Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen-Frommern

E-Mail: info@kern-sohn.com

Tel: 0049-[0]7433- 9933-0

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.com

GB

Service Manual

Compact Scales

Platform Balances and Terminals

Page 3

KERN FTB/FTC

KERN ITB/ITS/ITT

KERN KMB/KMS/KMT-TM

Version 2.0 03/2007

Page 2

FTx/ITx-SH-e-0720 3

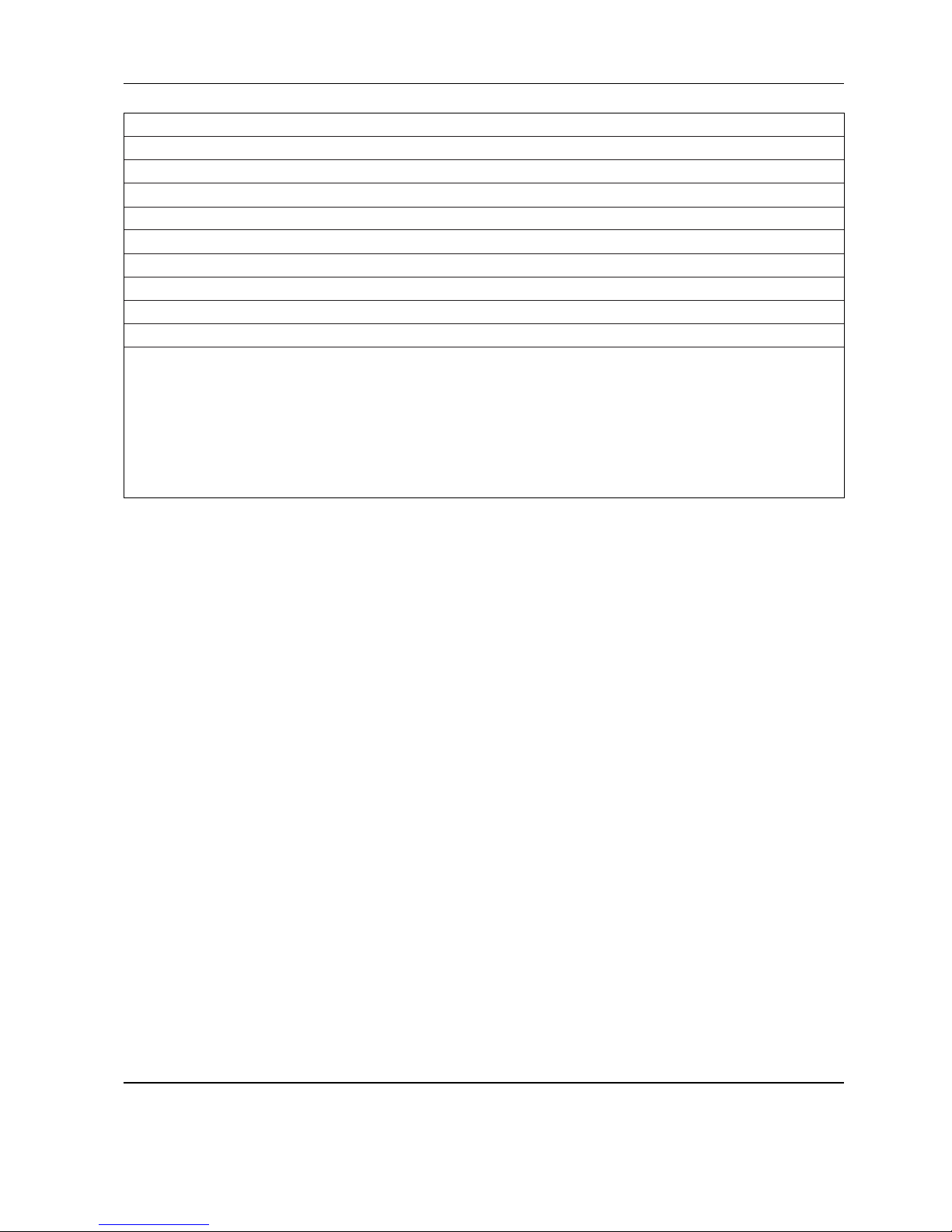

Contents

1 General .......................................................................................................................................... 5

1.1 How to use this service manual? ....................................................................................................... 5

1.2 Service concept ............................................................................................................................... 5

1.3 Introducing the product group ........................................................................................................... 6

1.4 Safety notes..................................................................................................................................... 7

2 Compact scales, small platform FTB/FTC (weighing pan 200x240mm) ............................................. 8

2.1 Scales with strain gauge weighing cells ............................................................................................. 8

2.2 Scales with strain gauge weighing cell and IP65 protection ................................................................. 12

2.3 Display unit FTB ............................................................................................................................... 16

2.4 Display unit FTC ............................................................................................................................... 18

3 Compact scales, large platform FTB/FTC (weighing pan 240x350mm) .............................................. 20

3.1 Scales with strain gauge weighing cell .............................................................................................. 20

3.2 Scales with strain gauge weighing cell and IP65 protection ................................................................. 25

3.3 Display unit FTB ............................................................................................................................... 29

3.4 Display unit FTC ............................................................................................................................... 31

4 Terminals ....................................................................................................................................... 33

4.1 KMB-TM terminal (ITB) ...................................................................................................................... 33

4.2 KMS-TM terminal (ITS) ...................................................................................................................... 35

4.3 KMT-TM terminal (ITT) ....................................................................................................................... 37

4.4 OptionPac ....................................................................................................................................... 39

4.5 Small parts set................................................................................................................................. 41

5 Replacing components with compact scales .................................................................................... 42

5.1 Important notes ............................................................................................................................... 42

5.2 Replacing the keypad overlay ........................................................................................................... 43

5.3 Replacing the AC adapter.................................................................................................................. 43

5.4 Replacing the battery ........................................................................................................................ 43

5.5 Replacing the charging PCB .............................................................................................................. 44

5.6 Replacing the analog PCB ................................................................................................................ 44

5.7 Replacing the display mounting plate, display unit and digital PCB ...................................................... 45

5.8 Replacing the weighing cell .............................................................................................................. 47

Page 3

4 FTx/ITx-SH-e-0720

6 Repair of terminals ......................................................................................................................... 49

6.1 Important information ....................................................................................................................... 49

6.2 Disassembling/reassembling the terminal .......................................................................................... 49

6.3 Replacing the keypad overlay ........................................................................................................... 50

6.4 Replacing the AC adapter.................................................................................................................. 50

6.5 Replacing the analog board.............................................................................................................. 50

6.6 Replacing the display mounting plate, display unit, and digital board .................................................. 51

6.7 Repairing the OptionPac ................................................................................................................... 53

7 Scale definition, settings and diagnostics ...................................................................................... 54

7.1 Accessing and using the technician menu ......................................................................................... 54

7.2 Technician menu – Overview ............................................................................................................ 55

7.3 Admissibility for certification (SCALE –> Metrology) ............................................................................. 56

7.4 Selecting the scale to be configured (SCALE –> Scale 1/Scale 2) ......................................................... 56

7.5 Querying the value of the analog/digital converter (SCALE –> Ramp) ................................................... 56

7.6 Serial number of the scale or terminal (SCALE –> Serial Number) ........................................................ 56

7.7 Entering configuration data (SCALE –> Scale Build) ...........................................................................56

7.8 Setting the GEO adjustment value (SCALE –> Geo Value) .................................................................... 58

7.9 Linearization with simultaneous calibration (SCALE –> LIN-CAL) .......................................................... 58

7.10 Basic calibration (SCALE –> Calibration) ........................................................................................... 59

7.11 Activating control mode (SCALE –> Control Mode) .............................................................................. 59

7.12 Settings for the zero point (SCALE –> Zero) ....................................................................................... 59

7.13 Defining MinWeigh value (SCALE–> Minweigh) .................................................................................. 60

7.14 Settings in the “TERMINAL” menu block .............................................................................................. 60

7.15 Setting of country version ................................................................................................................. 60

8 Additional information .................................................................................................................... 61

8.1 Technical data and tolerances .......................................................................................................... 61

8.2 Notes on load cell capacities ............................................................................................................ 66

8.3 Overview of load cells and preloads .................................................................................................. 67

8.4 Table of geo values.......................................................................................................................... 68

8.5 Interface data .................................................................................................................................. 69

8.6 Attaching weighing platforms ............................................................................................................ 71

9 Software ......................................................................................................................................... 74

9.1 Software architecture ........................................................................................................................ 74

9.2 Error messages after service work ..................................................................................................... 75

9.3 Deleting the scale data in the EAROM ................................................................................................. 75

9.4 Loading new scale software into Flash memory .................................................................................. 76

Page 4

FTx/ITx-SH-e-0720 5

1 General

1.1 How to use this service manual?

This service manual contains instructions for the repair and maintenance work to be performed by service engineers.

It is assumed that the reader is familiar with the operation of the scale and can refer to the relevant operating instructions when

necessary.

1.1.1 Layout of this service manual

This manual comprises nine main sections:

• General: This section which you are looking at now gives instructions on using the service manual, and also provides an

overview of the scales covered by it.

• FTB/FTC (small platform): This section contains the exploded view drawings and spare parts lists for compact scales

with the small platform (weighing pan 200 x 240 mm).

• FTB/FTC (large platform): This section contains the exploded view drawings and spare parts lists for compact scales

with the large platform (weighing pan 240 x 350 mm).

• KMB-/KMS-/KMT-TM: This section contains the exploded view drawings and spare parts lists for terminals.

• Replacing components with compact scales: This section describes all repair work and the replacement of components

for compact scales with large and small platforms. It also contains a list of the tools and working aids required.

• Replacing components with terminals: This section describes all repair work and the replacement of components for

terminals. It also contains a list of the tools and working aids required.

• Scale definition, settings and diagnostics: This section describes how to enter scale setup data, make various settings

and use the diagonstic functions.

• Additional information: This section contains certification tolerances and other technical information plus an overview of all

weighing cells and preloads and a table of geographical adjustment values.

• Software: This section contains information on the various software versions and their compatibility. It also describes

typical error messages that can appear following service work and provides troubleshooting instructions.

1.1.2 Working with the service manual

The exploded view drawings are provided as a guide for disassembly and assembly work and for identifying the order

numbers for spare parts.

When ordering spare parts, please use the information given in the spare parts lists. The item numbers in the first column

"Item" correspond to those on the exploded view drawing opposite.

1.2 Service concept

The scales have been designed so that defective components can be replaced with just a few simple tools. Technician mode

and supervisor mode will already be familiar to you, since this concept has already been used in other KERN & SOHN

products. As almost all parameters can be configured with the keyboard of the scale.

As you can see, we have kept it simple for efficient servicing.

Page 5

6 FTx/ITx-SH-e-0720

1.3 Introducing the product group

The product group comprises the following models, which are all covered by this manual:

FTB, ITB, KMB-TM

The FTB-,ITB-scales and the KMB-terminal possess basic weighing functions for simple weighing duties. They are IP65

versions.

FTC, ITS, KMS-TM

In addition to basic weighing functions, counting scales also have built-in functions for piece counting. An extended keypad

and a display with a visual weighing-in aid are available in order to use these additional functions.

ITT, KMT-TM

In addition to the simple piece counting functions these scales have a numeric keypad as well as totalising, checking and

ID functions.

Common features

Apart from the differences with regard to functions and operating and display elements, all models have the following

common features:

– All models are designed either for direct connection to the AC power line or contain a built-in rechargeable battery.

Rechargeable battery scales are connected to the AC power line via an AC adapter.

– All models are also available as certifiable instruments.

– The weighing cells are strain gauge.

Page 6

FTx/ITx-SH-e-0720 7

1.4 Safety notes

When carrying out service or repair work, always observe the following:

1.5 Environmental protection

Disposal of rechargeable batteries

Please note all current environmental directives when disposing of the terminal. If

the terminal is equipped with a rechargeable battery: The nickel-metal-hydride

(NiMH) storage battery may not be disposed of in the normal refuse. Please

observe local regulations when disposing of environmentally harmful materials.

Disposal of electronic components

Dispose of defective components in strict compliance with all local and national

regulations! In many countries electronic components are classified as hazardous

waste for whose disposal there are special regulations. In some countries

electronic components are collected separately for recycling. If necessary, find out

the applicable regulations from the local authorities!

• Before opening the scale, isolate it from the AC power line (pull out the plug).

• The scales contain precision electronic components that are sensitive to elec-

trostatic discharge. We recommend that you wear a grounding wrist strap

when doing any work in the interior of the scale, in order to prevent any

electrostatic charge building up. Grounding wrist straps are commercially

available from electronic component suppliers.

• Servicing work in explosion hazard zones is strictly prohibited! Ignition

power could inadvertently be generated, causing an explosion. Servicing work

should therefore only be undertaken in secure areas. Please also observe all

special instructions in this service manual relating to work on instruments that

are approved for use in potentially explosive environments. Such instructions

are indicated by the adjacent symbol.

Page 7

8 FTx/ITx-SH-e-0720

2 Compact scales, small platform

FTB/FTC (weighing pan 200x240mm)

2.1 Scales with strain gauge weighing cells

2

3

4

1

6

7

5

8

Page 8

FTx/ITx-SH-e-0720 9

Item Qty. Description Order No.

1 1 weighing pan 200 x 240 mm 21203071

2 4 rubber cushions

1)

21203073

3 2 countersunk Torx screw M6 x 30 *

4 1 pan support plate 200 x 240 mm –

5 1 housing, with small platform –

6 1 keypad overlay Chap. 2.3 – 2.4

7 1 mounting plate and display unit (digital PCB with LCD and backlighting unit) Chap. 2.3 – 2.4

8 2 EMV clamp 21203480

* included in the small parts set (Chapter 4.5)

1)

New rubber cushions have a hole in the surface to assist with assembly. A pin can be used to insert the cushion into the

corresponding drilled hole in the load plate support

Page 9

10 FTx/ITx-SH-e-0720

Scales with strain gauge weighing cells (continued)

1

2

3

6

5

4

7

8

9

10

16

11

17

15

13

12

18

14

19

19c

19d

19b

19a

Page 10

FTx/ITx-SH-e-0720 11

Item Qty. Description Order No.

1 4 adjustable foot Ø 44 mm (M10 x 0.75 mm) 21203434

2 6 countersunk Torx screw M4 x 12 *

3 1 bottom plate for small platform model –

4 4 button head Torx screw M4 x 12 *

5 4 wide flange washer 4.3 x 20 *

6 4 overload spring **

7 1 overload stop adjustment screw (with certain production series only) **

8 2 countersunk Torx screw M6 x 16 *

9 1 overload plate for small platform model –

10 1 weighing cell with cable (certifiable)

weighing range 3 kg:

LC0765-5-MRV (Standard cell) 21203873

LC0765-5-6TV (Premium cell) 21203877

weighing range 6 kg:

LC0765-10-MRV (Standard cell) 21203874

LC0765-10-6TV (Premium cell) 21203878

11 1 bench AC adapter (always order together with item 16):

EURO version 22011363

USA version 22011364

UK version 22011365

JAPAN version 22011366

Australian version 22011367

external power supply unit (battery charger) for operation with a storage battery

(without power cable) 22011300

socket for external power supply unit 22011311

12 2 spring clip *

13 1 analog PCB BBA AN DMS 7k 21203092

14 1 RS cable 460 mm 21203168

15 1 A/D cable 110 mm, for small platform model 21203164

16 1 adhesive patch for AC adapter or battery (for battery version order 2 pcs.) 21203184

17 1 RS connector plate –

(various types, depending on the equipment)

18 4 raised cheese head Torx screw M4 x 6 *

19 for scales with AccuPac only:

19a 1 accu 14.4V NiMH (always order together with item 16) 22011349

19b 1 battery connection cable –

19c 1 print charger NiMH 22011351

19d 1 battery cable (charging PCB – analog PCB) 21203233

*included in the small parts set (Chapter 4.5) ** see Chapter 5.8 "Replacing the weighing cell"

19d 1

battery cable (charging PCB - analog PCB)

21203233

Page 11

12 FTx/ITx-SH-e-0720

2.2 Scales with strain gauge weighing cell and IP65 protection

1

2

3

4

5

6

7

8

9

Page 12

FTx/ITx-SH-e-0720 13

Item Qty. Description Order No.

1 1 packing for cover plate 21203235

2 1 cover plate –

3 2 countersunk Torx screw M3 x 8 *

4 1 flange D = 100mm –

5 1 diap hragm 21203077

6 1 flange D = 58mm –

7 3 countersunk Torx screw M3 x 10 *

8 4 countersunk Torx screw M3 x 8 *

9 2 EMC clamp 21203480

* included in the small parts set (Chapter 4.5)

Note: Parts of the scale not numbered in the illustration are included in the normal version (Chapter 2.1).

Page 13

14 FTx/ITx-SH-e-0720

Scales with strain gauge weighing cell and IP65 protection (continued)

6

2

1

3

5

4

8

10

9

8

10

9

Page 14

FTx/ITx-SH-e-0720 15

Item Qty. Description Order No.

1 1 bottom plate for small platform model IP65 version 21203511

2 1 RS connector plate IP65 version (various types, depending on the equipment) –

3 1 air supply/extraction filter 21203860

4 1 packing for RS connector plate 21203236

5 6 raised cheese head Torx screw M4 x 6 *

6 1 RS cable 460mm IP65 21203717

8 1 pressure equalizer 21203611

9 1 pressure equalizer tube LA 21203862

10 1 adhesive patch for pressure equalizer 21203184

* included in the small parts set (Chapter 4.5)

Note: Parts of the scale not numbered in the illustration are included in the normal version (Chapter 2.1).

Page 15

16 FTx/ITx-SH-e-0720

2.3 Display unit FTB

1

2

3

4

5

6

Page 16

FTx/ITx-SH-e-0720 17

Item Qty. Description Order No.

1 1 keypad overlay for small platform model 22011400

2 1 display mounting plate (always order together with item 1) 21203120

3 1 LCD 21203134

4 1 backlighting unit 21203136

5 1 digital PCB with FLASH Memory Chip (soldered)

1)

21204025

6 1 Torx oval head tapping screw 2.9 x 13 (red) *

* included in the small parts set (Chapter 4.5)

1)

see Chapter 9.4 for information on loading the software

Page 17

18 FTx/ITx-SH-e-0720

2.4 Display unit FTC

1

2

3

4

5

6

Page 18

FTx/ITx-SH-e-0720 19

Item Qty. Description Order No.

1 1 keypad overlay for small platform model 22011401

2 1 BC display mounting plate (always order together with item 1) 21203120

3 1 LCD 21203687

4 1 backlighting unit 21203137

5 1 Digital PCB with FLASH Memory Chip soldered

1)

21204025

6 1 Torx oval head tapping screw 2.9 x 13 (red) *

* included in the small parts set (Chapter 4.5)

1)

see Chapter 9.4 for information on loading the software

Page 19

20 FTx/ITx-SH-e-0720

2

3

4

1

6

7

5

8

3 Compact scales, large platform

FTB/FTC (weighing pan 240x350mm)

3.1 Scales with strain gauge weighing cell

Page 20

FTx/ITx-SH-e-0720 21

Item Qty. Description Order No.

1 1 weighing pan 240 x 350 mm 21203072

2 4 rubber cushions

1)

21203073

3 2 countersunk Torx screw M6 x 30 *

4 1 pan support plate 240 x 350 mm –

5 1 housing, large platform –

6 1 keypad overlay Chap. 3.3 – 3.4

7 1 mounting plate and display unit (digital PCB with LCD and backlighting unit) Chap. 3.3 – 3.4

8 2 EMC clamp 21203480

* included in the small parts set (Chapter 4.5)

1)

New rubber cushions have a hole in the surface to assist with assembly. A pin can be used to insert the cushion into the

corresponding drilled hole in the load plate support

Page 21

22 FTx/ITx-SH-e-0720

Scales with strain gauge weighing cell (continued)

1

3

2

7

5

4

11

16

17

18

14

19

19c

19d

19b

19a

10

9

8

6

12

15

13

Page 22

FTx/ITx-SH-e-0720 23

Item Qty. Description Order No.

1 4 adjustable foot Ø 55mm (M10 x 0.75 mm) 21203433

2 11 countersunk Torx screw M4 x 10 *

3 1 bottom plate for large platform model –

4 4 button head Torx screw M5 x 12 *

5 4 wide flange washer 5.3 x 20 *

6 4 overload spring **

7 1 overload stop adjustment screw (with specific production series only) **

8 2 countersunk Torx screw M6 x 16 *

9 1 overload plate for large platform model –

10 1 weighing cell with cable (certifiable)

weighing range 15 kg:

LC0785-20-MRV (standard cell) 21203885

LC0785-20-6TV (premium cell) 21203889

weighing range 35 kg:

LC0785-50-MRV (standard cell) 21203886

LC0785-50-6TV (premium cell) 21203890

weighing range 60 kg:

LC0785-100-MRV (standard cell) 21203887

LC0785-100-6TV (premium cell) 21203891

11 1 bench AC adapter (always order together with item 16):

EURO version 22011363

USA version 22011364

UK version 22011365

JAPAN version 22011366

Australian version 22011367

external power supply unit (battery charger) for operation with a storage battery

(without power cable) 22011300

socket for external power supply 22011311

12 2 spring clip *

13 1 analog PCB BBA AN DMS 7k 21203092

14 1 RS cable 460 mm 21203168

15 1 A/D cable 300 mm for large platform model 21203167

16 1 adhesive patch for AC adapter 21203184

2 adhesive patch for battery, thick 21255260

2 adhesive patch for battery, thin 21203184

17 1 RS connector plate (various types, depending on the equipment) –

18 4 raised cheese head Torx screw M4 x 8 *

Page 23

24 FTx/ITx-SH-e-0720

19 for scales with with AccuPac only:

19a 1 accu 14,4V NiMH (always order together with item 16) 22011349

19b 1 battery connection cable –

19c 1 print charger NiMH 22011351

19d 1 battery cable (charging PCB – analog PCB) 21203233

* included in the small parts set (Chapter 4.5)

** see section 5.8 "Replacing the weighing cell"

Page 24

FTx/ITx-SH-e-0720 25

8

1

2

3

4

5

6

7

9

3.2 Scales with strain gauge weighing cell and IP65 protection

Page 25

26 FTx/ITx-SH-e-0720

Item Qty. Description Order No.

1 1 packing for cover plate 21203235

2 1 cover plate –

3 2 countersunk Torx screw M3 x 8 *

4 1 flange D = 100 mm –

5 1 diaphrag m 21203077

6 1 flange D = 58 mm –

7 3 countersunk Torx screw M3 x 10 *

8 4 countersunk Torx screw M3 x 8 *

9 2 EMC clamp 21203480

* included in the small parts set (Chapter 4.5)

Note: Parts of the scale not numbered in the illustration are included in the normal version (Chapter 3.1).

Page 26

FTx/ITx-SH-e-0720 27

Scales with strain gauge weighing cell and IP65 protection (continued)

1

6

2

3

5

4

8

10

9

Page 27

28 FTx/ITx-SH-e-0720

Item Qty. Description Order No.

1 1 bottom plate for large platform model IP65 version 21203512

2 1 RS connector plate IP65 version (various types, depending on the equipment) –

3 1 air supply/extraction filter 21203860

4 1 packing for RS connector plate 21203236

5 6 raised cheese head Torx screw M4 x 8 *

6 1 RS cable 460 mm IP65 21203717

8 1 pressure equalizer 21203611

9 1 pressure equalizer tube LA 21203862

10 1 adhesive patch for pressure equalizer 21203184

* included in the small parts set (Chapter 4.5)

Note: Parts of the scale not numbered in the illustration are included in the normal version (Chapter 3.1).

Page 28

FTx/ITx-SH-e-0720 29

3.3 Display unit FTB

1

2

3

4

5

6

Page 29

30 FTx/ITx-SH-e-0720

Item Qty. Description Order No.

1 1 keypad overlay for large platform model 22011404

2 1 display mounting plate (always order together with item 1) 21203120

3 1 LCD 21203134

4 1 backlighting unit 21203136

5 1 digital PCB with FLASH Memory Chip (soldered)

1)

21204025

6 1 Torx oval head tapping screw 2.9 x 13 (red) *

* included in the small parts set (Chapter 4.5)

1)

see Chapter 9.5 for information on loading the software

Page 30

FTx/ITx-SH-e-0720 31

3.4 Display unit FTC

1

2

3

4

5

6

Page 31

32 FTx/ITx-SH-e-0720

Item Qty. Description Order No.

1 1 keypad overlay for large platform model 22011404

2 1 display mounting plate (always order together with item 1) 21203120

3 1 LCD 21203134

4 1 backlighting unit 21203136

5 1 digital PCB with FLASH Memory Chip (soldered)

1)

21204025

6 1 Torx oval head tapping screw 2.9 x 13 (red) *

* included in the small parts set (Chapter 4.5)

1)

see Chapter 9.5 for information on loading the software

Page 32

FTx/ITx-SH-e-0720 33

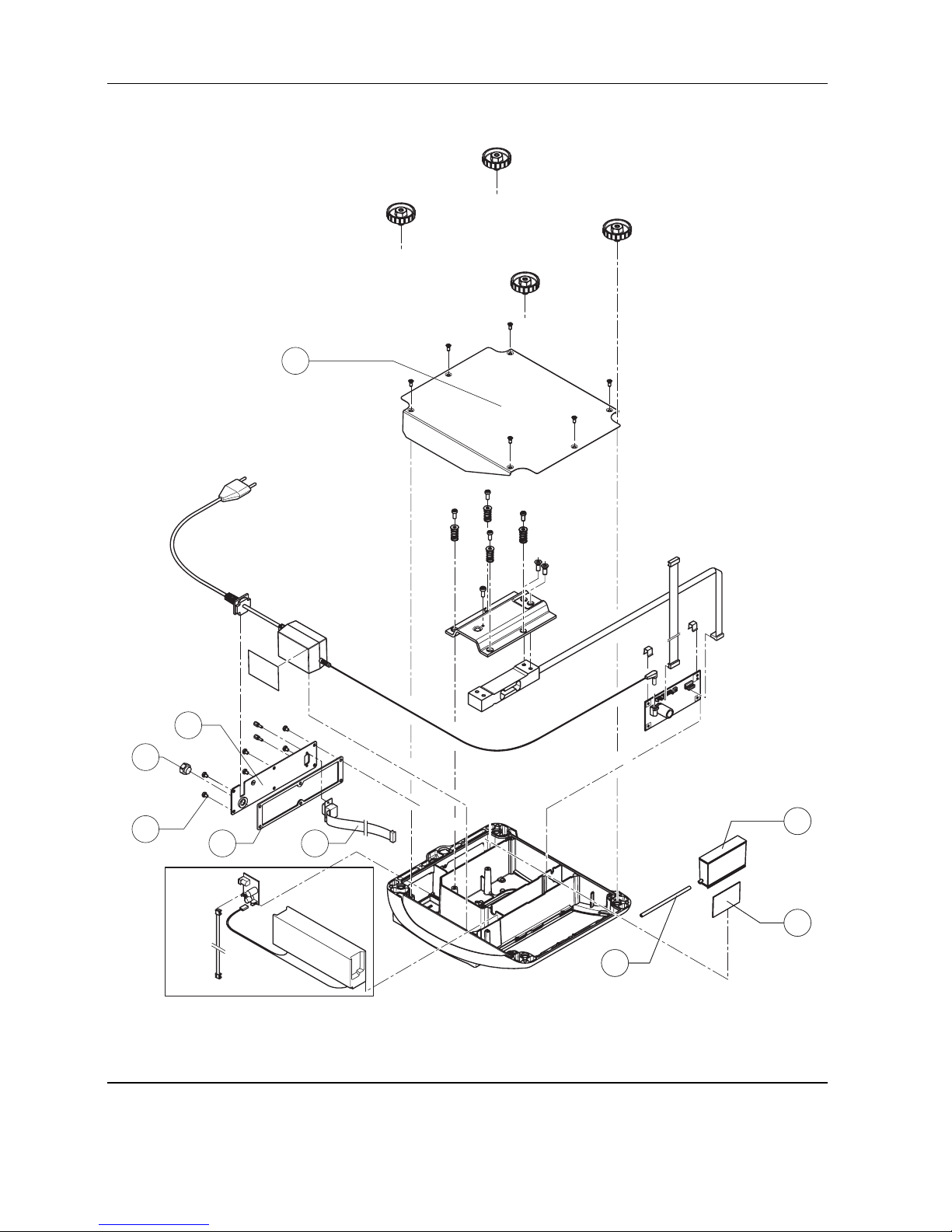

4 Terminals

4.1 KMB-TM terminal (ITB)

1

3

22

21

5

4

6

7

8

910

12

14

15

16

17

13

18

19

20

2

23

24

11

Page 33

34 FTx/ITx-SH-e-0720

Item Qty. Description Order No.

1 1 base plate with seal attached 21255118

2 4 rubber foot 00200068

3 8 countersunk screw M4 x 12 Torx T20 *

41 bench AC adapter 8VA (always order together with item 5):

EURO version 22011363

USA version 22011364

UK version 22011365

JAPAN version 22011366

Australian version 22011367

external power supply unit (battery charger) for operation with

a storage battery (without power cable) 22011300

socket for external power supply unit 22011311

5 1 adhesive tape for AC adapter 21203184

6 1 seal for terminal rear panel 21255012

7 1 connector plate for 1 interface (RS232C/load cell) standard –

8 1 countersunk screw M4 x 12 Torx T20 *

9 5 fillister head screw M4 x 8 Torx T20 *

10 1 RS232C interface IP65 with cable (soldered) standard 21203717

11 2 dust cover for interfaces 11101560

12 1 keypad overlay KMB-TM 22011414

13 1 display mounting plate BC (always order together with item 12) 21255041

14 1 LCD 21203134

15 1 backlighting 21203136

16 1 digital PCB with FLASH Memory Chip (soldered) 21204025

17 2 Torx oval head tapping screw 2.9 x 13 (red) *

18 1 analog board 7k 21255054

19 1 fastening clamp for analog board *

20 1 A/D cable 300 mm 21203167

21 1 EMC clamp short 21203480

22 1 EMC clamp long 21255047

23 4 screw lock *

24 1 EMC clamp for analog board 22007948

* included in the small parts set (Chapter 4.5)

Page 34

FTx/ITx-SH-e-0720 35

4.2 KMS-TM terminal (ITS)

1

3

22

21

5

4

7

910

12

14

15

16

17

13

18

19

20

8

2

23

24

6

11

Page 35

36 FTx/ITx-SH-e-0720

Item Qty. Description Order No.

1 1 base plate with seal attached 21255118

2 4 rubber foot 00200068

3 8 countersunk screw M4 x 12 Torx T20 *

41 bench AC adapter 8VA (always order together with item 5):

EURO version 22011363

USA version 22011364

UK version 22011365

JAPAN version 22011366

Australian version 22011367

external power supply unit (battery charger) for operation with a storage battery

(without power cable) 22011300

socket for external power supply unit 22011311

5 1 adhesive tape for AC adapter 21203184

6 1 seal for terminal rear panel 21255012

7 1 connector plate for 1 interface (RS232C/load cell) standard –

8 1 countersunk screw M4 x 12 Torx T20 *

9 5 fillister head screw M4 x 8 Torx T20 *

10 1 RS232C interface IP65 with cable (soldered) 21203717

11 2 dust cover for interfaces 11101560

12 1 keypad overlay KMS-TM 22011415

13 1 display mounting plate (always order together with item 12) 22010038

14 1 LCD 21203687

15 1 backlighting 21203137

16 1 digital board with FLASH Memory Chip (soldered) 21204025

17 2 Torx oval head tapping screw 2.9 x 13 (red) *

18 1 analog board 7 k 21255054

19 1 fastening clamp for analog board * *

20 1 A/D cable 300 mm 21203167

21 1 EMC clamp short 21203480

22 1 EMC clamp long 21255047

23 4 screw lock *

24 1 EMC clamp for analog board 22007948

* included in the small parts set (Chapter 4.5)

Page 36

FTx/ITx-SH-e-0720 37

4.3 KMT-TM terminal (ITT)

1

3

23

22

5

4

12

15

16

17

18

14

19

20

21

13

2

25

7

910

8

24

6

11

Page 37

38 FTx/ITx-SH-e-0720

Item Qty. Description Order No.

1 1 base plate with seal attached 21255118

2 4 rubber foot 00200068

3 8 countersunk screw M4 x 12 Torx T20 *

41 bench AC adapter 8VA (always order together with item 5):

EURO version 22011363

USA version 22011364

UK version 22011365

JAPAN version 22011366

Australian version 22011367

external power supply unit (battery charger) for operation with a storage battery

(without power cable) 22011300

socket for external power supply unit 22011311

5 1 adhesive tape for AC adapter 21203184

6 1 seal for terminal rear panel 21255012

7 1 connector plate for 1 interface (RS232C/load cell) standard –

8 1 countersunk screw M4 x 12 Torx T20 *

9 5 fillister head screw M4 x 8 Torx T20 *

10 1 RS232C interface IP65 with cable (soldered) 21203717

11 2 dust cover for interfaces 11101560

12 1 keypad overlay KMT-TM 22011416

13 1 numeric membrane keypad (always order together with item 12) 21203439

14 1 display mounting plate (always order together with items 12 and 13) 22010039

15 1 LCD 21203687

16 1 backlighting 21203137

17 1 digital board with FLASH Memory Chip (soldered) 22013719

18 2 Torx oval head tapping screw 2.9 x 13 (red) *

19 1 analog board 7k 21255054

20 1 fastening clamp for analog board *

21 1 A/D cable 300 mm 21203167

22 1 EMC clamp short 21203480

23 1 EMC clamp long 21255047

24 4 screw lock *

25 1 EMC clamp for analog board 22007948

* included in the small parts set (Chapter 4.5)

Page 38

FTx/ITx-SH-e-0720 39

1

3

7

8

9

10

12

13

18

17

16

15

4

5

14

6

11

2

4.4 OptionPac

Page 39

40 FTx/ITx-SH-e-0720

Item Qty. Description Order No.

1 1 base plate with seal attached 21255118

2 4 rubber foot 00200068

3 8 countersunk screw M4 x 12 Torx T20 *

4 4 fillister head screw M5 x 12 *

5 1 PCB for NiMH storage battery charger circuit 22011451

6 2 fastening clamp for charging circuit board *

7 1 connecting cable charging circuit – analog board 21203233

8 1 battery cable –

9 1 battery 14.4V NiMH (always order together with item 10) 22011350

10 2 adhesive tape for battery 21255260

11 1 bench AC adapter 8VA (always order together with adhesive tape order no. 21203184):

EURO version 22011363

USA version 22011364

UK version 22011365

JAPAN version 22011366

Australian version 22011367

external power supply unit (battery charger) for operation with a storage battery

(without power cable) 22011300

socket for external power supply unit 22011311

12 1 seal for back panel OptionPac 21255013

13 1 back panel without openings 21255003

14 1 analog interface option board only KMS/KMT-TM 21203383

15 4 tapping screw M3 x 6 –

16 1 EPROM with interface software for analog option (KMS/KMT-TM only) 22013444

17 1 cable for analog option (KMS/KMT-TM only) 21203604

18 1 seal (between OptionPac and terminal) 21255011

5 fillister head screw M4 x 8 Torx T20 *

1 countersunk screw M4 x 10 Torx T20 *

* included in the small parts set (Chapter 4.5)

Page 40

FTx/ITx-SH-e-0720 41

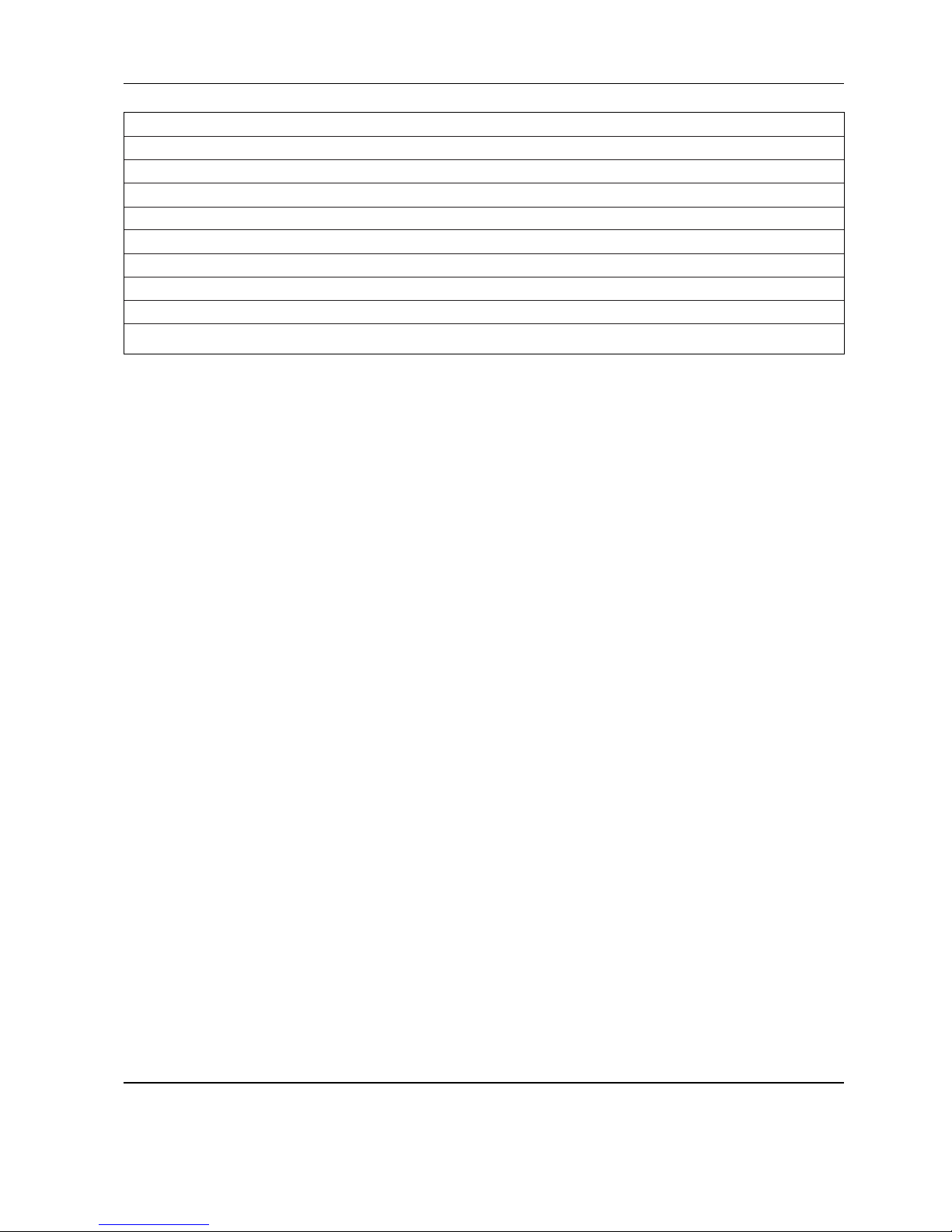

4.5 Small parts set

The small parts set comprises all the standard components (screws, washers, etc.) required for service work on scales and

terminals.

Qty. Description Order No.

1 small parts set 21203404

20 countersunk Torx screw M3 x 8 –

20 countersunk Torx screw M3 x 10 –

20 countersunk Torx screw M6 x 30 –

50 countersunk Torx screw M4 x 10 –

10 countersunk Torx screw M4 x 12 –

20 button head Torx screw M3 x 6 –

30 button head Torx screw M4 x 12 –

30 button head Torx screw M5 x 12 –

20 wide flange washer 4.3 x 20 –

20 wide flange washer 5.3 x 20 –

20 countersunk Torx screw M6 x 16 –

20 spring clip –

50 raised cheese head Torx screw M4 x 8 –

10 screw lock –

10 Torx oval head tapping screw 2.9 x 13 –

Page 41

42 FTx/ITx-SH-e-0720

5 Replacing components with compact scales

5.1 Important notes

This section describes how to change individual components of the compact scales. When doing this, please refer to the

exploded view drawings and spare parts lists in Chapters 2 and 3. Important: After replacing components, a functional check

of the scale must always be carried out.

5.1.1 Safety and environment

The following instructions must be observed for all repairs:

– Disconnect the scale from the power supply before starting repair work!

– The scale contains electronic components which can be damaged by electro-

static discharges. You must therefore always wear a grounded wriststrap

when performing repair work! Grounded wriststraps can be purchased from

specialist electronics dealers.

– Defective components must be disposed of according to the instructions in

Chapter 1!

• Servicing work in explosion hazard zones is strictly prohibited. Ignition

power could inadvertently be generated, causing an explosion. Servicing work

should therefore only be undertaken in secure areas. The location in which

the scale is installed must be declared by the system operator to be safe for the

duration of the repair work. If no such declaration is available, the scale must be

switched off and disconnected from the power supply and moved to a safe area.

• The scales can also be disconnected and reconnected to the power supply in

potentially explosive environments provided that the power supply has first been

switched off.

5.1.2 Tools and working aids

– Screwdrivers: Torx T10, T20, T25, and T30; Phillips 5 mm; flat type size 4

– Torque wrench up to 10 Nm

– Wrench heads Torx T25, T30, and hex 17 mm

– Open-end wrench, size 20

– Feeler gauge

– Carpet knife (“cutter”)

– Grounded wriststrap (as protection against electrostatic discharges)

– Weights of class M1 or F1

5.1.3 Work instructions

Take great care when inserting and tightening screws into holes tapped directly into the aluminum casting: After inserting the

screw, always turn it first about 1 turn counterclockwise until it engages in the existing thread, and only then screw it tight! Do

not tighten the screw too much, since this may damage the thread in the aluminum casting!

Page 42

FTx/ITx-SH-e-0720 43

5.2 Replacing the keypad overlay

• Lift up the defective keypad overlay (if necessary carefully prying it up with a knife) and gently peel it off the scale.

Caution: take care that the specification label is not damaged when the membrane is removed!

• Carefully clean display mounting plate and window (removing all traces of adhesive).

• Make sure that the specification label is in its correct position (must be visible through the window in the keypad overlay),

then peel off the protective film from the new overlay and carefully affix the latter to the display mounting plate.

• Press the keypad overlay down uniformly.

5.3 Replacing the AC adapter

Note: The AC adapter has a fuse as overcurrent protection. For safety reasons this fuse cannot be replaced, and the AC adapter

must therefore be replaced completely if the fuse blows. This applies only to scales that are connected directly to the AC power

line (without rechargeable battery and external AC adapter).

• Unscrew the adjustable feet and remove them.

• Undo the bottom plate retaining screws, removing them and the plate itself.

• Disconnect the AC adapter cable from the analog PCB.

• Remove the AC adapter (held on by an adhesive patch) from the wall of the housing. If necessary, carefully insert a flat

blade (knife or screwdriver) between adapter and housing and pry them apart. Remove all traces of adhesive from the

housing.

• Undo the screws holding the RS connector plate in place (rear panel of scale) and remove the plate.

• Slide the AC adapter power cord grommet out of the RS connector plate. Remove the AC adapter from the scale.

• Place the new AC adapter in the scale and fix it in place with the adhesive patch.

• Slide the power cord grommet into the slot of the RS connector plate and screw the plate in place.

Note for scales with IP65 protection: Check that the seal of the connector plate is still correctly fastened to the housing. If

it is not, the seal must be replaced as follows: Remove the existing seal from the housing so as to leave no trace. Clean and

degrease the surface to which it was fastened. Carefully affix the new seal to the housing in exactly the right position.

• Plug the AC adapter output cable onto the analog PCB.

• Replace the bottom plate and the adjustable feet.

5.4 Replacing the battery

Note: This procedure is only required for scales that have a built-in battery and an external AC adapter (“AccuPac” version).

• Unscrew the adjustable feet screws and remove them.

• Undo the bottom plate retaining screws, removing them and the plate itself.

• Undo the screws holding the RS connector plate in place (rear panel of scale) and remove the plate.

• Slide the charging PCB out from the guide and remove both plugs on the PCB (connection cable to battery or analog PCB).

• Remove the battery from the wall of the housing (held in place by the adhesive strip). If necessary, carefully insert a flat

blade (knife or screwdriver) between the battery and housing and pry them apart. Remove all traces of adhesive from the

housing.

• Remove the battery from the scale and disconnect the cable to the charging PCB.

• Attach the adhesive patch to the wall of the housing, remove its protective foil, place the battery in the scale and press it

Page 43

44 FTx/ITx-SH-e-0720

against the wall of the housing.

• Attach both plugs with connectors to the charging PCB and slide the PCB back it into the guide.

• Replace the RS connector plate and secure with the screws.

Note for scales with IP65 protection: Check that the seal of the connector plate is still correctly fastened to the housing. If

it is not, the seal must be replaced as follows: Remove the existing seal from the housing so as to leave no trace. Clean and

degrease the surface to which it was fastened. Carefully affix the new seal to the housing in exactly the right position.

• Check the connections of all cables: The cables must lie in the correct slots of the housing, to ensure they are not pinched

by the bottom plate.

• Replace the bottom plate and the adjustable feet.

5.5 Replacing the charging PCB

Note: This procedure is only required for scales with a built-in battery (“AccuPac” version). Before fitting the new charging

PCB, check that the correct AC adapter for “AccuPac” operation is used (see spare parts lists in Chapters 2 and 3). If not,

the AC adapter must also be replaced.

• Undo the screws holding the RS connector plate in place (rear panel of scale) and remove the plate.

• Slide the PCB out from the guide and remove both plugs on the PCB (connection cable to battery or analog PCB).

• Attach both plugs with connectors to the (new) charging PCB and slide it into the guide.

• Replace the RS connector plate and secure with the screws.

Note for scales with IP65 protection: Check that the seal of the connector plate is still correctly fastened to the housing. If

it is not, the seal must be replaced as follows: Remove the existing seal from the housing so as to leave no trace. Clean and

degrease the surface to which it was fastened. Carefully affix the new seal to the housing in exactly the right position.

5.6 Replacing the analog PCB

• Unscrew the adjustable feet and remove them. Undo the bottom plate retaining screws, removing them and the plate itself.

• Disconnect weighing cell cable, connecting cable to the digital PCB and the AC adapter output cable from the analog PCB.

• Pull off the two spring clips from the analog PCB and remove it.

• Fit the new analog PCB and fix it in place with the spring clips.

• Connect the weighing cell cable, the A/D cable from the digital PCB and the AC adapter output cable to the analog PCB.

• Replace the bottom plate and the adjustable feet.

Caution: After replacing the analog PCB all scale data must be entered again in technician mode (Chapter 7), plus all

supervisor mode settings must be re-entered! The scale must first be calibrated and a linearization and recalibration carried out

as required.

Page 44

FTx/ITx-SH-e-0720 45

5.7 Replacing the display mounting plate, display unit and digital PCB

The display mounting plate is located underneath the keypad membrane and is attached to the scale housing by 6 snaps. The

display unit comprises the digital PCB, the liquid crystal display (LCD) and the backlighting unit. It is held in place on the

mounting plate by snaps. The digital PCB is connected to the analog PCB and the RS232C interface by two ribbon cables.

5.7.1 Preliminary word

• Unscrew the adjustable feet and remove them.

• Undo the bottom plate retaining screws, removing them and the plate itself.

• Remove both EMC clamps. Undo the red retaining screw (since September 2005) which fastens the display unit to the

mounting plate. Pull back the front cantilever snaps holding the display unit to release it, raise the front edge of the

display unit and withdraw it from the rear snaps. Disconnect the RS232 cable and the connecting cable to the analog PCB

from the digital PCB. Remove the display unit.

5.7.2 Replacing the display mounting plate

Note: In order to replace the display mounting plate, the keypad overlay must be removed. This cannot then be reused and

must also be replaced.

• Remove keypad overlay (Chapter 5.2).

• Push the 3 cantilever snaps at the front edge of the display mounting plate backwards to release the plate and remove it to

the outside.

• Insert the new display mounting plate into the aperture so that it clicks into place.

• Apply the new self-adhesive keypad overlay (Chapter 5.2).

5.7.3 Replacing the liquid crystal display (LCD) or the backlighting unit

• Place the display unit with the digital PCB downwards on a conductive CMOS film.

• Disconnect the backlighting ribbon cable from the digital PCB.

• Carefully insert a flat blade screwdriver (size 4) between the digital PCB and the backlighting unit immediately adjacent to

the connectors.

• With the screwdriver pry the liquid crystal display and the backlighting unit out of the socket strips. When doing this, lever

the shaft of the screwdriver against the edge of the digital PCB. Never lever the tip of the screwdriver against the surface of

the PCB, as this could damage the latter!

• Remove the upper protective film of the backlighting unit.

• Place the new backlighting unit onto the digital PCB (it snaps into place on the board).

• Remove the upper and lower protective cover of the LCD.

• Carefully place the LCD onto the backlighting unit and ensure that the connector pins are correctly aligned with the socket

strips. When correctly positioned, the ends of the LCD and backlighting unit are flush. Use a flat object such as a ruler to

exert a uniform pressure on the LCD and gently push it home.

• Push the backlighting unit ribbon cable connector onto the digital PCB pins.

Page 45

46 FTx/ITx-SH-e-0720

5.7.4 Replacing the digital PCB

• Remove the LCD and backlighting unit as described in the previous chapter.

• Fit LCD and backlighting unit onto the new digital PCB (Chapter 5.7.3).

After the digital PCB has been replaced, the application software of the scale has to be downloaded into the flash memory of

the digital PCB (refer to Chapter 9 of this service manual). If the software was not loaded successfully via the PC, the complete

digital PCB with the soldered-on flash memory chip has to be replaced.

5.7.5 Final reassembly

• Connect the RS232 cable and the cable from the analog PCB to the digital PCB.

• Engage the display unit or the LCD module under the rear snaps of the display mounting plate and then lower its front edge

until it snaps into place. Fit the red retaining screw(s) (since September 2005).

Caution: The red screw is used for adjusting. It must first be tightened completely and then loosened by half a rotation.

If this is not done, the pushbuttons on the digital PCB are too close to the display insert and can no longer be pressed.

The distance between the pushbuttons of the digital PCB and the display insert can be modified by means of this red

adjusting screw. An additional manual keyboard test must always be carried out. In this context fine adjustment also has

to be carried out with the adjusting screw.

Caution: On FTB the LC display is only held in the connector strip on one side. Because of this, for assembly of the PCB,

the display, and the backlighting must be held together by hand, otherwise the backlighting may come out of the drilled

holes in the PCB and be displaced!

• Install both EMC clamps.

• Replace the bottom plate and adjustable feet.

Page 46

FTx/ITx-SH-e-0720 47

5.8 Replacing the weighing cell

5.8.1 Replacing a strain gauge weighing cell

Disassembly

• Remove the weighing pan.

• Scales without IP65 protection: Undo the pan support plate retaining screws and remove the pan support plate.

• Scales with IP65

protection (see exploded view drawings in Chapters 2 and 3):

• Undo the 4 M3 x 8 screws fastening the membrane to the load plate support.

• Undo the two M6 x 30 retaining screws of the load plate support and carefully lift the load plate support off.

Caution: If the load plate support remains attached to the membrane, the membrane must be released with a thin pin.

(Insert the pin through the drilled holes in the load plate and carefully press the membrane down.)

• Undo the 3 M3 x 10 screws fastening the small flange to the membrane. Remove the small flange, the membrane, and

the large flange.

• Undo the 2 M3 x 8 fastening screws of the cover plate. Carefully lift off the cover plate together with the rubber seal.

• Turn the scale upside down, unscrew the adjustable feet and remove them.

• Undo the bottom plate retaining screws, removing them and the plate itself.

Replacing the load cell

• Remove the weighing cell cable connector from the analog PCB.

• Undo the 4 retaining screws for the overload plate. Remove the screws, washers and springs.

• Remove the overload plate with the weighing cell screwed to it.

• Remove the weighing cell retaining screws.

• Screw the new weighing cell to the overload plate. Caution: Before tightening the screws, verify that the weighing cell is

aligned exactly parallel with the edges of the overload plate! Screw torque: 10 Nm!

• There is an adjustment screw for the overload stop with scales from specific production series. The overload stop must then

first be readjusted after replacing the load cell. If the adjustment screw has been removed, a drop of superglue should be

applied to the thread to keep the screw firmly in place after adjustment. A feeler gauge should be used to adjust the overload

stop. The adjustment screw is to be tightened until there is a gap between the screw and weighing cell according to the table

below. Caution: Turning the screw too tightly can damage the weighing cell!

Scale Color of overload spring Gap between adjustment screw and weighing cell

FTB/FTC 3 kg red 0.45 mm

FTB/FTC 6 kg red 0.45 mm

FTB/FTC 15 kg white 0.25 mm

FTB/FTC 35 kg brown 0.25 mm

FTB/FTC 60 kg black 0.40 mm

• Place the overload plate with the weighing cell screwed to it in the scale. Fit the springs and washers, then tighten the

screws.

• Fit the weighing cell cable connector onto the analog PCB pins.

Page 47

48 FTx/ITx-SH-e-0720

Assembly

• Replace the bottom plate and the adjustable feet.

• Scales without IP65 protection: Turn the scale the right way up, replace the pan support plate and secure it with the

screws. Before finally tightening the screws, make sure that the pan support plate is aligned squarely with the scale

housing. Caution: screw torque 10 Nm!

• Scales with IP65

protection (see exploded view drawings in Chapters 2 and 3 ):

• Mount the rubber seal and the cover plate and insert the 2 M3 x 8 fastening screws (but do not tighten them yet).

• Lay the large flange on the cover plate, then lay the membrane in position and align the 3 fastening holes. Next, lay the

small flange in position and align it exactly. Insert the 3 M3 x 10 screws and tighten them evenly together with the two

M3 x 8 screws of the cover plate.

• Align the large flange exactly on the 4 fastening holes of the membrane.

• Lay the load plate support in position, and then insert the two M6 x 30 fastening screws and slightly tighten them. Before

finally tightening the screws, make sure that the pan support plate is aligned squarely with the scale housing.

Caution: screw torque 10 Nm!

• To be able to screw the large flange and the membrane to the load plate support, the flange and the membrane must be

lifted slightly, because the fastening screws are too short to reach to the threaded holes in the flange. To do this, proceed

as follows:

Carefully insert a fine screwdriver under the side of the large flange and lift the flange slightly together with the membrane.

Insert one of the 4 M3 x 8 fastening screws in the corresponding drilled hole in the load plate support and screw it in only

slightly. Insert the remaining 3 M3 x 8 fastening screws into the membrane and then tighten all 4 screws evenly.

Note: Instead of using a screwdriver to lift the flange and membrane, this can also be done by temporarily inserting two

M3 screws at least 15 mm long into two opposite holes in the load plate support and slightly tightening them. (These

temporary screws are long enough to reach the threaded holes in the flange and to lift the flange together with the

membrane). Insert two of the 4 M3 x 8 fastening screws into the free drilled holes in the load plate support and screw

them in slightly. Undo the two temporary screws and insert the two remaining M3 x 8 screws in their place. Tighten all

4 screws evenly.

• Replace the weighing pan.

• Calibrate the scale in technician mode and linearize it (Chapter 7). If a weighing cell with another capacity has been

installed, the new weighing range (“Range”) and the resolution (“Resol.”) must also be selected.

Note: Scales with strain gauge weighing cells have fixed cornerload stops that do not need to be readjusted.

Page 48

FTx/ITx-SH-e-0720 49

6 Repair of terminals

6.1 Important information

When performing repairs please refer to the exploded view drawings and lists of spare parts in Chapter 4 of this manual.

Important: After replacing components, a functional check of the terminal must always be carried out.

6.1.1 Safety and environment

Whenever repairs are carried out, the following safety precautions must always be taken:

– The terminal must be disconnected from the power supply before repair

work is started!

– The terminal and the OptionPac contain electronic components which can be

damaged by electrostatic discharges. You must therefore always wear a

grounded wriststrap when performing repair work. Grounded wriststraps

can be purchased from specialist electronics dealers.

– Defective components must be disposed of according to the instructions in

Chapter 1!

6.1.2 Tools and working aids

– Torx screwdrivers T10, T20, and T30

– Phillips screwdrivers size 2

– Insulated slotted-head screwdriver (with plastic-covered shaft), size 4

– Grounded wriststrap (to protect against electrostatic discharges)

6.1.3 Work instructions

Take great care when inserting and tightening screws into holes tapped directly into the aluminum casting: After inserting

the screw, always turn it first about 1 turn counterclockwise until it engages in the existing thread, and only then screw it

tight! Do not tighten the screw too much, since this may damage the thread in the aluminum casting!

6.2 Disassembling/reassembling the terminal

• Remove base plate from terminal or OptionPac (8 screws, Torx T20).

• If OptionPac is installed: Disconnect all cable connections between OptionPac and terminal in OptionPac.

Tip: Note where cables are connected. Unfasten OptionPac from terminal (4 Phillips screws) and lift off.

• Reassemble in reverse order.

Page 49

50 FTx/ITx-SH-e-0720

6.3 Replacing the keypad overlay

• Lift the defective keypad overlay by a corner and gently peel it off.

• Carefully remove all traces of adhesive with, for example, a wooden or plastic scraper. Caution: Make sure not to

damage the keypad membrane of KMT-TM terminals!

• Carefully clean the windows of the keypad overlay and the display mounting plate.

• Peel off protective film from new overlay.

• Center the keypad overlay on the display mounting plate and press down uniformly.

6.4 Replacing the AC adapter

Note: The AC adapter has a fuse as overcurrent protection. For safety reasons this fuse cannot be replaced, and the AC

adapter must therefore be completely replaced if the fuse blows or the AC adapter is defective.

• Open terminal, remove OptionPac (if present) (Chapter 6.2).

• Peel output cable of AC adapter off analog board. Battery-operated scales only: The output cable of the AC adapter is

plugged into the charging circuit board of the OptionPac and is usually already removed when the OptionPac is

disassembled (Chapter 6.2).

• Remove

AC adapter from wall of housing (attached by adhesive patch). If necessary, carefully insert a flat blade (knife or

screwdriver) between AC adapter and housing and detach AC adapter. Remove all traces of adhesive from housing.

• Undo the 6 screws holding the RS connector plate in place (rear panel of terminal) and remove the plate. (Caution: cable

connections!).

• Remove power cord grommet of AC adapter from RS connector plate. Remove AC adapter from terminal.

• Attach new adhesive patch to housing wall and peel off protective film.

• Place new AC adapter in terminal and press onto adhesive patch.

• Locate the power cord grommet (with its closed side facing up!) in the center of the blanking plate slot, then press the

grommet down thoroughly. This requires a fair amount of force which is intended as it ensures proper IP protection.

Caution: Never use a hammer or similar tool for pushing the grommet into place because this may damage the

wires! Once the grommet is properly located in the slot you may fasten the blanking plate.

• Plug AC adapter output cable onto analog board. Battery-operated terminals: The output cable of the AC adapter must

be plugged onto the charging circuit board in the OptionPac.

• Install terminal/OptionPac (Chapter 6.2).

6.5 Replacing the analog board

• Open terminal, remove OptionPac (if present) (Chapter 6.2).

• Disconnect the load cell connection cable and all other cable connectors from analog board. Tip: Make a note of the

cable connections!

• Pull off the spring clip and the EMC clamp from the analog board and remove it.

• Fit new analog board and fasten in place with the spring clip and the EMC clamp.

• Plug the load cell connection cable and all other cable connectors onto the analog board.

• Close terminal, mount OptionPac (if present) (Chapter 6.2).

Caution: After replacing the analog board all scale data and user settings must be reentered, because they are saved

in the EAROM on the analog board! When they have been reentered, the weighing system must be calibrated/

linearized. These operations are described in Chapter 7 of the this service manual.

Page 50

FTx/ITx-SH-e-0720 51

6.6 Replacing the display mounting plate, display unit, and digital board

The display mounting plate is located underneath the keypad overlay and is attached to the scale housing by 6 snaps. The

display unit comprises the digital PCB, the liquid crystal display (LCD) and the backlighting unit. It is held in place on the

mounting plate and the housing by snaps and screws. The digital PCB is connected to the analog PCB and the RS232C

interface by two ribbon cables (on KMT-TM terminals there is an additional cable for the keypad).

6.6.1 Preliminary work

• Open terminal, remove OptionPac (if present) (Chapter 6.2).

• Undo the two screws (Torx T10) fastening the digital board to the display mounting plate.

• Push back the two (small) black snaps at the front of the display mounting plate and slowly raise the digital board until

it is vertical. Carefully pull the digital board vertically upward and out of the rear snaps.

• Disconnect all cables from the digital board, then remove the board. Tip: Make a note of the cable connections.

KMT-TM only: The membrane cable for the keypad of the KMT-TM (numeric keypad) must also be disconnected from the

digital board. Use a soft felt pen to mark first the membrane cable and then the plug, so you know afterwards how the

cable has to be plugged in. Then slightly pull out the two small black snaps on the left and right of the plug. This releases

the spring mechanism of the plug, and the cable can be pulled off.

6.6.2 Replacing the display mounting plate

Note: In order to replace the display mounting plate, the keypad overlay must be removed. This cannot be reused, and must

therefore also be replaced. On KMT-TM terminals the membrane keypad, which is fastened to the display mounting plate,

must also be replaced.

• Remove keypad overlay (Chapter 6.3).

• Push the 3 cantilever snaps at the front edge of the display mounting plate backwards to release the plate and remove it

to the outside.

• Insert the new display mounting plate into the aperture so that it clicks into place.

• KMT-TM only: Peel the protective film off the new membrane keypad and carefully apply the membrane keypad to the

display mounting plate. Pass the membrane cable through the aperture and into the inside of the terminal.

• Apply the new self-adhesive keypad overlay (Chapter 6.3).

6.6.3 Replacing the liquid crystal display (LCD) and/or the backlighting unit

• Place the display unit with the digital board downwards on a conductive CMOS film.

• Unplug the backlighting ribbon cable from the digital board.

• Carefully insert a flat-bladed screwdriver (size 4) between the digital board and the backlight unit immediately adjacent

to the connectors. Tip: Use an electrician’s screwdriver with an insulated shaft as this reduces the risk of causing

damage.

• Use the screwdriver to pry the liquid crystal display and the backlighting unit out of the socket strip(s). When doing this,

lever the shaft of the screwdriver against the edge of the digital board. Never lever the tip of the screwdriver

against the surface of the digital board, as this could damage the board!

• Peel off the upper protective film of the new backlighting unit.

• Place the new backlighting unit onto the digital board. Two of the four feet of the backlighting unit are in the form of pins.

These pins must be inserted into the corresponding holes in the digital board.

Page 51

52 FTx/ITx-SH-e-0720

• Peel the upper and lower protective films off the new LCD.

• Carefully place the LCD onto the backlighting unit and ensure that the contact pins are correctly aligned with the socket

strip(s). When correctly positioned, the ends of the LCD and the backlighting unit are flush. Use a flat object such as a

ruler to exert a uniform pressure on the LCD and gently push it home.

• Push the backlighting unit ribbon connector onto the digital board pins.

6.6.4 Replacing the digital board

• Remove the LCD and backlighting unit as described in the previous Chapter (6.6.3).

• After the digital board has been replaced, the application software for the terminal must be loaded into the flash memory

of the digital board from the PC (see Chapter 9 of this service manual). If downloading the terminal software via a

computer fails for any reason, the entire digital PCB inlcuding the soldered Flash Memory chip must be replaced.

• Mount the LCD and backlighting unit on the new digital board (Chapter 6.6.3).

Caution: The red screw (since September 2005) is used for adjusting! It must first be tightened completely and then

loosened by half a rotation. If this is not done, the pushbuttons on the digital PCB are too close to the display insert and can

no longer be pressed. The distance between the pushbuttons of the digital PCB and the display insert can be modified by

means of this adjusting screw. An additional manual keyboard test must always be carried out. In this context fine

adjustment also has to be carried out with the adjusting screw.

6.6.5 Final reassembly

• Connect all cables to the digital board (incluning the membrane keypad cable on KMT-TM terminals).

KMT-TM only: The membrane cable for the keypad must also be plugged into the digital board. To do so, pull out the two

small black snaps on the left and right of the plug. Then push the membrane cable into the plug as far as the stop, hold

it in this position and push the two snaps against the plug. The cable is then held fast.

• Engage the display unit under the rear snaps of the display mounting plate and then lower its front edge until it snaps into

place. Fit the retaining screws.

• Install both EMC clamps.

• Install the terminal/OptionPac, if present (Chapter 6.2).

• Replace the bottom plate and secure with 8 screws.

Page 52

FTx/ITx-SH-e-0720 53

6.7 Repairing the OptionPac

6.7.1 Replacing the battery

Note: This section relates only to terminals which have an OptionPac with built-in battery.

• Remove the base plate of the OptionPac (8 screws, Torx T20).

• Remove battery from wall of housing (attached by adhesive patch). If necessary, carefully insert a flat blade (knife or

screwdriver) between battery and housing, then release AC adapter. Remove all traces of adhesive from housing.

• Lift battery out of OptionPac and pull off cable connecting to charging circuit board.

• Fasten adhesive patch to wall of housing, peel off protective film, place battery in OptionPac and press latter against wall

of housing.

• Check all cables are correctly laid. The cables must lie in the correct recesses in the housing so they are not trapped by

the base plate.

• Screw the base plate of the OptionPac on again.

6.7.2 Replacing the charging circuit board

Note: This section relates only to terminals which have an OptionPac with built-in battery. The charging circuit board has an

electronic overload protector which automatically resets after being activated.

• Remove base plate of OptionPac (8 screws, Torx T20).

• Pull off cable from battery (blue plug), then remove the two snap fasteners of the charging circuit board and carefully lift

the board out of the housing.

• Undo all cable connections on charging circuit board.

• Plug cable onto new charging circuit board and place board in housing.

• Fasten board with the two snap fasteners and plug cable into battery (blue plug).

• Screw base plate of OptionPac on again.

6.7.3 Replacing the analog option board

Note: This section relates only to terminals fitted with an OptionPac containing the analog option for connecting a second

weighing platform.

• Remove base plate of OptionPac (8 screws, Torx T20).

• Undo all cable connections on the analog option board. Tip: Make a note of the cable connections.

• Undo the 4 screws fastening the board (Torx T10) and remove the board.

• Using a suitable tool, remove the EPROM from its socket and fit on the new board. Caution: The chamfered corner of the

EPROM must be aligned with the chamfered corner of the socket (see marking)!

• Place new board in housing and fasten with screws.

• Plug in all cables on the analog option board.

• Screw the base plate of the OptionPac on again.

Caution: After the analog option board has been replaced, all the data and user settings for the second weighing

platform must be reentered, because these are stored in the EAROM on the board! The second weighing platform must

then be calibrated and linearized. These steps are described in Chapter 7 of this service manual.

Page 53

54 FTx/ITx-SH-e-0720

7 Scale definition, settings and diagnostics

The menu of the compact scales and the terminals includes a special section dedicated to the service technician. The

technician setup offers settings and procedures for maintenance and diagnostics. Accessing this part of the menu requires

a special password while navigation within the technician menu is the same as with the user and supervsior menu (see User

Manual). Caution: Settings in the technician menu may only be made by qualified personnel. The wrong settings could

result in the scale or terminal not functioning correctly!

7.1 Accessing and using the technician menu

7.1.1 Accessing the technician menu of scales or terminals that are not certified

• Press and hold it down until the prompt to enter the password appears.

• Press . Once you have confirmed the password, the first menu block (“SCALE”) appears. Basically,

the technician menu is the same as the one for the supervisor (see User Manual) except that there are some additional

blocks for setup and diagnostics.

7.1 2 Accessing the technician menu of certified scales or terminals

With certified scales and terminals, direct access to the technician mode (with the and key) is blocked. This is

for technical reasons, and also to comply with regulations. To access the technician mode, proceed as follows:

• Switch off the scale or terminal.

• Remove the bottom plate of the scale by undoing the retaining screws (Torx T20) (see Chapters 4 and 5 for a detailed

description). Important: In order to remove the bottom plate it is necessary to break the certification seal affixed to them!

Once this seal has been destroyed, the scale must be recertified by an accredited organization, and a new

certification seal must be affixed before the instrument may be used as a certified scale again!

• Hold down the service switch (pushbutton) on the analog PCB (indicated by an arrow in the drawings below), while at the

same time switching on the scale or terminal. Keep the service switch pressed in until “SCALE” appears in the display.

small platform model

large platform model

terminals

Page 54

FTx/ITx-SH-e-0720 55

7.2 Technician menu – Overview

The overview below shows the menu blocks holding additional settings dedicated to the technician (“SCALE”, “TERMINAL”).

The settings available to the technician only are printed in boldface. The further menu blocks (“APPLICATION”,

“COMMUNICATION” and “DIAGNOSTICS”) are similar to the ones in the supervisor setup (see User Manual) and are not shown

below. The factory settings are marked with an asterisk (*). Depending on the model some menu items are not available.

Level 1 Level 2 Level 3 Level 4

SCALE Metrolo no Appr

OIML

NTEP

Scale 1/Scale 2 [choose]

Ramp

Serial Number

Scale Build Scale Type Single Range

2Multi Interval

2Multi Range

3Multi Interval

3Multi Range

Base Unit g, kg, oz, lb, t

Ver. Interval e = d, e = 10d

Scale Cap. 1 [entry]

Resolution 1 1200d ...

Scale Cap. 2 [entry]

Resolution 2 1200d ...

Scale Cap. 3 [entry]

Resolution 3 1200d ...

Geo Value 0 ... 31

LIN-CAL 3 Point [Start]

5 Point [Start]

Calibration [Start]

Control Mode

Display Unit 1 g, kg*, oz, lb, t

Unit 2 g*, kg, t, lb, oz

Resolution 1200d ...

Unt.roll Off*, On

Tare Auto tare Off*, On

Chain tare Off, On*

Auto clear tare Off*, On

Tare key Off, On*

Zero Zero-Capt. –2%+18%*, –2+2%

Set Zero [Start]

Auto zero Off, 0.5d, 1d, 2d, 5d, 10d

Restart Off*, On

Filter Vibration Low, Medium*, High

Process Universal*, Dosing

Stability Fast, Standard*, Precise

Fact Temp Off, 1K, 2K, 5K

MinWeigh Set Value [entry]

On/Off Off*, On

Reset [Start]

TERMINAL Device Language English, US English, German,

French, Italian, Spanish

Power off Off, 1 min., 3 min., 5 min., 15 min., 30 min

Power supply (akku) Off, 1 min., 3 min., 5 min., 15 min., 30 min

Contrast 0 ... 5* ... 10

Weight display small*, large

Date/Time Date format EU, US

Date [entry]

Time [entry]

AM*, PM

Beeper Off*, On

Password Supervisor Password [Enter Code], [Retype Code]

Timeout Mode Not active*, Leasing, Text only

Days 1 ... 999

Text1 [entry]

Text2 [entry]

Reset [Start]

Page 55

56 FTx/ITx-SH-e-0720

Only the settings and procedures for the “SCALE” and “TERMINAL” menus that are available exclusively to service technicians

are described here. The other menu options are described in the User Manual.

7.3 Admissibility for certification (

SCALE –> Metrology

)

The following settings are available:

“no Appr” do not certify scale / no certifiable state

“OIML” do certify to OIML / certified

“NTEP” do certify to NTEP / certified

Caution: If a scale is certified, a number of scale settings are no longer available.

7.4 Selecting the scale to be configured (

SCALE –> Scale 1/Scale 2

)

Here you specify which scale you want to configure. This option is only available for two-scale systems, i.e. when the scale

or terminal has an analog option for connecting a second weighing platform.

The same menu blocks that are described in the sections below are available for both scales in the technician menu.

7.5 Querying the value of the analog/digital converter (

SCALE –> Ramp

)

The percentage deflection of the analog/digital converter (“Ramp”) can be displayed in this menu. This value can be used to

determine whether the load cell is operating correctly. Scales with identical and correctly operating load cells have roughly the

same ramp values. The value is dynamic and changes with the load.

7.6 Serial number of the scale or terminal (

SCALE –> Serial Number

)

In this menu, you can display and change the serial number of the scale or terminal, which consists of seven digits. Note: The

number should only be changed or reentered if necessary (e.g. after a new scale PCB is installed). The serial number is found

on the rating plate of the scale or terminal.

The serial number can be entered with the numerical keypad for KMT-TM and terminals (ITT). Press for compact scales

FTx and KMB/KMS-TM terminals (ITB/ITS). The first digit starts flashing and can now be changed with the and

keys.

Confirm new digit with . The second digit starts flashing and can be changed in the same way. This also applies for all

following digits (seven total). To exit the block, press again after entering the last digit.

7.7 Entering configuration data (

SCALE –> Scale Build

)

This menu includes a number of different submenus for entering configuration data for the weighing system. These submenus

are described in the following sections:

Defining the scale type (“Scale Type”) ––> Chapter 7.7.1

Specifying the base unit (“Base Unit”) ––> Chapter 7.7.2

Choosing the verification interval (“Verification Interval”) ––> Chapter 7.7.3

Specifying the capacity of the weighing system (“Scale Capacity”) ––> Chapter 7.7.4

Choosing the resolution (“Resolution”) ––> Chapter 7.7.5

Page 56

FTx/ITx-SH-e-0720 57

7.7.1 Defining the scale type (

SCALE –> Scale Build –> Scale Type

)

The following scale types are available

“Single Range” Single-range scale.

“2 Multi Interval” Scale with coarse range and 1 movable fine range. Automatic switching between the ranges in

both directions.