Page 1

INSTRUCTION MANUAL

RA 19-1U

RACK ADAPTER

HOT SWAP RACK ADAPTER FOR 1U HSF SERIES POWER SUPPLIES

KEPCO INC.

An ISO 9001 Company.

RACK ADAPTER

ORDER NO. REV. NO.

IMPORTANT NOTES:

1) This manual is valid for the following Model and associated serial numbers:

MODEL SERIAL NO. REV. NO.

2) A Change Page may be included at the end of the manual. All applicable changes and

revision number changes are documented with reference to the equipment serial numbers. Before using this Instruction Manual, check your equipment serial number to identify

your model. If in doubt, contact your nearest Kepco Representative, or the Kepco Documentation Office in New York, (718) 461-7000, requesting the correct revision for your

particular model and serial number.

3) The contents of this manual are protected by copyright. Reproduction of any part can be

made only with the specific written permission of Kepco, Inc.

Data subject to change without notice.

MODEL

RA 19-1U

KEPCO®

©2013, KEPCO, INC

P/N 243-1025R3

KEPCO, INC. ! 131-38 SANFORD AVENUE ! FLUSHING, NY. 11355 U.S.A. ! TEL (718) 461-7000 ! FAX (718) 767-1102

email: hq@kepcopower.com

! World Wide Web: http://www.kepcopower.com

THE POWER SUPPLIER™

Page 2

Page 3

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual ..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

1.3 Mechanical .............................................................................................................................................. 1-1

1.4 Electrical.................................................................................................................................................. 1-1

1.5 Safety ...................................................................................................................................................... 1-2

1.6 RoHS Compliance................................................................................................................................... 1-2

1.7 Accessories ............................................................................................................................................. 1-3

1.8 Options .................................................................................................................................................... 1-3

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection ....................................................................................................................... 2-1

2.2 Configuring the Rack Adapter ................................................................................................................. 2-1

2.3 Rack Adapter Keying Instructions ........................................................................................................... 2-1

2.3.1 Establishing Key Positions................................................................................................................. 2-2

2.4 Slot Configuration.................................................................................................................................... 2-2

2.4.1 Independent Operation ...................................................................................................................... 2-3

2.4.1.1 Independent Operation - Local Sensing Using Rear Panel DIP switches ................................... 2-4

2.4.1.2 Independent Operation - Local Sensing Using External Wiring ................................................... 2-5

2.4.1.3 Independent Operation - Remote Sensing .................................................................................. 2-6

2.4.2 Parallel Operation.............................................................................................................................. 2-7

2.4.2.1 Parallel DC OUTPUT Connections.............................................................................................. 2-7

2.4.2.2 Parallel Current Share Connections ............................................................................................ 2-7

2.4.2.2.1 Parallel Current Share - Rear Panel DIP Switches....................................................................2-8

2.4.2.2.2 Parallel Current Share - External Wiring....................................................................................2-9

2.4.2.3 Sense Connections for Parallel Configurations ........................................................................... 2-10

2.4.2.3.1 Parallel Configuration Using DIP Switches to Connect Sense Lines in

Parallel and External Wires to Configure Local Sensing........................................................2-11

2.4.2.3.2 Parallel Configurations using External Wires to Connect Sense Lines

in Parallel and External Wires to Configure Local Sensing ....................................................2-12

2.4.2.3.3 Parallel Configurations using DIP Switches to Connect Sense Lines in

Parallel and External Wires to Configure Remote Sensing....................................................2-13

2.4.2.3.4 Parallel Configurations using External Wires to Connect Sense Lines

in Parallel and External Wires to Configure Remote Sensing ................................................2-14

2.4.3 Series Operation................................................................................................................................ 2-15

2.4.4 Alarm Configurations ......................................................................................................................... 2-17

2.4.4.1 N.O. Alarm Line (Close on Failure).............................................................................................. 2-17

2.4.4.1.1 Close on Failure Using Rear Panel Dip Switches......................................................................2-17

2.4.4.1.2 Close on Failure Using External Wiring at I/O Mating Connector ..............................................2-19

2.4.4.2 N.C. Alarm Line (Open on Failure) .............................................................................................. 2-20

2.4.4.2.1 Open on Failure Using Rear Panel Dip Switches ......................................................................2-20

2.4.4.2.2 Open on Failure Using External Wiring of I/O Mating Connector...............................................2-21

2.5 Current Monitoring (-1URC and -1URY Models only) ............................................................................. 2-22

2.6 Remote On-Off (-1URX and -1URY Models only)................................................................................... 2-23

2.7 Terminations............................................................................................................................................ 2-24

2.8 Cooling .................................................................................................................................................... 2-24

2.9 Installation ............................................................................................................................................... 2-24

2.9.1 Installing 1U HSF Power Supplies..................................................................................................... 2-24

2.10 Wiring Instructions................................................................................................................................... 2-24

RA 19-1U 020413 i

Page 4

TABLE OF CONTENTS

SECTION PAGE

2.10.1 Safety Grounding.............................................................................................................................. 2-25

2.10.2 Source Power Connections .............................................................................................................. 2-25

2.10.2.1 EMI Compliance.......................................................................................................................... 2-26

2.10.3 Control Signal Connections .............................................................................................................. 2-26

2.10.4 Output Load Connections ................................................................................................................. 2-26

2.10.4.1 Reducing Ripple and Noise......................................................................................................... 2-26

2.10.4.2 Parallel/Redundant Operation ..................................................................................................... 2-28

2.10.4.3 Series/Independent Operation .................................................................................................... 2-28

2.10.4.4 Mixed Operation.......................................................................................................................... 2-28

2.11 Removing/Replacing 1U HSF Power Supplies ....................................................................................... 2-28

2.12 Shipping.................................................................................................................................................. 2-28

ii RA 19-1U 020413

Page 5

LIST OF FIGURES

FIGURE TITLE PAGE

1-1 RA 19-1U Rack Adapter ............................................................................................................................... vi

1-2 RA 19-1U Rack Adapter with 1U HSF Power Supplies Installed ................................................................ 1-1

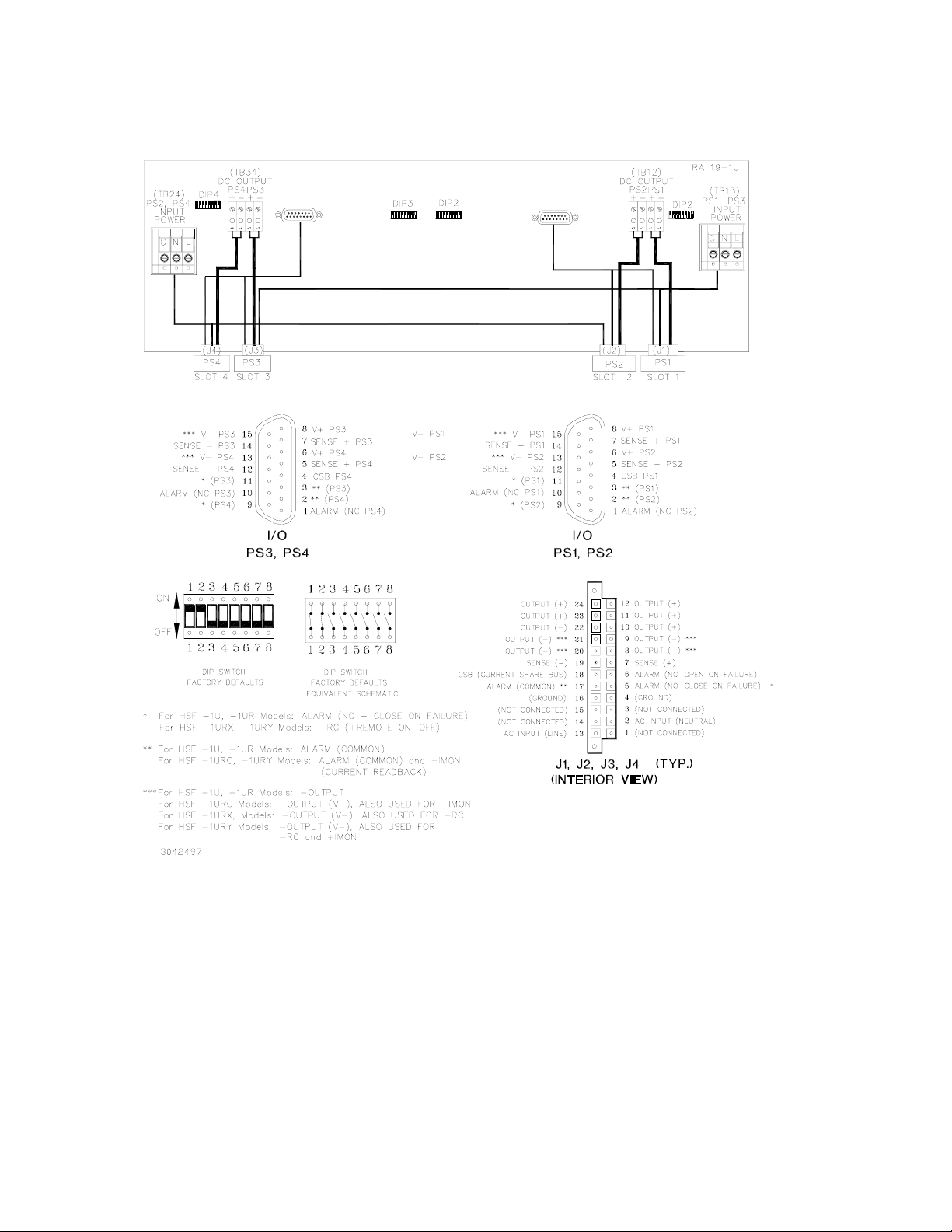

1-3 RA 19-1U Interconnections, Simplified Diagram......................................................................................... 1-2

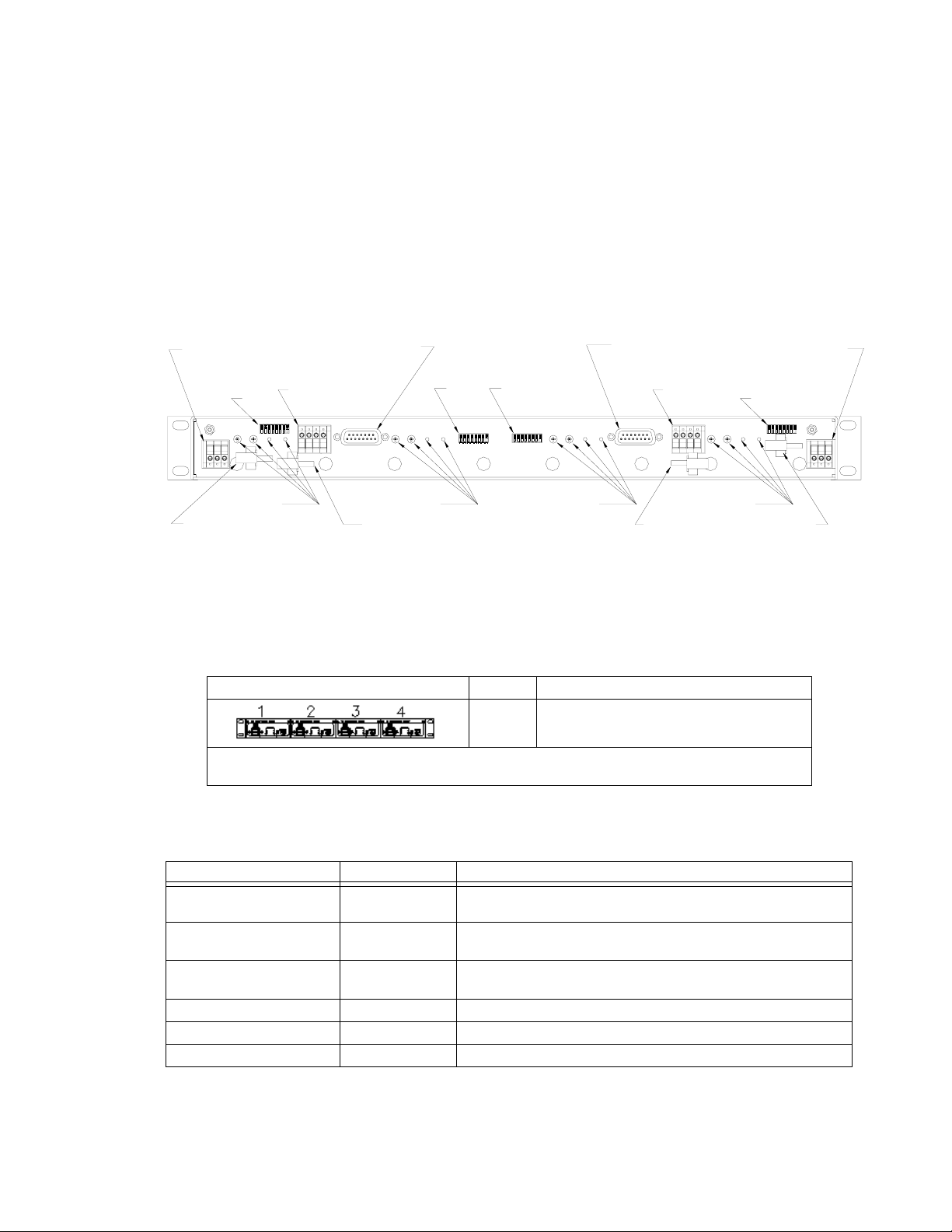

1-4 RA 19-1U Rack Adapter Rear Panel .......................................................................................................... 1-3

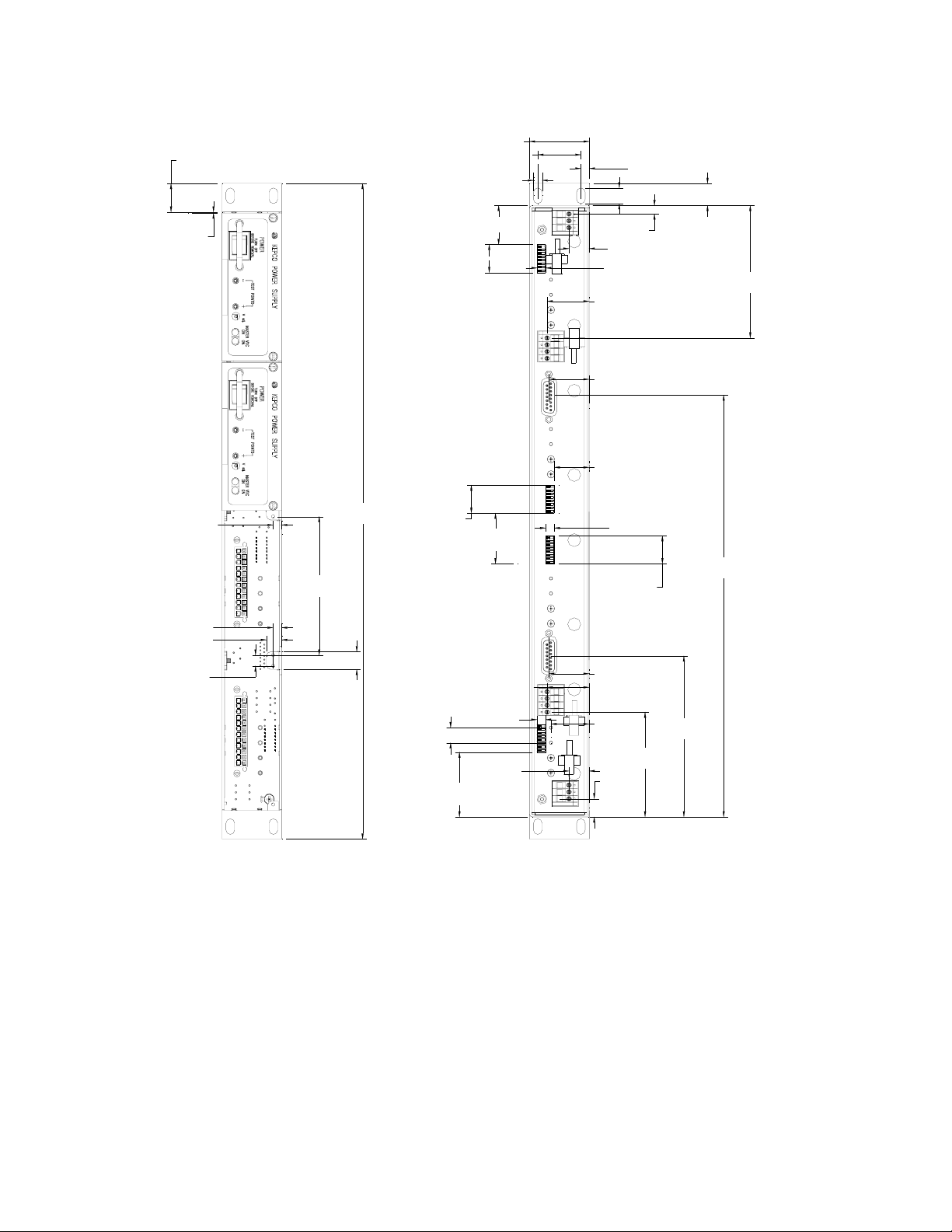

1-5 Mechanical Outline Drawing, RA 19-1U Rack Adapter............................................................................... 1-4

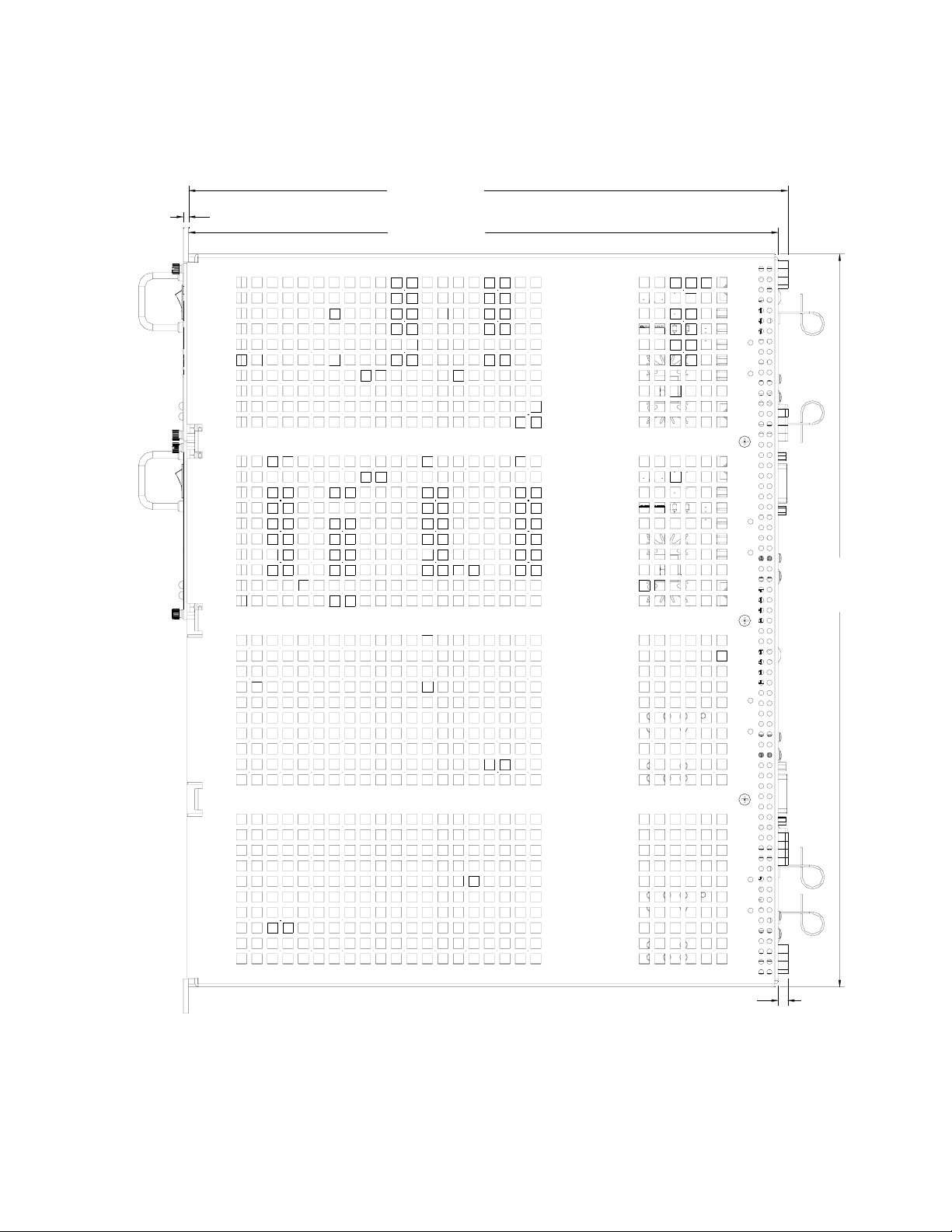

1-6 RA 19-1U Schematic Diagram.................................................................................................................... 1-7

2-1 RA 19-1U Rack Adapter Keying ................................................................................................................. 2-2

2-2 Independent Operation, Local Sensing for PS1 and PS2 using

Rear Panel DIP switches, Simplified Diagram ........................................................................................ 2-4

2-3 Independent Operation, Local Sensing for PS1 and PS2 using

External Jumpers at I/O Mating Connector, Simplified Diagram ............................................................. 2-5

2-4 Independent Operation, Remote Sensing for PS1 and PS2 using

External Wiring at I/O Mating Connector, Simplified Diagram................................................................. 2-6

2-5 Parallel Outputs Using Rear Panel DIP Switches to Parallel sense

lines and current share, PS1 and PS2 (Typical), Simplified Diagram ..................................................... 2-8

2-6 Parallel Outputs Using External Wiring, Typical Configuration, Simplified Diagram ................................... 2-9

2-7 Typical Parallel Connections Using External Wires for

Local Sensing and DIP switches to Parallel Sense Wires....................................................................... 2-11

2-8 Typical Parallel Connections using External Wires for Local Sensing

and I/O Mating Connector Jumpers to Parallel Sense Wires ................................................................... 2-12

2-9 Typical Parallel Connections, Remote Sensing using DIP Switches to Parallel Sense Wires.................... 2-13

2-10 Typical Parallel Connections, Remote Sensing using I/O Mating

Connector Jumpers to Parallel Sense Wires........................................................................................... 2-14

2-11 Series Configuration, Simplified Diagram ................................................................................................... 2-16

2-12 Close on Failure Alarm Configuration Using Rear Panel Dip Switches, Simplified Diagram ...................... 2-18

2-13 Close on Failure Alarm Configuration Using External Wiring at I/O Mating

Connector, Simplified Diagram................................................................................................................. 2-19

2-14 Open on Failure Alarm Configuration Using Rear Panel Dip Switches, Simplified Diagram ...................... 2-20

2-15 Open on Failure Alarm Configuration Using External Wiring

at I/O Mating Connector, Simplified Diagram ........................................................................................... 2-21

2-16 Using Current Monitoring (Typical), -1URC and -1URY Models only ......................................................... 2-22

2-17 Using Remote On-Off (Typical), -1URX and -1URY Models only............................................................... 2-23

2-18 Ripple and Noise Measurement Setup Diagram......................................................................................... 2-27

RA 19-1U 020413

iii/(iv Blank)

Page 6

Page 7

LIST OF TABLES

TABLE TITLE PAGE

1-1 Compatible 1U HSF Power Supplies ..........................................................................................................1-3

1-2 RA 19-1U Accessories ................................................................................................................................1-3

2-1 Equipment Supplied ....................................................................................................................................2-1

2-2 Rear Panel DIP Switch Functions ...............................................................................................................2-3

2-3 Sense Resistor Values ................................................................................................................................2-22

RA 19-1U 020413 v

Page 8

S

L

O

T

1

S

L

O

T

2

S

L

O

T

3

S

L

O

T

2

4

0

3

9

4

5

4

FIGURE 1-1. RA 19-1U RACK ADAPTER

vi RA 19-1U 020413

Page 9

1.1 SCOPE OF MANUAL

This manual contains instructions for the installation and operation of the RA 19-1U plug-in rack

adapter (Figure 1-1) used with 1U HSF Series power supplies, manufactured by Kepco, Inc.,

Flushing, New York, U.S.A. Unless otherwise noted, 1U HSF refers to the following models -1U,

-1UR, -1URT, -1URC, -1URX and -1URY.

SECTION 1 - INTRODUCTION

1.2 GENERAL DESCRIPTION

FIGURE 1-1.

Kepco RA 19-1U rack adapters are specifically designed for the installation of Kepco 1U HSF

Series Power Supplies into 19-inch EIA-RS-310D standard equipment racks. The RA 19-1U

Model accommodates up to four 50W, 100W or 150W 1U HSF power supplies (Figure 1-2).

The rack adapter is user-configurable for parallel, series, or independent power supply operation. Up to four identical units may connected in parallel. Multiple rack adapters may be paralleled for additional current capacity. Forced current sharing and OR’ing diodes for N+1

redundancy are built into the 1U HSF power supplies. Redundant a-c inputs are provided to

deliver independent source power to each power supply in a redundant pair. User-configurable

keying ensures that only the correct power supply can be installed in a keyed slot.

PS1 PS2

3042496

FIGURE 1-2. RA 19-1U RACK ADAPTER WITH 1U HSF POWER SUPPLIES INSTALLED

PS3

PS4

1.3 MECHANICAL

The rack adapter is equipped with mounting ears for mounting in EIA-RS-310D standard 19inch racks. For mounting in non-standard racks, consult Kepco Applications Engineering. The

rack adapter is not configured for slides. Optional blank filler panels (see Table 1-2) are available if the full complement of power supplies is not utilized.

Mechanical dimensions, material, and finish of the RA 19-1U Rack Adapter is provided in Figure

1-5.

1.4 ELECTRICAL

An internal PCB back plate mounts connectors which interface directly with the power and signal connectors of 1U HSF Series power supplies, permitting hot swappable insertion and

extraction. The other side of the back plate assembly, available from the rear, contains the fixed

power and signal connections. Figure 1-3 illustrates the interconnections provided by the RA

19-1U Rack Adapter. Dual input terminal blocks on the back plate assembly (Figure 1-4) distribute input power to each of the four powers supplies. Figure 1-6 is a schematic diagram of

the RA 19-1U rack Adapter.

RA 19-1U 020413 1-1

Page 10

All mechanical and electrical specifications are contained in the mechanical outline drawing:

Figure 1-5. See Figure 1-6 for electrical schematic diagram.

I/O CONNECTOR,

PS3, PS4

I/O CONNECTOR,

PS1, PS2

FIGURE 1-3. RA 19-1U INTERCONNECTIONS, SIMPLIFIED DIAGRAM

1.5 SAFETY

Certified to UL 60950-1, 1st Edition, 2007-10-31 (Information Technology Equipment - Safety Part 1: General Requirements) and CSA C22.2 No. 60950-1-03, 1st Edition, 2006-07 (Information Technology Equipment - Safety - Part 1: General Requirements). Units are CE marked per

the Low Voltage Directive (LVD), 2006/95/EC (LVD) and 2004/108/EC (EMC). [The standards

do not apply with either DC input operation or with a-c input frequency above 66Hz.]

1.6 RoHS COMPLIANCE

RoHS 5 of 6 compliant to EU directive 2011/65/EU if used as component within telecommunication systems.

1-2 RA 19-1U 020413

Page 11

1.7 ACCESSORIES

Accessories for RA 19-1U Rack Adapters are listed in Table 1-2; see also Table 2-1 for additional accessories supplied with the unit.

1.8 OPTIONS

Table 1-1 below describes the standard model options available with the RA 19-1U rack

adapter. For non-standard options, contact Kepco Applications Engineering for assistance.

SOURCE POWER

INPUT FOR

PS2 AND PS4

PS4 KEYING

CABLE CLAMP*

AC INPUT

PS2 AND PS4

3042498

DIP 4

I/O CONNECTOR,

PS3, PS4

DC OUTPUT

PS3, PS4

DIP 3 DIP 2

PS3 KEYING PS2 KEYING PS1 KEYING

CABLE CLAMP*

DC OUTPUT

PS2 AND PS4

* CABLE CLAMPS ARE USER

INSTALLED.

I/O CONNECTOR,

PS1, PS2

DC OUTPUT

PS1, PS2

CABLE CLAMP*

DC OUTPUT

PS1 AND PS2

FIGURE 1-4. RA 19-1U RACK ADAPTER REAR PANEL

TABLE 1-1. COMPATIBLE 1U HSF POWER SUPPLIES

RA 19-1U RACK ADAPTER SLOT COMPATIBLE POWER SUPPLIES

1, 2, 3, 4 HSF-1UR 50W, 100W and 150W Series

HSF-1U 50W and 100W Series

NOTES: 1. Contact Kepco Applications Engineering for assistance with non-standard configurations.

2. RA 19-1U is compatible with HSF-1U, -1UR, -1URC, -1URX, and -1URY models.

SOURCE POWER

INPUT FOR

PS1 AND PS3

DIP 1

CABLE CLAMP*

AC INPUT

PS1 AND PS3

TABLE 1-2. RA 19-1U ACCESSORIES

ACCESSORY PART NUMBER USE

Screw, Thread forming

(4-40, 0.75 in. long, PHPH)

Cable Clamp, Nylon, with

release lever

101-0480

108-0422

Line cord 118-0506

Connector 142-0449 Mating Connector for I/O connector. Two (2) supplied with unit.

Filler Panel (1/4 Rack) RFP 19-1U-14 Cover one unused 1/4 rack slot.

Filler Panel (1/2 Rack) RFP 19-1U-12 Cover two unused 1/4 rack slots.

RA 19-1U 020413 1-3

Module Keying. eight (8) supplied with unit. Installed by user (see PAR.

2.3).

Support weight of AC input and DC output cables. Four (4) supplied

with unit to be installed by user as desired (see Figure 1-4)

Supply 115 V a-c source power to rack adapter. Two (2) supplied with

unit.

Page 12

0.830 [21.1]

1.735 [44.1]

1.250 [31.8]

0.250 [6.4]

0.243 [6.2]

0.453 [11.5]

0.641 [16.3]

0.031 [0.8]

0.250 [6.4]

0.250 [6.4]

0.444 [11.3]

0.311 [7.9]

19.000 [482.6]

4.016 [102.0]

0.511 [13.0]

0.812 [20.6]

1.130 [28.7]

0.812 [20.6]

1.465 [37.2]

1.218 [30.9]

0.247 [6.3]

0.582 [14.8]

0.250 [6.4]

3.840 [97.5]

1.218 [30.9]

1.166 [29.6]

1.009 [25.6]

0.250 [6.4]

12.225 [310.5]

0.812 [20.6]

1.166 [29.6]

0.250 [6.4]

0.438 [11.1]

0.582 [14.8]

1.877 [47.7]

1.106

[28.1]

3.037 [77.1]

0.527

[13.4]

4.665 [118.5]

NOTES:

1. MATERIAL:

-CHASSIS,COVER,BACKPLATE 0.064" THK ALUM. 5052-H32

-PCB 0.063" THK. FR-4

2. FINISH

-IRIDITE GOLD ON ALL METAL PARTS.

-BACKPLATE SILKSCREEN BLACK INK.

3. IF KEYING IS REQUIRED USE THE INCLUDED SELF FORMING SCREWS 4-40x3/4" (1010480) AS PER FIGURE 2-1.

MAX. TORQUE 5 lbxin (0.6 Nxm).

4. MODULE ARE SECURED FOR HOT SWAP OPERATION WITH CAPTIVE PANEL SCREWS 4-40.

MAX. TORQUE 2 lbxin (0.23 Nxm).

5. FOR SHIPPING OR HIGH VIBRATION AND SHOCK ENVIRONMENTS,MODULES CAN EACH BE SECURED

WITH ONE FLAT HEAD SCREW 100~ , 6-32x1/4" MIN. to 1/2" MAX. LONG.(KEPCO P/N 1010408 ) OR SIMILAR.

THE SCREW WILL BE INSTALLED THRU THE COUNTERSUNK HOLES IN THE BOTTOM PAN.

6. DIMENSIONS ARE IN INCHES [DIMENSIONS IN BRACKETS ARE IN MILLIMETERS].

7. TOLERANCES (UNLESS OTHERWISE SPECIFIED): 3 PLACES: ±0.005, 2 PLACES ±0.01, FRACTIONS: ±1/64"

3010247

FIGURE 1-5. MECHANICAL OUTLINE DRAWING, RA 19-1U RACK ADAPTER (SHEET 1 OF 2)

1-4 RA 19-1U 020413

Page 13

0.125 [3.2]

14.497 [368.2]

14.267 [362.4]

17.715 max

[449.9 max.]

0.230 [5.8]

3010247

FIGURE 1-5. MECHANICAL OUTLINE DRAWING, RA 19-1U RACK ADAPTER (SHEET 2 OF 2)

RA 19-1U 020413 1-5/(1-6 Blank)

Page 14

Page 15

SECTION 1 - w

N1

123456789

1314151617181920212223

101112

JP39

JP40

101112

TB-IN24

L4

24

123

J3

PROPRIETARY DATA

N4

GND

GND

L4

N4

123456789

1314151617181920212223

JP6

101112

©2010, KEPCO, INC

J4

24

TB-IN13

123

L1

N1

GND

JP44

JP43

JP36

JP35

J1

24

JP1

JP2

N2

L2

123456789

1314151617181920212223

J2

101112

24

JP38

JP37

L3

JP4

JP3 JP5

JP42

JP41

N3

123456789

1314151617181920212223

V-2

V+2

S+2

V-1

V+1

815714613512411310291

S-2

NC1

S-1

CSB1

NO1

COM1

NO2

COM2

S+1

NC2 OR RET

DIP1

S+1

1

S-1

2

3

4

5

6

7

8 9

-2

+1

-1

+2

123

4

TB12

1

V+1

16

2

V-1

15

3

14

4

13

5

12

6

11

7

10

8

V+2

V-2

S+1

S-1

CSB

NO1

COM1

NC1

DIP2

1

JP16

1

2

2

3

JP14

3

4

JP13

4

5

JP12

5

6

JP11

6

7

JP10

7

8

JP9

8 9

S+2

16

S-2

15

S+2

14

S-2

13

CSB

12

NO2

11

COM2

10

COM2

V+3

V-3

S+2

S-2

CSB

NO2

COM2

NC2

1

2

3

4

5

6

7

8 9

NC2

DIP3

JP25

JP24JP15

JP23

JP22

JP21

JP20

JP19

JP18

JP17

+4L1-4

+3

-3

123

4

TB34

DIP4

1

S+3

16

2

S-3

15

3

S+3

14

4

S-3

13

5

CSB

12

6

NO3

11

7

COM3

10

8

COM3

RET

V+4

V-4

S+3

S-3

CSB

NO3

COM3

NC3

NC3

1

JP34

1

2

JP33

2

3

JP32

3

4

JP31

4

5

JP30

5

6

JP29

6

7

JP28

7

8

JP27

8 9

JP26

S+4

16

S-4

15

S+4

14

S-4

13

CSB

12

NO4

11

COM4

10

COM4

RET

RET NC4

JP45

COM4

S-4

NC3

CSB4

S+4

V+4

V-4

COM3

S-3

S+3

V-3

V+3

815714613512411310291

NO3

NO4

NC4

3020630

P-12

P-34

FIGURE 1-6. RA 19-1U SCHEMATIC DIAGRAM

020413 6-7

1-7/1-8 (Blank)

6-6/6-7

Page 16

Page 17

SECTION 2 - INSTALLATION

2.1 UNPACKING AND INSPECTION

This equipment has been thoroughly inspected and tested prior to packing and is ready for

operation. After careful unpacking, inspect for shipping damage before attempting to operate. If

any indication of damage is found, file an immediate claim with the responsible transport service. See Table 2-1 for a list of equipment supplied.

TABLE 2-1. EQUIPMENT SUPPLIED

ITEM QUANTITY PART NUMBER

Rack Adapter 1 RA 19-1U

I/O Connector (Mating) 2 142-0449

Line cord (115 V a-c, 15A max, North American style plug, 6 ft.) 2 118-0506

Instruction Manual 1 243-1025

Keying screws (4-40 x 0.75 in., thread forming) 8 101-0480

Hood for I/O Connector (Mating) P/N 142-0449 2 108-0204

Cable clamp with release latch 4 108-0422

2.2 CONFIGURING THE RACK ADAPTER

Prior to installation the rack adapter must be configured by the user. Configuration consists of

the following:

• For configurations that use multiple output voltages it is possible to key the rack adapter

to accept only a power supply with corresponding keying (see PAR 2.3).

• Configuring slots for independent, parallel, or series operation. This can be done by

means of DIP switches mounted on the rear panel, or externally by wiring the associated

I/O mating connector and DC OUTPUT terminals (see PAR. 2.4).

2.3 RACK ADAPTER KEYING INSTRUCTIONS

RA 19-1U rack adapters incorporate a keying mechanism to prevent accidental insertion of the

incorrect model 1U HSF power supply into any position. The 1U HSF power supplies are keyed

by voltage at the factory. The keying mechanism will prevent engagement of any of the 1U HSF

power supply's connectors with those on the rack adapter's back plate unless the key and keyway align. The key pins are on the 1U HSF power supply and are set at the factory. DO NOT

ALTER THE KEYING AT THE POWER SUPPLY. The keyway is established by installing screws

(provided) so that the only open holes match the power supply pins. The user can configure

each power supply slot for the desired voltage in the desired position. Figure 1-4 shows the

location of key positions for each slot and Figure 2-1 shows the configuration required for voltage selection.

RA 19-1U 020413 2-1

Page 18

2.3.1 ESTABLISHING KEY POSITIONS

To establish the keying of any position, simply install the 4-40 x 0.75 in. thread-forming screws

(Kepco P/N 101-0480) into the corresponding holes as indicated in Figure 2-1. DO NOT OVERTIGHTEN these screws (max torque 5 in.-lbs. (0.6 N x m). DO NOT ALTER THE KEYING AT

THE POWER SUPPLY.

FIGURE 2-1. RA 19-1U RACK ADAPTER KEYING

2.4 SLOT CONFIGURATION

Configuring slots of the rack adapter for independent, parallel or series operation is accomplished either by means of DIP switches mounted on the rear panel associated with each slot

(see Figure 1-3), or externally by connecting the appropriate pins of the associated I/O mating

connector. DIP switch functions are explained in Table 2-2.

Slot configuration requires the following selection:

1. Select independent (PAR. 2.4.1), parallel (PAR. 2.4.2), or series (PAR. 2.4.3) operation.

2. Select local or remote sensing; PAR. 2.4.1 (independent), 2.4.2, (parallel) or 2.4.3, (series).

3. Optional: Select close-on-failure or open-on-failure alarm (PAR. 2.4.4).

4. Current Monitoring (Models -1URC and -1URY only, see PAR. 2.5).

5. Remote On-Off (Models -1URX and -1URY only, see PAR. 2.6).

2-2 RA 19-1U 020413

Page 19

DIP

SWITCH

POSITION

TABLE 2-2. REAR PANEL DIP SWITCH FUNCTIONS

FUNCTION DIP SWITCH SET TO ON (CLOSED) DIP SWITCH SET TO OFF (OPEN)

NOTE: BOLD TYPE INDICATES FACTORY SETTINGS.

1, 2

3, 4

5

6, 7

8

Local /

Remote

Sensing

Selection

Connect

Sense

+ and –

in parallel

Current

Share

Close on

Failure

Alarm

** Open on

Failure

Alarm

Required ON for independent operation with

Local Sensing. Position 1 connects V+ to S+,

Position 2 connects V– to S– (see PAR.

2.4.1.1).

Required ON for parallel configurations using DIP

switch settings to connect the sense leads in parallel. Position 3 connects +S to adjacent slot +S,

Position 4 connects –S to adjacent slot –S (see

PAR. 2.4.2.3.1 for local sensing, PAR. 2.4.2.3.3

for remote sensing).

Required ON for parallel operation (connects current share lines in parallel) unless connections are

made via external wires (see PAR. 2.4.2.2.1)

When set to ON, allows a single alarm to provide

failure indication (contact closure between N.O.

pin and COM pin) if any one of many power supplies fails (see PAR. 2.4.4.1).

** When set to ON, allows a single alarm to provide failure indication (contact open between N.C.

pin and COM pin) if any one of many power supplies fails (see PAR. 2.4.4.2).

Position 1 and 2 required OFF for:

a) Independent configurations using Remote

Sensing (see PAR. 2.4.1.3).

b) Independent configurations using Local Sensing with user supplied connections from V+ to S+

and V– to S– (see PAR. 2.4.1.2).

c) All parallel configurations (sensing must be

established using external wires) (see PAR.

2.4.2.3).

d) All series connections (see PAR. 2.4.3).

Position 3 and 4 required OFF for all configurations except parallel configurations using DIP

switch settings to connect the sense leads in

parallel.

Required OFF for

a) independent and series configurations.

b) Parallel configurations using external wires

to connect current share lines in parallel.

When set to OFF, individual power supplies

produce closure between I/O connector N.O.

and COM pins upon failure (see PAR. 2.4.4.1).

** When set to OFF, individual power supplies

produce open between I/O connector N.C. and

COM pins upon failure (see PAR. 2.4.4.2).

** Not applicable for HSF-1URX and -1URY models (see PAR 2.6).

2.4.1 INDEPENDENT OPERATION

The rack adapter is preconfigured at the factory for independent operation of all slots. DIP

switch positions 3, 4 and 5 associated with each slot must be set to OFF (open) for each power

supply to be operated independently.

NOTE: Either local or remote sensing must be connected for the 1U HSF power supplies

to work properly.

The rack adapter is shipped from the factory with each power supply position configured for

local sensing (see Figure 2-2). Sensing for each slot can be configured independently:

• Local sensing using rear panel DIP switches

• Local sensing using external jumpers connected to the I/O mating connector or the DC

OUTPUT terminal block.

• Remote sensing

RA 19-1U 020413 2-3

Page 20

2.4.1.1 INDEPENDENT OPERATION - LOCAL SENSING USING REAR PANEL DIP SWITCHES

The rack adapter slots are preconfigured at the factory for local sensing using rear panel DIP

switches. If a slot has been configured for other than local sensing using DIP switches and it is

necessary to reconfigure it for local sensing, simply set positions 1 and 2 of the DIP switch associated with that slot to ON (closed). External sensing connections must be removed. When set

to ON (closed) DIP switch position 1 connects (V+) to (S+) and position 2 connects (V–) to (S–).

See Figure 1-3 for DIP switch locations. Figure 2-2 illustrates local sensing of PS1 and PS2 by

setting positions 1 and 2 of rear panel DIP 1 and 2 to ON (closed); positions 3 and 4 must be set

to OFF (open). Position 5 (current share) must be set to OFF and positions 6, 7, and 8 (alarms)

can be configured per PAR. 2.4.4.

FIGURE 2-2. INDEPENDENT OPERATION, LOCAL SENSING FOR PS1 AND PS2 USING

REAR PANEL DIP SWITCHES, SIMPLIFIED DIAGRAM

2-4 RA 19-1U 020413

Page 21

2.4.1.2 INDEPENDENT OPERATION - LOCAL SENSING USING EXTERNAL WIRING

To configure a slot for local sensing using external wiring, first set rear panel DIP switch positions 1 and 2 of the DIP switches associated with that slot to OFF (open).

External local sensing is accomplished by connecting (V+) to (S+) and (V–) to (S–). This can be

done at either the mating I/O connector supplied (see Table 2-1) or at the DC OUTPUT terminal

block. See Figure 1-3 for DIP socket locations. Figure 1-3 illustrates I/O connector pin assignments. Figure 2-3 illustrates local sensing of PS1 and PS2 using external jumpers connected to

the I/O mating connector.

NOTE: The rear panel DIP switch settings established at the factory for positions 1 and 2 of

the associated DIP switch MUST be changed to OFF (open) if this option is chosen.

Positions 3 and 4 (connecting sense lines in parallel) and Position 5 (current share) must be set

to OFF. Configure Positions 6, 7, and 8 (alarms) per PAR. 2.4.4.

FIGURE 2-3. INDEPENDENT OPERATION, LOCAL SENSING FOR PS1 AND PS2 USING

EXTERNAL JUMPERS AT I/O MATING CONNECTOR, SIMPLIFIED DIAGRAM

RA 19-1U 020413 2-5

Page 22

2.4.1.3 INDEPENDENT OPERATION - REMOTE SENSING

Remote sensing is accomplished by connecting +Load to (S+) and –Load to (S–). Figure 2-4

illustrates remote sensing for PS1 and PS2 using wires connected to the I/O mating connector.

NOTE: The rear panel DIP switch settings established at the factory for positions 1 and 2 of

the associated DIP switch MUST be changed to OFF (open) if this option is chosen.

Positions 3 and 4 (connecting sense lines in parallel) and Position 5 (current share) must be set

to OFF. Configure Positions 6, 7, and 8 (alarms) per PAR. 2.4.4.

FIGURE 2-4. INDEPENDENT OPERATION, REMOTE SENSING FOR PS1 AND PS2 USING

EXTERNAL WIRING AT I/O MATING CONNECTOR, SIMPLIFIED DIAGRAM

2-6 RA 19-1U 020413

Page 23

2.4.2 PARALLEL OPERATION

Up to four Identical 1U HSF power supplies can be connected in parallel to provide redundant

operation or increased output current to a common load. Blocking diodes are incorporated in

HSF -1U and -1UR power supplies. The power leads must be connected in parallel externally

(see PAR. 2.10.4.2). (Configurations using internal parallel busing are also possible; consult

Kepco’s Applications Engineering for details.) Three things must be considered when configuring the rack adapter for parallel operation:

• DC OUTPUT

• CURRENT SHARE

• SENSE

2.4.2.1 PARALLEL DC OUTPUT CONNECTIONS

The power leads must be connected in parallel externally (see PAR. 2.10.4.2). DC Output V(+)

and V(–) must be connected in parallel at the DC OUTPUT terminal block (see Figures 2-5

through 2-10).

2.4.2.2 PARALLEL CURRENT SHARE CONNECTIONS

The Current Share pins of the 1U HSF power supplies must be connected together for parallel

operation. This can be done using either the rear panel DIP switches to configure adjacent slots

in parallel (PAR 2.4.2.2.1), or externally by wiring the I/O mating connector for configuring slots

1 and 4 (PAR. 2.4.2.2.2).

RA 19-1U 020413 2-7

Page 24

2.4.2.2.1 PARALLEL CURRENT SHARE - REAR PANEL DIP SWITCHES

To configure adjacent slots, use the rear panel DIP switches to connect the Current Share bus.

Using rear panel DIP switches permits only adjacent power supplies be connected in parallel.

To connect the current share lines locate the applicable DIP switches: (see Figure 1-3) and set

position 3, 4, 5 to ON (closed). The example illustrated in Figure 2-5 shows two 50W units (slot

1 and slot 2) connected in parallel using rear panel DIP switches to configure the current share

bus, enabled via position 5 of DIP switch 2 for slots 1/2.

NOTE: If rear panel DIP switch positions 3, 4 are closed (ON), use only one pair of sense

lines to monitor voltage.

FIGURE 2-5. PARALLEL OUTPUTS USING REAR PANEL DIP SWITCHES TO PARALLEL SENSE

LINES AND CURRENT SHARE, PS1 AND PS2 (TYPICAL), SIMPLIFIED DIAGRAM

2-8 RA 19-1U 020413

Page 25

2.4.2.2.2 PARALLEL CURRENT SHARE - EXTERNAL WIRING

Only slots 1 and 4 can be configured for parallel operation using external wiring; To configure

slots 2 and 3 for parallel operation with current sharing the rear panel DIP switches must be

used (see PAR. 2.4.2.2.1). The Current Share lines for each supply must be connected

together at the I/O mating connector (pin 4) using external wiring (see Figure 2-6). Figure 2-6 is

a simplified diagram of a parallel configuration for slots 1 and 4 using external wiring at the I/O

mating connector.

I/O CONNECTOR,

PS3, PS4

I/O CONNECTOR,

PS1, PS2

FIGURE 2-6. PARALLEL OUTPUTS USING EXTERNAL WIRING, TYPICAL

CONFIGURATION, SIMPLIFIED DIAGRAM

RA 19-1U 020413 2-9

Page 26

2.4.2.3 SENSE CONNECTIONS FOR PARALLEL CONFIGURATIONS

NOTE: 1U HSF power supply sense lines MUST be connected to the respective output pins of

I/O connector; otherwise the power supplies will not work.

For parallel configurations the sense lines must be connected in parallel. This can be accomplished either by using the DIP switches (positions 3 and 4 set to ON) or by setting the DIP

switch positions 3 and 4 to OFF and using external wires. When configuring units to work in parallel, the current share bus (PAR. 2.4.2.2) must also be configured.

For local sensing (at the rack adapter) connect the sense lines in parallel using either the DIP

switches or external jumpers, then connect one +S and one –S from the I/O mating connector to

the DC OUTPUT terminal block using short jumpers.

For remote sensing (at the load) connect the sense lines in parallel using either the DIP

switches or external jumpers to connect the sense lines in parallel, then connect one +S and

one –S from the I/O connector to the load using external wires.

For both local and remote sensing Positions 1 and 2 of each DIP switch in the parallel configuration must be set to OFF (open); refer to Figure 1-3 to identify the DIP switch associated with a

corresponding slot.

See the following paragraphs for more details:

• PAR. 2.4.2.3.1: Parallel configurations using DIP switches to connect the sense lines in parallel and external wires to configure local sensing.

• PAR. 2.4.2.3.2: Parallel configurations using external wires to connect the sense lines in

parallel and external wires to configure local sensing.

• PAR. 2.4.2.3.3: Parallel configurations using DIP switches to connect the sense lines in parallel and external wires to configure remote sensing.

• PAR. 2.4.2.3.4: Parallel configurations using external wires to connect the sense lines in

parallel and external wires to configure remote sensing.

2-10 RA 19-1U 020413

Page 27

2.4.2.3.1 PARALLEL CONFIGURATION USING DIP SWITCHES TO CONNECT SENSE LINES IN PARALLEL AND EXTERNAL WIRES TO CONFIGURE LOCAL SENSING

Figure 2-7 is a simplified diagram of a typical parallel configuration using local sensing via external wires to connect V(+) to S(+), V(–) to S(–) and DIP switch settings to connect the sense

leads in parallel. This configuration requires the following:

1. For each supply in parallel set DIP switch positions 1 and 2 to OFF (open) (see Figure 1-3).

2. For each DIP switch between parallel-connected slots (DIP 2, DIP 3 and DIP 4), set DIP

switch positions 3 and 4 to ON (closed) to connect sense leads in parallel (see Figure 1-4).

3. For each DIP switch between parallel-connected slots configure position 5 to connect the

current share bus by referring to PAR. 2.4.2.2.

4. Configure Positions 6, 7, and 8 (alarms) of each DIP switch per PAR. 2.4.4.

5. Connect wire between I/O mating connector pin Sense (+) and corresponding power supply

V(+) terminal at DC OUTPUT terminal block.

6. Connect wire between I/O mating connector pin Sense (–) and corresponding power supply

V(–) terminal at DC OUTPUT terminal block.

FIGURE 2-7. TYPICAL PARALLEL CONNECTIONS USING EXTERNAL WIRES FOR

LOCAL SENSING AND DIP SWITCHES TO PARALLEL SENSE WIRES

RA 19-1U 020413 2-11

Page 28

2.4.2.3.2 PARALLEL CONFIGURATIONS USING EXTERNAL WIRES TO CONNECT SENSE LINES IN PARALLEL AND EXTERNAL WIRES TO CONFIGURE LOCAL SENSING

Figure 2-8 is a simplified diagram of a typical parallel configuration using local sensing via external wires to connect V(+) to S(+), V(–) to S(–) and jumpers connected to the I/O mating connector to connect the sense leads in parallel. This configuration requires the following:

1. For each supply in parallel set DIP switch positions 1 and 2 to OFF (open) (see Figure 1-3).

2. For each DIP switch between parallel-connected slots (DIP 2, DIP 3 and DIP 4), set DIP

switch positions 3 and 4 to OFF (open) (sense leads will be connected in parallel in steps 7

and 8) (see Figure 1-3).

3. For each DIP switch between parallel-connected slots configure position 5 to connect the

current share bus by referring to PAR. 2.4.2.2.

4. Configure Positions 6, 7, and 8 (alarms) of each DIP switch per PAR. 2.4.4.

5. Connect wire between I/O mating connector pin Sense (+) and corresponding power supply

V (+) terminal at DC OUTPUT terminal block.

6. Connect wire between I/O mating connector pin Sense (–) and corresponding power supply

V (–) terminal at DC OUTPUT terminal block.

7. Connect short jumper across I/O mating connector Sense (+) pins.

8. Connect short jumper across I/O mating connector Sense (–) pins.

FIGURE 2-8. TYPICAL PARALLEL CONNECTIONS USING EXTERNAL WIRES FOR LOCAL SENSING

AND I/O MATING CONNECTOR JUMPERS TO PARALLEL SENSE WIRES

2-12 RA 19-1U 020413

Page 29

2.4.2.3.3 PARALLEL CONFIGURATIONS USING DIP SWITCHES TO CONNECT SENSE LINES IN PARALLEL AND EXTERNAL WIRES TO CONFIGURE REMOTE SENSING

Figure 2-9 is a simplified diagram of a typical parallel configuration using remote sensing via

external wires to connect V(+) to S(+), V(–) to S(–) and DIP switch settings to connect the sense

leads in parallel. This configuration requires the following:

1. For each supply in parallel set DIP switch positions 1 and 2 to OFF (open) (see Figure 1-3).

2. For each DIP switch between parallel-connected slots (DIP 2, DIP 3, DIP 4), set DIP switch

positions 3 and 4 to ON (closed) to connect sense leads in parallel (see Figure 1-3).

3. For each DIP switch between parallel-connected slots configure position 5 to connect the

current share bus by referring to PAR. 2.4.2.2.

4. Configure Positions 6, 7, and 8 (alarms) of each DIP switch per PAR. 2.4.4.

5. Connect wire from I/O mating connector Sense (+) pin to V (+) at the load.

6. Connect wire from I/O mating connector Sense (–) pin to V (–) at the load.

FIGURE 2-9. TYPICAL PARALLEL CONNECTIONS, REMOTE SENSING

USING DIP SWITCHES TO PARALLEL SENSE WIRES

RA 19-1U 020413 2-13

Page 30

2.4.2.3.4 PARALLEL CONFIGURATIONS USING EXTERNAL WIRES TO CONNECT SENSE LINES IN PARALLEL AND EXTERNAL WIRES TO CONFIGURE REMOTE SENSING

Figure 2-10 is a simplified diagram of a typical parallel configuration using remote sensing via

external wires to connect V(+) to S(+), V(–) to S(–) and jumpers connected to the mating connector to connect the sense leads in parallel. This configuration requires the following:

1. For each supply in parallel set DIP switch positions 1 and 2 to OFF (open) (see Figure 1-3).

2. For each DIP switch between parallel-connected slots (DIP 2), set DIP switch positions 3

and 4 to OFF (open) (sense leads will be connected in parallel in steps 7 and 8) (see Figure

1-3).

3. For each DIP switch between parallel-connected slots, configure position 5 to connect the

current share bus by referring to PAR. 2.4.2.2.

4. Configure Positions 6, 7, and 8 (alarms) of each DIP switch per PAR. 2.4.4.

5. Connect short jumper across I/O mating connector Sense (+) pins.

6. Connect short jumper across I/O mating connector Sense (–) pins.

7. Connect wire from I/O mating connector Sense (+) pin to V (+) at the load.

8. Connect wire from I/O mating connector Sense (–) pin to V (–) at the load.

FIGURE 2-10. TYPICAL PARALLEL CONNECTIONS, REMOTE SENSING USING I/O MATING

CONNECTOR JUMPERS TO PARALLEL SENSE WIRES

2-14 RA 19-1U 020413

Page 31

2.4.3 SERIES OPERATION

HSF -1U and -1UR power supplies may be connected in series to obtain higher output voltages.

The RA 19-1U rack adapter is designed to safely handle a maximum output voltage of 500

Volts; contact Kepco applications engineering for additional information. The power supply with

the lowest rated value of maximum current establishes the maximum load current allowed.

Series configurations can only be accomplished by external wiring of the I/O mating connector.

V+ of one supply must be connected to V– of the next supply at the DC OUTPUT terminal block.

It is recommended that reverse diodes be connected at the output of each power supply connected in series.

The DC OUTPUT + terminal of one supply must be connected to DC OUTPUT – terminal of the

next supply. Each Power Supply in series must be protected by a reverse diode connected in

parallel with the output as shown in Figure 2-11. The diode protects against reverse voltages.

Protection diodes must conform to the following specifications:

•V

REV

> 2 x V

x N where V

NOM

is the output voltage of the HSF power supply and N

NOM

is the number of power supplies connected in series.

•I

FWD

> 1.5 x I

NOM

where I

is the output current of the HSF power supply.

NOM

DIP switches (positions 1 through 4) between series-connected supplies and at both ends of the

series-connected group must be set to OFF (open). Sensing can be either local or remote (PAR.

2.4.1.3). Local sensing requires external wiring (PAR.2.4.1.2). Figure 2-11 illustrates PS1, PS2

PS3 and PS4 connected in series.

RA 19-1U 020413 2-15

Page 32

FIGURE 2-11. SERIES CONFIGURATION, SIMPLIFIED DIAGRAM

2-16 RA 19-1U 020413

Page 33

2.4.4 ALARM CONFIGURATIONS

The 1U HSF Power Supplies each provide a normally closed (N.C.) and normally open (N.O.)

line referenced to common (COM) for use as an alarm at the users discretion. The N.C. line

opens upon failure, the N.O. line closes upon failure.

NOTE: HSF-1URX and -1URY models do not include the normally open (N.O.) line, so

close on failure configurations are not applicable.

The RA 19-1U is configured at the factory for independent operation of these lines. It is possible

to configure these alarm lines to allow multiple power supplies to provide a failure indication

using the N.O. (close on failure) lines, N.C (open on failure) lines, or both. Each alarm circuit

can be configured in two ways: either by rear panel DIP switches or by external wiring of the I/O

mating connector. Use external wiring of the I/O mating connector if DIP switch specifications

noted in the following CAUTION will be exceeded.

CAUTION: The user is responsible for ensuring that the alarm circuit does not exceed

the HSF alarm relay switching specifications: 1A @ 30V d-c or 0.5A @ 125V

a-c. If the alarm circuit is configured using the rear panel DIP switches, the

user is responsible for ensuring that the alarm circuit does not exceed DIP

switch specifications: 100mA, 50V d-c, maximum.

CAUTION: For HSF-1URX and -1URY models there is no isolation between ±RC, d-c out-

put and alarm circuit. For HSF-1URC and -1URY models there is no isolation

between ±IMON, d-c output and alarm circuit.

2.4.4.1 N.O. ALARM LINE (CLOSE ON FAILURE)

The N.O. and COM line of each 1U HSF supply provide a closed contact (short circuit) upon failure. To configure multiple power supplies so that a failure of any supply produces a failure indication, it is necessary to connect the N.O. lines in parallel and the COM lines in parallel.

2.4.4.1.1 CLOSE ON FAILURE USING REAR PANEL DIP SWITCHES

Close on failure for multiple power supplies can be accomplished by setting DIP switch positions

6 and 7 to ON (closed). associated with each adjacent slot included in the alarm circuit. For

example, for PS1 and PS2, set DIP switch 2, positions 6 and 7 to ON (closed). The failure indication (short circuit) will be present across both N.O.1 and COM1, and N.O.2 and COM2. Figure

2-12 is a simplified diagram illustrating a close on failure alarm configuration for four power supplies using rear panel DIP switches.

RA 19-1U 020413 2-17

Page 34

FIGURE 2-12. CLOSE ON FAILURE ALARM CONFIGURATION USING REAR PANEL DIP

SWITCHES, SIMPLIFIED DIAGRAM

2-18 RA 19-1U 020413

Page 35

2.4.4.1.2 CLOSE ON FAILURE USING EXTERNAL WIRING AT I/O MATING CONNECTOR

Close on failure for multiple power supplies can be accomplished by wiring N.O. and COM in

parallel at the I/O mating connector. DIP switches associated with slots included in the alarm circuit must have positions 6 and 7 set to OFF (open). The failure indication (short circuit) will be

present across any pair of N.O. and COM lines. Figure 2-13 is a simplified diagram illustrating a

close on failure alarm configuration for four power supplies using external wiring at the I/O mating connector.

FIGURE 2-13. CLOSE ON FAILURE ALARM CONFIGURATION USING EXTERNAL WIRING AT I/O MATING

CONNECTOR, SIMPLIFIED DIAGRAM

RA 19-1U 020413 2-19

Page 36

2.4.4.2 N.C. ALARM LINE (OPEN ON FAILURE)

The N.C and COM line of each 1U HSF supply provide an open contact (open circuit) upon failure. To configure multiple power supplies so that a failure of any supply produces a failure indication, it is necessary to connect the N.C. line of one, with the COM line of the next power

supply, so the alarm line is connected in series.

2.4.4.2.1 OPEN ON FAILURE USING REAR PANEL DIP SWITCHES

The open on failure alarm for multiple power supplies is accomplished by setting the associated

DIP switch, position 8, to ON (closed) for each slot included in the alarm circuit as indicated in

Figure 2-14. Setting DIP switch position 8 to ON (closed) connects the N.C. line to the COM line

of the adjacent power supply. Figure 2-14 illustrates an open on failure alarm configuration for

four power supplies using rear panel DIP switch settings.

CAUTION: The user is responsible for ensuring that the alarm circuit does not exceed

DIP switch specifications: 100mA, 50V d-c, maximum.

To configure PS1, PS2, PS3 and PS4 as open on failure, set position 8 of DIP switches DIP 2,

DIP 3, and DIP 4 to ON (closed). The failure indication (open circuit) will be present across

N.C.4 and COM 1.

FIGURE 2-14. OPEN ON FAILURE ALARM CONFIGURATION USING REAR PANEL

DIP SWITCHES, SIMPLIFIED DIAGRAM

2-20 RA 19-1U 020413

Page 37

2.4.4.2.2 OPEN ON FAILURE USING EXTERNAL WIRING OF I/O MATING CONNECTOR

Figure 2-15 illustrates an open on failure alarm configuration using external wiring of the I/O

mating connectors for four power supplies. It is necessary to set DIP switch position 8 to OFF

(open) for each slot included in the open on failure alarm circuit.

FIGURE 2-15. OPEN ON FAILURE ALARM CONFIGURATION USING EXTERNAL WIRING

AT I/O MATING CONNECTOR, SIMPLIFIED DIAGRAM

RA 19-1U 020413 2-21

Page 38

2.5 CURRENT MONITORING (-1URC AND -1URY MODELS ONLY)

Monitored Output Current (Amps) = Voltage drop across Rs (Volts) x Rs (Ohms), where voltage

drop across Rs (see Table 2-3) is measured across ± IMON pins (requires millivoltmeter, range

0 to 200mV). Accuracy of voltage drop across Rs (representing monitored output current) is

±10%; contact Kepco if greater accuracy is required. See Figure 2-16 for typical configuration.

TABLE 2-3. SENSE RESISTOR VALUES

SERIES 3.3V Model 5V Model 12V Model 15V Model 24V Model 28V Model 48V Model

HSF -1UR 50W 0.01 Ohm 0.01 Ohm 0.02 Ohm 0.03 Ohm 0.05 Ohm 0.05 Ohm 0.1 Ohm

HSF -1UR 100W 5 mOhm 5 mOhm 10 mOhm 20 mOhm 20 mOhm 30 mOhm 50 mOhm

HSF -1UR 150W 2.5 mOhm 2.5 mOhm 10 mOhm 10 mOhm 20 mOhm 20 mOhm 30 mOhm

I/O connector pins designated for use for current monitoring are as follows:

I/O Connector

+IMON –IMON

Slot 1 PS1, PS2 Pin 15 Pin 3

Slot 2 PS1, PS2 Pin 13 Pin 2

Slot 3 PS3, PS4 Pin 15 Pin 3

Slot 4 PS3, PS4 Pin 13 Pin 2

CAUTION: There is no isolation between ±IMON, alarm circuit and d-c output. +IMON is

also the –V output of the HSF power supply. For -1URY models, +IMON may

also be used for –RC.

FIGURE 2-16. USING CURRENT MONITORING (TYPICAL), -1URC AND -1URY MODELS ONLY

2-22 RA 19-1U 020413

Page 39

2.6 REMOTE ON-OFF (-1URX AND -1URY MODELS ONLY)

Power switch of HSF must be set to on. Use designated ±RC pins of applicable I/O connector

(see below) to set specified output on or off. See Figure 2-17 for typical configuration. Note that

when ±RC are used, only the normally-closed Alarm (open on failure) is available for use. Contact Kepco if isolation between alarm and remote on-off is required.

• Output OFF requires no voltage, or short circuit, or 0 to 0.8V across ±RC pins of I/O connector.

• Output ON requires 4.5 to 12.5V (or 12.5 to 24.5V through 1.5K Ohms) across ±RC pins

of I/O connector.

To reverse the polarity of the on-off voltage (where output ON requires no voltage, or short circuit, or 0 to 0.8V across ±RC pins of I/O connector), contact Kepco.

I/O connector pins designated for use for remote on-off are as follows:

I/O Connector

+RC –RC

Slot 1 PS1, PS2 Pin 11 Pin 15

Slot 2 PS1, PS2 Pin 9 Pin 13

Slot 3 PS3, PS4 Pin 11 Pin 15

Slot 4 PS3, PS4 Pin 9 Pin 13

CAUTION: –RC is also the –V output of the HSF power supply.

For -1URY models, –RC may also be used for +IMON.

+RC is also the Alarm Common of the HSF power supply.

±RC pins are NOT isolated from DC output pins.

NOTE: ±RC pins of I/O connector are isolated from AC input pins.

FIGURE 2-17. USING REMOTE ON-OFF (TYPICAL), -1URX AND -1URY MODELS ONLY

RA 19-1U 020413 2-23

Page 40

2.7 TERMINATIONS

All input, output and control terminations are located on the rear panel of the rack adapter (see

Figure 1-4).

2.8 COOLING

The 1U HSF power supplies mounted within the rack adapter are maintained within their operating temperature range by means of convection cooling. ALL OPENINGS AROUND THE RACK

ADAPTER CASE MUST BE KEPT CLEAR OF OBSTRUCTION TO ENSURE PROPER AIR

CIRCULATION. Care must be taken that the ambient temperature, which is the temperature of

the air immediately surrounding the rack adapter, does not rise above the specified limits for the

operating load conditions of the installed 1U HSF power supplies. Kepco recommends providing

additional space above and below the rack adapter where possible when the rack adapter is

fully populated.

2.9 INSTALLATION (Refer to “Mechanical Outline Drawing,” Figure 1-5.)

The rack adapter mounts directly to EIA-RS 310D standard 19" racks via the two mounting ears;

two screws are required per mounting ear for proper support.

CAUTION

RACK ADAPTER SHOULD BE MOUNTED BEFORE INSTALLING POWER SUPPLIES.

Provide adequate clearance around case and ensure that the temperature immediately surrounding the unit does not exceed the maximum specified ambient temperature for the operating conditions of the installed power supplies. For severe shock or vibration environments, see

NOTE to PAR. 2.9.1 below.

2.9.1 INSTALLING 1U HSF POWER SUPPLIES

Refer to Figure 1-1, for proper slot positions applicable to the RA 19-1U Rack Adapter. Insert 1U

HSF power supply in selected slot until power supply front panel is flush with rack adapter chassis and secure with two front panel screws on power supply. Do not overtighten these screws:

max. torque is 2 in.-lbs (0.23 N x m).

NOTE: For severe shock and vibration environments each 1U HSF module must be secured

to the rack adapter with a screw, P/N 101-0408 (flat head, 6-32, 1/2 in. lg., 100° CSK)

through the bottom of the rack adapter chassis. Do not overtighten these screws:

max. torque is 10 in.-lbs (1.1N x m); side support for the populated rack adapter may

also be required.

The rack adapter is supplied with four cable clamps equipped with release levers that can be

snapped into holes provided in the rear panel (see Figure 1-4) to support the weight of the input,

output and signal cables.

2.10 WIRING INSTRUCTIONS

Interconnections between an a-c power source and a stabilized power supply, and between the

power supply and its load are as critical as the interface between other types of electronic equipment. If optimum performance is expected, certain rules for the interconnection of source,

power supply and load must be observed by the user. These rules are described in detail in the

following paragraphs and in the operating instructions for 1U HSF Series power supplies.

2-24 RA 19-1U 020413

Page 41

2.10.1 SAFETY GROUNDING

Local, national and international safety rules dictate the grounding of the metal cover and case

of any instrument connected to the a-c power source, when such grounding is an intrinsic part of

the safety aspect of the instrument. The instructions below suggest wiring methods which comply with these safety requirements; however, in the event that the specific installation for the

power system involves differences with the recommended wiring, it is the customer's responsibility to ensure that all applicable electric codes for safety grounding requirements are met.

2.10.2 SOURCE POWER CONNECTIONS

When used in conjunction with Kepco 1U HSF series power supplies, these rack adapters can

be operated from single phase 95-264V a-c or 125-370V d-c source power without adjustment

or modification. Source power is applied to two 3-terminal terminal blocks at the rear panel and

distributed as indicated in Figure 1-3. Slots 1 and 3 are powered from one terminal block, slots 2

and 4 are powered from the other.

THE RA 19-1U DOES NOT INCORPORATE ANY SAFETY INTERRUPT DEVICES. PROTECTION OF INPUT WIRING REQUIRES USER-CONFIGURED SAFETY INTERRUPTS.

The terminals are labeled L, N, and G. Wires must be sized according to expected current. Wire

size range is 24-14 AWG; torque to 4 lb-in (0.4 N•M) maximum. Their functions are as follows:

CAUTION

• Terminal G (Ground) is the safety ground connection for the RA 19-1U. It is connected

to the RA 19-1U chassis and to the safety ground terminal of the input power connector

for each of the power supply mounting positions via the PCB backplane. Terminal G

must be connected to safety ground in order to ensure proper grounding of the 1U HSF

power supplies.

• Terminals L (Line Phase) and N (Neutral) are connected to the input power entry con-

nectors. Source power is provided to the power supplies indicated by the label on the

rear panel. The source power connectors are independent of each other, allowing the

user complete flexibility in wiring for common or redundant input power configurations.

When each terminal block receives power from a separate source, input redundancy for adjacent pairs of power supplies is achieved.

Source power can also be custom configured via jumpers on the internal PC board, e.g., all

slots can be powered from a single terminal block, or slots 1 and 2 can be powered from one

terminal block and slots 3 and 4 from the other. Contact Kepco Applications Engineering for further details.

The following standard wiring configuration is recommended by Kepco as being compliant with

applicable national and international safety standards. Please consult local electrical codes for

wire current ratings and other specific requirements:

• Connect Terminal G of each RA 19-1U input power terminal block to safety ground

• Connect a separate wire pair from each side of the input power to the L/N terminal pair of

the input power terminal block.

RA 19-1U 020413 2-25

Page 42

• Where 115V a-c source power is used, Kepco recommends the use of the line cords,

P/N 118-0506 supplied (North American style plug, 15A maximum, 6 ft. long).

• Wire size is determined by the maximum rated source current for each 1U HSF power

supply and the number of power supplies installed. For lower system power configurations, smaller wire can be used; contact Kepco Applications Engineering for assistance.

2.10.2.1 EMI COMPLIANCE

Depending on the application and system environment, special source power considerations

may be required to meet listed Input EMI specifications for HSF power supplies, particularly

FCC Class B. It may be necessary to add external source power filtering, such as installing

snap-on ferrite beads on the line cord wires of the RA 19-1U as close to the input a-c terminal

block as possible. Another option is to add an in-line cabinet-mounted EMI filter (available from

a number of manufacturers) between the source power and the RA 19-1U line cord. For additional assistance, contact Kepco Applications Engineering.

2.10.3 CONTROL SIGNAL CONNECTIONS

Access to the control signal (I/O) connector for each 1U HSF power supply is provided via the

15-pin D-subminiature connectors on the rear panel of the rack adapter (see Figure 1-4). Two

mating connectors (Kepco P/N 142-0449) are provided in a plastic bag. Consult PAR. 2.4 and

the 1U HSF operator's manual for instructions on wiring and use of these control lines.

2.10.4 OUTPUT LOAD CONNECTIONS

Load connections to the rack adapters are achieved via two terminal blocks located on the

backplate assembly. Wires must be sized according to expected current. Wire size range is 2414 AWG; torque to 4 lb-in (0.4 N•M) maximum. (Sensing connections are made through the I/O

mating connector, PAR. 2.4.1)

REGARDLESS OF OUTPUT CONFIGURATION, OUTPUT SENSE

LINES MUST BE PROPERLY CONNECTED FOR OPERATION.

2.10.4.1 REDUCING RIPPLE AND NOISE

Ripple and noise are measured under nominal load conditions to provide the rated output voltage/current of the 1U HSF power supply. Measurement of ripple/noise is illustrated in Figure 2-

18. It is most important to minimize impedance between the power supply output and the load.

As the length of load wires increases, ripple and noise may increase proportionally, therefore

length and placement are critical for minimum ripple and noise. A filter consisting of a 10pF

multi-layer ceramic capacitor for high frequency filtering in parallel with a 0.01µF capacitor must

be used to eliminate unwanted ripple and noise pickup on the load wire. For noise-sensitive

applications the load wires and sense wires must be twisted and/or shielded.

NOTE!

2-26 RA 19-1U 020413

Page 43

FIGURE 2-18. RIPPLE AND NOISE MEASUREMENT SETUP DIAGRAM

RA 19-1U 020413 2-27

Page 44

2.10.4.2 PARALLEL/REDUNDANT OPERATION

WARNING

Removal of an 1U HSF power supply from a “live” system must be done

only by authorized service personnel after 1U HSF power switch is set to

OFF. Dangerous voltages may be accessible through the open slot after a

power supply is removed.

Identical 1U HSF power supplies can be connected in parallel to provide redundant operation or

increased output current to a common load. Maximum output current for each terminal pair of

the DC OUTPUT terminal blocks is 35 Amperes. Connect (+) to (+) and (–) to (–) at the DC

OUTPUT terminal block (see Figure 2-5).

NOTE: Verify that the sense lines and current share bus are configured per PAR. 2.4.2.

2.10.4.3 SERIES/INDEPENDENT OPERATION

The rack adapter can be used for either independent or series operation of 1U HSF power supplies; it is factory configured for independent operation using local sensing. To select remote

sensing, refer to PAR. 2.4.1.3.

For series operation, connect (+) and (–) terminals at the DC OUTPUT terminal block of power

supplies to be connected in series (see Figure 2-11). The 1U HSF power supplies are equipped

with blocking diodes which allow series operation without further modification. The RA 19-1U

rack adapter is designed to safely handle a maximum output voltage of 500 Volts.

2.10.4.4 MIXED OPERATION

The design of the RA 19-1U rack adapters permits the user to configure 1U HSF power supplies

for almost any combination of independent, series and parallel operation, both within a single

rack adapter and between different RA 19-1U rack adapters, within the limits of the 1U HSF

operation envelope and the current and voltage ratings specified in PAR.s 2.10.4.2 and

2.10.4.3. The user must ensure that the requirements for each configuration stated above are

met. If any questions or problems arise, the user is encouraged to contact the Kepco Applications Engineering group for technical assistance.

2.11 REMOVING/REPLACING 1U HSF POWER SUPPLIES

WARNING

Removal of an 1U HSF power supply from a “live” system must be done

only by authorized service personnel after 1U HSF power switch is set to

OFF. Dangerous voltages may be accessible through the open slot after a

power supply is removed.

Refer to Figure 1-1, for proper slot positions applicable to the RA 19-1U Rack Adapter. Insert 1U

HSF power supply in selected slot until power supply front panel is flush with rack adapter chassis and secure with two front panel screws on power supply. Do not overtighten these screws:

max. torque is 2 in.-lbs (0.23 N x m).

2.12 SHIPPING

The rack adapter may be shipped with power supplies installed only after the 1U HSF power

supplies have been securely fastened to the rack adapter (PAR. 2.11). Contact Kepco Applications Engineering if further assistance is required.

2-28 RA 19-1U 020413

Loading...

Loading...