Page 1

QUICK START GUIDE

KEPCO

An ISO 9001 Company.

SINGLE OUTPUT

PROGAMMABLE POWER SUPPLIES

I — INTRODUCTION

SCOPE OF MANUAL This Quick Start Guide covers

the installation and operation of the Kepco HSP Series of

voltage and current stabilized d-c power supplies. Full

specifications are listed in the applicable Operator’s Manual that can be downloaded from the Kepco web site at

www.kepcopower.com/support/opmanls.htm/#hsp

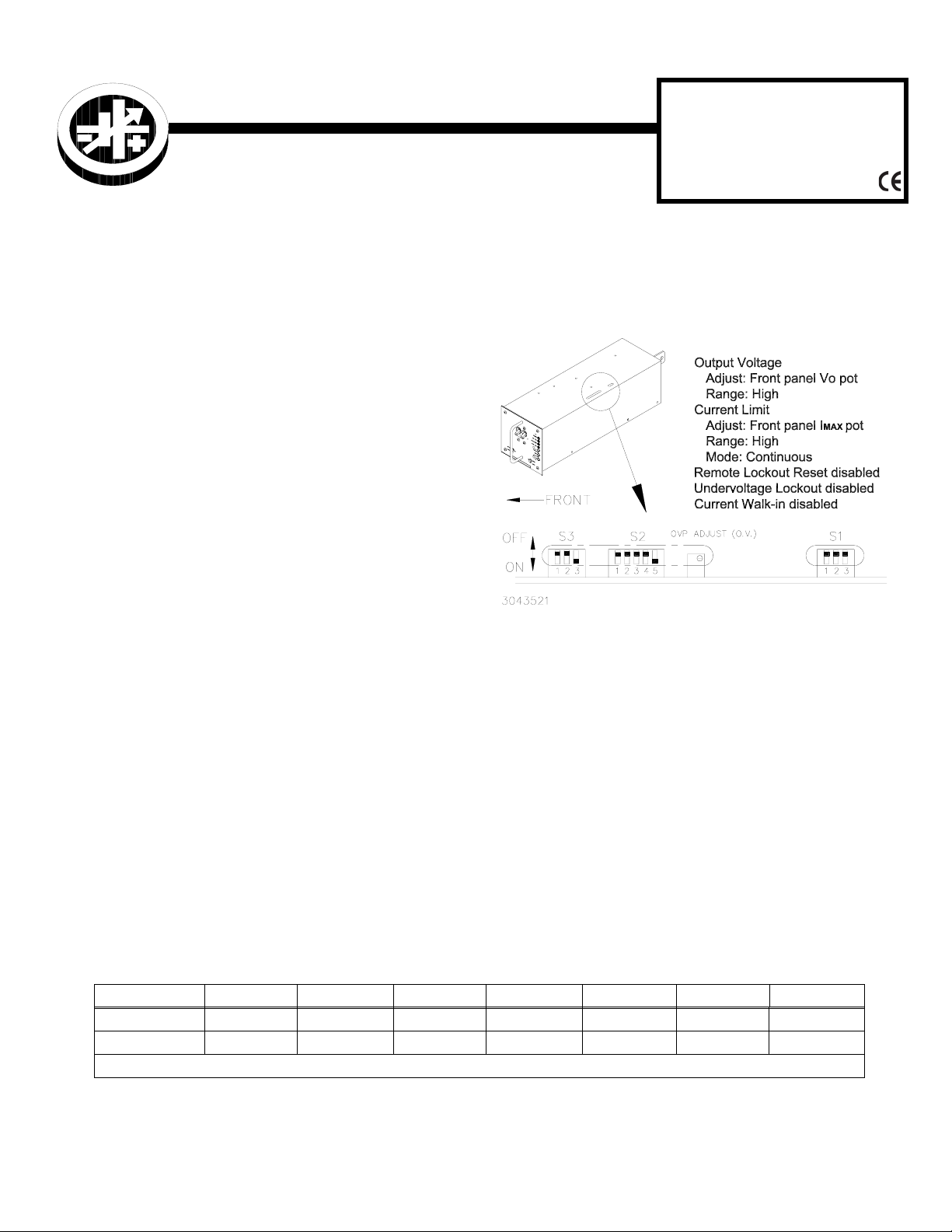

FACTORY DEFAULTS This guide covers only units as shipped from the factory with the three DIP switches set to default configuration (see Figure 1). For other configurations, refer to HSP Operator Manual.

DESCRIPTION The HSP power supply (Figure 1-1) is basically a voltage and current stabilized d-c source with a relatively sharp crossover between voltage and current mode operation.

HSP

1000W/1500W

HSP power supplies are nominally rated at either 1000 or

1500 Watts of output power, and include active power factor correction (PFC). HSP 1000W power supplies are

designed to operate over the universal a-c power mains

voltage range of 90-277V (47-63Hz), with operation from

125-420V d-c also available. HSP 1500W products provide

full power over the a-c mains range of range of 180-277V

a-c, and 1000W output power from 90-132V a-c; contact

Kepco for information on operation over other source voltage ranges. Cooling is provided via an internal d-c fan.

HSP permits adjustment of both output voltage (V

current limit (I

external (resistance or voltage) methods, selected via DIP

switches accessed through the top of the unit. Protection

against overvoltage, overcurrent and overtemperature failures is provided.

MODELS 3.3V 5V 12V 15V 24V 28V 48V

1000W HSP 3.3-230R HSP 5-200R HSP 12-84R HSP 15-66R HSP 24-42R HSP 28-36R HSP 48-21R

1500W N/A N/A N/A N/A HSP 24-60R HSP 28-53R HSP 48-30R

NOTE: Options include suffix M or B: M for meter; B for battery charger.

), either by internal (front panel pot) or

MAX

TABLE 1. HSP SERIES MODELS

) and

O

FIGURE 1. DIP SWITCH FACTORY DEFAULTS

The HSP power supply is specifically designed for use with

Kepco RA 60 or similar plug-in rack adapters as a hot

replaceable module in a redundant power system. Bench

top operation is also supported. Forced current sharing and

output blocking diodes enhance power system reliability.

Mechanical keying eliminates the risk of incorrect module

insertion. Tool-operated latches on the front panel guard

against casual removal of an operating module.

OPTIONS M models include a digital meter which displays either voltage or current as determined by a front panel switch. Another switch allows display of either actual HSP Output or the setpoint. B models are intended for battery charging applications, and include a Float/ Equalize switch to preset two different voltage values using two separate front panel adjustment pots.

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

©2010, KEPCO, INC 1

Data subject to change without notice 228-1706

Page 2

II — INSTALLATION

KEYING. The units are keyed by voltage at the factory.

Refer to the Operator Manual for details.

MOUNTING THE POWER SUPPLY To insert in a Kepco Rack Adapter, release the two cap head screw retaining latches (see Figure 4) by loosening the cap-head screw approximately 1/2 turn CCW (use 5/32" hex key) and slide to open (up) position. Insert power supply in the slot, then retighten the cap-head screws CW until snug. DO NOT OVERTIGHTEN! To release, follow the same procedure, except lift the latch to the top of the slot. Be sure to move the latch completely up or down to ensure full engagement/disengagement of the latching mechanism. When HSP is not installed in rack adapter, secure latch in open (up) position to prevent damage.

To use as a fixed, rack-mounted unit, see Operator manual for details and accessories.

For all installations, provide adequate clearance around

air inlet and exhaust locations.

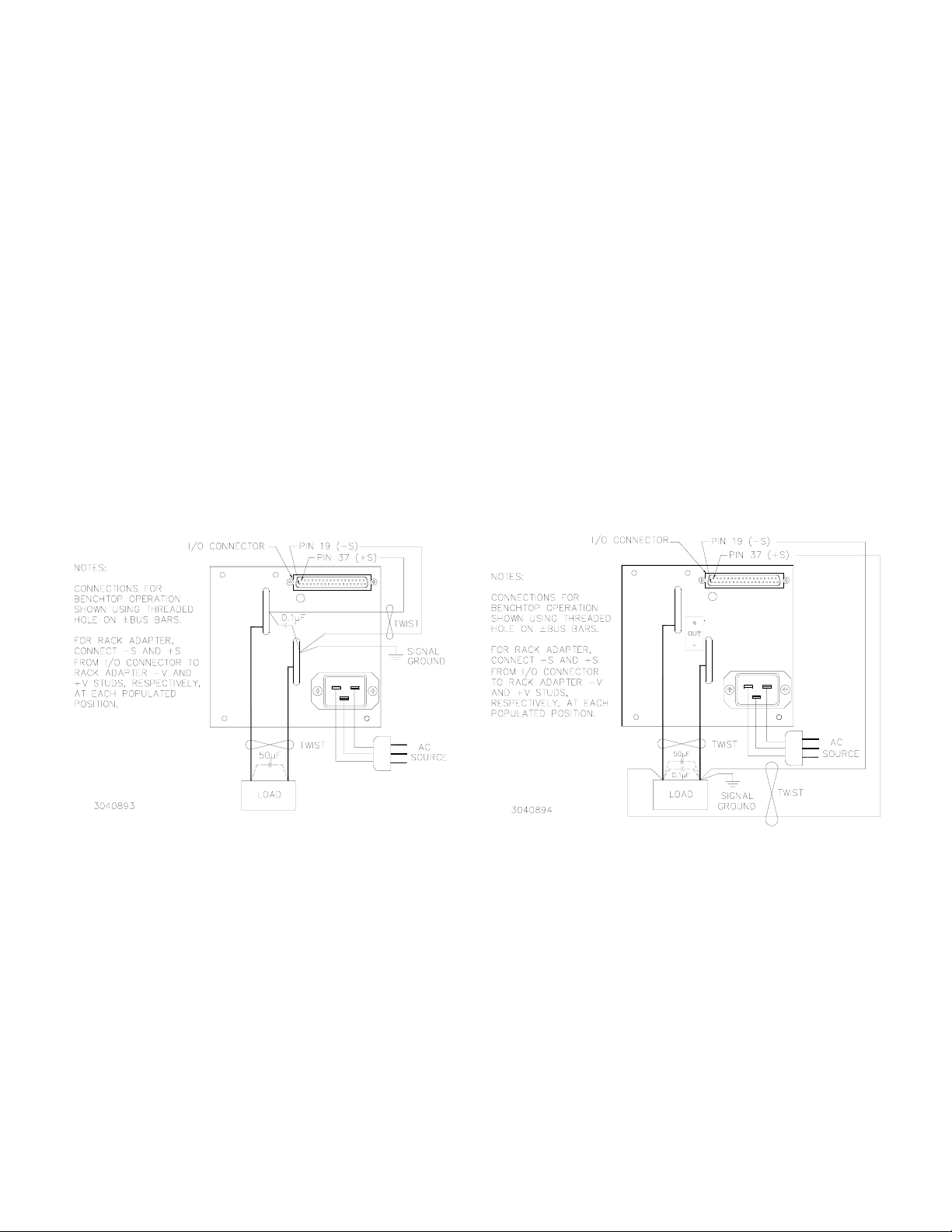

CONNECTIONS: Figure 2 shows proper connection of one or more loads using either remote or local sensing.

If local or remote sensing is not configured, the unit

will not work properly. Observe polarities: negative

sensing wire must be connected to negative load wire,

and positive sensing wire to positive load wire. When used

with plug-in rack adapters, local sense wires must be connected from the I/O connector to the ± studs of the rack

adapter.

Load connections to the HSP power supply are via bus

bars protruding from the rear panel (see Figure 2) or via

the rack adapter output studs.

Load cable or bus bar attachment should use either the

clearance hole of the HSP bus bar, using a 5/16" UNC

nut, bolt and lockwasher, or the rack adapter studs using

hardware supplied with the rack adapter. The proper hardware is critical to maintaining intimate contact between the

load conductor and output bus bar.

LOCAL ERROR SENSING

FIGURE 2. LOAD CONNECTIONS

PRELIMINARY ELECTRICAL CHECK A simple operational check after unpacking and before equipment installation is advisable to ascertain whether the power supply has suffered damage resulting from shipping.

1. Power supply will not operate unless remote

sense lines are properly connected to output terminals! Connect remote sense terminals to output

bus bars using mating I/O Connector (Kepco P/N 142-

0422) or other means as shown in Figure 2.

2. Connect power supply to source power. Connection

can be made using either a North American linecord

set (Kepco P/N 118-0776) or using a custom linecord

REMOTE ERROR SENSING

terminated at one end with an IEC 320/C19 plug

(Kepco P/N 142-0381).

3. Connect a static load, R, across output terminals.

Load value is determined by HSP nominal output voltage and must be capable of handling 2% of power

supply output rating (20 watts minimum). R is calculated as approximately equal to output voltage

2

(R = E

/P). For example, for the HSP 48-21, R = 482/

2

/20

20 = 115.2; use load of 120 ohms, 20W.

4. CAUTION: DO NOT repeatedly toggle circuit

breaker as this may damage unit. Set Power ON/

OFF circuit breaker on front panel to ON. If actuator

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

2 228-1706 091410

Page 3

does not lock when released, wait a few seconds

before trying again. The circuit breaker is "trip-free"

design; if overload exists, contacts cannot be held

closed by actuator. Verify that POWER indicator is lit,

and that all other front panel indicators are not lit.

5. Using a DVM, measure voltage across output bus

bars; this voltage is factory set to value shown in Table

1. If necessary, adjust output voltage using V

trim pot

O

accessed through front panel.

6. Using DVM, measure voltage across test points V

and COM; it should read 1/10 of output voltage measured in step 5 above, ±1%.

7. Using DVM, measure voltage across test points I

MAX

and COM. This voltage is factory adjusted to 10.0V,

and corresponds to 100% of maximum current. Refer

to Operator manual for adjustment.

III — OPERATION

CAUTION: DO NOT repeatedly toggle the circuit

breaker/switch as this may damage the unit. Set Power

ON/OFF circuit breaker to ON. When output voltage is

available, the green POWER LED is on (see Figure 4).

8. Verify that front panel indicators still appear as in step 4

above.

9. Disconnect sense lines with power supply still operating (remove mating I/O connector or open sense line

connected to pin 37. Verify that HSP output turns off,

and DC FAIL indicator is now lit along with POWER

indicator. (NOTE: At no load the output voltage will

drop slowly.) Turn circuit breaker off and wait until DC

FAIL indicator blinks. Reconnect sense lines, then turn

circuit breaker back on. Verify that output voltage

O

returns to value measured in step 5 above, and that

indicator LEDs appear as in step 4 above.

10. Turn off front panel circuit breaker and remove source

power connection.

programming range, this corresponds to 62% of the rated

module current, but for the high programming range the

number is 62% of 110%, or 68.2% of rated module current.

Current setpoint monitor accuracy is ±5%.

OUTPUT VOLTAGE PROGRAMMING Monitor output voltage setpoint across V adjusting V

pot on front panel. Voltage across VO and

O

and COM jacks while

O

COM represents 1/10 of the programmed output voltage.

As an example, V

of 4.63V corresponds to a programmed

O

output voltage of 46.3V ±1%. This relationship is constant,

regardless of the programming range selected.

Default programming resolution is set to high range: output

can be adjusted to 110% of nominal V

28V models, 125% of nominal V

for 48V models. For low

O

for 3.3V through

O

range (which offers increased resolution, while limiting output to V

), or for external voltage programming using either

O

resistance or voltage refer to Operator manual.

For metered (M option) units, if the V/A switch is set to V,

actual output voltage is displayed on the meter in Volts.

While the ACTUAL/SETPOINTS switch is held in, the programmed output voltage setpoint is displayed in Volts.

CURRENT LIMIT PROGRAMMING Monitor current limit setpoint across I I

pot on front panel. Voltage across I

MAX

and COM jacks while adjusting

MAX

and COM rep-

MAX

resents the percentage of available power supply current

as a percentage of rated current, with 10V corresponding

to 100%. Available current is defined as the maximum current limit available based on the programming range. This

voltage is always based on a 0-10V scale, regardless of

the range selected. For example, I

= 6.2V corresponds

MAX

to 62% of the maximum programmable current. For the low

Minimum programmable current limit is 50-60% of nominal.

Default programming resolution is set to high range: current limit can be adjusted to 110% of nominal I

. For low

O

range (which offers increased resolution, while limiting output to I

), or for external programming using voltage

O

source refer to Operator manual.

For metered (M option) units, if the V/A switch is set to A,

actual output current is displayed on the meter in Amperes.

While the ACTUAL/SETPOINTS switch is held in, the programmed current limit is displayed in Amperes.

OVERVOLTAGE PROTECTION The overvoltage protection (OVP) circuitry latches the output regulator off if output voltage rises above a predetermined level. To reset, remove source power for a minimum of 30 seconds (refer to Operator manual to enable remote reset). The trip level is preset at the factory for 130% of the nominal output voltage. The trip point can be adjusted from 100% to 140% of the nominal output (except Model HSP 48-21, which can be adjusted from 100% to 160% of the nominal output). To alter the preset OVP trip point, refer to the Operator manual.

CURRENT LIMIT CHARACTERISTIC The factory default setting is Continuous Limiting: When the output current of the power supply reaches the programmed current limit, the output regulator switches to current mode operation and maintains the output current by modulating output voltage. Current mode is maintained indefinitely, and

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

091410 228-1706 3

http://www.kepcopower.com email: hq@kepcopower.com

Page 4

recovery to voltage regulation mode is automatic upon

reduction of output current below the current limit point.

Current Limit can also be set to Undervoltage Lockout: if

current mode is maintained for more than 15 seconds, the

output is turned off, and source power must be recycled to

restart the unit. Refer to Operator manual for details.

OTHER FEATURES The following features of the HSP power supplies are covered in detail in the Operator manual:

• Parallel Operation, including load sharing requirements.

• Remote Inhibit, Remote Reset

• Remote Voltage and Current Limit adjustment

• Protection Circuits

• Status Flags and Indicators

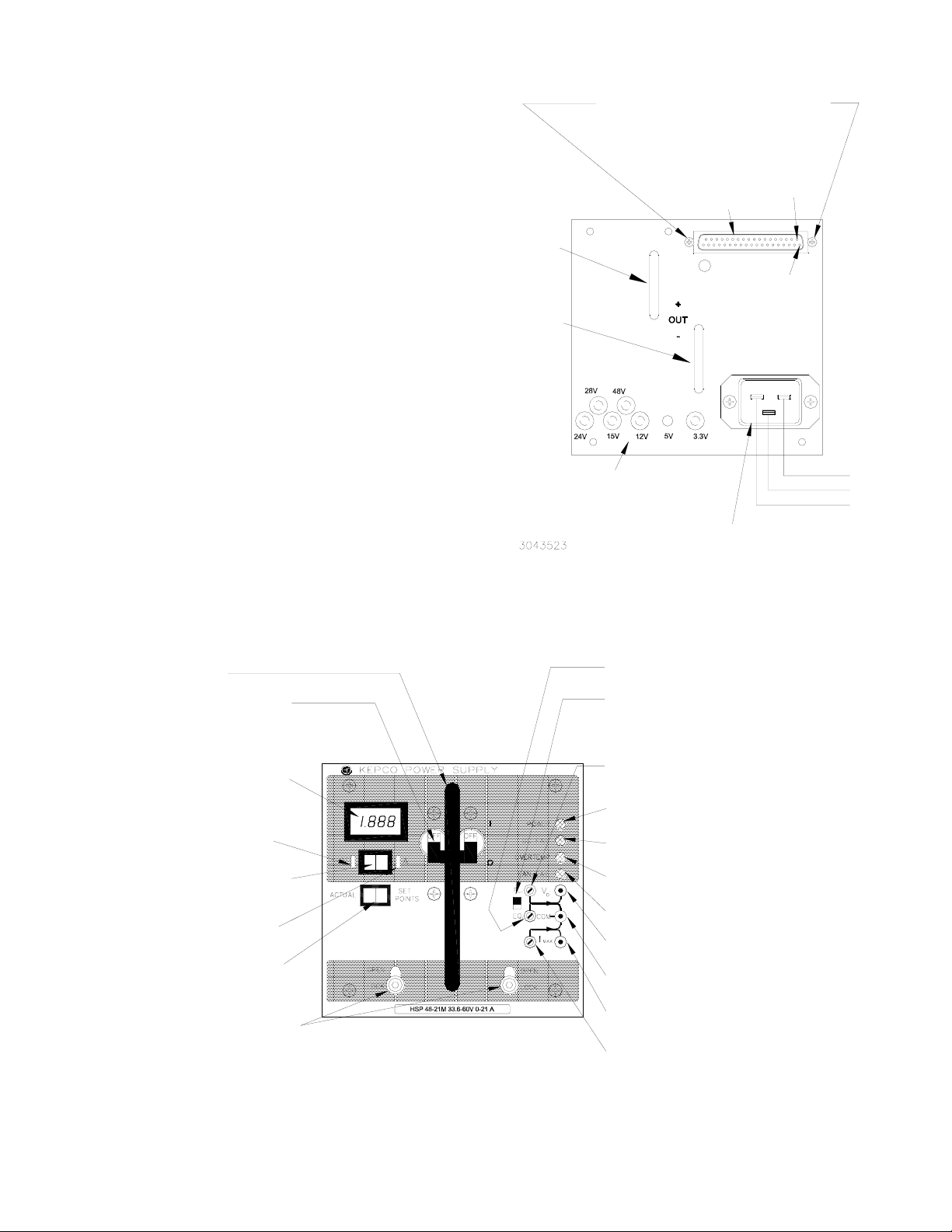

Output

Bus Bar

(+)

Output

Bus Bar

(-)

For Standalone operation, replace

connector mounting screws using

instructions and components supplied

in Standalone accessory KIT 219-0240

or KIT 219-0249.

I/O

Connector

Pin 20

Pin 1

• Load Monitor (Current)

• Current “Walk-In” for battery charging applications

• Load monitor

• Auxiliary supply

•Keying

• I/O Connector pin functions

• Options

Insertion/Extraction Handle

Power ON/OFF circuit breaker Applies

power to the unit. CAUTION: Power must

be OFF before unit is removed from the

rack adapter.

Voltage/Current Meter (M Suffix only)

Monitors output voltage or current

Meter Mode switch. Remote sensing required

for

voltmeter to display voltage at the load.

V (Voltage) indicator (M Suffix only)

Lights green when meter shows Volts.

Meter Mode switch (M Suffix only)

Set to V to show output voltage on meter,

set to A to show output current.

A (Amperes) indicator (M Suffix only)

amber when meter shows Amperes.

Lights

ACTUAL/SETPOINTS momentary switch

(M Suffix only) Meter normally shows actual

output voltage or current. Meter shows

setpoints while switch is pressed.

Retaining Latches (2) Prevents inadvertent

removal of unit from rack adapter.

3043522

per

Keyways and Plugs for module

keying (for use with Kepco

plug-in Rack Adapters)

Power Inlet

Connector

Line (Hot)

Ground

Neutral

FIGURE 3. HSP SERIES REAR PANEL CONNECTIONS

EQ Adjust pot (B suffix only) Used to adjust

Equalize voltage while monitoring Vo and COM.

FL/EQ Select switch (B suffix only) Allows

either Float or Equalize voltage to be monitored

across Vo and COM jacks. CAUTION: Adjust

only the pot selected by FL/EQ switch.

Vo Adjust pot Used to adjust output voltage

setpoint. Used to adjust Float voltage on

B suffix models.

POWER Indicator Lights green when

is operating.

DC FAIL Indicator Normally off. Lights red to

indicate failure.

OVERTEMP indicator Lights amber to indicate

overtemperature detected.

FAN FAIL indicator Lights red to indicate fan

failure.

Vo Setpoint monitor jack Used with COM jack to

monitor voltage setpoint.

COM jack Provides return for Vo and I

setpoint monitor jacks.

MAX Setpoint monitor jack Used with COM jack to

I

monitor current limit setpoint.

MAX Adjust pot Used to adjust current limit from

I

front panel.

Off when fault detected.

unit

MAX

FIGURE 4. COMPONENT LOCATIONS

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

4 228-1706 091410

Loading...

Loading...