Page 1

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

MOBILE LEEB HARDNESS TESTER

Table of contents

Cautions

1. Summary

1.1 Measuring Principle Scope

1.2 Hardness Value „L“

1.3 Features

1.4 Applications

1.5 Primary Industries

2. Technical Specifications

3. Instrument’s views

4. Checking Supplied Accessories

5. Operation Instruction

5.1 Keys and their Functions

5.2 LCD Screeen

5.3 Settings

5.3.1 Material Type

5.3.2 Hardness Scale

5.3.3 Data in One Group

5.3.4 How to browse Data

5.3.5 Setting Date and Time

5.3.6 Calibration

5.4 The Format of Memory Data

5.5 Backlight

5.6 Automatic Shut-Off

5.7 Charging

6. Data Printing

7. Hardness Testing

7.1 Checking of Settings

7.2 Sample Preparation

8. Troubles and solutions

9. Maintenance and Service

9.1 Impact Device Maintenance

9.2 How to Store the Reports

9.3 Normal Maintenance Procedures

Appendix 1 Daily Checking

Appendix 2 Factors affecting the Accuracy

Appendix 3 Measuring Range

Applicable Standards

10. Declaration of Conformity

Cautions

Please carefully read this first

1. Any components of the instrument may not be

submerged into water or exposed to rain, which could

HN-D

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

cause a battery explosion ort he display might be

damaged.

2. If the instrument isn’t used for a longer period, it should

be stored in dry environment and in its original transport

case. The environmental temperature should be within the

range of -30°C up to +80°C and relative humidity from

(RH) 5% bis 95%.

1. Summary

1.1 Measuring Principle Scope

When the test is carried out, an impact body with a

tungsten carbide test tip is being impelled by spring force

against the surface to be tested, from which it rebounds.

Impact and rebound velocities are measured by the

following method: a permanent magnet integrated in the

impact body passes through a coil and induces an electric

voltage during its travel back and forth. These voltages are

proportional to the velocities and are processed and

displayed as the hardness value “L” at the instrument.

Modern electronics with power saving features provide a

long operating life.

Illustration

The big-sized LCD display always shows how the HN-D is

configured to test.

Variable function keys allow quick changes of common test

parameters. No subjective measuring errors are possible,

giving highly repeatable results. Internal self diagnostics

with error messages assure reliable test results.

Readings can be stored automatically in the internal

memory or being directly sent to a printer. PC evaluation

software enables a data analysis. These conversions to

other scales (HRC, HRB, HB, HV, HSD etc.) are

programmed into the electronics and can be shown directly

on the display as test result.

1.2 Hardness Value „L“

This term, 1978 introduced by Dr. Dietmar Leeb into

measuring technology, is the quotient fort he impact body’s

rebound and impact velocity, multiplied by 1000. Harder

materials produce higher rebound velocities than less

harder ones. With reference to a particular material group

HN-D-BA-e-1213 1

Page 2

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

( e.g. steel, aluminium etc.) the L-value represents a direct

hardness measurement and it is used as such.

Comparison curves with standard static hardness values

have been established (Brinell, Vickers, Rockwell C, B,

Shore D) for the most prevalent materials, enabling the Lvalue to be converted into the relevant values for these

procedures. With HN-D, such hardness values can be

directly displayed in the hardness scales HLD, HRC, HRB,

HB, HV, HSD.

1.3 Features

- HN-D ist he most advanced integrated tester (which

means that the impact device D is integrated): no cables

- Integrated impact direction sensor

- High accuracy (± 4 HL) in any impact direction (360°) –

automatically

- Integrated display of results for all common hardness

scales

- Large high-contrast LCD for an optimum viewing in all

conditions

-Easy calibration

- Full USB communication with PC, internal storage of data

with day and time

- Rechargeable Li-ion battery, charges through USB port

- Intelligent sleep mode

- Wireless (Bluetooth) to mini printer possible

1.4 Applications

- Convenient for all materials

- Best suited for on-site testing of heavy, big or already

installed parts

- Handy for difficult to accessor confined test locations

- Automatic sensing and compensation for impact direction

- Excellent for material selection and acceptance tests.

1.5 Primary Industries

- Metal production & processing

- Automotive & transportation

- Machinery & power plants

- Petro-chemical, refinery

- Aerospace & shipyard

- Metal constructions testing services & laboratories

- Metallproduktion und Entwicklung

2. Technical Specifications

- Indication range: 0 to 999 HLD

- Accuracy: ± 4HLD

- Measuring direction: any direction

- LCD display: 128 x 64 dot LCD with backlight

- Data memory: 500 groups

- Measurement results can be automatically converted into

HRC, HRB, HB, HV, HSD

- Impact energy: 11N

- Weight of the impact body: 5,5 g

- Impact tip: Diameter: 3mm

HN-D

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Material: tungsten carbide

Hardness: ≥ 1600 HV

- Power: Li-ion rechargeable battery

- Charger: DC 5V/500mA or USB port

- Maximum continuous working time: approx. 16 hours

- Operating environment: - Temperature: -10°C to +60°C

- Humidity: 5% bis 95%

- Dimensions: 147 x 35 x 22 mm

- Weight: 63 g

3. Instrument’s views

4. Checking Supplied Accessories

You’ll have to check in advance whether you obtained all

accessories in the delivery of the HN-D. Other

accessories, not included in delivery, can be disponible at

any time by SAUTER GmbH. All items should be only used

with the original , authorized instruments. The use of these

accessories with other instruments could cause problems

and any repair costs would not be covered by warranty.

Packing list:

- Robust carrying case

- HN-D Metal hardness tester

- USB Cable

- Charger for HN-D

- Small support ring

- Cleaning brush

- Instruction Manual (CD)

-

Note: The test block is not included in the delivery!

5. Operation Instruction

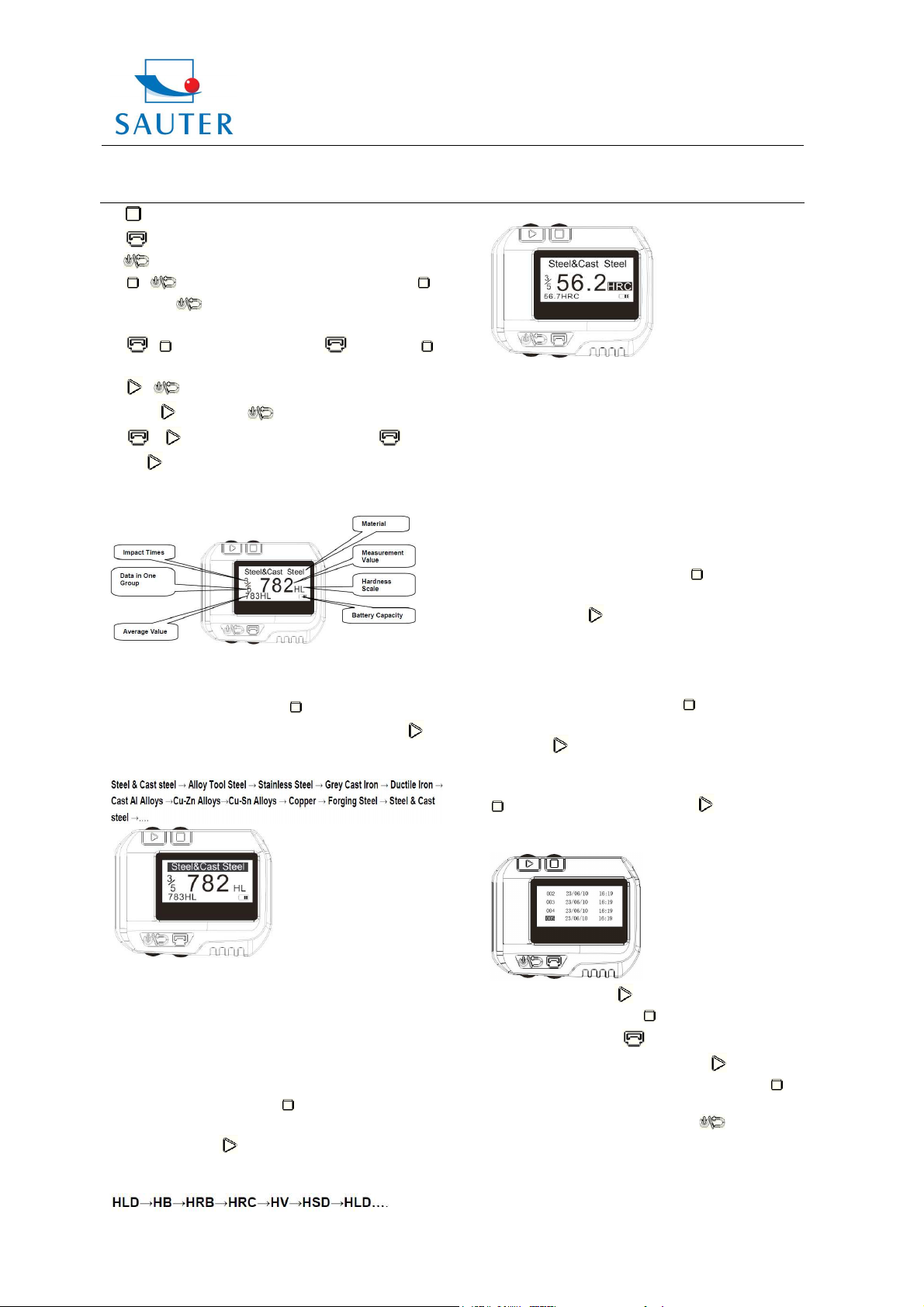

5.1 Keys and their Functions

1. “Next“, select material, scale etc. can be used

HN-D-BA-e-1213 2

Page 3

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

2. Menu & Select“

3.

“Print“

„ON / OFF & Back“

4.

5. + : „Hardness Calibration“: press and hold ,

then press

mode.

+ : „Delete“: Press and hold , then press

6.

to delete the current data.

7.

+ : „Set date and time“: in shut-off state, press

and hold

8. + : „Data browse“: Press and hold , then

press

5.2 LCD Display

5.3 Settings

5.3.1 Material Type

In measurement mode, press

material character will highlight, and then press to

select the material type. It changes according to the

following sequence:

for 2 seconds to display the calibration

, then press to set date and time.

to enter data browse.

three times and the

HN-D

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Illustration: highlighted Hardness Scale character

HLD= Leeb Hardness

HB= Brinell

HRB= Rockwell (B)

HRC= Rockwell (C)

HV= Vickers

HSD= Shore Hardness (D)

Note:

1. The value “---“ means „out of range“.

2. The default hardness scale is HLD.

5.3.3 Data in One Group

In measurement mode, the button

four times, the „Data in One Group“ character will be

highlighted; then

The maximum number is 9.

5.3.4 Browse Data

1. To browse the data in the current group: in

measurement mode, the button

once, the “impact time” character will be highlighted. Then

the button

current group.

2. Browse the historical data: in measurement mode,

has to be pressed and held. Then has to be pressed

to display the historical data browse mode.

has to be pressed to set the number.

has to be pressed to browse the data in the

has to be pressed

has to be pressed

Note: 1. It is necessary to select this classification. If

the material type is not known, it has to be referred to

the handbook.

2. When you change the material group, the impact

times counter will be set to “0” again.

5.3.2 Hardness Scale

In measuring mode, the button

then the hardness scale character will be highlighted. It

has to be pressed

hardness scale changes according to the following

sequence:

has to be pressed twice,

to select the hardness scale; The

By pressing the button , the next group can be selected

and by pressing the button

selected. If the button

can be browsed: By pressing the button

can be selected and by pressing the button

previous group can be selected. You can return to the

previous menu by pressing the button

Illustration: Browsing the data group:

, the previous group can be

is pressed, the selected data

, the next group

, the

.

HN-D-BA-e-1213 3

Page 4

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Instruction Manual

HN-D

5.3.5 Setting Date and Time

The HN-D has gota built-in real-time-clock. Clock and

calendar have to be adjusted if it is necessary. The

procedure is as follows:

In shut-off mode, the button

held, then has to be pressed for about 3 seconds to

enter the date and time setting mode.

Press

decrease the “day” from 31 to 1. Press

month. Then press

and press to decrease the month from 12 to 1. The

same way is used to set the year, hour, minute and

second. In the “second “ set-up process, the setting will be

finished by pressing the button

returns to the measuring mode.

5.3.6 Calibration

Calibration is used to calibrate the measured value (HLD)

of the hardness tester up to the minimum measuring error.

The procedure is as follows:

1. When the instrument is turned off, the button

be pressed and held; then

for about 3 seconds to display the calibration mode.

Now, 5 tests have to be performed on the test block to get

the average value of these values.

2. By pressing the button

be browsed and by pressing the button

values can be deleted.

3. If the button is pressed, it can be started to input the

value written on the test block: Primary, the „hundred“ bit

has to be set (see illustration below).

to increase the „day“ from 1 to 31, press to

has to be pressed and

to set the

to increase the month from 1 to 12

and the instrument

has to

has to be pressed and held

, the 5 measured values can

, the error

4. By pressing the button

9 to set the “hundred” bit.

5. By pressing the button

highlighted. By pressing the button

from 0 to 9 to set this bit.

6. By pressing the button

highlighted. By pressing the button

from 0 to 9 to set this bit.

7. If the button is pressed, the instrument returns to

the measurement mode and the calibration is finished.

Note: 1. Before the first use, the hardness tester has to

be calibrated on the test block.

2. The impact direction has to be set straight down.

5.4 The Format of Memory Data

The data (such as hardness value, scale , sample material

and impact direction, time, date etc.) will be saved in the

memory automatically after each individual impact. HN-D

can store 500 data. When the test times are more than

500, the last data will be stored in the 1

first dat will be erased, simultaneously the position of other

data will be automatically moved into the lower position.

5.5 Backlight

LED backlight is used for poor light conditions. If there is

no impact performed or any key operation has taken place

in 3 seconds, the backlight will be turned off automatically.

When testing continues or any key is pressed, the

backlight will be turned on again.

, it can be increased from 0 to

, the „ten“ bit will be

, it can be increased

, the “one” bit will be

, it can be increased

st

position and the

HN-D-BA-e-1213 4

Page 5

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

HN-D

5.6 Automatic Shut-Off

If there is no measurement performed and no key

operation takes place for 3 minutes, the display unit will

automatically switch off in order to saving battery power.

All the parameters will be automatically stored before

turning off.

5.7 Charging

Batteries have to be recharged when they are used for the

first time or an exhaustion of electricity arises. First the

HN-D has to be connected with the charger by using the

USB cable, then the charger has to be connected with the

AC socket to start charging.

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

A complete test report is shown below:

Meanwhile the screen will display the charging mode:

There can also be used other USB devices (e.g. Laptop) to

charge the HN-D. Charging time is 2 to 3 hours.

If charging is finished, the following is displayed on the

screen:

6. Data Printing

HN-D can be linked with the exclusive Bluetooth Mini

printer to print out the measured values. The maximum

distance between the hardness tester and the printer is

three meters. When the printer is turned on,

pressed to print out the current data.

Der HN-D kann mit dem optional erhältlichen Bluetooth

Minidrucker verbunden werden, um die Messdaten

auszudrucken. Der maximale Abstand zwischen HN-D und

dem Minidrucker beträgt drei Meter. Ist der Drucker

angeschaltet, so ist nur die Taste zu betätigen, um die

laufenden Messdaten auszudrucken.

Mini Printer SAUTER AHN-01,

has to be

www.sauter.eu

7. Hardness Testing

7.1 Checking of Settings

The button

instrument. First, it has to be checked if it has to be

charged. Then, it has to be inspected if every setting is

correctly, particularly material type and scale. If the setting

is inconsistent with the actual conditions, a great error

might be caused.

7.2 Sample Preparation

Inappropriate samples will cause great measurement

errors. Therefore, preparation and handling should be

performed on original conditions of the sample.

Preparation of the sample and the surface to test should

be coincident with the following basic requirements:

1) A thermal or cold processing of the impact sensors

during the process of sample preparation should be

avoided.

2) The surface of the sample should be plane, with a

metallic sheen, and not involve oxide layer or other stains.

3) Roughness of the test surface: Ra≤ 1.6

4) The sample has to be of sufficient quality and rigidity.

Otherwise displacements or shaking during the test might

happen. These could also lead to measurement errors.

A sample quality of ≥ 5 kg can be directly tested. If the

sample quality is 2~5 kg, it should be fixed before the test

by appropriate clamps. If the sample quality is 0.05~2 kg, it

should be coupled before the test; if it is < 0.05 kg, this

hardness tester is inappropriate to use.

Coupling method: The testing sample’s back should be

plane as well as the surface of the supporting object.

has to be pressed to turn on the

HN-D-BA-e-1213 5

Page 6

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

A little coupling substance (i.e. Industry Vaseline) has to

be filled between the two components. Then the two parts

have to be pressed together. If the weight of the supporting

object is more than 5 kg, it can be replaced by the test

block.

5) Samples should be thick enough with sufficient layered

surface. If the D-type of impact sensor is used, the

thickness of the sample should be less than 5 mm and the

surface absorption layer (surface- hardening layer) should

not be less than 0.8 mm. To perform accurate hardness

measurements, the best way is to remove this layer before

testing.

6) If the testing sample surface isn’t horizontal and flat, the

curvature radius of the testing and nearby surface should

be larger than 30 mm. An appropriate supporting ring has

to be selected and installed.

7) A sample should not be magnetic. The signal of the

impact sensor would be seriously affected, which might

cause inaccurate test results.

A long operating life is provided by modern electronics with

power saving features. The large LCD display always

shows how HN-D Impact Hardness Tester is configured to

the tests. Variable function screen allows a quick change

of common test parameters. On the screen hint line the

other active control keys are positioned. No subjective

measuring errors are possible, highly repeatable results

are given to the user. Reliable test results are assured by

internal self diagnostics with error messages.

Readings can be stored automatically in the internal

memory or can be directly sent to a printer. PC evaluation

software allows for data analysis.

Tests in more points can be carried out by repeating the

above steps 1 to 4.

8. Troubles and solutions

If there may occur any other failures or defects, please

don’t hesitate to contact SAUTER GmbH. We will care for

your problems with the HN-D as soon as possible.

9. Maintenance and Service

9.1 Impact Device Maintenance

After 1000- 2000 times use, the impact device and the

impact body should be cleaned with a nylon brush. The

screw of the supporting ring has to be turned off before the

catheter can be cleaned. Then the impact body has to be

taken out and it has to be rotated into the tube with the

nylon brush in anti-clockwise direction. The brush has to

be pulled out when touching the bottom. This procedure

HN-D

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

has to be repeated several times. Then the impact body

has to be loaded and the supporting ring reinstalled. The

impact body should be released after use. The use of any

lubricant is banned.

9.2 How to Store the Reports

Printing paper is thermal paper and it should be preserved

to avoid heat and direct light. If the print records are

necessary to be kept in long-term conservation, they

should be copied and preserved in time.

9.3 Normal Maintenance procedures

If the error is larger than 12HLD by calibrating the

hardness tester, the steel ball or the impact body has to be

renewed. Those parts may be worn out and this may lead

to failure in operation.

In case if any other abnormal phenomena occur to the

Hardness Tester, it should not be either demolished or any

fixed assembly parts may not be adjusted. Instead, just

contact our company, send your instrument to our address.

We will care for a prompt checking and if necessary, repair

of the device.

Appendix 1 Daily Checking

The test block (optional available) is mainly used to

calibrate the Hardness Tester. The error and repeatability

of it should be in the scope defined in following table:

Note:

HLD is the mean value of 5 Leeb Hardness values

measured on the test block.

HLD is the value marked on the test block.

is the maximum value of 5 Leeb Hardness values

measured on the test block.

ist he minimum value of 5 Leeb Hardness values

measured on the test block.

Appendix 2 Factors affecting the Accuracy

Incorrect operation or improper testing conditions can

seriously affect the accuracy. The following factors are the

main accounts in lack of accuracy:

1) Roughness of sample surface

When the impact body impacts on the sample, a small pit

will arise on the surface of it. The less roughness, the less

consumption of impact energy is needed. According to

this, the roughness of the surface should be Ra≤ 1.6.

HN-D-BA-e-1213 6

Page 7

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

2) The shape of the sample surface

Leeb testing principle demands that the velocity of rebound

and impact are on the same line, because the impact body

is moving in a metal tube. Of course, hardness can also be

shown if the velocity of rebound and impact are not on the

same line. In this case, the impact body would collide with

the tube wall when it rebounds, which will affect the

velocity of rebound. This will cause an error on test

accuracy. If the radius of curvature of the sample surface

is smaller, a suitable variant supporting circle has to be

used. We can contribute to design and release those

supporting circles, if needed.

3) The weight of the sample

If the weight of the sample is more than or equal to 5 kg,

testing can be directly started. If it is less than 5 kg, the

sample needs a special charge. The supporting piece has

to be coupled by a coupling medium and pressed onto the

surface of the test piece. By doing this, better test results

will be achieved.

The area of the testing points should be free of vibrations

or shaking. If the weight of the sample is not enough,

supporting, coupling and compressing must be increased

to avoid jitter and sloshing. Shocks should be avoided.

4) The sample stability

Any effective tests need to minimize possible interference

from outside. This is very important for dynamic

measurements, such as Leeb Hardness testing.

Therefore, measurements are only allowed in a stable

hardness testing system.

Appendix 3 Measuring Range

HN-D

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

10. Declaration of Conformity

DESIGNED IN REGARD TO THESE STANDARDS:

),

DIN 50156 (2007

(1998), JB/T 9378 (2001), JJG 747 (1999), DGZfP

Guideline MC 1 (2008), VDI/VDE Guideline 2616 Paper 1

(2002), ISO 18625 (2003), CNAL T0299 (2008), JIS B7731

(2000).

ASTM A956 (2006), GB/T 17394

HN-D-BA-e-1213 7

Loading...

Loading...