Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Operating manual

Electronic Moisture Analyser

KERN DAB

Version 1.3

2018-08

GB

DAB-BA-e-1813

Page 2

2 DAB-BA-e-1813

GB

KERN DAB

Version 1.3 2018-08

Operating manual

Electronic Moisture Analyser

Contents

1 TECHNICAL DATA ............................................................................................. 4

2 DECLARATION OF CONFORMITY ................................................................... 5

3 APPLIANCE OVERVIEW ................................................................................... 6

3.1 Keyboard overview ....................................................................................................................... 8

3.2 Overview of display ...................................................................................................................... 9

4 BASIC INFORMATION (GENERAL) ................................................................ 10

4.1 Proper use ................................................................................................................................... 10

4.2 Improper Use ............................................................................................................................... 10

4.3 Warranty ...................................................................................................................................... 10

4.4 Monitoring of Test Resources ................................................................................................... 10

5 BASIC SAFETY PRECAUTIONS ..................................................................... 11

5.1 Pay attention to the instructions in the Operation Manual .................................................... 11

5.2 Symbols used in the operating instructions ............................................................................ 11

5.2.1 Warning pictograms ............................................................................................................. 12

5.3 Personnel training ...................................................................................................................... 12

5.4 Danger Information ..................................................................................................................... 13

6 TR ANSPORT AND STORAGE ......................................................................... 15

6.1 Testing upon acceptance ........................................................................................................... 15

6.2 Packaging / return transport ...................................................................................................... 15

7 UNPACKING, SETUP AND COMMISSIONING ............................................... 15

7.1 Installation Site, Location of Use .............................................................................................. 15

7.2 Unpacking and checking ........................................................................................................... 16

7.2.1 Scope of delivery / serial accessories: ................................................................................. 16

7.3 Placing ......................................................................................................................................... 17

7.4 Levelling ...................................................................................................................................... 18

7.5 Mains connection........................................................................................................................ 19

7.6 Switching on and off................................................................................................................... 19

7.6.1 Initial Commissioning ........................................................................................................... 20

7.7 Connection of peripheral devices ............................................................................................. 20

8 ADJUSTMENT .................................................................................................. 21

8.1 Weight adjustment ...................................................................................................................... 21

8.2 Calibrate / adjust temperature of the heating module ............................................................ 23

8.2.1 Temperature calibration ....................................................................................................... 23

8.2.2 Temperature adjustment ...................................................................................................... 26

Page 3

DAB-BA-e-1813 3

9 CARRY OUT YOUR FIRST MEASUREMENT ................................................. 27

10 DEFINE DRYING PARAMETERS ................................................................. 29

1. Enter ident number for drying method ..................................................................................... 29

2. Set heating profile....................................................................................................................... 30

3. Selecting switch-off criterion .................................................................................................... 32

4. Set drying temperature .............................................................................................................. 33

5. Setting the drying period for time-controlled switching-off ................................................... 34

11 CARRYING OUT DRYING AND MEASURING PROCESSES ..................... 35

12 RS 232 INTERFACE ..................................................................................... 38

12.1 Technical data ......................................................................................................................... 38

12.2 S etting the baud rate .............................................................................................................. 38

12.3 P rint out protocol: .................................................................................................................. 39

12.4 Continuous data transmission .............................................................................................. 40

13 GENERAL INFORMATION CONCERNING MOISTURE ANALYSIS ........... 44

13.1 Application .............................................................................................................................. 44

13.2 Basics ...................................................................................................................................... 44

13.3 Adjustment to existing measuring method ......................................................................... 44

13.4 Preparing a sample ................................................................................................................ 45

13.5 Sample material ...................................................................................................................... 46

13.6 S ample size / originally weighted in quantity ...................................................................... 46

13.7 Drying temperature ................................................................................................................ 47

13.8 Recommendations / Guidelines ............................................................................................ 47

14 SERVICING, MAINTENANCE, DISPOSAL .................................................. 48

14.1 Cleaning .................................................................................................................................. 48

14.2 Servicing, maintenance ......................................................................................................... 48

14.3 Disposal ................................................................................................................................... 48

15 INSTANT HELP ............................................................................................. 49

Page 4

4 DAB-BA-e-1813

1 Technical data

Data DAB 100-3 DAB 200-2

Item no./ Type - TDAB 200-2-A

Maximum load (Max) 110 g 200g

Readability (d) 0,001 g / 0,01% 0,01 g / 0,05%

Sample size 1 g – 110 g 1 g – 200 g

Recommended adjustment

weight, not added (class)

100g (F2) 200g (F2)

Warm-up time 2 h 30 min

Reproducibility

Weighed-in quantity 2 g

0,15 % 1,5 %

Reproducibility

Weighed-in quantity 10 g

0.02 % 0,3 %

Radiator type

Halogen (1 x 400 W)

Infrared (1 x 400 W) Factory option TDAB-A02-A

Temperature range

Models DAB 100-3 / DAB 200-2

40°C - 199°C

1°C steps selectable

Temperature range

Factory option TDAB-A02-A

40°C - 160°C

1°C steps selectable

Heating profiles

Standard drying

Fast drying

Soft drying

Linearity ± 0.003 g

Stabilization time (typical) 3 sec

Environmental conditions

5°C….+40°C ambient tem perature

max 80% air humidity non-condensing

Page 5

DAB-BA-e-1813 5

Shutoff criterion

• Automatic switch off

(2mg weight loss in 45 s)

• Time-controlled switch off,

selectable 3 min – 99 min

• Manual switch-off by pressing stop key

Sample dishes included Ø 95 mm

Displays of result [%] moisture content

[%] dry content

[ g ] residual weight in grams

Internal memory Method memory Internal memory

Sample memory

Interface RS232

Dimensions (W x D x H) Housing 240 x 365 x 180 mm

Available

drying room

Ø 92 mm, 20 mm high

Net weight 4.8 kg

Electric Supply 220V 50 Hz AC

2 Declaration of Conformi ty

To view the current EC/EU Declaration of Conformity go to:

www.kern-sohn.com/ce

Page 6

6 DAB-BA-e-1813

3 Appliance overview

Pos. Designation

1

Viewing panel

2 Heating hood

3 Halogen lamp

4 Heat shield

5 Sample dish

6

Windshield

7 Removal aid

8 Display

9 Keyboard

10

Adjustable foot

Page 7

DAB-BA-e-1813 7

Pos. Designation

11 RS232C-interface connection

12

Bubble level

13 Fan

14 Mains connection socket

Page 8

8 DAB-BA-e-1813

3.1 Keyboard overview

Button Function

• Call up menu

• Switch over display of result

• Cancel

• Start / finish drying and measuring process

• Taring

• Confirm / store settings

• Turn on/off

• Select parameter (forward)

• Increase digit

• Switch on background illumination of display

• Select parameter (backward)

• Reduce digit

• Switch off background illumination of display

Page 9

DAB-BA-e-1813 9

3.2 Overview of display

Example: Working window during drying process

Pos. Designation

1

Status display - drying process enabled

2 Enabled heating profile flashes

Standard drying

Fast drying

Soft drying

3 Enabled switch-o ff crit er i on flashes

Automatic switch-off

Time controlled switch-off

Manual switch off

4 Previous drying time

5 Current temperature

6 Display in % moisture

7 Subtotal

Page 10

10 DAB-BA-e-1813

4 Basic Information (General)

4.1 Proper use

The device purchased by you is designed for a fast and reliable determination of

material moisture in liquid, porous and solid materials by applying the method of

thermogravimetrics.

4.2 Improper Use

Impacts and overloading exceeding the stated maximum load (max) of the device,

minus a possibly existing tare load, must be strictly avoided.

This could cause damage to the integrated balance.

Never operate device in explosive environment. The serial version is not explosion

protected.

Changes to the unit's design are not permitted. This may lead to incorrect weighing

results, safety-related faults and destr uction of the appliance.

The unit may only be operated in accordance with the described default settings.

Other areas of use must be released by KERN in writing.

4.3 Warranty

Loss of warranty due to

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• Changing or opening instrument

• Mechanical damage and damage caused by media, liquids

• Natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

4.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the

integrated balance and, if applicable, the testing weight, must be checked regularly.

The responsible user must define a suitable interval as well as type and scope of this

test. Information is available on KERN’s home page (www.kern-sohn.com) with

regard to the monitoring of balance test substances and the test weights required for

this. In KERN's accredited DKD calibration laboratory test weights and balances may

be calibrated (return to the nati onal s tan dar d) fas t and at mo der ate cost.

Page 11

DAB-BA-e-1813 11

5 Basic Safety Precautions

5.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN balances.

All language versions contain a non-binding translation.

The original German is binding.

5.2 Symbols used in the operating instructions

Please pay due attention to information denoted by the signal

words CAUTION or WARNING as well as a warning

pictogram.

The signal word WARNING indicates a hazardous situation

where disregard of the safety information may result in fatal or

severe injury.

The signal word CAUTION indicates a hazardous situation

where disregard may result in minor injury.

NOTE (or LOOK OUT) indicates actions that may result in

damage to property.

This symbol indicates helpful information.

Call to action.

This prompts you to perform certain operations

Page 12

12 DAB-BA-e-1813

5.2.1 Warning pictograms

High voltage

Chemical burn / corrosion

General hazard

Fire or explosion

Poisoning

Hot Surface

5.3 Personnel training

The instrument may only be operated and maintained by trained personnel.

Page 13

DAB-BA-e-1813 13

5.4 Danger Information

!

The moisture analyser is used to analyse the moisture content of materials.

This instrument must be used exclusively for this purpose. Any other usage

may cause a risk to personnel, damage to the instrument or other material

damage.

!

The moisture analyser should be used mainly for the drying of aqueous

substances.

!

The moisture analyser may not be used in a hazardous area.

!

Do not use the moisture analyser in an explosive environment.

!

The operation and maintenance of the moisture analyser is restricted to

trained competent specialist staff.

!

Carefully read this operation manual before setup and commissioning, even if

you are already familiar with KERN in s truments.

!

Never make any modifications or design changes to the equipment

whatsoever. Always use original spare parts and accessories.

!

Make sure that liquids cannot pen

etrate the interior of the device, the terminals

at the rear of the device and the connected peripherals (such as printer, PC).

If you spill liquid on the device, disconnect it immediately.

Afterwards do not operate the moisture meter and have it checked by a

competent KERN stockist before any further use.

Hazards during and after measuring

!

Ensure correct installation of all components, see chap. 7.3

!

Careful when removing the sample. The sample itself, the sample dish and the

heating unit may be very hot.

!

Use the sample retainer at all times as it allows safe working and prevents

burns.

!

Individual parts of the case (e. g. the ventilation grids) may heat up

considerably during operation.

Page 14

14 DAB-BA-e-1813

The moisture analyser operates using heat!

+ Maintain sufficient space in the environment of the instrument to

prevent heat build-up (distance from the instrument 20cm,

upwards 1m).

+ The heat extractor of the sample must never be covered, blocked,

taped up or altered in any other way.

+ Never place combustible materials on, under or next to the

instrument, as the environment of the instrument heats up to a

high temperature.

+ Careful when removing the sample. The sample itself, the sample

dish and the heating unit may be very hot.

Fire or explosion

+ Explosive, easily flammable samples and samples that go into a

chemical reaction when subjected to heat, may not be analysed

with the moisture analyser.

+ If in doubt, conduct a risk analysis.

+ Select a drying temperature for samples of this kind that is low

enough to prevent ignition or explosion.

+ Wear safety goggl es.

Substances that contain toxic or corrosive ingredients,

produce toxic gases when drying, cause irritation (eyes, skin,

airways), induce nausea or result in death

+ Sample materials emitting toxic substances must be dried with a

special extraction system in place. Create an environment that

prevents the inhalation of vapours hazardous to health.

Substances that liberate corrosive gases when heated up (such as

acids)

+ In that case, work with smaller sample amounts as the liberated

gases may condense on cooler casing parts and later cause

corrosion.

Page 15

DAB-BA-e-1813 15

6 T ransport and storage

6.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

6.2 Packaging / return transport

Keep all parts of the original packaging for a possibly required

return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Secure all parts against shi fting and damage.

7 Unpacking, Setup and Commis si oning

7.1 Installation Site, Location of Use

The instrument is designed to achieve reliable weighing results under normal

conditions of use.

You will work accurately and fast, if you select the right location for your moisture

analyser.

On the installation site observe the following:

!

Remove explosion prone and easily flammable material in the immediate

vicinity.

Emerging vapours, sample dish and all parts of the sample chamber are hot!

!

Protect the instrument against direct draughts due to open windows and

doors.

!

Avoid extreme heat and temperature fluctuations e.g. due to installation next

to radiators.

!

Do not expose the instrument to extreme dampness for longer periods of time.

Non-permitted condensation (condensation of air humidity on the instrument)

may occur if a cold instrument is taken to a considerably warmer environment.

In this case, acclimatize the disconnected instrument for ca. 2 hours at room

temperature.

!

Avoid direct sunlight

!

The air humidity should be between 45% and 75%, non-condensing.

Page 16

16 DAB-BA-e-1813

!

Sufficient distance from heat-sensitive materials in area around instrument.

!

Protect the instrument ag ai ns t hig h humidi ty, vapours and dust,

!

Major display deviations (incorrect weighing results) may be experienced

should electromagnetic fields (e.g. due to mobile phones or radio instruments),

static electricity accumulations or instable power supply occur. Change

location or remove source of interference.

!

Avoid static charging of the material to be weighed, weighing container and

windshield

!

Place the instrument on a firm, level surface.

!

Avoid jarring during weighing.

7.2 Unpacking and checking

Take the moisture analyser carefully out of its packaging, remove the plastic jacket

and install it at the designated work space.

7.2.1 Scope of delivery / serial accessories:

• Moisture analyser, see illustration chap. 2

• 50 sample dishes

• Power cable

• Operating manual

Page 17

DAB-BA-e-1813 17

7.3 Placing

The moisture analyser is supplied part-assembled. Control whether the delivery is

complete immediately after unpacking the individual parts and assemble the separate

component parts according to the sequences.

1. Put heat shield into the sample chamber.

2. Place windshield in a way that the pin in the heat shield is aligned to the hole

in the heat shield.

3. Place removal aid into the windshield. Ensure that the lug lies exactly in the

groove of the windshield.

4. Attach the sample dish holder carefully and rotate it until it locks.

5. Put the sample dish on the removal aid.

2

4

5

3

Page 18

18 DAB-BA-e-1813

7.4 Levelling

Precise alignment and stable installation are a precondition for repeatable results. To

compensate for minor unevenness or tilts of the base, level the instrument.

Level instrument with foot screws until the air bubble of the

water balance is in the prescribed circle.

Check levelling regularly

Page 19

DAB-BA-e-1813 19

7.5 Mains connection

Power supply is provided via the supplied mains cable.

Check, whether the voltage acceptance on the device is set correctly.

Do not connect the appliance to the power grid unless the information

on the instrument (sticker) matches the local mains voltage.

Do not eliminate the protective effect by using an extension lead

without earth terminal. For power supplies from power grids without

earth terminals call a specialist to establish equivalent protection

according to the relevant installation regulations.

The mains plug must be accessible at any time.

Prior to commissioning check the mains cable for damage.

Place the cable in a way that it cannot be damaged or handicaps

the measuring process.

Important:

Does the rating match the standard local mains current?

Do not connect if mains voltages are different!

If matching, connect the moisture analyser.

7.6 Switching on and off

Turn on appliance by pressing the ON/OFF key.

The display lights up and the equipment conducts a self-test. Wait

until basic configuration appears.

To switch off press the ON/OFF button, the display disappears.

Page 20

20 DAB-BA-e-1813

7.6.1 Initial Commissioning

In order to receive precise weighing results from electronic balances, the instrument

unit must have reached its operating temperature (see warming-up time chapter 1).

For this warm-up period the integrated balance must be connected to the power

supply.

The accuracy of the integrated balance depends on the local acceleration of gravity.

Please observe hints in chapter Adjustment.

7.7 Connection of peripheral devices

Before connecting or disconnecting of additional devices (printer, PC) to the data

interface, always disconnect the moisture analyser from the power supply.

Only use accessories and peripheral devices by KERN, as they are ideally tuned to

the appliance.

Page 21

DAB-BA-e-1813 21

8 Adjustment

8.1 Weight adjustment

The weight adjustment of the integrated balance is not absolutely necessary for a

correct moisture determination, as this measurement is only carried out relatively.

The instrument calculates the weight of the sample before and after the drying

process and the moisture content is determined with help of the ratio between wet

weight and dry weight.

The instrument however should be adjusted, if this is required due to the quality

system used by you.

Procedure:

• Observe stable environmental conditions.

A warming up time (see chapter

1) is required for stabilization.

• Carry out adjustment with placed sample dish.

Ensure that no objects are

within the sample dish.

•

Carry out adjustment as near as possible to the balance’s maximum

weight (recommended adjustment weight see chap. 1).

Info about test

weights can be found on the Intern et at : http://www.kern-sohn.com.

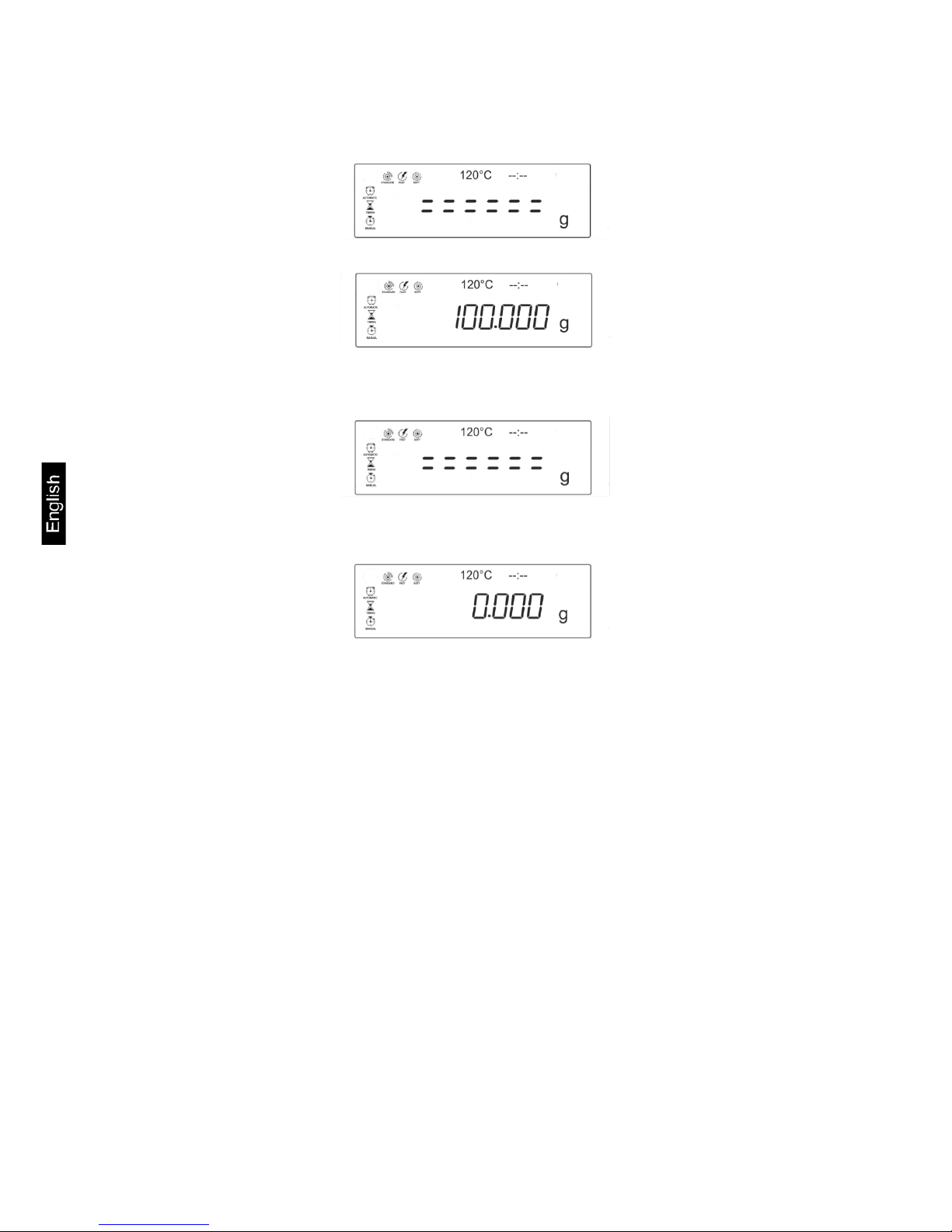

Press and keep pressed until „CAL“ is displayed.

Wait until the weighed value for the required adjustment weight appears

flashing.

Sample indication DAB 100-3

Page 22

22 DAB-BA-e-1813

Put the required adjustment weight carefully into the centre of the sample dish.

Adjustment is carried out automatically.

After successful adjustment the balance automatically returns to weighing

mode, „100,000 g“ will be displayed. Take away adjustment weight.

Wait until „0.000 g“ appears.

Page 23

DAB-BA-e-1813 23

8.2 Calibrate / adjust temperature of the heating module

8.2.1 Temperature calibr ation

We recommend performing occasional tests of the instrument’s temperature value,

using the optional temperature calibration set KERN DAB-A01.

Before you do this, allow the device to cool down for at least 3 hours after the last

heating phase.

Preparation:

Switch off moisture analyser

Install temperature calibration set as per illustration

Turn on moisture analyser

Page 24

24 DAB-BA-e-1813

Set test parameters:

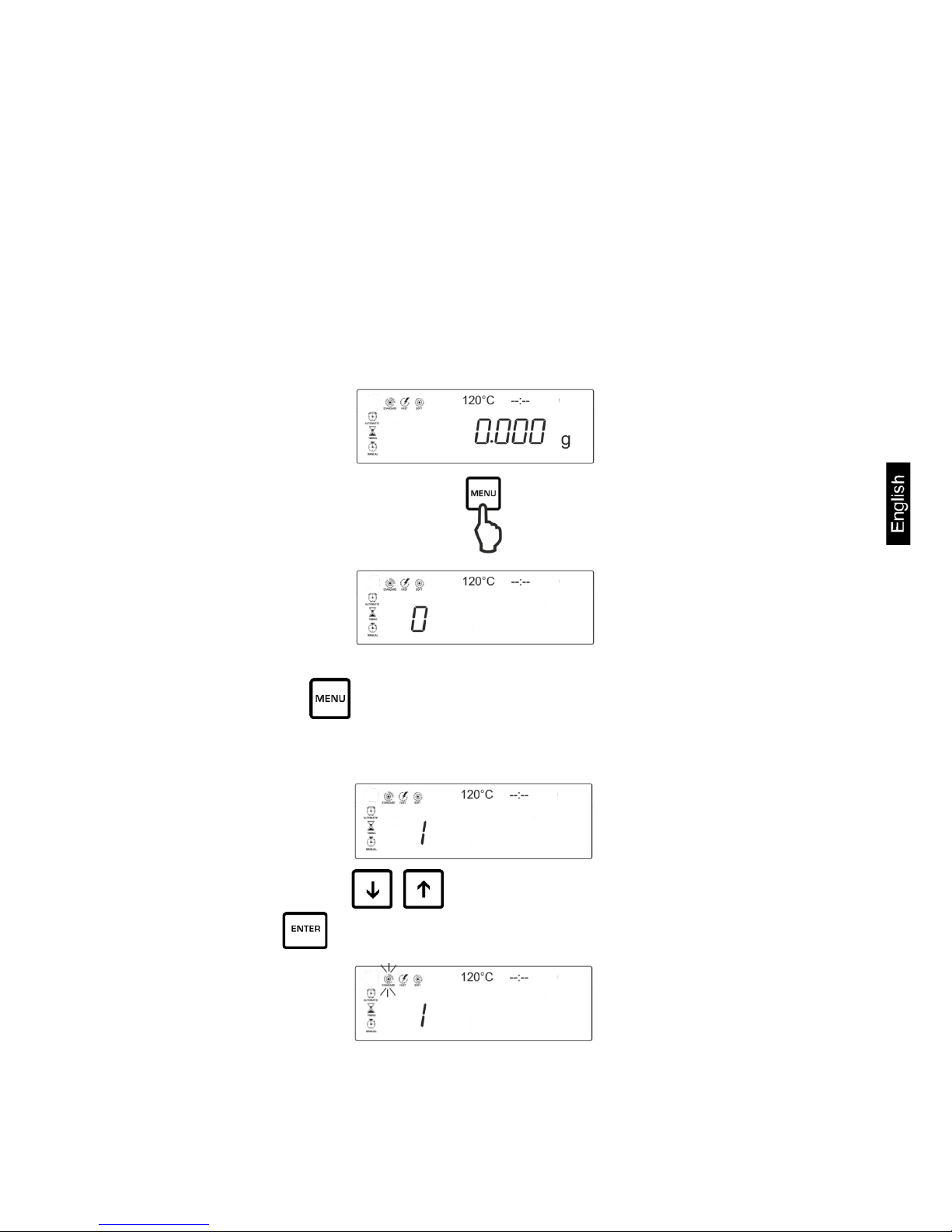

After pressing the first ident number <0> will be displayed.

Using arrow keys select e.g. ident number <1> and confirm by

. The currently set heating profile flashes.

Using arrow keys select heating profile <SOFT> and confirm by

.

The currently set heating profile and switch-off criter i on fl ashes.

Use the arrow keys to select switch-off criterion <MANUAL>.

Page 25

DAB-BA-e-1813 25

Confirm by , the currently set drying temperature flashes.

Use the arrow keys to enter the desired test temperature. For the

first or the first two digits select a value and confirm by .

Using arrow keys select the desired value for the last digit.

Confirm input by .

Page 26

26 DAB-BA-e-1813

Begin temperature calibration:

Switch on temperature calibration set.

Close heating hood and press . The instrument will be automatically

heated to the set temperature. The cur r ent temperature and the elaps ed ti me

will be indicated in the display.

After approx. 15 minutes finish by . Compare the temperature value of

the moisture analyser with that of the temperature calibration set. At a

difference of ±5°C we recommend to adjust the temperature, see following

chapter.

8.2.2 Temperature adju stm ent

If the admissible deviation is exceeded / not reached during temperature calibration

the temperature of the instr ument can be adj u s ted as des cr i bed bel o w.

1. Switch off instrument.

2. Press , quickly release, then press and at the same time.

„8.2X“ will be displayed. If not, separate device from power supply and restart

step two.

3. Adjust temperature using arrow keys . Each time you press the

button the temperature will be increased or reduced by 1°C.

4. Confirm input by .

Page 27

DAB-BA-e-1813 27

9 Carry out your first measurem e nt

We recommend to carry out a first simple measurement in order to get acquai nte d

with the device and the displays. Here you work with the ex-factory set drying

parameters (standard drying 120°C, automatic switch off).

In order to obtain exact results, the instrument must have reached its

operating temperature (see warm-up time chap. 1). For this warm-up time

the instrument must be connected to the power supply.

Place into the sample dish a dry piece of paper

Place removal aid with the sample dish on the sample dish retainer. Make

sure that the sample dish is resting flat on the sam ple dish retainer. Always

work with a removal aid as this will enable safe working and prevent burns.

Close heating hood and tare with .

Open heating hood.

Pour approx. 3 g of water on the paper in the sample dish.

Wait until the stability monitor „o“ goes out.

Close heating hood.

Start the drying process by .

The status display indicates the enabled drying process

You can watch the drying process on the display screen.

The current temperature, lapsed time as well as the current interim result will

be continuously updated and displayed.

The icons of the enabled heating profile and the switch-off criterion are

flashing.

Using the display con be switched over to the different displays of

results.

Page 28

28 DAB-BA-e-1813

When drying is finished, an acoustic signal will sound. The result will be

displayed.

Using the display of results can be switched over into

% moisture % dry content residual weight in grams.

Open the heating hood and remove the sample with the help of the removal

aid. Caution: Sample dish and all parts of the sample chamber are hot!

Using the result in the display will be deleted. The display returns to

weighing mode. The device is now ready for another measurement.

Page 29

DAB-BA-e-1813 29

10 Define drying parameters

In chapter 9 you have already carried out a first measurement with the factory

settings.

The device provides a great variety of setting options that allow you to adapt a drying

method to your sample.

Three heating profiles (standard drying, soft drying, fast drying) and three switch-off

criteria (time-controlled, automatic, manual) can be selected.

1. Enter ident number for drying method

16 memory locations, which can be simply called up and started as necessary under

the saved ident number (0 –F), are available for complete drying methods.

After pressing the first ident number <0> will be displayed.

This memory location is provided for the factory setti ng s (s tandar d dr y i ng

120°C, automatic swit ch-off) and cannot be changed.

Use the arrow keys to select the desired ident number and

confirm by . The currently set heating profile flashes.

Page 30

30 DAB-BA-e-1813

2. Set heating profile

Using arrow keys select required heating profile and confirm by

.

Options:

Standard drying

Fast drying

Soft drying

Standard drying <STANDARD>

This heating profile is suitable for

most samples.

The sample will be

heated up to the set drying

temperature and will be kept

constantly at this temperature.

Selectable 40°C -199°C

Page 31

DAB-BA-e-1813 31

Fast drying <FAST>

This heating profile is suitable for

samples with high moisture content

(such as liquids).

The temperature will initially rise very

fast after the start and for a short time

will exceed the set drying temperature

by 30%. That way the latent heat will be

compensated, thereby accelerating the

drying process.

Then the temperature is controlled down

to the set value.

Soft drying <SOFT>

This heating profile is suitable for soft

drying of substances prone to skin

formation (such as easily liquefiable

substances

or substances containing

sugar).

Skin formation affects the

evaporation of trapped moisture. The

temperature will be increased

continuously and will not reach the set

drying temperature before the so-called

ramp duration has elapsed.

Page 32

32 DAB-BA-e-1813

3. Se lecting switch-off criterion

A switch-off criterion defines under which conditions the device should cancel the

drying process. Switch-off criteria save continuous time controls and manual

cancelling of drying processes. Furthermore they ensure that measurement s ar e

always finished under the same conditions, thereby providing repeatable

measurements.

After acknowledgement of the selected heating profile by , the currently

set heating profile and switch-off criterion flashes.

Using arrow keys select required switch-off criterion and confirm

by .

Selectable settings suitable as switch-off criteria include:

<AUTO>

Automatic switch off

(2mg weight loss in 45 s)

This switch-off criterion is based on a

weight loss per time unit. As soon as the

medium weight loss drops below the

desired value per unit of time, the

measurement will be finished

automatically.

<TIMING>

Time-controlled switch off,

selectable 3 min – 99 min

When this switch-off criterion is selected

the measurement will continue until the set

drying time has lapsed

<MANUAL>

Manual switch-off by pressing stop key

Page 33

DAB-BA-e-1813 33

4. Set drying temperature

After acknowledgement of the selected switch-off criteri on by , the

currently set drying temperature is flashing.

Using arrow keys , select the desired value for the first or the first

two digits and confirm by .

Using arrow keys select the desired value for the last digit.

Confirm input by .

If as switch-off criteri on <AUTO> or <MANUAL> is selected, the parameter

setting is finished here. All parameter settings will be applied to a subsequent

drying process and displayed on screen. All settings are stored under the ident

number <1> until a new method is allocated to the ident number.

<AUTO>

<MANUAL>

When <TIMING> is selected, the display of setting the drying period of time is

flashing, see step „5“.

Page 34

34 DAB-BA-e-1813

5. Setting the drying period for time-controlled switching-off

After acknowledgement of the drying temperature by , the currently set

drying period is flashing.

Using arrow keys , select the desired value for the first digit and

confirm by , the next digit is flashing.

Using arrow keys , select the desired value for the next digit and

confirm by , the next digit is flashing. Repeat this procedure for all digits.

Confirm input by . All parameter settings will be applied to a subsequent

drying process and displayed on screen. All settings are stored under the ident

number <1> until a new method is allocated to the ident number.

Page 35

DAB-BA-e-1813 35

11 Carrying out drying and measuring processe s

In order to obtain exact results, the instrument must have reached its

operating temperature (see warm-up tim e chap. 1). For this warm-up

time the instrument must be connected to the power supply.

Either invoke a drying method stored beforehand or set drying

parameters as specified in chapter 10.

After pressing the button the first ident number <0> of a drying method

will be displayed.

Use arrow keys to select a desired ident number o f a dryi ng

method and confirm by . The currently set heating profile flashes.

Page 36

36 DAB-BA-e-1813

Confirm all flashing indicated par a met er s one by one by or change

them as necessary.

Open heating hood and place removal aid with an empty sample dish on the

sample dish retainer. Make sure that the sample dish is resting flat on the

sample dish retainer. Always work with a removal aid as this will enable safe

working and prevent burns.

Close heating hood and tare with .

Open heating hood.

Distribute sample evenly on the sample tray. A practical sample amount is

typically approx. 3- 5 g.

Close heating hood.

Start drying process by .

The status display indicates the enabled drying process

You can watch the drying process on the display screen.

The current temperature, lapsed time as well as the current interim result will

be continuously updated and displayed.

The icons of the enabled heating profile and the switch-off criterion are

flashing.

Using the display con be switched over to the different displays of

results.

Page 37

DAB-BA-e-1813 37

When drying is finished, an acoustic signal will sound. The result will be

displayed.

Using the display of results can be switched over into

% moisture % dry content residual weight in grams.

Open the heating hood and remove the sample with the help of the removal

aid. Caution: Sample dish and all parts of the sample chamber are hot!

Using the result in the display will be deleted. The display returns to

weighing mode. The device is now ready for another measurement.

Page 38

38 DAB-BA-e-1813

12 RS 232 interface

Condition:

The following conditions must be met to provide successful communication between

the moisture analyser and the printer.

Disconnect moisture analyser from the power supply and connect to the

appliance interface with a suitable cable. Faultless operation requires an

adequate KERN interface cable.

Communication parameters of the RS 232 interface of moisture analyser and

printer must match.

12.1 Technical data

Connection 9 pin d-subminiature bushing

Pin3 - TxD

Pin5 - GND

Baud-Rate 1200 / 2400 / 4800 /9600 selectable

Parity 7bits / 2 stop bits

12.2 Setting the baud rate

Press ,then release quick und press fast. The current baud rate is

indicated.

Using arrow keys select baud rate .

Confirm with .

Page 39

DAB-BA-e-1813 39

12.3 Print out protocol:

To edit a protocol press and keep it pressed until “PRINT“ appears. The

display changes automatically to „L-E“.

Acknowledge with . The protocol of the measurement carried out as last

is displayed under the ident number „1“. The instrument stores the last fiv e

protocols (ident number 1 -5). With every new measurement, the ident number

One will be overwritten.

Use the arrow keys to select the desired ident number and

confirm by . The protocol will be edited.

Page 40

40 DAB-BA-e-1813

Sample protocol (KERN YKB-01N):

MOISTURE DETERMINATION (1)

Protocol ident number (1)

Machine Type: DAB 100-3

Gerätetyp

Heating Mode: STANDARD

Selected heating profile

Stop Mode: AUTO STOP

Selected switch-off criterion

Heating Temp: 120 °C

Drying temperature

Time el apsed: 03:52

Overall duration of drying process

Wet W: 10.145 g

Start weight

Dry W: 10.010 g

Residual weight

Moisture: 1.32 %M

Final result in % moisture

12.4 Continuous data transmission

Settings:

Switch on the device, pressing key. During the auto test, press ,

<C---1> will be displayed.

Press to confirm. The first menu item with the current setting will be

displayed.

Page 41

DAB-BA-e-1813 41

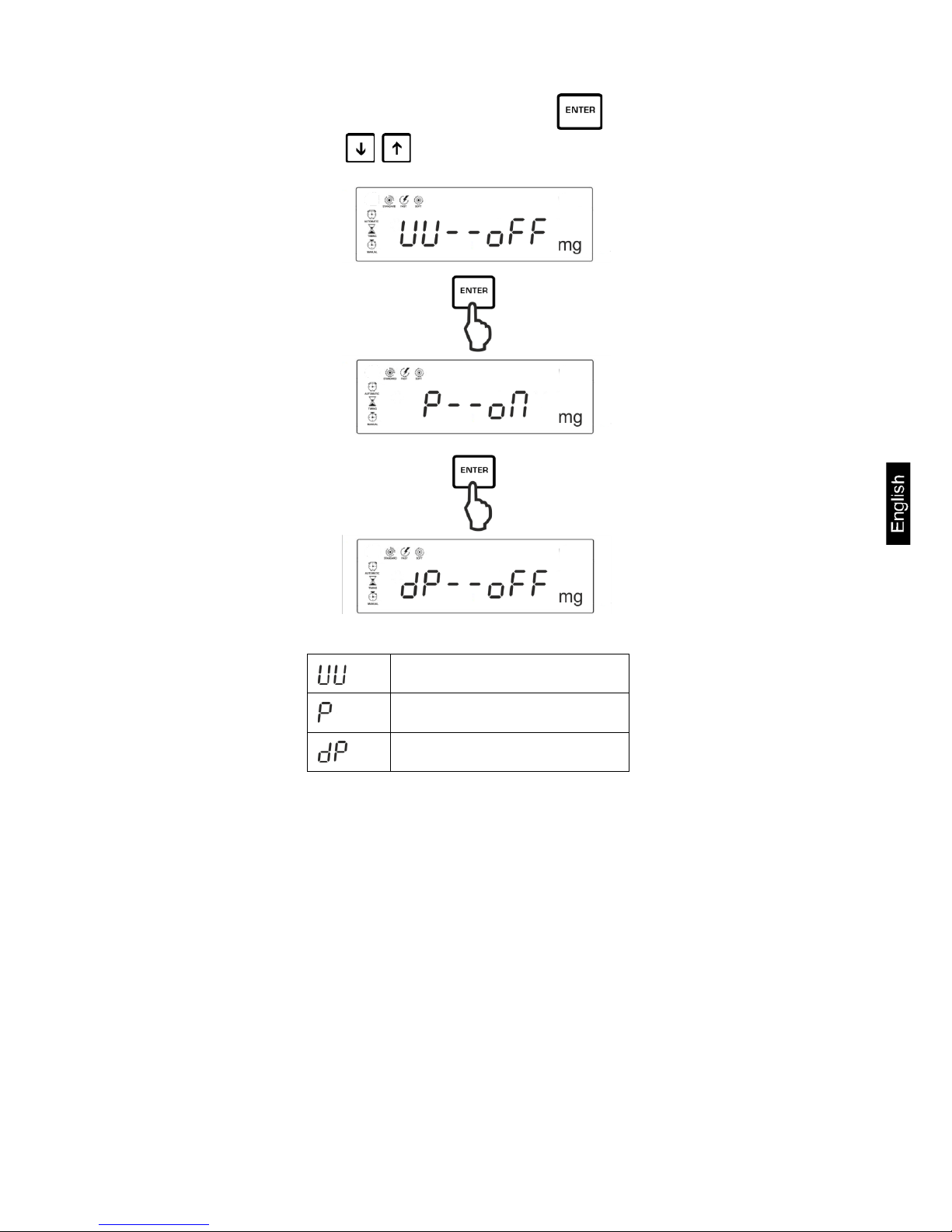

Choose the data transmission type, pressing , switch it on/off using the

navigation buttons .

residual mass in grams

% humidity

% solid content

Page 42

42 DAB-BA-e-1813

Press to confirm. The indication used to set the data transmission

cycle, i.e. <C---2> will be displayed.

Press to confirm and set the required data transmission cycle using the

navigation buttons (you can select from: 1, 2, 5, 10, 30, 60, 120,

300, 600 s).

Confirm your choice, pressing , wait until zero is displayed.

Page 43

DAB-BA-e-1813 43

Activation of continuous data transmission

Press button and hold it until <t> is displayed (if you get <PRINT>, keep

the button pressed). Wait until zero is displayed.

This is the starting/finishing time of continuous data transmission when the

measurement is started/completed.

Using our data transmission software, i.e. Balance connection (KERN SCD

4.0) the displayed values will be sent to the computer as per the pre-defined

data transmission cycle.

Simultaneously, the drying characteristics can be presented in a graphic form. It

presents the drying progress in real time and can be used for result checking

and evaluation.

Page 44

44 DAB-BA-e-1813

13 General information concerning moisture analysis

13.1 Application

In all cases where moisture is added to or removed from products, a fast

determination of the moisture content is of enormous importance. For countless

products the moisture content is not only a quality feature but also an important cost

factor. Very often fixed limits for moisture content apply to the trade in industrial or

agricultural goods as well as chemical or food products which are defined by terms of

delivery and general standards.

13.2 Basics

Moisture does not only mean water but includes all substances that evaporate when

heated up. In addition to water this includes,

Fats

Oils

Alcohol

Solvents

etc...

There are various methods to analyse moisture in a product.

KERN DAB uses a method called thermogravimetrics. In accord with this method, the

sample is weighed before and after heating, determining the material moisture by

looking at the difference.

The conventional drying chamber method follows the same principle, with the

exception that this method requires a considerably longer measuring period. . In

accord with the drying chamber method, the sample is heated from the outside to the

inside by a hot air current, so as to remove the moisture. The radiation applied in the

KERN DAB penetrates mainly the sample in order to be transformed inside it into

heat energy that is, warming from the inside to the outside. A minor amount of

radiation is reflected by the sample, a reflection that is less in dark samples than in

light-coloured ones. The depth of penetration of the radiation depends on the

permeability of the sample. In samples of low permeability the radiation only

penetrates the outer layers of the sample, possibly resulting in imperfect drying,

incrustation or burning. For that reason the preparation of a sample is of great

importance.

13.3 Adjustment to existing measuring method

KERN DAB frequently replaces a different drying method (such as drying cabinet) as

easier operation achieves shorter measuring periods. For that reason the

conventional measuring method must be matched to the KERN DAB in order to

achieve comparable results.

• Performing parallel measurements

Lower temperature setting for KERN DAB than for drying cabinet method

• Result of KERN DAB does not match reference

- Repeat meas ur em ent with changed temperature setting

- Vary shutoff criterion

Page 45

DAB-BA-e-1813 45

13.4 Preparing a sample

Prepare one sample at a time for measuring. This prevents the sa m ple fro m

exchanging moisture with its surroundings. If several samples have to be taken at the

same time, they should be packed in airtight boxes so that they do not undergo

changes during storage.

To receive reproducible results, spread the sample thinly and evenly on a sample

dish.

Patchy spreads will produce inhomogeneous heat distribution in the sample to be

dried resulting in incomplete drying and increased measuring time. Sample clusters

generate increased heating of the upper layers resulting in combustion or

incrustation. The high layer thickness or possibly arising incrustation makes it

impossible for the moistur e to escape from the sample. Due to this residual moi sture,

measured results calculated in this way will not be comprehensible or reproducible.

Preparing a sample from solids:

• Spread powdery or grainy samples evenly on the sample dish.

• Grind coarse samples using a mortar or a shredder. When grinding the sample avoid

any heat supply as this may cause loss of moisture.

Preparing a sample from liquids:

For liquids, pastes or melting samples we recommend to use a glass fiber filter. The glass

fiber filter has the following advantages:

• even distribution thanks to capillary attraction

• no formation of droplets

• fast evaporation due to a greater surface

Page 46

46 DAB-BA-e-1813

13.5 Sample material

Easy to determine are usually samples with the following characteristics:

Grainy to powdery, pourable solids

Thermally stable materials, emitting the moisture to be determined easily

without other substances evaporating at the same time

Liquids that vaporize to leave a dry substance without developing a film

Difficult to determine may be samples tha t are :

Glutinous or sticky

Become incrusted easily or tend to form a film

Decompose easily under the influence of heat or emit various elements

13.6 Sample size / originally weighted in quantity

Drying times, as well as achievable accuracy, are significantly influenced by sample

distribution. In the course of this arise two opposed requirements:

The lighter the originally weighted in quantity, the easier it is to achieve shorter drying

times. However, the heavier the originally weighted in quantity, the more accurat e a

result.

Page 47

DAB-BA-e-1813 47

13.7 Drying temperature

The temperature has to be selected in a manner that the sample is not decomposed

or changes its chemical structure. But on the other hand if the temperature is too low,

drying time may be unnecessarily extended.

Bear in mind the following factors when setting the drying temperature:

Surface of the sample:

Compared with powdery or grainy samples, liquid and spreadable samples have a

smaller surface for the transmission of heat energy.

The use of a glass fibre filter improves the heat application.

Colour of sample:

Light-coloured samples reflect more heat radiation than dark ones and therefore

require a higher drying temperature.

Availability of volatile substances:

The better and faster the water or other volatile substances can be disposed, the

lower a drying temperature is required. If water is difficult to get to (e. g. in

synthetics), it has to be calcined at high temperatures (the higher the temperature,

the higher the water vapour pressure).

Results equivalent to other moisture analysing methods (e. g. drying chamber) can

be achieved by experimentally optimising the setting parameters such as

temperature, heating level and shutoff criteria.

13.8 Recommendations / Guidelines

Prepare standard sample:

Crush sample, as required, and spread it evenly in the aluminium dish.

Prepare special samples:

For sensitive or hard to spread test materials (e. g. mercury) a glass fibre filter

is available for use.

Spread sample evenly on glass fibre filter and cover is with a second glass

fibre filter.

The glass fibre filter is also useful as a protection when splashing materials

are dealt with (each splash falsifies the final result).

You will find examples taken from actual use in our application manual, available

from the KERN home page (www.kern-sohn.com).

Page 48

48 DAB-BA-e-1813

14 Servicing, maintenance, disposal

Before any maintenance, cleaning and repair work disconnect the

appliance from the oper ati ng vol tage.

14.1 Cleaning

+

Only carry out cleaning tasks when the equipment has cooled down.

Open heating hood and remove all parts in the right order and clean.

Please do not use aggressive cleaning agents (solvents or similar agents), but a

cloth dampened with mild soap suds. Ensure that no liquid penetrates into the

device. Polish with a dry soft cloth.

Loose residue sample/powder can be removed carefully with a brush or manual

vacuum cleaner.

14.2 Servicing, maintenance

The appliance may only be opened by trained service technicians who are

authorized by KERN.

Ensure that the balance is regularly calibrated, see chap. Monitoring of test

resources.

14.3 Disposal

Disposal of packaging and appliance must be carried out by operator according

to valid national or regional law of the location where the appliance is used.

Page 49

DAB-BA-e-1813 49

15 Instant help

Possible causes of errors:

In case of an error in the program process, briefly turn off the balance and disconnect

from power supply. The weighing process must then restart from the beginning.

Fault Possible cause

Display is not lit up.

• The appliance is not switched on.

• The mains supply connection has been

interrupted (mains cable not plugged in/faulty).

• Power supply interrupted.

• Fuse has blown

The display does not change

when a sample is being loaded

• Sample dish / dish holder is fitted incorrectly.

The weight display changes

constantly / the stability display

does not appear.

• Sample dish has contact with windshield or

heating hood.

• Draught/air movement

• Table/floor vibrations

• Electromagnetic fields / static char g ing (choose

different location/switch off interfering device if

possible)

Incorrect measuring res ul t

• Check adjustment

• No resetting to zero before loading the sample

Measurement is taking too

long

• Incorrect shut-down criteria set

Measurement is not

reproducible

• Sample is not homogenous

• Drying time is too short

• Drying temperature too high (e.g. oxidation

sample material, boiling point of sample

exceeded)

• Temperature sensor soiled or defective

Drying does not start

• Heating hood open

• The mains supply connection has been

interrupted (mains cable not plugged in/faulty).

Loading...

Loading...