Page 1

SB-593 Satellite Board

Quick Start Guide

This quick start guide is made up of a specification sheet, basic installation drawings and information, and short

descriptions of key terms and concepts.

NOTE: The SB-593 may be used with PXL-250, PXL-500/PXL-510, or PXL-500G-1.

Figure 1: SB-593 Satellit e Board

Page 1 of 4 P/N: 01925-001 Rev. B

Page 2

SB-593 Satellite Board

Quick Start Guide

1.0 Specifications

Unit Dimensions

• PXL-250/PXL-500/PXL-510 controller PCB with an SB-593 Satellite Board (with or without an LCD-1 Alpha/

Numeric Display)

- 7.25 inches high by 6.00 inches wide by 1.75 inches deep, including wiring connectors

- (18.45 cm by 15.25 cm by 4.45 cm)

•Enclosure

- 9.70 inches high by 8.20 inches wide by 2.60 inches deep

- (24.65 cm by 20.85 cm by 6.60 cm)

Operating Temperature/Humidity Range

• 0°F to 140°F (-18°C to 60°C)

• 0% to 90% Relative Humidity, non-condensing

Controller with Satellite Board Power Requirements

• 12 VDC @ 1 Amp

Current Draw

• maximum current draw 270 mA for a controller plus reader current draw (refer to Table 1 for Reader current draw)

• 120 mA max for a PXL-250/PXL-500/PXL-510 Controller

• 150 mA max for an SB-593 Satellite Board

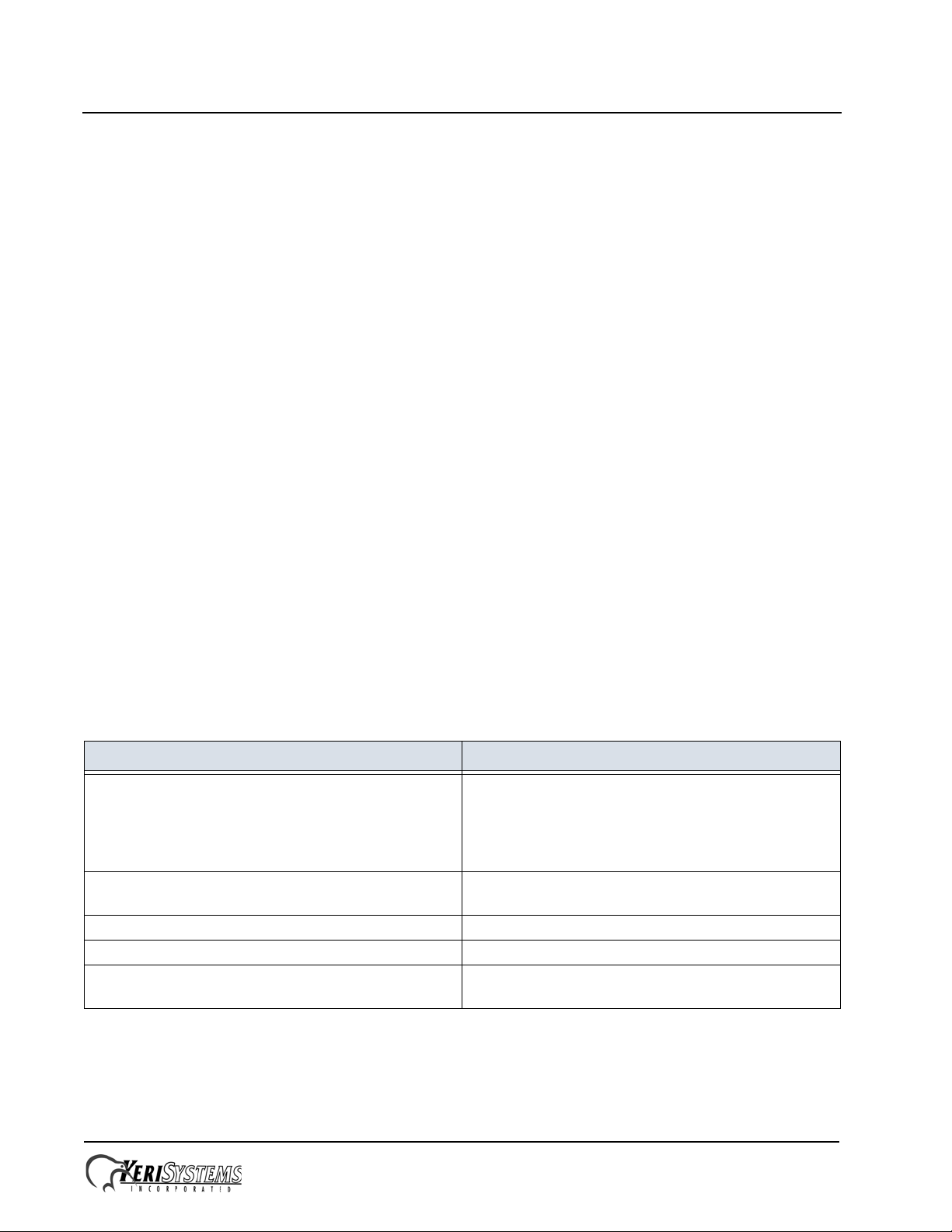

Table 1: Reader Current Draw

Reader Type

MS-3000 MS-4000 MS-5000 MS-7000

Current Draw 50 mA 50 mA 100 mA 200 m A

Output Relay Contact Rating

• 1 Amp @ 24 VDC

Input Device Configuration

• Door Sense normally closed

• Request to Exit normally open

• Global Unlock normally open, or

Auxiliary RTE A-Door normally open

2.0 Cable Requirements

• two conductor, AWG 22 or a larger gauge for all input connections

• two conductor, AWG 18 or a larger gauge for all output connections

NOTE: The Lock Output relay may require a heavier gauge of wire depending upon the current demands of the lock and

the length of the lock wiring run.

Page 2 of 4 P/N: 01925-001 Rev. B

Page 3

SB-593 Satellite Board

Quick Start Guide

3.0 When Installing Satellite Boards

DO

• route cables in accessible areas for ease of maintenance

• add transient suppression across electric devices attached to a satellite board output

• use an isolation relay (Keri Systems P/N IRP-1) if attaching to a parking gate, a turnstile, or any application using a

large electric motor

• for a single door application, install the door's reader to the TB-5, "A" reader connection on the controller

• for a two door application, install the primary door's reader to the TB-5, "A" reader connection on the controller and

install the secondary door's reader to the TB-6, "B" reader connection on the controller

DO NOT

• stretch or over-tension cables

• route cables over sharp objects

• let cables or wires get tangled

4.0 Jumper Setting

JP12 - Configures the Satellite Board (see Figure 2)

• Jumper across JP12, pins 1 and 2, configures the Satellite board for general purpose inputs and outputs.

• NO jumper across JP12 configures the Satellite board for second door control with additional inputs and outputs.

When the Satellite board is configured for second door control, the primary door must be connected to the "A" reader

(TB-5 on the PXL-500/PXL-510 controller board) and the secondary door must be connected to the "B" reader (TB-6

on the controller board).

Figure 2: Satellite Board Jumper Configuration (JP12)

Page 3 of 4 P/N: 01925-001 Rev. B

Page 4

SB-593 Satellite Board

Quick Start Guide

5.0 Board Installation

Perform the following steps to install an SB-593 Satellite Board on a PXL-250, PXL-500/PXL-510, or PXL-500G-1

controller. The SB-593 Satellite Board comes with two sizes of stand-offs. Due to changes made to the relays, some PXL

controllers will require the use of taller stand-offs.

• The smaller stand-offs are to be uses with PXL-500 controllers.

• The taller stand-offs are to be used when the Satellite Board is connecting to the new PXL-500-1 or PXL-500G-1

controllers.

Installation of these stand-offs are done exactly as before.

1. Turn the controller's power OFF.

2. Line up the upper left-hand corner of the Satellite PCB with the controller PCB.

3. Line up the stand-offs in the top two corners of the Satellite PCB with corresponding mounting holes in the controller

PCB.

4. Align the Satellite Board’s connector pins to the PXL mounting holes.

NOTE: If you are installing the SB-593 (which has two rows of connector pins) on a PXL-250 controller (which has one

row of mounting holes) it does not matter which row of connector pins are inserted in the mounting holes.

5. Gently press the two boards together with each stand-off into its mounting hole and with the connector pins meshing

together with their mounting holes.

6. Turn the controller’s power ON.

7. If the P2 mounting holes have the PXL J2 connector pins inserted correctly, the Power LED6 will illuminated and

remain so as long as the connection continues and power is supplied to the unit.

8. If the P3 mounting holes have the PXL J3 connector pins inserted correctly, the SDA LED5 will flicker and continue

to do so as long as the connection continues and power is supplied to the unit.

6.0 Contact Keri Systems

Keri USA Keri UK, Ireland, Europe

2305 Bering Drive

San Jose, CA 95131

T elephone: (800) 260-5265

(408) 435-8400

Fax: (408) 577-1792 Fax:+ 44 (0) 1763 274 106

Web: www.kerisys.com Web:www.kerisystems.co.uk

E-mail: sales@kerisys.com

techsupport@kerisys.com

Park Farm Industrial Estate

Telephone: + 44 (0) 1763 273 243

E-mail:sales@kerisystems.co.uk

tech-support@kerisystems.co.uk

Unit 17

Ermine Street

Buntingford

Herts SG9 9AZ UK

End of document.

Page 4 of 4 P/N: 01925-001 Rev. B

Loading...

Loading...