Page 1

Sauter GmbH

HB & TI

Shore A

Shore C/ 0

Shore D

Model

HBA 100-0

HBC100-0

HBD100-0

Indenter

Konus 35°

Durchm.1,3

Konus 30°

dimension

Depth of in

0 – 2,5 mm

0 – 2,5 mm

0 – 2,5 mm

Measuring

0,55–8,065N

0,55–8,065N

0,55-44,5N

Display

Skala von

Skala von

Skala von

Weight.net

250g

230g

250g

Thread

M7 x 0.5

M7 x 0.5

M7 x 0.5

Instruction Manual

MANUAL SHORE DUROMETER

Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

2. Specifications

Tip

dentation

Test

pressure

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

SR2,5mm

ca.12,5 N 12,5 N 50 N

Shore A

Shore C/ Shore 0

Shore D

Table of contents

1. Features

2. Specifications

3. Method of measurement

4. Maintenance

5. Calibration

1. Features

The hardness of plastics is m ost commonly measured by

the Shore Durometer, using either the Shore A or Shore D

scale. It is the preferred method for measuring rubbers/

elastomers and it’s also used for “softer” plastics s uch as

polyolefins, fluoropolymers and vinyls.

Shore A scale is used for “softer” rubbers, while Shore D

scale is used for “harder” ones.

Shore C/ Shore 0 scale is commonly used for tests with

foam rubbers, sponges or microporous plastics.

Designed in regard to these standards:

• DIN 53505

• ASTM D2240

• ISO 868

spring

force

range

Scale

Diameter

(gross)

Dimensions

3. Method of measurement

Shore Durometer, like many other hardness testers,

measures the depth of indentation in the material created

by a given force on a standardized presser foot. The depth

is dependant on the hardness of the material, its

viscoelastic properties, the shape of the presser foot as

well as the duration of the test. Shore durometers all ow the

measurement of the initial hardness or the indentation

hardness after a given period of time.

The basic test requires applying the force in a constant

manner without shocks, measuring the hardness (depth of

the indentation). If a timed hardness is desired, force is

applied for the required time and then the measurement

result is to be read.

The tested material should have a thickness of minimum

6.4 mm (0.25 inch).

4. Maintenance

After testing the instrument is to be put back in its packing

box. It should not be stored in following environmental

conditions: wet or dusty area, oil or chemicals.

5. Calibration

First the test plate is to be put on a hard and flat base.

The hardness tester is to be located on the test plate by

placing the measurement tip into the hole of the test plate.

The instrument is to be adjusted by turning the external

ring of the round Display to the setpoint of the test plate.

0 – 100

55 mm 55 mm 55 mm

(300g)

26x62x115

(LxBxH) mm

0 – 100

(350g)

26x62x115

(LxBxH) mm

0 – 100

(300g)

26x62x115

(LxBxH) mm

HB&TI-BA-e-1311 1

Page 2

Sauter GmbH

Ziegelei 1

HB & TI

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

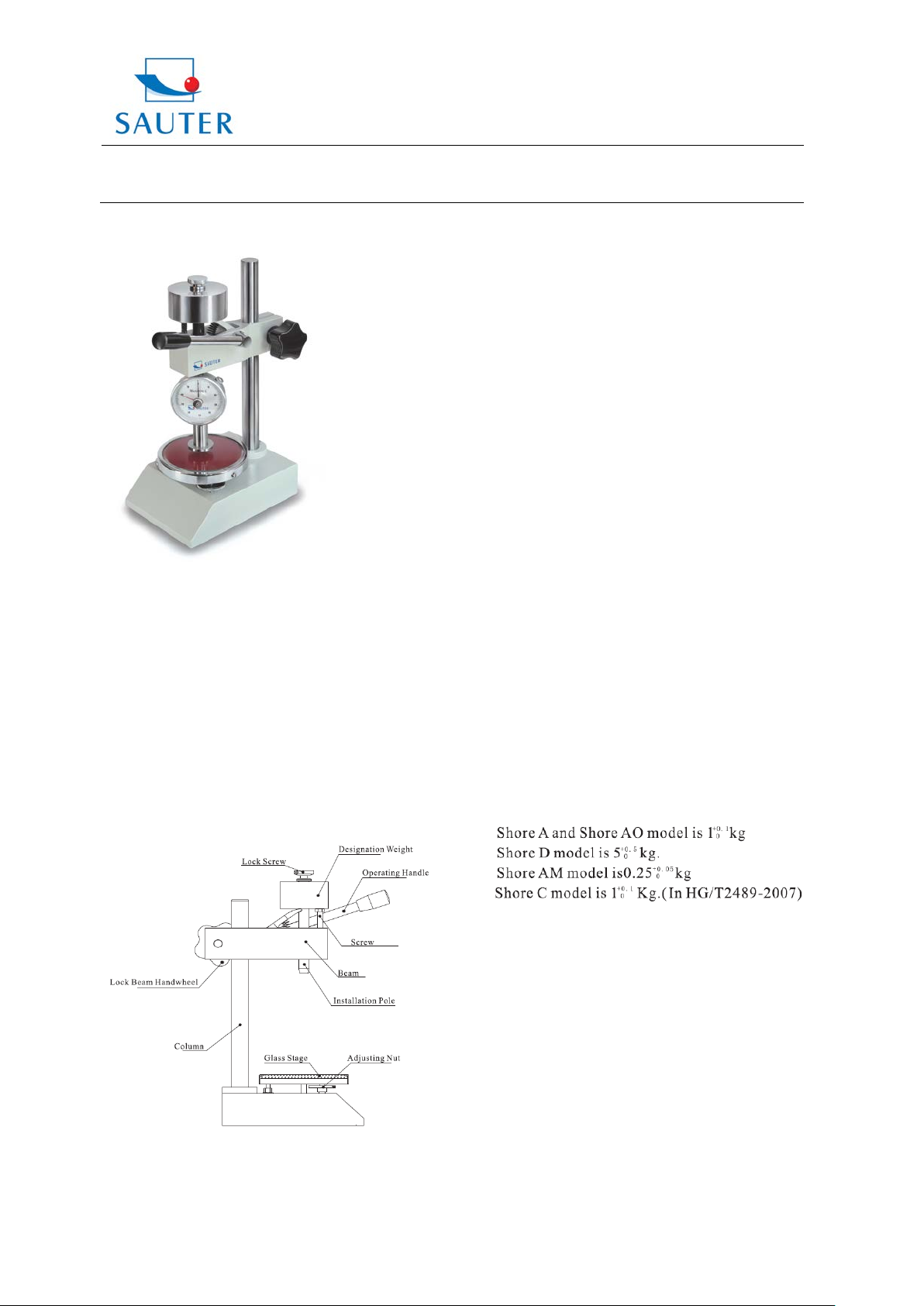

SHORE DUROMETER TEST ST AND

Thank you for buying a SAUTER Durometer Test Stand.

The ruggedness of this stand will allow many years of use

if you will care for an appropriate operation and

maintenance.

If there are any queries, wishes or helpful suggestions, do

not hesitate to call our service number.

Instruction

This Test Stand is produced for our Shore hardness

testers. Combined with this, tests can be made more

stable and accurate. TI-A0 is applied for HB instruments

Shore A and 0; TI-D is applied for HB instruments Shore

D.

Structure

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Operation

The Shore durometer has to be fixed on the test stand by

the installation pole. The hardness testing block has t o be

put onto the glass stage. Then the operating handl e has to

be pressed by poise to place the durometer tip into the

hole of the block until the foot of the durometer touches the

testing block completely. At this time, the hardness value

on the dial should be within ± 1 of the signed value on the

block (side below). If the value is not 100±1, the adjust ing

nut under the glass stage has to be adjus ted to make the

value turn to 100±1.

If the durometer is used without hardness block, the

operating handle also has to be pressed by poise t o place

the durometer tip on the glass stage, touching it

completely. Here, the hardness value on the di al should be

within 100±1. If not, it s hould be adjusted by the adjust ing

nut under the glass stage to make the value turn to 100±1.

The testing material has to be put on the glass stage, the

operation handle has to be moved down by force of the

designation weight. When the durometer touches the test

material completely, the value appears on the dial.

The reading value time of thermoplastic rubber is 15

seconds, vulcanised rubber or other unknown rubbers is 3

seconds. The Shore C model is able to read the value

within 1 second after the durometer has touched the

material completely.

Caution

1. This test stand can only be applied for Shore

durometers. If it is installed with different durometers, the

quality of weight first has to be adjusted according to the

requirements.

GB/T531.1-2008 has a rule for the adjustment of total

quality as shown below:

HB&TI-BA-e-1311 2

Note: Total quality includes quality of lock screws,

designation weight, screw, installation pole and durometer.

2. It has to be applied in environm ent without shock, the

max. pressing speed of the test should not be above

3.2mm/s.

Maintenance

The test stand had to be cleaned after using it with a

smooth cloth to avoid rust.

Loading...

Loading...