Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

email: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating instructions

Touch screen-Industrial Balance

KERN FKT / IKT / PKT

Version 3.5

11/2015

Fax: +49-[0]7433-9933-149

GB

FKT_IKT_PKT-BA-e-1435

Page 2

FKT_IKT_PKT-BA-e-1435 2

Page 3

KERN FKT / IKT / PKT

Touch screen-Industrial Balance

GB

Version 3.5 11/2015

Operating instructions

Table of Contents

1 Technical Data ........................................................................................................... 5

2 Basic Information (General) ................................................................................... 18

2.1 Proper use ............................................................................................................................................ 18

2.2 Improper Use ........................................................................................................................................ 18

2.3 Warranty ............................................................................................................................................... 18

2.4 Monitoring of Test Resources ............................................................................................................ 18

3 Basic Safety Precautions ....................................................................................... 19

3.1 Pay attention to the instructions in the Operation Manual ............................................................. 19

3.2 Personnel training ............................................................................................................................... 19

4 Transportation & Storage ....................................................................................... 19

4.1 Testing upon acceptance ................................................................................................................... 19

4.2 Packaging / return transport ............................................................................................................... 19

5 Unpacking, Setup and Commissioning................................................................. 20

5.1 Installation Site, Location of Use ....................................................................................................... 20

5.2 Unpacking ............................................................................................................................................ 20

5.2.1 Placing ................................................................................................................................................... 20

5.3 Mains connection ................................................................................................................................ 20

5.4 Batterie operation ................................................................................................................................ 21

5.5 Connection of peripheral devices ...................................................................................................... 21

5.6 Initial Commissioning ......................................................................................................................... 21

5.7 Adjustment ........................................................................................................................................... 21

5.8 Adjustment ........................................................................................................................................... 22

5.9 Verification ........................................................................................................................................... 22

6 Operation ................................................................................................................. 23

6.1 How to turn on/off balance ................................................................................................................. 23

6.2 Screen Operating mode Weighing ..................................................................................................... 26

6.3 Screen operating mode Counting ...................................................................................................... 27

6.4 Screen Operating mode Totalizing .................................................................................................... 29

6.5 Screen Operating mode Dispensing .................................................................................................. 31

6.6 Screen Operating mode Check weighing .......................................................................................... 33

6.7 Screen Operating mode Percentage .................................................................................................. 35

6.8 Screen Operating mode Animal weighing......................................................................................... 37

6.9 Screen Operating mode Fo rmulation ................................................................................................ 39

6.10 Screen Operating mode Surface weight ........................................................................................... 41

6.11 Screen Operating mode Density ........................................................................................................ 43

6.12 Forms .................................................................................................................................................... 45

3 FKT_IKT_PKT-BA-e-1435

Page 4

7 Print form ................................................................................................................. 46

7.1 Contents of the form impression ....................................................................................................... 46

7.2 Arrangement of form printout ............................................................................................................ 47

8 Interfaces ................................................................................................................. 48

8.1 Digital I/O output - open collectors (only model FKT/IKT) .............................................................. 48

8.2 Data output RS 232 C .......................................................................................................................... 49

8.3 Interface RS 232C ................................................................................................................................ 49

8.3.1 There are 4 kinds of data output via RS 232C ...................................................................................... 50

8.3.2 Explanation of the data transfer ............................................................................................................ 50

8.4 Printer ................................................................................................................................................... 51

8.5 Underfloor weighing ........................................................................................................................... 51

9 Service, maintenance, disposal ............................................................................. 52

9.1 Cleaning ............................................................................................................................................... 52

9.2 Service, maintenance .......................................................................................................................... 52

9.3 Disposal ................................................................................................................................................ 52

10 Instant help .............................................................................................................. 52

11 Declaration of c onform ity ....................................................................................... 53

FKT_IKT_PKT-BA-e-1435 4

Page 5

Taring range

(subtractive)

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

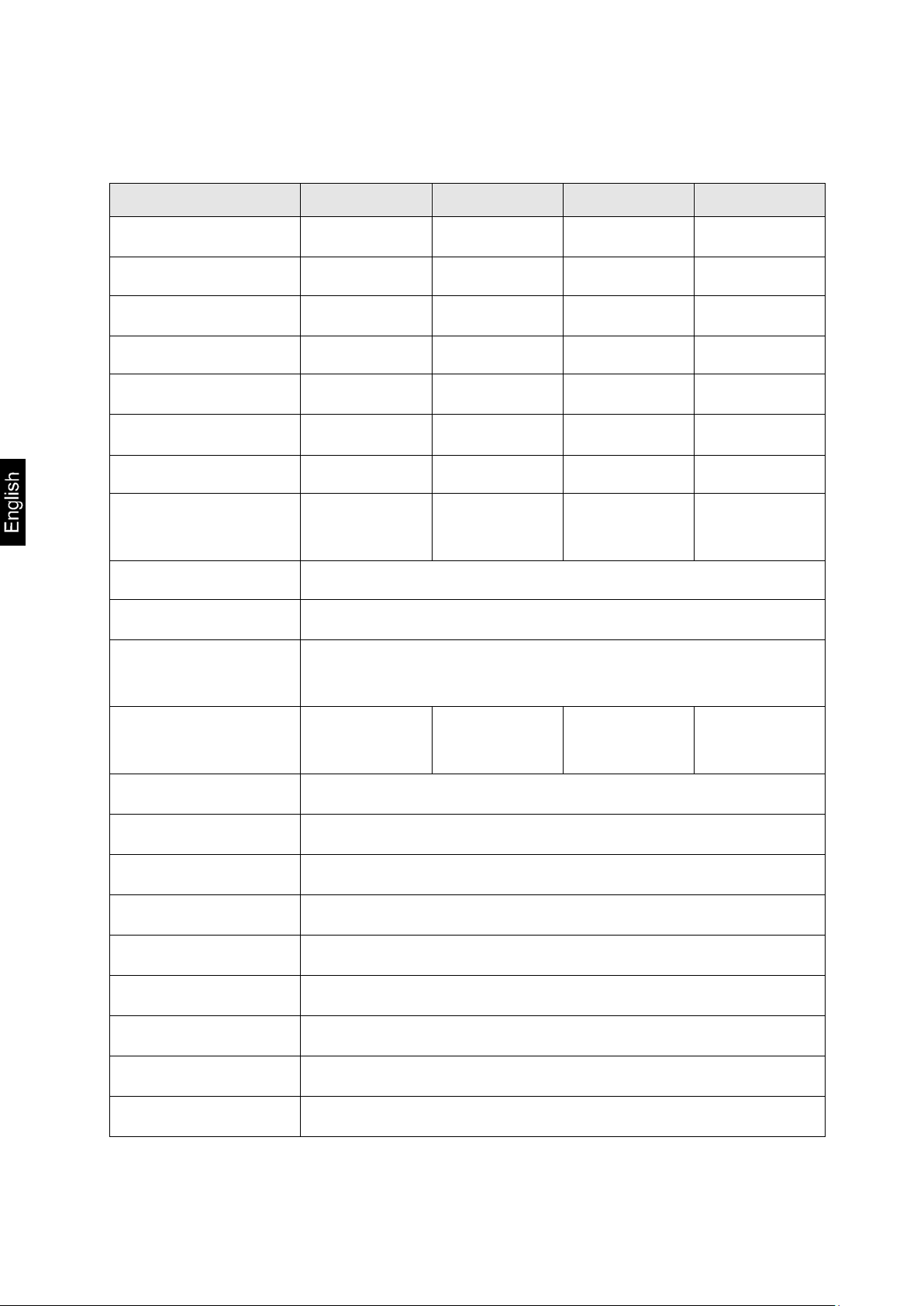

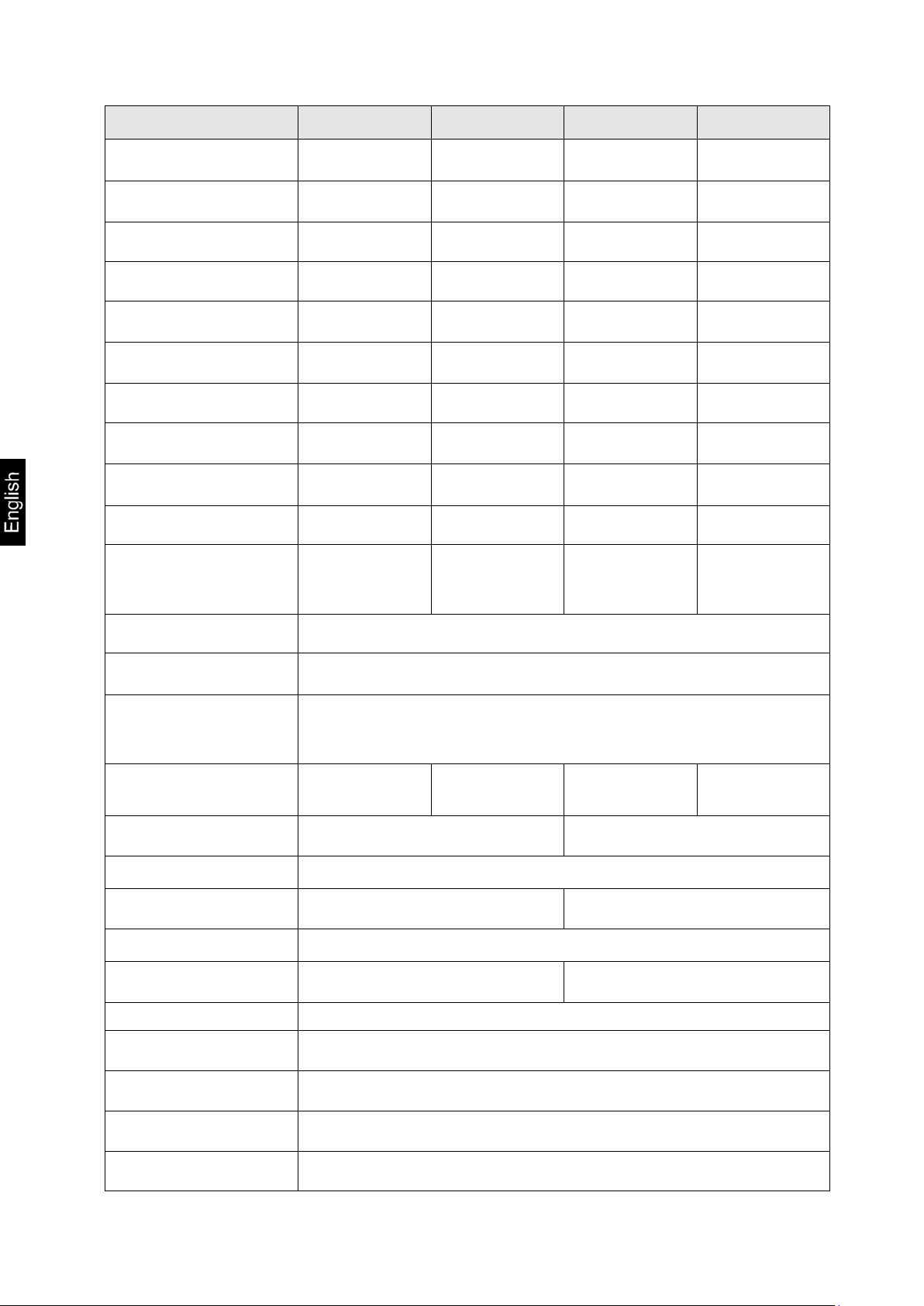

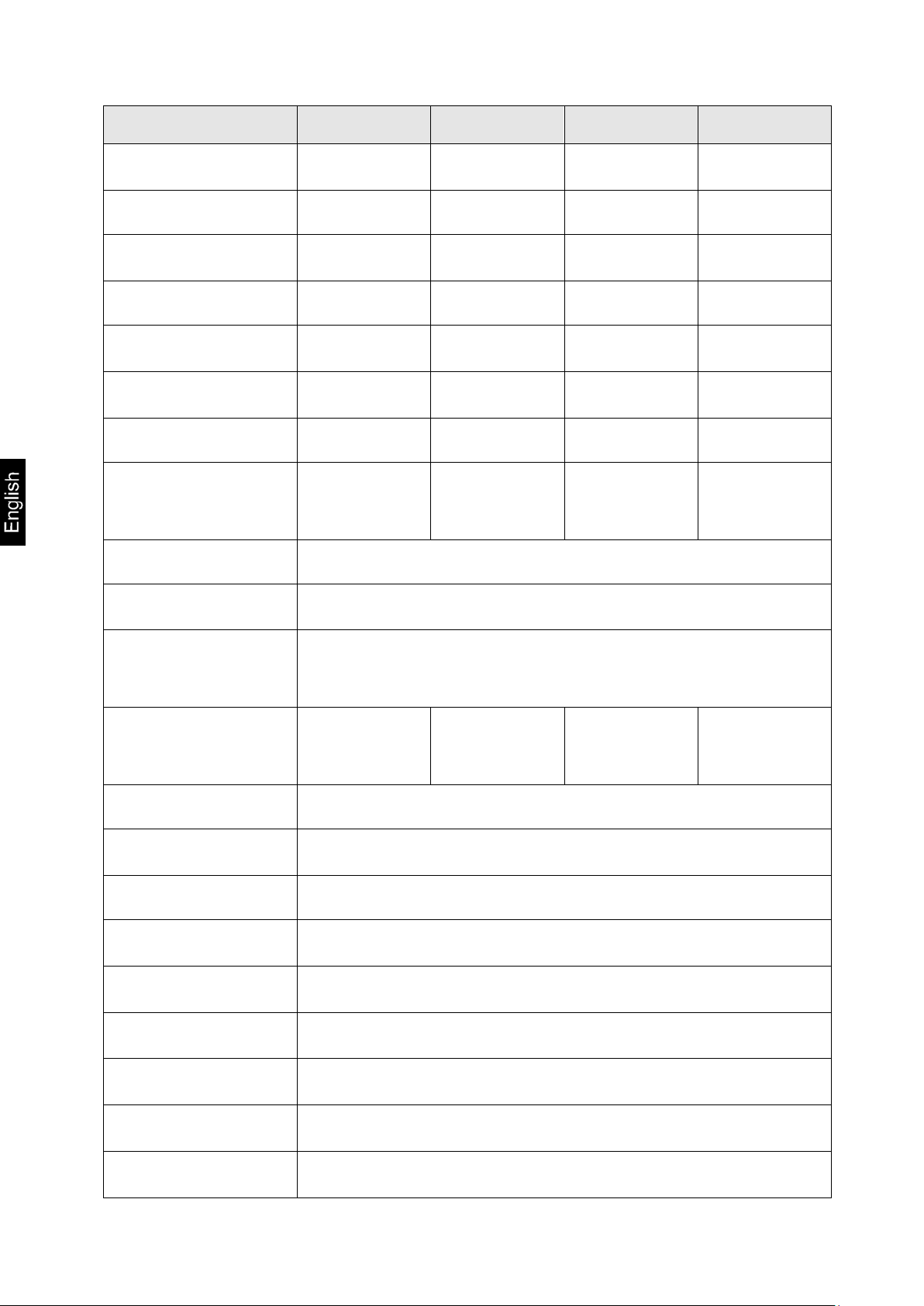

1 Technical Data

Models FKT:

KERN FKT 6K0.02 FKT 6K0.05 FKT 6K0.1 FKT 12K0.05

Readability (d) 0.02 g 0.05 g 0.1 g 0.05 g

Weighing r ange (max) 6 000 g 6 000 g 6 000 g 12 000 g

6 000 g 6 000 g 6 000 g 12 000 g

Reproducibility 0.04 g 0.05 g 0.2 g 0.05 g

Linearity ±0.1 g ±0.15 g ±0.2 g ±0.15 g

Smallest piece weight 0.02 g 0.05 g 0.1 g 0.05 g

Adjustment points 2/5/6 kg 2/5/6 kg 2/ 5/6 kg 2/5/10/12 kg

Recommended

adjusting weight F1

5 kg 5 kg 5 kg 10 kg

(not supplied)

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

+10 °C … + 40 °C

Warm-up time 4 h 2 h 2 h 2 h

270 x 345 x 106

Vibration filter yes

253 x 228

Units see menu

Weight kg (net) 3.3

Data interface yes (RS232)

5 FKT_IKT_PKT-BA-e-1435

80

16

99

Page 6

Taring range

(subtractive)

5/10/15/20/24

kg

5/10/15/20/24

kg

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

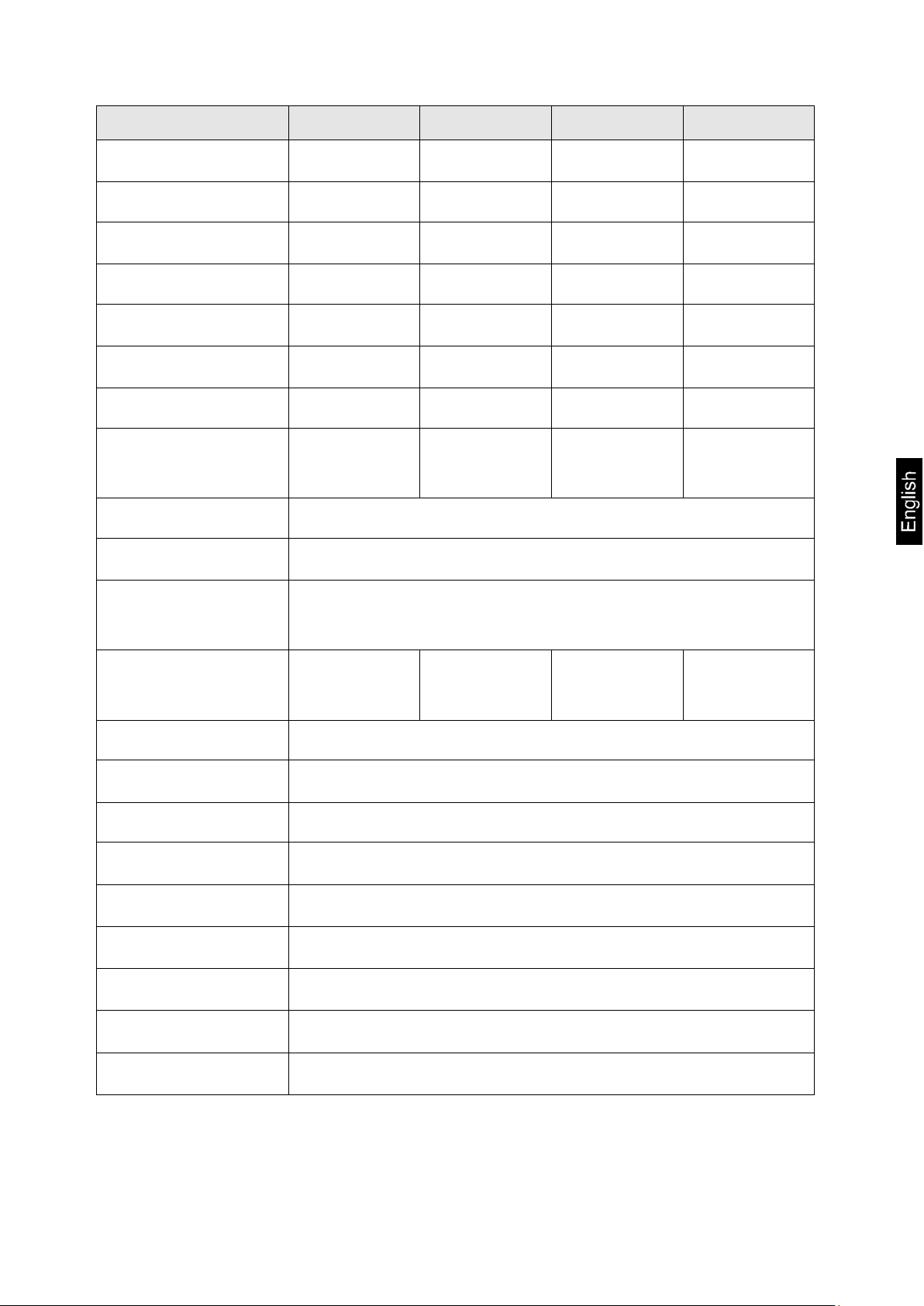

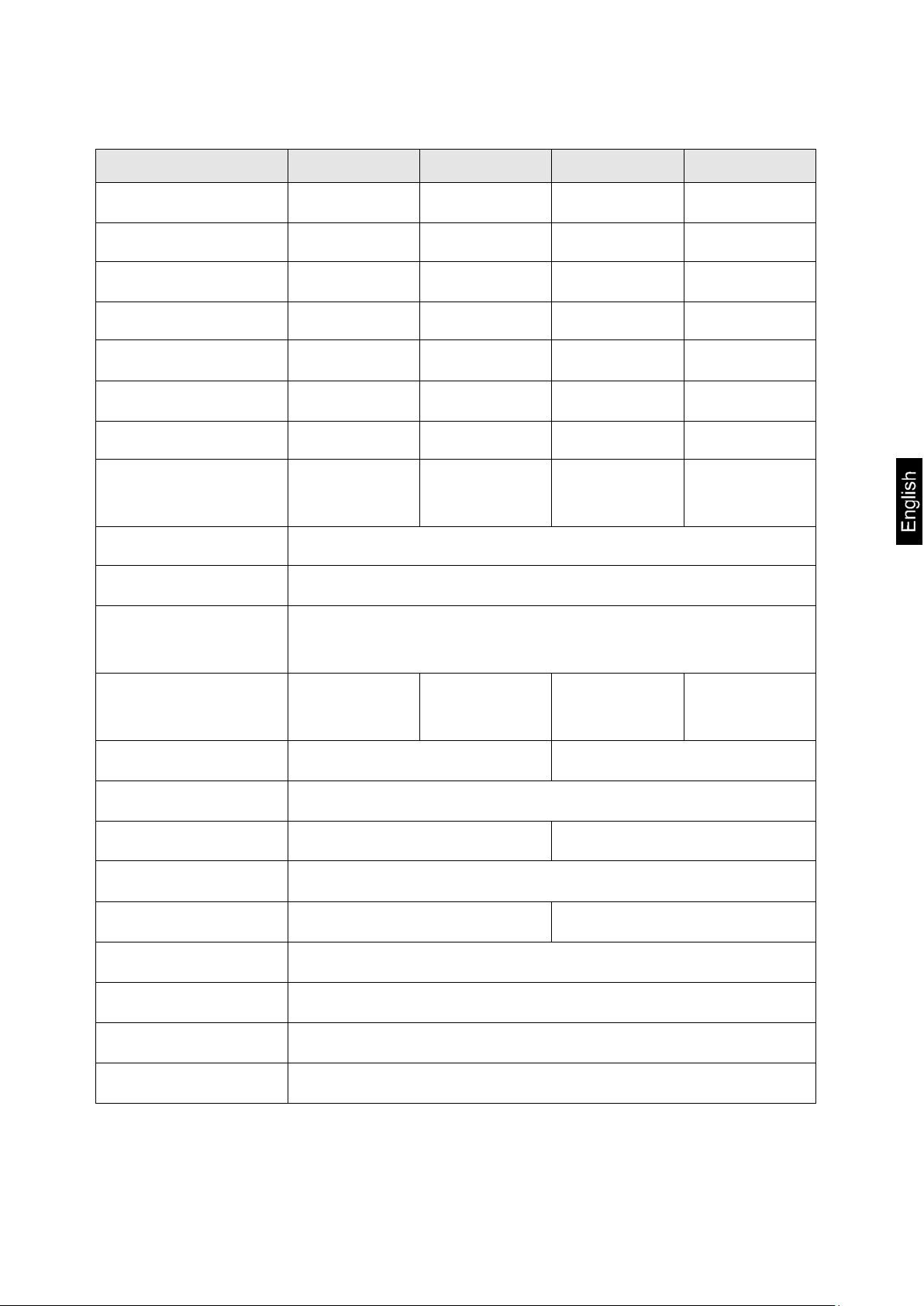

KERN FKT 12K0.1 FKT 12K0.2 FKT 24K0.1 FKT 24K0.2

Readability (d) 0.1 g 0.2 g 0.1 g 0.2 g

Weighing r ange (max) 12 000 g 12 000 g 24 000 g 24 000 g

12 000 g 12 000 g 24 000 g 24 000 g

Reproducibility 0.1 g 0, 2 g 0.1 g 0.2 g

Linearity ±0.3 g ±0.4 g ± 0. 3 g ±0.6 g

Smallest piece weight 0.1 g 0. 2 g 0.1 g 0.2 g

Adjustment points 2/5/10/12 kg 2/5/10/12 kg

Recommended

adjusting weight F1

(not supplied)

10 kg 10 kg 20 kg 20 kg

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

Warm-up time 4 h 2 h 2 h 2 h

Vibration filter yes

Units see menu

Weight kg (net) 3.3

Data interface yes (RS232)

+10 °C … + 40 °C

270 x 345 x 106

253 x 228

FKT_IKT_PKT-BA-e-1435 6

80

16

99

Page 7

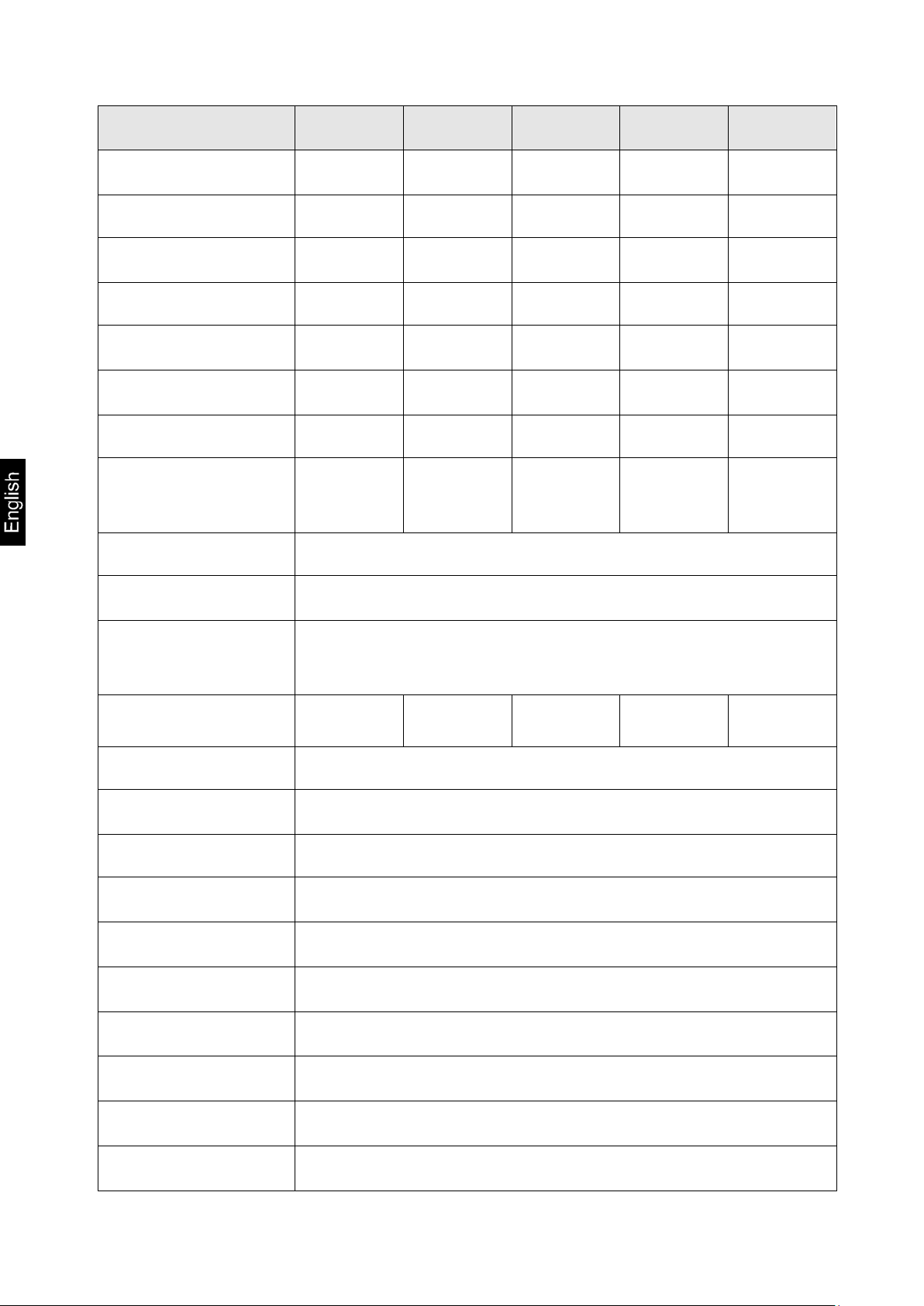

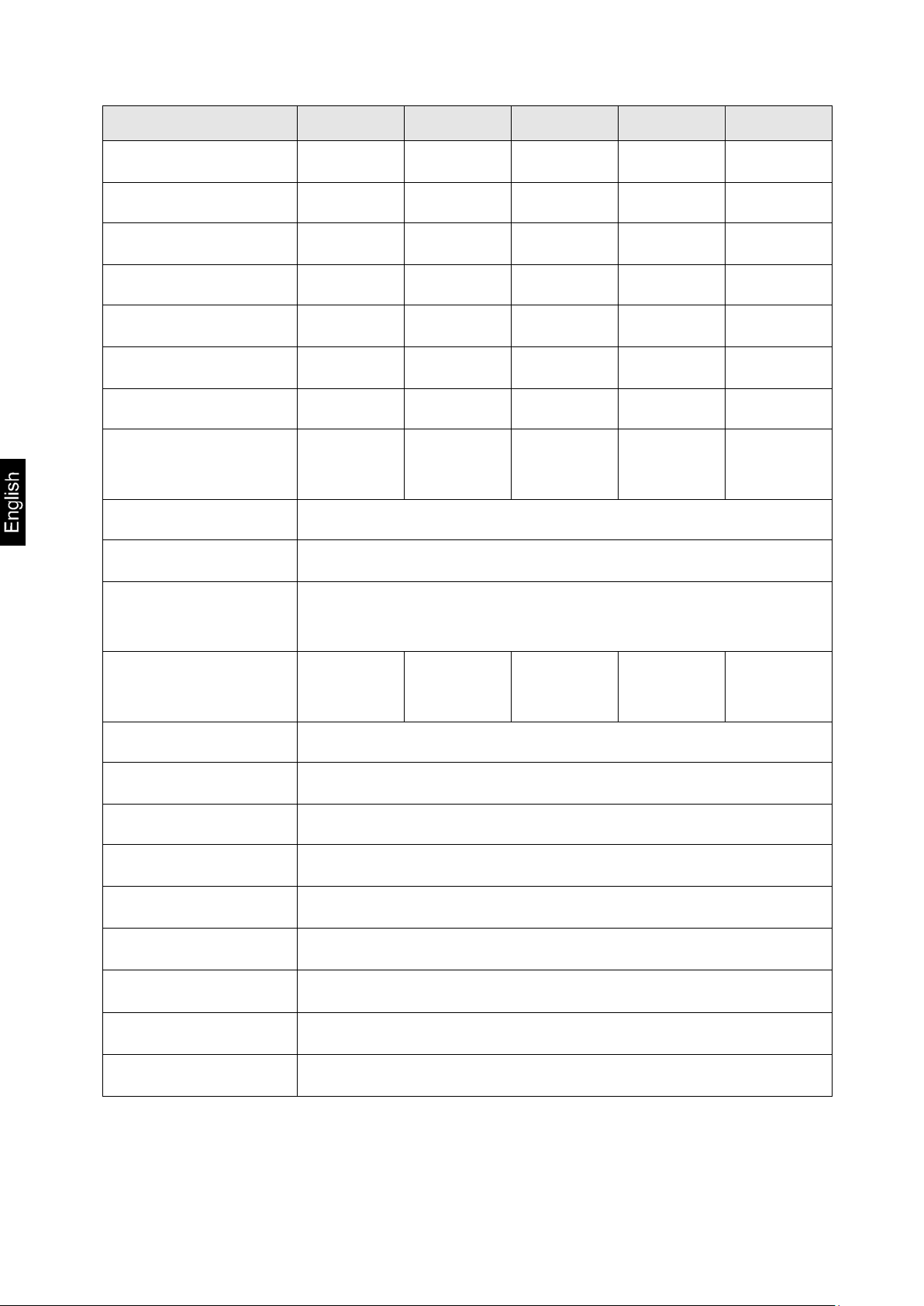

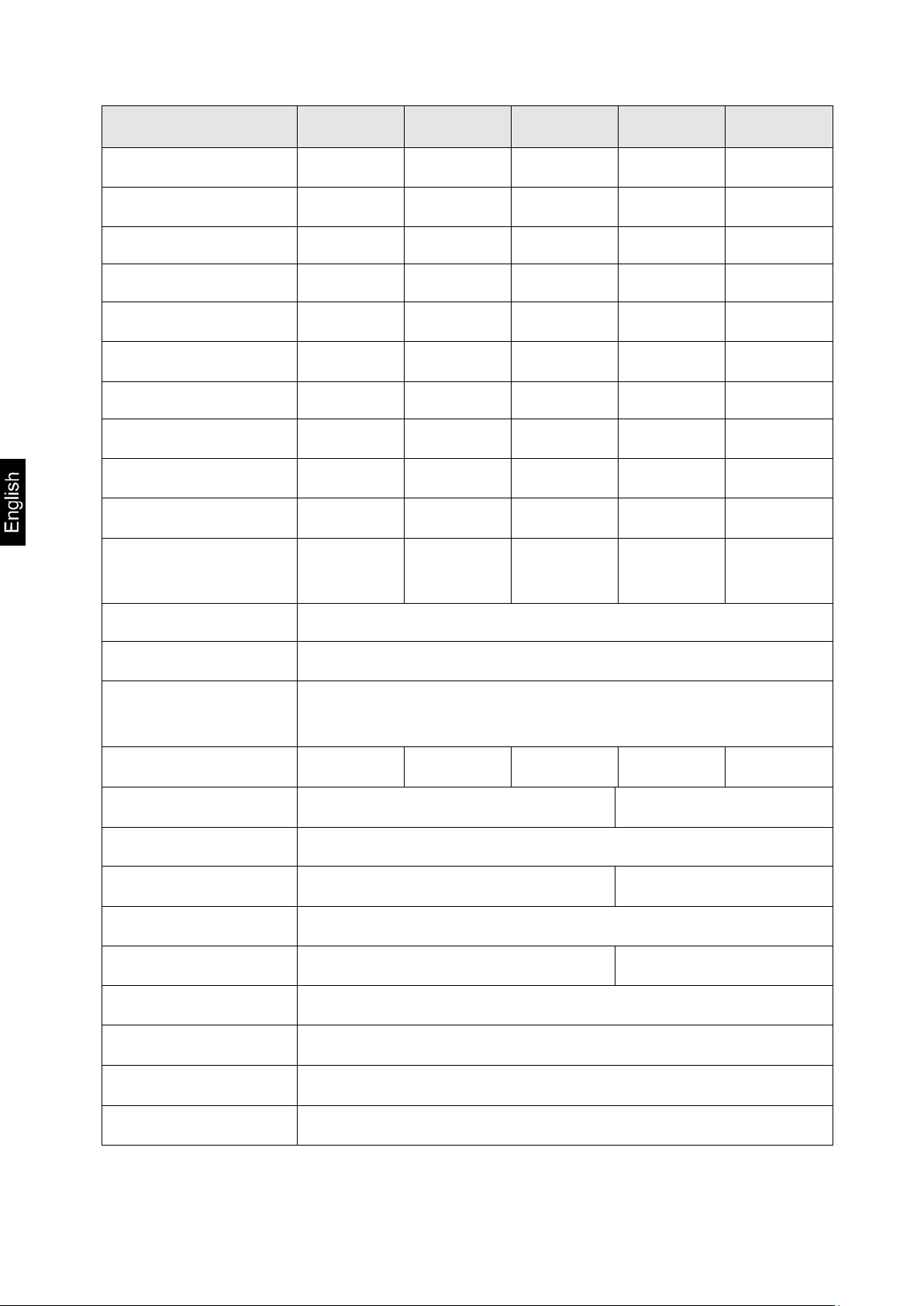

FKT

6K0.02L

FKT

16K0.05L

FKT

16K0.1L

FKT

30K0.5L

FKT

36K0.1L

5/10/15/16

kg

5/10/15/16

kg

10/20/30/36

kg

(typical)

Weighing plat e stainless

steel mm

x 1,5 V, Size C

KERN

Readability (d) 0.02 g 0.05 g 0.1 g 0,5 g 0.1 g

Weighing r ange (max) 6 000 g 16 000 g 16 000 g 30.000 g 36 000 g

Taring range

(subtractive)

Reproducibility 0.04 g 0.1 g 0.1 g 0,5 g 0. 2 g

Linearity ±0.1 g ±0.25 g ±0.3 g ±1,0 g ±0.5 g

Smallest piece weight 0.02 g 0.05 g 0.1 g 0,5 g 0. 1 g

Adjustment points 2/4/5/6 kg

Recommended

adjusting weight F1 (not

supplied)

Humidity of air max. 80% rel. (non-condensing)

Stabilization time

Permitted environmental

temperature

6 000 g 16 000 g 16 000 g 30.000 g 36 000 g

10/20/30 kg

5 kg 10 kg + 5 kg 10 kg + 5 kg 20 kg+10 kg

3 sec.

+10 °C … + 40 °C

20 kg + 10

kg

Warm-up time 4 h 4 h 2 h 2 h 4 h

Housing (B x D x H) mm 350 x 390 x 120

Vibration filter yes

340 x 240

Units see menu

Weight kg (net) 6.5

Data interface yes (RS232)

Master data storage for

all operating modes

Print forms with up to 20

informations

Recipes with up to 10

components

Battery operation with 6

80

16

99

yes

7 FKT_IKT_PKT-BA-e-1435

Page 8

Taring range

(subtractive)

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

Battery operation with

6 x 1,5 V, Size C

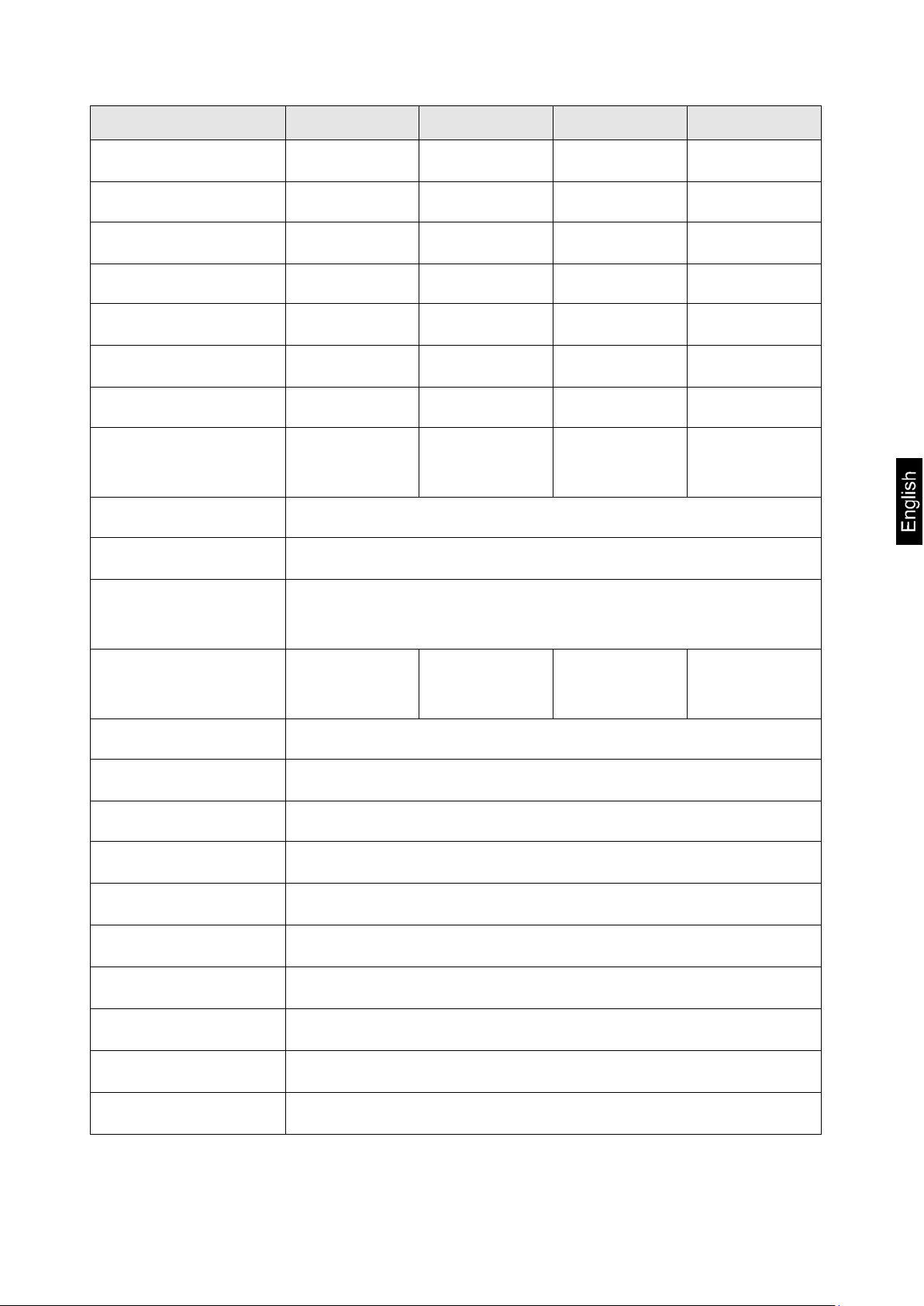

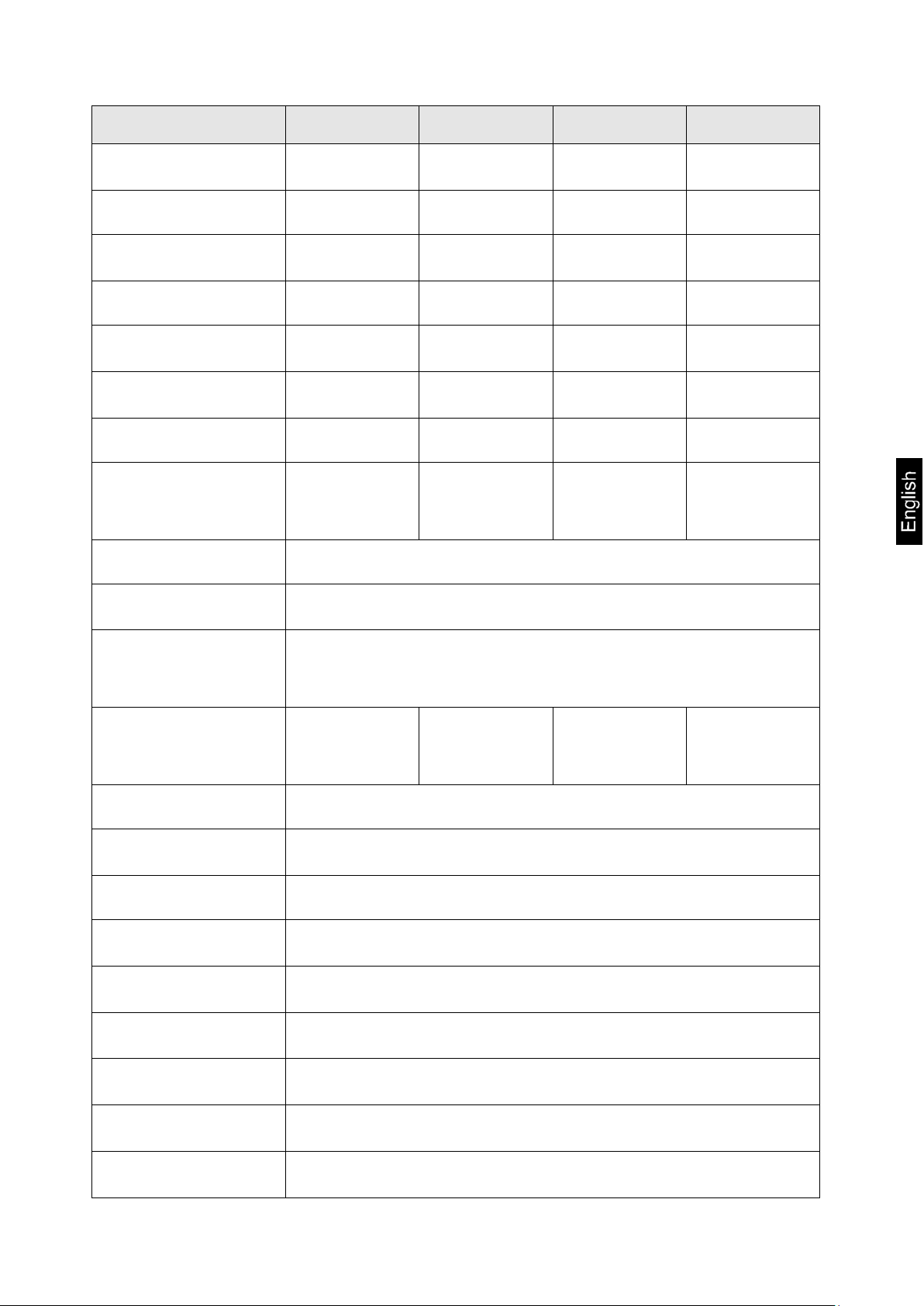

KERN FKT 36K0.2L FKT 60K1L FKT 65K0.2L FKT 65K0.5L

Readability (d) 0.2 g 1 g 0.2 g 0.5 g

Weighing r ange (max) 36 000 g 60 000 g 65 000 g 65 000 g

36 000 g 60 000 g 65 000 g 65 000 g

Reproducibility 0.2 g 1 g 0.4 g 0.5 g

Linearity ±0.6 g ±2 g ± 1.0 g ± 1.5 g

Smallest piece weight 0.2 g 1 g 0.2 g 0.5 g

Adjustment points 10/20/30/36 kg 20/50/60 kg 20/ 30/50/60 kg 20/30/50/60 kg

Recommended

adjusting weight F1

(not supplied)

20 kg + 10 kg 50 kg 50 kg 50 kg

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

Warm-up time 2 h 2 h 4 h 2 h

Vibration filter yes

Units see menu

Weight kg (net) 6,5

Data interface yes (RS232)

+10 °C … + 40 °C

350 x 390 x 120

340 x 240

FKT_IKT_PKT-BA-e-1435 8

80

16

99

yes

Page 9

Taring range

(subtractive)

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 7

components

Battery operation with

6 x 1,5 V, Size C

KERN FKT 6K1LM FKT 12K2LM FKT 30K5LM

Accuracy class III III III III

Readability (d) 1 g 2 g 5 g 10 g

Verification value (e) 1 g 2 g 5 g 10 g

Weighing r ange (max) 6 000 g 12 000 g 30 000 g 60 000 g

Minimum load (Min) 20 g 40 g 100 g 200 g

6 000 g 12 000 g 30 000 g 60 000 g

Reproducibility 0.5 g 1 g 2. 5 g 5 g

Linearity ±0.5 g ±1 g ± 2.5 g ± 5 g

Smallest piece weight 1 g 2 g 5 g 10 g

Adjustment points 2/5/6 kg 2/5/10/12 kg 10/20/30 k g 20/50/60 kg

Recommended

adjusting weight M1

(not supplied)

5 kg 10 kg 20 + 10 kg 50 kg

FKT 60K10LM

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

Warm-up time 2 h 2 h 2 h 2 h

270 x 345 x 106 350 x 390 x 120

Vibration filter yes

253 x 228 340 x 240

Units see menu

Weight kg (net) 3.3 6.5

Data interface yes (RS232)

+10 °C … + 40 °C

40

9 FKT_IKT_PKT-BA-e-1435

1

5

yes

Page 10

Taring range

(subtractive)

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

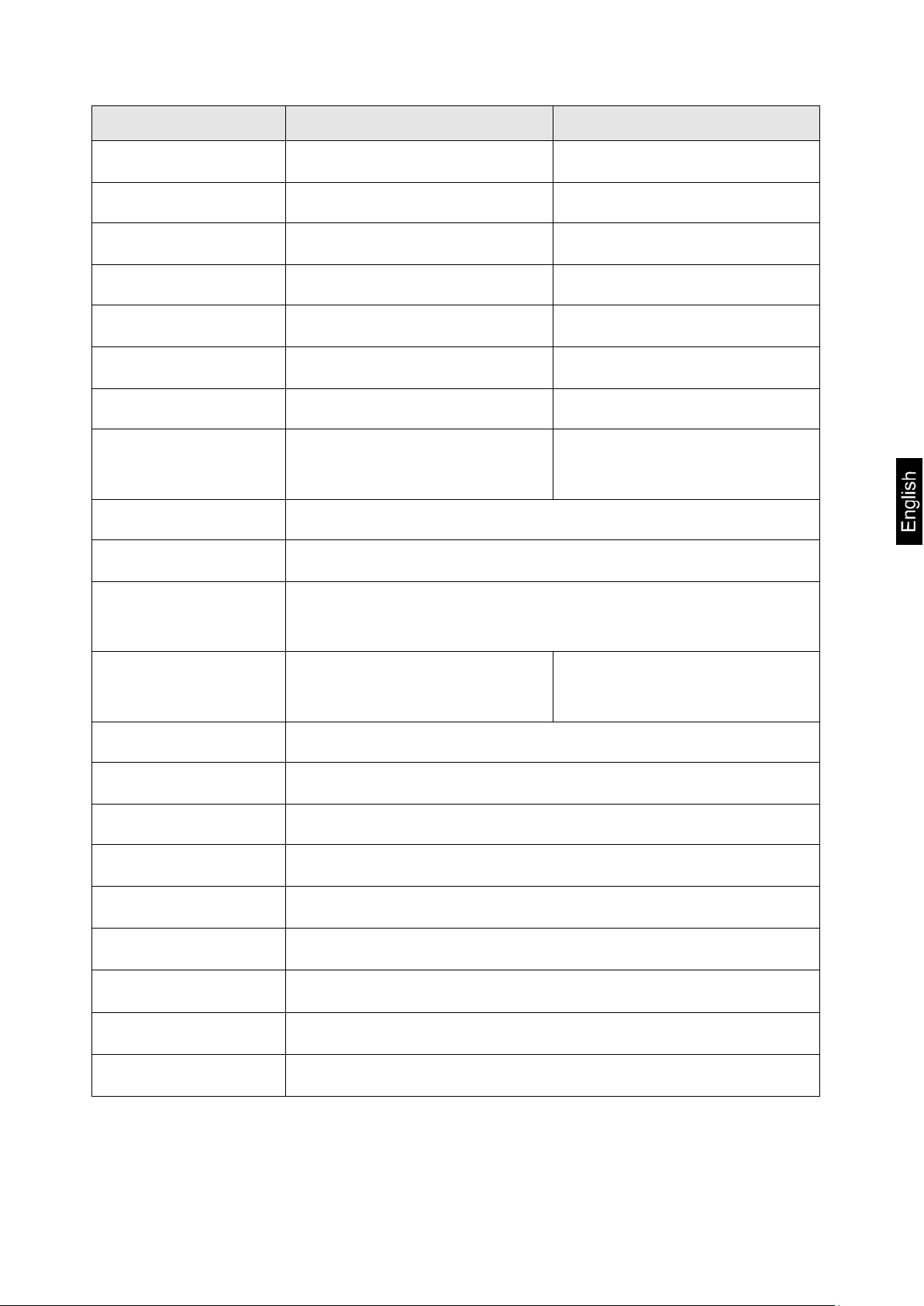

Models IKT:

KERN IKT 3K0.01S IKT 10K0.1S IKT 6K0.1 IKT 8K0.05

Readability (d) 0.01 g 0.1 g 0.1 g 0.05 g

Weighing r ange (max) 3 000 g 10 000 g 6 000 g 8 000 g

3 000 g 10 000 g 6 000 g 8 000 g

Reproducibility 0.02 g 0.1 g 0.1 g 0.05 g

Linearity ±0.05 g ±0.3 g ±0.3 g ±0.15 g

Smallest piece weight 0.01 g 0.1 g 0.1 g 0.05 g

Adjustment points 1/2/3 kg 2/5/10 kg 2/ 5/ 10 kg 2/4/5/7/8 kg

Recommended

adjusting weight F1

(not supplied)

3 kg 10 kg 6 kg 5 k g + 2 kg

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

Warm-up time 4 h 2 h 2 h 2 h

228 x 228 x 70 315 x 305 x 70

Vibration filter yes

228 x 228 315 x 305

Units see m enu

Weight kg (net) 5.5 7.5

Data interface yes (RS232)

+10 °C … + 40 °C

FKT_IKT_PKT-BA-e-1435 10

80

16

99

Page 11

Taring range

(subtractive)

5/10/15/16

kg

10/15/20/30

kg

10/15/20/30

kg

10/15/20/30/

36 kg

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

KERN IKT 12K0.2 IKT 16K0.1 IKT 30K0.1 IKT 30K0.5 IKT 36K0.2

Readability (d) 0.2 g 0.1 g 0.1 g 0.5 g 0.2 g

Weighing range (max) 12 000 g 16 000 g 30 000 g 30 000 g 36 000 g

12 000 g 16 000 g 30 000 g 30 000 g 36 000 g

Reproducibility 0.2 g 0.1 g 0.2 g 0.5 g 0.2 g

Linearity ±0.6 g ±0.3 g ±0.5 g ±1.0 g ±0.6 g

Smallest piece weight 0.2 g 0.1 g 0.1 g 0.5 g 0.2 g

Adjustment points 5/10/12 kg

Recommended

adjusting weight F1

(not supplied)

10 kg 10 kg + 5 kg 20kg + 10kg 20kg + 10kg

20kg + 10kg

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

Warm-up time 2 h 2 h 4 h 2 h 2 h

Vibration filter yes

Units see menu

Weight kg (net) 7,5

Data interface yes (RS232)

+10 °C … + 40 °C

315 x 305 x 70

315 x 305

11 FKT_IKT_PKT-BA-e-1435

80

16

99

Page 12

(subtractive)

kg

mm

stainless steel mm

KERN IKT 30K0.1L IKT 36K0.2L IKT 60K0.2L IKT 60K1L

Readability (d) 0.1 g 0.2 g 0. 2 g 1 g

Weighing r ange (max) 30 000 g 36 000 g 60 000 g 60 000 g

Taring range

Reproducibility 0.2 g 0.2 g 0.4 g 1 g

Linearity ±0.5 g ±0.6 g ±1.0 g ±2.0 g

Smallest piece weight 0.1 g 0.2 g 0.2 g 1 g

Adjustment points 10/ 15/20/30 kg

Recommended

adjusting weight F1

(not supplied)

Humidity of air max. 80% rel. (non-condensing)

Stabilization time

(typical)

Allowable ambient

temperature

30 000 g 36 000 g 60 000 g 60 000 g

10/15/20/30/36

20 kg + 10 kg 20 kg + 10 kg 50 k g 50 kg

+10 °C … + 40 °C

20/30/50/60 kg 20/30/50/60 kg

3 sec.

Warm-up time 4 h 2 h 4 h 2 h

Housing (B x D x H)

Vibration filter yes

Weighing plat e

Units see menu

Weight kg (net) 9.5

Data interface yes (RS232)

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

450 x 350 x 115

450 x 350

80

16

99

FKT_IKT_PKT-BA-e-1435 12

Page 13

(subtractive)

mm

stainless steel mm

KERN IKT 65K0.5L IKT 100K0.5L IKT 120K2L IKT 150K1L

Readability (d) 0.5 g 0.5 g 2 g 1 g

Weighing r ange (max) 65 000 g 100 000 g 120 000 g 150 000 g

Taring range

Reproducibility 0.5 g 0.5 g 2 g 1 g

Linearity ±1,5 g ±1,5 g ±4 g ±3 g

Smallest piece weight 0.5 g 0.5 g 2 g 1 g

Adjustment points 20/ 30/50/60 kg 20/50/100 kg 20/30/50/60 kg 50/100/150 kg

Recommended

adjusting weight F1

(not supplied)

Humidity of air max. 80% rel. (non-condensing)

Stabilization time

(typical)

Allowable ambient

temperature

65 000 g 100 000 g 120 000 g 150 000 g

50 kg 50 kg + 50 kg 50 kg 3 x 50 kg

3 sec.

+10 °C … + 40 °C

Warm-up time 2 h 2 h 2 h 2 h

Housing (B x D x H)

Vibration filter yes

Weighing plat e

Units see menu

Weight kg (net) 9.5

Data interface yes (RS232)

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

450 x 350 x 115

450 x 350

80

16

99

13 FKT_IKT_PKT-BA-e-1435

Page 14

Taring range

(subtractive)

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

KERN IKT 150K2XL IKT 300K5XL

Readability (d) 2 g 5 g

Weighing r ange (max) 150 000 g 300 000 g

150 000 g 300 000 g

Reproducibility 2 g 5 g

Linearity ±4 g ±10 g

Smallest piece weight 2 g 10 g

Adjustment points 20/50/ 100 kg 20/30/50/60 kg

Recommended

adjusting weight F1

(not supplied)

3 x 50 kg 3 x 100 kg

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

Warm-up time 2 h 2 h

Vibration filter yes

Units see menu

Weight kg (net) 20

Data interface yes (RS232)

+10 °C … + 40 °C

650 x 500 x 142

650 x 500

FKT_IKT_PKT-BA-e-1435 14

80

16

99

Page 15

IKT

60K10LM

IKT

120K20LM

Taring range

(subtractive)

20/50/100/

120 kg

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 7

components

KERN IKT 6K1M IKT 12K2M IKT 30K5M

Accuracy class III III III III III

Readability (d) 1 g 2 g 5 g 10 g 20 g

Verification value (e) 1 g 2 g 5 g 10 g 20 g

Weighing r ange (max) 6 000 g 12 000 g 30 000 g 60 000 g 120 000 g

Minimum load (Min) 20 g 40 g 100 g 200 g 400 g

6 000 g 12 000 g 30 000 g 60 000 g 120 000 g

Reproducibility 0.5 g 1 g 2.5 g 5 g 10 g

Linearity ±0.5 g ±1 g ± 2.5 g ± 5 g ± 10 g

Smallest piece weight 1 g 2 g 5 g 10 g 20 g

Adjustment points 2/5/6 kg 2/5/10/12 kg 10/20/30 kg 20/50/60 kg

Recommended

adjusting weight M1

(not supplied)

Humidity of air max. 80% rel. (non-condensing)

Allowable ambient

temperature

Warm-up time 2 h 2 h 2 h 2 h 2 h

Vibration filter yes

Units see menu

Weight kg (net) 7.5 9.5

10 kg 10 kg 20 + 10 kg 50 kg 50kg+50kg

3 sec.

+10 °C … + 40 °C

315 x 305 x 70 450 x 350 x 115

315 x 305 450 x 350

Data interface yes (RS232)

15 FKT_IKT_PKT-BA-e-1435

40

1

5

Page 16

Taring range

(subtractive)

50/100/200/300

g

100/200/300/

400 g

1.0/1.5/2.0/3.0

g

1.0/2.0/3.0/4.0

g

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plate

stainless steel mm

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

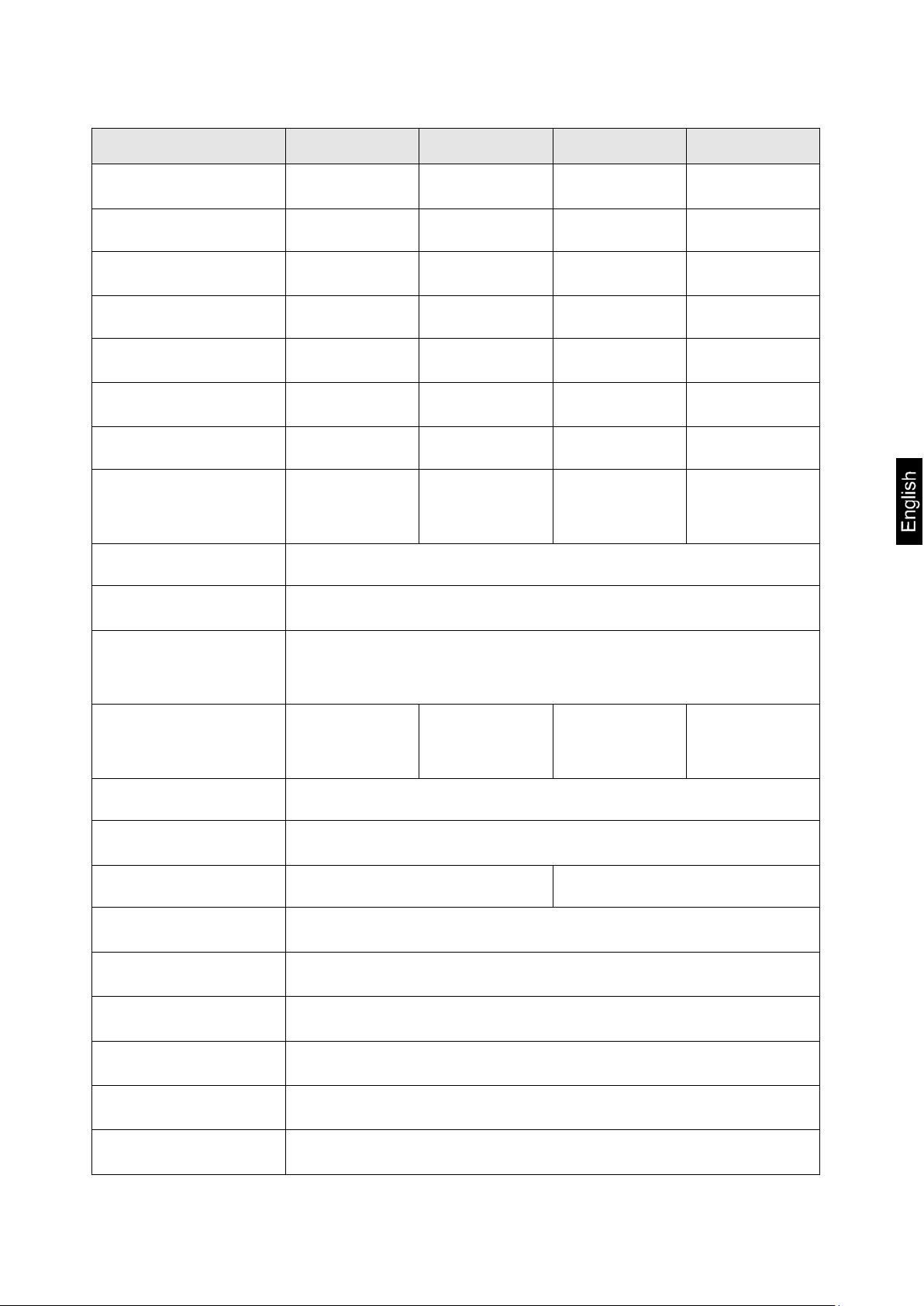

Models PKT:

KERN PKT 300-3 PKT 420-3 PKT 3000-2 PKT4200-2

Readability (d) 0.001 g 0.001 g 0. 01 g 0.01 g

Weighing r ange (max) 300 g 420 g 3 000 g 4 200 g

300 g 420 g 3 000 g 4 200 g

Reproducibility 0.002 g 0.002 g 0. 02 g 0.02 g

Linearity ±0.005 g ±0.005 g ±0.05 g ±0.05 g

Smallest piece weight 0.001 g 0.001 g 0. 01 g 0.01 g

Adjustment points

Recommended

adjusting weight F1

(not supplied)

200 g + 100 g 200 g + 200 g 2 kg + 1 kg 2 kg + 2 kg

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

Warm-up time 4 h 4 h 4 h 4 h

Vibration filter yes

Ø 106 Ø 150

Units see menu

Weight kg (net) 2.3

+10 °C … + 40 °C

180 x 310 x 90

Data interface yes (RS232)

Master data storage for

FKT_IKT_PKT-BA-e-1435 16

80

16

99

Page 17

Taring range

(subtractive)

Stabilization time

(typical)

Housing (B x D x H)

mm

Weighing plat e

stainless steel mm

Master data storage for

all operating modes

Print forms with up to

20 informations

Recipes with up to 10

components

KERN PKT 12K0.05 PKT 16K0.1 PKT 24K0.1

Readability (d) 0.05 g 0.1 g 0.1 g

Weighing r ange (max) 12 000 g 16 000 g 24 000 g

12 000 g 16 000 g 24 000 g

Reproducibility 0.05 g 0.1 g 0.1 g

Linearity ±0.15 g ±0.3 g ±0.3 g

Smallest piece weight 0.05 g 0.1 g 0.1 g

Adjustment points 2/5/10/12 kg 5/10/15/16 kg 5/10/15/20/24 kg

Recommended

adjusting weight F1

(not supplied)

10 kg 10 kg + 5 kg 20 kg

Humidity of air max. 80% rel. (non-condensing)

3 sec.

Allowable ambient

temperature

Warm-up time 2 h 2 h 2 h

Vibration filter yes

Units see menu

Weight kg (net) 2.7

Data interface yes (RS232)

+10 °C … + 40 °C

180 x 310 x 90

160 x 200

17 FKT_IKT_PKT-BA-e-1435

80

16

99

Page 18

2 Basic Information (General)

It is absolutely necessary that you read and understand the operating instructions prior to

installation and commissioning and follow the instructions during the process!

2.1 Proper use

The balance you purchased is intended to determine the weighing value of material to be

weighed. It is intended to be used as a “non-automatic“ balance, i.e. the material to be

weighed is manually and carefully placed in the centre of the weighing plate. As soon as a

stable weighing value is reached the weighing value can be read.

2.2 Improper Use

Do not use balance for dynamic weighing. In the event that small quantities are removed or

added to the material to be weighed, incorrect weighing results can be displayed due to the

“stability compensation“ in the balance (Example: Slowly draining fluids from a container on

the balance.).

Do not leave permanent load on the weighing plate. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the balance, minus

a possibly existing tare load, must be strictly avoided. Balance may be damage by this.

Never operate balance in explosive environment. The serial version is not explosion

protected.

The structure of the balance may not be modified. This may lead to incorrect weighing

results, safety-related faults and destruction of the balance.

The balance may only be used according to the described conditions. Other areas of use

must be released by KERN in writing.

2.3 Warranty

Warranty claims shall be voided in case

- Our conditions in the operation manual are ignored

- The appliance is used outside the described uses

- The appliance is modified or opened

- mechanical damage and damage caused by media, liquids

- natural wear and tear

- The appliance is improperly set up or incorrectly electrically connected

- The measuring system is overloaded

2.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the balance and,

if applicable, the testing weight, must be checked regularly. The responsible user must

define a suitable interval as well as type and scope of this test. Information is available on

KERN’s home page (www.kern-sohn.com) with regard to the monitoring of balance test

substances and the test weights required for this. Our accredited DKD calibration laboratory

offers fast and inexpensive adjustment for test weights and weighing balances (reset to

national normal weight).

FKT_IKT_PKT-BA-e-1435 18

Page 19

3 Basic Safety Precautions

3.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN

balances.

Versions in other languages are non-binding translations.

The only binding version is the original document in German.

3.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

4 Transportation & Storage

4.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the appliance

itself when unpacking for possible visible damage.

In case of visible damage have the damage verified by the messenger’s signature. Do not

alter goods or packaging and do not remove any parts of the delivery. Report the damage

immediately (within 24 hours) in writing to the parcel service.

4.2 Packaging / return transport

Keep all parts of the original packaging for a possibly required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the weighing platform,

power unit etc. against shifting and damage.

19 FKT_IKT_PKT-BA-e-1435

Page 20

5 Unpacking, Setup and Commissioning

5.1 Installation Site, Location of Use

The balances are designed in a way that reliable weighing results are achieved in common

conditions of use.

You will work accurately and fast, if you select the right location for your balance.

Therefore, observe the following for the installation site:

- Place the balance on a firm, level surface;

- Avoid extreme heat as well as temperature fluctuation caused by installing next to a

radiator or in the direct sunlight;

- Protect the balance against direct draughts due to open windows and doors;

- Avoid jarring during weighing;

- Protect the balance against high humidity, vapors and dust;

- Do not expose the device to extreme dampness for longer periods of time. Non-

permitted condensation (condensation of air humidity on the appliance) may occur if

a cold appliance is taken to a considerably warmer environment. In this case,

acclimatize the disconnected appliance for ca. 2 hours at room temperature.

- Avoid static charging of the material to be weighed, weighing container and

windshield.

If electro-magnetic fields or static charge occur, or if the power supply is unstable major

deviations on the display (incorrect weighing results) are possible. In that case, the location

must be changed.

5.2 Unpacking

Carefully remove the balance from the packaging, remove plastic cover and setup balance

at the intended workstation.

5.2.1 Placing

Level balance with foot screws until the air bubble of the water

balance is in the prescribed circle.

5.3 Mains connection

Power is supplied via the external mains adapter. The stated voltage value must be the

same as the local voltage.

Only use original KERN mains adapters. Using other makes requires consent by KERN.

FKT_IKT_PKT-BA-e-1435 20

Page 21

5.4 Batterie operation

5.5 Connection of peripheral devices

Before connecting or disconnecting of additional devices (printer, PC) to the data interface,

always disconnect the balance from the power supply. With your balance, only use

accessories and peripheral devices by KERN, as they are ideally tuned to your balance.

5.6 Initial Commissioning

A warming up time of 2 hours after switching on stabilizes the measuring values.

The accuracy of the balance depends on the local acceleration of gravity.

Strictly observe hints in chapter “Adjustment”.

5.7 Adjustment

As the acceleration value due to gravity is not the same at every location on earth, each

balance must be coordinated - in compliance with the underlying physical weighing principle

- to the existing acceleration due to gravity at its place of location (only if the balance has

not already been adjusted to the location in the factory). This adjustment process must be

carried out during the initial start-up, after change in location and variation of surrounding

temperature. To receive accurate measuring values it is also recommended to adjust the

balance periodically in weighing operation.

21 FKT_IKT_PKT-BA-e-1435

Page 22

5.8 Adjustment

With an adjustment weight, the weighing accuracy can be checked and re-adjusted at any

time.

Attention: In the verified balances the adjustment is not possible.

Procedure when a djusting:

Observe stable environmental conditions. A short warming up time of ca. 15 minutes is

recommended for stabilization.

5.9 Verification

General introduction:

According to EU directive 90/384/EEC balances must be verified if they are used as follows

(legally controlled area):

a) For commercial transactions if the price of goods is determined by weighing.

b) For the production of medicines in pharmacies as well as for analyses in the medical

and pharmaceutical laboratory.

c) For official purposes

d) For manufacturing final packages

In cases of doubt, please contact your local trade in standard.

Verification instructions

An EU type approval exists for balances described in their technical data as verifiable. If a

balance is used where obligation to verify exists as described above, it must verified and reverified in regular intervals.

Re-verification of a balance is carried out according to the respective national regulations.

The validity for verification of balances in Germany is e.g. 2 years.

The legal regulation of the country where the balance is used must be observed!

FKT_IKT_PKT-BA-e-1435 22

Page 23

6 Operation

6.1 How to turn on/off balance

To turn on touch the screen surface

Turn off by touching the OFF surface command

All fields with rounded corners are touch fields.

23 FKT_IKT_PKT-BA-e-1435

Page 24

FKT_IKT_PKT-BA-e-1435 24

Page 25

25 FKT_IKT_PKT-BA-e-1435

Page 26

Display

Designation

1

2

Time

3

4

Operation modus

5

6

Range display

7

Unity of displayed value

8

Tare and zero set button

9

Print button

10

Menu button

11

„Switch-off“ button

12

13

Zeroing display

14

15

6.2 Screen Operating mode We i ghing

Date

Battery or mains operation

Tare value

Weighing stoppage

Gross value

Info line for operator, article, etc.

FKT_IKT_PKT-BA-e-1435 26

Page 27

Display

Designation

1

2

Time

3

4

Operation modus

5

Net value

6

Range display

7

Unity of displayed value

8

Tare and zero set button

9

Print button

10

Selection button REF quantity

11

Confirmation button for REF formation

12

13

„Switch-off“ button

14

15

16

Piece weight

17

18

Ref quantity

6.3 Screen operating mode Counting

Date

Battery or mains operation

Menu button (memory locations)

Weighing stoppage

Zeroing display

Info line for operator, article, etc.

27 FKT_IKT_PKT-BA-e-1435

Page 28

FKT_IKT_PKT-BA-e-1435 28

Page 29

Display

Designation

1

2

Time

3

4

Operation modus

5

Sum value

6

Range display

7

Unity of displayed value

8

Tare and zero set button

9

Print button

10

Delete key

11

Addition button

12

13

„Switch-off“ button

14

15

16

Number of positions

17

6.4 Screen Operating mode Totalizing

Date

Battery or mains operation

Menu button (memory locations)

Weighing stoppage

Zeroing display

Info line for operator, article, etc.

29 FKT_IKT_PKT-BA-e-1435

Page 30

FKT_IKT_PKT-BA-e-1435 30

Page 31

Display

Designation

1

2

Time

3

4

Operation modus

5

6

Range display for target weight

7

Unity of displayed value

8

Tare and zero set button

9

Print button

10

Tolerance default

11

Target weight input

12

13

„Switch-off“ button

14

15

16

17

18

Target weight default

6.5 Screen Operating mode Dispensing

Date

Battery or mains operation

Tare value

Menu button (memory locations)

Weighing stoppage

Zeroing display

Gross value

Info line for operator, article, etc.

31 FKT_IKT_PKT-BA-e-1435

Page 32

FKT_IKT_PKT-BA-e-1435 32

Page 33

Display

Designation

1

2

Time

3

4

Operation modus

5

6

Range display

7

Input / evaluation field plus-tolerance

8

Tare and zero set button

9

Print button

10

Input / evaluation field Setpoint value default

11

Input / evaluation field Minus-tolerance

12

13

„Switch-off“ button

14

15

16

17

6.6 Screen Operating mode Check weighing

Date

Battery or mains operation

Tare value

Menu button (memory locations)

Weighing stoppage

Zeroing display

Gross value

Info line for operator, article, etc.

33 FKT_IKT_PKT-BA-e-1435

Page 34

FKT_IKT_PKT-BA-e-1435 34

Page 35

Display

Designation

1

2

Time

3

4

Operation modus

5

Net value

6

Range display

7

Unity of displayed value

8

Tare and zero set button

9

Print button

10

Input of REF weight

11

Confirmation of nominal weight

12

Menu button (memory locations)

13

„Switch-off“ button

14

15

16

REF weight

17

18

Difference percentage

6.7 Screen Operating mode Percentage

Date

Battery or mains operation

Weighing stoppage

Zeroing display

Info line for operator, article, etc.

35 FKT_IKT_PKT-BA-e-1435

Page 36

FKT_IKT_PKT-BA-e-1435 36

Page 37

Display

Designation

1

2

Time

3

4

Operation modus

5

6

Measuring period

7

Unity of displayed value

8

Tare and zero set button

9

Print button / deleting the mean value

10

Start measurement

11

Mean value for animal weighing

12

13

„Switch-off“ button

14

15

16

17

18

Net value

6.8 Screen Operating mode Animal wei ghing

Date

Battery or mains operation

Tare value

Menu button (memory locations)

Weighing stoppage

Zeroing display

Gross value

Info line for operator, article, etc.

37 FKT_IKT_PKT-BA-e-1435

Page 38

FKT_IKT_PKT-BA-e-1435 38

Page 39

Display

Designation

1

2

Time

3

4

Operation modus

5

6

Range display

7

Unity of displayed value

8

Tare and zero set button

9

Print button

10

Confirmation of component / Transfer of new target weight

11

Selection of formula

12

13

„Switch-off“ button

14

15

16

17

18

Target weight default

6.9 Screen Operating mode Formula tion

Date

Battery or mains operation

Tare value

Menu button (memory locations)

Weighing stoppage

Zeroing display

Gross value

Info line for operator, article, etc.

39 FKT_IKT_PKT-BA-e-1435

Page 40

FKT_IKT_PKT-BA-e-1435 40

Page 41

Display

Designation

1

2

Time

3

4

Operation modus

5

6

Range display

7

Unity of displayed value

8

Tare and zero set button

9

Print button

10

Input of variable factor

11

Selection of paper format

12

13

„Switch-off“ button

14

15

16

17

6.10 Screen Operating mode Surface weight

Date

Battery or mains operation

Tare value

Menu button (memory locations)

Weighing stoppage

Zeroing display

Gross value

Info line for operator, article, etc.

41 FKT_IKT_PKT-BA-e-1435

Page 42

FKT_IKT_PKT-BA-e-1435 42

Page 43

Display

Designation

1

2

Time

3

4

Operation modus

5

Test equipment / water temperature

6

Net value

7

Range display

8

Unity of displayed value

9

Tare and zero set button

10

Print button for printout and delete the density value

11

Button for reference confirmation

12

13

„Switch-off“ button

14

15

16

17

6.11 Screen Operating mode Density

Date

Battery or mains operation

Menu button (memory locations)

Weighing stoppage

Zeroing display

Gross value

Info line for operator, article, etc.

43 FKT_IKT_PKT-BA-e-1435

Page 44

FKT_IKT_PKT-BA-e-1435 44

Page 45

6.12 Forms

45 FKT_IKT_PKT-BA-e-1435

Page 46

7 Print form

7.1 Contents of the form impression

FKT_IKT_PKT-BA-e-1435 46

Page 47

7.2 Arrangement of form printout

x = space character

• The fields „line“ and „column“ are position printing input fields

• Field „Variable“ is a selection field of fixed printing possibilities

• Field „Fix text“ offers the possibility to specify texts for printout.

• The field „designation“ is a text input field to add information such as gross, tare, net,

pcs to the values.

• Field „Activated: on“ takes over this line into the print form.

47 FKT_IKT_PKT-BA-e-1435

Page 48

8 Interfaces

8.1 Digital I/O output - open collectors (only model FKT/IKT)

Out 1 PIN

1 Diode connecting plug 5 pol.

Typ Masei 5100 S version D

2

Out 2 5 4

2

3 1

Out 3 3

Performance data: Vcemax = 35 V DC

+ 12V Icmax = 80 mA DC

4

5

0,0g Limit 1 Limit 2 Limit 3 n kg

Out 1 Out 2 Out 3

FKT_IKT_PKT-BA-e-1435 48

Page 49

5 1

9 6

8.2 Data output RS 232 C Technical data:

8-bit ASCII Code

1 start bit, 8 data bits, 1 stop bit, no parity bit

Baud rate selectable from 2400, 4800, 9600 Baud (factory setting) and 19200 Baud.

Sub-D plug 9-channel required

For operation with interface faultless operation is only ensured with the correct KERN –

interface cable (max. 2m)

Pin allocation of the balance output socket (front view)

Sub-D jack 9-channel

Pin 2: Transmit data

Pin 3: Receive data

Pin 5: Signal ground

8.3 Interface RS 232C Data output via interface RS 232C

General

The previous condition for the data transfer between balance and a peripheral device (e.g.

printer, PC ...) is that the appliances are set to the same interface parameters (e.g. baud

rate, parity ...).

49 FKT_IKT_PKT-BA-e-1435

Page 50

Bit.Nr.

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

17

18

19

20 N N N N N B B B B B B B B B B B 0 • 0 0

Bit.Nr.

21

22

23

24

25

26 E E E E CR

LF

8.3.1 There are 4 kinds of data output via RS 232C Data output using the PRINT key

The printing process can be triggered by pressing the PRINT key.

The settings AUTOPRINT and AUTOPRINT should be disabled for this process.

AUTOPRINT (data output according to weight application)

The setting AUTOPRINT is located on the PRINTER path where you can turn it on or off.

When AUTOPRINT is active, the current weighing value will be sent via the RS 232 date

interface after unloading and subsequent loading of the balance as soon as the balance is

in resting position.

Permanent PRINT (continuous data output)

The setting permanent Print is located on the PRINTER path and where you can turn it on

or off. When permanent Print is active, the current weighing values will be sent continuously

via the RS 232 data interface.

Data output and remote control commands

Remote control commands transferred as ASCII characters to the balance can be used to

trigger the following functions on the balance (always finish with CR, LF!):

t Taring

w The balance sends a weighing value (also unstable) via the serial interface.

s The balance sends a stable weighing value via the serial interface.

After receiving either character w or s, the balance will send without a printer pause

between the characters.

8.3.2 Explanation of the data transfer

Each data transfer is structured as follows:

N = Numerator

B*: = Blank or for autotare on in zero range.

B, 0, ., g: = Blank or weighing value giving unit according to loading of the balance

E = Unit

CR: = Carriage Return

LF: = Line Feed

FKT_IKT_PKT-BA-e-1435 50

Page 51

Always ensure that all suspended objects are stable enough to hold the

damaged underneath the load.

After completing the underfloor weighing the opening on the bottom of the

balance must always be closed (dust protection).

8.4 Printer

The serial interface RS 232 facilitates the connection of a printer. The printout shows the

weight in grams. In counting mode either the piece number or the weight details will be

printed out.

In percentage mode the percentage proportion or the weight details will be printed out.

Printout will take place after pressing the PRINT key.

It is possible to number each printout continuously with the help of the numerator.

The numerator will be reset to (000) each time the balance is turned off or the CLEAR

function is actuated.

8.5 Underfloor weighing

Objects which are unsuitable for placement on the weighing tray due to their size or shape

can be weighed with the help of the underfloor weighing facility.

Proceed as follows:

• Switch off balance.

• Turn over the balance and in doing so take care that the weighing plate is not loaded.

• Open the closing lid on the bottom of your balance.

• Mount the hooks for underfloor weighing.

• Put the balance over an opening

• Suspend the goods to be weighed from the hook and carry out the weighing.

▬

desired goods to be weighed safely (danger of breaking).

▬ Never suspend loads that exceed the stated maximum load (max)

CAUTION

(danger of breaking)

▬ Always ensure that there are no persons, animals or objects that might be

51 FKT_IKT_PKT-BA-e-1435

Page 52

The displayed weight does not glow.

• The balance is not switched on.

(mains cable not plugged in/fault y).

• Power supply interrupted.

The displayed weight is permanently

changing

• Table/floor vibrations

possible)

The weighing value is obviously

• The display of the balance is not at zero

wrong

• Adjustment is no longer correct.

possible)

9 Service, maintenance, disposal

9.1 Cleaning

Before cleaning, please disconnect the appliance from the operating voltage.

Please do not use aggressive cleaning agents (solvents or similar agents), but a cloth

dampened with mild soap suds. Ensure that no liquid penetrates into the device and wipe

with a dry soft cloth. Loose residue sample/powder can be removed carefully with a brush

or manual vacuum cleaner.

Spilled weighing goods m ust be removed immediately.

9.2 Service, maintenance

The appliance may only be opened by trained service technicians who are authorized by

KERN. Before opening, disconnect from power supply.

9.3 Disposal

Disposal of packaging and appliance must be carried out by operator according to valid

national or regional law of the location where the appliance is used.

10 Instant help

In case of an error in the program process, briefly turn off the balance and disconnect from

power supply. The weighing process must then be restarted from the beginning.

Help:

Fault Possible cause

•

The mains supply connection has been interrupted

• Draught/air movement

• Weighing plate has contact with other objects.

•

Electromagnetic fields / st at ic c har ging (choose

different location/switch off interfering device if

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

FKT_IKT_PKT-BA-e-1435 52

• Great fluctuations in temperature.

•

Electromagnetic fields / st at ic c har ging (choose

different location/switch off interfering device if

Page 53

KERN & Sohn GmbH

D-72322 Balingen-Frommern

E-Mail: info@kern-sohn.de

Tel: 0049-[0]7433- 9933-0

Internet: www.kern-sohn.de

D

Konformitätserklärung

Wir erk lären hiermit, dass das Produkt, auf das sich diese Erk lärung bezieht,

mit den nachstehenden Normen übereinstimmt.

GB

Declaration of

conformity

We hereby declare that the product to which this declaration refers conf orms

with the following standards.

CZ

Prohlášení o

shode

Tímto prohlašujem e, že výrobek, kterého se toto prohlášení týká, je v souladu

s níže uvedenými normami.

E

Declaración de

conformidad

Manifestamos en la presente que el producto al que se refiere esta

declaración está de acuerdo con las normas siguientes

F

Déclaration de

conformité

Nous déclarons avec cela responsabilité que le produit, auquel se rapport e la

présente déclaration, est conforme aux normes citées ci-après.

I

Dichiarazione di

conformitá

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si

riferisce è conforme alle norme di seguito citate.

NL

Conformiteitverklaring

Wij verklaren hiermede dat het product, waarop deze verklaring betrekking

heeft, met de hierna vermelde normen overeenstemt.

P

Declaração de

conformidade

Declaramos por meio da presente que o produto no qual se refere esta

declaração, corresponde às normas seguintes.

PL

Deklaracja

zgodności

Niniejszym oświadczamy, że produkt, którego niniejsze oświadczenie dotyczy,

jest zgodny z poniższymi normami.

RUS

Заявление о

соответствии

Мы заявляем, что продукт, к которому относится данная декларация,

соответствует перечисленным ниже нормам.

EU Directive

Standards

2004/10 EN 55024:

EN 55011: 2009/A1:2010

EN 45501 :1992-10+AC :1993-08

2006/95/EC

EN 60950

2011/65/EC

EN 50581:2012

Signature

Datum

25.09.2014

Ort der Ausstellung

Place of issue

72336 Balingen

Albert Sauter

KERN & Sohn GmbH

Geschäftsführer

Managing director

KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-[0]7433/9933-0

Fax +49-[0]7433/9933-149, E-Mail: info@kern-sohn.com, Internet: www.kern-sohn.com

11 Declar a t ion of conformity

Postfach 4052

Fax: 0049-[0]7433-9933-149

Declaration of conformity

EC-Konformitätserklärung EC-Declarati on of -Conformity

Déclaration de conformité EC-Declaración de Conformidad

ECEC-Dichiarazione di conformità EC-Conformiteitverklaring

EC- Declaração de conformidade EC- Prohlášení o shode

EC-Deklaracja zgodności EC-Заявление о соответствии

Electronic Balance: KERN FKT / IKT / PKT

2010

8/EC

Date

EN 55022: 2010/AC:2011

EN 55024: 2010

EN 61000-3-2 :2006-04 + A1 : 2009 + A2 : 2009

EN 61000-3-3 :2008

OIML R 76-1 :2006

Signatur

53 FKT_IKT_PKT-BA-e-1435

Loading...

Loading...