Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating instructions

PLS-A / PLJ-A, PLS-F / PLJ-F, PLE-N

KERN ALT-A02 / PLT A01

Version 1.0

01/2013

Fax: +49-[0]7433-9933-149

Set for density determination for analytical and

precision balances

KERN ALT-B,PLT-A, PLT-F, ALS-A / ALJ-A,

GB

ALT-A02/PLT-A01-BA-e-1310

Page 2

PLJ-A, PLS-F / P LJ-F, PLE-N

KERN ALT-A02 / PLT A01

GB

Contents:

1 INTRODUCTION ............................................................................................................................ 3

1.1 SCOPE OF DELIVERY ................................................................................................................. 4

2 PRINCIPLE OF DENSITY DETERMINATION ............................................................................... 5

2.1 INFLUENCING MAGNITUDES AND ERROR SOURCES ...................................................................... 6

3 HOW TO PREPARE THE WEIGHING BALANCE ........................................................................ 7

4 INSTALLING THE DENSITY DETERMINATION SET .................................................................. 8

5 DENSITY DETERMINATION OF SOLIDS ................................................................................... 10

5.1 BALANCES WITH GRAPHIC DISPLAY (KERN ALT-B, PLT-A, PLT-F) .......................................... 13

5.2 BALANCES WITH LCD DISPLAY (KERN ALS-A / ALJ-A, PLS-A / PLJ-A, PLS-F / PLJ-F, PLE-N)

17

Version 1.0 01/2013

Operating instructions

Set for density determination for analytical and precision

balances KERN ALT-B,PLT-A, PLT-F, ALS-A / ALJ-A, PLS-A /

6 DETERMINING DENSITY OF LIQUIDS ...................................................................................... 20

6.1 BALANCES WITH GRAPHIC DISPLAY (KERN ALT-B, PLT-A, PLT-F) .......................................... 21

6.2 BALANCES WITH LCD DISPLAY (KERN ALS-A / ALJ-A, PLS-A / PLJ-A, PLS-F / PLJ-F, PLE-N)

25

7 PRECONDITIONS FOR PRECISE MEASUREMENTS............................................................... 28

7.1 CALCULATION OF RESULTS ..................................................................................................... 28

7.2 INFLUENCE FACTORS FOR MEASUREMENT ERRORS ................................................................. 28

7.2.1 Air bubbles ....................................................................................................................... 28

7.2.2 Temperature .................................................................................................................... 28

7.2.3 Solid matter sample ......................................................................................................... 29

7.2.4 Liquids .............................................................................................................................. 29

7.2.5 Surface ............................................................................................................................. 29

7.3 GENERAL INFORMATION .......................................................................................................... 29

7.3.1 Density / Relative Density ................................................................................................ 29

7.3.2 Drift of Balance Display ................................................................................................... 29

8 DENSITY TABLE FOR LIQUIDS ................................................................................................. 30

9 USER INSTRUCTIONS ................................................................................................................ 31

2 ALT-A02/PLT-A01-BA-e-1310

Page 3

1 Introduction

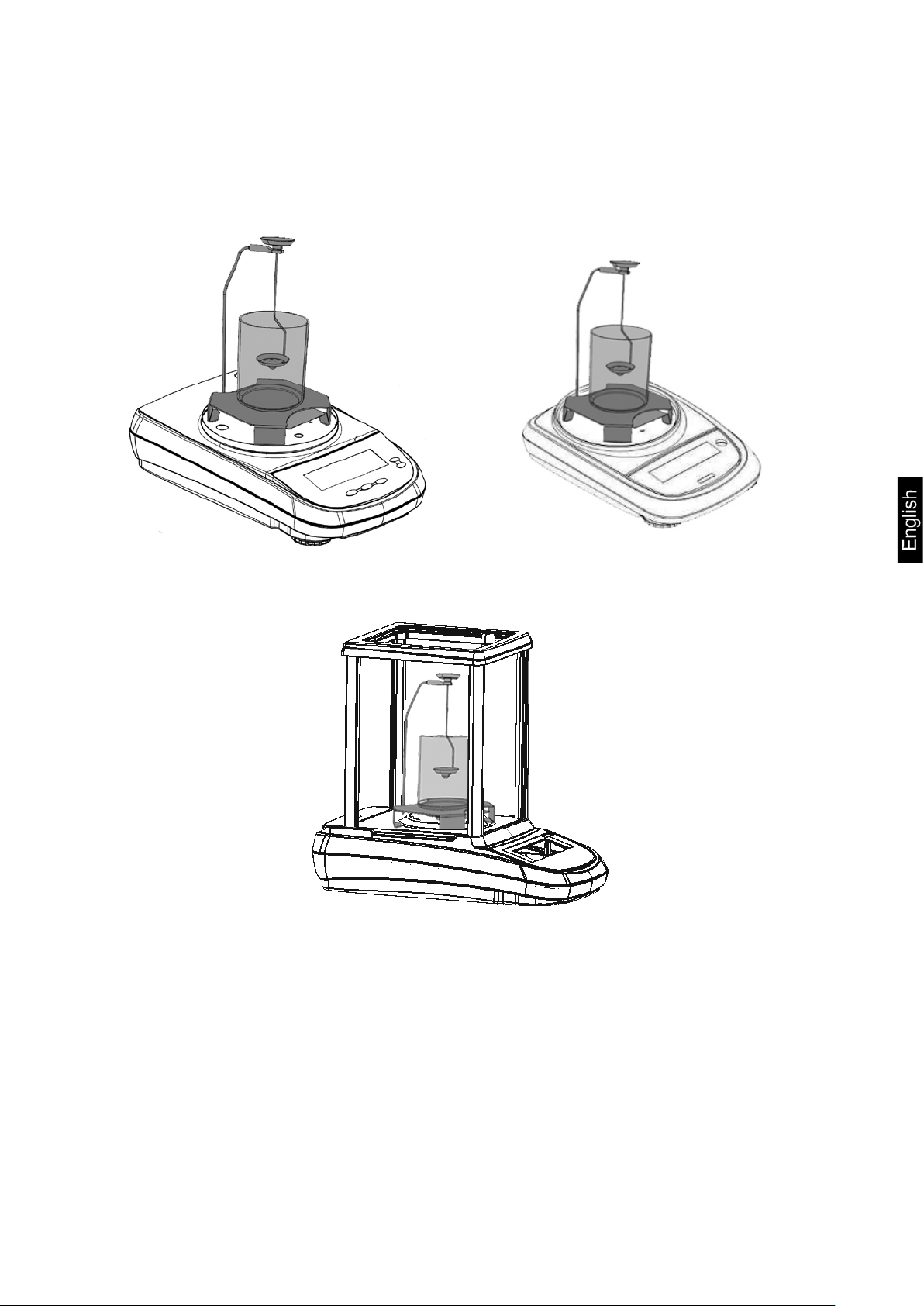

The density sets ALT-A02 and PLT-A01 differ in the support of the weighing plate.

For the density set suitable for your balance, please refer to the following overview.

KERN ALT-A02 KERN PLT-A01

Set for density determinati o n for

analytical and precision balances

d= 0.1 mg / 1 mg

KERN ALT-B / PLT-A / PLT-F,

ALS-A / ALJ-A, PLS-A / PLJ-A,

PLS-F / PLJ-F,

PLE-N

• In order to guarantee a safe and trouble-free operation, please

read carefully the operating instructions.

• These operating instructions only describe the operation of the

density determinati on set . For further information on how to

operate your balance please refer to the operating instructions

supplied with each balance.

Set for density determinati o n for

precision balances

d= 10 mg

KERN PLT-A, PLT-F

PLS-A / PLJ-A,

PLS-F / PLJ-F

ALT-A02/PLT-A01-BA-e-1310 3

Page 4

Thermometer

Sinker with storage box

Allen key

3.356g/cm3

1.1 Scope of delivery

Check packaging and density determination set immediately when unpacking for

possible visible damage.

Make sure that all parts are completely present.

Retainer of immersion basket Universal immersion basket for

floating and descending solid

matter

∅ 70 mm, 95 mm high

Retainer for sinker Glass beaker for density

determination „solid matter“

Platform for glass container

∅ 55 mm, 150 mm high

Glass beaker for

density determination „liquid“

4 ALT-A02/PLT-A01-BA-e-1310

Page 5

ρ =

A

A-B

o

ρ

ρ =

m

V

1

g

cm

3

1

kg

m

3

1

g

l

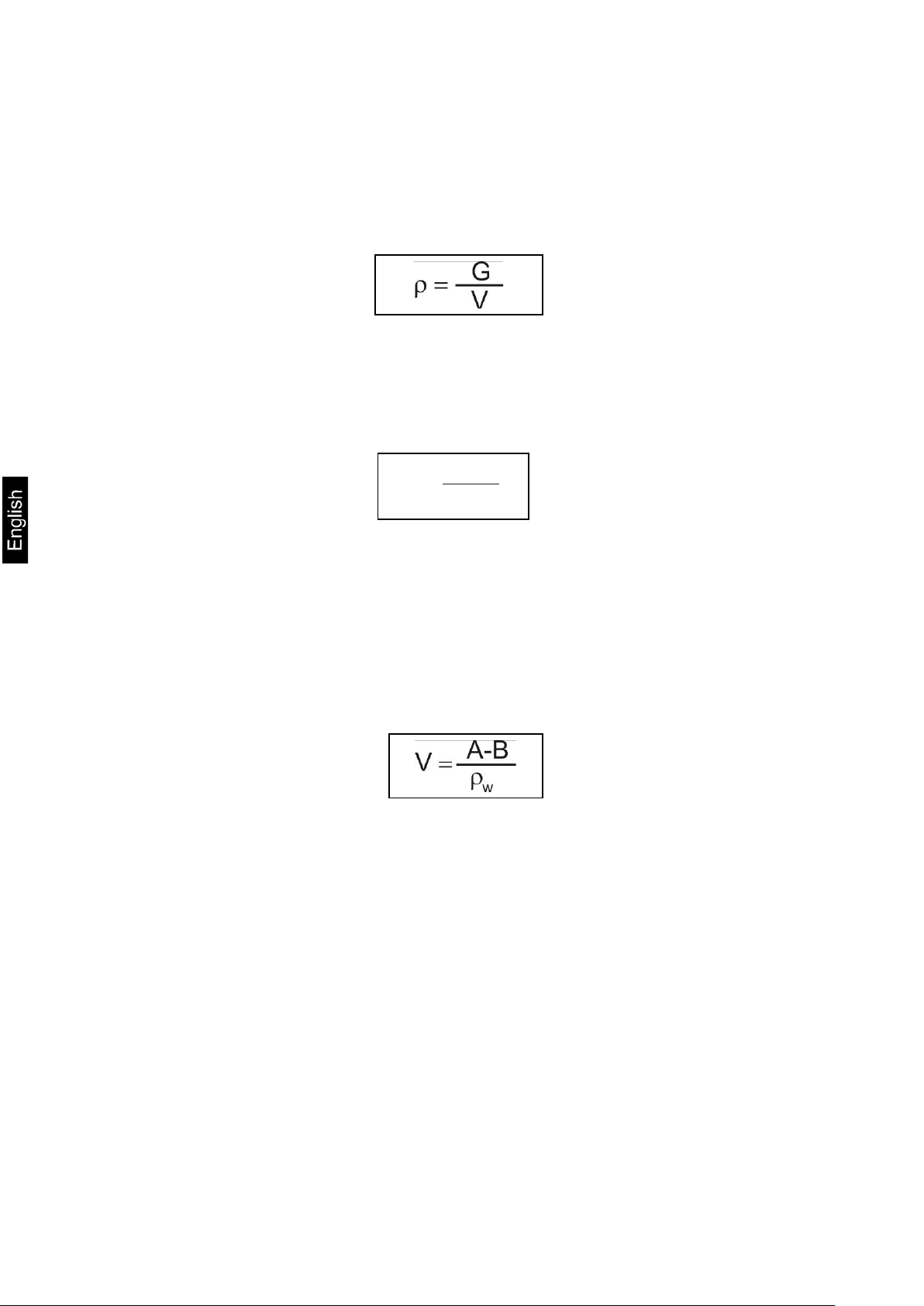

2 Principle of Density Determinat ion

Three physical magnitudes are the volume and the mass of bodies as well as the

density of matter. In density mass and volume are related.

Density [ ρ ] is the relation of mass [ m ] to volume [ V ].

SI-unit of density is kilogram divided by cubic meter (kg/m³). 1 kg/m³ equals the

density of a homogenous body that, for a mass of 1 kg, has the volume of 1 m³.

Additional frequentl y applied units include:

, ,

The application of this density determination set in combination with the KERN

ABS/ABJ balances provides fast and safe determination of solids and liquids. Our set

uses the "Principle of Archimedes" to determine density:

BUOYANCY IS A FORCE. IT AFFECTS A BODY THAT IS IMMERSED INTO A LIQUID. THE

BUOYANCY OF THE BODY EQUALS THE WEIGHT FORCE OF THE DISPLACED LIQUID. THE

FORCE OF BUOYANCY ACTS VERTICALLY UPWARDS.

Thus, density is calculated according to the formulae below:

To determine the density of solid matter

Our balances enable weighing of solids in air [ A ] as well as water [ B ]. If the density

of the buoyancy medium is known [ ρo ] the density of the solid [ ρ ] is calculated as

follows:

ρ = Density of sample

A = Weight of the sample in air

B = Weight of the sample in the aid liquid

ρ

= Density of the aid liquid

o

ALT-A02/PLT-A01-BA-e-1310 5

Page 6

ρ =

V

A-B

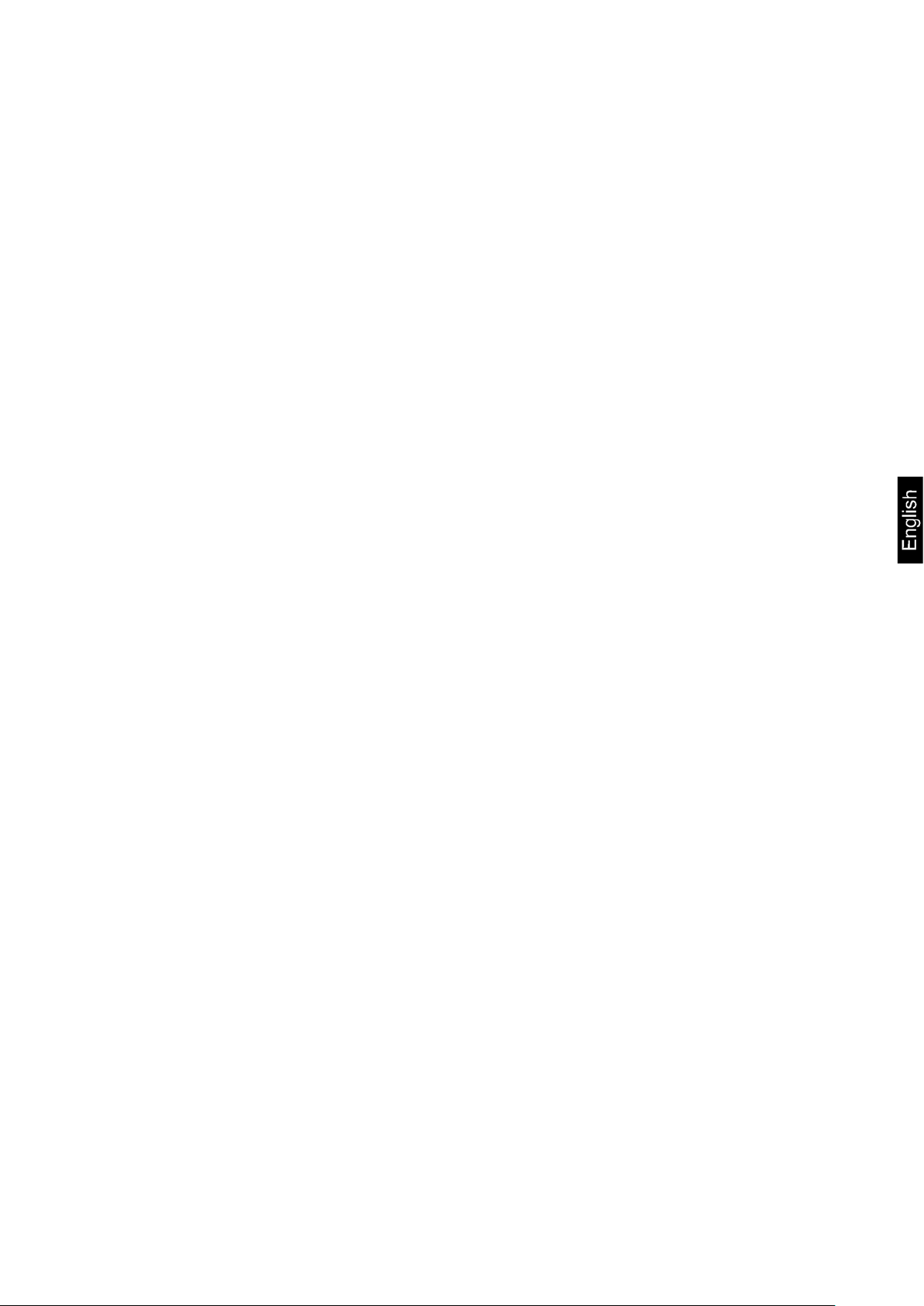

Determining density of liquids

The density of a liquid is determined with the help of a sinker providing a known

volume [ V ]. The sinker is weighed in air [ A ] as well as in the test liquid [ B ].

According to the Archimedes’ Principle a body immersed in a liquid experiences a

force of buoyancy [ G ]. This force equals the weight force of the liquid displaced by

the volume of the body.

The volume [ V ] of the immersed body equals the volume of the displaced liquid.

G = buoyancy of sinker

Buoyancy of sinker =

Weight of the sinker in air [ A ] - weight of sinker in test liquid [ B ]

From this follows:

ρ = density of sample liquid

A = weight of sinker in air

B = weight of the sinkers in test liquid

V = volume of sinker*

* If the volume of the sinker is unknown, this can be determined by a solid body

density measurement e.g. in water and be calculated as follows.

V = volume of sinker

A = weight of sinker in air

B = weight of sinker in water

ρ

= density of water

W

2.1 Influencing magnitudes and error sources

Air pressure

Temperature

Volume deviation of the sinker

Surface tension of the liquid

Air bubbles

Immersion depth of the sample dish or of the sinker

Porosity of the solid

6 ALT-A02/PLT-A01-BA-e-1310

Page 7

3 How to prepare the weighing balance

When the density set is installed, correct adjustment is not possible.

Perform necessary adjustment before installation of the density set using the

standard weighing plate.

If the balance is equipped with an internal adjustment weight (ALT / PLT, ALJ-A,

PLJ-A, PLJ-F) carry out an internal adjustment. After adjustment, enable “external

adjustment” in the adjus tme nt mo de me nu. This will avoid a request of an internal

adjustment, when the density set is installed.

If the balance is equipped with an external adjustment weight (ALS-A, PLS-A, PLS-

F, PLE-N) carry out an external adjustment.

For carrying out please refer to the operating instructions supplied with each balance

ALT-A02/PLT-A01-BA-e-1310 7

Page 8

weighing plate.

4 Installing the density determin ation set

• When the density set is installed, correct adjustment is not possible.

• For reasons of adjustment, take away the density set and place the standard

Disconnect scale fr om power supply.

Remove the standard weighing plate acc. to fig.

Models ALT, ALS/ALJ Models PLE, PLS/PLJ, PLT; d = 0.1 mg - 1 mg

Models PLS/PLJ, PLT; d = 10 mg

8 ALT-A02/PLT-A01-BA-e-1310

Page 9

Installed density set for solid matter „precision balances“

d= 10 mg

d = 0.1 mg - 1 mg

Install density determination set

(for solid matter please see chap. 5, for liquids see chap. 6)

Installed density set for solid matter “analytical balances”

ALT-A02/PLT-A01-BA-e-1310 9

Page 10

5 Density determination of solids

For the determination of the density of solids, the solid is first weighed in air and then

in the aid liquid, whose density is known. From the weight difference results the

buoyancy from where the software calculates the density.

As aid liquid, usually distilled water or ethanol is used, see density table chapter 8.

Prepare balance as described in chapter 3 "Installation of density determination set".

Place the retainer of the immersion basket on the cone of the weighing plate.

Place the platform for glass containers in a way that it does not touch the

retainer of the immersion basket.

Place beaker in the centre of the platform Make sure that it has no contact with

the retainer or with the immersion basket.

Hang the immersion basket on the retainer. Make sure that it is centred in the

recess.

Fill the aid liquid into a glass beaker. Fill in so much liquid that the solid matter

after immersion remains at least 1 cm under the liquid level. Immerse

thermometer

Bring aid liquid / instruments / sample to the right temperature until you

achieve a constant temperature. Observe the warm-up time of the balance.

Connect balance to power supply, the balance will carry out a self-test. Switch

on using the ON/OFF button and wait until the gram display appears.

10 ALT-A02/PLT-A01-BA-e-1310

Page 11

d > 1 g /cm3

For descending solid matter suspend the immersion basket as shown in fig. 1.

Liquid

Fig. 1

For determination of density of solid matter, the universal immersion basket for

floating (d > 1 g /cm3) and descending solid matter (d < 1 g /cm3) must be used.

ALT-A02/PLT-A01-BA-e-1310 11

Page 12

d < 1 g /cm3

!

If the buoyancy of the sample is so much that the immersion basket is lifted, place

weighing in air.

For floating solid matter suspend the immersion basket as shown in fig. 2.

Fig. 2

Liquid

At solid material with density less than 1 g/cm3, a density determination with two

different methods is pos si bl e.

Method 1:

As aid liquid is used a liquid with less density than that of the solid material, e.g.

ethanol approx. 0.8 g/cm3.

This method should be applied when the density of the solid is just slightly

different from that of the distilled water.

Using ethanol is not recommended, when the solid material is being attacked.

When working with ethanol, you must observe the applicable safety

regulations.

Method 2:

Here the sample is not placed upon, but under the sample dish. For that purpose

the sample dish of the immersion basket must be assembled upside down as

shown in fig. 2 with the help of the delivered Allen key.

an additional weight on it in the upper sample dish and tare it away when

12 ALT-A02/PLT-A01-BA-e-1310

Page 13

5.1 Ba lances with graphic display (KERN ALT-B, PLT-A, PLT-F)

In weighing mode press MENU button. The master menu will be displayed.

Use the navigation buttons to select the menu item „Density“.

Acknowledge using PRINT button, the current setting is displayed.

Use the navigation buttons to select setting „Solid body“.

Confirm using the PRINT button, the set density of the aid liquid is displayed

(factory setting 1.0000 g /cm3 for distilled water at 20°C).

To change (see table chap. 8) press the TARE button.

To delete keep pressed the TARE button. Use the navigation buttons to

increase/reduce the digit. Use the TARE button to select the next digit. Repeat

this sequence for each digit.

Confirm entry with PRINT button, the display for calculation of „Weight in air“ is

displayed.

Should the balance not show Zero, press the TARE button.

ALT-A02/PLT-A01-BA-e-1310 13

Page 14

Sample

Place sample in the upper sample dish.

Wait for stability display [ ], then take over the weight value using the PRINT

button.

14 ALT-A02/PLT-A01-BA-e-1310

Page 15

Sample

Wait until the display for determination of „sample in aid liquid“ appears. Remove

the sample and if required tare by using the TARE button.

Lay the sample into the lower sample dish and immerse it in the aid liquid trying

to avoid bubble formation.

Make sure that the sample is at least 1 cm immersed.

Wait for stability display [ ], take over the weight value using PRINT button. The

density of the sample is shown.

ALT-A02/PLT-A01-BA-e-1310 15

Page 16

If at the density determination errors have appeared, „d-----„ is displayed.

When an optional printer is connected, the displayed value can be edited using

the PRINT button.

Printout example (KERN YKB-01N):

07-09-11 11:14:57

d : 8.0700 g/cm3

For further measurements go back to density determination mode, press MENU

button.

Back to weighing mode, press ON/OFF button.

16 ALT-A02/PLT-A01-BA-e-1310

Page 17

5.2 Ba lances with LCD display (KERN ALS-A / ALJ-A, PLS-A / PLJ-A, PLS-F / PLJ-F, PLE-N)

In weighing mode press MENU button. The first menu item „count“ is displayed.

Press MENU button

Acknowledge using PRINT button, the current setting is displayed.

Using MENU button select „d SoLid“

Confirm by pressing the PRINT button. The currently set density of the aid liquid

is displayed (factory setting 1.0000 g /cm3 for distilled water at 20°C).

To change, enter the density of the aid liquid using arrow keys .

Confirm input by pressing the PRINT button.

ALT-A02/PLT-A01-BA-e-1310 17

Page 18

], then take over the weight value „sample in air“ using

Sample

The display for weight determination of the "sample in air“ appears.

Confirm by pressing the PRINT button.

Should the balance not show Zero, press the TARE button.

Lay the solid matter in the upper sample dish.

Wait for stability display [

the PRINT button.

Wait until the display for weight determination of „sample in aid liquid“ appears.

Confirm by pressing the PRINT button.

Remove the sample and if required tare by using the TARE button.

18 ALT-A02/PLT-A01-BA-e-1310

Page 19

If at the density determination errors have appeared, „d-----„ is displayed.

Sample

Lay the sample into the lower sample dish and immerse it in the aid liquid trying

to avoid bubble formation.

Make sure that the sample is at least 1 cm immersed.

Wait for stability display [ ], then take over the weight value „sample in aid

liquid“ using the PRINT button. The density of the sample is shown.

When an optional printer is connected, the displayed value can be edited using

the PRINT button.

Printout example (KERN YKB-01N):

d : 2.0000 g/cm3

Return to weighing mode

Press the ON/OFF button

or use the MENU button to start a new measuring cycle.

ALT-A02/PLT-A01-BA-e-1310 19

Page 20

6 Determining density of liquids

At the density determination of liquids, a glass sinker is used whose density is

known. The glass sinker is weighed first in air and then in the liquid whose density is

to be determined. From the weight difference results the buoyancy from where the

software calculates the density.

Prepare balance as described in chapter 3 "Installation of density determination set".

Place the retainer of the immersion basket on the cone of the weighing plate.

Place the platform for glass containers in a way that it does not touch the

retainer of the immersion basket.

Place a high glass beaker in the centre of the platform. Suspend thermometer.

Keep the sinker ready

Bring test liquid / instruments / sinker to the right temperature until you achieve

a constant temperature. Observe the warm-up time of the balance.

Connect the balance to the power supply, the balance carries out a self-test.

Switch on by the ON/OFF button and wait until the gram display appears.

20 ALT-A02/PLT-A01-BA-e-1310

Page 21

3.1000g/cm3

6.1 Ba lances with graphic display (KERN ALT-B, PLT-A, PLT-F)

In weighing mode press MENU button. The master menu will be displayed.

Use the navigation buttons to select the menu item „Density“.

Acknowledge using PRINT button, the current setting is displayed.

Use the navigation buttons to select the setting „Liquid“.

Confirm using the PRINT button, the currently set density of the sinker is

displayed (factory setting 3.0000 g/cm3).

Read off the density of the sinker on the storage box and enter it. To delete keep

pressed the TARE button. Use the navigation buttons to increase/reduce the

digit. Use the TARE button to select the next digit. Repeat this sequence for

each digit.

Confirm by pressing the PRINT button. The display for weight determination of

the "Sinker in air“ appears.

If weighing balance does not show Zero, press TARE.

ALT-A02/PLT-A01-BA-e-1310 21

Page 22

Attach the sinker.

Wait for stability display [ ], take over the weight value using PRINT button

Wait until the display for weight determination of „sinker in test liquid“ appears.

Remove the sinker and if required tare by using the TARE button.

Fill the glass beaker with test liquid

22 ALT-A02/PLT-A01-BA-e-1310

Page 23

If possible, immerse the sinker bubble-free in the test liquid.

Make sure that the sinker is at least 1 cm immersed.

Wait for stability display [ ], take over the weight value using PRINT button. The

density of the test liquid is shown at the temperature displayed by the

thermometer.

ALT-A02/PLT-A01-BA-e-1310 23

Page 24

If at the density determination errors have appeared, „d-----„ is displayed.

07-09-11 11:14:57

0.9748 g/cm3

When an optional printer is connected, the displayed value can be edited using

PRINT.

Printout example (KERN YKB-01N):

d :

For further measurements go back to density determination mode, press MENU

button.

Back to weighing mode, press ON/OFF button.

24 ALT-A02/PLT-A01-BA-e-1310

Page 25

3.1000g/cm3

6.2 Ba lances with LCD display (KERN ALS-A / ALJ-A, PLS-A / PLJ-A, PLS-F / PLJ-F, PLE-N)

In weighing mode press MENU button. The first menu item „count“ is displayed.

Press MENU button

Acknowledge using PRINT button, the current setting is displayed.

Using MENU button select „d Liquid“

Confirm using the PRINT button, the currently set density of the sinker is

displayed (factory setting 3.0000 g/cm3).

Read off and enter the density of the sinker on the storage box or suspension

bracket. To delete keep pressed the TARE button. Use the navigation buttons

to increase/reduce the di g i t. Use the TARE button to select the next digit . Repeat

this sequence for each digit.

ALT-A02/PLT-A01-BA-e-1310 25

Page 26

Confirm input by pressing the PRINT button. The display for weight

determination of the "Sinker in air“ appears.

Confirm by pressing the PRINT button.

If weighing balance does not show Zero, press TARE.

Attach the sinker centrically.

Wait for stability display [ ], take over the weight value „sinker in air“ using the

PRINT button.

Wait until the display for weight determination of „sinker in test liquid“ appears.

Confirm by pressing the PRINT button.

Remove the sinker and if required tare by using the TARE button.

Fill the glass beaker with test liquid

26 ALT-A02/PLT-A01-BA-e-1310

Page 27

If at the density determination errors have appeared, „d-----„ is displayed.

If possible, immerse the sinker bubble-free in the test liquid.

Make sure that the sinker is at least 1 cm immersed.

Wait for stability display [ ], take over the weight value „sinker in test liquid“

using the PRINT button. The density of the test liquid is shown at the

temperature displayed by the thermometer.

When an optional printer is connected, the displayed value can be edited using

the PRINT button.

Printout example (KERN YKB-01N):

d: 2.0000 g/cm3

Return to weighing mode

Press the ON/OFF key

or use the MENU button to start a new measuring cycle.

ALT-A02/PLT-A01-BA-e-1310 27

Page 28

ρ =

A

A-B

o

ρ

7 Preconditions for Precise Measurements

There are numerous error possibilities during density determination.

Accurate knowledge and caution are required to achieve precise results when

applying this density set in combination with the balance.

7.1 Ca lculation of Results

The balance displays results for density determination by giving four decimal places.

However, this does not mean that the results are accurate down to the last decimal

place as this would be the case for a calculated value. Therefore all weighing results

used for calculations have to be examined closely.

Example for density determination of solids:

To ensure high-grade results, numerators as well as common denominators of the

formula below must show the desired accuracy. If either of them is instable or flawed,

the result, too, will be instable or flawed.

ρ = Density of sample

A = Weight of the sample in air

B = Weight of the sample in the aid liquid

ρ

= Density of the aid liquid

o

7.2 Influence Factors for Measurement Errors

7.2.1 Air bubbles

A small bubble with a diameter of 1 mm results in a buoyancy of 0.5 mg, while those

with 2 mm Ø already produces a buoyancy of 4 mg.

Therefore, make sure that no air bubbles adhere on the solid object or sinker that is

immersed in the liquid.

An oily surface causes air bubbles when immersing in the liquid, so

remove grease from solvent resistant solid matter sample

clean all parts that are immersed regularly and don't touch them with bare

fingers

Don't lay solid samples (particularly flat objects) outside of the liquid on the sample

bowl, because this results in air bubbles by the joint immersion.

7.2.2 Temperature

Normally solid matter is insensitive to temperature changes, therefore the respective

changes of density can be ignored. Nevertheless the temperature of the liquid used

for density determination of solid matter must be taken into consideration as any

temperature change by one degree °C causes a change of density from 0.1 to 1%.

This has an effect on the third decimal point of the result.

28 ALT-A02/PLT-A01-BA-e-1310

Page 29

7.2.3 Solid matter sample

A sample possessing too great a volume that is immersed in liquid will result in an

increase in liquid level inside the glass pitcher. As a result, part of the suspension

bracket of the sample dish will also be immersed causing buoyancy to increase. As a

consequence the weight of the specimen in the liquid will drop.

Samples that change the volume or assimilate liquid are unsuitable for measurement.

7.2.4 Liquids

Solids are generally not sensitive to temperature changes, so that the corresponding

density changes are not rel ev ant . However, since you work with an aid liquid by the

density determination of solids, according to the "Archimedean Principle", its

temperature is taken into account. The temperature change effects liquids greater

and causes changes in the density in order of 0.1 to 1 ‰ per °C. Hereby, the third

digit after the decimal point is affected.

7.2.5 Surface

The suspension bracket of the sample dish penetrates the surface of the liquid. This

state undergoes continuous change. If the sample or the sinker is relatively small, the

surface tension will impair repeatability. Adding a small amount of tenside (detergent)

makes surface tension negligible and increases reproducibility.

7.3 G eneral information

7.3.1 Density / Relative Density

Relative density follows from the weight of a specimen divided by the weight of water

(at 4° Celsius) of the same volume. For this reason relative density does not have a

unit. Density equals mass divided by volume.

The application of the relative density instead of the density of a liquid in a formula

produces an incorrect result. In the case of liquids only their density is

physically meaningful.

7.3.2 Drift of Balance Display

The drifting of a balance does not influence the final result of the density

determination although the shown weight of weighing in air is affected. Accurate

values are merely required if the density of liquids is determined by means of a

sinker.

When changing the ambient temperature or location, an adjustment of the balance is

necessary. For this purpose, remove the density set and carry out adjustment using

the standard weighing pan.

ALT-A02/PLT-A01-BA-e-1310 29

Page 30

Temperature

Density ρ [g/cm

3

]

Water

Ethyl alcohol

Methyl alcohol

10

0.9997

0.7978

0.8009

11

0.9996

0.7969

0.8000

12

0.9995

0.7961

0.7991

13

0.9994

0.7953

0.7982

14

0.9993

0.7944

0.7972

15

0.9991

0.7935

0.7963

16

0.9990

0.7927

0.7954

17

0.9988

0.7918

0.7945

18

0.9986

0.7909

0.7935

19

0.9984

0.7901

0.7926

20

0.9982

0.7893

0.7917

21

0.9980

0.7884

0.7907

22

0.9978

0.7876

0.7898

23

0.9976

0.7867

0.7880

24

0.9973

0.7859

0.7870

25

0.9971

0.7851

0.7870

26

0.9968

0.7842

0.7861

27

0.9965

0.7833

0.7852

28

0.9963

0.7824

0.7842

29

0.9960

0.7816

0.7833

30

0.9957

0.7808

0.7824

31

0.9954

0.7800

0.7814

32

0.9951

0.7791

0.7805

33

0.9947

0.7783

0.7896

34

0.9944

0.7774

0.7886

35

0.9941

0.7766

0.7877

8 Density Table for Liquids

[°C]

30 ALT-A02/PLT-A01-BA-e-1310

Page 31

9 User Instructions

• T o form a reproducible mean value several density measurement are necessary

• Remove fat from solvent-resistant sample / /glass sinker /beaker.

• Regularly clean sample dishes/glass sinker/glass beaker, do not touch immersing

part with your hands

• Dry sample/glass sinker/pincers after each measurement.

• Adjust sample size to sample dish (ideal sample size > 5 g).

• Only use distilled water.

• When immersing for the first time, lightly shake sample dishes and sinker, in order

to dissolve air bubbles.

• Always ensure that, when re-immersing into the liquid no additional bubbles

adhere; it is better to use pincers to place the sample.

• Remove firmly adherent air bubbles with a fine brush or a similar tool.

• T o avoid adherent air bubbles smoothen samples with rough surface.

• T ake care that no water drips onto the upper sample dish when weighing with the

help of tweezers.

• In order to reduce the surface tension of water and the friction of the liquid on the

wire, add three drops of a common detergent (washing-up liquid) to the

measuring liquid (density modification of distilled water occurring due to the

addition of tensides can be ignored).

• Oval samples can be held more easily with pincers when you cut grooves into

them.

• T he density of porous solids may only be determined approximately. Buoyancy

errors occur when not all the air is eliminated from the por es dur i ng immer si on in

the measuring liquid.

• T o avoid great vibrations of the balance, place sample carefully.

• Avoid static charge, e. g. dry glass sinker with cotton cloth only.

• If the density of your solid only deviates slightly from that of disti ll ed water, ethanol

may be used as measuring liquid. However, check beforehand whether the

sample is solvent-proof. In addition you must observe the applicable safety

regulations when working with ethanol.

• Handle glass sinker with care

(no warranty claims in case of damage).

• To avoid corrosion, don't leave the density set immersed in liquid for a long time.

ALT-A02/PLT-A01-BA-e-1310 31

Loading...

Loading...