KERN NTEP Series, NTEP 600K200M, NTNN Series, NTEP 1.5T0.5M, NTNN 600K200M Installation Information

...Page 1

NTEP/NTNN-IA-defsi-0710

12

GB

KERN NTEP/NTNN

Version 1.0 02/2007

Installation Information

Drive-through-scale

Contents

1 General Description ........................................................................................ 13

2 Standard Configuration and Working Principle............................................ 13

2.1 Major Components...............................................................................................13

2.2 Platform Assembly...............................................................................................14

2.3 Working Principle.................................................................................................14

3 Specifications.................................................................................................. 15

3.1 Load Cell ...............................................................................................................15

4 Inspection and Site Selection......................................................................... 15

4.1 Inspection..............................................................................................................15

4.2 Site Selection........................................................................................................16

5 Installation ....................................................................................................... 16

5.1 Locate....................................................................................................................16

5.2 Installation Procedure..........................................................................................16

6 Ramp Installation ............................................................................................ 19

7 System Connection......................................................................................... 19

8 Technical Data................................................................................................. 20

Page 2

NTEP/NTNN-IA-defsi-0710

13

1 General Description

Thank you for choosing our NTEP/NTNN series floor scale. The scale consist of new

design ultra-low profile steel platform, four high precision shearing beam load cells.

NTEP/NTNN floor scales have the features of high accuracy, quick weighing and reliable weighing performance. The ultra-low platform means less effort required to

manually place the load on the scale. It is suitable to weigh drums, totes, small mixing vats, etc.

The NTEP/NTNN series are designed to provide excellent performance required for

weighing applications in postal distribution centre, distribution centre of commerce,

storage and consignment enterprises, and workshop production line, semi finished or

finished product storehouse of pharmaceutical and food enterprises

2 Standard Configuration and Working Principle

2.1 Major Components

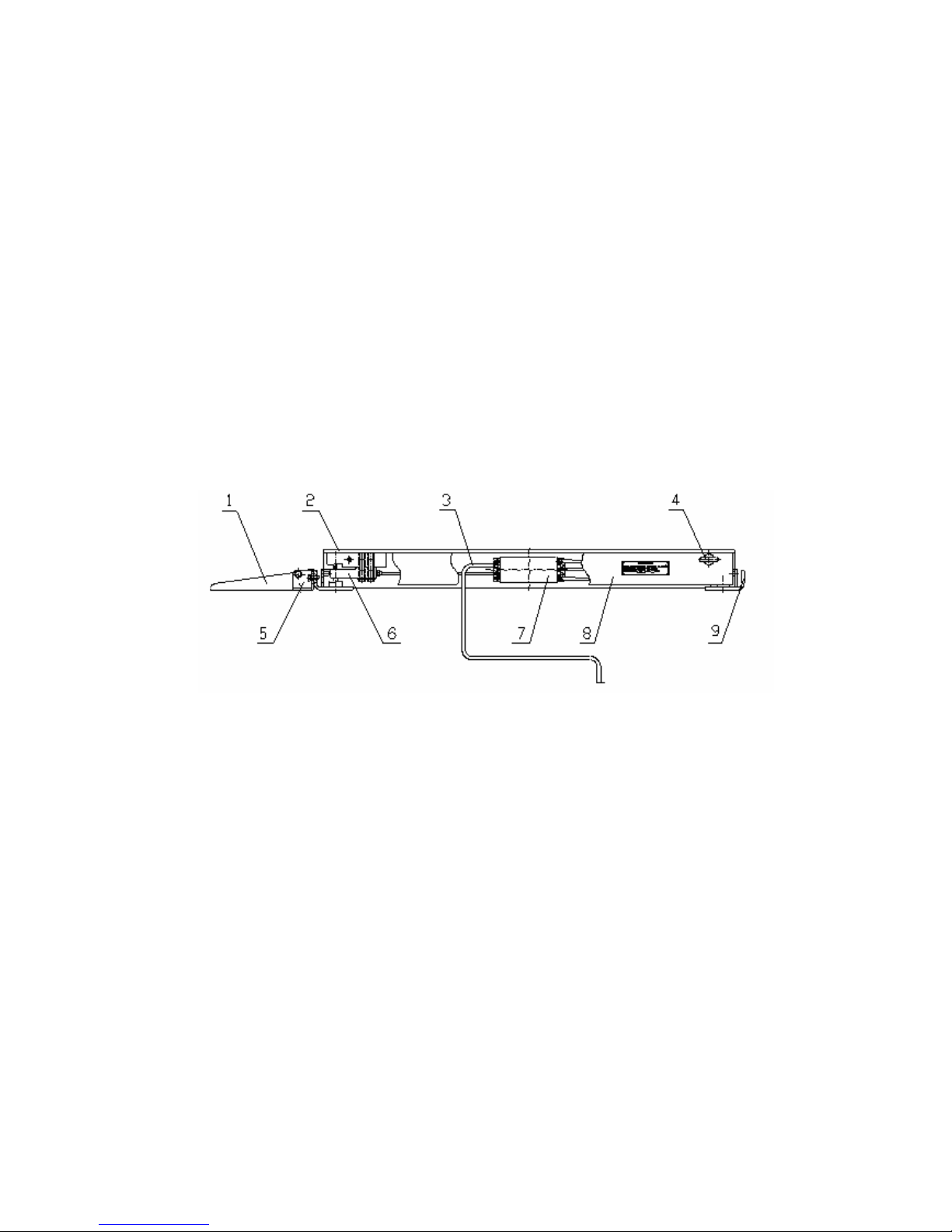

Figure 2-1 Major Components

1 Ramp (Option) 2 Platform

3 Instrument Cable 4 Lifting Eyebolt

5 Connecting Component (ramp) 6 Load Cell

7 Junction box 8 Cover

9 Limit support

Page 3

NTEP/NTNN-IA-defsi-0710

14

2.2 Platform Assembly

The scales have a channel reinforced platform with two angle steel welding on two

sides of platform. The junction box is mounted on the angle steel. The covers on the

angle steel can be removed to gain access to the junction box. Threaded holes are

provided on two sides of platform. When installing or removing a platform, screw lifting eyebolts into these holes and lift the platform by the eyebolts.

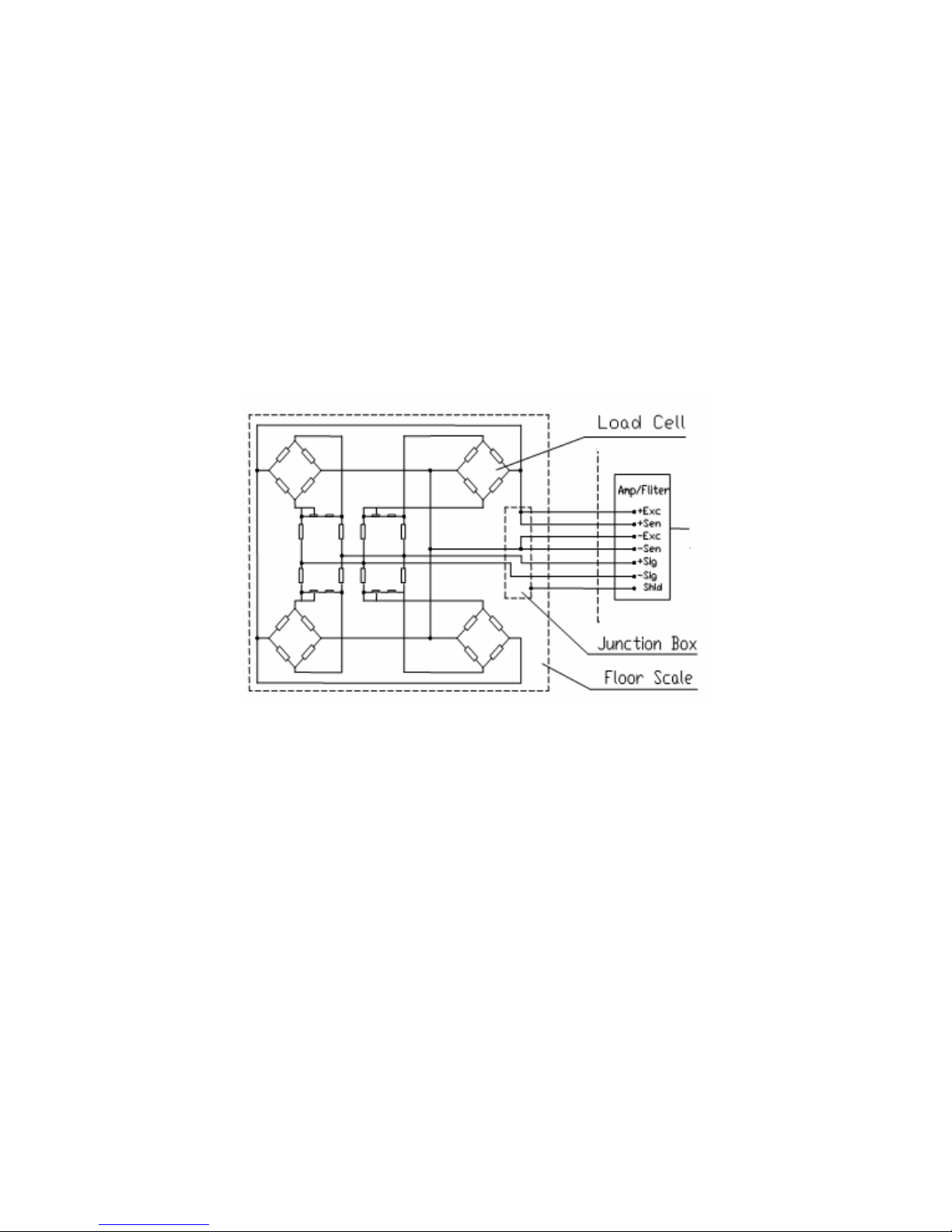

2.3 Working Principle

The elastic body of a load cell deforms under the weight onto the platform. The

Wheatstone bridge bonded to the elastic body loses its resistance balance and outputs an analog electric signal proportional to the weight. See Figure 2-2 for the Wiring

Scheme of Floor Scale with four load cells equipped.

Figure 2-2 Wiring Scheme

Page 4

NTEP/NTNN-IA-defsi-0710

15

3 Specifications

3.1 Load Cell

SBC or SBH shearing beam load cells are provided in all NTEP/NTNN floor scales

with integral 6-conductor, shielded cables (see the table below). The load cell suspension utilizes a rocker pin positioned between the cell and a fixed receiver in the

limit support (see Figure 5-3). The main features of the load cell are:

Recommended Excitation Voltage 6 - 15V (DC/AC)

Maximum Excitation Voltage 20 (DC/AC)

Rated Output 2 ± 0.1% mV/V

Non-linearity 0.02% F.S.

Hysteresis 0.02% F.S.

Repeatability 0.01% F.S.

Creep (30 minutes) 0.02% F.S.

Output Terminal Resistance 350 ± 1 Ohm

Safe Overload 150% F.S.

Ultimate Overload 250% F.S.

Function Color Code Function Color Code

+ Excitation Green - Excitation Black

+ Signal White - Signal Red

+ Sense Yellow - Sense Blue

Shield

Yellow (Thicker)

4 Inspection and Site Selection

4.1 Inspection

Upon delivery of the NTEP/NTNN, visually inspect the scale for any damages which

may have occurred during shipment and handling. Inspect the following areas:

• Platform assembly for any warp.

• Load cell and suspension assemblies.

• Load cell cables.

• Load cell summing junction box.

• Overall platform assembly.

If any damage is found, please contact your freight carrier immediately.

Page 5

NTEP/NTNN-IA-defsi-0710

16

4.2 Site Selection

Many problems associated with floor scale installations are caused by improper site

conditions. Before installing the scale, check the proposed location for the following

conditions:

• The area where the scale will be located should be level to within 4mm

from the highest to the lowest corner.

• The floor at each corner of the scale must be strong enough to maintain

support throughout the entire weighing capacity of the scale.

• There should be proper drainage away from the scale.

• There should be no heavy vibrations or wind currents at or near the scale.

• The scale should not be subjected to excessive or unusual loading due to

the location or type of equipment used.

If the site is acceptable, proceed with the installation. If not, choose a new location or

select another scale.

5 Installation

5.1 Locate

Place the NTEP/NTNN in the desired location after inspecting the site per Section 4

of this manual.

5.2 Installation Procedure

Place the scale to the ideal location – Pre-install the scale - Remove the platform with

eyebolts – Anchor the limit supports – Reinstall the platform - Route the instrument

cable - Check if installed properly.

Page 6

NTEP/NTNN-IA-defsi-0710

17

5.2.1 Place Scale

Install eyebolts in the threaded holes provided on two sides of platform. Ensure that

the eyebolts are snug and fully threaded into the holes before lifting. Utilize the lifting

eyebolts when lifting the platform (see Figure 5-1).

Figure 5-1 Scale Lifting

5.2.2 Pre-install Scale

Disassemble the covers on two sides of platform. Place four limit supports under the

load cells, and install the platform. Oscillate the platform to ensure that the rocker

pins are seated in the receivers on the limit support and no binding exists. Place the

ramp at desired side of platform. Connect the ramp and limit supports by connecting

component with M10×15 bolts.

5.2.3 Remove Platform

Attach a chain or strap to the eyebolts, and lift the platform with a forklift or crane.

Take care to keep the positions of limit supports and connecting components.

5.2.4 Anchor Limit Supports

1. Locate the anchor holes in four limit supports. There are a total of 4 anchor

holes (1 per limit support).

2. Drill the anchor holes, using the limit support as a guide. Four M10 selfexpansion bolts are provided with each NTEP/NTNN floor scale for securing

limit supports to floor (see Figure 5-2).

3. All limit supports must bear pressure applied by platform. If the scale is out-oflevel or a limit support doesn’t bear pressure, shimming is required.

4. Secure the limit supports to the floor by installing the anchors and flat head

socket cap screws. The screws are provided with the scale. Be sure to use flat

head screws to maintain clearance between the head of the screw and the

bottom of the deck throughout the weighing range.

Page 7

NTEP/NTNN-IA-defsi-0710

18

The weighing platform must be aligned with

the use of a water balance.

All foot screws must equally touch the

floor.

5.2.5 Reinstall Platform

1. Clear all debris from the scale area. Ensure that all four load pin receivers in the

limit support are clean and free of foreign material.

Figure 5-2 Top-of-Floor Installation

Figure 5-3 Suspension Details & δ

2. Replace the platform into the limit supports.

3. Oscillate the platform to ensure that the rocker pins are seated in the receivers

and no binding exists.

Page 8

NTEP/NTNN-IA-defsi-0710

19

5.2.6 Route Instrument Cable

1. A loose coil of instrument cable should be stashed inside the angle steel, on

either side of the junction box assembly.

2. Route the instrument cable under the slot provided in the cover, stopping at

the indicator location.

3. Reinstall the covers on two sides of platform.

6 Ramp Installation (Option)

All model NTEP/NTNN floor scales have a single ramp to accommodate single traffic. Order an optional ramp if dual direction traffic required. Select which side(s) of the

scale platform is to have a ramp attachment.

1. Each ramp is shipped complete with an attachment kit of parts: including four

bolts (M10×15), four washers (10) and four spring washers (10) for connecting

ramp and limit support by connecting component.

2. Insert the M10×15 bolts with washers and spring washers through the holes

on connecting component into the threading holes on limit support and ramp

(see Figure 6-1). Tighten the bolts then (see Figure 5-2).

3. Check to make sure that the ramp is stable and the gap S is between 3 ~ 7mm

(see chap. 5.2.5). Otherwise, shim with ϕ10 washers between limit support

and connecting component to meet this requirement.

7 System Connection

Load Cell Wiring Analog Instrument Cable

Function Color Function Color

+ Excitation

Green

+ Excitation

Green

+ Signal White + Signal White

- Excitation

Black

- Excitation

Black

-Signal Red -Signal Red

Shield

Yellow(thicker)

Shield

Yellow/Green

+Sense

Yellow

-Sense

Blue

Figure 7-1 System Connection DWG

Page 9

NTEP/NTNN-IA-defsi-0710

20

8 Technical Data

KERN

NTEP

600K200M

NTEP

1.5T0.5M

NTNN

600K200M

NTNN

1.5T0.5M

Readability 200 g 500 g 200 g 500 g

Weighing range 600 kg 1500 kg 600 kg 1500 kg

Verification value 200 g 500 g 200 g 500 g

Minimum load 4 kg 10 kg 4 kg 10 kg

Accuracy class III

Dimensions (in mm) 1000 x 1000 x 45

Operating temperature -10°C bis 40°C

Operating humidity 10% ~ 95% relative humidity, non-condensing

Loading...

Loading...