Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Tel: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Service manual

Platform balances

KERN EOE/EOS…N

Version 2.1

4/2009

GB

EOE, EOS…N-SH-e-0921

Page 2

GB

KERN EOE, EOS…N

Version 2.1 4/2009

Service manual

Platform balances

2 EOE, EOS…N-SH-e-0921

Table of Contents

1 Basic Information........................................................................................................3

2 Features.......................................................................................................................4

3 Error Message Indication...........................................................................................4

4 Trouble Shooting........................................................................................................5

5 Calibration Procedure................................................................................................6

6 Inspection Mode for Technical Maintenance ...........................................................7

6.1 Zero Count and Span Count Adjustment............................................................................ 8

7 Functions Setting-up Sequence................................................................................9

8 Schematic of Main Board CH-0509..........................................................................10

9 Circuit Diagram for Adapter System.......................................................................11

9.1 CH-0521 (Inside EOE Platform).......................................................................................... 11

9.2 CH-0525 (Inside EOS Platform).......................................................................................... 12

10 System Block Diagram.........................................................................................13

11 Display Format......................................................................................................14

12 Layout....................................................................................................................15

12.1 Layout of Main Board CH-0509........................................................................................ 15

12.2 Layout of CH-0521 (Inside EOE Platform)....................................................................... 16

12.3 Layout of CH-0525 (Inside EOS…N Platform) ................................................................ 17

13 Explosion Diagram................................................................................................18

Page 3

EOE, EOS…N-SH-e-0921 3

1 Basic Information

Grundlegende Hinweise

The device must be repaired only by trained specialist staff or personnel with

professional formation (such as a repair-specialist accredited by law

concerning verification).

The service manual is obligatory for repair work.

After repair, original conditions of the device have to be restored.

Only original spare parts should be used.

Das Gerät darf nur von geschultem oder beruflich ausgebildetem

Fachpersonal (z. B. eichrechtlich anerkannter Instandsetzer) repariert werden.

Die Serviceanleitung ist bindend für Reparaturen.

Das Gerät muss nach erfolgter Reparatur wieder in den Originalzustand

zurückversetzt werden.

Es dürfen nur Originalersatzteile verwendet werden.

Page 4

2 Features

1. Compact Dimension: 310 x 300 x 65 mm, 505 x 505 x 65, 945 x 505 x 65 mm,

900 x 550 x 65 mm

2. Material: Stainless Steel or Lacquered Steel

3. Overload Protection on Load Cell

4. Display options: 1.0 inch LCD display with 4 3/8 digital LCD

5. Capacity/Division: 6kgx5g, 15kgx10g, 35kgx20g, 60kgx50g, 150kgx100g,

300kgx200g

6. Power: AA 1.5VX6 batteries / 9V 100mA DC adapter

7. Power saving (auto shut-off timing selectable: 120 sec / 180 sec / 240 sec /

300 sec)

8. Operating Temperature: +10°C ~ +35°C

9. Operating Humidity: 25% ~ 80%

10. Function keys (4 key): ON/OFF, HOLD, UNIT, TARE

ON/OFF Switch the balance on or off by pressing the ON/OFF key.

HOLD Place the animal on the weighing platform and press the HOLD key to start

the animal weighing function (mean value).

A triangle will start to flash on the left hand side of the display, and during

this time the balance will record several values, then calculate and display

a mean value.

By pressing the HOLD key again, the weighing machine will be reset to

standard weighing mode.

Remark: With to lively movement (strong diplay fluctuation) no mean value

can take place.

UNIT Select weight unit kg lb

TARE By pressing the TARE key the display will appear “0”.

11. Weight units: kg/lb

12. Tare (to full capacity)

13. External Calibration (see chapter 5)

14. Functions setting-up (see chapter 7)

3 Error Message Indication

A. ErrE or ErrP : EEprom Error

B. ErrL : Low zero count

C. Err : Overload & High zero count

D. : Low battery indication

If scale shows any of the above error messages, it will auto shut-off after 30

seconds.

4 EOE, EOS…N-SH-e-0921

Page 5

4 Trouble Shooting

EOE, EOS…N-SH-e-0921 5

Page 6

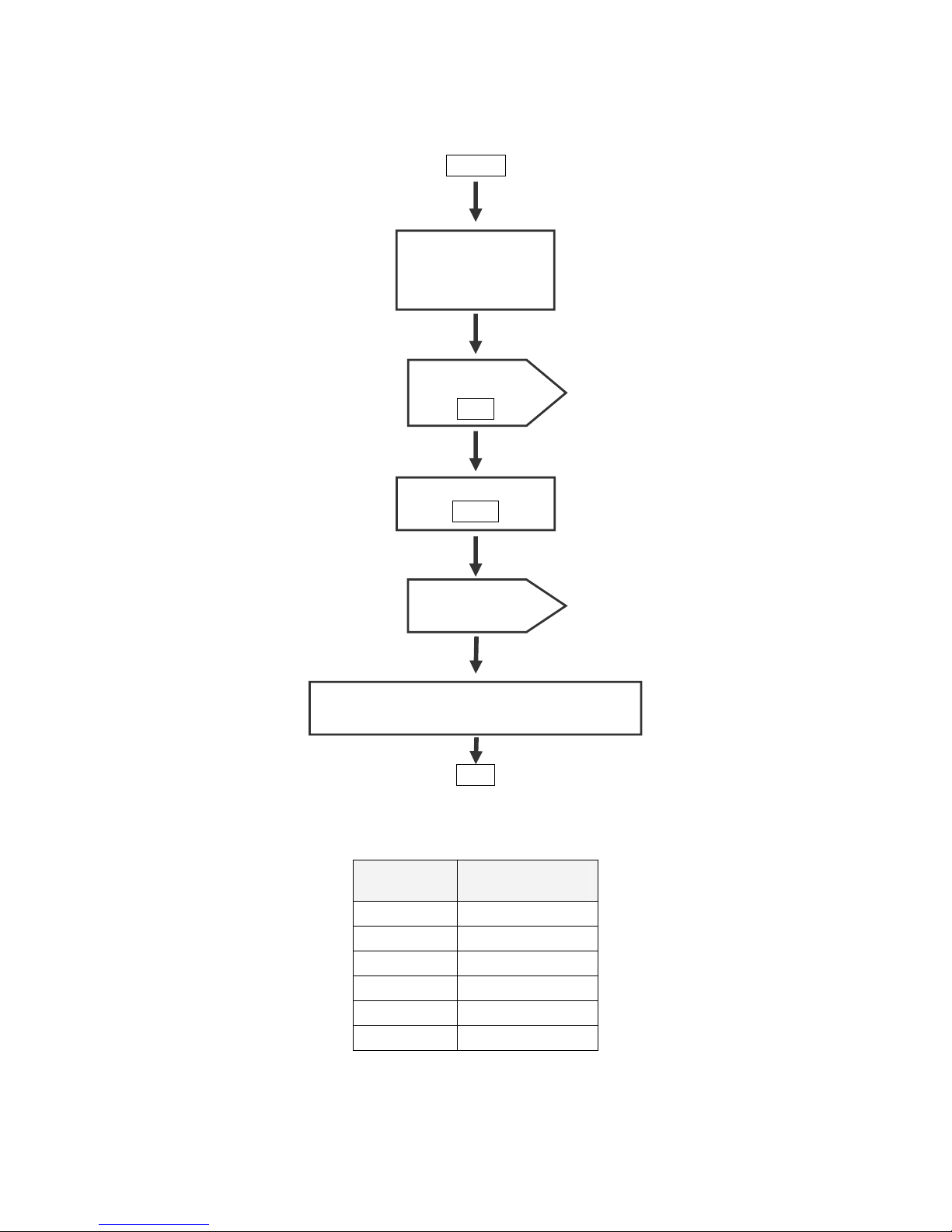

5 Calibration Procedure

START

Press and hold

UNIT key for 6

seconds

Display shows

CAL

Display shows

LoAd

Load weight

(see Note 1.)

Press UNIT key once to confirm.

Display shows calibration weight.

END

Note 1:

Capacity Calibration

Weight

6kg 5kg

15kg 10kg

35kg 20kg

60kg 40kg

150kg 100kg

300kg 200kg

6 EOE, EOS…N-SH-e-0921

Page 7

6 Inspection Mode for Technical Maintenance

START A

Press ON key without releasing, and Loading calibration weight

press UNIT key 3 times (see note 1)

Display shows zero count Display shows span count.

XXXX. Please see note 1 Please see Note 1 for span

for the zero count count range

Press TARE key Adjust RX1 value. Please see

note 1 for recommended RX1

value

EOE, EOS…N-SH-e-0921 7

Display show

0 Proceed calibration

procedure as per

chapter 5

A

Note 1:

Capacity Zero Count Span Count Calibration

Weight

Span Control

(RX1)

6kg 2000~12000 4000~8000 5kg 80K

15kg 2000~12000 4000~8000 10kg 62K

35kg 2000~12000 4000~8000 20kg 50K

60kg 2000~12000 3200~6400 40kg 25K

150kg 2000~12000 4000~8000 100kg 60K

300kg 2000~12000 4000~8000 200kg 30K

The total internal count is 32768. Overload was set at 32500 (in production).

<--------------------------------------32768 -------------------------------------------------------------------->

------

<----- ---------------------------32500 ------------------------------------------------------> Overload

<-2000~12000 (zero) + 4000~8000 (span)= 6000~20000 -> Safety range

Page 8

6.1 Zero Count and Span Count Adjustment

If the ZERO COUNT value is out of range, adjust R1 or R2 on the main board.

If zero count is below 2000, use a variable resistor on R1 to adjust the zero count

(see note 1 chapter 6).

If zero count is above 12000, use

a

variable resistor on R2 to adjust the zero count

(see note 1 chapter 6).

After determination of the required resistor, solder it on the main board.

If the SPAN COUNT value is out of range, adjust RX1 on the main board.

Use a variable resistor on RX1 to adjust the span count

(see note 1 chapter 6).

After determination of the required resistor, solder it on the main board.

8 EOE, EOS…N-SH-e-0921

Page 9

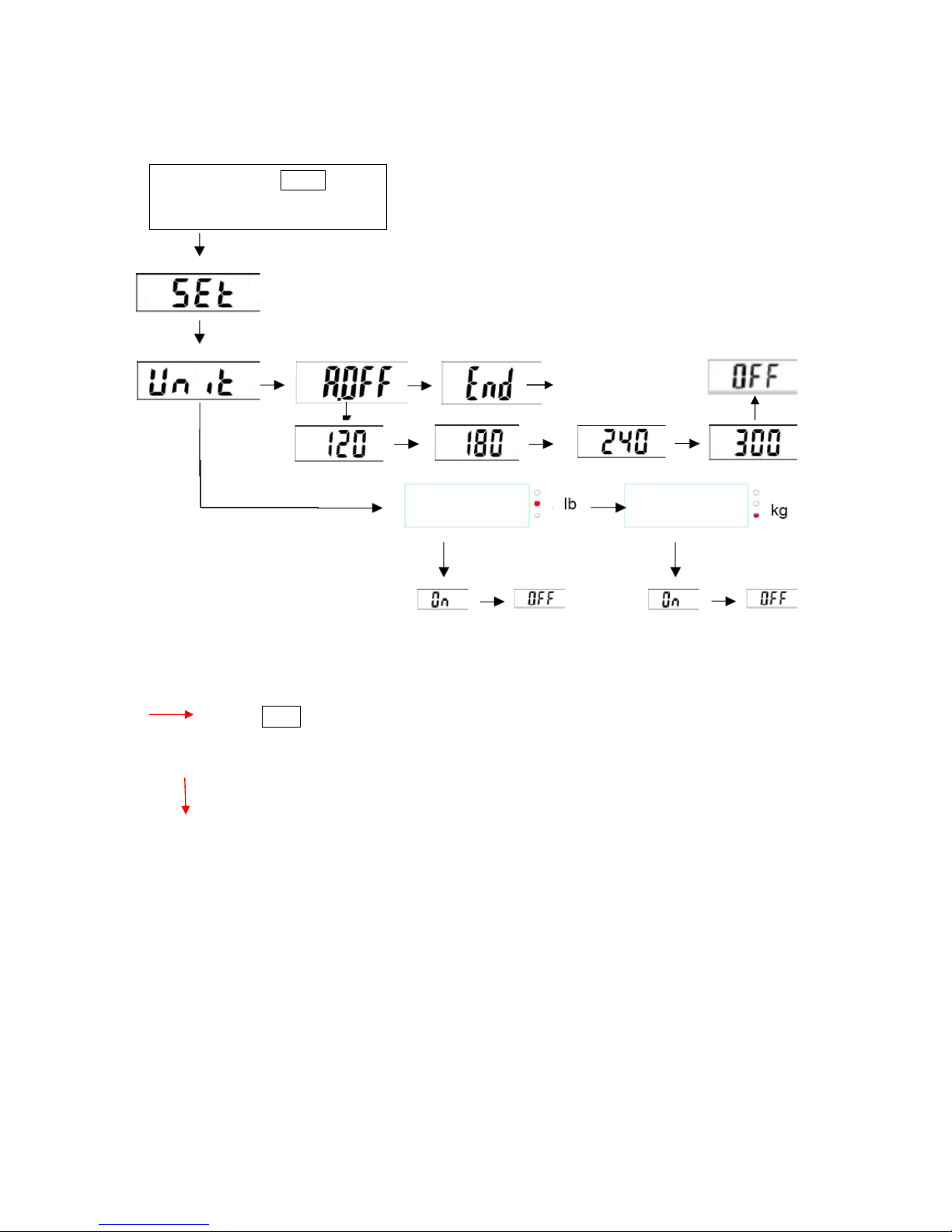

7 Functions Setting-up Sequence

EOE, EOS…N-SH-e-0921 9

Press and hold TARE for 6

seconds

Operating:

The Tare key is used for the rejection of a proffered option and has the same

meaning as “NO”

The [UNIT] key serves to select an available option and means the same as

„YES“

UNIT

TARE

TARE

UNIT

TARE

UNIT

TARE

TARE

TARE

UNIT

UNIT

TARE

TARE

Page 10

8 Schematic of Main Board CH-0509

10 EOE, EOS…N-SH-e-0921

Page 11

9 Circuit Diagram for Adapter System

9.1 CH-0521 (Inside EOE Platform)

EOE, EOS…N-SH-e-0921 11

Page 12

9.2 CH-0525 (Inside EOS Platform)

12 EOE, EOS…N-SH-e-0921

Page 13

10 System Block Diagram

EOE, EOS…N-SH-e-0921 13

Page 14

11 Display Format

14 EOE, EOS…N-SH-e-0921

Page 15

12 Layout

12.1 Layout of Main Board CH-0509

EOE, EOS…N-SH-e-0921 15

Page 16

12.2 Layout of CH-0521 (Inside EOE Platform)

16 EOE, EOS…N-SH-e-0921

Page 17

12.3 Layout of CH-0525 (Inside EOS…N Platform)

EOE, EOS…N-SH-e-0921 17

Page 18

13 Explosion Diagram

1 Panel NP-xxxx

2 Lens LS-8045

3 Control Panel NP-8149

4 Screw SW-8060

5 Plastic Cover CR-8085

6 Bracket WP-8006

7 Screw M3x8

8 PCB Module CH-xxxx

9 Nut

10 Plastic Base BM-8055

11 Screw M3x8

12 Feet SW-0170

13 AC Jack LD-0201

14 Screw M2x5

15 Battery Box SN-36-1/6P

16 Battery Snap AE-013E

17 Strain Relief SB-5M-2

18 Foam 3x20x40mm

18 EOE, EOS…N-SH-e-0921

Loading...

Loading...