Page 1

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

DIGITAL LEEB HARDNESS TESTER

Model: HMR

Table of contents

1. Overview

1.1 HMR Advantages

1.2 Main Application & Testing Range

1.2.1 Main Application

1.2.2 Testing Range

1.3 Configuration

1.4 Working Conditions

2. Structure Feature & Testing Principle

2.1 Structure Feature

2.1.1 Hardness Tester Appearance

2.1.2 Parts of the Main body

2.1.3 D Type Impact Device

2.1.4 Different types of Impact Devices

2.2 Leeb Hardness Testing Principle

3. Technical Specifications

4. Preparation & Testing

4.1 Preparation and Inspection before Testing

4.1.1 Preparation of Sample Surface

4.1.2 System Setting

4.1.3 Presetting Testing conditions

4.2 Testing Program

4.2.1 Start-up

4.2.2 Testing

4.2.3 Reading the Measured Value

4.2.4 Power Off

5. Advice

6. Operation in Details

6.1 Power On

6.2 Power Off

6.3 Testing

6.3.1 Full description of the Main Display

6.3.2 Testing Operation at the Main Display

6.3.3 Key Operation at the Main Display

6.4 Menu Structure

6.5 Test Set

6.5.1 Impact Direction Setting

6.5.2 Average Times Setting

6.5.3 Material Setting

6.5.4 Hardness Scale Setting

6.5.5 Tolerance Limit Setting

6.5.6 Hardness / б b Setting

6.6 Print Set

6.7 Memory Management

6.7.1 View from No.1 Group/ View from Ending Group

6.7.2 View from Selected No. Group

6.7.3 Data Transfer

6.7.4 Delete by Group No.

6.7.5 Delete all Data

6.7.6 Deletion Confirmation

6.8 Browsing Memory Data Groups

6.9 System Reset

6.9.1 LCD Brightness Setting

6.9.2 Date/ Time Setting

6.10 Software Information

6.11 System Calibration

6.12 EL Background Light

6.13 Auto Power Off

6.14 Battery Replacement

6.15 Connection of Data Transmission Cable

7. Fault Analysis & Fault Clearance

8. Servicing & Maintenance

8.1 Impact Device Servicing

8.2 Normal Maintenance Program

9. Calibration

10. Transport and Storage Conditions

11. Declaration of Conformity

APPENDIX

Table 1

Table 2

Table 3

Table 4

1. Overview

1.1 HMR Advantages

Wide measuring range based on the principle of

Leeb Hardness testing theory. Leeb Hardness of

all metallic materials can be measured.

Large screen (128 x 64 dot matrix LCD) showing

all functions and parameters.

Testing at any angle, even upside down

With EL background light

Direct display of hardness scales HRB, HRC,

HV, HB, HS, HL

Seven impact devices are available for special

applications. Automatical identification of type of

impact devices

Large capacity memory can store 500 groups,

information including single measured value,

mean value, testing date, impact direction,

impact times, material, hardness scale etc.

Upper and lower limit can be preset. It will alarm

automatically if the result value is exceeding the

limit.

Battery information: rest capacity of battery is

indicated.

HMR-BA-e-1212 1

Page 2

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

No.

Item

Qua

ntity

Remarks

Stan

dard

Config

uration

1

Main body

1

2

D type impact

device

1

With cable

3

Standard test

block

1 4

Cleaning brush

(I)

1

5

Small support

ring

1

6

Alkaline battery

4

AA size

7

Manual

1 8

Instrument case

1 9

Optio

nal

Config

uration

11

Cleaning brush

(II)

1

For use with G

type impact

device

12

Other type of

impact devices

and support

rings

Refer to Table 3

and Table 4 in

the appendix.

13

DataPro for

HL200 software

1 14

Communication

cable

1

Software calibration function

Software to connect with PC and USB port

Compact metal case, suitable for use under poor

working conditions

Continuous working period of not less than 50

hours with two Alkaline batteries (AA size);

Auto Power Off to save energy

Dimensions: 132 mm x 76.2 mm

Weight: 345 g

1.2 Main Application & Testing Range

1.2.1 Main Application

Die cavity of molds

Bearings and other parts

Failure analysis of pressure vessels, steam

generators and other equipment

Heavy work piece

Testing the surface of a small hollow space

Material identification in the range of metallic

materials

1.2.2 Testing Range

Please refer to Table 1 and Table 2 in the APPENDIX.

1.3 Configuration

Table 1-1

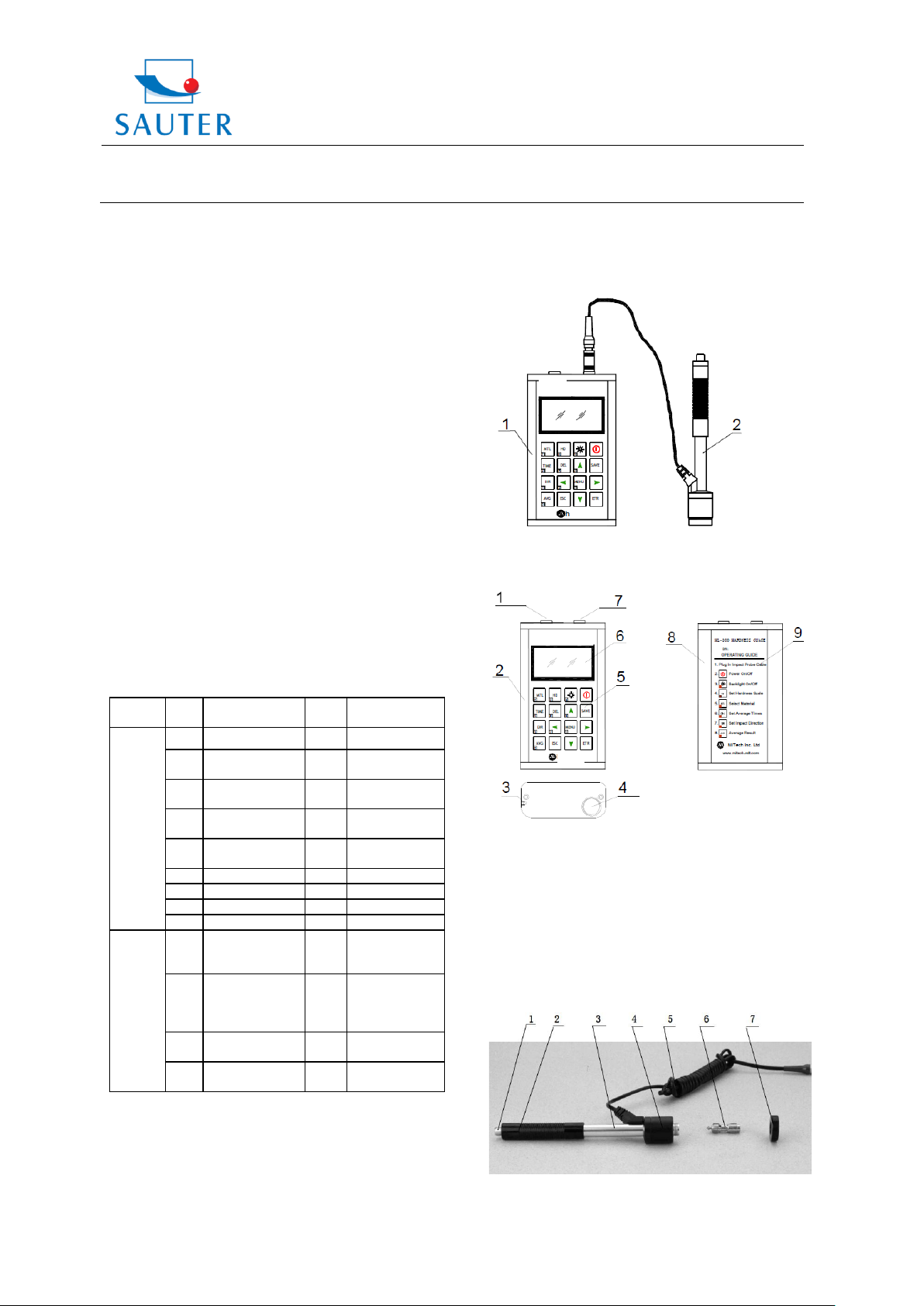

2. Structure Feature & Testing Principle

2.1 Structure Feature

2.1.1 Hardness Tester Appearance

1. Main body 2.Impact device

2.1.2 Parts of the Main body

1.4 Working Conditions

Working Temperature: 0°C up to +40°C

Storage Temperature: -30°C up to +60°C

Relative humidity: ≤ 90%

Vibrations, strong magnetic field, corrosive medium and

heavy dust should be avoided in the surroundings.

HMR-BA-e-1212 2

1 Socket of USB

2 Aluminium case

3 Belt hole

4 Battery cover

5 Keypad

6 LCD Display

7 Socket of Impact Device

8 Aluminium case, (backside)

9 Label (backside)

2.1.3 D Type of Impact Device

1. Release button

2. Loading Tube

Page 3

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

N

o

.

Typ

e of

im

pact

devi

ce

Hardness value

of Leeb

standard

hardness block

Error of

displayed

value

Repeata

bility

1

D

760±30HLD

530±40HLD

±6 HLD

±10 HLD

6 HLD

10 HLD

2

DC

760±30HLDC

530±40HLDC

±6 HLDC

±10 HLDC

6 HLD

10 HLD

3

DL

878±30HLDL

736±40HLDL

±12 HLDL

12 HLDL

4

D+

15

766±30HLD+15

544±40HLD+15

±12

HLD+15

12

HLD+15

5

G

590±40HLG

500±40HLG

±12 HLG

12 HLG

6

E

725±30HLE

508±40HLE

±12 HLE

12 HLE

7

C

822±30HLC

590±40HLC

±12 HLC

12 HLC

3. Guide Tube

4. Coil unit

5. Connection cable

6. Impact body

7. Support ring

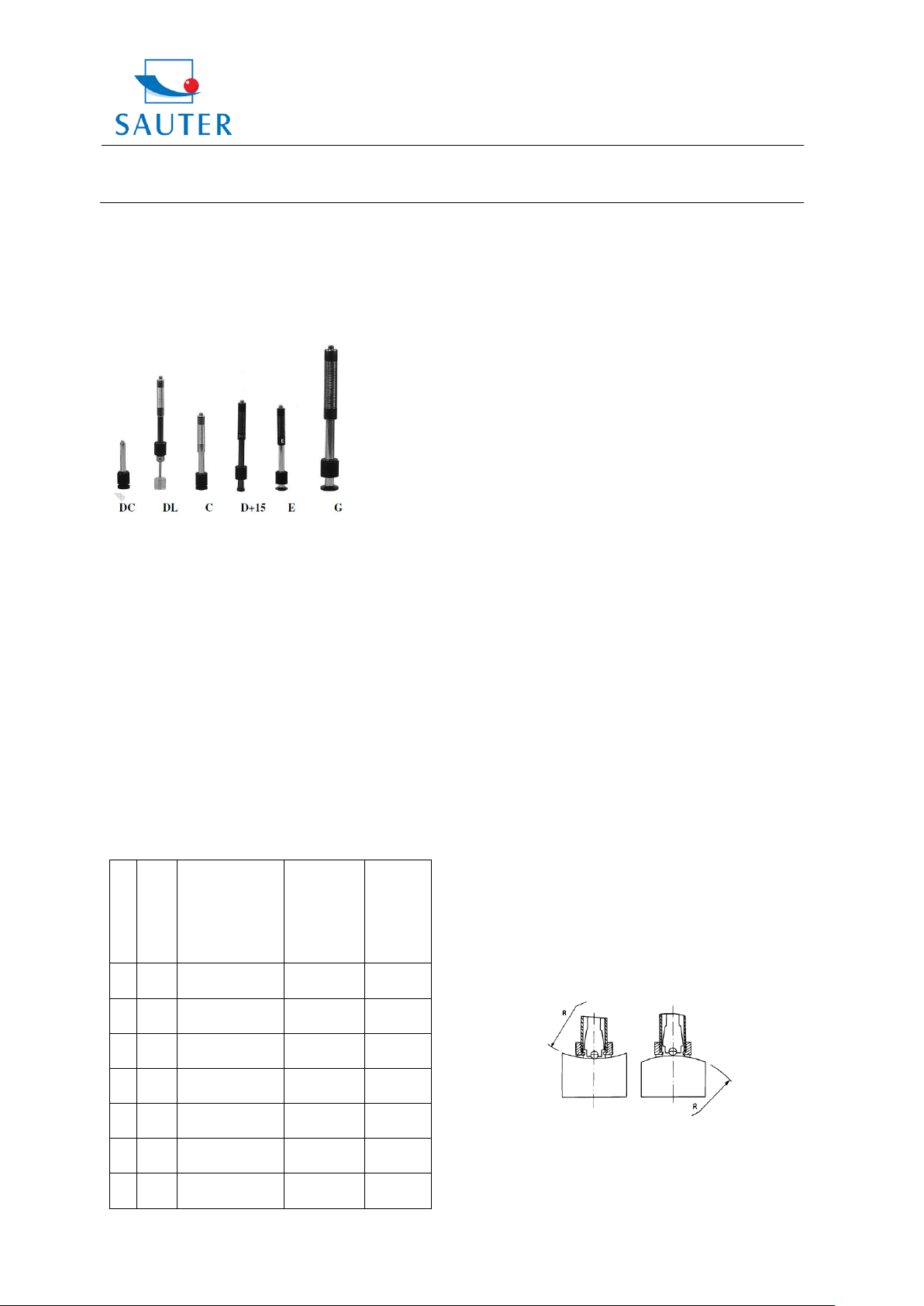

2.1.4 Different types of Impact Devices

2.2 Leeb Hardness Testing Principle

The basic testing principle is to use an impact body of a

certain weight which impacts against the testing surface

under certain test force. The impact velocity and the

rebound velocity of the impact body are measured

respectively when the spherical test tip is located 1mm

above the surface being tested.

The calculation formula is as follows:

HL= 1000 x VB/VA

Where HL= Leeb Hardness Value

VB= Rebounding velocity of the impact body

VA= Impact velocity of the impact body

3. Technical Specifications

Error and repeatability of the displayed value,

see Table 3-1:

HMR-BA-e-1212 3

Measuring range: HLD: (170 ~ 960) HLD

Measuring direction: 0 ~ 360°

Hardness Scale: HL, HB, HRB, HRC, HRA,

HV, HS

Display: dot matrix LCD,128 x 64 dots

Data memory: max. 500 groups

Power supply: 3V, (2AA size Alkaline batteries)

Continuous working period: about 50 hours

(with backlight off)

Communication interface: USB1.1

4. Preparation & Testing

4.1 Preparation and Inspection before Testing

4.1.1 Preparation of Sample Surface

Preparation of the sample surface should conform to the

relative requirements in APPENDIX Table 3.

During the preparation of the sample surface,

any heating or cold processing on this surface

should be avoided.

Too big roughness of the surface being

measured could cause errors. The surface of the

sample should show metallic luster, be smooth

and polished, without any stains of oil etc.

Support of the sample is not necessary for

heavy objects. Medium-weight samples have to

be placed onto a smooth and stable plane. It

must be placed in absolute equability and

without any wobble.

Curved surface: The best testing surface, of

course, is flat. When the curvature radius R of

the surface to be tested is smaller than 30 mm

(D, DC, D+15, C, E and DL type of impact

device) and smaller than 50 mm (G type of

impact device), the small support rings should

be chosen.

The sample should have enough thickness, the

minimum thickness of it should conform to

Table 3.

*For a sample with a hardened layer on its surface,

the depth of the hardened layer should also conform

to Table 3.

Coupling: Light-weight samples must be firmly

coupled with a heavy base plate. Both coupled

surfaces have to be flat and smooth; there may

not rest any redundant coupling agent. The

impact direction must be vertical to the coupled

Page 4

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

surface. If the sample is a big plate, long rod or

bending piece, it can be deformed and become

unstable, even though its weight and thickness

is big enough; accordingly, the test value might

not be accurate. So the sample should be

reinforced or supported at its back.

Magnetism of the sample itself should be

avoided.

4.1.2 System Setting

See 6.9 for details.

4.1.3 Presetting Testing conditions

See 6.5 for details.

4.2 Testing Program

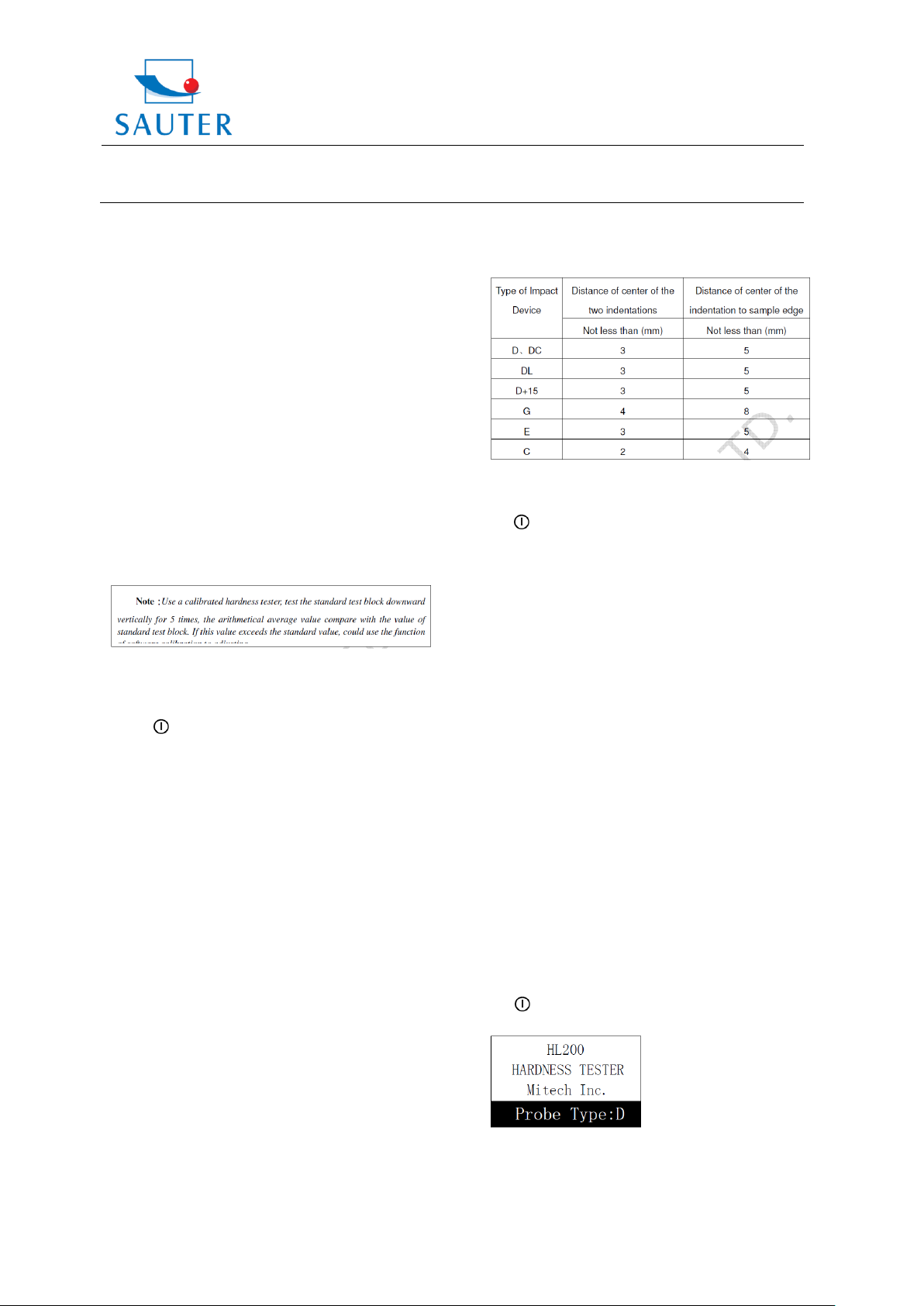

The hardness tester has to be verificated by using the

hardness block. The error and repeatability of the

displayed value should be within the regulation of

APPENDIX Table 2.

4.2.1 Start-up

1) The plug of the impact device has to be inserted into the

socket of the impact device of the instrument.

2) The key has to be pressed to power on. Now the

instrument is in testing condition.

4.2.2 Testing

- The release button on the upside of the impact device

has to be pressed to start testing. The sample and the

impact device as well as the operator are all required to be

stable now. The action direction should pass the axis of

the impact device.

- Each measurement area of the sample usually needs 3

to 5 times of testing operations. The result data dispersion

should not be more than the mean value ± 15 HL.

- The distance between any two impact points or from the

centre of any impact point to the edge of the sample

should conform to the regulation of Table 4-1.

- If an accurate conversion from the Leeb hardness value

to another hardness value is requested, a contrastive test

is needed to get conversion relations for the special

material. An inspected qualified Leeb hardness tester and

a corresponding hardness tester have to be used to test at

the same sample respectively. For each hardness value,

each homogeneous measurement, 5 points of Leeb

hardness value are needed. They are in the surroundings

of more than three indentations which need conversion of

hardness. The Leeb hardness arithmetic average value

and the corresponding hardness average value as

correlative value respectively are used to establish an

individual hardness contrastive curve. The contrastive

curve at least should include three groups of correlative

data.

Table 4-1

4.2.3 Reading the Measured Value

4.2.4 Power Off

The key has to be pressed to power off.

5. Advice

- The impact device must be replaced during the

instrument is powered off. Otherwise the type of impact

device cannot be identified by the main body. The circuit

board of the main body may get damaged.

- If the testing times are less than the preset times value,

the current test value can not be saved. 【 AVG 】 can be

pressed to end the testing process in advance if the values

shall be saved.

- When pressing 【 AVG 】 to end testing in advance, the

【 Auto save】 , 【 Auto transfer】 settings will not work.

- Only D and DC type of impact device have got the

function of strength measurement. Using other types of

impact device, the 【 Set hardness orбb 】 can not be

modified. The 【 Set hardness orбb 】 setting will be set

to【 Hardness 】 automatically after replacing the impact

device, whether the setting is【 Hardness 】 or not before.

- Not all materials can be converted to all hardness style

values. The hardness style is reset to HL automatically

after changing material. So, material has to be selected

first before changing the hardness style.

6. Operation in Details

6.1 Power On

The key has to be pressed to power on the instrument.

Following is shown on the screen:

The type of impact device will automatically be detected

during powering on. This information will be displayed on

the screen (Probe Type). After several seconds, the

HMR-BA-e-1212 4

Page 5

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

Material

Average value

indicator

Hardness

scale

Meas

ured

value

Impact times

count

Impact

direction

Battery

Inform.

screen will exit and the main display interface will be

entered.

6.2 Power Off

By pressing the key the system can be powered off in

any state.

6.3 Testing

Below, the main display is shown:

6.3.1 Full description of the Main Display

Battery information: displays the rest capacity of the

battery.

Impact direction: displays the present impact direction.

Average value indicator: it appears to show the mean

value when the preset impact times are reached.

Hardness scale: Hardness method of the present

measured value.

Measured value: displays the present single time

measured value (without mean value indicator), or displays

the present mean value (with average value indicator

prompting). ↑ means that the value is over conversion or

measurement range. ↓ means that it is lower than

conversion or measurement range.

Material: The present preset material.

Impact times count: Times that have been impacted.

6.3.2 Testing Operation at the Main Display

Testing operation can be carried out under this interface.

After each impact operation, the current measured value

can be displayed. Impact times count plus one, the buzzer

will alert a long howl if the measured value is not within the

tolerance limit. As soon as the preset impact times are

reached, the buzzer will alert a long howl. After two

seconds, the buzzer will alert a short howl and the mean

value will be displayed.

6.3.3 Key Operation at the Main Display

- The 【 SAVE 】 key has to be pressed to store the present

group of measured values into memory. This operation is

only valid after displaying the mean value.

- The 【 DEL】 key has to be pressed to delete the latest

single measured value. After pressing this key, on the

screen will be shown following:

The key or the key has to be pressed to

move the cursor to 【 YES 】 or 【 NO 】 .

【 ETR 】 has to be pressed to confirm.

【 ESC 】 has to be pressed to cancel deletion.

- The 【 】 or 【 】 key has to be pressed to display the

single measured value.

- By pressing 【 AVG , testing can be ended although the

preset impact times have not been reached and to display

the average value.

- The background light of LCD has to be switched on and

off by pressing 【 】 .

- 【 MENU 】 has to be pressed to enter the system Preset

Menu.

- By pressing , the impact direction can be preset.

- 【 TIME 】 key has to be pressed to change the impact

times in one group. The impact times count item will be

highlighted when the 【 TIME 】 key has been pressed. The

impact times count value will be added one with each

pressing. The value will roll back to 1 after 32 has been

reached.

- The 【 HD】 key has to be pressed to change the hardness

scale.

- By pressing 【 MTL 】 material setting can be changed.

Presetting the hardness scale, HL is automatically

recovered after material presetting has been changed.

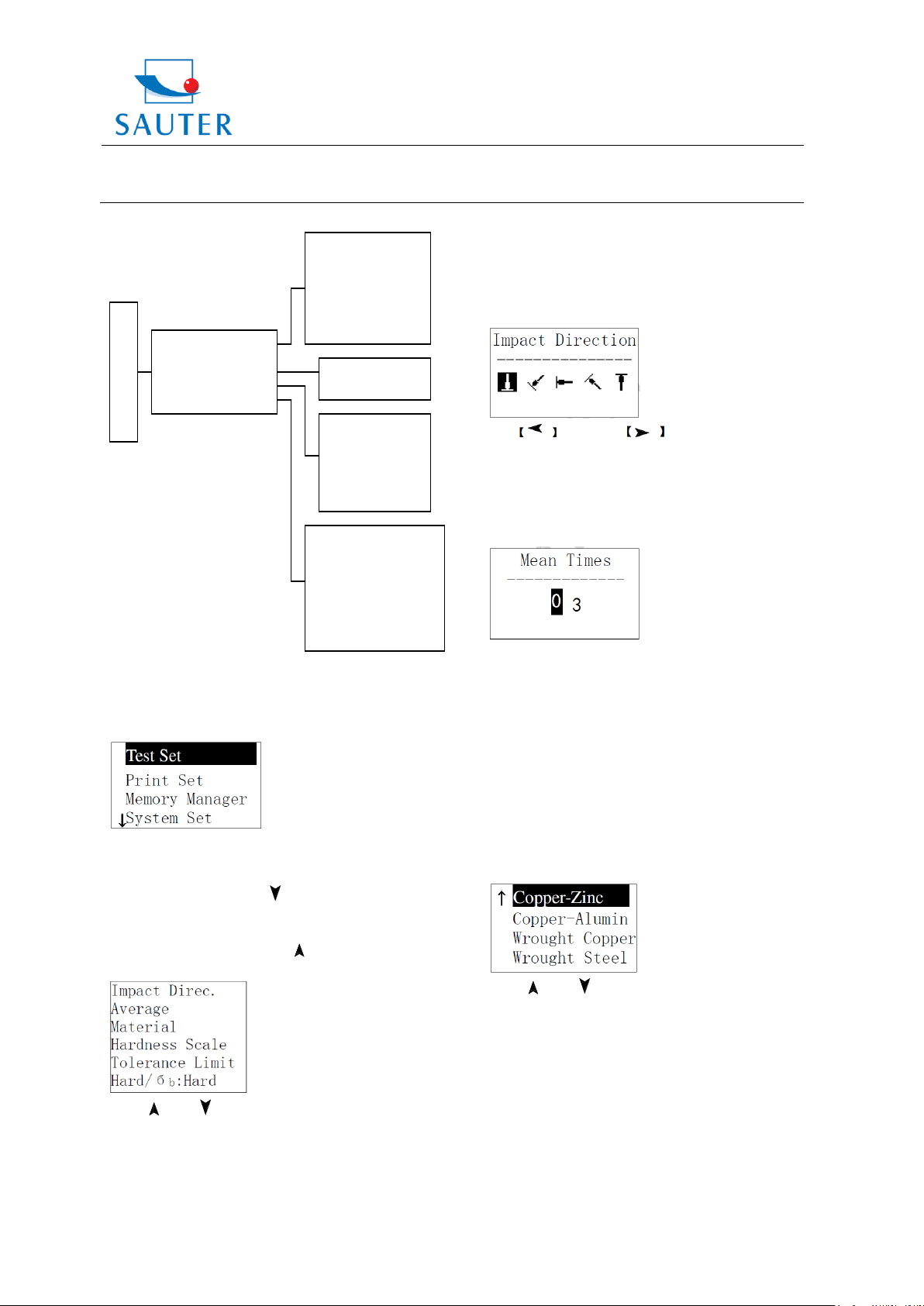

6.4 Menu Structure

Both, presetting system parameters and additional

functions, can be realised by menu operation. At the main

display interface, 【 MENU 】 key has to be pressed to enter

the main menu, as shown in following picture:

HMR-BA-e-1212 5

Page 6

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

Main display interface

Test Set

Print Set

Memory Manager

System Set

Software Info

Impact Direc.

Average

Material

Hardness Scale

Tolerance Limit

Hard/бb:Hard

(Print Set is NOT

available)

View From No.1

View From End

View From No.

Transfer

Delete by No.

Delete All

Auto Save:

Auto Print:

(N/A)

Auto Delete:

Auto Trans.:

Key Sound:

Warn. Sound:

6.5 Test Set

At the main display interface, 【 MENU 】 key has to be

pressed to enter the main menu.

【 ETR 】 has to be pressed to enter Test Set Menu. The

symbol ↓ at the left side of underside menu indicates that

the menu has not ended. 【 】 key has to be pressed to

glance downward continuously.

The symbol ↑ at the left side of the upside menu indicates

that the menu has not ended. 【 】 has to be pressed to

glance upward continuously.

The 【 】 or 【 】 key has to be pressed to move the

cursor to the desired line to set and 【 ETR 】 has to be

pressed to confirm.

Note: 1. When 【Hard/бb】 is switched to бb, hardness

scale cannot be selected. The cursor will skip over

【

Hardness Scale】while it is moved.

HMR-BA-e-1212 6

2. Only D type of impact device has got the function of

бb measurement. So the cursor cannot be moved to

【

Hard/бb】while another impact device is used.

6.5.1 Impact Direction Setting

The key or the key has to be pressed to

move the cursor to the desired impact direction.

【 ETR 】 has to be pressed to confirm.

【 ESC 】 has to be pressed to cancel.

6.5.2 Average Times Setting

Average times can be modified within the range of 1 to 32.

The 【 0 】 ~ 【 9 】 key has to be pressed to input the

number value. The cursor will shift right around

automatically when inputting the number.

【 ETR 】 has to be pressed to confirm.

【 ESC 】 has to be pressed to cancel.

6.5.3 Material Setting

If 【Hard/бb】is preset to hardness, following material will

be displayed: Steel and Cast Steel, Cold Work Tool Steel,

Stainless Steel, Grey Cast Iron, Nodular Cast Iron, Cast

Aluminium Alloys, Copper-Zinc Alloys, Copper-Aluminium

Alloys, Wrought Copper and Wrought Steel.

The 【 】 or 【 】 key has to be pressed to move the

cursor to the material desired to preset.

【 ETR 】 has to be pressed to confirm.

【 ESC 】 has to be pressed to cancel.

Note: 1. Presetting the hardness scale, HL is

automatically recovered after material presetting has

been changed.

2. Please select material first and then select hardness

scale.

If 【Hard/бb】is preset to бb, following material will be

displayed: Mild Steel, High-Carbon Steel, Cr Steel, Cr-V

Page 7

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

Steel, Cr-Ni Steel, Cr-Mo Steel, Cr-Ni-Mo Steel, Cr-Mn-Si

Steel, Super Strength Steel and Stainless Steel.

The 【 】 or 【 】 key has to be pressed to move the

cursor to the material desired to preset.

【 ETR 】 has to be pressed to confirm.

【 ESC 】 has to be pressed to cancel.

6.5.4 Hardness Scale Setting

【 ETR 】 has to be pressed to switch between Hard and

бb.

Note: Only D and DC type of impact device have got

the function of бb measurement. So, “Hard” is the only

selection if the impact device is not D or DC type.

6.6 Print Set

At the main display interface, 【 MENU 】 key has to be

pressed to enter the main menu. Printing function is not

available at Hardness Tester HMR.

6.7 Memory Management

At the main display interface, the 【 MENU 】 key has to be

pressed to enter the main menu.

The 【 】 or 【 】 key has to be pressed to move the

cursor to the hardness scale desired to preset.

【 ETR 】 has to be pressed to confirm.

【 ESC 】 has to be pressed to cancel.

Note: 1. Only the valid hardness scale for the present

selected impact device and material are displayed.

An invalid hardness scale will not be displayed.

2. Please select material first and then select hardness

scale.

3. Presetting the hardness scale, HL is automatically

recovered after material presetting has been changed.

6.5.5 Tolerance Limit Setting

The 【 0 】 ~ 【 9 】 key has to be pressed to input the

number value. The cursor will shift right around

automatically when inputting.

【 ETR 】 has to be pressed to confirm.

【 ESC 】 has to be pressed to cancel.

Note: 1. If the preset value exceeds the measurement

range, the user will be reminded by the Tester to reset.

2. If the bottom limit is larger than the upper limit, they

will be exchanged automatically.

6.5.6 Hardness / бb Setting

The 【 】 or 【 】 key has to be pressed to move the

cursor to 【 Memory Manager】 . 【 ETR 】 key has to be

pressed in 【 Memory Manager】 menu. If there is no data in

memory, <No Data!> will be displayed. Then it has to be

returned.

The 【 】 or 【 】 key has to be pressed to move the

cursor to the desired function.

【 ETR 】 has to be pressed to confirm.

6.7.1 View from No.1 Group/ View from Ending Group

【 View From No.1 】 : values in the memory from the first

group are displayed.

【 View From End 】 : values in the memory from the

ending group are displayed.

6.7.2 View from Selected No. Group

The digit figure keys have to be pressed to input the

number.

【 ETR 】 has to be pressed to start displaying memory

data from the selected beginning group.

【 ESC 】 has to be pressed to cancel.

HMR-BA-e-1212 7

Page 8

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

Auto Save: Off

Auto Print: Off

Auto Delete: Off

Auto Trans: Off

Key sound: On

Warn. Sound: On

LCD Brightness

Time Date Set 日

No.001 12/03 652HL

No.002 12/03 587HL

No.003 12/03 820HL

No.004 12/03 693HL

No.005 12/03 783HL

No.006 12/03 782HL

No.007 12/03 579HL

No.008 12/03 687HL

No.002 12/03 785HL

No.003 12/03 516HL

No.004 12/03 789HL

No.005 12/03 570HL

No.006 12/03 852HL

No.007 12/03 523HL

No.008 12/03 796HL

No.001 12/03 514HL

6.7.3 Data Transfer

【 Transfer 】 has to be pressed to export the values stored

in memory as text format to PC by USB port.

6.7.4 Delete by Group No.

The 【 】 or 【 】 key has to be pressed to see previous

or next page.

【 ESC 】 has to be pressed to exit browsing.

【 ETR 】 has to be pressed and then 【 】 or 【 】 to

move the cursor to the desired line you want to see the

details from. 【 ETR 】 has to be pressed to see details of

that group.

【 Delete by No. 】 :The range of deleted groups is

displayed. The digit figure keys have to be pressed to input

the number.

【 ETR 】 has to be pressed to delete the selected groups.

【 ESC 】 has to be pressed to cancel the operation.

Note: 1.If the present group exceeds the actual range,

the actual groups among them will be deleted!

2. The instrument may not be powered off while

deleting data. This could lead to unpredicted

consequences!

6.7.5 Delete all Data

By pressing 【 Delete All 】 , all data in memory will be

deleted.

6.7.6 Deletion Confirmation

The key or the key has to be pressed to

move the cursor to 【 YES 】 and 【 】 key deletion.

The key or the key has to be pressed to

move the cursor to 【 NO 】 and 【 ETR 】 has to be pressed

to cancel deletion.

【 ESC 】 has to be pressed to cancel deletion, no matter

where the cursor is located.

6.8 Browsing Memory Data Groups

HMR-BA-e-1212 8

The 【 】 or 【 】 key has to be pressed to browse details

including average value, test set and each single value.

【 ESC 】 has to be pressed to return to previous display.

6.9 System Set

At the main display interface, 【 MENU 】 key has to be

pressed to enter the main menu.

【 】 or 【 】 key has to be pressed to move the cursor

to 【 System Set 】 Menu. 【 ETR 】 has to be pressed to

enter 【 System Set 】 Menu.

【 】 or 【 】 key has to be pressed to move the cursor

to the desired item.

By pressing, the setting can be directly modified or into the

corresponding screen. 【 ESC 】 has to be pressed to exit.

【 Auto Save 】 , 【 Auto Delete 】 , 【 Auto Trans. 】 , 【 Key

Sound 】 , 【 Warn. Sound 】 can be switched on or off now.

If 【 Auto Save 】 is set to <On>, according to 3б rule, gross

errors can be cancelled automatically after having

measured preset average times or pressing end in

advance. If there is any data cancelled, it needs

supplemental measurement to reach the preset times.

If 【 Auto Trans. 】 is set to <On>, the value of the present

group can be exported by USB after measuring and

displaying the average value.

If 【 Key Sound 】 is set to <On>, the buzzer will make a

short hoot while a key is being pressed each time.

Page 9

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

Time Date Set

-------------------10/05/2009 11:02

If 【 Warn. Sound 】 is set to <On>, if the measured value

exceeds the tolerance limit, the preset average times or

deleting data are reached, the buzzer will make a long

hoot.

6.9.1 LCD Brightness Setting

The 【 】 key has to be pressed to enhance brightness.

Brightness can be weakened by pressing 【 】 key.

【 ETR 】 has to be pressed to confirm.

【 ESC 】 has to be pressed to cancel.

6.9.2 Date/ Time Setting

Present time and date are displayed as „M/D/Y H/M“.

The figure (0~9) key has to be pressed to modify the

present figure. The cursor will move automatically from the

left to the right after modifying.

【 ETR 】 has to be pressed to confirm,

【 ESC 】 has to be pressed to cancel modification.

6.10 Software Information

At the main display interface, 【 MENU 】 key has to be

pressed to enter the main menu.

【 】 or 【 】 key has to be pressed to move the cursor

to 【 Software Info 】 . The 【 ETR 】 key has to be pressed to

enter 【 Software Info 】 screen.

This screen displays information about the main body and

the firmware. The version, Code and SN are changing with

the firmware.

6.11 System Calibration

HMR Hardness Tester and the impact device have to be

calibrated by using the hardness block before the first use

or if it hasn’t been used for a longer time or after having

reset the system.

The 【 】 key and the 【 ETR 】 key have to be pressed to

power on the system. Then the software calibration screen

will display following:

The impact direction has to be set at 【 】 .

5 points have to be measured on the standard hardness

block.

The average value will be displayed after measuring 5

times.

【 】 or 【 】 key has to be pressed to input the nominal

value. 【 ETR 】 has to be pressed to confirm,

【 ESC 】 has to be pressed to cancel this operation.

Range of adjustment: ±15HL.

6.12 EL Background Light

By means of the background light it is convenient to work

in dark conditions. 【 】 key has to be pressed to switch

on or off the background light at any time if necessary,

after the instrument is powered on.

6.13 Auto Power Off

- This hardness tester has got the function of powering off

automatically to save power in case if there is neither key

operation nor measurement within 5 minutes. Any key,

except 【 】 key, can be pressed to stop the twinkle of

the LCD screen and thus, stop the operation of powering

off at that moment.

- While the voltage of battery is too low, <Battery empty!>

will be shown on the screen. Then the instrument powers

off automatically.

6.14 Battery Replacement

Two AA size Alkaline batteries are necessary as power

resource. After several hours’ usage, the battery symbol

on the screen will be shown as . The less dark parts

are indicated, the more close to get filled. When the

capacity runs out, the battery symbol will be shown as

and the symbol will begin to flash. Now batteries

have to be replaced.

HMR-BA-e-1212 9

Page 10

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

M

0

1

2

5

4

8

7

+

-

+

-

An o d e

Ca t ho d e

HA RD

HL -2 00

MT L HD

DE L

TIM E

DIR

ES C

AV G

If batteries are exhausted, they

should be replaced as follows:

- The instrument has to be

powered off.

- The circular battery cover has

to be removed and the batte ries have to be taken off.

- The new batteries have to be

installed and the battery

cover has to be reset.

- The instrument has to be

powered on again to check.

Pay attention to the polarity of the batteries!

The batteries have to be taken out if the instrument

hasn’t been used for a longer period of time.

6.15 Connection of Data Transmission Cable

One connection plug of transmission cable (optional parts)

has to be inserted into the socket on the up left side of the

main body. The other plug has to be inserted into the USB

socket in the back of the computer.

7. Fault Analysis & Fault Clearance

The warranty card has to be filled in and sent to SAUTER

GmbH. The warranty service will be performed within a few

working days.

9. Calibration

The HMR hardness tester has to be calibrated every year.

10. Transport and Storage Conditions

* The instrument has to be kept away from vibration,

strong magnetic field, corrosive medium, dampness and

dust. Safekeeping in ordinary temperature.

DESIGNED IN REGARD TO THESE STANDARDS:

ASTM A956

DIN 50156

11. Declaration of Conformity

8. Servicing & Maintenance

8.1 Impact Device Servicing

After 1000 to 2000 times of usage, the impact

body and the guide tube have to be cleaned with

the provided nylon brush. When cleaning the

guide tube, the support ring has to be

unscrewed first. Then the impact body has to be

taken out. The nylon brush has to be spiralled in

counter-clock direction into the bottom of the

guide tube. It has to be taken out and repeated

for 5 times. At last, the impact body and the

support ring have to be installed again.

The impact body has to be released after use.

Any lubricant is absolutely prohibited inside the

impact device.

8.2 Normal Maintenance Program

* If the standard Rockwell hardness block is used to test

and if all the error is bigger than 2 HRC, the ball top of the

impact device or the impact object may have to be

changed. The invalidation may be caused by abrasion.

* If any other abnormal phenomena appear to the

hardness tester, nothing may be dismantled or any fixed

parts may not be adjusted by the user himself.

HMR-BA-e-1212 10

Page 11

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

Material

Method

Impact device

D/DC

D+15

C G E

DL

Steel and cast steel

HRC

20~68.5

19.3~67.9

20.0~69.5

22.4~70.7

20.6~68.2

HRB

38.4~99.6

47.7~99.9

37.0~99.9

HRA

59.1~85.8

61.7~88.0

HB

127~651

80~638

80~683

90~646

83~663

81~646

HV

83~976

80~937

80~996

84~1042

80~950

HS

32.2~99.5

33.3~99.3

31.8~102.1

35.8~102.6

30.6~96.8

Cold work tool steel

HRC

20.4~67.1

19.8~68.2

20.7~68.2

22.6~70.2

HV

80~898

80~935

100~941

82~1009

Stainless steel

HRB

46.5~101.

7

HB

85~655

HV

85~802

Grey cast iron

HRC

HB

93~334

92~326

HV

Nodular cast iron

HRC

HB

131~387

127~364

HV

Cast aluminium

alloys

HB

19~164

23~210

32~168

HRB

23.8~84.6

22.7~85.0

23.8~85.5

BRASS (copper-zinc

alloys)

HB

40~173

HRB

13.5~95.3

BRONZE (copperalum./tin alloys)

HB

60~290

Wrought copper

alloys

HB

45~315

No.

Material

HLD

Strength σ

b

(MPa)

1

Mild steel

350~522

374~780

2

High-carbon steel

500~710

737~1670

3

Cr- Steel

500~730

707~1829

4

Cr-V Steel

500~750

704~1980

5

Cr-Ni Steel

500~750

763~2007

6

Cr-Mo Steel

500~738

721~1875

7

Cr-Ni-Mo Steel

540~738

844~1933

8

Cr-Mn-Si Steel

500~750

755~1993

9

Super strength steel

630~800

1180~2652

10

Stainless steel

500~710

703~1676

APPENDIX Table 1

Table 2

HMR-BA-e-1212 11

Page 12

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.sauter.eu

Instruction Manual

HMR

Type of impact device

DC(D)/DL

D+15

C G E

Impact energy

Mass of impact body

11mJ

5.5g/7.2g

11mJ

7.8g

2.7mJ

3.0g

90mJ

20.0g

11mJ

5.5g

Test tip hardness:

Diam. Test tip:

Material of test tip:

1600HV

3mm

Tungsten

carbide

1600HV

3mm

Tungsten

carbide

1600HV

3mm

Tungsten carbide

1600HV

5mm

Tungsten carbide

5000HV

3mm

synthetic diamond

Impact device diameter:

Impact device length:

Impact device weight:

20mm

86(147)/ 75mm

50g

20mm

162mm

80g

20mm

141mm

75g

30mm

254mm

250g

20mm

155mm

80g

Max. hardness of sample

940HV

940HV

1000HV

650HB

1200HV

Mean roughness value of

sample surface Ra:

1.6μm

1.6μm

0.4μm

6.3μm

1.6μm

Min.weight of sample:

Measure directly

Need support firmly

Need coupling tightly

>5kg

2~5kg

0.05~2kg

>5kg

2~5kg

0.05~2kg

>1.5kg

0.5~1.5kg

0.02~0.5kg

>15kg

5~15kg

0.5~5kg

>5kg

2~5kg

0.05~2kg

Min. Thickness of sample :

Coupling tightly

Min. layer thickness for

surface hardening

5mm

≥0.8mm

5mm

≥0.8mm

1mm

≥0.2mm

10mm

≥1.2mm

5mm

≥0.8mm

Size of tip indentation

Hardness

300HV

Indentation

diameter

Depth of indentation

0.54mm

24μm

0.54mm

24μm

0.38mm

12μm

1.03mm

53μm

0.54mm

24μm

Hardness

600HV

Indentation

diameter

Depth of indentation

0.54mm

17μm

0.54mm

17μm

0.32mm

8μm

0.90mm

41μm

0.54mm

17μm

Hardness

800HV

Indentation

diameter

Depth of indentation

0.35mm

10μm

0.35mm

10μm

0.35mm

7μm

--

--

0.35mm

10μm

Available types of impact devices

DC: test hole or

hollow cylindrical

DL: test slender

narrow groove or

hole

D+15: test

groove or

reentrant

surface

C: test small, light

thin parts and

surface of

hardened layer

G: test large,

thick, heavy and

rough surface

steel

E: test super high

hardness material

Table 3

HMR-BA-e-1212 12

Loading...

Loading...