Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Tel: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Operating instruction

Platform scale

KERN ILT

Version 1.2

04/2006

GB

ILT-BA-e-0612

Page 2

ILT-BA-e-0612

2

GB

KERN ILT

Version 1.2 04/2006

Operating instruction

Platform scale

Contents

1 Technical data__________________________________________________ 4

2 Declaration of conformity ________________________________________

6

3 Appliance overview _____________________________________________ 8

4 Basic Information (General)______________________________________ 10

4.1 Proper use______________________________________________________ 10

4.2 Improper Use ___________________________________________________ 10

4.3 Warranty _______________________________________________________ 10

4.4 Monitoring of Test Resources ______________________________________ 10

5 Basic Safety Precautions________________________________________ 11

5.1 Pay attention to the instructions in the Operation Manual_______________ 11

5.2 Personnel training _______________________________________________ 11

6 Transport and storage __________________________________________ 11

6.1 Testing upon acceptance _________________________________________ 11

6.2 Packaging ______________________________________________________ 11

7 Unpacking, Setup and Commissioning ____________________________

11

7.1 Installation Site, Location of Use ___________________________________ 11

7.2 Unpacking ______________________________________________________ 12

7.2.1 Setup ______________________________________________________________ 13

7.2.2 Scope of delivery _____________________________________________________ 13

7.3 Mains connection ________________________________________________ 13

7.4 Connection of peripheral devices___________________________________ 13

7.5 Initial Commissioning ____________________________________________ 13

Page 3

ILT-BA-e-0612

3

8 User menu ____________________________________________________ 14

8.1 User principle of the menu control __________________________________ 17

8.2 Operation of the balance with PS/2-keyboard _________________________ 18

8.3 Menu selection __________________________________________________ 19

8.3.1 P1 Calibration (adjustment) _____________________________________________ 19

8.3.2 P2 GLP (Good laboratory practice) _______________________________________ 25

8.3.3 P3 Date/time_________________________________________________________ 27

8.3.4 P4 Readout__________________________________________________________ 29

8.3.5 P5 RS-232 __________________________________________________________ 32

8.3.6 P6 Printout __________________________________________________________ 34

8.3.7 P7 Units ____________________________________________________________ 40

8.3.8 P8 Operating modes___________________________________________________ 40

8.3.9 P9 Globals __________________________________________________________ 41

9 Operation_____________________________________________________ 42

9.1 Operating modes (P8) ____________________________________________ 44

9.1.1 Simple weighing ______________________________________________________ 46

9.1.2 Counting ____________________________________________________________ 47

9.1.3 Checkweighing (weighing with tolerance range) _____________________________ 55

9.1.4 Filling ______________________________________________________________ 57

9.1.5 Percent weighing _____________________________________________________ 58

9.1.6 Animal weighing (dynamic weighing) ______________________________________ 60

9.1.7 Formulation__________________________________________________________ 63

9.1.8 Statistics: ___________________________________________________________ 67

10 Data output _________________________________________________ 70

10.1 Technical data___________________________________________________ 70

10.2 Pin allocation of the balance output plug (front view) __________________ 70

10.3 Remote control instructions _______________________________________ 71

11 Service, maintenance, disposal_________________________________ 72

11.1 Cleaning _______________________________________________________ 72

11.2 Service, maintenance_____________________________________________ 72

11.3 Disposal________________________________________________________ 72

12 Instant help _________________________________________________

73

Page 4

ILT-BA-e-0612

4

1 Technical data

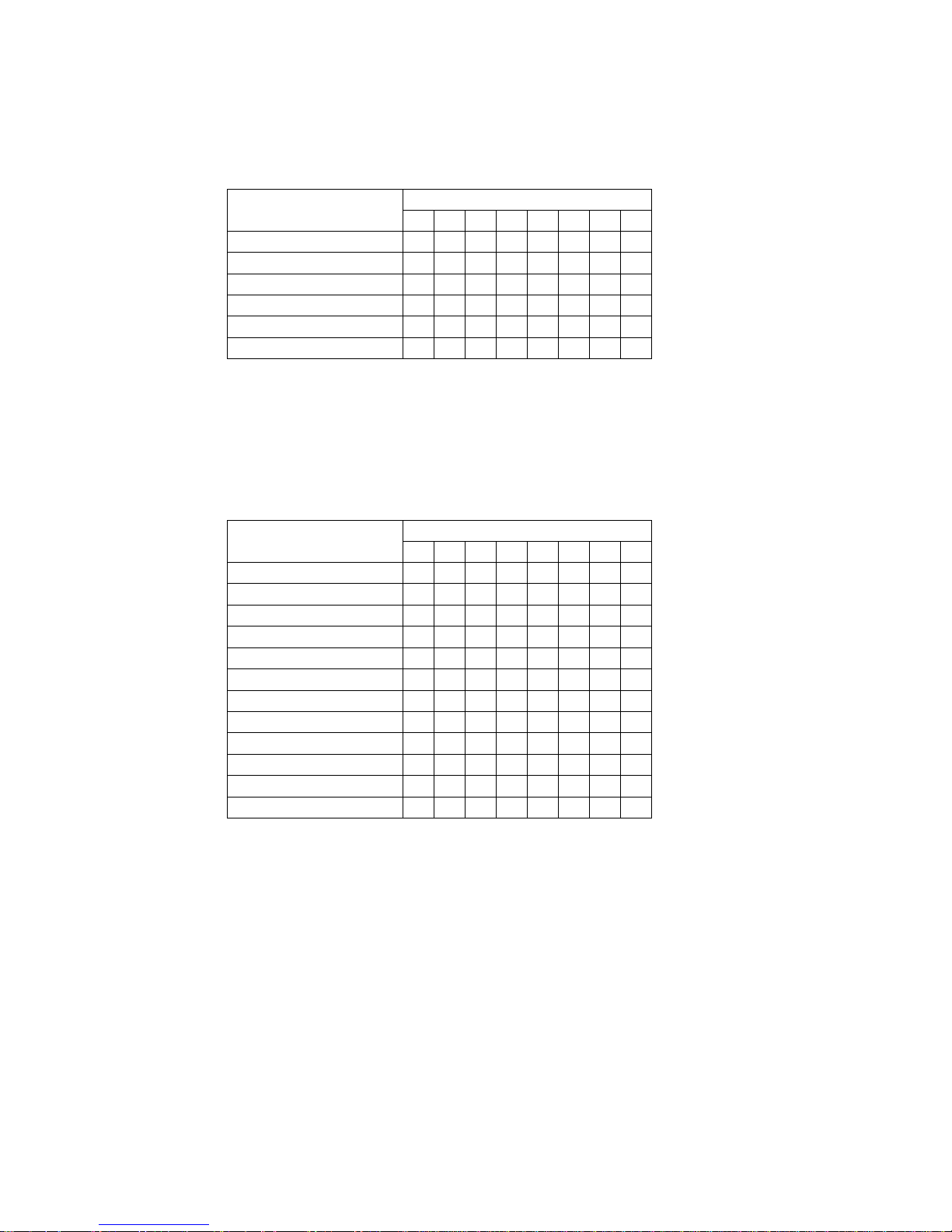

KERN ILT 12K0.1DM ILT 30K0.2DM

Readability (d) 0.1/0.2 g 0.2/0.5 g

Weighing range (max) 6/12 kg 12/30 kg

Minimum load 5/10 g 10/25 g

Verification value 1/2 g 2/5 g

Verification class II II

Reproducibility 0.2/0.4 g 0.4/1 g

Linearity ± 0.2/0.4 g ± 0.4/1 g

Recommended adjusting

weight (not supplied)

10 kg (F2) 20 kg (F2)

Minimum piece weight for

counting function

> 0.1 g > 0.2 g

Stabilization time 4 sec.

Weighing units

(calibrated appliances)

g, kg

Weighing units

(non-calibrated appliances)

g, kg, ct, lb, oz, ozt, dwt, t {h}, t {S}, t {t}, mom, GN, N, t,

freely programmable

Reference quantities at

piece counting

10, 20, 50,100, freely selectable

Weighing plate, stainless

steel

300 x 300 mm

Dimensions of the housing

(B x D x H)

300 x 300 x 75 (platform)

197 x 110 x 35 ( display)

Net weight (kg) 7,7

Permitted environmental

condition

-15° C to 30° C

Humidity of air max. 80 % relative (not condensing)

Voltage 230 V/50Hz

Page 5

ILT-BA-e-0612

5

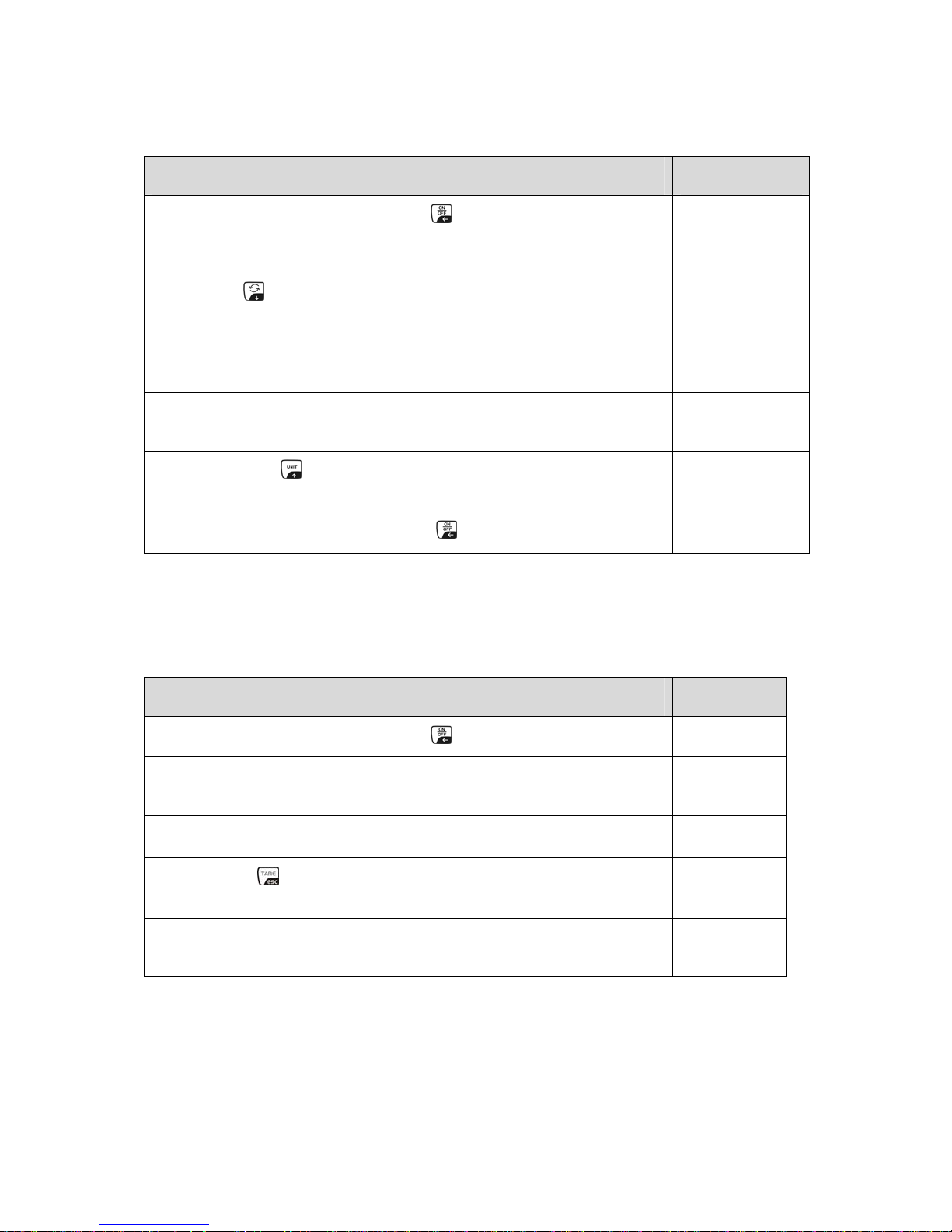

KERN ILT 60K0.5DM ILT 120K1DM

Readability (d) 0.5/1 g 1/2 g

Weighing range (max) 30/60 kg 60/120 kg

Minimum load 25/50 g 50/100 g

Verification value 5/10 g 10/20 g

Verification class II II

Reproducibility 1/2 g 2/4 g

Linearity ± 1/2 g ± 2/4 g

Recommended adjusting

weight (not supplied)

50 kg (F2) 100 kg (F2)

Minimum piece weight for

counting function

> 1 g > 1 g

Stabilization time 4 sec.

Weighing units

(calibrated appliances)

g, kg

Weighing units

(non-calibrated appliances)

g, kg, ct, lb, oz, ozt, dwt, t {h}, t {S}, t {t}, mom, GN, N, t,

freely programmable

Reference quantities at

piece counting

10, 20, 50,100, freely selectable

Weighing plate, stainless

steel

410 x 410 mm

Dimensions of the housing

(B x D x H)

410 x 410 x 90 (platform)

197 x 110 x 35 ( display)

Net weight (kg) 13

Permitted environmental

condition

-15° C to 30° C

Humidity of air max. 80 % relative (not condensing)

Voltage 230 V/50Hz

Page 6

ILT-BA-e-0612

6

2 Declaration of conformity

KERN & Sohn GmbH

D-72322 Balingen-Frommern

Postfach 4052

E-Mail: info@kern-sohn.de

Tel: 0049-[0]7433- 9933-0

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.de

Konformitätserklärung

Declaration of conformity for apparatus with CE mark

Konformitätserklärung für Geräte mit CE-Zeichen

Déclaration de conformité pour appareils portant la marque CE

Declaración de conformidad para aparatos con marca CE

Dichiarazione di conformitá per apparecchi contrassegnati con la marcatura CE

English

We hereby declare that the product to which this declaration refers conforms with the

following standards.

Deutsch

Wir erklären hiermit, dass das Produkt, auf das sich diese Erklärung bezieht, mit den

nachstehenden Normen übereinstimmt.

Français

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la présente

déclaration, est conforme aux normes citées ci-après.

Español

Manifestamos en la presente que el producto al que se refiere esta declaración est´´a de

acuerdo con las normas siguientes

Italiano

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si riferisce è

conforme alle norme di seguito citate.

Electronic Balance: KERN ILT

Mark applied EU Directive Standards

89/336/EEC EMC

EN45501

EN55022

73/23/EEC Low Voltage EN60950

Date: 30.01.2006 Signature:

Gottl. KERN & Sohn GmbH

Management

Gottl. KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-[0]7433/9933-0,Fax +49-[0]7433/9933-149

Page 7

ILT-BA-e-0612

7

KERN & Sohn GmbH

D-72322 Balingen-Frommern

Postfach 4052

E-Mail: info@kern-sohn.de

Tel: 0049-[0]7433- 9933-0

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.de

Konformitätserklärung

Declaration of conformity for apparatus with CE mark

Konformitätserklärung für Geräte mit CE-Zeichen

Déclaration de conformité pour appareils portant la marque CE

Declaración de conformidad para aparatos con marca CE

Dichiarazione di conformitá per apparecchi contrassegnati con la marcatura CE

English

We hereby declare that the product to which this declaration refers conforms with the

following standards.

This declaration is only valid with the certificate of conformity by a notified body.

Deutsch

Wir erklären hiermit, dass das Produkt, auf das sich diese Erklärung bezieht, mit den

nachstehenden Normen übereinstimmt.

Diese Erklärung gilt nur in Verbindung mit der Konformitätsbescheinigung einer

benannten Stelle.

Français

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la présente

déclaration, est conforme aux normes citées ci-après.

Cette déclaration est valide seulement avec un certificat de conformité d’un

organisme notifié.

Español

Manifestamos en la presente que el producto al que se refiere esta declaración está de

acuerdo con las normas siguientes.

Esta declaración solo será válida acompañada del certificado de conformidad de

conformidad de la parte nominal.

Italiano

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si riferisce è

conforme alle norme di seguito citate.

Questa dichiarazione sarà valida solo se accompagnata dal certificato di conformità

della parte nominale.

Model: KERN ILT

EU Directive Standards

EC-type-approval certificate no. Issued by

90/384/EEC EN 45501 PL 06 001

GUM

Date: 30.01.2006 Signature:

Gottl. KERN & Sohn GmbH

Management

Gottl. KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-07433/9933-0,Fax +49-074433/9933-149

Page 8

ILT-BA-e-0612

8

3 Appliance overview

Models: ILT 12K0.1DM, ILT 30K0.2M

1. Mains connection

2. PS/2 keyboard

3. RS 232 interface

Air bubble

ON/OFF switch

Page 9

ILT-BA-e-0612

9

Models: ILT 60k0.50M, ILT 120K1DM

1. ON/OFF switch

2. Mains connection

3. PS/2 keyboard

4. RS 232 interface

Air bubble (underneath weighing plate)

Page 10

ILT-BA-e-0612

10

4 Basic Information (General)

4.1 Proper use

The balance you purchased is intended to determine the weighing value of material

to be weighed. It is intended to be used as a “non-automatic“ balance, i.e. the

material to be weighed is manually and carefully placed in the centre of the weighing

plate. As soon as a stable weighing value is reached the weighing value can be read.

4.2 Improper Use

Do not use balance for dynamic add-on weighing procedures, if small amounts of

goods to be weighed are removed or added. The “stability compensation“ installed in

the balance may result in displaying an incorrect measuring value! (Example: Slowly

draining fluids from a container on the balance.)

Do not leave permanent load on the weighing plate. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the balance,

minus a possibly existing tare load, must be strictly avoided. Balance may be

damage by this.

Never operate balance in explosive environment. The serial version is not explosion

protected.

The structure of the balance may not be modified. This may lead to incorrect

weighing results, safety-related faults and destruction of the balance.

The balance may only be used according to the described conditions. Other areas of

use must be released by KERN in writing.

4.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical dammage or dammage by media, liquids, natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

4.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the

balance and, if applicable, the testing weight, must be checked regularly. The

responsible user must define a suitable interval as well as type and scope of this test.

Information is available on KERN’s home page (www.kern-sohn.com with regard to

the monitoring of balance test substances and the test weights required for this. In

KERN’s accredited DKD calibration laboratory test weights and balances may be

calibrated (return to the national standard) fast and at moderate cost.

Page 11

ILT-BA-e-0612

11

5 Basic Safety Precautions

5.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and commissioning, even if you

are already familiar with KERN balances.

5.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

6 Transport and storage

6.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

6.2 Packaging

Keep all parts of the original packaging in case you need to return the appliance.

Only use original packaging for returning.

Before sending, disconnect all connected cables and loose/movable parts.

Attach possibly existing transport safeguards. Secure all parts, e.g. weighing plate,

power unit etc., to prevent slipping and damage.

7 Unpacking, Setup and Commissioning

7.1 Installation Site, Location of Use

The balances are designed in a way that reliable weighing results are achieved in

common conditions of use.

You will work accurately and fast, if you select the right location for your balance.

Therefore, observe the following for the installation site:

• Place the balance on a firm, level surface;

• Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

• Protect the balance against direct draughts due to open windows and doors;

• Avoid jarring during weighing;

• Protect the balance against high humidity, vapours and dust;

• Do not expose the device to extreme dampness for longer periods of time.

Non-permitted condensation (condensation of air humidity on the appliance)

may occur if a cold appliance is taken to a considerably warmer environment.

In this case, acclimatize the disconnected appliance for ca. 2 hours at room

temperature.

• Avoid static charge of goods to be weighed or weighing container.

Page 12

ILT-BA-e-0612

12

If electro-magnetic fields or static charge occur, or if the power supply is unstable

major deviations on the display (incorrect weighing results) are possible. In that case,

the location must be changed.

7.2 Unpacking

Carefully remove the balance from the packaging and setup balance at the intended

workstation.

Remove the transport arrestment (models ILT 60k0.50M, ILT 120K1DM):

• Screw in the 4 foot screws

• Remove the 4 plastic inserts (2)

• Place the weighing pan (3) on the balance

Page 13

ILT-BA-e-0612

13

7.2.1 Setup

Level balance with foot screws until the air bubble of the water balance is in the

prescribed circle.

7.2.2 Scope of delivery

Serial accessories:

• Balance

• Weighing plate

• Mains power supply

• Operating Manual

• Safety hood above control panel

7.3 Mains connection

Power is supplied via the external mains power supply. The stated voltage value

must be the same as the local voltage.

Only use original KERN mains power supplies. Using other makes requires consent

by KERN.

7.4 Connection of peripheral devices

Before connecting or disconnecting of additional devices (printer, PC) to the data

interface, always disconnect the balance from the power supply.

With your balance, only use accessories and peripheral devices by KERN, as they

are ideally tuned to your balance.

7.5 Initial Commissioning

A warming up time of 15 minutes after switching on stabilizes the measuring values.

The accuracy of the balance depends on the local acceleration of gravity.

Strictly observe hints in chapter Adjustment.

Page 14

ILT-BA-e-0612

14

8 User menu

The user menu has nine main menus (P1 - P9), arranged in the following sub-menus:

P1 Calibration

01 External calibration * * * * * * * * Function

02 User calibration * * * * * * * * Function

03 Calibration test * * * * * * * * Function

04 Print report 1 on

P2 GLP

01 User

02 Project

03 Time print 1 on

04 Date print 1 on

05 User print 1 on

06 Project print 1 on

07 Id printout 1 on

08 Last Cal. print 1 on

P3 Date/time

01 Date format 0 DA/MO/YR

02 Time format 0 24 hour

03 Time * * * * * * * * Function

04 Date * * * * * * * * Function

05 Display time 1 on

06 Display date 1 on

P4 Readout

01 Filter 3 normal

02 Med. filter 1 active

03 Disp.refresh 1

04 Auto zero 1 on

05 Last digit 1 always

06 Negative 0 disabled

Page 15

ILT-BA-e-0612

15

P5 RS-232

01 Baud rate 1 4800

02 Parity 0 None

03 Data bits 2 8 bit

04 Stop bits 1 1 Stop bit

05 Handshake 0 none

06 Auto. Print 0 None

07 Interval 1 * 0.04 s

08 Min. mass 4 10 d

09 Print on stab 1 enabled

10 Pause 1 * 0.1 s

P6 Printouts

01 Prontout men. * * * * * * * * Function

02 1. Printout dest. 0 RS+Mem

03 Printout No. 0 Standard

04 Printout Mem. No. 0 Standard

05 1. Printout start 1

06 1. Printout stop 1

07 2. Printout start 1

08 2. Printout stop 1

.. ………………….

13 1. String

14 2. String

.. ………………….

92 80. String

P7 Units

01 Gram 1 enabled

02 Kilogram 0 disabled

03 Pound 0 disabled

04 Ounce 0 disabled

05 Troy ounce 0 disabled

06 Carat 0 disabled

07 Dwt 0 disabled

08 Teal Hk. 0 disabled

09 Teal S. 0 disabled

10 T.eal T 0 disabled

11 Momme 0 disabled

12 Grain 0 disabled

13 Newton 0 disabled

14 Tical 0 disabled

15 User defined 0 disabled

16 User factor 0.1

P8 Operating modes

01 Parts Count 1 enabled

02 Checkweighing 1 enabled

03 Filling 1 enabled

04 Percent 1 enabled

05 Animal 1 enabled

06 Density 1 enabled

07 Formulation 1 enabled

08 Statistics 1 enabled

Page 16

ILT-BA-e-0612

16

P9 Globals

01 ID setting * * * * * * * * Function

02 ID autoprint 0 no

03 Beep 1 on

04 Language * * * * * * * * Function

05 Backlight 1 on

06 Contrast * * * * * * * * Function

07 Screensaver 0 disabled

08 Balance Id WL141475

09 Software rev. MBT 1b24

10 Parameter printout * * * * * * * * Function

11 Parameter receive. * * * * * * * * Function

Main menu:

1. Menu number (P1 - P9)

2. Menu designation

3. Cursor ( ► ) indicates the current

menu item

Submenu:

1. Main menu number (P1 – P9)

2. Sub-menu number and designation

3. Parameter value or ****** i.e. this

menu item is stored as function

4. Description of function

5. Cursor ( ► ) shows the current

menu item (e.g. P1).

6. Cursor ( ► ) shows the current

setting (e.g. 06).

7. Status

8. Use the arrow key to modify the

parameter value, the active

parameter blinks.

Page 17

ILT-BA-e-0612

17

8.1 User principle of the menu control

In the menu the settings of the balance can be modified and functions can be

activated.

This way, the balance can be adjusted to individual weighing requirements. Proceed

as follows:

Ö Switch on the balance using the -key

Ö After actuating the key the display shows the main menus that can be set

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Global

s

Setup2.02.05

Ö Use the cursor ( ► ) to select your setting

Use the key to move the cursor ( ► ) down, the key to move it up

Ö The key confirms your selected setting, the display shows the sub-menu or the

active menu item blinks:

Setup

P1

01 Int. calibr.

02 Ext. calibr.

03 User calibr.

04 Calib r. test

05 Weig ht. co rr.

06 Aut calibr.

07

Print report

o

Auto cal. time

08

********

********

********

********

0.0

0

1

function

function

function

of f

on

function

31.01.05

1

1 hour

Ö Use the arrow keys to move within and enter into the menu:

• Cursor control up

• Parameter selection within function

• Increasing the value for selected numeral or number

• Access to main menu

• Access to sub-menu

• Move to next menu item

on the right inside menu

• Selection of the number

to be changed to the

right (the respective

active position flashes)

• Return to main menu

• Selection of the number

to be changed to the left

(the respective active

position flashes)

• Cursor control down

• Parameter selection within function

• Decreasing the value for selected numeral or number

Page 18

ILT-BA-e-0612

18

Ö Actuating the -key will confirm your setting; to interrupt use the -key

Ö Press -key to return to menu

Ö Actuate -key again, a message will inquire whether you want to save the

changes you made.

Ö Actuating the key will save the selected setting.

Ö If you do not want to save your selected setting, press the key

Ö The balance returns automatically into weighing mode.

Weighing

0.0000

g

0% 100%

0

27.01.05

8.2 Operation of the balance with PS/2-keyboard

Using a PS/2 keyboard will help you to enter numbers and texts faster and easier.

Key allocation:

Balance keyboard

PS- keyboard

Page 19

ILT-BA-e-0612

19

8.3 Menu selection

8.3.1 P1 Calibration (adjustment)

As the acceleration value due to gravity is not the same at every location on earth,

each balance must be coordinated - in compliance with the underlying physical

weighing principle - to the existing acceleration due to gravity at its place of location

(only if the balance has not already been adjusted to the location in the factory). This

adjustment process must be carried out for the first commissioning, after each

change of location as well as in case of fluctuating environment temperature. To

receive accurate measuring values it is also recommended to adjust the balance

periodically in weighing operation.

Procedure when adjusting:

Observe stable environmental conditions. A warming up time of ca. 1 hour is required

for stabilization.

Note!

During the adjustment process no objects should be on the weighing plate.

In calibrated balances the adjustment function is switch locked. To carry out an

adjustment, the switch must be unlocked, see chpt. 8.3.1.2

Operation Display

Ö Call up menu item "P1 Calibration" (see chapt. 8.1)

Ö Press -button

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Globals

Setup2.02.05

01 Ext. Cal - adjustment with external weight (locked for verifiable devices)

Ö Use the cursor ( ► ) to select "01 Ext. cal."

Einstellungen

P1

01

02

03

04

Ext.

test

Pr

User calibr.

C

int report

calibr.

alibr.

********

********

********

1

func tion

func tion

on

func tion

29.12.04

Ö Press -button

Ensure that there are no objects on the weighing

plate.

Ö Press -key, on the display appears the weight

value of the adjusting weight.

Page 20

ILT-BA-e-0612

20

Ö Now move the adjusting weight to the centre of

the weighing plate, press -key. If the

adjustment was successful, this will be followed

by automatic reset to the menu.

The -key may be used to cancel the

adjustment. Errors during adjustment or the use

of an incorrect adjusting weight will result in an

error message. Repeat adjustment.

Einstellungen

P1

01

02

03

04

Ext.

test

Pr

User calib r.

C

int repo rt

calibr.

alibr.

********

********

********

1

func tion

func tion

on

func tion

29.12.04

Ö Press -key until you enter the menu/weighing

mode (see chapt. 8.1)

02 User cal. (locked in calibrated appliances)

Ö Use the cursor ( ► ) to select „02 User cal.“

Einstellungen

P1

01

02

03

04

Ext.

test

Pr

calibr.

alibr.

User calib r.

C

int repo rt

********

********

********

1

func tion

func tion

on

func tion

29.12.04

Ö Press -key, on the display appears the weight

value of the adjusting weight. The first digit of the

displayed value is flashing. Now you can change

the weight value by pressing the arrow keys.

After adjusting, confirm your new adjusting weight

by pressing the -key.

Einstellungen

Benutzerk ierungalibr

Masse eingeben g :

12000.00

[]

Ö Ensure that there are no objects on the weighing

plate. Press -button

Ö Press -key, the display shows the weight

value of the adjusting value set by you

Page 21

ILT-BA-e-0612

21

Ö Now move the adjusting weight to the centre of

the weighing plate, press -key. If the

adjustment was successful, this will be followed

by automatic reset to the menu.

The -key may be used to cancel the

adjustment.

Errors during adjustment or the use of an

incorrect adjusting weight will result in an error

message. Repeat adjustment.

Einstellungen

P1

01

02

03

04

Ext.

test

Pr

calibr.

alibr.

User calib r.

C

int repo rt

********

********

********

1

func tion

func tion

on

func tion

29.12.04

We recommend:

Carry out all adjustments as close as possible to the maximum load of the

balance. Info about test weights can be found on the Internet at: http://www.kernsohn.com

03 Cal. test

Here, deviation from the last adjustment is determined. This is only a check, i.e. no

values are changed.

Ö Use the cursor ( ► ) to select "03 Cal. test"

Einstellungen

P1

01

02

03

04

Ext.

test

Pr

calibr.

alibr.

User ca libr.

C

int rep ort

********

********

********

1

func tion

func tion

on

func tion

29.12.04

Ö Press -button

Calibration

Calibration check

Clear the p an

[Enter]

Ö Press -key, on the display appears the weight

value of the adjusting weight.

Calibration

Calibration check

weight measuring

Einstellungen

Calibration check

Load weight

[]

12000.0g

Enter

Ö Now set the adjusting weight in the centre of the

weighing plate. Press -key; calibration test will

be executed automatically

Kalibrierung

Kalibrierungstest

Bitte warten

Ö The result is displayed

Calibration

Check results

Cal.: 180.1354

Act.: 180.1438

Diff.: - 0.0084

Page 22

ILT-BA-e-0612

22

04 Print report – printout of adjusting data

Ö Use the cursor ( ► ) to select "04 Print report"

Ö Press -key, the current menu items starts

flashing

Highlight your settings by using the arrow keys

0 Print report deactivated

1 Print report activated

Einstellungen

P1

01

02

03

04

Ext.

test

Pr

calibr.

alibr.

User calib r.

C

int repo rt

********

********

********

1

func tion

func tion

on

func tion

29.12.04

Ö Confirm with the -key

Ö With "Print report" activated, you will receive a printout of your adjustment data

after each adjustment (example):

8.3.1.1 Verification

General introduction:

According to EU directive 90/384/EEC balances must be officially verified if they are

used as follows (legally controlled area):

a) For commercial transactions if the price of goods is determined by weighing

b) For the production of medicines in pharmacies as well as for analyses in the

medical and pharmaceutical laboratory

c) For official purposes.

d) For manufacturing final packages.

In cases of doubt, please contact your local trade in standard.

Verification instructions

An EU type approval exists for balances described in their technical data as

verifyable. If a balance is used where obligation to verify exists as described above, it

must officially verified and re-verified in regular intervals.

Re-verification of a balance is carried out according to the respective national

regulations. The validity for verification of balances in Germany is e.g. 2 years.

The legal regulation of the country where the balance is used must be observed!

***Report of external calibration***

Calibration : external

Diff.. : 0.0038 g

Signature………………………….

Page 23

ILT-BA-e-0612

23

Seal of approval

Balances with obligation to verify must be taken out of operation if:

• The weighing result of the balance is outside the error limit.

Therefore, in regular intervals load balance with known test weight (ca.

1/3 of the max. load) and compare with displayed value.

• The reverification deadline has been exceeded.

8.3.1.2 Seals and unlocking switch

After verification the balance is sealed at the indicated positions.

Verification of the balance is invalid without the "seal".

1. Top of the balance

• Remove weighing plate

2. Lateral view

Seal of approval

Unlocking switch

Page 24

ILT-BA-e-0612

24

Unlock the balance for the adjusting process:

Operation Display

Ö Remove the seal of approval

(Attention: Verification no longer valid!)

Ö Switch off the balance

Ö Switch on the balance whilst keeping the

adjusting switch pressed down

Ö As soon as the pictograph for “balance“ appears,

release the adjusting switch.

Ö Wait until the balance is in weighing mode

Ö Press -button

13:47:32

0.0000

Weighi ng29.12.04

Ø

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Globals

Setup2.02.05

Access to service menu P0 factory settings:

Ö Press -button

P0 Factory

n

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Globals

P1 Calibratio

Setup2.02.05

Ö Press -key, selection of parameters appears

Ö Trigger parameter 18 LFT by pressing the

-key and select ”0” setting. Your balance is

now unlocked for the adjusting process and all

weighing units are activated.

Einstellungen

P 0

14 Autozero delay 6 2.0 s

15 Stable rang e 10 1.0 d

16 Stable s peed 4 0.8 s

17 Filter range 7 100 d

18 LFT 0 off

Ö Confirm and store by pressing the -key

(see chpt. 8.1)

Ö To reset the balance to the calibrated setting,

select setting "1“ for parameter 18 LFT. Now only

the metric weighing units (g, kg) are activated.

Page 25

ILT-BA-e-0612

25

8.3.2 P2 GLP (Good laboratory practice)

Quality assurance systems require printouts of weighing results as well as of correct

adjustment of the balance stating date and time and balance identification. The

easiest way is to have a printer connected.

Definition of a standard log:

Operation Display

Ö Call up menu item "P2 GLP" (see chapt. 8.1)

Ö Press

-button

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Globals

Setup20.02.05

01 User

Ö Use the cursor ( ► ) to select "01 User"

Ö Press -key, the current menu item is flashing

Use the arrow keys, to enter user name or

number (maximal 8 characters) with the arrow

keys.

Setup

P2

01 User

02 Pr

03 Time print

04 Date print

05 User print

oject

ojekt

Last Cal

06 P print

07 Id print

08 Print

WX/235

0

1

Nowak

0

1

1

0

off

on

off

on

on

off

31.01.05

Ö Confirm with -key

02 Project

Ö Use the cursor ( ► ) to select "02 Project"

Ö Press

-key, the current menu item is flashing

Use the arrow keys, to enter project name or

number (maximal 8 characters)

Setup

P2

01 User

02 Pr

03 Time print

04 Date print

05 User print

oject

ojekt

Last Cal

06 P print

07 Id print

08 Print

WX/235

0

1

Nowak

0

1

1

0

off

on

off

on

on

off

31.01.05

Ö Confirm with -key

All other settings (03 - 08) are executed in the same

way.

Page 26

ILT-BA-e-0612

26

All settings that are supposed to be printed must be activated with "1 / yes" .

Example 1:

Setting Printout

P2 03 Printout time

1

yes

P2 04 Printout date

1

yes

P2 05 User printout

1

yes

P2 06 Project printout

1

yes

P2 07 ID-printout

1

yes

P2 08 Cal. printout

1

yes

Example 2:

Setting Printout

P2 03 Printout time

0 no

P2 04 Printout date

1 yes

P2 05 User printout

1 yes

P2 06 Project printout

0 no

P2 07 ID-printout

1 yes

P2 08 Cal. printout

0 no

Date : 18.01.05

Time : 10:41:05

User : Mustermann

Project : AB/007

Balance no: : WL 041078

----------------------------

18.01.05 07:48

Automatic calibration

Deviation : 0.003[5] g

-----------------------------------

10.429[0] g

Date: 22/10/2004

User: Mustermann

Balance no: 10

---------------------------------------

13.0521 g

Page 27

ILT-BA-e-0612

27

8.3.3 P3 Date/time

Under this menu item you can set output and formatting of date and time in the status

bar.

Operation Display

Ö Call up menu item "P3 Date/time" (see chap. 8.1)

Ö Press -button

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Global

s

Setup20.02.05

01 Date format

Ö Use the cursor ( ► ) to select "01 Date format"

Ö Press the -key; the current menu item blinks

Ö Use the -key to select between the following

settings:

1 Month/Day/Year

0 Day/Month/Year

Setup

P3

01

02

03

04

05

Date forma t

Time for ma t

Time

Date

Disp. time

Date06 Disp.

1

1

0

1

DA /MO/Y R

24 Std.

********

Function

********

On

On

Function

29.12.04

Ö Confirm with -key

02 Time format

Ö Use the cursor ( ► ) to select "02 Time format"

Ö Press the

-key; the current menu item blinks

Ö Use the -key to select between the following

settings:

0 24 hours

1 12 hours (PM/AM)

Setup

P3

01

02

03

04

05

Date format

Time for ma t

Time

Date

Disp. time

Date06 Disp.

1

1

0

1

DA /MO/Y R

24 Std.

********

Function

********

On

On

Function

29.12.04

Ö Confirm with -key

Page 28

ILT-BA-e-0612

28

03 Time

Ö Use the cursor ( ► ) to select "03 Time"

Setup

P3

01

02

03

04

05

Date forma t

Time for ma t

Time

Date

Disp. time

Date06 Disp.

1

1

0

1

DA /MO/Y R

24 Std.

********

Function

********

On

On

Function

29.12.04

Ö Press -button

Ö Use the - or -key to trigger your selection

Ö Use the -key to confirm your selection (e.g.

hours), the current menu item blinks

Ö Use the -key, to increase and the -key to

decrease the number value

Ö Use the - and -keys to select the place to be

changed (the respective active place blinks)

Ö Use the -key to confirm your selection (e.g.

hours).

Ö To change minutes and seconds proceed in the

same way.

Ö Confirm with -key

04 Date

Ö Use the cursor ( ► ) to select "04 Date"

Setup

P3

01

02

03

04

05

Date forma t

Time for ma t

Time

Date

Disp. time

Date06 Disp.

1

1

0

1

DA /MO/Y R

24 Std.

********

Function

********

On

On

Function

29.12.04

Ö Press -button

Setup

Year 200

Mo 11

10

4

nth

Day

APRIL 2004

Setup

29.12.04

Ö All other settings are made in the same way as time

(03 Time).

Page 29

ILT-BA-e-0612

29

05/06 Displ. Time/Date

Ö Use the cursor ( ► ) to select e.g.

"05 Displ.time/date"

Ö Press the -key; the current menu item blinks

Ö Use the -key to select between the following

settings:

0 Time/date is displayed in the status bar

1 Time/date is not displayed in status bar

Setup

P3

01

02

03

04

05

Date forma t

Time for ma t

Time

Date

Disp. time

Date06 Disp.

1

1

0

1

DA /MO/Y R

24 Std.

********

Function

********

On

On

Function

29.12.04

Ö Confirm with -key

8.3.4 P4 Readout

Operation Display

Ö Call up menu item "P4 Readout" (see chapt. 8.1)

Ö Press -button

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Global

s

Setup20.02.05

01 Filter

Ö Use the cursor ( ► ) to select "01 Filter"

Ö Press the -key; the current menu item blinks

Ö Use the - and -key to select between the

following settings:

1 Very quiet and stable environment:

Balance works very fast but is more

sensitive to external influences

5 Busy environment:

Balance works more slowly but is less

sensitive to outside influences

Setup

P4

01 Filter

0

0

0

02 Med. Filter

3 Disp refresh

4 Autozero

5 Last digit

06 Negative

5

1

Slowest.

enabled

0.08 s

On

Always

1

1

1

0 disabled

Setup

29.12.05

Ö Confirm with -key

Page 30

ILT-BA-e-0612

30

02 Med. Filter

This is a filter that is adjustable for e.g. 50 sample weighing procedures/ collects,

organizes, averages during a certain interval e.g. in 1 s. Especially useful in case of

impacts or shocks.

Ö Use the cursor ( ► ) to select "02 Med. filter"

Ö Press the -key; the current menu item blinks

Ö Use the - and -key to select one of the

following settings:

0 blocked

1 active

Setup

P4

01 Filter

0

0

0

02 Med. Filter

3 Disp refresh

4 Autozero

5 Last digit

06 Negative

5

1

Slowest.

enabled

0.08 s

On

Always

1

1

1

0 disabled

Setup

29.12.05

Ö Confirm with -key

03 Disp.refresh

Ö Use the cursor ( ► ) to select "03 Disp.refresh"

Ö Press the -key; the current menu item blinks

Ö Use the - and -key to set the time it takes

before the display is refreshed after the weight value

has changed.

1 0.08/ s

5 1.0 s

Setup

P4

01 Filter

0

0

0

02 Med. Filter

3 Disp refresh

4 Autozero

5 Last digit

06 Negative

5

1

Slowest.

enabled

0.08 s

On

Always

1

1

1

0 disabled

Setup

29.12.05

Ö Confirm with -key

04 Autozero

Ö Use the cursor ( ► ) to select "04 Autozero"

Ö Press the -key; the current menu item blinks

Ö Use the - and -key to select one of the

following settings:

0 Deviations from the Zero display are

not automatically tared.

1 Deviations from the Zero display are

automatically tared.

Setup

P4

01 Filter

0

0

0

02 Med. Filter

3 Disp refresh

4 Autozero

5 Last digit

06 Negative

5

1

Slowest.

enabled

0.08 s

On

Always

1

1

1

0 disabled

Setup

29.12.05

Ö Confirm with -key

Page 31

ILT-BA-e-0612

31

05 Last digit

Ö Use the cursor ( ► ) to select “05 Last digit"

Ö Press the -key; the current menu item blinks

Ö Use the - and -key to select one of the

following settings:

0 Last fractional digits are omitted

1 All fractional digits

Setup

P4

01 Filter

0

0

0

02 Med. Filter

3 Disp refresh

4 Autozero

5 Last digit

06 Negative

5

1

Slowest.

enabled

0.08 s

On

Always

1

1

1

0 disabled

Setup

29.12.05

Ö Confirm with -key

06 Negative

Ö Use the cursor ( ► ) to select “06 Negative"

Ö Press the -key; the current menu item blinks

Ö Use the - and -key to reverse the colour

setting of the display

0 blocked

1 active

Setup

P4

01 Filter

0

0

0

02 Med. Filter

3 Disp refresh

4 Autozero

5 Last digit

06 Negative

5

1

Slowest.

enabled

0.08 s

On

Always

1

1

1

0 disabled

Setup

29.12.05

Weighing

0.0000

g

0% 100%

0

27.01.05

Ø

Wiegen

100%

27.01.05

0.0000

g

0%

0

27.01.05

Weighing

Ö Confirm with -key

Page 32

ILT-BA-e-0612

32

8.3.5 P5 RS-232

In this menu item you can save your settings for the interface.

Operation Display

Ö Call up menu item "P5 RS-232" (see chapt. 8.1)

Ö Press -button

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Global

s

Setup20.02.05

01 -10 Parameter selection

Ö Use the cursor ( ► ) to select your parameters

(01 - 10)

Setup

P5

01 B ud rate

02 Parity

03 Data bits

04 Stop bits

05 Handshake

a

Min.mass

09 Print on stab 1 enabled

06 Auto print

07 Inetrval

08

0

0

2

0

9600

8 bits

1 bit

2

1

* 0.1 s

1 d

25

none

1

none

none

29.12.04

01 Baud rate 0

2400

1

4800

2

9600

3

19200

02 Parity 0

none

1

even

2

uneven

03 Data bits 1

7 Bit

2

8 Bit

04 Stop bits 1

1 Stop bit

2

2 Stop bit

05 Handshake 0

None

1

RTS/CTS

2

XON/XOFF

06 Autom. Printout 0

None No data output

1

steady

Continuous serial data

output

2

interval

(discrete)

Serial data output after a

certain interval, defined in

parameter „07 Interval“

3

at resting

Unique autom. Data output

for steady weighing value.

New output only after

removing the weight and

new loading

Page 33

ILT-BA-e-0612

33

07 Interval

1 – 9999

(Enter via

arrow keys)

Definition of an interval after which data output

is executed.

Pulse = parameter value x 0.1 sec

08 Min. measuring

value

1

1 d

2

2 d

3

5 d

13

10000 d

Definition of a minimum measuring

value from which serial data output

is executed

0

blocked

09 Printout at stab.

1

active

Data output for steady weighing

value.

10 Pause 1(factor)

* 0.1s

Period of time between variables

sent by the balance

Ö Press -key, the current menu items starts flashing

Highlight your settings by using the arrow keys

Ö Confirm with -key

Page 34

ILT-BA-e-0612

34

8.3.6 P6 Printout

In this menu item you can select between 5 different types of data output:

Operation Display

Ö Call up menu item "P6 Printout" (see chapt. 8.1)

Ö Press -button

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Global

s

Setup20.02.05

01 Printout memory – This is where you can store and file your standard printouts or,

if required, new printouts can be made

Ö Press -key

The memory capacity is displayed

(max. 500 000 characters).

Ö After data output has taken place (e. g. of 17

printouts) your data will be displayed in the

memory. Use the cursor ( ► ), to select one of

the settings below:

Run: Input as from which printout you require

printouts/deletions

Stop : End, up to which printout you require

printouts/deletions

Print : Printing of data selected by you

Erase : Deletion of data selected by you

Ö Press the -key; the current menu item blinks

Ö Use the - and -key, to select your settings

Ö Use the -key, to confirm your selection

Setup

P6

01 Printout

0 Pr. 1 start

0 Pr. 1 stop

0

0

mem

02 Printout dest.

03 Printout No.

04 Pr. Mem. No.

5

6

7

8

9

10

11

12

3

4

Pr. 2 start

Pr. 2 stop

0 Pr. 3 start

Pr. 3 stop

Pr. 4 start

Pr. 4 stop

1 String 1

1 String 2

88 String 79

89 String 80

0

0

********

2 Rs+M em

function

0 stan dard

0 standard

0

0

0

29.12.04

Page 35

ILT-BA-e-0612

35

02 Printout dest.

Ö Use the cursor ( ► ), to select “02 Printout dest.“

Ö Press -key, the current menu items starts

flashing

Highlight your settings by using the arrow keys

Ö 0 Rs for RS 232 interface

1 Mem for the memory /archive

2 Rs +Mem for RS 232 interface and memory

Setup

P6

01 Printout

0 Pr. 1 start

0 Pr. 1 stop

0

0

mem

02 Printout dest.

03 Printout No.

04 Pr. Mem. No.

5

6

7

8

9

10

11

12

3

4

Pr. 2 start

Pr. 2 stop

0 Pr. 3 start

Pr. 3 stop

Pr. 4 start

Pr. 4 stop

1 String 1

1 String 2

88 String 79

89 String 80

0

0

********

2 Rs+M em

fun ctio n

0 standard

0 standard

0

0

0

29.12.04

03 Printout no.

Ö Use the cursor ( ► ) to select “03 Printout no."

Ö Press the -key; the current menu item blinks

Ö Use the - and -key to select one of the

settings below:

0 standard

1 1. Printout

4 4. Printout

Setup

P6

01 Printout

0 Pr. 1 start

0 Pr. 1 stop

0

0

mem

02 Printout dest.

03 Printout No.

04 Pr. Mem. No.

5

6

7

8

9

10

11

12

3

4

Pr. 2 start

Pr. 2 stop

0 Pr. 3 start

Pr. 3 stop

Pr. 4 start

Pr. 4 stop

1 String 1

1 String 2

88 String 79

89 String 80

0

0

********

2 Rs+M em

fun ctio n

0 standard

0 standard

0

0

0

29.12.04

Ö Use the -key to confirm your selection

8.3.6.1 Standard data output (0 standard)

Data output is carried out by actuating the -key.

Definition of the log header is executed in menu item “P2 GLP”.

Examples.

*: ? = instable measuring value

Date: 22/10/2004

Time: 13.16.49

User: Mustermann

Project: XW/456

Balance 10

? 62.685 g *

Date: 22/10/2004

Time: 13.04.23

User: Mustermann

Project: XW/456

0.008 g

Page 36

ILT-BA-e-0612

36

8.3.6.2 User-defined data output (1. Printout ↔ 4. Printout )

Here you can define 4 different types of data output.

Ö The content of the data output is defined as follows.

First line 1. Printout start - 1, i.e. text begins at line 1 (1. Text)

Last line 1. Printout stop - 20, i.e. text ends at line 20 (20. Text)

Ö Text input per line is carried out via the arrow keys (see chapter 8.1)

in the respective strings.

1. string Start of text input

20. string End of text input

During text input lines may overlap, e.g.:

1. Printout start - 1

1. Printout stop - 40

2. Printout start - 20

2. Printout stop - 40

Text input:

• Max. 640 characters

• 80 lines

• 8 characters per line

Ö After each line confirm your text input using the -key.

Ö After completely entering the text use the

-key to confirm (see chapt. 8.1).

Page 37

ILT-BA-e-0612

37

Apart from flow text (characters, numbers and numerals) the following variables

are stored in the menu:

General variables

%%

Printout of 1 character “%” (i.e. in order to print out 1 character %, two

%% must be entered)

%N

Net weight

%d

Current date

%t

Current time

%i

Balance ID-no.

%R

Program no.

%P

Project no.

%U

User no.

%F

Current function (operating mode)

%C

Date and time of last adjustment

%K

Type of last adjustment

%I

Deviation from last adjustment

%1-5

Code 1-5

Print related variables

\\

Printout of 1 character “/” (i.e. in order to print out 1 character /, two //

must be entered)

\c

CRLF (carriage return line feed)

line beginning next line

\r

CR (carriage return)

line beginning

\n

LF (line feed) next line

\t

Tabulator

\s

Next "Text"

\0

End of data input

Page 38

ILT-BA-e-0612

38

Variables in the various operating modes

Variable Description Operating mode

%W

Reference quantity Parts counting

%H

Lower limit

%L

Upper limit

Weighing with tolerance range

%Z

Nominal value Filling

%B

Reference mass Percent weighing

%A

Sensitivity

%b

Mean Value

Dynamic weighing

(animal weighing)

%I

Liquid

%p

Method

%c

Temperature

%a

Density liquid

%v

Sinker

Density determination

Variable for statistics

%n

Number weighing processes

%x

Mean Value

%S

Sum of all measuring values

%m

Min value

%M

Max value

%D

Difference min and max value

%s

Standard Deviation

%r

Variance

Page 39

ILT-BA-e-0612

39

Examples for text input:

Example 1: Max mass can not exceed 11.250 g!

Text

Parameter No.

1 2 3 4 5 6 7 8

20 string 10 M a x m a s s

21 string 11

c a n n o t

22 string 12

e x c e e d

23 string 13 1 1 . 2 5 0 g

24 string 14

!

25 string 15

Example 2: Kern & Sohn GmbH

Date:

Time:

Weight:

*****Signature:..........

*** Weighing with tolerance range ***

Text

Parameter No.

1 2 3 4 5 6 7 8

26 string 16 K e r n & S

27 string 17 o h n G m b H

28 string 18 \ c D a t u m :

29 string 19 % d \ c Z e i t

30 string 20 : % t \ r \ n G

31 string 21 e w i c h t : %

32 string 22 N \ c \ c * * *

33 string 23 * * U n t e r s

34 string 24 c h r i f t : .

35 string 25 . . . . . . .

36 string 26 . . \ c * * % F

37 string 27 * * * *

Page 40

ILT-BA-e-0612

40

8.3.7 P7 Units

In this menu item you can activate various different weighing units (see chapter 1

“Technical data“). The switchover to the activated units is achieved by pressing the

- key several times.

Operation Display

Ö Call up menu item "P7 Weighing units"

(see chapt. 8.1)

Ö Press -button

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Global

s

Setup20.02.05

01 -16 Parameter selection

Ö Use the cursor ( ► ) to select your setting (01 -16)

Ö Press -key, the current menu items starts

flashing

Highlight your settings by using the arrow keys

0 Weighing unit deactivated

1 Weighing unit activated

Setup

P7

01 Gram

02 gram

03 K

04 P

05

m

Kilo m

arat

fund

Unze

Troy Unze

Dwt

T

Momm es

Grains

Newtons

Tica l

Custom

Custom factor

06

07

08 Taels Hk.

09 Taels S

10 Taels .

11

12

13

14

15

16

0

0

1

0

1

0

0

0

0

0

0

0

0

0

0

1.0

ena bled

disabled

enabled

disabled

disabled

disabled

disabled

disabled

disabled

disabled

disabled

disabled

disabled

disabled

disabled

Setup

29.12.05

Ö Use the -key to confirm your selection

Ö Save (see chapter 8.1)

8.3.8 P8 Operating modes

See Chapter 9.1

Page 41

ILT-BA-e-0612

41

8.3.9 P9 Globals

Operation Display

Ö Call up menu item "P9 Global" (see chapt. 8.1)

Ö Press -button

P1 Calibration

P2 GLP

P3 Date/Time

P4 Readout

P5 RS-232

P6 Printouts

P7 Units

P8 Modes

P9 Global

s

Setup20.02.05

01 -11 Parameter selection

Ö Use the - and -key to select the parameters

“01 - 11“

P9

01

02

03

04

05

ID setting

ID autoprint

Beep

Language

Backlight

Contrast

Screensaver

8 Balance ID

09 Software rev..

0 Par. printout

11 Par. receive

06

07

0

1

1

0

1

Fcun tion

1

on

Fcun tion

On

On

********

********

********

Fcun tion

un tionFc

Setup29.12.04

********

Off

Wl04305

MXA0.40

********

un tionFc

01 ID setting

Entering a user code

02 ID autoprint

User code can also be printed

03 Beep

Tone on/off

04 Language

User control options available in German, English, French,

Spanish, Polish and Czech

05 Backlight

Back lighting of the display on/off

06 Contrast

Contrast of the display

07 Screensaver

Back lighting automatically switches off as soon as a stable

measuring value is reached (Condition: Backlight on)

08 Balance Id

Balance identification no.

09 Software rev.

Software issue

10 Par. Printout

Balance parameters are printed out

11 Par. receive.

Not documented

Ö Press the -key; the current menu item blinks.

Ö Use the - and -key to activate/deactivate parameters

Ö Confirm your selection with the -key

Page 42

ILT-BA-e-0612

42

9 Operation

Operating elements

• Display:

• Overview of display:

Weighing

0.0000

g

0% 100%

0

27.01.05

Stability display

Balance zero-display

Balance zero display:

If the balance does not show exactly zero although the pan scale is unloaded, press

the -button and the balance will be reset to zero. (Display [ → 0 ← ] )

Stability display:

If the display shows the stability display [

] the balance is in a stable status. If

the status is instable the [ ] display disappears.

Page 43

ILT-BA-e-0612

43

Weighing

0.0000

g

0%

100%

4

1

3

6 5

7

0

2

27.01.05

1.

Weight display

2.

Balance zero display

3.

Stability display

4.

Capacity display

5.

Operating mode (status)

6.

Current date

7.

Current time

• Keyboard overview:

Key Function

• Turn on/off

• Set weight display at zero

• Menu item to the left

• Access to the user menu

• Menu item to the right

• Switch-over key into operating modes

• Decreasing the value for selected numeral or number

• Parameter selection (cursor control down)

• Switching-over to other weighing units

• Parameter selection (cursor control up)

• Increasing the value for selected numeral or number

• Printout of the weighed value on an external appliance

(printer or PC)

• Confirm/save settings

• Taring

• Leave menu

Page 44

ILT-BA-e-0612

44

9.1 Operating modes (P8)

Under this menu item you can activate or test weigh the following operating modes of

the balance

P8 01: Parts count

P8 02: Checkweighing

P8 03: Filling

P8 04: Percent weighing

P8 05: Animal weighing

P8 06: Density

P8 07: Formulation

P8 08: Statistics:

Notice: Some operating modes may be combined (e.g. statistics/counting,

statistics/Percent determination). Further details are described in the

respective chapters.

Activation/deactivation of the operating modes:

Ö In main menu call up menu item P8 "Operating mode" (see chapt. 8.1)

Ö Press the -key; the overview of the operating modes is displayed:

Mode

P8

01 Parts Count

02 Checkweighing

03 Filling

04 Perc nt

05 Animal

e

Formulation

08

06 Density

07

Statistics

0

1

0

disabled

1

1

0

1

enabled

disabled

disabled

disabled

enabled

enabled

20.02.05

Ö Use the arrow keys (see chapt. 8.1) to activate (1) or deactivate (0) the desired

operating modes.

Ö Confirm your selection with the

key.

Ö Save (see chapter 8.1)

All activated operating modes are now stored in a sub-menu (M0 - M8) and can be

directly called up directly with the

key:

M0 Basic weighing

M1 Parts coun ting

M2 Ch eckweigh ing

M3 Filling

M4 Percent

M5 Animal weighing

M6 Density

M7 Formulation

M8 Statistics

Mode20.02.05

Page 45

ILT-BA-e-0612

45

Navigating in operating modes mode:

Ö Press -button

Ö Use the cursor ( ► ) to select your operating

mode

M0 Basic weigh ing

M1 Parts counting

M2 Checkweighing

M3 Filling

M4 Percen t

M5 An imal weighing

M6 Density

M7 Formulation

M8 Statistics

Mode20.02.05

Ö Press the -key; the parameter selection appears

Ö Use the cursor ( ► ) to select parameter

Ö Press the -key; the current menu item blinks

Ö Use the arrow keys (see chapter 8.1) to save your settings.

All possible settings are described in the chapters of the respective operating

mode

Ö Confirm your selection with the key.

Ö Press -key again; the graphic display of the

respective operating mode is displayed.

You are now in operating modes mode.

0.0000

g

0% 100%

Dif=- 60.0000

Hi

Lo

Hi=70.0000

Lo=50.0000

LO

Checkweighing

29.12.04

Return to weighing mode:

Ö Press -button

Ö Cursor ( ► ) for "M0 Weighing"

M0 Basic weigh ing

M1 Parts counting

M2 Checkweighing

M3 Filling

M4 Percen t

M5 An imal weighing

M6 Density

M7 Formulation

M8 Statistics

Mode20.02.05

Ö Press the - or -key

13:47:32

0.0000

Wei ghing29.12.04

Page 46

ILT-BA-e-0612

46

9.1.1 Simple weighing

Operation: Display:

Ö Switch on the balance using the -key

or

Ö Use the key to call the menu item „M0 Weighing"

(chap.9.1)

Ö Your balance is ready to weigh as soon as the “0.000" display

appears.

0,0000

Ö Put on items to be weighed; after stability time the measuring

value is displayed.

19.6879 g

Ö Pressing the -key provides option to switch to a different

weighing unit, e.g. ct (see chapt. 8.3.7 " P7 Weighing units")

98.4380 ct

Ö To turn off the balance press the -key

9.1.1.1 Taring

The dead weight of any weighing container may be tared away by pressing a button,

so that the following weighings show the net weight of the goods to be weighed.

Operation: Display:

Ö Switch on the balance using the -key

Ö Your balance is ready to weigh as soon as the “0.0000"

display appears.

0.0000 g

Ö Put on items to be weighed, weighed value is displayed.

19.6879 g

Ö Press the -key to start the tare procedure.

The weight of the container is now saved internally.

0.0000 g

Ö Place the goods to be weighed into the tare container. Read

the weight of the goods on the display.

53.2587 g

The taring process can be repeated any number of times, e.g. when adding several

components for a mixture (adding).

The limit is reached when the whole weighing range is exhausted.

After removing the taring container the total weight is displayed as negative display.

Page 47

ILT-BA-e-0612

47

9.1.2 Counting

Before the balance can count parts, it must know the average part weight (i.e.

reference). This is either entered manually or determined by weighing. Proceed by

putting on a certain number of the parts to be counted. The balance determines the

total weight and divides it by the number of parts (the so-called reference quantity).

Counting is then carried out on the basis of the calculated average piece weight.

As a rule:

The higher the reference quantity the higher the counting exactness.

Display overview for parts counting operation:

1. Number of all parts on the weighing plate

2. Weighing assistance coarse/fine (only displayed for active dispensing)

3. Operating mode (status bar)

4. Reference weight

5. Weight of all parts on the weighing plate

6. Tolerance marker (only displayed for active tolerance weighing)

too light

nominal

value

too heavy

7. Display for parts counting operation

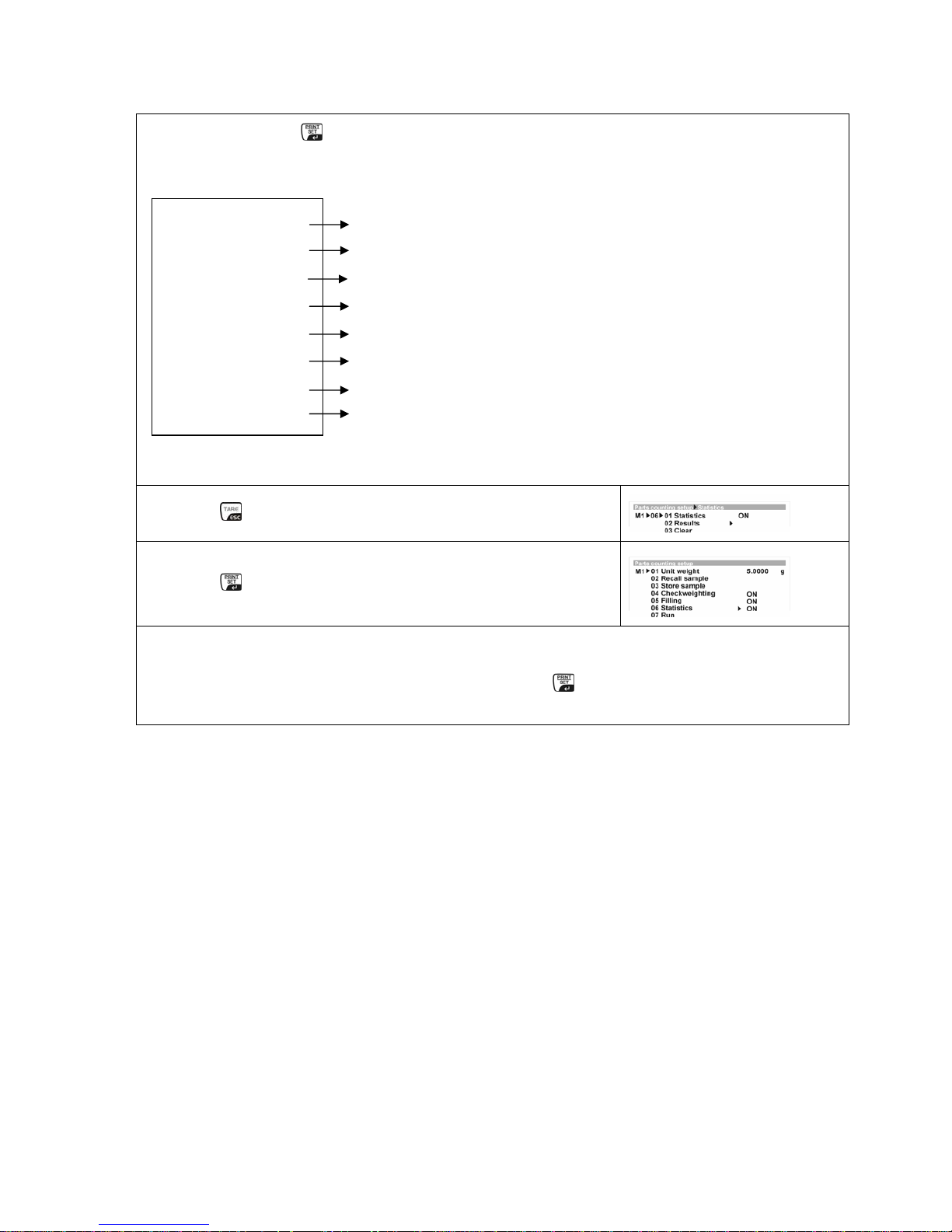

Operation Display

Ö Call up menu item "M1 Counting" (see chap. 9.1)

Ö Press -button

Ö Use the cursor ( ► ) to select your setting (01 - 07)

Parts counting setup

M1 01 U nit weight

02 Recall sample

03 Store samp le

04 Checkweightin g

05 Fillin g

06

07 Run

Statistics

5.0000 g

ON

ON

OFF

01 Reference weight – manual entering of the reference weight

Ö Press the -key; the current menu item blinks.

Use the arrow keys to enter the reference weight for a

unit. Confirm with

-key.

Page 48

ILT-BA-e-0612

48

Ö Press -key; the display changes into parts counting

operation

Ö The balance is now in parts counting mode counting all

units on the weighing plate

01 Reference weight – determination of reference weight through weighing

Ö Press -key; display changes to counting mode

Parts counting setup

M1 01 U nit weight

02 Recall sample

03 Store samp le

04 Checkweightin g

05 Fillin g

06

07 Run

Statistics

5.0000 g

OFF

OFF

OFF

Ö Press the -key; select reference quantity (factory-

defined are quantities of 10, 20, 50,100, or freely

selectable) with the arrow keys,

use the -key to confirm

Ö Place as many counting parts on the weighing plate as

the set reference quantity requires, confirm by pressing

the -key. If you are using a weighing container first

tare your balance pressing the key.

Ö Press -button

The symbol ( ) in the display indicates that automatic

reference optimization is switched on. Every time more

pieces are added the balance carries out optimization

automatically. It is not necessary to press another key to

start the optimization process. For each reference

optimization the average piece weight (reference) is

newly calculated. As the additional pieces increase the

base for the calculation, the reference also becomes

more exact.

Ö Operate the -key. The reference quantity is saved

under "01 Unit weight".

Ö Press the -key; the balance is now in parts counting

mode counting all units on the weighing plate.

Page 49

ILT-BA-e-0612

49

02 Recall sample – calling up a reference weight from the data base

Ö Use the cursor ( ► ) to select "02 Recall sample"

Ö Press -key; the sub-menu "02 Recall sample" is

displayed.

Ö Use the arrow keys to select the desired reference

weight

M1

01 BBBB 01

02 BBBB

03 CCCC

49 AAAA

50 AAAA

02

03

49

50

1.5000

0.4520

1.0032

0.0015

2.0300

g

g

g

g

g

02

Parts counting setup

Ö Use the -key to confirm; the selected reference weight

appears under “01 Unit weight“.

Ö Press the -key; the balance is now in parts counting

mode counting all units on the weighing plate.

03 Store sample - saving a reference weight in the database

The reference weight stored in menu item "01 Reference weight" can be saved in the

data base as follows (max. 200 parameters):

Ö Use the cursor ( ► ) to select "03 Store sample"

Ö Press -key; the sub-menu "03 Store sample" is

displayed.

Page 50

ILT-BA-e-0612

50

Ö Use the arrow keys to select the parameter no.

Ö Press the -key; use the arrow keys to enter

parameter name (max. 10 characters)

Ö Use the -key, to confirm, the blinking section stops

flashing

Ö Use the -key, to return to menu

04 Checkweighing

The combination Counting / Checkweighing enables you to check whether your

reference weight is within your set tolerance

Ö Use the cursor ( ► ) to select "04 Checkweighing".

Ö Press -button

Parts counting setup

M1 01 Unit weig ht

02 Recall sample

03 Store sam ple

04 Checkweigh ting

05 Fillin g

06

07 Run

Statistics

5.0000 g

OFF

on

OFF

Ö Press the -key; the current menu item blinks

Ö Activate operating mode „Checkweighing“ via the arrow

keys (yes).

Ö Set tolerance markers

Ö Each time confirm by pressing the -key

Ö Use the -key, to return to menu

Parts counting setup

M1 01 Unit weig ht

02 Recall sample

03 Store sam ple

04 Checkweigh ting

05 Fillin g

06

07 Run

Statistics

5.0000 g

OFF

on

OFF

Page 51

ILT-BA-e-0612

51

05 Filling

The combination Counting/Filling enables you to define a target quantity

Ö Use the cursor ( ► ) to select "05 Filling"

Ö Press -button

Parts counting setup

M1 01 Un it weigh t

02 Recall sample

03 Store samp le

04 Checkweightin g

05 Fillin g

06

07 Run

Statistics

5.0000 g

OFF

on

on

Ö Press the -key; the current menu item blinks

Ö Activate operating mode "Filling" via arrow keys

Ö Enter value for target weight

Ö Each time confirm by pressing the -key

Ö Use the -key, to return to menu

Parts counting setup

M1 01 Un it weigh t

02 Recall sample

03 Store samp le

04 Checkweightin g

05 Fillin g

06

07 Run

Statistics

5.0000 g

OFF

on

on

06 Statistics

When combining parts counting /statistics the displayed value is accepted by pressing the

-key.

Ö Use the cursor ( ► ) to select “06 Statistics"

Ö Press -button

Ö Press the -key; the current menu item blinks

Ö Use the cursor ( ► ) to select menu item "03 Clear"

Ö Press -button

Ö Use the -key, data will be deleted

Page 52

ILT-BA-e-0612

52

Ö Use the cursor ( ► ) to select "01 Statistics"

Ö Press -button

Ö Activate operating mode “statistics” via the arrow keys

and confirm by pressing the -key

Ö Use the -key, to return to menu

Ö Press -key; display changes into parts counting mode

Ö After each measuring (stable measuring value) press the

-key; the displayed value will be saved and added to

the saved number of values (N).

Ö How to call statistical results after, for example,

10 measurements (N=10)

Use the -key, to call the menu

Ö Use the cursor ( ► ) to select menu item "06

Statistics"

Ö Confirm with -key

Ö Use the cursor ( ► ) to select menu item "02 Results"

Ö Use the -key, to confirm; your statistical results will be

shown on the display

Page 53

ILT-BA-e-0612

53

Ö By actuating the -key you can print your statistical results on a connected printer

(see example).

Ö Press -button

Ö Press -key to return to menu

07 Run

With parameter selection "M1 07 Run" (confirm with -key) you will get directly into

counting mode.

Number weighing processes

Sum of all weighing procedures

Mean Value

Smallest value

Largest value

MAX – MIN

Standard Deviation

Variance

N : 10

SUM : 40 pcs

X : 4 pcs

MIN : 4 pcs

MAX : 5 pcs

D : 1 pcs

SDV : 2 pcs

RDV : 52,7 %

Page 54

ILT-BA-e-0612

54

9.1.2.1 Data output in counting mode

Standard data output:

Key Display GLP parameter Data output

Zählen

17

pcs

0%

100%

APW=5.000 WGH=100.000

20.1.05

P2 03 Printout Time 0: no

P2 04 Printout Date 0: no

P2 05 User printout 0: no

P2 06 Proj. Printout 0: no

P2 07 ID- printout 0: no

P2 08 Cal. printout 0: no

17 pcs

Zählen

17

pcs

0%

100%

APW=5.000 WGH=100.000

20.1.05

P2 03 Printout Time 1: yes

P2 04 Printout Date 1: yes

P2 05 User printout 1: yes

P2 06 Proj. Printout 1: yes

P2 07 ID- printout 1: yes

P2 08 Cal. printout 1: yes

Date: 16/01/2004

Time: 13:12:30

User: Maier

Project: Checking.

Weight: 11111111

Last calibration:

---------------------16/01/2004 13:02

External calibration:

0.0001 g

--------------------- 17 pcs

User-defined data output

Key Display Variable selection Data output

Zählen

15

pcs

0% 100%

0%

90% 110%

90%

N=10

APW=5.000

WGH=100.000

20.01.05

%d;

%t;

%i;

%R;

%P;

%U;

%F;

%V;

%N;

%W;

%n;

%x;

%S;

%m;

%M;

%D;

%s;

%r;

%C;

%K;

%I;

17/01/2004

08:16:09

11111111

MBA 0.01

Checking.

Mustermann.

Pieces

15 pcs

15.048 g

5.30000 g

13

15 pcs

195 pcs

15 pcs

17 pcs

2 pcs

0 pcs

0.00 %

16/01/2004 13:02

External calibration

0.01 g

Page 55

ILT-BA-e-0612

55

9.1.3 Checkweighing (weighing with tolerance range)

Overview of display:

1. Current weighing value

2. Weighing assistance

3. Operating mode

4. Nominal value

5. Upper limit (Hi), lower limit (Lo)

6. Tolerance marker

too light

nominal

value

too heavy

Operation Display

Ö Call up menu item "M2 Checkweighing"

(see chap. 9.1)

Ö Press -button

01 - 02 Lower/upper limit – entering limit values

Ö Use the cursor ( ► ) to select „01 Lower limit or

02 Upper limit“

Ö Press the -key; the current menu item blinks.

Use the arrow keys, to enter the limits and confirm by

pressing the -key

Notice: First enter upper limit.

Page 56

ILT-BA-e-0612

56

Ö Use the cursor ( ► ), to select “04 Run” or press the

-key several times. Confirm with -key

Ö The balance is now in checkweighing mode

Ö Put on goods to be weighed, tolerance control is

started

03 Statistics - combination Checkweighing/Statistics

Ö Use the cursor ( ► ) to select “03 Statistics",