Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Tel: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Operating instruction

Precision balances

KERN EW/EG-N/EWB

Version 2.5

10/2011

GB

EW/EG-N/EWB-BA-e-1125

Page 2

2

GB

KERN EW/EG-N/EWB

Version 2.5 10/2011

Operating instruction

Precision balances

Table of contents

1 Technical data ............................................................................................ 4

1.1 Read-off of the various weighing units ........................................................................... 10

1.2 Weighing unit conversion charts ..................................................................................... 11

2 Fundamental information (general) ........................................................ 12

2.1 Intended use ....................................................................................................................... 12

2.2 Inappropriate use ............................................................................................................... 12

2.3 Guarantee ............................................................................................................................ 12

2.4 Monitoring the test substances ........................................................................................ 13

3 Fundamental safety information ............................................................. 13

3.1 Observe the information in the operating instructions .................................................. 13

3.2 Staff training ....................................................................................................................... 13

4 Transport and storage ............................................................................. 13

4.1 Acceptance check .............................................................................................................. 13

4.2 Packaging / return transport ............................................................................................. 13

5 Unpacking, installation and commissioning ......................................... 14

5.1 Place of installation, place of use ..................................................................................... 14

5.2 Unpacking ........................................................................................................................... 15

5.2.1 Installation ............................................................................................................................ 15

5.2.2 List of items supplied ............................................................................................................ 15

5.2.3 Positioning the weighing plate .............................................................................................. 16

5.2.4 Serial draft shield installation ................................................................................................ 16

5.2.5 Draft shield installation – optional ......................................................................................... 17

5.2.6 Draft shield with glass sliding doors (only model KERN EW 120-4NM standard)............... 17

5.3 Mains supply....................................................................................................................... 18

5.4 Operation using a rechargeable battery (optional) ......................................................... 18

5.5 Connecting peripheral equipment .................................................................................... 19

5.6 Initial start-up...................................................................................................................... 19

5.6.1 Power display ....................................................................................................................... 19

5.6.2 Bar graph display.................................................................................................................. 19

5.6.3 Stability indication ................................................................................................................. 20

5.6.4 Zero display on the balance ................................................................................................. 20

5.7 Adjustment .......................................................................................................................... 21

5.8 Adjusting ............................................................................................................................. 21

5.8.1 Adjusting with externall weight (only KERN EW-B, EW-N) .................................................. 21

5.8.2 Adjusting with internal weight (only KERN EG) .................................................................... 21

5.8.3 Adjusting with external weight (only KERN EW and EWB) .................................................. 23

5.9 Verification .......................................................................................................................... 25

5.10 Verification switch and official seal ................................................................................. 26

EW/EG-N/EWB-e-1125

Page 3

3

6 Operation .................................................................................................. 27

6.1 Operating elements ............................................................................................................ 27

6.1.1 Overview of the keypad ........................................................................................................ 28

6.1.2 Overview of display .............................................................................................................. 29

6.2 Operation ............................................................................................................................ 30

6.2.1 Weighing .............................................................................................................................. 30

6.2.1.1 Underfloor weighing ........................................................................................................................... 31

6.2.1.2 Tare weighing (tare) .......................................................................................................................... 32

6.2.2 Piece counting (excl. model KERN EW120-4NM) ............................................................... 34

6.2.2.1 Add mode ........................................................................................................................................... 36

6.2.3 Percent weighing (excl. model KERN EW120-4NM) ........................................................... 38

6.2.4 Weighing using a tolerance range (excl. model KERN EW120-4NM) ................................ 39

6.2.4.1 Basic settings when weighing using a tolerance range ...................................................................... 40

6.2.4.2 Entering the limit values by weighing ................................................................................................. 42

6.2.4.3 Entering the limit values using the keyboard ...................................................................................... 44

7 Functions .................................................................................................. 46

7.1 Access and changing of numerous functions: ............................................................... 46

7.2 List of the function parameters ........................................................................................ 47

7.2.1 Parameters when weighing with a tolerance range (excl. model KERN EW120-4NM) ...... 49

7.2.2 Parameters for the serial interface ....................................................................................... 50

8 Data output ............................................................................................... 51

8.1 Description of the serial data output (RS 232C).............................................................. 51

8.2 Technical data of the interface ......................................................................................... 51

8.3 Interface description .......................................................................................................... 52

8.4 Data Output ......................................................................................................................... 52

8.4.1 Data Transmission Formats ................................................................................................. 52

8.4.2 Algebraic sign ....................................................................................................................... 52

8.4.3 Data ...................................................................................................................................... 52

8.4.4 Units ..................................................................................................................................... 53

8.4.5 Result of the evaluation / Type of data ................................................................................. 53

8.4.6 Data state ............................................................................................................................. 53

8.5 Data input commands ........................................................................................................ 54

8.5.1 Command input format......................................................................................................... 54

8.5.2 External taring command ..................................................................................................... 54

8.5.3 External control commands .................................................................................................. 54

8.6 Feedback message after data transmission .................................................................... 55

9 Maintenance, upkeep, disposal .............................................................. 55

9.1 Cleaning .............................................................................................................................. 55

9.2 Maintenance, upkeep ......................................................................................................... 55

9.3 Disposal .............................................................................................................................. 55

10 Troubleshooting ....................................................................................... 56

EW/EG-N/EWB-e-1125

Page 4

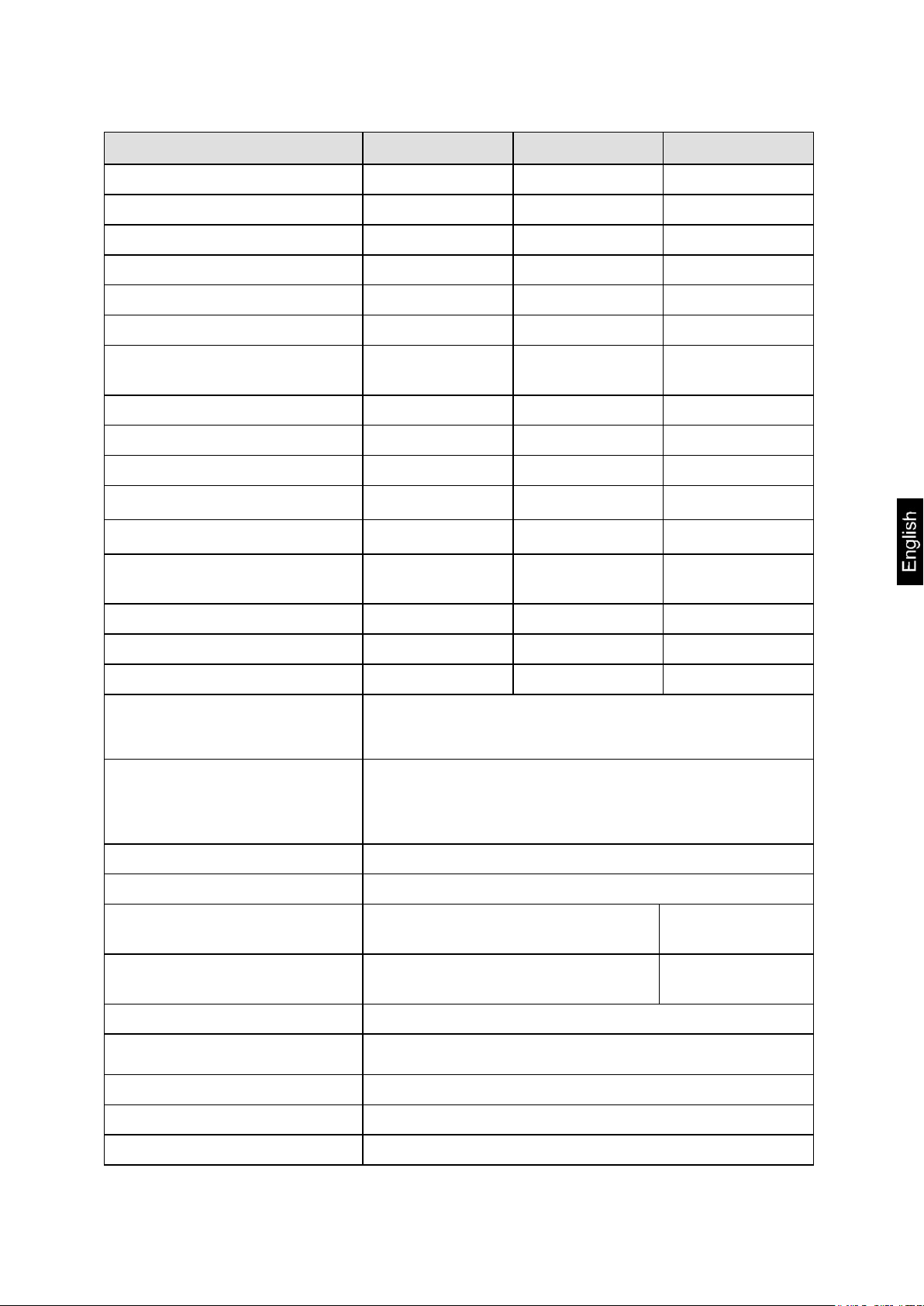

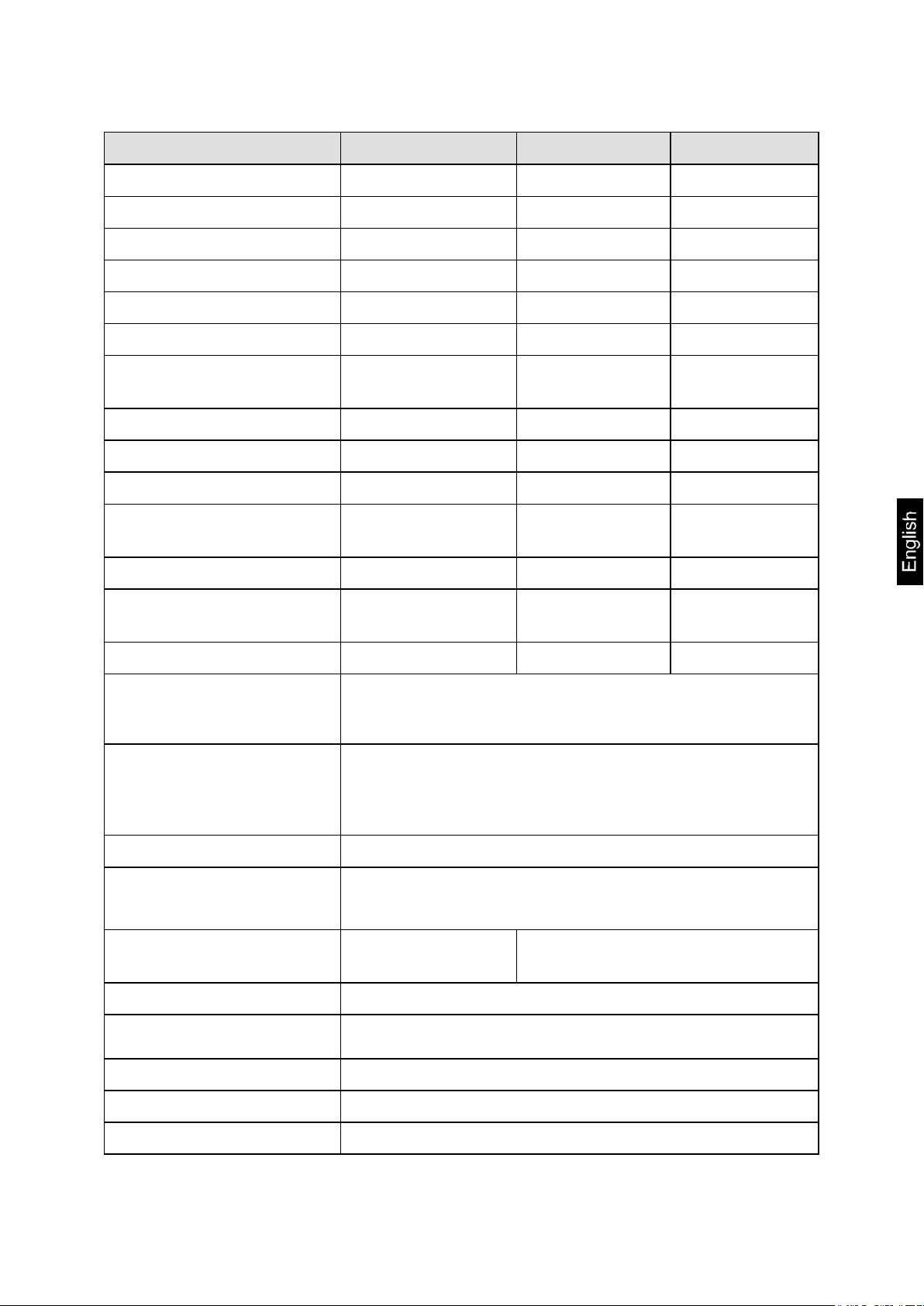

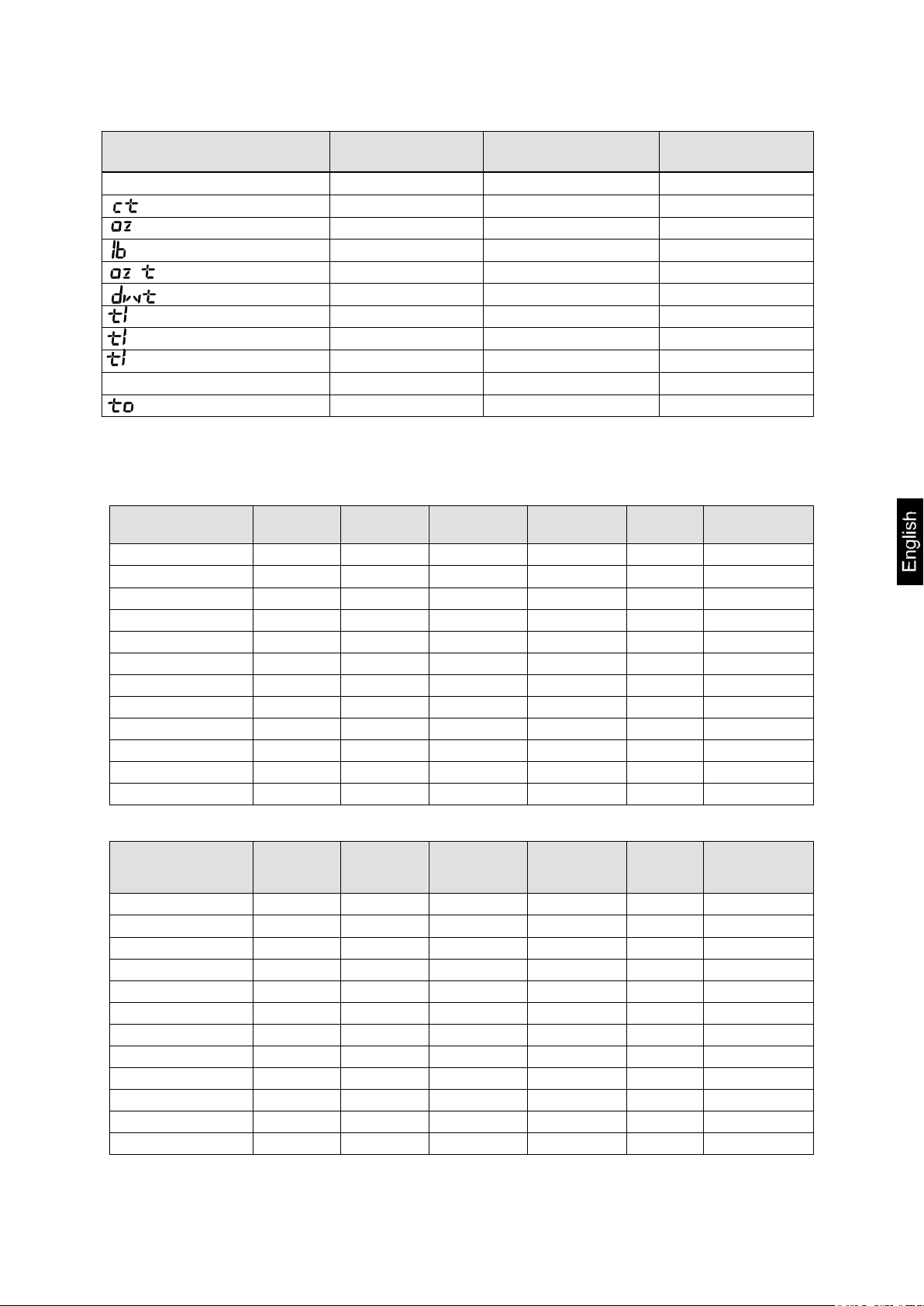

4

KERN

EG 220-3NM

EG 420-3NM

EG 620-3NM

Readout

0,001 g

0,001 g

0,001 g

Verification value (e)

0,01 g

0,01 g

0,01 g

Weighing range (max.)

220 g

420 g

620 g

Class of accuracy

II

II

I

Taring range (subtractive)

220g

420 g

620 g

Minimum load (Min)

0,02 g

0,02 g

0,1 g

Minimum weight for counting parts

0,001 g

0,001 g

0,001 g

Reference quantity

10, 30, 50, 100

10, 30, 50, 100

10, 30, 50, 100

Reproducibility

0,001 g

0,001 g

0,001 g

Linearity

± 0,002 g

± 0,003 g

± 0,004 g

Adjusting weight

internal

internal

internal

Stabilization time

3 sec.

3 sec.

3 sec.

Weighing plate stainless

steel

Ø 118 mm

Ø 118 mm

Ø 118 mm

Weight kg (net)

2,0

2,0

2,0

Units,

verification switch in verification position,(chap. 5.10)

g, ct

Units ,

verification switch not in

verification position,

(chap. 5.10)

g, ct, oz, lb, ozt, dwt, GN, tl (HongKong), tl (Taiwan),

tl (Singapore, Malaysia), momme, tola

Air humidity

max. 80 % relative (not condensing)

Permissible ambient

condition

10° C to 30° C

Balance dimensions

235 x 180 x 75 mm (excluding draft shield)

235 x 185 x 165 mm (including draft shield)

Vibratory filter

4

Mains supply

Mains adaptor 230 V, 50/60 Hz ;

9 V DC balance, 200 mA

Interface

RS 232 C interfaced

Rechargeable battery

optional

Underfloor weighing

Hanging loop optional

1 Technical data

EW/EG-N/EWB-e-1125

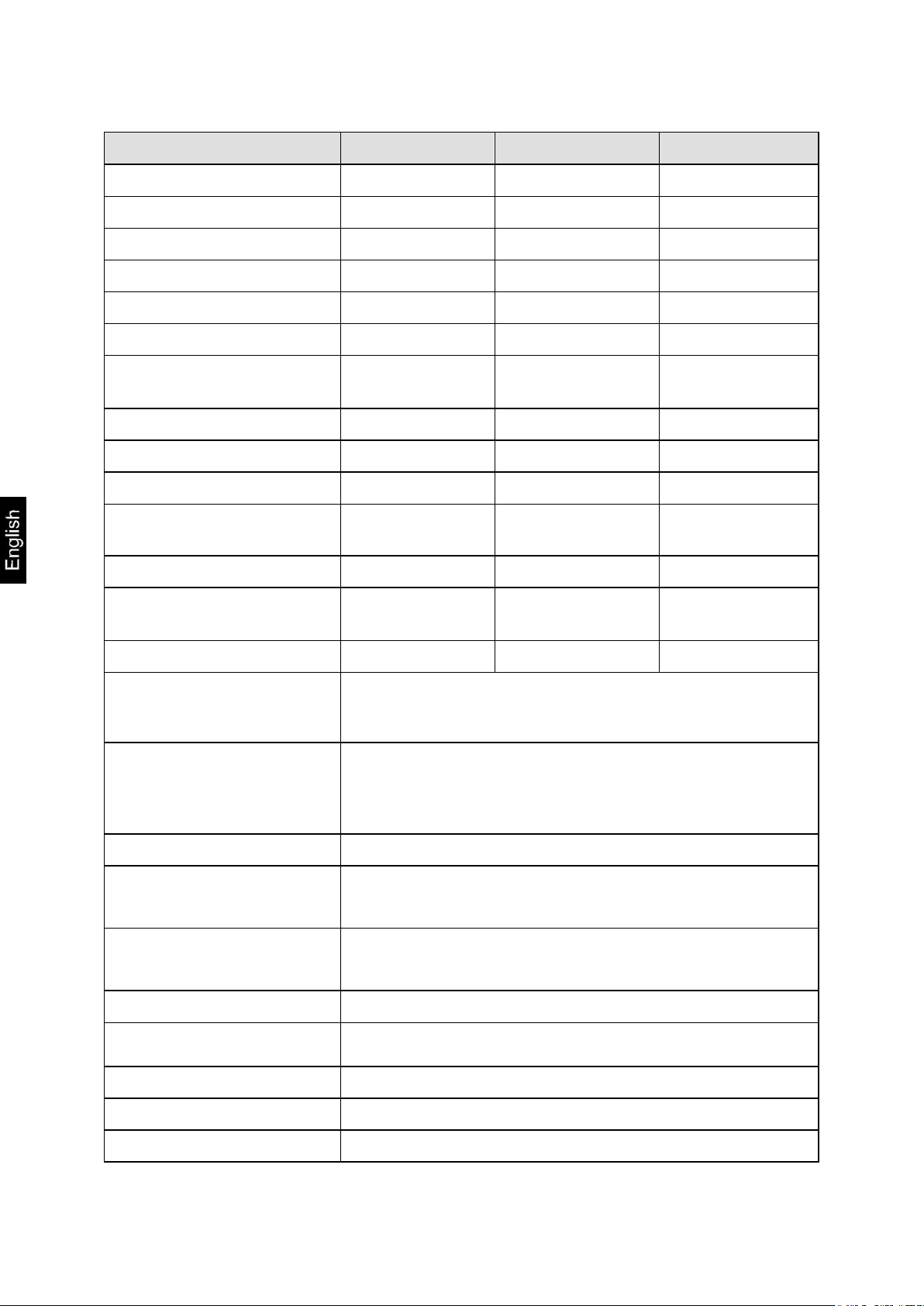

Page 5

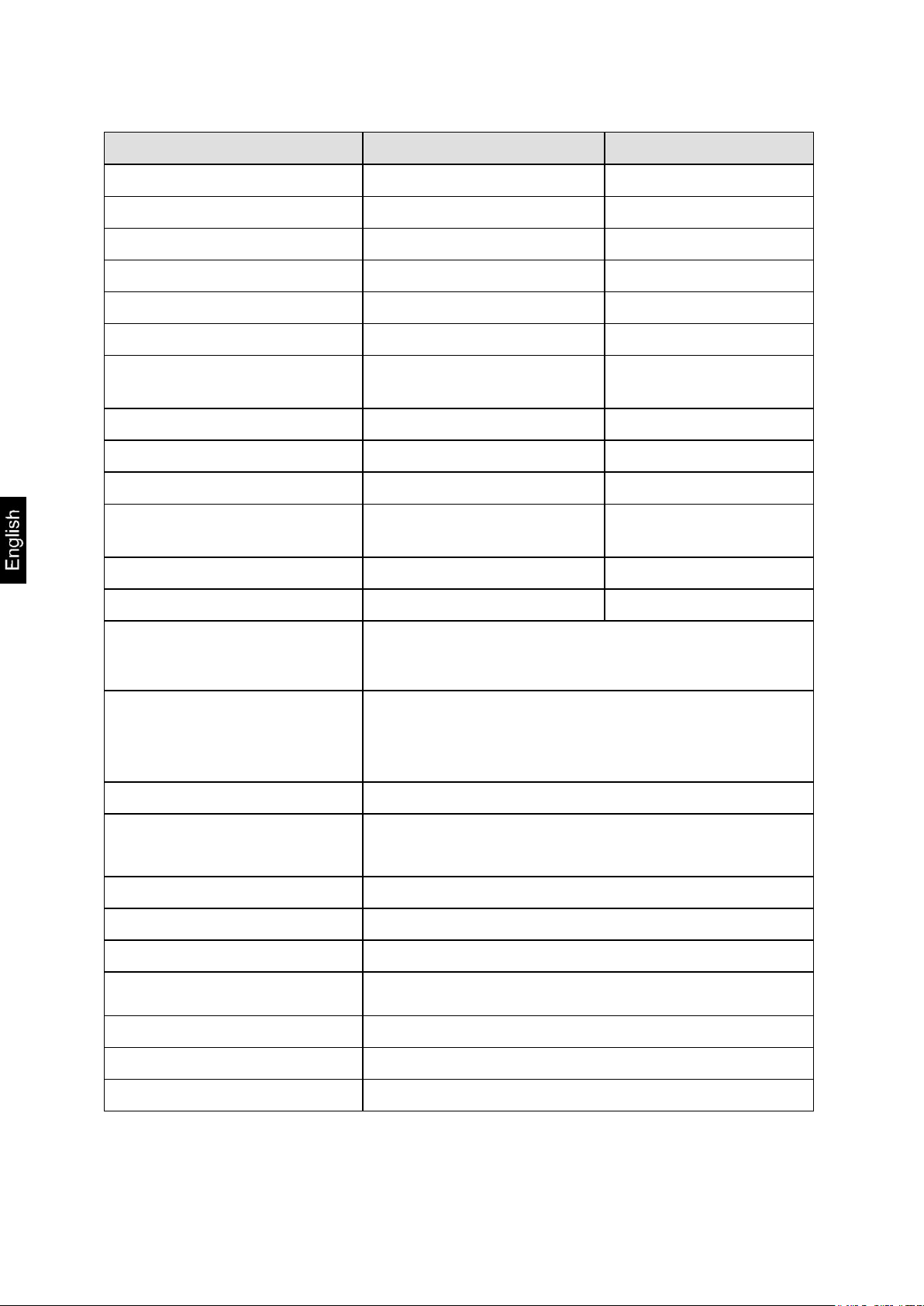

5

KERN

EG 2200-2NM

EG 4200-2NM

EW 120-4NM

Readout

0,01 g

0,01 g

0,0002 g

Verification value (e)

0,1 g

0,1 g

0,001 g

Weighing range (max.)

2200 g

4200 g

120 g

Class of accuracy

II

II

I

Taring range (subtractive)

2200 g

4200 g

120g

Minimum load (Min)

0,5 g

0,5 g

0,02 g

Minimum weight for counting

parts

0,01 g

0,01 g

-

Reference quantity

10, 30, 50, 100

10, 30, 50, 100

-

Reproducibility

0,01 g

0,01 g

0,0002 g

Linearity

± 0, 02 g

± 0,02 g

± 0,0008 g

Adjusting weight

internal

internal

-

Test weight, included

-

-

50 g (F1)

Recommended adjusting

weight, not included (class)

-

-

100g (E2)

Stabilization time

3 sec.

3 sec.

3 sec.

Weighing plate stainless steel

180 x 160 mm

180 x 160 mm

Ø 80 mm

Weight kg (net)

3,7

3,7

2,4

Units,

verification switch in verification

position,(chap. 5.10)

g, ct

Units ,

verification switch not in verification position,

(chap. 5.10)

g, ct, oz, lb, ozt, dwt, GN, tl (HongKong), tl (Taiwan),

tl (Singapore, Malaysia), momme, tola

Air humidity

max. 80 % relative (not condensing)

Permissible ambient condition

10° C to 30° C

Balance dimensions

including draft shield

195 x 251 x 254

mm

Balance dimensions

excluding draft shield

190 x 265 x 90 mm

180 x 235 x 75

mm

Vibratory filter

4

Mains supply

Mains adapter 230 V, 50/60 Hz ; 9 V DC balance,

200 mA

Interface

RS 232 C interfaced

Rechargeable battery

optional

Underfloor weighing

Hanging loop optional

EW/EG-N/EWB-e-1125

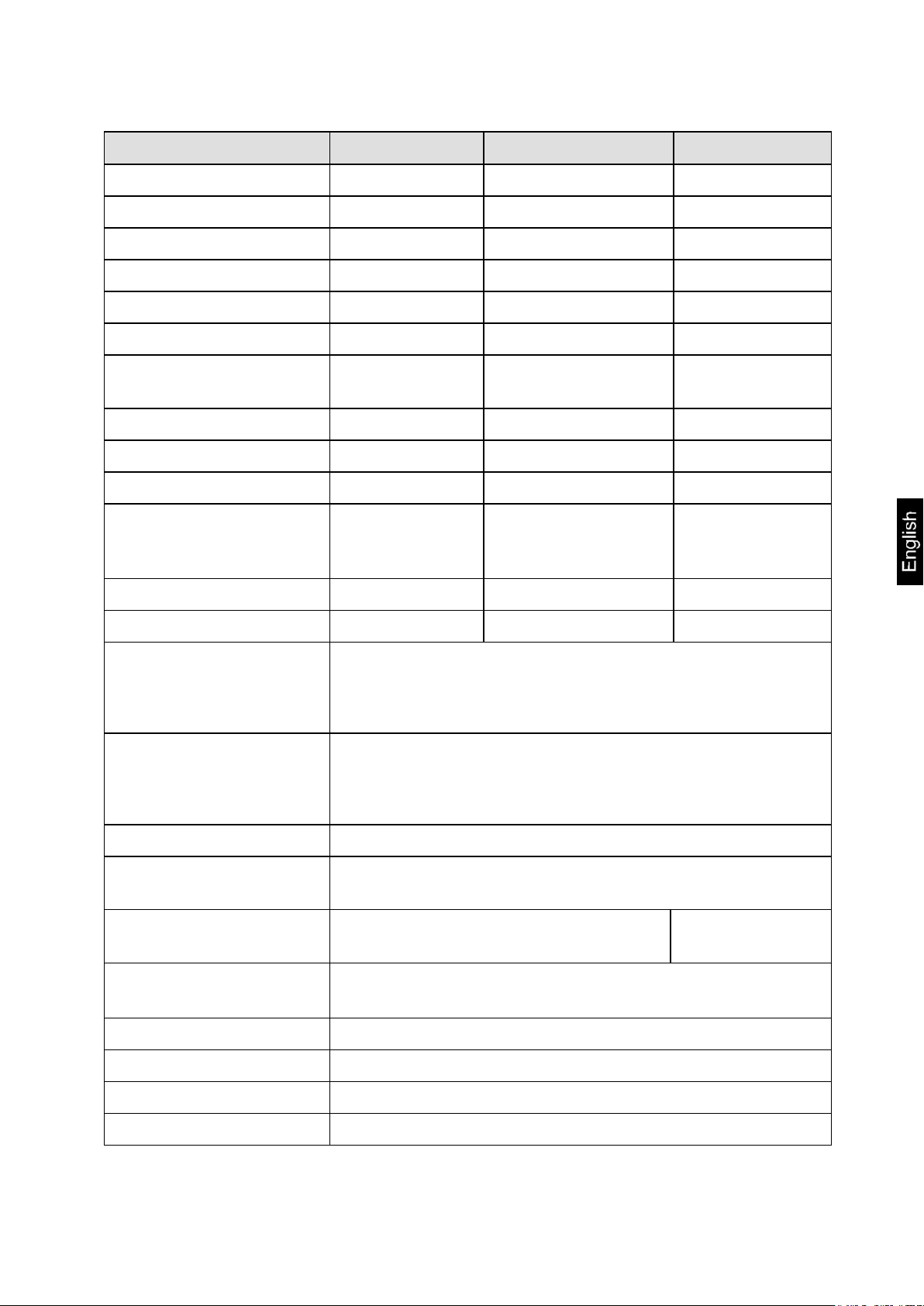

Page 6

6

KERN

EW 220-3NM

EW 420-3NM

EW 620-3NM

Readout

0,001 g

0,001 g

0,001 g

Verification value (e)

0,01 g

0,01 g

0,01 g

Weighing range (max.)

220 g

420 g

620 g

Class of accuracy

II

II

I

Taring range (subtractive)

220g

420 g

620 g

Minimum load (Min)

0,02 g

0,02 g

0,1 g

Minimum weight for counting parts

0,001 g

0,001 g

0,001 g

Reference quantity

10, 30, 50, 100

10, 30, 50, 100

10, 30, 50, 100

Reproducibility

0,001 g

0,001 g

0,001 g

Linearity

± 0,002 g

± 0,003 g

± 0,004 g

Recommended adjusting

weight, not included (class)

200g (F1)

2 x 200g (E2)

500 g (E2)

Stabilization time

2 sec.

2 sec.

2 sec.

Weighing plate stainless

steel

Ø 118 mm

Ø 118 mm

Ø 118 mm

Weight kg (net)

1,3

1,3

1,3

Units,

verification switch in verification position,(chap. 5.10)

g, ct

Units ,

verification switch not in

verification position,

(chap. 5.10)

g, ct, oz, lb, ozt, dwt, GN, tl (HongKong), tl (Taiwan),

tl (Singapore, Malaysia), momme, tola

Air humidity

max. 80 % relative (not condensing)

Permissible ambient

condition

10° C to 30° C

Balance dimensions

235 x 180 x 75 mm (excluding draft shield)

235 x 185 x 165 mm (including draft shield)

Vibratory filter

4

Mains supply

Mains adaptor 230 V, 50/60 Hz ; 9 V DC balance,

200 mA

Interface

RS 232 C interfaced

Rechargeable battery

optional

Underfloor weighing

Hanging loop optional

EW/EG-N/EWB-e-1125

Page 7

7

KERN

EW 820-2NM

EW 2200-2NM

EW 4200-2NM

Readout

0,01 g

0,01 g

0,01 g

Verification value (e)

0,01 g

0,1 g

0,1 g

Weighing range (max.)

820 g

2200 g

4200 g

Class of accuracy

I

II

II

Taring range (subtractive)

820 g

2200 g

4200 g

Minimum load (Min)

1 g

0,5 g

0,5 g

Minimum weight for counting parts

0,01 g

0,01 g

0,01 g

Reference quantity

10, 30, 50, 100

10, 30, 50, 100

10, 30, 50, 100

Reproducibility

0,01 g

0,01 g

0,01 g

Linearity

± 0,01 g

± 0,02 g

± 0,02 g

Recommended adjusting

weight, not included (class)

1 x 200 g

+ 1 x 500 g(F1)

2000 g (F1)

2 x 2 kg (E2)

Stabilization time

2 sec.

2 sec.

2 sec.

Weighing plate stainless

steel

170 x 142 mm

180 x 160 mm

180 x 160 mm

Weight kg (net)

1,3

2,8

2,8

Units,

verification switch in verification position,(chap. 5.10)

g, ct

Units ,

verification switch not in

verification position,

(chap. 5.10)

g, ct, oz, lb, ozt, dwt, GN, tl (HongKong), tl (Taiwan),

tl (Singapore, Malaysia), momme, tola

Air humidity

max. 80 % relative (not condensing)

Permissible ambient

condition

10° C to 30° C

Balance dimensions

excluding draft shield

180 x 235 x 75 mm

190 x 265 x 90 mm

Vibratory filter

4

Mains supply

Mains adaptor 230 V, 50/60 Hz ; 9 V DC balance,

200 mA

Interface

RS 232 C interfaced

Rechargeable battery

optional

Underfloor weighing

Hanging loop optional

EW/EG-N/EWB-e-1125

Page 8

8

KERN

EW 6200-2NM

EW 12000-1NM

Readout

0,01 g

0,1 g

Verification value (e)

0,1 g

1 g

Weighing range (max.)

6 200 g

12 000 g

Class of accuracy

I

II

Taring range (subtractive)

6 200 g

12 000 g

Minimum load (Min)

1 g

5 g

Minimum weight for counting

parts

0,01 g

0,1 g

Reference quantity

10, 30, 50, 100

10, 30, 50, 100

Reproducibility

0,02 g

0,1 g

Linearity

± 0, 03 g

± 0,1 g

Recommended adjusting

weight, not included (class)

5 kg (E2)

10 kg (F1)

Stabilization time

3 sec.

3 sec.

Weight kg (net)

2,8

2,8

Units,

verification switch in verification position,(chap. 5.10)

g, ct

Units ,

verification switch not in verification position,

(chap. 5.10)

g, ct, oz, lb, ozt, dwt, GN, tl (HongKong), tl (Taiwan),

tl (Singapore, Malaysia), momme, tola

Air humidity

max. 80 % relative (not condensing)

Permissible ambient

condition

10° C to 30° C

Weighing plate stainless steel

180 x 160 mm

Balance dimensions

190 x 265 x 90 mm (excluding draft shield)

Vibratory filter

4

Mains supply

Mains adapter 230 V, 50/60 Hz ; 9 V DC balance,

200 mA

Interface

RS 232 C interfaced

Rechargeable battery

optional

Underfloor weighing

Hanging loop optional

EW/EG-N/EWB-e-1125

Page 9

9

KERN

EWB 220-2M

EWB 620-2M

EWB 1200-1M

Readout

0,01 g

0,01 g

0,1 g

Verification value (e)

0,01 g

0,1 g

0,1 g

Weighing range (max.)

220 g

620 g

1 200 g

Class of accuracy

II

II

II

Taring range (subtractive)

220 g

620 g

1 200 g

Minimum load (Min)

0,2 g

0,5 g

5 g

Minimum weight for

counting parts

0,01 g

0,01 g

0,1 g

Reference quantity

10, 30, 50, 100

10, 30, 50, 100

10, 30, 50, 100

Reproducibility

0,01 g

0,01 g

0,1 g

Linearity

± 0,01 g

± 0,01 g

± 0,1 g

Recommended adjusting

weight, not included

(class)

200 g (M1)

500 g (F2)

1 000 g (M1)

Stabilization time

2 sec

2 sec

3 sec

Weight kg (net)

1,1

1,1

1,3

Units,

verification switch in verification position,(chap.

5.10)

g, ct

Units ,

verification switch not in

verification position,

(chap. 5.10)

g, ct, oz, lb, ozt, dwt, tl (HongKong),

tl (Taiwan), tl (Singapore, Malaysia), momme, tola

Air humidity

max. 80 % relative (not condensing)

Permissible ambient

condition

10° C bis 30° C

Weighing plate stainless

steel

ø 140 mm

170 x 140

Balance dimensions

182 x 235 x 75 mm

Vibratory filter

4

Mains supply

Mains adapter 230 V, 50/60 Hz ; 9 V DC balance, 300 mA

Rechargeable battery

optional

Underfloor weighing

Hanging loop optional

EW/EG-N/EWB-e-1125

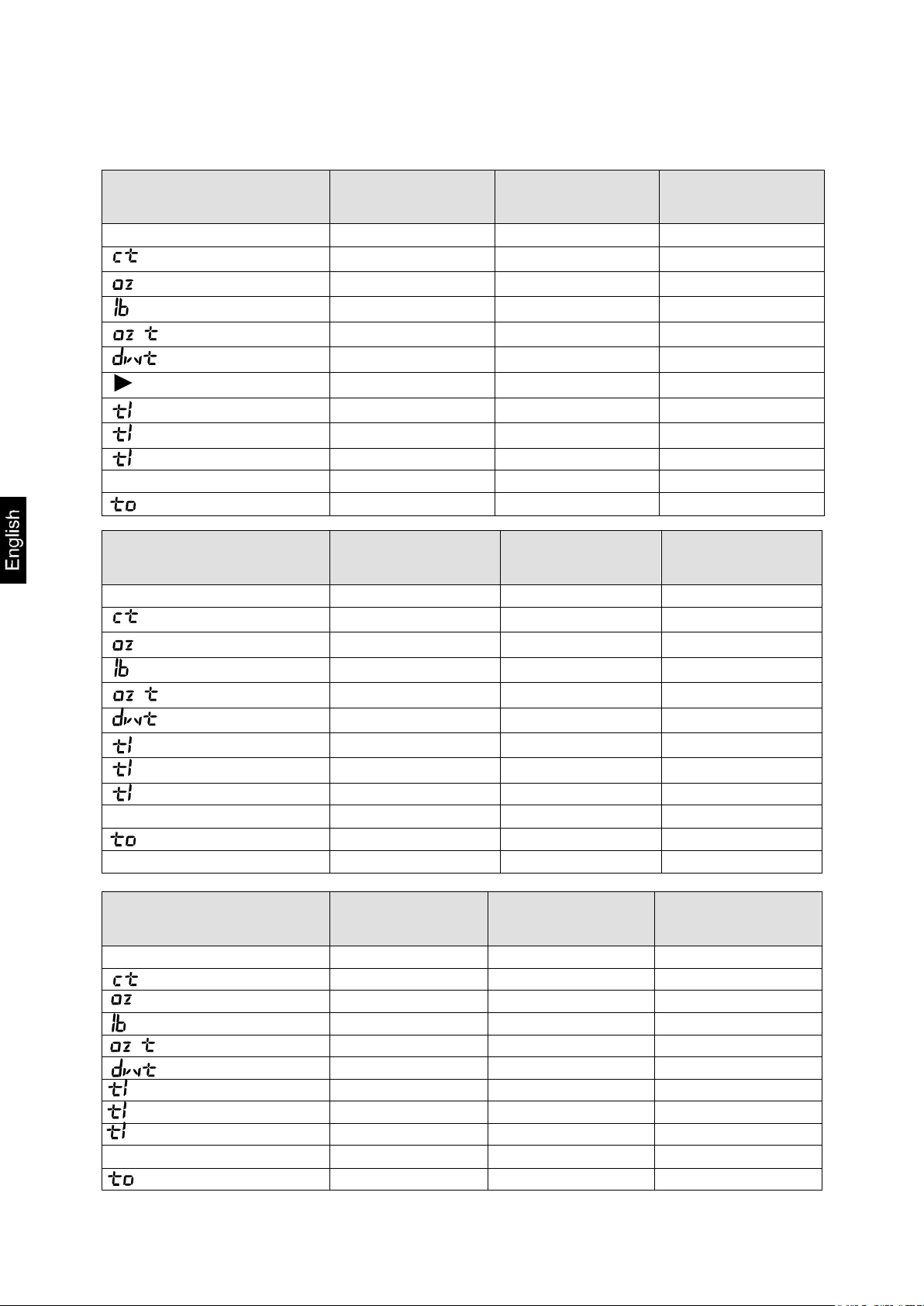

Page 10

10

Weighing unit

EW 120-4NM

EG 220-3NM /

EW 220-3NM

EG 420-3NM /

EW 420-3NM

g

0.0002

0.001

0.001

(ct)

0.001

0.01

0.01

(oz)

0.00001

0.0001

0.0001

(lb)

0.00001

0.00001

0.00001

(ozt)

0.00001

0.0001

0.0001

(dwt)

0.0002

0.001

0.001

(grain)

0.01

0.1

0.1

(Hong Kong)

0.00001

0.0001

0.0001

(Singapore,Malaysia)

0.00001

0.0001

0.0001

(Taiwan)

0.00001

0.0001

0.0001

mom

0.0001

0.001

0.001

(to)

0.00002

0.0001

0.0001

Weighing unit

EG 620-3NM /

EW 620-3NM

EW 820-2NM

EG 2200-2NM/

EW 2200-2NM

g

0.001

0.01

0.01

(ct)

0.01

0.05

0.1

(oz)

0.0001

0.0005

0.001

(lb)

0.00001

0.00005

0.0001

(ozt)

0.0001

0.0005

0.001

(dwt)

0.001

0.01

0.01

(Hong Kong)

0.1

0.0005

0.001

(Singapore,Malaysia)

0.0001

0.0005

0.001

(Taiwan)

0.0001

0.0005

0.001

mom

0.0001

0.005

0.01

(to)

0.001

0.001

0.001

0.0001

Weighing unit

EG 4200-2NM/

EW 4200-2NM

EW 6200-2NM

EW 12000-1NM

g

0.01

0.01

0.1

(ct)

0.1

0.1

1

(oz)

0.001

0.001

0.01

(lb)

0.0001

0.0001

0.001

(ozt)

0.001

0.001

0.01

(dwt)

0.01

0.01

0.1

(Hong Kong)

0.001

0.001

0.01

(Singapore,Malaysia)

0.001

0.001

0.01

(Taiwan)

0.001

0.001

0.01

mom

0.01

0.01

0.1

(to)

0.001

0.001

0.01

1.1 Read-off of the various weighing units

EW/EG-N/EWB-e-1125

Page 11

11

Weighing unit

EWB 220-2M

EWB 620-2M

EWB 1200-1M

g

0.01

0.01

0.1

(ct)

0.1

0.1

1

(oz)

0.001

0.001

0.01

(lb)

0.0001

0.0001

0.001

(ozt)

0.001

0.001

0.01

(dwt)

0.01

0.01

0.1

(Hong Kong)

0.001

0.001

0.01

(Singapore,Malaysia)

0.001

0.001

0.01

(Taiwan)

0.001

0.001

0.01

mom

0.01

0.01

0.1

(to)

0.001

0.001

0.01

Weighing unit

Gramm

Carat

Ounze

Pound

Fine

ounze

Penny weight

1g 1 5

0.03527

0.00220

0.03215

0.64301

1ct

0.2 1 0.00705

0.00044

0.00643

0.12860

1oz

28.34952

141.74762

1

0.06250

0.91146

18.22917

1lb

453.59237

2267.96185

16 1 14.58333

291.66667

1ozt

31.10348

155.51738

1.09714

0.06857

1

20

1dwt

1.55517

7.77587

0.05486

0.00343

0.05

1

1GN

0.06480

0.32399

0.00229

0.00014

0.00208

0.04167

1tl (HK)

37.429

187.145

1.32027

0.08252

1.20337

24.06741

1tl (SGP,Mal)

37.79936

188.99682

1.33333

0.08333

1.21528

24.30556

1tl (Taiwan)

37.5

187.5

1.32277

0.08267

1.20565

24.11306

1mom

3.75

18.75

0.13228

0.00827

0.12057

2.41131

1to

11.66380

58.31902

0.41143

0.02571

0.37500

7.5

Weighing unit

Grain

Tael

(Hong Kong)

Tael

(Singapore,

Malaysia)

Tael

(Taiwan)

Momme

Tola

1g

15.43236

0.02672

0.02646

0.02667

0.26667

0.08574

1ct

3.08647

0.00534

0.00529

0.00533

0.05333

0.01715

1oz

437.5

0.75742

0.75

0.75599

7.55987

2.43056

1lb

7000

12.11874

12

12.09580

120.95797

38.88889

1ozt

480

0.83100

0.82286

0.82943

8.29426

2.66667

1dwt

24

0.04155

0.04114

0.04147

0.41471

0.13333

1GN

1

0.00173

0.00171

0.00173

0.01728

0.00556

1tl (HK)

577.61774

1

0.99020

0.99811

9.98107

3.20899

1tl (SGP,Mal)

583.33333

1.00990

1

1.00798

10.07983

3.24074

1tl (Taiwan)

578.71344

1.00190

0.99208

1

10

3.21507

1mom

57.87134

0.10019

0.09921

0.1 1 0.32151

1to

180

0.31162

0.30857

0.31103

3.11035

1

1.2 Weighing unit conversion charts

EW/EG-N/EWB-e-1125

Page 12

12

2 Fundamental information (general)

2.1 Intended use

The balance you have acquired serves to determine the weighing value of the material to be weighed. It is intended to be used as a “non-automatic“ balance, i.e. the

material to be weighed is manually and carefully placed in the centre of the weighing

plate. The weighing value can be read off after a stable weighing value has been

obtained.

2.2 Inappropriate use

Do not use the balance for dynamic weighing. In the event that small quantities are

removed or added to the material to be weighed, incorrect weighing results can be

displayed due to the “stability compensation“ in the balance. (Example: Slowly draining fluids from a container on the balance.)

Do not leave a permanent load on the weighing plate. This can damage the measuring equipment.

Be sure to avoid impact shock and overloading the balance in excess of the prescribed maximum load rating (max.), minus any possible tare weight that is already

present. This could cause damage to the balance.

Never operate the balance in hazardous locations. The series design is not explosion-proof.

Structural alterations may not be made to the balance. This can lead to incorrect

weighing results, faults concerning safety regulations as well as to destruction of the

balance.

The balance may only be used in compliance with the described guidelines. Varying

areas of application/planned use must be approved by KERN in writing.

2.3 Guarantee

The guarantee is not valid following

- non-observation of our guidelines in the operating instructions

- use outside the described applications

- alteration to or opening of the device

- mechanical damage and damage caused by media, liquids

- natural wear and tear

- inappropriate erection or electric installation

- overloading of the measuring equipment

EW/EG-N/EWB-e-1125

Page 13

13

Keep all parts of the original packaging for a possibly required re-

turn.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove loose/mobile

parts.

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the weighing plat-

form, power unit etc. against shifting and damage.

2.4 Monitoring the test substances

The metrology features of the balance and any possible available adjusting weight

must be checked at regular intervals within the scope of quality assurance. For this

purpose, the answerable user must define a suitable interval as well as the nature

and scope of this check. Information is available on KERN’s home page (www.kernsohn.com) with regard to the monitoring of balance test substances and the test

weights required for this. Test weights and balances can be adjusted quickly and at

a reasonable price in KERN’s accredited DKD calibration laboratory (return to national normal).

3 Fundamental safety information

3.1 Observe the information in the operating instructions

Please read the operating instructions carefully before erecting and commissioning,

even if you already have experience with KERN balances.

3.2 Staff training

The device may only be operated and looked after by trained members of staff.

4 Transport and storage

4.1 Acceptance check

Please check the packaging immediately upon delivery and the device during unpacking for any visible signs of external damage.

4.2 Packaging / return transport

EW/EG-N/EWB-e-1125

Page 14

14

5 Unpacking, installation and commissioning

5.1 Place of installation, place of use

The balance is constructed in such a way that reliable weighing results can be

achieved under normal application conditions.

By selecting the correct location for your balance, you will be able to work quickly

and precisely.

Therefore please observe the following at the place of installation:

- Place the balance on a firm, level surface;

- Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

- Protect the balance against direct draughts due to open windows and doors;

- Avoid jarring during weighing;

- Protect the balance against high humidity, vapours and dust;

- Do not expose the device to extreme dampness for longer periods of time. In-

admissible bedewing (condensation of air moisture on the device) can occur if

a cold device is taken into a significantly warmer environment. In this case,

please acclimatise the device for approx. 2 hours at room temperature after it

has been disconnected from the mains.

- Avoid static charging of the material to be weighed, weighing container and

windshield.

Major display deviations (incorrect weighing results) are possible if electromagnetic

fields occur as well as due to static charging and instable power supply. It is then

necessary to change the location.

EW/EG-N/EWB-e-1125

Page 15

15

(1) Balance

(2) Weighing plate

(3) Weighing plate bracket

(4) Windbreak

(excl. EWB models)

(5) Interface connector set

(excl. EWB models)

(6) Operating instructions

(7) Mains adaptor

5.2 Unpacking

Carefully remove the balance from its packaging, remove the plastic wrapping and

position the balance in its intended working location.

5.2.1 Installation

Use the foot screws to level the balance until the air bubble in the bubble level is in

the prescribed circle.

5.2.2 List of items supplied

Standard accessories:

EW/EG-N/EWB-e-1125

Page 16

16

Screw the bracket on tightly according to

the drawing and subsequently attach the

weighing plate.

5.2.3 Positioning the weighing plate

5.2.4 Serial draft shield installation

(Only for models with readout d = 0,001 g standard)

EW/EG-N/EWB-e-1125

Page 17

17

5.2.5 Draft shield installation – optional

Remove the weighing plate and loosen the screws to remove the bracket. Use a

screwdriver to loosen both screws to the left and right of the bracket guide and remove.

Now place the draft shield to fit on the housing and and secure through the opened

sliding doors using both screws.

Screw the bracket on tightly according to the drawing and subsequently attach the

weighing plate.

5.2.6 Draft shield with glass sliding doors

(only model KERN EW 120-4NM standard)

EW/EG-N/EWB-e-1125

Page 18

18

Mains adaptor

connection

5.3 Mains supply

Electric power supply is by means of the external mains supply circuit. The printed

voltage level must comply with the local voltage.

Only use original KERN mains supply circuits. The use of other makes is subject to

approval by KERN.

Mains adaptor connection:

5.4 Operation using a rechargeable battery (optional)

Take off the weighing plate and remove the bracket by loosening the screw. Use a

screwdriver to loosen both screws to the left and right of the bracket guide and remove.

Release both retaining hooks on the lower housing section and carefully remove the

lower housing section to the rear (please observe the upper housing section guides

on the back of the balance).

Loosen and remove both fastening screws as shown on the illustration.

Remove the rechargeable battery from the packaging and begin by connecting the

electric power supply to the circuit board of the rechargeable battery.

Subsequently set up the plug-in connection to the computer circuit board of the balance (CN5).

The rechargeable battery is placed on the left side of the housing in such a way that

it can be screwed onto the balance through the existing mounting using the screw

loosened previously. Press lightly into the housing prior to this, (there is only one correct installation possibility). Now also re-attach the display using the loosened screw.

Place the upper housing section on the rear guides and tilt forward until both retaining hooks on the lower housing section audibly lock into place.

Screw down both screws to the left and right of the bracket guide tightly and resecure the bracket. Attach the weighing plate.

Information:

Though the rechargeable battery is immediately operative, it should be charged for at

least 8 hours using the mains adaptor before being used for the first time.

EW/EG-N/EWB-e-1125

Page 19

19

If the (*) sign can be seen, the balance is being

supplied with power via the mains adaptor. The

balance is in weighing mode when the key is

operated.

The power display is then no longer to be seen

on the display overview.

*

5.5 Connecting peripheral equipment

The balance must be disconnected from the mains before connecting or disconnecting additional equipment (printer, PC) to or from the data interface (see chap. 8.)

Only use KERN accessories and peripheral equipment with your balance. These

have been ideally coordinated to your balance.

5.6 Initial start-up

A warm-up time of 10 minutes stabilises the measured values after switching on.

The accuracy of the balance depends on the local acceleration of the fall.

Please be sure to observe the information in the chapter on adjusting (chap. 5.7).

5.6.1 Power display

5.6.2 Bar graph display

weihging dish unloaded half of weighing range weighing range is used

to full capacity

The weighing range of the balance is divided into 20 graphic cuboids. Zero (0) will

appear on the graphic display if there is no weighing value on the balance. 10

graphic cuboids are displayed if the balance is loaded up to one half of its weighing

range.

Information:

If tare weighing is being carried out, the graphic weight display will continue to indicate the number of cuboids of the tare weight.

EW/EG-N/EWB-e-1125

Page 20

20

Operation

Display

If an exact zero reading is not displayed on

the balance in spite of the weighing dish be-

ing empty, press the key and the balance

will start resetting to zero.

Your balance will be set to zero after a short

standby time.

In addition to this, the sign for the balance

zero setting will be displayed [0].

ο 0 I I I F

0.000 g

0 I I I F

0.000 g

0 0 I I I F

0.000 g

5.6.3 Stability indication

Stable

Unstable

The balance is in a stable condition if the [ο] stability indication appears on the dis-

play. The [ο] indication disappears if the condition is unstable. Stable ambient conditions can be achieved by using the draft shield (See chap. 5.2.4 for installation)

5.6.4 Zero display on the balance

Environmental influences can lead to the exact figure of “0.000“ not being displayed

in spite of an empty weighing dish. It is, however, possible to reset your balance to

zero at any time and thus ensure that weighing really does commence at zero. Setting to zero when a weight is applied is only possible within a certain type-dependent

range. In the event that the balance cannot be reset to zero with an applied weight,

this range has been exceeded.

[o - Err ] will appear on the display.

EW/EG-N/EWB-e-1125

Page 21

21

Operation

Display

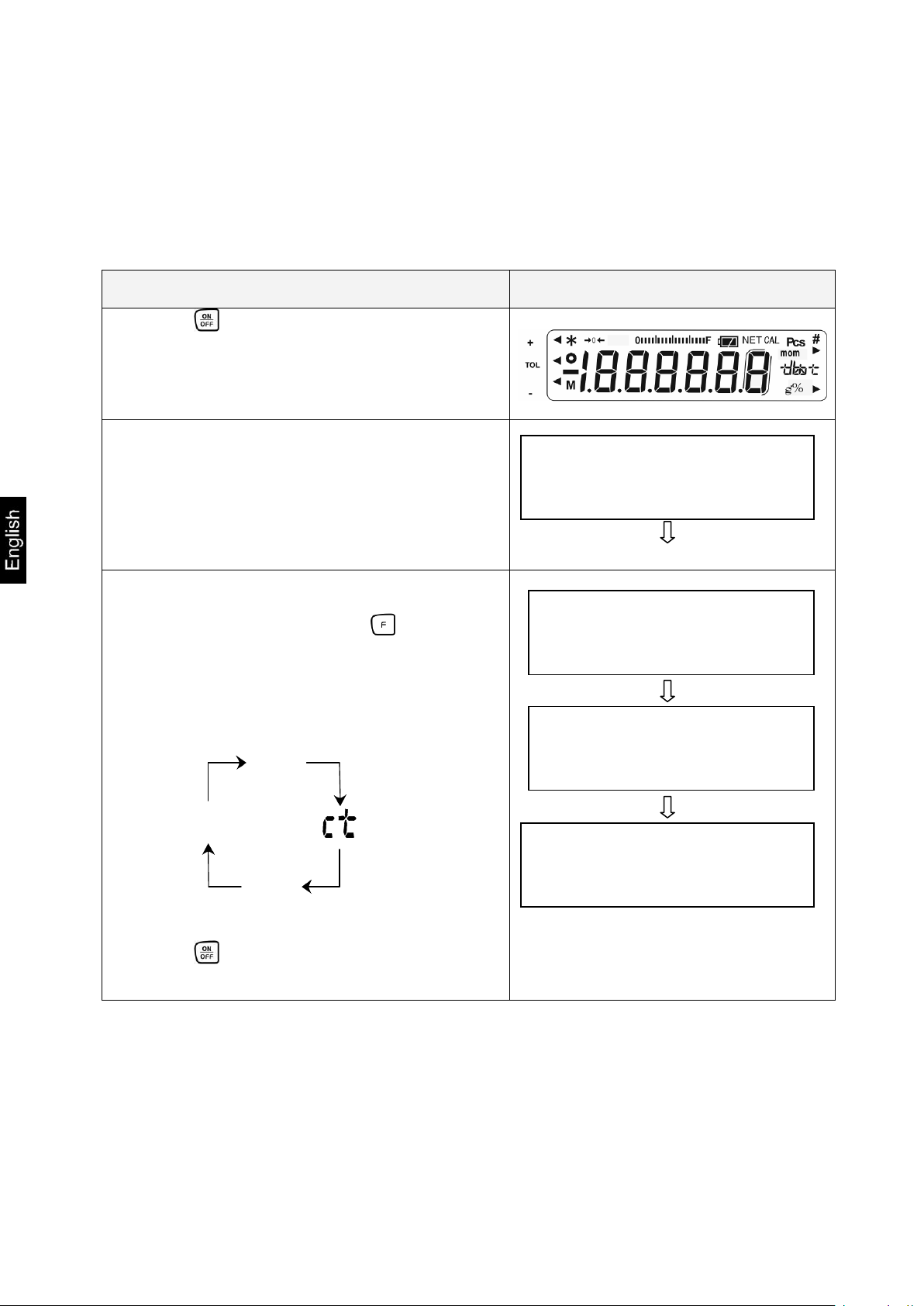

Switch on the balance using the key

Press and hold the key until

[S.A. CAL] appears. Now release the key.

Func

S.A. CAL

5.7 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each balance must be coordinated – in compliance with the underlying physical

weighing principle - to the existing acceleration due to gravity at its place of location (

only if the balance has not already been adjusted to the location in the factory). This

adjustment process must be carried out at every start-up, after every change of location as well as in case of fluctuating environment temperature. It is also recommendable to adjust the balance periodically during weighing operation in order to obtain

exact measured values.

5.8 Adjusting

5.8.1 Adjusting with externall weight (only KERN EW-B, EW-N)

For verified balances the verification switch is locked (except for class of accuracy I).

In order to proceed with the verification, please unlock the verification switch (except

for class of accuracy I).

5.8.2 Adjusting with internal weight (only KERN EG)

Using a precision weight, the accuracy of the balance can be checked at any time

and adjusted.

Adjustment procedure:

Check that the surrounding conditions are stable.

A short warm-up time of about 10 minutes is recommended for stabilisation.

EW/EG-N/EWB-e-1125

Page 22

22

Press the key while holding down the

key. Subsequently release both keys si-

multaneously.

The zero point will be stored.

Turn the adjusting knob on the right side of the

balance to the CAL position.

Calibration will be carried out automatically.

Calibration process has been concluded.

S.A. CAL

CAL

CAL. 0

CAL

CAL. on

CAL

CAL. on

CAL

CAL. on

CAL

CAL. oFF

VAIt

(only EG 4200-2NM)

EW/EG-N/EWB-e-1125

Page 23

23

Turn the adjusting knob on the right side of the

balance to the WEIGH position.

Calibration is now finalised.

The balance will automatically return to weigh-

ing mode.

Model

Alternative adjusting weight

EW 220-3NM

100 g

EW 420-3NM

100 g

EW 620-3NM

200 g

EW 820-2NM

200 g

EW 2200-2NM

500 g

EW 4200-2NM

1000 g

EW 6200-2NM

2000 g

EW 12000-1NM

5000 g

EWB 220-2M

100 g

EWB 620-2M

200 g

EWB 1200-1M

500 g

CAL

buSY

End.

5.8.3 Adjusting with external weight (only KERN EW and EWB)

Carry out adjustment with the recommended adjusting weight (see Chapter 1 „Tech-

nical Data“). The adjustment can also be carried out with different adjusting weights

(see table), but not ideal from a metrological point of view. Information concerning

the adjusting weights is available at: http://www.kern-sohn.com

EW/EG-N/EWB-e-1125

Page 24

24

Operation

Display

Switch on the balance using the key

Press and hold the key until

[ CAL] appears. Now release the key.

Press the key while holding down the

key. Subsequently release both keys si-

multaneously.

The zero point will be stored.

Place the adjusting weight carefully on the

centre of the weighing plate.

Display flashing [on F.S ] then a moment later

the weight value of the adjusting weight will be

indicated.Remove the adjusting weight, the

adjusting is terminated.

The balance will automatically return to weighing mode.

In case of an adjusting error or a wrong adjusting weight [- Err] appears in the display, repeat the adjustment procedure.

Func

CAL

CAL

on 0

CAL

on F.S

CAL

on F.S

200.000 g

CAL

buSY

Adjustment procedure:

Check that the surrounding conditions are stable.

A short warm-up time of about 10 minutes is recommended for stabilisation.

EW/EG-N/EWB-e-1125

Page 25

25

5.9 Verification

General:

According to the EU guideline 90/384/EEC balances must be verified if they are to be

used as follows (legally regulated area):

a) For commercial transactions if the price of goods is determined by weighing

b) For the production of medines in pharmacies as well as for analyses in the

medical and pharmaceutical laboratory

c) For official purposes

d) For the production of finished packages

In case of doubt, please contact your local office of weights and measures.

Verification information

An EU qualification approval is available for those balances marked as appropriate

for verification in the technical data. In the event that the balance is applied in an

area subject to verification as described above, it must be verified and re-verified at

regular intervals.

Re-verification of a balance is carried out in compliance with the respective legal provisions of the states. The term of verification validity for balances in Germany, for

example, is normally 2 years.

The legal provisions of the country of use are to be observed.

EW/EG-N/EWB-e-1125

Page 26

26

Official seal

Official seal

5.10 Verification switch and official seal

Prior to verification the verification switch must be moved from the displayed position

(see direction of arrow) to verification position. Once in this position, a parenthesis

will be displayed around the last display point.

Following calibration the balance is sealed at the marked position.

Balance calibration is not valid without the “official seals“.

Position of the “official seals“:

Move verification switch

Balances that are subject to compulsory verification must be taken out of operation if:

The weighing result of the balance is outside the error limit. Therefore, apply a

known test weight (approx. 1/3 of the nominal load) to the balance at regular intervals and compare with the display value.

The reverification deadline has been exceeded.

EW/EG-N/EWB-e-1125

Page 27

27

Bubble

level

Draft shield

Display

Keyboard

Adjustable device feet

Mains adaptor connection

RS232C interface connection

(excl. EWB models)

Adjusting switch

(KERN EG)

6 Operation

6.1 Operating elements

EW/EG-N/EWB-e-1125

Page 28

28

Choice

Function

Switch on and off

Output of weight value on an external device

(printer) or PC

Save the respective mode settings (unit counter, percent

weighing, tolerance weighing)

Unit counter and percent mode:

Choice menu for unit and %

Save function parameters

Call up lower and upper tolerance levels

Key to alter the weight unit (g, ct, Pcs, %)

Entry of lower and upper tolerance levels

Choosing the function values within the function

Call up individual functions (multiple print)

Call up adjusting functions (permanent print)

The entry point is moved to the left each time by one

step (chap. 6.2.4.3).

Tare or set weight display to zero

Individual setting within the individual function

Changing the parameters

6.1.1 Overview of the keypad

EW/EG-N/EWB-e-1125

Page 29

29

Display

Description

g

Gramme

0

Zero setting display

ο

Stability indication

*

Power display (standby)

Pcs

Unit counter display (excl. EW 120-4NM)

%

Percent weighing display (excl. EW 120-4NM)

Tolerance weighing display (excl. EW 120-4NM)

mom

Momme

M

Balance carry out balance function, e.g. unit count / display of

stored value

CAL

Calibration display. Signalises calibration procedure.

Bar graph

[ ] (ct) carat

[ ] (oz) ounce

[ ] (lb) pound

[ ] (ozt) fine ounce

[ ] (dwt) penny weight

[ (upper right) ] grain

[ ](tl)Tael (Hong Kong)

[ upper right] (tl

upper right) Tael (Singapore,Malaysia)

[ lower right ] (tl lower right) Tael (Taiwan)

[ ] (to) Tola

Rechargeable battery mode (optional).

[ ] Display changes to mains-powered mode if the voltage falls

below the prescribed minimum.

0

F

Indication of

weighing units

6.1.2 Overview of display

EW/EG-N/EWB-e-1125

Page 30

30

Operation

Display

Press the key to switch on the balance.

The balance will carry out a self-test.

Your balance is ready to weigh as soon as the

“0.000" display appears.

Apply the item to be weighed. The weight value

is displayed.

A switch can be made from one unit to an-

other, e.g. from ”g“ to another unit, for example

”ct“, by repeatedly pressing the key. Setting

– see chapter 7 on “Functions“.

[g] [ct] [Pcs] [%] [g] …….

Press the key to switch the balance off.

ο 0 I I I F

0.000 g

g

Pcs

%

ο 0 I I I F

0.00 ct

ο 0 I I I F PCS

0

ο 0 I I I F

0.00%

6.2 Operation

6.2.1 Weighing

Display symbol: g

EW/EG-N/EWB-e-1125

Page 31

31

CAUTION

Take care that the hooks used for the underfloor weighing are stable enough to hold

the goods which you wish to weigh (risk of breakage).

Always make sure that there are no living beings or materials below the load that

could be injured or damaged.

NOTE

After completing the underfloor weighing, the opening in the floor of the balance

must be closed again (dust protection).

!

6.2.1.1 Underfloor weighing

Objects which, because of their size or shape, cannot be put on the scale, can be

weighed by means of underfloor weighing.

Proceed as follows:

Switch off the balance.

Turn the balance over.

Open the cover plate (1) on the base of the balance.

Hang on the hanging loop (optional) completely for underfloor weighing.

Place the balance over an opening.

Hang the item to be weighed on the hanging loop and carry out weighing.

EW/EG-N/EWB-e-1125

Page 32

32

Operation

Display

Place the empty tare container on the

weighing plate. The total weight of the

applied container is displayed.

Press the key to start the tare procedure.

The weight of the container is now

stored internally.

Place the items to be weighed in the tare

container.

Now read off the weight of the items on

the display.

0 I I I F

23.456 g

0 0 I I I F

0.000 g

0 I I I F

53.258 g

6.2.1.2 Tare weighing (tare)

The empty weight of any weighing container can be tared at the push of a button, so

that the net weight of the item to be weighed is displayed during subsequent weighings.

EW/EG-N/EWB-e-1125

Page 33

33

Press the key to set the display to

”0.000".

The total weight of the container is removed by taring.

Apply further components to the weighing container (weighing in).

Now read off the weight of the added

item to be weighed on the display.

0 0 I I I F

0.000 g

0 I I I F

83.456 g

The tare procedure can be repeated as often as desired, for example when weighing

several components into a mixture (weighing in).

Information:

The balance is only ever able to store one tare value.

The stored tare value is displayed prefixed by a minus sign when the balance is

empty.

Remove all items from the weighing plate in order to delete the stored tare value

and subsequently press the key.

The tare procedure can be repeated as often as desired. The limit has been

reached when the entire weighing range is used to full capacity.

EW/EG-N/EWB-e-1125

Page 34

34

Operation

Display

1. Use the key to switch the balance

on. Use the key to select unit

change-over Pcs

(see chap. 6.2.1).

2. Tare containers can also be used

during unit counting. Before starting unit

counting use the key to tare out the

container.

3. Operate the key.

The reference unit will flash on the display.

ο 0 I I I F Pcs

0

ο 0 I I I F Pcs

0

Pcs

M on 10

6.2.2 Piece counting

(excl. model KERN EW120-4NM)

Display symbol: PCS

When counting units you can either count items into or out of the container. In order

to be able to count a substantial number of items, the average weight per item must

be determined using a small quantity (reference units).

The greater the reference unit, the greater the counting accuracy.

A particularly high reference must be chosen for small or greatly varying parts.

The work cycle is divided into four stages:

Tare the weighing container

Determine the reference unit

Weigh in the reference unit

Count the items

EW/EG-N/EWB-e-1125

Page 35

35

4. Further reference units of 10, 30, 50

and 100 can be called up by repeatedly

operating the key.

Important: The greater the reference

unit, the more accurate the unit count.

5. Place as many items to be counted

on the balance as required by the set

reference unit.

6. Operate the key.

The reference unit is stored.

Now place the items to be counted in the

container. The appropriate number of

items will be shown on the display.

7. Use the key to return to the de-

sired weighing mode.

10

30

50

100

Pcs

M on 30

Pcs

M on 30

0 I I I F Pcs

30

g

Pcs

%

Information:

If the“L-Err “ error message is displayed, the smallest counting weight has been

fallen short of – see chap. 1 ”Technical Data“.

EW/EG-N/EWB-e-1125

Page 36

36

Operation

Display

1. Carry out item 1-5 as in

chap. 6.2.2 “Parts counter“.

e.g. place 10 items on the weighing

plate.

2. Operate the key.

The reference weight of the 10 items is

stored.

Counting accuracy can be increased by

carrying out the following steps.

3. Doubling the items to be weighed:

Apply a further 10 items (approx.).

Operate the key

The reference weight of the 20 items is

stored.

Pcs

M on 10

Pcs

M 10

Pcs

M 20

6.2.2.1 Add mode

This function is used to increase the counting accuracy by increasing the reference

quantity. It can thereby be avoided that an inadequate reference unit is used, as this

could lead to inaccurate results.

When applying this function, the necessary minimum number of items is automatically ensured.

EW/EG-N/EWB-e-1125

Page 37

37

4. Double again (see item 3)

Information:

Every additionally applied number of

items increases the reference and improves the counting accuracy.

A particularly high quantity of reference

units must be chosen for small items or

items with greatly varying own weight.

5. Operate the key.

The reference unit is stored.

Now place the items to be counted in the

container. The appropriate number of

items will be shown on the display

Use the key to return to the desired

weighing mode.

Pcs

M 40

Pcs

M 125

g

Pcs

%

Information:

If the “Add“ error message appears, the applied number of items is too small

for correct determination of the reference. Place further items on the balance

to determine the reference.

The determined reference is preserved until the balance is disconnected from

the mains.

EW/EG-N/EWB-e-1125

Page 38

38

Operation

Display

1. Use the key to switch the bal-

ance on. Use the key to select unit

change-over [ % ] (see chap. 6.2.1).

Information:

Tare containers can also be used during

percent weighing. Before starting percent

weighing use the key to tare out the

container.

2. Operate the key.

[P. SEt] will flash on the display.

3. Place the reference weight = 100% in

the balance dish.

4. Operate the key.

The reference weight is stored.

ο 0 I I I F

0 %

P. SEt %

P. SEt %

ο 0 I I I F

100.00 %

6.2.3 Percent weighing

(excl. model KERN EW120-4NM)

Display symbol: %

Percent weighing allows the weight to be displayed as a percentage in relation to a

reference weight. The displayed weight value is adopted as a fixed prescribed percent value. (Standard setting: 100%).

EW/EG-N/EWB-e-1125

Page 39

39

From now on the applied weight is

shown as a percentage.

Use the key to return to the desired

weighing mode.

0 I I I F

85.37 %

g

Pcs

%

Information:

If the “o-Err “ error message appears:

- the reference weight is outside the weighing range (see chap. 1 ”Tech-

nical Data“).

- the set key was operated during step 2 when the weight had been ap-

plied.

The 100% reference is preserved until the balance is disconnected from the

mains.

6.2.4 Weighing using a tolerance range

(excl. model KERN EW120-4NM)

This balance can be used as a measuring and sorting balance, whereby the respective lower and upper tolerance limits are programmable.

Limit values can be entered in the following operating modes:

Weighing

Unit counting

Percent weighing

EW/EG-N/EWB-e-1125

Page 40

40

+ 0 I I I F

- 0.000 g

Operation

Display

1. Use the key to switch the balance

on.

Call up the function menu:

Press the key until [Func] appears,

then release.

The first balance mode will appear:

2. Tolerance weighing

Operate the key to call up tolerance

weighing mode.

2.SEL 0 (Off)

2.SEL 1 (ON)

Use the key to change the standard

factory configuration.

3. Tolerance mark display

Operate the key. The tolerance mark

is always displayed (factory setting).

Use the key to change the setting

(1 / 2).

The tolerance mark is only displayed

when the balance display is at a standstill.

ο 0 I I I F

0.000 g

Func

1 b.G. 1

2.SEL 0

2.SEL 1

21.Co. 1

21.Co. 2

6.2.4.1 Basic settings when weighing using a tolerance range

EW/EG-N/EWB-e-1125

Page 41

41

4. Setting the tolerance range

Operate the key

The tolerance mark is displayed in all

ranges.

Use the key to change the setting:

Tolerance mark is only displayed above

a zero point range (+5).

5. Number of tolerance points

Use the key to set the tolerance

mark.

1 tolerance mark can be displayed:

-

too light

Use the key to change the setting:

2 tolerance marks can be displayed:

+

too heavy

TOL target value

-

too light

Operate the key:

You will now leave the function menu

and return to weighing mode.

22.L ı. 1

22.L ı. 0

23.P ı. 1

23.P ı. 2

ο 0 I I I F

0.000 g

+ 0 I I I F

- 0.000 g

EW/EG-N/EWB-e-1125

Page 42

42

Operation

Display

1. Use the key to switch the balance

on.

Set to tolerance weighing:

Press the key until [L. SEt] appears

and then release.

2. The tolerance mark

will flash [ - ].

The lower limit value can be set.

Place a sample for the lower (i.e.

smaller) limit value on the weighing

plate:

Store using the key. The stored lower

weight value is displayed briefly.

Entry is now completed if 1 tolerance

mark was selected in the basic setting

(see chap. 7.2.1).

ο 0 I I I F

0.000 g

L. SEt

M 0.000 g

M 93.835 g

6.2.4.2 Entering the limit values by weighing

Important information !

Always begin by entering the lower limit value, followed by the upper limit

value.

EW/EG-N/EWB-e-1125

Page 43

43

4. If 2 tolerance marks have been se-

lected, the upper limit value must now be

determined.

The tolerance mark is flashing [ + ],

and the upper limit value can be set.

Place a sample for the upper (i.e. larger)

limit value on the weighing plate:

5. Use the key to store. The stored

upper weight value is displayed briefly;

entry is completed.

M 0000 g

H. SEt

M 158.487g

EW/EG-N/EWB-e-1125

Page 44

44

Operation

Display

1. Use the key to switch the balance

on.

Set tolerance weighing:

Press the key until [L. SEt] appears

and then release.

2. Flashing display is either 000.000 or

the currently stored lower limit value.

Press the key:

The last digit in the display starts to

flash.

3. Use the key to increase the nu-

merical value of the selected digit.

4. Use the key to select the digit you

wish to alter (from right to left).

5. Further entries as described in items

3 and 4.

6. Use the key to store. The stored

lower weight value is displayed briefly.

Entry is now completed if 1 tolerance

mark was selected in the basic setting

(chap. 7.2.1).

ο 0 I I I F

0.000 g

L. SEt

M 000.000 g

M 000.001 g

M 000.005 g

M 000.025 g

M 77.385 g

6.2.4.3 Entering the limit values using the keyboard

EW/EG-N/EWB-e-1125

Page 45

45

7. If 2 tolerance marks have been

selected, the upper limit value must now

be determined.

Please proceed as described in item 2,

starting with the last display digit.

8. Enter the upper limit value and store.

H. SEt

M 000.000 g

EW/EG-N/EWB-e-1125

Page 46

46

Operation

Display

1. Access to the functions.

Switch on the balance:

Press the key for about 4 seconds

until [FUNC] appears:

When released the following will appear :

(possible configurations are listed in

chap. 7.2.2).

2. Changing the functions

Run through the various functions for

configuration by continuing to press the

key.

Operate the key in order to change

the last position in the parameter.

Store the chosen function by operating

the key.

You will now leave the function menu

and return to weighing mode.

ο 0 I I I F

0.000 g

Func

1 b.G. 1

2.SEL 0

2.SEL 1

ο 0 I I I F

0.000 g

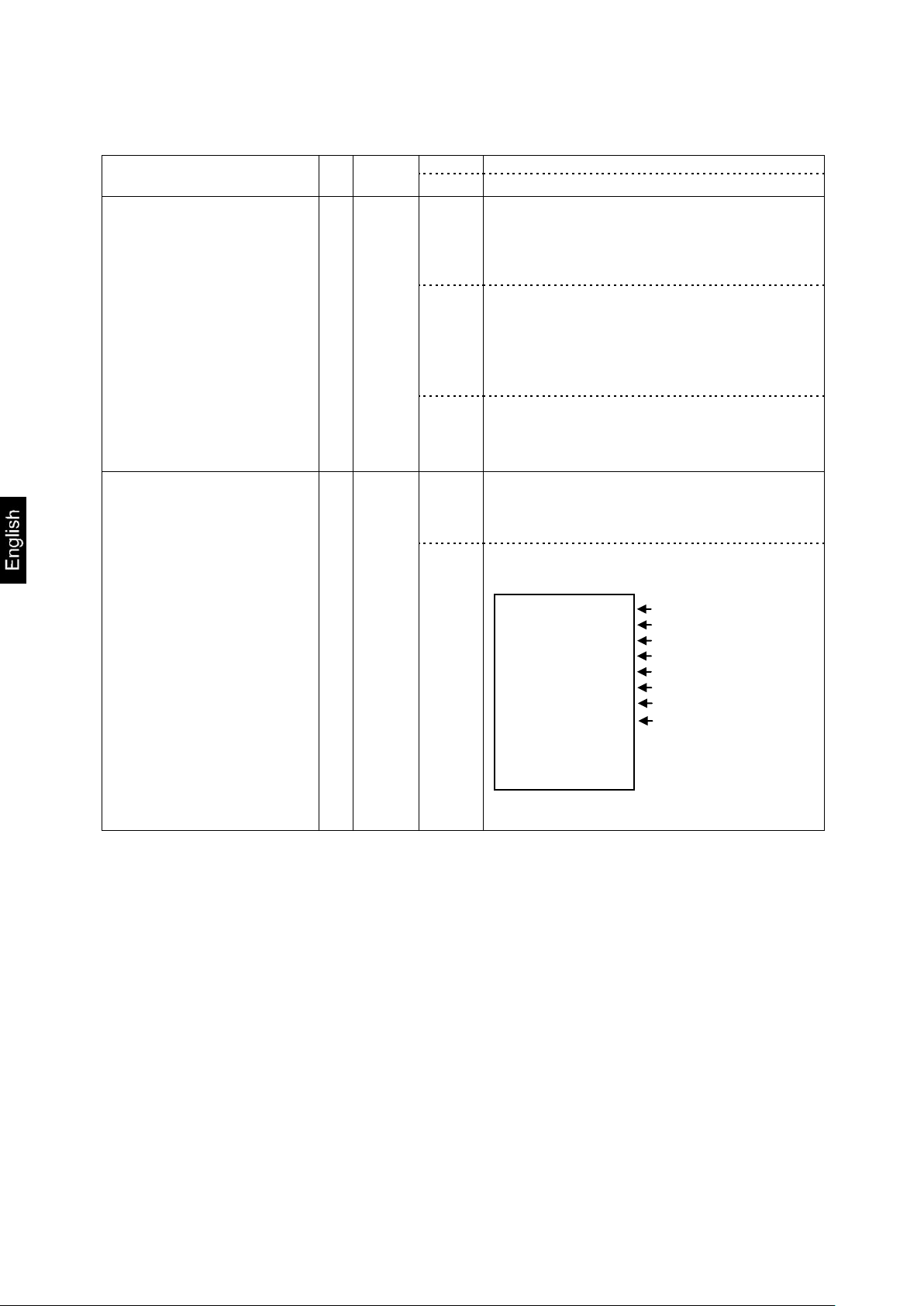

7 Functions

7.1 Access and changing of numerous functions:

The balance has been set to a certain standard configuration in the factory. This configuration is marked by a ☆.

The configuration can be changed as follows:

EW/EG-N/EWB-e-1125

Page 47

47

Function

Display

Choice

Description of the choice

possibilities

Bar graph

1

b.G.

0

Off

☆1

On

Tolerance weighing

(excl. EW-120-4NM)

2

SEL

☆0

Off

1

On (chap. 7.2.1)

Zero alignment

3

A.0

0

No zero point correction

☆1

Automatic zero point correction activated.

Automatic shutoff after 3 min.

for rechargeable battery operation (function is only available inrechargeable battery

mode)

4

A.P.

0

Automatic shutoff deactivated for rechargeable battery operation (optional).

☆1

Automatic shutoff activated for rechargeable battery operation (optional).

Display speed

5

rE.

0

Setting for metering

1

Sensitive and fast

2

☆3

4

5

Non-sensitive but slow

Vibratory filter

6

S.d.

1

Sensitive and fast (very tranquil installation

location).

☆2

3

4

Non-sensitive but slow (very unsettled

installation location).

5 only EW-120-4NM

6 only EW-120-4NM

Interface

7

I.F.

0

Interface not active

(excl. EWB models)

☆1

6-digit data format (excl. EW-120-4NM)

2

7-digit data format (chap. 7.2.2)

Weight unit

(only selectable, if the calibration switch is not in the

calibration position see

Ch. 6.10)

81

85

S.u.

1☆01

(g)

2☆14

(ct)

15

(oz)

16

(lb)

17

(ozt)

18

(dwt)

19

(grain), (excl. EWB models)

1A

(tl Hong Kong)

1b

(tl Singapore,Malaysia)

1C

(tl Taiwan)

1d

(mom)

1E

(to)

3☆20

(Pcs) excl. EW-120-4NM

4☆IF

(%) excl. EW-120-4NM

5☆00

Unit not set (can not be set at 81.S.u.)

7.2 List of the function parameters

The balance has been set to a certain standard configuration in the factory. This is

marked by a ☆.

EW/EG-N/EWB-e-1125

Page 48

48

Not documented

9.

Ai

0

Not documented

☆1

Always use this setting.

Data-out

(only selectable, if the calibration switch is not in the

calibration position see

Ch. 6.10)

A.

PrF.

1

No printout possible, if the last display location

is enclosed in brackets.

☆2

Printout possible, even if the last display location is enclosed in brackets.

Comment: Always select this setting, before

the balance is calibrated, as this menu item

can no longer be called due to the calibration

3

The printout is only carried out, if the calibration

switch is not in the calibration position see

Ch. 5.10.

Enhanced log printout following adjustment

(only selectable on

EG models)

0

GLP

0

Off

☆1

On

**CALIBRATION**

MODEL:

S/N:

ID:

DATA:

TIME:

*CAL. END

NAME

********************

Title

Model of balance

Serial no.

ID no.

Date of calibration

Time of calibration

End of calibration

Signatur

EW/EG-N/EWB-e-1125

Page 49

49

Function

Display

Choice

Description of the choice

possibilities

Display conditions of

the tolerance mark

21.

Co.

☆1

Tolerance mark is always displayed, even if standstill check not

yet indicated.

2

Tolerance mark only displayed in

connection with standstill check.

Tolerance range

22.

L I.

0

Tolerance mark only displayed

above the zero point range (at

least + 5).

☆1

Tolerance mark displayed

throughout entire range.

Setting the tolerance

mark

23.

P I.

1

1 tolerance step is displayed:

“-“ or “+”

☆2

2 tolerance steps are displayed:

“- “ and “+”

7.2.1 Parameters when weighing with a tolerance range

(excl. model KERN EW120-4NM)

Settings 21. Co. to 23. P I. can only be set if the tolerance weighing function

has been activated.

EW/EG-N/EWB-e-1125

Page 50

50

Function

Display

Choice

Description of the choice pos-

sibilities

Output format at interface

7

I.F. 0

Interface not active

☆1

6-digit data format

2

7-digit data format

Output condition at

interface

71.

o.c.

0

No data issued.

(Menu setting “7 I.F. [1] or

[2]“ only )

1

Continuous serial output.

2

Continuous serial output upon

stabilised display.

3

Output following printing of

PRINT/M.

4

Automatic output upon stable

weighing value. The first value to

stabilise is adopted if this is -0.00

or less. No new output until weight

is removed and a new load applied.

5

Output upon stabilisation, no output if data unstable.

6

Output upon stabilisation, constant output if data unstable.

☆7

Output following printing of

PRINT/M.

Baud rate

72.

b.L.

☆1

1200 bps

2

2400 bps

3

4800 bps

4

9600 bps

Parity

73.

PA.

☆0

No parity bit

(Menu setting

1

Uneven parity

“7 I.F. 2“ only )

2

Even parity

7.2.2 Parameters for the serial interface

(excl. EWB models)

EW/EG-N/EWB-e-1125

Page 51

51

Data-bit:

8-bit (Standard-ASCII-Format)

Start-bit:

1 bit

Stop-bit:

2 bits

Parity:

NON, ODD, EVEN

Baudrate:

1200 / 2400 / 4800 / 9600 baud can be set

(see chap. 7.2.2 “Functions“)

1 4 2 5 3

- System- internal

- TXD

- GND

- RXD

- System- internal

8 Data output

(excl. EWB models)

The balance is supplied as standard with an interface RS 232C.

8.1 Description of the serial data output (RS 232C)

The data output is placed at the rear side of the balance. It is a 5-pole standard

socket.

Pin description see following illustration

8.2 Technical data of the interface

Transfer format: serial data transfer

EW/EG-N/EWB-e-1125

Page 52

52

1 2 3 4 5 6 7 8 9

10

11

12

13

14

P1

D1

D2

D3

D4

D5

D6

D7

U1

U2

S1

S2

CR

LF

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

P1

D1

D2

D3

D4

D5

D6

D7

D8

U1

U2

S1

S2

CR

LF

P 1

Code

Meaning

+

2 B H

Data are 0 or positive

-

2 D H

Data are negative

sp

20 H

Date are 0 or positive

D *

Code

Meaning

0 - 9

30 H – 39 H

Data 0 to 9 (max. 6 characters in 6-type format)

. (Point)

2 EH

Decimal point, position not fixed

Sp

20 H

Space character, leading zero oppressed

8.3 Interface description

The output format, output control, transfer speed and parity bit can be set following

the choice of a certain operating mode. The various possibilities are described in

chap. 7.2.2 “Parameters for the serial interface “.

8.4 Data Output

8.4.1 Data Transmission Formats

By selecting the corresponding function at your balance one of the two following data

formats can be set:

6-digit data format

(excl. model KERN EW-120-4NM)

Consisting of 14 words including the final signal; CR=0DH, LF=0AH (CR=return

travel / LF=line feed)

7-digit data format

Note: The 7-digit format is identical with the 6-digit format except for the addi-

tional signal D8.

8.4.2 Algebraic sign

P 1 = 1 word

8.4.3 Data

D 1 to D 7 7 words with 6-digit format (excl. model KERN EW-120-4NM)

D 1 to D 8 8 words with 7-digit format

EW/EG-N/EWB-e-1125

Page 53

53

U1

U2

Code

Meaning

Symbol

(SP)

G

20H

47H

Gramme

g C T

43H

54H

Carat

O Z

4FH

5AH

Ounze

L B

4CH

42H

Pound

O T

4FH

54H

Fine ounze

D W

44H

57H

Pennyweight

G R 47H

52H

Grain

(upper right)

T L 54H

4CH

Tael (Hong Kong)

T L 54H

4CH

Tael (Singapore, Malaysia)

(upper right)

T L 54H

4CH

Tael (Taiwan)

(lower right)

M O 4DH

4FH

Momme

mom t o

74H

6FH

Tola

(SP)

%

20H

25H

Percent

% (excl. EW-120-4NM)

P C 50H

43H

Quantity

Pcs (excl. EW-120-4NM)

S 1

Code

Meaning

When weighing using tolerance range:

L

4 CH

Weighing value below the tolerance range

G

47 H

Weighing value within the tolerance range

Result of the evaluation issued at two points:

Low / high

H

48 H

Weighing value above the talorance range

S 2

Code

Meaning

S

53 H

Stabilised data *

U

55 H

Data not stabilised (fluctuating) *

E

45 H

Data error, all data unreliable with the exception of S 2.

Balance displays error (o-Err, u-Err)

sp

20 H

No special status

8.4.4 Units

U 1, U 2 = 2 words as ASCII codes

8.4.5 Result of the evaluation / Type of data

S 1 = 1 Word

8.4.6 Data state

S 2 = 1 Word

EW/EG-N/EWB-e-1125

Page 54

54

1 2 3 4 C1

C2

CR

LF

C1

C2

Code

Content

T

SP

54H

20H

Tare out command

C1

C2

Code

Meaning

O 0 4FH

30H

No data output

O 1 4FH

31H

Continuous data output

O 2 4FH

32H

Continuous output of stable weight value data

O 3 4FH

33H

Output of stable and unstable weight values after pressing the

PRINT button

O 4 4FH

34H

Data output upon stable weight value, having previously unloaded

the weighing scale

O 5 4FH

35H

Data output upon stable weight value. No data output at unstable

weight value. Data output again, after stabilization has been

reached

O 6 4FH

36H

Data output upon stable weight value. Continuous data outputting

at unstable weight value.

O 7 4FH

37H

Output of stable weight values after pressing the PRINT button

O 8 4FH

38H

One-time immediate data output*

O 9 4FH

39H

One-time data output after stabilization has been reached*

O A 4FH

41H

One-time, immediate data output after lapse of a defined period of

time*

O B 4FH

42H

One-time, immediate data output after lapse of a defined period of

time and upon stable weight value*

8.5 Data input commands

8.5.1 Command input format

is made up of 4 characters, CR=0DH, LF=0AH

8.5.2 External taring command

8.5.3 External control commands

* While using these commands for remote control purposes, do not press the PRINT button (data

transmission error). In case data transmission error occurs, briefly cut off the weighing scale from its

power supply source.

EW/EG-N/EWB-e-1125

Page 55

55

1 2 3 4 5

A1

A2

A3

CR

LF

A1

A2

A3

Code

Description

A 0 0

41H

30H

30H

No errors

E 0 1

45H

30H

31H

Error message

Remarks:

Control of data output through “O0~O7” commands as well as setting up

weighing scale’s functions, are actions that bring about similar effects.

Implementation of commands “O8 and O9" is connected with data input com-

mands.

If any command from the “O0~O9” range has been carried out, then its status

will remain active until the next command is inputted. If, however, the weighing

scale is switched off, then the output data control system will return to its previous setup.

8.6 Feedback message after data transmission

is made up of 5 characters, CR=0DH, LF=0AH

Types of feedback messages:

9 Maintenance, upkeep, disposal

9.1 Cleaning

Please disconnect the device from the operating voltage before cleaning.

Only use a cloth dampened with mild suds and not aggressive cleaning agents (sol-

vents or similar). Please ensure that fluids are not able to get into the device and rub

off using a clean, soft cloth.

Loose sample residue/powder can be removed carefully using a brush or hand vacuum cleaner.

Remove any spilt material to be weighed immediately.

9.2 Maintenance, upkeep

The device may only be opened by trained service engineers authorised by KERN.

Disconnect from the mains supply before opening.

9.3 Disposal

The operating company shall dispose of the packaging and the device in compliance

with the valid national or regional law of the operating location.

EW/EG-N/EWB-e-1125

Page 56

56

Interruption

Possible cause

Weight display is not illuminated.

The balance is not switched on.

The mains supply connection has been

interrupted (mains cable not plugged

in/faulty).

Power supply interrupted.

The weight display changes continually

Draught/air movement

Table/floor vibrations

The weighing plate is in contact with for-

eign matter.

Electromagnetic fields / static charging

(choose different location/switch off interfering device if possible)

The weighing result is obviously

incorrect

The balance display is not set to zero

Adjustment is no longer correct.

Great fluctuations in temperature.

Electromagnetic fields / static charging

(choose different location/switch off interfering device if possible)

10 Troubleshooting

The balance should be switched off for a short time following an interruption in the

programme sequence and disconnected from the mains supply. It is then necessary

to repeat the weighing process from the beginning.

Help:

Switch the balance off if other error messages should appear and then switch on

again. Contact the manufacturer if the error message does not disappear.