Page 1

OPERATOR’S MANUAL

TMA VXI-27

plug & play POWER MODULE CONTROLLER

INTERACTIVE DIGITALLY CONTROLLED

POWER MODULE SYSTEM

KEPCO INC.

An ISO 9001 Company.

plug & play POWER MODULE

MODEL

TMA VXI-27

CONTROLLER

ORDER NO. REV. NO.

IMPORTANT NOTES:

1) This manual is valid for the following Model and associated serial numbers:

MODEL SERIAL NO. REV. NO.

2) A Change Page may be included at the end of the manual. All applicable changes and

revision number changes are documented with reference to the equipment serial numbers. Before using this Instruction Manual, check your equipment serial number to identify

your model. If in doubt, contact your nearest Kepco Representative, or the Kepco Documentation Office in New York, (718) 461-7000, requesting the correct revision for your particular model and serial number.

3) The contents of this manual are protected by copyright. Reproduction of any part can be

made only with the specific written permission of Kepco, Inc.

Data subject to change without notice.

KEPCO®

©2007, KEPCO, INC

P/N 243-0886R8a

KEPCO, INC. z 131-38 SANFORD AVENUE z FLUSHING, NY. 11352 U.S.A. z TEL (718) 461-7000 z FAX (718) 767-1102

email: hq@kepcopower.com z World Wide Web: http://www.kepcopower.com

THE POWER SUPPLIER™

Page 2

Page 3

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual ..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

1.3 Specifications ......................................................................................................................................... 1-2

1.4 TMA VXI-27 Interconnections ................................................................................................................. 1-2

1.5 Accessories ............................................................................................................................................. 1-3

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection ....................................................................................................................... 2-1

2.2 Installation ............................................................................................................................................... 2-1

2.2.1 VXI Address Select............................................................................................................................ 2-1

2.3 Front Panel Terminations ........................................................................................................................ 2-1

SECTION 3 - OPERATION

3.1 Local Operation....................................................................................................................................... 3-1

3.1.1 Front panel indicators ........................................................................................................................ 3-1

3.1.2 Auxiliary Signals ................................................................................................................................ 3-1

3.1.2.1 Emergency Output Shutdown...................................................................................................... 3-1

3.1.2.2 Discrete Fault Line....................................................................................................................... 3-1

3.1.2.3 +5V Output................................................................................................................................... 3-2

3.2 Remote Operation................................................................................................................................... 3-2

3.3 VXI

3.3.1 Background........................................................................................................................................ 3-2

3.3.2 Driver Installation ............................................................................................................................... 3-2

3.3.3 Operating the Soft Panel ................................................................................................................... 3-3

3.3.3.1 Understanding the Controls. ........................................................................................................ 3-4

3.3.3.2 Select the Channel....................................................................................................................... 3-6

3.3.3.3 Set the Voltage/current................................................................................................................ 3-6

3.3.3.4 Apply Programmed Settings to the Power Supply....................................................................... 3-6

3.3.3.5 Enable the Power Supply Output................................................................................................. 3-6

3.4 VXIbus Communication........................................................................................................................... 3-6

3.4.1 Typical VXIbus Start-up Sequence.................................................................................................... 3-8

3.5 SCPI Programming ................................................................................................................................. 3-8

3.5.1 SCPI Messages................................................................................................................................. 3-8

3.5.2 Common Commands/Queries ........................................................................................................... 3-9

3.5.3 SCPI Subsystem Command/Query Structure.................................................................................... 3-9

3.5.4 Program Message Structure.............................................................................................................. 3-10

3.5.4.1 Keyword....................................................................................................................................... 3-11

3.5.4.2 Keyword Separator ...................................................................................................................... 3-12

3.5.4.3 Query Indicator ............................................................................................................................ 3-12

3.5.4.4 Data ............................................................................................................................................. 3-12

3.5.4.5 Data Separator............................................................................................................................. 3-12

3.5.4.6 Message Unit Separator.............................................................................................................. 3-12

3.5.4.7 Root Specifier .............................................................................................................................. 3-12

3.5.4.8 Message Terminator.................................................................................................................... 3-13

3.5.5 Understanding The Command Structure........................................................................................... 3-13

3.5.6 Addressing Multiple Power Supplies ................................................................................................. 3-14

3.5.7 Understanding The Command Structure........................................................................................... 3-14

3.5.8 Program Message Syntax Summary................................................................................................. 3-15

3.5.9 Status Reporting................................................................................................................................ 3-15

3.5.9.1 STATUS REPORTING STRUCTURE ......................................................................................... 3-16

3.5.9.2 Operational Status Register......................................................................................................... 3-16

3.5.9.3 QUEStionable Status Register..................................................................................................... 3-16

3.5.9.4 Multiple Logical Instruments ........................................................................................................ 3-18

3.5.10 Program Example.............................................................................................................................. 3-19

3.6 CIIL Programming ................................................................................................................................... 3-19

plug&play

Operation........................................................................................................................ 3-2

TMA VXI-27 SVC 101602

i

Page 4

TABLE OF CONTENTS

SECTION PAGE

3.7 Calibration............................................................................................................................................... 3-19

3.8 Maintenance ........................................................................................................................................... 3-19

APPENDIX A - MS WINDOWS HELP FILES

A-1 Soft Front Panel...................................................................................................................................... 1

A.1.1 Soft Front Panel Overview ............................................................................................................... A-1

A.1.2 Soft Front Panel Controls................................................................................................................. A-1

A.1.2.1 Init ............................................................................................................................................... A-1

A.1.2.2 Channel....................................................................................................................................... A-1

A.1.2.3 Voltage ........................................................................................................................................ A-1

A.1.2.4 Current ........................................................................................................................................ A-1

A.1.2.5 Mode ........................................................................................................................................... A-1

A.1.2.6 Output ......................................................................................................................................... A-1

A.1.2.7 Polarity ........................................................................................................................................ A-1

A.1.2.8 Sys Reset.................................................................................................................................... A-2

A.1.2.9 Chan Reset ................................................................................................................................. A-2

A.1.2.10 Test ............................................................................................................................................. A-2

A-2 LabView Library...................................................................................................................................... 2

A.2.1 LabView Library Overview ................................................................................................................ A-2

A.2.1.1 Instr handle in.............................................................................................................................. A-2

A.2.1.2 Instr handle out ........................................................................................................................... A-2

A.2.1.3 Error in ........................................................................................................................................ A-2

A.2.1.4 Error out ...................................................................................................................................... A-2

A.2.2 LabView Library Functions................................................................................................................ A-3

A.2.2.1 About........................................................................................................................................... A-3

A.2.2.2 AutoCon ...................................................................................................................................... A-3

A.2.2.3 Chanl........................................................................................................................................... A-3

A.2.2.4 Close ........................................................................................................................................... A-3

A.2.2.5 GetStatus .................................................................................................................................... A-3

A.2.2.6 Initialize ....................................................................................................................................... A-4

A.2.2.7 Mode ........................................................................................................................................... A-4

A.2.2.8 Outp ............................................................................................................................................ A-4

A.2.2.9 Read............................................................................................................................................ A-4

A.2.2.10 Reset ........................................................................................................................................... A-5

A.2.2.11 RevisionQuery............................................................................................................................. A-5

A.2.2.12 SelfTest ....................................................................................................................................... A-5

A.2.2.13 Set ............................................................................................................................................... A-5

A.2.2.14 Vers ............................................................................................................................................. A-6

A-6 Knowledge Base..................................................................................................................................... 6

APPENDIX B - SCPI COMMON COMMAND/QUERY DEFINITIONS

B.1 Introduction ............................................................................................................................................. B-1

B.2 *CLS — Clear Status Command .......................................................................................................... B-1

B.3 *ESE — Standard Event Status Enable Command................................................................................ B-1

B.4 *ESE? — Standard Event Status Enable Query..................................................................................... B-1

B.5 *ESR? — Event Status Register Query................................................................................................. B-2

B.6 *IDN? — Identification Query.................................................................................................................. B-2

B.7 *OPC — Operation Complete Command ............................................................................................... B-2

B.8 *OPC? — Operation Complete Query.................................................................................................... B-2

B.9 *OPT? — Options Query ........................................................................................................................ B-3

B.10 *RST — Reset Command....................................................................................................................... B-3

B.11 *SRE — Service Request Enable Command ........................................................................................ B-4

B.12 *SRE? — Service Request Enable Query .............................................................................................. B-4

B.13 *STB? — Status Byte Register Query ................................................................................................... B-4

ii

TMA VXI-27 SVC 101602

Page 5

TABLE OF CONTENTS

SECTION PAGE

B.14 *TRG — Trigger Command................................................................................................................... B-4

B.15 *TST? — Self Test Query....................................................................................................................... B-4

B.16 *WAI — Wait-to-Continue Command ..................................................................................................... B-5

APPENDIX C - SCPI COMMAND/QUERY DEFINITIONS

C.1 Introduction............................................................................................................................................. C-1

C.2 INITiate[:IMMediate] Command ............................................................................................................. C-1

C.3 INITiate:CONTinuous Command ........................................................................................................... C-1

C.4 INITiate:CONTinuous Query .................................................................................................................. C-2

C.5 INSTrument:CATalog Query .................................................................................................................. C-2

C.6 INSTrument[:NSELect] Command ......................................................................................................... C-2

C.7 INSTrument[:SELect] Command............................................................................................................ C-2

C.8 INSTrument[:SELect]? Query................................................................................................................. C-3

C.9 INSTrument:STATe Command .............................................................................................................. C-3

C.10 MEASure[:SCALar]:CURRent[:DC]? Query ........................................................................................... C-3

C.11 MEASure[:VOLTage][:SCALar][:DC]? Query......................................................................................... C-3

C.12 OUTPut[:STATe] Command................................................................................................................... C-4

C.13 OUTPut[:STATe] Query ......................................................................................................................... C-4

C.14 [SOURce:]CURRent[:LEVel][:IMMediate][:AMPlitude] Command.......................................................... C-4

C.15 [SOURce:]CURRent[:LEVel][:IMMediate][:AMPlitude] Query ................................................................ C-4

C.16 [SOURce:]CURRent:[:LEVel]TRIGgered[:AMPlitude] Command........................................................... C-5

C.17 [SOURce:]CURRent:[:LEVel]TRIGgered[:AMPlitude]? Query ............................................................... C-5

C.18 [SOURce:]VOLTage[:LEVel][:IMMediate][:AMPlitude] Command.......................................................... C-6

C.19 [SOURce:]VOLTage[:LEVel][:IMMediate][:AMPlitude]? Query .............................................................. C-6

C.20 [SOURce:]VOLTage:[:LEVel]TRIGgered[:AMPlitude] Command........................................................... C-6

C.21 [SOURce:]VOLTage:[:LEVel]TRIGgered[:AMPlitude]? Query ............................................................... C-6

C.22 [SOURce:]FUNCtion:MODE Command ................................................................................................. C-7

C.23 STATus:OPERation:CONDition Query................................................................................................... C-7

C.24 STATus:OPEReration:ENABle Command ............................................................................................. C-7

C.25 STATus:OPEReration:ENABle? Query.................................................................................................. C-7

C.26 STATus:OPERation[:EVENt] Query....................................................................................................... C-7

C.27 STATus:PRESet Command ................................................................................................................... C-8

C.28 STATus:QUEStionable[:EVENt]? Query ................................................................................................ C-8

C.29 STATus:QUEStionable:CONDition? Query............................................................................................ C-9

C.30 STATus:QUEStionable:ENABle Command............................................................................................ C-9

C.31 STATus:QUEStionable:ENABle? Query ................................................................................................ C-9

C.32 STATus:QUEStionable:INSTrument? Query.......................................................................................... C-9

C.33 STATus:QUEStionable:INSTrument1? Query........................................................................................ C-10

C.34 STATus:QUEStionable:INSTrument2? Query........................................................................................ C-10

C.35 STATus:QUEStionable:INSTrument:ENABle Command....................................................................... C-10

C.36 STATus:QUEStionable:INSTrument:ENABle Query.............................................................................. C-11

C.37 STATus:QUEStionable:INSTrument1:ENABle Command ..................................................................... C-11

C.38 STATus:QUEStionable:INSTrument1:ENABle? Query .......................................................................... C-11

C.39 STATus:QUEStionable:INSTrument2:ENABle Command ..................................................................... C-11

C.40 STATus:QUEStionable:INSTrument2:ENABle? Query .......................................................................... C-11

C.41 STATus:QUEStionable:INSTrument:ISUM Query.................................................................................. C-11

C.42 STATus:QUEStionable:INSTrument:ISUM:ENABle Command ............................................................. C-11

C.43 STATus:QUEStionable:INSTrument:ISUM:ENABle? Query .................................................................. C-12

C.44 SYSTem:ERRor[:NEXT]? Query............................................................................................................ C-12

C.45 SYSTem:ERRor:CODE? Query ............................................................................................................. C-12

C.46 SYSTem:ERRor:CODE:ALL? Query...................................................................................................... C-12

C.47 SYSTem:LANGuage Command............................................................................................................. C-12

C.48 SYSTem:SET Command ....................................................................................................................... C-13

C.49 SYSTem:VERSion Query....................................................................................................................... C-13

TMA VXI-27 SVC 101602

iii

Page 6

TABLE OF CONTENTS

SECTION PAGE

APPENDIX D - CIIL COMMAND DEFINITIONS

D-1 Introduction ............................................................................................................................................. 1

APPENDIX E - GLOSSARY OF VXI TERMS

E-1 Introduction............................................................................................................................................. 1

APPENDIX F - SAMPLE PROGRAM

F-1 Introduction ............................................................................................................................................. 1

F-1 Description.............................................................................................................................................. 1

iv

TMA VXI-27 SVC 101602

Page 7

LIST OF FIGURES

FIGURE TITLE PAGE

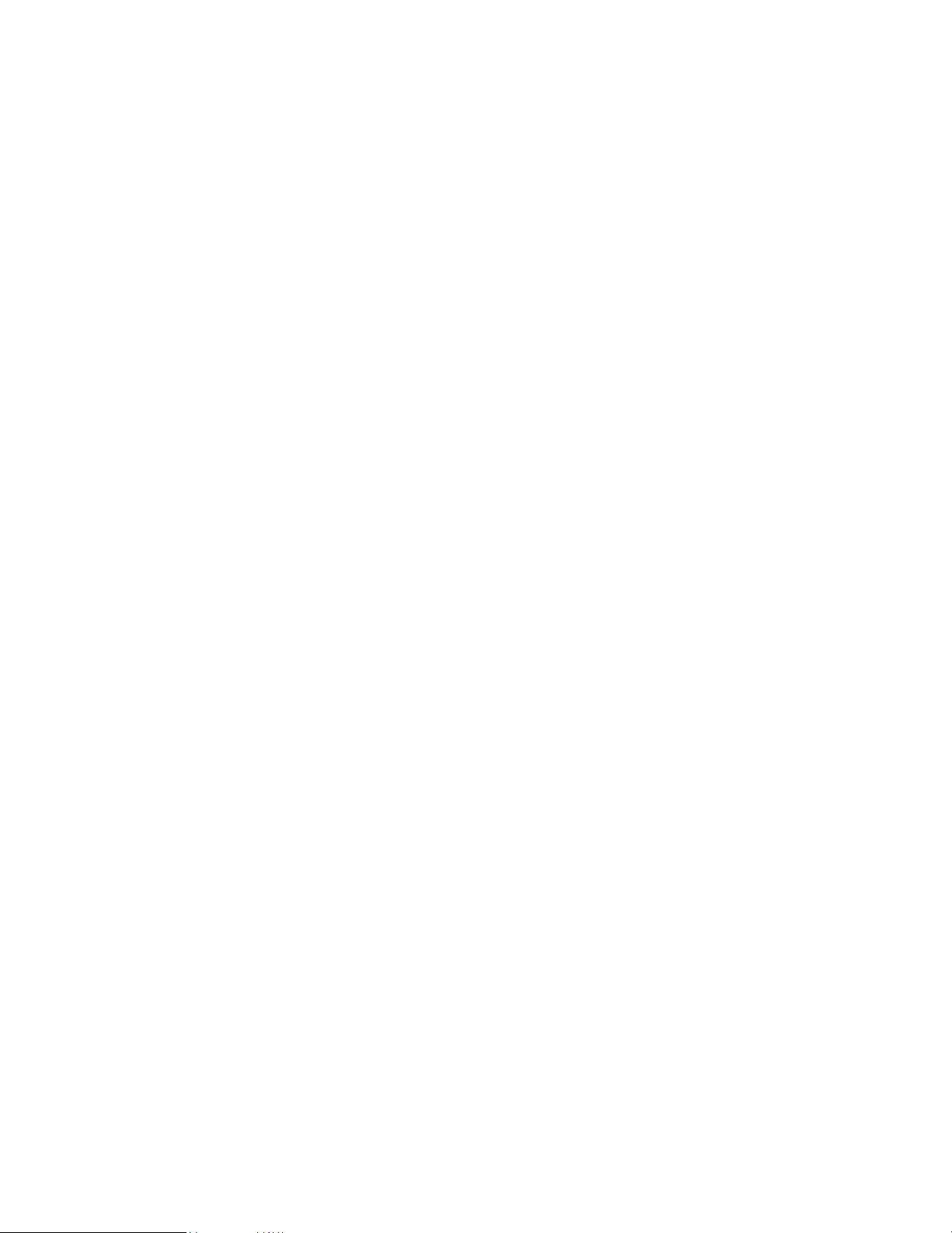

1-1 Remotely Controlled Power Supply Configurations Using Kepco Products................................................ viii

1-2 Typical Controller to Power Module Interface ............................................................................................. 1-3

1-3 Mechanical Outline Drawing ....................................................................................................................... 1-4

2-1 VXI Address Select..................................................................................................................................... 2-2

2-2 TMA VXI-27 Front Panel............................................................................................................................. 2-3

3-1 TMA VXI-27 plug&play Directory Structure................................................................................................. 3-3

3-2 TMA VXI-27

3-3 TMA VXI-27 plag&pla

3-4 Tree Diagram of SCPI Commands Used with TMA VXI-27 Controller ....................................................... 3-9

3-5 Message Structure...................................................................................................................................... 3-11

3-6 Status Reporting Structure.......................................................................................................................... 3-17

3-7 Expansion of QUEStionable Register for Multiple Logical Instruments ...................................................... 3-19

B-1 GPIB Commands ....................................................................................................................................... B-3

B-2 Using the *WAIt-to-continue Command ..................................................................................................... B-5

C-1 Use of INSTrument:CATalog Query .......................................................................................................... C-2

C-2 Identifying and Selecting Devices on BITBUS ........................................................................................... C-3

C-3 Programming the Output............................................................................................................................ C-5

C-4 Programming Current ................................................................................................................................ C-6

C-5 Using Status Commands and Queries....................................................................................................... C-8

D-1 FNC — Function Command....................................................................................................................... D-1

D-2 INX — Initiate Op Code Command............................................................................................................ D-2

D-3 FTH — Fetch Command............................................................................................................................ D-2

D-4 SET Command .......................................................................................................................................... D-3

D-5 OPN, CLS — Open, Close Relay Commands ........................................................................................... D-4

D-6 RST — Reset Command ........................................................................................................................... D-4

D-7 CNF, IST — Confidence Test, Internal Self Test Commands.................................................................... D-4

D-8 STA — Status Command........................................................................................................................... D-5

D-9 GAL — Go to Alternate Language Command .......................................................................................... D-6

plug&play Controller Selection ............................................................................................... 3-3

y

panel...................................................................................................................... 3-4

TMA VXI-27 101602

v/(vi Blank)

Page 8

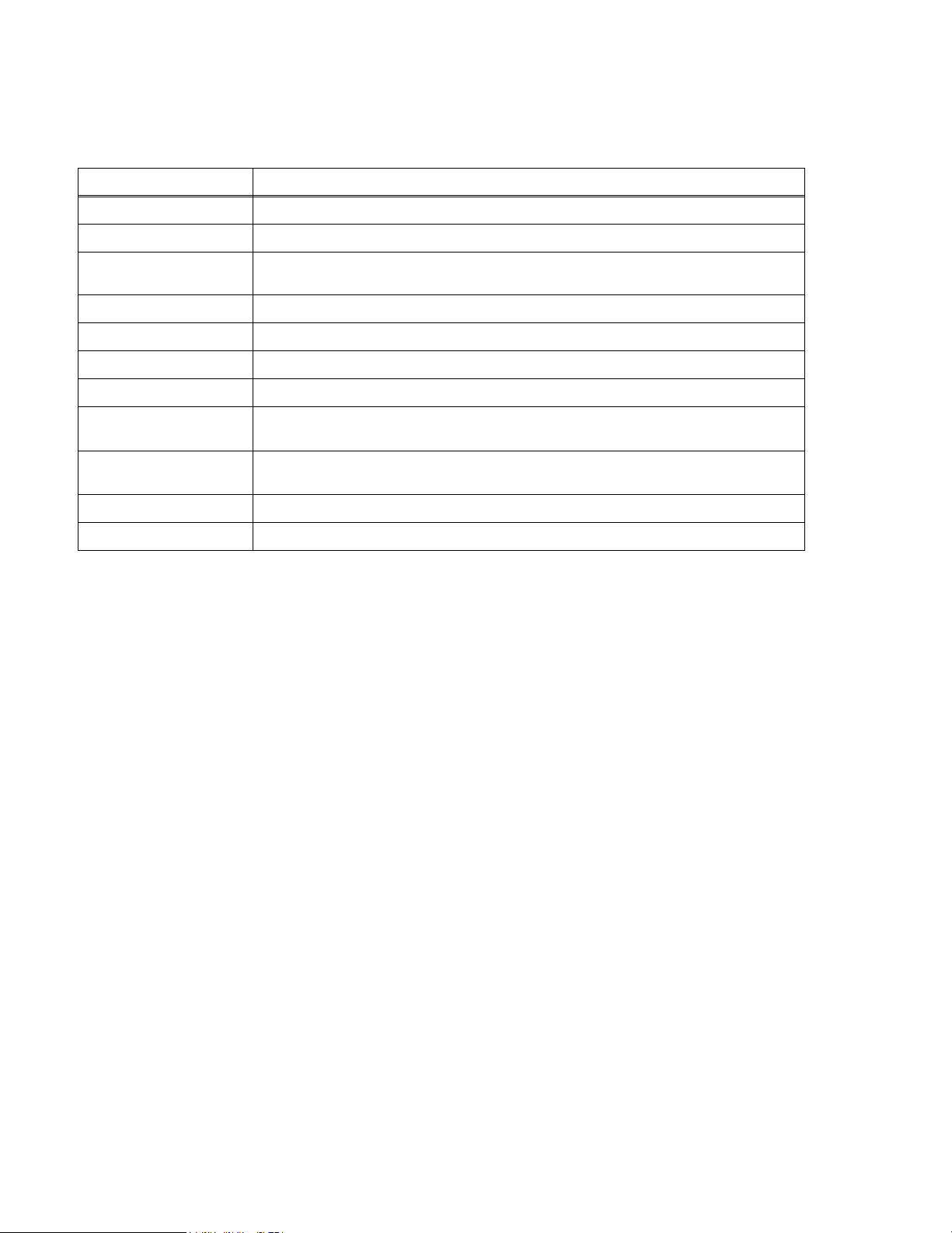

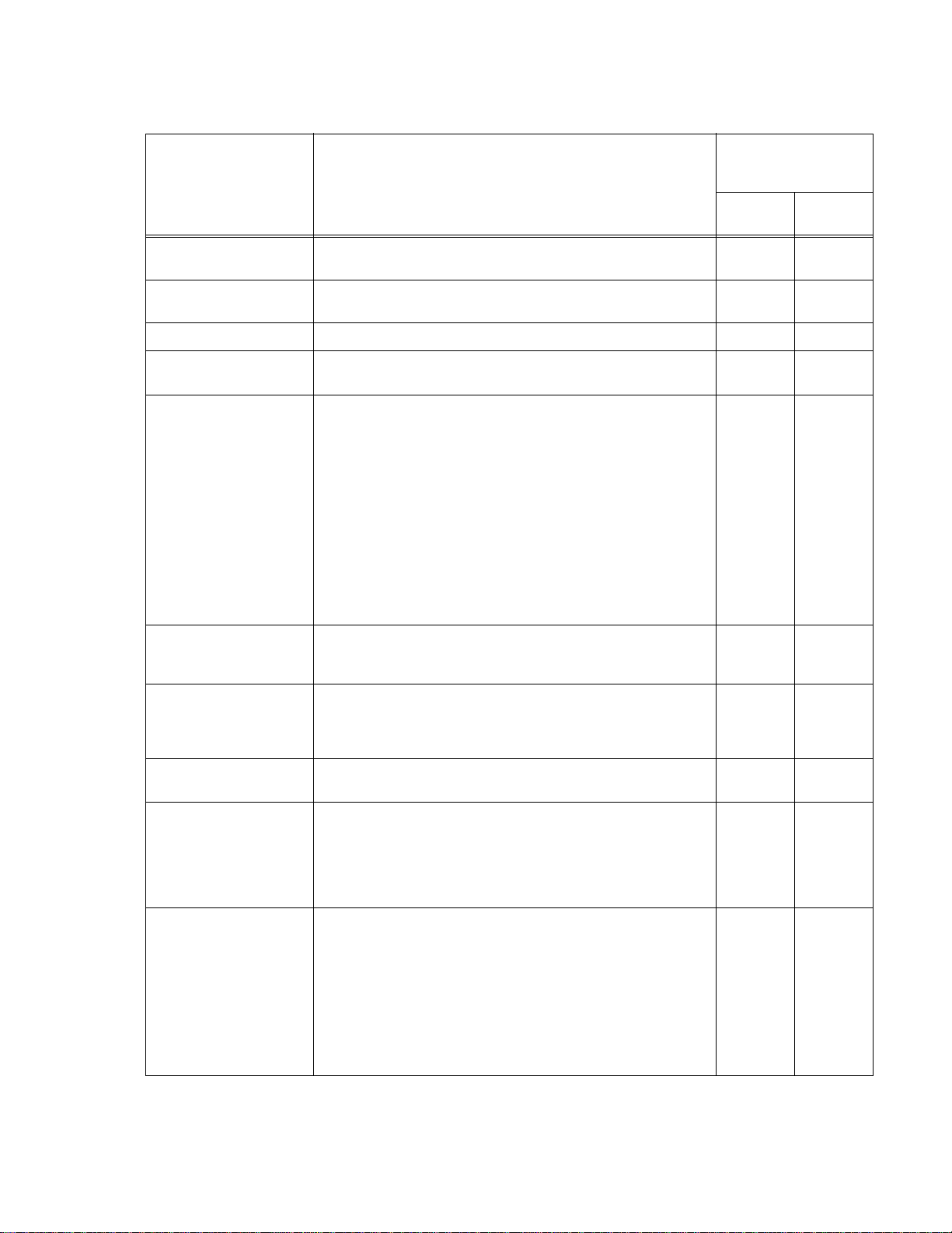

LIST OF TABLES

TABLE TITLE PAGE

1-1 Specifications ..............................................................................................................................................1-2

1-2 Accessories .................................................................................................................................................1-3

2-1 Input/output Pin Assignments .....................................................................................................................2-3

3-1 Plug&play Panel Controls and Indicators ....................................................................................................3-4

3-2 VXI Bus Commands ....................................................................................................................................3-6

3-3 SCPI Command Index ................................................................................................................................3-10

3-4 Rules Governing Shortform Keywords ........................................................................................................3-11

B-1 IEEE 488.2 Command/query Index ........................................................................................................... B-1

B-2 Standard Event Status Enable Register and Standard Event Status Register Bits ................................... B-1

B-3 Service Request Enable and Status Byte Register Bits ............................................................................. B-4

C-1 SCPI Subsystem Command/query Index ..................................................................................................C-1

C-2 Operation Condition Register, Operation Enable Register,

and Operation Event Register Bits ..........................................................................................................C-7

C-3 Questionable Event Register, Questionable Condition Register

and Questionable Condition Enable Register Bits ..................................................................................C-9

C-4 Questionable Instrument Register 0 Bits ................................................................................................... C-10

C-5 Questionable Instrument Register 1 Bits ................................................................................................... C-10

C-6 Questionable Instrument Register 2 Bits ................................................................................................... C-10

C-7 Error Messages ..........................................................................................................................................C-13

D-1 CIIL Subsystem Command/query Index ....................................................................................................D-1

D-2 CIIL Error Messages ..................................................................................................................................D-5

D-3 CIIL Error Handling Utility Commands .......................................................................................................D-6

TMA VXI -27 101602

vii

Page 9

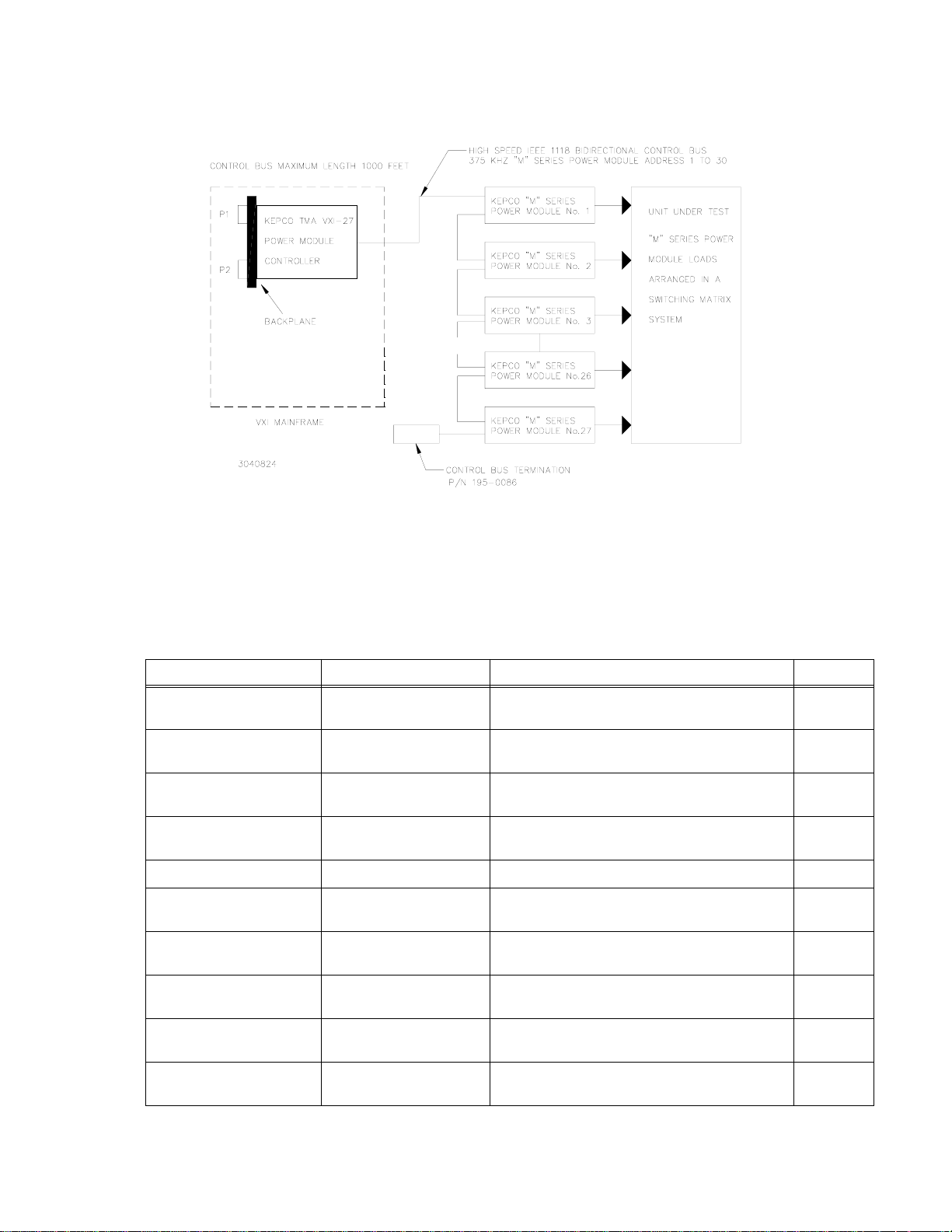

FIGURE 1-1. REMOTELY CONTROLLED POWER SUPPLY CONFIGURATIONS USING KEPCO PRODUCTS

viii

TMA VXI -27 101602

Page 10

1.1 SCOPE OF MANUAL

This service manual contains the specifications and instructions for the installation and operation of the Model TMA VXI-27 Power Module Controller, manufactured by Kepco, Inc. Flushing,

N.Y. U.S.A. A parts list and schematic diagrams are located in Section 4

1.2 GENERAL DESCRIPTION

The Kepco model TMA VXI-27 is a Power Module Controller which plugs into a VXI computer

chassis and allows the user to program a VXI computer to control and monitor the outputs of up

to 27 Kepco power modules (such as “MAT”s, “MBT”'s, “MST”s and “BOP”s) equipped for communication via the IEEE 1118 two-wire serial bus (see Figure 1-1). The IEEE 1118 two-wire

serial bus, also referred to as the Control Bus, allows the TMA VXI-27 to communicate with the

27 power modules up to a maximum distance of 1000 feet (300 meters).

The TMA VXI-27 includes plug&play software drivers which greatly simplify programming of the

power supplies connected to the IEEE 1118 serial bus. This is accomplished through a “soft

panel,” a virtual panel that gives the operator access to power supply operating controls and

indicators, allowing power supply operation by clicking a mouse on the virtual control, and

observing power supply indicators and measured values on a computer monitor.

The TMA VXI-27 communicates with the VXI computer via the VXIbus (an abbreviation for

“VMEbus eXtensions for Instrumentation”) which is based on the worldwide VMEbus standard

(IEEE STD 1014). The VXI backplane includes the 32-bit VME computer bus as well as

high-performance instrumentation buses for precision timing and synchronization between

instrument components. (See Appendix E for a Glossary of VXI terms.)

SECTION 1 - INTRODUCTION

The TMA VXI-27 is a Message Based VXI servant interface with Programmable Interrupter

capabilities for Event generation, conforming to Specification VXI-1, REV. 1.4. As a Message

Based Device it implements all Word Serial Commands required for an I4 class (IEEE 488 compatible) Instrument (see Table 2-1). It is a Single Width C sized card.

The TMA VXI-27 communicates through the VXI backplane with the Resource Manager (Slot 0

Controller) using commands in either the default language, SCPI (Standard Commands for Programmable Instruments) commands (default), or CIIL (Control Interface Intermediate Language), the alternate language. The VXI Resource Manager, known as the Slot 0 Controller, is a

common resource system module containing the VMEbus Resource Manager and VMEbus

System Controller. The Resource Manager provides configuration management services, commander/servant mapping, self test and diagnostics.

The VXI Slot 0 Controller can set the output voltage with current limit, or the output current with

voltage limit of any one of the 27 KEPCO Power Supplies interconnected through the Control

Bus to the TMA VXI-27. It can then program the TMA VXI-27 to read back (through the Control

Bus) the actual output voltage and current delivered by each of the power modules to their

respective loads. The TMA VXI-27 continually polls all of the power modules on the Control Bus

for error flags. All data transmissions between the Slot 0 Controller and the TMA VXI-27 are

ASCII encoded. The values for the command parameters can be written in integer, decimal or

scientific notation.

TMA VXI-27 101602

1-1

Page 11

1.3 SPECIFICATIONS (SEE TABLE 1-1)

TABLE 1-1. SPECIFICATIONS

SPECIFICATION DESCRIPTION

Device Type Message-based

Device Substates Initialize, Configure, Normal Operation

Applicable

VXI Commands

Addresses Static, configurable between 1 and 254 using DIP switch (see PAR. 2.2.1).

Manufacturer ID 380410, (0EDCH), read from register 0

Address Space A16, normal handshake only

Programmable Interrupt Generates Request True or Request False events

Interrupt Priority

Capabilities

Input Power Requirement Approximately 2A from +5V backplane of VXI.

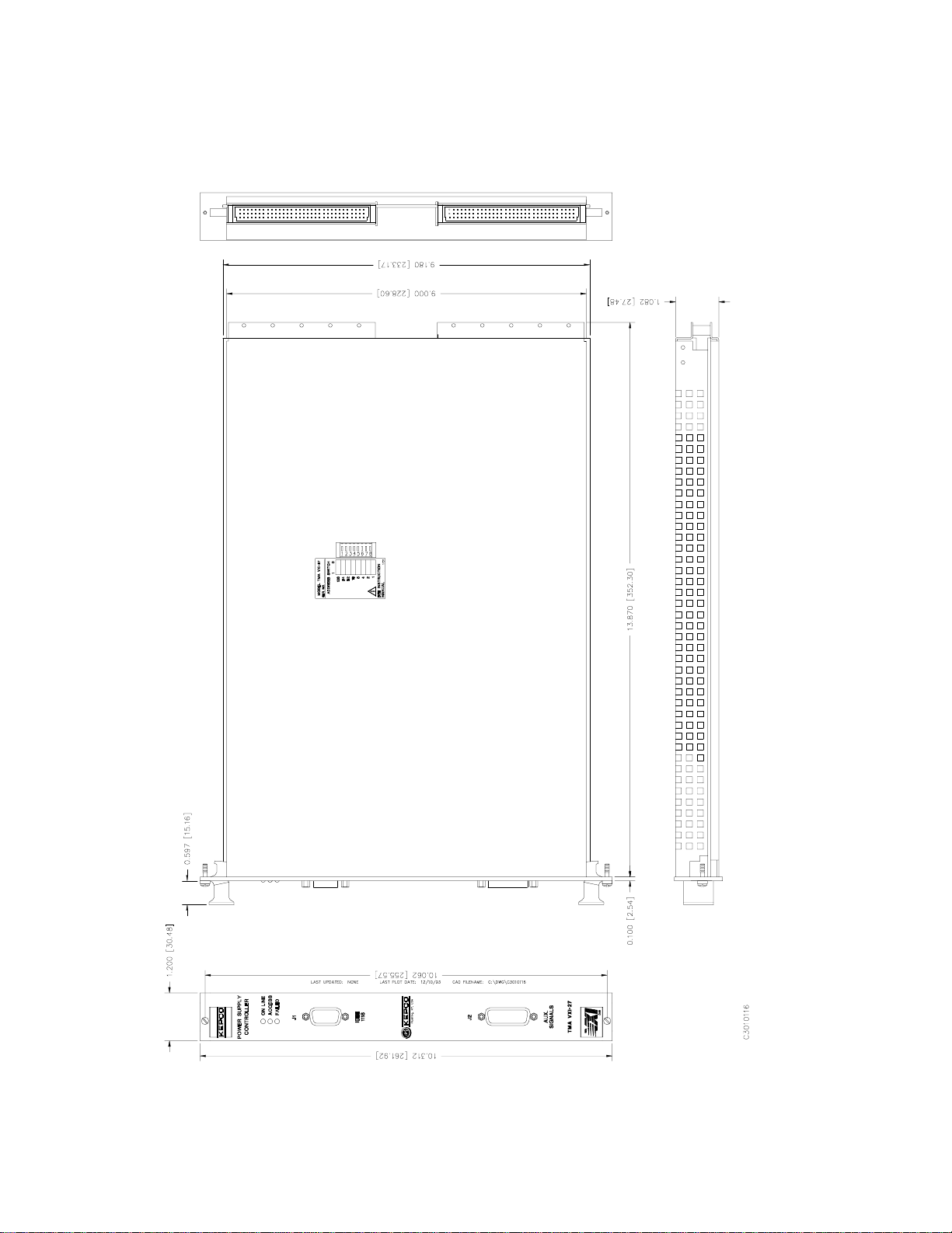

Physical Dimensions See Outline Drawing, Figure 1-3.

See Table 3-2.

Software assigned (via Slot 0 Controller) from 0 to 7;

0 = no interrupt (default),1 = highest priority, 7 = lowest priority

Message-based Device with Word Serial Capabilities; VXIbus Instrument Protocol;

I4 Class VXI Instrument

1.4 TMA VXI-27 INTERCONNECTIONS

A shielded two (2) wire twisted-pair cable equipped with a 9 pin D-type, male, plug-in connector

(supplied) is used to connect the TMA VXI-27 with the power modules. Input power and input/

output signals are provided through the VXI backplane (see Figure 1-2).

An opto-isolated, active high or non-isolated, active low, emergency shutdown input is provided

on the 15 pin D-type female connector located on the front pane (see PAR. 3.1.2.1)l. On the

same connector 2 additional lines provide a normally open contact indicating the proper functioning of the internal microsystem (Discrete Fault line). If either a serious malfunction or a catastrophic error occurs, the contacts will close (see PAR. 3.1.2.2)

FIGURE 1-1.

1-2

In configurations where power modules are daisy chained on the IEEE 1118 control bus (see

Figure 1-2), the last power module control bus outlet (in the daisy chain) must be terminated

with the IEEE Control Bus Terminator supplied with the controller to reduce spurious noise and

provide proper impedance matching. The terminator supplied is a 9-pin, D-type connector; for

Kepco MAT Power Supplies with a round 5 pin connector use the 5 pin terminator listed in Table

1-2.

TMA VXI-27 101602

Page 12

.

FIGURE 1-2. TYPICAL CONTROLLER TO POWER MODULE INTERFACE

1.5 ACC ESSORIES

Table 1-2 lists the accessories for the TMA VXI-27 Controller.

TABLE 1-2. ACCESSORIES

ACCESSORY PART NUMBER USE NOTE

Cable - two 9-pin connectors, ~ 6 ft. (2 m)

15 -Pin

Connector

Hood 108-0204

(Amphenol P/N 17-2588-6)

Snap-in 107-0187

Terminator, 9-pin 195-0086 Terminate IEEE 1118 bus daisy chain Supplied

Terminator,

5-pin

Cable - two 5-pin connectors

Cable - one 5-pin and one 9pin connector, ~6 ft. (2 m)

118-0844

142-0276

(Amp P/N 205206-1)

(Amp P/N 66504-2)

195-0075 Terminate IEEE 1118 bus daisy chain (for MAT

118-0699

118-0749 Daisy chain TMA VXI-27 and Kepco Power Supplies

Daisy chain TMA 4882-27and Kepco Power Supplies with 9-pin connector on IEEE 1118 bus.

Mating Connector for AUXILIARY SIGNALS connector

Used with 15-Pin Connector Supplied

Used with 15-Pin Connector Supplied

power supply with 5 pin round connector)

Daisy chain Kepco Power Supplies with 5-pin con-

nectors on IEEE 1118 bus.

with 5-pin connector on IEEE 1118 bus.

Supplied

Supplied

Not

supplied

Not

supplied

Not

supplied

Cable - one 5-pin and one 9pin connector, ~12 ft. (4 m)

Cable - two 9-pin connectors, ~ 12 ft. (4 m)

TMA VXI-27 040507 1-3

118-0852

118-0853

Daisy chain TMA VXI-27and Kepco Power Supplies

with 5-pin connector on IEEE 1118 bus.

Daisy chain TMA VXI-27and Kepco Power Supplies

with 9-pin connector on IEEE 1118 bus.

Not

supplied

Not

supplied

Page 13

FIGURE 1-3. MECHANICAL OUTLINE DRAWING

1-4

TMA VXI-27 101602

Page 14

SECTION 2 - INSTALLATION

2.1 UNPACKING AND INSPECTION

The Model TMA VXI-27 has been carefully inspected and tested prior to packing. Inspect the

shipping carton immediately upon receipt for evidence of damage during transit. Save the original packing material. If any indication of damage is found file a claim immediately with the

responsible transport service.

For repairs of a product damaged in shipment, contact the Kepco Factory Representative

nearest you or the Kepco Customer Service Department directly for further instruction.

2.2 INSTALLATION

The installation and setup procedure for the TMA VXI-27 consists of the following steps:

1. Set the VXI Address Selector (PAR. 2.2.1)

2. Select an empty slot in the C size VXI chassis and remove the slot cover plate.

3. Turn off the power if it is on and slide the TMA VXI-27 module into the chassis with the

LEDs up (or to the left in the case of a horizontal chassis). Secure TMA VXI-27 to chassis

with self-retaining screws at the top and bottom of the front panel

4. Connect the 9 pin D-type connector located on the front panel to the power modules

through the Control Bus in a daisy chain configuration using the control bus cable supplied

(see Figure 1-2). For installations that exceed the length of the control bus cable supplied,

refer to Table 1-2 for cable specifications; the maximum cable length is 300 meters (1000

feet).

5. Connect Terminator (supplied) to last IEEE 1118 control bus connector in daisy chain (see

Figure 1-2). (For Kepco MAT power supplies with 5-pin round connector, use terminator P/

N 195-0075; see Table 1-2.)

NOTE: Terminator must be used even if only one power supply is connected to the Controller

to ensure reduction of spurious noise and proper impedance matching.

6. To use the AUX. SIGNALS connector refer to PAR. 3.1.2 for a description of the available

signals and PAR. 2.3 for connector type and pin assignments.

7. Connect all power module outputs to their respective loads.

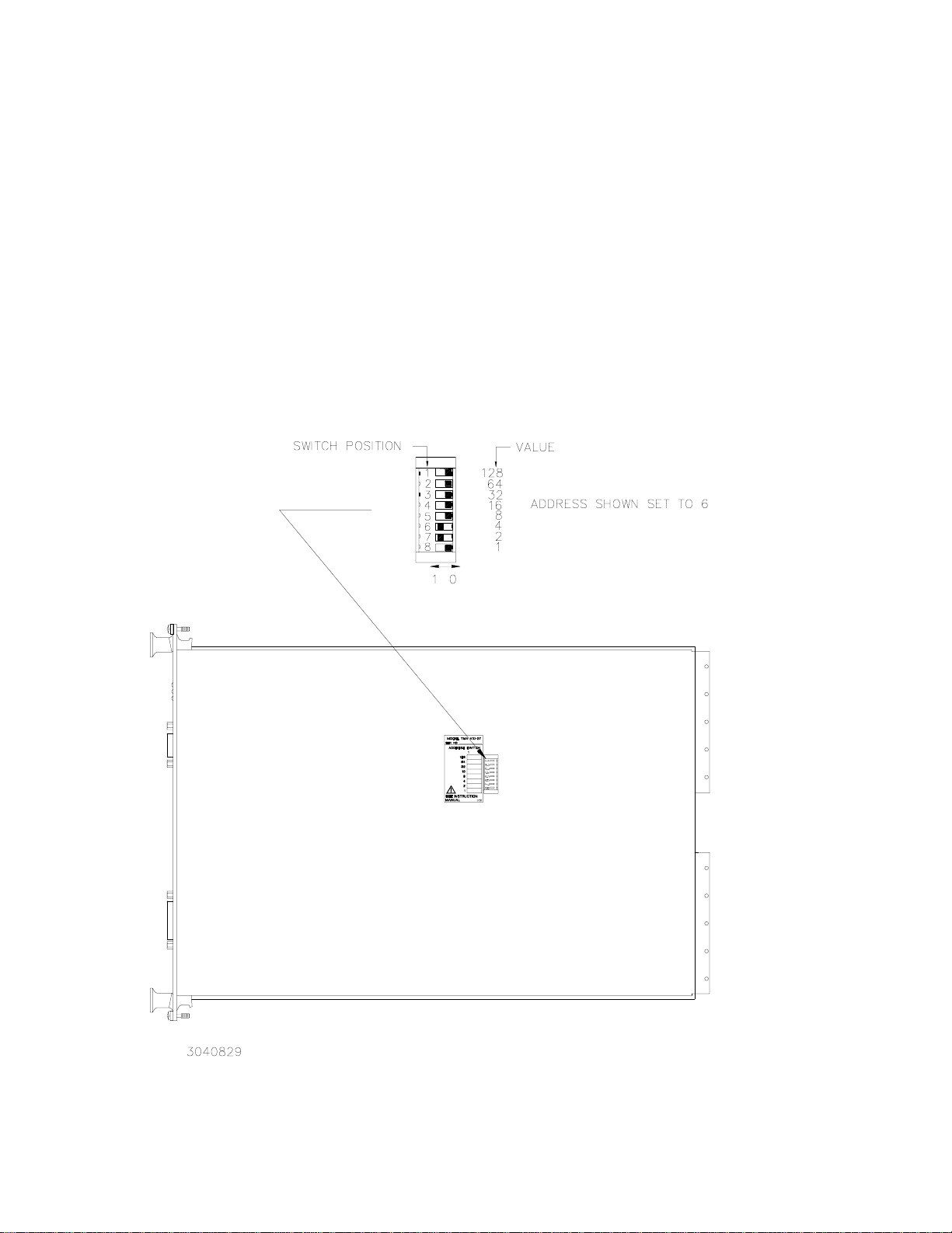

2.2.1 VXI ADDRESS SELECT

Set the VXI address selector to an unused VXI address between 1 and 254 using DIP

switches accessible through the right shield as shown in Figure 2-1. The TMA VXI-27 address

is preset to the factory default address of 6.

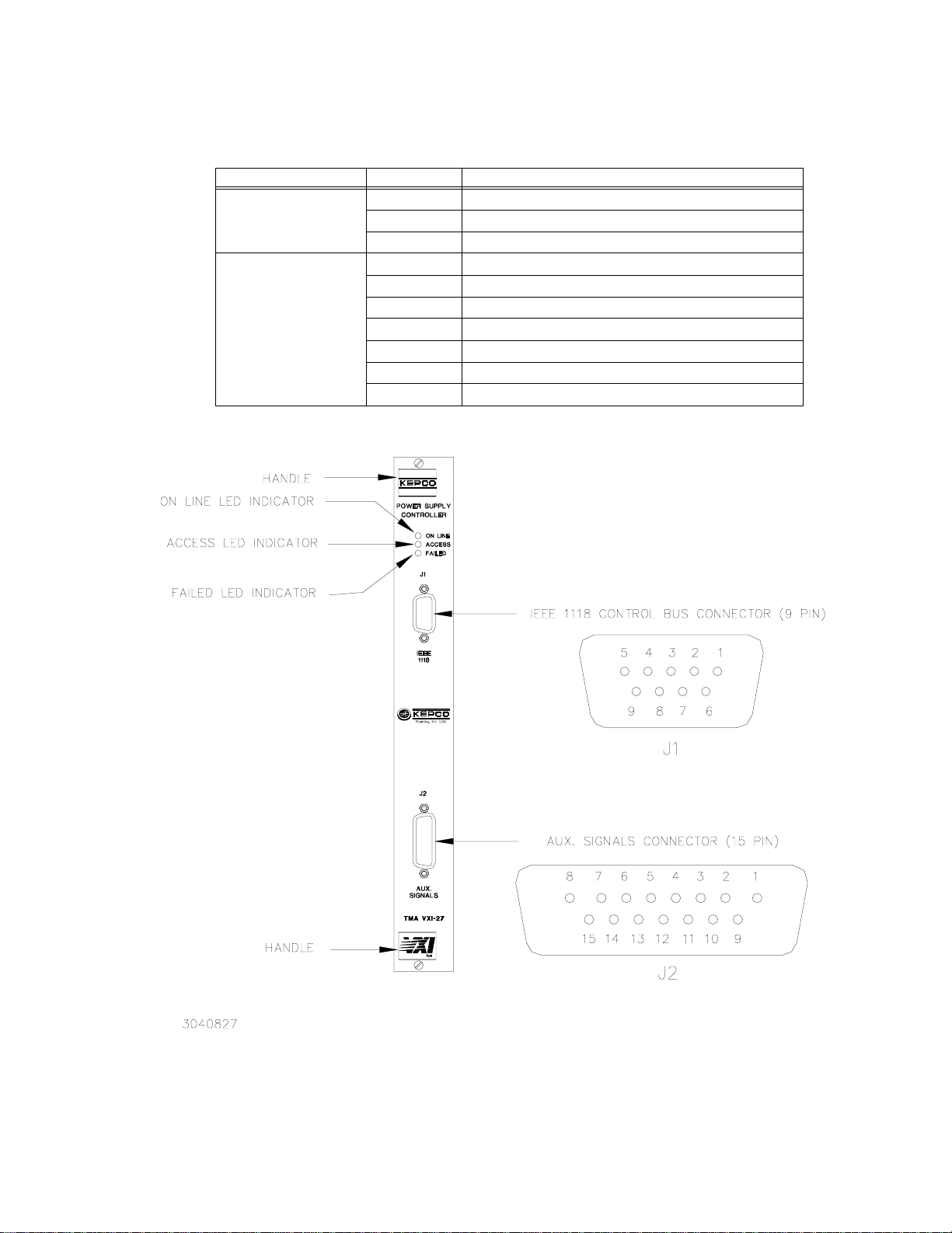

2.3 FRONT PANEL TERMINATIONS (SEE FIGURE 2-2.)

a. IEEE 1118 (Control Bus) connector. Connections to the control bus are made through the

IEEE 1118 connector, a 9 pin D-type female receptacle. Refer to Table 2-1 for pin assignments.

TMA VXI -27 101602

2-1

Page 15

b. Auxiliary Signals connector. This is a 15 pin D-type female receptacle. Refer to Table 2-1 for

pin assignments.

The DISCRETE FAULT LINE relay has the contacts open if the internal microsystem is

functioning normal by monitoring a pulse generated in the timer interrupt routine. If the microsystem is not functioning normally or a catastrophic condition appears on one of the power modules the contacts will close and then reopen when the catastrophic condition disappears and the

error buffer has been read (if the Command Language is CIIL) or when the Device Dependent

Error from the Event Status Register has been read (if the Command Language is SCPI).

The ISOLATED and NON ISOLATED EMERGENCY SHUT-DOWN INPUTS activates the

non-maskable interrupt of the microsystem forcing the microsystem to send a reset to all

KEPCO power supplies.

2-2

FIGURE 2-1. VXI ADDRESS SELECT

TMA VXI -27 101602

Page 16

TABLE 2-1. INPUT/OUTPUT PIN ASSIGNMENTS

CONNECTOR PIN FUNCTION

IEEE 1118

(9-Pin, D-type, female)

AUX. SIGNALS

(15-Pin, D-type, female)

1, 2, 6, 7 Ground

3, 4, 5 IEEE 1118 (2-Wire Differential Interface)

8, 9 IEEE 1118 (2-Wire Differential Interface)

1, 7. 8 Emergency Shut-down - Isolated Input Cathode (–)

2, 5, 6 Emergency Shut-down - Isolated Input Anode (+)

3, 4 +5v Output (Through 390 Ohm)

9, 11 Ground

10 Emergency Shut-down Input - Non Isolated

12, 13 Discrete Fault Line - Relay Contact Pin 1

14, 15 Discrete Fault Line - Relay Contact Pin 2

TMA VXI -27 101602

FIGURE 2-2. TMA VXI-27 FRONT PANEL

2-3/(2-4 Blank)

Page 17

Page 18

SECTION 3 - OPERATION

3.1 LOCAL OPERATION

There is no local operation of the TMA VXI-27 controller; however, the controller provides three

front panel LEDs (see PAR. 3.1.1) and three auxiliary functions (see PAR.3.1.2) to the user in

addition to the remote programming capability described in PAR.’s 3.2 through 3.5.

3.1.1 FRONT PANEL INDICATORS

The TMA VXI-27 is equipped with 3 front panel LEDs which have the following functions: (see

Figure 2-2)

a. ONLINE. The top LED (for vertically mounted unit), green colored, indicates that the power is

applied and the internal microsystem is ON LINE. It is turned ON by an output port instruction executed by the internal microprocessor.

b. ACCESS. The middle position LED, green colored, indicates that a VXI ACCESS cycle to

address the module has been executed.

c. FAILED. The bottom LED (for vertically mounted unit), red colored, indicates the FAILED

condition. It is on during the power-up self test which is executed by the module every time

the power is first applied or after a hardware reset. The VXI standard requires that this LED

go off within 5 seconds. If this LED is still ON after 5 seconds, the VXI module is defective

and has to be serviced.

3.1.2 AUXILIARY SIGNALS

The AUX SIGNALS connector (see Table 2-1 and Figure 2-2) at the front panel provides the following auxiliary functions: emergency output shutdown, discrete fault, and +5V output.

3.1.2.1 EMERGENCY OUTPUT SHUTDOWN

The emergency output shutdown function allows the user to reset all the power modules connected to the Control Bus with a single discrete signal. A user-initiated emergency shutdown

activates the non-maskable interrupt of the microsystem, forcing the microsystem to send a

reset to all power modules connected to the Control Bus. The NON-ISOLATED EMERGENCY

SHUT-DOWN INPUT accepts a TTL input signal to initiate shutdown; this signal is referred to

signal common. The ISOLATED EMERGENCY SHUT-DOWN INPUT requires a 2-wire isolated

signal and return path.

3.1.2.2 DISCRETE FAULT LINE

The DISCRETE FAULT LINE function provides a discrete controller fault indication by means of

an internal relay. The DISCRETE FAULT LINE relay contacts are open (open circuit between

DISCRETE FAULT LINE PIN 1 and PIN 2) if the internal microsystem is functioning normally;

this is accomplished by monitoring a pulse generated in the timer interrupt routine. If the microsystem is not functioning normally, or a catastrophic condition appears on one of the power

modules, the contacts will close. The contacts reopen when the catastrophic condition disappears and either the error buffer has been read (if the Command Language is CIIL) or when the

Device Dependent Error from the Event Status Register has been read (if the Command Language is SCPI).

TMA VXI -27 101602

3-1

Page 19

3.1.2.3 +5V OUTPUT

The +5V output is an auxiliary +5V source supplied through a 390 ohm resistor which can be

used to power user-supplied external TTL circuits.

3.2 REMOTE OPERATION

The TMA VXI-27 Power Module Controller is programmed over the VXIbus using either SCPI

(Standard Commands for Programmable Instruments) or CIIL (Control Interface Intermediate

Language) commands. SCPI and CIIL provide a common language used in an automatic test

system.

VXI plug&play drivers included with the TMA VXI-27 greatly simplify programming of power supplies connected to the controller via the IEEE 1118 serial bus (see PAR. 3.3). For detailed programming information, refer to PAR. 3.4 for VXIbus implementation, PAR. 3.5 for an explanation

of SCPI programming, and PAR. 3.6 for CIIL programming.

3.3 VXI plug&play OPERATION

The TMA VXI-27 Controller includes two disks used to install VXI plug&play drivers. Once these

drivers are installed, any of the power supplies connected to the TMA VXI-27 may be programmed directly; knowledge of the programming languages (SCPI and CIIL) and corresponding syntax is not required if the plug&play drivers are used.

3.3.1 BACKGROUND

The VXI plug&play Systems Alliance was formed in September, 1993 with the objective of

increasing ease of use for end users of VXI technoloogy. The Alliance endorsed and implemented additional common standards and practices in both hardware and software which

exceeded the scope of the VXI Specifications. These standards are used to define system

“frameworks” which give end users true “plug and play” interoperability at both the hardware and

software levels. Of the three currently defined frameworks, DOS, WIN and GWIN, the TMA VXI27 supports the GWIN (Graphical Windows) framework: an MS-DOS framework with key elements consisting of MS-Windows Soft Front Panel and LabView Drivers and documentation.

3.3.2 DRIVER INSTALLATION

The VXI plug&play install program uses the following structure: Drive C: is the default drive on

MS-DOS based computers (this may be changed during installation). The root directory for all

VXI plug&play drivers is VXIPNP. Each framework (DOS, WIN, and GWIN) is assigned a separate subdirectory and each instrument is assigned a subdirectory of the applicable framework;

Figure 3-1 illlustrates the directory structure for the TMA VXI-27 plug&play drivers.

• kptmavxi.exe — MS-Windows standalone executable file for TMA VXI-27 soft panel.

• kptmavxi.llb — LabView driver for soft panel.

• kptmavxi.hlp — MS-Windows help file (the MS Windows help files are also found in

Appendix A).

• kptmavxi.kb — Knowledge base file which describes the TMA VXI-27.

3-2

To install the plug&play drivers, install floppy disk No. 1 in the appropropriate drive and run

SETUP.EXE, then follow directions as they appear on the screen.

TMA VXI -27 101602

Page 20

VXIPNP

KBASE

(KNOWLEDGE BASE SUBDIRECTORY)

kptmavxi.kb

(knowledge base file for TMA VXI-27)

GWIN

(INSTRUMENT SUBDIRECTORY)

KPTMAVXI

kptmavxi.exe

kptmavxi.llb

kptmavxi.hlp

FIGURE 3-1. TMA VXI-27

3.3.3 OPERATING THE SOFT PANEL

To intiate operation of the soft panel, either choose this option after plug&play driver installation

is complete, or double-click on the TMA VXI-27 icon in the VXIPNP program group available

from Windows Program Manager, or run kptmavxi.exe.

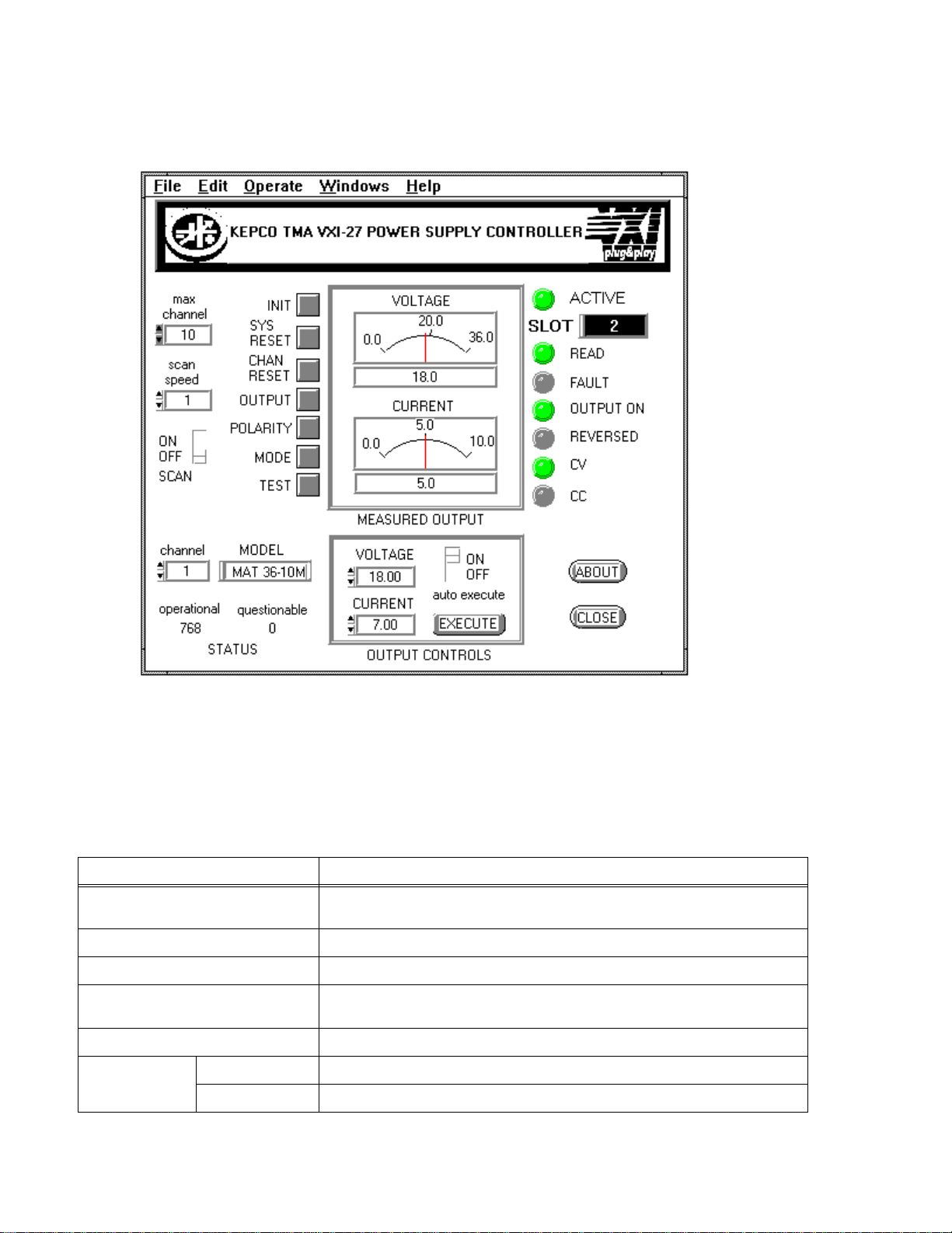

The software will search for TMA VXI-27 controllers installed in the VXI mainframe. The first

screen (shown below, Figure 3-2) lists the TMA VXI-27 Controller(s) installed, showing the

associated slot and assigned logical address. Leave ID QUERY and RESET switches set to

NO.

If only one controller is installed, click on the CONNECT button. If more than one controller is

installed, click on a box at the left to select one controller. (Figure 3-2 shows two TMA VXI-27

controllers installed in slots 2 and 4 corresponding to logical addresses 7 and 6, respectively.)

(KEPCO TMA VXI-27 SUBDIRECTORY)

(standalone soft front panel for TMA VXI-27)

(LabView drivers for TMA VXI-27)

(MS-Windows help file for TMA VXI-27)

plug&play

DIRECTORY STRUCTURE

The ID QUERY and RESET switches should be left in the NO position. (ID QUERY set to ON

will send a verification of the type of instrument installed to the VXI Resource Manager. RESET

set to ON will cause all power supplies to be reset to the initial power on condition when the controller is initialized.)

TMA VXI -27 101602

FIGURE 3-2. TMA VXI-27

plug&play

CONTROLLER SELECTION

3-3

Page 21

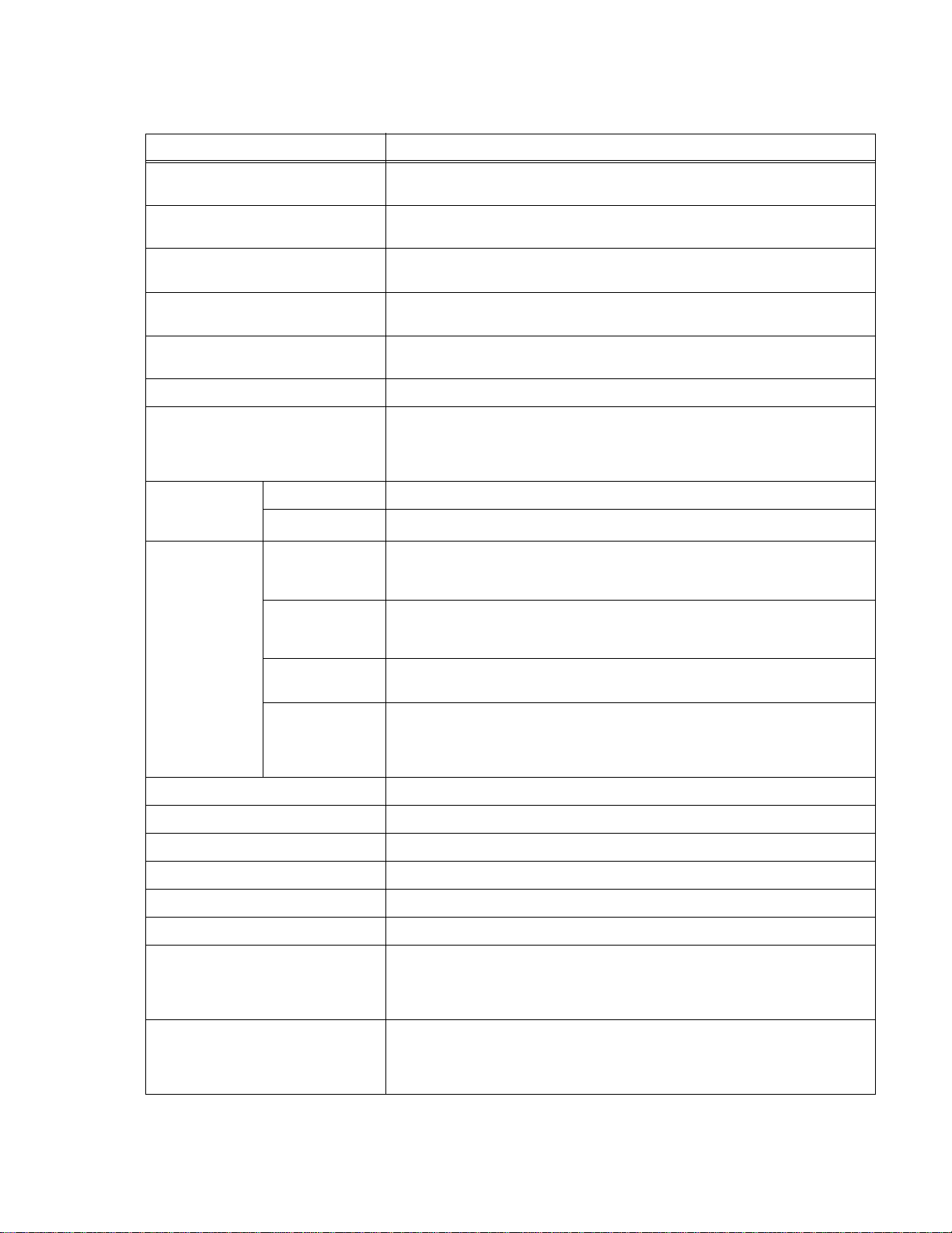

Once a controller has been selected, you will see the "virtual" panel of the Kepco power supply,

(Figure 3-3). The slot selected is displayed in the SLOT window at the upper left corner of the

panel. To operate the controls, click the mouse.

FIGURE 3-3. TMA VXI-27

plag&play

PANEL

3.3.3.1 UNDERSTANDING THE CONTROLS. For on-line information about controls and indicators,

click on SHOW HELP from the HELP menu. Then move the cursor over each control and indicator on the panel. Help text will appear and explain the function of each. Table 3-1 lists the

function of each control and indicator.

TABLE 3-1. Plug&play PANEL CONTROLS AND INDICATORS

CONTROL/INDICATOR FUNCTION

Click on arrows to increase or decrease the number of channels to be scanned; set to

correspond to the number of power supplies actually connected to the controller.

Click on arrows to select channel. Power supply connected to selected channel (indicated by MODEL indicator) is visible on “virtual” panel.

TMA VXI -27 101602

3-4

MAX CHANNEL (switch)

SCAN SPEED(switch) Click on arrows to select scan speed from fastest (10) to slowest (1).

SCAN ON/OFF (switch) Click to enables or disable polling of power supplies connected to the active controller.

CHANNEL (switch)

MODEL (indicator) Indicates power supplly model connected to selected channel.

STATUS

(indicators)

OPERATIONAL Indicates value of status bits in operational register (see Figure B-17)

QUESTIONABLE Indicates value of status bits in questionable register (see Figure B-23)

Page 22

TABLE 3-1. Plug&play PANEL CONTROLS AND INDICATORS (CONTINUED)

CONTROL/INDICATOR FUNCTION

INIT (switch)

SYS RESET (switch)

CHAN RESET (switch)

OUTPUT (switch)

POLARITY (switch)

MODE (switch) Click to select Constant Voltage or Constant Current (alternate action).

TEST (switch)

MEASURED

OUTPUT

(indicators)

OUTPUT

CONTROLS

Click to select a different controller. If only one controller is installed, it will be automatically selected.

Click to reset all power supplies connected to the selected controller (power supplies

are reset to initial power-on condition)

Click to reset only the selected power supply (power supply is reset to initial power-on

condition)

Click to enable or disable the selected power supply output. (Operates relays on

power supply models with relays; otherwise output voltage and current is set to zero.

Click to reverse polarity of power supply models incorporating polarity reversal feature.

Programs all power supplies connected to the controller to their maximum value,

resets them, opens all relays (if present), then checks for errors in output. If error is

detected, the channel number of the failed unit is selected, and the status values indicate the type of error detected.

VOLTAGE meter Provides analog and digital indication of measured voltage.

CURRENT meter

VOLTAGE

CURRENT

EXECUTE

(switch)

Provides analog and digital indication of measured current

Click on arrows to set voltage. If AUTOEXECUTE is set to ON, voltage value is immediately applied to power suply. If AUTOEXECUTE is set to OFF, voltage value is not

applied to selected power supply until EXECUTE is clicked.

Click on arrows to set current. If AUTOEXECUTE is set to ON, current value is immediately applied to power suply. If AUTOEXECUTE is set to OFF, current value is not

applied to selected power supply until EXECUTE is clicked.

With AUTOEXECUTE set to OFF, click to apply VOLTAGE and CURRENT values to

selected power supply.

ACTIVE (indicator) Lights (green) to indicate controller is active.

SLOT (indicator) Displays slot of active controller

READ (indicator) Lights (green) to indicate controller is reading infirmation from power supply.

FAULT (indicator) Lights (red) to indicate error detected. Error indicated by STATUS register values.

OUTPUT ON (indicator) Lights (green) when power supply output is enabled.

REVERSED (indicator) Lights (green) when power supply output polarity is reversed.

CV (indicator)

CC (indicator)

TMA VXI -27 101602

AUTOEXECUTE

ON/OFF

(switch)

Click to set ON/OFF (alternate action). When set to OFF, EXECUTE must be clicked

to apply VOLTAGE and CURRENT values to selected power supply. When set to ON,

VOLTAGE and CURRENT values are immediately applied to the selected power supply.

Lights (green) when power supply is in Constant Voltage mode. (If the Voltage Limit is

exceeded while the power supply was programmed to be in Constant Current mode,

the power supply will be forced into Constant Voltage mode (CV turns green) and the

FAULT indicator lights (red).

Lights (green) when power supply is in Constant Current mode. (If the Current Limit is

exceeded while the power supply was programmed to be in Constant Voltage mode,

the power supply will be forced into Constant Current mode (CC turns green) and the

FAULT indicator lights (red).

3-5

Page 23

TABLE 3-1. Plug&play PANEL CONTROLS AND INDICATORS (CONTINUED)

CONTROL/INDICATOR FUNCTION

ABOUT Click for information about TMA VXI-27 plug&play driver.

CLOSE Click to close plug&play soft panel. Closing the panel does not

3.3.3.2 SELECT THE CHANNEL. Click on the arrows on the CHANNEL box at the lower left. You will see the Kepco power supply Models connected to the system.

3.3.3.3 SET THE VOLTAGE/CURRENT. In the OUTPUT CONTROLS box at the lower center, click on the arrows to increase or decrease the voltage and current. If the power supply is set to Constant Voltage mode (CV indicator green), the CURRENT setting is the Current Limit. Similarly, if the power supply is set to Constant Current mode (CC green), the VOLTAGE setting is the voltage limit.

3.3.3.4 APPLY PROGRAMMED SETTINGS TO THE POWER SUPPLY. Click on EXECUTE. The programmed values for voltage and current limit are now applied to the selected power supply. If AUTOEXECUTE is clicked to ON, the VOLTAGE and CURRENT settings will be immediately applied to the selected power supply.

3.3.3.5 ENABLE THE POWER SUPPLY OUTPUT. Click on the OUTPUT button to the left of the meters to enable the output. The OUTPUT ON indicator turns green. The measured values of voltage and current are indicated by the VOLTAGE and CURRENT meters. Note that the meters give both a digital and analog representation of voltage and current.

3.4 VXIBUS COMMUNICATION

Table 3-2 defines the VXI commands implemented in the TMA VXI-27 in accordance with Specification VXI-1, Rev. 1.4 for a class I4 instrument.

TABLE 3-2. VXI BUS COMMANDS

VXI Command Description

ABORT NORMAL

OPERATION

ASSIGN INTERRUPTER

LINE

ASYNCHRONOUS MODE

CONTROL

BEGIN NORMAL OPERATION (With or without TOP

LEVEL bit)

Causes the TMA VXI-27 to cease normal operation and return to its

default configuration (the same configuration occurring after hardware

reset at power up) with interrupt unasserted.

Used to assign a VXIbus IRQ line to the TMA VXI-27 module interrupter. The default value is 0 which means NO INTERRUPTS.

Used to direct the path of events and responses and also enable or

disable the generation of events and responses. The TMA VXI-27

supports only EVENTS as INTERRUPTS; any other combination will

generate an error

Notifies the TMA VXI-27 that it can begin normal operation. In

response, the TMA VXI-27 sets the corresponding flags in order to be

ready to receive commands through the WORD SERIAL PROTOCOL.

The TOP LEVEL bit (bit 8) is used to identify the device as a Top Level

Commander.

TMA VXI-27

Responds if active

substate is:

Configure

YES NO

YES NO

YES NO

YES NO

Normal

Operation

3-6

TMA VXI -27 101602

Page 24

TABLE 3-2. VXI BUS COMMANDS (CONTINUED)

VXI Command Description

TMA VXI-27

Responds if active

substate is:

Configure

Normal

Operation

BYTE AVAILABLE Sends SCPI or CIIL commands to the TMA VXI-27. Also used to send

BYTE AVAILABLE + END Same as BYTE AVAILABLE except that bit 8 (END) is set to identify

BYTE REQUEST Reads responses from commands previously sent to the TMA VXI-27. NO YES

CLEAR Causes the TMA VXI-27 to clear its internal buffers and reset the VXI

CONTROL EVENT Causes the TMA VXI-27 to selectively enable or disable the genera-

CONTROL RESPONSE Implemented; however, since the TMA VXI-27 does not generate

END NORMAL

OPERATION

IEEE 488.2 common commands.

the byte as the last byte of the message.

error.

tion of a specific event. The TMA VXI-27 can generate two events,

REQUEST TRUE and REQUEST FALSE. After power up, these

events are both enabled (in accordance with the VXI Specification).

The REQUEST TRUE event is sent when the TMA VXI-27 requires

service from its commander (the SERVICE REQUEST bit from the

status byte goes TRUE and the EVENTS AS INTERRUPT and

REQUEST TRUE FLAG are enabled).

The REQUEST FALSE event is sent by the TMA VXI-27 when it no

longer requires service from its commander (the SERVICE REQUEST

bit from the status byte goes FALSE and the EVENTS AS INTERRUPT and REQUEST FALSE FLAG are enabled).

response signals or response interrupts, any attempt to enable

responses will generate an error.

Causes the TMA VXI-27 to end the normal operation and to go back to

the CONFIGURE sub-state. This command will report an error (7 in

the STATUS FIELD) if the device was already in the configure state

when the command was issued.

NO YES

NO YES

YES NO

YES NO

YES NO

YES NO

READ INTERRUPTER

LINE

READ INTERRUPTERS Used to determine the number of interrupters within a SERVANT

READ PROTOCOL Used to determine what protocols, in addition to the Word Serial Pro-

TMA VXI -27 101602

Used to determine the VXIbus IRQ line assigned to the TMA VXI-27

interrupter. The default value is 0 which means NO INTERRUPTS.

device. The TMA VXI-27 has only one interrupter, therefore 1 will be

returned in the answer word. This result will be used in the next command (READ INTERRUPTER LINE) in which the commander can

interrogate the TMA VXI-27 to determine which IRQ line is connected

to this interrupter.

tocol, the TMA VXI-27 supports. This is usually the first command sent

by the Resource Manager after power up and determines all subsequent commands issued to the device. The TMA VXI-27 response to

this command is 8623 Hex which means that it is capable of Event

Generation, that it has a Programmable Interrupter (which means it

supports the Read Interrupters, Read Interrupter Line, and Assign

Interrupter Line commands), that it supports Word Serial TRIGGER

command and that it also supports the VXIbus Instrument Protocol as

an I4 class Instrument.

YES NO

YES NO

YES NO

3-7

Page 25

TABLE 3-2. VXI BUS COMMANDS (CONTINUED)

VXI Command Description

TMA VXI-27

Responds if active

substate is:

Configure

Normal

Operation

READ PROTOCOL

ERROR

READ STB Used to read the status word from the TMA VXI-27. Because the TMA

NOTE: It is more advantageous to execute the VXIbus Word Serial Protocol READ STB command than the *STB? because it is

faster (only one VXI cycle) and more accurate than *STB? It is more accurate because STB? is a query (which asks for

Word Serial Read; BYTE REQUEST command is the reply) which will always have the Message Available bit reset

(because taking the reply empties the output queue). Instead, the VXI READ STB shows the exact status of the output

queue (it does not use the output queue for the reply).

Issued by the COMMANDER to interrogate the TMA VXI-27 about the

cause of its current error (the TMA VXI-27 has activated the Err bit in

the Response register). The errors which can be reported by the TMA

VXI-27 are the following: Multiple Queries, Unsupported Command,

DIR Violation, DOR Violation, Write Ready Violation.

VXI-27 is a class I4 Instrument (implementing the IEEE 488.2 common commands), the value returned is the same as the value read by

executing *STB?.

YES NO

NO YES

3.4.1 TYPICAL VXIBUS START-UP SEQUENCE

The following is a typical sequence of commands which are sent to the TMA VXI-27 by the

resource manager upon power up:

1. The first command is READ PROTOCOL; the TMA VXI-27 replies with 8623 Hex (as

described in Table 3-2 above).

2. the next command is READ INTERRUPTERS to determine the IRQ line assigned to the

TMA VXI-27 interrupter.

3. This is followed by ASSIGN INTERRUPTER LINE which connects the TMA VXI-27 inter-

rupter to an active IRQ line (between 1 and 7) if the resource manager wants events sent as

interrupts. This can be followed by READ INTERRUPTER LINE if the resource manager

wants to verify that the interrupter is connected to the requested IRQ line.

4. After configuration commands described above, it is expected that the resource manager will

issue the BEGIN NORMAL OPERATION COMMAND followed by *idn? (SCPI command) to

identify the TMA VXI-27.

5. The power modules connected to the TMA VXI-27 can now be programmed using either

SCPI (PAR. 3.5) or CILL (PAR. 3.6) commands sent as Word Serial Protocol Messages.

3.5 SCPI PROGRAMMING

SCPI (Standard Commands for Programmable Instruments) is a programming language conforming to the protocols and standards established by IEEE 488.2 (reference document ANSI/

IEEE Std 488.2, IEEE Standard Codes, Formats, Protocols, and Common Commands). SCPI commands are sent to the TMA VXI-27 controller as output strings within the selected programming

language (PASCAL, BASIC, etc.) in accordance with the VXIbus command protocol (PAR. 3.4).

3.5.1 SCPI MESSAGES

There are two kinds of SCPI messages: program messages from controller to power supply,

and response messages from the power supply to the controller. Program messages consist of

one or more properly formatted commands/queries and instruct the power supply to perform an

3-8

TMA VXI -27 101602

Page 26

action; the controller may send a program message at any time. Response messages consist of

formatted data; the data can contain information regarding operating parameters, power supply

state, status, or error conditions.

3.5.2 COMMON COMMANDS/QUERIES

Common commands and queries are defined by the IEEE 488.2 standard to perform overall

power supply functions (such as identification, status, or synchronization) unrelated to specific

power supply operation (such as setting voltage/current). Common commands and queries are

preceded by an asterisk (*) and are defined and explained in APPENDIX A (see Table 3-3).

Refer also to syntax considerations (PAR.s 3.5.3 through 3.5.8).

3.5.3 SCPI SUBSYSTEM COMMAND/QUERY STRUCTURE

Subsystem commands/queries are related to specific power supply functions (such as setting

output voltage, current limit, etc.) Figure 3-4 is a tree diagram illustrating the structure of SCPI

subsystem commands used in the TMA VXI-27 with the “root” at the left side, and specific commands forming the branches. The subsystem commands are defined and explained in Appendix

B (see Table 3-3).

ROOT : (colon)

INITiate

[:IMMediate]

:CONTinuous

INSTrument

:CATalog

:NSELect

:SELect

:STATe

MEASure

:CURRent?

:VOLTage?

OUTPut

[:STATe]

[SOURce:]

VOLTage

[:LEVel]

[:IMMediate]

:TRIGgered

CURRent

[:LEVel]

[:IMMediate]

:TRIGgered

FUNCtion

:MODE

STATus

:OPERation

:CONDition?

:ENABle

[:EVENt]?

:PRESet

:QUEStionable

:CONDition?

:ENABle

[:EVENt]?

:INSTrument?

:ENB

:ISUM

:INSTrument1?

:ENB

:INSTrument2?

:ENB

SYSTem

:COMMunication

:GPIB:ADDRess

:SERial

:BAUD

:ECHO

:PACE

:PROM

:ERRor?

:CODE?

:ALL?

:LANGuage

:SET

:VERSion?

FIGURE 3-4. TREE DIAGRAM OF SCPI COMMANDS USED WITH TMA VXI-27 CONTROLLER

TMA VXI -27 101602

3-9

Page 27

TABLE 3-3. SCPI COMMAND INDEX

COMMAND

*CLS B.2 INST:STAT C.9 STAT:QUES? C.28

*ESE B.3 MEAS:CURR? C.10 STAT:QUES:COND? C.29

*ESE? B.4 MEAS:VOLT? C.11 STAT:QUES:ENAB C.30

*ESR? B.5 OUTP:[STAT] C.12 STAT:QUES:ENAB? C.31

*IDN? B.6 OUTP:[STAT}? C.13 STAT:QUES:INST? C.32

*OPC, *OPC? B.7, B.8 [SOUR]:CURR C.14 STAT:QUES:INST1? C.33

OPT? B.9 [SOUR]:CURR? C.15 STAT:QUES:INST2? C.34

*RST B.10 [SOUR]:CURR:TRIG C.16 STAT:QUES:INST:ENAB, ? C.35, C.36

*SRE B.11 [SOUR]:CURR:TRIG? C.17 STAT:QUES:INST1:ENAB, ? C.37, C.38

*SRE? B.12 [SOUR]:VOLT C.18 STAT:QUES:INST2:ENAB, ? C.39, C.40

*STB? B.13 [SOUR]:VOLT? C.19 STAT:QUES:INST:ISUM? C.41

*TRG B.14 [SOUR]:VOLT:TRIG C.20 STAT:QUES:INST:ISUM:ENAB, ? C.42, C.43

*TST B.15 [SOUR]:VOLT:TRIG? C.21 SYST:ERR C.44

*WAI B.16 [SOUR]:FUNC:MODE C.22 SYST:ERR:CODE? C.45

INIT[:IMM] C.2 STAT:OPER:COND? C.23 SYST:ERR:CODE:ALL? C.46

PAR.

REFERENCE

COMMAND

PAR.

REFERENCE

COMMAND

PAR.

REFERENCE

INIT:CONT C.3 STAT:OPER:ENAB C.24 SYST:LANG C.47

INIT:CONT? C.4 STAT:OPER:ENAB? C.25 SYST:SET C.48

INST:CAT C.5 STAT:OPER? C.26 SYST:VERS? C.49

INST, INST? C.6, C.7, C.8 STAT:PRES C.27

3.5.4 PROGRAM MESSAGE STRUCTURE

SCPI program messages (commands from controller to power supply) consist of one or more

message units ending in a message terminator. The message terminator is not part of the syntax; it

is defined by the way your programming language indicates the end of a line (such as a “newline” or “end-of-line” character). The message unit is a keyword consisting of a single command

or query word followed by a message terminator (e.g., CURR?<newline> or TRIG<end-ofline>). The message unit may include a data parameter after the keyword separated by a space;

the parameter is usually numeric (e.g., CURR 5<newline>), but may also be a string (e.g.,

OUTP ON<newline>). Figure 3-5 illustrates the message structure, showing how message units

are combined. The following subparagraphs explain each component of the message structure.

NOTE: An alternative to using the message structure for multiple messages defined in the fol-

lowing paragraphs is to send each command as a separate line. In this case each command must use the full syntax shown in Appendix B.

3-10

TMA VXI -27 101602

Page 28

KEYWORD

ROOT SPECIFIER

MESSAGE UNIT SEPARATOR

DATA SEPARATOR

DATA

DATA SEPARATOR

KEYWORD

KEYWORD SEPARATOR

KEYWORD

3.5.4.1 KEYWORD

Keywords are instructions recognized by a decoder within the TMA VXI-27, referred to as a

“parser.” Each keyword describes a command function; all keywords used by the TMA VXI-27

are listed in Figure 3-4.

DATA

CURR:LEV 3.5;:OUTP ON;:CURR?<NL>

FIGURE 3-5. MESSAGE STRUCTURE

MESSAGE UNIT SEPARATOR

ROOT SPECIFIER

KEYWORD

QUERY INDICATOR

MESSAGE TERMINATOR

MESSAGE UNIT

Each keyword has a long form and a short form. For the long form the word is spelled out completely (e.g., STATUS, OUTPUT, VOLTAGE, and TRIGGER are long form keywords). For the

short form only the first three or four letters of the long form are used (e.g., STAT, VOLT, OUTP,

and TRIG). The rules governing short form keywords are presented in Table 3-4.

IF NUMBER OF LETTERS IN

LONGFORM KEYWORD IS:

4 OR FEWER (DOES NOT MATTER) ALL LONG FORM LETTERS MODE

5 OR MORE NO

5 OR MORE YES

TMA VXI -27 101602

TABLE 3-4. RULES GOVERNING SHORTFORM KEYWORDS

AND FOURTH LETTER

IS A VOWEL?

THEN SHORT FORM

CONSISTS OF:

THE FIRST FOUR

LONG FORM LETTERS

THE FIRST THREE

LONG FORM LETTERS

MEASure, OUTPut, EVENt

LEVel, IMMediate, ERRor

EXAMPLES

3-11

Page 29

You must use the rules above when using keywords. Using an arbitrary short form such as

ENABL for ENAB (ENABLE) or IMME for IMM (IMMEDIATE) will result in an error. Regardless

of which form chosen, you must include all the letters required by that form.

To identify the short form and long form in this manual, keywords are written in upper case letters to represent the short form, followed by lower case letters indicating the long form (e.g.,

IMMediate, EVENt, and OUTPut). The parser, however, is not sensitive to case (e.g., outp,

OutP, OUTPUt, ouTPut, or OUTp are all valid).

3.5.4.2 KEYWORD SEPARATOR

If a command has two or more keywords, adjacent keywords must be separated by a colon (:)

which acts as the keyword separator (e.g., CURR:LEV:TRIG). The colon can also act as a root

specifier (PAR. 3.5.4.7).

3.5.4.3 QUERY INDICATOR

The question mark (?) following a keyword is a query indicator. This changes the command into

a query. If there is more than one keyword in the command, the query indicator follows the last

keyword. (e.g., VOLT? and MEAS:CURR?).

3.5.4.4 DATA

Some commands require data to accompany the keyword either in the form of a numeric value

or character string. Data always follows the last keyword of a command or query (e.g.,

VOLT:LEV:TRIG 14 or SOUR:VOLT? MAX

3.5.4.5 DATA SEPARATOR

Data must be separated from the last keyword by a space (e.g., VOLT:LEV:TRIG 14 or

SOUR:VOLT? MAX

3.5.4.6 MESSAGE UNIT SEPARATOR

When two or more message units are combined in a program message, they must be separated

by a semicolon (;) (e.g., VOLT 15;MEAS:VOLT? and CURR 12; CURR:TRIG 12.5).

3.5.4.7 ROOT SPECIFIER

The root specifier is a colon (:) that precedes the first keyword of a program message. This

places the parser at the root (top left, Figure 3-4) of the command tree. Note the difference

between using the colon as a keyword separator and a root specifier in the following examples:

VOLT:LEV:IMM 16 Both colons are keyword separators.

:CURR:LEV:IMM 4 The first colon is the root specifier, the other two are keyword separators.

VOLT:LEV 6;:CURR:LEV 15 The second colon is the root specifier, the first and third are keyword separators

:INIT ON;:TRIG;:MEAS:CURR?;VOLT? The first three colons are root specifiers.

3-12

TMA VXI -27 101602

Page 30

3.5.4.8 MESSAGE TERMINATOR

The message terminator defines the end of a message. Three message terminators are permitted:

• new line (<NL>), ASCII 10 (decimal) or 0A (hex)

• (<CR>), ASCII 13 (decimal) or 0D (hex)

• both of the above (<CR> <NL>)

Your GPIB interface card software will automatically send a message terminator. For example,

the HP BASIC OUTPUT statement inserts <NL> after the last data byte. When binary data is

exchanged, <END> must be used. The combination <NL><END> terminator can be used for all

data except binary data.

NOTE: Kepco power modules require a message terminator at the end of each program mes-

sage. The examples shown in this manual assume a message terminator will be added

at the end of each message. Where a message terminator is shown it is represented

as <NL> regardless of the actual terminator character.

3.5.5 UNDERSTANDING THE COMMAND STRUCTURE

Understanding the command structure requires an understanding of the subsystem command

tree illustrated in Figure 3-4. The “root” is located at the top left corner of the diagram. The

parser goes to the root if:

• a message terminator is recognized by the parser

• a root specifier is recognized by the parser

Optional keywords are enclosed in brackets [ ] for identification; optional keywords can be omitted and the power supply will respond as if they were included in the message. The root level

keyword [SOURce] is an optional keyword. Starting at the root, there are various branches or

paths corresponding to the subsystems. The root keywords for the TMA VXI-27 are :INITiate,

:MEASure, :OUTPut, [:SOURce], :STATus, and :SYSTem. Because the [SOURce] keyword is

optional, the parser moves the path to the next level, so that VOLTage, CURRent, and FUNCtion commands are at the root level.

Each time the parser encounters a keyword separator, the parser moves to the next indented

level of the tree diagram. As an example, the STATus branch is a root level branch that has