Page 1

KERN & Sohn GmbH

Ziegelei 1

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating and Installation

Display Unit

KERN KIB-TM

Version 1.2

2019-01

Instructions

GB

D-72336 Balingen

Fax: +49-[0]7433-9933-149

KIB-TM-BA_IA-e-1912

Page 2

KERN KIB-TM

Display unit

GB

Version 1.2 2019-01

Operating and installa t ion instructions

Contents

1 Technical data ................................................................................................ 4

2 Appliance overview ....................................................................................... 5

2.1 Keyboard overview ..................................................................................................................... 6

2.1.1 Numeric entry via navigation keys .............................................................................................. 7

2.2 Overview of display .................................................................................................................... 8

3 Basic Information (Gen eral) .......................................................................... 9

3.1 Proper use .................................................................................................................................. 9

3.2 Improper Use .............................................................................................................................. 9

3.3 Warranty ..................................................................................................................................... 9

3.4 Monitoring of Test Resources .................................................................................................. 10

4 Basic Safety Precauti o ns ............................................................................ 10

4.1 Pay attention to the instructions in the Operation Manual........................................................ 10

4.2 Personnel training ..................................................................................................................... 10

5 Transport and storage ................................................................................. 10

5.1 Testing upon acceptance ......................................................................................................... 10

5.2 Packaging / return transport ..................................................................................................... 10

6 Unpacking and installation ......................................................................... 11

6.1 Installation Site, Location of Use .............................................................................................. 11

6.2 Unpacking ................................................................................................................................. 11

6.3 Scope of delivery / serial accessories: ..................................................................................... 11

6.4 Transportation lock (illustration example) ................................................................................. 12

6.5 Error message .......................................................................................................................... 12

6.6 Placing ...................................................................................................................................... 12

6.7 Mains connection ...................................................................................................................... 14

6.8 Storage battery operation (optional) ......................................................................................... 14

6.9 Adjustment ................................................................................................................................ 15

6.10 Linearization ............................................................................................................................. 17

7 Operation ...................................................................................................... 19

7.1 Start-up ..................................................................................................................................... 19

7.2 Switching Off ............................................................................................................................ 19

7.3 Zeroing ..................................................................................................................................... 19

7.4 Simple weighing ....................................................................................................................... 19

7.5 Switch-over weighing unit ......................................................................................................... 20

7.6 Weighing with tare .................................................................................................................... 21

7.6.1 Pre-Tare ................................................................................................................................... 21

7.7 Weighing with tolerance range ................................................................................................. 22

7.7.1 Tolerance check for target weight ............................................................................................ 23

2 KIB-TM-BA_IA-e-1912

Page 3

7.7.2 Tolerance check for target quantity .......................................................................................... 25

7.8 Manual totalizing ....................................................................................................................... 27

7.9 Automatic adding-up ................................................................................................................. 29

7.10 Parts counting ........................................................................................................................... 30

7.11 Percent weighing ...................................................................................................................... 31

7.12 Animal weighing ....................................................................................................................... 32

7.13 Lock keyboard .......................................................................................................................... 33

7.14 Display background illum inatio n ............................................................................................... 33

7.15 Automatic switch-off function „AUTO OFF“ .............................................................................. 34

7.16 Setting time and date................................................................................................................ 35

7.17 Alphabet ................................................................................................................................... 35

8 Menu ............................................................................................................. 36

8.1 Navigation in the menu: ............................................................................................................ 36

8.2 Menu overview ......................................................................................................................... 37

9 Servicing, maintenance, disposal .............................................................. 41

9.1 Cleaning ................................................................................................................................... 41

9.2 Servicing, maintenance ............................................................................................................ 41

9.3 Disposal .................................................................................................................................... 41

9.4 Error messages ........................................................................................................................ 42

10 RS 232 interface ........................................................................................... 43

10.1 Technical data .......................................................................................................................... 43

10.2 Printer operation / sample logs (KERN YKB-01N) ................................................................... 44

10.3 Output log (continuous output) ................................................................................................. 46

10.4 KERN Communications Protocol (KERN Interface Protocol)................................................... 46

11 Instant help ................................................................................................... 48

12 Installing display unit / weighing bridge .................................................... 49

12.1 Technical data .......................................................................................................................... 49

12.2 Weighing system design........................................................................................................... 49

12.3 How to connect the platform ..................................................................................................... 50

12.4 Configure display unit ............................................................................................................... 51

13 Conformity explanation/ test certificate ..................................................... 54

KIB-TM-BA_IA-e-1912 3

Page 4

1 Technical data

KERN KIB-TM

Display 7-digit

Resolution

(non-verifiable)

Weighing ranges 2

Divisions 1,2,5,…10n

Weighing Units g, oz, kg, lb

Functions

Display LCD 24 mm digits with back lighting

Load cell resistance

Range calibration We recommend ≥ 50 % max.

Data output RS232

Electric Supply

Display unit

(W x D x H) mm

Tolerance weighing, totalling, parts counting,

percentage calculation, animal weighing

Input voltage power unit 100 V - 240 V, 50 / 60 Hz

Input voltage device 12V, 1000mA

30,000 d

87 Ω

260 x 115 x 70

Admissible

ambient temperature

Humidity of air max. 80 % (not condensing)

Net weight 0.8 kg

Operating time backlight on 22 h

Rechargeable battery

(optional)

RS 232 interface Standard

Operating time backlight off 36 h

-10°C – 40°C

Loading time 3 h

4 KIB-TM-BA_IA-e-1912

Page 5

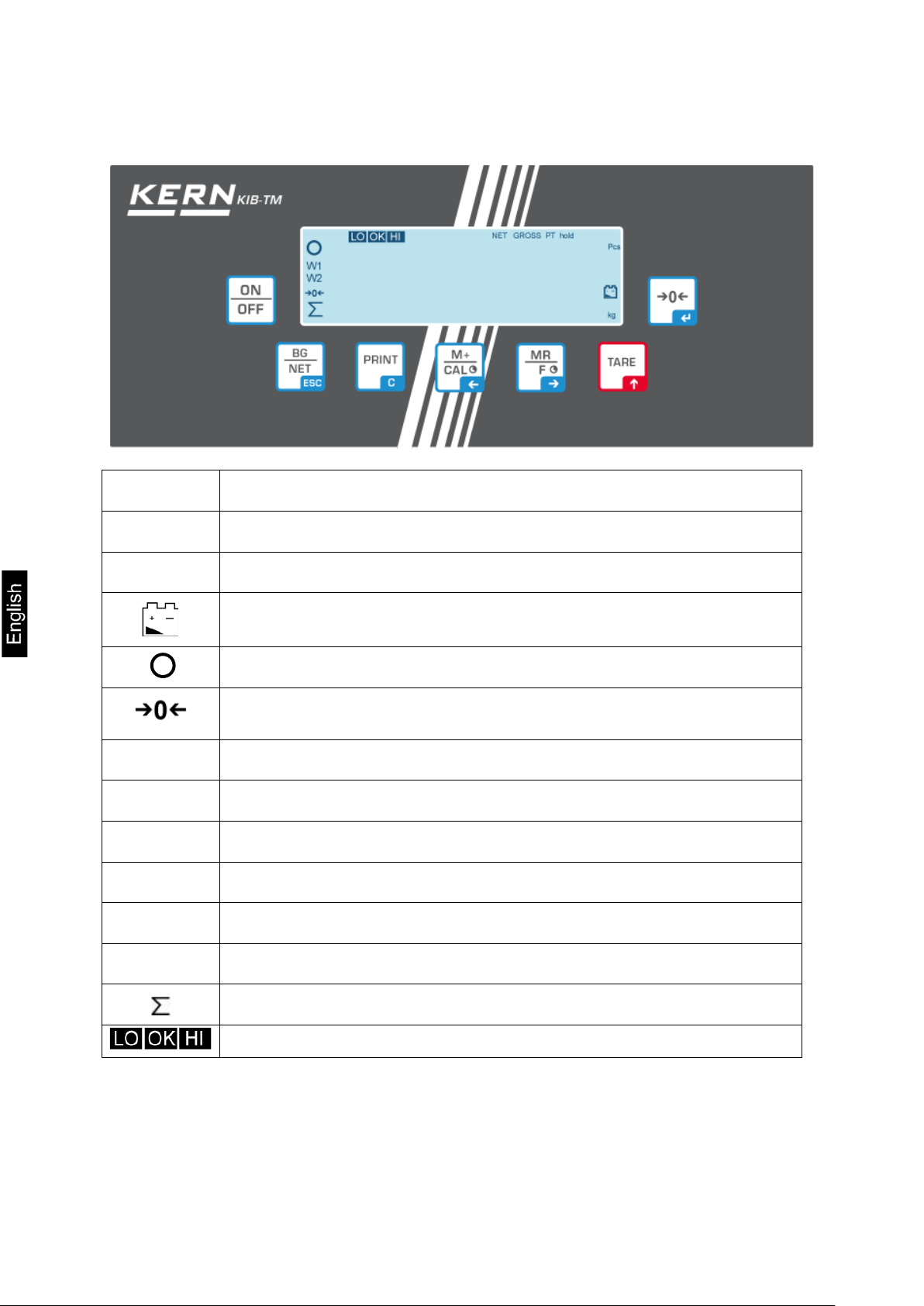

2 Appliance overview

1. Weight display

2. Weighing unit

3. Keyboard

4. Connection of mains adapt er

5. RS232 interface

6. Input connection load cell cable

KIB-TM-BA_IA-e-1912 5

Page 6

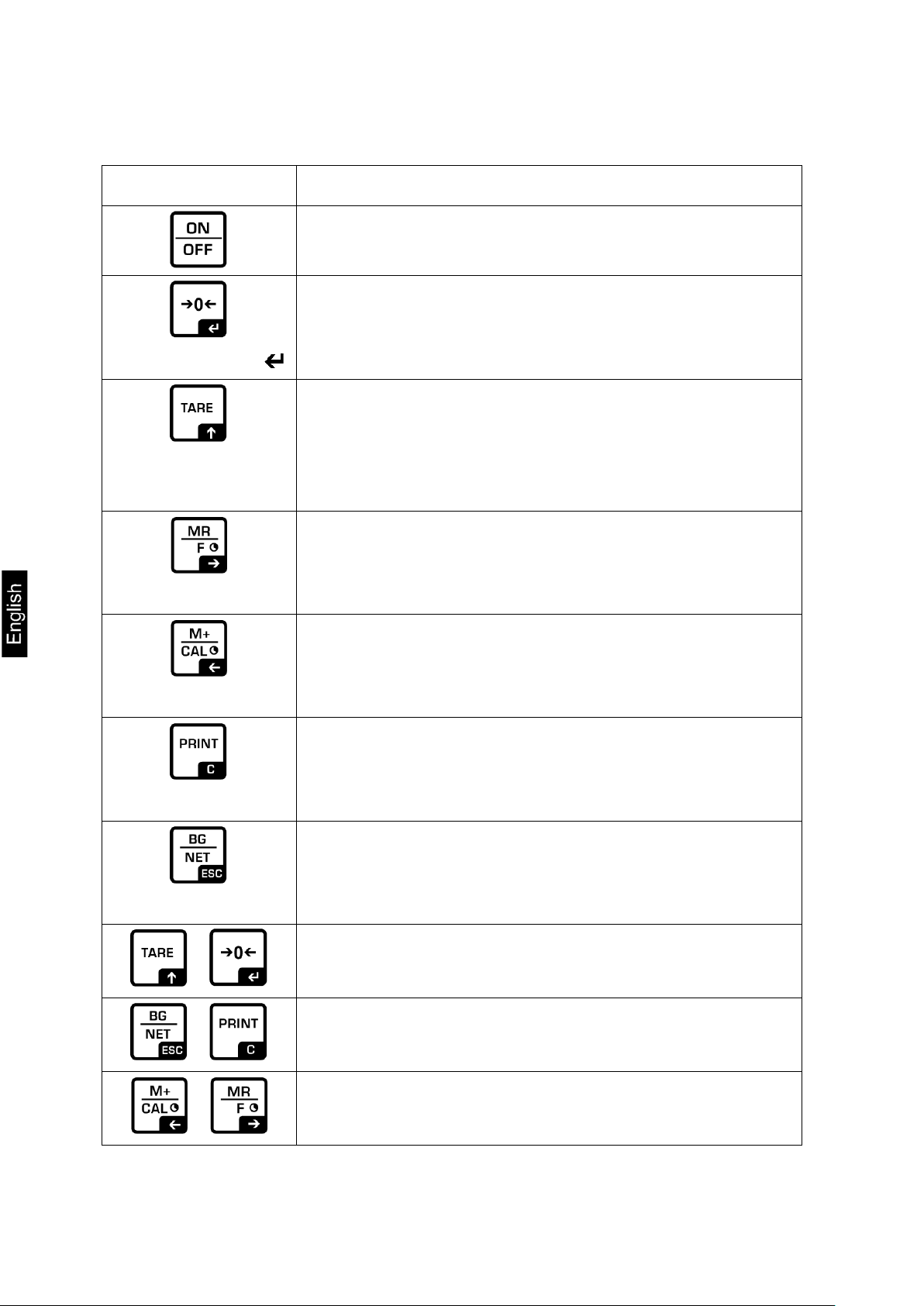

2.1 Keyboard overview

Button Function

• Turn on/off

• Zeroing

Navigation button

Navigation button

Navigation button

Navigation button

C

• Confirm entry

• Taring

• At numeric input increase flashing digit

• Scroll forward in menu

• Display sum total

• Digit selection to the right

• Add weighing value to summation memory

• Digit selection to the left

• Calculate weighing data via interface

• Delete

• Change between gross and net weight

ESC

+

+

+

6 KIB-TM-BA_IA-e-1912

• Back to menu/weighing mode

• Call up animal weighing function

• Retrieve tolerance weighing

• Delete total added memory

Page 7

to access further digits and change them by

2.1.1 Numeric entry via navigation keys

Press , the current setting will be displayed. The first digit will be flashing

and is ready for changing.

If you do not wish to change the first digit, press and the second digit will

start flashing.

Each time you press , the display will move to the subsequent digit, after

the last digit the display will return to the first digit.

To change the selected (flashing) digit, press repeatedly until the desired

value is displayed. Then press

.

Complete your entry by .

KIB-TM-BA_IA-e-1912 7

Page 8

2.2 Overview of display

Display Significance

W1 Weighing range 1

W2 Weighing range 2

Stability display

GROSS Gross weight

NET Net weight

PT Pre-Tare

hold Hold function

Pcs Parts counting

Kg Weighing unit

Rechargeable battery very low

Zero indicator

8 KIB-TM-BA_IA-e-1912

Totalization

Indicators for weighing with tolerance range

Page 9

3 Basic Information (General)

3.1 Proper use

The display unit acquired by you is used in combination with a weighing plate and

serves to determine the weighing value of material to be weighed. It is intended to be

used as a “non-automatic weighing system”, i.e. the material to be weighed is

manually and carefully placed in the centre of the weighing plate. As soon as a stable

weighing value is reached the weighing value can be read.

3.2 Improper Use

Do not use display unit for dynamic weighing. In the event that small quantities are

removed or added to the material to be weighed, incorrect weighing results can be

displayed due to the “stability compensation“ in the display unit. (Example: Slowly

draining fluids from a container on the balance.)

Do not leave permanent load on the weighing pan. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the weighing

plate, minus a possibly existing tare load, must be strictly avoided. Both, the weighing

plate and the display unit may be damaged during this process.

Never operate display unit in explosive environment. The serial version is not

explosion protected.

Changes to the display unit's design are not permitted. This may lead to incorrect

weighing results, safety-related faul ts and des tr uct ion of the display unit.

The display unit may only be operated in accordance with the described default

settings. Other areas of use must be released by KERN in writing.

3.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical damage or damage by media, liquids, natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

KIB-TM-BA_IA-e-1912 9

Page 10

3.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the display

unit and, if applicable, the testing weight, must be checked regularly. The responsible

user must define a suitable interval as well as type and scope of this test. Information

is available on KERN’s home page (www.kern-sohn.com with regard to the

monitoring of display units’ test substances and the test weights required for this. In

KERN’s accredited DKD calibration laboratory test weights and display units may be

calibrated (return to the national standard) fast and at moderate cost.

4 Basic Safety Precautions

4.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN balances.

4.2 Personnel training

The appliance may only be operated and maintained by train ed per sonnel.

5 T ransport and storage

5.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

5.2 Packaging / return transport

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the

weighing platform, power unit etc. against shifting and

damage.

10 KIB-TM-BA_IA-e-1912

Page 11

• Display Unit

6 Unpacking and installation

6.1 Installation Site, Location of Use

The display units are designed in a way that reliable weighing results are achieved in

common conditions of use.

Precise and fast work is achieved by selecting the right place for your display unit

and your weighing plate.

On the installation site observe the following:

• Place the display unit and the weighing plate on a stable, even surface.

• Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

• Protect the display unit and the weighing plate against direct draft from open

windows or doors.

• Avoid jarring during weighing;

• Protect the display unit and the weighing plate against high humidity, vapours

and dust.

• Do not expose the display unit to extreme dampness for longer periods of

time. Non-permitted condensation (condensation of air humidity on the

appliance) may occur if a cold appliance is taken to a considerably warmer

environment. In this case, acclimatize the disconnected appliance for ca. 2

hours at room temperature.

• Avoid static charge of goods to be weighed or weighing container.

Major display deviations (incorrect weighing results) may be experienced should

electromagnetic fields (e.g. due to mobile phones or radio equipment), static

electricity accumulations or instable power supply occur. Change location or remove

source of interference.

6.2 Unpacking

Carefully remove the display unit from packaging, remove plastic cover and place it

in the designated work area.

and place it in the designated work area.

Mount the display unit in a way that facilitates operation and where it is easy to see.

6.3 Scope of delivery / serial accessories:

• Mains adapter

• Table leg

• Wall bracket

• Operating manual

KIB-TM-BA_IA-e-1912 11

Page 12

Transport Securing

6.4 Transportation lock (illustration example)

Please note: if the display unit is used together with platform with transportation lock,

this transportation lock must be released prior to use:

6.5 Error message

As soon as an error message appears in the balance display,

the balance must not more be used, e.g. Err 4

6.6 Placing

Mount the display unit in a way that facilitates operation and where it is easy to see.

There are many ways of positioning the display unit, such as free-standing or wall-

mounted (optional).

Wall-mounted (optional) Free standing

12 KIB-TM-BA_IA-e-1912

Page 13

Version with support base/wall bracket

Version with tripod EOC-A05 (optional)

In order to raise the display, the display unit can be mounted on an optional stand.

Usage with fitting panel EOC-A03 (optional):

1. Platform

2. Fitting panel

3. Display Unit

KIB-TM-BA_IA-e-1912 13

Page 14

Check, whether the voltage acceptance on the scales is set correctly.

Do not connect the scales to the power mains unless the information on

consent by KERN.

6.7 Mains connection

6.8 Storage battery operation (optional)

Before the first use, the battery should be charged by connecting it to the mains

power supply for at least 12 hours.

If the weight display shows the flashing symbol , this is an indication that the

capacity of the rechargeable battery is almost exhausted. Charge the battery with the

help of the supplied power pack.

Select a country-specific power plug and insert it in the mains adapter.

the scales (sticker) matches the local mains voltage.

Only use KERN original mains adapter. Using other makes requires

Important:

Before starting your weighing balance, check the mains cable for

damage.

Ensure that the power unit does not come into contact with liquids.

Ensure access to mains plug at all times.

14 KIB-TM-BA_IA-e-1912

Page 15

Observe stable environmental conditions. Stabilisation requires a certain

warm-up time.

6.9 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each display unit with conn ec ted weighing plate must be coordinated - in compliance

with the underlying physical weighing principle - to the existing acceleration due to

gravity at its place of location (only if the weighing system has not already been

adjusted to the location in the factory). This adjustment process must be carried out

for the first commissioning, after each change of location as well as in case of

fluctuating environment temperature. To receive accurate measuring values it is also

recommended to adjust the display unit periodically in weighing operation.

• Prepare the required adjustment weight. The adjustment weight to be

Adjustment switch:

The adjustment switch is located in the battery cartridge(see the photo).

used depends on the capacity of the weighing system. Carry out

adjustment as near as possible to the weighing system’s maximum

weight. Info about test weights can be found on the I nter n et at:

http://www.kern-sohn.com.

•

Adjustment switch in the “ADJ” setting:

• All menu items are available.

Adjustment switch in the “LOCK” position:

• Some of the menu items are locked (see the section “Menu overview”)

To unblock these menu items, place the adjustment switch in the ”ADJ”

position.

KIB-TM-BA_IA-e-1912 15

Page 16

Call up menu:

Switch-on balance and during the selftest press .

„Pn“ will be displayed

Press , , , subsequently, the first menu block

„PO CHK“ will be displayed.

Press repeatedly until „P3 CAL“ will be displayed.

Acknowledge with . „CoUnt“ is displayed.

Press repeatedly until „CAL“ will be displayed.

Acknowledge using , the current setting is displayed.

Press to select the desired setting and confirm by .

noLin = adjustment

LineAr = linearization, see chap. 6.10

16 KIB-TM-BA_IA-e-1912

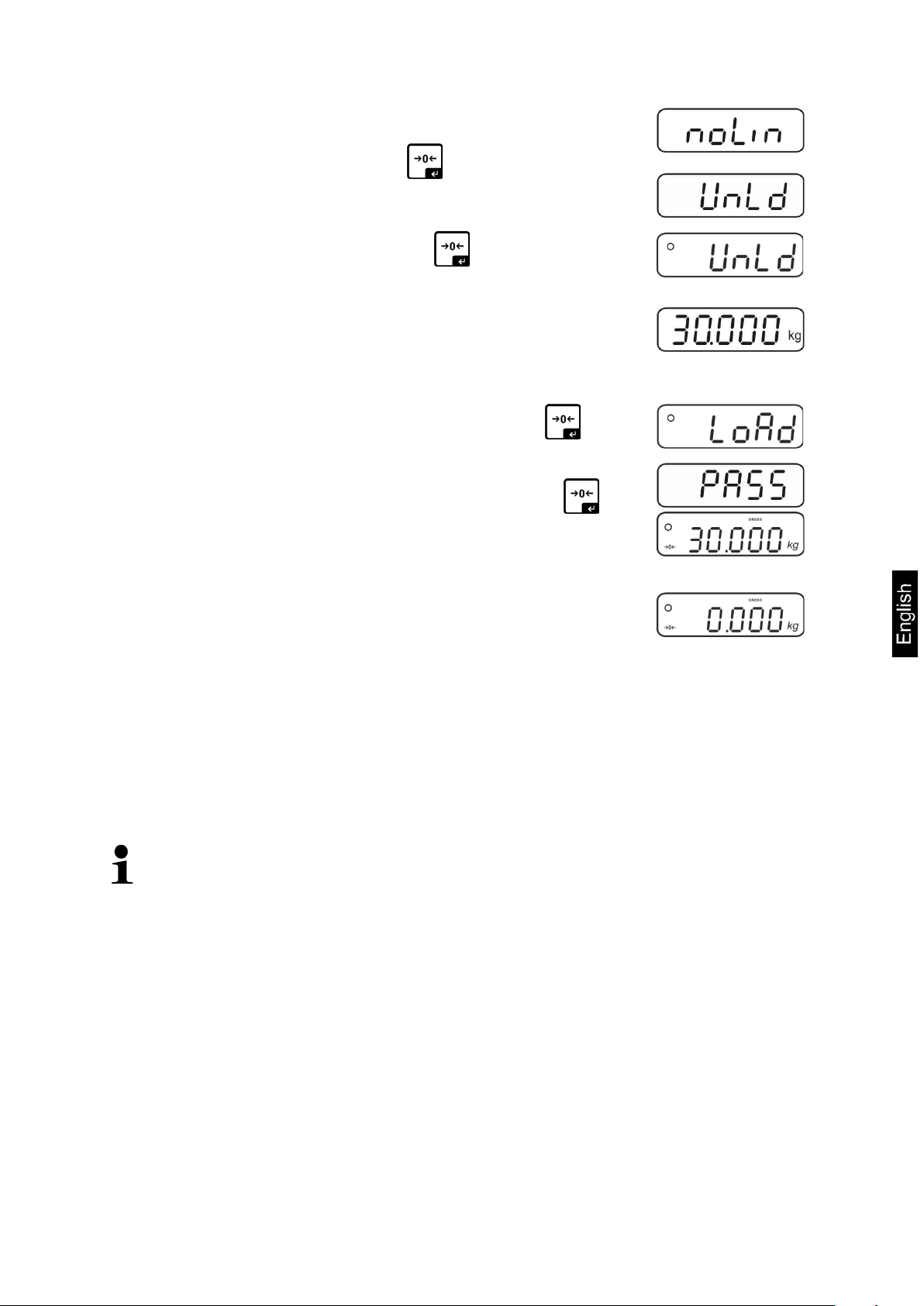

Page 17

• In balances with a resolution of > 15 000 dividing steps carrying out a

see chapter 3.4 “Monitoring of test equipment”.

How to carry out adjustment:

Confir m me nu sett ing „noLin“ by .

Ensure that there are no objects on the weighing plate.

Wait for stability display, then press .

The currently set adjustment weight will be displayed.

Either use adjustment weight displayed

or

change with the help of the navigation keys (see chap.2.1.1),

the active digit will be flashing.

Confirm value for adjustment weight by pressing .

Carefully place adjustment weight in the centre of the

(example)

weighing plate. Wait for stability display, then press .

”PASS“ will be shown briefly, followed by the weight of the

placed adjustment weight.

Remove adjustment weight, balance will return into weighing

mode automatically. An adjusting error or incorrect

adjustment weight will be indicated by the error message;

repeat adjustment procedure.

6.10 Linearization

Linearity shows the greatest deviation of a weight display on the scale to the value of

the respective test weight according to plus and minus over the entire weighing

range. If linearity deviation is discovered during a monitoring of test resources, you

can improve this by means of linearization.

linearisation is recommended.

• Carrying out linearization is restricted to specialist staff possessing

well acquainted with the workings of weighing scales.

• The test weights to be used must be adapted to the weighing scale’s

specifications; see chapter “Monitoring of test equipment”.

• Observe stable environmental conditions. Stabilisation requires a

certain warm-up time.

• After successful linearisation you will have to carry out calibration;

KIB-TM-BA_IA-e-1912 17

Page 18

Remove adjustment weight, balance will return into weighing

Procedure:

Call-up menu item P3 CALCalLiner, see chap. 6.9

Confirm by , the password query „Pn“ will be displayed.

Press , , subsequently.

Ensure that there are no objects on the weighing pan.

Wait for stability display, then press .

When “Ld 1“ is displayed, put the first adjustment weight

(1/3 max) carefully in the centre of the weighing platform.

Wait for stability display, then press .

When “Ld 2“ is displayed, put the second adjustment weight

(2/3 max) carefully in the centre of the weighing platform.

Wait for stability display, then press .

When “Ld 3“ is displayed, put the third adjustment weight

(max) carefully in the centre of the weighing platform.

Wait for stability display, then press .

”PASS“ will be shown briefly, followed by the weight of the

placed adjustment weight.

mode automatically. An adjusting error or incorrect

adjustment weight will be indicated by the error message;

repeat adjustment procedure.

18 KIB-TM-BA_IA-e-1912

Page 19

Overloading exceeding the stated maximum load (max) of the device, minus a

7 Operation

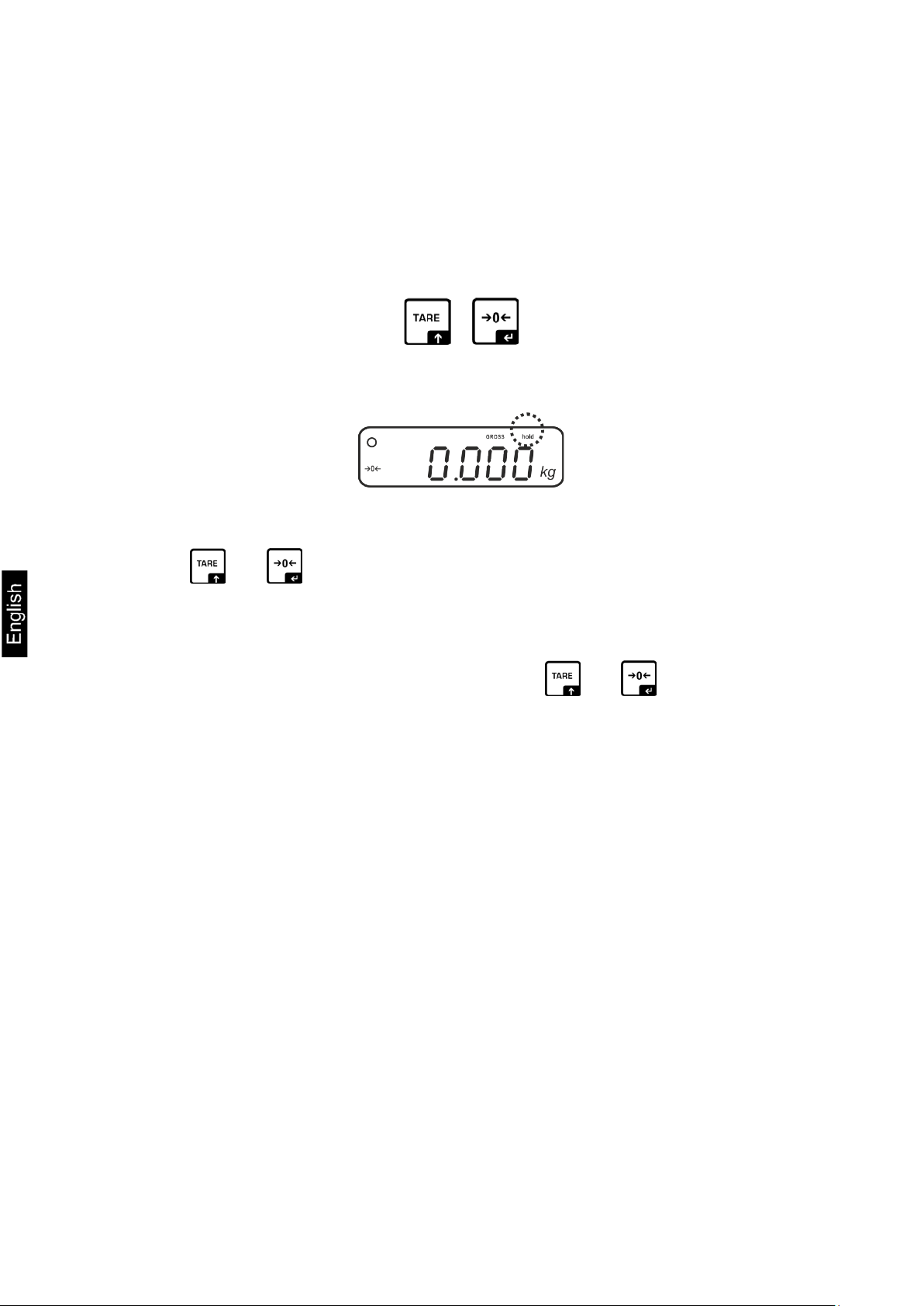

7.1 Start-up

Press , the appliance will carry out a self-test. As soon as the weight display

appears, the instrument will be ready to weigh.

7.2 Switching Off

Press , the display will disappear.

7.3 Zeroing

Resetting to zero corrects the influence of light soiling on the weighing plate. The unit

is equipped with an automatic zero setting function. Therefore the unit can be reset to

zero at any time as follows:

To unload the weighing system

Press and zero display as well as indicator will appear.

7.4 Simple weighing

Place goods to be weighed on balance.

Wait for stability display .

Read weighing result.

Overload warning

possibly existing tare load, must be strictly avoided. This could damage the

instrument.

Exceeding the maximum load is indicated by the display

and an audio sound. Unload weighing system or reduce preload.

KIB-TM-BA_IA-e-1912 19

Page 20

7.5 Switch-over weighing unit

How to enable weighing units:

Invoke menu item P5 Unt, see chap. 8

Press and the first weighing unit with the current setting

will be displayed.

To enable [on] / disable [off] the displayed weighing unit,

press

Acknowledge with . The next unit with the current setting

will be displayed.

To enable [on] / disable [off] the displayed weighing unit,

press

Acknowledge with .

Repeat seque nc e for each weighing unit.

Note:

„tj“ and „Hj“ cannot be activated at the same time,

only either ... or ... .

Press back to weighing mode several times.

Switch-over weighing unit:

Keep pressed, the display changes over to the weighing

units activated before (e.g. kg lb)

20 KIB-TM-BA_IA-e-1912

Page 21

7.6 Weighing with tare

Deposit weighing vessel. After successful standstill control press the button.

Zero display and indicator NET appear.

The weight of the container is now internally saved.

Weigh the material, the net weight will be indicated.

The weight of the weighing container will be displayed as a minus number after

removing the weighing container.

The tare procedure can be repeated as many times as necessary, for example

with initial weighing of several components for a mix (add-on weighing). The limit

is reached when the taring range capacity (see type plate)is full.

To change between gross weight and net weight, press .

To delete the tare value, remove load from weighing plate and press .

7.6.1 Pre-Tare

It is possible to enter a pre-tare value beforehand.

Ensure that there are no objects on the weighing pan.

Press and hold until 0.0 is displayed and the left digit is flashing

Use the arrow keys to enter the pre-tare value and confirm by pressing

The pre-tare value will be shown as a negative value.

KIB-TM-BA_IA-e-1912 21

Page 22

An acoustic signal sounds when load is beyond tolerance

7.7 Weighing with tolerance range

You can set an upper or lower limit when weighing with tolerance range and thus

ensure that the weighed load remains exactly within the set limits.

During tolerance tests such as dosing, portioning and sorting the unit will indicate

exceeded or undershot limits by emitting an optical or acoustic signal.

Audio signal:

The acoustic signal depends on the settings in menu block „BEEP“.

Options:

• no

• ok

Acoustic signal turned off

An acoustic signal sounds when load is within tolerance

limits

• ng

limits

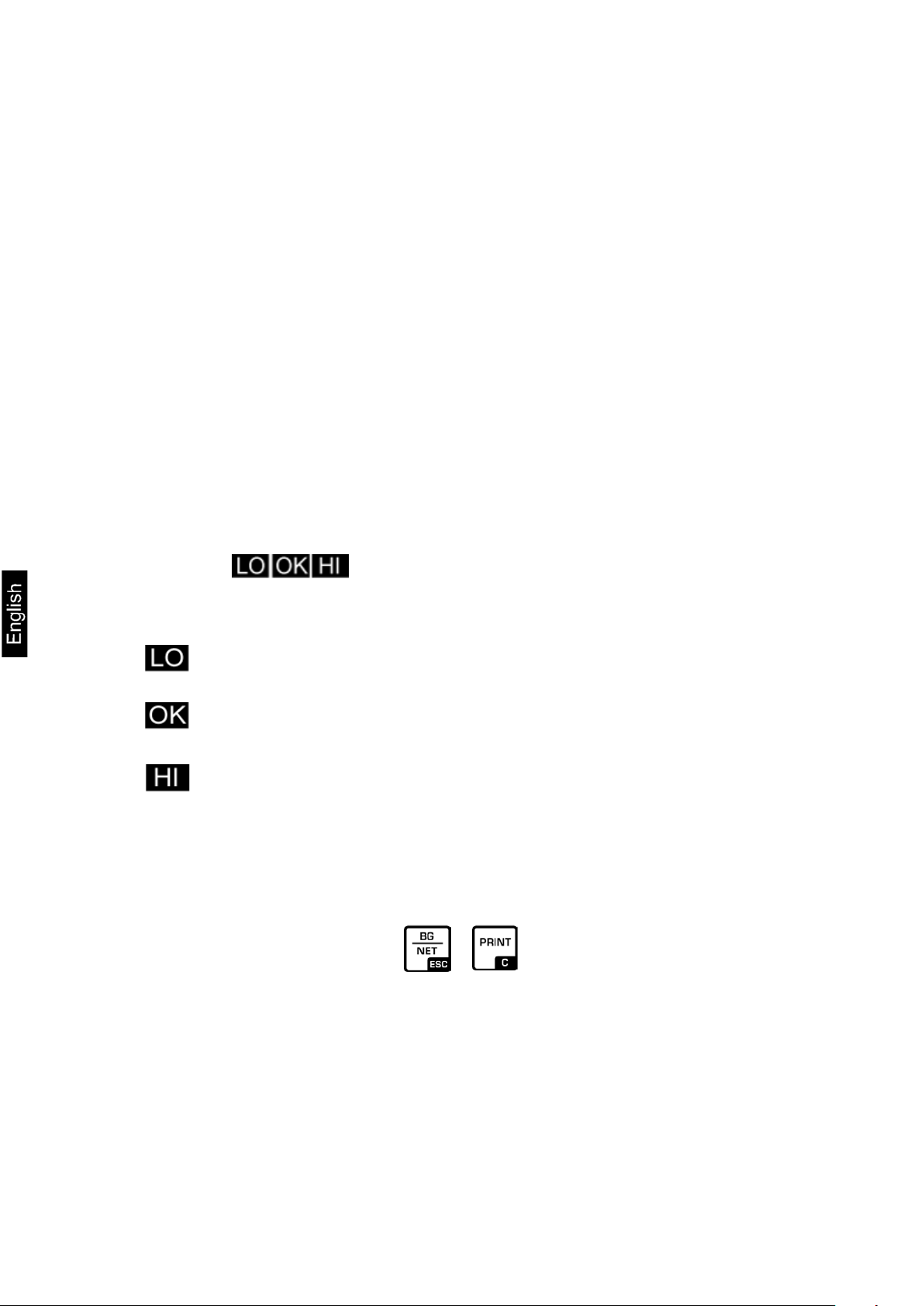

Optical signal:

The indicators show whether the load is within the two set tolerance

limits.

Target quantity / target weight below minimum tolerance limit

Target quantity / target weight within tolerance range

Target quantity / target weight exceeds maximum tolerance limit

The settings for tolerance check may be called up either via menu block „P0 CHK“

(see chap. 8) or faster via the key combination

+

22 KIB-TM-BA_IA-e-1912

Page 23

7.7.1 Tolerance check for target weight

Settings

Press and at the same time in weighing mode.

Press until the display for entering the lower limit value

appears.

Press , the current setting will be displayed.

To enter the lower limit, e. g. 1000 Kg, press the navigation

keys (See chap. 2.1.1); the currently enabled digit will be

flashing.

Confir m input by .

Press repeatedly until is displayed.

Press , the current setting for the upper limit will be

displayed.

Press the navigation keys (See chap. 2.1.1) to enter the

upper limit, e.g. 1100 kg; the currently enabled digit will be

flashing.

Confir m input by .

Press repeatedly until is displayed.

KIB-TM-BA_IA-e-1912 23

Page 24

Press , the current setting for the acoustic signal will be

shown.

Select desired setting (no, ok, ng, s. chap. 8) by .

Confir m input by .

Press ; weighing system is in tolerance weighing mode.

From here evaluation takes place whether the goods to be

weighed are within the two tolerance limits.

Weighing with tolerance range

Tare when using a weighing container.

Put on goods to be weighed, tolerance control is started. The signal lights

indicate whether the load is within the two set limits.

Load below specified

tolerance

Indicator will be

displayed

• The tolerance control is not active when the weight is under 20d.

• To delete limits, enter “00.000 kg“.

Load within specified

tolerance

Indicator will be

displayed

Load exceeds specified

tolerance

Indicator will be

displayed

24 KIB-TM-BA_IA-e-1912

Page 25

7.7.2 Tolerance check for target quantity

Settings

Press and at the same time in weighing mode.

Press until the display for entering the lower limit value

appears.

Press , the current setting will be displayed.

To enter the lower limit, e. g. 75 items, press the navigation

buttons (see chap. 2.1.1); the currently enabled digit will be

flashing.

Confir m input by .

Press repeatedly until is displayed.

Press , the current setting for the upper limit will be

displayed.

To enter the upper limit, e. g. 100 items, press the navigation

buttons (see chap. 2.1.1); the currently enabled digit will be

flashing.

Confir m input by .

Press repeatedly until is displayed.

KIB-TM-BA_IA-e-1912 25

Page 26

Press , the current setting for the acoustic signal will be

shown.

Select desired setting (no, ok, ng, s. chap. 8) by .

Confir m input by .

Press ; weighing system is in tolerance weighing mode.

From here evaluation takes place whether the goods to be

weighed are within the two tolerance limits.

Weighing with tolerance range

Set item weight, see chap. 7.10.

Tare when using a weighing container.

Put on goods to be weighed, tolerance control is started. The signal lights

indicate whether the load is within the two set limits.

Load below specified

tolerance

Indicator will be

displayed

• The tolerance control is not active when the weight is under 20d.

• To delete limits, enter „00000 PCS“.

Load within specified

tolerance

Indicator will be

displayed

Load exceeds specified

tolerance

Indicator will be

displayed

26 KIB-TM-BA_IA-e-1912

Page 27

• Menu setting:

• The totalizing function is not active when the weight is under 20d.

7.8 Manual totalizing

With this function the individual weighing values are added into the summation

memory by pressing and edited, when an optional printer is connected.

Add up:

Place load A.

Wait until the stability display appears, then press . The weight value will

be saved and printed if an optional printer is connected.

Remove the weighed good. More weighed goods can only be added when the

display ≤ zero.

Place good to be weighed B.

Wait until the stability display appears, then press . The weight value will be

added to the summation memory and printed, as required. The number of

weighings, the whole weight and the currently placed weight will be shown in

succession.

„P2 COM“ „MODE“ „PR2““, see chap. 8

Add more weighed goods as described before.

Please note that the weighi ng system must be unloaded between the individual

weighing procedures.

This process may be repeated 99 times or till such time as the capacity of the

weighing system has been exhausted.

Display and edit sum „Total“:

Press , the number of weighings, followed by the total weight will be displayed

for 2 sec. Press to print out this display.

KIB-TM-BA_IA-e-1912 27

Page 28

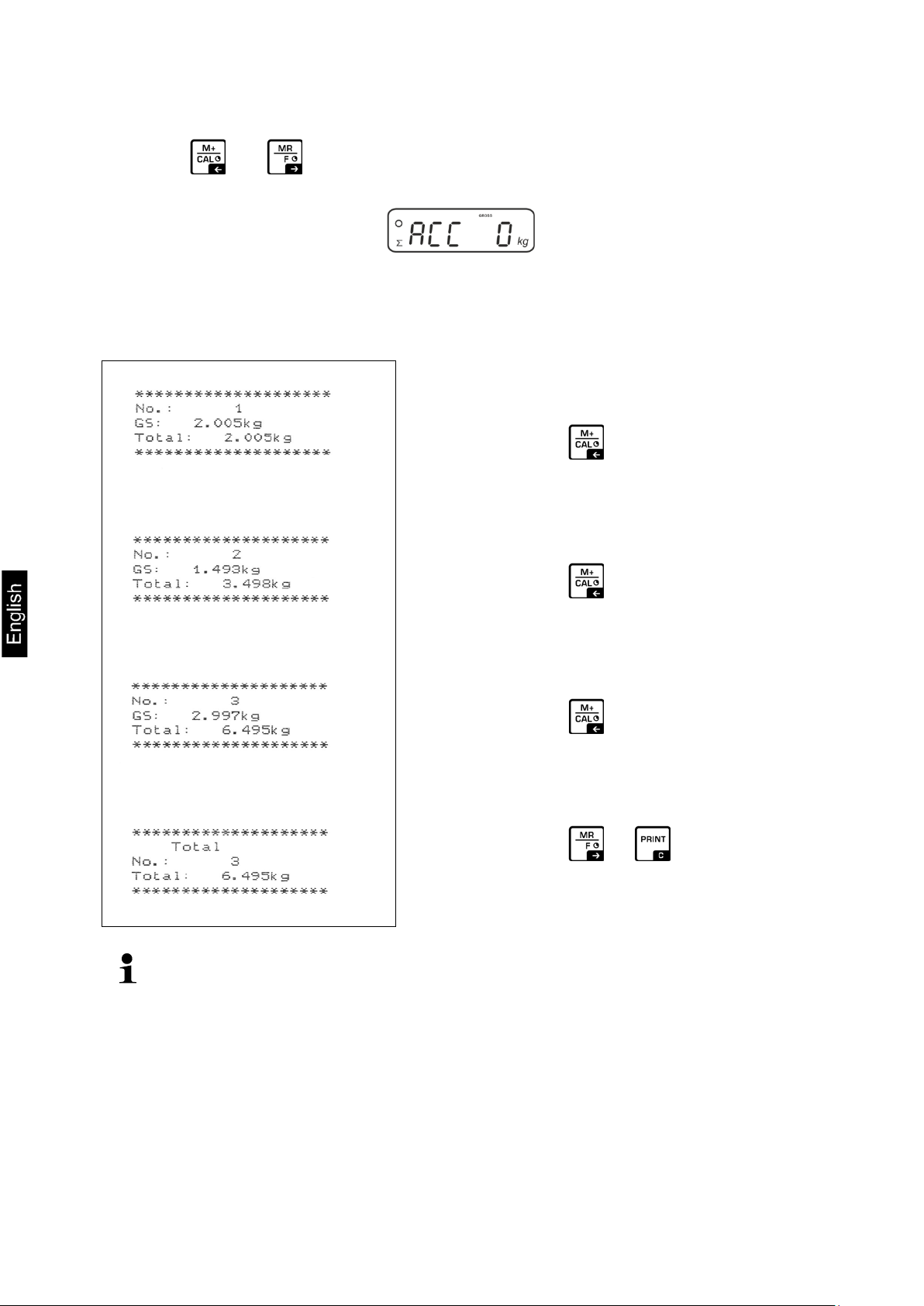

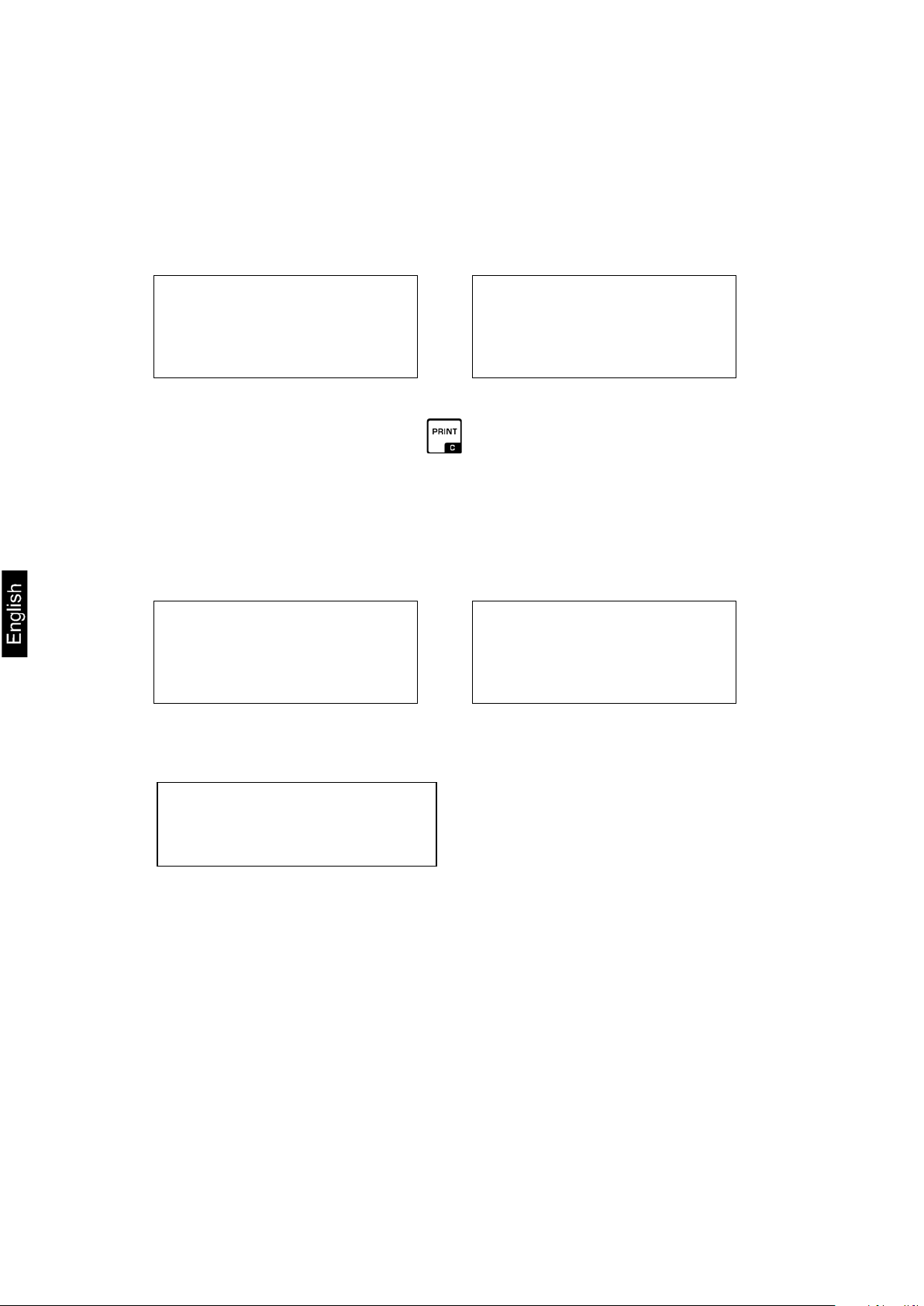

Sample log (KERN YKB-01N):

Delete weighing data:

Press and at the same time The data in the summation memory are

deleted.

Menu setting “P2 COM“ “Lab 2“ / Prt 4 - 7“

First weighing

Second weighing

Third weighing

Number of

+

weighings/

Total

For additional sample logs see chap. 0

28 KIB-TM-BA_IA-e-1912

Page 29

• Menu settings:

7.8

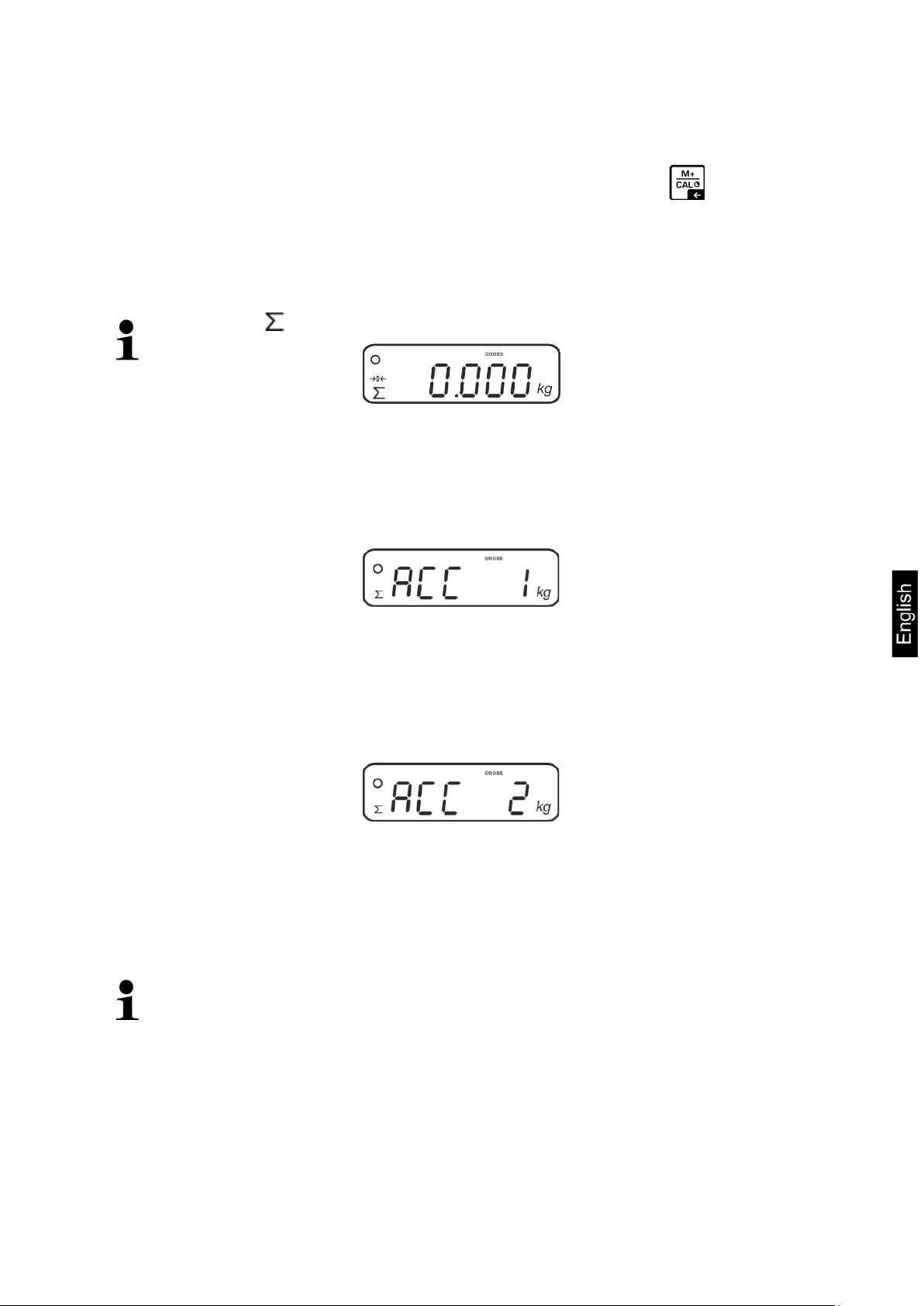

7.9 Automatic adding-up

With this function the individual weighing values are automatically added into the

summation memory when the bala nce is unloaded without pressi n g and edited,

when an optional printer is connected.

„P2 COM „MODE“ „AUTO““, s. chap. 8

Indicator will be displayed.

Add up:

Place load A.

After the standstill control sounds a signal tone. The weighing value will be added

to the summation memory and printed.

Remove the weighed good. More weighed goods can only be added when the

display ≤ zero.

Place good to be weighed B.

After the standstill control sounds a signal tone. The weighing value will be added

to the summation memory and printed, as required. The number of weighings,

followed by the currently placed weight will be shown in succession.

Add more weighed goods as described before.

Please note that the weighing system must be unloaded between the individual

weighing procedures.

This process may be repeated 99 times or till such time as the capacity of the

weighing system has been exhausted.

For how to display and delete weighing data as well as sample logs see chap.

KIB-TM-BA_IA-e-1912 29

Page 30

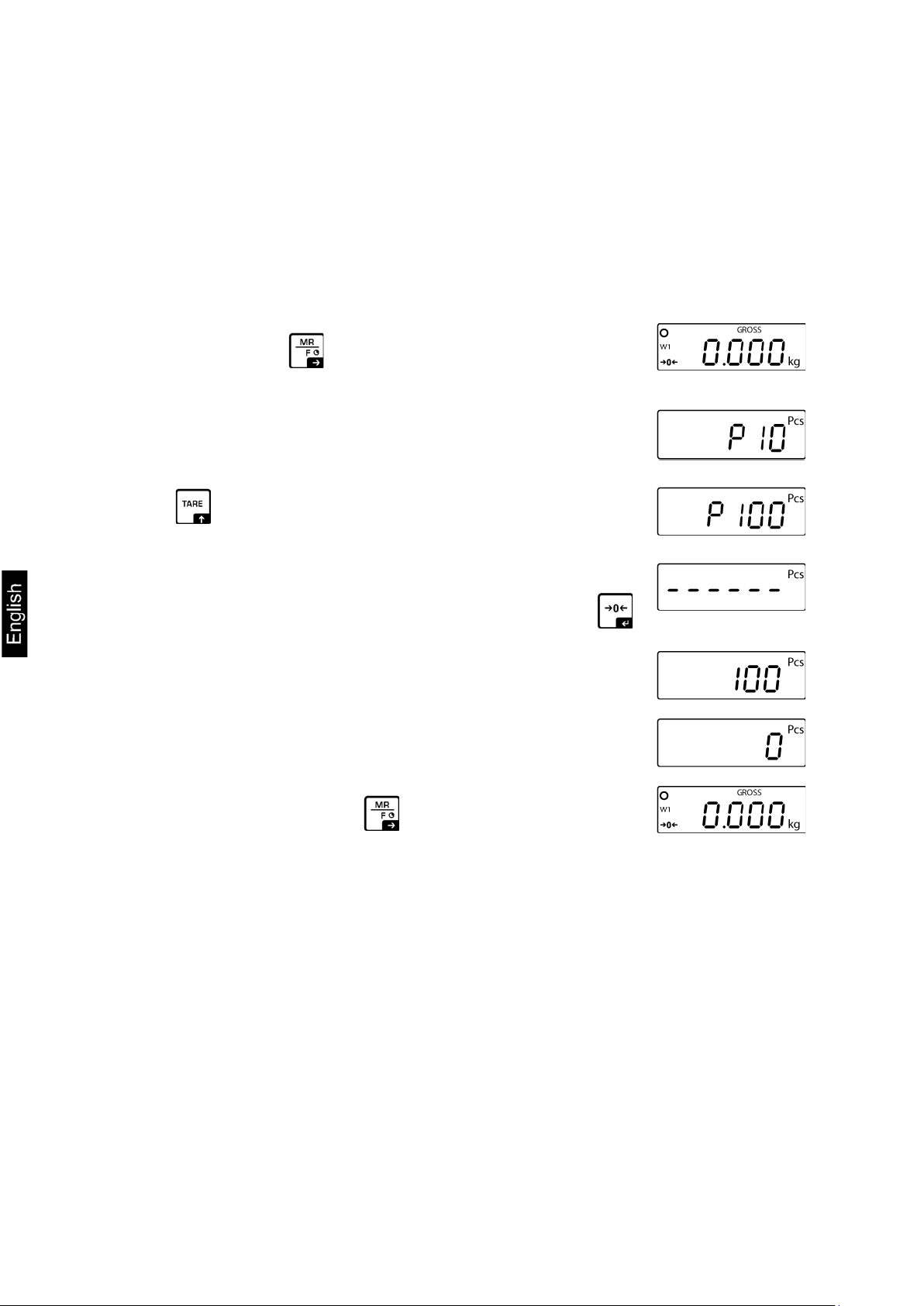

7.10 Parts counting

Before the balance can count parts, it must know the average part weight (i.e.

reference). Proceed by putting on a certain number of the parts to be counted. The

balance determines the total weight and divides it by the number of parts, the socalled reference quantity. Counting is then carried out on the basis of the calculated

average piece weight.

As a rule:

The higher the reference quantity the higher the counting exactness.

In weighing mode , press and hold until the message

„P 10“ appears that is used to set the reference quantity.

Use to set the desired reference quantity (such as 100),

options include P 10, P 20, P 50, P100, P 200.

Place as many items to be counted (such as 100 items) as

demanded by the set reference quantity and confirm by .

The weighing scales calculate the reference weight. The

current quantity (such as 100 items) will be displayed.

Remove reference weight. The balance is from now in parts

counting mode counting all units on the weighing plate.

Back to Weighing mode by .

30 KIB-TM-BA_IA-e-1912

Page 31

7.11 Percent weighing

Percentage weighing allows you to display the weight in percent related to

reference weight.

Press in weighing mode (approx. 3 sec.) until “rEF 10%“

is displayed.

Use to set the desired percentage value to be applied

as reference (selectable rEF 10, rEF 20, rEF 50, rEF 100,

rEF 200, rEF 500).

Place a sample matching the set percentage value on the

weighing platform and pr ess . “-------%“ will be briefly

displayed.

The percentage value for the sample will be displayed.

Remove reference weight

The display returns to „0.0 %“

Put on specimen

In the display appears the percentage of the specimen with

reference to the reference weight.

Back to weighing mode by pressing the button.

KIB-TM-BA_IA-e-1912 31

Page 32

7.12 Animal weighing

The animal weighing function is suitable for weighing restless loads.

The weighing system will display a mean value derived from several weighing results.

The animal weighing program can be enabled by either calling up menu block

„P4 OTH“ „ANM“ „ON“ (see chap. 8) or faster via key combination.

+

The indicator shows HOLD as long as the animal weighing function remains enabled.

Place the load on the weighing system and wait until the scale is steady.

Press and at the same time; you will hear an acoustic signal, indicating

that the mean value function is ena bled.

Whilst averaging is taking place you can add or remove loads as the measuring

value will be constantly updated.

To deactivate the animal weighing function press and at the same time.

32 KIB-TM-BA_IA-e-1912

Page 33

7.13 Lock keyboard

In the menu item „P4 OTH“ „LOCK“ (see chap. 8) the keyboard lock can be

enabled/disabled.

Whilst the function is enabled the keyboard will self-lock after no key has been

pressed for 10 minutes. „K-LCK“ will be displayed as soon as a key is pressed.

To disable the lock, keep , and pressed at the same time (2 s) until

„U LCK“ appears.

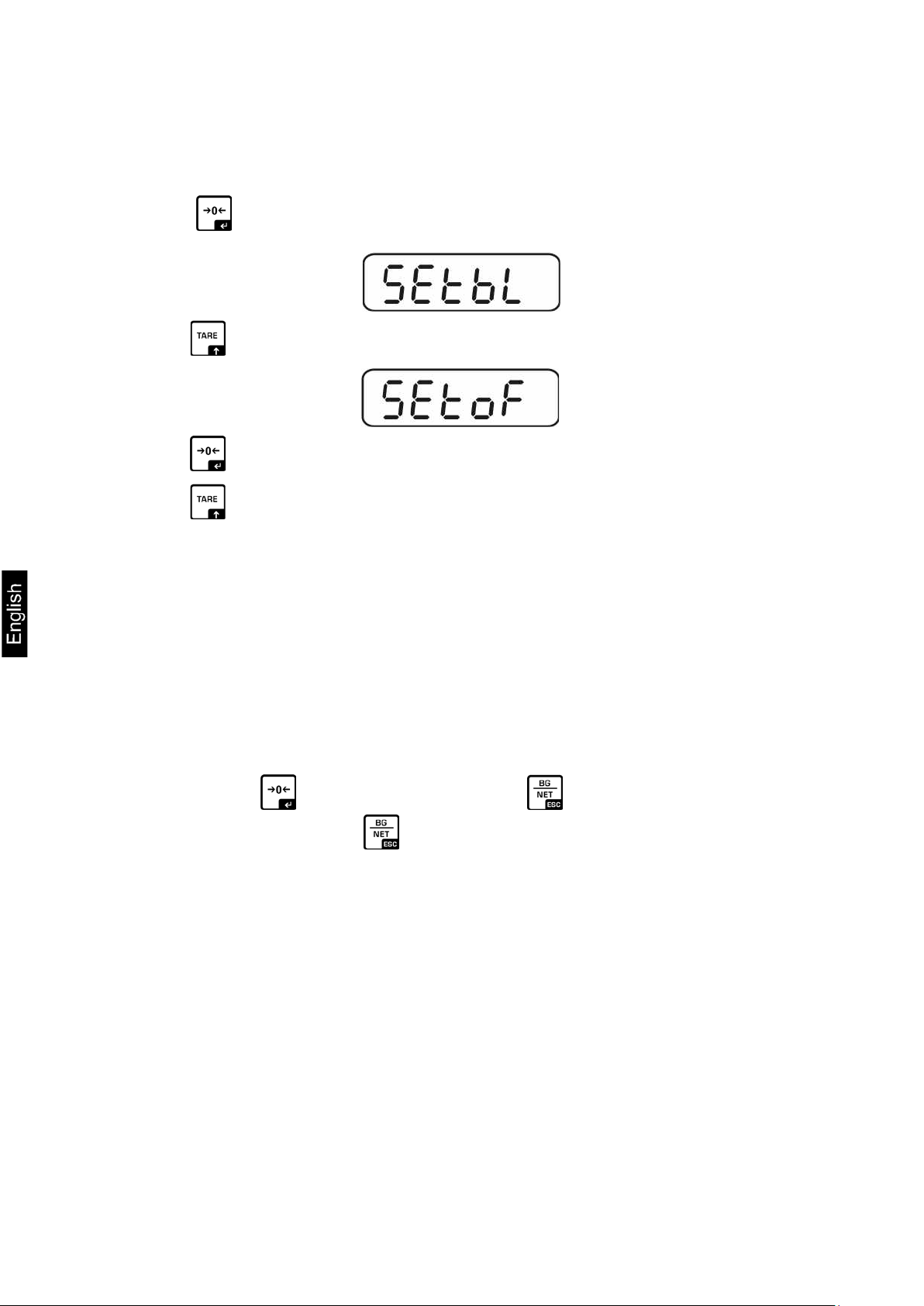

7.14 Display background illumination

Keep pressed (3s) until „setbl“ appears.

Press again, the current setting will be displayed.

Press to select the desired setting.

bl on Continuous background lighting

bl off Background illumination off

bl Auto Automatic background illumination on when weighing pate is

loaded or key pressed.

Either save by or cancel input by pressing .

Back to Weighing mode by .

KIB-TM-BA_IA-e-1912 33

Page 34

7.15 Automatic switch-off function „AUTO OFF“

The unit is automatically switched off within the preset time when the display unit or

the weighing bridge are not operated.

Keep pressed (3s) until „setbl“ appears.

Press to call up AUTO OFF-function

Press , the current setting will be displayed.

Press to select the desired setting.

of 0 Function deactivated

of 3 Weighing sy s tem w il l be turned off after 3 mi n .

of 5 Weighing sy s tem w il l be turned off after 5 mi n .

of 15 Weighing system wi ll be turned off a fter 15 mi n.

of 30 Weighing system will be turned off after 30 min.

Either save by or cancel input by pressing .

Back to Weighing mode by .

34 KIB-TM-BA_IA-e-1912

Page 35

A B b C D E F G H h I J K

L

7.16 Setting time and date

To change date and time go to menu item "P8 ind" "dAtE" or "tIME"

(See chap. 8):

Setting date:

Select menu item "dAtE"

Press to confirm and the last date entered will be displayed. The first digit is

flashing

(example)

Use the navigation keys, as described in chap. 2.1.1, to enter the current date

and press to confirm.

The current date will be shown in standby mode.

Setting time:

Select menu item "tiME"

Press to confirm and the last time entered will be shown. The first digit is

flashing.

(example)

Use the navigation keys, as described in chap. 2.1.1, to enter the current time

and press to confirm.

The time will be shown in standby mode.

7.17 Alphabet

Letters are ordered in the following order:

l M N O P Q R S U V W X Y Z

KIB-TM-BA_IA-e-1912 35

Page 36

Enter the password (see above.)

selected one after the other.

current setting will be displayed.

.

8 Menu

8.1 Navigation in the menu:

Call up menu

Switch-on balance and during the selftest press .

Press , , , subsequently, the first menu

block „PO CHK“ will be displayed.

From the weighing mode:

Press and hold until Pn appears.

Select menu block

With help of , the individual menu items can be

Select setting

Confirm selected menu item by pressing . The

Change settings To change to the available settings, press the

navigations keys as described in chap. 2.1.1.

Acknowledge setting /

exit the menu

Return to weighing

mode

36 KIB-TM-BA_IA-e-1912

Either save by pressing or cancel by pressing

Press repeatedly to exit menu.

Page 37

Menu block

Main menu

Menu item

Submenu

Acoustic signal for weighing with tolerance range

switched off

Audio sound when weighed load is within

tolerance limits

Audio sound when weighed load is beyond

tolerance limits

Relay pilot light

P1 rEF1

P2 COM

MODE

8.2 Menu overview

Available settings / explanation

PO CHK

Weighing with

tolerance range,

see chap. 7.7

Zero point

settings

nEt H Upper limit value „Tolerance check weighing“, input see

chap. 7.7.1

nEt L

PCS H

Lower limit value „Tolerance check weighing“, input see

chap. 7.7.1

Upper limit value „Tolerance check counting“, input

see chap. 7.7.2

PCS L

Lower limit value „Tolerance check counting“, input

see chap. 7.7.2

BEEP no

ok

nG

rELAY on

oFF

A2n0 Automatic zero point correction (Autozero) by changing the

display, digits selectable (0, 0.5d, 1d, 2d, 4d)

0AUto Zero setting range

Load range where the display after switching-on the

balance is set to zero. Selectable 0, 2, 5, 10, 20, 30, 50,

100 %

0rAGE Zero setting range

0tArE Automatic taring „on / off“, taring range adjustable in menu

Interface

parameter

Load range where the display is set to zero by pressing

. Selectable 0, 2, 4, 10 , 20* , 50, 100%.

item „0Auto“.

CONT S0 off Continuous data output,

S0 on

ST1 One output for stable weighing value

STC Continuous data output of stable weighing

values

PR1

• Output after pressing

• Precondition for alibi memory

PR2 Manual totalizing, see chap. 7.8

Press and the weighing value will be added

to the summation memory and issued.

selectable „sending 0“, yes / no

KIB-TM-BA_IA-e-1912 37

Page 38

AUTO*

For automatic totalizing see chap. 7.9

memory on unloading of weighing scale.

ASK

Remote control instructions

wirel

Not documented

BAUD

Available Baudrate: 600, 1200, 2400, 4800, 9600*

Pr

7E1

7 bits, even parity

7o1

7 bits, odd parity

8n1*

8 bits, no parity

PTYPE

tPUP*

Standard printer setting

LP50

Not documented

KCP

KERN Communication Protocol

LAb

LAb x

For data output format,

see table below. 1

Prt

Prt x

LAnG

eng*

Standard settings English

chn

Not documented

P3 CAL1

COUNT

Display internal resolution

DECI

Position of the decimal dot

DUAL

Setting balance type, capacity (Max) and readability (d)

off

Single-range balance

R1 inc

Readability

R1 cap

Capacity

on

Dual range balance

R1 inc

Readability 1st weighing range

R1 cap

Capacity 1st weighing range

R2 inc

Readability 2nd weighing range

R2 cap

Capacity 2nd weighing range

CAL

noLin

For adjustment, see chap. 6.9.2

Liner

For linearization, see chap. 6.10.2

GrA

Gravitational constant at place of installation

GrB

Gravitational constant at place of manufacture

on

Keyboard lock enabled, see chap. 7.13

off*

Keyboard lock disabled

on

Animal weighing enabled, see chap. 7.12

off*

Animal weighing disabled

SCr

on

watch as screensaver enabled

off*

watch as screensaver disabled

Configuration

data

see chap. 12.4

This function is used to issue and add individual

weighing values automatically to the summation

LOCK

ANM1

P4 OTH

38 KIB-TM-BA_IA-e-1912

Page 39

kg

on* off g on

off*

lb

on

off*

oz

on

off*

tJ

on

off

HJ

on

off

dAtE

Setting date: Format: TTMMJJ

tIME

Setting time: Format: HHMMSS

ALibi

Alibi memory

dAtA

Number of saved records

rdAtA

Read the record value

ErASE

Delete all data

ExPT

Export data (USB stick)

PrEt

Enter pre-tare value

485

ModE

2disP,

Count

Export mode (2nd display)

bAUd

600,

9600

Baud rate

Pr

7o1

7 Bit, odd Parity, 1 Stop bit

7E1

7 Bit, equal Parity, 1 Stop bit

8n1

8 Bit, no Parity, 1 Stop bit

io

i_tSt

Test input

o_tSt

Test output

oPt

intF

USB,

WiFi, EnEt

Select connections

ModE

(output)

no, CoUnt (USB, Bt, Wi-Fi, EnEt)

no, Expt (UdiSK)

iP_1

IP addresses KIB-TM

iP_2

iP_3

iP_4

MASK_1

Subnet mask

MASK_2

MASK_3

MASK_4

GAtE_1

KIB-TM Gateway

GAtE_2

GAtE_3

GAtE_4

P5 Unt1

Change weighing

unit

see chap. 7.5

P6 xcl1

P7 rst1

Factory setting

P8 ind

P9 Prt

Not documented

Use to reset balance settings to factory default.

1200,

2400,

4800,

KIB-TM-BA_IA-e-1912 39

UdiSK, Bt,

Page 40

oPt

riP_1

remote (IP-Adresse PC)

riP_2

riP_3

riP_4

rPort

Remote port (Port for communication

between PC and KIB-TM

SSid_1

SSID

SSid_2

PSW_1

WLAN Passwo rd

PSW_2

Lab

Continuation menu item P9 Prt

P9 Prt

Factory settings are marked by *.

1

Function blocked when the adjustment switch is in the position “balance is

calibratable” (adjus tment switch in the “L OC K ” pos ition).

Tab. 1.: Sample logs

• Menu setting P2 Com Mode PR2

• Data output after pressing of

Prt

0~3

*******************

GS: 5,000kg

*******************

4~7

*******************

No.: 1

GS: 5,000kg

*******************

0 1 2 3

*******************

NT: 5,000kg

TW: 5,000kg

GW: 10,000kg

*******************

*******************

No.: 1

NT: 5,000kg

TW: 5,000kg

GW: 10,000kg

*******************

GS Gross weight

**********************

GS: 5,000kg

TOTAL: 10,000kg

**********************

**********************

No.: 1

GS: 5,000kg

Total: 10,000kg

**********************

**********************

NT: 5,000kg

TW: 5,000kg

GW: 10,000kg

Total: 10,000kg

**********************

**********************

No.: 1

NT: 5,000kg

TW: 5,000kg

GW: 10,000kg

Total: 10,000kg

**********************

NT Net weight

TW Tare weight

NO Number weighing processes

Total Total of all individual

weighings

40 KIB-TM-BA_IA-e-1912

Page 41

9 Servicing, maintenance, disposal

9.1 Cleaning

• Before cleaning, disconnect the appliance from the operating voltage.

• Do not use aggressive detergents (solvents or similar).

9.2 Servicing, maintenance

The appliance may only be opened by trained service technicians who are authorized

by KERN.

Before opening, disconnect from power supply.

9.3 Disposal

Disposal of packaging and appliance must be carried out by operator according to

valid national or regional law of the location where the appliance is used.

KIB-TM-BA_IA-e-1912 41

Page 42

Error message

Description

9.4 Error messages

Excess load if weight exceeds capacity of +9d

Underweight (less than 20 d)

The weight is too low (less than -20 d)

Zero setting range exceeded on start-up of balance.

Zero setting range during start-up of weighing scale or on

pressing of exceeded.

Incorrectly connect ed verification plug

Is displayed on setting weighing scale to zero with ,

without load

For parts counting and percentage calculation:

Weighed value < zero

For add-up:

Total number of weighings above 999

For add-up:

Total weight above 999999

Adjustment failed

Keyboard locked

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

42 KIB-TM-BA_IA-e-1912

Keyboard unlocked

Capacity of batteries exhausted.

(Battery voltage below 5.7 V, automatic shutdown

happens at less than 5.4 V)

Page 43

Pin1

RX

Input

Pin2

TX

Output

Pin3

GND

Signal ground

Pin4

N/C

Not connected

10 RS 232 interface

You can print weighing data automatically via the RS 232C interface or manually by

pressing via the interface according to the setting in the menu.

This data exchange is asynchronous using ASCII - Code.

The following conditions must be met to provide successful communi cati on between

the weighing system and the printer.

• Use a suitable cable to connect the display unit to the interface of the printer.

Faultless operation requires an adequate KERN interface cable.

• Communication parameters (ba ud ra te, bit s and parity) of display unit and

printer must match. For a detailed description of interface parameters, please

refer to chapter 8, Menu block “P2 COM“

10.1 Technical data

Connection 4 pin d-subminiature bushing

Baud rate Optional 600/1200/2400/4800/9600

Parity 8 bits, no parity / 7 bits, even parity / 7 bits, odd parity

KIB-TM-BA_IA-e-1912 43

Page 44

****************************

10.2 Printer operation / sample logs (KERN YKB-01N)

• Weighing

1. Continuous data output

(menu setting P2 Com Mode Com S0 on)

Menu setting P2 Com LAb 0 / Prt 0:

****************************

ST, GS 53.2 kg

****************************

2. Data output after pressing of

(menu settings: P2 Com Mode Pr1,

Changes to the menu settings Lab and Prt do not affect the layout of the

sample log)

Menu setting P2 Com LAb 0 / Prt 0~3 or LAb 3 / Prt 4~7:

****************************

ST, GS 53.2 kg

****************************

****************************

US, GS 53.2 kg

****************************

****************************

ST, NT : 52.6 kg

****************************

• Counting

PCS 100

****************************

44 KIB-TM-BA_IA-e-1912

Page 45

ST

Stable value

US

Instable value

GS / GW

Gross weight

NT

Net weight

TW

Tare weight

NO

Number weighing processes

TOTAL

Total of all individual weighings

<lf>

Space line

<lf>

Space line

• Totalization

3. Data output after pressing of (menu setting P2 Com Mode Pr2)

P2 Com LAb 3 / Prt 4~7: Menu setting P2 Com LAb 0 / Prt 0:

Symbols:

KIB-TM-BA_IA-e-1912 45

Page 46

I0

I1

I2

I3

I4

Query serial number

I4˽A˽“xxxxxxxx“

I5

S

SI

Send weight value immediately

SIR

10.3 Output log (continuous output)

• Weighing

HEADER1: ST=STABLE, US=UNSTABLE

HEADER2: NT=NET, GS=GROSS

Menu setting: P2 ComPTYPE tPUP or LP50

10.4 KERN Communications Protocol (KERN Interface Protocol)

KCP (KERN communication protocol) contains the commands that are used to

control the KERN balances via the interface.

• Menu setting P2 Com Mode ASK

• Menu setting P2 Com PTYPE KCP

• Finish commands with CR/LF character.

• Consult the KCP manual for more inform ati o n , av ai labl e on

our KERN website (www.kern-sohn.com).

The following commands are supported:

@ Cancel

List all implemented KCP commands

Query KCP level and KCP versions

Query device information (type, capacity)

Query device software version

Set serial number (default value is K123456)

Query SW-Identification number

46 KIB-TM-BA_IA-e-1912

Send stable weight value

Send weight value immediately and repeat

Page 47

Z

ZI

D

D˽“˽“

DW

K

SR

T

MM

TAC

TI

Tare immediately

Zero

Zero immediately

Display: Write text to display

Clear Display (after D-Command)

Display: Show weight

Keys: Set configuration

Send weight value on weight change (send and repeat)

Tare

Query/preset tare weight value

Clear tare value

Polling-Intervall

• The time between periodic inquiries or when sending requests

(queries) by the interface must be longer than 100 ms.

KIB-TM-BA_IA-e-1912 47

Page 48

The displayed weight does

not glow.

• Mains power supply interrupted (mains cable

defective).

• Power supply interrupted.

• (Rechargeable) batteries are inserted incorrectly or

empty

• No (rechargeable) batteries inserted.

The displayed weight is

• Table/floor vibrations

• Weighing pan has contact with other objects.

possible)

The weighing result is

obviously incorrect

• Adjustment is no longer correct.

• Great fluctuations in temperature.

possible)

11 Instant help

In case of an error in the program process, briefly turn off the display unit and

disconnect from power supply. The weighing process must then be restarted from the

beginning.

Help:

Fault Possible cause

• The display unit is not switched on.

permanently changing

Should other error messages occur, switch display unit off and then on again. If the

error message remains inform manufacturer.

• Draught/air movement

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

• The display of the balance is not at zero

• Warm-up time was ignored.

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

48 KIB-TM-BA_IA-e-1912

Page 49

Installation / configuration of a weighing system must be carried out by a

12 Installing display unit / weighi ng bridge

•

12.1 Technical data

Supply voltage 12 V / 1000mA

Max. signal voltage 5V

Zeroing range 0-2mV

Sensitivity ≥ 0.15uV/d

Resistance parameter 87 - 1100 Ω

12.2 Weighing system design

The display unit is suitable for connection to any analogue load cell in compliance

with the required specifications.

The following data must be established before selecting a load cell:

well acquainted specialist with the workings of weighing balances.

• Weighing balance capacity

This usually corresponds to the heaviest load to be weighed.

• Preload

This corresponds to the total weight of all parts that are to be placed on the

weighing cell such as upper part of platform, weighing pan etc.

• Total zero setting range

This is composed of the start-up zero setting range (± 2%) and the zero

setting range available to the user via the ZERO-key (2%). The total zero

setting range equals therefore 4 % of the scale’s capacity.

The addition of weighing scales capacity, preload and the total zero setting

range give the required capacity for the weighing cell.

To avoid overloading of the weighing cell, include an additional safety

margin.

• Smallest desired display division

KIB-TM-BA_IA-e-1912 49

Page 50

In 4-wire load cells or connection boxes (junction boxes), bridge the solder

EXC+

SEN+

SEN-

EXC-

SIG+

SIG-

SHIELD

7

6

3

2

5

4

1

LOAD

CELL

12.3 How to connect the platform

Disconnect the display unit from the power supply.

Solder the individual wires of the load cell cable to the printed circuit board (See

fig.).

joints J1 and J2.

50 KIB-TM-BA_IA-e-1912

Page 51

12.4 Configur e display unit

+ For menu overview see chap. 8.

Call up menu:

Switch-on balance and during the selftest press . „Pn“

will be displayed

Press , , , subsequently, the first menu block

„PO CHK“ will be displayed.

Press repeatedly until „P3 CAL“ will be displayed.

Acknowledge with . „CoUnt“ is displayed.

Navigation in the menu

With help of , the individual menu items can be selected

one after the other.

Confirm selected menu item by pressing . The current

setting will be displayed.

To change to the available settings, press the navigations

keys as described in chap. 2.1.1.

Either save by pressing or reject by pressing .

Press repeatedly to exit menu.

Parameter selection

1. Display internal resolution

Press , the internal resolution will be shown.

Return to menu by .

Use to select another men u ite m.

KIB-TM-BA_IA-e-1912 51

Page 52

2. Position decimal point

Press , the currently set position of the decimal dot is

displayed.

Press to select the desired setting. Selectable 0, 0.0,

0.00, 0.000, 0.0000.

Confirm input by .

Use to select another men u ite m.

3. Weighing scales type, capacity and readability

Press , the current setting will be displayed.

Select des ir ed s etti ng by .

„off“ Single-range balance

„on“ Dual range balance

Press to confirm, the display for entering readability (for

dual range scales for the first weighing range) appears.

Press , the current setting will be displayed.

52 KIB-TM-BA_IA-e-1912

Page 53

Select des ir ed s etti ng with and acknowledge by .

Press , the display for entering capacity will appear (at

dual range balance for the first ra nge).

Press , the current setting will be displayed.

Using the navigation buttons (see chap. 2.1.1) select the

desired setting, the active digit is flashing.

Acknowledge with .

In a single-range balance the entry of capacity / readability

is finished.

either in single-range balance

Press , the unit will return to the menu Press to call

up next menu item „CAL“.

or

In a dual range balance enter readability and capacity of

the second weighing range.

Press , the display for entering the readability of the

second weighing range will appear.

Press , the current setting will be displayed.

Select des ir ed s etti ng with and acknowledge by .

KIB-TM-BA_IA-e-1912 53

Page 54

6.10 for linearisation

Press , the display for entering the capacity of the

second weighing range will appear.

Press , the current setting will be displayed.

Using the navigation buttons (see chap. 2.1.1) select the

desired setting, the active digit is flashing.

Confir m input by .

Press , the unit will return to the menu

Press to call up next menu item „CAL“.

4. Adjustment or linearisation

Adjustment or linearisation is required after entering

configuration data.

For carrying out adjustment see chap. 6.9 step 4 or chap.

Acknowledge using , the current setting is displayed.

Press to confirm, pres s to select the desired setting

noLin = Adjustment

LineAr = Linearisation

13 Conformity explanation/ t est certificate

The curre nt EC/EU Conformity declaration can be found online in:

www.kern-sohn.com/ce

54 KIB-TM-BA_IA-e-1912

Loading...

Loading...