Page 1

PRS/PRJ/ARS/ARJ-BA-def-0622 85

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Tel: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Operating instruction

Precision and analytical balances

KERN PRS/PRJ/ARS/ARJ

Version 2.2

11/2006

GB

PRS/PRJ/ARS/ARJ-BA-e-0622

Page 2

86 PRS/PRJ/ARS/ARJ-BA-def-0622

GB

KERN PRS/PRJ/ARS/ARJ

Version 2.2 11/2006

Operating Instructions

Precision and analytical balance

Table of Contents

1 Technical data _____________________________________________________89

2 Declaration of conformity____________________________________________95

3 Fundamental information (general)____________________________________ 97

3.1 Intended use ________________________________________________________97

3.2 Inappropriate use ____________________________________________________97

3.3 Guarantee __________________________________________________________97

3.4 Monitoring the test equipment__________________________________________98

4 Fundamental safety information ______________________________________98

4.1 Observe the information in the operating instructions______________________98

4.2 Staff training ________________________________________________________98

5 Transport and storage ______________________________________________98

5.1 Acceptance check____________________________________________________98

5.2 Packaging __________________________________________________________98

6 Unpacking, installation and commissioning ____________________________99

6.1 Place of installation, place of use _______________________________________99

6.2 Unpacking __________________________________________________________99

6.3 Installation _________________________________________________________100

6.3.1 Windshield for PRS and PRJ balances (d=0.1 mg)_______________________________ 101

6.4 Functions of the balance _____________________________________________102

6.5 Equipment overview: ________________________________________________103

6.6 Scope of delivery ___________________________________________________104

6.7 Mains supply _______________________________________________________105

6.8 Connecting peripheral devices ________________________________________105

6.9 Commissioning _____________________________________________________105

6.10 Calibration _________________________________________________________105

6.10.1 External calibration by means of ICM _______________________________________ 106

6.10.2 External calibration with freely selectable weight ______________________________ 107

6.10.3 Internal calibration (only ARJ/PRJ models) __________________________________ 108

6.10.4 Automatic calibration (only ARJ/PRJ models)_________________________________ 108

6.10.5 Balances appropriate for verification (only ARJ/PRJ models)_____________________ 109

6.10.6 Position of verification safety seal (only on ARJ/P RJ models appropriate for verification)110

6.11 Suspended weighing ________________________________________________111

7 Modes of operation and use_________________________________________112

Page 3

PRS/PRJ/ARS/ARJ-BA-def-0622 87

7.1 Switching on the balance_____________________________________________112

7.2 Auto-Standby-Mode _________________________________________________112

7.3 Significance of the two main menus____________________________________112

7.4 Activating the two main menus ________________________________________113

7.4.1 Activating the configuration menu ____________________________________________ 113

7.4.2 Activating the application menu______________________________________________ 113

7.5 How the menu control operates________________________________________113

7.5.1 Control panel____________________________________________________________ 114

7.5.2 Operation in weighing mode ________________________________________________ 114

7.5.3 Operation in programming mode_____________________________________________ 115

7.5.4 Display_________________________________________________________________ 116

7.5.5 Info-line and function keys__________________________________________________ 116

7.5.6 Example of display: Statistics program ________________________________________ 117

7.6 Password protection of the menus _____________________________________118

7.7 Anti-theft encoding __________________________________________________118

8 Working with the configuration menu_________________________________120

8.1 Structure of the configuration menu____________________________________120

8.2 Language function __________________________________________________121

8.3 Defining the configuration ____________________________________________122

8.4 Selecting the weight unit _____________________________________________122

8.5 Print functions______________________________________________________123

8.6 Calibration functions ________________________________________________124

8.7 Weighing mode _____________________________________________________125

8.8 Interface functions __________________________________________________126

8.9 Date and time (only PRJ and ARJ models) ________________________________126

8.10 Password protection_________________________________________________127

8.11 Anti-theft encoding __________________________________________________127

9 Working with the application menu___________________________________128

9.1 Structure of the application menu______________________________________128

9.2 Selecting an application______________________________________________129

9.3 Setup for “SET APP UNITS”: __________________________________________130

9.4 Setup for “SET APP COUNT”__________________________________________131

9.5 Setup for “SET APP PERCENT” _______________________________________132

9.6 Setup for “SET APP CALCULATOR”____________________________________133

9.7 Setup for “SET APP PAPER”__________________________________________134

9.8 Setup for “SET APP NET TOTAL” ______________________________________135

9.9 Setup for “SET APP TOTALISE” _______________________________________136

9.10 Setup for “SET APP ANIMAL WEIGHING” _______________________________137

9.11 Setup for “SET APP DENSITY” ________________________________________138

9.12 Setup for the statistics program _______________________________________140

9.13 Setup for CHECK weighing ___________________________________________142

Page 4

88 PRS/PRJ/ARS/ARJ-BA-def-0622

10 Special operating keys ___________________________________________143

10.1 The Tare key “T” ____________________________________________________143

10.2 The CAL key “CAL”__________________________________________________143

10.3 The Print key “PRINT” _______________________________________________144

10.4 The Change key « » _______________________________________________144

11 Data transfer to peripheral devices _________________________________145

11.1 Connection to peripheral devices ______________________________________146

11.2 Data transfer _______________________________________________________147

11.3 Remote-control commands ___________________________________________148

11.4 Examples for the remote control of the balance __________________________149

12 Practical examples ______________________________________________150

12.1 Changing the configuration menu______________________________________150

12.1.1 Setting the choice of language ____________________________________________ 150

12.1.2 Setting the Weight unit __________________________________________________ 150

12.1.3 Setting the Print functions________________________________________________ 151

12.1.4 Activation of password protection __________________________________________ 152

12.2 Selecting an application program ______________________________________153

12.2.1 Setting for Counting by weighing___________________________________________ 153

12.2.2 Setting the statistics function______________________________________________ 155

13 Further information ______________________________________________158

13.1 Notes on Weighing mode_____________________________________________158

13.1.1 Set Weighing mode: Floati ng display _______________________________________ 158

13.1.2 Set Weighing mode: Stability control________________________________________ 158

13.1.3 Set Weighing mode: Auto-Standby_________________________________________ 159

13.1.4 Set Weighing mode: Auto-Zero____________________________________________ 159

13.2 Notes on density determination________________________________________160

13.2.1 Density determination “Solid on bottom mode ”________________________________ 160

13.2.2 Density determination “Solid in air mode”____________________________________ 160

13.2.3 Density determination “Liquid mode”________________________________________ 160

13.2.4 14.3.4 Density determination “Porous solid mode” _____________________________ 160

14 Configuration menu tree__________________________________________161

15 Application Menu Tree ___________________________________________ 164

15.1 Software updates via Internet _________________________________________165

16 Servicing, maintenance, disposal __________________________________165

16.1 Cleaning___________________________________________________________165

16.2 Servicing, maintenance ______________________________________________165

16.3 Disposal ___________________________________________________________165

17 Troubleshooting ________________________________________________166

18 Error messages and correction of faults_____________________________167

18.1 Notes on correcting faults ____________________________________________167

Page 5

PRS/PRJ/ARS/ARJ-BA-def-0622 89

1 Technical data

KERN PRS 320-3N PRS 620-3N PRS 4200-2N PRS 4200-

2IP65N

Readout (d) 0.001 g 0.001 g 0.01 g 0.01 g

Weighing range (Max) 320 g 620 g 4,200 g 4,200 g

Repeatability 1 mg 1 mg 10 mg 10 mg

Linearity ± 1.5 mg ± 1.5 mg ± 15 mg ± 15 mg

Recommended adjusting

weight, not included (class)

200 g (E2) 500 g (E2) 4000 g (E2) 4000 g (E2)

Minimum piece weight in

count mode

0.001 g 0.001 g 0.01 g 0.01 g

Reference quantity when

counting parts

1-999 1-999 1-999 1-999

Weighing plate, stainless

steel [mm]

135 x 135 135 x 135 170 x 170 170 x 170

Dimensions of housing

(W x D x H) [mm]

210 x 340 x 150 210 x 340 x 150 210 x 340 x 150 210 x 340 x 150

Dimensions of weighing

space glass windshield

[mm]

155 x 155 x 55 155 x 155 x 55 - -

Net weight (kg) 5.1 5.1 4.5 4.5

Stabilisation time 2 seconds

Weight units

(verified equipment)

mg, g

Weight units

(non-verified equipment)

mg, g, GN, dwt, ozt, oz, lb, ct, C.M. tLH, tLM, tLT, mo, Tola

Permissible ambient

conditions

10° C to 30° C

Air humidity max. 80 % relative (non condensing)

Page 6

90 PRS/PRJ/ARS/ARJ-BA-def-0622

KERN PRS 6200-2N PRS 8200-1N PRS 8200-1IP65N PRS 12200-1N

Readout (d) 0.01 g 0.1 g 0.1 g 0.1 g

Weighing range (Max) 6,200 g 8,200 g 8,200 g 12,200 g

Repeatability 10 mg 0.1 g 0.1 g 0.1 g

Linearity ± 15 mg ± 0.1 g ± 0.1 g ± 0.1 g

Recommended adjusting

weight, not included (class)

5000 g (E2) 5000 g (F2) 5000 g (F2) 10 000 g (F1)

Minimum piece weight in

count mode

0.01 g 0.1 g 0.1 g 0.1 g

Reference quantity when

counting parts

1-999 1-999 1-999 1-999

Weighing plate, stainless

steel [mm]

170 x 170 200 x 200 200 x 200 200 x 200

Dimensions of housing

(W x D x H) [mm]

210 x 340 x 150 210 x 340 x 150 210 x 340 x 150

210 x 340 x

150

Net weight (kg) 4.5 4.7 4.7 4.7

Stabilisation time 2 seconds

Weight units

(verified equipment)

mg, g

Weight units

(non-verified equipment)

mg, g, GN, dwt, ozt, oz, lb, ct, C.M. tLH, tLM, tLT, mo, Tola

Permissible ambient

conditions

10° C to 30° C

Air humidity max. 80 % relative (non condensing)

Page 7

PRS/PRJ/ARS/ARJ-BA-def-0622 91

KERN PRS 12200-

1IP65N

PRJ 320-3NM PRJ 620-3NM PRJ 1200-3N

Readout (d) 0.1 g 0.001 g 0.001 g 0.001 g

Weighing range (Max) 12,200 g 320 g 620 g 1,220 g

Minimum load - 0.02 g 0.02 g Verification value - 0.01 g 0.01 g Verification categories - II II Repeatability 0.1 g 1 mg 1 mg 1 mg

Linearity ± 0.1 g ± 1.5 mg ± 1.5 mg ± 2 m g

Recommended adjustment

weight

10 000 g (F1) - - -

Adjustment weight - internal internal internal

Minimum piece weight in

count mode

0.1 g 0.001 g 0.001 g 0.001 g

Reference quantity when

counting parts

1-999 1-999 1-999 1-999

Weighing plate, stainless

steel [mm]

200 x 200 135 x 135 135 x 135 135 x 135

Dimensions of housing

(W x D x H) [mm]

210 x 340 x 150

210 x 340 x

150

210 x 340 x 150

210 x 340 x

150

Dimensions of glass

windshield [mm]

-

Weighing

space 155 x

155 x 55

Weighing space

155 x 155 x 55

150 x 150 x 60

Net weight (kg) 4.7 5.5 5.5 5.5

Weight units

mg, g, GN, dwt,

ozt, oz, lb, ct, C.M.

tLH, tLM, tLT, mo,

Tola

mg, g mg, g

mg, g, GN,

dwt, ozt, oz, lb,

ct, C.M. tLH,

tLM, tLT, mo,

Tola

Permissible ambient

conditions

10° C to 30° C

Stabilisation time 2 seconds

Air humidity max. 80 % relative (non condensing)

Page 8

92 PRS/PRJ/ARS/ARJ-BA-def-0622

KERN PRJ 4200-2NM PRJ 6200-2NM PRJ 6200-1IP65NM PRJ 8200-1NM

Readout (d) 0.01 g 0.01 g 0.1 g 0.1 g

Weighing range (Max) 4,200 g 6,200 g 6,200 g 8,200 g

Minimum load 0.5 g 0.5 g 5 g 5 g

Verification value 0.1 g 0.1 g 1 g 1 g

Verification categories II II II II

Repeatability 10 mg 10 mg 0.1 g 0.1 g

Linearity ± 15 mg ± 15 mg ± 0.1 g ± 0.1 g

Adjustment weight internal internal internal internal

Minimum piece weight in

count mode

0.01 g 0.01 g 0.1 g 0.1 g

Reference quantity when

counting parts

1-999 1-999 1-999 1-999

Weighing plate, stainless

steel [mm]

170 x 170 170 x 170 200 x 200 200 x 200

Dimensions of housing

(W x D x H) [mm]

210 x 340 x

150

210 x 340 x

150

210 x 340 x 150

210 x 340 x

150

Net weight (kg) 5.5 5.5 5.6 5.6

Weight units

mg, g, kg

Permissible ambient

conditions

10° C to 30° C

Stabilisation time 2 seconds

Air humidity max. 80 % relative (non condensing)

Page 9

PRS/PRJ/ARS/ARJ-BA-def-0622 93

KERN PRJ 8200-

1IP65NM

PRJ 10200-

1IP65NM

ARS 120-4N ARS 220-4N

Readout (d) 0.1 g 0.1 g 0.1 mg 0.1 mg

Weighing range (Max) 8,200 g 10,200 g 120 g 220 g

Minimum load 5 g 5 g - Verification value 1 g 1 g - Verification categories II II - Repeatability 0.1 g 0.1 g 0.1 mg 0.1 mg

Linearity ± 0.1 g ± 0.1 g ± 0.2 mg ± 0.2 mg

Recommended adjusting

weight, not included (class)

- 100 g (E2) 200 g (E2)

Adjustment weight internal internal

Minimum piece weight in

count mode

0.1 g 0.1 g 0.1 mg 0.1 mg

Reference quantity when

counting parts

1-999 1-999 1-999 1-999

Weighing plate, stainless

steel [mm]

200 x 200 200 x 200

Ø 80 Ø 80

Dimensions of housing

(W x D x H) [mm]

210 x 340 x 150

210 x 340 x

150

210 x 340 x 345 210 x 340 x 345

Dimensions of glass

windshield [mm]

- -

205 x 205 x 260

weighing space:

180 x 200 x 240

205 x 205 x 260

weighing space:

180 x 200 x 240

Net weight (kg) 5.6 5.6 5.9 5.9

Weight units

mg, g, kg mg, g, kg

mg, g, GN, dwt, ozt, oz, lb, ct, C.M.

tLH, tLM, tLT, mo, Tola

Permissible ambient

conditions

10° C to 30° C 15° C to 25° C

Stabilisation time 2 seconds 3 seconds

Air humidity max. 80 % relative (non condensing)

Page 10

94 PRS/PRJ/ARS/ARJ-BA-def-0622

KERN ARJ 120-4NM ARJ 205-5DM ARJ 220-4NM

Readout (d) 0.1 mg 0.01/0.1 m g 0.1 mg

Weighing range (Max) 120 g 90/205 g 220 g

Minimum load 0.01 g 0.01 g 0.01 g

Verification value 1 mg 1 mg 1 mg

Verification categories I I I

Repeatability 0.1 mg 0.03/0.1 mg 0.1 mg

Linearity ± 0.2 mg ± 0.06/0.2 mg ± 0.2 mg

Stabilisation time 3 secon d s 10/3 seconds 3 seconds

Adjustment weight internal internal internal

Minimum piece weight in

count mode

0.1 mg 0.01 mg 0.1 mg

Reference quantity when

counting parts

1-999 1-999 1-999

Weighing plate, stainless

steel [mm]

Ø 80 Ø 80 Ø 80

Dimensions of housing

(W x D x H) [mm]

210 x 340 x 345 210 x 340 x 345 210 x 340 x 345

Dimensions of glass

windshield [mm]

205 x 205 x 260

weighing space:

180 x 200 x 240

205 x 205 x 260

205 x 205 x 260

weighing space:

180 x 200 x 240

Net weight (kg) 6.9 6.9 6.9

Weight units mg, g

Permissible ambient

conditions

15° C to 25° C

Air humidity max. 80 % relative (non condensing)

Page 11

PRS/PRJ/ARS/ARJ-BA-def-0622 95

2 Declaration of conformity

KERN & Sohn GmbH

D-72322 Balingen-Frommern

Postfach 4052

E-Mail: info@kern-sohn.de

Tel: 0049-[0]7433- 9933-0

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.de

Declaration of conformity

Declaration of conformity for apparatus with CE mark

Konformitätserklärung für Geräte mit CE-Zeichen

Déclaration de conformité pour appareils portant la marque CE

Declaración de conformidad para aparatos con marca CE

Dichiarazione di conformitá per apparecchi contrassegnati con la marcatura CE

English

We hereby declare that the product to which this declaration refers conforms with the

following standards.

Deutsch

Wir erklären hiermit, dass das Produkt, auf das sich diese Erklärung bezieht, mit den

nachstehenden Normen übereinstimmt.

Français

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la présente

déclaration, est conforme aux normes citées ci-après.

Español

Manifestamos en la presente que el producto al que se refiere esta declaración está de

acuerdo con las normas siguientes.

Italiano

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si riferisce è

conforme alle norme di seguito citate.

Electronic Balance: KERN ARS, ARJ

KERN PRS, PRJ

Mark applied EU Directive Standards

89/336EEC EMC EN 50081-1

EN 50082-1

EN 55022

Date: 15.01.2006 Signature:

Gottl. KERN & Sohn GmbH

Management

Gottl. KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-[0]7433/9933-0,Fax +49-[0]7433/993 3-149

Page 12

96 PRS/PRJ/ARS/ARJ-BA-def-0622

KERN & Sohn GmbH

D-72322 Balingen-Frommern

Postfach 4052

E-Mail: info@kern-sohn.de

Tel: 0049-[0]7433- 9933-0

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.de

Declaration of conformity

Declaration of conformity for apparatus with CE mark

Konformitätserklärung für Geräte mit CE-Zeichen

Déclaration de conformité pour appareils portant la marque CE

Declaración de conformidad para aparatos con marca CE

Dichiarazione di conformitá per apparecchi contrassegnati con la marcatura CE

English

We hereby declare that the product to which this declaration refers conforms with the following

standards. This declaration is only valid with the certificate of conformity by a notified body.

Deutsch

Wir erklären hiermit, dass das Produkt, auf das sich diese Erklärung bezieht, mit den

nachstehenden Normen übereinstimmt. Diese Erklärung gilt nur in Verbindung mit der

Konformitätsbescheinigung einer benannten Stelle.

Français

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la présente déclaration,

est conforme aux normes citées ci-après. Cette déclaration est valide seulement avec un

certificat de conformité d’un organisme notifié.

Español

Manifestamos en la presente que el producto al que se refiere esta declaración está de acuerdo

con las normas siguientes. Esta declaratión solo será válida acompañada del certificado de

conformidad de conformidad de la parte nominal.

Italiano

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si riferisce è conforme alle

norme di seguito citate. Questa dichiarazione sarà valida solo se accompagnata dal certificato

di conformità della parte nominale.

Model: KERN ARJ

PRJ 320-3NM

PRJ 620-3NM

PRJ 1200-3N

PRJ 4200-2NM

PRJ 6200-2NM

PRJ 6200-1IP65NM

PRJ 8200-1NM

PRJ 8200-1IP65NM

PRJ 10200-1IP65NM

EU Directive Standards

EC-type-approval

certificate no.

Issued by

90/384/EEC EN 45501 D00-09-029

PTB

Date: 15.01.2006 Signature:

Gottl. KERN & Sohn GmbH

Management

Gottl. KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-07433/9933-0,Fax +49-074433/9933-149

Page 13

PRS/PRJ/ARS/ARJ-BA-def-0622 97

3 Fundamental information (general)

3.1 Intended use

The balance you have purchased is to be used to determine the weight of the material to

be weighed. It is intended to be used as a “non-automatic” balance, i.e. the material to be

weighed is manually and carefully placed in the centre of the weighing plate. The

weighing value can be read off after a stable weighing value has been obtained.

3.2 Inappropriate use

Do not use the balance for dynamic weighing, if small quantities of the material to be

weighed are removed or added. The “stability compensation” function in the balance itself

can result in incorrect weighing results being displayed! (Example: Slowly draining fluids

from a container on the balance.)

Do not leave a permanent load on the weighing plate. This can damage the measuring

equipment.

Be sure to avoid impact shock and overloading the balance in excess of the prescribed

maximum load rating (max.), minus any possible tare weight that is already present. This

could cause damage to the balance.

Never operate the balance in hazardous areas. The standard model is not explosionproof.

Structural alterations may not be made to the balance. This can lead to incorrect weighing

results, faults concerning safety regulations and also to serious damage to the balance.

The balance may only be used in compliance with the described guidelines. Varying

areas of application/planned use must be approved by KERN in writing.

3.3 Guarantee

The guarantee is not valid following

• non-observation of our guidelines in the operating instructions

• use other than for the applications described

• alteration to or opening of the device

• mechanical damage and damage caused by media, liquids, or natural wear and tear

• inappropriate installation or electric installation

• overloading of the measuring equipment

Page 14

98 PRS/PRJ/ARS/ARJ-BA-def-0622

3.4 Monitoring the test equipment

The metrology features of the balance and any possible available test weight must be

checked at regular intervals within the scope of quality assurance. For this purpose, the

user responsible must define a suitable interval as well as the nature and scope of this

check. Please see KERN’s home page (www.kern-sohn.com) for information regarding

the monitoring of balance test equipment and the test weights required for this. Test

weights and balances can be calibrated quickly and at a reasonable price in KERN’s

accredited DKD calibration laboratory (return to national standard).

4 Fundamental safety information

4.1 Observe the information in the operating instructions

Please read the operating instructions carefully before installing and commissioning, even

if you already have experience with KERN balances.

4.2 Staff training

The device may only be operated and maintained by trained members of staff.

5 Transport and storage

5.1 Acceptance check

Please check the packaging immediately upon delivery and check the device during

unpacking for any visible signs of external damage.

5.2 Packaging

Please retain all parts of the original packaging in case it should be necessary to return

items at any time.

Only the original packaging should be used for return consignments.

Before despatch, disconnect all attached cables and loose/movable parts.

Affix any intended transport security devices. Secure all parts, e.g. weighing plate, power

supply unit etc. to prevent slipping and damage.

Page 15

PRS/PRJ/ARS/ARJ-BA-def-0622 99

6 Unpacking, installation and commissioning

6.1 Place of installation, place of use

The balance is constructed in such a way that reliable weighing results can be achieved

under normal application conditions.

By selecting the correct location for your balance, you will be able to work quickly and

precisely.

Therefore please observe the following at the place of installation:

• Place the balance on a firm, level surface;

• Avoid extreme heat as well as temperature fluctuation caused by installing next to

a radiator or in direct sunlight;

• Protect the balance against direct draughts due to open windows and doors;

• Avoid jarring during weighing;

• Protect the balance against high humidity, vapours and dust;

• Do not expose the device to extreme dampness for long periods of time.

Inadmissible bedewing (condensation of air moisture on the device) can occur if a

cold device is taken into a significantly warmer environment. In this case, please

acclimatise the device for approx. 2 hours at room temperature after it has been

disconnected from the mains.

• Avoid static charging of the material to be weighed and weighing container.

Major display deviations (incorrect weighing results) are possible if electromagnetic fields

occur, as well as due to static charging, currents and unstable power supply. It is then

necessary to change the location.

6.2 Unpacking

Carefully remove the balance from the packaging, remove the plastic cover and install the

balance in the intended workplace.

Page 16

100 PRS/PRJ/ARS/ARJ-BA-def-0622

6.3 Installation

The balance consists of the balance body (1), the scale pan holder (4) and the pan (5),

which, depending on the model, may be square (fig. 1, right) or round (fig. 1, left).

Depending on the model (see Chapter 1 “Technical Data”) the balance additionally has a

simple windshield (fig. 1, right) or a windshield with sliding doors (fig. 1, left) (2) and/or a

protective ring (3).

Fig. 1 Your balance

Use the foot screws to level the balance until the air bubble is in the prescribed circle in

the spirit level.

Page 17

PRS/PRJ/ARS/ARJ-BA-def-0622 101

6.3.1 Windshield for PRS and PRJ balances (d=0.1 mg)

The position of the windshield on the

balance can be seen in figure 1 (see 2a).

Note:

If the windshield is not even after assembly,

it can be adjusted according to drawing

below.

Press down the higher corner (arrow) with

moderate force.

If necessary, turn windshield by 90° and

carry out the same operation again until the

windshield sits evenly.

Page 18

102 PRS/PRJ/ARS/ARJ-BA-def-0622

6.4 Functions of the balance

The versatile weighing program allows you to use the KERN balances of the PRS, PRJ,

ARS, ARJ series not only for simple weighings but also using a simple method to carry

out various weighing applications such as, for example, percentage or component

counting applications and documenting the measurements obtained accurately and

unequivocally.

The most important basic production features of the KERN PRS, PRJ, ARS, ARJ series

include:

• Anti-theft encoding with four-digit numerical code

• Multi-stage password protection for the program menus

• ICM-Autocalibration (Intelligent Calibration Mode)

• 5-key multifunction control panel

• LCD display with multi-line display

• ISO and GLP compliant reporting of measurement results

• RS232/V24 serial interface for data transfer

• Storable user-configuration (UMM User Menu Memorized)

• Functions programmed in the factory for:

Parts counting

Percentage weighing

Weighing in different, internationally-valid units

Density determination

Net-total weighing function

• Device for suspended weighing

Page 19

PRS/PRJ/ARS/ARJ-BA-def-0622 103

6.5 Equipment overview:

1 Cover of the device for suspended weighings

2 Name plate

3 Adjustable feet (for levelling)

4 Weighing plate

5 Multifunction display

6 10-key control panel

7 Serial No. plate

8 Connecting socket for power adaptor

9 RS232 Interface

10 Spirit level

11 Eyelet for attaching a safety chain

Page 20

104 PRS/PRJ/ARS/ARJ-BA-def-0622

6.6 Scope of delivery

Inspect delivery for completeness immediately on unpacking all components.

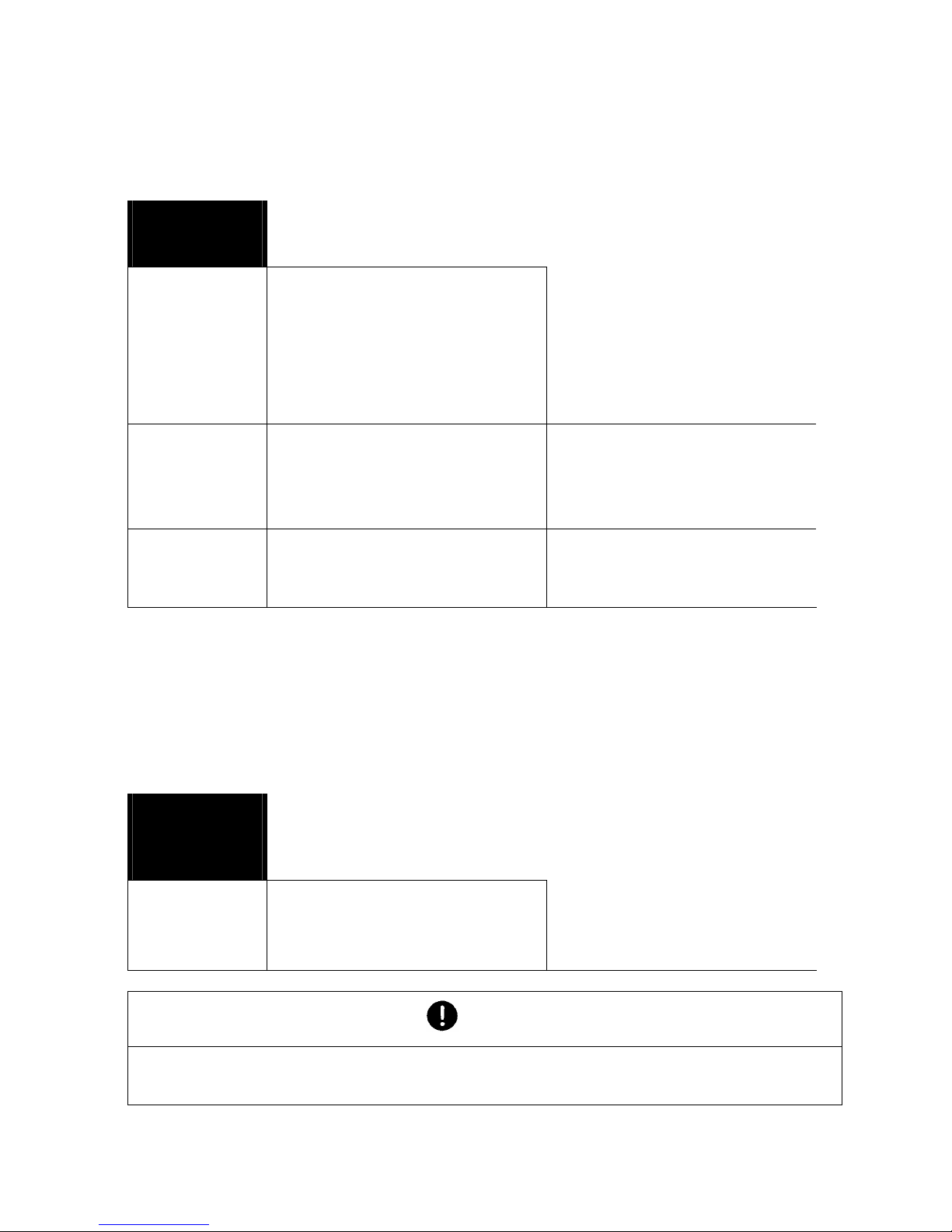

d = 0,1 mg d = 1 mg

d = 10 mg

d = 0,1 mg d = 1 g

Standard accessories

Balance

Scale pan support with weighing plate

Power adaptor

Protective cover for the display

Windshield BASIC

(only balances d = 0.1 mg)

Simple windshield

(only balances d = 1 mg)

Protective ring

(only balances d = 1 mg, d = 10 mg)

Operating instructions

Page 21

PRS/PRJ/ARS/ARJ-BA-def-0622 105

6.7 Mains supply

Electric power supply is by means of the external power adaptor. The printed voltage

level must comply with the local voltage.

Only use original KERN power adaptors. The use of other makes is subject to approval by

KERN.

6.8 Connecting peripheral devices

The balance must be disconnected from the mains before connecting or disconnecting

additional equipment (printer, PC) to or from the data interface.

Only use KERN accessories and peripheral devices with your balance as these have

been specially adapted to function best with your balance.

6.9 Commissioning

A warm up time of 1 hour after switching the balance on will stabilise the measuring

values.

The accuracy of the balance depends on the local gravity.

Please be sure to observe the information in the chapter on Calibration.

6.10 Calibration

Since the Earth's gravity is not the same everywhere, each balance must – in accordance

with the underlying physical weighing principle – be adjusted to compensate for the

gravity at each location. This adjustment process, known as “calibration”, must be carried

out on commissioning and after each subsequent relocation. It is also advisable that you

adjust the balance periodically during weighing operation in order to obtain exact

measured values.

NOTE

The balance must be calibrated on commissioning and after every relocation.

If you work in accordance with “Good Laboratory Practice GLP”, observe the prescribed

intervals between calibrations (adjustments).

Adjusting the calibration is carried out in the configuration menu. Depending on the model

of balance, this may be done externally, internally or automatically (see Chapter 8.6

“Calibration functions”).

Adjustment should be carried out with the recommended adjusting weight (KERN

ARS/PRS, see Chapter 1 „Technical Data“). The adjustment can also be carried out with

different adjusting weights, but not ideal from a metrological point of view.

Using the “Intelligent Calibration Mode” (ICM) the balance can itself determine the size of

the calibration weight, which enables an exact calibration with different weights (in 10 g,

50 g, 100 g and 500 g steps, depending on model).

You can find information about test weights on the Internet: http://www.kern-sohn.com

Page 22

106 PRS/PRJ/ARS/ARJ-BA-def-0622

The calibration of the balance is set in the configuration menu (see Chapter 8.6

“Calibration of the balance”).

Possible types of calibration, depending on the balance model:

• External calibration by means of ICM (Intelligent Calibration Mode)

• External calibration with freely selectable weight

• Internal calibration

• Automatic calibration

NOTE

The calibration can be interrupted at any time by pressing the “ON/OFF” key.

6.10.1 External calibration b y means of ICM

(only ARS/PRS models)

Depending on the type of balance, calibration weights in steps of 10 g, 50 g, 100 g and

500 g can be used, where the calibration weight must relate to the accuracy of the

balance.

For an external calibration by means of ICM, “SET CALIBRATION MODE EXTERNAL”

must be selected in the configuration menu (see Chapter 8.6 “Calibration functions”).

• Switch to “WEIGHING” using the “ ” key

CALIBRATION

• Press “CAL” until “CALIBRATION” appears.

- - 0000 g

• The balance carries out a zero measurement

(0000 g is shown flashing)

- - 2000 g

• After the zero measurement has been taken,

the display flashes with the recommended

calibration weight

• Place the calibration weight on the pan

- - 2000 g

• The display continues to flash

• Calibration is complete when the display

stops flashing

+ 2000 g

Page 23

PRS/PRJ/ARS/ARJ-BA-def-0622 107

6.10.2 External calibration with freely selectable weight

(only ARS/PRS models)

For an external calibration with user-definable weight, “SET CALIBRATION MODE EXT.DEF.” must be selected in the configuration menu (see Chapter 8.6 “Calibration

functions”).

Then, the effective value of the calibration weight (DEF. n.nnn g) must be entered with up

to ten times precision when compared with the balance.

NOTE

If calibration is carried out with the free weight, then only this weight may be used.

Then proceed as follows:

• Switch to “WEIGHING” using the “ ” key

CALIBRATION

• Press “CAL” until “CALIBRATION” appears.

- - 0000 g

• The balance carries out a zero measurement

(0000 g is shown flashing)

- - 372 g

• After the zero measurement has been taken,

the display flashes with the previously

entered calibration weight

• Place the calibration weight on the pan

- - 372 g

• The display flashes rapidly

• Calibration is complete when the display

stops flashing (the exact weight is shown)

+372.15 g

Page 24

108 PRS/PRJ/ARS/ARJ-BA-def-0622

6.10.3 Internal calibration

(only ARJ/PRJ models)

For an internal calibration with the built-in calibration weight, “SET CALIBRATION MODE

INTERNAL” must be selected in the configuration menu (see Chapter 8.6 “Calibration

functions”).

Then proceed as follows:

• Switch to “WEIGHING” using the “ ” key

• Press “CAL” until “CALIBRATION” appears.

• The calibration is finished after a certain period of time.

6.10.4 Automatic calibration

(onl

y ARJ/PRJ models)

For automatic calibration with the built-in calibration weight, “SET CALIBRATION MODE

AUTO” must be selected in the configuration menu (see Chapter 8.6 “Calibration

functions”).

The balance now calibrates itself automatically every 24 hours and/or after each

temperature change of 3 degrees Celsius, depending on how “SET CALIBRATION

AUTOCAL” has been defined in the configuration menu.

The timing of the automatic calibration is as determined in the configuration menu under

“SET CALIBRATION AUTOCAL.-TIME n h”. (e.g. 6 h for 06.00 o'clock in the morning).

NOTE

For automatic calibration by time and by time/temp., the date and time of the balance must

first be set correctly (see Chapter 8.9 “Date and time”).

The calibration can also be initiated manually at any time, even when auto-calibration is

activated.

The automatic calibration then takes place only if no weight is placed on the pan for at

least five minutes.

It is recommended that the time for the auto-calibration be set at a time outside the normal

business hours (for example, in the early morning).

Page 25

PRS/PRJ/ARS/ARJ-BA-def-0622 109

6.10.5 Balances appropriate for verification (only ARJ/PRJ models)

Balances appropriate for verification are provided with EU/OIML approval or meet the EU

regulations for verified balances.

The balance program and certain functions of the weighing output differ from the standard

program in the case of balances which are appropriate for verification – in accordance

with EU regulations.

General:

According to EU guideline 90/384/EEC, balances must be verified officially if they are to

be used as follows (in a legally regulated area):

a) For commercial transactions if the price of goods is determined by weighing.

b) For the production of medicines in pharmacies as well as for analyses in the

medical and pharmaceutical laboratory.

c) For official purposes.

d) For the production of packed goods.

In case of doubt, please contact your local weights and measures office.

Verification information

For those balances marked as appropriate for verification in the technical data, an EC

type approval is available. In the event that the balance is used in an area subject to

verification as described above, it must be officially verified and re-verified at regular

intervals.

Re-verification of a balance is carried out in compliance with the respective legal

provisions of that particular country. The period of verification validity for balances in

Germany, for example, is normally 2 years.

The legal provisions of the country of use are to be observed.

After the verification process, the scale is sealed at the marked points.

Without the “seal”, the verification of the scale is not valid.

Balances appropriate for verification are provided with EU approval or meet the EU

regulations for verified balances.

The balance program and certain functions of the weighing output differ from the standard

program in the case of balances which are appropriate for verification – in accordance

with EU regulations.

NOTE

If a circle appears in the main display of a verified balance, then the displayed value is not

verified.

In balances of class (I) the circle also denotes the warm-up phase.

Your KERN trader will be happy to assist you at any time if you have any questions on the

verification of the balance or on working with verified balances.

Page 26

110 PRS/PRJ/ARS/ARJ-BA-def-0622

6.10.6 Position of verification safety seal (only on ARJ/PRJ models appropriate

for verification)

M sign for EU – first calibration

(green M)

Balances which are subject to verification must be taken out of operation

if:

- The weighing result from the balance is outside the operational error limit.

Therefore at regular intervals, load the balance with known test weights

(approx. 1/3 of the maximum load) and compare with the display value.

- The re-verification date has been exceeded.

S Safety seals

(self-sticking seal or lead)

K shield of mark with CE-sign and date

of the year

M sign for EU – first calibration

(green M)

Interface

Page 27

PRS/PRJ/ARS/ARJ-BA-def-0622 111

6.11 Suspended weighing

Objects which, because of their size or shape, cannot be put on the scale, can be

weighed by means of suspended weighing.

Proceed as follows:.

Turn the balance off.

• Remove the scale-pan and the scale pan support and turn the balance over.

• Push the metal-cover (1) on the underside of the balance to one side.

• Hang a small hook (available as an accessory) into the aperture (3) of the now

visible metal casting (2).

• Place the balance over an opening.

• Replace the scale pan support and the scale pan.

• Level the balance.

• Switch on the balance.

• Hang the object to be weighed on the hook and carry out the weighing.

Fig.: Setting up the balance for suspended weighings

CAUTION

Take care that the hooks used for the suspended weighing are stable enough to

safely hold the goods which you wish to weigh.

NOTE

Take care that no dirt or moisture can get into the balance while the scale pan support is

removed.

After completing the suspended weighing, the opening on the underside of the balance

must be closed again (dust protection).

Page 28

112 PRS/PRJ/ARS/ARJ-BA-def-0622

7 Modes of operation and use

7.1 Switching on the balance

• Press “ON/OFF“ to switch the scale on.

The balance carries out a self-diagnosis in order to test the most important functions.

After completion of the start-up process (approximately ten seconds) “Zero” appears in

the display.

The balance is ready for operation and is in weighing mode.

7.2 Auto-Standby-Mode

The balance is equipped with an Auto-Standby mode, which can be activated or

deactivated in the configuration menu.

If Auto-Standby mode is activated, the balance automatically switches to Standby mode

shortly after the last weighing or key operation (current-saving function).

The delay before switching to Standby is defined in the configuration menu (see Chapter

8.7 “Weighing mode”).

Press any key or put on a weight in order to switch the balance from Standby mode back

to weighing mode again.

7.3 Significance of the two main menus

The balance has two main menus available: the configuration menu and the application

menu.

The basic program of the balance is defined in the configuration menu.

In this way, you can either work with the basic configuration as programmed

in the factory, or define and store a user configuration adapted to your specific needs.

In the application menu, you define a working program, which is adapted to the specific

weighing situation.

In addition, you can also define the parameters for the statistics program and the

checkweighing program in the application menu.

Page 29

PRS/PRJ/ARS/ARJ-BA-def-0622 113

7.4 Activating the two main menus

7.4.1 Activating the configuration menu

• Press “ON/OFF“ to switch the scale on.

• During the start-up sequence (about 10 seconds), keep the “MENU” key depressed

until “SET CONFIGURATION” appears in the display.

• You can then alter the configuration menu

7.4.2 Activating the application menu

• To get into the application menu, press “MENU” after the start-up sequence is

complete.

7.5 How the menu control operates

The configuration menu and the application menu each have a main path and up to two

sub-paths in which the parameters for the different function programs of the balance are

defined.

The cursor keys “Õ“, “Ö“, “×” and “Ø“ allow you to move within the paths.

NOTE

The menu tree diagrams shown have the same layout as the paths of the two main

menus.

Page 30

114 PRS/PRJ/ARS/ARJ-BA-def-0622

7.5.1 Control panel

Eight of the ten keys on the Multifunctional Control Panel serve multiple functions

(functions for weighing mode and programming mode respectively).

7.5.2 Operation in weighing mode

In weighing mode, the grey shaded key symbols in the control panel apply.

Key(s) Name Function in weighing mode

“ON/OFF”

• Switches the balance on and off

“MENU”

• Calls up the configuration menu and

the application menu

“CAL”

• Initiates calibration functions

“T”

• Initiates tare functions

• Switches between the basic

program and the selected

application

“PRINT”

• Initiates print functions

• Function keys. Initiate the functions

in the info-line (see Chapter 7.5.5

“Info-line and function keys”).

NOTE

For the use of the “T”, “CAL”, “ ” and “PRINT” keys, see Chapter 10 “Special operating

keys“.

Page 31

PRS/PRJ/ARS/ARJ-BA-def-0622 115

7.5.3 Operation in programming mode

In programming mode, the blue shaded key symbols in the control panel apply.

Key(s) Name Function during weighing mode

• Toggles between menu main path

and sub-path

• Moves up and down within the main

or sub-path.

• Alters the selected parameters

• Selects parameters

• Stores the altered parameters

esc

• Aborts an entry

• Exits the menu

ins

• Places cursor

(when entering text)

clr

• Deletes entry (when entering text)

PRINT

• Enters a full-stop

(when entering text)

The balance can also be operated by remote control. For the relevant remote control

commands, see Chapter 11 “Data transfer to peripheral devices”.

For an illustration of the method of operation see Chapter 12 “Practical examples”.

Page 32

116 PRS/PRJ/ARS/ARJ-BA-def-0622

7.5.4 Display

The balance display has two lines (1 and 2).

The upper display-line (1) includes the 8-digit measurement display (3) as well as various

symbols (4).

The lower line (2) serves as a 20-character info-line and is used in conjunction with the

cursor keys to control the working programs.

7.5.5 Info-line and function keys

If an application (working program) is used, then as well as the measurement display (1),

the four column info-line also appears at the bottom edge of the display.

Any function displayed in the info-line corresponds to the function key which is directly

below it (marked by G (3)).

The cursor keys (4) “Õ”, “Ö”, “×” and “Ø” serve as function keys in the applications.

These initiate the functions displayed in the info-line (2).

Page 33

PRS/PRJ/ARS/ARJ-BA-def-0622 117

7.5.6 Example of display: Statistics program

• Display on the balance in the statistics program

• Relevant displays in the operating instructions

+ 123,456 9

normal weight display

STO 0 RES INF

Info-line

U U U U

“Õ” “Ö” “×” “Ø” Function keys

• Function key legends as shown in the example:

– STO initiates the manual store function “STO”

– RES activates the “RES” (Reset) function

– INF activates the “INF” function (display sequence of the statistic parameters:

average value, standard deviation, relative standard deviation, maximum,

minimum …)

NOTE

If the statistics program is activated in parallel with a working program, then “Ø” is

reserved for storing (“STO function”) or recalling statistical parameters (“INF function“).

If the statistics program is not active, then “Ø“ can be used for the working program.

Page 34

118 PRS/PRJ/ARS/ARJ-BA-def-0622

7.6 Password protection of the menus

The two main menus of the balance can be protected against unintentional changes by a

freely selectable, four-digit password.

• With password protection deactivated, any operator can change the balance

configuration and application menu.

• With “medium” password protection activated, only the configuration menu is protected

against unintentional changes.

• With “high” password protection activated, both the configuration menu and the

application menu are protected against unintentional changes. Only after entering the

correct, four-digit password can changes be made to the configuration menu and the

application menu.

NOTE

The password protection is deactivated from the factory.

The pre-programmed password set from the factory is: 7 9 1 4

This password is the same for all KERN balances and is always valid, in parallel with a

self-selected password.

Make a note of your personal password.

The possibilities for setting the password protection and changing the password are

described in Chapter 8.10 “Password protection”.

7.7 Anti-theft encoding

The balance can be protected against theft by a freely selectable, four-digit numerical

code:

• With anti-theft encoding deactivated, the balance can be switched on again and

operated after interruption of the power supply without entering a code.

• With anti-theft encoding activated, the balance requires the entry of the four-digit code

after each interruption to the power supply.

• If the code is entered incorrectly, the balance is blocked.

Page 35

PRS/PRJ/ARS/ARJ-BA-def-0622 119

• If the balance is blocked, it must first be disconnected from the power supply, then

reconnected and unblocked by entering the correct four-digit code.

• After seven consecutive incorrect entries the display will read “NO ACCESS, CALL

SERVICE”. In this case, only KERN Service can unblock the balance again.

NOTE

The anti-theft-encoding is deactivated from the factory.

The pre-programmed password set from the factory is: 8 9 3 7

This password is the same for all KERN balances. For reasons of security you should

therefore always enter your own code.

Keep your personal code in a safe place.

To activate the anti-theft encoding and to alter the code programmed in the factory to one

which you have chosen yourself, see Chapter 8.11 “Anti-theft encoding”.

Page 36

120 PRS/PRJ/ARS/ARJ-BA-def-0622

8 Working with the configuration menu

This chapter describes the configuration menu and its functions.

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

8.1 Structure of the configuration menu

The basic setting of the balance is defined in the configuration menu:

Main path Definable functions

SET

CONFIGURATION

Selection of the basic configuration (factory setting, user

setting or storing a

new user setting)

UNIT 1

Unit in which the results of the weighing are displayed

SET

DATA PRINT

Print formats; type of value to be printed out

(individual value, continuous print, time or load change

dependant values, date, time, user etc.)

SET

CALIBRATION

Calibration method

SET

WEIGHING MODE

Stability mode (Quality of the balance location), AutoStandby mode, zero correction, tare method (rapid or

standard tare); Chapter 6.6

SET

INTERFACE

Baud rate, parity, handshake functions of the

peripheral interfaces

SET

DATE AND TIME

Date and time (standard format or American format p.m.

and a.m.) [only ARJ and PRJ]

PASSWORD

Password protection for menu definition

THEFTCODE

Activation/deactivation and changing the

Anti-theft encoding

KEY TONE

Key Tone on/off

LANGUAGE

Language (E, G, F)

Page 37

PRS/PRJ/ARS/ARJ-BA-def-0622 121

Printing conventions used in this document:

• The settings in the sub-paths pre-programmed in the factory are printed in bold in

these operating instructions.

• For greater clarity, only that part of the menu tree which corresponds to the function is

shown with each description of the function.

• You will find the entire menu tree for the configuration menu in Chapter 14

“Configuration menu tree”.

• Explanations of the menu functions are printed in italics.

8.2 Language function

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• LANGUAGE

SPRACHE DEUTSCH

LANGUAGE ENGLISH

LANGUE FRANCAISE

Select language

In order to alter the language, proceed as follows:

• Activate the configuration menu (see Chapter 7.4.1 “Activating the configuration

menu”)

• Press ”Ø” repeatedly until the current language is displayed.

• Press “ ”. The display starts to flash.

• Press ”Ø” repeatedly until the language you require is displayed.

• Press ” ” to confirm the selection.

• Press “esc” to exit the menu.

•SPR

Page 38

122 PRS/PRJ/ARS/ARJ-BA-def-0622

8.3 Defining the configuration

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SET

CONFIGURATION

FACTORY CONFIG. USER

CONFIG.

STORE CONFIG.

8.4 Selecting the weight unit

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• UNIT 1

UNIT 1 g

kg

------

t

Gramme

Kilogramme

-----Tola

The balance can show results in different units, although on some balances display it is

not possible to display in milligrammes or kilogrammes because of the current weighing

range.

Display Weight unit Conversion to grammes

g

Gramme

(mg) Milligramme 0.001 g

(kg) Kilogramme 1,000 g

GN Grain 0.06479891 g

dwt Pennyweight 1.555174 g

ozt Troy ounce 31.10347 g

oz Ounce 28.34952 g

LB Pound 453.59237 g

ct Carat 0.2 g

C.M. Carat Metric 0.2 g

tLH Tael Hong Kong 37.4290 g

tLM Tael Malay sia 37.799366256 g

tLT Tael Taiwan 37.5 g

mo Momme 3.75 g

t Tola 11.6638038 g

Bht Baht 15.2 g

For further information on “Setting the weight unit”, see the example in Chapter 12.1.2.

Page 39

PRS/PRJ/ARS/ARJ-BA-def-0622 123

8.5 Print functions

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SET

DATA

PRINT

AUTO-START ON/OFF

Start print automatically on

switch on/off

MODE UNSTABLE

Individual print, each value

MODE STABLE

Individual print, stable value

MODE LOAD CHANGE

Print after change of load

MODE CONTINUOUS

Continuous print after every

integration time

MODE TIMEBASE

Continuous print with timebase

TIMEBASE 2.0

Timebase (in seconds)

SET PRINT FORMAT

DATE AND TIME ON/OFF

BALANCE ID ON/OFF

PRODUCT ID ON/OFF

GROSS AND TARE ON/OFF

UNITS ON/OFF

OPERATOR ID ON/OFF

VERIFICATION MODE ON/OFF

PRODUCT * ttt...

PRODUCT MODE HOLD

PRODUCT MODE DELETE

PRODUCT MODE COUNT

OPERATOR ttt...

Using “SET PRINT FORMAT”, those elements which are switched on are printed in each

case:

• With “UNITS”, all units active at that time are printed out,

• with “PRODUCT ttt...”, the product name can be entered alphanumerically,

• with “PRODUCT MODE HOLD”, this product name is stored,

• with “PRODUCT MODE DELETE”, it is deleted after each expression,

• with “PRODUCT MODE COUNT” a counter is printed after every product name and

this counter is incremented by 1 after each print out.

• with “OPERATOR ttt...” the operator can be entered alphanumerically.

When a peripheral device (for example a printer) is connected, the balance interface must

be configured in the “SET INTERFACE” sub-menu (see Chapter 8.8 “Interface

functions”).

For further information on “Setting the print function”, see the example in Chapter 12.1.3.

Page 40

124 PRS/PRJ/ARS/ARJ-BA-def-0622

8.6 Calibration functions

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SET CALI-

BRATION

MODE OFF

MODE EXTERNAL

MODE EXT.-DEF.

MODE INTERNAL

MODE AUTO

no access

external

external with user-defined weight

(DEF n.nnn g)

with internal weight

automatic (AUTOCAL)

only PRJ and ARJ models

DEF. 0.000 g

Calibration weight for EXT.-DEF.

mode

AUTOCAL. TIME/TEMP.

AUTOCAL. TEMPERATURE

AUTOCAL. TIME

Autocal. on time and temp.

Autocal. on temperature

Autocal. on time

only PRJ and ARJ models

AUTOCAL. TIME 6 h

Time for Autocalibration

For calibration of the balance see Chapter 6.10 “Calibration of the balance” and Chapter

6.10.1 “Notes on calibration”.

NOTE

The factory setting depends on the balance model. The internal calibration modes are only

available on the PRJ and ARJ models.

Page 41

PRS/PRJ/ARS/ARJ-BA-def-0622 125

8.7 Weighing mode

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SET

WEIGHING

MODE

FLOATING DISPLAY 0.04

FLOATING DISPLAY 0.08

FLOATING DISPLAY 0.16

FLOATING DISPLAY 0.32

Enter integration time (in

seconds)

STABILITY LOW

STABILITY MEDIUM

STABILITY HIGH

Setting the stability control

(instability of the balance

location)

AUTO-STANDBY OFF

AUTO-STANDBY 5 MIN.

AUTO-STANDBY 10 MIN.

AUTO-STANDBY 30 MIN.

Auto-Standby not active or active

after nn minutes

AUTO-ZERO ON/OFF

Automatic zero correction on/off

QUICK TARE ON/OFF

Quick tare on/off

By using the weighing mode functions, you can describe the quality of the balance

location.

By using the AUTO-STANDBY function, you can define the period of non-use before the

balance automatically goes into the energy-saving mode.

NOTE

The automatic standby function only operates if automatic zero point compensation is

activated.

For further information see Chapter 13.

Page 42

126 PRS/PRJ/ARS/ARJ-BA-def-0622

8.8 Interface functions

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SET

INTERFACE

BAUD RATE 300

BAUD RATE 600

BAUD RATE 1200

BAUD RATE 2400

BAUD RATE 4800

BAUD RATE 9600

Select baud rate

PARITY 7-EVEN-1STOP

PARITY 7-ODD-1STOP

PARITY 7-NO-2STOP

PARITY 8-NO-1STOP

Select parity

HANDSHAKE NO

HANDSHAKE XON-XOFF

HANDSHAKE HARDWARE.

Enter handshake function

By using the interface functions, the RS232/V24 interface of the balance is matched to

the interface of a peripheral device (see Chapter 11 “Data transfer to peripheral devices”).

•SET

8.9 Date and time (only PRJ and ARJ models)

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SET

DATE

AND

TIME

DATE [DD.MM.YY]

DATE [DD.MM.YY]

FORMAT STANDARD/US

Set date and time

NOTE

The date and time display continues in the event of a power failure. If this is not the case,

the balance backup battery is exhausted and must be replaced by KERN trader.

Page 43

PRS/PRJ/ARS/ARJ-BA-def-0622 127

8.10 Password protection

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• PASS-

WORD

PASSWORD

----

DATA PROTECTION OFF

DATA PROTECTION MEDIUM

DATA PROTECTION HIGH

No protection

The configuration menu is

protected

The configuration menu and the

application menu are protected

PASSWORD NEW ----

Enter new password

Password protection permits you to protect the application menu and/or the configuration

menu against unintentional changes.

For further information on password protection, see Chapter 7.6 “Password protection of

the menus” and Chapter 12.1.4 “Activation of password protection”.

•SET

8.11 Anti-theft encoding

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• THEFT

CODE

THEFTCODE ----

THEFTCODE ON/OFF

Switch encoding on/

off

NEW CODE ––––

Enter new

code

If the anti-theft encoding is activated, a four-digit code must be entered after every

interruption of the power supply in order to unblock the balance for use.

For further information on the anti-theft encoding see Chapter 7.7 “Anti-theft encoding”.

To activate the anti-theft encoding, proceed as described for password protection.

Page 44

128 PRS/PRJ/ARS/ARJ-BA-def-0622

9 Working with the application menu

This chapter explains which working programs are contained within the balance and how

these are operated (see also Chapter 7.4 “Activating the two main menus” and Chapter

7.5 “How the menu control operates”).

If “PRINT” is operated in an application, a report is printed out which relates to the

application.

9.1 Structure of the application menu

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

The application menu is used to recall the working programmes of the balance and to

adapt them to the user's needs:

Main path Definable functions

SET APP.

Select application program:

SETUP

APPLICATION

Specify parameters for the working program as selected

under “Application”

SET STATISTICS

Statistics and store functions

SET CHECK +/-

Define nominal weight and limits for comparative

weighings

AUTO-START

ON/OFF

The selected application program can, if required, be loaded

automatically every time the balance is switched on

Printing conventions used in this document:

• The settings for the sub-menus programmed in the factory are printed in bold in these

operating instructions

• For a greater clarity, only that part of the menu tree which corresponds to this

application is shown with each application description.

• You will find the complete menu tree for the application menu in Chapter 15

“Application menu tree”.

• Explanations of the menu functions are printed in italics.

Page 45

PRS/PRJ/ARS/ARJ-BA-def-0622 129

9.2 Selecting an application

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SELECT APPLICATION

SET APP OFF

UNITS

COUNT

PERCENT

CALCULATOR

PAPER

NET TOTAL

TOTALISE

ANIMAL WEIGHING

DENSITY

Normal weighing mode

Different units

Parts counting

Percent weighings

Conversions

Determine paper weights

(in g/cm2)

Totalise weighing results

with intermediate tare

Totalise weighing results

without intermediate tare

Animal weighings

Determining density

In this function field, select the desired application.

If an application is selected in the “SET APP.” menu, then only those sub-menus, which

contain functions and parameters necessary to define the selected application are shown

in the “SETUP APPLICATION” menu.

Page 46

130 PRS/PRJ/ARS/ARJ-BA-def-0622

9.3 Setup for “SET APP UNITS”:

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SETUP

APPLICATION

UNIT 2 kg

UNIT 2 mg

UNIT 2 -----UNIT 2 OFF

Kilogramme

Milligramme

-----

not active

UNIT 3 GN

UNIT 3

UNIT 3 OFF

Grain

-----

not active

UNITS

UNIT 4 C.M.

UNIT 4 -----UNIT 4 OFF

Carat Metric

-----

not active

• Function key legends:

“g”: “Display value in unit 1”, e.g. gramme

“kg”: “Display value in unit 2”, e.g. kilogramme

“GN”: “Display value in unit 3”, e.g. grain

“ct”: “Display value in unit 4", e.g. carat or

Statistics functions (if statistics program is activated)

NOTE

For basic operation, Unit 1 is defined in the configuration menu (standard unit for all

weighings, if the “UNITS” application is not activated, see Chapter 8.4 “Selecting the

weight unit”).

• Display in the “UNITS” application:

+ 8.070 g

g kg TLH CT

U U U U

“Õ” “Ö” “×” “Ø”

By pressing the relevant function

key, the weight display is

switched to the corresponding

unit

Page 47

PRS/PRJ/ARS/ARJ-BA-def-0622 131

9.4 Setup for “SET APP COUNT”

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SETUP

APPLICATION

COUNT KEY 1 5

KEY 2 10

KEY 3 25

KEY 4 50

Reference quantity = 5

Reference quantity = 10

Reference quantity = 25

Reference quantity = 50

By using the “COUNT” program you can count items of uniform weight (screws, balls,

coins, etc.).

To do this you must first weigh a defined quantity of items (e.g. 5 items) and assign the

acquired reference weight to the reference quantity by pressing the relevant function key.

Depending on the weight and tolerances of the objects to be counted, you should count a

representative number of items to determine the reference weight.

• Function key legends:

«5» Definition of reference quantity as 5

up to

«50» Definition of reference quantity as 50

For further information on “Setting up parts counting”, see the example in Chapter 12.2.1.

• Display in the “COUNT” application:

+ 123.456 g

5 10 25 50

U U U U

«Õ» «Ö» «×» «Ø»

The value is first displayed in

gramme

Then press e.g. "5"

+ 5 g

5 10 25 50

U U U U

“Õ” “Ö” “×” “Ø”

The value is converted to items

(PCS) and displayed or printed out

Page 48

132 PRS/PRJ/ARS/ARJ-BA-def-0622

9.5 Setup for “SET APP PERCENT”

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

Main menus” and Chapter 4.5 “How the menu control operates”.

• SETUP

APPLICATION

PERCENT DECIMALS AUTO

0

1

2

3

Enter number of decimal places

for the percentage display

Using the “PERCENT” program you can display and print out the weight of different

measurements as a percentage of a previously defined reference weight.

Place the reference weight on the weighing plate and press “SET” to set the reference

weight to be 100 %.

• Function key legends:

“SET” Define the reference weight with the number of decimal places as defined in

"Decimals"

• Display in the “PERCENT” application:

+ 13.456 g

SET

U U U U

“Õ” “Ö” “×” “Ø”

The value is first displayed in

gramme

The press “SET”

+ 100,00 %

SET

U U U U

“Õ” “Ö” “×” “Ø”

The value is set as 100 %. All

further values are then either

displayed or printed out as a

percentage of the defined

reference weight.

Page 49

PRS/PRJ/ARS/ARJ-BA-def-0622 133

9.6 Setup for “SET APP CALCULATOR”

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SETUP

APPLICATION

CALCULATOR SET KEY 1

NAME nnnnn

FACTOR n.nnn e+n

DECIMAL PLACES n

DISPLAY TEXT nnn

PRINTER TEXT nnnnnnnn

SET KEY 2

NAME nnnnn

FACTOR n.nnn e+n

DECIMAL PLACES n

DISPLAY TEXT nnn

PRINTER TEXT nnnnnnnn

SET KEY 3/4

same as for key 1 and 2

When activating the “CALCULATOR” application, each of the four function keys is first

assigned a name, then a particular conversion factor, decimal place definition, display unit

and unit for the printout.

• Display in the “CALCULATOR” application:

+ 123.456 g/M

NAME 1 NAME 2 NAME 3 NAME 4

U U U U

“Õ” “Ö” “×” “Ø”

The value is converted and

printed out.

In programming mode, the previously defined key names are shown above the function

keys.

After pressing a function key, the current value is converted in accordance with the

assigned factor and the result is displayed or printed out after the print key is pressed.

In this way, for example, you can convert the weights of samples of a known size directly

into “grammes per square metre” and these will be displayed.

Page 50

134 PRS/PRJ/ARS/ARJ-BA-def-0622

9.7 Setup for “SET APP PAPER”

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

Setting the paper program is carried out in the same way as for the calculator. See

Chapter 9.6 “Setup for “SET APP CALCULATOR”.

By using this program you can convert the weights of paper items with standard sizes

(e.g. 100 cm2, 20 x 25 cm, A4, 40 x 25 cm) directly into “Grammes per square meter” and

these will then be displayed.

• Display in the “PAPER” application:

+ 123.456 g/M2

100 20 x 25 A4 40 x 25

U U U U

“Õ” “Ö” “×” “Ø”

The value is converted and

displayed or printed out.

This application is a special application of the calculator (see Chapter 9.6 “Setup for “SET

APP. CALCULATOR“).

Page 51

PRS/PRJ/ARS/ARJ-BA-def-0622 135

9.8 Setup for “SET APP NET TOTAL”

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SETUP

APPLICATION

NET TOTAL

For this application there is no

setup menu!

By using the working program “NET TOTAL” you can add individual weighings, whereby

the balance is tared off to zero before each individual weighing.

• Function key legends:

“STO”: Accept stable value and then add to total of components

“RES”: Reset

“INF”: Change to total weight, remaining capacity, individual components and back

to current value

Exit the INF display using the “esc” key

• Display for “NET TOTAL” application:

+ 70.456 g

STO 2 RES INF

U U U U

“Õ” “Ö” “×” “Ø”

• Procedure, if display is changed with ”Ø”:

+ 100.579 g

Total 100.579 g RES INF

U U U U

“Õ” “Ö” “×” “Ø”

Display sequence:

TOTAL: 100.579

REM.-CAP.: 209.421 g

“individual components”

+ 100.579 g

REM.-CAP.209.421 g RES INF

Exit with “esc”

U U U U

“Õ” “Ö” “×” “Ø”

Page 52

136 PRS/PRJ/ARS/ARJ-BA-def-0622

9.9 Setup for “SET APP TOTALISE”

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SETUP

APPLICATION

TOTALISE

For this application there is no

setup menu!

By using the working program “TOTALISE” you can add individual weighings, whereby the

balance is not tared off to zero before each individual weighing.

• Function key legends:

“STO”: Accept stable value and add

“RES”: Reset

“INF”: Change to total weight, remaining capacity, individual components and back

to current value

Exit the INF display using the “esc” key

• Display for “TOTALISE” application :

+ 70.456 g

STO 2 RES INF

U U U U

“Õ” “Ö” “×” “Ø”

• Procedure, if display is changed with “Ø”:

+ 70.456 g

Total 70.456 g RES INF

U U U U

“Õ” “Ö” “×” “Ø”

Display sequence:

TOTAL: 70.456 g

REM.-CAP.: 239.543 g

“individual components”

+ 70.456 g

REM.-CAP.239.543 g RES INF

Exit with “esc”

U U U U

“Õ” “Ö” “×” “Ø”

Page 53

PRS/PRJ/ARS/ARJ-BA-def-0622 137

9.10 Setup for “SET APP ANIMAL WEIGHING”

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SETUP

APPLICATION

ANIMAL

WEIGHING

MEASURING DURATION 4

Enter time period in seconds

By using the working program “ANIMAL WEIGHING” you can weigh living animals

accurately, even when they move around on the weighing plate.

Throughout the measuring period as defined by the user in the setup menu, the scale

measures continuously, then at the end of the measuring period it averages the stored

values and then gives the resulting average value.

• Function key legends:

“MAN”: Manual trigger for the measuring process

“AUTO”: Automatic trigger for the measuring process with one

second delay after each change in load

“STO”: Statistics and store functions

• Display for “ANIMAL WEIGHING” application:

+ 56.879 g

MAN AUTO STO

U U U U

“Õ” “Ö” “×” “Ø”

Page 54

138 PRS/PRJ/ARS/ARJ-BA-def-0622

9.11 Setup for “SET APP DENSITY”

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SETUP

APPLICATION

DENSITY

MODE SOLID ON

BOTTOM

MODE SOLID IN AIR

MODE LIQUID

MODE SOLID POROUS

Solid

Solid

Measure liquids

Porous solid

INDEX ON/OFF

Index on/off

REFERENCE 8000

Reference for INDEX

TIMEBASE 0.0

Timebase for repeat operation in

seconds

REF. DENSITY 0.998205

Density of the liquid used for

measurement (factory setting:

water at 20 °C)

TEMPERATURE 20 C

Temperature in °C of the water

to be used in the measurement

By using the “DENSITY” working program, you can carry out density determination.

• Function key legends on start-up:

“OK”: Accept current reference density

“CAL”: Determine reference density of measuring liquid

“T-H2o”: Set reference density of water at nn.n °C

“20.0C”: Set reference density of water at nn.n °C

Page 55

PRS/PRJ/ARS/ARJ-BA-def-0622 139

• Display for “DENSITY” application on start-up

+ 0.9988205 g/cm

OK CAL T-H20 20.0C

U U U U

“Õ” “Ö” “×” “Ø”

• Function key legends during the weighing:

“AIR”, etc Request for measurement of the relevant value

«<–>»: “switch over” from index to density

“SET”: initiate the relevant step

“STO”: store the relevant value (statistics)

• Function key legends during the weighing:

Step

+ 123.456

9

1

AIR SET

2

FLOOR SET

3

POROUS SET

4

LIQUID SET

5

DENSITY <—> STO

6

INDEX <—> STO

U U U U

«Õ» «Ö» «×» «Ø»

During operating steps (up to six may be

necessary), the info-line shows the

indications seen in this table.

If during step 5 or 6, the tare key “T” is pressed, then a reset is triggered.

The program guides the user through the individual operating steps.

For further information see Chapter 13.2.

Page 56

140 PRS/PRJ/ARS/ARJ-BA-def-0622

9.12 Setup for the statistics program

To activate the menu see Chapter 7.4 “Activating the two main menus” and Chapter 7.5

“How the menu control operates”.

• SETUP

STATISTICS

STATISTICS

MODE OFF

MODE STATISTICS

MODE RECORDER

MODE STAT./RECORDER

Statistics program only from

statistics

Only data storing stat. and

storing

NUMBER 100

Number of values which

should be collected

automatically (1 … 999).

MANUAL COLLECTION

COLLECTION ON TIMEBASE

COLLECTION ON LOAD

CHANGE

with function key

“STO”

on timebase

after every change in load

TIMEBASE 2.0

Timebase for “storing” in

seconds

• Functions of the statistics program and storing functions:

• MODE

- In this function field, you can define whether only the statistics program, only the