Page 1

KERN & Sohn GmbH

Ziegelei 1

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating and Installation

Instructions Dis pl a y units

KERN VHP-T

Version 1.1

05/2016

GB

D-72336 Balingen

Fax: +49-[0]7433-9933-149

Importør:

Impex Produkter AS

Gamle Drammensvei 107

1363 Høvik

www.impex.no

info@impex.no

Tel.: 22 32 77 20

VHP-T-BA_IA-e-1611

Page 2

KERN VHP-T

Display units

GB

Version 1.1 05/2016

Operating and installa t ion instructions

Contents

1 Technical data ................................................................................................ 4

2 Device overview VHP-T ................................................................................. 5

3 Keyboard overview ........................................................................................ 6

3.1 Overview of display .................................................................................................................... 7

4 Basic Information (Gen eral) .......................................................................... 7

4.1 Proper use .................................................................................................................................. 7

4.2 Improper Use .............................................................................................................................. 7

4.3 Warranty ..................................................................................................................................... 8

4.4 Monitoring of Test Resources .................................................................................................... 8

5 Basic Safety Precauti o ns .............................................................................. 8

5.1 Pay attention to the instructions in the Operation Manual.......................................................... 8

5.2 Personnel training ....................................................................................................................... 8

6 Transport and storage ................................................................................... 9

6.1 Testing upon acceptance ........................................................................................................... 9

6.2 Packaging / return transport ....................................................................................................... 9

7 Unpacking and placing ................................................................................ 10

7.1 Installation Site, Location of Use .............................................................................................. 10

7.2 Unpacking ................................................................................................................................. 11

7.3 Scope of delivery / serial accessories: ..................................................................................... 11

7.4 Placing ...................................................................................................................................... 11

7.5 Storage battery operation (optional) ......................................................................................... 11

7.6 Selection of platform quantity ................................................................................................... 12

7.7 Adjustment ................................................................................................................................ 12

7.8 How to carry out adjustments ................................................................................................... 14

8 Operation ...................................................................................................... 15

8.1 Start-up ..................................................................................................................................... 15

8.2 Switching Off ............................................................................................................................ 15

8.3 Zeroing ..................................................................................................................................... 15

8.4 Simple weighing ....................................................................................................................... 15

8.5 Weighing with tare .................................................................................................................... 16

8.6 Manual totalizing ....................................................................................................................... 17

8.7 Display background illum inatio n ............................................................................................... 17

8.8 Automatic switch-off function „AUTO OFF“ .............................................................................. 18

2 VHP-T-BA_IA-e-1611

Page 3

9 Menu ............................................................................................................. 19

10 Servicing, maintenance, disposal .............................................................. 20

10.1 Cleaning ................................................................................................................................... 20

10.2 Servicing, maintenance ............................................................................................................ 20

10.3 Disposal .................................................................................................................................... 20

10.4 Error messages ........................................................................................................................ 20

11 Instant help ................................................................................................... 21

12 Configure display unit ................................................................................. 22

13 Declaration of Conformity ........................................................................... 23

VHP-T-BA_IA-e-1611 3

Page 4

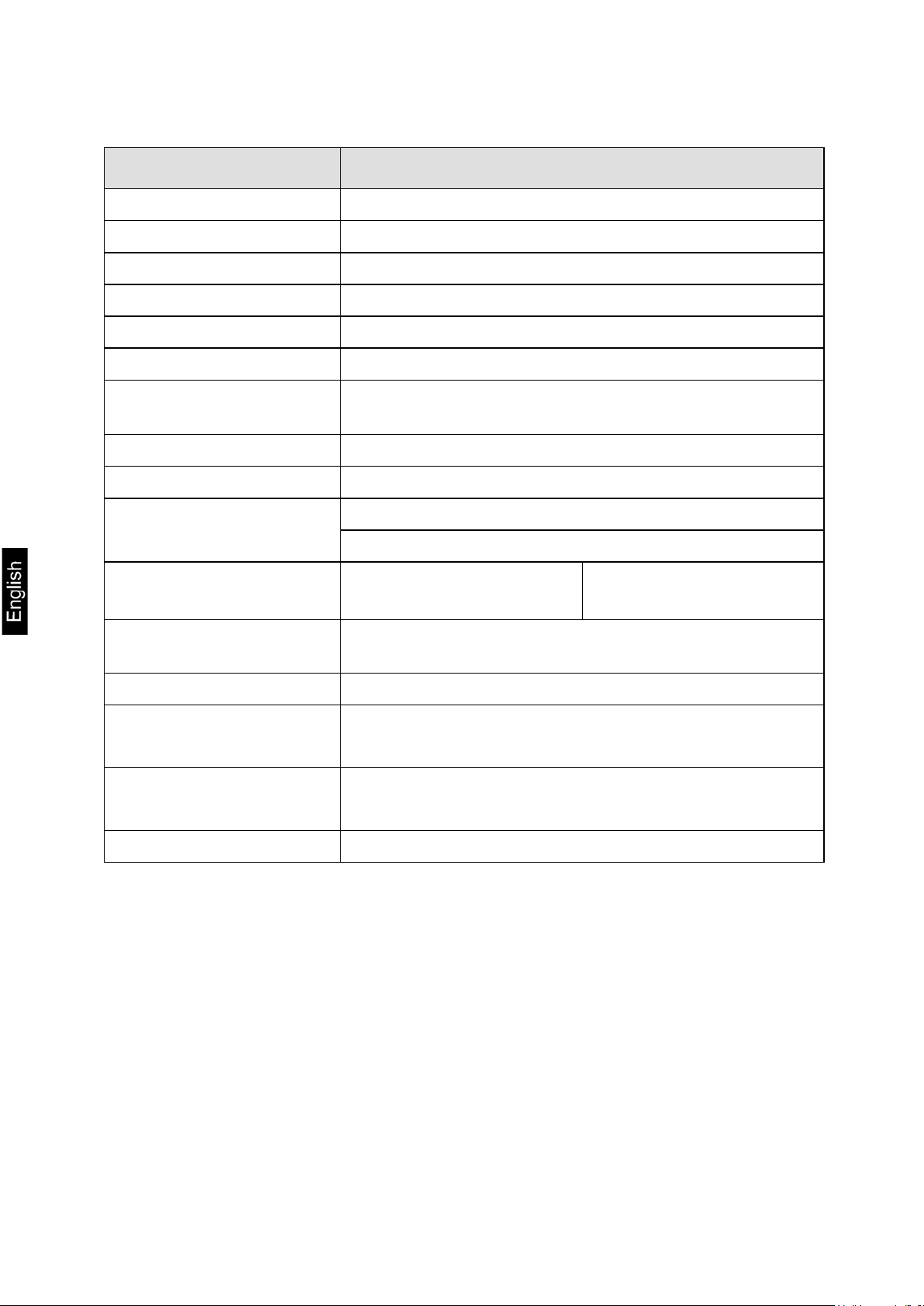

1 Technical data

KERN VHP-T

Display 5-digit

Resolution 3000

Divisions 1,2,5,10,20,50

Weighing Units Kg

Functions Totalization

Display LCD 10 mm digits with back lighting

DMS weighing cells

Range calibration We recommend ≥ 50 % max.

Data output RS232

Electric Supply

Installed recharg eabl e batt er y: DC 6V 10Ah

Housing With case: 510x340x220

Admissible

ambient temperature

Net weight 6 kg

Operating / charge time of

battery

RS 232 interface Serially

IP protection IP 54

Max. 6 items 700 Ω;

sensibility: 1±0.2mv/V.

Input voltage 100 V – 240 V

Without case:

350x280x170

0°C – 40°C

13 h / 12 h

4 VHP-T-BA_IA-e-1611

Page 5

1

2

3

4

5

2 Device overview VHP-T

1. Printer

2. Display

3. Keyboard

4. Connections (platforms, load connection of battery)

5. Case

VHP-T-BA_IA-e-1611 5

Page 6

3 Keyboard overview

Button Function

• Switch-on

• Switch-off

• Taring

• Display sum total

• Store weighing value

• Delete weighing values

• Printing

• Return key

• Setting the date

• Setting the time

• Entry of license plate

• Switch on and off background illumination

• Input of letters

• Input of numbers

• Zero setting key

6 VHP-T-BA_IA-e-1611

Page 7

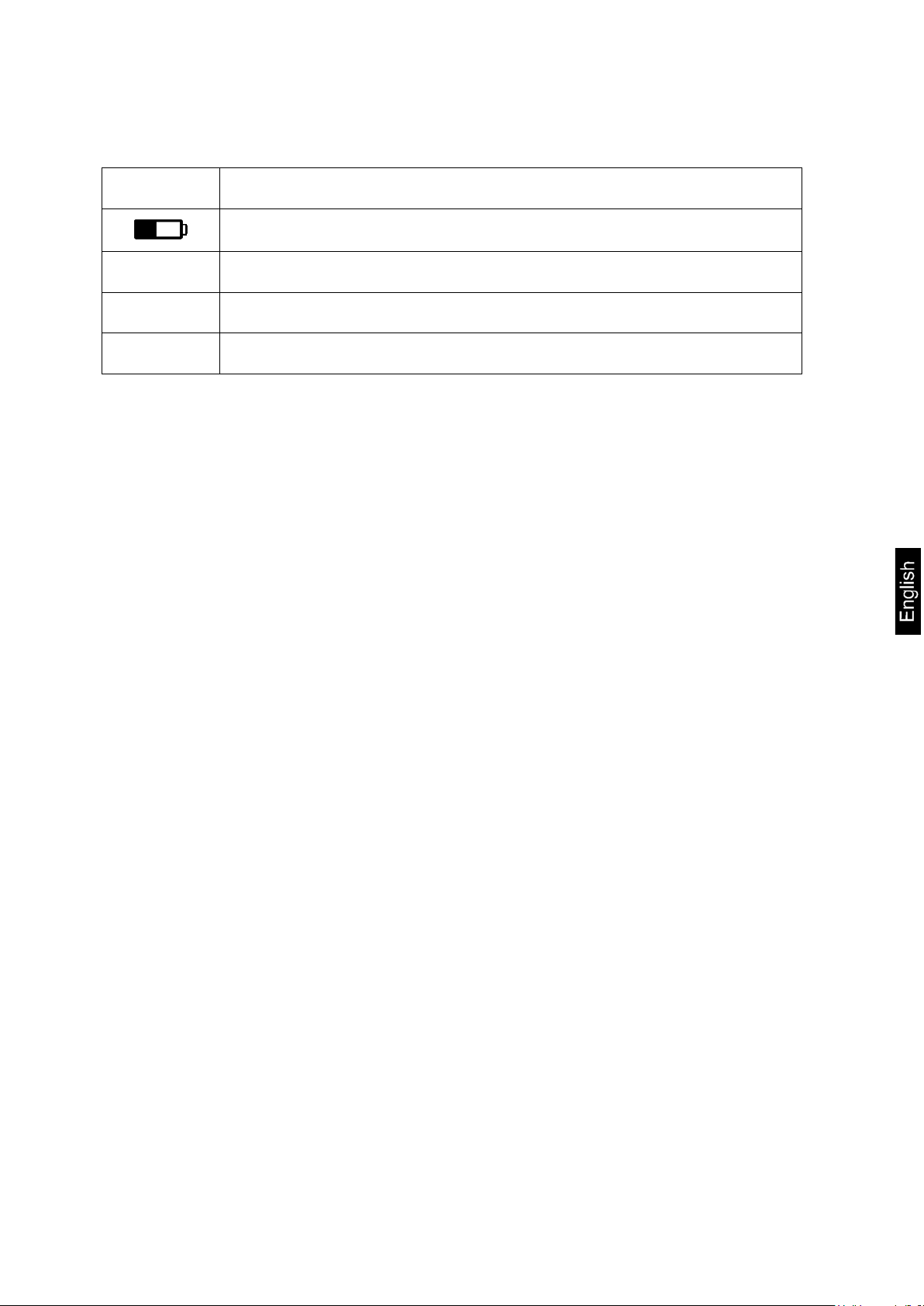

3.1 Overview of display

Display Significance

Battery very low

G Gross weight

NT Net weight

Kg Weighing unit

4 Basic Information (General)

4.1 Proper use

The display unit acquired by you is used in combination with a weighing plate and

serves to determine the weighing value of material to be weighed. It is intended to be

used as a “non-automatic weighing system”, i.e. the material to be weighed is

manually and carefully placed in the centre of the weighing plate. As soon as a stable

weighing value is reached the weighing value can be read.

4.2 Improper Use

Do not use display unit for dynamic weighing. In the event that small quantities are

removed or added to the material to be weighed, incorrect weighing results can be

displayed due to the “stability compensation“ in the display unit. (Example: Slowly

draining fluids from a container on the balance.)

Do not leave permanent load on the weighing pan. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the weighing

plate, minus a possibly existing tare load, must be strictly avoided. Both, the weighing

plate and the display unit may be damaged during this process.

Never operate display unit in explosive environment. The serial version is not

explosion protected.

Changes to the display unit's design are not permitted. This may lead to incorrect

weighing results, safety-related faul ts and des tr uct ion of the display unit.

The display unit may only be operated in accordance with the described default

settings. Other areas of use must be released by KERN in writing.

VHP-T-BA_IA-e-1611 7

Page 8

4.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical damage or damage by media, liquids, natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

4.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the display

unit and, if applicable, the testing weight, must be checked regularly. The responsible

user must define a suitable interval as well as type and scope of this test. Information

is available on KERN’s home page (www.kern-sohn.com with regard to the

monitoring of display units’ test substances and the test weights required for this. In

KERN’s accredited DKD calibration laboratory test weights and display units may be

calibrated (return to the national standard) fast and at moderate cost.

5 Basic Safety Precautions

5.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN balances.

All language versions contain a non-binding translation.

The original German is binding.

5.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

8 VHP-T-BA_IA-e-1611

Page 9

6 T ransport and storage

6.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

6.2 Packaging / return transport

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the

weighing platform, power unit etc. against shifting and

damage.

VHP-T-BA_IA-e-1611 9

Page 10

7 Unpacking and placing

7.1 Installation Site, Location of Use

The display units are designed in a way that reliable weighing results are achieved in

common conditions of use.

Precise and fast work is achieved by selecting the right place for your display unit

and your weighing plate.

On the installation site observe the following:

• Place the display unit and the weighing plate on a stable, even surface.

• Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

• Protect the display unit and the weighing plate against direct draft from open

windows or doors.

• Avoid jarring during weighing;

• Protect the display unit and the weighing plate against high humidity, vapours

and dust.

• Do not expose the display unit to extreme dampness for longer periods of

time. Non-permitted condensation (condensation of air humidity on the

appliance) may occur if a cold appliance is taken to a considerably warmer

environment. In this case, acclimatize the disconnected appliance for ca.

2 hours at room temperature.

• Avoid static charge of goods to be weighed or weighing container.

Major display deviations (incorrect weighing results) may be experienced should

electromagnetic fi elds ( e.g . due to mobi l e pho nes or radio equipment), static

electricity accumulations or instable power supply occur. Change location or remove

source of interference.

10 VHP-T-BA_IA-e-1611

Page 11

• Display Unit

7.2 Unpacking

Carefully remove the display unit from packaging, remove plastic cover and place it

in the designated work area.

and place it in the designated work area.

7.3 Scope of delivery / serial accessories:

• Mains adapter for loading the battery

• RS 232 interface cable

• Operating manual

• 1 x paper roll for printer

7.4 Placing

Mount the display unit in a way that facilitates operation and where it is easy to see.

7.5 Storage battery operation (optional)

Before the first use, the battery should be charged by connecting it to the mains

power supply for at least 12 hours.

Charge the battery with the help of the supplied power pack.

The LED display at the mains adapter informs you during loading about the loading

status of the rechargeable battery.

red: Voltage has dropped below prescribed minimum.

green: Rechargeable battery completely reloaded

To conserve energy, enable the automatic switch-off function „AUTO OFF“, see

chap. 8.8.

VHP-T-BA_IA-e-1611 11

Page 12

warm-up time.

7.6 Selection of platform quantity

1. Turn on device using the - - button

2. Use button to change into the window for date

input.

3. Now enter the following password: 878586 (the last two

ciphers can be ignored)

4. Use the C button to change between the individual

parameters.

5. Select the parameter (8): Mode

6. Confirm by pressing the button

7. Now enter the quantity of platforms. As per standard

there are 2. (up to 6 platforms available)

7.7 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each display unit with connected weighing plate must be coordinated - in compliance

with the underlying physical weighing principle - to the existing acceleration due to

gravity at its place of location (only if the weighing system has not already been

adjusted to the location in the factory). This adjustment process must be carried out

for the first commissioning, after each change of location as well as in case of

fluctuating environment temperature. To receive accurate measuring values it is also

recommended to adjust the display unit periodically in weighing operation.

• Prepare the required adjustment weight. The weight to be used depends

on the capacity of the scale. Carry out adjustment as near as possible to

the scale’s maximum weight. Info about test weights can be found on

the Internet at: http://www.kern-sohn.com.

• Observe stable environmental conditions. Stabilisation requires a certain

12 VHP-T-BA_IA-e-1611

Page 13

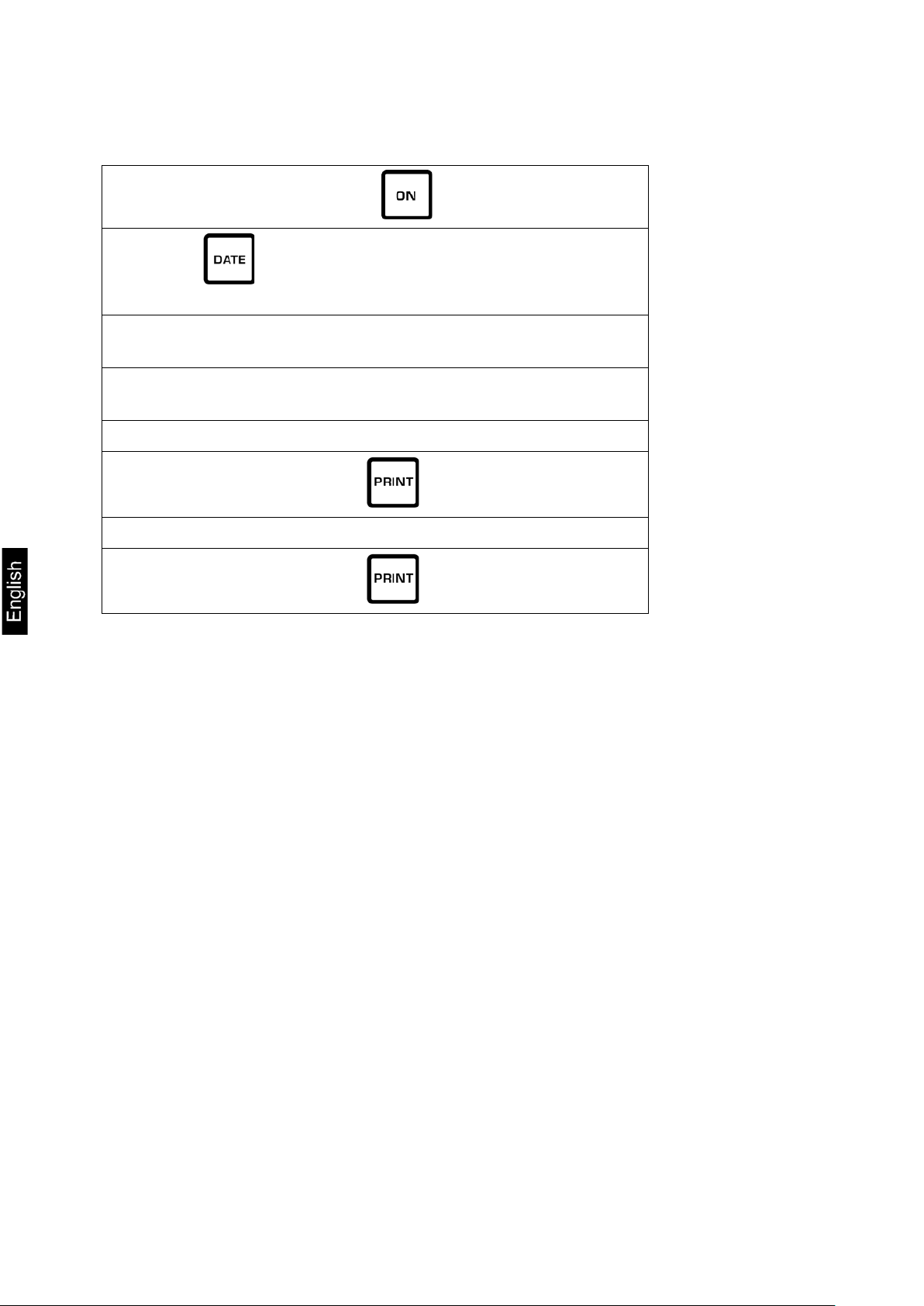

Call up menu:

1. Turn on device using the - - button

2. Use button to change into the window for date

input.

3. Now enter the following password: 878586 (the last two

ciphers can be ignored)

4. Use the C button to change between the individual

parameters.

5. Select the parameter (5): Select Calibration

6. Confirm by pressing the button

VHP-T-BA_IA-e-1611 13

Page 14

Zero point adjustment platform 1

Zero point adjustment platform 2

Adjustment platform 1

Adjustment platform 2

7.8 How to carry out adjustments

Important: Always adjust both weighing platforms in a parallel manner. Not one by

one. Always place the adjustment weight evenly on both platforms. In menu define

the respective platform as a half.

Example: Place 15 tons of adjustment weight on both platforms. In the menu

adjust each platform with the following input:

Platform 1: 7500kg

Platform 2: 7500kg

The following display appears after acknowledgement of parameter (5) Calibration:

To select the platforms, press the C button

Use the button to select the respective platform.

Carry out zero point adjustment (CAL ZERO) at platform 1

(SP1) and platform 2 (SP2). During cero point adjustment

the weighing plate must not be charged.

Always place the adjustment weight evenly on both

platforms.

Carry out adjustment at platform 1 (SP1) and platform 2

(SP2). (please note the example above: 50% of the total

load per platform must be defined.)

14 VHP-T-BA_IA-e-1611

Page 15

Overloading exceeding the stated maximum load (max) of the device, minus a

8 Operation

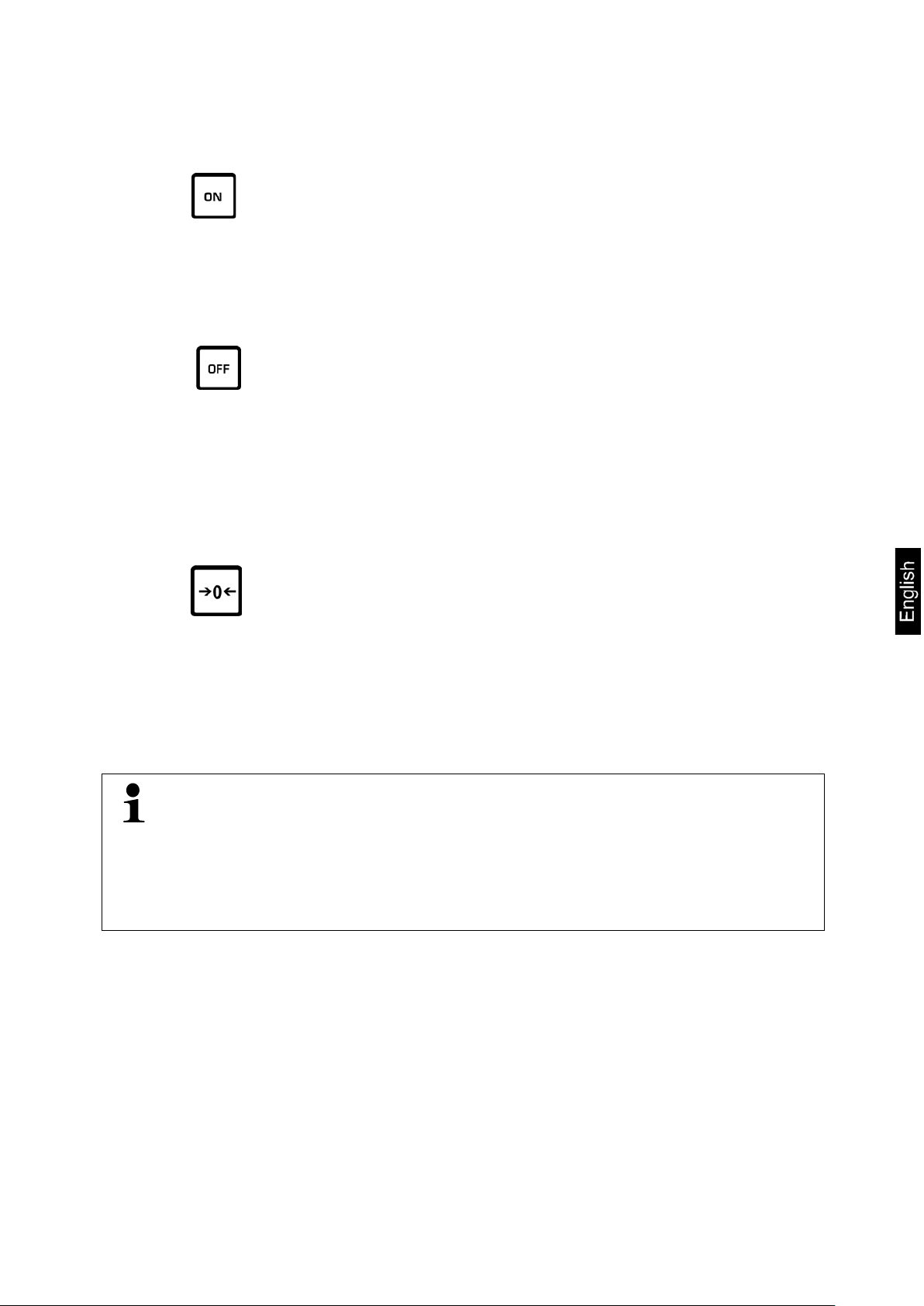

8.1 Start-up

Press . As soon as the weight display appears, the instrument will be ready

to weigh.

8.2 Switching Off

Press , the display will disappear.

8.3 Zeroing

Resetting to zero corrects the influence of light soiling on the weighing plate. If

required, the device may be reset to zero at any time.

To unload the weighing system

Press , the zero display appears.

8.4 Simple weighing

Place/drive-on weighing goods (at walking speed)

Read weighing result.

Overload warning

possibly existing tare load, must be strictly avoided. This could damage the

instrument.

Exceeding the maximum load is indicated by the display „----“.

Unload weighing system or reduce preload.

VHP-T-BA_IA-e-1611 15

Page 16

8.5 Weighing with tare

Deposit weighing vessel. After successful standstill control press the

button.

The zero display appears.

The weight of the container is now internally saved.

Weigh the material, the net weight will be indicated.

The weight of the weighing container will be displayed as a minus number after

removing the weighing container.

The tare procedure can be repeated as many times as necessary, for example

with initial weighing of several components for a mix (add-on weighing). The limit

is reached when the taring range reaches its capacity limit.

To delete the tare value, remove load from weighing plate and press .

16 VHP-T-BA_IA-e-1611

Page 17

Axle load - report

30/11/2014

16:03:34

SN. 2

HGV license plate:

BLM

Article: 01

--------------------------

Wheel 1:

70 kg

Wheel 2:

40 kg

--------------------------

Axle 1:

110 kg

--------------------------

G =

110 kg

T =

0 kg

NT=

110 kg

User:

8.6 Manual totalizing

After pressing the button, the separate weighing results of the platforms are

added up to a total result (axle) and printed out.

See printout example below:

8.7 Display background illumination

The background illumination can be turned on and off by using button.

VHP-T-BA_IA-e-1611 17

Page 18

8.8 Automatic switch-off function „AUTO OFF“

1. Turn on device using the - - button

2. Use button to change into the window for date

input.

3. Now enter the following password: 878586 (the last two

ciphers can be ignored)

4. Use the C button to change between the individual

parameters.

5. Select the parameter (9): Select “Auto-Off time“.

6. Confirm by pressing the button

7. Now a time of 1-99 minutes can be defined.

8. Confirm by pressing the button

18 VHP-T-BA_IA-e-1611

Page 19

9 Menu

Navigation in the menu:

Access to menu

1. Turn on device using the - - button

2. Use button to change into the window for date

input.

3. Now enter the following password: 878586 (the last two

ciphers can be ignored)

4. Use the C button to change between the individual

parameters.

5. Using button select the corresponding

parameter.

Menu overview

Menu Function

(1) Capacity

(2) Readability

(3) Decimal point

(4)

(5) Calibration

(6)

(7) Language

(8) Mode

• Setting weighing scale capacity

• Setting weighing scale readability.

• Setting decimal point (decimal place).

• (please do not modify standard setting on „5“)

• Adjustment of balance.

• Not documented

• Selection of language German and English

• Selection of quantity of platforms (up to 6 platforms

possible)

VHP-T-BA_IA-e-1611 19

Page 20

10 Servicing, maintenance, di s pos al

10.1 Cleaning

• Before cleaning, disconnect the appliance from the operating voltage.

• Do not use aggressive detergents (solvents or similar).

10.2 Servicing, maintenance

The appliance may only be opened by trained service technicians who are authorized

by KERN.

Before opening, disconnect from power supply.

10.3 Disposal

Disposal of packaging and appliance must be carried out by operator according to

valid national or regional law of the location where the appliance is used.

10.4 Error messages

Error message Description Possible causes

+/-RRR(EEE)

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

No defined signal

Overload display

Underload display

• Weighing plat for m not connected.

• Too much weight on the weighing

platform.

• Insufficient weight on the weighing

platform.

20 VHP-T-BA_IA-e-1611

Page 21

The displayed weight does

not glow.

• Mains power supply interrupted (mains cable

defective).

• Power supply interrupted.

• (Rechargeable) batteries are inserted incorrectly or

empty

• No (rechargeable) batteries inserted.

The displayed weight is

• Table/floor vibrations

• Weighing pan has contact with other objects.

possible)

The weighing result is

obviously incorrect

• Adjustment is no longer correct.

• Great fluctuations in temperature.

possible)

11 Instant help

In case of an error in the program process, briefly turn off the display unit and

disconnect from power supply. The weighing process must then be restarted from the

beginning.

Help:

Fault Possible cause

• The display unit is not switched on.

permanently changing

Should other error messages occur, switch display unit off and then on again. If the

error message remains inform manufacturer.

• Draught/air movement

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

• The display of the balance is not at zero

• Warm-up time was ignored.

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

VHP-T-BA_IA-e-1611 21

Page 22

Enter capacity with the numeric keypad and subsequently

12 Configure display unit

1. Turn on device using the - - button

2. Use button to change into the window for date

input.

3. Now enter the following password: 878586 (the last two

ciphers in the display can be ignored)

4. Use the C button to change between the individual

parameters.

5. Select the parameter (1) capacity.

6. Confirm by pressing the button

confirm with button.

7. Use the button to return to the parameter list

8. Select the parameter (2) readability.

Confirm by pressing the button

Enter readability via the numeric keypad and

subsequently confir m with button. (Possible

values: 1,2,5,10,20,50)

9. Use the button to return to the parameter list

22 VHP-T-BA_IA-e-1611

Page 23

Enter the corresponding platform quantity via the numeric

10. Select the parameter (3) decimal point.

Confirm by pressing the button.

Enter the decimal point (decimal places) via the numeric

keyboard. Possible values: 0-3)

11. Confirm by pressing the button

12. Use the button to return to the parameter list

13. Select the parameter (8) Mode.

keyboard. (up to 6 platforms available)

14. Use the button to return to the parameter list

15. Select the parameter (5) Calibration.

16. Adjusting the balance (see item 6.8)

13 Declaration of Conformity

To view the current EC/EU Declaration of Conformity go to:

www.kern-sohn.com/ce

VHP-T-BA_IA-e-1611 23

Loading...

Loading...