KERN ITS 600K200M, ITB 600K200M, ITB 1500K500M, ITS 1500K500M, ITT 600K200M Operating Instructions Manual

...Page 1

Operating Instructions

GB Electronic Platform Balance

KERN ITB

Version 1.0 04/03

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

Tel: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

E-Mail: info@kern-sohn.com

Page 2

Overview of your ITB scale

Rear view

Overview

Display

Keypad

27 26

25

24

1311

10

14

Page 3

Overview

1 Terminal (benchtop version)

2 Operating keys (see detailed illustration)

3 Display (see detailed illustration)

4 Type plate

5 Weighing platform

6 Weighing pan

7 Leveling feet

8 Level indicator (certified scales only)

9 AccuPac (optional)

Rear view

10 Power supply cable

11 Connector cable to weighing platform

13 RS232C interface (standard)

14 AccuPac (optional)

Display

15 Piece counting unit (has no function)

16 Weighing unit

17 Stability detector

18 Changed resolution (certified scales only)

19 Active interface (only displayed if more than one interface is installed)

20 Weighing range

21 Net weight symbol

22 Storage battery charge status (only on scales with storage battery)

23 Dynamic weighing display

Keypad

24 Transfer key

25 Tare key

26 Zeroing key

27 On/off key

Page 4

Contents

4

Contents

1 Setting up the scale .....................................................................................................................................6

1.1 Important ...................................................................................................................................................... 6

1.2 Unpacking and checking the delivered items ....................................................................................................6

1.3 Safety and environment ..................................................................................................................................6

1.4 Selecting a location and leveling the scale .......................................................................................................7

1.5 Connecting the power supply ..........................................................................................................................7

1.6 Monitoring the test substances ........................................................................................................................8

1.7 Verification ....................................................................................................................................................8

2 Weighing ..................................................................................................................................................... 9

2.1 Switching on/off and setting to zero ................................................................................................................. 9

2.2 Simple weighing ............................................................................................................................................ 9

2.3 Weighing with tare .........................................................................................................................................9

2.4 Dynamic weighing ....................................................................................................................................... 10

3 The menu ................................................................................................................................................... 11

3.1 Overview and operation................................................................................................................................ 11

3.2 Calling up the menu and entering the password .............................................................................................11

3.3 Menu overview .............................................................................................................................................12

3.4 Scale settings (SCALE) .................................................................................................................................14

3.4.1 Adjust/calibrate scale (SCALE > Cal) ............................................................................................................ 14

3.4.2 Display accuracy and weighing unit (SCALE > Display) ................................................................................17

3.4.3 Automatic taring (SCALE > A-Tare) .............................................................................................................. 17

3.4.4 Automatic zero point correction (SCALE > A-Zero) .........................................................................................17

3.4.5 Automatic save of tare and zero values (SCALE > Restart) ............................................................................. 18

3.4.6 Aadaptation to environmental conditions and weighing mode (SCALE > Filter) ................................................18

3.4.7 Reset scale settings to factory settings (SCALE > Reset) ................................................................................. 18

3.5 Application settings (APPLICATION)................................................................................................................ 19

3.5.1 Activating the dynamic weighing function (APPLICATION > Dynamic).............................................................. 19

3.5.2 Reset application settings to factory settings (APPLICATION > Reset) ...............................................................19

3.6 Terminal settings (TERMINAL)........................................................................................................................ 20

3.6.1 Standby, energy-saving mode, and display backlighting (TERMINAL > Device) ............................................... 20

3.6.2 Password for menu access (TERMINAL > Access) .........................................................................................21

3.6.3 Reset terminal settings to factory settings (TERMINAL > Reset) ........................................................................ 21

Page 5

Contents

5

3.7 Configure interfaces (COMMUNICATION) .......................................................................................................... 22

3.7.1 Operating mode of interface (COMMUNICATION > Mode) ................................................................................22

3.7.2 Communication parameters (COMMUNICATION > Parameters) ........................................................................ 23

3.7.3 Settings for printed reports (COMMUNICATION > Definition String) ................................................................... 24

3.7.4 Inserting line feeds into the report (COMMUNICATION > Add Line Feed) ...........................................................25

3.7.5 Reset interface settings to factory settings (COMMUNICATION > Reset) .............................................................25

3.8 Diagnosis and printout of menu settings (DIAGNOSTICS) ................................................................................. 25

3.8.1 Checking the keyboard (DIAGNOSTICS > Keyboard) ...................................................................................... 26

3.8.2 Checking the display (DIAGNOSTICS > Display) ............................................................................................26

3.8.3 Display serial number (DIAGNOSTICS > SNR) ............................................................................................... 26

3.8.4 Printing the menu settings (DIAGNOSTICS > List) .......................................................................................... 26

3.8.5 Reset all menu settings to the factory settings (DIAGNOSTICS > Reset All) ........................................................27

3.9 Saving the settings and quitting the menu (End ) ........................................................................................... 27

4 Additional important information ................................................................................................................ 28

4.1 Preconditions for communication between scale and PC .................................................................................28

4.2 Warning and error messages ........................................................................................................................28

4.3 Sample reports ............................................................................................................................................29

4.4 Cleaning instructions .................................................................................................................................... 29

5 Technical data and interface .........................................................................................................................30

5.1 General data and delivered items ..................................................................................................................30

5.2 Dimensions and weights .............................................................................................................................. 31

5.2.1 Terminal ...................................................................................................................................................... 31

5.2.2 Weighing platforms ...................................................................................................................................... 31

5.3 RS232C interface.......................................................................................................................................... 32

5.4 Declaration of conformity ..............................................................................................................................33

5.5 Emergency password .................................................................................................................................. 37

Page 6

Chapter 1: Setting up the scale

6

1 Setting up the scale

Please read these operating instructions carefully and follow them exactly! If you find that any items are missing or incorrect, or if

you have any other problems with your scale, please contact your authorized METTLER TOLEDO representative.

1.1 Important

Various different models of the ITB scale terminal are available. Only the benchtop model is described in these instructions.

If you ordered a wall- or stand-mount terminal, please refer to the installation instructions delivered separately. The AccuPac

(special equipment) can contain a number of options, such as additional interfaces or a storage battery. If you ordered an

AccuPac it will have been configured at the factory with the options you requested and fastened below the terminal. The installation

of an AccuPac after delivery is possible, but it is very costly.

1.2 Unpacking and checking the delivered items

Remove the scale and accessories from the packaging and check the delivered items:

Terminal and weighing plaform with installed weighing pan and level indicator (certified scales only)

Open-end wrench for leveling the weighing platform

Operating instructions (this document)

Special accessories (if any) as per packing list

1.3 Safety and environment

For safe and environmentally harmless operation of your scale, observe the following instructions:

Do not use the scale in hazardous environments (unless it is specially marked).

Although the ITB scale is protected to IP65, it must not be used in environments where

there is a corrosion hazard. Never flood the scale or immerse it in liquids!

If the power supply cable is damaged, the scale must not be used. Check the cable

regularly.

Do not open the weighing platform or terminal since this will void the guarantee. Do

not use rigid objects to clean inside the weighing platform.

Treat the scale with care, it is a precision instrument. Avoid knocking the weighing pan

or placing excessively heavy loads on it.

If the ITB scale will be used in food processing areas: Those parts of the scale

which may come into contact with food have a smooth surface and are easy to clean.

The materials used do not shatter and contain no harmful substances. In food

processing areas, it is advisable to use the protective cover (accessory). This must

be regularly cleaned like the scale itself. A damaged or heavily soiled protective cover

must be replaced immediately.

When disposing of the scale, observe the applicable environmental regulations. If the

scale is fitted with a storage battery, note that the battery contains heavy metals and

must therfore not be disposed of as normal waste! Observe local regulations for disposal

of environmentally harmful substances.

IP 65

Page 7

Chapter 1: Setting up the scale

7

1.4 Selecting a location and leveling the scale

The proper location can influence the accuracy of the weighing results!

Choose a stable, vibration-free flat surface. The surface must be able to bear the

weight of the fully loaded scale safely.

Pay attention to environmental conditions:

No direct sunlight

No strong drafts (e.g. from fans or air conditioning)

No excessive temperature fluctuations

Adjust the scale horizontally by turning the leveling feet, then use the open-end wrench

supplied to tighten the locknuts of all the leveling feet so as to prevent unintentional

movement.

On certified scales, the weighing platform has a level indicator. The air bubble must lie

within the inner circle of the indicator.

Note: The level indicator can be mounted in a different position. Undo the two fastening

screws and move the level indicator to one of the positions provided (drilled holes in

the weighing platform).

Major changes of geographical location

Each scale is adjusted by the manufacturer for the local gravitational conditions (geo

value). If there is a major change of geographical location, this adjustment must be

corrected by a service technician (see chapter 3.4.1). Certified scales must also be

recertified in accordance with local national regulations for certification.

=000Ð

Before connecting the power supply, check that the voltage printed on the back of

the scale is the same as the local power supply. If it is not, do not connect the scale,

and contact your authorized representative.

If the voltage is correct, connect the plug on the power cable to the power supply.

After the scale has been connected, it performs a display test. When the display shows

zero, the scale is ready for operation. For maximum precision, after installing the scale

carry out an adjustment/calibration (Chapter 3.4.1). Important: Certified scales must

be adjusted by an authorized laboratory. Ask your authorized representative.

Scales which have an AccuPac with built-in storage battery can operate under

normal conditions for approx. 30 hours disconnected from the power supply (with

backlighting turned off and no accessories connected). As soon as the power supply

is interrupted, the scale automatically switches over to battery operation. When power

is restored, the scale automatically switches back to power supply operation. The

battery symbol indicates the current charge status of the storage battery (1 segment =

approx. 25% capacity). If the symbol flashes, the storage battery must be recharged

(8 hours minimum). If work continues while recharging, it takes longer. The storage

battery is protected against ovecharging, so the scale can be permanently connected

to the power supply without problem.

1.5 Connecting the power supply

Page 8

Chapter 1: Setting up the scale

8

The metrology features of the balance and any possible available adjusting weight must be checked at regular intervals

within the scope of quality assurance. For this purpose, the answerable user must define a suitable interval as well as

the nature and scope of this check. Information is available on KERNs home page (www.kern-sohn.com) with regard to

the monitoring of balance test substances and the test weights required for this. Test weights and balances can be

adjusted quickly and at a reasonable price in KERNs accredited DKD calibration laboratory (return to national normal).

General:

According to the EU guideline 90/384/EEC balances must be verified officially if they are to be used as follows (legally

regulated area):

a) For commercial transactions if the price of goods is determined by weighing

b) For the production of medines in pharmacies as well as for analyses in the medical and pharmaceutical

laboratory

c) For official purposes

d) For the production of finished packages

In case of doubt, please contact your local office of weights and measures.

Verification information

An EU qualification approval is available for those balances marked as appropriate for verification in the technical data.

In the event that the balance is applied in an area subject to verification as described above, it must be officially verified

and re-verified at regular intervals.

Re-verification of a balance is carried out in compliance with the respective legal provisions of the states. The term of

verification validity for balances in Germany, for example, is normally 2 years.

The legal provisions of the country of use are to be observed.

1.7 Verification

1.6 Monitoring the test substances

Page 9

Chapter 2: Weighing

9

=00Ð

NET

2 Weighing

This chapter explains how you switch the scale on and off, adjust the zero setting, tare the scale, carry out weighings, and record

weighing results.

2.1 Switching on/off and setting to zero

You switch the scale on and off by pressing the key.

After it has been switched on, the scale carries out a display test. When the weight

display appears, the scale is ready for weighing and is automatically set to zero.

Note: The key can be used to set the scale to zero at any time.

2.2 Simple weighing

Place the weighing sample on the pan.

Wait until the stability detector (small ring at left-hand edge of display) goes off and then

read the weighing result.

You can use the key to transmit the weighing result via the interface to a

peripheral device (printer, computer) (see Chapter 4.3 for sample report).

(65Ð

2.3 Weighing with tare

Place the empty weighing container or the packaging material on the weighing pan

and press the key to tare the scale.

The zero display and the NET (net weight) symbol appear. Note: If the automatic

tare function is active (Chapter 3.4.3), you need not press the key, since the first

weight added is taken to be the tare (T flashes in the display until the tare is added).

Page 10

Chapter 2: Weighing

10

Place the weighing sample on the weighing pan and ...

... read the result (net weight of the weighing sample).

Note: The tare weight is retained until either a new tare is determined, or the scale is set

to zero or switched off.

If the automatic taring function is active, the tare is automatically cleared when weighing

is completed and the weighing pan emptied; the scale is then ready for the next taring

and weighing.

"46Ð

NET

2.4 Dynamic weighing

For unstable weighing objects (e.g. animals) the dynamic weighing function with

automatic or manual start can be activated (section 3.5.1). If the dynamic weighing

function is active, the mouse symbol appears at the bottom edge of the display.

With dynamic weighing the scale measures 56 weighing values in 4 seconds and

calculates their mean value.

With dynamic weighing and automatic start the measurement begins automatically as

soon as there is a change in weight.

With dynamic weighing and manual start the measurement is started by touching

the key.

During dynamic weighing, horizontal segments appear in the display, after which the

calculated mean value is displayed. The star symbol at the left-hand edge indicates that

the result is a calculated one. To start a new weighing cycle, the scale must be unloaded.

Note: Only activate the dynamic weighing function to weigh unstable goods. In normal

operation the standard weighing function yields more accurate results more rapidly.

2(55Ð

Page 11

Chapter 3: The menu

11

3The menu

The menu can be used to change the settings for the scale and to activate functions, thereby allowing the scale to be adapted to

individual weighing neeeds.

Important: To avoid incorrect operation of the scale in normal use, the menu can be protected with a password. The scale

differentiates between a user and a supervisor. When the scale leaves the factory, the entire menu can be accessed by both user

and supervisor. We therefore recommend you to define your own supervisor password as soon as you set up the scale

(Chapter 3.6.2). This limits access by the user to a small number of menu items (calibration, and settings for energy-saving

mode and backlighting).

3.1 Overview and operation

Chapter 3.3 contains a complete overview of the menu and all the possible settings.

3.2 Calling up the menu and entering the password

COdE

Press the key and hold it down until the prompt to enter the password appears.

User: No password required, just press the key.

Supervisor: Enter password (sequence of keystrokes) immediately and confirm with

the key, otherwise after a few seconds the scale returns to weighing mode. If an

incorrect password is entered, the menu cannot be called up.

Note: When the scale leaves the factory no supervisor password is defined, so when

the password is requested, just press the key.

If the password entered is correct, the first block of the menu appears (SCALE).

J

○○○○○

Request password

CodE

=.00Ð

Weighing mode

Chapter 3.2

Enter password

- - - -

J

Operator Supervisor

J

Quit menu

End

Diagnosis

d1AGNOS

Interfaces

COMMUN1

Terminal

tERM1NL

Applications

APPL1C

Scale

SCALE

J

J

J

J

J

J

J

J

Chapter 3.4

J

Chapter 3.5

J

Chapter 3.6

J

Chapter 3.7

J

Chapter 3.8 Chapter 3.9

J

Press and hold down (call up menu)

Press key briefly (Yes)

Press key briefly (No)

key jumps direct to end of menu (End)

navigates backward through the menu

If no key is operated for 3 min. the menu is closed (without saving changes

to settings)

J

J

J

Page 12

Chapter 3: The menu

12

3.3 Menu overview

Operation

Press key (Yes)

Press key (No)

key jumps direct to the end of the menu (End)

navigates backward through the menu

0.00 ∆

ãããã

±

±

CodE

0.00 ∆

CAL d1SPLAY

RESOLU

ã 0 ã

6.000∆

0.0001∆

0.05∆

Un1t

Un1t

Un1t

Un1t

RESEt

UN1t

2.000∆

donE

Un1t

NJ

OE

J

R]

W

AãtARE

OFF

ON

Aã2ERO

ON

OFF

REStARt

OFF

ON

FiLtER

V1bRAt

UN1VEr

dOS1NG

PROCESS

LOW

MEd

H1GH

SCALE

SURE?

APPL1C

dYNAM1C

SURE?

RESEt

tERM1NL

SLEEP

OFF

ON

ACCESS

SURE?

RESEt

dEV1CE

PWROFF

YES

NO

b.L1GHt

SUPERV1

ENtER.C

ãããã

REtYPE.C

ãããã

On

OFF

OFF

AUtO

MAnuAL

3

2

3

21

21

* * *

*

*

33

*

*

*

*

4

5

Scale

Applications

Terminal

Page 13

Chapter 3: The menu

13

Menu (continued)

* Factory setting

1) Available settings depend on model.

2) Factory setting depends on model.

3) Not available on certified scales.

4) Not available on scales with storage battery.

5) Not available on scales driven from power supply (without storage battery).

6) Only available for Print and AutoPrint operating modes.

7) Not available for COM2.

8) Only available if Handshake is set to Net 422 or Net 485.

9) In DigiTOL operating modes dtb and dtg the weights to betransmitted can also be specified (tare, net, gross).

0.00 ∆

CON 1

MOdE

CON 2

PARAMEt

bAUd

CONNUN1

H.SHAKE

nEt.Addr

L1NE.FNt

Print

A.Print

CONt1NU

d1ALOG

2nd.d1SP

300

600

1200

2400

4800

9600

19200

38400

7 EVEN

7 nonE

8 nonE

7 odd

HONOFF

nEt 422

nEt 485

NO

0

MULt1

S1NGLE

FORMAt

StdArd

31

L1NE 1

L1NE 20

CUStOM

NOt.USEd

HEAdEr

GROSS

tArE

NEt

StARLN

CrLF

F FEEd

4

0

Add LF

SURE?

rSt.CON.

PAritY

dEFStr

CONt.OLd

d1AL.OLd

dt- b

9

dt- G

9

COnt-IIt

8 EVEN

8 odd

KboARd d1SPLAY

d1AGNOS

PUSH 1

PUSH 10

SURE?

rESEt.ALSNR

0000000

LiSt

End

SAVE

*

*

*

*

7

7

8

*

*

6 6

Interfaces

Diagnosis

Quit menu

Page 14

Chapter 3: The menu

14

Scale settings and functions:

Adjust/calibrate scale > Chapter 3.4.1

Display accuracy and weighing unit > Chapter 3.4.2

Automatic taring > Chapter 3.4.3

Automatic zero point correction > Chapter 3.4.4

Automatic storage of tare and zero values > Chapter 3.4.5

Adaptation to environmental conditions/weighing mode > Chapter 3.4.6

Reset scale settings to factory settings > Chapter 3.4.7

3.4.1 Adjust/calibrate scale (SCALE > Cal )

3.4.1.1 Calibration (adusting) of non verifiable balances

Calling up the menu:

JJJ

J

J

CAL

d1SPLAY

A - tARE

SCALE

JJJ

A - 2ERO

REStARt

FiLtEr

J

RESEt

3.4 Scale settings (SCALE )

Display Explanation

COdE

SCALE

CAL

Press and hold down the key until "CODE" appears.

Press the key.

The first block of the menu is shown.

Press the key.

Display "CAL"

Page 15

Chapter 3: The menu

15

Sequence (adjustment by means of adjusting weights):

Press the key in order to start the calibration procedure.

Display "0."

You will subsequently be asked to adjust your weighing system at a certain value.

In the event that you do not wish to make the adjustment using this value

e.g. because you do not have sufficient weights at your disposal, keep pressing the key until the desired adjusting

weight appears on the display screen (the adjusting weight is reduced each time the key is pressed).

Note: It is recommended in general to adjust the balance when fully loaded

Apply the selected adjusting weight and use the key to confirm.

Successful completion of adjustment is confirmed when done appears on the display screen.

"display will appear automatically on the display screen.

Press the key until "END" appears.

Remove the adjusting weights from the weighing plate!

Press the key order to save the alterations.

SAVE will appear on the display screen.

Press the key to confirm.

Following this the balance will return to weighing mode.

After you exit from the service mode, the scale must be switched off and then

back on again!

3.4.1.2 Calibration (adjusting) of verifiable balances

Switch off the terminal (do not isolate from the power supply!).

Undo the rear cover plate of the terminal (6 Torx T20 screws) and fold down

carefully (cable connections!).

Important: The seal must be broken to remove the rear cover plate. Once the

seal is broken, the scale must be recertified by an approved certification center

and a new seal applied before it can be used again as a certified scale!

The service switch (push button) must first be pressed to call up the service

level. This is recessed and located next to the connector for the weighing

platform (see opposite figure). Use a suitable object or instrument to press

down the switch (the blunt tip of a pencil is recommended). Note: Before

pressing the service switch, the switch of battery-operated terminals

must first be switched on.

The terminal is switched on by pressing the switch, and the first block of the

menu (SCALE) is shown in the display.

Reassemble the rear cover plate of the terminal.

Page 16

Chapter 3: The menu

16

Display SCALE

Press the key

Display METROLO

Press the key until "GEO" appears..

Display GEO (adjustment by means of GEO value)

The GEO value can be set in this block and the balance also adapted to the local gravity ratios without adjusting weights.

Case a)You are familiar with the GEO values.

In this case, adjustment can be carried out without adjusting weights.Once the key has been pressed, the

current GEO value will be displayed. Press the key in order to alter the GEO value. The next value is displayed

every time the key is pressed (adjustment range: 0 - 31). See the GEO value chart in chapter 5.4 for the

appropriate value. Confirm the selected GEO value using the key . LIN-CAL will appear on the display screen

and adjustment is now completed. Press the key until "END" appears. Press the key SAVE will appear on

the display screen.Use the key to confirm. Following this the balance will return to weighing mode.

Please note: The GEO value may not be re-adjusted following this adjustment by means of GEO value, as this

would cause the set adjusting values to become invalid.

Case b)You are NOT familiar with the GEO values.

In this case adjustment must be made using adjusting weights.

Press the key .

Display LIN-CAL

Press the key .

Display CAL (adjustment by means of adjusting weights)

Press the key. PRELOAD will appear on the display screen.

Press the key in ordfer to start the calibration procedure.

You will subsequently be asked to adjust your weighing system at a certain value

In the event that you do not wish to make the adjustment using this value

(e.g. because you do not have sufficient weights at your disposal, keep pressing the key

until the desired adjusting weight appears on the display screen (the adjusting weight is

reduced each time the key is pressed).

Note: It is recommended in general to adjust the balance when fully loaded

Apply the selected adjusting weight and use the key to confirm.

Successful completion of adjustment is confirmed when done appears on the display screen.

"display will appear automatically on the display screen.

Press the key until "END" appears.

Remove the adjusting weights from the weighing plate!

Press the key order to save the alterations.

SAVE will appear on the display screen.

Press the key to confirm.

Following this the balance will return to weighing mode.

After you exit from the service mode, the scale must be switched off and then

back on again!

Page 17

Chapter 3: The menu

17

J

JJ

J

J

J

J

J J

d1SPLAY

RESOLU

oz

kg

lb

t

UN1t

J

J

J

J

JJ

=0001Ð

=05Ð

J

3.4.2 Display accuracy and weighing unit (SCALE > Display)

Display Explanation

Block can only be accessed by supervisor.

Display accuracy (resolution):

Setting values and factory setting depend on model.

On certified scales, resolutions which deviate from the scale

definition are displayed without the weighing unit and with

a star symbol (weighing result does not correspond to

calibrated resolution). On dual-range balances resolutions

marked with I<>I 1/2 are spread over two weighing

ranges (e.g. B 2 x 3,000d).

Weighing unit (factory setting according to type plate):

Kilogram

Ounce (not availble on certified scales)

Pound (not available on certified scales)

Ton (metric ton)

Gram

g

OFF

On

A - tARE

J

J

J

J

Block can only be accessed by supervisor.

Automatic taring function switched off (factory setting).

Automatic taring function switched on. The first weight placed on the scale

isinterpreted as the tare.

3.4.3 Automatic taring ( SCALE > A-Tare)

Display Explanation

J

Can only be accessed by supervisor. Not available on certified scales.

Auto zero switched on (factory setting).

Auto zero switched off (display can be set to zero manually with the key).

On

OFF

A - 2ERO

J

J

J

J

3.4.4 Automatic zero point correction (SCALE > A-Zero)

Display Explanation

Page 18

Chapter 3: The menu

18

Resets all scale settings to the factory settings. This block can only be accessed by

the supervisor.

Confirm resetting or cancel.

J

SURE?

RESEt

J

J

3.4.7 Reset scale settings to factory settings (SCALE > Reset )

Display Explanation

J

J

J

J

Block can only be accessed by supervisor. Not available on certified scales.

Automatic save switched off (factory setting).

Automatic save switched on, last tare and zero values are saved and are available

again after a power outage or switching off.

OFF

On

REStARt

J

J

J

J

3.4.5 Automatic save of tare and zero values (SCALE > Restart )

Display Explanation

J J

FiLtEr

V1bRAt

dOS1NG

UN1VEr

PROCESS

J

J

J

MEd

H1GH

J

J

3.4.6 Aadaptation to environmental conditions and weighing mode (SCALE > Filter)

Display Explanation

Block can only be accessed by supervisor.

Environmental conditions (vibration adapter):

Normal environmental conditions (medium): scale operates

at medium speed (factory setting).

Unstable environment (high): scale operates more slowly but

is less sensitive to external influences.

Very stable and stable enviroment (low): scale operates very

quickly but is more sensitive to external influences.

Weighing mode (weighing process adapter):

Universal setting for all weighing types and normal weighing

goods (factory setting).

Dispensing liquids or powdery substances.

LOW

J

J

J

J

Page 19

Chapter 3: The menu

19

Application settings: can only be accessed by supervisor!

Activate dynamic weighing function > Chapter 3.5.1

Reset application settings to factory settings > Chapter 3.5.2

This function facilitates weighing unstable weighing goods (e.g. animals).

Dynamic weighing function switched off (factory setting).

Dynamic weighing function with automatic start switched on (for notes on use, see

Chapter 2.4).

Dynamic weighing function with manual start switched on (for notes on use, see

Chapter 2.4).

JJ

APPL1C

J

J

dYNAMIC

RESEt

3.5 Application settings (APPLIC ATION)

Display Explanation

Resets all application settings to the factory settings.

Confirm resetting or cancel.

J

SURE?

RESEt

J

J

J

3.5.2 Reset application settings to factory settings (APPLICATION > Reset )

Display Explanation

J

OFF

AUtO

dYNAM1C

J

J

J

MAnuAL

J

J

3.5.1 Activating the dynamic weighing function (APPLICATION > Dynamic)

Display Explanation

Page 20

Chapter 3: The menu

20

JJJ

Only the Device block is available to the user!

Standby, energy-saving mode, and display backlighting > Chapter 3.6.1

Password for menu access > Chapter 3.6.2

Reset terminal settings to factory settings > Chapter 3.6.3

JJJ

tERM1NL

J

J

dEV1CE

ACCESS

RESEt

3.6 Terminal settings (TERMINAL)

Display Explanation

Can be accessed by user!

Standby (only for scales operated from power supply):

Standby switched off, display permanently activated (factory

setting).

Standby switched on. If there is no activity for 3 minutes,thedisplay and backlighting are deactivated (SLEEP). They arereactivated when a key is pressed or the weight is changed.

Energy saving mode (for battery-operated scales only):

Energy saving mode active. If there is no activity for 3 minutes,

the scale is switched off (factory setting).

Energy saving mode inactive, scale does not switch off automatically.

Display backlighting:

Backlighting switched on (factory setting). Battery-operated

scales: switches off automatically after 5 seconds.

Backlighting switched off.

J J

dEV1CE

SLEEP

NO

YES

PWROFF

J

J

J

OFF

ON

J

J

J

J

J

3.6.1 Standby, energy-saving mode, and display backlighting (TERMINAL > Device)

Display Explanation

J

OFF

On

b.L1GHt

J

J

Page 21

Chapter 3: The menu

21

Can only be accessed by supervisor!

Define supervisor password:

Prompt to enter password.

Enter password (min. 1, max. 4 characters) and confirm with

.

Important: The key cannot be used as part of thepassword because it terminates the input! If is pressedim-

mediately after the entry prompt, the existing password is

cleared. The user then has complete access to the menu again.

The key can only be used in combination with at least one

other key!

Re-enter the password and confirm with .

Resets all terminal settings to the factory settings. Only the settings in the Device

block are reset, not the password for menu access.

Confirm resetting or cancel.

J

SURE?

RESEt

J

J

J

3.6.3 Reset terminal settings to factory settings (TERMINAL > Reset)

Display Explanation

J

J

ACCESS

SUPERV1

J

J

ENtER.C

- - - -

J

J

REtYPE.C

J

3.6.2 Password for menu access (TERMINAL > Access)

Display Explanation

Page 22

Chapter 3: The menu

22

Configures the scale interfaces: can only be accessed by supervisor!

Standard interface COM1 (RS232C).

Optional interface COM2 (RS232C).

Settings:

Operating mode of interface > Chapter 3.7.1

Communication parameters > Chapter 3.7.2

Settings for printed reports > Chapter 3.7.3

Insert line feeds into printed reports > Chapter 3.7.4

Reset interface settings to factory settings > Chapter 3.7.5

Manual data output on printer ( key). Factory setting.

Automatic output of stable results on printer (for series weighings).

Continuous output of all weight values via the interace.

Bidirectional communication using MT-SICS commands (to control scale from a PC).

Same as Continuous (see above), but with 2 fixed blanks before the unit (compatible

with KERN TB/TS/TT).

Same as Dialog (see above), but scale sends 2 fixed blanks before the

unit(compatible with KERN TB/TS/TT).

DigiTOL-compatible format. Weights for transfer can be selected: tare, net, gross

(gross weight is marked with B).

Same as dtb mode (see above) but gross weight is marked with G.

Continuous Weight mode.

Connects a second display.

COMMUN1

J

J

COM 1

COM 2

J

3.7 Configure interfaces (COMMUNICATION )

Display Explanation

J

A. Print

CONt1NU

d1ALOG

2nd.d1SP

Print

J

J

J

J

J

J

J

J

J

J

J

J

CONt.OLd

d1AL.OLd

dt - b

dt - G

COnt - Wt

MOdE

3.7.1 Operating mode of interface (COMMUNICATION > Mode)

Display Explanation

Page 23

Chapter 3: The menu

23

Parameters on the connected device (printer, PC, second

display) must be set to the same values:

Interface data transmission rate:

300 baud 38400 baud. Factory setting = 2400 baud.

Number of data bits and parity:

7 data bits, even parity (factory setting)

8 data bits, odd parity

8 data bits, even parity

7 data bits, no parity

8 data bits, no parity

7 data bits, odd parity

Factory setting depends on operating mode of interface.

Transmission protocol:

Xon/Xoff protocol (factory setting).

Not documented

Not documented

No communication protocol.

Not documented

J J J J

J

PARAMEt

nEt 422

nEt 485

NO

J

J

J

J

J

J

JJJJ

31

300

38400

J

J

J

J

J

J

J

J

8 EVEN

J

J

J

7 nonE

8 nonE

7 odd

8 odd

JJJ

0

nEt.Addr

H.SHAKE

HONHOFF

PAritY

7 EVEN

bAUd

3.7.2 Communication parameters (COMMUNICATION > Parameters)

Display Explanation

Page 24

Chapter 3: The menu

24

Only available for Print and A.Print operating modes

(Chapter 3.7.1).

Report formatting:

Each value on the report is printed on a separate line (factory

setting).

Several values are printed on one line.

Data to be reported:

Standard report (factory setting) containing report header,

gross, net, and tare weight (if present). For piece counting, also

reference piece weight, number of reference pieces, and result

of piece counting.

Defines customized report:

Defines the values to be reported on up to 20 report lines.

The following settings are available for each line:

Report line not used (factory setting).

Report header

Gross weight

Tare weight

Net weight

Line of stars (Starline)

Line feed (for empty line)

Form feed for label printer.

J

J

J J

J

J

○○

S1NGLE

MULt1

StdArd

CUStOM

dEFStr

L1NE.FMt

FORMAt

GROSS

tArE

NEt

StARLN

CrLF

F FEEd

HEAdEr

NOt.USEd

L1NE 20

L1NE 1

J

J

J

J

J

J

3.7.3 Settings for printed reports (COMMUNICATION > Definition String)

Display Explanation

Page 25

Chapter 3: The menu

25

J

J

Inserts additional line feeds at the end of the report. On printers with tear-off edge

(e.g. Sprinter printer) the paper can be fed forward far enough for the report to be

torn off. Only available for Print and A.Print operating modes (Chapter 3.7.1):

4 additional line feeds at end of report (factory setting).

No additional line feeds at end of report.

J

4

0

SURE?

Add LF

rSt.COM1

rSt.COM 2

J

J

J

J

JJ

J

J

3.7.4 Inserting line feeds into the report (COMMUNICATION > Add Line Feed)

Display Explanation

3.7.5 Reset interface settings to factory settings (COMMUNICATION > Reset)

Display Explanation

Resets all settings in the COMMUNICATION menu block to the factory settings.Resetting

only affects the selected interface (COM1 or COM2).

Confirms or cancels resetting. After confirmation the scale uses the factory settings

again.

Can only be accessed by supervisor!

Check keyboard > Chapter 3.8.1

Check display > Chapter 3.8.2

Display serial number > Chapter 3.8.3

Print menu settings > Chapter 3.8.4

Reset all menu settings to factory settings > Chapter 3.8.5

JJJ

d1AGNOS

J

J

KboARd

d1SPLAY

SNR

J

LiSt

J

rESEt. AL

3.8 Diagnosis and printout of menu settings (DIAGNOSTICS)

Display Explanation

Page 26

Chapter 3: The menu

26

J

○○○○○○○○

J

KboARd

PUSH 1

PUSH 4

J

○○○○○○○○○○

J

J

d1SPLAY

J

J

J

J

1234567

SNR

J

J

J

LiSt

1432

NJ

WE]

3

&6

1(7

&RP

SOFTWARE VER 21-2.00

SNR :1234567

METROLO :NO APPr

SCAL.TYP :2MULT.RN

BAS.UNIT :k g

SCL.CAP1 :15.000 kg

RESOL.1 :0.005 kg

SCL.CAP2 :30.00 kg

RESOL.2 :0.01 kg

Press all 4 keys in sequence. If a key is functioning, the scale jumps to the next key.

The keys are numbered as follows:

3.8.1 Checking the keyboard (DIAGNOSTICS > Keyboard)

Display Explanation

The scale displays the functioning segments. Check whether all segments are visible

(compare with illustration on first inside page of these instructions).

3.8.2 Checking the display (DIAGNOSTICS > Display)

Display Explanation

Serial number of ITB-scale (max. 7 characters).

3.8.3 Display serial number (DIAGNOSTICS > SNR )

Display Explanation

Menu settings for the ITB-scale are output on a printer (see sample printout in

Chapter 4.3).

3.8.4 Printing the menu settings (DIAGNOSTICS > List)

Display Explanation

Page 27

Chapter 3: The menu

27

Resets all menu settings to the factory settings. Caution: All the individual settings

are lost except for the supervisor password (TERMINAL menu block), thecalibration data and the settings in the COMMUNICATION block!

Confirm resetting or cancel.

J

SURE?

rESEt.AL

J

J

J

3.8.5 Reset all menu settings to the factory settings (DIAGNOSTICS > Reset All)

Display Explanation

You can go directly to this menu block from any point in the menu by using the

key!

Save the changed settings or cancel.

J

SAVE

End

J

J

J

3.9 Saving the settings and quitting the menu (End )

Display Explanation

=00Ð

Page 28

Chapter 4: Additional important information

28

4 Additional important information

In this chapter you will find information about the interface commands, error messages, and cleaning your scale.

4.1 Preconditions for communication between scale and PC

The scale must be connected to the RS232C interface of a PC by a suitable cable.

The interface of the scale must be set to Dialog mode (Chapter 3.7.1).

The PC must have a terminal program installed on it.

The communication parameters (data transmission rate, bits, and parity) in the terminal program must be set to the same

values as on the scale (Chapter 3.7.2).

Definition of the journal header

Up to 5 lines, each with a maximum of 24 characters, can be defined and these appear at the beginning of every

journal that is printed off. The company name and address are generally inserted into the journal. The journal

header can be configured using the demo version of the BalanceConnection version 3.0 PC software. This demo

version is freely available at www.Kern-Sohn.com.

4.2 Warning and error messages

Overload: Reduce the load on the scale or reduce the preload.

Underload: Place the weighing pan on the scale and ensure it can move freely.

Result not stable: Always appears when not stable (when zeroing, taring, etc.). If the scale still does not

become stable after a long time, check the environmental conditions. If necessary, change the setting of

the vibration adapter (Chapter 3.4.6) or use the dynamic weighing function (Chapter 2.4/3.5.1).

Function not allowed: The requested function cannot be executed because it is not allowed at the time

of the request.

Zeroing not possible: Make sure that zeroing is being performed in the allowed range and not with

overload or underload.

Not calibrated/adjusted: Disconnect the power supply plug and reconnect it (or if the scale is batteryoperated, switch it off and then on again). If the message appears again, calibrate/adjust scale (Chapter

3.4.1). If message still appears, contact your authorized representative.

EAROM checksum error: Disconnect the power supply plug and reconnect it (or if the scale is batteryoperated, switch the scale off and then on again). If the message re-appears, contact your authorized

representative.

неееем

î____ï

гггггг

ããnoãã

òãnoãô

î_no_ï

Err 6

Err 53

Page 29

Chapter 4: Additional important information

29

4.3 Sample reports

Weighing with tare Dynamic weighing Printout with report header

G = gross weight

N = net weight

T = tare

Dyn WT = dynamically determined weight

Printout of scale settings (List, Chapter 3.8.4)

4.4 Cleaning instructions

Before you start to clean your scale, disconnect it from the power supply!

Use a moist cloth (no acids, caustics, or strong solvents).

Do not use abrasive cleaning agents, they can scratch the display.

Do not clean the scale with a high-pressure cleaner or under running water.

If heavily soiled, remove the weighing pan, protective cover (if present), and leveling

feet, and clean them separately.

Never use a rigid object to clean under the load plate support when the weighing pan

is removed!

Observe the regulations of your company and industry with regard to cleaning

intervals and permitted cleaning agents.

Dyn WT 43.52 kg

T 3.78 kg

G 4.876 kg

T 0.223 kg

N 4.653 kg

RS232

MODE 1:Print

BAUD 1:2400

PAriTY 1:7 EVEN

H.SHAKE 1:XONXOFF

LINE.FMT 1:MULTI

FORMAT 1:StdArd

ADD LF 1:4

MODE 2:Print

BAUD 2:2400

PAriTY 2:7 EVEN

H.SHAKE 2:XONXOFF

LINE.FMT 2:MULTI

FORMAT 2:StdArd

ADD LF 2:4

J

SOFTWARE VER 21-2.00

SNR :1234567

METROLO :NO APPr

SCAL.TYP :2MULT.RN

BAS.UNIT :kg

SCL.CAP1 :15.000 kg

RESOL.1 :0.005 kg

SCL.CAP2 :30.00 kg

RESOL.2 :0.01 kg

GEO :18

DISPLAY

RESOLU :0.005 kg

UNIT :kg

A-TARE :OFF

A-ZERO :ON

RESTART :OFF

VIBRAT :MED

PROCESS :UNIVEr

DYNAMIC :OFF

SLEEP :OFF

B.LIGHt :ON

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

Telefon +49-(0)7433/9933-0

Internet www.kern-sohn.com

G 4.876 kg

T 0.223 kg

N 4.653 kg

Page 30

Chapter 5: Technical data, interfaces, and accessories

30

5 Technical data and interface

In this chapter you will find technical specifications for your scale and information about standards and directives.

5.1 General data and delivered items

Applications Weighing

Dynamic weighing

Settings Selectable resolution

Selectable weighing unit

Automatic taring function

Automatic zeroing (at switchon and during operation)

Filter for adaptation to environmental conditions (vibration adapter)

Filter for adaptation to weighing mode, e.g. dispensing (weighing process adapter)

Switchoff function, standby and energy-saving modes

Display backlighting

Display Liquid crystal display (LCD), 23 mm high, backlit, with linear weighing range display

Interface 1 RS232C interface built in (for data s. Chapter 5.3), optional interfaces available

Environmental conditions Accuracy is guaranteed in the following ranges:

Temperature range: 10 ... +40 °C / 14 ... 104 °F

Relative air humidity: 15 ... 85% rh (noncondensing)

Overvoltage category: II

Pollution degree: 2

Dimensions See Chapter 5.2.2

Standard delivery package Complete scale

Operating instructions

Open-end wrench (for leveling)

Page 31

Chapter 5: Technical data, interfaces, and accessories

31

G

B

A

D

C

F

E

5.2 Dimensions and weights

5.2.1 Terminal

A

1)

B C D E (AccuPac)

1)

Dimensions 71mm 36mm 200mm 277mm 49mm

Net weight 3.5 kg

1)

Without fixed feet (with fixed feet: +4.5 mm)

5.2.2 Weighing platforms

1)

With leveling feet fully screwed in

D

B

A

E

C

Side view Front view

AccuPac AccuPac

ITB6K0.2IP/ITB6K1DIPM

ITB15K0.5IP/ITB15K2DIPM

ITB35K1IP/ITB35K5DIPM

ITB60K2LIP/ITB60K10DLIPM

ITB150K5IP/ITB150K20DIPM

ITB60K2XLIP/ITB60K10DXLIPM

ITB150K5LIP/ITB150K20DLIPM

ITB300K10IP/ITB300K50DIPM

ABCD1)EFG

Modell [mm] [mm] [mm] [mm] [mm] [mm] [mm]

175 240 62 80 235 300 22

235 300 66 86 335 400 22

335 400 66 86 435 500 22

435 500 85 100 587 650 22

Page 32

Chapter 5: Technical data, interfaces, and accessories

32

53214

6789

Standard ITB-scales are fitted with one voltage interface according to EIA RS-232C/

DIN 66020 (CCITT V24/V.28, maximum cable length 50 ft /15 m).

The illustration at left shows the numbering of the individual pins (looking onto the

socket). The pin designations for the different interfaces are shown in the

followingtables.

Standard interface

Interface type: RS232C

Pin 1 VCC

Pin 2 TxD 1

Pin 3 RxD 1

Pin 4 Not available for connection

Pin 5 GND

Pin 6 Not available for connection

Pin 7 Not available for connection

Pin 8 Not available for connection

Pin 9 VCC

TxD: transmit data RxD: receive data GND: signal ground VCC: supply voltage +5 V

5.3 RS232C interface

Page 33

Chapter 5: Technical data, interfaces, and accessories

33

5.4 Declaration of conformity

Konformitätserklärungen

Declaration of conformity for apparatus with CE mark

Konformitätserklärung für Geräte mit CE-Zeichen

Déclaration de conformité pour appareils portant la marque CE

Declaración de conformidad para aparatos con disitintivo CE

Dichiarazione di cofnromitá per apparecchi contrassegnati con la marcatura CE

English

We hereby declare that the product to which this declaration refers conforms with the

following standards.

Deutsch

Wir erklären hiermit, daß das Produkt, auf das sich diese Erklärung bezieht, mit den

nachstehenden Normen übereinstimmt.

Français

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la présente

déclaration, est conforme aux normes citées ci-après.

Español

Manifestamos en la presente que el producto al que se refiere esta declaración est´´a de

acuerdo con las normas siguientes

Italiano

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si riferisce è

conforme alle norme di seguito citate.

Balance lines: ITB/ITS/ITT (with maximum capacity Max < 600kg)

Plattform line: TP

Mark applied EU Directive Standards Approval/Test-

certificate N°

73/23/EEC

93/68/EEC

Low Voltage

EN61010-1

EN60529

89/336/EEC

93/68/EEC

92/31/EEC

EMC

EN61326-1 Kl. B (Emission)

EN61326-1

EN61000-3-2

EN61000-3-3

[year] [code] M 1)

90/384/EEC

93/68/EEC

Non automatic

weighing Instruments

1), 2), 3)

EN45501 1),

2), 3) T6189 1), 2)

TC6194 1), 2)

1) applies only to certified balances

gilt nur für geeichte Waagen

valable uniquement pour les balances vérifiées

sólo aplicable a balanzas verficadas

la dichiarazione vale solo per le bilance omologate

2) valid only for ITB/ITS/ITT terminals in connection with approved load cells

nur gültig für ITB/ITS/ITT Terminals in Verbindung mit zugelassenen Lastzellen

valable uniquement pour les termineaux ITB/ITS/ITT en liaison avec des cellules de charge homologuées

sólo válido para terminales ITB/ITS/ITT en combinación con células de carga aprobadas

valido solo per terminali ITB/ITS/ITT in collegamento con celle di carico approvate

3) valid only for TP weighing platforms in connection with an approved weighing indicator

nur gültig für TP Wägebrücken in Verbindung mit einem zugelassenen Waagenterminal

valable uniquement pour les plates-formes TP en liaison avec un terminal de pesée homologué

sólo válido para plataformas de pesaje TP en combinatión con un terminal de balanza aprobado

valido solo per basamenti TP in collegamento con un terminale di pesata approvato

Page 34

Chapter 5: Technical data, interfaces, and accessories

34

M

M

Floor Scale: ITB 600K200M, ITB 1500K500M

ITS 600K200M, ITS 1500K500M,

ITT 600K200M, ITT 1500K500M

EU Directive Standards Approval/Test-certificate N°

73/23/EEC

93/68/EEC

Low Voltage

EN61010-1

89/336/EEC

93/68/EEC

92/31/EEC

EMC

EN61326-1 Kl. B

(Emission)

EN61326-1

EN61000-3-2

EN61000-3-3

90/384/EEC

93/68/EEC

Non automatic weighing

Instruments 1), 2), 3)

EN45501 1), 2), 3) T6189 1), 2)

TC6194 1), 2)

English

Weighing instruments verified at the place of manufacture bear the preceeding mark on the packing label

and a green M-sticker on the descriptive plate. They may be set to work immediately.

Weighing instruments which are verified in two steps has no green "M" on the descriptive plate, bear the

aforementioned identification on the packing label. The second step of te verification must be carried out by

the W&M authorities.

The first step of the verification has been carried out in the manufacturing company. It comprises all tests according EN45501-

8.2.2. In regards to scales with analog connection to the weighing-platform, a weighing test according to EN45501-3.5.3.3

must be carried out additionally. This test ist not necessary if the terminal bears the serial-number of the weighing-platform.

Deutsch

Werksgeeichte Waagen tragen vorstehendes Kennzeichen auf dem Packetikett und eine grünen M-Kleber.

auf dem Eichschild.

Sie dürfen sofort in Betrieb genommen werden.

Waagen die in zwei Schritten geeicht werden und kein grünes "M" auf dem Eichschild haben, tragen

vorstehendes Kennzeichen auf dem Packetikett.

Der zweite Schritt der Eichung ist durch den Eichbeamten durchzuführen.

Der erste Schritt der Eichung wurde im Herstellerwerk durchgeführt. Er umfaßt alle Prüfungen gemäß EN45501-8.2.2.

Bei Waagen mit analogen Wägebrückenanschluss muß zusätzlich die Richtigkeit gemäß EN45501-3.5.3.3 geprüft werden.

Diese Prüfung ist nicht notwendig, wenn das Terminal die Serien-Nr. der Wägebrücke trägt.

Français

Les instruments de pesage vérifiés en usine sont identifiés par un M sur leur emballage et par un sticker M vert sur

la plaque d'identification.

Ils peuvent être utilisés aprés leur installation.

Les instruments de pesage vérifiés en deux étapes portent l'identification M barré sur leur emballage. La seconde

étape de la vérification doit être effectuée par l’assistant téchnique de l’administration des poids et mesures.

La première étape de la vérification a été effectuée en usine. Cela comprend tous les essais suivant la norme EN45501-8.2.2. Pour

les instruments de pesage avec une connexion analogique à la plate-forme de pesage, un essai de pesage suivant la norme

EN45501-3.5.3.3 droit être effectué en plus. Cela n'est pas nécessaire si le terminal porte le numéro de la plate-forme de pesage.

Español

Las básculas verificadas en origen llevan esta indicación en la etiqueta del embalaje y con la etiqueta M

sobre fondo verde en la placa de caracteristicas pueden ser utilizadas inmediatamente.

Básculas cuya verificación se realiza en dos fases llevan esta indicación en la etiqueta del embalaje. La

segunda fase de la verificación debe ser realizada por el asistente técnico de la oficina de contraste.

La primera fase de la verificatión ha sido realizada en origen. Incluye todos los ensayos según la norma EN45501-8.2.2. Para

las básculas con plataforma de pesaje con salida analogica debe realizarse además el ensayo según EN45501-3.5.3.3.

Este ensayo no es necesario si el terminal lleva el número de la plataforma de pesaje.

M

M

M

M

M

M

Page 35

Chapter 5: Technical data, interfaces, and accessories

35

Italiano

Le bilance verificate in fabbrica portano questo contrassegno sull'etichetta dell'imballo e con il siglio M su

sfondo verde sulla targhetta metrologica possono essere messe in uso immediatamente.

Le bilance che vengono verificate in due fasi, portano questo contrassegno sull'etichetta dell'imballo. La

seconda fase della verifica deve essere eseguita dal dal servizio asistenza technica dell'ufficio di pesi e

misure.

La prima fase della verifica è stata eseguita dal produttore e comprende tutte le prove previste dalla norma di riferimento

EN45501-8.22. Riguardo le bilance con connesione analogica a plattaforma di pesata, una ulteriore prova deve essere

eseguita in accordo alla norma EN45501-3.5.3.3. Questa prova non è necessaria se il terminale porta il numero di serie della

plattaforma.

Netherlands

In de fabriek geijkte weegschalen dragen dit kenteken op het emballage-etiket en een groene M-sticker op

het ijklabel.

Deze kunnen meteen in gebruik genomen worden.

Bij weegschalen die in twee stappen geijkt moeten worden en geen groene “M” op het ijklabel hebben, staat

dit kenteken op het emballage-etiket.

De tweede stap van de ijking moet door het ijkwezen uitgevoerd worden.

De eerste stap van de ijking werd in de fabriek uitgevoerd. Deze stap omvat alle tests overeenkomstig EN45501-8.2.2.

Bij weegschalen met een analoge weegbruggenaansluiting moet aanvullend de nauwkeurigheid overeenkomstig EN45501-

3.5.3.3 getest worden.

Deze controle is niet nodig als de terminal het serienummer van de weegbrug heeft.

Date: 21.03.2003 Signature:

Gottl. KERN & Sohn GmbH

Management

Gottl. KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-[0]7433/9933-0,Fax +49-[0]7433/9933-149

M

M

M

M

Page 36

Chapter 5: Technical data, interfaces, and accessories

36

Notice

Certified balances and balances used for legal applications have the EU type approval. The year of

the initial verification is shown next to the CE mark. Such balances are verified in the factory and carry

the „M“ mark on the actual balance and the packaging. The year of initial verification is shown next to

the CE mark. The GEO value of verified balances explains for which location of use the balance has

been verified. This GEO value is shown on the balance itself and on the packing. Further details see

GEO value table.

Hinweise

Für geeichte/eichpflichtige Waagen liegt eine EU Bauartzulassung vor. Das Jahr der ersten Eichung

ist neben dem CE Zeichen aufgeführt. Solche Waagen sind ab Werk geeicht und tragen die

Kennzeichnung „M“ auf dem Gerät selbst und auf der Verpackung. Der GEO-Wert gibt bei vom

Hersteller geeichten Waagen an, für welchen Aufstellungsort die Waage geeicht ist. Dieser GEO-Wert

befindet sich auf der Waage sowie der Verpackung. Genaueres ist der GEO-Wert-Tabelle zu

entnehmen.

Remarques

Les balances vérifiées/admissibles à la vérification font l’objet d’une approbation de modèle UE.

L’année de la vérification primitive est indiqués à côté de la marque CE. Ces balances sont vérifiées

d’origine et portent la marque „M“ sur l’appareil lui-même et sur l’emballage. Le valeur GEO indique le

lieu d’utilisation pour lequel la balance été vérifiée. Ce valeur GEO se trouve sur la balance ainsi que

sur l’emballage. Veuillez trouver plus de détails dans le tableau GEO.

Notas

Las balanzas verificadas/verificables cuentan con una aprobación de modelo UE. El año de la primera

verificación está indicado al lado del distintivo CE. Estas balanzas están verificadas en fábrica y llevan

la designación „M“ sobre el propio aparato y sobre el embalaje. El valor GEO indica el lugar de

ubicación por lo cual la balanza está verificado. El valor se encuentra sobre la balanza así como sobre

el embalaje. Por favor toman demßas detalles de la tabla GEO.

Avvertenza

Per le bilance approvate esiste un’approvazione CE del tipo. L´anno della prima verifica è indicato a

fianco della marcatura CE. I tipi marcati con un contrassegno „M“ su sfondo verde peino possono

essere impiegati da subito. Il coefficiente GEO di bilance omolgate indca per quale luogo la bilancia è

stata omologata. Questo coefficiente GEO si trova sulla bilancia e sull’imballo. Ulteriroi informazioni

vedi tabella coefficente GEO.

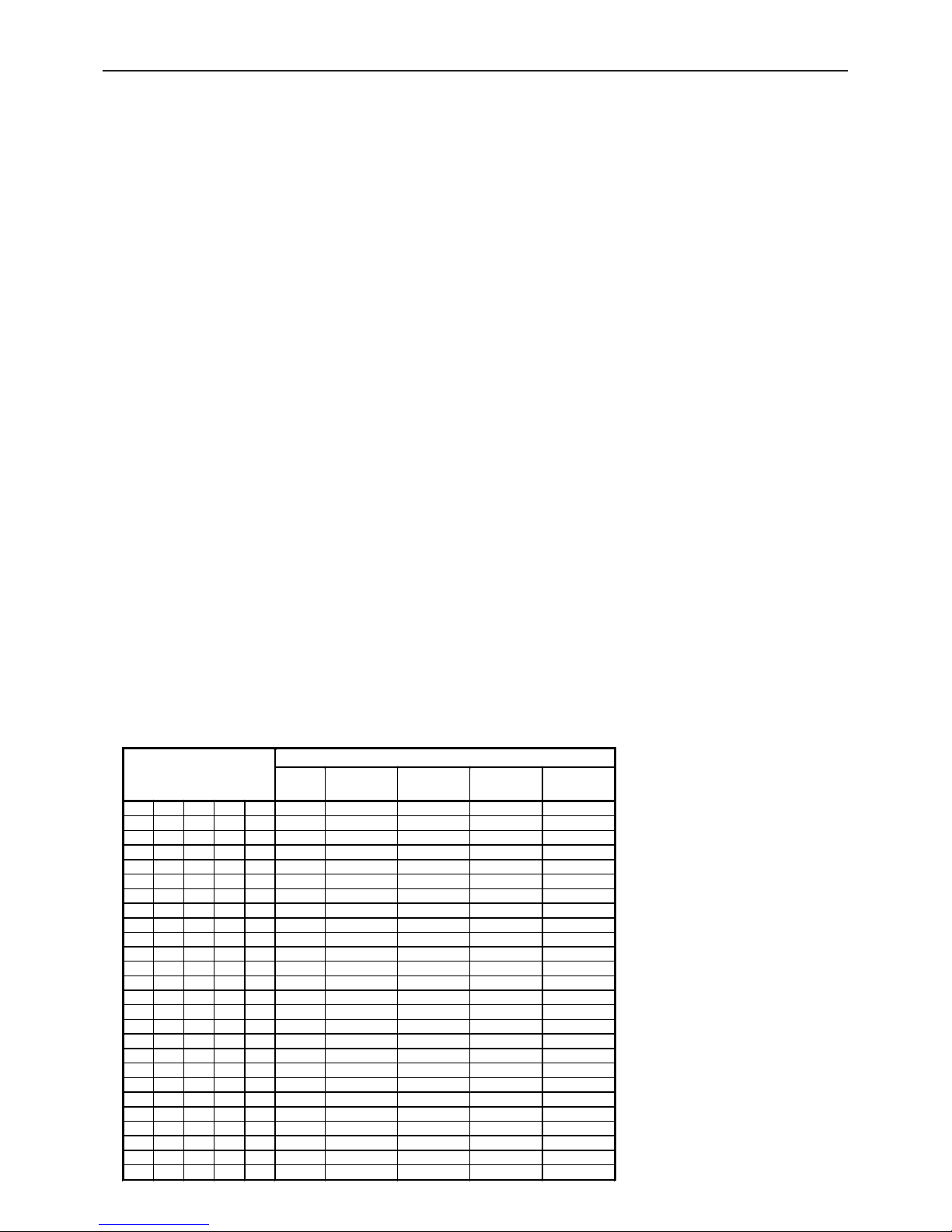

GEO-WERT-Tabelle / GEO-value table

Höhe über Meer in Metern / altitude

geographische

Breite /geographical latitude

0-650 650-1300 1300-1950 1950-2600 2600-3250

0° 0‘ - 9° 52‘

4 / 5 3 / 4 2 / 3 1 / 2 0 / 1

9° 52‘ - 15° 6‘

5 / 6 4 / 5 3 / 4 2 / 3 1 / 2

15° 6‘ - 19° 2‘

6 / 7 5 / 6 4/ 5 3 / 4 2 / 3

19° 2‘ - 22° 22‘

7 / 8 6 / 7 5 / 6 4 / 5 3 / 4

22° 22‘ - 25° 21‘

8 / 9 7 / 8 6 / 7 5 / 6 4 / 5

25° 21‘ - 28° 6‘

9 / 10 8 / 9 7 / 8 6 / 7 5 / 6

28° 6‘ - 30° 41‘

10 / 11 9 / 10 8 / 9 7 / 8 6 / 7

30° 41‘ - 33° 9‘

11 / 12 10 / 11 9 / 10 8 / 9 7 / 8

33° 9‘ - 35° 31‘

12 / 13 11 / 12 10 / 11 9 / 10 8 / 9

35° 31‘ - 37° 50‘

13 / 14 12 / 13 11 / 12 10 / 11 9 / 10

37° 50‘ - 40° 5‘

14 / 15 13 / 14 12 / 13 11 / 12 10 / 11

40° 5‘ - 42° 19‘

15 / 16 14 / 15 13 / 14 12 / 13 11 / 12

42° 19‘ - 44° 32‘

16 / 17 15 / 16 14 / 15 13 / 14 12 / 13

44° 32‘ - 46° 45‘

17 / 18 16 / 17 15 / 16 14 / 15 13 / 14

46° 45‘ - 48° 58‘

18 / 19 17 / 18 16 / 17 15 / 16 14 / 15

48° 58‘ - 51° 13‘

19 / 20 18 / 19 17 / 18 16 / 17 15 / 16

51° 13‘ - 53° 31‘

20 / 21 19 / 20 18 / 19 17 / 18 16 / 17

53° 31‘ - 55° 52‘

21 / 22 20 / 21 19 / 20 18 / 19 17 / 18

55° 52‘ - 58° 17‘

22 / 23 21 / 22 20 / 21 19 / 20 18 / 19

58° 17‘ - 60° 49‘

23 / 24 22 / 23 21 / 22 20 / 21 19 / 20

60° 49‘ - 63° 30‘

24 / 25 23 / 24 22 / 23 21 / 22 20 / 21

63° 30‘ - 66° 24‘

25 / 26 24 / 25 23 / 24 22 / 23 21 / 22

66° 24‘ - 69° 35‘

26 / 27 25 / 26 24 / 25 23 / 24 22 / 23

69° 35‘ - 73° 16‘

27 / 28 26 / 27 25 / 26 24 / 25 23 / 24

73° 16‘ - 77° 52‘

28 / 29 27 / 28 26 / 27 25 / 26 24 / 25

77° 52‘ - 85° 45‘

29 / 30 28 / 29 27 / 28 26 / 27 25 / 26

Page 37

Chapter 5: Technical data, interfaces, and accessories

37

Emergency password for supervisor access to menu

Please cut out and keep in a safe place!

Use this emergency password if you have defined a supervisor password and then forgotten it.

Press the key 3 times,

followed by .

5.5 Emergency password

ME-Nr.:22009676

Loading...

Loading...