Page 1

KERN & Sohn GmbH

Ziegelei 1

email: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating instructions

Analytical balance

KERN ABS-N_ABJ-NM

Version 1.2

03/2013

GB

D-72336 Balingen

Fax: +49-[0]7433-9933-149

ABS-N_ABJ-NM-BA -e-1312

Page 2

KERN ABS-N_ABJ-NM

Analytical balance

GB

Version 1.2 03/2013

Operating instructions

Table of Contents

1 Technical Specifications ............................................................................... 4

2 Declaration of conformity ............................................................................. 7

3 Appliance overview ....................................................................................... 8

3.1 Keyboard overview ................................................................................................................... 9

3.1.1 Numeric entry ........................................................................................................................... 10

3.2 Overview of displays .............................................................................................................. 11

4 Basic Information (General) ........................................................................ 12

4.1 Proper use ............................................................................................................................... 12

4.2 Improper Use........................................................................................................................... 12

4.3 Warranty .................................................................................................................................. 12

4.4 Monitoring of Test Resources ............................................................................................... 13

5 Basic Safety Precautions ............................................................................ 13

5.1 Pay attention to the instructions in the Operatio n Manual ................................................ 13

5.2 Personnel training .................................................................................................................. 13

6 Transportation & Storage ............................................................................ 13

6.1 Testing upon acceptance ...................................................................................................... 13

6.2 Packaging / retur n transport ................................................................................................. 14

7 Unpacking, Setup and Commissioning ..................................................... 16

7.1 Installation Site, Lo cation of Use .......................................................................................... 16

7.2 Unpacking and checking ....................................................................................................... 16

7.2.1 Scope of delivery / serial accessories....................................................................................... 17

7.2.2 Placing ...................................................................................................................................... 18

7.3 Mains connection ................................................................................................................... 19

7.3.1 Turning On the Power............................................................................................................... 19

7.4 Initial Commissioning ............................................................................................................ 19

7.5 Connection of periphera l devices ......................................................................................... 19

8 Adjustment ................................................................................................... 20

8.1 Automatic adjustment by PSC (Pe rfect Self Calibration), only models ABJ .................... 20

8.2 Menu settings „I.CAL“ / „E.CAL“ .......................................................................................... 23

8.2.1 Adjustment with internal weight (KERN ABJ) ........................................................................... 24

8.2.2 Adjustment with external weight (KERN ABS).......................................................................... 25

8.3 Adjustment lo g ........................................................................................................................ 26

8.4 Balance identification no. ...................................................................................................... 27

9 Verification ................................................................................................... 28

10 Weighing ....................................................................................................... 30

10.1 Switch-on balance / call-up weighing mode ........................................................................ 30

10.2 Switch off the balance ............................................................................................................ 30

10.3 Set the start display................................................................................................................ 31

10.4 Auto Power-Off function (auto matic switch-off function) .................................................. 33

10.5 Simple weighing ..................................................................................................................... 34

10.6 Taring ....................................................................................................................................... 35

10.7 Switch-over weighing unit ..................................................................................................... 36

2 ABS-N_ABJ-NM-BA -e-1312

Page 3

10.7.1 Freely programmable weighing unit ..................................................................................... 37

10.7.2 Change position of decimal dot for freely programmable weighing unit ............................... 38

10.7.3 Input minimum weight for freely programmable weighing unit ............................................. 38

10.8 Change readability (1D/10D) .................................................................................................. 39

10.9 Display decimal dot as point or comma ............................................................................... 40

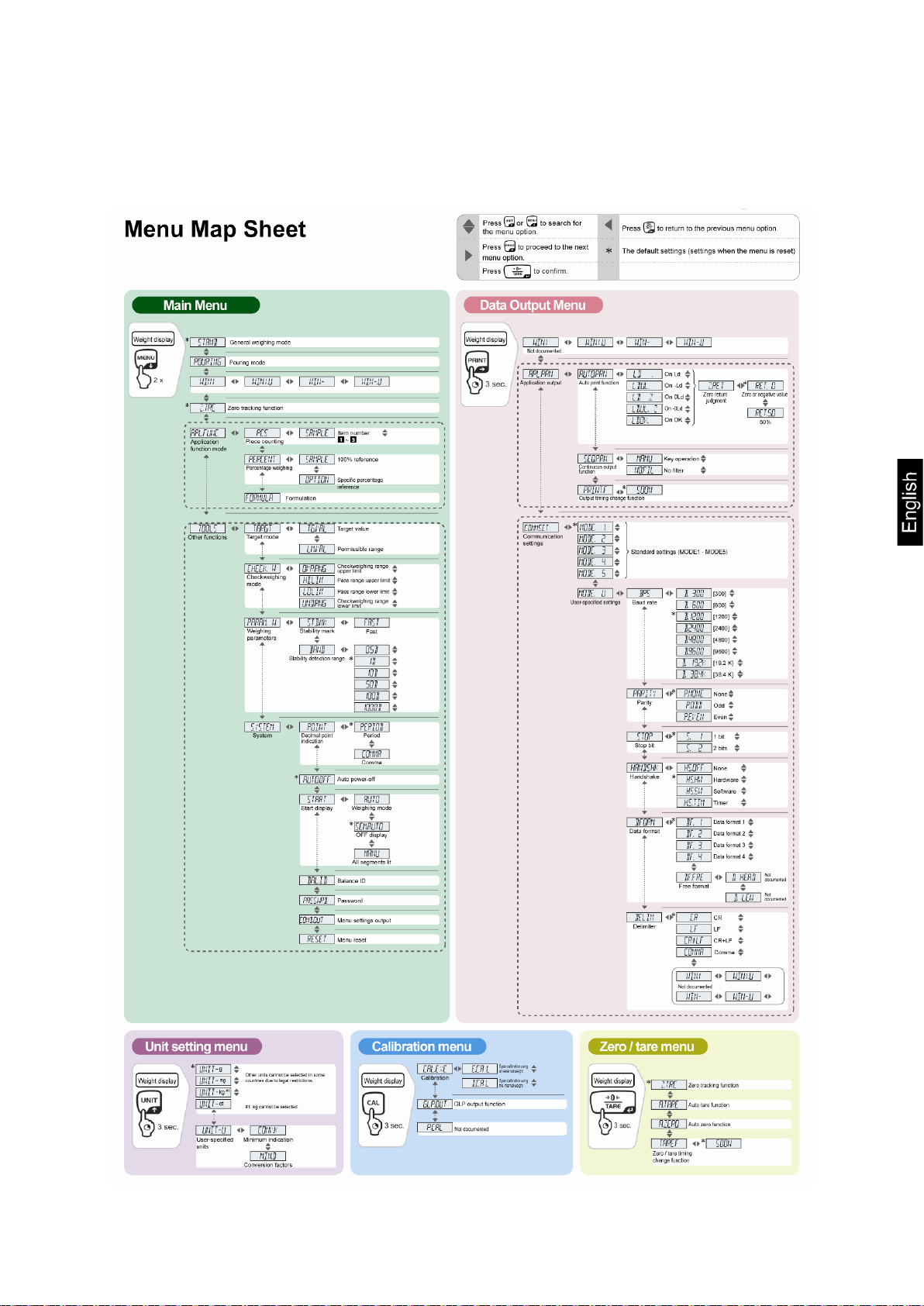

11 Menu ............................................................................................................. 41

11.1 Menu symbol ........................................................................................................................... 41

11.2 Navigation in the menu .......................................................................................................... 42

11.3 Menu overview ........................................................................................................................ 43

11.4 Resetting the menu ................................................................................................................ 44

11.5 Menu Lock ............................................................................................................................... 45

11.5.1 Change password ................................................................................................................ 46

11.6 Log menu settings .................................................................................................................. 47

12 Zero / tare me nu (zeroing and taring functions) ....................................... 48

12.1 Zero tracking function ............................................................................................................ 49

12.2 Auto zero functi o n .................................................................................................................. 50

12.3 Auto Tare function .................................................................................................................. 51

12.4 Zero / tare timing cha n g e function........................................................................................ 52

13 Settings for Stability and Response ........................................................... 53

13.1 Stability and reaction settings via „Easy Setting display“ (without invoking menu) ...... 53

13.2 Selection weighing / dosing mo d e ....................................................................................... 54

13.3 Standstill width ....................................................................................................................... 55

14 Application Functions ................................................................................. 57

14.1 Parts counting ........................................................................................................................ 57

14.2 Percent determination ............................................................................................................ 60

14.2.1 Reference weight = 100 % ................................................................................................... 61

14.2.2 User-defined reference ........................................................................................................ 62

14.2.3 Percent determination .......................................................................................................... 63

14.3 Formula mode ......................................................................................................................... 64

14.3.1 Enable edition „component no.“ ........................................................................................... 66

14.3.2 Enable issue „TOTAL“ .......................................................................................................... 67

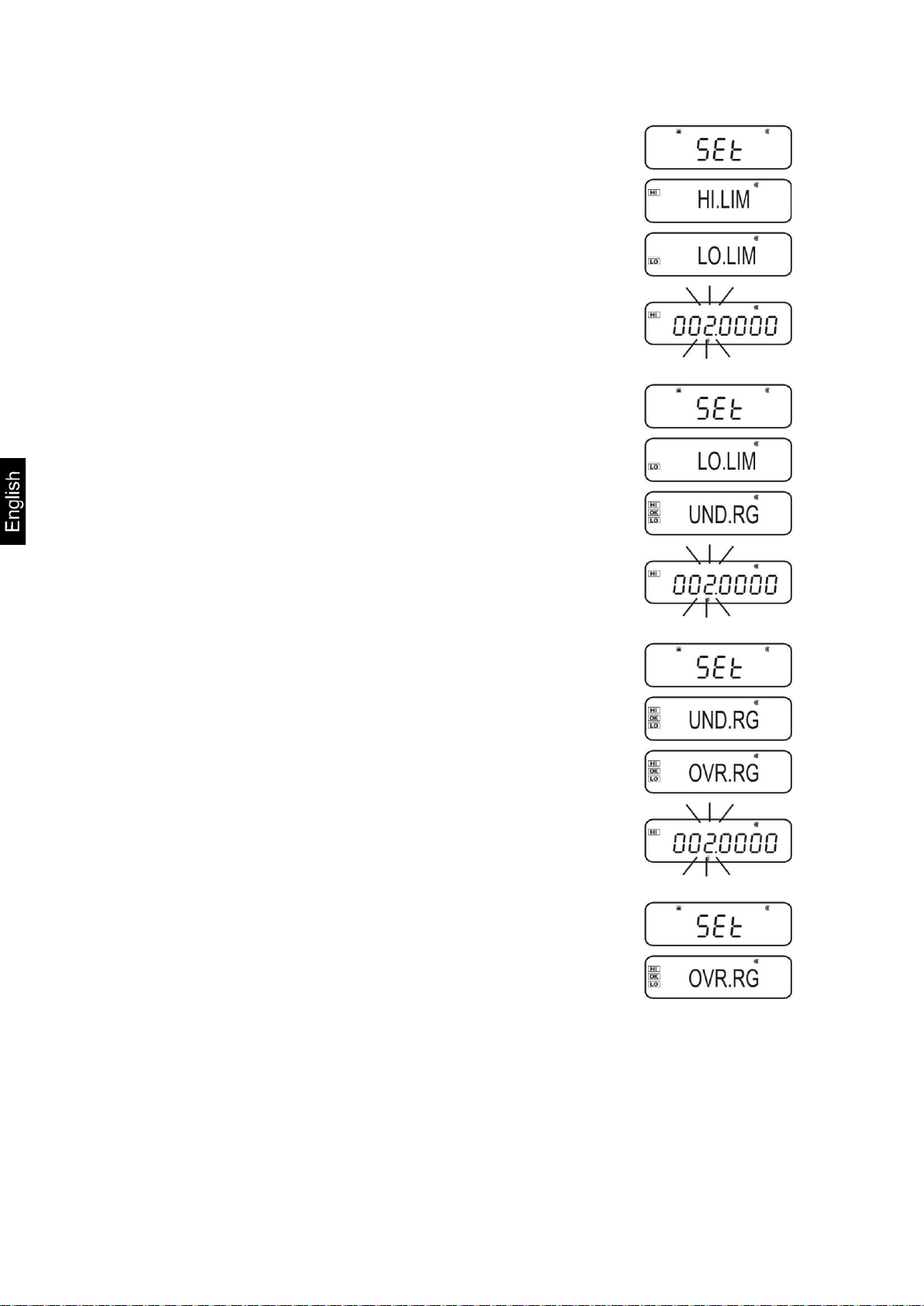

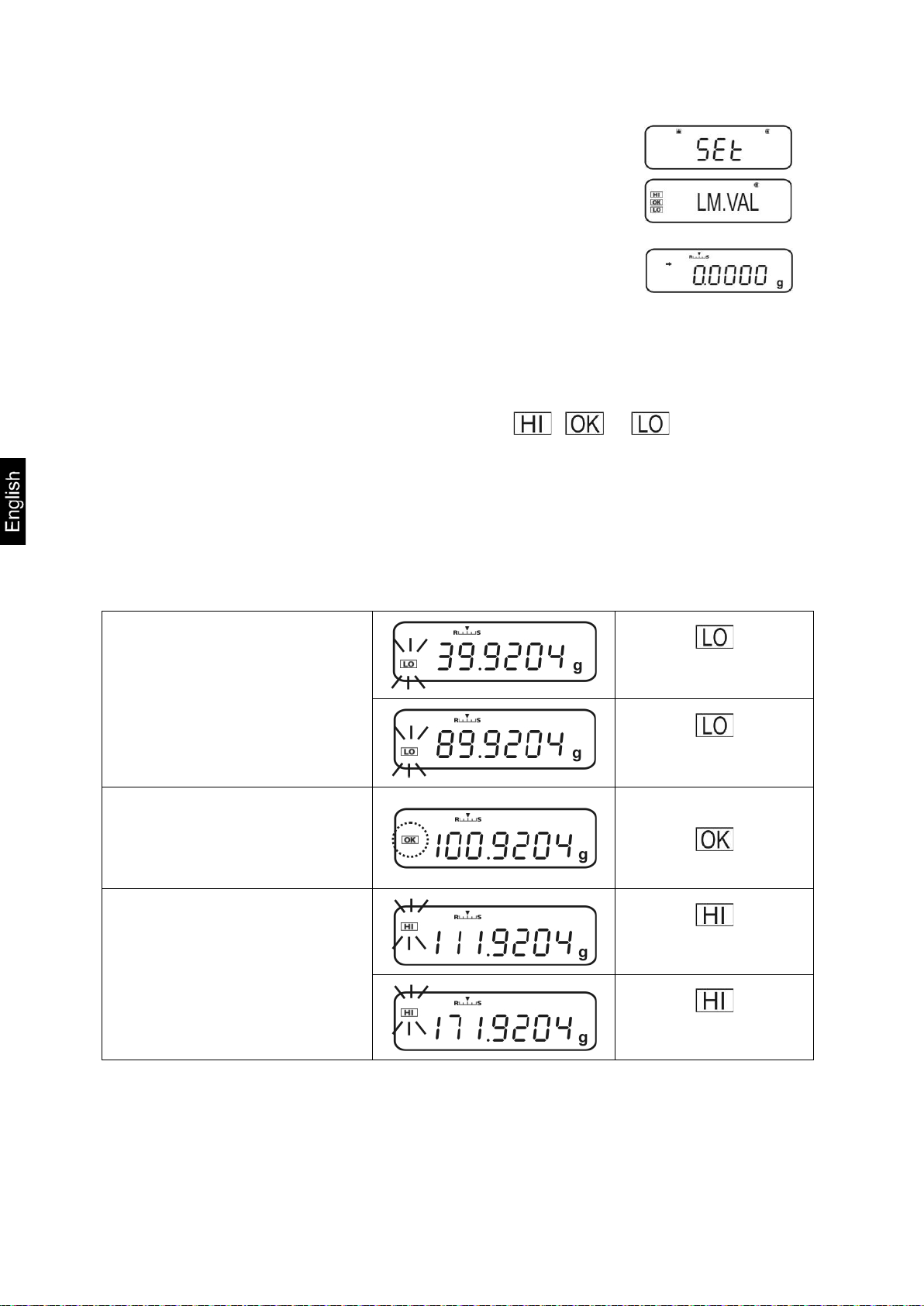

15 Check weighing and targe t mode (check and target weighing) .............. 68

15.1 Check weighing ...................................................................................................................... 68

15.2 Target mode ............................................................................................................................ 72

16 Data output ................................................................................................... 75

16.1 Pin connection ........................................................................................................................ 75

16.2 Issue functions ....................................................................................................................... 76

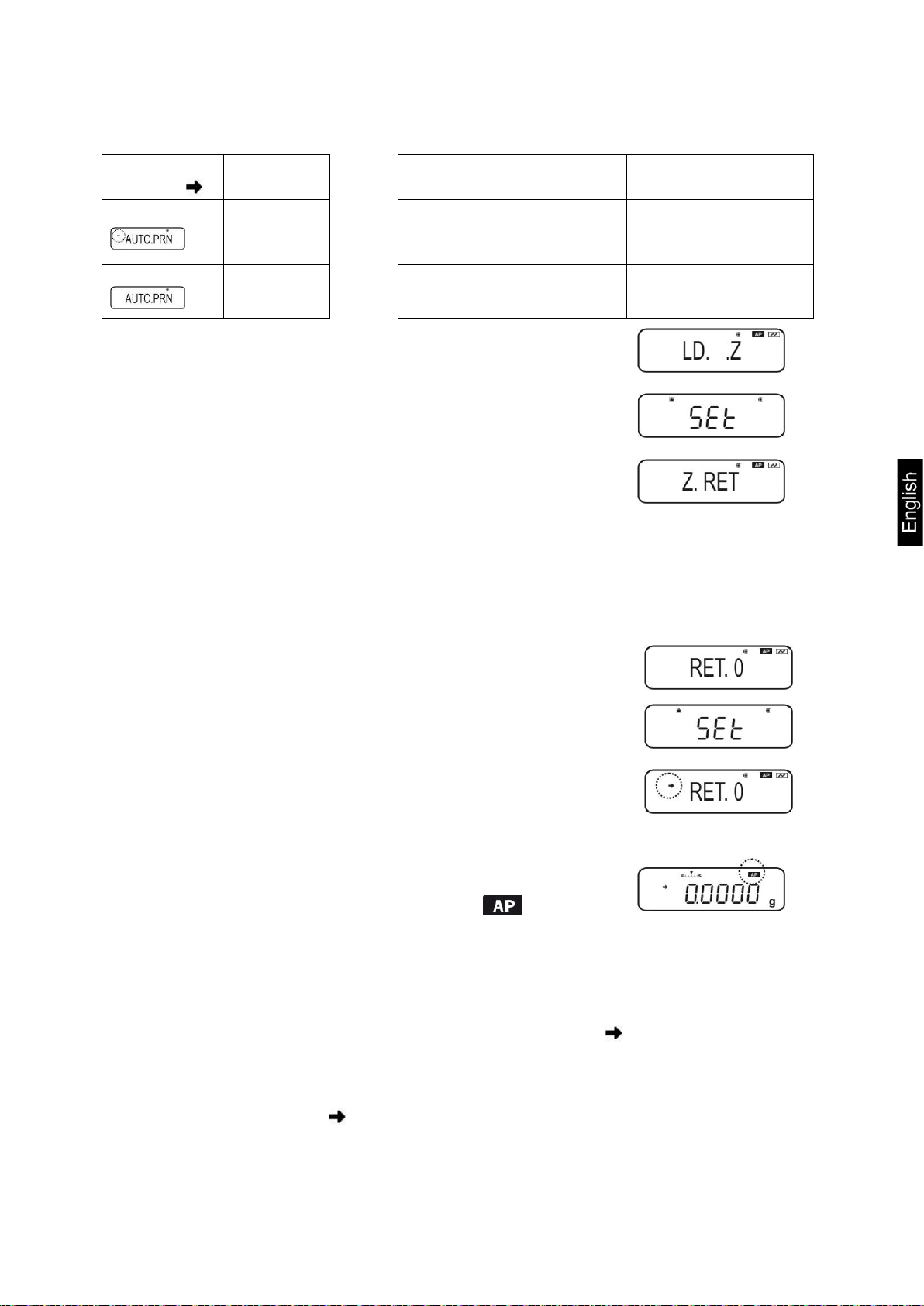

16.2.1 Automatic data output / Auto Print function .......................................................................... 76

16.2.2 Continuous Output function .................................................................................................. 78

16.2.3 Output Timing Change function ........................................................................................... 80

16.2.4 GLP Output function / balance identification number ........................................................... 81

16.3 Communication parameters .................................................................................................. 82

16.3.1 Selection of a standard setting „MODE 1 - MODE 5“ ........................................................... 83

16.3.2 User-defined settings „MODE U“ / setting for KERN –YKB-01N ......................................... 84

16.4 Data Formats ........................................................................................................................... 88

16.5 Remote control instructions .................................................................................................. 92

17 Service, maintenance, disposal .................................................................. 93

17.1 Cleaning................................................................................................................................... 93

17.2 Service, maintenance ............................................................................................................. 95

17.3 Disposal ................................................................................................................................... 95

18 Instant help ................................................................................................... 95

18.1 Error messages ....................................................................................................................... 96

ABS-N_ABJ-NM-BA-e-1312 3

Page 4

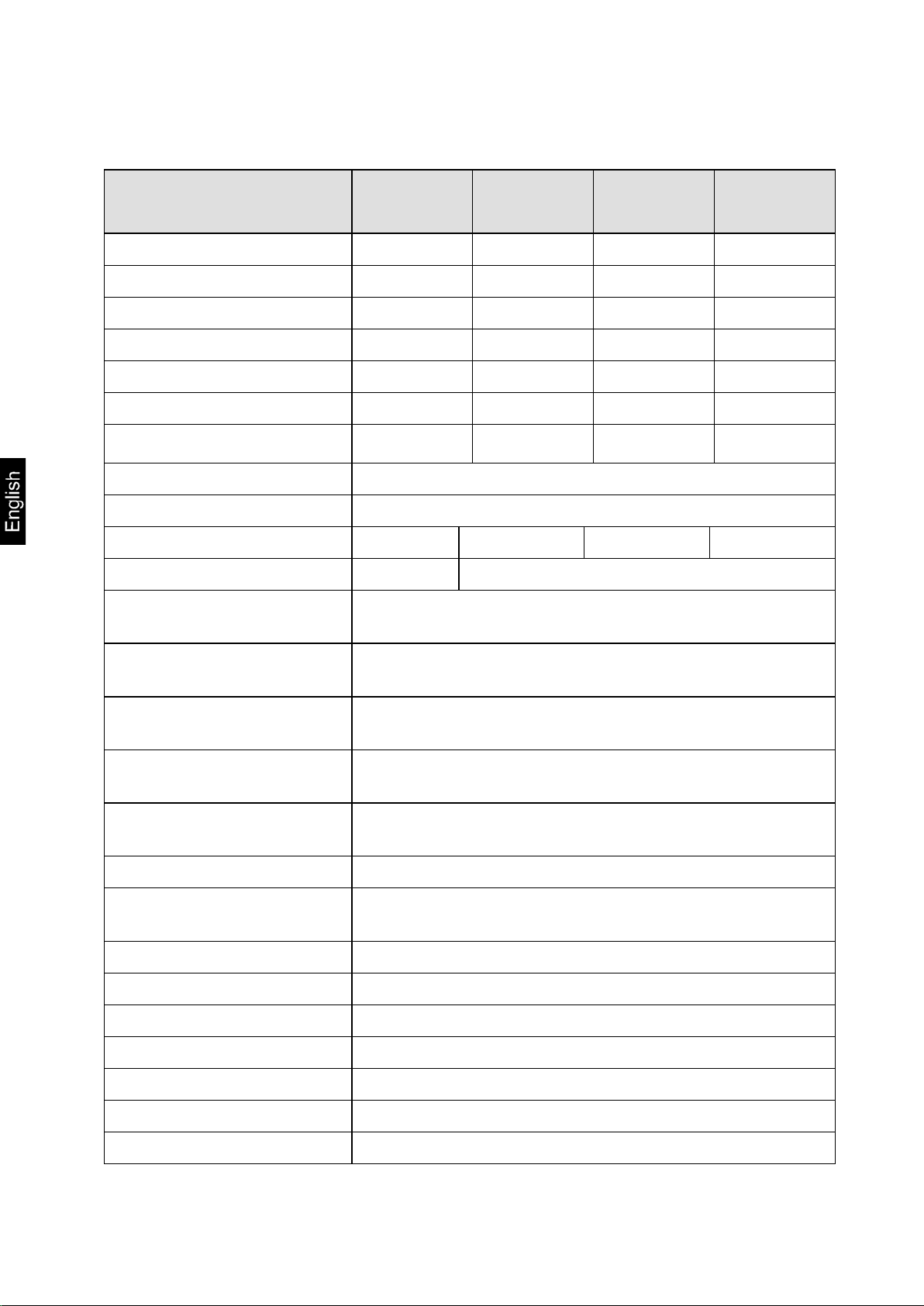

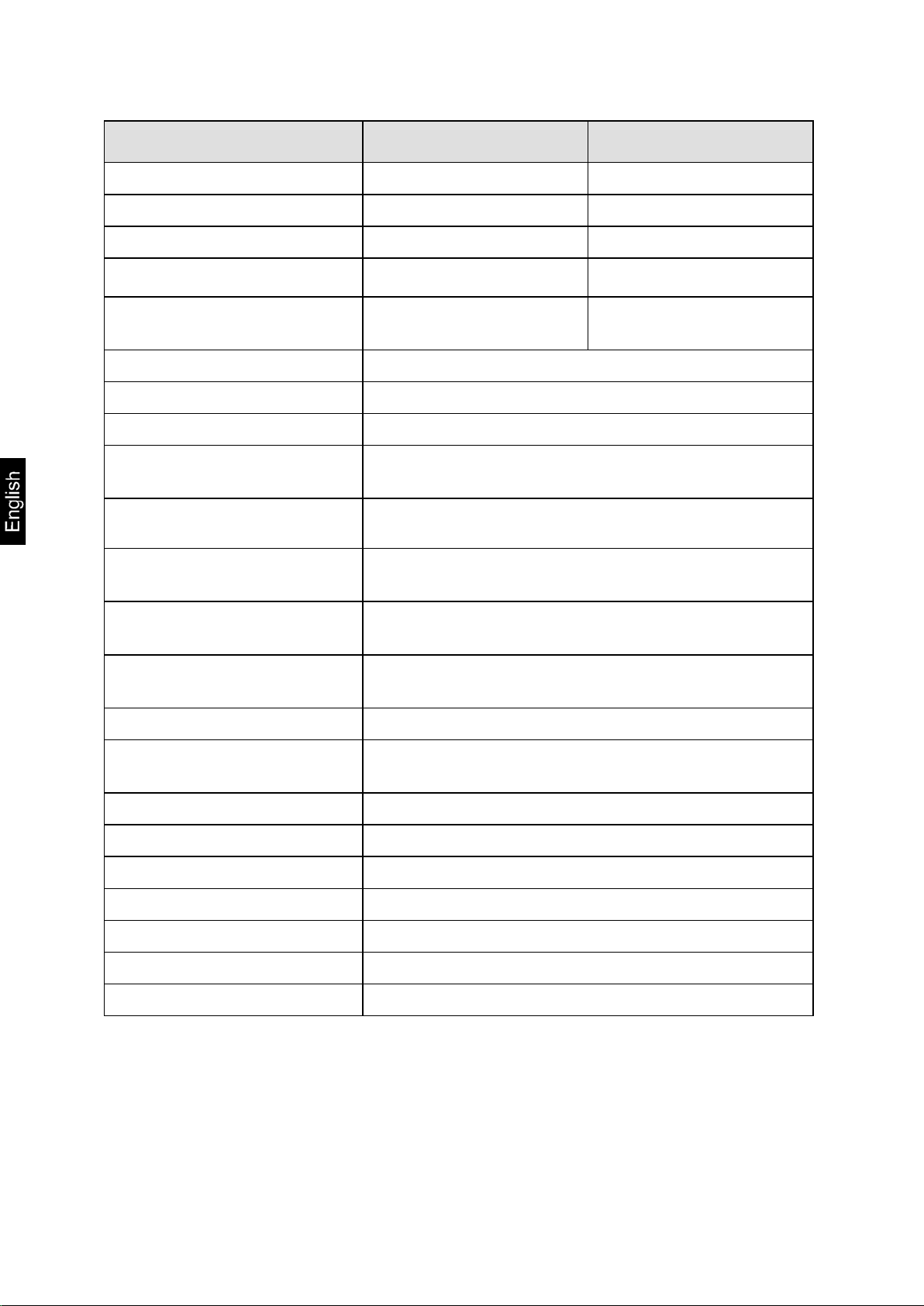

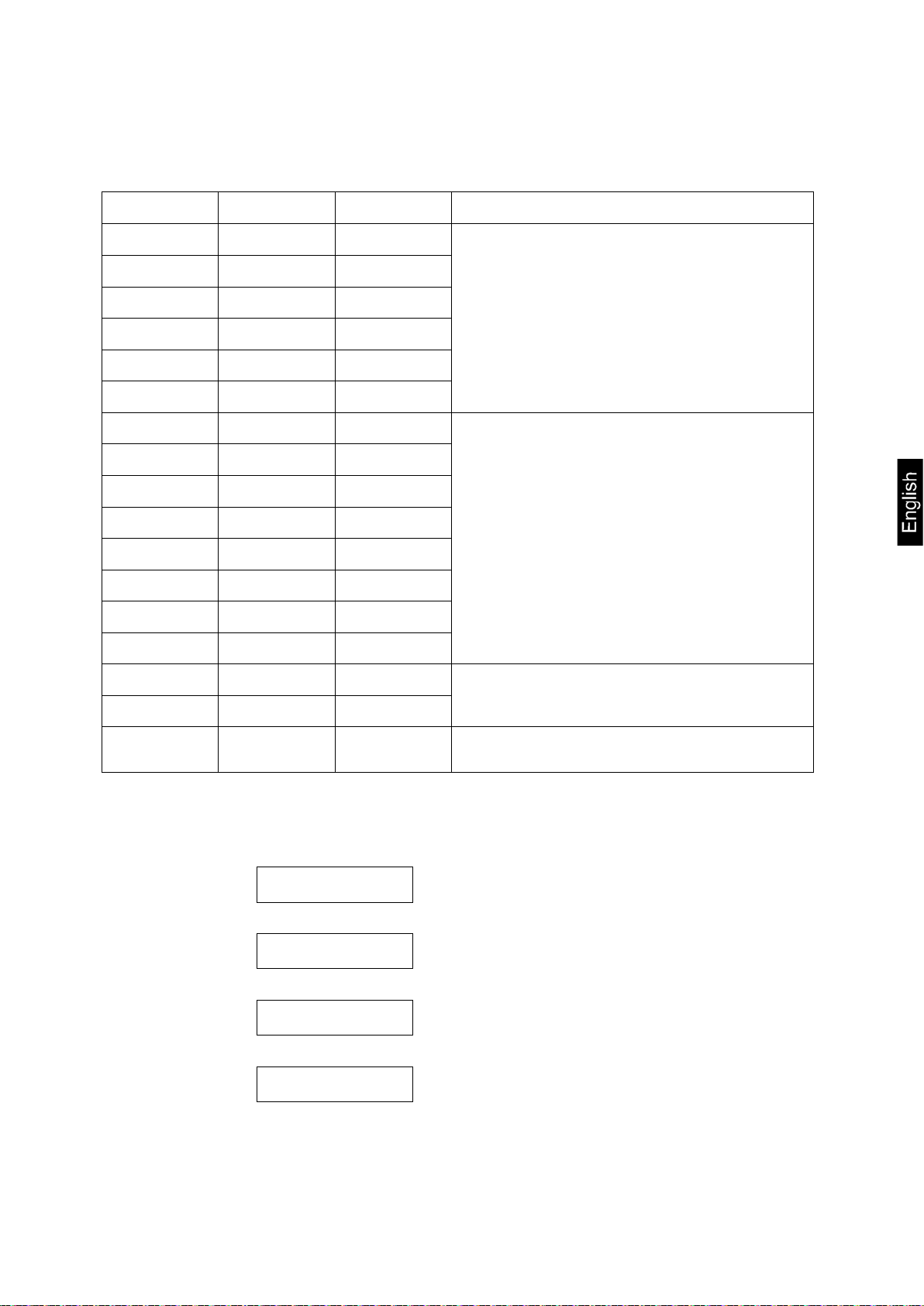

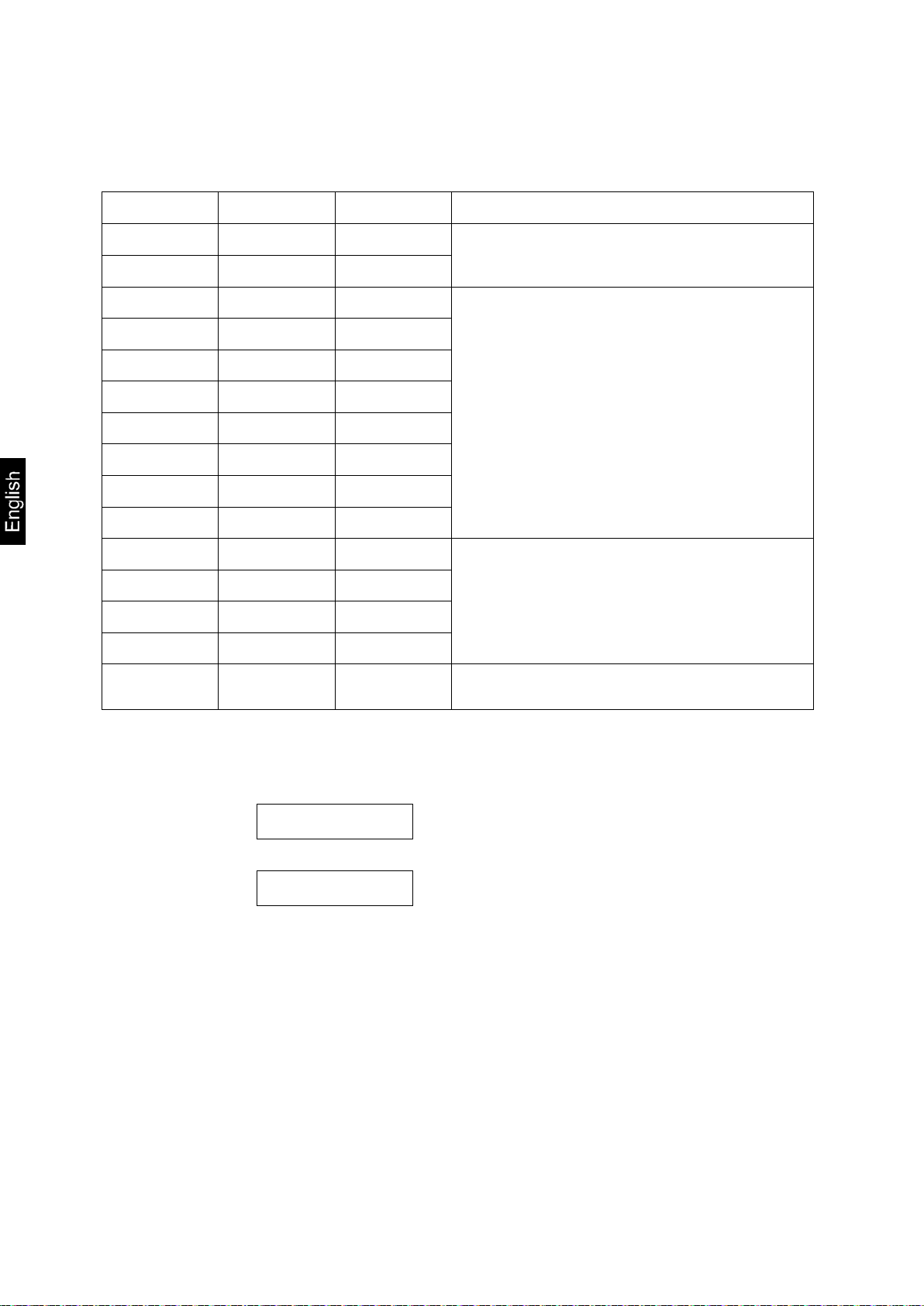

1 Technical Specifications

KERN ABJ

80-4NM

Readability (d) 0.1 mg 0.1 mg 0.1 mg 0.1 mg

Weighing range (max) 80 g 120 g 220 g 320 g

Minimum load (Min) 10 mg 10 mg 10 mg 10 mg

Verification value (e) 1 mg 1 mg 1 mg 1 mg

Verification class I I I I

Reproducibility 0.2 mg 0.2 mg 0.2 mg 0.2 mg

Linearity ± 0.3 mg ± 0.3 mg ± 0.3 mg ± 0.3 mg

Stabilization time 3 sec.

Adjustment weight internal

Warm-up time 4 h 8 h 8 h 8 h

Weighing Units mg, g mg, g, ct

Smallest part weight for

piece counting

ABJ

120-4NM

1 mg

ABJ

220-4NM

ABJ

320-4NM

Reference quantities at

piece counting

Weighing plate, stainless

steel

Dimensions of the housing

(B x D x H) [mm]

Dimensions

Glass wind screen [mm]

Net weight (kg) 6

Permissible

ambient condition

Humidity of air 20 ~ 85 % relative (not condensing)

AC adapter (Primary) AC 100 -240 V, 400 mA 50/60Hz

Rated electric power supply DC 12 V, 1.25 A

Pollution Degree 2

Overvoltage Category Category II

174 x 162 x 227 (weighing space)

5, 10, 20, 50,100

ø 91mm

210 x 340 x 325

+10° C bis +30° C

Altitude Up to 2000 m

Installation Site device may only be used indoors

4 ABS-N_ABJ-NM-BA -e-1312

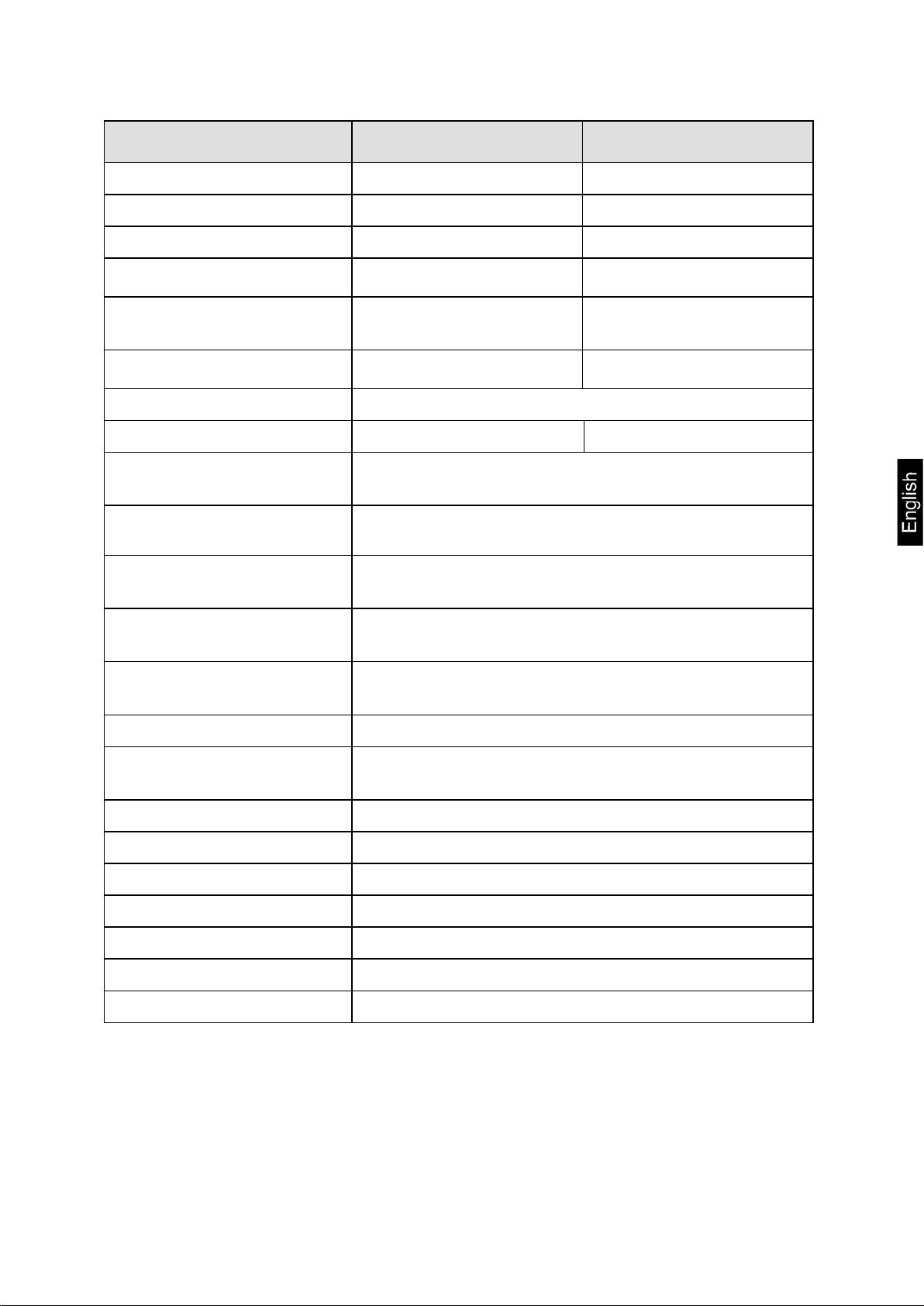

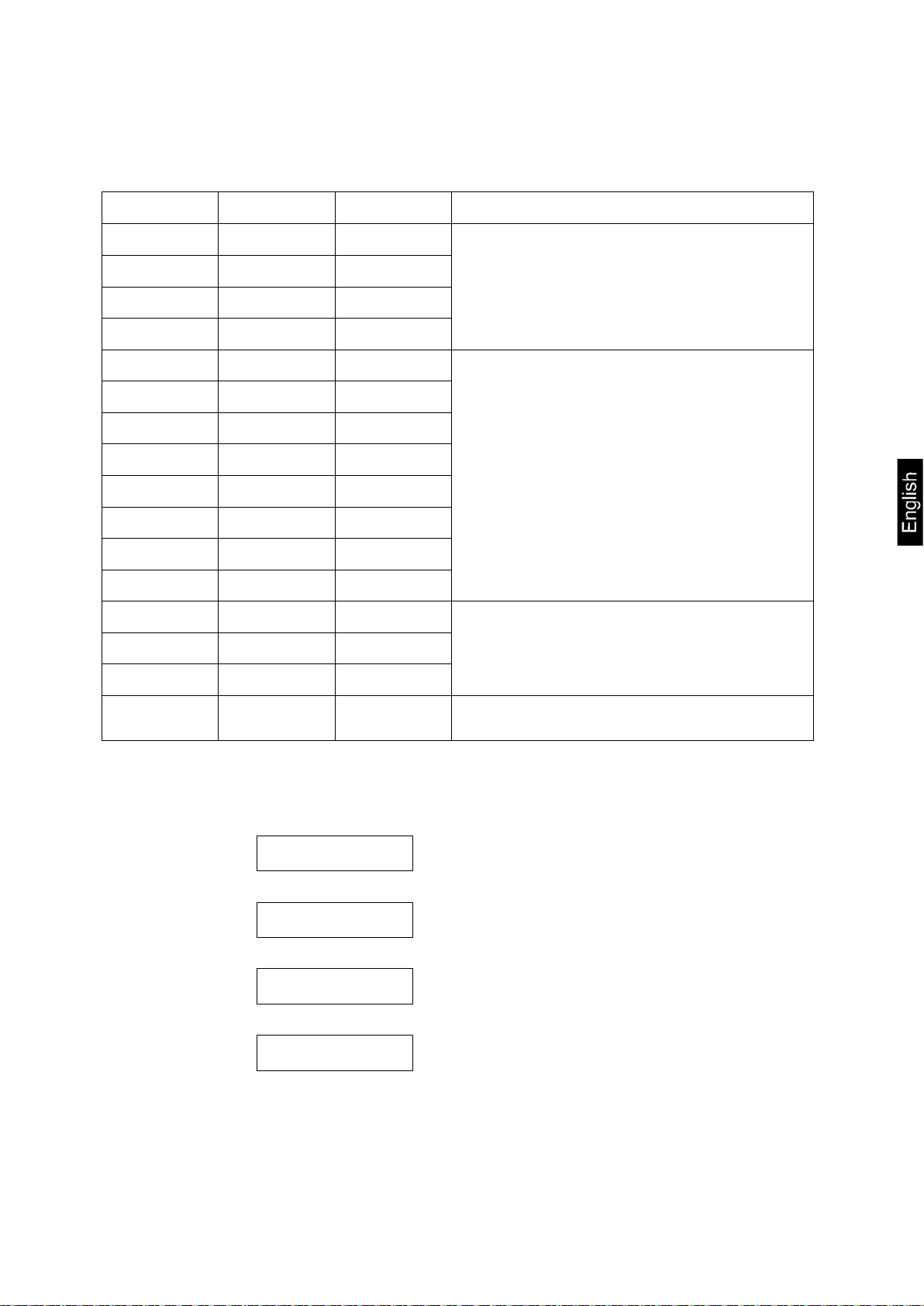

Page 5

KERN ABS 80-4N ABS 120-4N

Readability (d) 0.1 mg 0.1 mg

Weighing range (max) 80 g 120 g

Reproducibility 0.2 mg 0.2 mg

Linearity ± 0.3 mg ± 0.3 mg

Recommended adjusting

weight not supplied (class)

80 g (E2) 100 g (E2)

Warm-up time 4 h 8 h

Stabilization time 3 sec.

Weighing Units

Smallest part weight for

piece counting

Reference quantities at

piece counting

Weighing plate, stainless

steel

Dimensions of the housing

(B x D x H) [mm]

Dimensions

Glass wind screen [mm]

mg, g mg, g, ct

1 mg

5, 10, 20, 50,100

ø 91mm

210 x 340 x 325

174 x 162 x 227 (weighing space)

Net weight (kg) 6

Permissible

ambient condition

+5° C to +40° C

Humidity of air 20 ~ 85 % relative (not condensing)

AC adapter (Primary) AC 100 -240 V, 400 mA 50/60Hz

Rated electric power supply DC 12 V, 1.25 A

Pollution Degree 2

Overvoltage Category Category II

Altitude Up to 2000 m

Installation Site device may only be used indoors

ABS-N_ABJ-NM-BA-e-1312 5

Page 6

Smallest part weight for piece

KERN ABS 220-4N ABS 320-4N

Readability (d) 0.1 mg 0.1 mg

Weighing range (max) 220 g 320 g

Reproducibility 0.2 mg 0.2 mg

Linearity ± 0.3 mg ± 0.3 mg

Recommended adjusting

weight not supplied (class)

200 g (E2) 300 g (E2)

Stabilization time 3 sec.

Warm-up time 8 h

Weighing Units

counting

Reference quantities at

piece counting

Weighing plate, stainless

steel

Dimensions of the housing (B

x D x H) [mm]

Dimensions

Glass wind screen [mm]

174 x 162 x 227 (weighing space)

mg, g, ct

1 mg

5, 10, 20, 50,100

ø 91mm

210 x 340 x 325

Net weight (kg) 6

Permissible

ambient condition

+5° C to +40° C

Humidity of air 20 ~ 85 % relative (not condensing)

AC adapter (Primary) AC 100 -240 V, 400 mA 50/60Hz

Rated electric power supply DC 12 V, 1.25 A

Pollution Degree 2

Overvoltage Category Category II

Altitude Up to 2000 m

Installation Site device may only be used indoors

6 ABS-N_ABJ-NM-BA -e-1312

Page 7

2 Declaration of c onf ormity

KERN & Sohn GmbH

D-72322 Balingen-Frommern

Phone: 0049-[0]7433-9933-0

EN

Konformitätserklärung

Wir erklären hiermit, dass das Produkt, auf das sich diese Erklärung bezieht,

mit den nachstehenden Normen übereinstimmt.

GB

Declaration of

conformity

We hereby declare that the product to which this declaration refers conforms

to the following standards.

CZ

Prohlášení o

shode

Tímto prohlašujeme, že výrobek, kterého se toto prohlášení týká, je v souladu

s níže uvedenými normami.

E

Declaración de

conformidad

Manifestamos en la presente que el producto al que se refiere esta

declaración está de acuerdo con las normas siguientes

F

Déclaration de

conformité

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la

présente déclaration, est conforme aux normes citées ci-après.

I

Dichiarazione di

conformitá

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si

riferisce è conforme alle norme di seguito citate.

NL

Conformiteitverklaring

Wij verklaren hiermede dat het product, waarop deze verklaring betrekking

heeft, met de hierna vermelde normen overeenstemt.

P

Declaração de

conformidade

Declaramos por meio da presente que o produto no qual se refere esta

declaração, corresponde às normas seguintes.

PL

Deklaracja

zgodności

Niniejszym oświadczamy, że produkt, którego niniejsze oświadczenie dotyczy,

jest zgodny z poniższymi normami.

RUS

Заявление о

соответствии

Мы заявляем, что продукт, к которому относится данная декларация,

соответствует перечисленным ниже нормам.

Signature

Datum

27.03.2013

Ort der Ausstellung

Place of issue

72336 Balingen

Albert Sauter

KERN & Sohn GmbH

Geschäftsführer

Managing director

KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-[0]7433/9933-0

Fax +49-[0]7433/9933-149, E-Mail: info@kern-sohn.com, Internet: www.kern-sohn.com

Postbox 4052

email: info@kern-sohn.de

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.de

Declaration of conformity

EC-Konformitätserklärung EC-Declaration of -Conformity

Déclaration de conformité EC-Declaración de Conformidad

ECEC-Dichiarazione di conformit à EC-Conformiteitverklaring

EC- Declaração de conformidade EC- Prohlášení o shode

EC-Deklaracja zgodności EC-Заявление о соответствии

Electronic Balan ce: KERN ABJ-NM, ABS-N

EU Directive Standards

2004/108/EC EN 61326-1:2006

2006/95/EC EN 61010-1: 2010

Date

Signatur

ABS-N_ABJ-NM-BA-e-1312 7

Page 8

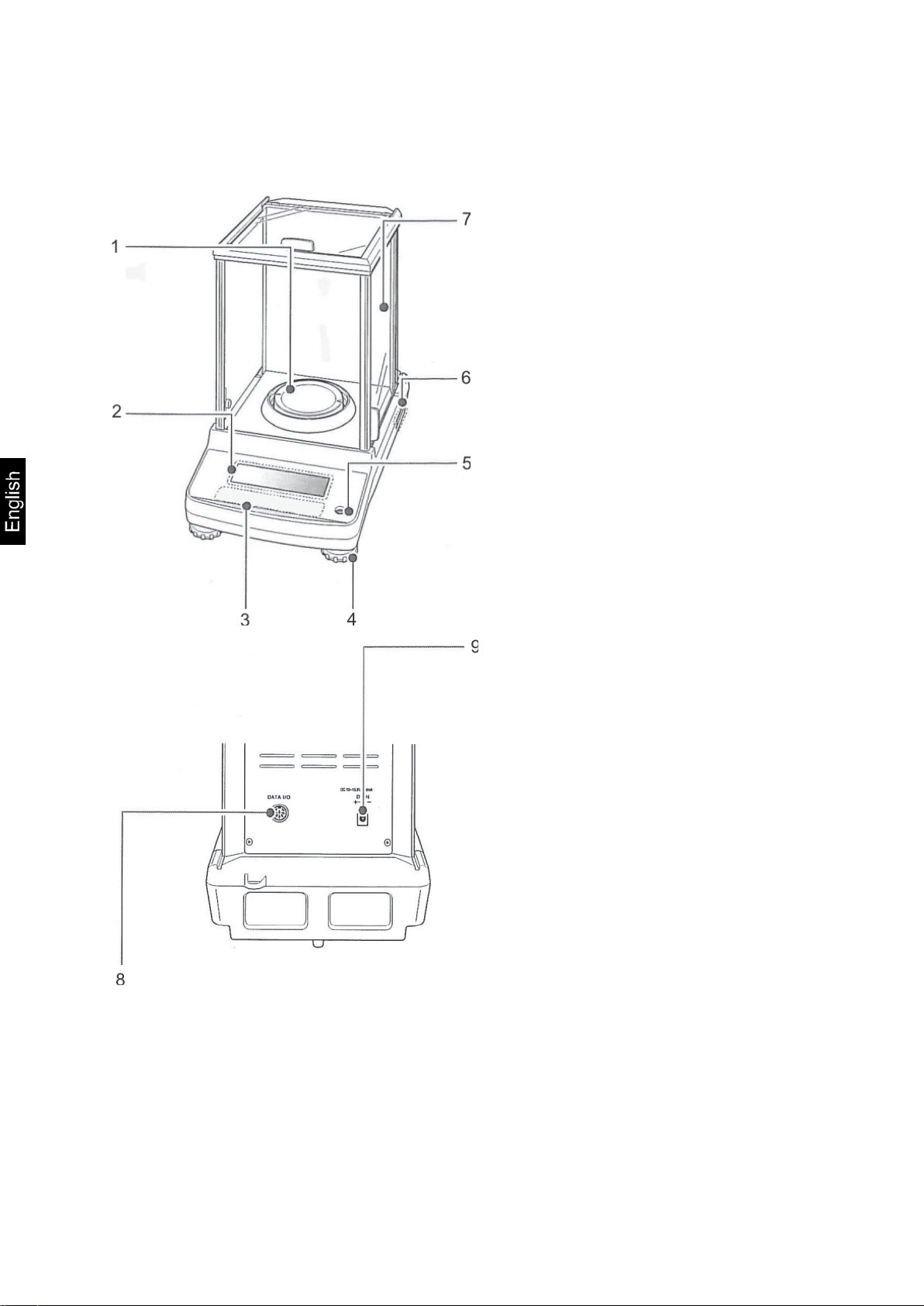

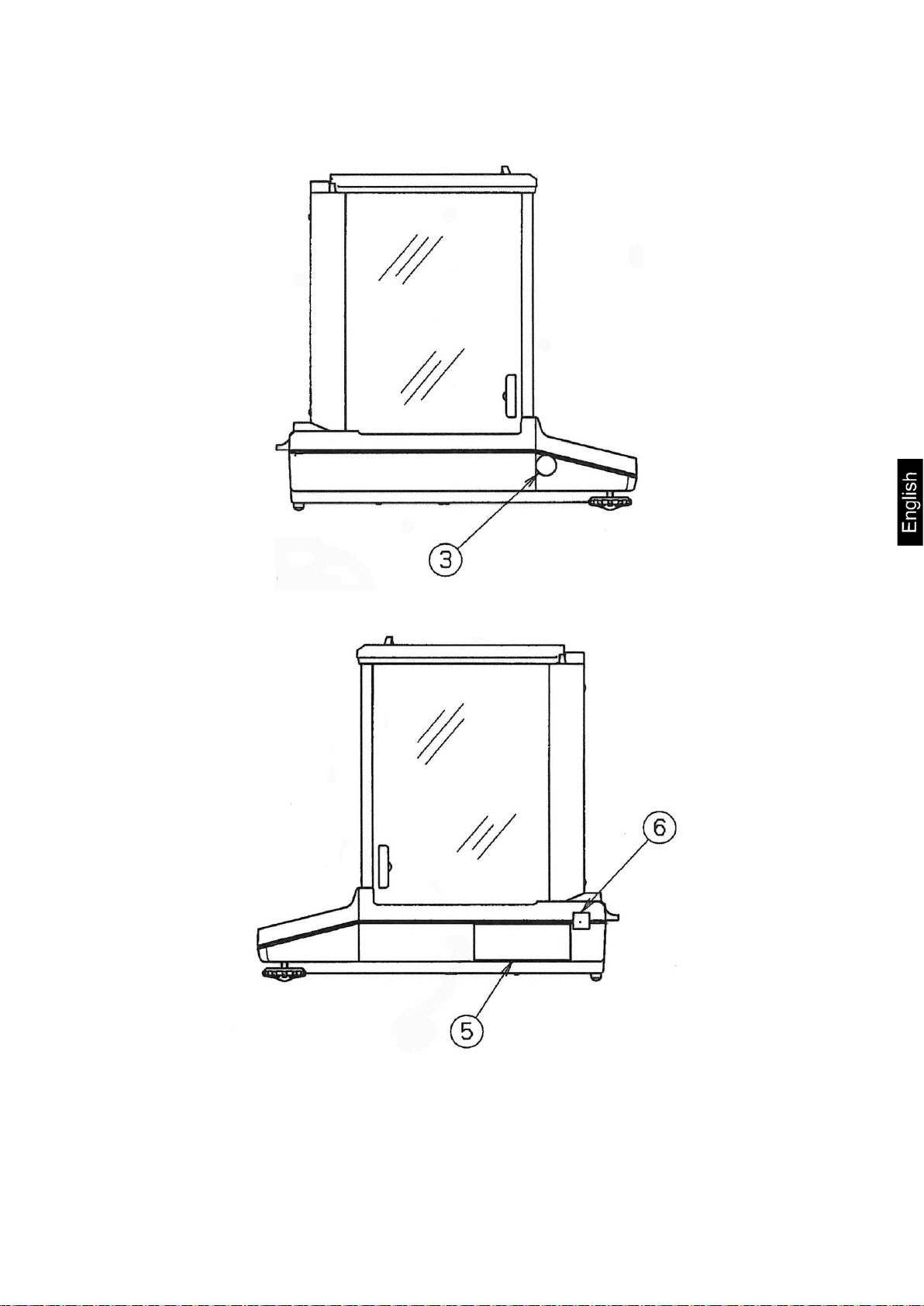

3 Appliance overview

1. Weighing plate

2. Display

3. Keyboard

4. Levelling screw

5. Bubble level

6. Name plate

7. Wind protection

8. Appliance interface

9. Mains adapter connection

8 ABS-N_ABJ-NM-BA -e-1312

Page 9

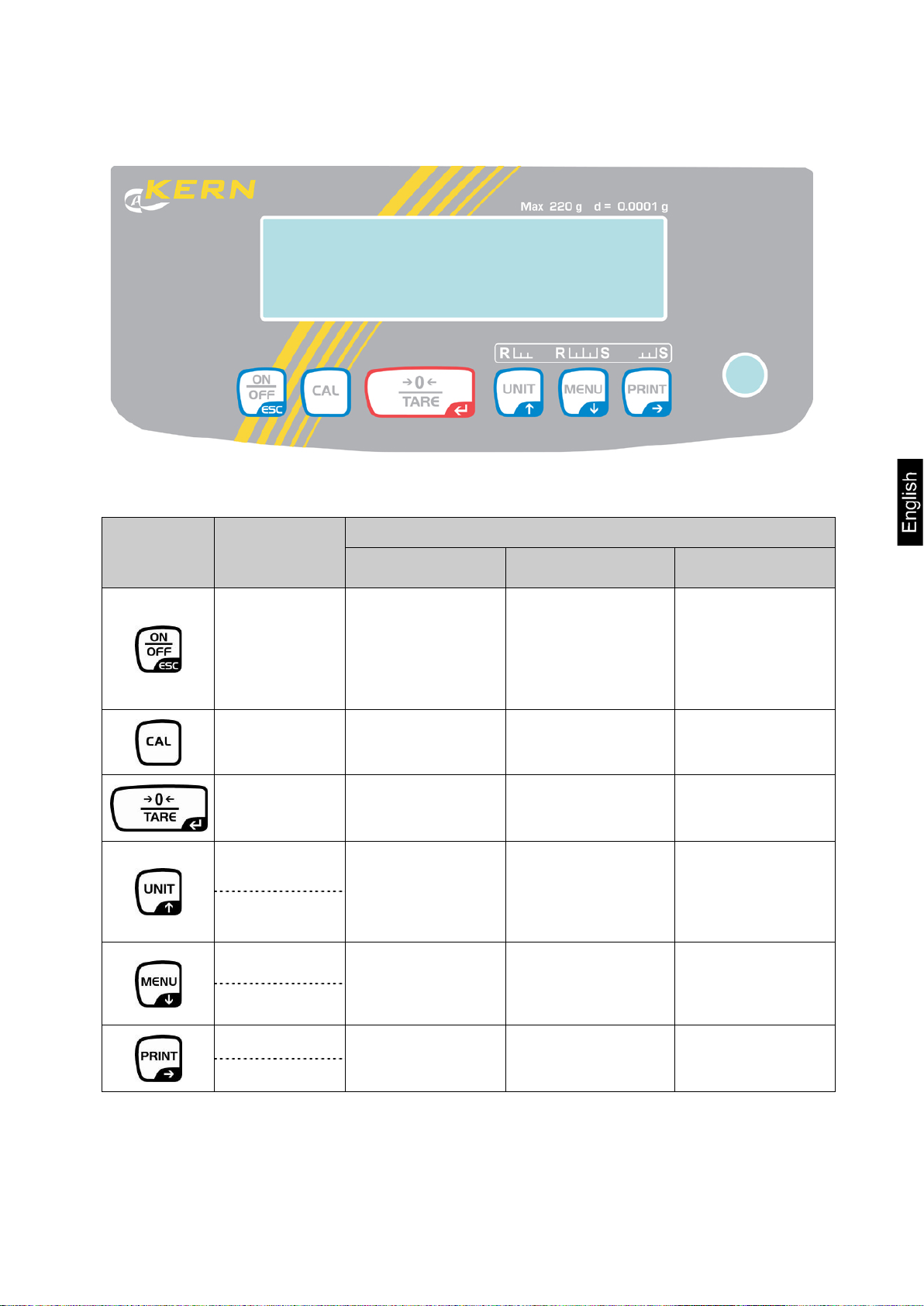

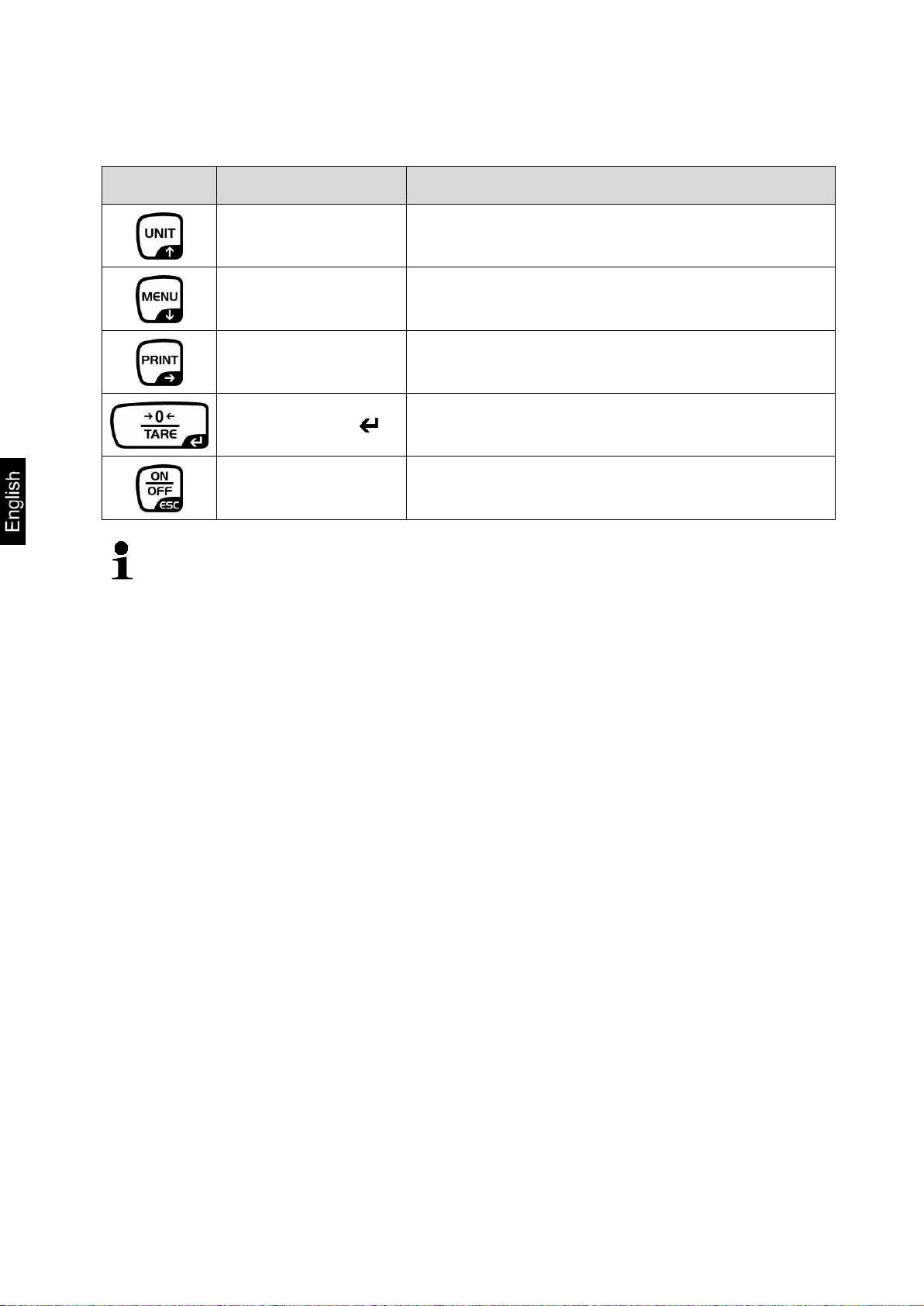

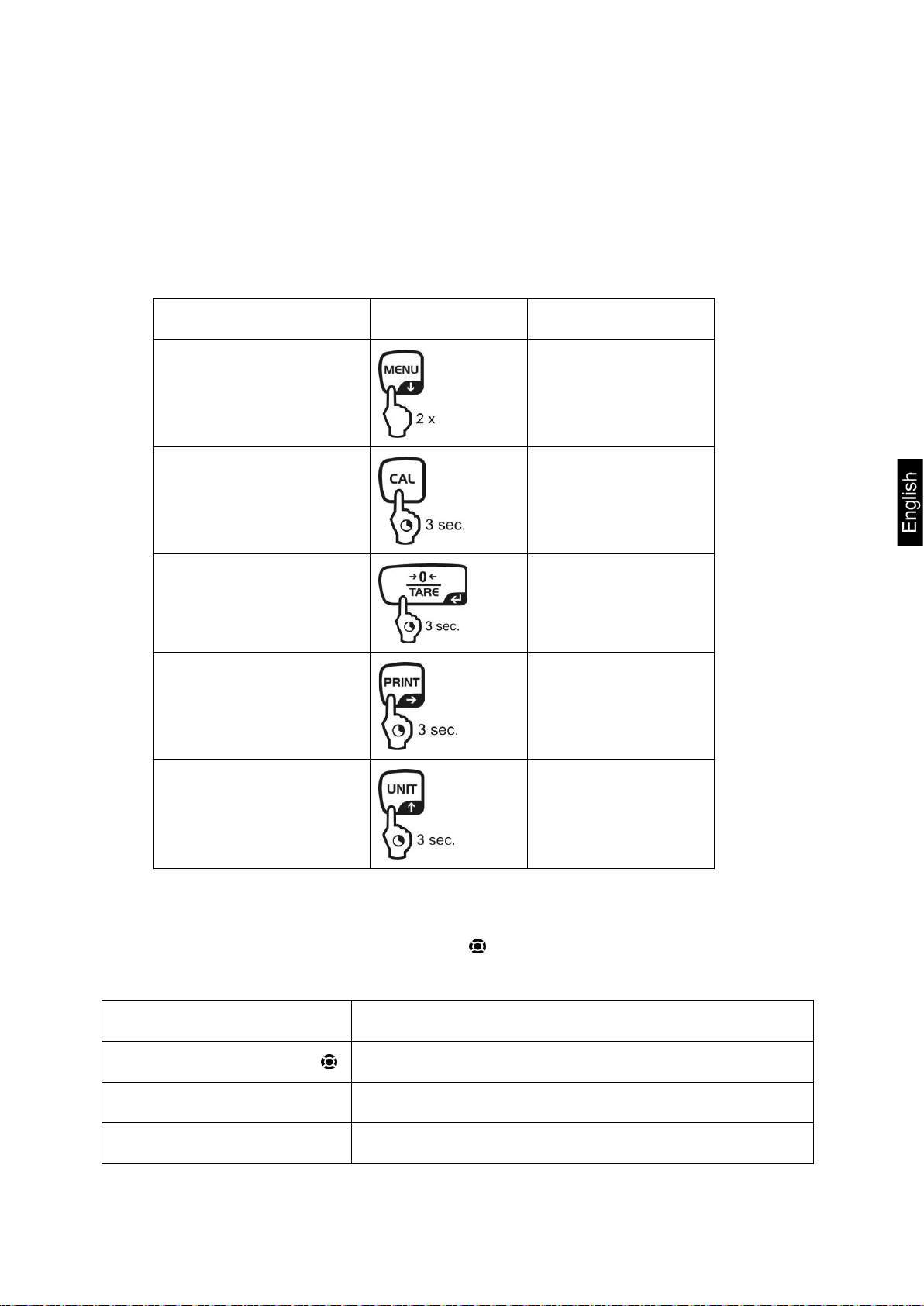

3.1 Keyboard overview

Pressed once and

released

Keep pressed for

about 3 seconds

the operation and

Cancel procedure

(PCS, %).

Switch over

menu

In menu:

Key Designation:

Function

In menu

Menu item back.

Switches between

ON/OFF

CAL

TARE

UNIT

Navigation key

MENU

Navigation key

PRINT

Navigation key

standby modes.

Start adjustment

Tare or set weight

display to zero

Switch-over

weighing unit.

Display stored

reference weight

Calculate weighing

data via interface

Invoke calibration

menu

Invoke zero / tare

menu

Invoke unit setting

menu.

weighing mode /

application mode

Invoke Data Output

menu

-

Return to weighing

mode:

Press ON/OFF

repeatedly or for 3 s.

-

Confirm entry

Scroll forward in

menu

Invoke main menu

(press twice)

Scroll backwards in

Select next menu

item.

ABS-N_ABJ-NM-BA-e-1312 9

Page 10

3.1.1 Numeric entry

Key Designation: Function

Navigation key

Navigation key

Navigation key Digit selection to the right

Navigation key Confirm entry

ESC Cancel input

With numerical input the indicator [#] appears.

Increase flashing digit

Shift flashing decimal dot to the left

Decrease flashing digit

Shift flashing decimal dot to the right

10 ABS-N_ABJ-NM-BA -e-1312

Page 11

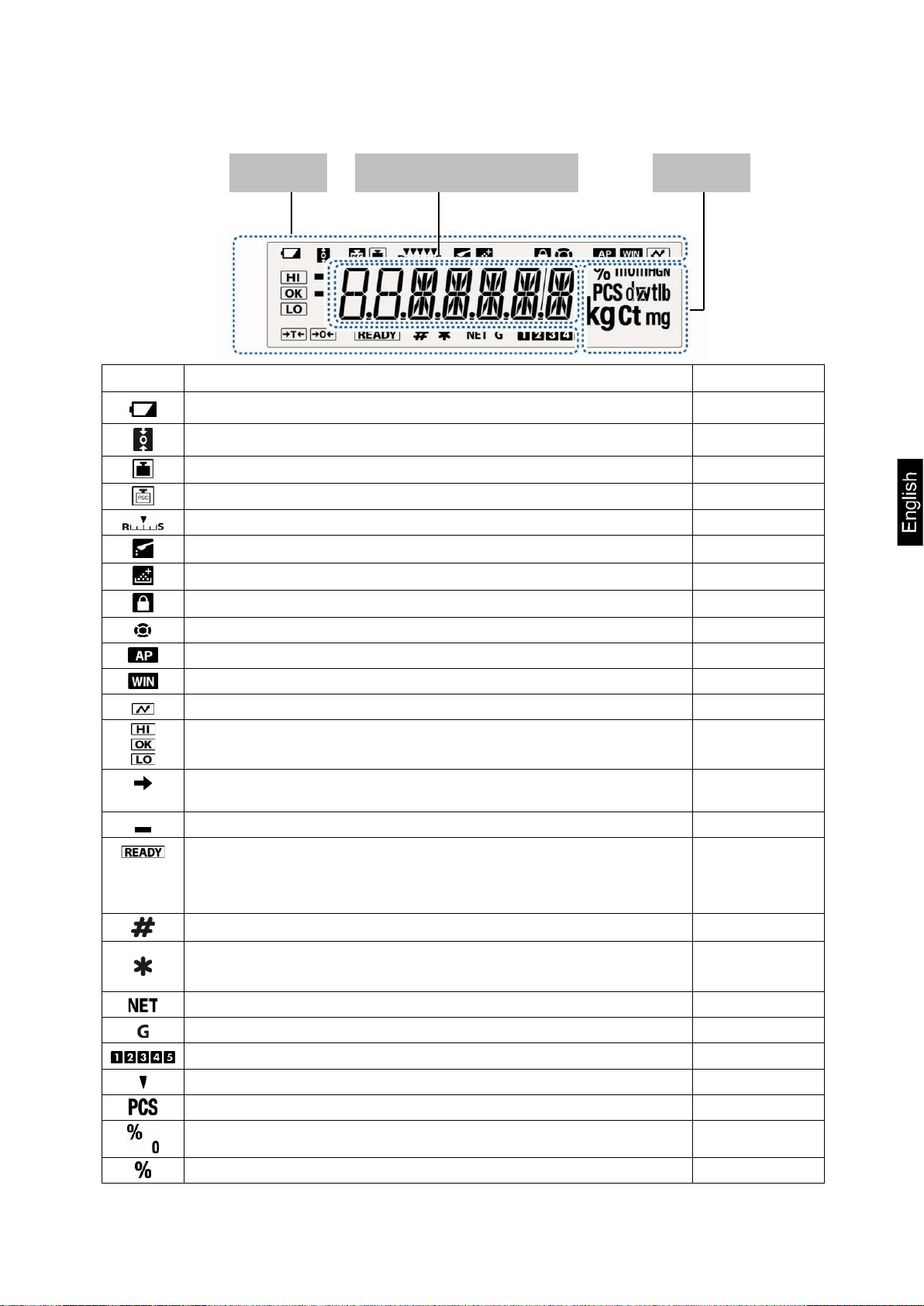

3.2 Overview of displays

Chpt. 14.3

Units

Symbols

Numerical display/menu

Display Description see chpt.

Battery symbol

Zero tracking function active

Displays adjustment

Flashes prior to start of automatic adjustment, only models ABJ

Stability and reaction settings via „Easy Setting display“ +

Balance is in dosing mode (pouring mode) +

Balance is in formula mode +

Menu lock active +

Menu symbol +

Auto Print function active +

Not documented

Log menu settings

Tolerance marks in check weighing and target mode + Chpt. 15

The stability display indicates that the weighing value is stable.

Highlights current setting in the menu.

Negative weighed value

Stand-by mode

Ready for start formulation

Ready for start continuous data output („MANU ON“)

Chpt.12.1

+

+

Chpt. 8.2.1

+

Chpt. 8.1

Chpt.13.1

Chpt. 13.2

Chpt. 14.3

Chpt. 11.5

Chpt. 11.2

Chpt. 16.2.1

+

Chpt. 10.2

+ Chpt. 14.3

+ Chpt. 16.5.2

ABS-N_ABJ-NM-BA-e-1312 11

Indicates numeric value entry. +

Shows the stored reference in piece number or percent determination mode.

Chpt. 3.1.1

+

Chpt.14.1

+ Chpt.14.2.3

Net weight in formula mode +

Total weight (TOTAL) of all components in formula mode +

Memory space piece weight +

Change position decimal dot for freely programmable weighing unit +

Balance is in piece counting mode +

Balance is in percent determination mode with user-defined reference weight + Chpt.14.2.1

Balance is in percent determination mode, reference weight =100% +

Chpt. 14.3

Chpt.14.1

Chpt.10.7.2

Chpt.14.1

Chpt.14.2.2

Page 12

4 Basic Information (General)

4.1 Proper use

The balance you purchased is intended to determine the weighing value of material

to be weighed. It is intended to be used as a “non-automatic“ balance, i.e. the

material to be weighed is manually and carefully placed in the centre of the weighing

plate. As soon as a stable weighing value is reached the weighing value can be read.

4.2 Improper Use

Do not use balance for dynamic add-on weighing procedures, if small amounts of

goods to be weighed are removed or added. The “stability compensation“ installed in

the balance may result in displaying an incorrect measuring value! (Example: Slowly

draining fluids from a container on the balance.)

Do not leave permanent load on the weighing plate. This may damage the

measuring system.

Impacts and overloading exceeding the stated maximum load (max) of the balance,

minus a possibly existing tare load, must be strictly avoided. Balance may be

damage by this.

Never operate balance in explosive environment. The serial version is not explosion

protected.

The structure of the balance may not be modified. This may lead to incorrect

weighing results, safety-related faults and destruction of the balance.

The balance may only be used according to the described conditions. Other areas of

use must be released by KERN in writing.

4.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described use

• The appliance is modified or opened

• Mechanical damage or damage by media, liquids, natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

12 ABS-N_ABJ-NM-BA -e-1312

Page 13

4.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the

balance and, if applicable, the testing weight, must be checked regularly. The

responsible user must define a suitable interval as well as type and scope of this

test. Information is available on KERN’s home page (www.kern-sohn.com with

regard to the monitoring of balance test substances and the test weights required for

this. In KERN’s accredited DKD calibration laboratory test weights and balances may

be calibrated (return to the national standard) fast and at moderate cost.

5 Basic Safety Precautions

5.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and commissioning, even if you

are already familiar with KERN balances.

5.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

6 Transportation & Storage

6.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

ABS-N_ABJ-NM-BA-e-1312 13

Page 14

6.2 Packaging / return transport

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the weighing

platform, power unit etc. against shifting and damage.

14 ABS-N_ABJ-NM-BA -e-1312

Page 15

ABS-N_ABJ-NM-BA-e-1312 15

Page 16

7 Unpacking, Setup and Commissioning

7.1 Installation Site, Location of Use

The balances are designed in a way that reliable weighing results are achieved in

common conditions of use.

You will work accurately and fast, if you select the right location for your balance.

Therefore, observe the following for the installation site:

• Operate the device only indoors.

• Place the balance on a firm, level surface;

• Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

• Protect the balance against direct draughts due to open windows and doors;

• Avoid jarring during weighing;

• Protect the balance against high humidity, vapours and dust;

• Do not expose the device to extreme dampness for longer periods of time.

Non-permitted condensation (condensation of air humidity on the appliance)

may occur if a cold appliance is taken to a considerably warmer environment.

In this case, acclimatize the disconnected appliance for ca. 2 hours at room

temperature.

• Avoid static charge of goods to be weighed or weighing container.

If electro-magnetic fields or static charge occur, or if the power supply is unstable

major deviations on the display (incorrect weighing results) are possible. In that case,

the location must be changed.

7.2 Unpacking and checking

Open package, take out the appliance and accessories. Verify that there has been

no damage and that all packing items are present.

16 ABS-N_ABJ-NM-BA -e-1312

Page 17

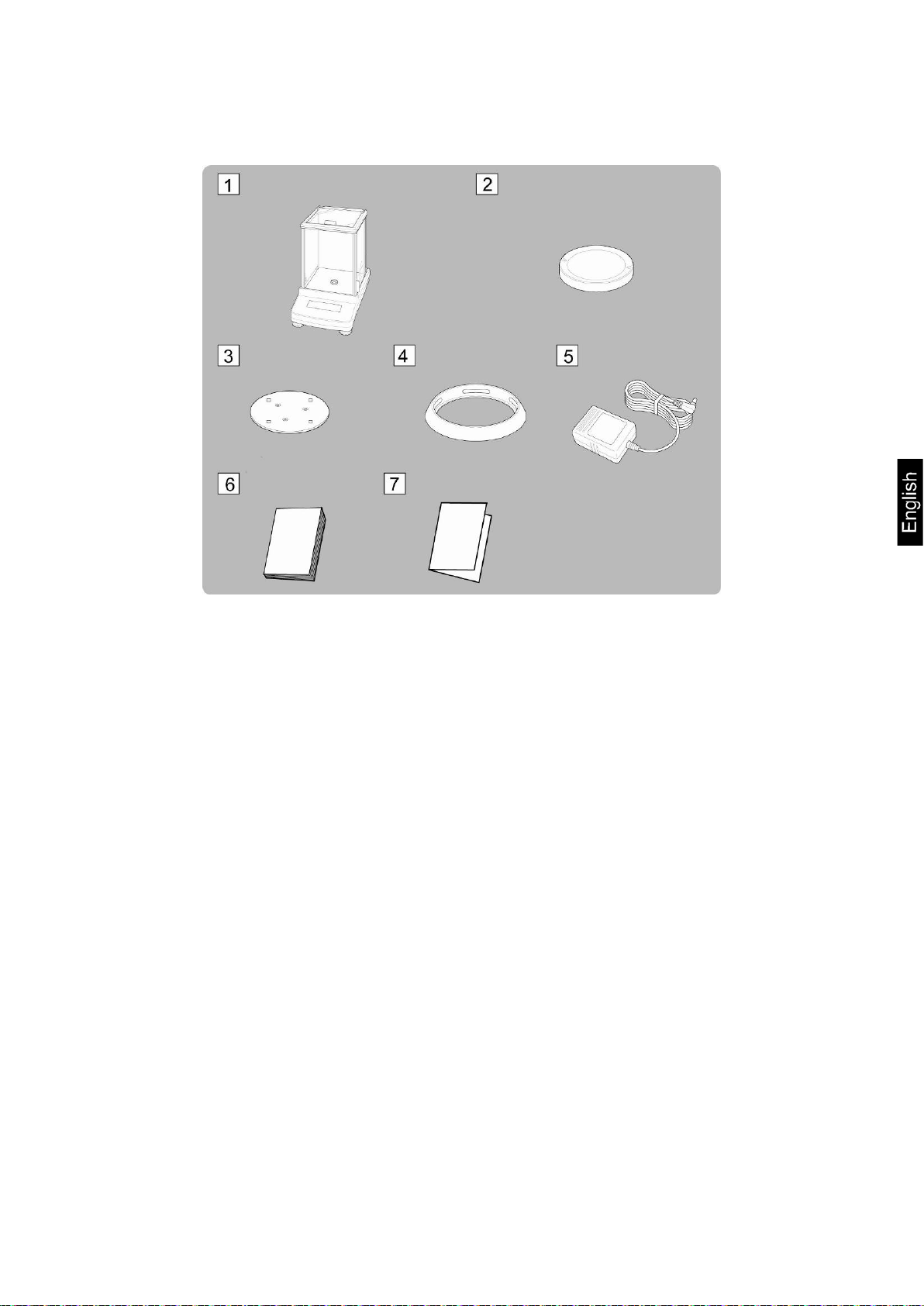

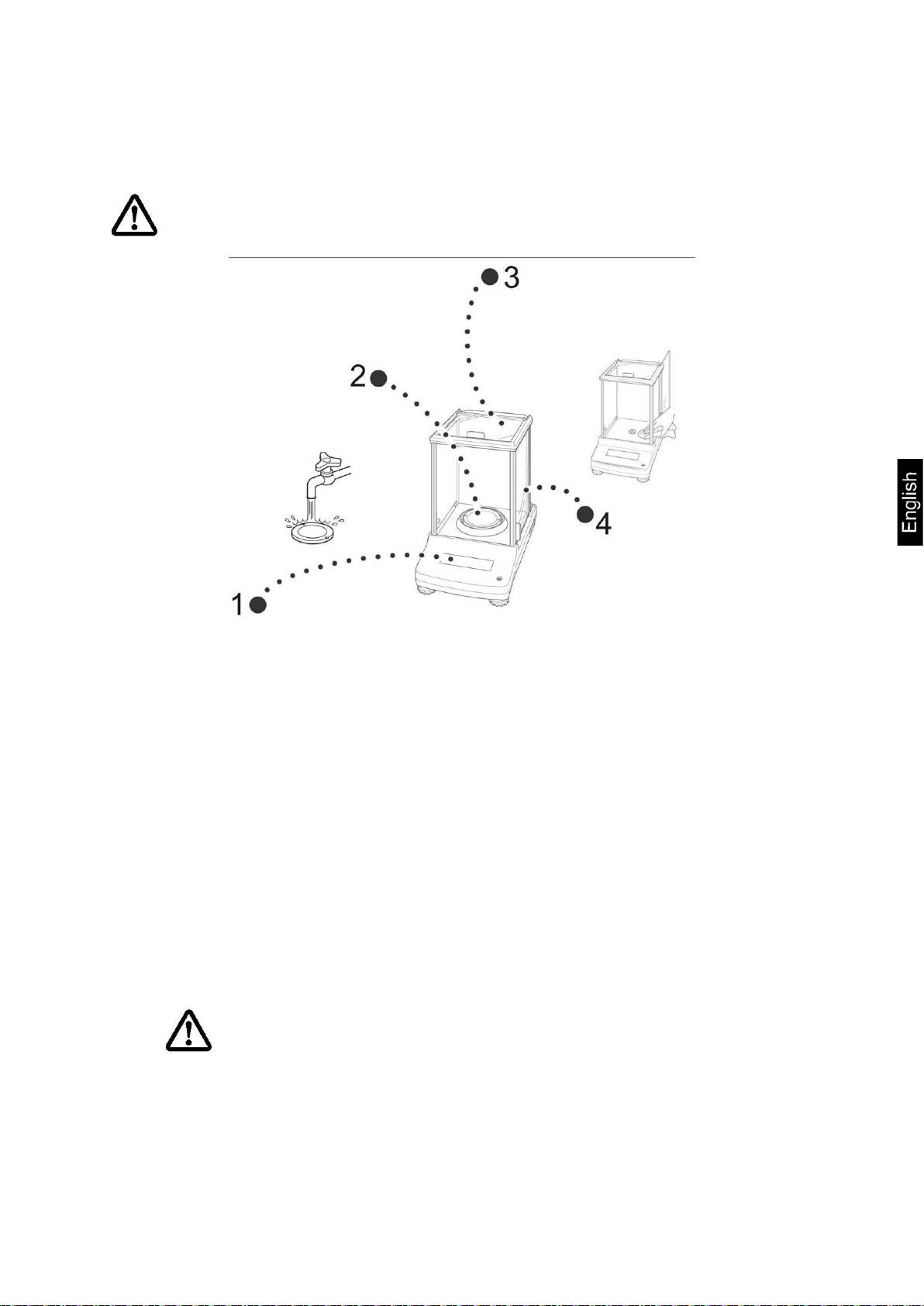

7.2.1 Scope of delivery / serial accessories

1. Balance

2. Weighing plate

3. Carrier weighing plate

4. Screening ring

5. Mains adapter

6. Operating instructions

7. Menu overview

ABS-N_ABJ-NM-BA-e-1312 17

Page 18

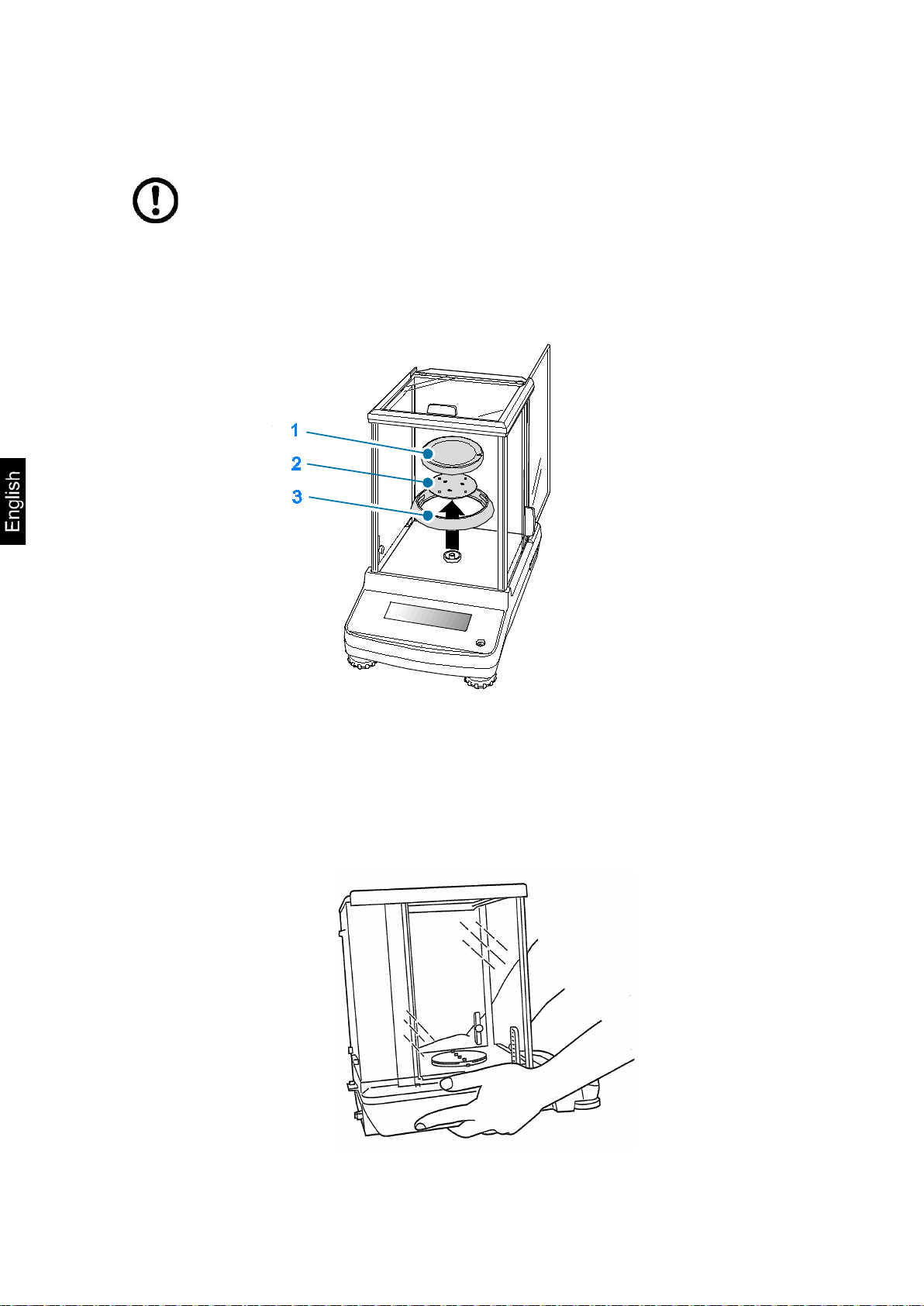

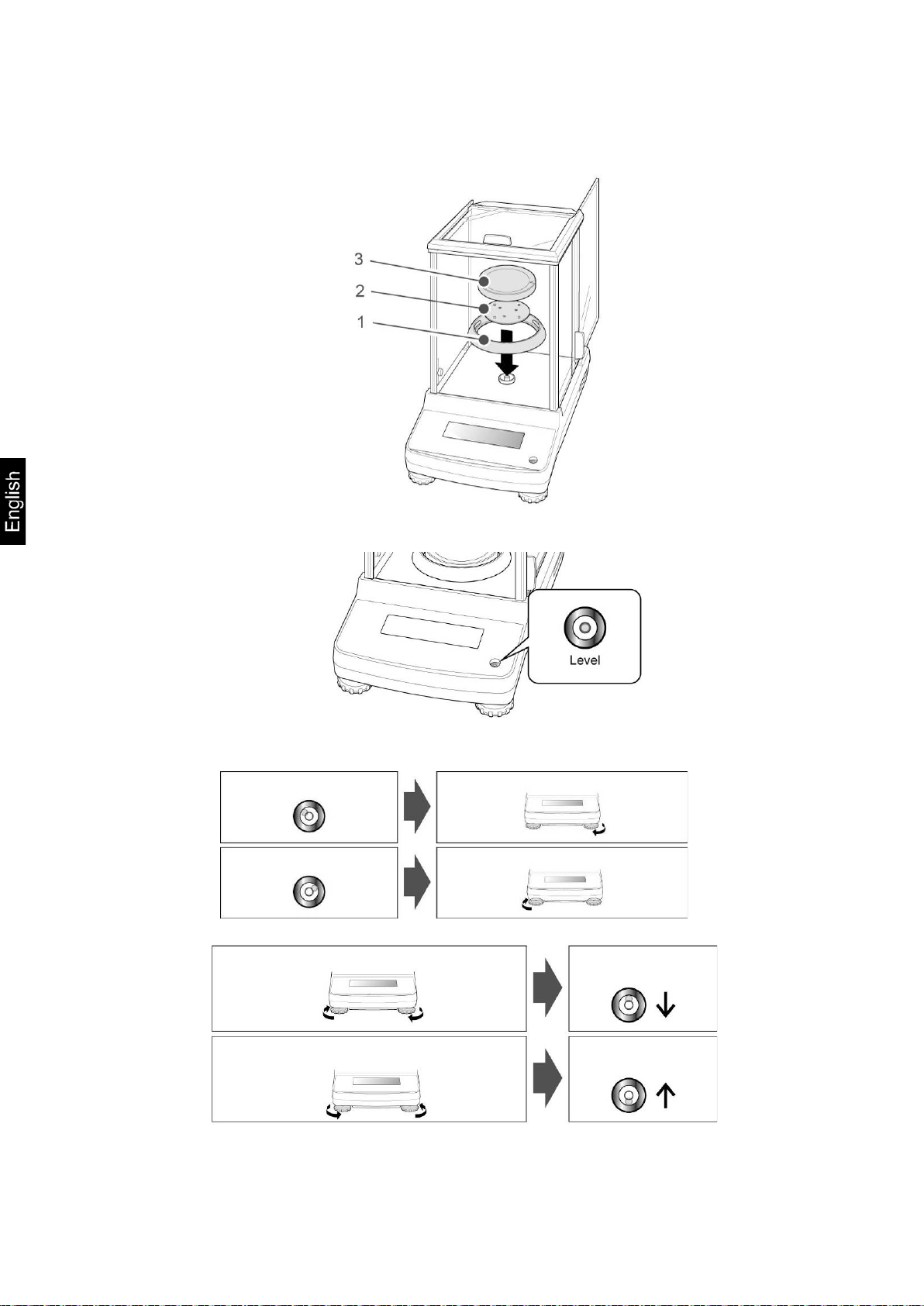

7.2.2 Placing

Attach circular screen, carrier of weighing plate and weighing plate in order.

Level balance with foot screws until the air bubble of the water balance is in the

prescribed circle.

Check levelling regularly

18 ABS-N_ABJ-NM-BA -e-1312

Page 19

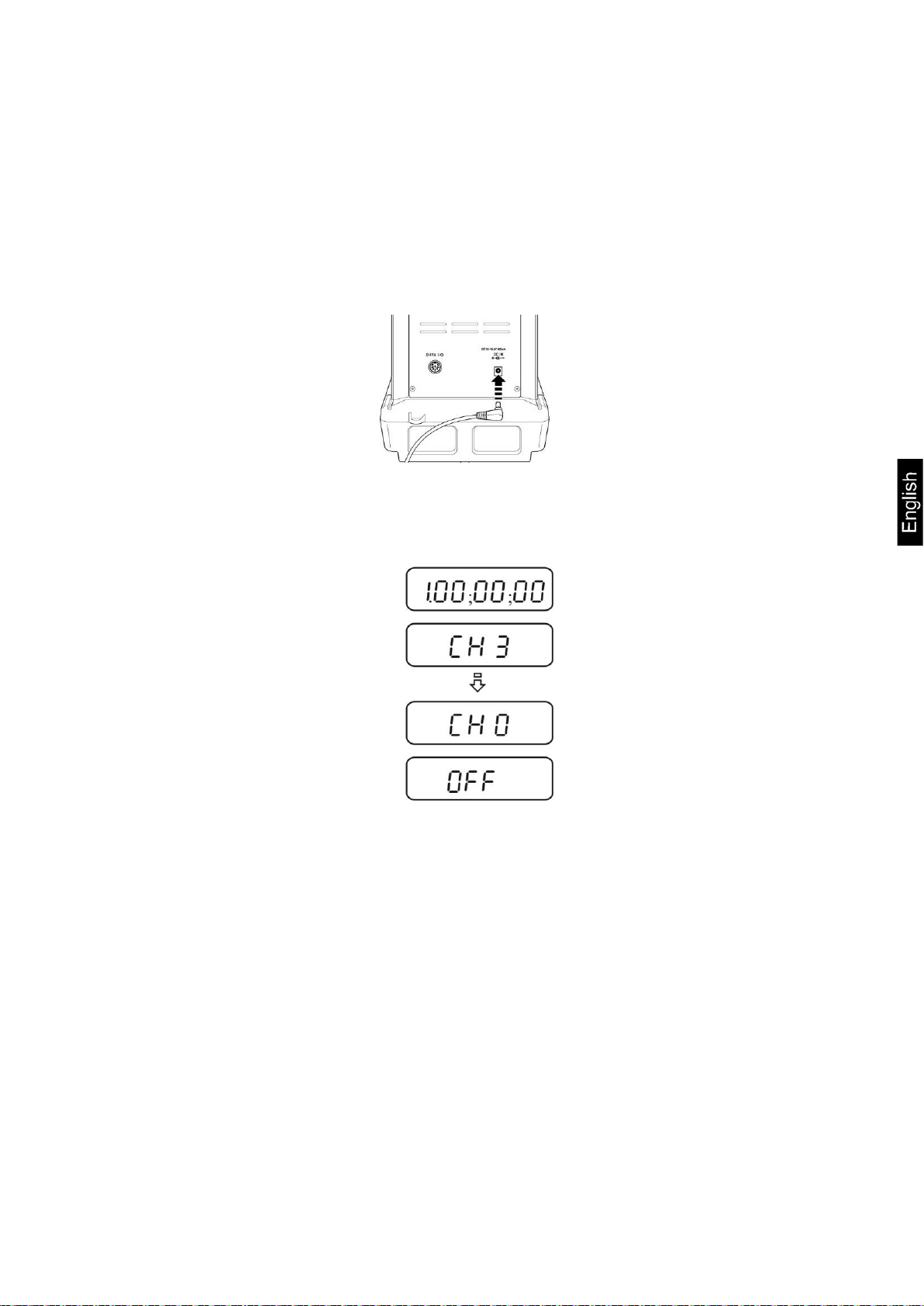

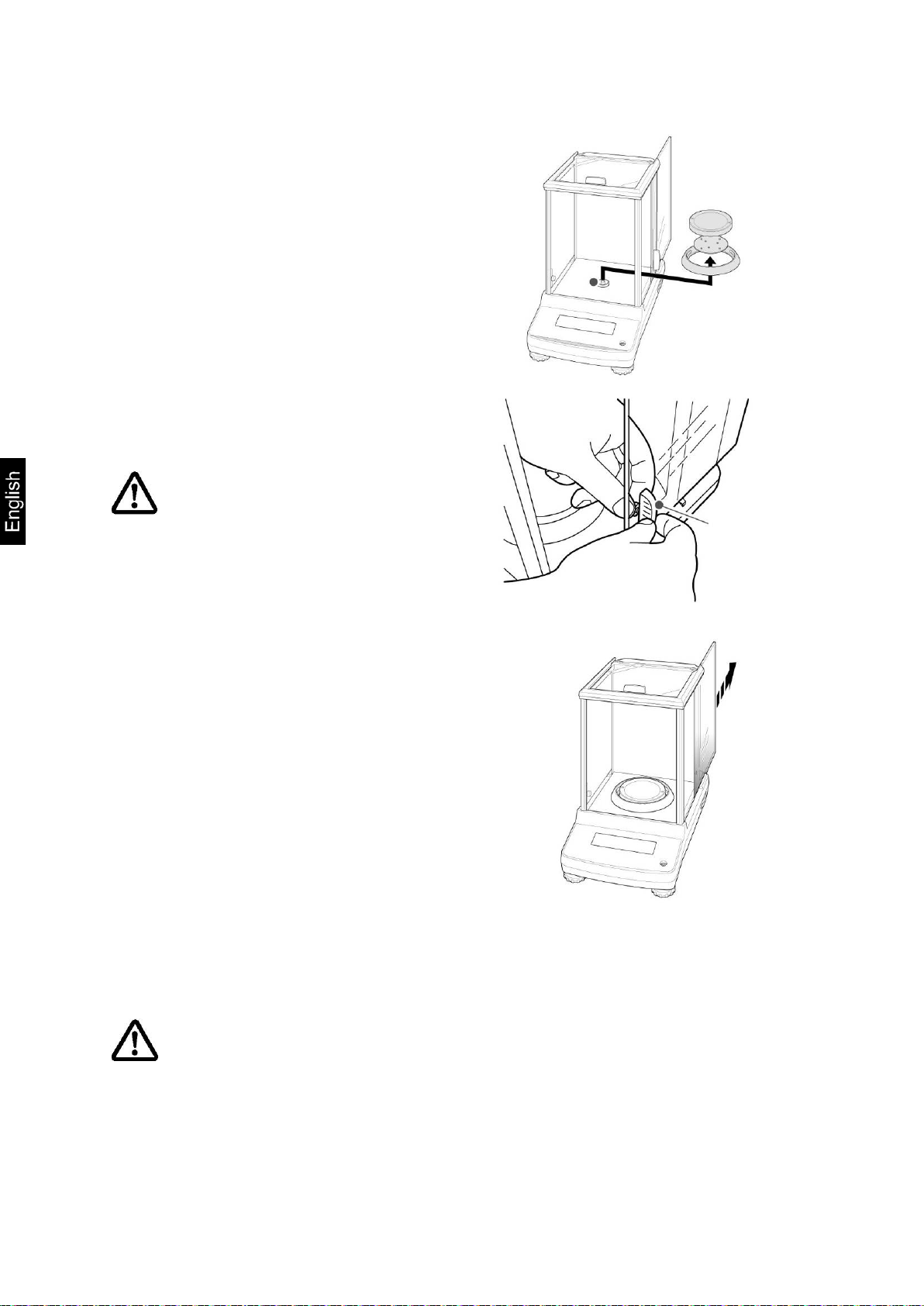

7.3 Mains connection

Supply power to balance via mains adapter. The display lights up and the

The selftest is completed when „OFF“ appears on the display.

Power is supplied via the external mains adapter. The stated voltage value must be

the same as the local voltage.

Only use original KERN mains adapters. Using other makes requires consent by

KERN.

7.3.1 Turning On the Powe r

balance carries out a selftest.

In the ABJ models an automatic adjustment takes place.

7.4 Initial Commissioning

In order to obtain exact results with the electronic balances, your balance must have

reached the operating temperature (see warming up time chpt. 1). During this

warming up time the balance must be connected to the power supply (mains,

accumulator or battery).

The accuracy of the balance depends on the local acceleration of gravity.

Strictly observe hints in chapter Adjustment.

7.5 Connection of peripheral devices

Before connecting or disconnecting of additional devices (printer, PC) to the data

interface, always disconnect the balance from the power supply.

With your balance, only use accessories and peripheral devices by KERN, as they

are ideally tuned to your balance.

ABS-N_ABJ-NM-BA-e-1312 19

Page 20

8 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each balance must be coordinated - in compliance with the underlying physical

weighing principle - to the existing acceleration due to gravity at its place of location

(only if the balance has not already been adjusted to the location in the factory). This

adjustment process must be carried out for the first commissioning, after each

change of location as well as in case of fluctuating environment temperature. To

receive accurate measuring values it is also recommended to adjust the balance

periodically in weighing operation.

Observe stable environmental conditions. A warming up time (see chapter 1) is

required for stabilization. Ensure that there are no objects on the weighing plate.

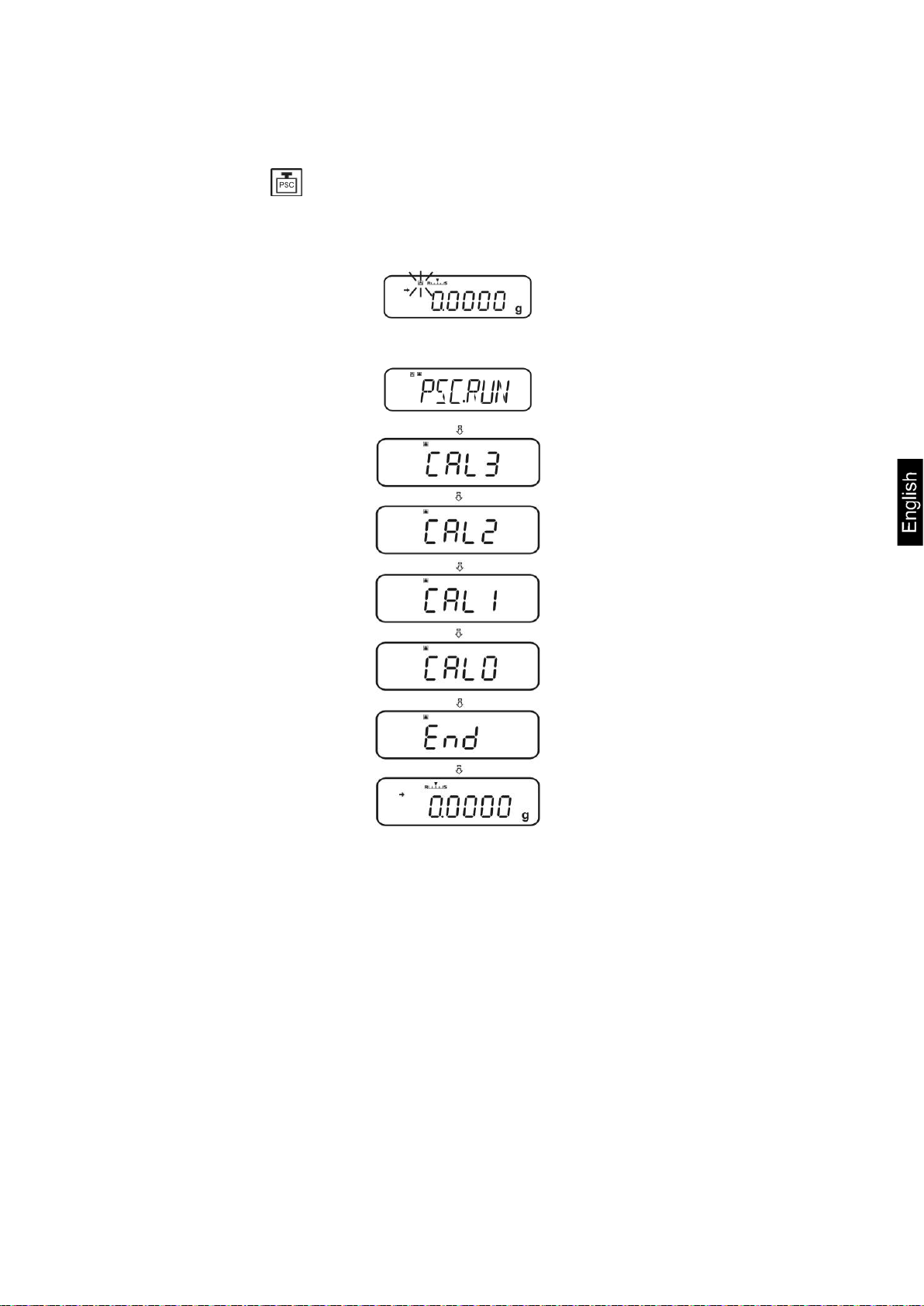

8.1 Automatic adjustment by PSC (Perfect Self Calibration), only models ABJ

The default setting for balances of the series ABJ prompts automatic adjustment via

the PSC function (cannot be switched off).

The moment a change in temperature is detected this function uses the internal tare

weight to carry out fully-automatic adjustment with the help of a temperature sensor.

Adjustment in weighing mode is carried out automatically under the following

conditions:

(1) When there is a change in the surrounding temperature (∆t 2°C)

(2) When about four hours has passed since the previous calibration.

(3) When the balance is switched from standby status to weighing mode

and condition (1) or (2) has been met.

If one of the above conditions was met in weighing mode, the weight symbol

flashes for about two minutes in order to notify the pending adjustment;

20 ABS-N_ABJ-NM-BA -e-1312

Page 21

Case 1: The load on the weighing plate is near zero.

The weight symbol flashes for approx. two minutes, followed by „PSC.RUN“.

After that the internal adjustment is started automatically. In order to ensure proper

PSC operation, prevent vibrations and air flow.

As soon as the display in grams reappears after completing adjustment via PSC,

the balance returns to weighing mode.

ABS-N_ABJ-NM-BA-e-1312 21

Page 22

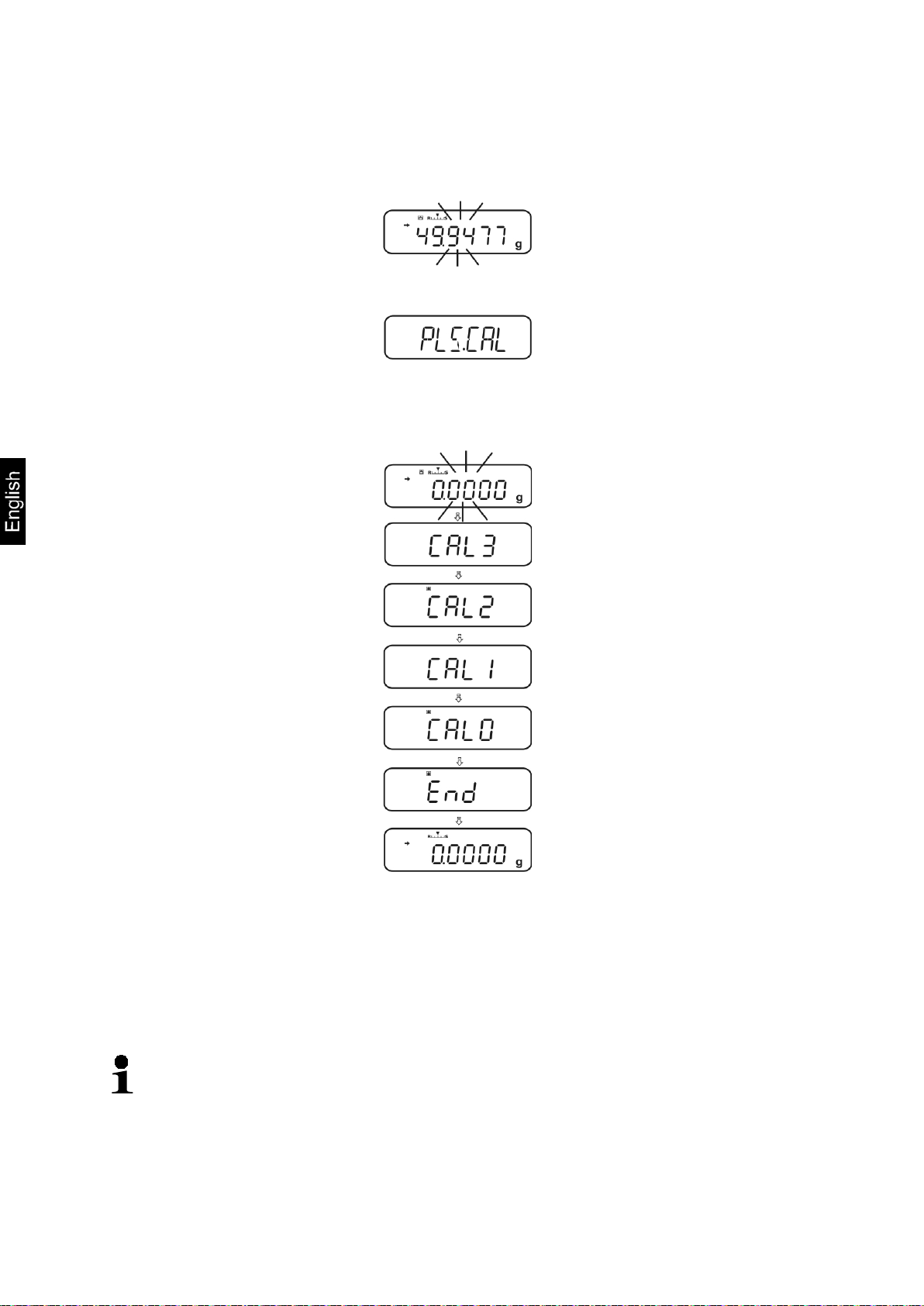

To prevent a start-up of adjustment during a measuring process, actuate the

again for two minutes, followed by „PLS.CAL“.

Case 2: Weighing plate loaded

The gram display flashes for two minutes, followed by „PLS.CAL“.

Unload weighing plate. The gram display flashes again for 2 minutes; after that the

internal adjustment is started automatically. In order to ensure proper PSC

operation, prevent vibrations and air flow.

As soon as the display in grams reappears after completing adjustment via PSC,

the balance returns to weighing mode.

ON/OFF button as soon as „PLS.CAL“ is displayed. The gram display flashes

22 ABS-N_ABJ-NM-BA -e-1312

Page 23

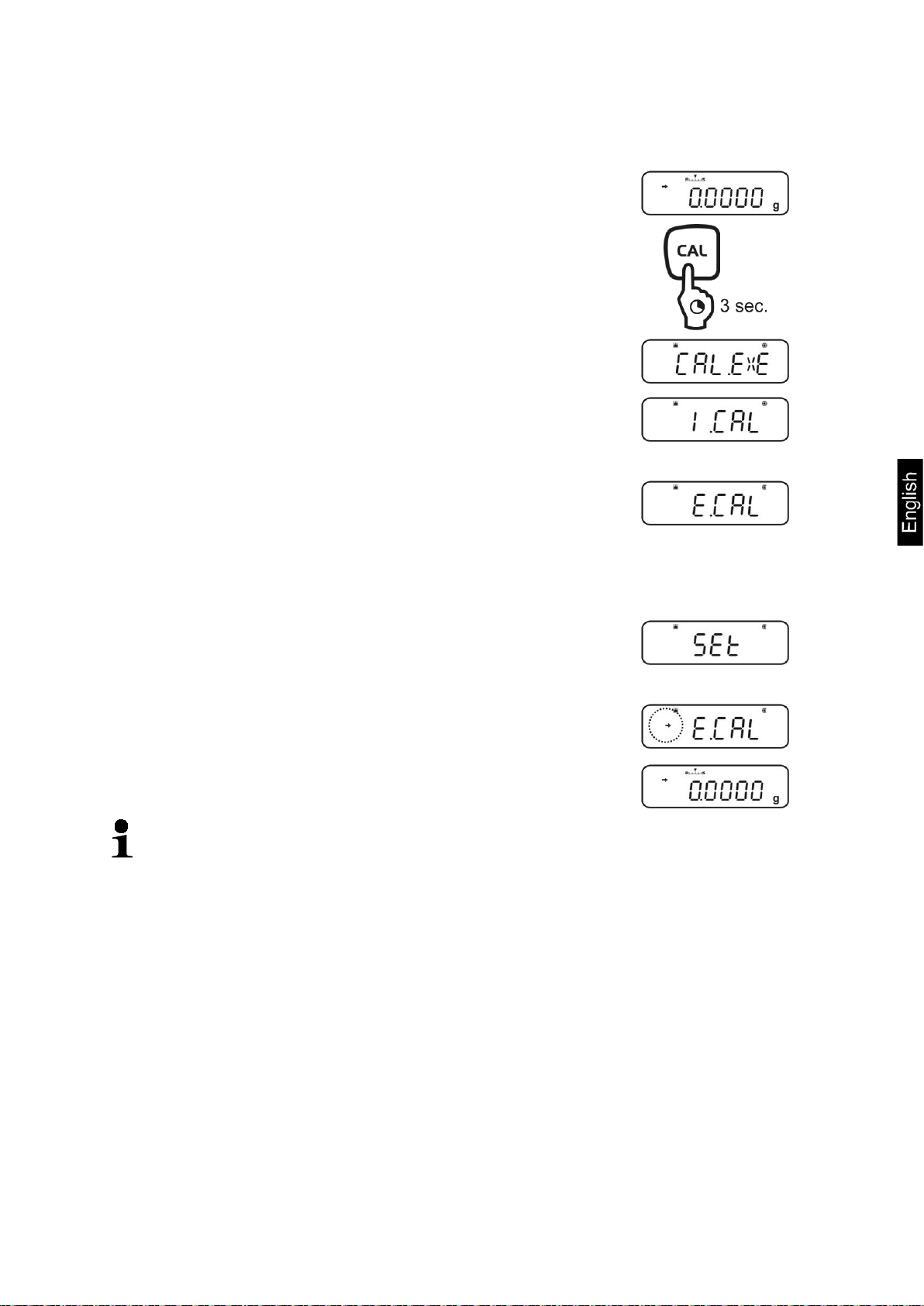

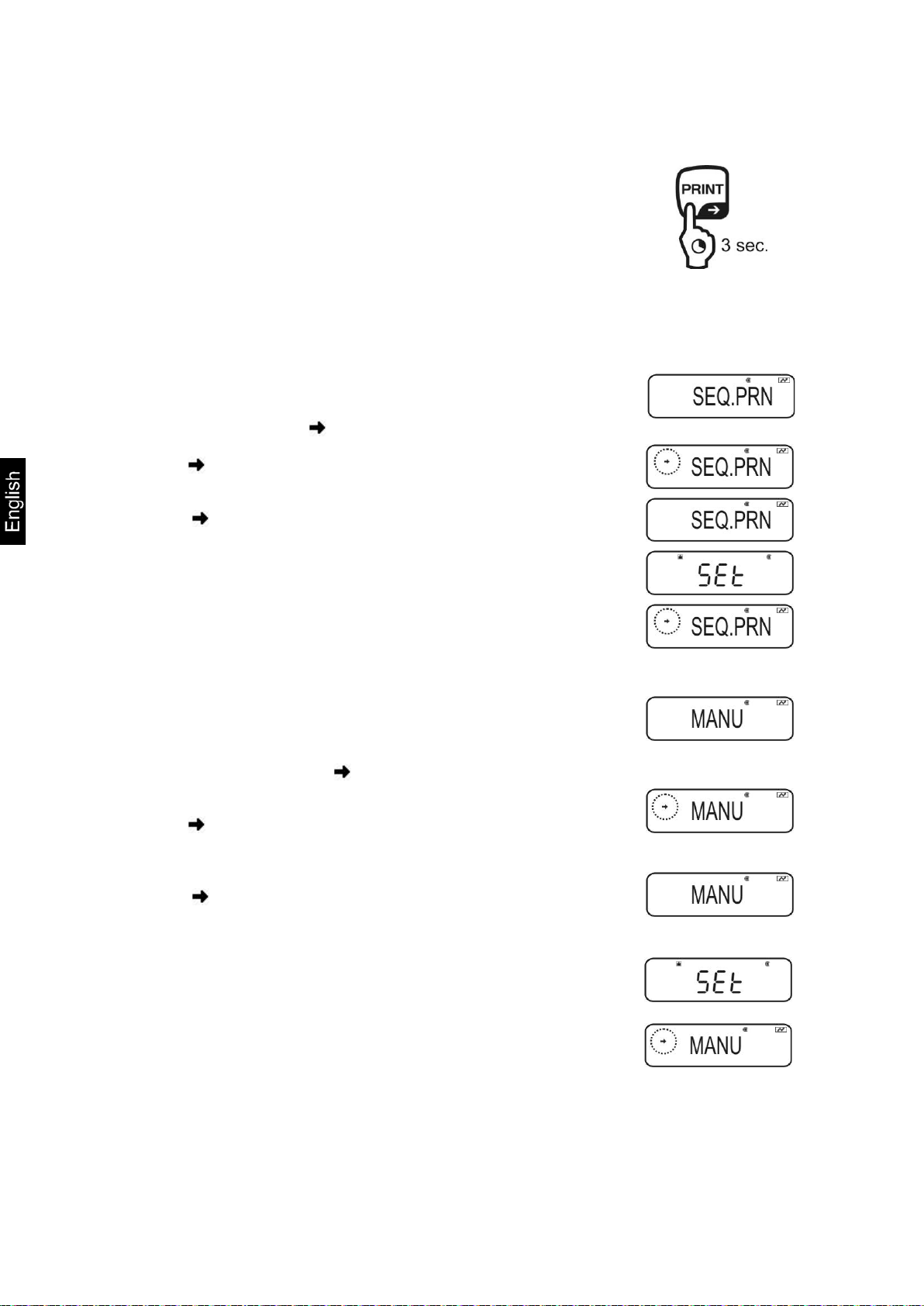

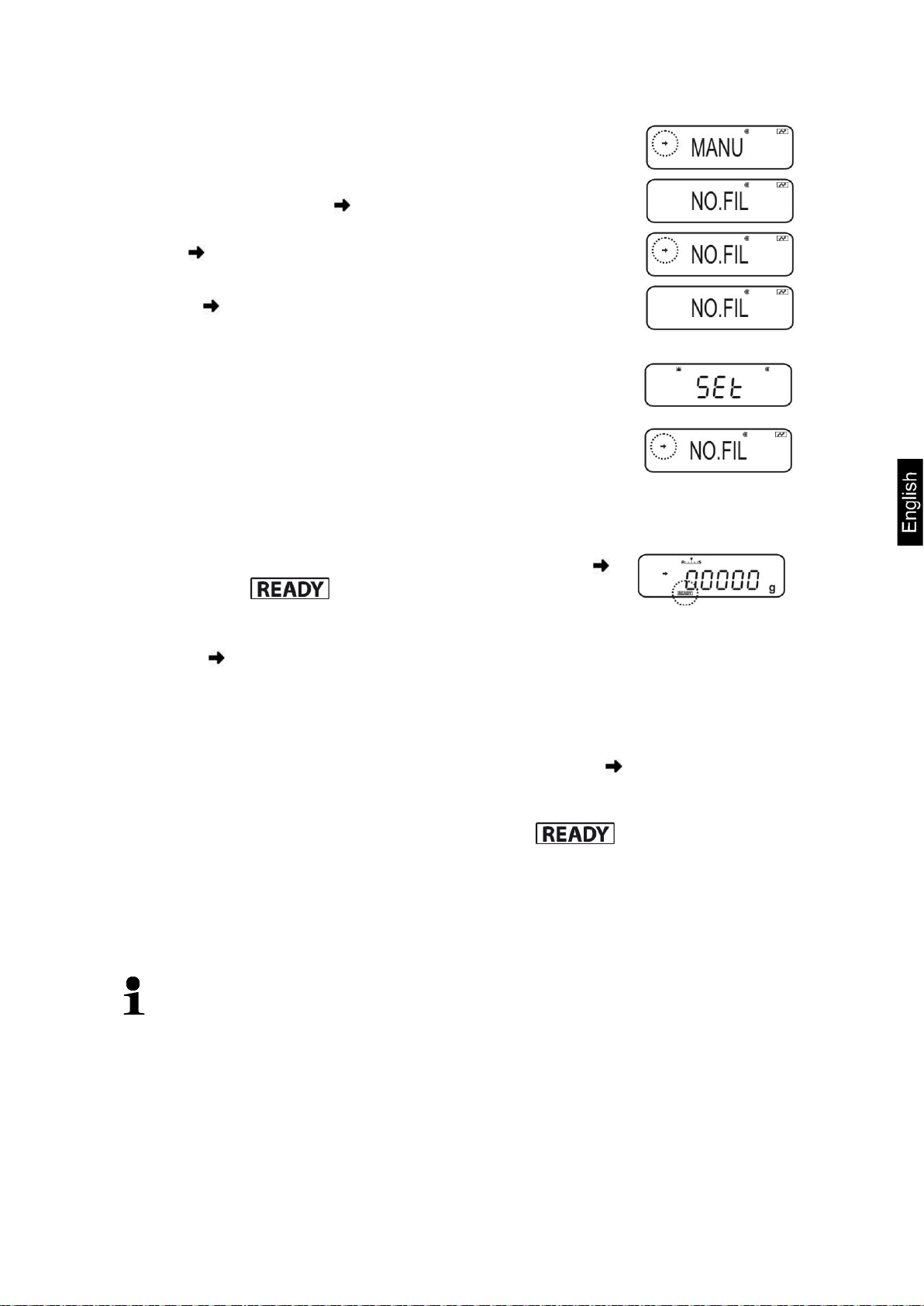

8.2 Menu settings „I.CAL“ / „E.CAL“

I.CAL:

Adjustment with internal weight (see chpt.

8.1)

E.CAL:

Adjustment with external weight (see chpt.

8.2)

The saved adjustment (I.CAL or E.CAL) can now directly be invoked via the

CAL button.

To invoke the adjustment function in weighing mode,

press CAL for 3 sec.

Acknowledge using PRINT, the current setting is

displayed.

Select the desired adjustment using the navigation keys

( )

Confirm with TARE

Press ON/OFF repeatedly or 3 sec., the balance will

return into weighing mode

ABS-N_ABJ-NM-BA-e-1312 23

Page 24

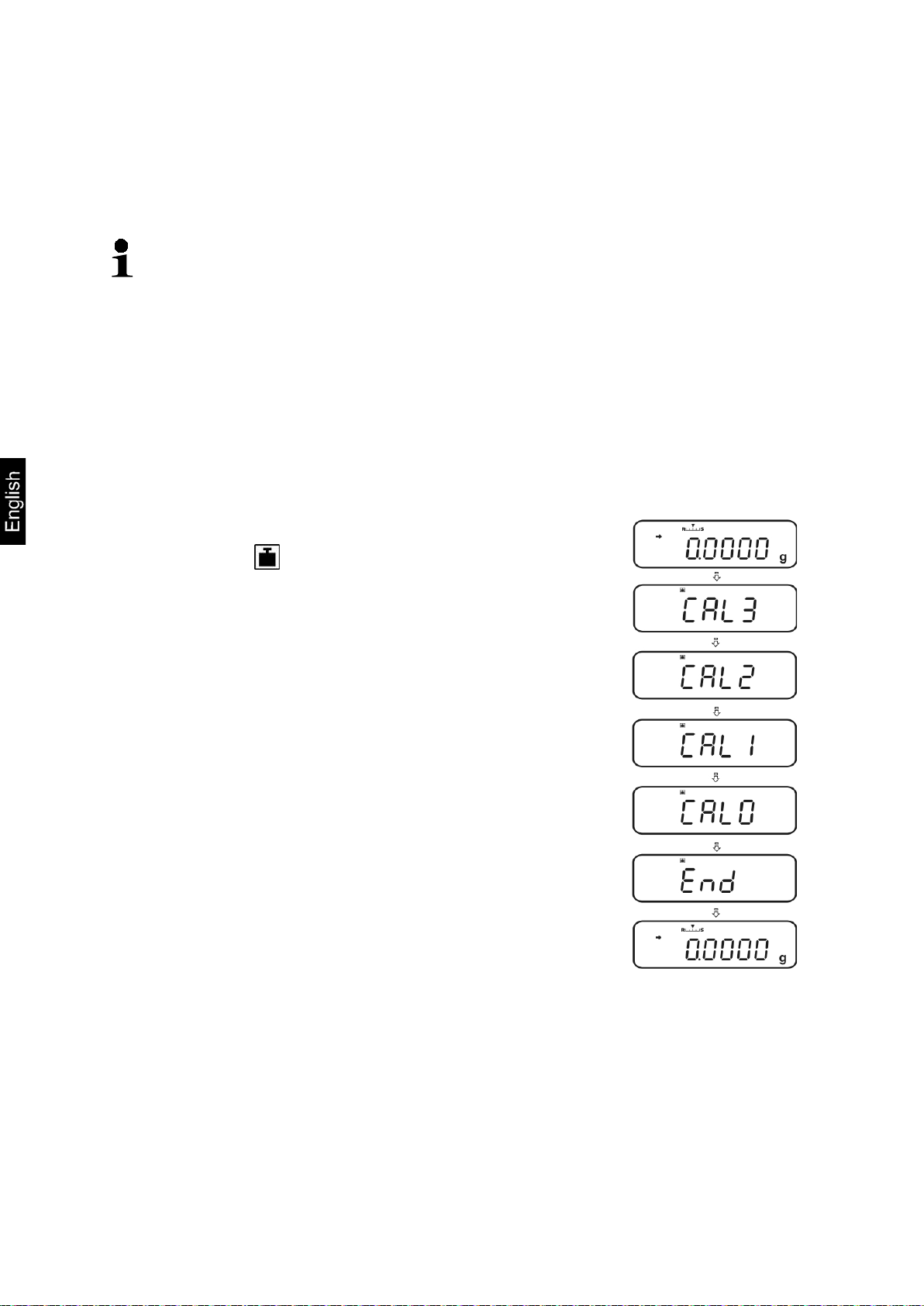

8.2.1 Adjustment with internal weight (KERN ABJ)

When an optional printer is connected and the GLP function activated,

fter the

With the internal adjustment weight, the weighing accuracy can be checked and readjusted at any time.

• Condition: Menu setting „I.CAL“.

•

while starting the adjustment log „WAIT“ will be displayed. A

printout the adjustment will be continued automatically.

• Adjustment may be interrupted with ON/OFF, „ABORT“ is displayed.

Press the CAL-button and adjustment will take place

automatically.

The indicator will be shown.

After successful adjustment the balance automatically

returns to weighing mode.

In case of an adjustment error (e.g. objects on the

weighing plate) the display will show an error message,

repeat adjustment.

When an optional printer is connected and the GLP

function is connected, the adjustment log will be edited,

see chpt. 8.3.

24 ABS-N_ABJ-NM-BA -e-1312

Page 25

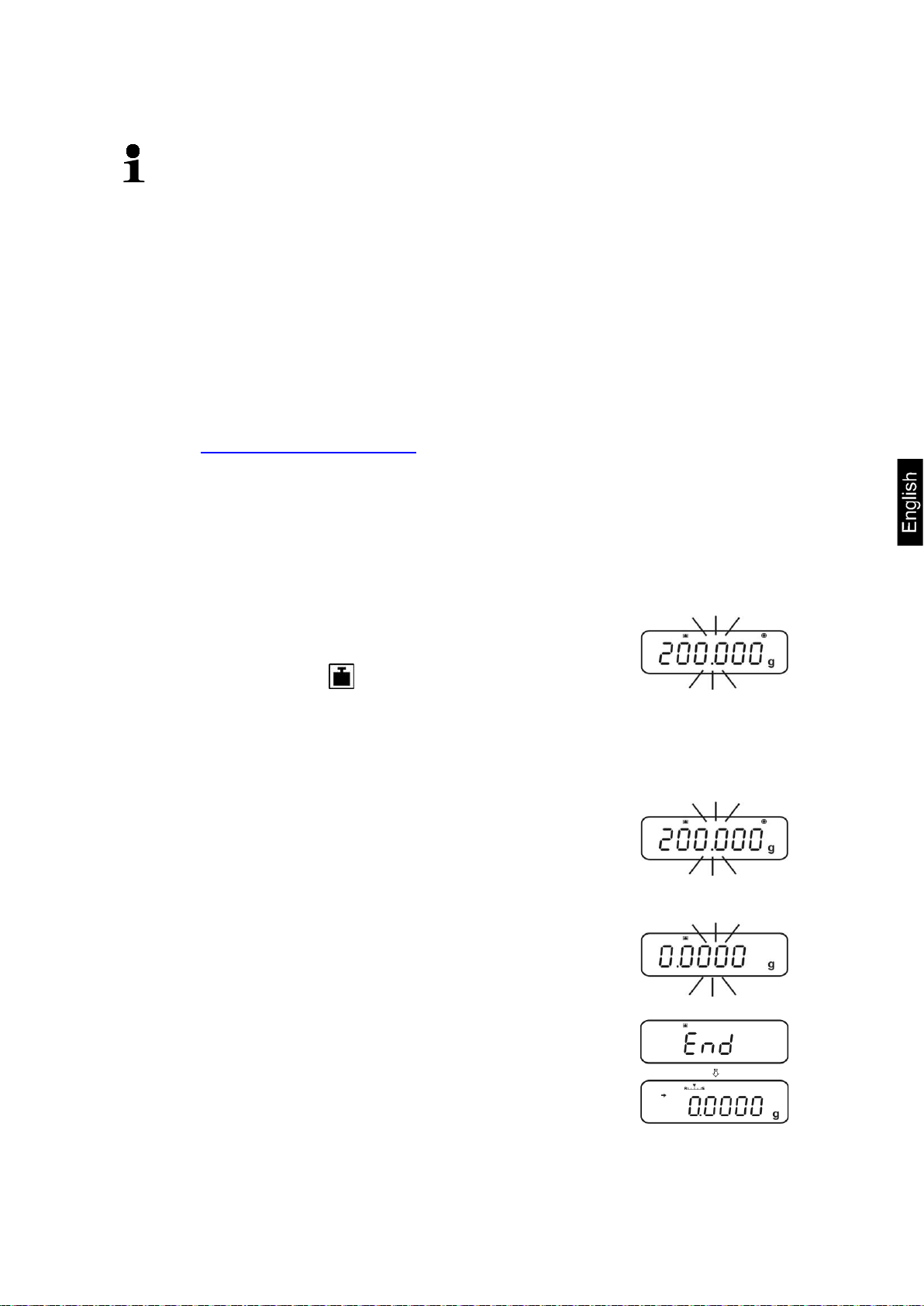

8.2.2 Adjustment with external we ight (KERN ABS)

When an optional printer is connected and the GLP function activated,

After the

g the adjustment process within 60 s no operation is carried out,

• Condition: Menu setting „E.CAL“.

• The weight to be used depends on the capacity of the scale. Carry out

adjustment as near as possible to the balance’s maximum weight

(recommended adjustment weight see chpt. 1). Weights of different

nominal values or tolerance classes may be used for adjustment but are

not optimal for technical measuring. The accuracy of the adjustment

weight must correspond approximately to or, if possible, be better than,

the readability of the balance.

Minimum weight „Adjustment weight“:

ABS 80-4N / ABS 120-4N : 50 g

ABS 220-4N / ABS 320-4N:100 g

Information about test weights you will find in the internet under:

http://www.kern-sohn.com

•

while starting the adjustment log „WAIT“ will be displayed.

printout the adjustment process will be continued automatically.

• If durin

„ERR C“ will be displayed. Press ON/OFF a restart.

In weighing mode press CAL. The weight value of the

recommended adjustment weight (see chpt. 1) appears

flashing. The indicator will be shown.

If the value shall be changed, press MENU, the active

digit flashes.

Carry out the desired setting using navigation buttons

(see chapter 3.1.1 „Numeric input“).

With flashing adjustment weight display, place the

adjustment weight carefully on the center of the

weighing plate within 60 s. Close wind screen doors

completely.

Wait until the zero display flashes.

Take away the adjustment weight and close the wind

screen doors. After successful adjustment the balance

automatically returns to weighing mode.

In case of an adjustment error (e.g. objects on the

weighing plate) the display will show an error message,

repeat adjustment.

When an optional printer is connected and the GLP

function is connected, the adjustment log will be edited,

see chpt. 8.3.

ABS-N_ABJ-NM-BA-e-1312 25

Page 26

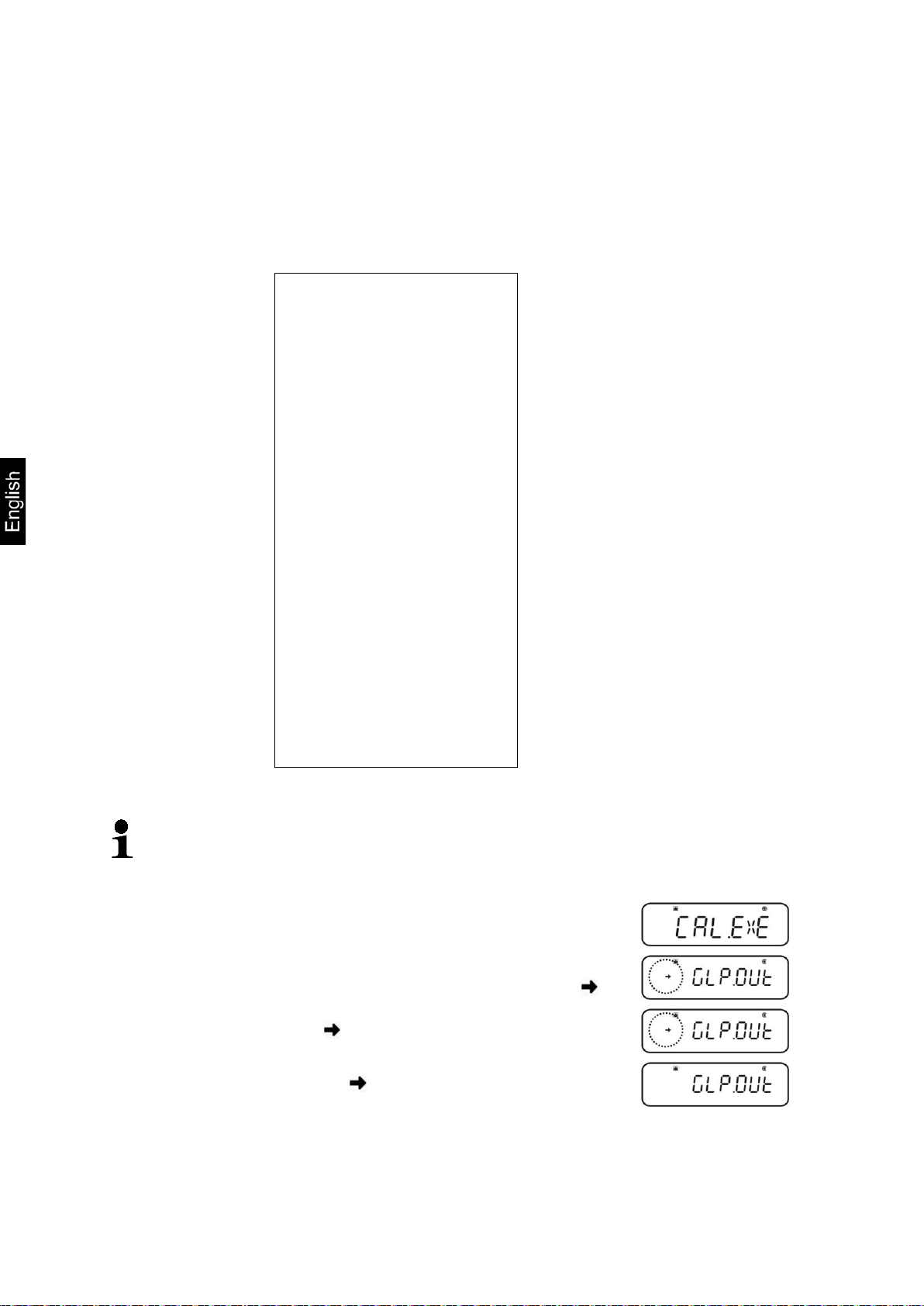

8.3 Adjustment log

- - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - -

KERN & Sohn GmbH

Company

Balance identification no. (see chpt. 8.4)

-COMPLETE

-SIGNATURE-

prepared by

- - - - - - - - - - - - - - - - -

Make sure that the communication parameter of balance and printer are the

Call function

This function enables automatic log issue after each adjustment. These logs may be

issued by using an optional printer.

Printout example (KERN YKB-01N):

CAL –EXTERNAL

TYPE ABJ 220-4NM

SN WBIIAB000I

ID 1234

REF 200.0000g

BFR 200.0001g

AFT 200.0000g

Mode of adjustment

Model

Serial no.

Used adjustment weight

Before adjustment

After adjustment

same.

In weighing mode press the CAL key for 3 sec.

Use the navigation buttons ( ) to select „GLP.OUT“.

The current setting is marked by the stability display ( )

With stability display ( ) Function activated

Without stability display ( ) Function disabled

26 ABS-N_ABJ-NM-BA -e-1312

Page 27

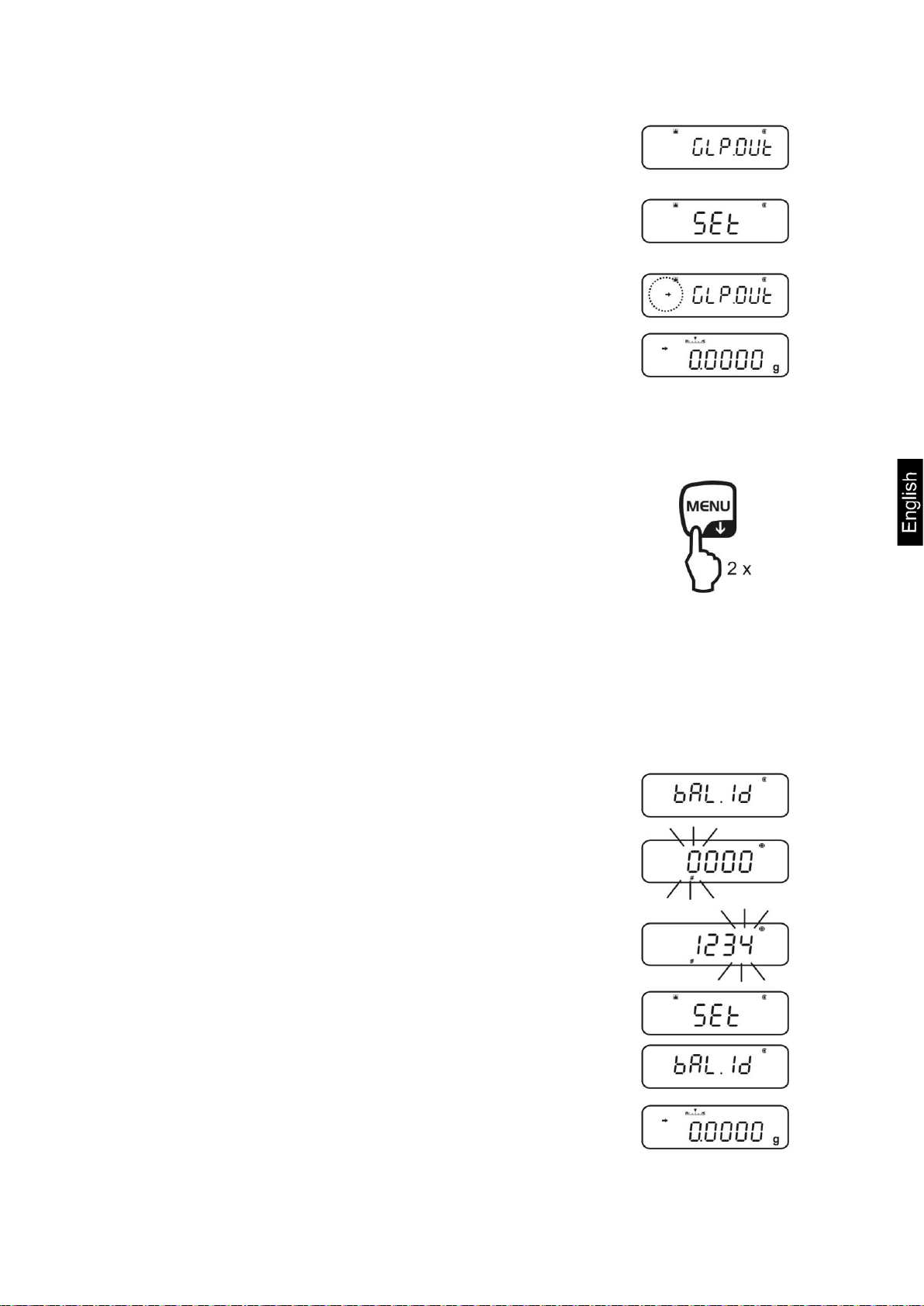

How to change settings

Select menu item

Enter balance identification no. (max. 4 characters)

Press TARE

Press ON/OFF repeatedly or for 3 sec., the balance will

return into weighing mode

8.4 Balance identification no.

This setting is for the balance ID number that is output along with the adjustment

report.

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „SYSTEM“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly until

„BAL.ID“ is displayed.

Press TARE, the currently set ID no. is displayed

(factory setting 0000).

Enter the desired ID no. using navigation buttons (see

chapter 3.1.1 „Numeric input“).

Press ON/OFF repeatedly or 3 sec., the balance will

return into weighing mode

ABS-N_ABJ-NM-BA-e-1312 27

Page 28

9 Verification

General introduction:

According to EU directive 90/384/EEC or 2009/23EG balances must be officially

verified if they are used as follows (legally controlled area):

a) For commercial transactions if the price of goods is determined by weighing.

b) For the production of medicines in pharmacies as well as for analyses in the

medical and pharmaceutical laboratory.

c) For official purposes

d) For manufacturing final packages

In cases of doubt, please contact your local trade in standard.

Verification notes:

An EU type approval exists for balances described in their technical data as

verifiable. If a balance is used where obligation to verify exists as described above, it

must be verified and re-verified at regular intervals.

Re-verification of a balance is carried out according to the respective national

regulations. The validity for verification of balances in Germany is e.g. 2 years.

The legal regulation of the country where the balance is used must be observed!

Verification of the balance is invalid without the seal.

The seal marks attached on verified balances point out that the balance may

only be opened and serviced by trained and authorised specialist staff. If the

seal mark is destroyed, verification looses its validity. Please observe all

national laws and legal regulations. In Germany a re-verification will be

necessary.

28 ABS-N_ABJ-NM-BA -e-1312

Page 29

Position of seals

Seal

Data plate

Seal

ABS-N_ABJ-NM-BA-e-1312 29

Page 30

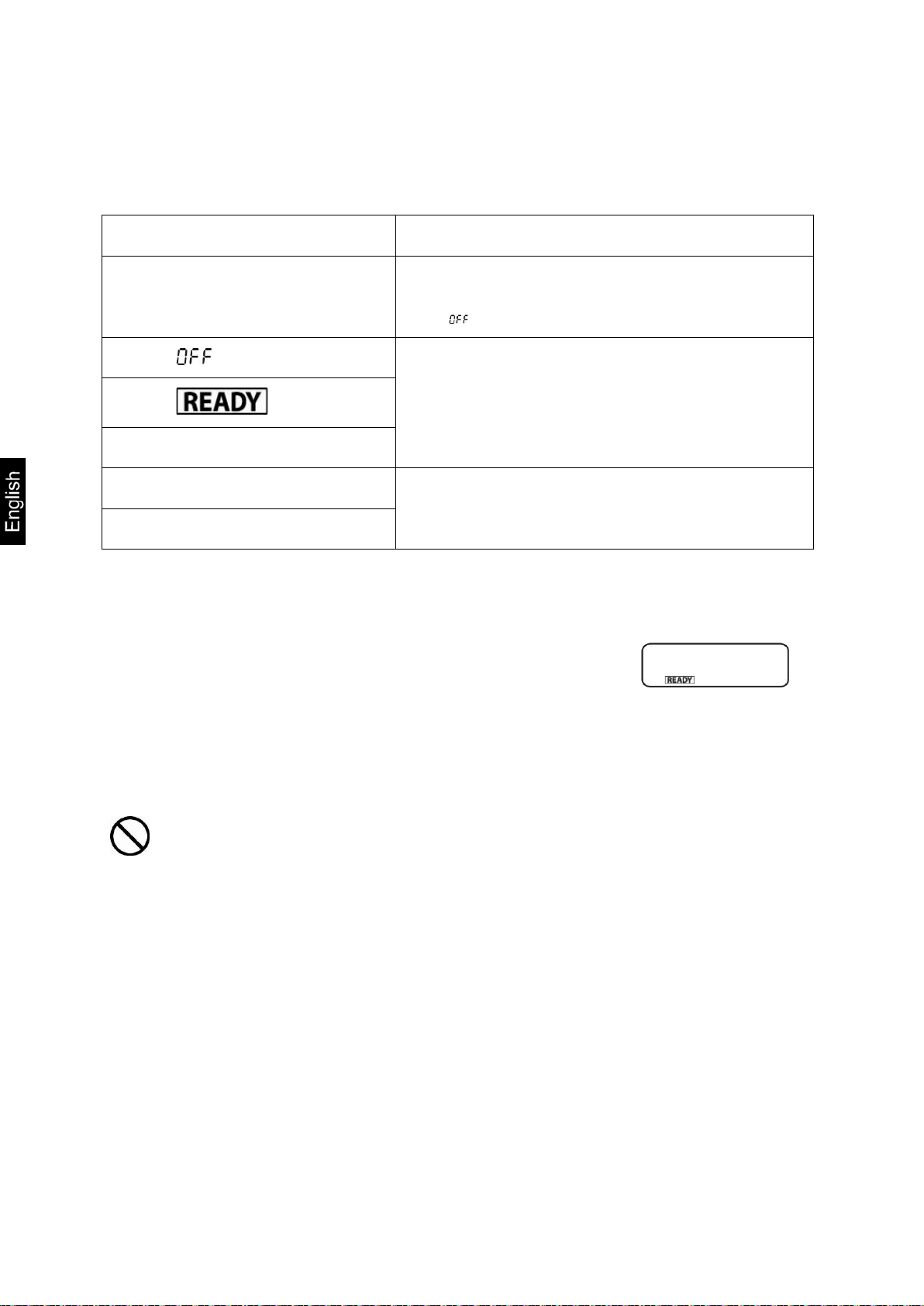

10 Weighing

10.1 Switch-on balance / call-up weighing mode

Status balance Call-up weighing mode

Display switched off

Display

Display

All segments light up

Balance is in menu

After numeric input

10.2 Switch off the balance

Press ON/OFF. The balance is in standby mode, that

means that the balance is now in state ready-foroperation. Immediately after switching-on it is ready for

operation (press any key) without warm-up time.

Press ON/OFF.

After display press any key

Press any key

Press ON/OFF repeatedly or for 3 sec.

To switch-off the balance completely, separate balance

from power supply.

If [WAIT] or [SET] are displayed, do not separate the balance from power

supply.

30 ABS-N_ABJ-NM-BA -e-1312

Page 31

10.3 Set the start display

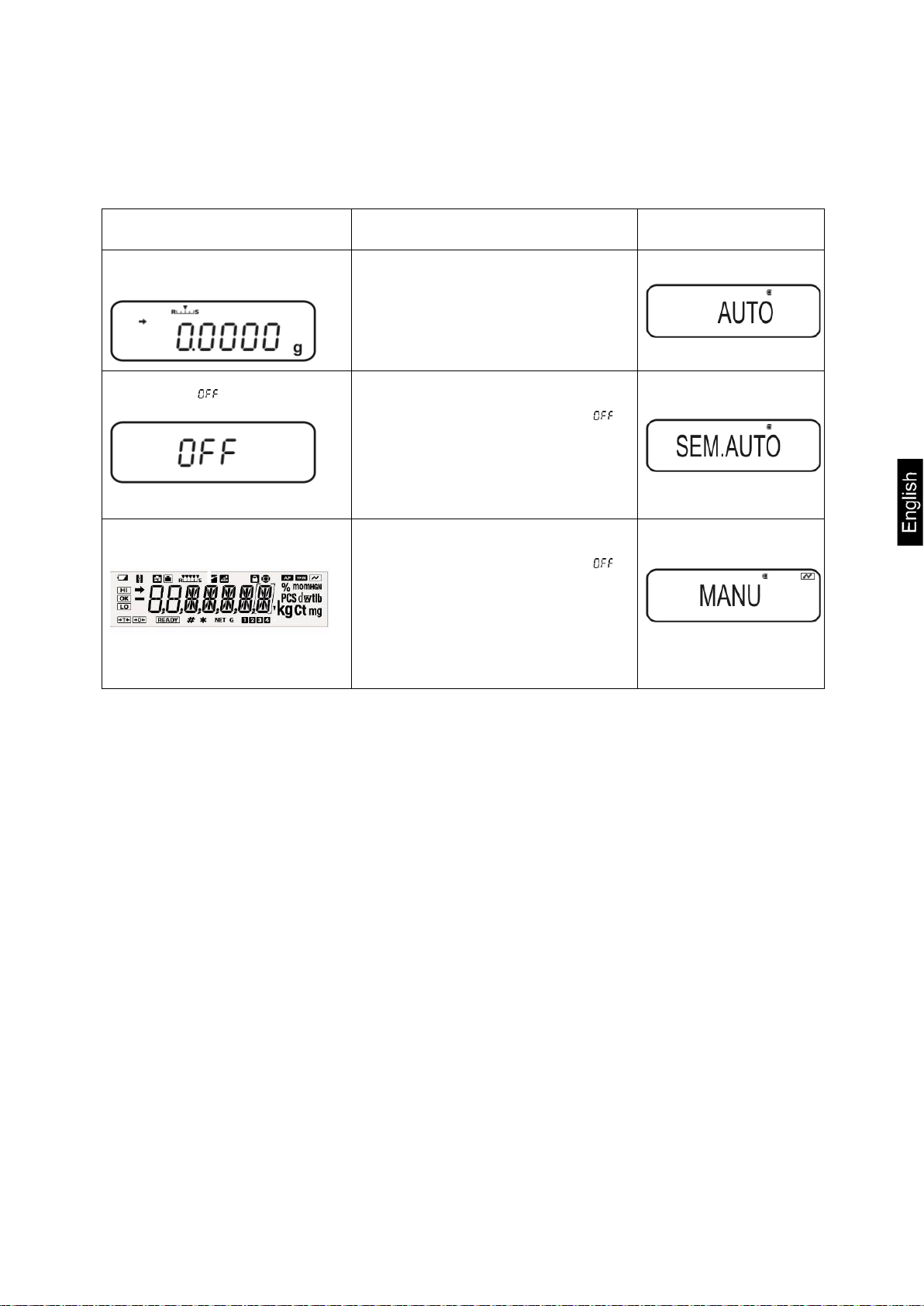

For the start display you can choose between three types.

Start display Explanation Menu setting

1. Weighing mode

2. Display

3. All segments

After connection to the power

supply the balance will start in

weighing mode.

After connection to the power

supply the balance displays .

After pressing a certain key the

balance will carry out a segment

test and start in weighing mode

automatically.

After connection to the power

supply the balance displays .

After pressing any key the

balance will carry out a segment

test. Only after having pressed

TARE the weighing mode will

start.

ABS-N_ABJ-NM-BA-e-1312 31

Page 32

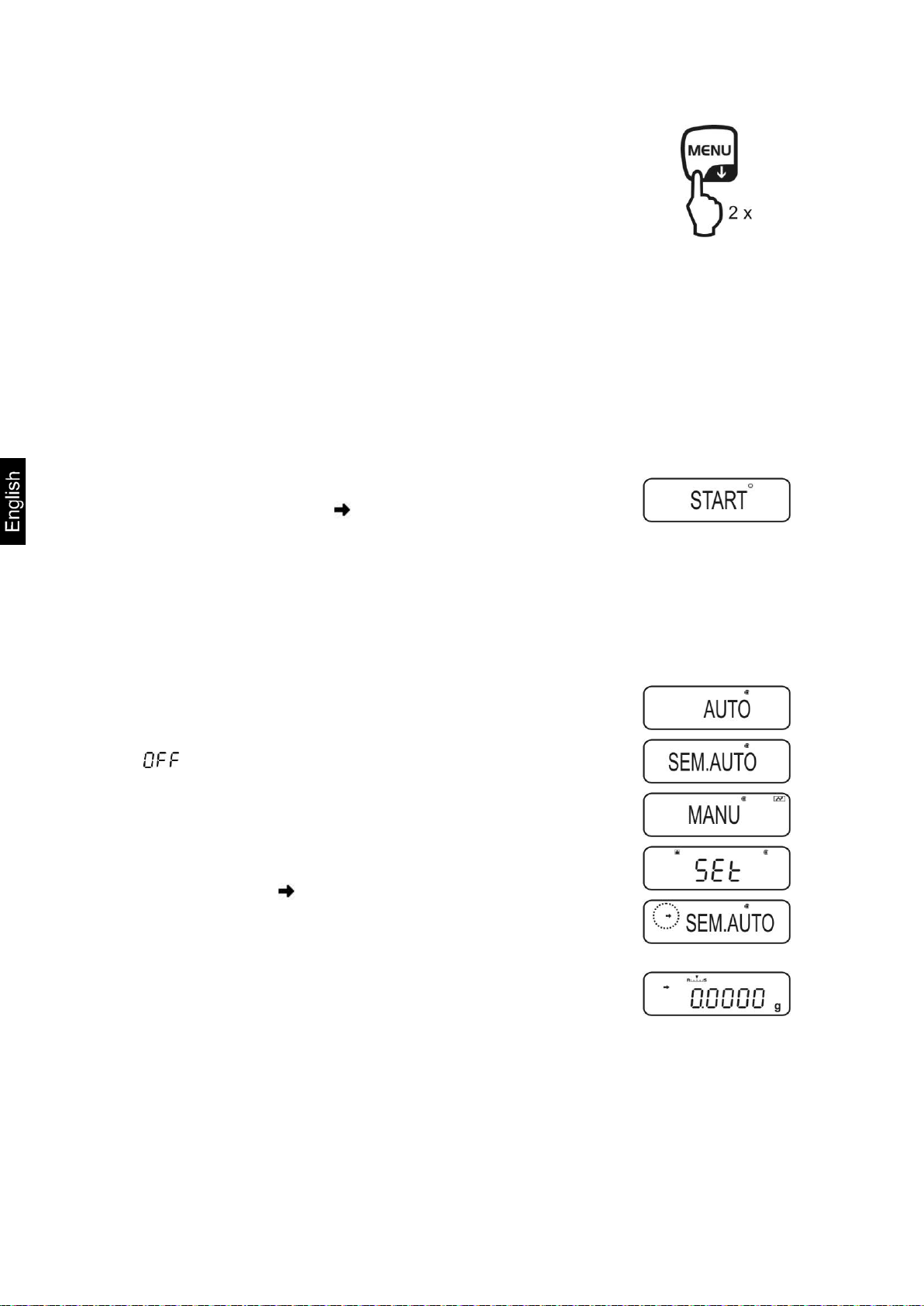

Select menu item

Set display type

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „SYSTEM“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „START“ is displayed. The current setting is marked

by the stability display ( ).

Acknowledge using PRINT, the current setting is

displayed.

Use the navigation buttons ( ) to select the desired

setting, e.g. „SEM.AUTO“.

Weighing mode

All segments

Confirm with TARE. The current setting is marked by the

stability display ( ).

Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

display

32 ABS-N_ABJ-NM-BA -e-1312

Page 33

10.4 Auto Power-Off function (automatic switch-off function)

Stability display

( )

yes

no

To save battery when function is enabled backlight of display will automatically

switch off after a defined time during which there was no change of load or activity.

1. Call up menu

In weighing mode press the MENU button twice

2. Select function

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „SYSTEM“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „AUTO.OFF“ is displayed. The current setting is

marked by the stability display ( ).

Further steps depend on the desired setting:

Function set/update cancel

ON

off

Press PRINT and

continue with step 3.

Press TARE and

continue with step 3.

Press TARE and

continue with step 4.

continue with step 4.

3. Set time, after which the display has to switch off

Use the navigation key ( ) to enter the desired time in

Confirm with TARE.

4. Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

ABS-N_ABJ-NM-BA-e-1312 33

minutes (max. 99 min.),

„Numeric input“. see chpt. 3.1.1.

Page 34

10.5 Simple weighing

- - - - - - - - - - - - - - - - -

KERN & Sohn GmbH

Balance identification no. (see chpt. 8.4)

- - - - - - - - - - - - - - - - -

50.0010 g

Measuring Value

-SIGNATURE-

prepared by

- - - - - - - - - - - - - - - - -

50.0010 g

Measuring Value

A warm-up time is required for stabilisation (see chpt. 1).

Wait for zero display, reset to zero using TARE.

Place the goods to be weighed and close the wind screen doors

Wait until the stability display appears [ ].

Read weighing result.

When an optional printer is connected, the weighing value can be edited.

Print-out example with enabled GLP function (see chpt. 8.3):

Company

TYPE ABJ 220-4NM

SN WBIIAB000I

Model

Serial no.

ID 1234

Print-out example with disabled GLP function (see chpt. 8.3):

34 ABS-N_ABJ-NM-BA -e-1312

Page 35

10.6 Taring

When the balance is unloaded the saved taring value is displayed with

To delete the stored tare value, remove load from weighing pan and

The dead weight of any weighing container may be tared away by pressing a button,

so that the following weighings show the net weight of the goods to be weighed.

Put vessel of goods to be weighed on weighing plate and close the wind

screen doors.

Wait until the stability display appears ( ), then press TARE. The weight of

the container is now internally saved.

Weigh the goods to be weighed and close the wind screen doors.

Wait until the stability display appears ( ).

Read net weight.

Note:

• The balance is able to only store one taring value at a time.

•

negative sign.

•

press TARE.

• The taring process can be repeated any number of times. The limit is

reached when the whole weighing range is exhausted.

ABS-N_ABJ-NM-BA-e-1312 35

Page 36

10.7 Switch-over w eighing unit

Enable/disable units

on the balance, the unit in which the balance has been

By pressing the UNIT key, the display can be switched over to the units enabled

before in the menu.

Call up menu

In weighing mode press the UNIT key for 3 sec. The

current setting is marked by the stability display ( ).

With stability display ( ) Unit enabled

Without stability display ( ) Unit disabled

Press TARE

Use the navigation buttons ( ) to select more units and

to enable/disable them as described before.

Press ON/OFF repeatedly or for 3 sec., the balance will

return into weighing mode

How to change weighing units

To return to the previously enabled weighing units go to

weighing mode by UNIT.

When switchingswitched off, will be displayed.

36 ABS-N_ABJ-NM-BA -e-1312

Page 37

10.7.1 Freely programmable weighing unit

if necessary enable units

• With a numeric input of the conversion factor, the position of the decimal

For the freely programmable weighing unit, no unit symbol will appear in

the display.

Call up menu

In weighing mode press the UNIT key for 3 sec. Use the

navigation buttons ( ) to select „UNIT.U“. The

current setting is marked by the stability display ( ).

With stability display ( ) Unit enabled

Without stability display ( ) Unit disabled

Press TARE

Enter conversion factor

1. Press TARE and current setting will be displayed.

2. Use the navigation buttons to enter the desired

conversion factor (see chapter 3.1.1 „Numeric input“).

3. Press ON/OFF repeatedly or for 3 sec., the balance will

return into weighing mode

How to change weighing units

To return to the previously enabled weighing units go to weighing mode by

UNIT.

ABS-N_ABJ-NM-BA-e-1312 37

dot can be changed, see chpt. 10.7.2

•

Page 38

10.7.2 Change pos ition of decimal dot for freely programmable weighing unit

The position of the decimal dot can only be changed by a numeric input of the

conversion factor (see chpt. 9.7.1, step 2).

When the first cipher flashes, press PRINT repeatedly

until the decimal dot flashes.

Select the desired position using the navigation keys

( ). If no decimal dot shall be set, press MENU

repeatedly until the display symbol appears.

Confirm with TARE.

Press ON/OFF repeatedly or for 3 sec., the balance will

return into weighing mode

10.7.3 Input minimum weight for freely programmable weighing unit

Call up menu

In the menu item „CONV.K“ (see chpt. 9.7.1) use the

navigation buttons to select ( ) „MIN.D“.

Press TARE and current setting will be displayed.

Use the navigation buttons to enter the desired

minimum weight, see chapter 3.1.1 „Numeric input“.

Press ON/OFF repeatedly or for 3 sec., the balance will

return into weighing mode

38 ABS-N_ABJ-NM-BA -e-1312

Page 39

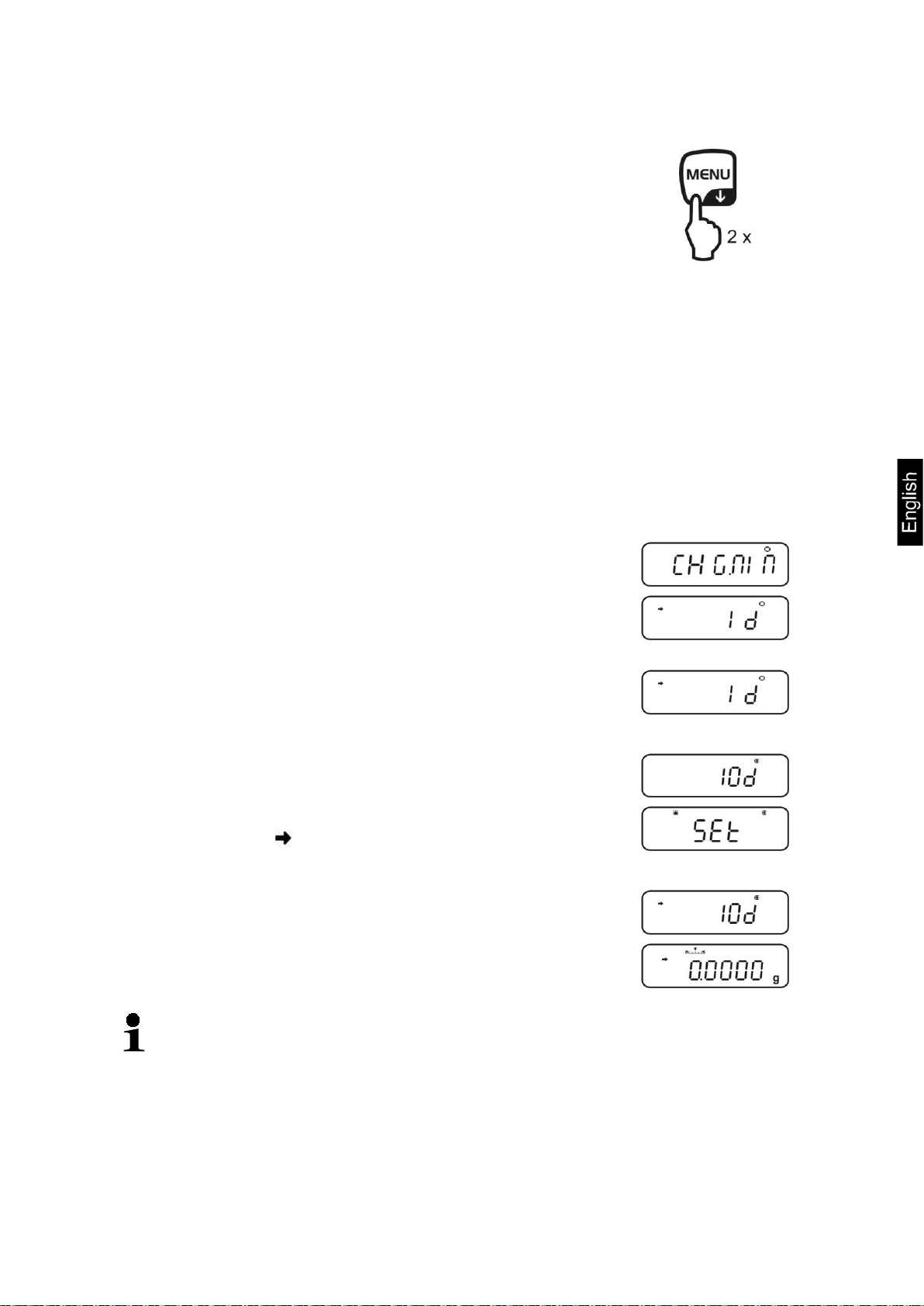

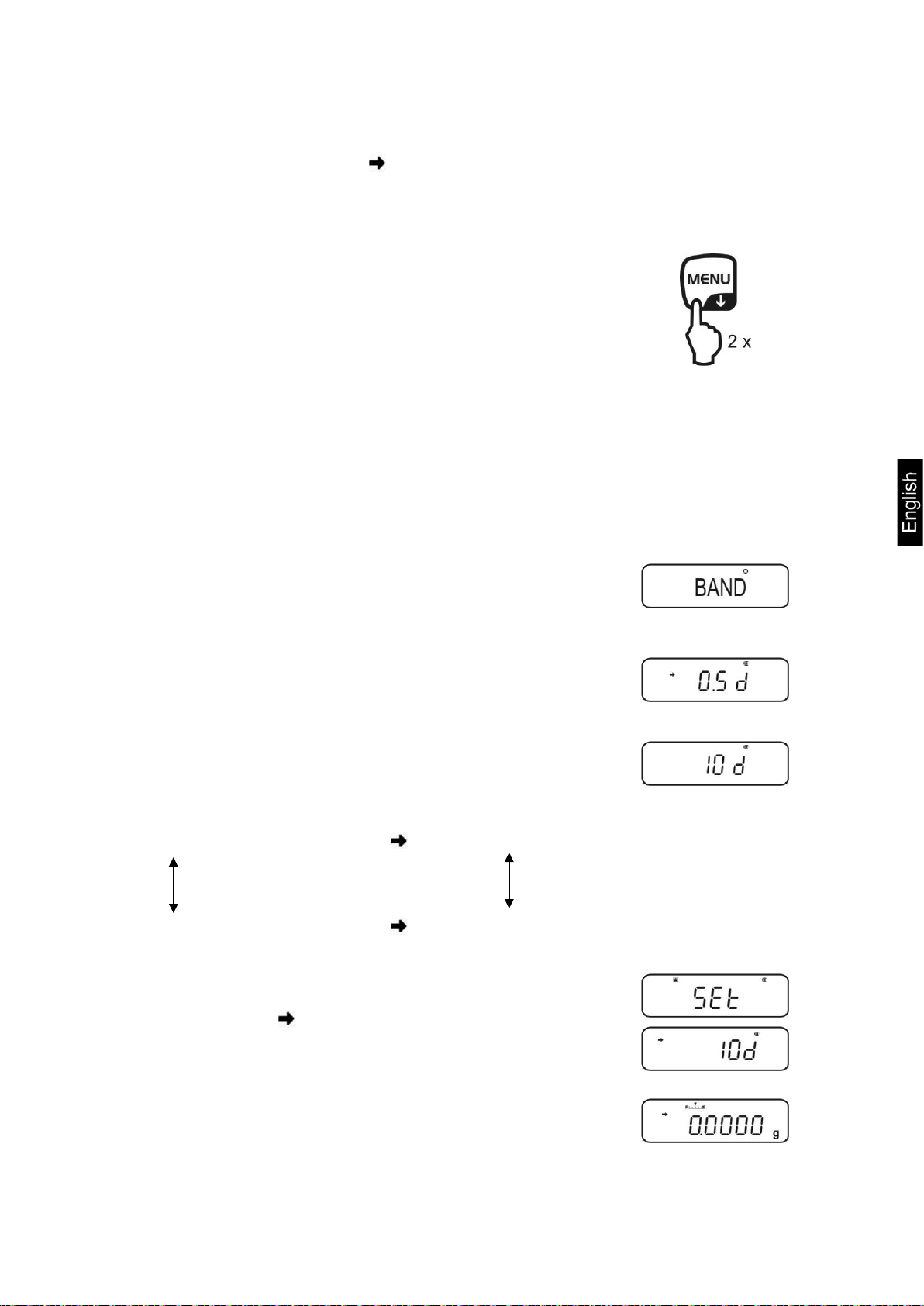

10.8 Change readability (1D/10D)

Select menu item

Change readability from 1D to 10 D

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „TARGET“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „PARAM.W“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „CHG.MIN“ is displayed.

Confirm with PRINT

1. Use the navigation buttons ( ) to select „10 D“.

2. Confirm with TARE. The current setting is marked by the

stability display ( ).

3. Press ON/OFF repeatedly or for 3 sec., the balance will

return into weighing mode

In order to reset readability to 1D, repeat step 1 – 3 accordingly for 1D.

ABS-N_ABJ-NM-BA-e-1312 39

Page 40

10.9 Display decimal dot as point or comma

Select menu item

Selection point/comma

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „SYSTEM“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „POINT“ is displayed.

Acknowledge using PRINT, the current setting is

displayed.

Select the desired adjustment using the navigation keys

( )

PERIOD:

COMMA

Confirm with TARE. The current setting is marked by the

stability display ( ).

Decimal dot is displayed as a point

Decimal dot is displayed as a comma

Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

40 ABS-N_ABJ-NM-BA -e-1312

Page 41

11 Menu

To adapt the behaviour of the balance to your requirements, go to the menu. Usually

the default setting of the menu is such that you do not need to make any changes. If

you encounter special conditions of use, go to the menu in order to set your balance

according to your individual requirements.

Menu structure:

Menu designation Invoke menu Explanation

Main Menu

Calibration Menu

Zero / tare Menu

Data Output Menu

Unit setting Menu

Main menu

Adjustment

Set to zero/taring

Data output

Weighing Units

11.1 Menu symbol

After invoking the menu, the menu symbol [ ] will appear. The arrangement

depends on the navigation in the menu.

Symbol arrangement Explanation

Arrangement filled inside Shows the current setting

Circular arch left/right Higher or lower menu level selectable

Circular arch top / bottom Further selectable menu settings

ABS-N_ABJ-NM-BA-e-1312 41

Page 42

11.2 Na vigation in the m enu

• After selecting the function in the display via the navigation

the present setting for the function.

• Selecting a menu item to the left.

Back to weighing mode.

• How to invoke a menu, see chpt. 11

• Menu structure

• Select and pass through menu items to bottom ().

• Select setting within one function

• Select and pass through menu items to top ().

• Select setting within one function

buttons ( ), the change is invoked by pressing the TARE key.

• Confirm and store the setting momentarily appearing on the

display by actuating the TARE key. The stability display shows

• Selecting a menu item to the right ().

• Leaving the function

Press shortly the ON/OFF key:

Back to previous menu.

Long actuation of ON/OFF key:

42 ABS-N_ABJ-NM-BA -e-1312

Page 43

11.3 Menu overview

+ See also the attached menu map

ABS-N_ABJ-NM-BA-e-1312 43

Page 44

11.4 Resetting the menu

Select menu item

Resetting the menu

This will return all the settings to factory setting. The reference value stored in

previous use of piece counting or percentage conversion will also be cleared. Factory

settings are marked by a “*” in the menu oversight.

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „SYSTEM“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „RESET“ is displayed.

Confirm with TARE.

Confirm OK inquiry by pressing TARE, the password

inquiry will be shown.

Use the navigation keys ( ) to enter the password

see chpt. 3.1.1 „Numeric input“.

+ Standard password (factory setting): „9999“.

+

Change password see chpt. 11.5.1

Confirm with TARE. The balance will be reset to factory

setting and automatically returns into the weighing

mode.

44 ABS-N_ABJ-NM-BA -e-1312

Page 45

11.5 Menu Lock

Either

The menu setting operations can be locked so that the settings cannot be

inadvertently changed. This menu lock is set with the following procedure.

Switch-on power supply of the balance and wait until

„OFF“ is displayed

or

Set balance into stand-by mode, see chpt. 10.2

Select menu item

1. Press MENU for 3 sec., the password inquiry appears.

2. Use the navigation keys ( ) to enter the password

see chpt. 3.1.1 „Numeric input“.

+

Standard password (factory setting): „9999“.

+ Change password, see following chapter

+ If a wrong password is entered, „ERR N“

will appear. Restart with step 1.

3. Confirm with TARE. The menu lock is enabled, the

symbol is activated. This is followed by a

reappearance of "oFF" or .

or

In weighing mode the symbol shows the menu lock.

If a menu item selection is attempted in locked status,

the message “LOCKED” appears and the menu

selection is not allowed. To deactivate menu disabled,

follow the sequence of operations below:

Remove the menu lock

With indication “oFF” or „ “, repeat step 1 – 3

ABS-N_ABJ-NM-BA-e-1312 45

Page 46

11.5.1 Change password

Select menu item

Change password

Standard password (factory setting): „9999“

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „SYSTEM“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „PASS.WRD“ is displayed.

Confirm with TARE.

Use the navigation keys ( ) to enter the currently set

password

see chpt. 3.1.1 „Numeric input“.

Confirm with TARE. When „OK“ appears, the password

input has been correct, if „ERR N“ appears, it was

wrong. In this case repeat the input with the correct

password.

Use the navigation keys ( ) to enter the new

password

„Numeric input“ see chpt. 3.1.1.

Confirm with TARE.

Confirm again with TARE (or discard by ON/OFF).

Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

46 ABS-N_ABJ-NM-BA -e-1312

Page 47

11.6 Log menu settings

Select menu item

Activate menu item

When an optional printer is connected, a list of the current menu settings can be

printed out.

+ Data output, see chpt. 16

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „SYSTEM“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „COND.OUT“ is displayed.

Confirm with TARE.

Confirm OK inquiry using TARE.

Confirm with TARE. The printout is started, the symbol

is displayed.

The balance returns automatically into weighing mode.

ABS-N_ABJ-NM-BA-e-1312 47

Page 48

12 Zero / tare menu (ze roing and taring functions)

In the event that small quantities are removed or added

is advisable to switch off this function.

This function is used to correct automatically small

Selectable functions:

1. Zero tracking function

+ see chpt 12.1

2. Auto zero function

+ see chpt 12.2

3. Auto tare function

+

see chpt 12.3

This function is used to correct automatically small

weight variations which appear directly after

switching-on.

to the material to be weighed, incorrect weighing results

can be displayed due to the “stability compensation“ in

the balance. (e.g. slow flow of liquids from a container

placed on the balance, evaporating processes).

When apportioning involves small variations of weight, it

weight variations which appear after a measurement

(e.g. soiled weighing plate) after the stability display.

After data output an automatic taring is carried out

4. Zero / tare timing

change function

+

see chpt 12.4

Selectable if the balance tares or gets set to zero

before or after indication of the stability mark.

48 ABS-N_ABJ-NM-BA -e-1312

Page 49

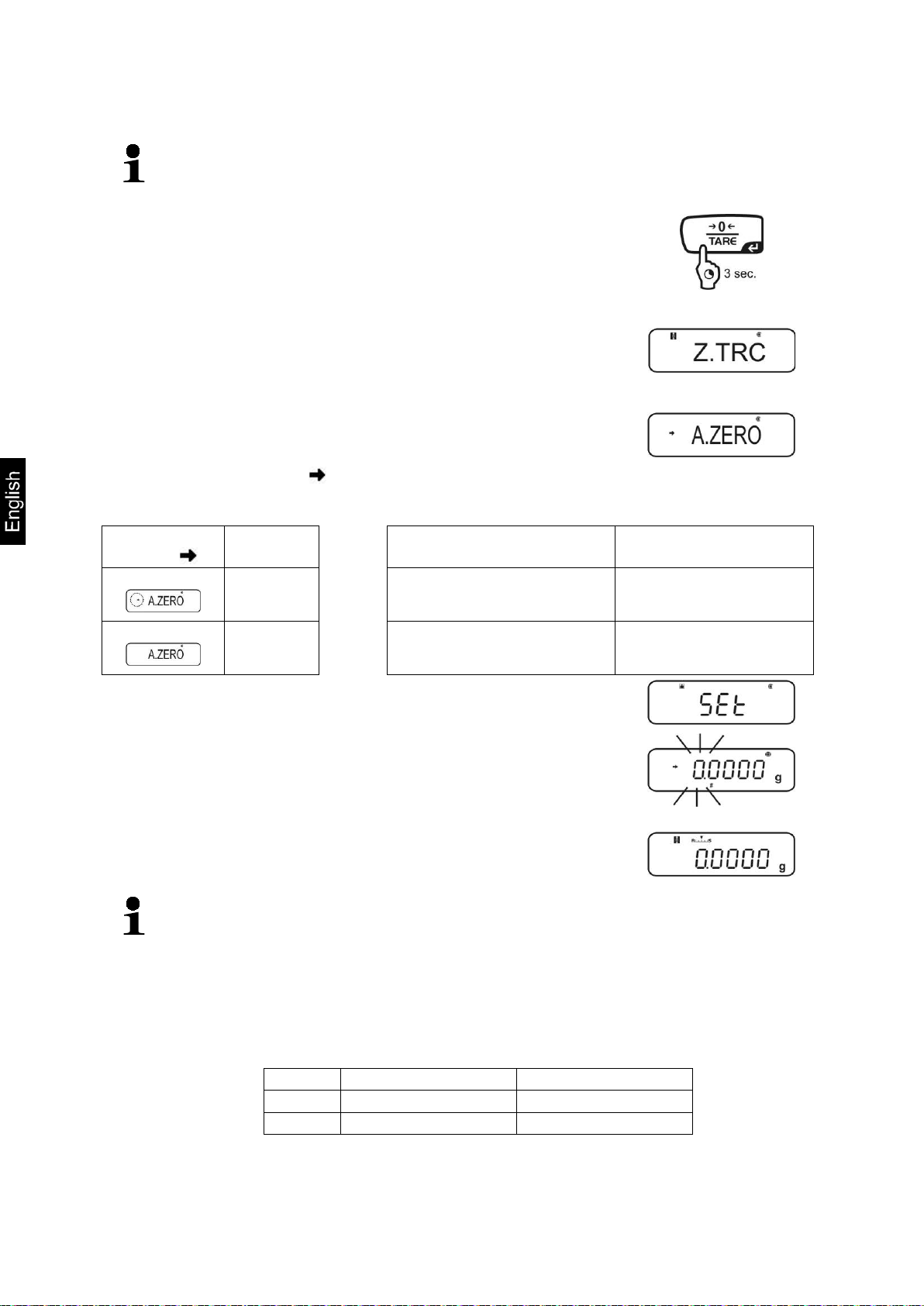

12.1 Zero tracking function

The zero tracking function „A.ZERO“ is turned-on by factory.

1. Check menu setting

Zero tracking symbol Zero tracking function

is displayed

is not displayed

2. Call function

In weighing mode press TARE for 3 sec. and if

necessary press repeatedly the navigation buttons (

). until „Z.TRC“ is displayed. The current setting is

marked by the stability display ( ).

With stability display ( ) Function turned on

Without stability display ( ) Function switched off

3. Enable/dis able function

Press TARE

switched on

switched off

4. Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

ABS-N_ABJ-NM-BA-e-1312 49

Page 50

12.2 Auto zero function

The auto zero function is not available when formula mode is enabled

(see chapter 14.3).

Stability

display ( )

yes

no

When entering the zero range observe the currently set weighing unit.

Example for a balance d = 0.0001 g

Unit

Lower limit

Upper limit

g

0.0001 g

0.0099 g

ct

0.001 ct

0.099 ct

1. Call up menu

Press TARE for 3 sec. in weighing mode.

2. Select function

Press the navigation buttons ( ) repeatedly until

„A.ZERO“ is displayed. The current setting is marked by

the stability display ( ).

Further steps depend on the desired setting:

Function set/update cancel

3. Define zero range

Press TARE

ON

off

Press PRINT and

continue with step 3.

Press TARE and

continue with step 3.

Press TARE and

continue with step 4.

continue with step 4.

Use the navigation keys ( ) to enter the zero range

see chpt. 3.1.1 „Numeric input“.

4. Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

If the weighing unit is changed at a later moment, the zero range must be

adapted to the new weighing unit (step 3.).

Upper limit zero range: 99 d (in the displayed weighing unit)

Lower limit zero range: 1d (in the displayed weighing unit)

50 ABS-N_ABJ-NM-BA -e-1312

Page 51

12.3 Auto Tare function

1. Call up menu

Press TARE for 3 sec. in weighing mode.

2. Select function

Press the navigation buttons ( ) repeatedly

until „A.TARE“ is displayed. The current setting is marked

by the stability display ( ).

With stability display ( ) Function turned on

Without stability display ( ) Function switched off

3. Enable/dis able function

Press TARE

4. Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

ABS-N_ABJ-NM-BA-e-1312 51

Page 52

12.4 Zero / tare timing change function

The zero / tare timing change function can be switched-on, when the „Auto

zero“ and the „Auto tare“ function are enabled.

1. Call up menu

Press TARE for 3 sec. in weighing mode.

2. Select function

Press the navigation buttons ( ) repeatedly

until „TARE.F“ is displayed.

Confirm with PRINT. The current setting is marked by the

stability display ( ).

With stability display ( ) Function turned on

Without stability display ( ) Function switched off

3. Enable/dis able function

Press TARE

4. Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

52 ABS-N_ABJ-NM-BA -e-1312

Page 53

13 Settings for Stability and Response

The easy setting display flashes for a short time. Inputs are only possible

switched off.

Exists the possibility to tune the stability of the display and the degree of reaction of

the balance to the requirements of certain applications or the environmental

conditions.

Most measurements can be carried out using default settings, that is, standard

mode. In standard weighing mode, stability and reaction have the same priority. For

certain applications such as e.g. dosage do use the dosing mode (pouring mode). In

dosing mode the reaction degree has the higher priority.

Beside the selection standard / dosing mode the stability of the display and the

reaction degree of the balance can additionally adapted in the menu.

Please note that data processing for greater stability generally slows the response

and processing for higher response reduces stability.

13.1 Stability and reaction settings via „Easy Setting display“

(without invoking menu)

In weighing mode press MENU shortly. The easy setting

display [ ] flashes.

When the display is flashing, set stability or reaction via

UNIT or PRINT as described in the following.

Priority on reaction

Easy setting display

Operation

Every time the button is hit,

reaction will increase

Priority on stability

Every time the button is hit,

stability will increase

within this time. Using ON/OFF the flashing Easy setting display can be

ABS-N_ABJ-NM-BA-e-1312 53

Page 54

13.2 S election weighing / dosi ng m ode

Select menu item

Select menu item

Call-up weighing mode:

This is the default setting. Use this mode, when neither stability nor reaction time

must be increased or reduced.

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„STAND“ is displayed.

Confirm with TARE. The balance returns automatically

into weighing mode.

Call-up dosing mode:

Use this function if you wish to increase display speed, e.g. during apportioning.

However, please note that the balance is very susceptible to ambience conditions.

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly

until „POURING“ is displayed.

Confirm with TARE. From here on the balance is in

dosing mode (pouring mode), symbolised by the

indicator .

54 ABS-N_ABJ-NM-BA -e-1312

Page 55

13.3 Standstill width

Select menu item

Set range

If the stability display lights up ( ), the weighing result will be stable within the range

indicated by the standstill width.

Set range for stability determination:

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „PARAMW“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „BAND“ is displayed.

Acknowledge using PRINT, the current setting is

displayed.

Use the navigation buttons ( ) to select the desired

setting (0.5d, 1d, 10d, 50d, 100d, 1000d can be

selected).

0.5D

1000d

Stability display ( ) very quiet environment

Stability display ( ) busy environment

Confirm with TARE. The current setting is marked by the

stability display ( ).

Return to weighing mode

Press ON/OFF repeatedly or for 3 sec.

ABS-N_ABJ-NM-BA-e-1312 55

Page 56

Set reaction time:

Select menu item

Call up menu

In weighing mode press the MENU button twice

Press the navigation buttons ( ) repeatedly until

„TOOLS“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „PARAMW“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „STB.Mk“ is displayed.

Set reaction time

Confirm with PRINT. The current setting is marked by

the stability display ( ).

with ( )

without ( ) Default

Confirm with TARE. The current setting is marked by the

stability display ( ).

Return to weighing mode

Stability display appears faster, but with

less exactness.

Press ON/OFF repeatedly or for 3 sec.

56 ABS-N_ABJ-NM-BA -e-1312

Page 57

14 Application Functions

• The application functions can be combined with the check weighing or

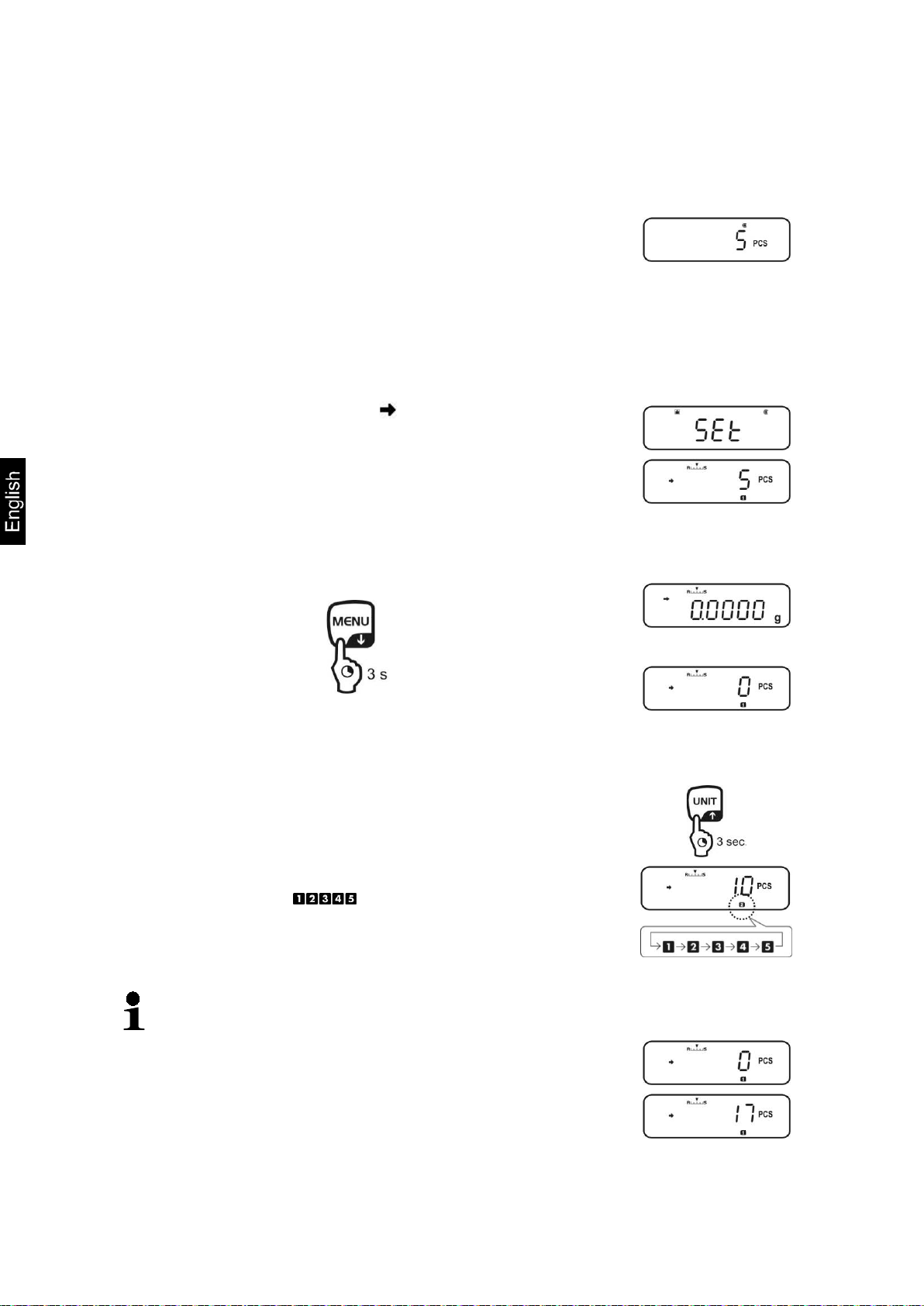

14.1 P arts counting

With parts counting you can either count parts into a container or remove parts from

a container. To count a greater number of parts the average weight per part has to

be determined with a small quantity (reference quantity). The larger the reference

quantity, the higher the counting exactness. High reference must be selected for

small parts or parts with considerably different sizes.

1. Enable function and set reference

Call up menu

In weighing mode press the MENU button twice

target function (see chpt. 14).

• The balance starts in the mode, in which it has been switched off.

• For switching over between application and weighing mode, press MENU

for 3 sec.

Select piece counting mode

Press the navigation buttons ( ) repeatedly until

„APL.FUNC“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „PCS“ is displayed.

Press TARE. The display shows the currently set

memory location.

Enter memory location for reference

The balance offers the possibility to store five different

piece weights at the same time.

Press the navigation buttons ( ) repeatedly until the

desired memory location is displayed, then

press TARE.

Display, if no piece weight is stored

Display, if a piece weight is stored

ABS-N_ABJ-NM-BA-e-1312 57

Page 58

Set reference

If under the indicated memory location no reference is stored,

[- - -] will be displayed.

Place an empty container on the balance and tare it by

pressing TARE.

Press MENU twice.

Press the navigation buttons ( ) repeatedly until the

desired reference quantity is displayed (possible

reference quantities 5, 10, 20, 50, 100).

Use MENU to scroll forward.

Use UNIT to scroll backward.

Fill number of pieces into the container according to the

selected reference quantity.

Wait for the stability display ( ), then confirm by

pressing TARE. The balance determines the average

piece weight.

From here on the appliance is in piece counting mode

and counts all pieces which are on the weighing plate.

2. Switching over betw een piece counting and weighing mode

3. Count the items

Call-up the piece weight stored in piece counting mode

Every time UNIT is pressed (approx. for 3 sec.), the next

Place an empty container on the balance and tare it by

Fill weighing goods into the container and read the piece

memory location [ ] is called up.

pressing TARE.

quantity.

58 ABS-N_ABJ-NM-BA -e-1312

Page 59

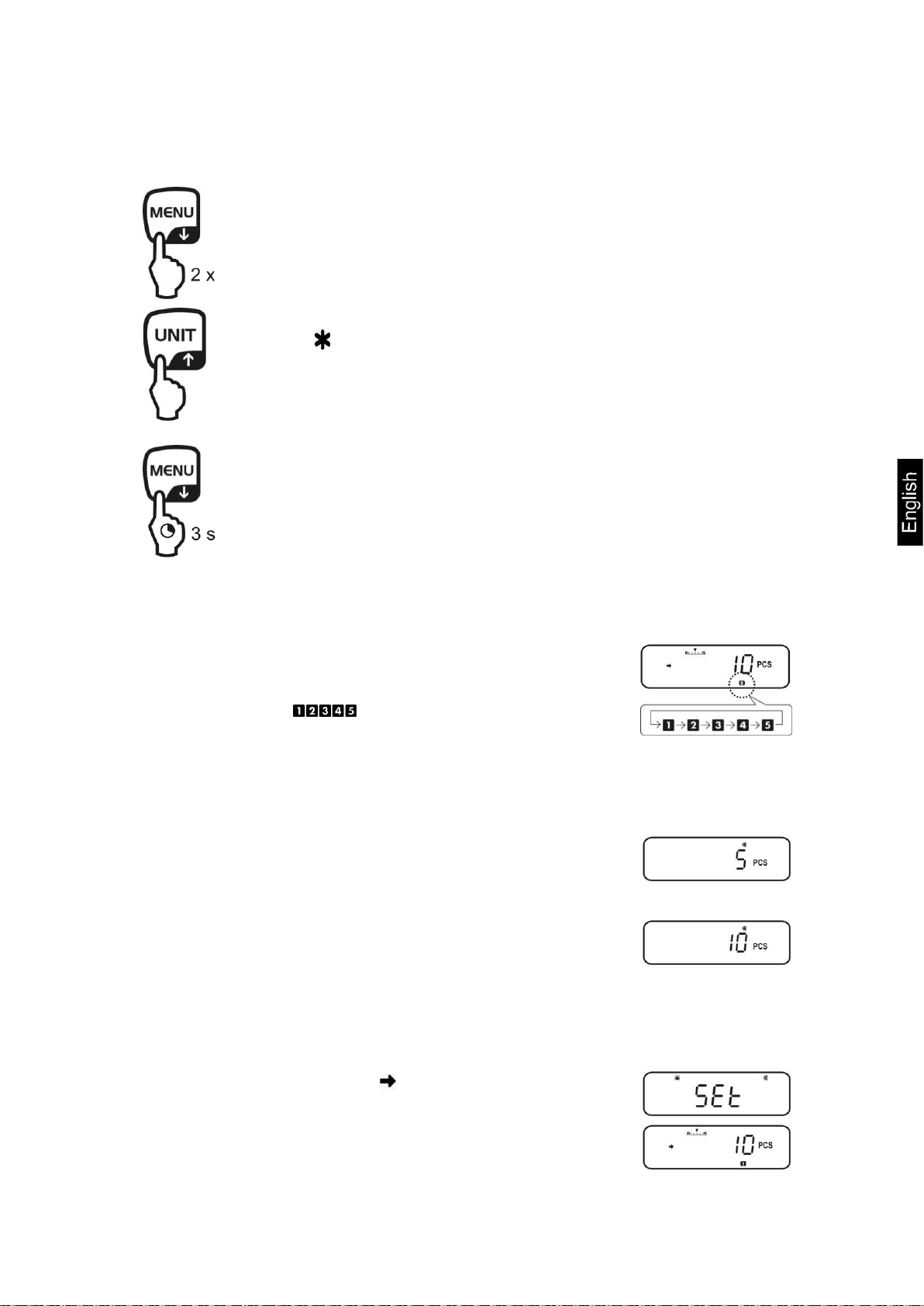

Change or add piece w eight

Or count more pieces

or

The menu item to change the stored reference is called up, the

currently set reference quantity is displayed.

+ see „4. Change or add piece weight“

The stored piece weight is displayed in grams, marked by the

symbol . Using PRINT the reference weight (UW= Unit weight)

can be edited when a printer is connected.

e.g.: UW = 1.0001

To go back to piece counting display press UNIT anew.

Switching over between piece counting and weighing mode

4. Change or add piece weight

In piece counting mode call-up the desired memory

location

Every time UNIT is pressed (approx. for 3 sec.), the next

memory location [ ] is called up.

Place an empty container on the balance and tare it by

pressing TARE.

Press MENU twice, the currently set reference quantity

is displayed.

Press the navigation buttons ( ) repeatedly until the

desired reference quantity is displayed (possible

reference quantities 5, 10, 20, 50, 100).

Use MENU to scroll forward.

Use UNIT to scroll backward.

Fill number of pieces into the container according to the

selected reference quantity.

Wait for the stability display ( ), then confirm by

pressing TARE.

The balance is now in parts counting mode and counts

all units on the weighing plate.

ABS-N_ABJ-NM-BA-e-1312 59

Page 60

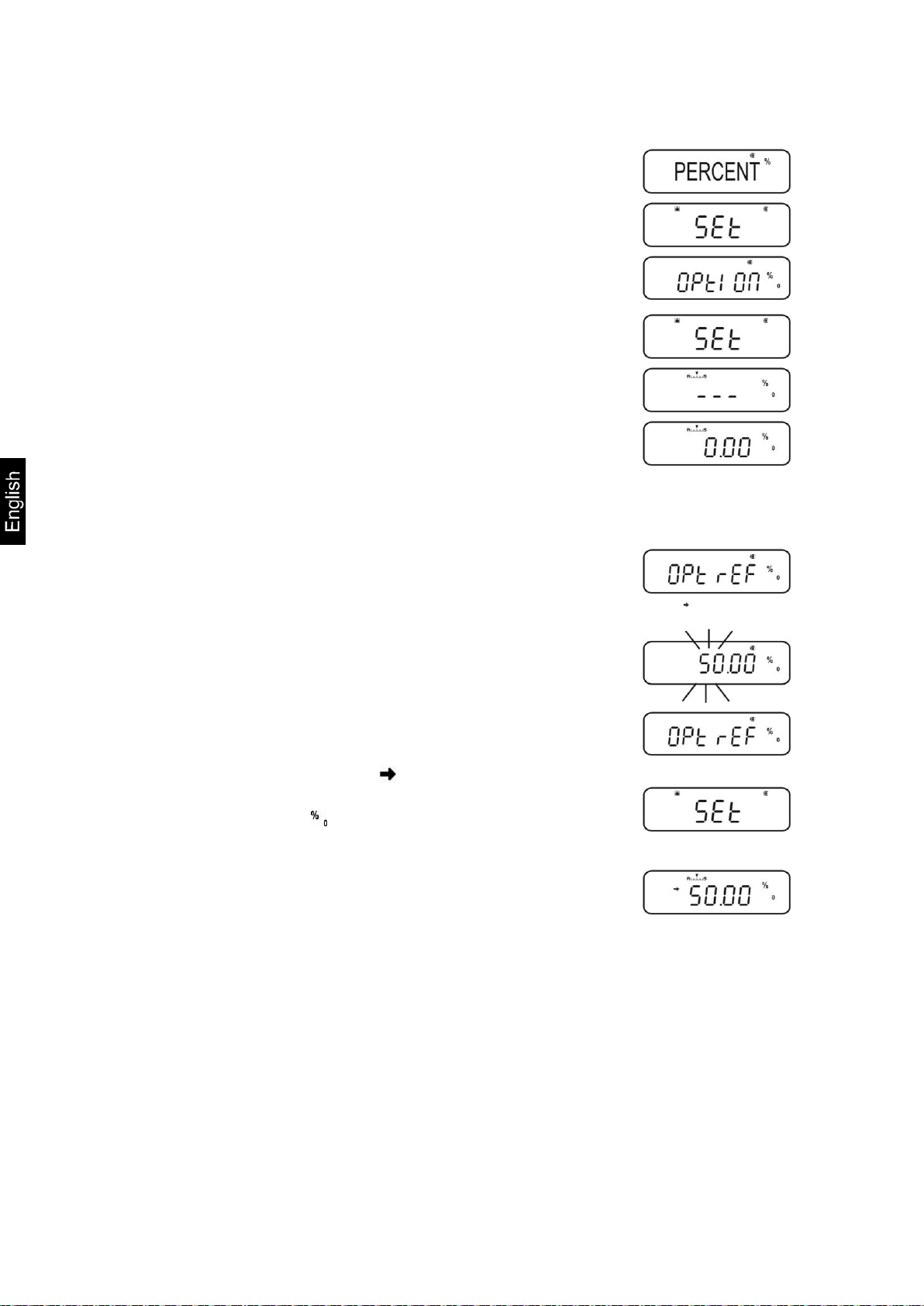

14.2 Percent determination

Percent weighing allows to display weight in percent, in relation to a reference

weight.

The balance offers two possibilities:

1. Reference = 100 %

2. Reference = defined by user

Call up menu

In weighing mode press the MENU button twice

Select percent weighing mode

Press the navigation buttons ( ) repeatedly until

„APL.FUNC“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „PERCENT“ is displayed.

Further steps:

+ Reference weight = 100 %, see chpt. 14.2.1

+ Reference weight = XX %, see chpt. 14.2.2

60 ABS-N_ABJ-NM-BA -e-1312

Page 61

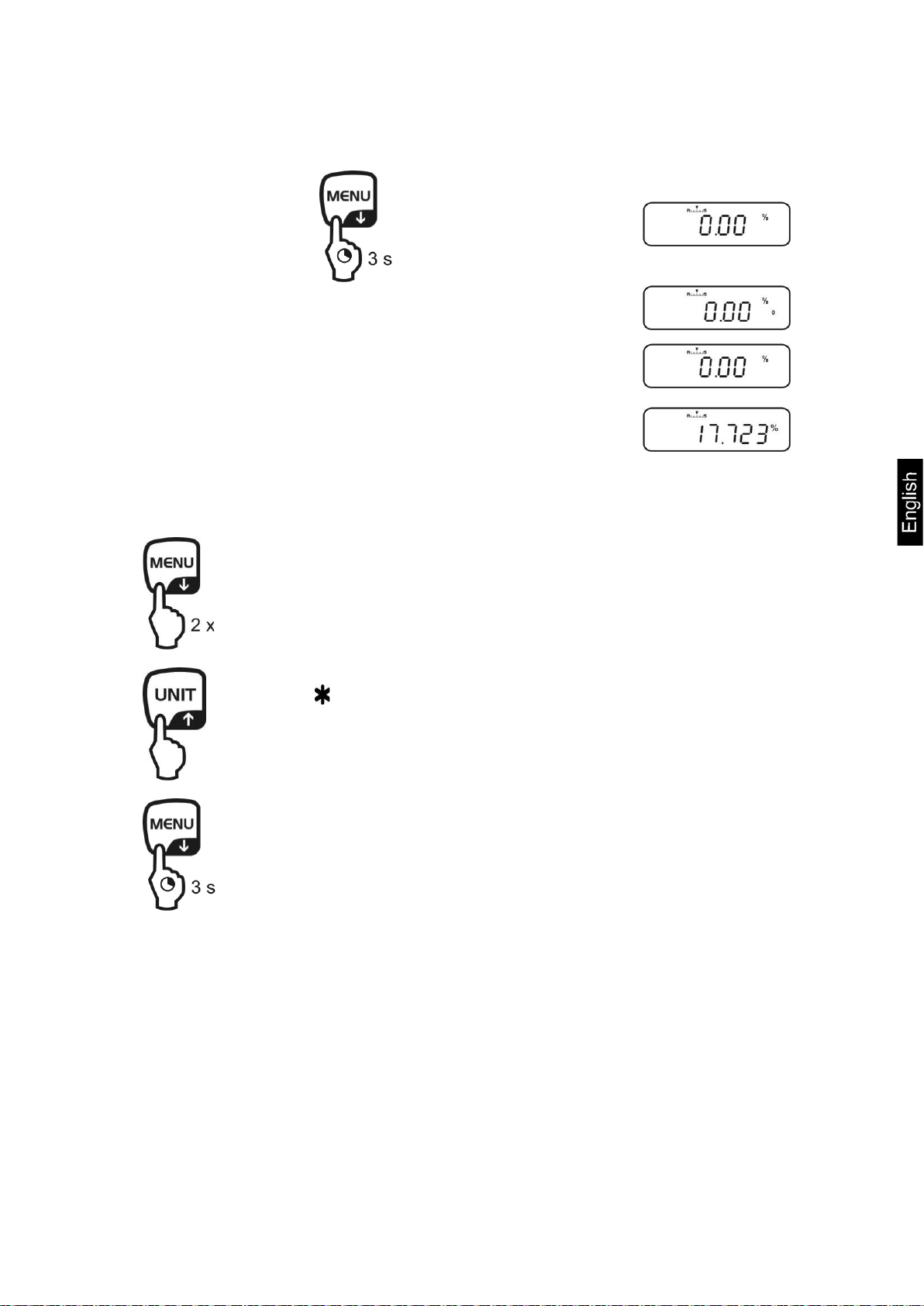

14.2.1 Reference weight = 100 %

Set reference

(Minimum weight: Readability d x 100)

Select percent weighing mode, see chpt. 14.2

Press TARE.

If necessary, press the navigation buttons ( )

repeatedly until „SAMPLE“ is displayed.

Press TARE.

Display, if no reference weight is stored

Display, if a reference weight is stored

If necessary, place an empty container on the balance

and tare it by pressing TARE.

Press MENU twice.

Put a reference weight which corresponds to 100 %.

Wait for the stability display ( ), then confirm by

pressing TARE.

From here on the weight of the sample is displayed in

percentage in terms of the reference weight, see chpt.

13.2.3.

ABS-N_ABJ-NM-BA-e-1312 61

Page 62

14.2.2 User-defined reference

Set reference

Select percent weighing mode, see chpt. 13.2

Press TARE.

If necessary, press the navigation buttons ( )

repeatedly until „OPTION“ is displayed.

Press TARE.

Display, if no reference is stored

Display, if a reference is stored

If necessary, place an empty container on the balance

and tare it by pressing TARE.

Press MENU twice.

Press PRINT and current setting will be displayed.

Enter a percentage of your choice via the navigation

buttons, see chpt. 3.1.1 „Numeric input“

Put a reference weight which corresponds to the entered

percent value.

Wait for the stability display ( ), then confirm by

pressing TARE.

The display symbol [ ] characterises the percentage

determination with user-defined reference value.

From here on the weight of the sample is displayed in

percentage in terms of the reference weight, see chpt.

14.2.3.

62 ABS-N_ABJ-NM-BA -e-1312

Page 63

14.2.3 Percent determination

In weighing mode press MENU for 3 sec., the currently

set percentage determination mode is displayed.

Place an empty container on the balance and tare it by

pressing TARE.

Place goods to be weighed on balance.

The weight of the sample is displayed in percentage in

terms of the reference weight.

Either carry out more percent weighing

or

The menu item to change the stored reference appears.

+ see chpt. 14.2.2 / 14.2.3 „Set reference“

The stored reference weight is displayed in grams, marked by the

symbol . Use PRINT to edit the weight value of the reference

value when a printer is connected.

or

Back to percent display, press UNIT anew.

Switching over between percentage determination and weighing

mode

ABS-N_ABJ-NM-BA-e-1312 63

Page 64

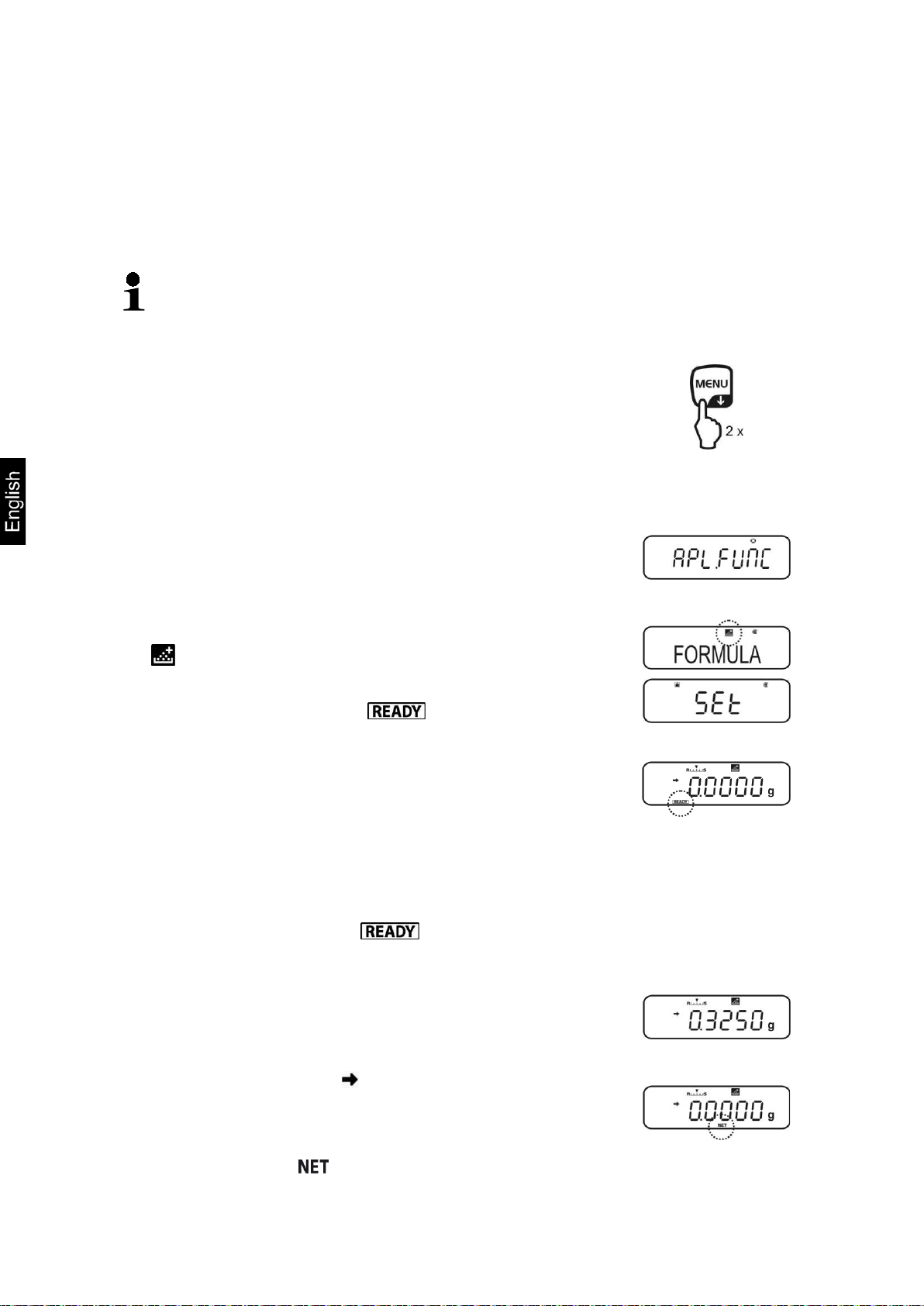

14.3 Formula mode

The formula function allows to add on various components of a mixture. For check

purpose, the weight of all components (CMP001, (CMP002 etc.), as well as the total

weight (TOTAL) can be printed out. The balance works with a separated memory for

the weight of the weighing container and of the formula components.

In formula mode the „Auto zero“ function is not active (see chpt. 12.2).

1. Connect printer (see chpt. 15 „Data output“)

2. Call up menu

In weighing mode press the MENU button twice

3. Select formula mode

Press the navigation buttons ( ) repeatedly until

„APL.FUNC“ is displayed.

Confirm with PRINT

Press the navigation buttons ( ) repeatedly

until „FORMULA“ is displayed. The formula symbol

[ ] appears.

Press TARE. The indicator is displayed, from

here on the balance is in formula mode.

Enable the edition „component no.“(see chpt. 14.3.1)

and „Total“ (see chpt. 14.3.2).

4. Weighing components

If necessary, place an empty container on the balance

and tare it by pressing TARE.

Press PRINT , the symbol goes out.

When the GLP function (see chpt. 8.3) is activated, the

headline will be printed.

Weigh first component.

Press PRINT.

When standstill control ( ) is completed, the weighing

value of the first component (CMP001) is issued to the

optional printer. The displayed value is added into the

total adding memory. This is followed by the automatic

taring, the symbol [ ] is displayed.

64 ABS-N_ABJ-NM-BA -e-1312

Page 65

Company

Weigh further components in the same way

During formulation weighing can be displayed at any time by pressing

MENU (for 3 sec.).

5. Complete formulation process

Press ON/OFF. When the symbol [G] is displayed, the

total weight (TOTAL) of all components is displayed and

edited to the printer.

When the symbol is displayed, the balance is ready

for further measurements.

6. Return to weighing mode

Press ON/OFF for 3 sec.

Printout example „GLP ON“ (KERN YKB-01N):

Model

Serial no.

ID no.

prepared by

ABS-N_ABJ-NM-BA-e-1312 65

Page 66

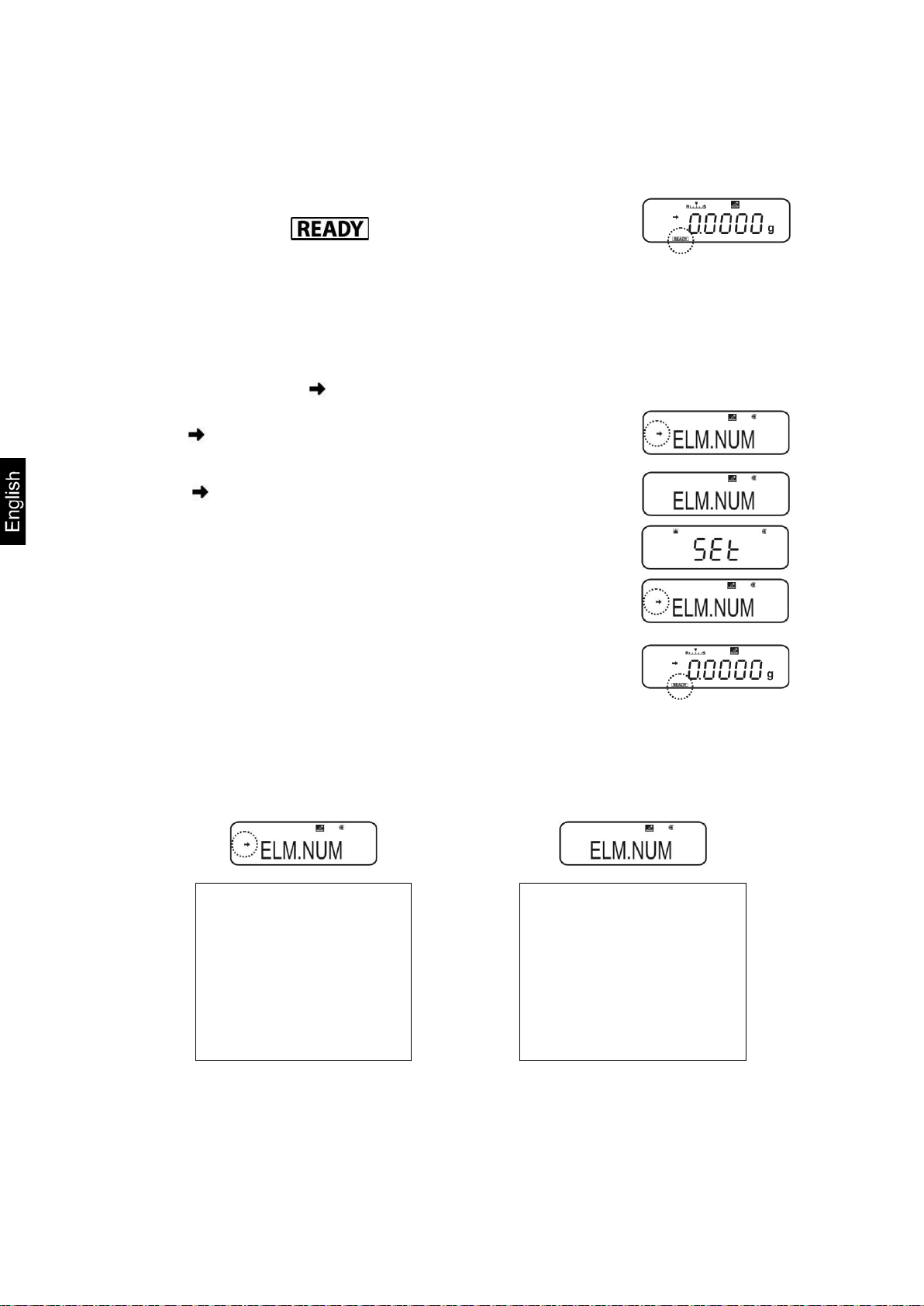

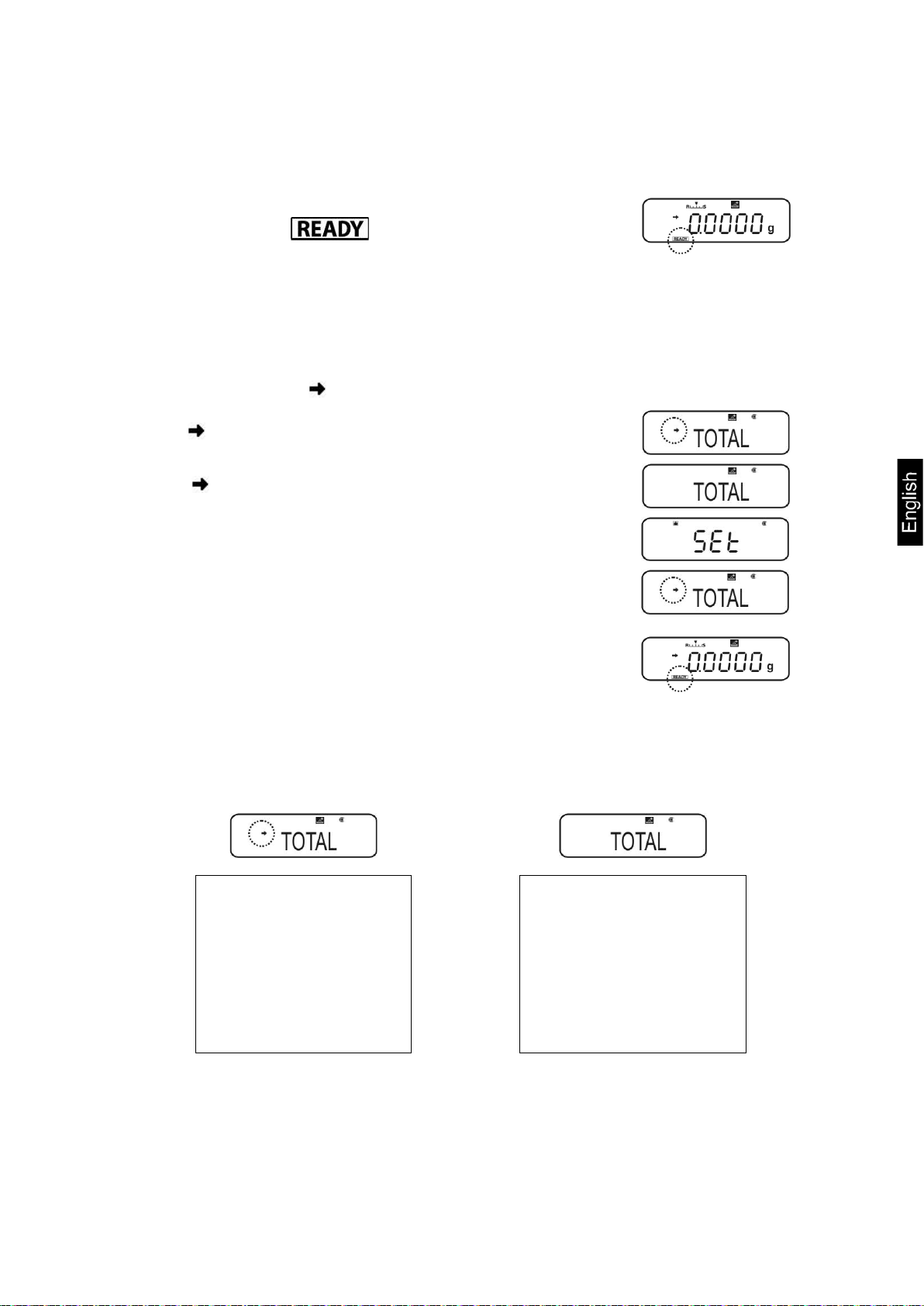

14.3.1 Enable edition „component no.“

Function ELM.NUM enabled

Function ELM.NUM disabled

FORMULATION MODE

FORMULATION MODE

CMP001=

0.5361 g

0.5361 g

CMP002=

0.5422 g

0.5422 g