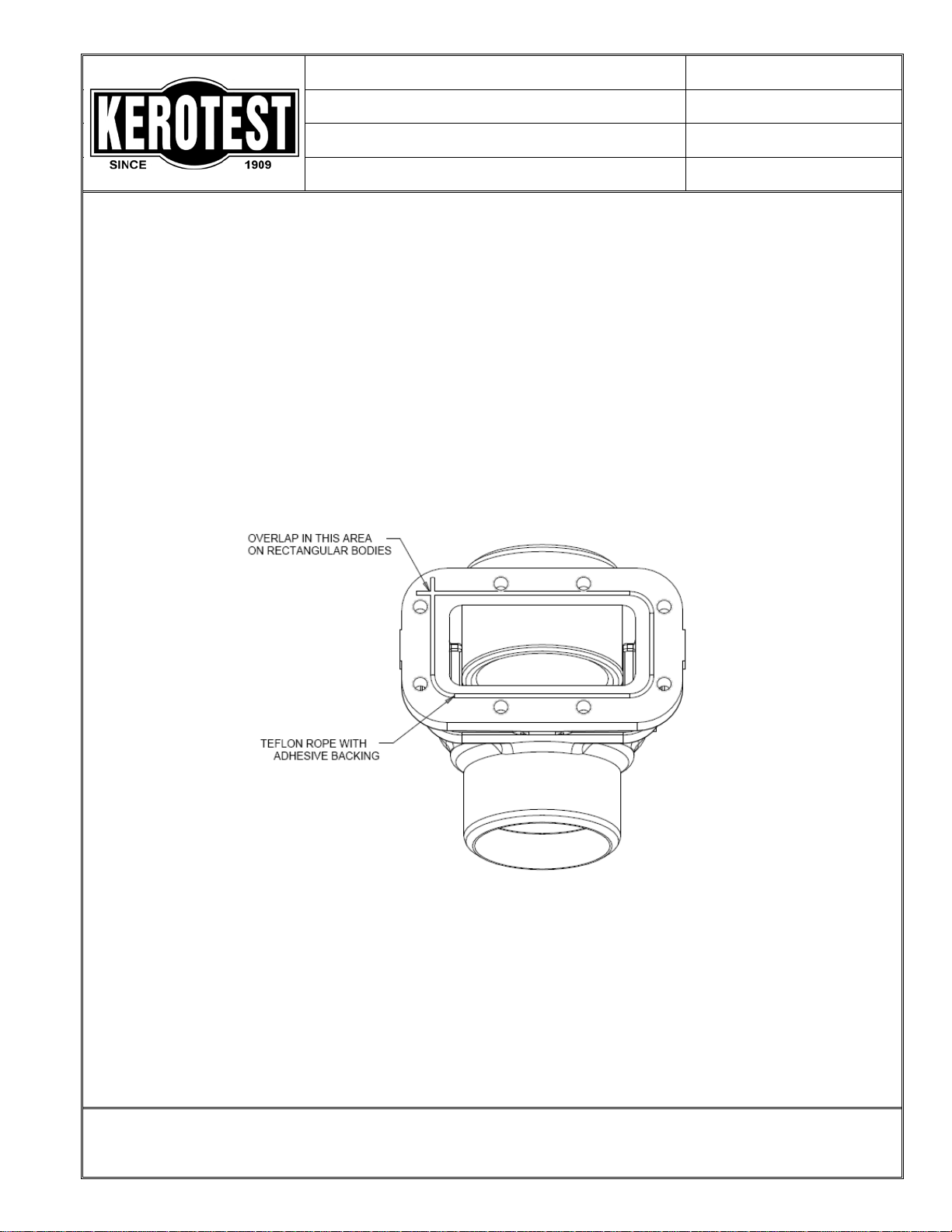

5. If after performing the procedure in Item 4 bonnet leakage continues at an unacceptable

rate, then repeat Steps 4A through 4D. After the cover is raised, cut and remove the

existing metal bonnet gasket and replace it with a section of teflon rope as shown in the

diagram below. Tighten bonnet bolts in proper sequence and to specified torque listed in

Enclosure 2. This procedure must only be performed by Kerotest Factory Trained

Personnel.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 7 OF 13

ENCLOSURE 1

BROKEN BOLT REMOVAL

If bolt is not broken below the top of cover flange shown below, a small chisel or punch could

be used to try and extract the bolt.

When bolt is broken down below the flange, an easy out must be used to extract it. If

available, a left handed drill bit will sometimes remove the bolt during drilling.

The center of these bolts are softer than the outer threaded edges. A sharp drill bit will easily

penetrate the bolt with or without cutting oil. Cutting oil is preferred because it reduces the

likelihood of sparks occurring during drilling.

A good quality center punch will be needed. Bolts should be punched and drilled as close to

the center of the bolt as possible.

Kerotest offers a Model-1 Bolt Repair Tool Kit, Part Number 72631146. This kit includes all

necessary punches, drill bits and easy-outs for removing cover bolts on valve sizes 1-1/4"

through 8".

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

BONNET BOLT REMOVAL CHART

GATE VALVE SIZE

EASY-OUT NUMBER

DRILL BIT SIZE

1-1/4"

#2

7/64"

2" THROUGH 6"

#3

3/16"

8"

#4

1/4"

10" AND 12"

*#5

*17/64"

*Not included in Model-1 Bolt Repair Tool Kit. Available from Kerotest.

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 8 OF 13

ENCLOSURE 1

MODEL-1 BOLT REMOVAL GUIDE

1. Secure cover to body with clamps on sizes 6" and smaller.

2. Spray penetrating oil on bolt surface

3. Tap bolt 3 to 4 times to loosen rust around threads

4. Position punch at the center of the bolt and tap 3 to 4 times

5. Apply cutting oil (provided) to bolt surface

6. Drill shallow hole (1/4" to 3/8" deep) into bolt head with proper size cobalt bit (see size

chart listed below)

7. Tap easy-out into drilled hole until tight

8. Turn easy-out in a counter clockwise direction with a small wrench to remove bolt

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NONCIRCULAR MULTIBOLT

VALVE SIZE

RECOMMENDED TORQUE

(MAX. FT.-LBS.)

1"

50

1-1/4"

50

2"

75

3"

115

4"

115

6"

115

8"

225

10"

370

12"

370

16"

1200

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 9 OF 13

ENCLOSURE 2

BONNET SCREW TIGHTENING SEQUENCE

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 10 OF 13

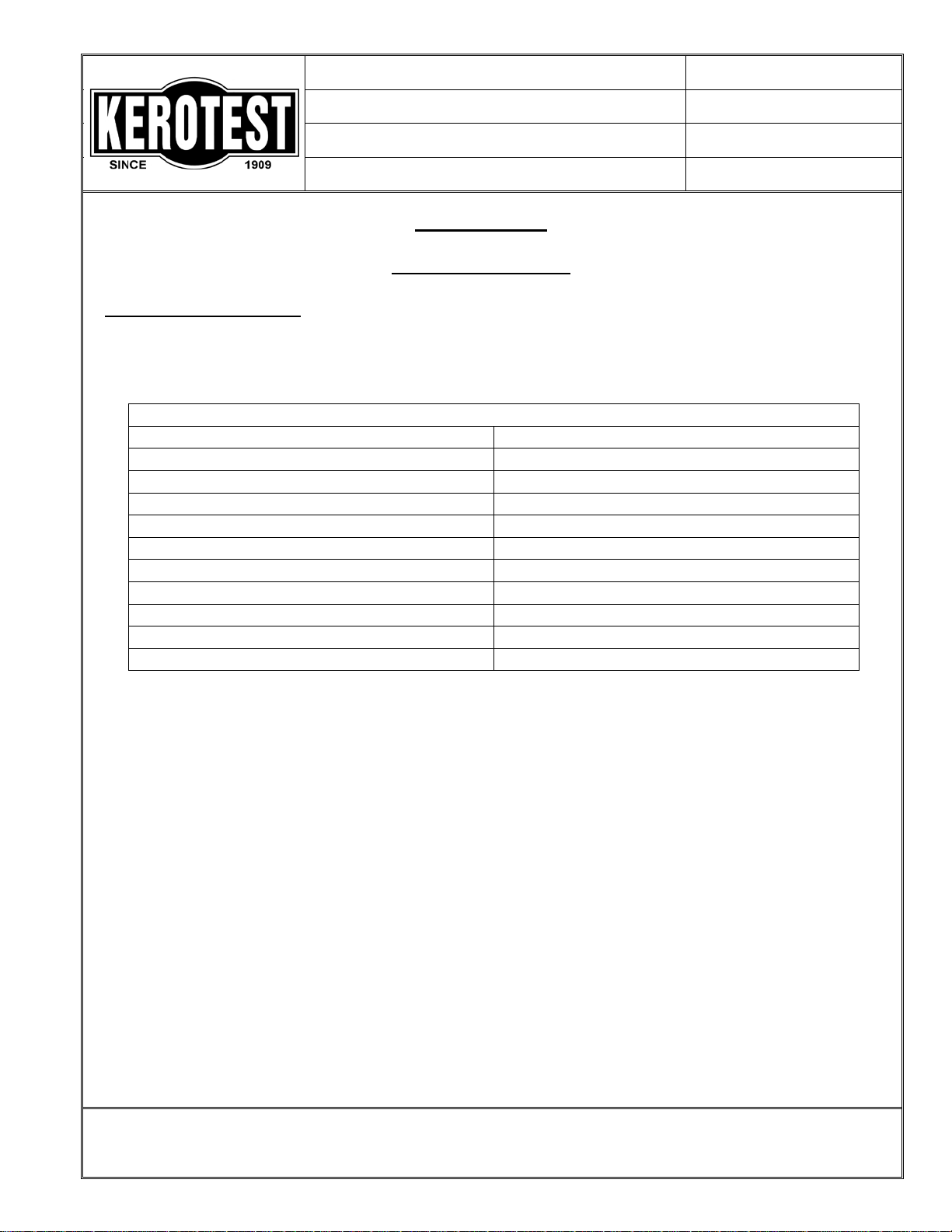

ENCLOSURE 3

MODEL-1 – 1" BOLT REPLACEMENT FIXTURE

FOR FIELD SERVICE REPAIR

(REFER TO SKETCH ON NEXT P AGE)

1. Backseat the valve using 50 ft-lbs. of torq ue.

2. Carefully remove operating square. A gear puller device allows for easy removal –

Caution: Before proceeding with operating square removal insure gland plate is

securely fastened to valve.

3. Screw threaded bushing on top of stem.

4. Locate bottom clamp on valve and install top clamp "A" – secure.

5. Remove gland and bolt to underside of top clamp "A" – 1/4" – 20 x 1-3/4 hex cap screw

with nut – optional

6. Slip middle clamp "B" between flanged nuts and arou nd stem – secure

Note: Clamp "A" can be kept in place if enough working room is available.

7. Remove broken bolts one (1) at a time and replace with new hardware.

Note: Use hardened drill bushing to guide 3/36" or 1/8" drills – for (easy out) – (air drill)

8. Replace all other bolts and torque to assembly procedure.

9. Remove clamp "B" and replace gland.

10. Remove threaded bushing and replace actuator.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 11 OF 13

ENCLOSURE 3

MODEL-1 – 1" BOLT REPLACEMENT FIXTURE

FOR FIELD SERVICE REPAIR

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

OPERATING TORQUE (FT.-LBS.)

VALVE SIZE

OPERATING TORQUE (FT.-LBS.)

1"

50

1-1/4"

50

2"

60

3"

70

4"

75

6"

125

8"

150

10"

210

12"

280

16"

450

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

ENCLOSURE 4

VALVE OPERATION

OPERATING TORQUE

Valves are designed to operate at the prescribed torque values below.

REV.: E

DATE: 7/12/07

PAGE: 12 OF 13

For Venturi Valve: 2" x 1-1/4" read 1-1/4"

3" x 2" read 2" and etc.

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

TITLE:

MODEL-1 REPAIR CLAMPS AND 1/-1/4" BO LT REPAIR FIXTURE

PART NUMBER

DESCRIPTION

72544794

2" AND 3" MODEL-1 VALVE REPAIR CLAMP

(SET OF 2 REQUIRED)

72544802

4" AND 6" MODEL-1 VALVE REPAIR CLAMP

(SET OF 2 REQUIRED)

72630510

1-1/4" MODEL-1 VALVE BOLT REPAIR FIXTURE

NO.:

KEROTEST MODEL-1

GATE VALVE BONNET LEAK

REPAIR PROCEDURE

REV.: E

DATE: 7/12/07

PAGE: 13 OF 13

This report is the property of Kerotest Manufacturing Corp. 5500 Second Avenue, Pittsburgh, PA 15207 and may not be

copied by any means without the expressed written consent of Kerotest. It is intended for the sole purpose of helping

Kerotest customers evaluate Kerotest products and may not be released to any third party or otherwise used in any

manner injurious to the interests of Kerotest.

Loading...

Loading...