Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Service manual

Precision balance

KERN PFB

Version 1.0

1/2010

GB

Tel: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

PFB-SH-e-1010

Page 2

GB

KERN PFB

Version 1.0 1/2010

Service manual

Table of Contents

1 Basic information .................................................................................................. 3

2 Transportation lock ............................................................................................... 3

3 Keyboard description ............................................................................................ 4

4 Battery operation ................................................................................................... 5

5 Calibration .............................................................................................................. 6

6 Parameter setting (incl. linearity adjustment) ............................................................ 7

6.1 Navigation in the menu ............................................................................................... 7

6.2 Parameter table ........................................................................................................... 8

7 Error messages.................................................................................................... 10

8 Trouble shooting ................................................................................................. 11

9 Countermeasures for each trouble .................................................................... 12

Precision balance

10 Schematics ........................................................................................................... 17

11 Exploded drawing ................................................................................................ 23

11.1 Capacity 120g~3000g ................................................................................................ 23

11.2 Capacity 6000g .......................................................................................................... 25

12 LCD display – numeric and alphabetic characters ........................................... 27

2

PFB-SH-e-1010

Page 3

1 Basic information

Grundlegende Hinweise

The device must be repaired only by trained specialist staff or personnel with

professional formation (such as a repair-specialist accredited by law concerning

verification).

The service manual is obligatory for repair work.

After repair, original conditions of the device have to be restored.

Only original spare parts should be used.

Das Gerät darf nur von geschultem oder beruflich ausgebildetem Fachpersonal (z. B.

eichrechtlich anerkannter Instandsetzer) repariert werden.

Die Serviceanleitung ist bindend für Reparaturen.

Das Gerät muss nach erfolgter Reparatur wieder in den Originalzustand zurückversetzt

werden.

Es dürfen nur Originalersatzteile verwendet werden.

2 Transportation lock

The balance must be installed in a way that the weighing plate is exactly in horizontal

position.

Remove the transportation lock [ 1 ] (PFB 120-3, PFB 200-3, PFB 1200-2, PFB 2000-2):

[1]

PFB-SH-e-1010

3

Page 4

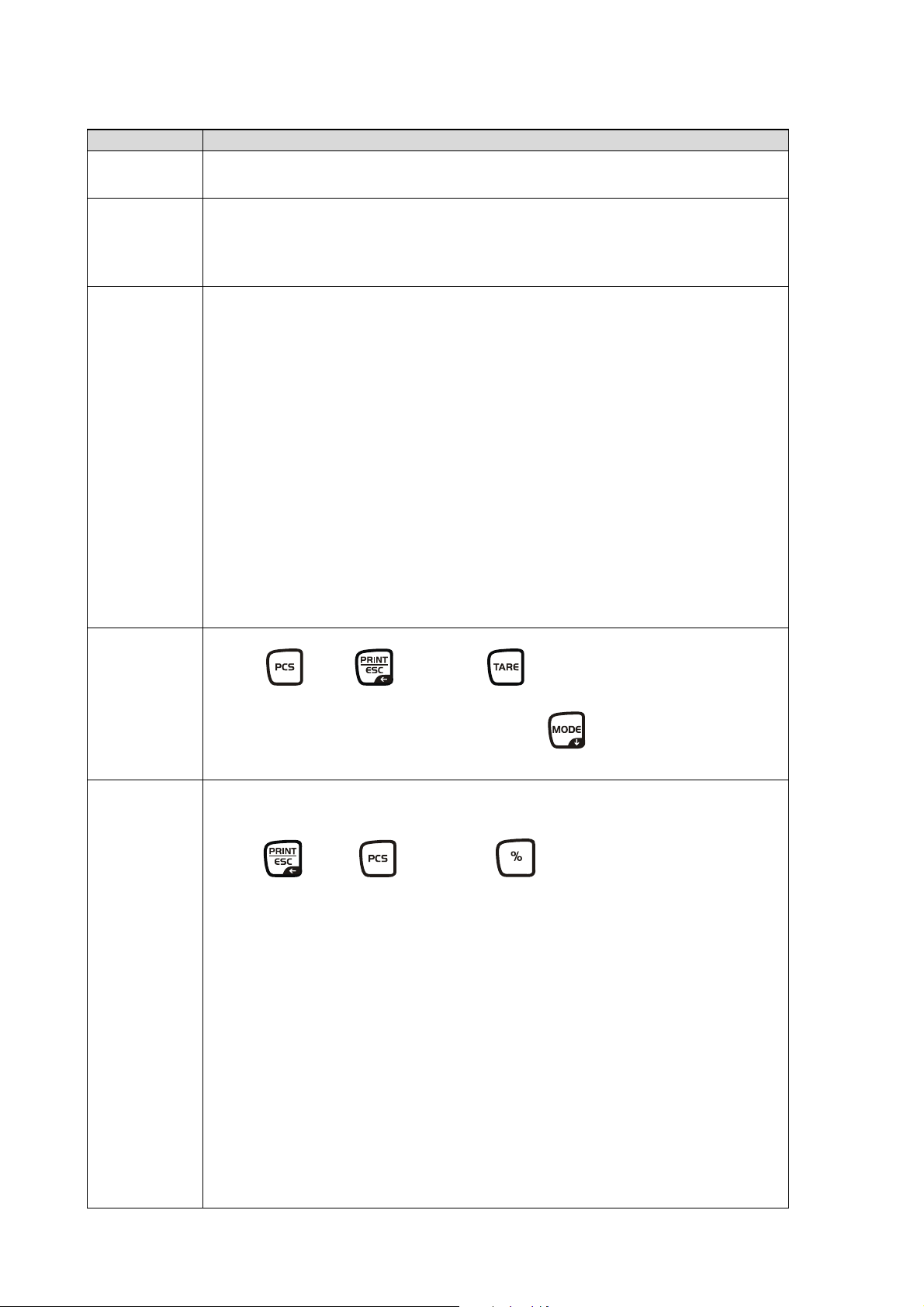

3 Keyboard description

Key Designation Pressed once and released

ON

OFF

[ON/OFF]

Ö Turn on/off

[ZERO]

Ö Set weight display at zero

Ö Activate the current element in the menu

Ö Select in Weighing units (menu F UNIT):

change to the next unit

[TARE]

Ö Taring

[%]

Ö Call-up %-function

Ö In the percent mode back to weighing mode

Ö Only % function

[PCS]

Ö Call-up piece counting mode

Ö In the piece count mode back to weighing mode

[MODE]

Ö Weighing units switch-over;

Ö At weighing unit switch-over (menu „F UNIT“):

Set weighing unit on/off

Ö Counting up in piece counting mode

Ö Select menu and pass through menu items

from top to bottom

Ö Changing readability

[PRINT/ESC]

Ö Print out weighing result

Ö Exit menu (jumping back to weighing mode)

4

PFB-SH-e-1010

Page 5

4 Battery operation

The balance come with a rechargeable battery, can be operated from the battery if

desired. The battery life is approximately 40 hours.

There is a battery symbol on display used to indicator battery status

Flick: charging battery

Full: battery full or charge finished

Half: battery with half power

When battery symbol become blank, please change battery or use AC adapter, the

scale does not need to be turned on. The battery should be charged for 12 hours for

full capacity.

As the battery is used it may fail to hold a full charge.

Note: new batteries are shipped partially charged. Before you can use your scale,

you need to charge the battery, as indicated by the following instructions.

Some batteries perform best after several full charge/discharge cycles.

Battery performance depends on many factors, including your backlight setting and

operate.

To maximize your battery’s performance:

• Always use original batteries and AC adapter. The scale warranty does not cover

damage caused from using non original batteries and/or battery chargers.

• New batteries or batteries that have been stored for long periods of time may

require a longer charge time.

• Maintain the battery at or near room temperature when charging.

• Do not expose batteries to temperatures below -10°C (14°F) or above 45°C

(113°F).

• Over extended periods of time, batteries gradually wear down and require longer

charging times.

This is normal. If you charge your battery regularly and notice a decrease in operate

time or an increase in charging time, then it is probably time to purchase a new

battery.

Blank: need be charged

Never use any charger or battery which is damaged.

Do not short-circuit the battery. Accidental short-circuiting

can occur when a metallic object (coin, clip or pen) causes

direct connection of the + and - terminals of the battery

(metal strips on the battery).

Do not dispose of batteries in a fire

Dispose of batteries according to local regulations (e.g.

recycling). Do not dispose as household waste.

Avoid charging under airless conditions

PFB-SH-e-1010

5

Page 6

5 Calibration

Observe stable environmental conditions.

A warming up time of approx. 2 hours is required for stabilization.

Ensure that there are no objects on the weighing plate.

Balance display Operation

Ö In weighing mode press approx. 3 sec. until

When display „LoAd“ appears, put the necessary

calibration weight on the center of the weighing plate.

PFB 120-3: 100g (F1)

PFB 200-3: 200g (F1)

PFB 1200-2: 1000g (F1)

PFB 2000-2: 2000g (F1)

PFB 6K0.05: 5000g (F1)

PFB 6000-1: 5000g (F1)

„UnLoAd“ appears.

Calibration will be carried out automatically after dead

stop control.

Ö Wait for stability display

„Pass“ appears, the calibration process has been

finished successfully.

Ö Take away calibration weight

Wait until the balance is again in the weighing mode.

6

PFB-SH-e-1010

Page 7

6 Parameter setting (incl. linearity adjustment)

The scale has 9 parameters (include 6 technical parameter) plus a method of

entering the calibration section.

The menu is called-up by pressing the key during self

test.

The display appears the first parameter "F1 UNT".

6.1 Navigation in the menu

Key Direction in the

Description

menu

Select menu and pass through menu items from

top to bottom

Select current element

Exit the current element, return to weighing mode

Note: When display shows “tECH”, press key to enter. Display shows “Pin”.

Press , then and finally key to enter technical parameter setting mode.

The display appears “P1 L in”. With the key you can select the desired pa-

rameter.

PFB-SH-e-1010

7

Page 8

6.2 Parameter table

)

FUNCTION DESCRIPTION

Selection of weighing units

F1 Unt

ct / lb / oz / d / gn / ozt / dwt / mom / tl.T / tl.c / tl.t / t / bt / n

Backlight on/automatic/off

F2 bL

EL on

EL AU

EL oFF

: backlight always on

: backlight switches on automatically

: backlight always off

RS-232-interface (ASCII code, 8 data bits, no parity)

F3

Con

Select RS-232 or USB (not used):

S 232

S USB

: RS-232 interface

: USB interface (not used)

Select communication mode:

P Prt:

data output via Print-key (After each weighing unload the pan)

P Cont:

P AUto:

beep. Remove the weight immediately. The automatic printout – number + weighing

value – starts.)

WirELE

Select interface settings:

b

xxx: baud rate 600/ 1200/ 2400/ 4800/ 9600bps

tP

or

LP-50

Pin:

tECH

Press , then and finally key to enter technical parameter setting mode.

continuous data output

autom. Printout (After the stability marks appears, there is a

: wireless (not used)

: tP: normal printer / LP-50: label printer (not used

P1

Lin

The display appears “P1 L in”. With the key you can select the

desired parameter.

Linearity adjustment:

Pin:

Press , then and finally key.

Display will show

LoAd 0.

Remove

all weights from the pan

and wait until display shows next step.

Display appears

LoAd

1.

Put the first weight on the pan and wait for next step.

Display appears

LoAd

2.

Put the second weight on the pan and wait for next step.

Display appears

LoAd

3.

Put a weight of full capacity on the pan.

Short time later the balance automatically returns to weighing mode.

During that time remove the weights.

Note: Calibration weights of LoAd1, LoAd2 and LoAd3 must be

integer.

Example: PFB 6000-1: LoAd 1: e.g. 1kg, 2kg or 3kg

LoAd 2: e.g. 3kg, 4kg or 5kg LoAd 3: maximum weight (6kg)

8

PFB-SH-e-1010

Page 9

P2 CAL

P3 Cnt

Calibration procedure:

The display appears "UnLoAd

Remove all weights from the pan and wait for stabilization.

When display „LoAd“ appears, put the necessary calibration weight

on the center of the weighing plate.

PFB 120-3: 100g (F1)

PFB 200-3: 200g (F1)

PFB 1200-2: 1000g (F1)

PFB 2000-2: 2000g (F1)

PFB 6K0.05: 5000g (F1)

PFB 6000-1: 5000g (F1)

Calibration will be carried out automatically after dead

stop control.

„PASS“ appears, the calibration process has been finished successfully. Take away calibration weight.

Display will show the internal counts, e.g. 74130.

Press key to escape.

".

P4 AZn

P5 GrA

P6 CAP

Autozero function:

Options: oFF, 0.5d, 1d, 2d, 4d

Gravity adjustment:

When the balance is first used or has been moved to different

place, it should be calibrated using a calibration weight.

When a calibration weight is not available, the correction of the

gravity factor will compensate the balance. Change the gravity

factor of the balance to the value of the area where it will be

used.

For example:

Local latitude= 9.85, latitude of calibrated place= 9.75

Input new gravity factor (9,85 : 9,75). In this case 1.01025.

Note: After you do the calibration “P2 CAL”, the gravity

factor will reset to 1.00000

Set scale capacity

For example PFB 6000-1= 6000 G

Note: This parameter is not available at all software versions.

PFB-SH-e-1010

9

Page 10

7 Error messages

Err 3

Calibration error

• Incorrect calibration weight

• Put on correct calibration

weight

Err 4

Err 5

Err 6

Err 7

Err 8

• Remove load and press

Zero range exceeded/

Initial zero error

(> 4% of maximum capacity)

Keyboard error • Inadmissible input

A/D count outside range when

turning on the balance

Percentage setting error • 0.01% must be > 0.5d

External calibration weight error

to reset balance to zero.

• Improper calibration of the

balance

• Load cell damaged

• Electronics damaged

• Weighing pan not installed

• Load cell damaged

• Electronics damaged

• Difference of calibration

weight to stored value more

than 4%

10

PFB-SH-e-1010

Page 11

8 Trouble shooting

Problem Possible cause

Display is blank

Unit does not turn on

Power supply faulty

Internal battery not charged

Electronic defective

Unit turns on but the display appears

an error message or stays on self test

Balance shows OL or ---- Maximum capacity exceeded

Balance shows ---- or NULL

Unstable readout

Balance shows wrong weight

Cannot use full capacity

Pan not installed correctly

Unstable readout

Load cell damaged

Load cell damaged

Power supply faulty

Pan has been removed

Pan support not installed correctly

Power supply faulty

Load cell damaged

Air drafts or vibration or unstable table

Pan rubbing against case or not installed correctly

Sample is moving (animal weighing)

Load cell damaged

Power supply faulty

Calibration error

Linearity error

Balance have not been leveled

Selected wrong weighing unit

Overload stopper adjusted incorrectly

Transportation lock not removed

Electronic problem (A/D)

Set-up of parameters incorrectly

Load cell damaged

Linearity error

Off-center load error

Battery will not charge

Wrong linearity adjustment

Load cell damaged

Overload stopper adjusted incorrectly

Load cell damaged

Power supply faulty

Charging circuit board failure

Battery defective

PFB-SH-e-1010

11

Page 12

9 Countermeasures for each trouble

Some abbreviations:

M/B means main board

D/B means display board

CHK means check

A - No function

12

PFB-SH-e-1010

Page 13

B – No display readout / display is blank

PFB-SH-e-1010

13

Page 14

C – Battery will not charge

14

PFB-SH-e-1010

Page 15

D – No weighing value

PFB-SH-e-1010

15

Page 16

E – Unstable reading

F – Keyboard without function

16

PFB-SH-e-1010

Page 17

10 Schematics

Main board

PFB-SH-e-1010

17

Page 18

ADC

18

PFB-SH-e-1010

Page 19

Display board

PFB-SH-e-1010

19

Page 20

Power supply

20

PFB-SH-e-1010

Page 21

Interface

PFB-SH-e-1010

21

Page 22

Other

22

PFB-SH-e-1010

Page 23

11 Exploded drawing

11.1 Capacity 120g~3000g

PFB-SH-e-1010

23

Page 24

No Description QtyMaterial Spec

w

A

A

A

A

A

A

A

A

A

A

1

2 toughened glass 1 2 glass 152.5x80x3t

3 pole for glass 4

4 Round rubber spacer 4

5 toughened glass 2 2 glass 138.5x80x3t

6 SST pan 1 SUS304 Ø 80/120

7 "+" screw 1 S18C M4x12, 6.8

ind shield top cover 1

L

L

8 plastic pan 1

10 SST cover 1 SUS304 0.5t

11 internal hexagon screw 4

12 load cell shim 2 SUS304 16x13x1t

13 load cell upper bracket 1

14 battery 1 lead acid 6v/1.2Ah

15 self thread screw 10 S18C 3x10, 6.8

16 interface PCBA 1

17 "+" screw 4 S18C M4x10, 6.8

18 load cell lower bracket 1

19 washer 2

20 bottom cover 1

21 foot 2 2

22 key panel 1 PC

23 level bubble 1

24 top cover 1

25 dislay PCBA 1

BS Ø 80/120

BS

L

BS

BS

BS

M3x12,8.8

RS232/USB

M3

14.7mm

26 insulative washer 10 EDPM 8x3.1x1.5t

27 "+" screw 1 S18C 4x12, optional

28 L type below weighing screw 1 SUS304 Optional

29 Hexagon nut 1

30 Below weighing pole 1

31 load cell 1

32 "+" screw 1 S18C M3x6,

33 Screw (big head) 1 SUS304 M4x10

34 main PCBA 1

35 "+" screw 4 S18C 4x12,8.8

36 foot 1 2

37 Name plate 1

24

L SPL

BS

M4, optional

optional

PFB-SH-e-1010

Page 25

11.2 Capacity 6000g

PFB-SH-e-1010

25

Page 26

No Description QtyMaterial Spec

A

A

A

A

A

A

A

A

A

1 SST pan 1 SUS304 145x155

2 "+" screw 1 S18C M4x12, 6.8

3 plastic pan 1

4 SST cover 1 SUS304 0.5t

6 key panel 1 PC

7 top cover 1

8 internal hexagon screw 4

9 Pan support 1

10 load cell upper bracket 1

11 washer 2

12 Internal Hexagon screw 2

13 load cell 1

14 load cell lower bracket 1

15 battery 1 lead acid 6v/1.2Ah

16 self thread screw 10 S18C 3x10, 6.8

17 insulative washer 10 EDPM 8x3.1x1.5t

18 interface PCBA 1

19 bottom cover 1

20 foot 2 2

21 level bubble 1

BS 145x155

BS

l

l

L PW6K

L

BS

BS

M6x20

M3

M3x12

RS232/USB

14.7mm

22 load cell shim 2 SUS304 16x13x1t

23 dislay PCBA 1

24 "+" screw 4 S18C M4x20

25 Hexagon Screw 1 SUS304 M4x10

26 Hexagon nut 2

27 Below weighing pole 1

28 main PCBA 1

29 "+" self thread screw 4 S18C 4x12

30 foot 1 2

31 Name plate 1

BS

M4, optional

optional

26

PFB-SH-e-1010

Page 27

12 LCD display – numeric and alphabetic characters

PFB-SH-e-1010

27

Loading...

Loading...